Page 1

x

T6200

Ics triple

User’s Guide

__________________________________________________________________________ ___________________________

T6200

Compressor Anti-Surge and Capacity Controller

Issue 1

May 2004

Page 2

Copyright 2004 ICS Triplex

Contents of this manual may not be reproduced

in any form without the written permission of ICS Triplex.

Printed in the United States of America.

Specifications are subject to change without notice.

A/S VIEW MOPS, and T6200

are trademarks of ICS Triplex,

Information furnished by ICS TRIPLEX is believed to be

accurate and reliable. However, no responsibility

is assumed by ICS TRIPLEX for its use.

T6200

USER’S GUIDE

ICS Triplex p/n 9001-0220

Issued May 2004

ICS Triplex, Inc.

4325 West Sam Houston Pkwy. North

Suite 100

Houston, Texas 77043-1219 USA

Phone: 713-353-2400 Fax: 713-353-2401

www.icstriplextmc.com

Page 3

T6200

User’s Guide

TABLE OF CONTENTS

SECTION 1 – PRODUCT OVERVIEW

Design Structure.............................................................. ................................................................................1-3

Analog and Discrete Input/Output.................................. ................................................................................1-4

Line Power and Transmitter Power................................ ................................................................................1-5

System Security .............................................................. ................................................................................1-5

On Line Diagnostics........................................................ ................................................................................1-6

Configuration Security..................................................... ................................................................................1-6

Controller Redundancy................................................... ................................................................................1-6

Dual Non-Redundant Controller………………………………………………………………………………….1-6

SECTION 2 – INPUT/OUTPUT CIRCUIT DESCRIPTION

Analog Voltage Inputs..................................................... ................................................................................2-3

Analog Current Inputs..................................................... ................................................................................2-4

Analog Current Outputs .................................................. ....................................................... .........................2-4

Isolated Discrete Inputs .................................................. ................................................................................2-6

Discrete Inputs with Excitation from Controller.............. ................................................................................2-6

Discrete Outputs.............................................................. ................................................................................2-8

Discrete Outputs with Internal Power............................. ................................................................................2-8

Discrete Outputs with External Power............................ ................................................................................2-9

Active/Standby Logic....................................................... ................................................................................2-9

SECTION 3 – HARDWARE INSTALLATION/MAINTENANCE

Site Selection Considerations......................................... ................................................................................3-3

Access Considerations ................................................... ................................................................................3-3

T6200 Controller Mounting ............................................. ......................................................... .......................3-4

T6200 Controller Electrical Power Wiring...................... ................................................................................3-6

T6200R Subrack Electrical Power Connection ............. ................................................................................3-8

Input/Output Hardware Configuration ............................ ................................................................................3-9

Signal Wiring.................................................................... ...............................................................................3-10

Wiring and Jumper Placement for T6200C Channels 1-8............................................................................3-12

Wiring and Jumper Placement for T6200C Channels 9-16..........................................................................3-13

Wiring and Jumper Placement for T6200C Channels 17-22, 31, and 32.................................................... 3-14

Wiring and Jumper Placement for T6200C Channels 23-26 .......................................................................3-16

Wiring for T6200C Channels 27-30................................ ...............................................................................3-17

Wiring and Jumper Placement for T6200D Channels 1-26, 31, and 32 ......................................................3-17

Wiring for T6200D Channels 27-30................................ ...............................................................................3-19

Ethernet Communication Network ................................. ...............................................................................3-19

Network Security ............................................................. .................................................. .............................3-19

Ethernet Network Connectors………………………………………………………… ....................................3-19

Network Cabling.............................................................. ...............................................................................3-20

Non-Redundant Network................................................ ...............................................................................3-20

Redundant Network………………………………………………………………………………………………3-21

T6200R Subrack Ethernet…… .....................................................................................................................3-23

Operator Interface Installation ........................................ ...............................................................................3-24

Firmware Changes.......................................................... ...............................................................................3-27

Serial Communication Connection................................. ...............................................................................3-28

3

Page 4

T6200

User’s Guide

SECTION 4 - SOFTWARE INSTALLANTION

The Micon OPC Server Compact Disc .......................... ................................................................................4-2

Install the Packet Driver Software .................................. ........................................................... .....................4-2

Install the Micon OPC Server and Related Components...............................................................................4-5

Ethernet Addresses......................................................... ................................................................................4-7

SECTION 5 - T6200 CONTROLLER OPERATION

Push to Activate Switch .................................................. ................................................................................5-5

System Start-up............................................................... ................................................................................5-6

Replacing Control Boards............................................... ................................................................................5-6

Loading Controller Configuration.................................... ................................................................................5-8

Watchdog Timer.............................................................. ................................................................................5-8

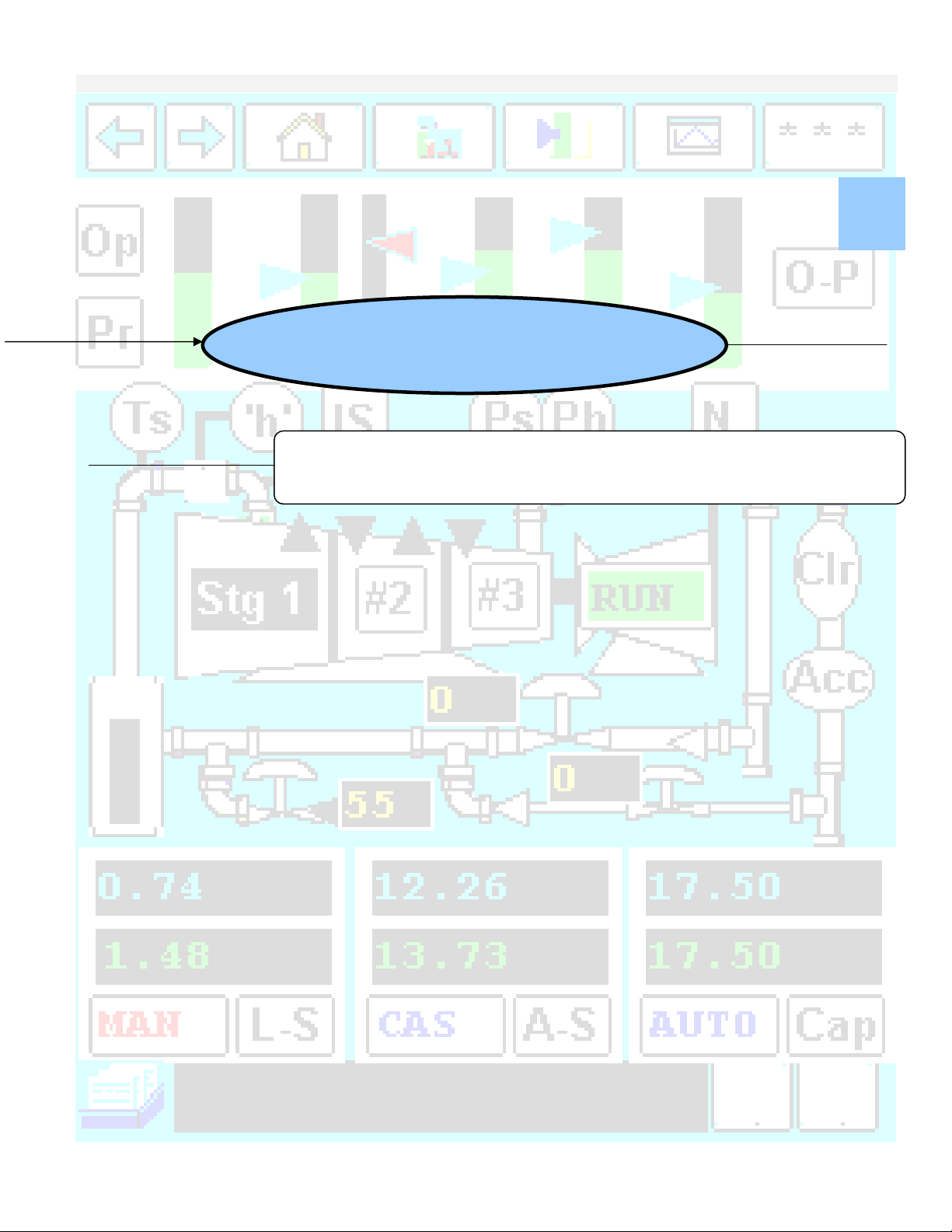

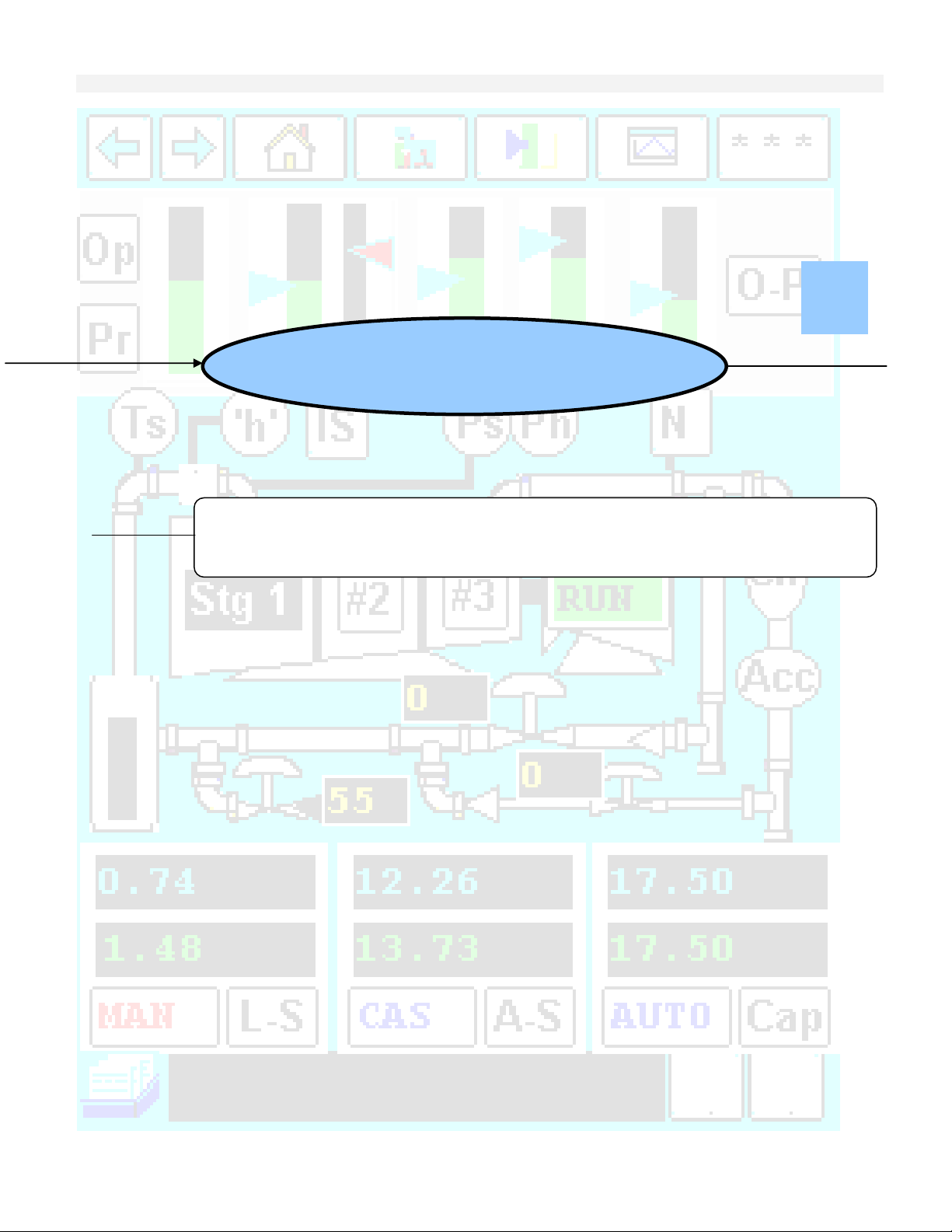

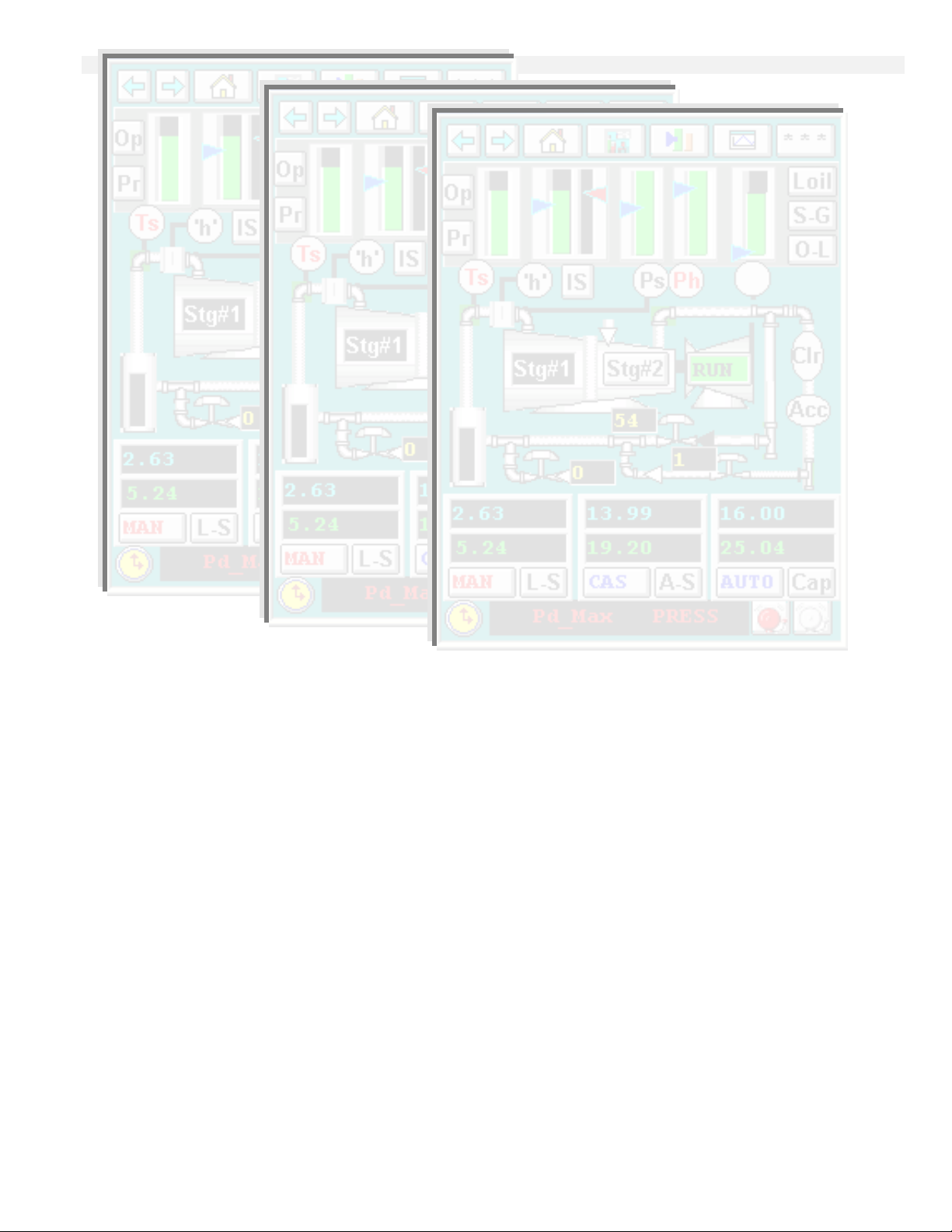

SECTION 6 – HMI-6200 OPERATOR INTERFACE

Preface............................................................................. ................................................................................6-2

Overview of HMI-6200 Features .................................... ................................................................................6-4

Event Information Processing......................................... ................................................................................6-6

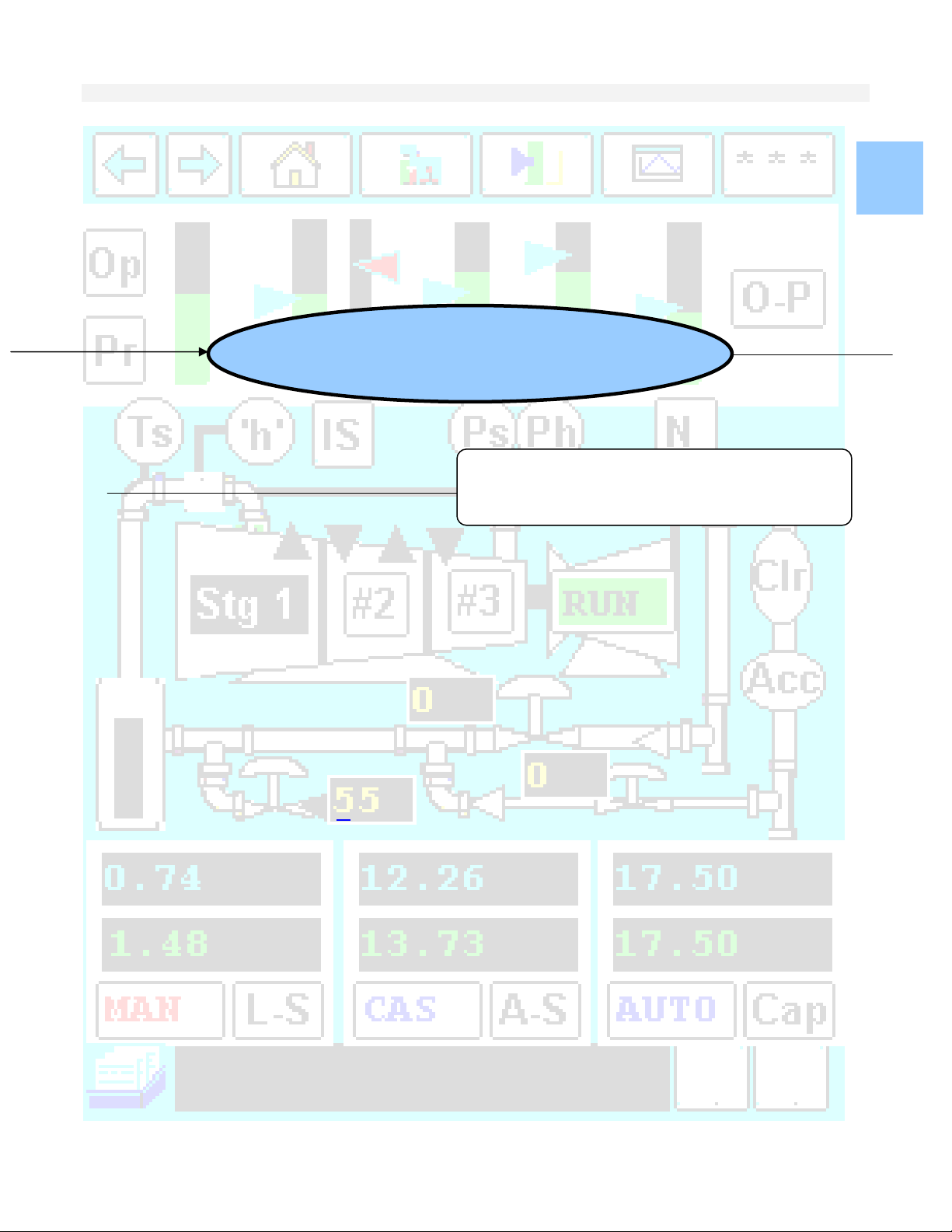

Display Layout................................................................. ...............................................................................6-15

General Display Description........................................... ...............................................................................6-18

Graphic Displays Configuration...................................... ...............................................................................6-21

