Page 1

ICS Regent

®

PD-6044

Industrial Control Services

1

Continuous Control Package for

W

INTERPRET

Continuous Control Function Block for PID

Control (T3834)

Issue 1,

March, 06

The Continuous Control package for WINTERPRET

is an

add-in software package which allows the user to create

co

ntinuous control function blocks for Regent application

programs. When installed on the PC, the continuous

control package is seamlessly integrated with the base

W

INTERPRET

software.

Continuous Control is used to maintain a measured

process signal at a pr

edetermined value and provides the

user with three different control modes: Proportional,

Integral and Derivative. These modes give Continuous

Control the term ‘PID’. Each function block allows the user

to define up to 16 control loops (also known as con

trollers).

Software Installation

The Continuous Control package is installed on the PC

running the WINTERPRET

application software. The

W

INTERPRET base package provides the necessary

installation software to install this add-in package. The

Continuous Control package should be installed at the

same time or after you have installed the WINTERPRET

base package.

Installation Procedure

IMPORTANT!

The files on the Continuous Control package diskette are

in compressed form. You cannot simply copy the files to

your hard drive — they must be decompressed before they

will run. You must have the WINTERPRET

base package

Page 2

Continuous Control Package for W

INTERPRET

(T3834)

2

Industrial Control Services

distribution disk in order to run the setup procedure to

install the Continuous Control package.

To install the Continuous Control package, use the

following sequence:

1. Insert the WINTERPRET base package distribution disk

into drive A: or B:

2. Start Windows (if it isn’t already running).

3. Choose Run from the Program Manager’s File menu.

4. Type a:\

setup.exe

in the text box. (if you inserted the

W

INTERPRET base package disk in drive B: type

b:\setup.exe

.) Choose OK or press ENTER.

5. In the WINTERPRET Setup dialog box enter the name of

the directory in which you have installed the

W

INTERPRET base package (This assumes that you have

already insta

lled W

INTERPRET). Choose Continue.

6. In the WINTERPRET Installation dialog box check the

Continuous Control package box.

7. Choose OK to have the setup program install the

Continuous Control package software.

When the installation is completed, you can r

un the

W

INTERPRET application and create continuous control

function blocks in your application programs.

Working With Continuous Control (PID) Function Blocks

Application programs consist of one or more logical units

called function blocks. Each function

block performs part

of a program. These function blocks allow you to create

modular programs that are easily updated and

manipulated. Each function block can be used in one or

many programs.

Different types of function blocks can be combined to create

a

program.

Continuous control function blocks let you coordinate and

interlock the loop control functions with the discrete and

sequential functions of ladder logic. The shared variables

in the Regent provide a convenient way to do this.

Page 3

Continuous Control Package for W

INTERPRET

(T3834)

PD-6044

March, 06

3

Shared variables are data values internal to the Regent

that may be commonly referenced by all function blocks of

any application program. Use the Shared Variable Editor

to define the shared variables in the Regent.

Each controller may have up to 10 alarms associated with

it, each of which may be defined by assigning a name.

Continuous Control is used to maintain a measured

process signal at a predetermined value. A Continuous

Control process requires four fundamental items:

·

A process variable (PV) that can be measured

·

A s

etpoint (SP) at which the process variable should be

maintained

·

A control output that affects the process such that the

process variable is changed

·

A set of rules that govern how the controlled output

should be changed to make the process variable equal to

its setpoint

Most of the parameters in the Continuous Control loop

may be assigned a name instead of a constant value.

When a parameter is given a name, that value may be

dynamically modified by other application program

function blocks.

Examples of how

this dynamic modification might be used

include:

·

Assigning a name to the auto/manual parameter would

enable a ladder logic function block to place the

Continuous Control loop in automatic mode when

required by the process

·

Assigning a name to the setpoint p

arameter would

enable a ladder logic function block to modify the

setpoint automatically. Remote setpoint and ramp/soak

functions could be initiated automatically based upon

sequential process events.

·

Continuous Control alarms can be assigned names to

ena

ble them to be referenced in ladder logic function

blocks

Page 4

Continuous Control Package for W

INTERPRET

(T3834)

4

Industrial Control Services

Proportional Control

Making the controlled output a continuous variable that is

proportional to the process error provides a precise means

of controlling the process. The process error is the

diff

erence between the setpoint and the process variable.

