Page 1

ICS Regent

Important!

®

PD-6048

MODBUS Master Package

for

MODBUS Master Function Block

The MODBUS Master package for W

package which allows the user to MODBUS Master function blocks for

Regent application programs. W

seamlessly integrated with the base WINTERPRET

MODBUS Master function blocks allow the Regent to use devices which

respond to MODBUS commands to collect and disseminate data for non

safety-related application.

hen installed on the PC, the package is

INTERPRET

W

INTERPRET

(T3837)

Issue 1, August, 96

is an add-in software

software.

-

Software Installation

The MODBUS Master package is installed on the PC running the

W

INTERPRET application software. The WINTERPRET

provides the necessary installation software to install this add-in package.

The package should be install

the W

INTERPRET

Installation Procedure

The files on the MODBUS Master package diskette are in compressed

form. You cannot simply copy the files to your hard drive — they must be

decompressed before they will run. You must have the W

package distribution disk in order to run the setup procedure to install the

MODBUS Master package.

To install the MODBUS Master package, use the following sequence:

1.

Insert the WINTERPRET base package distribution disk into drive A: or

B:

2.

Start Windows (if it isn’t already running).

3.

Choose Run from the Program Manager’s File menu.

base package.

base package

ed at the same time or after you have installed

INTERPRET

base

Industrial Control Services

(Issue 1)

1

Page 2

MODBUS Master Package for

4. Type a:\

base package disk in drive B: type b:\

press ENTER.

5. In the WINTERPRET

which you have installed the W

that you have already installed W

6. In t

Master package box.

7. Choose

When the installation is completed, you can run the WINTERPRET

application and create MODBUS Master function blocks in your

application programs.

he W

setup.exe

INTERPRET

OK

in the text box. (if you inserted the WINTERPRET

Setup dialog box enter the name of the directory in

Installation dialog box check the MODBUS

to have the setup program install the package software.

W

INTERPRET

setup.exe

INTERPRET

INTERPRET

(T3837)

.) Choose OK or

base package (This assumes

). Choose

Continue.

Working with MODBUS Master Function Blocks

MODBUS Master function blocks are created as part of an application

program which may also contain other types of function blocks. A single

application program is made up of as many as 50 function blocks of any

type or combination.

When you installed the MODBUS Master package, additional software

was added to W

function blocks. With this additional software you can create MODBUS

Master function blocks by opening a project, opening a program, and

opening (or creating) a function block.

The code generated by W

(MODBUS Master function block code) responds to control signals,

prepares MODBUS commands to be sent, decodes received MODBUS

responses, and in general performs the operations that are associated with a

MODBUS Master.

The MODBUS Master code is executed in the Regent in the same manner

as any other function block code. It is called once per application scan as

long as the program to which the MODBUS Master function block belongs

is in the run state. Instead of performing a complete MODBUS scan each

INTERPRET

INTERPRET

to allow you to work with MODBUS Master

for the MODBUS Master

PD-6048 August, 96

(Issue 1)

2

Page 3

MODBUS Master Package for

time it is called, the MODBUS Master function block code splits up the

tasks so that it can be done a

a time. This allows the Regent system to remain responsive, as well as

eliminating the potential loss of time while waiting for MODBUS responses.

For an overview about Regent application programs and function blocks

and how to create them using W

with Programs and Function Blocks

little at

INTERPRET

W

INTERPRET

, refer to Section 5,

, in the Regent User’s Guide.

(T3837)

Working

Using MODBUS Master Function Blocks

The MODBUS Master function block allows the user to specify the

following Regent variables:

·

Variables to receive data from MODBUS slaves

·

Variables to be the source of data sent to MODBUS slaves

·

Variables to serve as control signals for the function block

·

Variables to receive the current status and other information about the

function block.

Each Regent variable used to send or receive data may be associated with a

different MODBUS node and address. The user may specify which port on

the Regent to use, including the s

configuration.

The MODBUS Master function block compiler may be invoked from the

File menu in the MODBUS function block editor when the editor is closed

and the changes have been saved for the current function block. The

compiler translates the user’s inputs from the source file into an object file to

be loaded into and executed in the Regent.

The compiler has two separate phases: registration and generation. In the

registration phase, the compiler registers t

from the project dictionary. The generation phase consists of parameter

validation followed by code and data segments generation. The registration

phase follows the conventions (and requirements) imposed by other

W

INTERPRET

each function block compiler, and is where MODBUS-Master-specific

code is introduced.

function block compilers. The generation phase is unique to

election of a secondary port for a dual-link

ag names and retrieves definitions

PD-6048 August, 96

(Issue 1)

3

Page 4

MODBUS Master Package for

Name

Size Type

Description

E

NABLE

Coil Input

Enables execution of the function block. Energize to

execute the function block.

E

RROR

Coil

Output

Enunciates a MODBUS function block error.