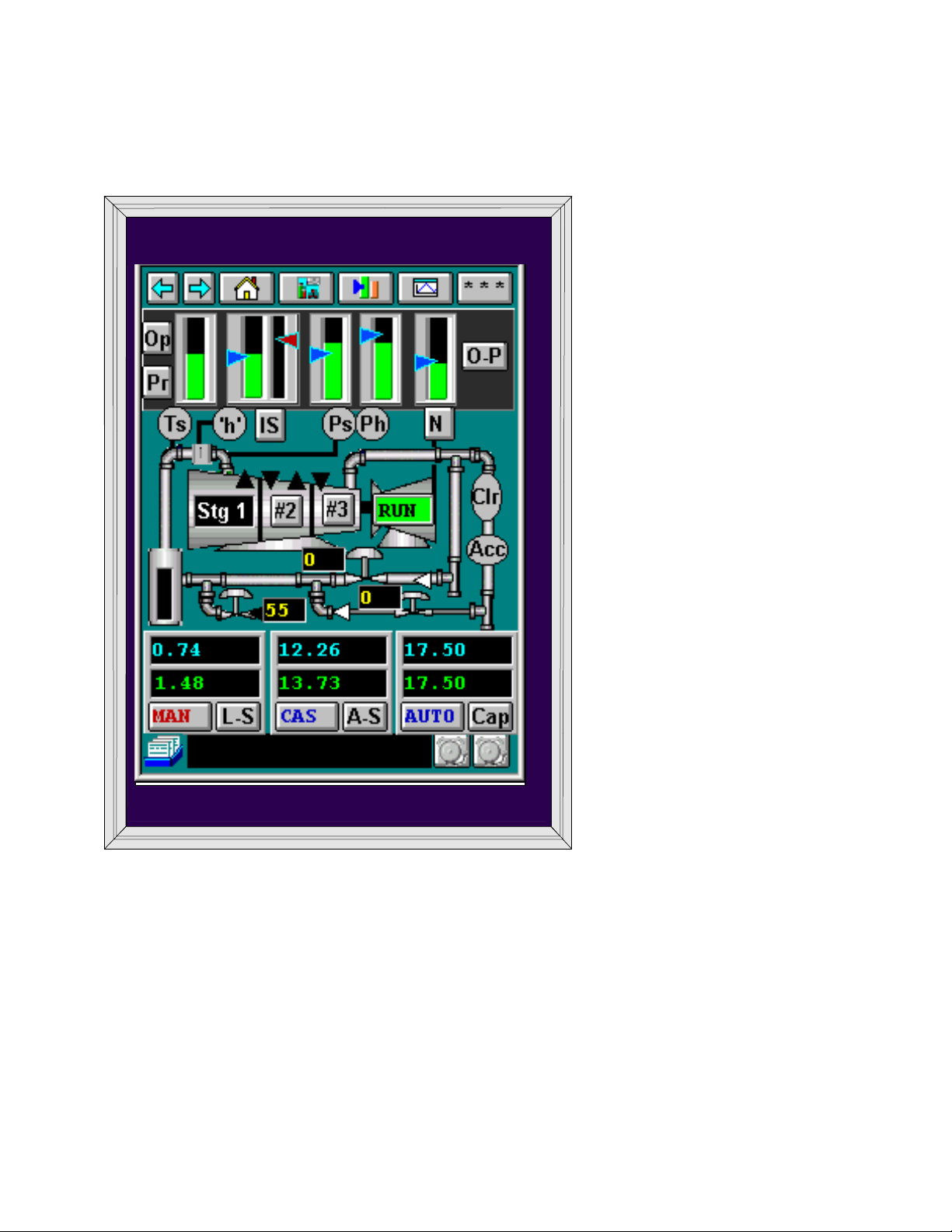

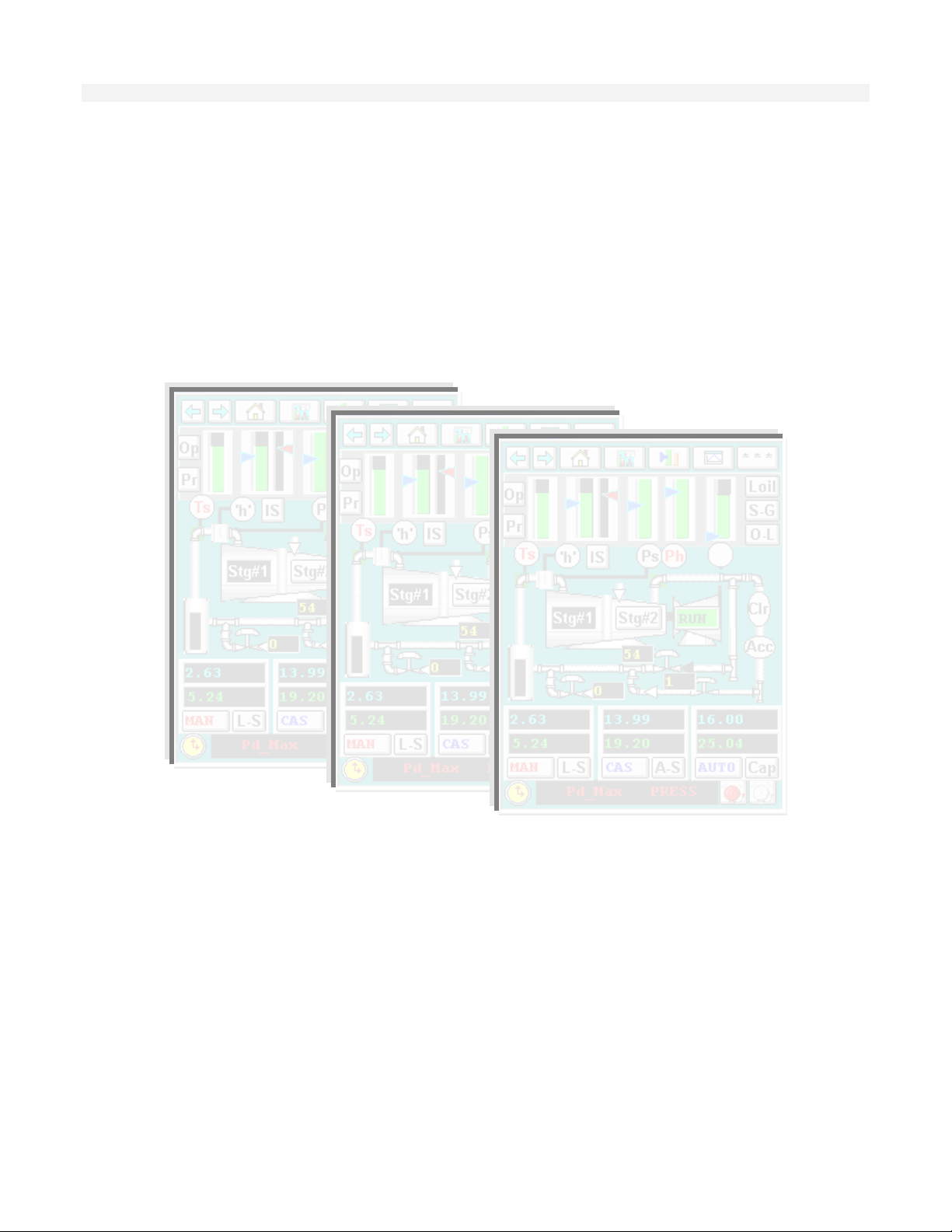

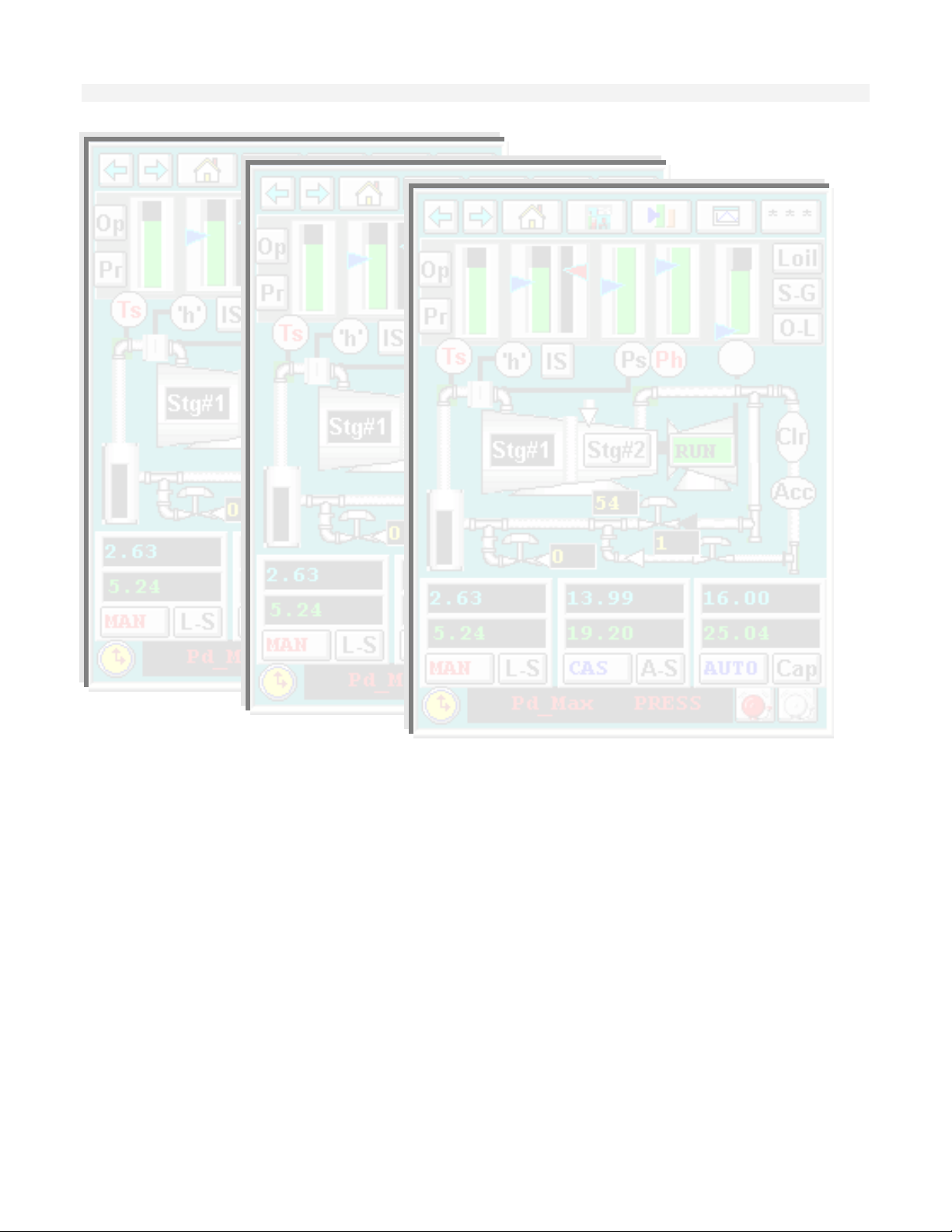

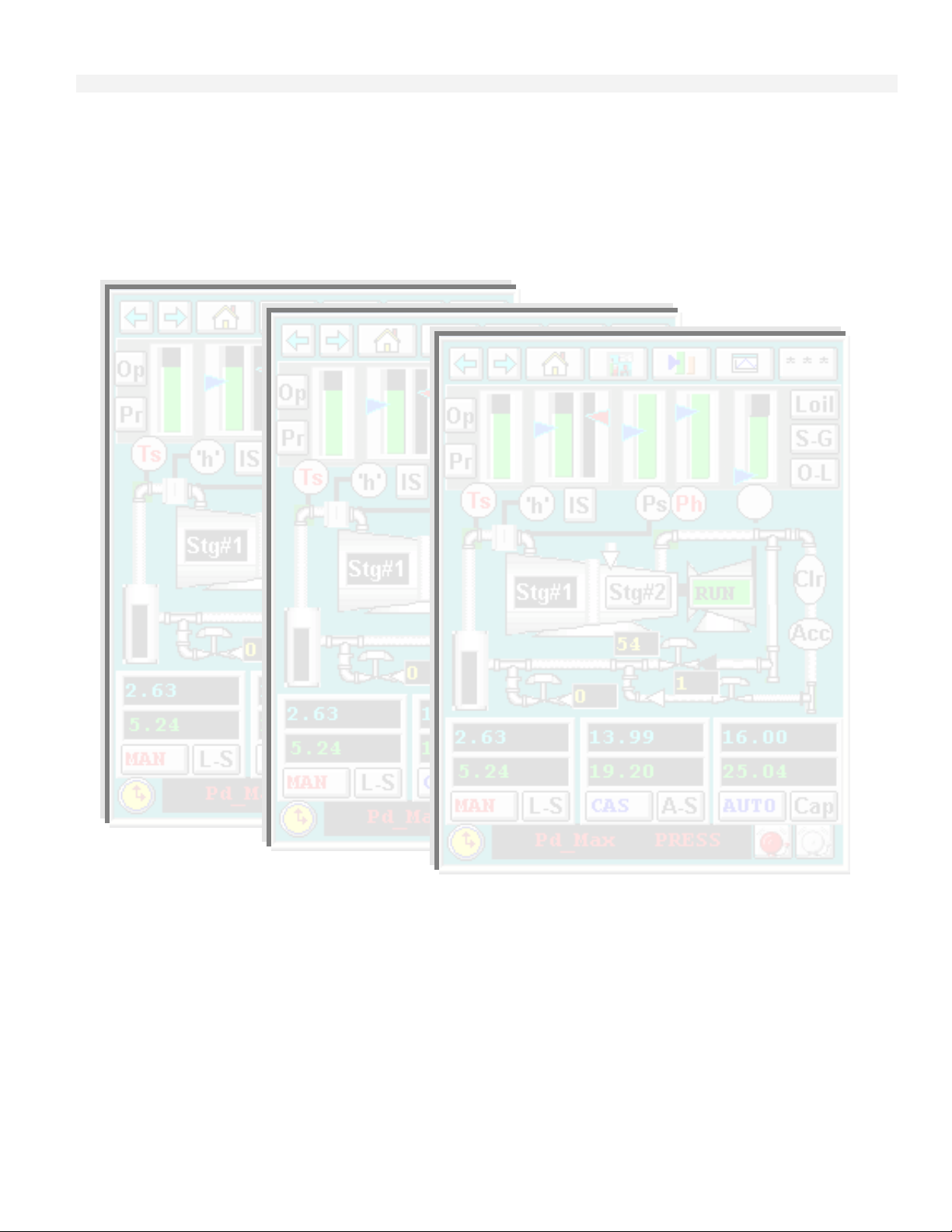

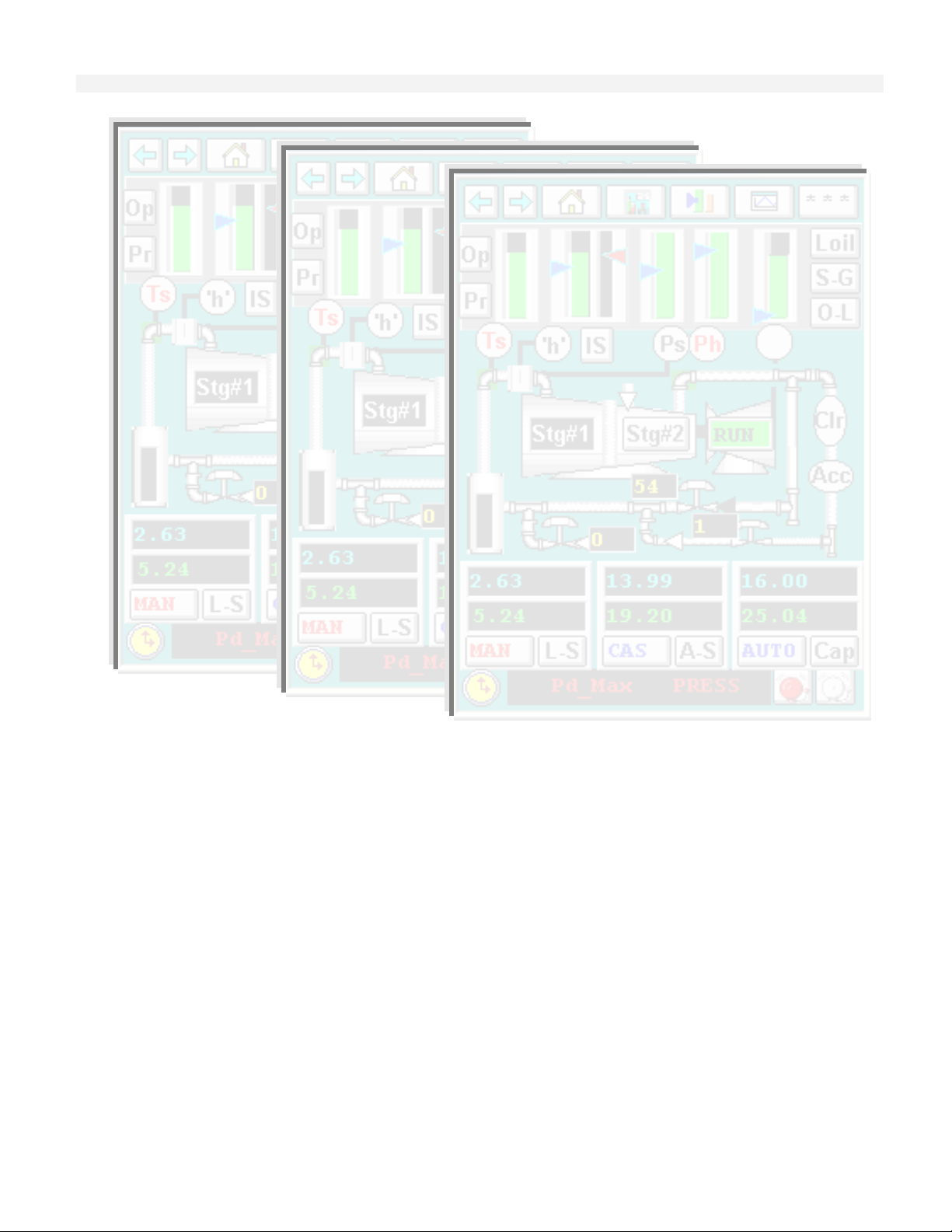

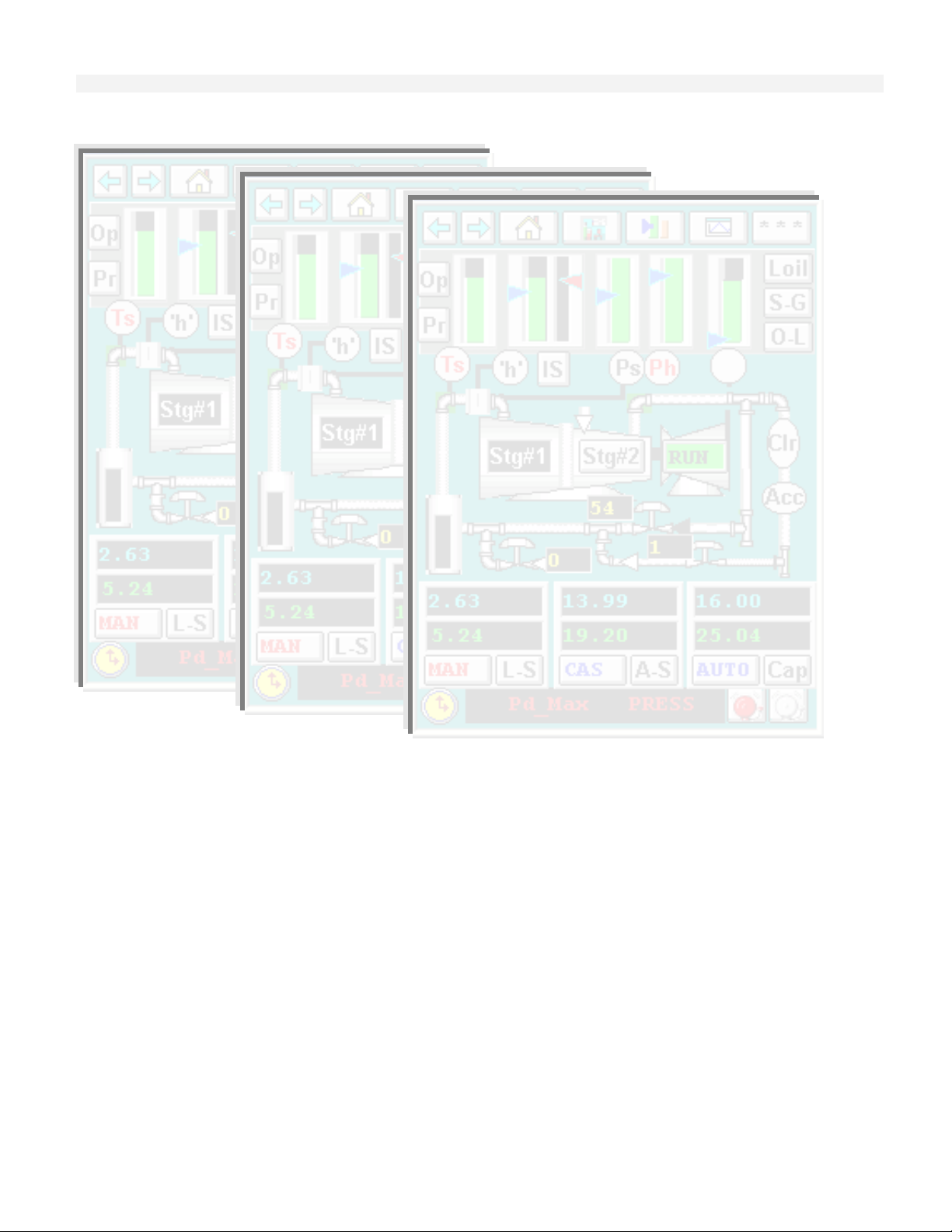

HMI Example – Single Stage Compressor.................... ...............................................................................6-22

