Page 1

ICS Regent+ Plus

®

PD-7013

AC Digital Input Module

110 VAC

(T7404)

Issue 1,

The AC digital input module provides input sensing for 16

field input switches. One type of module is available for

interfacing to inputs powered from 110 VAC field power

su

pplies. The module's triplicated I/O Safetybus interface

ensures that no failure in the module can affect the operation

of the Regent system or other I/O modules in the system.

Extensive fault detection and annunciation of critical

redundant circuits help prevent the controllers from receiving

erroneous data from a faulty input module.

March, 06

Features

·

Sixteen input circuits, configured as two isolated groups of

eight circuits each.

·

Fault toleran

redundant modules of the same type.

·

Hot-replaceable.

·

Automatic self-testing of triplicated I/O Safetybus circuits and

many simplex logic circuits.

·

Individual front panel indicators on each module show active

and fault status and logic-side input on/off status.

·

2500 volt minimum electrical isolation between field and logic

circuits.

·

TÜV certified, Risk Class 5.

Three AC digital input modules can be connected in parallel

to obtain fault tolerant input sensing. In this triple module

configuration, a failed module can be removed and replaced

without interrupting the input signals.

t operation when connected in parallel with

Industrial Control Services

1

Page 2

AC Digital Input Module

(T7404)

