Page 1

ICS Regent +Plus

PD-7000

Processor Modules

110 VAC, 220/240 VAC and 24 VDC

(128K: T7110, T7111 and T7112)

(512K: T7120, T7121 and T7122)

The controller assembly's three processor modules store and

execute application programs, scan and update the I/O modules,

process communications, and detect system faults. Each of the

processor modules executes the application programs

independently, but in lock-step synchronization with the other two.

And each processor module independently communicates in lockstep synchronization with the I/O assembly over its own dedicated

I/O Safetybus link.

®

Issue 1, September, 04

Features

• Triple modular redundant, fault tolerant (3-2-0) operation.

• Two-out-three hardware voting of all internal operations.

• Automatic fault handling without nuisance alarming.

• Time-stamped fault historian.

• Hot replacement with pushbutton education of new module

(no need to re-load programs).

• Battery-backed program storage for power outage protection.

• Structured function block programming.

• Multiple program execution.

• Front panel indicators on each module show processor,

communications, I/O, program, battery, memory lock, and

power status.

• TÜV certified for safety, Risk Class 5.

The processor modules use a two-out-of-three voting scheme to

detect faults in the system. The Regent identifies, isolates, and

records transient and permanent faults as they occur. All faults are

recorded in the system's fault history. Permanent faults are also

Industrial Control Services (Issue 1) 1

Page 2

Processor Mo dules (T7110, 11, 12, 20, 21, and 2 2)

annunciated by an LED on the front of the processor module. In

addition, redundant fault contacts are activated to signal an

external device to alert operators to any permanent fault.