Energized when an error occurs.

R

ESET

Coil Input

Resets the error information. Energize to reset the

information. While energized, no errors w

ill be

reported.

N

ODE

Word

Output

The MODBUS node associated with the error. 0 when

there is no error.

C

ODE

Word

Output

The MODBUS function block error code. 0 when there

is no error.

T

IME

Float

Output

The time it took to complete the last MODBUS scan in

ms. 0 until a scan has been completed.

T

OGGLE

Coil

Output

This control signal changes state at the beginning of

each MODBUS scan. (Its period it typically 2 *

Time)

W

INTERPRET

(T3837)

Operation

The MODBUS function block uses control signals to report information and

accept runtime control

used like normal Regent variables. Table 1 identifies these control signals.

Table 1 - Control Signals

E

NABLE

E

NABLE is de

and all other signals are invalid (exception: the RESET

honored).

E

RROR

enunciates any errors that the MODBUS function block code

encounters.

N

ODE

and

when

E

RROR is active. NODE

a zero [0] indicating the MODBUS master itself).

specific MODBUS exception code.

The

T

OGGLE

the initial scan,

T

OGGLE

desired instead of a toggle, external application code (in the same program)

may reset

directives. The signals are user defined, and may be

controls the execution of the function block at runtime. When

-

ener

gized (OFF), the function block code is not executed

input signal will still be

C

ODE

are used to further define an error. They are valid only

contains the MODBUS node that is in error (

C

ODE contains the

state changes each time a MODBUS

T

IME

contains the length (in ms) of the MODBUS scan.

is initialized to de-energized (OFF) for the initial scan. If a pulse is

T

OGGLE

to the de-energized state after a rising edge is detected.

scan is completed. After

PD-6048 August, 96

(Issue 1)

4

Page 5

MODBUS Master Package for

Field Size

Description

Node Byte

The MODBUS node to broadcast this command to.

Function

Byte

The MODBUS function to broadcast.

Address

Word

The starting MODBUS address for this command.

Count

Word

The number of MODBUS variables to be returned.

CRC Word

The pre-calculated CRC for the MODBUS command.

Offset

Word

The index into the Read Var table for the initial MODBUS

variable.

Reserved

Word

Reserved for internal use.

Field Size

Description

Value

Word

The value of the regent varia

ble.

Note:

W

INTERPRET

(T3837)

Tables define the work that the MODBUS function block performs. The

primary table used is the ‘Read Command’ (RC) table. Each entry in the

RC table is eight bytes wide, with the first six bytes corresponding exactly

to the same fields in a MODBUS command. Each entry (starting with the

first) in the RC table sends a MODBUS command. When the response is

received, the Count field is used to decode the received data. The Index

field, in conjunction with the Read Variable table, is used to store the data in

its proper place. Tables 2 and 3 define the Read Command and Read

Variable Tables, respectively.

Table 2 - Read Command Table

Table 3 - Read Variable Table

When each entry in the Read Command table has been sent, the function

block code waits for all the replies to be returned. When all of the replies

have been received and processed, a single MODBUS scan has been

completed. At the start of the next MODBUS scan, the entire process

starts over at the beginning of the RC table.

Abstractly, the RC table can be thought of as a “Read” queue. This queue is

replenished at the start of each MODBUS scan, and is empty at the scan’s

completion. Future pseu

queue as the READQ.

PD-6048 August, 96

(Issue 1)

do code examples refer to the abstract RC table

5

Page 6

MODBUS Master Package for

Field Size

Description

Node Byte

The MODBUS node to notify when the v

alue changes.

Function

Byte

The MODBUS function to use for notification.

MODBUS

Address

Word

The MODBUS address to use for notification.

Value

Word

The current value of the variable.

CRC Word

Placeholder for the run-time calculated CRC of the MODBUS

command.

Last Value

Word

The last known value of the variable.

Reserved

Word

Reserved for internal use.

Note:

W

INTERPRET

(T3837)

The ‘Write Command’ (WC) table is also used by the MODBUS master

function block code. In many ways, the WC table is similar to the RC table.

However, the WC table does not utilize a corresponding Write Variable

table because each “Write” only references a single variable. Table 4

defines the Write Command Table.

Table 4 - Write Command Table

Every application scan the function block code is executed, each variable

defined in the WC table is examined by comparing its current value to the

co

ntents of the Last Value field. If the two value differ, the Send Flag field is

set and the current value is copied into the Last Value field.

Each entry in the WC table, with the Send Flag set, causes a MODBUS

command to be sent. When the response is received, the Send Flag for that

variable is cleared. For the initial MODBUS scan, the Send Flag field is set

for every entry in the table. The WC table is processed from the initial entry

to the final entry in sequence. If no more MODBUS commands can be

sen

t, WC processing stops and resumes again on the same entry the next

time the function block code is executed.