Module Operation

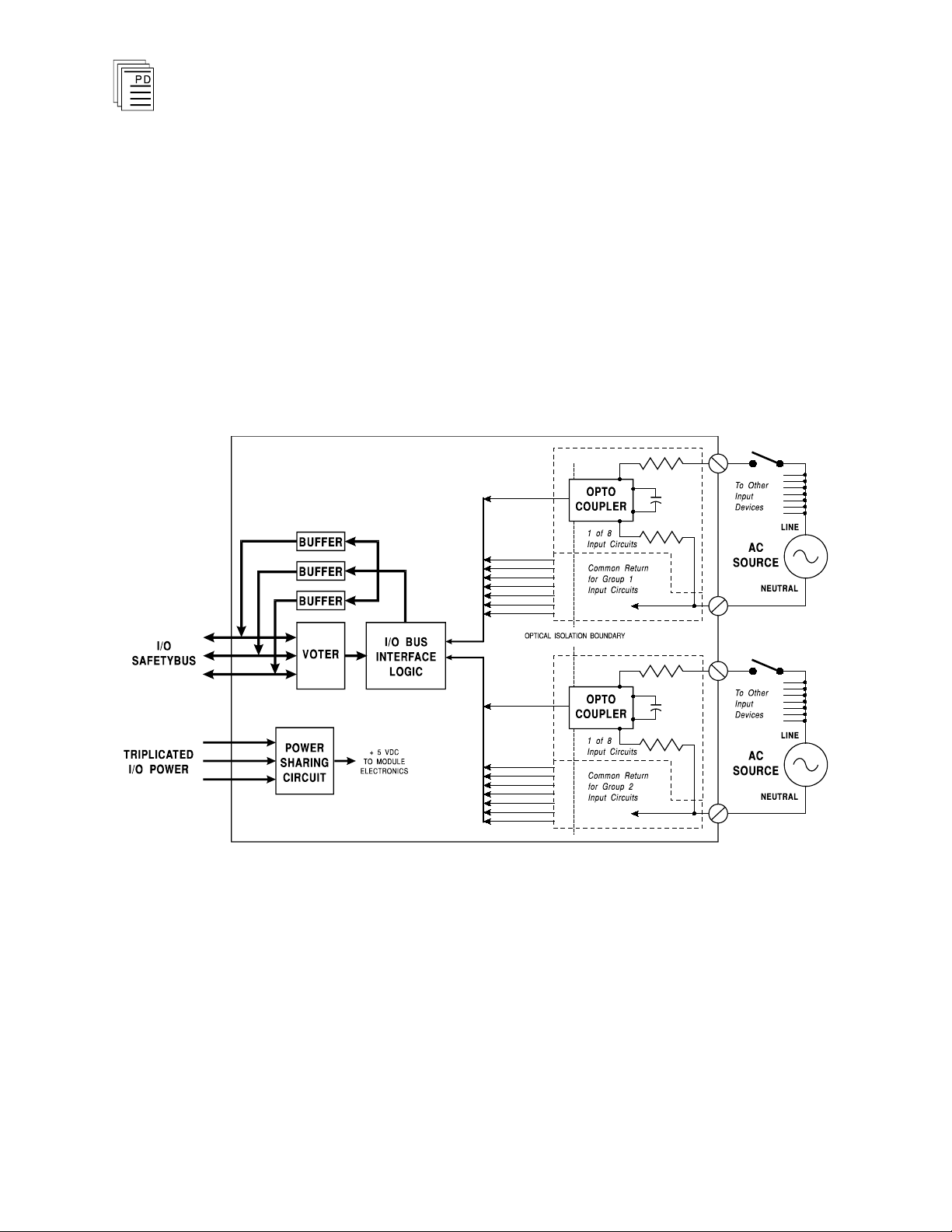

A block diagram of an AC digital input module is shown in

Figure 1.

Optical isolation between field wiring and the module’s logic

circuitry provides field-to-logic isolation —

module’s logic circuits from field signal over-voltages,

transients, and other electrical disturbances. It also provides

a safety barrier between the primary field voltages and user

accessible circuits.

prote

cting the

2

Figure 1. Block Diagram of AC Digital Input Module.

When the field switch is closed, the input to the module is on.

When the field switch opens, the input to the module turns off.

Data from the logic side of the optical isolators are bused to

the

I/O bus interface logic.

The processor modules send triplicated read data requests to

the input module over the I/O Safetybus. The processors’

addressing data and data read requests are voted by the

Industrial Control Services

Page 3

(T7404)

module (preventing I/O Safetybus failures upstream from the

module from affecting its ability to be read). The voted result

is then passed to the I/O bus interface logic.

After receiving the voted data read request, the I/O bus

interface logic sends its input data to the module’s three bus

drivers. Each of t

powered and controlled by the I/O transceiver modules—

preventing failures in a single driver from propagating to the

other two busses.

The bus drivers transmit the data across the backplane I/O

Safetybus to the I/O transceivers which, in turn, transmit the

data to the processors.

he three bus drivers is independently

AC Digital Input Module

Testing and Diagnostics

Each module’s voter circuits are periodically tested by the

processor modules. Discrepant data are sent through one of

three legs of the I/O Safetybus to determine whe

module’s voter is able to outvote the incorrect data. A failure

to return the correct majority-voted result to the processors

produces an I/O module error indication at the processor

modules and a module fault indication at the I/O module.

Each type of module has a unique identification code that is

read by the controller. This code lets the controller know

which type of module is installed in each I/O chassis slot and

how to address that module and its points specifically. If a

module is removed, or is replaced with a module of a different

type, the processor modules will indicate I/O module errors.

Loopback logic tests periodically write data to the module and

then read it back to determine whether the module’s I/O bus

interface logic is functioning correctly.