Adaptation of Pre-Defined Displays ............................... .............................................................. .................6-25

Surge Curve Screens...................................................... ...............................................................................6-29

Custom Graphic Screens................................................ ...............................................................................6-30

Configuring the Security System.................................... ...............................................................................6-31

Communications.............................................................. ...............................................................................6-34

Downloading the Updated Application........................... ...............................................................................6-38

SECTION 7 – CONTROL PRIMER

Proportional (P) Action.................................................... ................................................................................7-4

Integral (I) Action… ......................................................... ................................................................................7-8

Derivative (D) Action ....................................................... ................................................................................7-8

Proportional-Plus-Integral (PI) Action……………………………………………………………………………7-9

Proportional-Plus-Derivative (PD) Action………………………………………………………………………..7-10

Proportional-Plus-Integral-Plus-Derivative (PID) Action………………………………………………………..7-11

Interactive and Non-Interactive Control………………………………………………………………………….7-12

Deadtime……………………………………………………………………………………………………………7-13

Cascade Control.............................................................. ................................................................................7-14

Ratio Control.................................................................... ................................................................................7-16

Damping........................................................................... ................................................................................7-16

4

Page 5

T6200

User’s Guide

SECTION 8 – CONFIGURATION

Preface............................................................................. ................................................................................8-3

Configuration Studio........................................................ ................................................................................8-4

Running the FBD Configurator Workbench................... ................................................................................8-4

Function Block Diagram (FBD) Editor............................ ...............................................................................8-10

Miscellaneous Workbench Features.............................. ...............................................................................8-16

Adaptation of Pre-Defined Configuration....................... ...............................................................................8-22

MICON OPC Server Start-up........................................................................................................................8-39

SECTION 9 – SPECIFICATIONS

APPENDIX A – DATA STRUCTURES AND EXPRESSIONS

Tags................................................................................. ................................................................................A-3

Reserved Words.............................................................. ................................................................................A-6

Labels............................................................................... ................................................................................A-7

Data Types ...................................................................... ................................................................................A-7

Logical Operations .......................................................... ................................................... .............................A-7

Arithmetic Operations...................................................... ................................................................................A-8

Relational Operations...................................................... ................................................................................A-8

Unary Operations............................................................ ................................................................................A-8

Expression....................................................................... ................................................................................A-9

Truth Tables..................................................................... ...............................................................................A-11

Logic Evaluation Rules ................................................... ...............................................................................A-11

Boolean Logic Rules ......................................................................................................................................A-11

APPENDIX B – MODBUS INTERFACE – RS-232

Preface............................................................................. ................................................................................B-2

T6200 MODBUS Functions Supported………………………………………………………………………….B-2

T6200 MODBUS Configuration…………………………………………………………………………………..B-3

5

Page 6

T6200

User’s Guide

6

Page 7

Product Overview

Section One

1

Product Overview

Design Structure 3

Analog and Discrete Input/Output 4

Line Power and Transmitter Power 5

System Security 5

On Line Diagnostics 6

Configuration Security 6

Controller Redundancy 6

Dual Non-Redundant Controller 6

1-1

Page 8

Product Overview

1-2

Page 9

Product Overview

PRODUCT OVERVIEW

The T6200 Controller is made up of two parts: The Operator Interface and the T6200 Controller.

The Operator Interface with the Windows CE platform enables complete interaction with the T6200

Controller. Through the touch screen and LCD display users can change setpoints, outputs, start/stop

devices, scroll through trends, or acknowledge alarms. The T6200 Controller functions as a

multiapplication Controller or intelligent RTU capable of performing all data acquisition, continuous

control, batch control, logic control and RTU requirements. Each T6200 Controller includes 999

function blocks in which control/logic functions can reside. The integral input/output (I/O) section

of each T6200 Controller accommodates 32 I/O points. The large library of functions (over 100) and

the practically unlimited number of blocks allow for pre-configuration of a wide variety of strategies

by the factory and permits field application optim izat ion.

Design Structure

The Operator Interface is an embedded PC. It is independent of the T6200 Controller and it

communicates with the T6200 Controller via Ethernet.

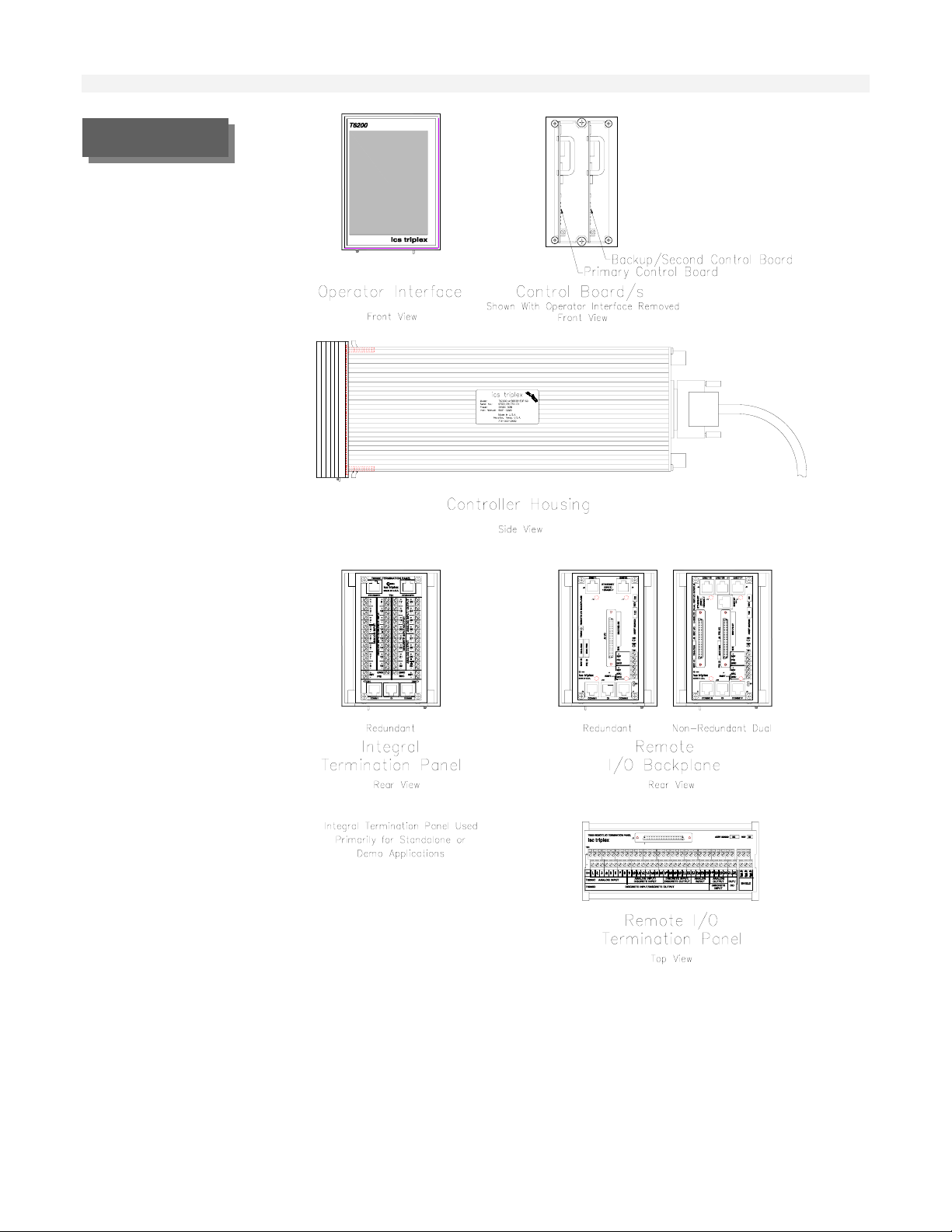

The T6200 Controller consists of three physical parts: the control board/s (single or redundant), the

controller housing, and the termination panel. Refer to Figure 1-1. The termination panel may also

include a remote termination panel for the I/O connections.

The control boards are a single printed circuit board design. The board contains the microprocessor

circuitry, the memory chips, the communication interfaces, and the input/output conditioning

components. Primary and backup control boards are identical.

1-3

Page 10

FIGURE 1-1.

T6200 Unit Controller

Product Overview

Analog and Discrete Input/Output

Analog inputs can be either current or voltage. High common mode (200 Volts) amplifiers are

utilized. Each input has a separate input amplifier. Also, each two wire transmitter input (4-20mA)

is provided with a separate internal 24 volt regulator. Analog outputs source up to 20 milliamperes

to the user’s receiver (load).

Most discrete inputs are opto-isolated (refer to specifications). The sample rate resolution of one

millisecond provides for first out sequence of events capability. Three of these inputs can be

1-4

Page 11

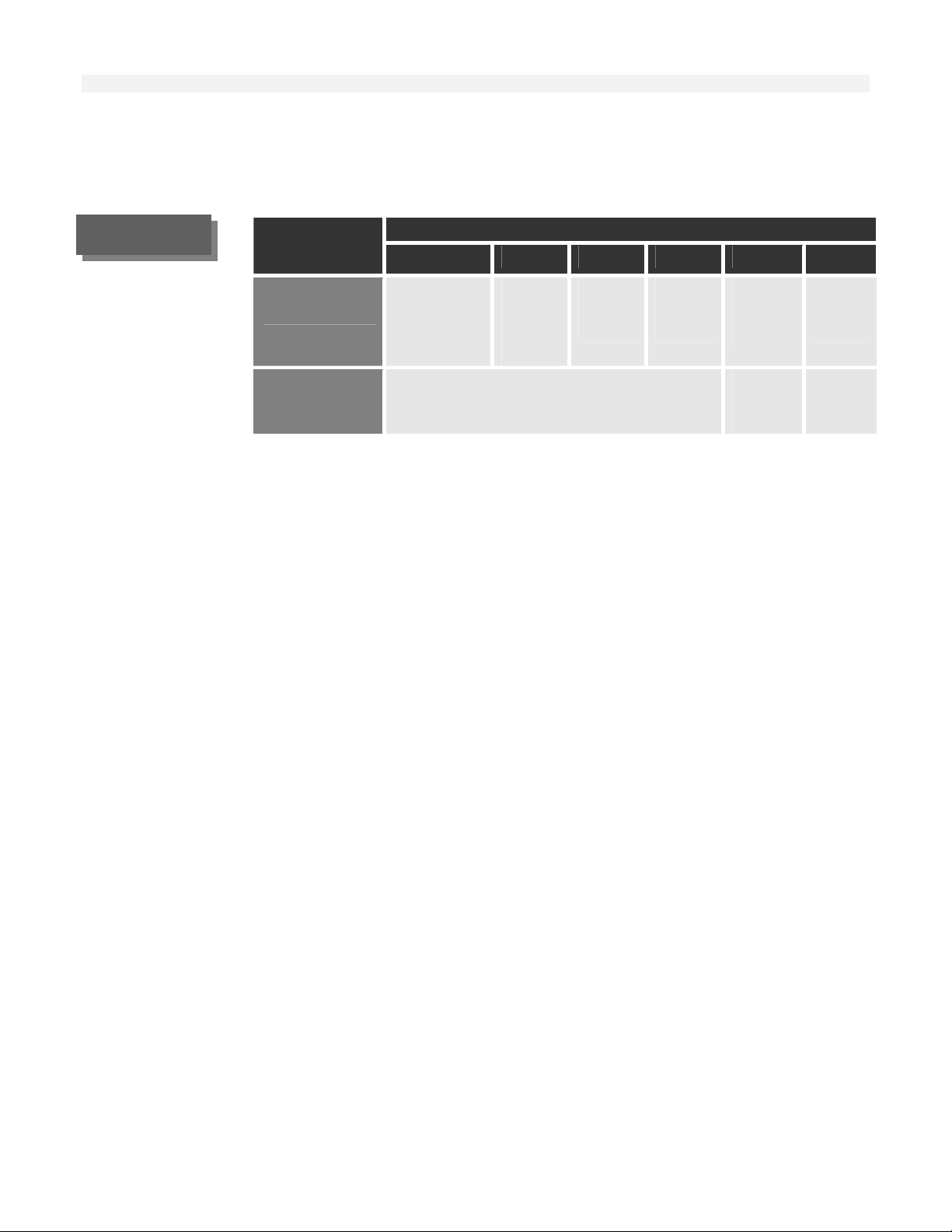

TABLE 1-1 .

TABLE 1-1.

Input/Output

Channel Assignments

Product Overview

configured as frequency/pulse inputs. Discrete outputs are transistor configurations. A separate

internal 24 volt regulator is supplied for each input/output.

The internal I/O section of the Controller accommodates 32 I/O points. Refer to Table 1-1 for I/O

channel assignment information.

I/O Channel Numbers

Type

T6200C

T6200D

1 - 8 9 – 16 17 - 22 23-26 27 - 30 31 - 32

Analog

Input

Analog

or

Discrete

Discrete

I/O *

Analog

I/O

Analog

Output

Discr

I/O*

Input

Discrete I/O

Discrete

Input

Discr

I/O*

* Channels 22, 31 and 32 can also be configured as a frequency/pulse input. C hannel 32 can also be

configured as a frequency/pulse output.

The process signals supported by the T6200 Controllers are:

• Analog Inputs (4-20 mA, ±20 mA, ±10 Vdc) internally or ext ernally powered

• Analog Outputs (4-20 mA, 0-20 mA)

Discrete Inputs (On-Off contacts) internally or externally powered

Discrete Outputs - internally or externally powered

Pulse Inputs (up to 25 kHz)

Line Power and Transmitter Power

The T6200 Controllers operate on 26 Vdc power. The T6200R subrack supplies redundant AC to

DC power supplies or the 26 Vdc can be obtained from any other reliable power source. Terminal

blocks are provided on the termination panel for primary and secondary (redundant) 26 Vdc power

input. Power for field transmitters, I/Ps, field switches, etc., is distributed through the T6200

Controller eliminating separate input/output power supplies and circuitry.

Both power supplies operate continuously. If one unit fails, it is not necessary to switch to the other

power supply. Both of the 26 Vdc sources are diode-isolated in the T6200 Controller to prevent the

failure of one from affecting the other. The supplies feed redundant power distribution traces on the

termination panel.

System Security

The Controller maximizes its reliability and availability by a design incorporating complete

redundancy of memory, intelligence, communication, and power. The redundancy includes total

process input/output circuitry backup. And, since each termination panel can accommodate both the

primary and backup control boards, the architecture allows for simple plug-in of the redundant

control board. No wiring or cabling is required for redunda nt confi gurati ons.

The integral backup communication link of each unit assures that both control boards (primary and

backup) maintain the same data base. Each control board has its own on-line, sophisticated

1-5

Page 12

diagnostics and also monitors the status of the other control board which provides for a reliable

transfer and redundancy scheme.

On Line Diagnostics

The T6200 Controller has on-line diagnostics designed to identify failures quickly. On all (primary

and backup) operator interfaces, highways, local communications, the Controller run diagnostics on

a continuous basis. These routines continuously check the status of critical device functi ons t o det ect

failures.

If a failure is detected an alarm is activated to inform the operator and the backup unit is enable d.

Configuration Security

The T6200 Controllers maintain identical configuration at all times. At startup, when both control

boards are powered up, the backup control board’s memory is always cleared, and the active control

board transfers the configuration to the backup control board through the backup serial link, if it has

a backup control board.

During operation (runtime), if new configuration is downloaded (to active control board), it

automatically goes to both the primary and the backup control board. Thus configuration integrity is

achieved and there are no mismatches.

Uninterrupted communication and control is provided by automatically transferring all configuration

and communications of the active control board to the backup redundant control board. There is a

complete transparency in the redundant control board. Apart from notification of failure, there is no

change in the operator interface.

Product Overview

Controller Redundancy

The T6200 Controller redundancy concept allows the user to simply plug-in a backup control board

side-by-side with the primary control board. The user has no installation or cable connection

requirements. Termination panel data links enable the backup to copy the input/output and control

configuration of the primary control board and to assume virtually immediately the input/output and

control functions in case of a primary malfunction.

Each control board contains, in addition to the input/output functions, an extensive library of control

algorithms. Thus, the T6200 Controllers can be configured as totally stand-alone intelligent

controllers or RTUs. This minimizes dependency on communications, resulting i n high reliabi lity.

Dual Non-Redundant Controller

The T6200 Dual Non-Redundant Controller concept allows the user to have two independent

controllers (a primary and a second controller) in one chassis thereby reducing the required panel

space by half. With this option, two T6200-C Controller cards or two T6200-D Controller cards or a

T6200-C and a T6200-D Controller card may be plugged into a single chassis. Two Rem ote I/O

Termination Panels (one for the primary controller and one for the second controller) are requi red

with this concept. The Dual Non-Redundant Controller option should onl y be used when c ontrol le r

redundancy is not foreseen as a requirement.

1-6

Page 13

Input/Output Circuit Description

Section Two

Analog Voltage Inputs 3

Analog Current Inputs 4

Analog Current Outputs 4

Isolated Discrete Inputs 6

Discrete Inputs with Excitation from Controller 6

Discrete Outputs 8

Discrete Outputs with Internal Power 8

Discrete Outputs with External Power 9

Active/Standby Logic 9

Input/Output Circuit Description

2

2-1

Page 14

Input/Output Circuit Description

2-2

Page 15

Input/Output Circuit Description

INPUT/OUTPUT CIRCUIT

DESCRIPTION

Each control board in the T6200 Controller incorporates the µP, memory, communicat ions and I/O

circuitry. Separate I/O modules are not required.