PD-6048 August, 96

Abstractly, the WC table can be thought of as a “Write” queue. This queue

is full for the initial MODBUS scan. Future pseudo code example refer to

the abstract WC table queue as the WRITEQ.

The tasks performed each time the function block code is executed are as

follows:

· ENABLE

·

is checked to see if the function block should be executed.

A check is made to see if this is the initial MODBUS scan. If so, local

variables and tables are initialized.

(Issue 1)

6

Page 7

MODBUS Master Package for

·

A check is made to see if this is the start of a MODBUS scan. If so, the

‘MODBUS Scan Time’ timer is reset.

·

Each “Write” variable is check to see if it has changed state (or value),

and those that have are added to the WRITEQ.

·

Outgoing packets are sent.

While !FULL(SENDQ)

If !EMPTY

(WRITWQ)

ENQ(SENDQ, DEQ(WRITWQ))

Else If !EMPTY(READQ)

ENQ(SENDQ, DEQ(READQ))

End If

End While

·

Incoming responses are received, and the appropriate actions are

taken.

·

While !EMPTY(RECVQ)

PROCESS(DEQ(RECVQ))

End While

A check is made to see if this is the end of the MODBUS scan. If so,

copy the timer and toggle the toggle.

·

RESET

is checked to see if the error signals should be cleared. This

occurs even if the function block is not executed.

W

INTERPRET

(T3837)

The MODBUS function block code keeps track of how many me

ssages

are outstanding by incrementing a counter for each ENQ(SENDQ,

DEQ(READQ)), and decrementing the same counter for each

DEQ(RECVQ) when the response is a “Read” response. A MODBUS

scan is considered complete when the counter is zero (0) and the READQ

is empty (COUNT == 0 && EMPTY(READQ)).

At the beginning of each MODBUS scan, a copy of the system millisecond

timer is made. At the completion of a MODBUS scan, this value is copied

into the T

IME

variable and the

T

OGGLE

signal is inverted.

Placing a MODB

US command on the SENDQ involves copying the

MODBUS command to a buffer, generating the appropriate error-check

code, and sending the command to the correct port (primary or secondary).

Internal variables are used to determine the port.

If a secondary port was defined, once each MODBUS scan the initial

MODBUS ‘Read Command’ for each node is sent via the secondary port.

The result of this command is ignored, it is used only to check for a valid

connection. The MODBUS Node table is used to track the status o

node’s response. Table 5 defines the MODBUS Node Table.

f each

PD-6048 August, 96

(Issue 1)

7

Page 8

MODBUS Master Package for

Field Size

Description

Node Byte

A MODBUS slave node

Reserved

Byte

Reserved for internal use.

Field Type

Description

Primary Port

Constant

Must be a number between 2 and 6.

Secondary Port

Constant

If specified, must be a number between 1 and 6 and

cannot be equal to the value specified for the

Primary Port. If not specified, a secondary MODBUS

port will not be used.

W

INTERPRET

(T3837)

Table 5 - MODBUS Node Table

If a non-MODBUS error is reported for any MODBUS slave on the

current primary port, the ports are swapped and the secondary port is used

as the primary port for the next MODBUS scan. If no errors are reported,

the Primary port is used for the next MODBUS scan. This approach results

in the MODBUS ma

diagnostic error, and remaining there until another error occurs.

ster switching over to the secondary port on any

When the responses are being processed, any MODBUS exceptions

energize the E

RROR

signal. If the

N

ODE

and

C

ODE

variables are both zero,

the MODBUS node and exception code are copied into them. This action

preserves the initial MODBUS error until

RESET is activated.

In addition to reporting MODBUS exception codes, some additional error

information is reported. In these cases, the

N

ODE

variable

is set to an invalid

MODBUS node number (0 or 248+). Just before the end of each

execution scan, the RESET signal is examined. If it is energized (ON), the

E

RROR

signal is de-energized (turned OFF) and the

variables are set to zero.

As long as the

no MODBUS errors are reported

R

ESET

N

ODE

and

C

ODE

signal remains energized,

Validation

Before any code is generated, all parameters are validated according to the

criteria presented in Table 6.

Table 6 - Parameter Validation Rules

PD-6048 August, 96

(Issue 1)

8

Page 9

MODBUS Master Package for

Field Type

Description

E

NABLE

Tag

If specified, must be the name of a valid bit variable.

If not specified, the MODBUS function block is

assumed to always be enabled.

R

ESET

Tag

If specified, must be the name of a valid bit variable.

If not specified, the

E

RROR

o

utput can only be

cleared by stopping, and then restarting the

MODBUS function block.

E

RROR

Tag

If specified, must be the name of a valid bit variable.

C

ODE

Tag

If specified, must be the name of a valid word

variable.

N

ODE

Tag

If specified, must be the name of a valid word

variable.

T

IME

Tag

If specified, must be the name of a valid floating

point variable.

