Page 1

ICS Regent

®

PD-6008

I/O Power Supply Modules

110 VAC, 220/240 VAC and 24 VDC

(T3510, T3511 and T3512)

Issue 1,

I/O power supply modules convert main line voltages of either

110 VAC, 220/240 VAC or 24 VDC to +15 VDC power that is

used to drive the I/O assembly (I/O chassis, I/O modules, and

I/O transceivers).

Three I/O power supply modules installed in an I/O power

supply chassis make up a triple redundant power supply unit.

March, 06

Features

·

Three modules provide triplicated power to as many as four

I/O assemblies.

·

Hot replaceable.

·

Front panel indicator on each module shows DC output

status.

·

TÜV certified for safety, Risk Class 5 (see Safety

Considerations).

Failed I/O power supply modules can be hot replaced without

interrupting system operation.

Module Operation

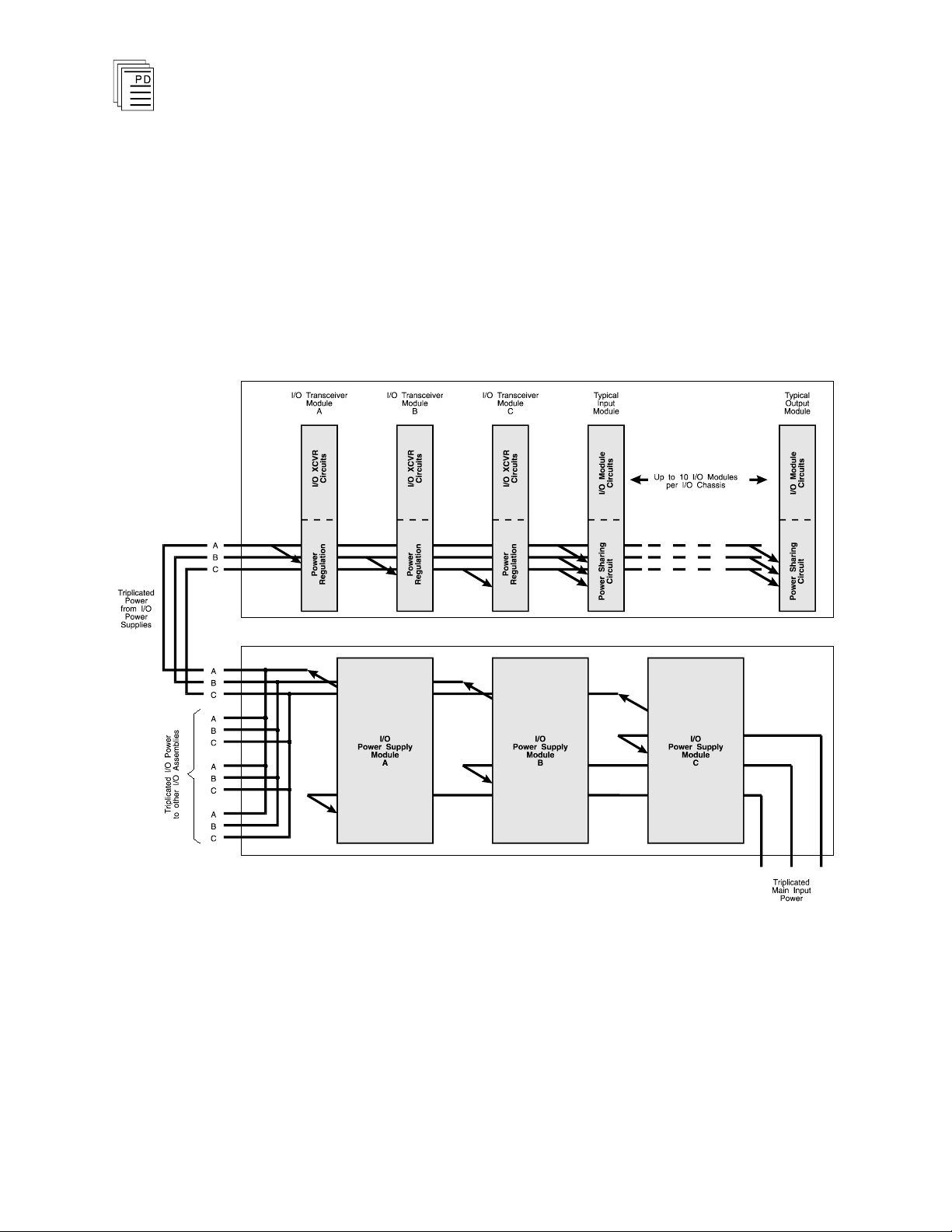

Triplicated Power Distribution

Each of the triple redundant I/O power supply modules within

the I/O power supply assembly provides power for one leg of

the three redundant legs of the I/O Safetybus transceivers,

and provides power to all the I/O modules within its associated

I/O chassis. Each I/O module contains a diode OR power

-

Industrial Control Services

1

Page 2

I/O Power Supply Modules

sharing circuit that receives power from all three I/O power

supply modules.