Module Operation

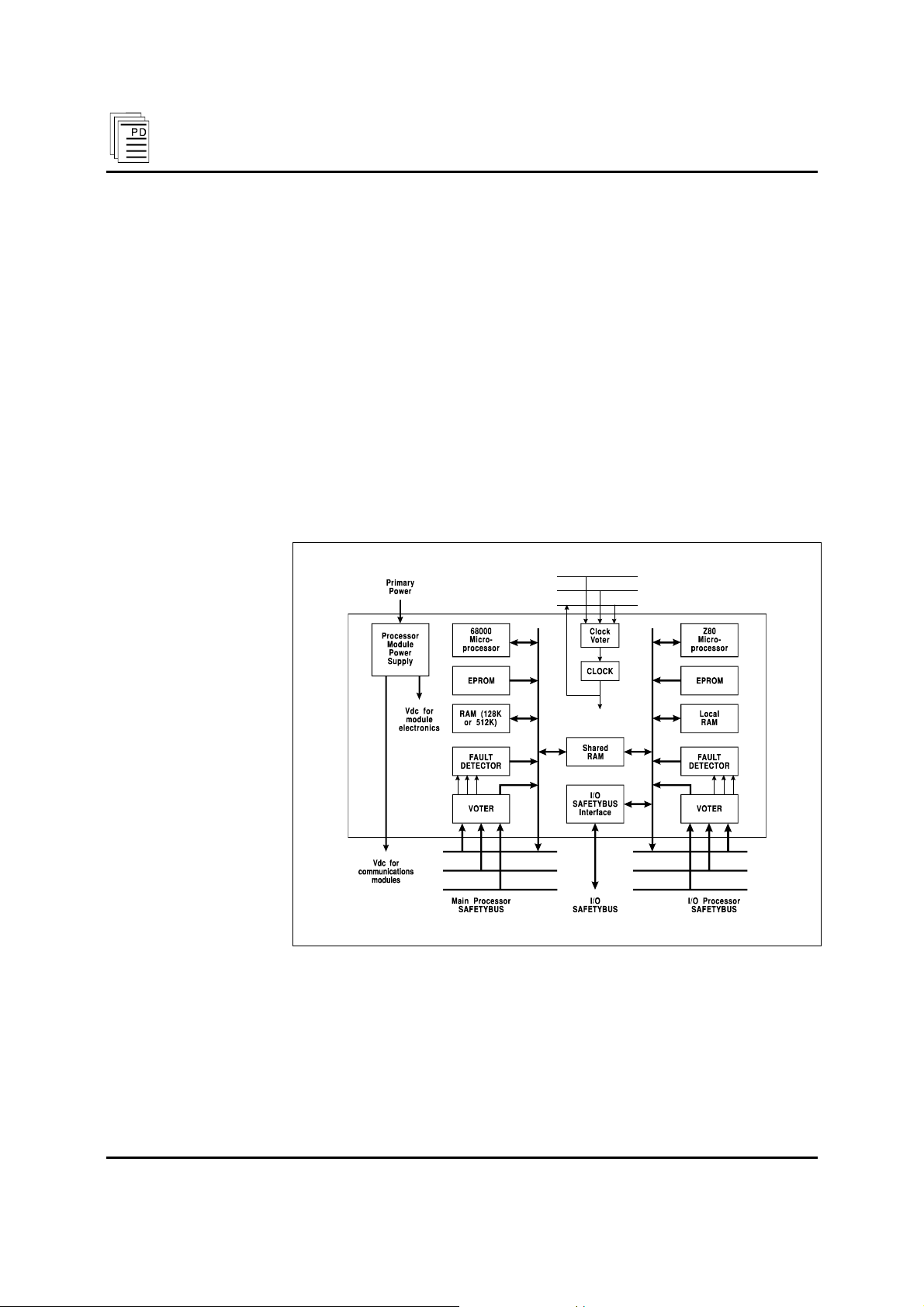

A block diagram of a typical processor module is shown in Figure

1.

Inside each processor module is a main processor, an I/O proc-

essor, and a power supply. A battery inside each of the processor

module maintains user application programs and the downloadable

portions of the system's RAMcode if there is a power failure. Each

processor module has interfaces to the processor Safetybus and the

I/O Safetybus. These interfaces consist of an input voter,

discrepancy detector logic, and an output driver.

Figure 1. Block Diagram of a Processor Module.

The voting and fault detection circuits allow the processor modules

to identify and isolate transient, intermittent, and permanent faults

as they occur. All faults are recorded in the system's fault history.

Each processor module contains its own power supply that

converts input power to the logic power levels used by the internal

processor circuits. The failure of one power supply will only effect

2 (Issue 1) Industrial Control Services

Page 3

Processor Mod ules (T7110, 11, 12, 20, 21, and 22 )

one processor module — allowing the other two modules to

continue operating — thus keeping the Regent on-line by virtue of

its majority two-out-of-three voting architecture.

Programs are stored in on-board battery-backed RAM. Program

instructions are fetched from each processor’s memory and

executed by the processors. Data from inputs are read from the

I/O modules in the I/O assembly. The main processor coordinates

the Regent’s activities and solves the application algorithms

programmed by the user. Outputs are driven by transmitting data

through the processor module’s I/O processor to the I/O assembly.

Communications between the main processor and the I/O

processor are maintained through shared RAM that is used as a

“mail box” for data transfers between the two processors.