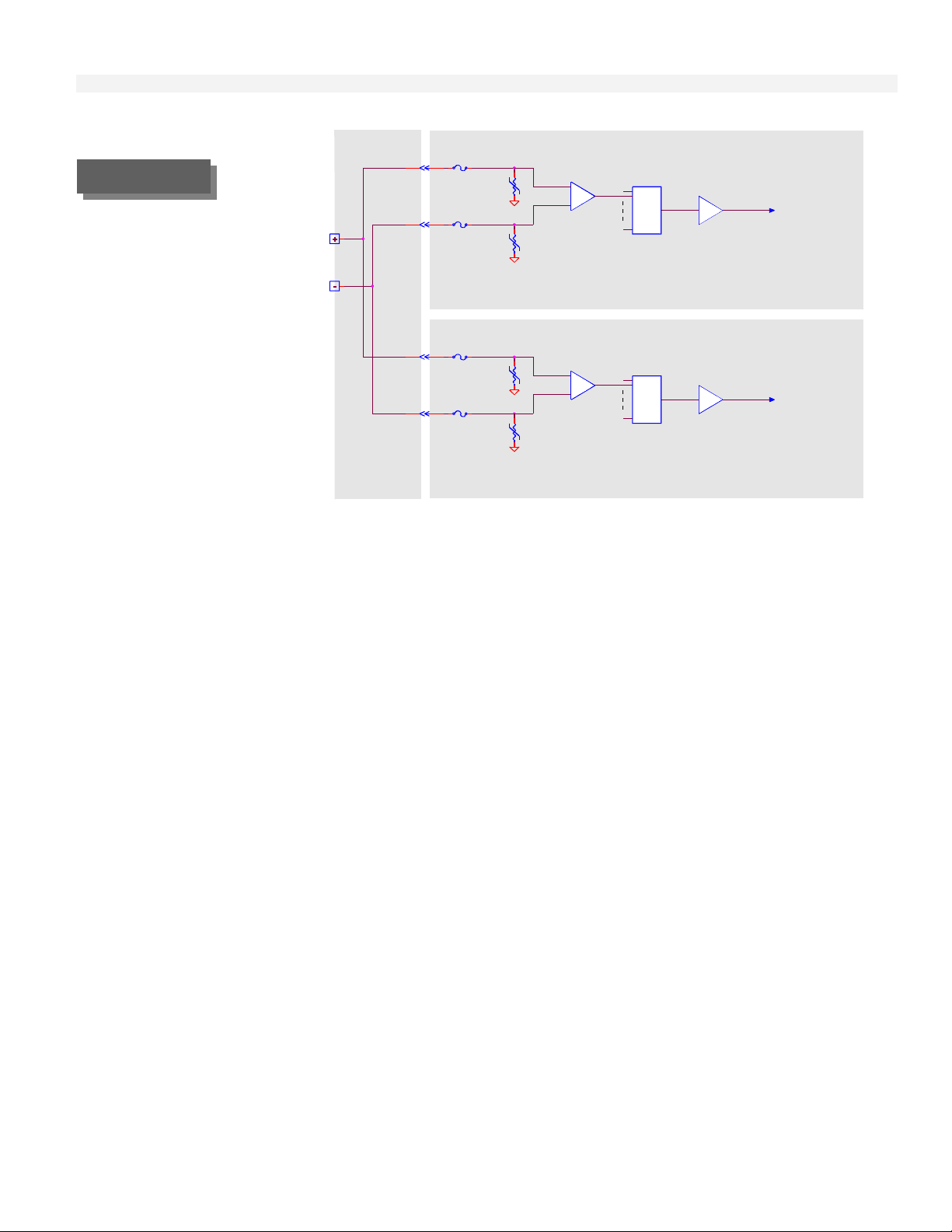

Analog Voltage Inputs

Up to 20 channels in the T6200-C Controller can be configured with field changeable jumpers for

voltage inputs. In reference to Figure 2-1, the input amplifier does not have galvanic isolation but it

appears to have it in most applications because of its high common-mode voltage and its high input

resistance. The 100 volt transient absorbers on each input will allow up to 100 volts dc or 75 volts

ac (rms, sine wave) continuously or up to 104 volts impulse voltage to enter the amplifier. The

amplifier will continue to operate with up to 200 volt s on it s inputs.

Each input has a separate input amplifier. The output of each of these amplifiers passes to the

analog switch. Only one of these inputs is selected at one time. The selected signal continues to the

programmable gain amplifier (PGA). The microprocessor selects the optimum gain setting for the

PGA. The possible input full scale ranges that can be selected are 0.625, 1.25, 2.5, 5, and 10 volts.

Inputs may be either polarity.

The voltage input configuration can be used as a current input by putting a resistor between the “+”

and “-” input terminals. Use a 250 ohm resistor for a 4 to 20 milliampere loop and a 100 ohm

resistor for a 10 to 50 milliampere loop.

2-3

Page 16

Input/Output Circuit Description

Primary Control Board

To ADC

FIGURE 2-1

Analog Voltage

Input

Analog

Voltage

Input

Termination

Panel

1A

100V

1A

100V

200 Volt

Common-mode

Amplifier

Analog

Switch

Programmable

Gain Amplifier

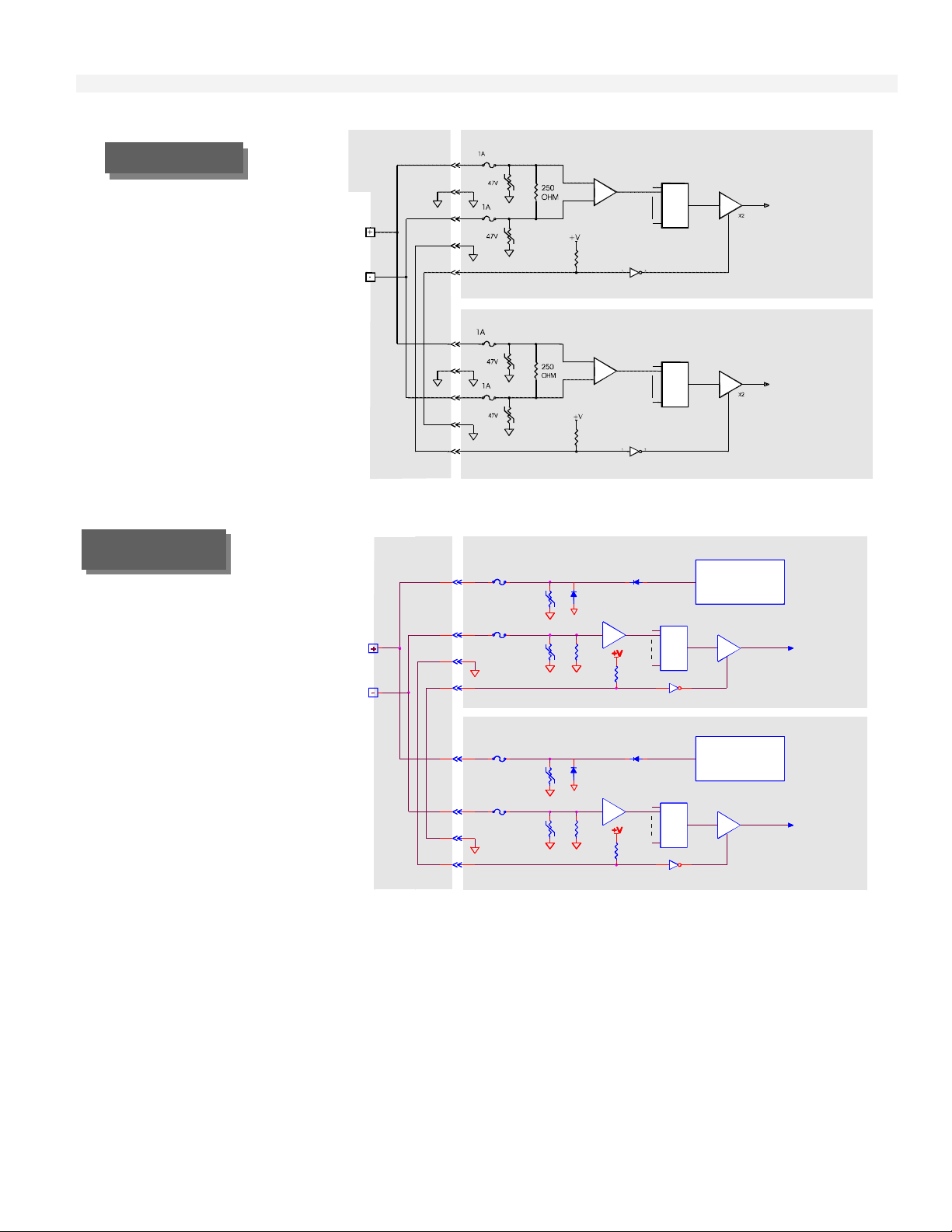

Analog Current Inputs

The current input is similar to the voltage input with 250 ohm resistor across the amplifier inputs. Field

changeable jumpers are used to select between voltage or current input. The maximum continuous input

current is 20 mA and 40 mA momentary. Refer to Figure 2-2. Also the gain is increased in the PGA by a

factor of two when a backup control board is present, to compensate for the decrease in voltage that the

additional 250 ohm resistor will cause.

When an isolated two-wire 4 to 20 milliampere transmitter is used, the circuit shown in Figure 2-3 m ay be

used. In this configuration a separate internal +24 volt voltage regulator is used for each transmitter. Each

voltage regulator has thermal, reverse voltage, and short-circuit protection. In this arrangement, one end

of the 250 ohm resistor is connected to circuit common. The two-wire 4-20 mA represents the standard

analog input jumper selection.

1A

100V

1A

100V

200 Volt

Common-mode

Amplifier

Analog

Switch

Programmable

Gain Amplifier

Backup Control Board

To ADC

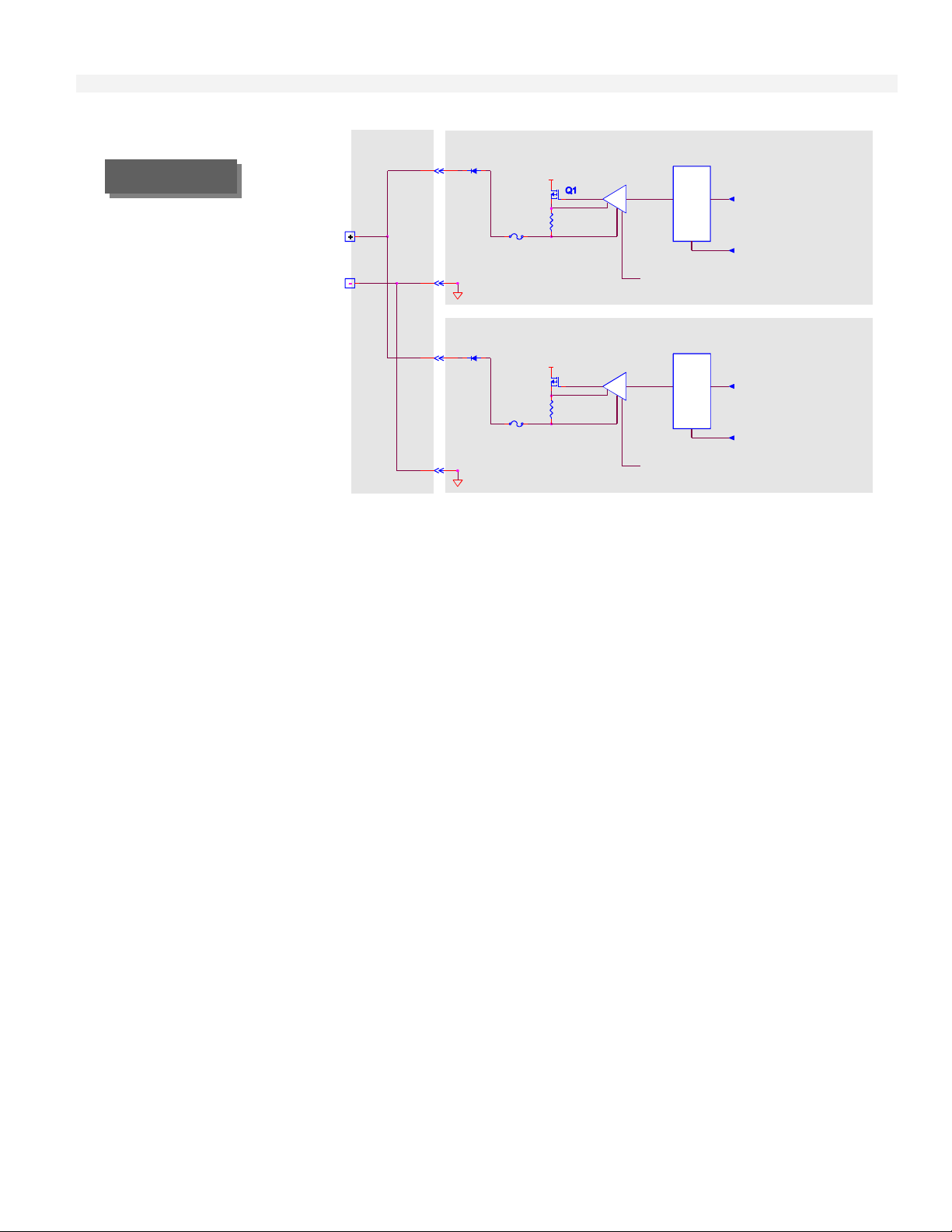

Analog Current Outputs

The T6200 Controller can be configured from four to eight current out put s. The current out put will source

from 0 to 20 milliamperes to the user's receiver (load). The receiver must share the same circuit common

as the T6200 Controller. The maximum receiver resistance is 1000 ohms.

In reference to Figure 2-4, the digital to analog converter (DAC) receives a digital value from the

microprocessor and converts it to an analog voltage. The voltage to the current converter, combined with

transistor Q1 and the 50 ohm resistor, converts the voltage to a current signal.

The output of the primary and backup control boards are connected together on the Controller termination

panel. The output is only enabled in the active control board. The diode is used to block the current from

the active control board.

2-4

Page 17

Input/Output Circuit Description

FIGURE 2- 2

Analog Current

Input

4-20 MA

Input

Termination

Panel

200 Volt

Common-mode

Amplifier

Analog

Switch

Primary Control Board

Program mable

Gain Amplifier

To AD C

FIGURE 2- 3

Two-Wire

Transmitter Input

200 Volt

Common-mode

Amplifier

Analog

Switch

Backup Control Board

Program mable

Gain Amplifier

To AD C

Primary Control Board

Voltage

Regulator with

short-circuit

protection

Programmable

Gain Amplifier

X2

Backup Control Board

Voltage

Regulator with

short-circuit

protection

Gain Amplifier

X2

To ADC

To ADC

Two-Wire

Transmitter

Input

Termination

Panel

1A

100V

1A

100V

1A

100V

1A

100V

24 VDC

250

OHM

24 VDC

250

OHM

Analog

Switch

Analog

Switch Programmable

+V

2-5

Page 18

Input/Output Circuit Description

FIGURE 2-4.

Analog Current

Output

Analog

Current

Output

Termination

Panel

125mA

125mA

+25.2V

+25.2V

50

OHM

50

OHM

Voltag e to

Current

Converter

DAC

Reset

Active from Figure 2-9

Voltag e to

Current

Converter

Q1

DAC

Reset

Active from Figure 2-9

Primary Control Board

From

Microprocessor

Inhibit from Figure 2-9

Primary Control Board

From

Microprocessor

Inhibit from Figure 2-9

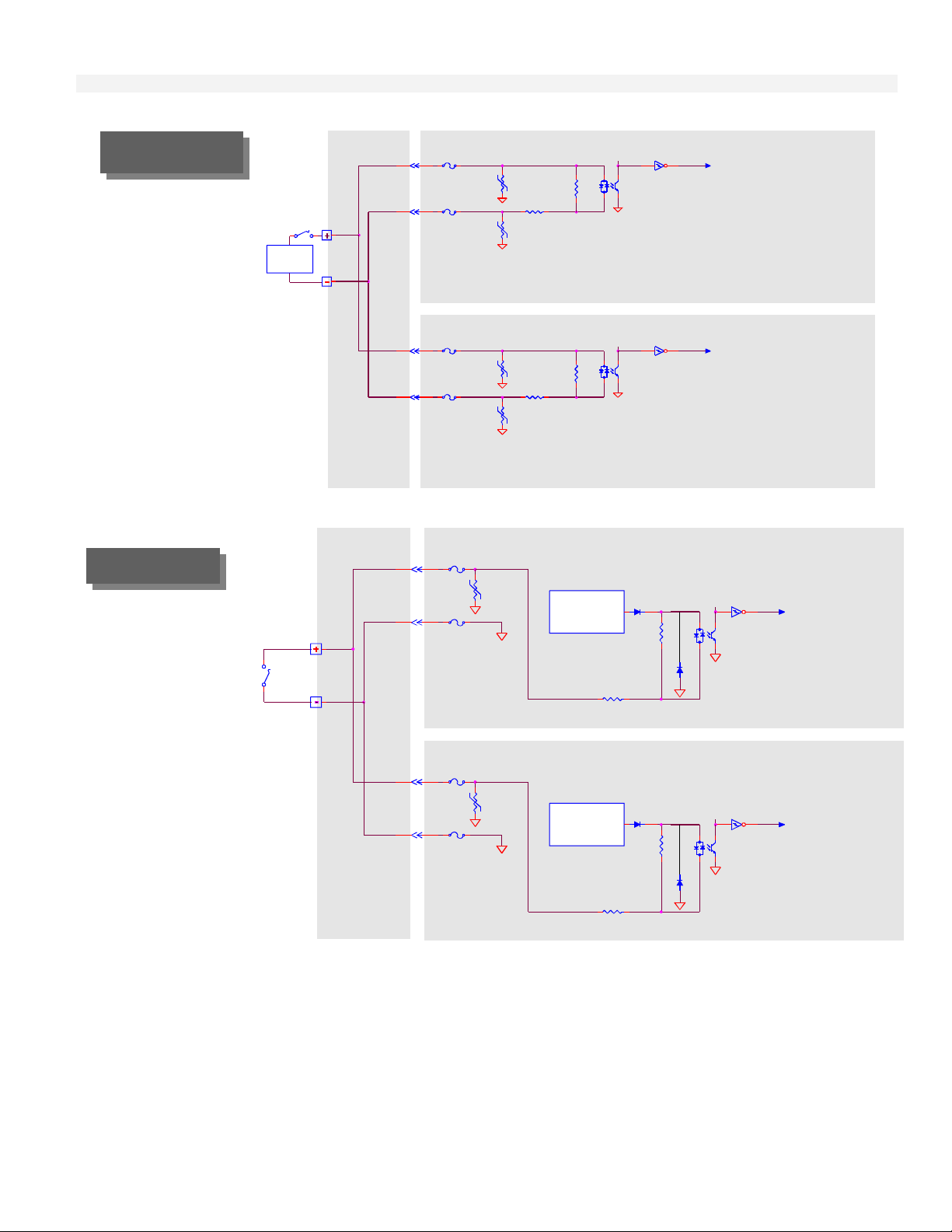

Isolated Discrete Inputs

The T6200-C Controller can be configured for up to 16 isolated discrete inputs. The T6200-D Controller

can be configured for up to 28 isolated discrete inputs in addition to the four internally power discrete

inputs. The resistor, in series with the input, is used to limit the maximum current to less than 6.5

milliamperes. In reference to Figure 2-5, the resistor across the opto-isolator is used to increase the

minimum input current to greater than one milliampere.

The opto-isolator provides electrical isolation between inputs and other circuits. Each input is protected

with fuses. A 100 volt transient absorber is provided on each input terminal to prevent arcing between

conductors on the circuit board. The maximum voltage that can be applied continuously is 38 volts dc or

30 volts ac (rms, sine wave). Discrete input channels 22, 31, and 32 can be used as frequency inputs, with

input frequencies up to 25 kHz. Other discrete inputs can be used as frequency inputs with input

frequencies up to 500 Hz.

Discrete Inputs with Excitation from Controller

The discrete input is similar to the isolated discrete input above, without the isolation. The input is

internally powered. In this configuration a separate internal +24 volt regulator is provided for each dry

contact input. Each voltage regulator has thermal, reverse voltage, and short circuit protection. The

regulator supplies up to five milliamperes.

A contact closure between + and – terminals will activate the input. Refer to Figure 2-6. The internally

powered discrete input represents the standard discrete input jumper selection. The T6200 Controller has

a minimum of four internally powered discrete inputs.

2-6

Page 19

Input/Output Circuit Description

FIGURE 2- 5.

Isolated Discrete

Input

Power

Termination

Panel

1A

100V

1A

100V

1A

100V

1A

100V

1.8K

4.7K

1.8K

4.7K

Primary Control Board

Input to

Microprocessor

Backup ControlBoard

Input to

Microprocessor

FIGURE 2-6.