T

OGGLE

Tag

If specified, must be the name of a valid bit variable.

Field Type

Description

Name Tag

Must be the name of a valid variable. The size and

usage of the variable must match the attributes as

specified by the value of the Address field. (Refer to

Table 8 for additional information.)

Address

Constant

Must be between 0 and 49,999.

Node

Constant

Must be between 1 and 247.

Usage Switch

Must specify either Read or Write.

Address Range

Regent Type

MODBUS Type

MODBUS Cmd

Usage

0

9999

Bit Variable

Coil 01

Read or Write

10000

19999

Bit Variable

Input 02

Read Only

20000

29999

Reserved - - -

30000

39999

Word Variable

Input Register

04

Read Only

40000

49999

Word Variable

Holding register

03

Read or Write

W

INTERPRET

(T3837)

A rule violation results in an error message, but the validation procedure

con

tinues until all parameters have been checked. After the parameters are

checked, each variable definition is validated according to the criteria

presented in Table 7.

Table 7 - Variable Definition Validation Rules

PD-6048 August, 96

(Issue 1)

9

Page 10

MODBUS Master Package for

W

INTERPRET

(T3837)

A rule violation results in an error message, but the validation procedure

continues until all variables have been checked. The special condition where

there are no variables defined also generates an error message. The

compiler proceeds only after all parameters and variables have been

validated and no errors have occurred.

The special condition where there are no variables defined also generates an

error message. The compiler proceeds only after all parameters and

variables have been validated and no errors have occurred.

Generation

After all parameters and variables have been validated, the compiler

generates the code and da

ta segments for the function block. The majority

of the code segment remains the same across all MODBUS Master

function blocks, because the specific behavior of the MODBUS Master is

defined in the tables generated as a part of the data segment.

PD-6048 August, 96

(Issue 1)

10

Page 11

MODBUS Master Package for

W

INTERPRET

(T3837)