This can be represented by:

Mn = P = Kcen

where,

Mn = controller output

P = proportional action

Kc = proportional constant, Gain

en = process error = setpoint (SP) - process variable (PV)

In practice this representation is not satisfactory because

the output is zero when the error is zero. Usually some

output is required to maintain the process variable at the

setpoint. This is called the output bias. The rules

governing the control output then become:

Mn = P + M

r

= Kcen + Mr

where,

Mr = output bias

With the addition of the output bias we have an output

value to keep the process variable at the setpoint. This

indicates that there is a finite controller output for a finite

process error. In many cases this finite value will not bring

the process variable back to the setpoint due to system

disturbances or setpoint changes. In effect, it becomes

necessary to continuously adjust or reset the output bias to

bring the process back in control.

Integral Control

The most common method used to automatically reset the

output bias is integral control. Integral control

automatically adjusts the output bias as long as there is a

process error. This is accomplished by integrating the error

with respect to time. The int

egral term can be expressed as:

In = I

n -1

+ (TS/Tl) * en

where,

n = current integral action

I

n-1

= previous integral action

Page 5

Continuous Control Package for W

INTERPRET

(T3834)

PD-6044

March, 06

5

TS = loop sample time

Tl = reset time

The amount of reset action is defined by the integral time

constant: reset time (Tl). The re

set time represents the time

required for the integral sum to equal the proportional

action. This assumes that the process error remains

constant. Thus a smaller value for reset time creates more

reset action. A larger value for reset time creates less res

et

action.

The integral term can be added to the equation to provide

an automatic reset function. When integral and

proportional control are combined the control output is

expressed as:

Mn = P+l+Mr = Kc [en + I

n-1

+ (TS/TI) * en] + Mr

Derivative Control

A

third type of control action is derivative control.

Derivative control causes the control output to change

based upon the rate of change of the error. It acts as an

anticipatory control action used to compensate for sudden

process changes or upsets. The derivative action can be

represented as:

Dn = (TD/TS ) * d

where,

Dn = derivative action

TD = derivative time constant, rate time

d = differential:

for error differential, de:

de = (en - e

n-1

)

where,

en = current error

e

n-1

= previous error

for process differential, dp:

dp = (PVn - PV

n-1

)

where,

PVn = current process variable

PV

n -1

= previous process variable

Page 6

Continuous Control Package for W

INTERPRET

(T3834)

6

Industrial Control Services

The amount of derivative action is defined by the

derivative time constant: rate time (TD). The rate time is

the time period over which the error rate of change is

extrapolated and a control action is based. A larger rate

time causes more derivative action. A smaller rate time

causes less derivative action. Derivative action is never

used alone but only in conjunction with proportional or

bo

th proportional and integral. When derivative control is

combined with proportional control and integral control,

the output equation is expressed as:

Mn = Kc [en + In

-

1

+ (TS/Tl) * en + (TD/TS) * de] + M

r

Often all three control modes are used. This three-mode

control is referred to as PID control, which has been widely

accepted as a general set of rules suitable for most

continuous control systems. The PID algorithm can be

"tuned" to reflect the unique dynamics of a particular

process by modifying the proportional, integral and

derivative constants (gain, reset time and rate time) until

the desired system response is achieved.

Page 7

Continuous Control Package for W

INTERPRET

(T3834)