Front Panel Indicators

ther the

PD-7013

Mar-06

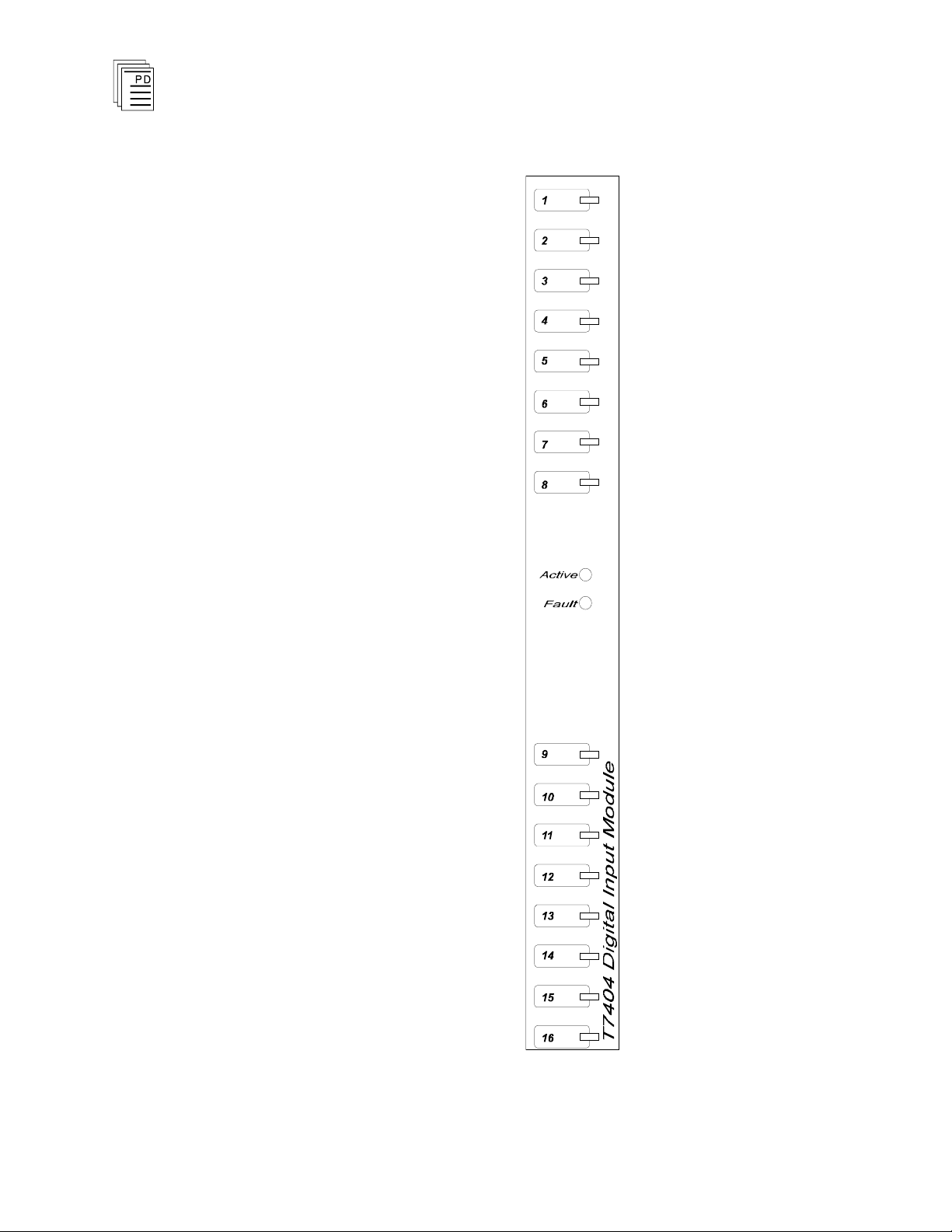

Figure 2 shows the physical features of the AC digital input

module. The front panel of each module contains active and

fault status indicators and field signal status indicators fo

each circuit.

3

r

Page 4

AC Digital Input Module

(T7404)

4

Figure 2. AC Digital Input Module.

Industrial Control Services

Page 5

(T7404)

AC Digital Input Module

Application

Active and Fault Status Indicators

These green and red LEDs indicate the overall health of the

module. During normal operation the green ACTIVE

indicator flashes at the controller's scan rate. If a module

fault is detected the red FAULT indicator turns on and the

green indicator turns off.

Field Status Indicators

Input status indicators are located on the logic-side (after the

signal conditioning and isolation).

are lit when current is flowing through the input.

