Page 1

ICS Regent +Plus

PD-7009

I/O Transceiver Modules

I/O transceiver modules provide an interface between the

processor modules in the controller chassis and the I/O modules in

the I/O chassis. Three I/O transceiver modules are installed in the

three left slots of each I/O chassis.

Features

• Three modules per I/O chassis for triple redundant operation.

®

I/O XCVR

(T7310)

Issue 1, September, 04

• Interfaces processor modules to I/O modules.

• Hot replaceable.

• Front panel indicators on each module show active and fault

status.

• TÜV certified for safety, Risk Class 5.

I/O transceiver modules are triple redundant and can be removed

and replaced without interrupting system operation.

Module Operation

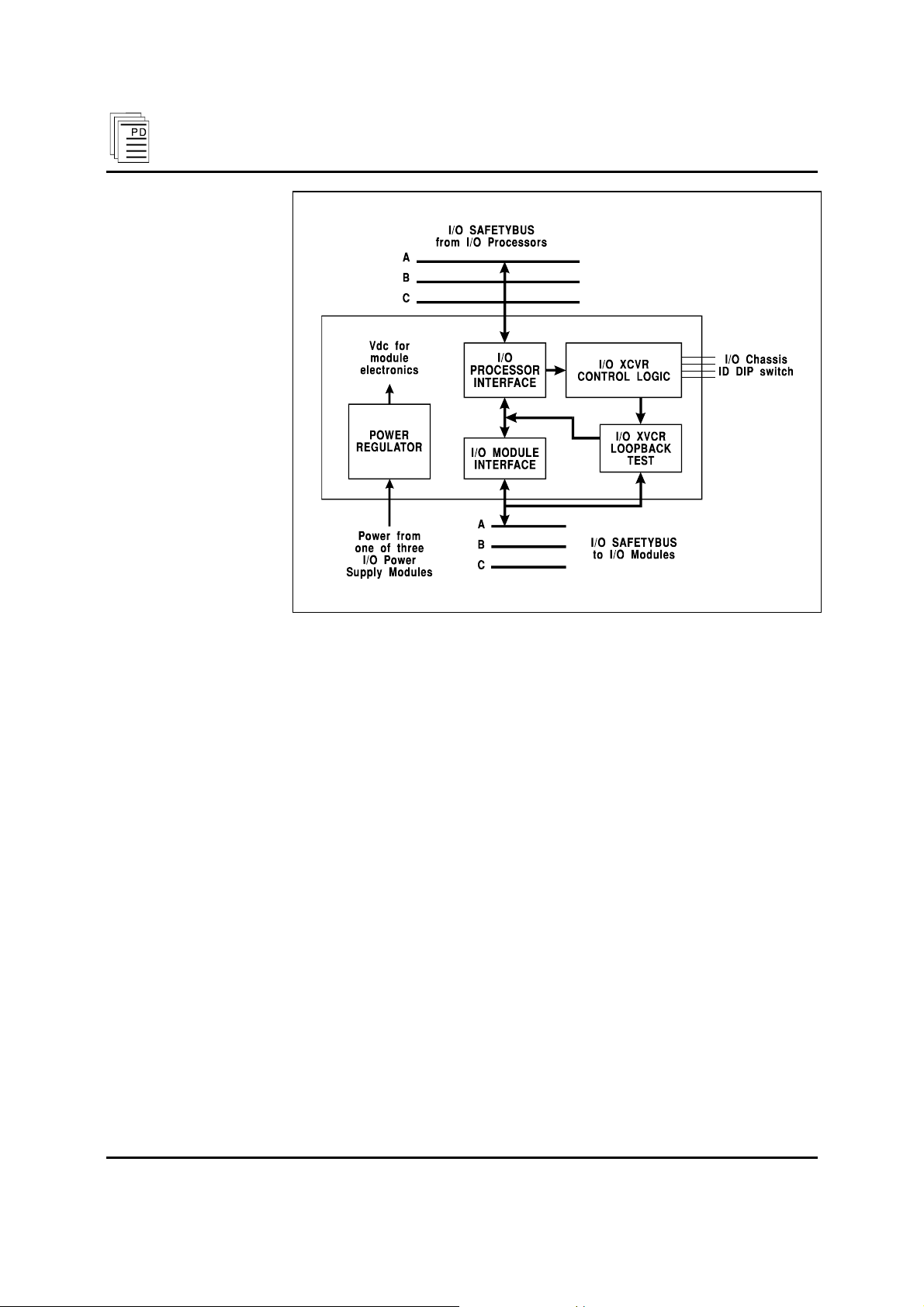

A block diagram of a typical I/O transceiver module is shown in

Figure 1.