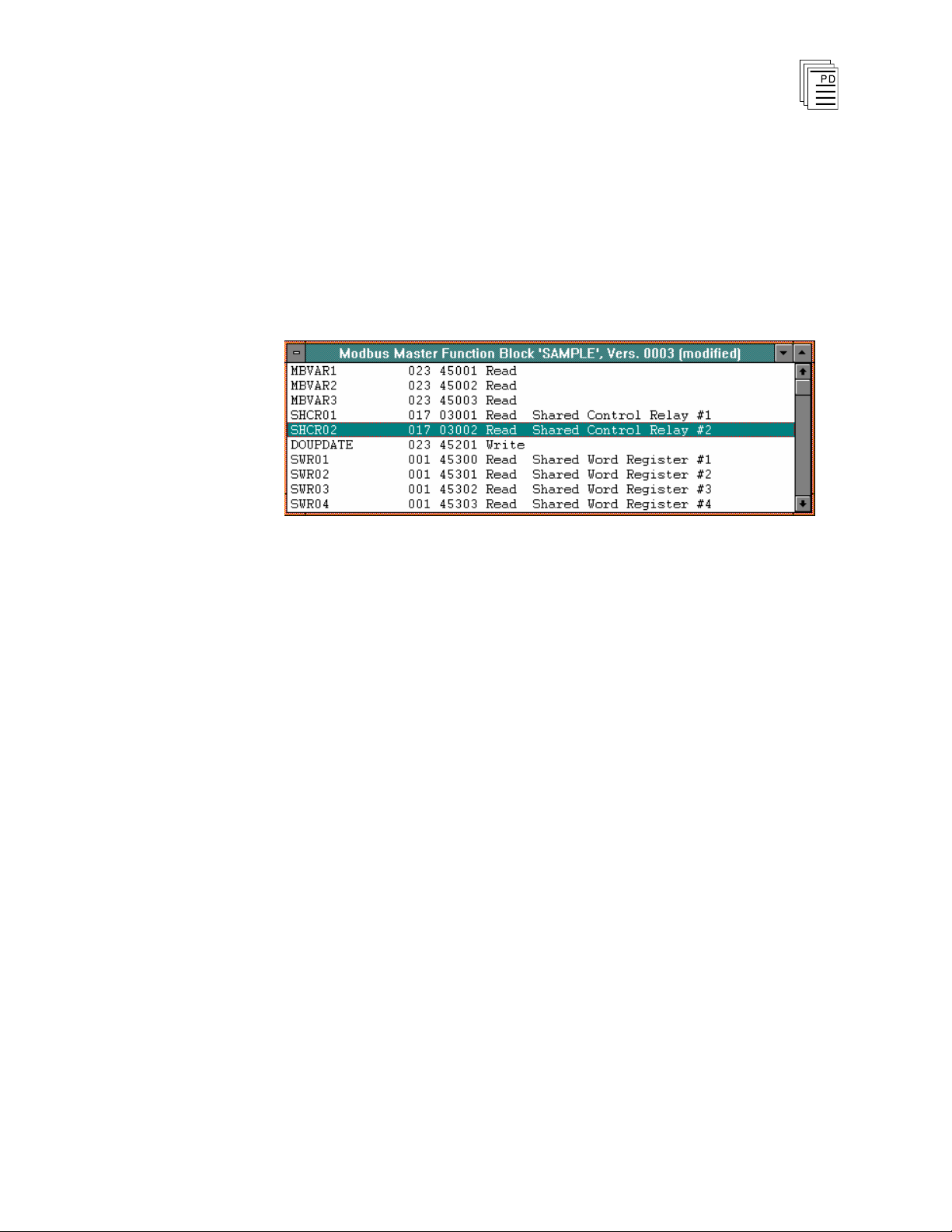

Using the MODBUS Master Function Block Editor

MODBUS Master function blocks are created using Add Function Block

or Insert Function Block from the Program Editor. After you have created a

new function block, the MODBUS Master Function Block Editor window

is opened

Figure 1. The MODBUS Master Function Block Editor Window

The primary user interface for the MODBUS Master function block will be

the MODBUS Master function block window. This window displays a list

of variables known to the MODBUS Master function block. Each line

includes the variable’s name, type, MODBUS node, MODBUS address,

and whether the MODBUS master is Read or Write.

as shown in Figure 1.

The MODBUS Master function block compiler may be invoked from the

File menu in the MODBUS function block edi

and the changes have been saved for the current function block. The

compiler translates the user’s inputs from the source file into an object file to

be loaded into and executed in the Regent.

Using drop-down menus, you select commands to configure and print the

function block and perform other options.

File Menu

The File Menu allows you to access the standard function block file

commands including Save Function Block, Revert to Last Saved, Compile,

View Error Messages, Edit Fu

Block Details, Print Function Block, Print Setup, Log Off, and Exit. For

more information on these commands, refer to

Function Blocks

PD-6048 August, 96

(Issue 1)

tor when the editor is closed

nction Block Description, Edit Function

Commands Common to All

in Section 5 of the Regent Ò + Plus User’s Guide.

11

Page 12

MODBUS Master Package for

W

INTERPRET

(T3837)

Edit Menu

The Edit menu (see Figure 2) allows you to select Add Variable, Edit

Variable, Insert Variable, Delete Variable, Add Multiple, and Edit

Parameters commands.

Figure 2. The

Edit Menu

Add Variable/Edit Variable/Insert Variable

The Add Variable command allows you to add a variable to the end of the

function block variable list. The Edit Variable command allows you to edit a

selected variable. The Insert Variable command allow to enter a new

variable.

After choosing to add, edit, or insert a variable, the dialog box shown in

Figure 3 opens.

PD-6048 August, 96

(Issue 1)

Figure 3. The MODBUS Variable Editor Dialog Box

12

Page 13

MODBUS Master Package for

W

INTERPRET

(T3837)

The variable parameters are as follows:

Name

The variable to be associated with the specified MODBUS address. This is

a required field and

must be a valid Winterpret tag name.

Node

The MODBUS node to be associated with the specified MODBUS

variable. This is a required field and must contain a valid node number in the

range of 1 - 247.

Address

The MODBUS address to be associated with the specified MODBUS

variable. This is a required field and must contain a valid MODBUS

address in the range of 0 - 49,999. This address determines the MODBUS

function to be used.

Usage: Read/Write

The MODBUS function usage: to send data or receive data from a

MO

DBUS slave. This is a required field and must follow the MODBUS

variable type as implied by the MODBUS address.

Delete Variable

The Delete Variable command allows you to remove the currently selected

variable from the MODBUS Master variable list.