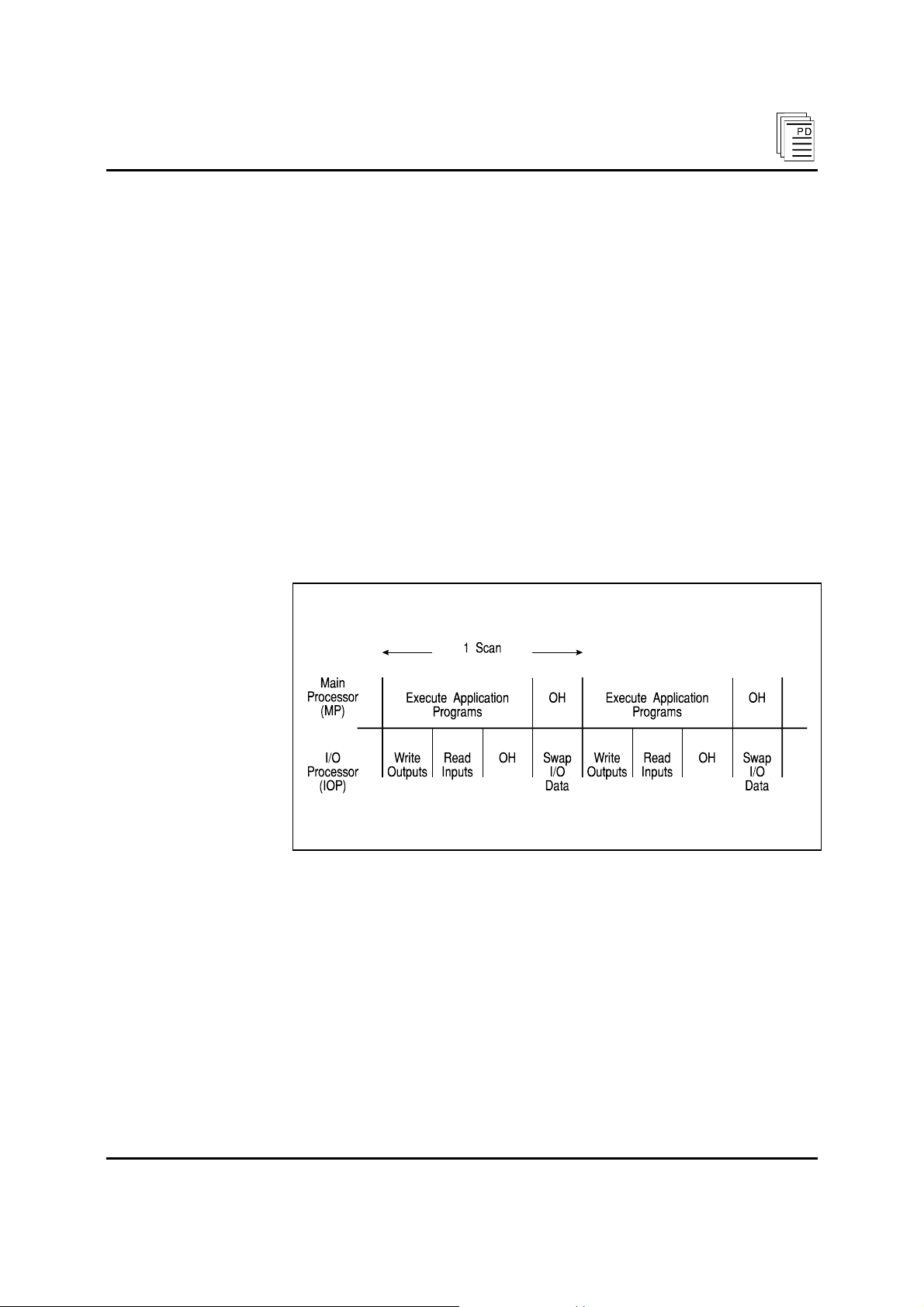

All three processor modules operate independently in lock-step

synchronization with the other two modules, continuously

repeating a scan cycle (Figure 2).

Figure 2. The Regent’s Scan Cycle.

The main processors in each of the three processor modules run

programs and process communications synchronously, while the

I/O processors in each module read and write I/O synchronously.

During these synchronous operations, all instructions and data are

distributed across the Safetybus where automatic voting and fault

detection occur.

Main Processor

During each scan cycle, the main processor executes application

programs, reading inputs from the shared RAM and writing

outputs to the shared RAM.

PD-7000 Sep-04 (Issue 1) 3

Page 4

Processor Mo dules (T7110, 11, 12, 20, 21, and 2 2)

In addition to running application programs, the main processor

takes care of system overhead, such as:

• Background diagnostics including voter tests, read tests of the

EPROMs, and read-write tests of the RAM (this automatic test

is also what re-educates a new processor).

• Communications processing including reading from and

writing to the communications modules every one millisecond

and checking the communications messages at the end of each

scan.

• Fault filtering and reporting (which are available through

W

INTERPRET’s fault status and fault history features).

• Reading the communications module’s real-time clock (if a

real-time clock communications module is installed).

I/O Processor

During each scan cycle the I/O processor receives voted input data

into its local RAM and transfers it to the shared RAM — making it

available to the main processor. After being processed by the main

processor, output data are placed into the shared RAM and read by

the I/O processor into its local RAM and written to the outputs.

The I/O processor also shares in managing system overhead. This

overhead includes:

• Background I/O processor tests (voter tests, read EPROM tests,

and read-write local RAM tests).

• I/O module tests (I/O module voter tests, logic loopback tests,

and coordinating other I/O module tests).