PD-6044

March, 06

7

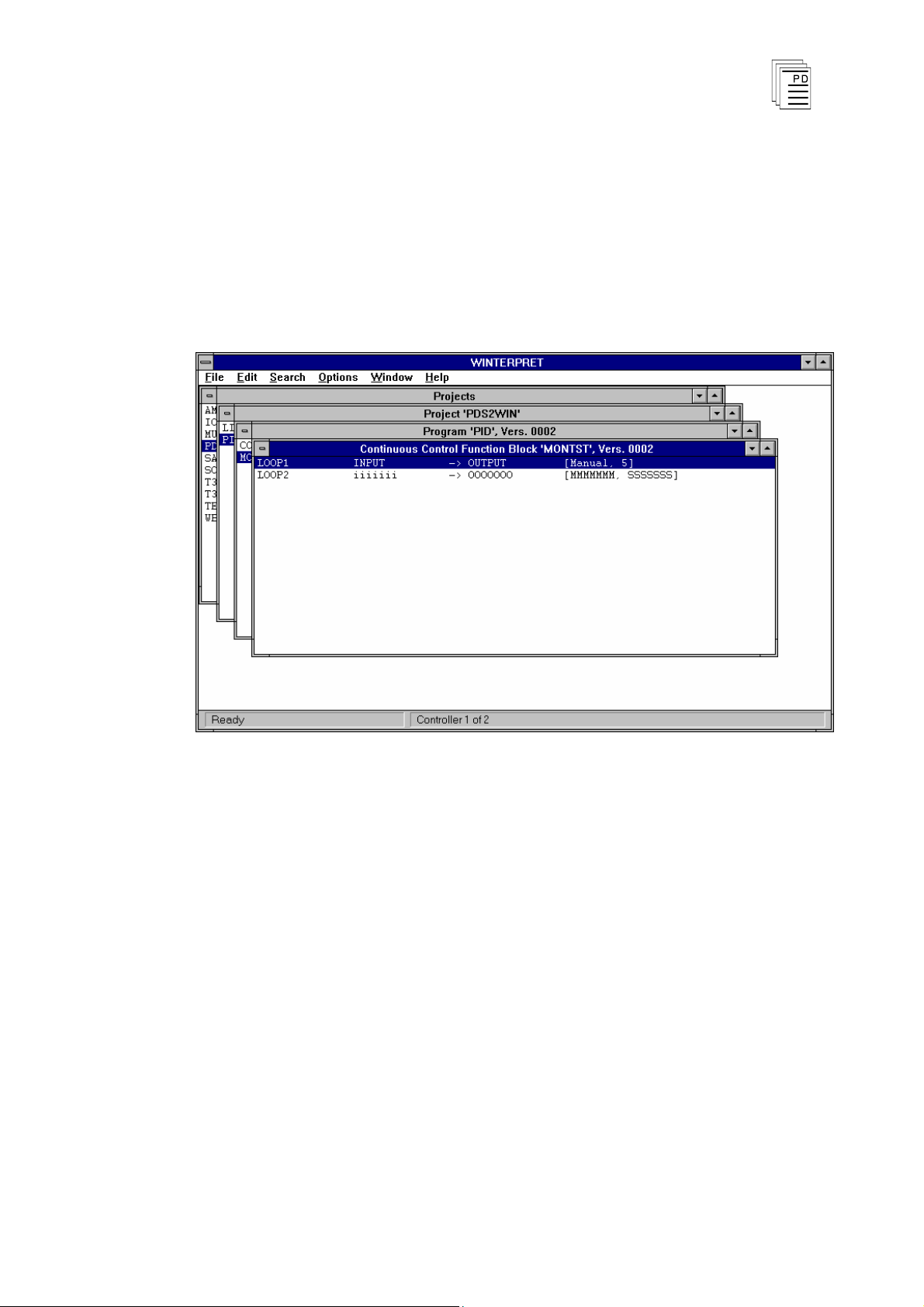

Using the Continuous Control (PID) Editor

Continuous Control function blocks are created using Add

Function Block or Insert Function Block from the Program

Editor. After you have created a new function block the

Continuous Control Editor window is opened as shown in

Figure 1.

Figure 1. The Continuous Control (PID) Editor Window.

The Continuous Control Editor lets you create an

d edit

continuous control function blocks. When you create a

continuous control function block you will enter your

parameters in the dialog boxes.

It should be noted that output and output bias variables

must be unique to a controller.

Using drop-down

menus you can select commands to

configure controllers in the function block, print the

function block and perform a host of other options.

Page 8

Continuous Control Package for W

INTERPRET

(T3834)

8

Industrial Control Services

File Menu

The File Menu gives you access to the standard function

block file commands which include: Save Function

Block,

Revert to Last Saved, Compile, View Error Messages, Edit

Function Block Description, Edit Function Block Details,

Print Function Block, Print Setup, Log Off and Exit. For

more information on all of these commands refer to

Commands Common to all Function Blocks in Section 5 of

the Regent User’s Guide.

Edit Menu

From the Edit Menu the user can select the Add

Controller, Edit Controller, Insert Controller and Delete

Controller commands.

Add Controller/Insert Controller

The Add Controller command lets you add a controller to

the function block. The new controller is added at the end

of the list. The Insert Controller command lets you add a

new controller to the function block. The new controller is

inserted just above, or before, the selected controller.

After choosing Add or Insert Controller, the dialog box

shown in Figure 2 will open. The Controller dialog opens

with the default values shown.