Discrete Input with

Excitation from

Controller

Termination

Panel

1A

100V

1A

1A

100V

1A

Voltage

Regulator

Voltage

Regulator

24 VDC

1.8K

4.7K

24 VDC

1.8K

4.7K

Primary Control Board

Input to

Microprocessor

Backup Control Board

Input to

Microprocessor

2-7

Page 20

Input/Output Circuit Description

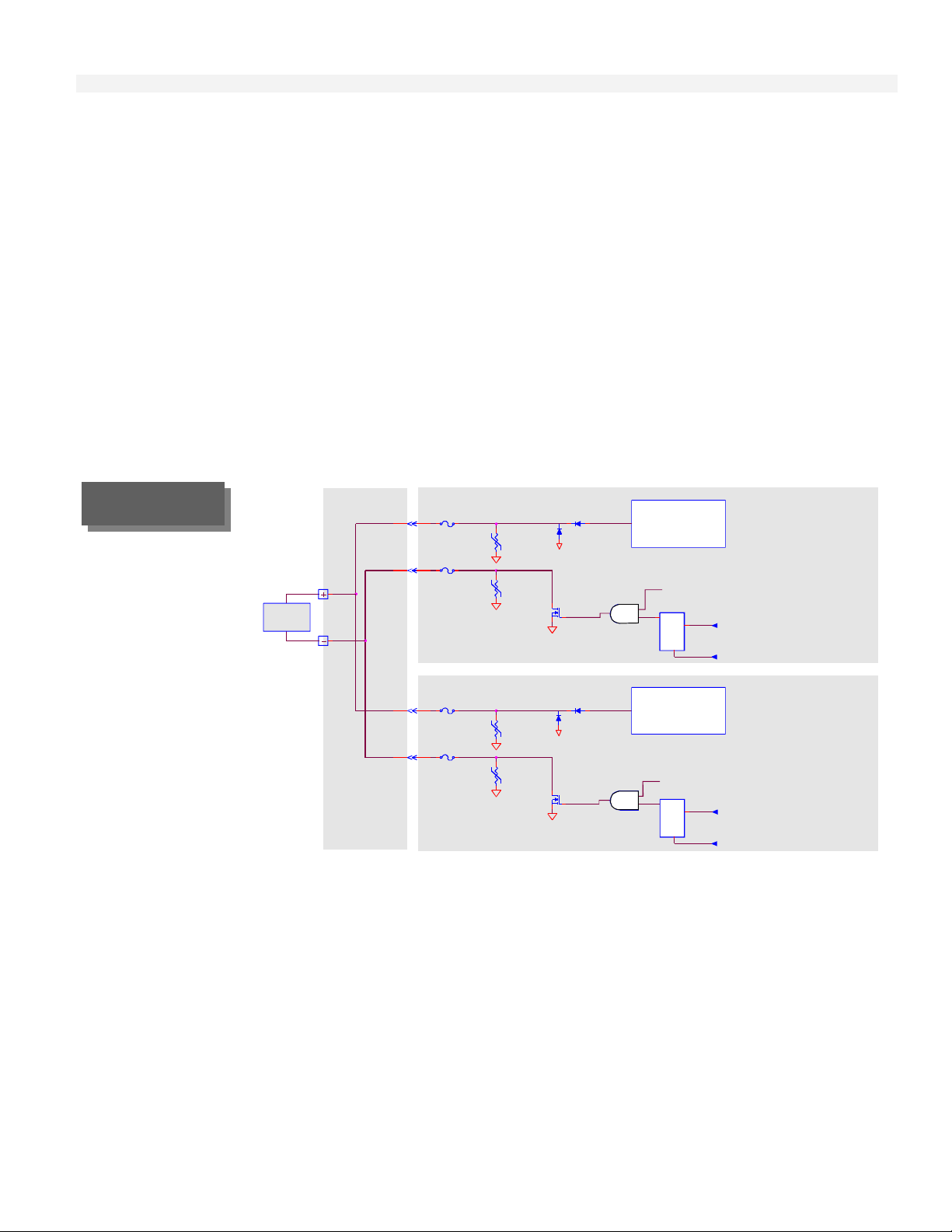

Discrete Outputs

The T6200-C Controller can be configured for up to eight discrete outputs. The T6200-D Controller can

be configured for up to 28 discrete outputs. A 100 volt transient absorber is connected on each terminal to

protect the output transistor and to prevent arching between conductors on the circuit board. Each

terminal is protected with a one ampere fuse.

The output transistor in the standby (not ACTIVE) control board is alway s open.

Discrete output 32 can be used as frequency output, with output frequencies up to 10 kHz. Other discrete

outputs can be used as frequency outputs with output frequencies up to 100 Hz.

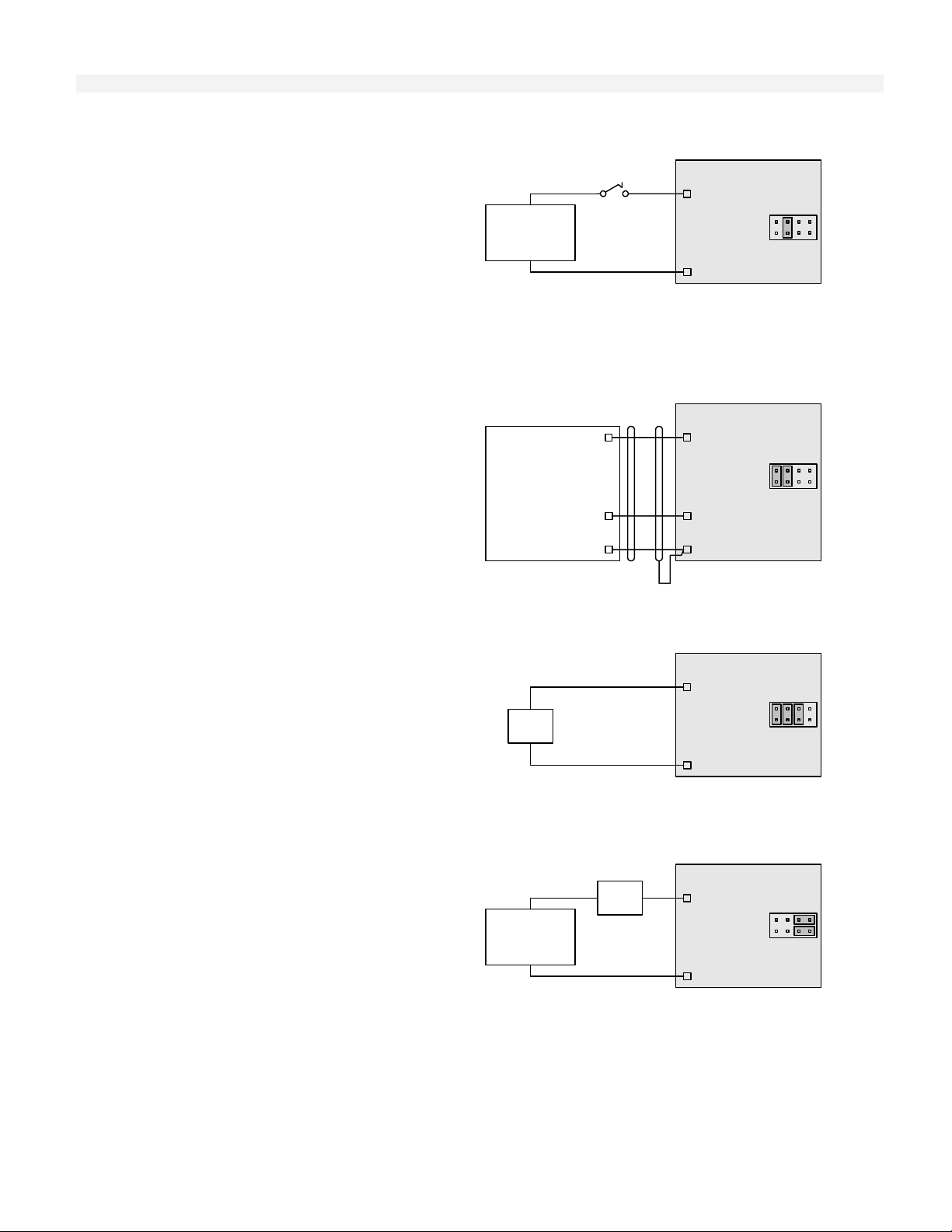

Discrete Outputs with Internal Power

In reference to Figure 2-7, a separate internal +24 volt voltage regulator is provided for each output. Each

voltage regulator has thermal, reverse voltage, and short-circuit protection. The regulator can supply 24

Vdc power for a load up to 20 milliamperes continuously and 100 mill iam peres momentarily .

FIGURE 2-7

Discrete

Output with

Internal Power

LOAD

<20 mA

Termination

Panel

1A

100V

1A

100V

24 VDC

Voltage

Regulator with

short-circuit

protection

Active from Figure 2-9

Latch

RS

Primary Control Board

Output from

Microprocessor

Inhibit from Figure 2-9

1A

100V

1A

100V

24 VDC

Voltage

Regulator with

short-circuit

protection

Active from Figure 2-9

Latch

RS

Backup Control Board

Output from

Microprocessor

Inhibit from Figure 2-9

2-8

Page 21

Input/Output Circuit Description

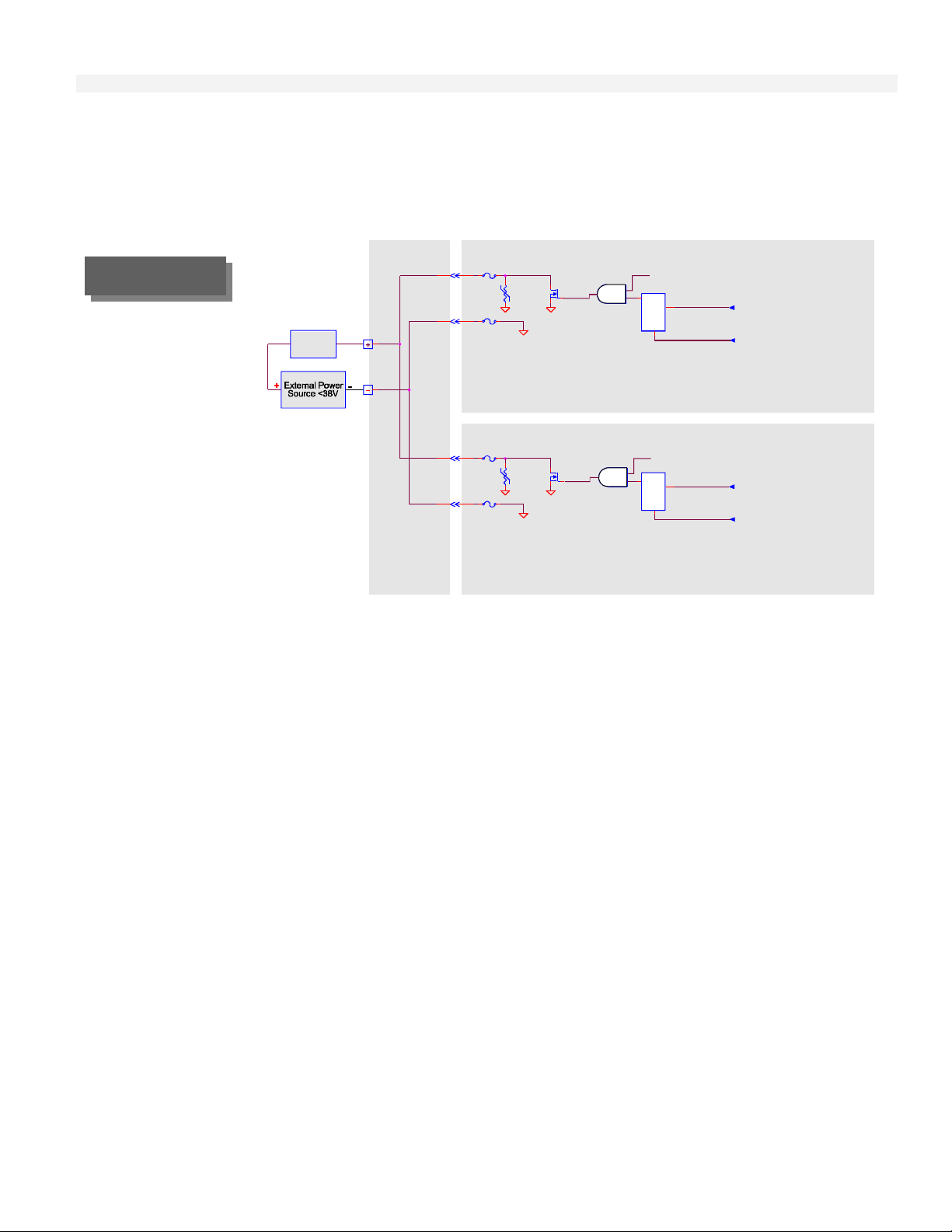

Discrete Outputs with External Power

In reference to Figure 2-8, the discrete transistor output with an external power source can sink up to 0.25

amperes continuously and one ampere momentarily. The maximum voltage that can be applied

continuously is 38 volts DC. The return (-) of the external power source must be connected to the “-”

input or “-” power terminal of the T6200 Controller.

Primary Control Board

Output fr om

Microprocessor

Inhibit from Figure 2-9

Backup Contr ol Board

Output fr om

Microprocessor

Inhibit from Figure 2-9

FIGURE 2-8.

Discrete Output

with External

Power

Load

<0.25A

T e rmination

Panel

1A

100V

1A

1A

100V

1A

Active from Figure 2-9

Latch

RS

Active from Figure 2-9

Latch

RS

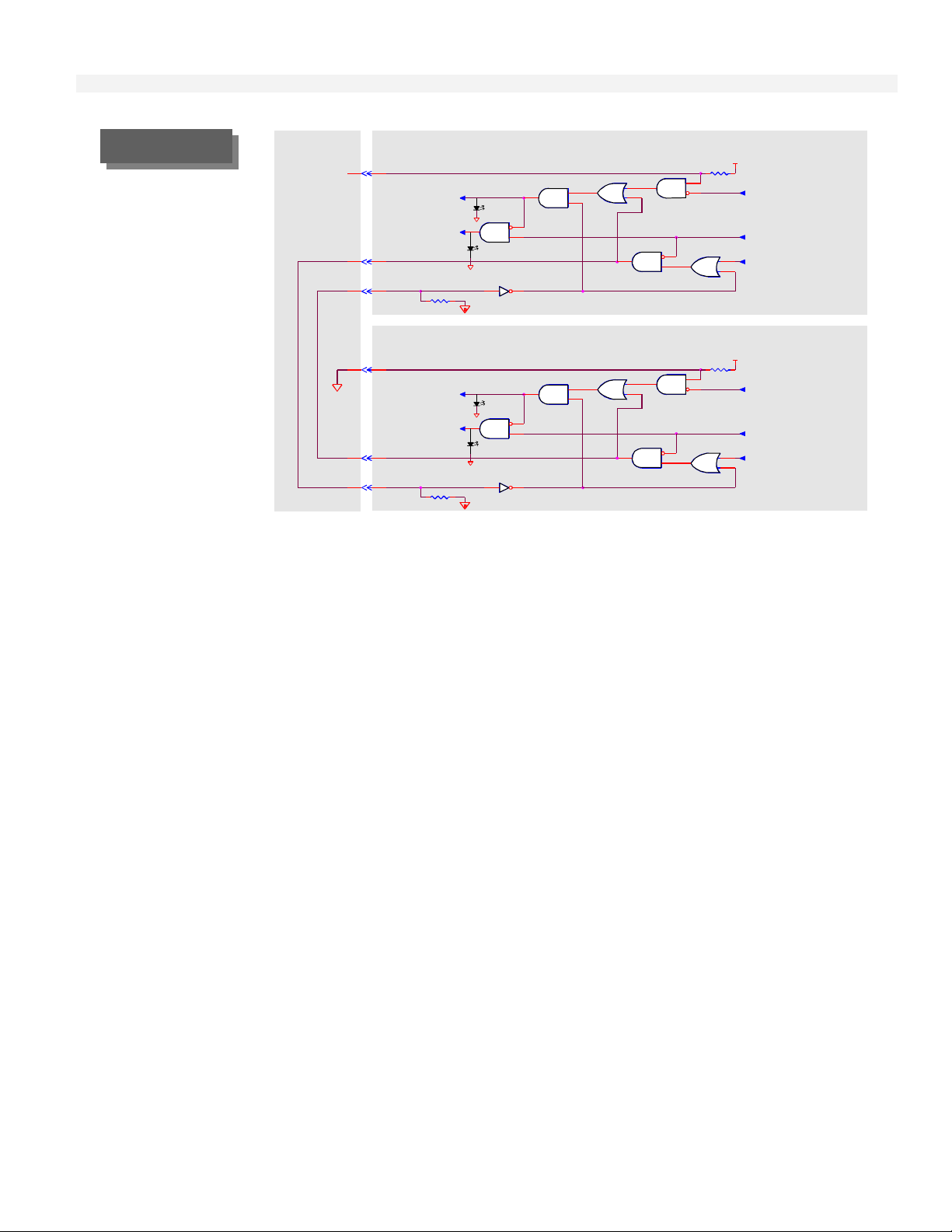

Active/Standby Logic

The active/standby logic determines which control board (primary or backup) is active and if the outputs

are active. Only one control board can assume the active role at any given time. Refer to Figure 2-9.

The inhibit signal is true when the control board is not active and the system fail signal is true. The inhibit

signal when true will reset the analog outputs to zero and reset the discrete output latches causing the

output transistors to open.

The only time the inhibit signal can be true, in a primary control board that does not have a good control

board in its backup position, is the first 0.2 second after power is first applied. This will allow the outputs

to reset on power up and to freeze the outputs if the system fail signal should become true when the

control board is active and must remain active.

2-9

Page 22

Input/Output Circuit Description

FIGURE 2-9

Termination

Panel

Primary Control B oard

Active/Standby

Logic

Active

Inhibit

Active

Inhibit

ACT

LED

OUT LED

ACT

LED

OUT LED

Power Up

Reset

System Fail

Activate

switch

Backup Control Board

Power Up

Reset

System Fail

Activate

switch

2-10

Page 23

Section Three

Site Selection Considerations 3

Access Considerations 3

T6200 Unit Automating System Mounting 4

T6200 Controller Electrical Power Wiring 6

T6200R Subrack Electrical Power Connection 8

Input/Output Hardware Configuration 9

Signal Wiring 10

Wiring and Jumper Placement for T6200-C Channels 1-8 12

Wiring and Jumper Placement for T6200-C Channels 9-16 13

Wiring and Jumper Placement for T6200-C Channels 17-22, 31, and 32 14

Wiring and Jumper Placement for T6200-C Channels 23-26 16

Wiring for T6200-C Channels 27-30 17

Wiring and Jumper Placement for T6200-D Channels 1-26, 31, and 32 17

Wiring for T6200-D Channels 27-30 19

Ethernet Communication Network 19

Network Security 19

Ethernet Network Connectors 19

Network Cabling 20

Non-Redundant Network 20

Redundant Network 21

T6200R Subrack Ethernet 23

Operator Interface Installation 24

Firmware Changes 27

Serial Communication Connection 28

Hardware Installation/Maintenance

Hardware Installation/Maintenance

3

3-1

Page 24

Hardware Installation/Maintenance

3-2

Page 25

Hardware Installation/Maintenance

Hardware

Installation/Maintenance

`

Site Selection Considerations

The T6200 Controller requires following conditions during normal operation:

32 to 122º F (0 to 50º C)

5 to 96% Relative humidity

Protection from direct contact with water, chemicals, and conductive dust.

Protection from exposure to sulfur compounds, acid, other corrosive or reactive vapors or

fumes, dust, and lint.

For estimating heat load requirements, the T6200 Controller dissipates a maximum of 10 BTU/hr.

(or 24 KGM-CAL/Hr) to the inside of the control panel.

Access Considerations

There are very few restrictions on the mounting position of the T6200 Controller. The following should

be taken into consideration:

All electrical power and input/outputs are connected on the rear termination panel.

Because as many as 70 conductors and four cables can be terminated to each T6200 Controller

adequate wireway space should be provided.

The T6200 Controller is operated from the front of the unit with switches on the

bottom. The Operator Interface slides up 0.5 in. (12 mm) to remove.

3-3

Page 26

The control boards slide out the front of the unit.

To ensure a proper viewing angle, the Controller should be installed approximately

64 inches (1.6 m) above the floor.

Outdoor installation is not recommended. However, for outdoor installations, the

face of the Controller should be shielded from direct sunlight, since bright light produces a

poor display contrast.