Should any I/O power supply module fail, only one leg of the

transceiver modules will lose power: the two remaining legs

will maintain proper operation of the Regent. In addition, all

the I/O modules will continue to operate properly by drawing

their current from the two remaining power supplies within

the I/O power supply assembly.

(T3510, 11, and 12)

2

Figure 1. I/O Power Distribution.

Input Power Regulation

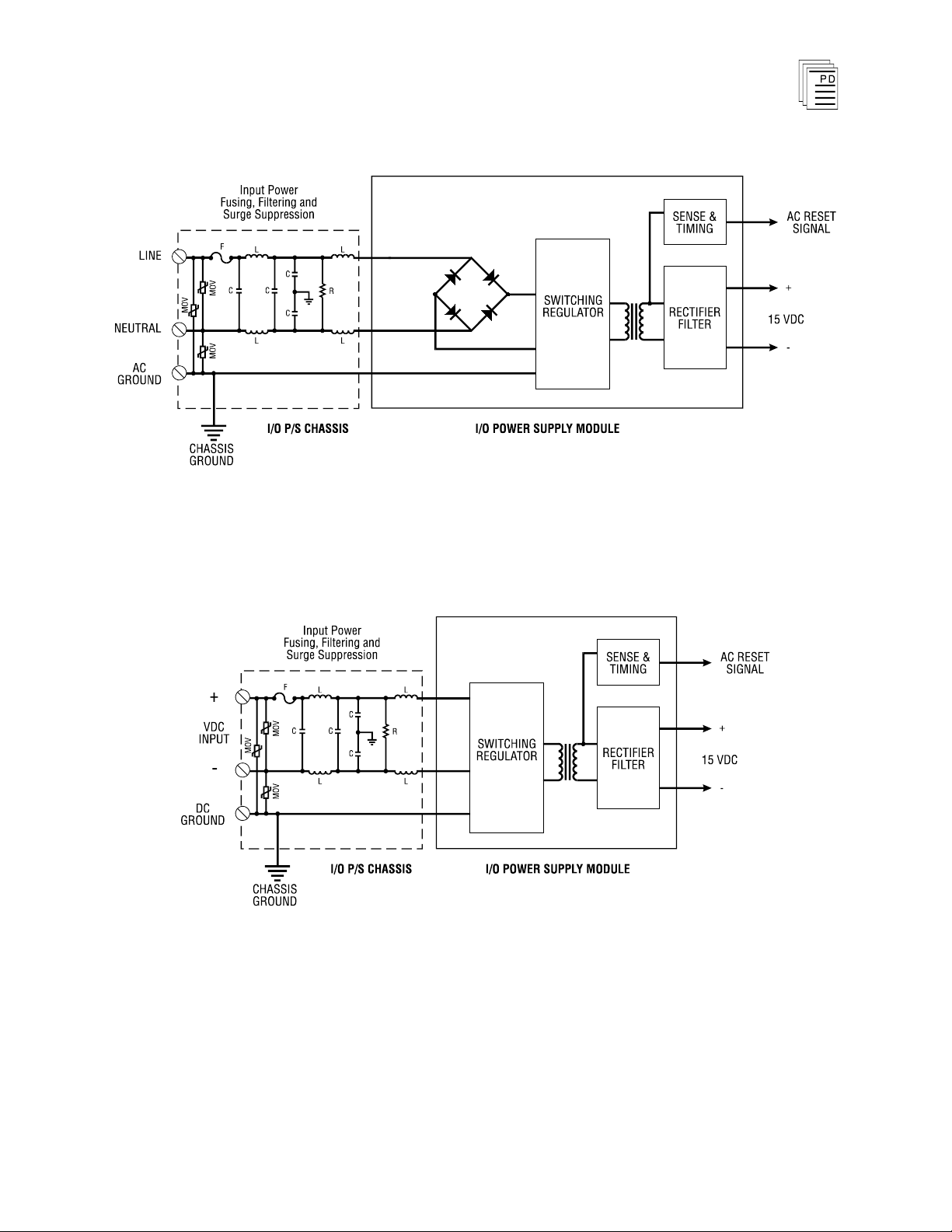

A block diagram of a typical AC I/O power supply module is

shown in Figure 2. A DC I/O power supply module is shown in

Figure 3.

Industrial Control Services

Page 3

I/O Power Supply Modules

(T3510, 11, and 12)

Figure 2. Block Diagram of an AC I/O Power Supply Module.

Figure 3. Block Diagram of

a DC I/O Power Supply Module.

PD-6008

Mar-06

Each primary power input is individually fused and filtered

(with both standard line filters and metal oxide varistors, or

MOVs) at the chassis. The filters are used to attenuate high

frequency common mode and normal mode noise that can be

3

Page 4

I/O Power Supply Modules

present in power distribution systems. The MOVs provide

clamping of high voltage transients.

On board the power supply module the switching regulator

and rectifier filter circuits convert the primary input power to

15 VDC. Sensing and timing circuits monitor for over

voltage, over-current (including current limiting), and power

failure.