• Fault filtering and reporting (which are available through

W

INTERPRET’s fault status and fault history features).

Testing and Diagnostics

Each processor module’s error detection logic is periodically tested

to ensure its continued correct operation. Testing is done using

self-tests that are automatically scheduled by each processor

module’s real-time operating system.

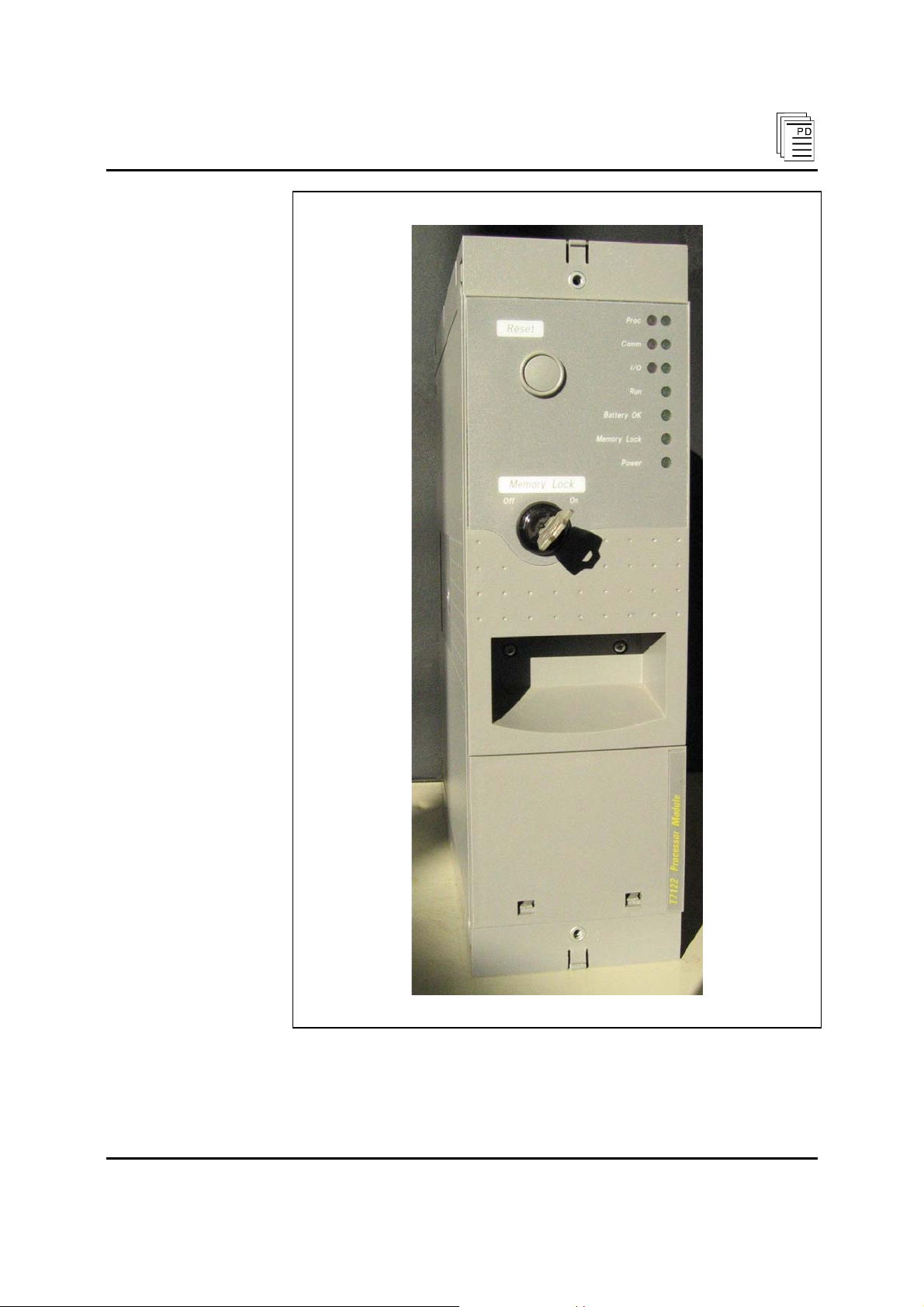

Front Panel Indicators and Controls

Figure 3 shows the physical features of the processor modules. The

front panel of each module contains status indicators as well as a

reset button and a memory lock keyswitch.