T6200 Controller Mounting

T6200 Controller Mounting

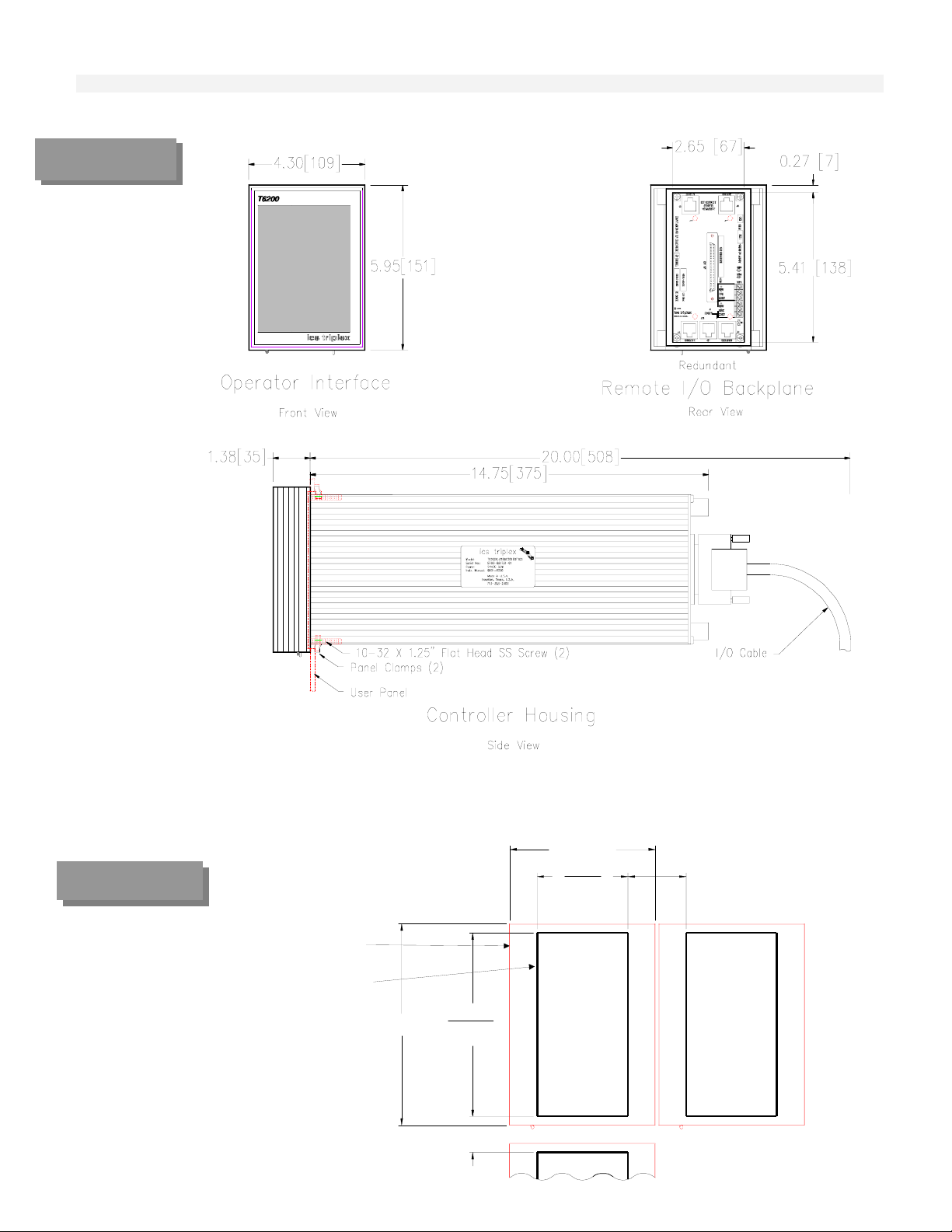

Figure 3-1 provides mounting dimensions for the T6200 Controller. Dimensions are shown in inches

(mm).

Remove Operator Interface by pushing up and pulling out at the bottom. Disconnect cable

from Operator Interface

Use the two Phillips head screws and clamps to mount the T6200 Controller in the user’s

panel.

When the T6200 Controller is positioned properly, hand-tighten both clamps in place. Note:

Do not exceed 15 in-lbs (17 cm-kgs) of torque on panel clamp screws.

The panel cut-out dimensions, as well as the Operator Interface front outline dimensions are shown in

Figure 3-2. The T6200 Controller would normally be mounted in a vertical posit ion.

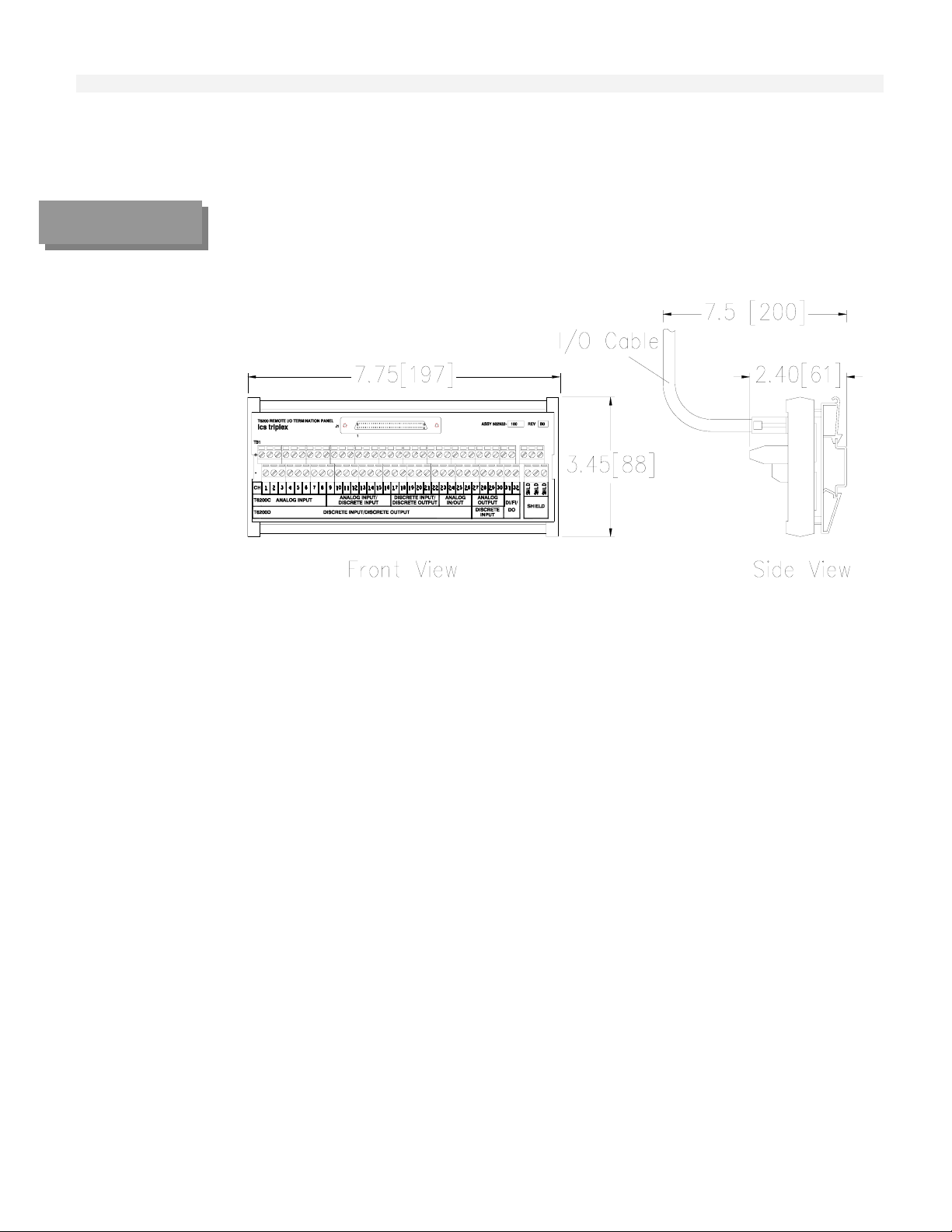

Figure 3-3 provides mounting dimensions for the optional Remote I/O Termination Panel. The I/O

cable that connects the T6200 Controller to the Remote I/O Termination Panel is 6 ft. (2m) long.

Dimensions are shown in inches (mm). The Remote I/O Termination Panel can be snapped onto a user

supplied standard 35 mm DIN rail.

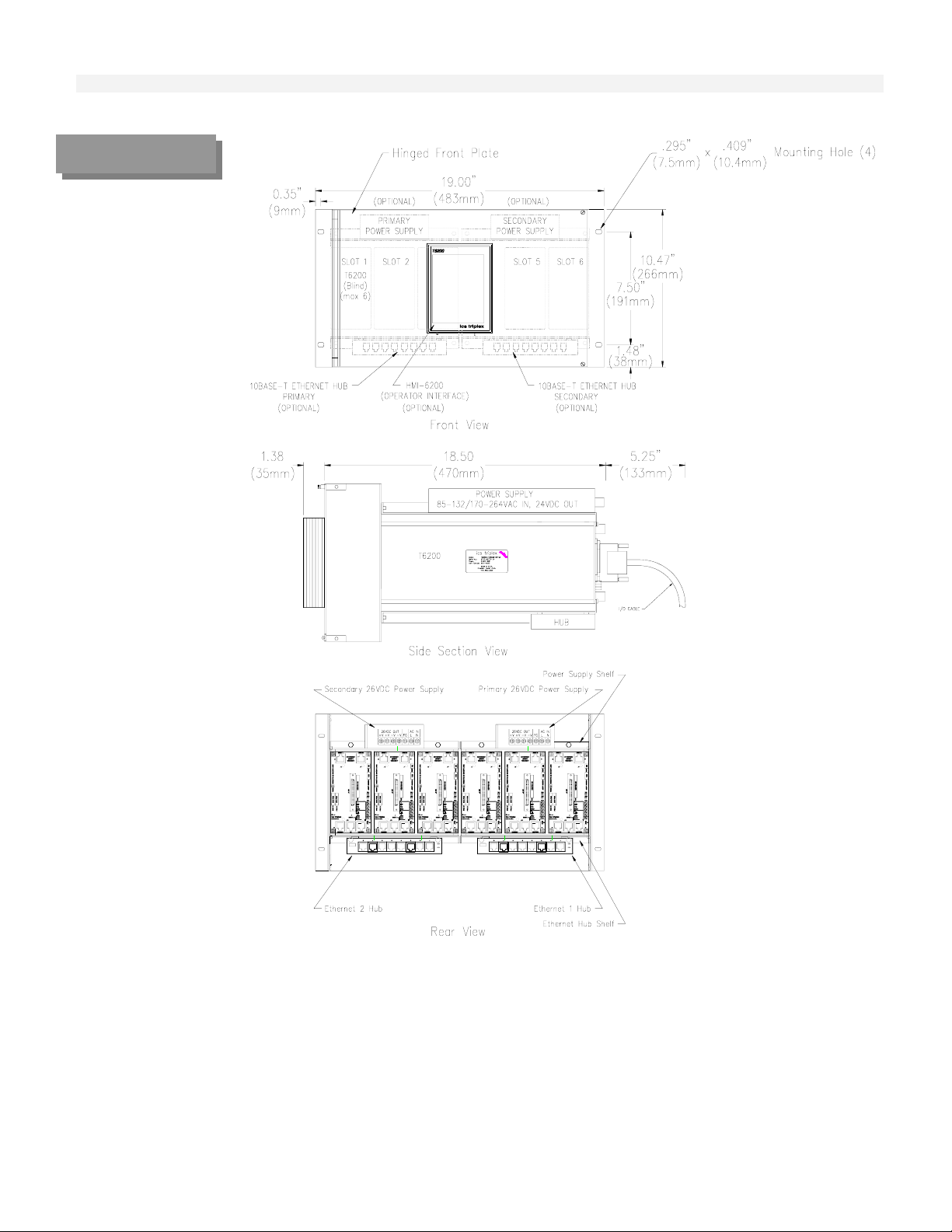

T6200R Subrack Mounting

Each T6200R Subrack Housing accommodates up to six redundant T6200 Controllers. The subrack

may also include two power supplies, Operator Interface, and two Ethernet hubs. Refer to Figure 3-4

for T6200R Subrack mounting dimensions. The subrack should be mounted in a EIA standard 19 inch

rack. Refer to Section Nine Specifications for more detailed physical dimensions.

Hardware Installation/Maintenance

3-4

Page 27

FIGURE 3-1.

T6200

Mounting

Hardware Installation/Maintenance

FIGURE 3-2.

T6200 Controller

Panel Cutout

Dimensions

OPERATOR INTERFACE

PANE L CU TO U T

5.95 [151]

5.44 [138]

5.50 [139]

1.375 [35]

4.30 [109]

2.74 [69]

2.68 [68]

1.72 [44] MIN

3-5

Page 28

FIGURE 3-3

Remote I/O

Terminal Panel

Mounting

Dimensions

Hardware Installation/Maintenance

T6200 Controller Electrical Power Wiring

The guidelines below should be followed when wiring the power to the T6200 Controlle r:

The maximum wire size is 16 AWG stranded.

All wiring should be multi-stranded annealed copper with insulation that meets the

requirements of all applicable electrical codes.

AC power wiring should be run in a separate conduit from the T6200 Controller power and the

I/O.

The stripped portion of the wire should be 3/16” (5 mm) long.

Wires should be inserted in the clamp type terminals until they touch the internal stops. The

terminal screw should be tightened while holding the wire in place. Check for proper clamp

pressure with a gentle tug on the wire.

Electrical power should be provided from a redundant, highly reliable, dedicat ed 26 Vdc power

source.

Power consumption is 15 watts for the T6200 Controller and 15 watts for the Operator

Interface, not including field devices.

The T6200 Controller has redundant 26 Vdc power supply connections.

3-6

Page 29

FIGURE 3-4

T6200R Subrack

Mounting

Dimensions

Hardware Installation/Maintenance

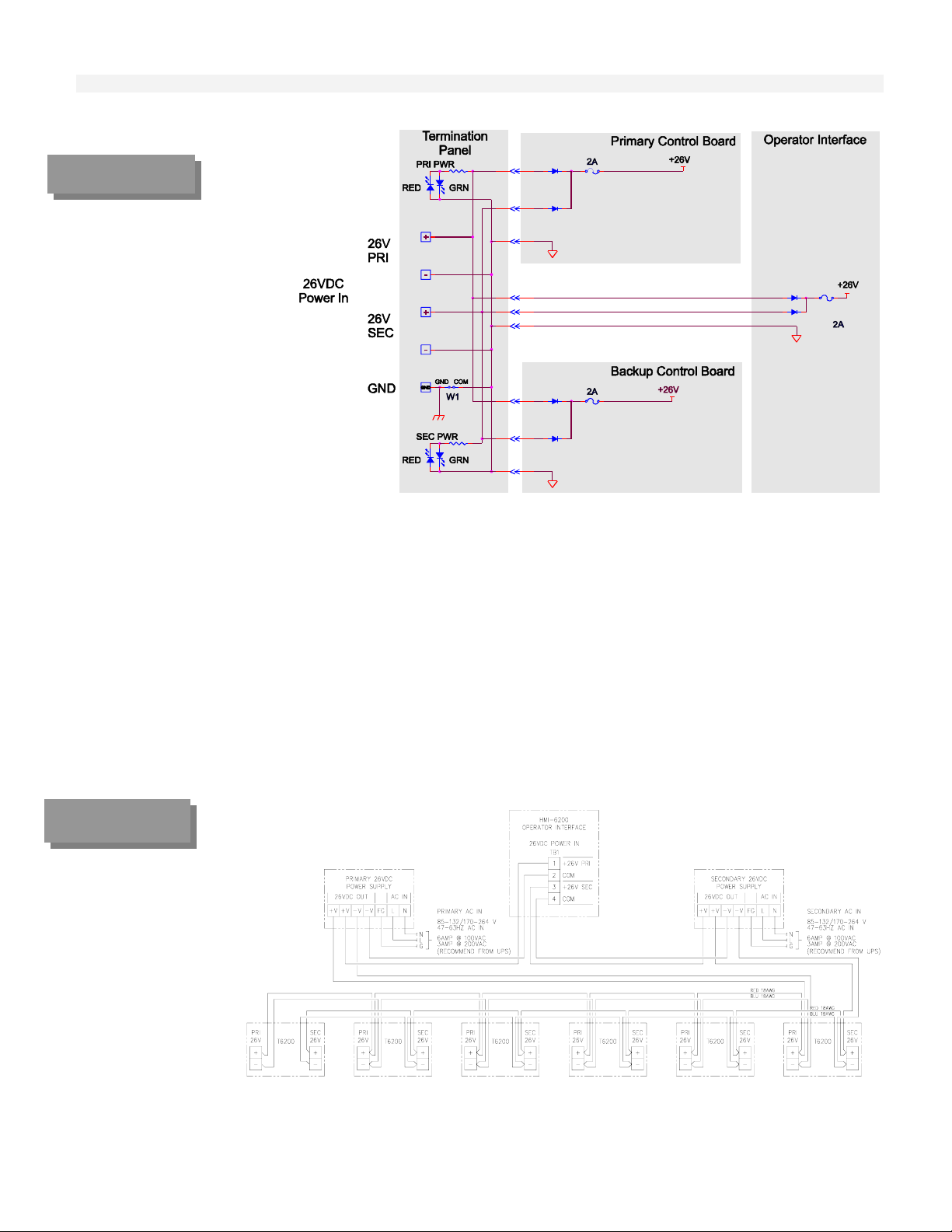

Figure 3-5 shows the internal power distribution for the T6200 Unit Automation System. Connect 26

Vdc (18-32 Vdc) power to the 26V PRI (Primary) terminals and to the 26V SEC (Secondary)

terminals.

There is a jumper (W1) on the T6200 Termination Panel that connects the minus side of the 26 volt

supply to earth ground. This jumper may be cut if the power source is referenced to earth ground

somewhere else in the system.

3-7

Page 30

FIGURE 3-5

Internal Power

Distribution

Hardware Installation/Maintenance

T6200R Subrack Electrical Power Connection

Once the T6200R Subrack is mounted, plug the included external power supply’s DC power cord into

the matching power jack on each of the Ethernet Hub’s rear panel. The Ethernet Hub shelf may be

removed to connect the power. Plug each of the power supply’s transformers into an AC receptacle that

is six feet (two meters) or less away. The green “Pwr” LED should light up.

Refer to the guidelines in T6200 Controller Electrical Power Wiring above and Figure

3-6 and connect AC power wiring to each of the 26 Vdc Power Supplies.

The 26 Vdc power to the T6200 Controllers and Operator Interface is usually prewired as shown in

Figure 3-6.

Figure 3-6

T6200R Subrack

Power Wiring

3-8

Page 31

Input/Output Hardware Configuration

There are several different ways the hardware can be configured for each input/output. Refer to

Section Two Input/Output Circuit Description for details on each configuration. The different

configurations are achieved by the placement of jumpers (shorting bars) on a multi-pin headers located

on the printed circuit board. Each channel has a separate header and can be configured independently.

To access the jumpers:

CAUTION

Unplug the optional front panel Operator Interface

Carefully slide the printed circuit board out the front of the chassis.

The Controller contains parts susceptible to damage by electrostatic

discharge. Normal precautions should be taken to avoid high static

voltages.

When facing the component side of the printed circuit board with the LEDs on the left, the

headers/jumpers will be at the right Pin one on the headers will be as shown in the illustrations. Pin one

also has a square pad on the circuit side of the printed circuit board. Refer to Figure 3-7 for T6200C.

Refer to Figure 3-11 for T6200D.

Hardware Installation/Maintenance

FIGURE 3-7.

T6200C Control

Board

The headers may vary from input/output group to group. All the headers are oriented the same way

within one group. A group is where a`ll consecutive inputs/outputs have the same configuration

options. For example, channels one through eight are in the same group.

3-9

Page 32

Signal Wiring

FIGURE 3-8

Hardware Installation/Maintenance

Individually shielded wires are not required (except for frequency inputs). Twisted pairs and overall

cable shields are recommended. Each multipair cable should contain a few pairs of spare wires. Shiel ds

and unused conductors should be terminated to ground at Controller end only. Refer to appropriate

Wiring and Jumper Placement.