Each I/O transceiver module communicates with one of the three

processor modules in the controller assembly. During I/O

Safetybus communications, the control logic on the I/O transceiver

module reads the I/O chassis’ identification code from the I/O

commands and compares them to the chassis’ identification switch

settings. Appropriately addressed I/O commands are directed

along the chassis’ backplane Safetybus to the I/O modules.

Industrial Control Services (Issue 1) 1

Page 2

I/O Transceiver Modules (T7310)

Figure 1. Block Diagram of I/O Transceiver Module.

I/O module responses are buffered and transmitted back along the

chassis’ backplane Safetybus to the I/O transceiver, and from the

I/O transceiver along the I/O Safetybus cable to the processor

modules.

Triplicated power is cabled into the I/O chassis and distributed to

the I/O transceiver modules. Each I/O transceiver module

receives power from one of the three I/O power supplies. Power

regulation circuits in the I/O transceiver modules provide the

necessary regulated voltages for the module’s electronics. Should a

single power supply fail, an interlock signal from the failed power

supply will cause the I/O transceiver it normally powers to shut

down.

2 (Issue 1) Industrial Control Services

Page 3

I/O Transceiver Mo dules (T7310)

Testing and Diagnostics

Loopback tests, periodically sent from the processor modules, are

used to test the health of the I/O transceiver modules.

All detected failures produce an I/O module error indication on

the processor modules and a module fault indication on the I/O

transceiver module.

Front Panel Indicators

Figure 2 shows the physical features of the I/O transceiver

modules. The front panel of each module contains active and fault

status indicators.

Active and Fault Status Indicators

These green and red LEDs indicate the overall health of the

module. During normal operation the green ACTIVE indicator is

on. If a module fault occurs the red FAULT indicator turns on and

the green ACTIVE indicator turns off.

PD-7009 Sep-04 (Issue 1) 3

Page 4

I/O Transceiver Modules (T7310)

Figure 2. I/O Transceiver Module.

4 (Issue 1) Industrial Control Services

Page 5

I/O Transceiver Mo dules (T7310)

Maintenance

No periodic maintenance or calibration is required for I/O

transceiver modules. There are no user replaceable parts inside

these modules.

Safety Considerations

The I/O transceiver modules are TÜV certified for Risk Class 5

safety critical applications.

Specifications

Safetybus Power

I/O Interface

Heat Dissipation

Operating Temperature

Storage Temperature

Operating Humidity

Vibration

10 to 55 Hz:

Shock

Operating:

Not applicable (included in

I/O power supply output

capacity, see PD-6008: I/O

Power Supply Modules)

One leg of triplicated I/O

Safetybus

8 Watts, 27 BTUs/hour

0° to 60° C

(32° to 140° F)

-40° to 85° C

(-40° to 185° F)

0 to 95% relative humidity,

non-condensing

±0.15mm

15 g, ½ sine wave, 11 msec

PD-7009 Sep-04 (Issue 1) 5

Page 6

I/O Transceiver Modules (T7310)

Electromagnetic

Interference

• IEC 801 Part 2 - Electrostatic

Discharges

• IEC 801 Part 3 - Radiated

Electromagnetic Fields

• IEC 801 Part 4 - Transients

and Bursts

• IEC 801 Part 5 - Surge

Immunity

• ANSI/IEEE C37.90 - Surge

Withstand Capability

Safety

Dimensions

Width:

Depth:

Height:

Level 3: Contact discharge of 6

kV

Level 3: 10 V/M, 27 MHz 500 MHz

Level 4: 2 kV, 2.5 kHz for t =

60 sec

Level 3: 2 kV

2.5 kV damped 1 MHz sine

wave

4 kV bi-directional impulse, 10

nsec rise time, fast transient

Certified to DIN V VDE 0801

for Risk Class 5. Also designed

to meet UL 508 and CSA 22.2,

No. 142-M1981

12.6" (320 mm)

1.27" (32 mm)

10.12" (257 mm)

Weight

3.0 lbs (1.4 kg)

6 (Issue 1) Industrial Control Services

Loading...

Loading...