4 (Issue 1) Industrial Control Services

Page 5

Processor Mod ules (T7110, 11, 12, 20, 21, and 22 )

Figure 3. Processor Module.

PD-7000 Sep-04 (Issue 1) 5

Page 6

Processor Mo dules (T7110, 11, 12, 20, 21, and 2 2)

Processor Indicator

This red and green LED pair indicates the overall health of the

processor module. During normal operation the green PROC

indicator is on. If a module fault occurs the red indicator turns on

and the green indicator turns off.

Communications Indicator

This red and green LED pair indicates the overall health of the

system’s communications. During normal operation the green

COMM indicator is on. If a communications fault occurs the red

COMM indicator turns on and the green COMM indicator turns

off.

I/O Indicator

This red and green LED pair indicates the overall health of the

system’s I/O. During normal operation the green I/O indicator is

on. If an I/O fault occurs the red I/O indicator turns on and the

green indicator turns off.

An I/O module failure causes all of the processor modules to

indicate an I/O fault. An I/O transceiver module, I/O power

supply module, or I/O Safetybus cable fault causes only the

associated processor module to indicate an I/O fault.

Run Indicator

This green LED is off if the Regent has cold-started (system powerup without 2oo3 validated programs). After the RAMcode is

loaded the Run LED flashes slowly (about ½ Hertz). With at least

one program loaded and running this indicator will flash faster

(about 2 Hertz).

The RUN indicator will be on steadily when an application

program scan exceeds the maximum allowable scan time

(approximately 200 milliseconds for the 128 kbyte modules, and

400 milliseconds for the 512 kbyte modules).

Battery Indicator

The green BATT OK indicator shows whether the module’s battery

has sufficient power to maintain the programs in the processor. If

the battery has adequate power, this LED will be on. If the battery

needs to be replaced this LED will be off .

Memory Lock Indicator

This green LED indicates whether the module’s memory lock

keyswitch is in the on or off position. The MEMLK indicator will

be green when the keyswitch is in the on position.

6 (Issue 1) Industrial Control Services

Page 7

Processor Mod ules (T7110, 11, 12, 20, 21, and 22 )

The system’s memory lock status is voted: If at least two processor

modules are locked, the system is memory locked, if at least two

processor modules are unlocked, the system memory is unlocked.

Power Indicator

The green POWER indicator is on when the module is receiving

adequate power and its internal power supply is healthy.

Reset Button

A reset button is used to initiate the voted reset function. A voted

reset clears system fault indicators after a fault has been detected

and a module has been removed and replaced.

Pressing the reset buttons on two operating modules performs a

voted reset. During a voted reset, the processors continue to

execute the application programs and fault reporting is temporarily

suspended. If a new processor module has been inserted it is

synchronized and automatically educated by standard diagnostic

tests performed by the system. At the end of the voted reset all of

the internal fault status bits are reset and normal fault reporting is

enabled.

Note:

The time it takes the system to complete a voted reset may range

from a couple seconds to a few minutes. Larger processor memory

sizes and application program scan times will result in longer voted

reset times. However, during the voted reset, the system always

continues to read and write I/O, solve application programs and

perform communications functions normally.

Memory Lock Keyswitch

The memory lock keyswitch is used to prevent changes or

modifications to the system’s application programs. When the

memory lock keyswitch is in the off position, programs can be

modified.

The system’s memory lock status is voted: If at least two processor

modules are locked the system is memory locked, if at least two

processor modules are unlocked, the system memory is unlocked.

In WINTERPRET developed systems, changing the memory lock

status from off (unlocked) to on (locked) automatically disables all

input and output forcing. Forcing can be restored only by

unlocking the system memory and enabling the force tables again

using WINTERPRET.

PD-7000 Sep-04 (Issue 1) 7

Page 8

Processor Mo dules (T7110, 11, 12, 20, 21, and 2 2)

Application

Processor module type should be selected based on the main input

power voltage (110 VAC, 220 VAC, or 24 VDC) and on memory

requirements (128 kbytes or 512 kbytes). Each memory size

supports all programming functions and up to 16 chassis of I/O.