Page 9

Continuous Control Package for W

INTERPRET

(T3834)

PD-6044

March, 06

9

Figure 2. Add/Insert Controller Dialog Box

The PID controller parameters are as follows:

Page 10

Continuous Control Package for W

INTERPRET

(T3834)

10

Industrial Control Services

Low Scaling Va

lue

The low engineering value corresponding to the analog

value of 0. The low scaling value must always be less than

the high scaling value (-32768 < x < high scaling value).

PID Controller Name

The name of the control loop. Follows the same format as

ta

g names. The controller name must not be the name of a

variable.

PID Controller Title

A controller may be given a title containing up to 40

characters of descriptive text. This is the only optional

parameter for a controller.

Input

The name of the process variable which is to be maintained

at the desired setpoint.

High Scaling Value

The high engineering value corresponding to the analog

value of 4,095. The high value must always be greater

than the low value (low scaling value < x < 32767).

Scaling Type

Choose the Linear option button for linear value

conversion. Choose the Square Root option button for

square root extraction (square root extraction is typically

used to linearize flow signals that are measured using

differential pressure transmitters).

O

utput

The name of the variable which receives the result of the

current control computation.

Output Bias %

The bias portion of the control loop. May be in the range

0.0 to 100%. The default value is 0.0%. The corrective

output that maintains the output

at the setpoint.

Output Delta %

The maximum change of output allowed between two loop

calculations. May be in the range 0.0 to 100%. The default

value is 100%.

Page 11

Continuous Control Package for W

INTERPRET

(T3834)

PD-6044

March, 06

11

Direct/Reverse (Control Direction)

Determines the control output gain. In Direct mode, the

c

ontrol output increases as the gain increases (direct acting

or positive gain). In Reverse mode, the control output

decreases as the gain increases (reverse acting or negative

gain). The default value is Direct.

Sample Time

The sample time is the time be

tween loop calculations to

determine how often the controller is solved. May be in the

range 0.01 to 650 seconds. The default value is 1.00 second.

Gain

The gain constant value, including the process gain and

the controller gain. May be in the range 0.01

to 50

(unitless). The default value is 1.00. The desired ratio of

change in corrective action for a given change in the error.

Reset Time

The reset time is the time required to eliminate the effects

of offset introduced by the proportional term. May be

in

the range 0.0 to 3600 seconds. The default value is 0.0

seconds.

Rate Time

The rate time is the time required for the derivative action

to advance the effects of the proportional action. A value of

0 disables the computation of the derivative compone

nt.

May be in the range 0.0 to 250 seconds. The default value

is 0.0 seconds.

Setpoint

The setpoint at which the process value is maintained.

May be in the range Setpoint Low < x < Setpoint High.

There is no default value.

Setpoint Low Limit

The setpoint low limit is the smallest value that the

setpoint can become from the actions of bumpless transfer

or cascade. May be in the range Scale Low < x < Setpoint

High. There is no default value.

Page 12

Continuous Control Package for W

INTERPRET

(T3834)

12

Industrial Control Services

Setpoint High Limit

The setpoint high limit is the largest va

lue that the

setpoint can become from the actions of bumpless transfer

or cascade. May be in the range Setpoint Low < x < Scale

High. There is no default value.

Setpoint Tracking

Select Yes or No. If Yes is selected, the setpoint becomes

the process var

iable value upon mode change from manual

to automatic (bumpless transfer). If No is selected, the

setpoint remains unchanged upon mode change from

manual to automatic. The default value is Yes.

Low Integral Windup %

The lower limit on the control loop ou

tput (%) where

integral windup is prevented. May be in the range 0.0 to

100%. The default value is 0.0%. The smallest value for

the integral error. The integral sum is not updated for

values smaller than the limit.

High Integral Windup %

The upper limit on the control loop output (%) where

integral windup is prevented. May be in the range 0.0 to

100%. The default value is 100%. The highest value for

the integral error. The integral sum is not updated for

values larger than the limit.

Auto/Manual (Oper

ational Mode)

Loop calculation. In Manual, loop calculation is not

performed (ie. the controller is driven by the operator). In

Automatic, loop calculation is performed (ie. The controller

is driven by the Regent PID algorithm). The default value

is Man

ual.

Automatic On

(Yes/No) Controls the master control loop switching. If Yes

is selected, the master control loop of a cascaded system is

switched to automatic when the slave control loop is in

automatic mode. The default value is Yes.

Maximum Error

The

maximum error value allowed for the loop calculation

(in engineering units). May be in the range 0 < x < Scaling

Range. There is no default value. The largest value for

the error for any sample of the process variable.