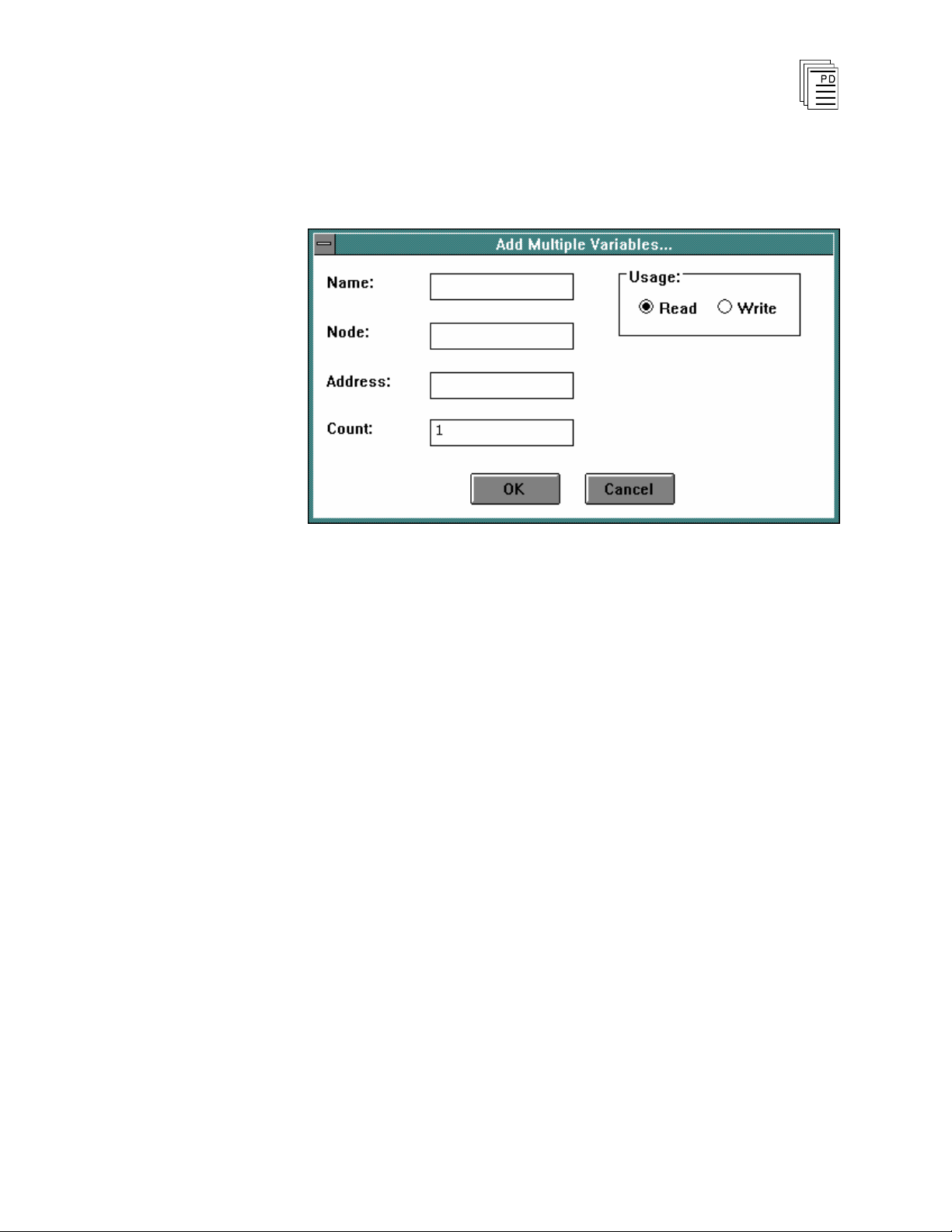

Add Multiple

The Add Multiple command allows you to add a number of MODBUS

variables to the MODBUS Master Function Block Editor window with a

single action. Choosing this command opens the dialog box shown in

Figure 4.

PD-6048 August, 96

(Issue 1)

13

Page 14

MODBUS Master Package for

W

INTERPRET

(T3837)

Figure 4. The Add Multiple MOD

BUS Variables Dialog Box

The variable parameters are as follows:

Name (Starting)

The name of the initial variable to be added. This is a required field and

must contain a valid W

Node

INTERPRET

tag name picture.

The MODBUS node to be associated with each MODBUS variable. This

required field must contain a valid MODBUS node number in the range of 1

-

247.

Address (Starting)

The starting MODBUS address to be used. This required field must contain

a valid MODBUS address in the range of 0 - 49,999. The specifi

address determines the MODBUS function to be used.

ed

PD-6048 August, 96

(Issue 1)

14

Page 15

MODBUS Master Package for

W

INTERPRET

(T3837)

Usage: Read/Write

The MODBUS function usage: to send data or receive data from a

MODBUS slave. This is a required field and must follow the MODBUS

variable type as implied by the MODBUS address.

Count

The number of MODBUS variables to be added. This required field must

contain a valid count in the range of 1 - 999.

Edit Parameters

This command allows you to specify or change the compile-time

configuration options for the MODBUS Master function bloc

this command opens the dialog box shown in Figure 5.

k. Choosing

The parameters are as follows:

Primary Port

The compile time parameter which selects the Regent serial port to be used

as the primary MODBUS port. This required field must be a valid port

PD-6048 August, 96

(Issue 1)

Figure 5. The MODBUS Parameters Dialog Box

15

Page 16

MODBUS Master Package for

W

INTERPRET

(T3837)

number in the range of 2 - 6, and must not be the same as the Secondary

Port field.

Secondary Port

The compile time parameter which selects the Regent serial port to be used

as the secondary MODBUS port. If not left

blank, this field must be a valid

port number in the range of 2 - 6, and must not be the same as the Primary

Port field.

Enable

The variable to be used as the ENABLE control relay. If not left blank, this

field must contain a valid W

Error

INTERPRET

tag name.