Typically, systems with more that 300 I/O points will require 512

kbytes of memory due the larger program size, increased data

handling, etc.

Note:

In WINTERPRET developed systems, approximately 64K bytes of

memory are used to store the RAMcode portion of the operating

system (27K) and internal workspace memory (37K) required for

miscellaneous system features.

Maintenance

Each of the Regent's processor modules has a replaceable lithium

battery. These batteries provide sufficient backup power to prevent

loss of memory during a power failure.

The batteries have a shelf life of approximately 10 years. When

providing power to the module's memory during a power failure,

the battery can provide backup power to a processor module's

memory for approximately six months.

Battery Replacement

To replace the battery in a processor module, lift the cover at the

bottom of the front panel,by easing the two retaining clips with a

screwdriver. Carefully remove the battery clips from the battery. Fit

a new battery, taking care to route the wires back inside the

module. Close the cover.

Replacing the battery on a live module will not cause a shutdown.

8 (Issue 1) Industrial Control Services

Page 9

Processor Mod ules (T7110, 11, 12, 20, 21, and 22 )

EPROM Replacement

EPROM replacement is necessary only when upgrading to a new

version of the TRIOS operating system.

Important!

Important!

Because processor modules with different EPROM sets cannot

operate together in the same system, replacing EPROMs in an

installed system will require shutting down the entire Regent

system.

To prevent damage to module components when replacing

EPROMs always follow proper electrostatic discharge prevention

procedures during disassembly and handling. This includes the use

of ESD mats and wrist straps.

Module Removal

Loosen the retaining screw at the top of the module. Open the two

module release levers by rotating them outward (toward you).

Carefully pull the module out of the controller chassis.