The following general guidelines apply to all signal wiring discussed in the following paragraphs.

Wire size range for the terminal panel is 26-16 AWG stranded; recommended wire size range

is 18-14 AWG.

Wire size range for the remote I/O terminal is 26-14 AWG stranded; recommended wire size

range is 18-14 AWG.

All wiring should be multi-stranded annealed copper with insulation that meets the

requirements of all applicable electrical codes.

Keep all wire runs as short and direct as possible. Long wire runs are vulnerable to picking up

stray electrical noise. Use care when running signal wiring near to or crossing conduit or

wiring that supplies power to motors, solenoids, lighting, horns, bells, et c.

Avoid bringing signal wiring into junction boxes which contain ot her wiri ng.

AC power wiring should be run in a separate conduit from the signal wiring.

The stripped portion of the wires should be 5/16” (8 mm) long.

Wires should be inserted in the clamp type terminals until they touch the internal stops. The

terminal screw should be tightened while holding the wire in place. Check for proper clamp

pressure with a gentle tug on the wire.

Integral

Termination

Panels

3-10

Page 33

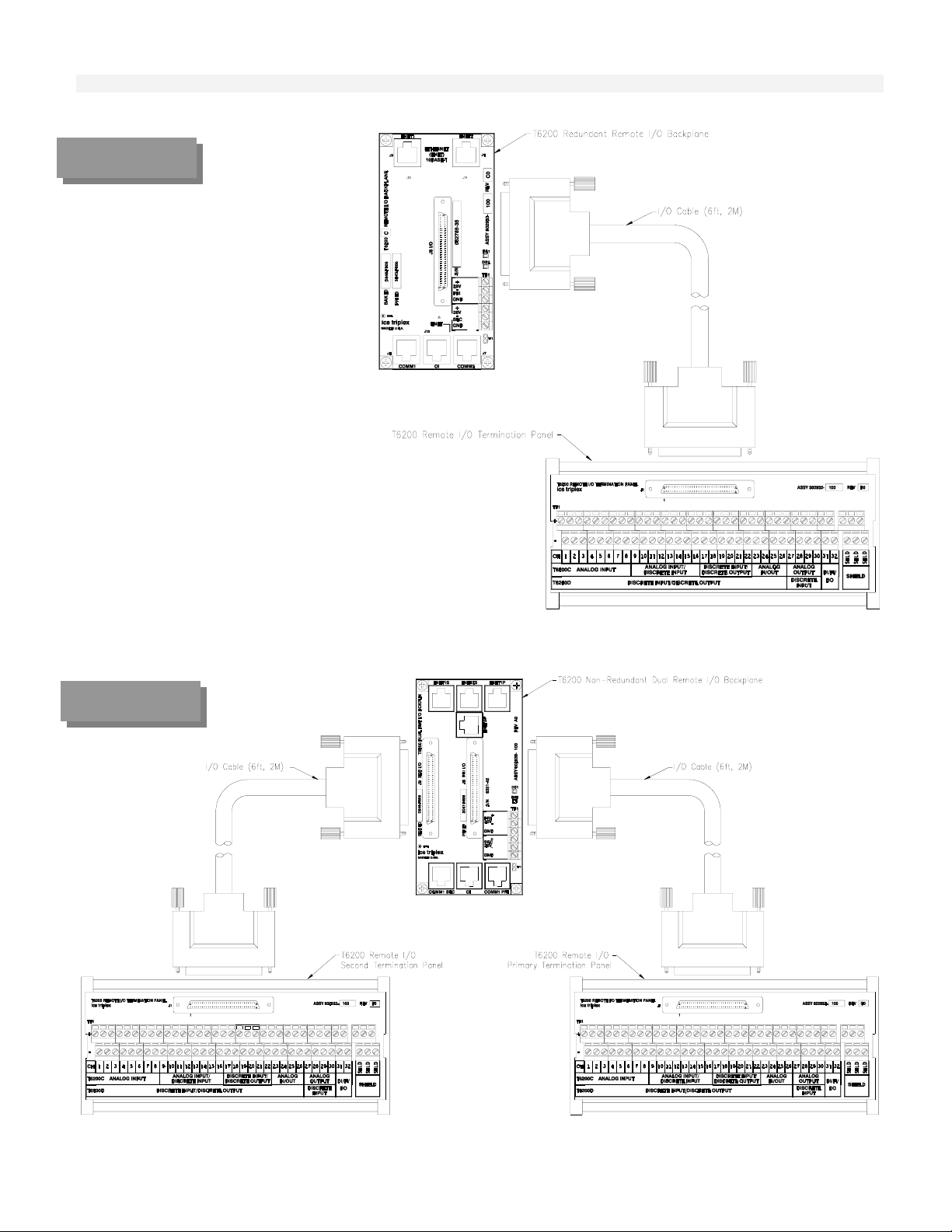

FIGURE 3-9

Redundant

Remote I/O

Termination

Panel

Hardware Installation/Maintenance

FIGURE 3-10

Dual

Non-Redundant

Remote I/O

Termination

Panel

3-11

Page 34

Wiring and Jumper Placement for T6200C

Channels 1-8

Two-Wire Transmitter

This wiring and jumper

placement is normally used

with isolated two-wire

transmitters where the

transmitter power is

supplied by the Controller.

Refer to Figure 2-3.

Analog Current Inputs

This wiring and jumper

placement is normally used

with four-wire current

transmitters when the power

is not

supplied by the

Power

Source

Controller. Refer to Figure

2-2.

Analog Voltage Inputs

This wiring and jumper

placement is for voltage

inputs. Refer to Figure 2-1.

Power

Source

+

4-20 mA

Two-Wire

Transmitter

(Isolated)

-

+

4-20 mA

Transmitter

-

Transmitter output

may be referenced

to common

+

DC Voltage

Transmitter

-

Transmitter output

may be referenced

to common

Hardware Installation/Maintenance

T6200C Controller

24 Vdc

+

Supply

mA Input

(reference to

-

common

through resistor)

SHLD

T6200C Controller

+

mA Input

(Isolated from

common)

-

SHLD

T6200C Controller

+

DC Voltage Input

(Isolated from

common)

-

SHLD

1

Factory

Default

1

1

3-12

Page 35

Wiring and Jumper Placement for T6200C

Channels 9-16

Two-Wire Transmitter

Hardware Installation/Maintenance

This wiring and jumper

placement is normally used

with isolated two-wire

transmitters where the

transmitter power is

supplied by the Controller.

Refer to Figure 2-3.

Analog Current Input

This wiring and jumper

placement is normally used

with four-wire current

transmitters when the power

is not

supplied by the

Controller. Refer to Figure

2-2.

Analog Voltage Input

This wiring and jumper

placement is for voltage

inputs. Refer to Figure 2-1.

Power

Source

Power

Source

+

4-20 mA

Two-Wire

Transmitter

(Isolated)

-

+

4-20 mA

Transmitter

-

Transmitter output

may be referenced

to common

+

DC Voltage

Transmitter

-

Transmitter output

may be referenced

to common

T6200C Controller

24 Vdc

+

Supply

mA Input

(reference to

-

common

through resistor)

SHLD

T6200C Controller

+

mA Input

(Isolated from

common)

-

SHLD

T6200C Controller

+

DC Voltage Input

(Isolated from

common)

-

SHLD

1

Factory

Default

1

1

3-13

Page 36

Hardware Installation/Maintenance

Discrete Inputs with Excitation from Controller

This wiring and jumper

placement is for discrete

(On/Off) inputs. The

Controller supplies 24 VDC

power for the input. Refer to

Figure 2-6.

Alternate

Open Collector

Transistor

Contact

T6200C Controller

Discrete Input

+

(24 Vdc/5 mA

excitation)

Circuit

-

Common

1

Isolated Discrete Inputs

This wiring and jumper

placement is for discrete

(On/Off) inputs. The

discrete inputs are isolated

from other circuits and the

external power for the input

Power Source

18 V to 32 V

ac/dc

Contact

Polarity

Arbitrary

is either 18-32 Volt AC or

DC. Refer to Figure 2-5.

T6200C Controller

+

+

Discrete Input

(Optically

coupled)

-

-

1

Wiring and Jumper Placement for T6200C

Channels 17-22, 31, and 32

Discrete Inputs with Excitation from Controller

This wiring and jumper

placement is for discrete

(On/Off) inputs. The

Controller supplies 24

VDC power for the input.

Refer to Figure 2-6.

Isolated Discrete Inputs

This wiring and jumper

placement is for discrete

(On/Off) inputs. The

discrete inputs are isolated

from other circuits and the

external power for the

input is either 18-32 Volt

AC or DC. Refer to

Figure 2-5.

Power Source

18 V to 32 V

Open Collector

ac/dc

Alternate

Transistor

Contact

Polarity

Arbitrary

Contact

T6200C Controller

Discrete Input

+

(24 Vdc/5 mA

excitation)

Circuit

-

Common

T6200C Controller

+

+

Discrete Input

(Optically

coupled)

-

-

1

Factory

Default

1

3-14

Page 37

Hardware Installation/Maintenance

Frequency Inputs

This wiring and jumper

placement is for a

PWR

frequency/pulse

preamplifier input with

the Controller supplying

the power (Channel 22,31

and 32).

Frequency/Pulse

Preamplifier or other

Discrete Device

0-25KHz only for

Channels 22, 31 &

32

OUT

COM

Discrete Outputs with Internal Power

This wiring and jumper

placement is for discrete

(On/Off) outputs. The

Controller supplies 24

VDC power for the 20

mA max load. Load

Example: Entrelec RB

+

Discrete

Load

<20 mA

-

131 (010055.23) relay.

Refer to Figure 2-7.

Discrete Outputs with External Power

T6200C Controller

24 Vdc

+

Supply

1

Input

(Circuit Common)

-

SHLD

Discrete

T6200C Controller

24 Vdc

+

+

Supply

Discrete Output

(Open Collector

-

-

Transistor)

1

This wiring and jumper

placement is for discrete

(On/Off) outputs. The

power source (less than 38

VDC) is external. The

discrete load is 0.25 Amp

max. Refer to Figure 2-8.

+

Power Source

<38 Vdc

-

Discrete

+-

Load

<0.25 A

T6200C Controller

Discrete Output

+-+

(Open Collector

Transistor)

Circuit

Common

1

3-15

Page 38

Wiring and Jumper Placement for T6200C

Channels 23-26

Two-Wire Transmitter

Hardware Installation/Maintenance

This wiring and jumper

placement is normally

used with isolated

two-wire transmitters

where the transmitter

power is supplied by the

Controller. Refer to

Figure 2-3.

+

4-20 mA

Two-Wire

Transmitter

(Isolated)

-

T6200C Controller

24 Vdc

+

Supply

mA Input

(reference to

-

common

through resistor)

SHLD

1

Factory

Default

Current Inputs

This wiring and jumper

placement is normally

used with four-wire

current transmitters when

the power is not

supplied

by the Controller. Refer

to Figure 2-2.

Power

Source

+

4-20 mA

Transmitter

-

Transmitter output

may be referenced

to common

T6200C Controller

+

mA Input

(Isolated from

common)

-

SHLD

1

Analog Voltage Inputs

This wiring and jumper

placement is used for

voltage input. Refer to

Figure 2-1.

Power

Source

+

DC Voltage

Transmitter

-

Transmitter output

may be referenced

to common

T6200C Controller

+

DC Voltage Input

(Isolated from

common)

-

SHLD

1

Analog Current Outputs

0-20mA (4-20mA)

Analog current outputs.

Refer to Figure 2-4.

+

4-20 mA or

0-20 mA

Receiver

(Isolated)

-

T6200C Controller

+-mA Output

Circuit

Common

1

SHLD

3-16

Page 39

Wiring for T6200C

Channels 27-30

Analog Current Outputs

Hardware Installation/Maintenance

FIGURE 3-11

T6200D Control

Board

0-20mA (4-20mA)

Analog current outputs.

Refer to Figure 2-4.

Channels 27-30 do not

have jumper placements.

+

4-20 mA or

0-20 mA

Receiver

(Isolated)

-

T6200C Controller

+-mA Output

Circuit

Common

SHLD

Wiring and Jumper Placement for T6200D

Channels 1-26, 31, and 32

Discrete Input with Excitation from Controller

This wiring and jumper

placement is for discrete

(On/Off) inputs. The

Controller supplies 24

VDC power for the input.

Refer to Figure 2-6.

Alternate

Open Collector

Transistor

Contact

T6200D Controller

Discrete Input

+

(24 Vdc/5 mA

excitation)

Circuit

-

Common

1

Factory

Default

3-17

Page 40

Hardware Installation/Maintenance

Isolated Discrete Input

This wiring and jumper

placement is for discrete

(On/Off) inputs. The

discrete inputs are isolated

from other circuits and the

external power for the

input is either 18-32 Volt

AC or DC. Refer to

Figure 2-5.

Power Source

18 V to 32 V

ac/dc

Contact

Polarity

Arbitrary

T6200D Controller

+

+

Discrete Input

(Optically

coupled)

-

-

1

1

Frequency Input

This wiring and jumper

placement is for a

PWR

frequency/pulse

preamplifier input with

the Controller supplying

the power (Channel 22,31

and 32).

Frequency/Pulse

Preamplifier or other

Discrete Device

0-25KHz only for

Channels 22, 31 &

32

OUT

COM

Discrete Output with Internal Power

This wiring and jumper

placement is for discrete

(On/Off) outputs. The

Controller supplies 24

VDC power for the 20

mA max load. Load

example: Entrelec RB 131

+

Discrete

Load

<20 mA

-

(010055.23) relay Refer to

Figure 2-7.

Discrete Outputs with External Power

This wiring and jumper

placement is for discrete

(On/Off) outputs. The

power source (less than 38

Vdc) is external. The

discrete load is 0.25 Amp

max. Refer to Figure 2-8.

+

Power Source

<38 Vdc

-

Discrete

+-

Load

<0.25 A

T6200D Controller

24 Vdc

+

Supply

Discrete

-

Input

(Circuit Common)

SHLD

T6200D Controller

24 Vdc

+

+

Supply

Discrete Output

(Open Collector

-

-

Transistor)

T6200D Controller

Discrete Output

+-+

(Open Collector

Transistor)

Circuit

Common

1

1

1

3-18

Page 41

Wiring for T6200D

Channels 27-30

Discrete Inputs with Excitation from

Controller

Hardware Installation/Maintenance

These channels are for

placement is for discrete

(On/Off) Inputs only. The

Controller supplies 24

VDC power for the input.

Refer to Figure 2-6

Channels 27-30 do not

have jumper placements.

Ethernet Communication Network

The T6200 Controller uses IEEE 802.3 10Base-T Ethernet communication network. Ethernet uses

the Carrier Sense, Multiple Access, Collision Detect (CSMA/CD) datalink protocol, which employs a

broadcast method for communicating with nodes. When a station senses that the network is idle and

it is ready to send, it transmits its data packets to the network. Since all nodes hear the data, each

node checks to see if the packet is intended for it. The station that matches the d estination address in

the packet is the one that responds. The collision detection part of CSMA/CD tells nodes to halt

transmission if a collision is detected and to try again later at a randomly determined delay period.

Network Security

The T6200 Controller incorporates automatic control redundancy to insure process equipment

operation in the event of failure. Redundant network components can further enhance overall system

security by maintaining communications in case of certain device malfunction and by allowing online

repair of faulty components. With proper redundancy implementation an Ethernet network can detect

when a particular path cannot pass data and then automatically switch to a backup path. Refer to

T6200 Equipment Selection and Planning G ui de for more information on network security.

Alternate

Open Collector

Transistor

Contact

T6200D Controller

Discrete Input

+

(24 Vdc/5 mA

excitation)

Circuit

-

Common

Ethernet Network Connectors

The T6200 Controller includes two individual IEEE 802.3 10Base-T Ethernet connections (ENET1 and

ENET2) with standard RJ-45 connectors to facilitate control network communication. Refer to Figure

3-8 (Integral Termination Panel), Figure 3-9 (Redundant Remote I/O Backplane) or Figure 3-10 (NonRedundant Dual Remote I/O Backplane) for connector location and Figure 3-12 for Ethernet ENET1

and ENET2 connector pin assignments.

Note on Figure 3-10 (Non-Redundant Dual Remote I/O Backplane) ENET1 on the Primary Control

Board is referenced as ENET1P and ENET2 is referenced as ENET2P. ENET1 on the Second Control

Board is referenced as ENET1S and ENET2 is referenced as ENET2S.

3-19

Page 42

FIGURE 3-12

Ethernet

ENET1 and ENET2

Connector

Pin Assignments

Network Cabling

Pin Signal

1 TXD+

2 TXD3 RXD+

4 NC

5 NC

6 RXD7 NC

8 NC

Ethernet is used as the high-speed wire media to provide the control network communication

capabilities for the T6200 Controller systems. Typically, the control network is an isolated Ethernet

network that provides communication between the T6200 Controller and workstations. It uses

Ethernet hubs and/or switches for communication connections.

Use Ethernet category five (Cat 5) cables for the Ethernet network cables. The maximum cable

length from the T6200 Controller to the hub/switch is 10 ft. (3 m). The maximum cable length from

the hub/switch to any other node is 330 ft. (100 m) for longer distances, fiber optic cables are

required.

Pin 1

Hardware Installation/Maintenance

Pin 8

Non-Redundant Network

The basic simplex network consists of a hub and Cat 5 cables that connect to each node. The T6200

Controllers have redundant Ethernet ports as a standard feature (whether they contain simplex or

redundant control boards). When installing a simplex network, using Ethernet 2 port is optional.

Refer to Figure 3-13 for a single T6200 Controller and Figure 3-14 for multiple T6200 Controllers.

FIGURE 3-13

Non-Redundant

Network with

Single T6200

Controller and

Single

Workstation

3-20

Page 43

FIGURE 3-14

Non-Redundant

Network with

Multiple T6200

Controllers and

Dual

Workstations

Hardware Installation/Maintenance

Redundant Network

Network redundancy for communication security is provided by a secondary hub and cables that

establish a secondary network identical to the primary netw ork. The secondary n etwork is connected

to the redundant communications port of each workstation and Controller, and is connected to a

separate hub/switch. Refer to Figure 3-15.

FIGURE 3-15

Redundant

Network with

Single T6200

Controller and

Redundant

Workstations

3-21

Page 44

FIGURE 3-16

Redundant

Network with

Multiple T6200

Controllers and

Redundant

Workstations

Hardware Installation/Maintenance

FIGURE 3-17

Redundant

Network with

Multiple T6200

Controllers

Mounted in a

T6200R Subrack

and

Redundant

Workstations

3-22

Page 45

FIGURE 3-18

Non-Redundant

Network with

Single Dual T6200

Controller and

Single

Workstation

Hardware Installation/Maintenance

FIGURE 3-19

Redundant

Network with

Multiple

Dual T6200

Controller and

Redundant

Workstations

T6200R Subrack Ethernet

The Ethernet Hubs on the T6200R Subrack are usually connected as shown in Figure 3-17.

If the workstation is not part of an existing network, connect the workstation to port eight on the

hubs. Set the Up-Link switch to “Normal”.

To connect the hubs to an existing network; set the Up-Link switch to “Up-Link” and connect

existing network to port eight.

The Operator Interface is usually connected to port seven on Ethernet 1 Hub.