The variable to be used as the ERROR output coil. If not left blank, this

field must contain a valid W

INTERPRET

tag name.

Reset

The variable to be used as the ERROR output coil. If not left blank, this

field must contain a valid W

INTERPRET

tag name.

Error Code

The variable to be used as the [ERROR] CODE output register. If not left

blank, this field must contain a valid W

Error Node

INTERPRET

tag name

The variable to be used as the [ERROR] NODE output register. If not left

blank, this field must contain a valid W

MODBUS Scan Time

INTERPRET

tag name.

The variable to be uses as the [MODBUS Scan] TIME output floating

point register. If not blank, this field must contain a valid WINTERPRET tag

name.

MODBUS Scan Toggle

The variable to be uses as the [MODBUS

not blank, this field must contain a valid W

Search Menu

Scan] TOGGLE output coil. If

INTERPRET

tag name.

From the Search Menu (see Figure 6), you can select the Go To Variable,

Find, and Find Next commands.

PD-6048 August, 96

(Issue 1)

16

Page 17

MODBUS Master Package for

W

INTERPRET

(T3837)

Figure 6. The Search Menu

Go To Variable

The Go To Variable command allows you to quickly move to different

entries in the MODBUS variables list and the MODBUS parameters. After

choosing this command, the dialog box shown in Figure 7 opens.

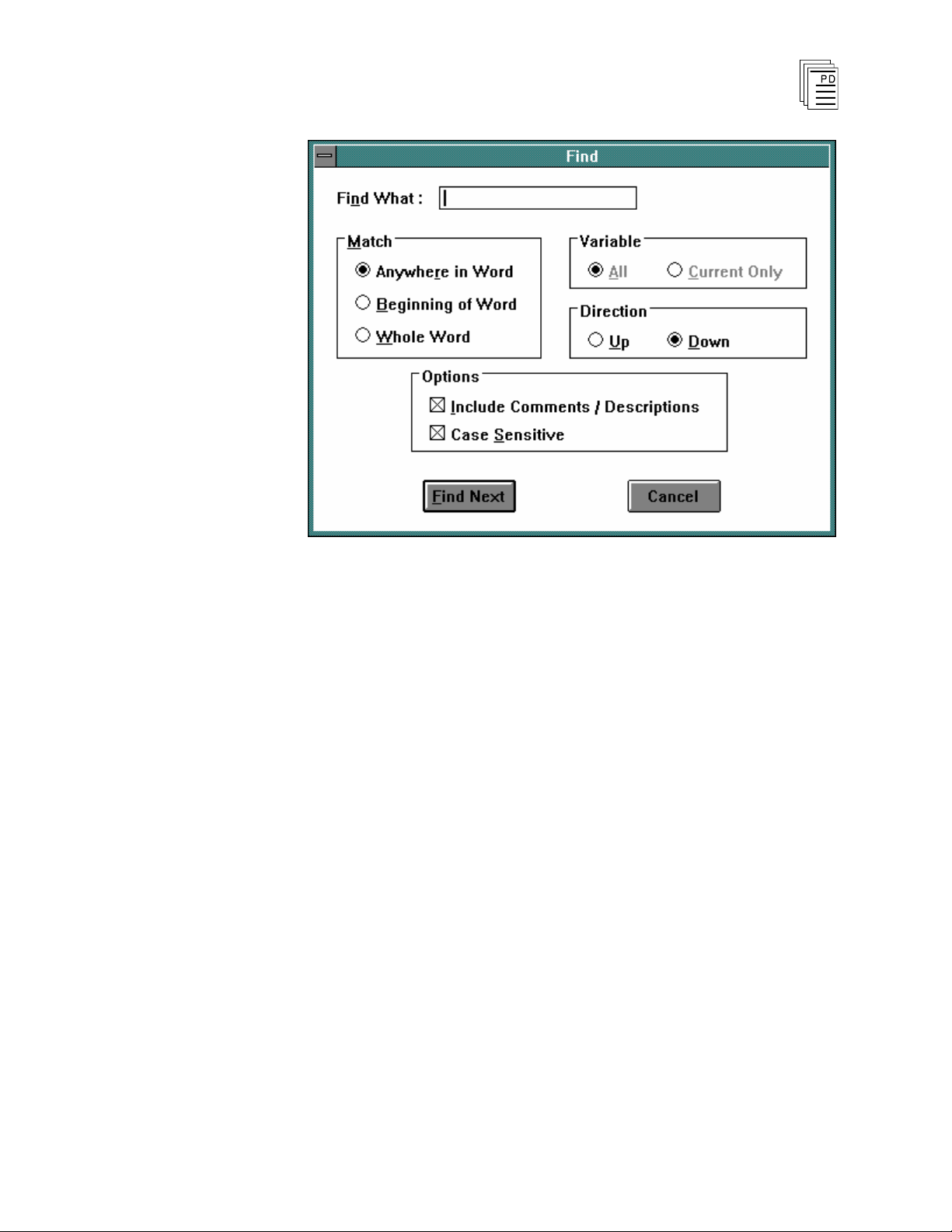

Find

The Find c

Figure 7. The Go To Variable Dialog Box

ommand allows you to locate different entries in the MODBUS

variables list and the MODBUS parameters. After choosing this command,

the dialog box shown in Figure 8 opens.