An AC reset signal is used in the I/O transceivers for power

system interlocking within the I/O system. Should a power

failure occur (either input power or module fault), the AC

reset signal is activated and the front panel indicator is

turned off.

(T3510, 11, and 12)

-

Front Panel Indicator

Figure 4 shows the physical features of the I/O power supply

modules. The front panel of each module contains

power indicator.

Output Power Indicator

an output

The green OUTPUT POWER indicator is turned on when the

I/O power supply module's DC output is within tolerance. Out

of tolerance conditions, loss of input power or brown-out, and

module failures will cause the OUTPUT POWER indicator to

turn off.

4

Industrial Control Services

Page 5

I/O Power Supply Modules

(T3510, 11, and 12)

Application

PD-6008

Mar-06

5

Figure 4. I/O Power Supply Module.

Input Power Voltages

Before installing I/O power supply modules, always make

certain that their input power voltage matches the voltage of

the I/O power supply chassis. All the power supply modules on

the chassis must also have the same voltage.

Page 6

Input Power Voltage

I/O Power Supply

Chassis

I/O Power Supply

Module

110 VAC

T3500

T3510

220/240 VAC

T3501

T3511

24 VDC

T3502

T3512

I/O Power Supply Modules

Use Table 1 to verify voltage compatibility for your I/O power

supply chassis and I/O power supply modules.

(T3510, 11, and 12)

Table 1. Matching Input Power Voltages.

Power Supply Load Units

P

ower supply unit loading is based on the number of I/O

modules in the chassis and the load imposed by each I/O

module. Load units for each I/O module are shown in that

module’s product description and specification sheet under the

heading “Safetybus Power.” I/O power supply load units are

shown on page 7, as “Available Load Units.”

Calculating the number of load units in your system will help

you determine the number of I/O power supplies your system

will need. For economic power di

stribution, and to avoid

overloading individual power supply units, power supply

loading should be calculated when configuring systems.

Maintenance

Safety C

6

onsiderations

No periodic maintenance or calibration is required for I/O

power supply modules. There are no user replaceable parts

inside these modules.

When an I/O power supply module fails, it can be hot-replaced

without disrupting system operations. Main power wiring and

I/O power cables (connected to the chassis) are not disturbed

during module replacement.

The T3510 (110 VAC) and T3512 (24 VDC) I/O power supply

modules are TÜV certified for Risk Class 5 safety critical

applications. Model T3511 (220 VAC) is excluded as it does

Industrial Control Services

Page 7

I/O Power Supply Modules

Available Load Units

Number of I/O Units:

Load Unit Capacity:

1 2 3 4

52

48

44

40

Voltage Range

T3510

T3511

T3512

85 to 132 VAC

170 to 263 VAC

20 to 30 VDC

Frequency Range

T3510

T3511

T3512

47 to 63 Hz

47 to 63 Hz

—

Maximum Load

250 VA, per module

Heat Dissipation

22 Watts, 75 BTUs/hour

Use with Chassis

T3510

T3511

T3512

T3500

T3501

T3502

Fusing (on chassis)

T3510 (110 VAC)

T3511 (220 VAC)

T3512 (24 VDC)

4A, 250 V, 3AG Slow Blow

2A, 250 V, 3AG Slow Blow

10 A, 250 V, 3AB Slow Blow

Output Voltage

+15 volts

Power Hold-up Time

10 msec, minimum

Operating Temperature

0°

to 60° C

(32° to 140° F)

Storage Temperature

-40°

to 85° C

(-40°

to 185° F)

Operating Humidity

0 to 95% relative humidity,

non-condensing

Vibration

10 to 55 Hz:

±0.15mm

(T3510, 11, and 12)

not meet the DIN VDE 0110 specification for creepage and

clearance required by TÜV.

Specifications

PD-6008

Mar-06

7

Page 8

Shock

Operating:

15 g, ½ sine wave, 11 msec

Electromagnetic

Interference

•

IEC 801 Part 2 - Electrostatic

Discharges

•

IEC 801 Part 3 - Radiated

Electromagnetic Fields

•

IEC 801 Part 4 - Transients

and Bursts

•

IEC 801 Part 5 - Surge

Immunity

•

ANSI/IEEE C37.90 - Surge

Withstand Capability

Level 3: Contact discharge of

6 kV

Level 3: 10 V/M, 27 MHz 500 MHz

Level 4: 2 kV, 2.5 kHz for t =

60 sec

Level 3: 2 kV

2.5 kV damped 1 MHz sine

wave

4 kV bi-directional impulse,

10 nsec rise time, fast

transient

Safety

Certified to DIN V VDE

0801 for Risk Class 5. Also

designed to meet UL 508 and

CSA 22.2, No. 142-M1981

Dimensions

Height:

Width:

Depth:

13.0" (330 mm)

4.12" (105 mm)

10.25" (260 mm)

Weight

7.5 lbs (3.4 kg)

I/O Power Supply Modules

(T3510, 11, and 12)

8

Industrial Control Services

Loading...

Loading...