The field status indicators

Simplex Configuration

Digital input modules provide a suitable interface to non

critical input signals. Although many of the circuits in the

digital input modules are automatically tested and

annunciated, some logic circuits and all of the field-side

sensing circuits are simplex and non-tested. This simplex

input configuration is illustrated in Figure 3.

-

PD-7013

Mar-06

Figure 3. Simplex Digital Input Configuration.

Fault Tolerant Connection

For critical inputs, redundant input modules are used in a

2oo3 or 1oo2 fault tolerant configuration. In these

configurations the redundant input modules are connected to

single or multiple sensors. If redundant sensors are installed

5

Page 6

AC Digital Input Module

in the field, the redundant modules are connected so that each

sensor connects to one of the redundant modules. These

configurations are illustrated in Figure 4, showing triple

redundant input modules. Each AC digital input module is

hot replaceable. In triple redundant input configurations, if a

fault occurs on one module, it can be removed and replaced

while the system continues to sense the inputs from the

remaining two input modules.

(T7404)

Figure 4. Fault Tolerant Digital Input Configurations.

Field Wiring

6

For field wiring details, refer to PD-7901 - I/O Termination

Assembly.

Industrial Control Services

Page 7

(T7404)

AC Digital Input Module

Keying

The I/O chassis can be physically keyed to prevent accidental

damage caused by inserting a module into a slot wired for a

different module type. Figure 5 illustrates how the slot keys

are installed on the I/O chassis slot field wiring connectors.

The slot key positions for the AC digital input module are

listed in Table 1.

PD-7013

Mar-06

Figure 5. Installing Slot Keys.

7

Page 8

Module

Upper

Connector

Lower

C

onnector

T7404

17 15

AC Digital Input Module

(T7404)

Table 1. Slot Key Positions.

Configuration

Each input module is configured using the

W

INTERPRET

I/O

Configuration Editor. In the editor, you will perform the

three steps described below to configure the input module.

1) Set the Module Type:

Position the cursor on the module slot you wish to define.

Choose Set Module Type from the Edit Menu and select

the appropriate digital input module from the list.

2) Edit the Module Definition:

Choose Edit Module Definition from the Edit Menu. A

dialog box will open whe

definitions.

re you can define the input point

8

Figure 6. Digital Input Module Definition.

3) Edit each point:

Choose Edit from the Module Definition dialog box to

define a name and description for each I/O point. In the

Industrial Control Services

Page 9

(T7404)

AC Digital Input Module

Digital Input Point dialog, enter a tag name (up to 12

characters) and a description (up to 40 characters).

Figure 7. Defining a Digital Input Point.

The tag names are used in the application program to

represent the input state. In addition, a module tag n

ame can

be entered to represent the combined state of all 16 inputs.

This module tag name represents the 16 inputs as a signed,

16-bit integer. In this format, input point one is the least

significant bit (LSB) and input point 16 is the most significant

bit (MSB).

Programming

Inputs are referenced in the application program through the

tag names defined in the I/O Configuration Editor. When

current flows through the input (field switch closed) the input

is said to be on, or have a value of one. In ladde

r logic, the on

state would produce power flow in a normally open (N.O.)

contact.

To program fault tolerant configurations using triplicated

digital input modules, a voter element can be used as shown

in Figure 8.

PD-7013

Mar-06

Figure 8. Programming Fault Tolerant Digital Inputs.

9

Page 10

AC Digital Input Module

In this illustration, VOTE_A_NAME, VOTE_B_NAME, and

VOTE_C_NAME represent the three digital inputs to be two

out-of-three voted. ERROR_A_NAME, ERROR_B_NAME

and ERROR_C_NA

inputs. RESULT_NAME is the result of the voter instruction.

The field Msec is the time, in milliseconds, an input can be

incorrect before signaling an error. RESET_NAME is the

reset bit used to reset the latched error bits.