PD-6048 August, 96

(Issue 1)

17

Page 18

MODBUS Master Package for

W

INTERPRET

(T3837)

Find Next

Figure 8. The Find Dialog Box

The Find command searches for the next occurrence of whatever was

previously searched for using the Find command.

PD-6048 August, 96

(Issue 1)

18

Page 19

MODBUS Master Package for

W

INTERPRET

(T3837)

Using the MODBUS Master Function Block Monitor

The MODBUS Master function block monitor displays the parameters,

variables, addresses, and values of a MODBUS Master function bloc

executing in a Regent.

When you have selected a MODBUS Master function block in the

Program Monitor window and have chosen the Monitor command from the

Control Menu, the MODBUS Master Function Block Monitor Window is

opened, as shown in Figure 9.

Figure 9. The MODBUS Master Function Block Monitor Window

The MODBUS Function Block Monitor Window is essentially the same as

its editor counterpart except that no changes can be made to the variable

list, and the current value of each variable is displayed i

column.

n the left-most

k

File Menu

The File Menu provides access to several commands common to all

function block monitors, including View Function Block Details, View

Function Block Descriptions, Log Off, and Exit. For descriptions of these

commands, refer to

Monitors

PD-6048 August, 96

(Issue 1)

Commands Common to All Function Block

in Section 7 of the Regent

Ò

+ Plus User’s Guide.

19

Page 20

MODBUS Master Package for

W

INTERPRET

(T3837)

Control Menu

The Control menu provides access to several commands common to all

function block monitors, including Run, Sto

these commands, refer to

Monitors

The Control Menu command specific to the MODBUS Master Function

Block Monitor is the Take Monitor Offline command.

in Section 7 of the Regent Ò + Plus User’s Guide.

Take Monitor Offline

The Take Monitor Offline command allows you to toggle on and off the

constant update of the monitor with information from the Regent.

Search Menu

The Search menu allows you to perform standar

MODBUS Master function block. This menu is implemented exactly as

Search menu in the MODBUS Master Function Block Editor section of this

document.

Monitor Variable Dialog Box

p, and Scan. For descriptions of

Commands Common to All Function Block

d search operations on the

The MODBUS Variable Dialog Box (see Figure 10) is essentially the same

as that used in the editor, except that you cannot make any changes to the

variable definition, and the current value of each variable is displayed in a

separate field.

Figure 10. The MODBUS Master Monitor Parameter Dialog Box

PD-6048 August, 96

(Issue 1)

20

Page 21

MODBUS Master Package for

W

INTERPRET

(T3837)

Configur

Block

ing a MODBUS Master Function

Serial Port Definition

The MODBUS function block requires you to define a Regent serial port to

use as the primary and/or secondary MODBUS Master port. To allow the

user to reserve a port for this use, and so that the port definition can be

check at runtime a new type of serial port, called MOD MASTER, is used.

(This is a MODBUS master port type, but the current length restrictions

limit the length of port types to 10 characters.)

Serial Port List Dialog Box

From the Proj

display the Serial Port List Dialog Box (see Figure 11).

ect Editor "Definitions" menu, select Serial Ports. This will

The Type drop-down control now displays MOD MASTER between the

ASCII and MODBUS selections. The dialog box functions normally,

except that an additional validation rule is added for the MOD MASTER

port type.

PD-6048 August, 96

(Issue 1)

Figure 11. Serial Port List Dialog Box

21

Page 22

MODBUS Master Package for

W

INTERPRET

(T3837)

A MOD MASTER type port has the following restrictions:

·

8 data bits

·

2 stop bits an

d no parity bit, or 1 stop bit and 1 parity bit.

In addition, the Node field is not valid in this context, and is set to zero (0).

Figure 12. Serial Port Settings Dialog Box

Refer to Section 4 of the Regent Ò + Plus User’s Guide for more

information on working with serial ports.

PD-6048 August, 96

(Issue 1)

22

Page 23

MODBUS Master Package for

W

INTERPRET

(T3837)

Safety Considerations

The MODBUS Master function block is TÜV certified for Risk Class 5 as

non-interfering. These function blocks may only be used in safety

applications if they do not perform any control actions that affect the value

of Risk Class 5 safety critical variables.

Availability

The MODBUS Master function block is available as an add on package to

Winterpret/TRIOS versions 3.40 and later.

critical

PD-6048 August, 96

(Issue 1)

23

Loading...

Loading...