Replacing EPROMs

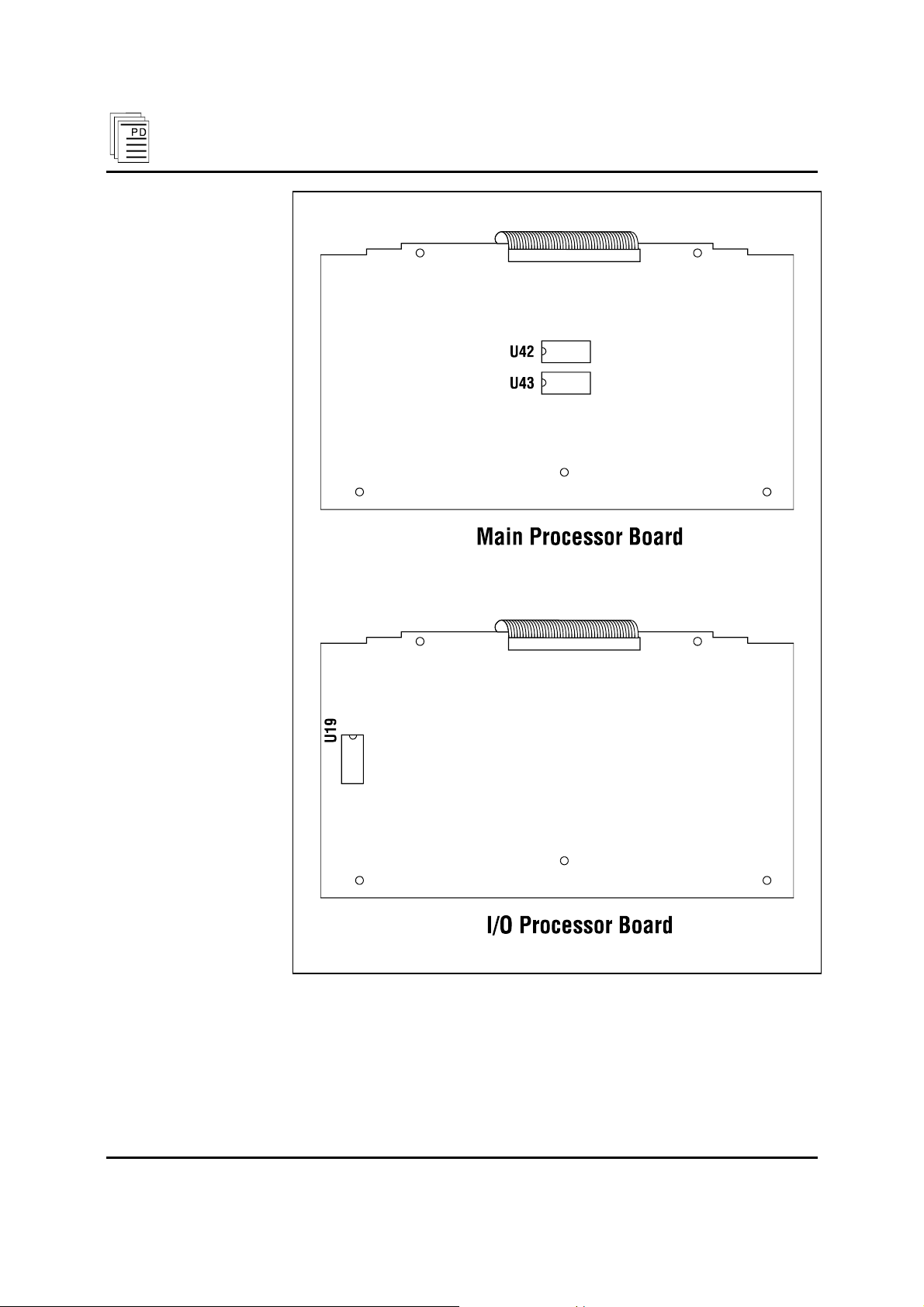

The three EPROMs in each module are labeled U42 and U43

(main processor) and U19 (I/O processor). Figure 4 shows the

locations of the EPROMs on each printed circuit board.

PD-7000 Sep-04 (Issue 1) 9

Page 10

Processor Mo dules (T7110, 11, 12, 20, 21, and 2 2)

Figure 4. Processor Module EPROM locations.

Remove EPROM U42 from the main processor board by rotating

the chip socket’s retaining clips outward. This will eject the chip

from its socket. Remove the old EPROM and place it on antistatic

foam off to one side.

10 (Issue 1) Industrial Control Services

Page 11

Processor Mod ules (T7110, 11, 12, 20, 21, and 22 )

Remove the new U42 EPROM from its packaging and inspect its

pins to make sure they are not bent.

Find the pin one index point (or notch) on the new EPROM.

Position the new EPROM in the chip socket so that the pin one

index point is facing the U42 label on the printed circuit board.

Carefully insert the new EPROM into the chip socket. It is often

easiest to align and partially insert the pins on one side of the chip

first, then align the other pins on the other side, and press the

EPROM carefully into place.

Before pressing the chip into place, check that all pins are properly

aligned in their respective holes. If the pins are not properly

aligned, carefully remove the chip and repeat the previous step.

Gently press the EPROM into the chip socket. As the EPROM is

pressed home the chip socket’s retaining clips will rotate inward to

secure the EPROM.

After fully inserting the EPROM, make a final check to ensure that

the pins are not bent, the pins are fully engaged and the EPROM

orientation is correct. If any pins are bent or the EPROM is not

oriented correctly, remove the EPROM and reinstall it.

Important!

If you install and apply power to a module with an EPROM

installed backwards the EPROM may be damaged. When the

EPROM is inserted backwards, power will be applied to incorrect

pins of the EPROM. If this happens, do not remove and re-insert

the same EPROM. Replace the incorrectly positioned EPROM

with a new EPROM.

Repeat the above steps for the U43 EPROM.

After installing the two new EPROMs in the main processor board,

rotate (or flip) the main processor board to one side to expose the

I/O processor board.

Locate the U19 EPROM on the I/O processor board and use the

steps described above to remove the old EPROM and install the

new EPROM.

PD-7000 Sep-04 (Issue 1) 11

Page 12

Processor Mo dules (T7110, 11, 12, 20, 21, and 2 2)

Reinstalling Modules

Reinstall the modules one at a time. To help make alignment

easier, install the first processor module in the left-most position,

the second module in the center position, and the third module in

the right-most position.

Open the two module release levers by pulling them toward you.

Carefully slide the module into the chassis. Be careful to keep the

module aligned while sliding it straight into the chassis.