Page 13

Continuous Control Package for W

INTERPRET

(T3834)

PD-6044

March, 06

13

Error Rate

The maximum rate of change of error allowed for the loop

calculation (in engineering units). May be in the range 0

<

x < Scaling Range. There is no default value.

Differential

Applicable only to the derivative term, calculations may be

based on Error or Process differential

. The default value is

Error.

Error SQR P

Enables proportional action to be based on error (No) or

error squared (Yes). The default value is No.

Error SQR I

Enables integral action to be based on error (No) or error

squared (Yes). The default value is No.

Error Deadband

The distance above and below the setpoint for which the

error is ignored (in engineering units). May be in the

range 0 < x < Scaling Range. There is no default value.

Simple/Mod (Error Mode)

Determines the way in which the error within the

deadband is treated. In Simple mode, the error is treated

as zero for P, I and D terms. In Modified mode, the error is

treated as zero for P and D terms and Integral action is

calculated using the error value. The default value is

Simple

Low Deviation

The smallest change about the setpoint that causes a

warning alarm (in engineering units). May be in the range

0 < x < Deviation High. There is no default value.

High Deviation

The largest change about the setpoint that causes a

warning alarm (in engineering units). May be in the range

Deviation Low < x < Scaling Range. There is no default

value.

Page 14

Continuous Control Package for W

INTERPRET

(T3834)

14

Industrial Control Services

The Alarms dialog is launched from the Controller dialog

by pressing the ‘Alarms...’ button. All alarms are optional if required, an alarm is specified by entering a variable

name. The same name may be used for alarms in different

controllers within a function block, but a warning message

will be displayed on compilation.

Figure 3. The Continuous Control (PID) Alarms

Dialog Box.

The PID alarms are a

s follows:

Page 15

Continuous Control Package for W

INTERPRET

(T3834)

PD-6044

March, 06

15

Low Integral Windup Alarm

On if the integral error is smaller than the low integral

value.

High Integral Windup Alarm

On if the integral alarm error is larger than the high

integral value.

Maximum Error Alarm

On when the error term is larger than the maximum error.

Maximum Error Rate Alarm

On when the rate of change for the error exceeds the

maximum error rate.

Setpoint Low Alarm

On when the setpoint is lower than the setpoint low limit.

Setpoint High Alarm

On when the setpoint is higher than the setpoint high

limit.

Deviation Low Alarm

On when the change about the setpoint is smaller than the

deviation low limit.

Deviation High Alarm

On when the change about the setpoint is larger than the

deviation high limit.

Negative Deviation

On to indicate

the controller output is decreasing.

Control On Status

On to indicate that the control loop is running in automatic

mode, off to indicate that the control loop is running in

manual mode or algorithm cannot be calculated in

automatic mode.

Edit Controller

T

he Edit Controller command lets you edit a controller.

The Edit Controller command brings up the same dialog as

add/insert controller, but with the values filled in.

Delete Controller

The Delete Controller command deletes a controller from

the function bl

ock.

Page 16

Continuous Control Package for W

INTERPRET

(T3834)

16

Industrial Control Services

Search Menu

From the Search Menu the user can select the Go to

Controller, Find and Find Next commands.

Go To Controller

The Go to Controller command lets you quickly move to

different entries in the controller list.

Figure 4. Go to Controller Dia

log Box

Entry Number:

Enter the controller number that you want to go to.

Go:

Choose Go to move to the controller number that you

entered in the Entry Number text box.

First:

Go to the first controller in the list.

Last:

Go to the last controller i

n the list.

Page 17

Continuous Control Package for W

INTERPRET

(T3834)

PD-6044

March, 06

17

Find

The Find command can be used to locate variables in the

controller list.

Figure 5. The Find Dialog Box

Find What text box:

Type in the source name of the entry or character string

you want to search for. The Find What text box ret

ains the

name of the last entry or character string that was

searched for. Use the Find Next command button or press

F3 to repeat the search.

Match:

Lets you to match character strings as they occur

anywhere in a word, only at the beginning of a word, o

r as a

whole word.

Direction:

Determines whether the search will move upward or

downward from the current function block. The search will

stop when it reaches either the top or the bottom of the list.

Options:

The Options check boxes let you decide wh

ether to search

for the character string in the entries' comments and

Page 18

Continuous Control Package for W

INTERPRET

(T3834)

18

Industrial Control Services

descriptions and whether the search should be case

-

sensitive.