The voter instruction can be used to vote digital input points

or entire digital input modules. When voting digital input

modules, the tag names VOTE_A_NAME, VOTE_B_NAME,

and VOTE_C_NAME would be the names of the digital input

modules and RESULT_NAME would be a shared variable

register. After voting the modules, a block move instruction

should be used to move the contents of the register

RESULT_NAME into individual shared variable control

relays. Refer to the

information about the block move instruction and shared

variable definitions.

(T7404)

ME are the error bits for the digital

W

INTERPRET

Help files for more

-

Maintenance

No periodic maintenance or calibration is required for the AC

digital input module. There are no user replaceable parts

inside the module. In safety critical input appli

inputs should be dynamically transitioned at a period not

greater than six months.

Safety Considerations

The AC voltage digital input module is TÜV certified as non

interfering and when properly configured is also certified for

Risk Class 5 safety critical inputs. Safety critical

configurations include 2oo3 and 1oo2 voting methods.

In safety critical input applications using a single sensor, it is

important that the sensor failure modes be predictable and

well und

not responding to a critical process condition. In such a

configuration, it is important that the sensor be tested

erstood, so there is little probability of a failed sensor

cations, the

-

10

Industrial Control Services

Page 11

(T7404)

AC Digital Input Module

regularly, either by dynamic process conditions that are

verified in the Regent, or by manual intervention testing.

Redundant sensors can be used with redundant input

modules to eliminate any single points of failure and extend

fault tolerance to include the sensors.

In all safety critical configurations and applications, the AC

voltag

trip inputs,

a period not greater than six months.

e digital input module can be used for de-energized to

only

if the inputs are dynamically transitioned at

For additional safety considerations, please refer to the Safety

Considerations section of the Regent User’s Guide.

PD-7013

Mar-06

11

Page 12

Safetybus Power

1.15 load units

Number of Inputs

16 circuits divided into two

groups of eight

Voltage Range

90 to 130 VAC

Frequency Range

47 to 63 Hz

Turn-On Voltage

89 VAC, minimum

Turn-Off Voltage

30 VAC, maximum

In

put Current

3.9 mA, typical

Turn-On Delay

minimum

maximum

3.5 msec

20 msec

Turn-Off Delay

minimum

maximum

3.5 msec

15 msec

Over Voltage Protection

continuous:

burst:

160 VAC

260 VAC, for 5 sec

Heat Dissipation

14 Watts, 48 BTUs/hour

Fusing

None, fuse external if

required

Isolation

2500 volts minimum (field

wiring to control logic)

2500 volts minimum (input

group 1-8 to input group

9-16)

Operating Temperature

0°

to 60° C

(32° to 140° F)

Storage Temperature

-40°

to 85° C

(-40°

to 185° F)

Operating Humidity

0 to 95% relative humidity,

non-condensing

Vibration

10 to 55 Hz:

±0.15mm

AC Digital Input Module

(T7404)

Specifications

12

Industrial Control Services

Page 13

(T7404)

Shock

Operating:

15 g, ½ sine wave, 11 msec

Electromagnetic

Interference

•

IEC 801 Part 2 - Electrostatic

Discharges

•

IEC 801 Part 3 - Radia

ted

Electromagnetic Fields

•

ANSI/IEEE C37.90 - Surge

Withstand Capability

Level 3: Contact discharge of

6 kV

Level 3: 10 V/M, 27 MHz 500 MHz

2.5 kV damped 1 MHz sine

wave

Safety

Certified to DIN V VDE

0801 for Risk Class 5. Also

designed to meet UL 508 and

CSA 22.2, No. 142-M1981

Dimensions

Height:

Width:

Depth:

12.6" (320 mm)

1.27" (32 mm)

10.12" (257 mm)

Weight

3.0 lbs (1.4 kg)

AC Digital Input Module

PD-7013

Mar-06

13

Loading...

Loading...