The module should mount into the chassis with a minimum of

resistance. If the module does not mount easily, do not force it.

Remove it and check it for bent or damaged pins. If the pins look

okay, try reinstalling the module.

When the module is almost fully into the chassis, the release levers

will contact the chassis and begin to rotate closed. Press the levers

closed to seat the module in the chassis.

If the module does not seem to have seated correctly, open the

release levers and gently pull it back off the seat and out of the

chassis. Check for bent or damaged pins. If any pins are bent or

damaged do not install the module. Do not try to straighten bent

pins. Instead return the module to ICS for repair or replacement.

If the pins look okay, try reinstalling the module. You may need to

remove the board assembly and realign the CPU boards in the

assembly. See the tip, above.

After the module is properly seated, tighten the retaining screw at

the top of the module.

12 (Issue 1) Industrial Control Services

Page 13

Processor Mod ules (T7110, 11, 12, 20, 21, and 22 )

Safety Considerations

Processor module catalog numbers T7110, T7112, T7120 and

T7122 are TÜV certified for Risk Class 5 safety critical

applications. Catalog numbers T7111 and T7121 (220 VAC

powered modules) have not been certified as they do not meet the

DIN VDE 0110 requirements for creepage and clearances.

Specifications

Voltage Range

T7110/T7120:

T7111/T7121:

T7112/T7122:

Frequency Range

T7110/T7120:

T7111/T7121:

T7112/T7122:

Maximum Load

Fusing

Use with Chassis

T7110/T7120:

T7111/T7121:

T7112/T7122:

Power Hold-Up Time

Heat Dissipation

Fault Contact Rating

(Class II Connection Only)

Load Current (max.):

Load (min.):

Voltage (max.):

Switching Capacity

(max.):

85 to 132 VAC

170 to 263 VAC

20 to 30 VDC

47 to 63 Hz

47 to 63 Hz

—

100 VA

2 A, 250 V, slo blo (3AG),

(located on controller chassis)

T7100

T7101

T7102

10 msec, minimum

46 Watts, 156 BTUs/hour

1 amp

10 mV, 0.1 mA

30 VAC, 42.5 VDC

30 VA, 42.5 VAC (resistive)

Memory Size

128K:

512K:

Memory Type

PD-7000 Sep-04 (Issue 1) 13

T7110, T7111, T7112

T7120, T7121, T7122

Battery-backed CMOS RAM

Page 14

Processor Mo dules (T7110, 11, 12, 20, 21, and 2 2)

Battery Type

Battery Life

Under Load:

Shelf Life:

I/O Interface

Cable Length:

I/O Chassis:

Operating Temperature

Storage Temperature

Operating Humidity

Vibration

10 to 55 Hz:

Shock

Operating:

Li/SO2

6 months

10 years

Triple redundant I/O

Safetybus

150 cable feet (45 m),

maximum

16 chassis, maximum

0° to 60° C

(32° to 140° F)

-40° to 85° C

(-40° to 185° F)

0 to 95% relative humidity,

non-condensing

±0.15mm

15 g, ½ sine wave, 11 msec

Electromagnetic

Interference

• IEC 801 Part 2 - Electrostatic

Discharges

• IEC 801 Part 3 - Radiated

Electromagnetic Fields

• IEC 801 Part 4 - Transients

and Bursts

• IEC 801 Part 5 - Surge

Immunity

• ANSI/IEEE C37.90 - Surge

Withstand Capability

Safety

Dimensions

Height:

Width:

Depth:

Level 3: Contact discharge of 6

kV

Level 3: 10 V/M, 27 MHz 500 MHz

Level 4: 2 kV, 2.5 kHz for t =

60 sec

Level 3: 2 kV

2.5 kV damped 1 MHz sine

wave

4 kV bi-directional impulse, 10

nsec rise time, fast transient

Designed to meet UL 508 and

CSA 22.2, No. 142-M1981

12.6" (320 mm)

1.27" (32 mm)

10.125" (257 mm)

14 (Issue 1) Industrial Control Services

Page 15

Processor Mod ules (T7110, 11, 12, 20, 21, and 22 )

Weight

7.5 lbs (3.4 kg)

PD-7000 Sep-04 (Issue 1) 15

Loading...

Loading...