Find Next

The Find Next command searches for the next occurrence

of whatever name (or character string) was previously

searc

hed for using the Find command.

Options Menu

The Options Menu allows you to enable and disable the

Prompt for Delete option common to all delete operations

used in W

INTERPRET

.

Window Menu

The Window menu commands are standard throughout all

W

INTERPRET

wind

ows. For more information on using the

Window menu commands see Commands Common to all

W

INTERPRET Windows in Section 3, Installing the

W

INTERPRET Application of the Regent User’s Guide.

Help Menu

The Help menu commands are standard throughout all

W

INTERPRET windows. For more information on using the

Help menu commands see Commands Common to all

W

INTERPRET Windows in Section 3, Installing the

W

INTERPRET Application of the Regent User’s Guide.

Page 19

Continuous Control Package for W

INTERPRET

(T3834)

PD-6044

March, 06

19

Using the Continuous Control (PID) Monitor

The Continuous Control (PID) Monitor displays the

current status of the continuous control function block

defined in your system.

When you have selected a Continuous Control function

block in the Program Monitor window and chosen the

Monitor command from the Control Menu, the Continuous

Control Monitor window is opened as shown below.

Figure 6. Continuous Control Monitor Window.

File Menu

The File Menu provides access to several commands

common to all function block monitors. These include View

Function Block Details, View Function Block Description,

Log Off and Exit. For descriptions of these commands see

Commands Common to all Function Block Monitors in

Section 7, Loading, Monitoring and Testing Application

Programs in the Regent User’s Guide.

Page 20

Continuous Control Package for W

INTERPRET

(T3834)

20

Industrial Control Services

Control Menu

The Contro

l Menu provides certain commands that are

common to all function block monitors. These include Run,

Stop and Scan commands to control the execution status of

the entire application program. For descriptions of these

commands see Commands Common to all Function Block

Monitors in Section 7, Loading, Monitoring and Testing

Application Programs in the Regent User’s Guide.

Control Menu commands which are Continuous Control

specific are: Tune Controller and Monitor Controller.

Tune Controller

The Tune Controller command displays the dialog box

shown in Figure 7. All parameters for the controller are

displayed. For parameters which have been defined as

constants, only the constant value is displayed. For

parameters which have been defined as variables, the

v

ariable name is displayed in the right hand field and the

continuously updated value of the variable obtained from

the Regent is displayed in the left hand field. Due to the

size of the dialog, the full dialog cannot be seen on systems

with VGA resolution. The Windows ‘move window’ facility

can, however, be used to move the dialog around the screen

to view different sections.

Figure 7. Tune Controller Dialog Box.

Page 21

Continuous Control Package for W

INTERPRET

(T3834)

PD-6044

March, 06

21

Note: In order to tune a controller while it is running in a

Regent, each parameter to be tuned should be defined as a

variable (shared variables may be defined with initial

values, local variables may not). The Data Monitor should

be used to change the values of the variables as required.

Monitor Controller

The Monitor Controller command displays the dialog box

shown in Figure 8. In order that the whole dialog can be

viewed on systems with VGA resolution, this dialog

displays only ‘key’ variables.

Figure 8. Monitor Controller Dialog Box.

Search Menu

The Search Menu provides commands to locate

information in a continuous controller function block. You

can choose Go to Controller (to move to a particular control

loop), Find (to search for text strings) or Find Next (to

repeat the last Find selection).

Page 22

Continuous Control Package for W

INTERPRET

(T3834)

22

Industrial Control Services

Window Menu

The Window menu commands are standard throughout all

W

INTERPRET windows. For more information on using the

Window menu commands see Commands Common to all

W

INTERPRET Windows in Section 3, Installing the

W

INTERPRET Application of the Regent User’s Guide.

Help Menu

The Help menu commands are standard throughout all

W

INTERPRET windows. For more information on using the

Help menu commands see Commands Common to all

W

INTERPRET Windows in Section 3, Installing the

W

INTERPRET Application of the Regent User’s Guide.

Safety Consideration

s

The continuous control function block is TÜV certified for

Risk Class 5 as non-interfering. These function blocks may

only be used in safety critical applications if they do not

perform any control actions that affect the v

alue of Risk

Class 5 safety critical variables.

Page 23

Continuous Control Package for W

INTERPRET

(T3834)

PD-6044

March, 06

23

Loading...

Loading...