3-23

Page 46

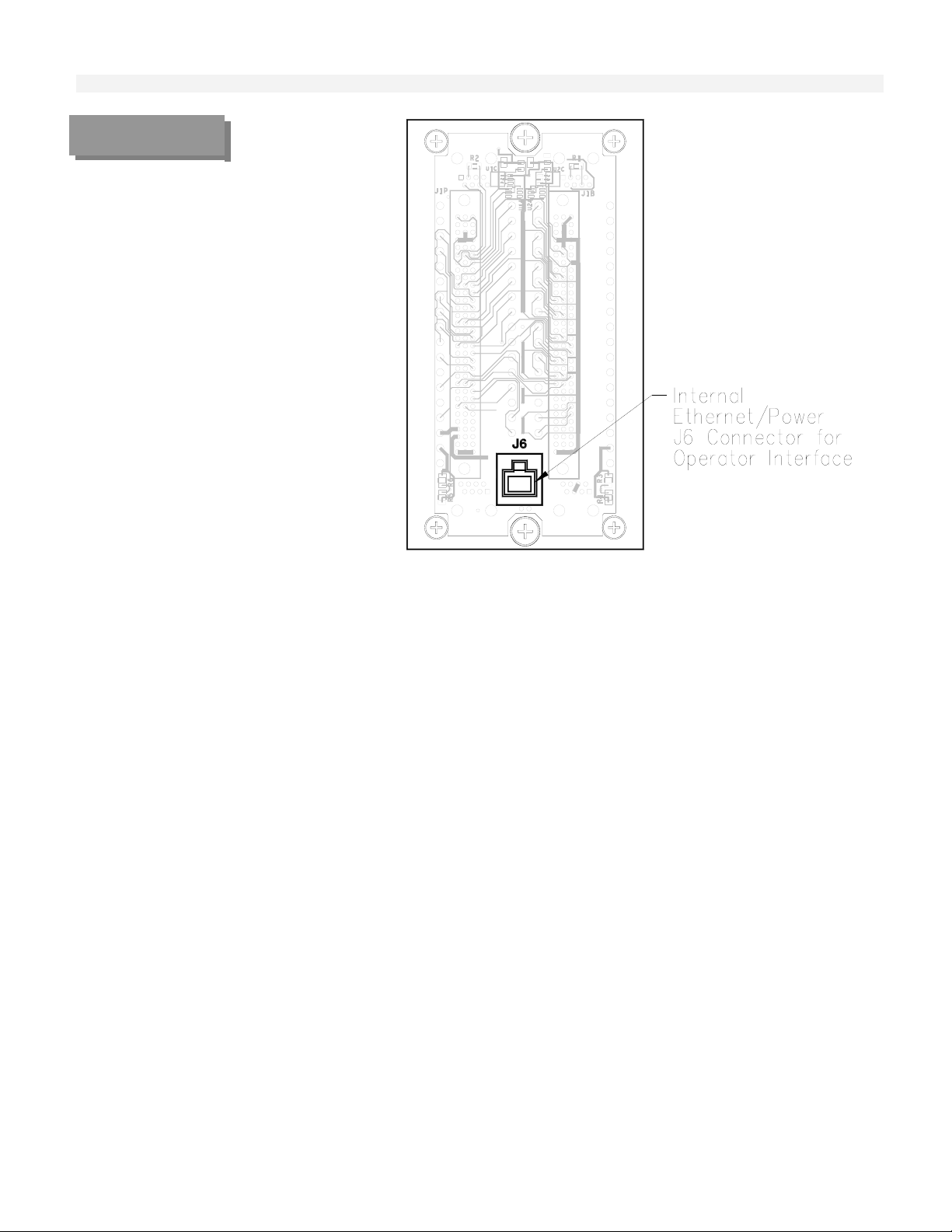

p

FIGURE 3-20

Internal

Ethernet/Power

J6 Connector for

O

erator Interface

Hardware Installation/Maintenance

Operator Interface Installation

Ethernet/Power Cable Installation

The Operator Interface Ethernet/Power cable is routed thru the center of the T6200 Controller

housing and plugged into connector J6 inside the Controller on the Termination Panel or I/O

Backplane. Refer to Figures 3-20 and 3-21. The Ethernet cable carries the 10Base-T Ethernet

communications and the 26Vdc power from the T6200 Controller. Refer to Figure 3-22 for connector

J6 pin assignments.

3-24

Page 47

FIGURE 3-21

Operator Interface

Internal

Ethernet/Power

Cable

Installation

Hardware Installation/Maintenance

FIGURE 3-22

Operator

Interface J6

Connector Pin

Assignments

Pin Signal

1 TXD+

2 TXD3 RXD+

4 +26V PRI

5 +26V SEC

6 RXD7 COM

8 COM

Pin 1

Pin 8

Operator Interface Attachment to T6200 Chassis

The Operator Interface is attached to the T6200 Chassis by four screw collars.

The Operator Interface is installed by placing the two top screw collar slots at the rear of the case

over the two top screw collars. The case should be angled slightly out at the bottom. Once the top

screw collars align thru the top screw collar slots, the case can be straightened vertically and then

slide down until it stops on the case slots edge. Refer to Figure 3-23.

The Operator Interface may be removed by pulling the Latch Release Pull located at the bottom right

of the case at the same time sliding the case up then away from the T6200 Chassis.

FIGURE 3-23

Operator Interface

Attachment to

T6200 Chassis

3-25

Page 48

FIGURE 3-24

Standalone

T6200 Controller

Operator Interface

Ethernet Crossover

External Cable

Connection

Hardware Installation/Maintenance

Standalone T6200 Controller Operator Interface Ethernet

External Cable Connection

For Standalone T6200 Controller applications where no communications to other controllers or

workstations are required, the T6200 Controller ENET1 connector may be connected directly to the

OI (Operator Interface) connector with a short Ethernet crossover cable (ICS Triplex p/n 6009-0 030)

eliminating the necessity of an Ethernet hub. Refer to Figure 3-24.

3-26

Page 49

Firmware Changes

Firmware is the software, operating system, and function library that has been programmed into an

EPROM (erasable programmable read-only memory). Should it become necessary to update the

firmware or install a custom firmware in the field, the EPROM will have to be replace. To change the

EPROM:

CAUTION

FIGURE 3-25

Carefully slide the control board out the front of the chassis.

Use an Amp 44 pin PLCC extraction tool number 82159-1 to remove the EPROM from the

socket. The EPROM is the 44 pin IC with a label. Refer to Figure 3-25.

Install the new EPROM. The EPROM is keyed with a notch on one corner. This notch must

be in the same orientation as the notch on the EPROM socket while plugging the EPROM into

the socket.

Replace the control board.

Load configuration.

Hardware Installation/Maintenance

The Controller contains parts susceptible to damage by electrostatic discharge.

Normal precautions should be taken to avoid high static voltages.

T6200 EPROM

Placement

3-27

Page 50

Serial Communication Connection

The T6200 includes two individual RS-232/RS-485 serial port connections (COMM 1 and COMM 2)

with RJ-45 connectors to facilitate serial communication. COMM 1 and COMM 2 are software

configurable for either RS-232 or RS-485. See Appendix C Modbus Interface RS-232 for COMM

1 and COMM 2 RS-232/RS-485 Configuration. Note: RS-485 is not multidrop. Refer to Figure 3-8,

Figure 3-9, or Figure 3-10 for appropriate COMM 1 and COMM 2 connector location. Note: NonRedundant Dual Remote I/O Backplane (Figure 3-10) has only COMM 1 for the Primary and Second

Control Board. Refer to Figure 3-26 for COMM 1 and COMM 2 connector pi n assignme nts.

FIGURE 3-26

Serial

Communication

Connector

Pin Signal

1 NC

2 NC

3 TD (RS-232)/COMM-(RS-485)

4 SG (SIGNAL GND)/COM

5 SG (SIGNAL GND)/COM

6 RD (RS-232)/COMM+ (RS-485)

7 NC

8 NC

Hardware Installation/Maintenance

Pin 1

Pin 8

3-28

Page 51

Section Four

The Micon OPC Server Compact Disc 2

Install The Packet Driver Software 2

Install the MICON OPC Server and Related Components 5

Ethernet Addresses 7

Software Installation

Software Installation

4

4-1

Page 52

Software Installation

Software Installation

Instructions for the installation of the MICON OPC Server and a sample OPC Client software on

Microsoft Windows XP.

The Micon OPC Server Compact Disc

The MICON OPC compact disc contains the Micon OPC Server, a sample OPC Cliente. The setup

program for the MICON OPC Server software and the sample OPC Client software are located in the

“MICON” folder. Create a directory "C:\MICON" on the installation computer. Note that the "MICON"

folder must be in the root directory of the "C" drive.

IMPORTANT NOTE: If you plan to use the IEC-61131 based graphical configurator from MICON

called “Straton for MICON”, then you MUST install that package before installing the MICON OPC

Server.

Install The Packet Driver Software

Open the Network Connections window:

Right-click “My Network Places” icon, located on the desktop (Figure 4-1)

Select “Properties”

4-2

Page 53

Figure 4-.1

Software Installation

Desktop Window

Figure 4-2

Network Connections

Window

Open the “Local Area Connection Properties” window:

Right-click “Local Area Connection” (Figure 4-2)

Select “Properties”

Open the “Select Network Component Type” window:

Select “In

stall…” (Figure 4-3)

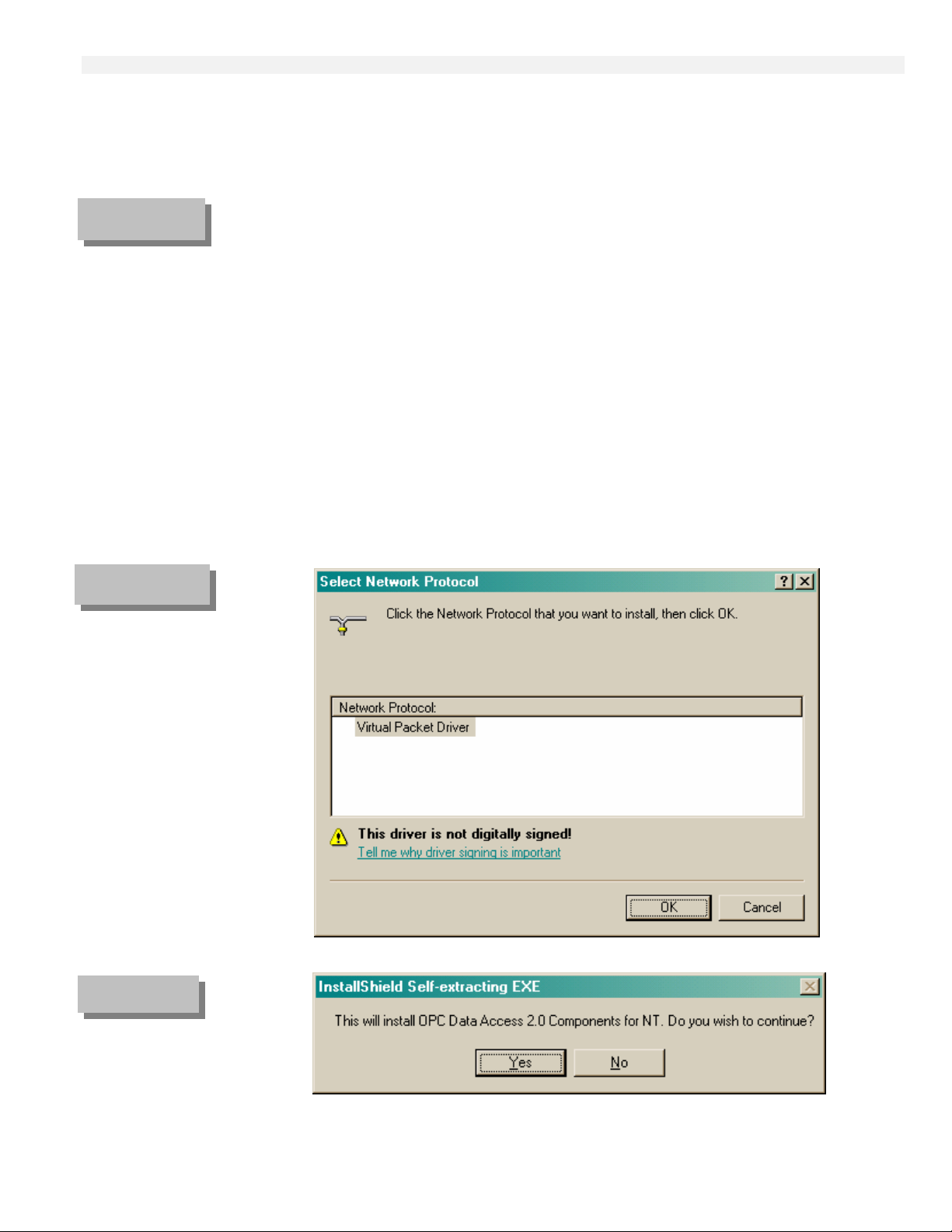

Open the “Select Network Protocol” window:

Select “Protocol” (Figure 4-4)

Select “A

dd…”

Open the “Install From Disk” window:

Select “H

ave Disk…” (Figure 4-5)

4-3

Page 54

Software Installation

Figure 4-3

Local Area

Connection

Properties Window

Figure 4-4

Select Network

Component

Type Window

Open the “Locate File” window:

Select “B

rowse” (Figure 4-6)

Locate the "\ndisnt” folder on the installation CD

Select “OK”

4-4

Page 55

Figure 4-5

Select Network

Protocol Window

Software Installation

Figure 4-6

Install From Disk

Window

Windows will select “OEMSETUP.INF” in the “File name:” field as shown in Figure 4-7. Select

“O

pen” to install the NDIS3P2K.INF driver.

The “Virtual Packet Driver” will be highlighted as shown in Figure 4-8. Select “OK” to complete

the driver installation.

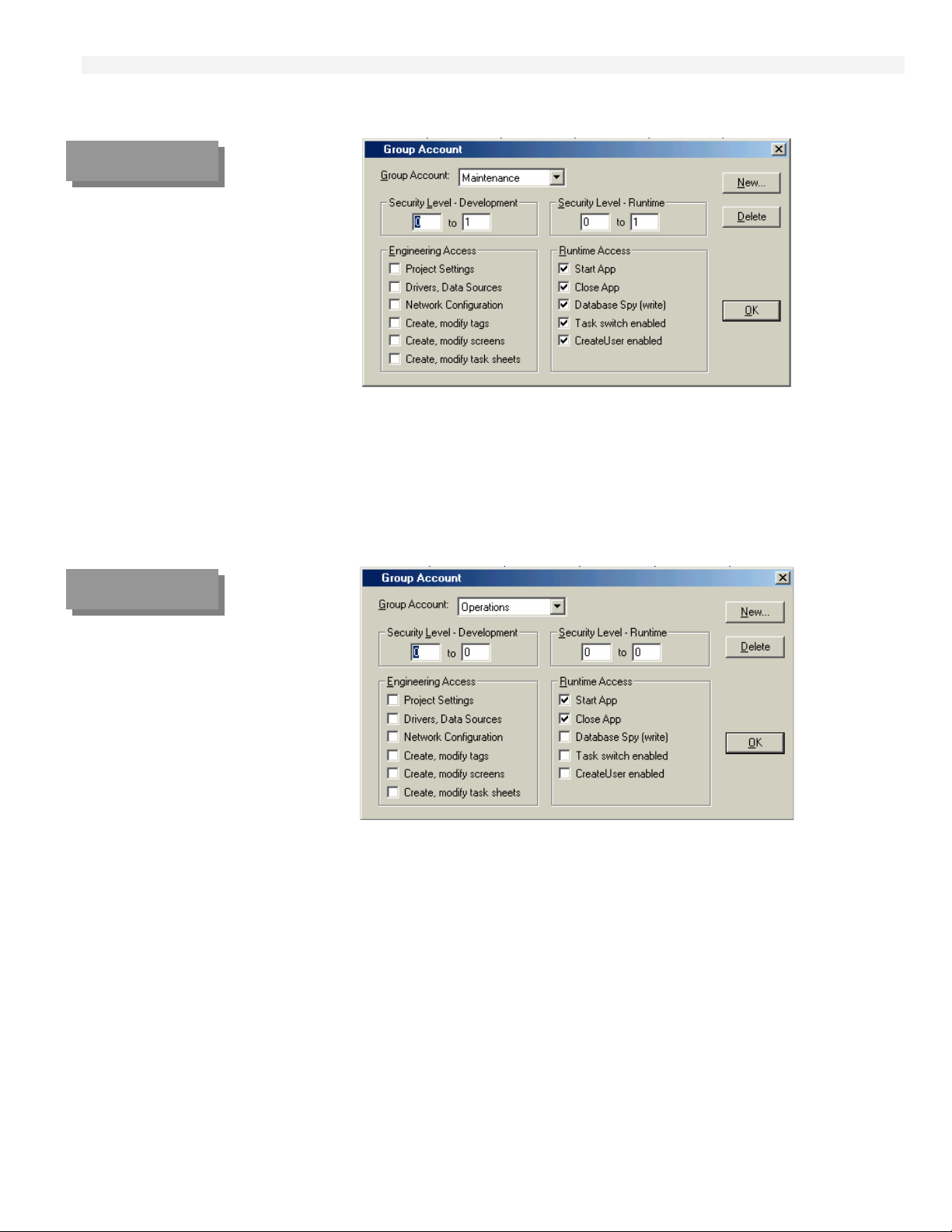

Install the MICON OPC Server and Related Components

Install the MICON OPC Server and related components. Execute the file "\MICON\Setup.exe” on

the CD:

Double click “MICON” folder located in the root directory of the CDROM drive

Double click “Setup.exe”. The setup program will copy various files to your hard disk drive

and copy the OPC Server and related files to a directory of your choice. Then the setup

program will proceed to install the OPC Data Access components. This will open the

“InstallShield Self-extracting EXE” window (Figure 4-9).

4-5

Page 56

Figure 4-7

Locate File

Window

Software Installation

Select “Yes”. This will open the “Readme Information” window (Figure 4-10).

Select “Next”. This will open the “Setup Complete” window (Figure 4-11).

Select “Finish”

Figure 4-8

Select Network

Protocol

Window

Figure 4-9

InstallShield Selfextracting

EXE Window

4-6

Page 57

Figure 4-10

Readme

Information

Window

Software Installation

Figure 4-11

Setup Complete

Window

Ethernet Addresses

Edit or create a file "C:\MICON\devlist.txt" using Notepad or some other text editor. In this file, add

one line for each T6200 Controller's Ethernet addresses as follows:

4-7

Page 58

Software Installation

Primary Control Board E thernet Address

Backup Control Board Ethernet Address

UC254,00:08:9A:D2:05:02,00:0D:9A:D2:05:02,

UC255,00:08:9A:D2:06:02,00:0D:9A:D2:06:02,

BAK ID from I/O Backplane

PRI ID from I/O Backplane

Figure 4-12

devlist.txt – Notepad

Window

Figure 4-13

T6200 Controller Name

The strings are separated by a comma. The first string is the name for the T6200 Controller. The

second string is the Ethernet address for the primary control board and the third string is the Ethernet

address for the backup. Make sure there is a comma at the end of each line. There can be only one

Controller per line. Refer to Figure 4-12. The Controller/s listed in this file will be the only one/s that

the MICON OPC Server will communicate with at runtime.

The T6200 Controller name must be a unique name and should have from one to 16 alphanumeric, dash (), and/or underscore (_) characters. The name cannot contain spaces (blanks) or other symbols. The first

character of a name cannot be a dash or number. Both upper and lower case letters are accepted.

The PRI ID and BAK ID numbers on the T6200 Controller I/O Backplane is used to build the Ethernet

addresses. Refer to Figure 4-13. Add “00:” in front of each number, add “:” between every other digit,

and add “:02,” to the end.

T6200 PRI ID and

BAK ID

4-8

Page 59

T6200 Controller Operation

Push to Activate Switch 5

System Start-up 6

Replacing Control Boards 6

Loading Controller Configuration 8

Watchdog Timer 8

T6200 Controller Operation

5

Section Five

5-1

Page 60

T6200 Controller Operation

5-2

Page 61

T6200 Controller Operation

T6200 Controller Operation

The redundant T6200 Controller consists of two identical control boards, primary and backup, and one

termination panel. Refer to Figure 5-1. The primary control board is always on the left and the backup

is always on the right. Normally, the primary board is the active board and the backup board is the

standby board. These roles may be reversed. When the backup board is active, it transmits a “Backup

Active” alarm to the host.

The active board controls both the analog and discrete outputs to the field. The analog and discrete

outputs are disabled on the standby board. Refer to Figure 5-2. When the outputs are required to

feedback as inputs, the outputs of the active board are used in both boards. A primary board without a

backup is always active. The active and standby boards have the same inputs and configuration.

Push to Activate Switch

A PUSH TO ACTIVATE switch (SW1) is located at the front of each control board at the bottom.

Refer to Figure 5-3. The switch has three functions: