Page 1

ICS Regent

®

PD-6035

Multiplexed I/O Modules

(T3491)

Issue 1,

Multiplexed I/O modules provide two RS-422 serial port

interfaces between the Regent system and ICS’s remote

multiplexed I/O Unit (MIU) equipment, providing an

economical interface to digital inputs and outputs. MIU

equipment is often used for matrix and mimic displays in

safety and fire and gas systems or low cost, remote simplex

input and outputs.

March, 06

Features

•

Occupies one slot in the I/O chassis.

•

Two isolated RS-422 serial ports for remote multiplexed I/O.

•

Supports up to 512 digital inputs and 256 digital outputs of

remote MIU equipment.

·

Individual front panel indicators on each module show module

active and fault status; and transmit, receive and fault status

for each port.

•

Serial ports can be used in simplex or duplex modes (with

2oo2 testing in dual mode).

·

1000 volt minimum electrical isolation between serial ports

and between serial and logic circuits.

·

TÜV certified, Risk Class 5, non-interfering.

Multiplexed I/O mo

remote MIU equipment up to 4000 feet (1220 meters) away at

19200 baud. The two serial ports of the Mux I/O module can

be configured for simplex or duplex mode. In duplex mode,

2oo2 voting is performed on the I/O data.

dules support multi-drop connection to

Industrial Control Services

1

Page 2

Multiplexed I/O Module (T3491)

The following MIU equipment may be interfaced to the

Multiplexed I/O Module

· MIU3201

· MIU3202

· MIU3204

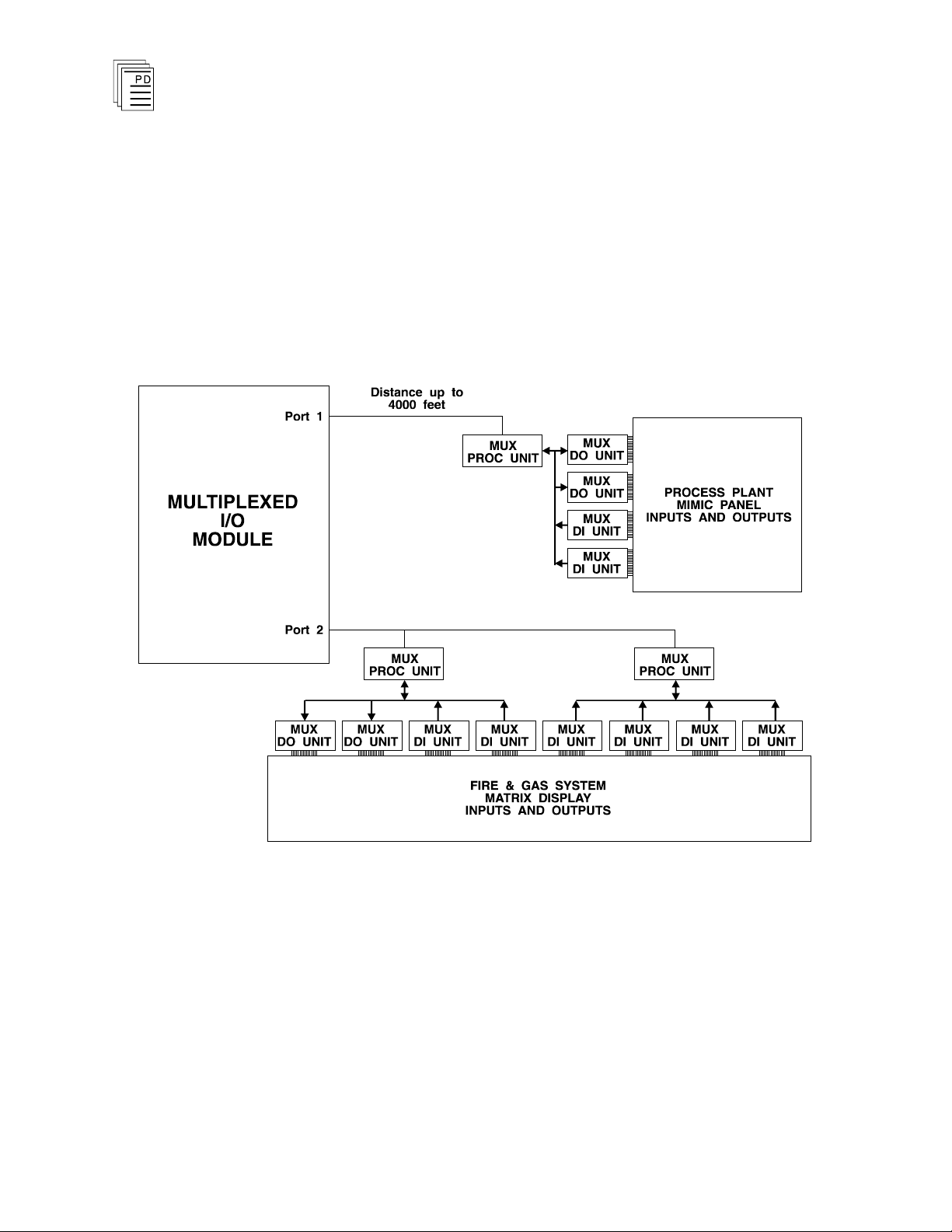

A typical simplex application for multiplexed I/O is shown in

Figure 1.

Multiplexed I/O Processor Unit

Multiplexed Input Unit (64 point)

Multiplexed Output Unit (64 point)

Figure 1. Typical Multiplexed I/O Configuration.

Module Operation

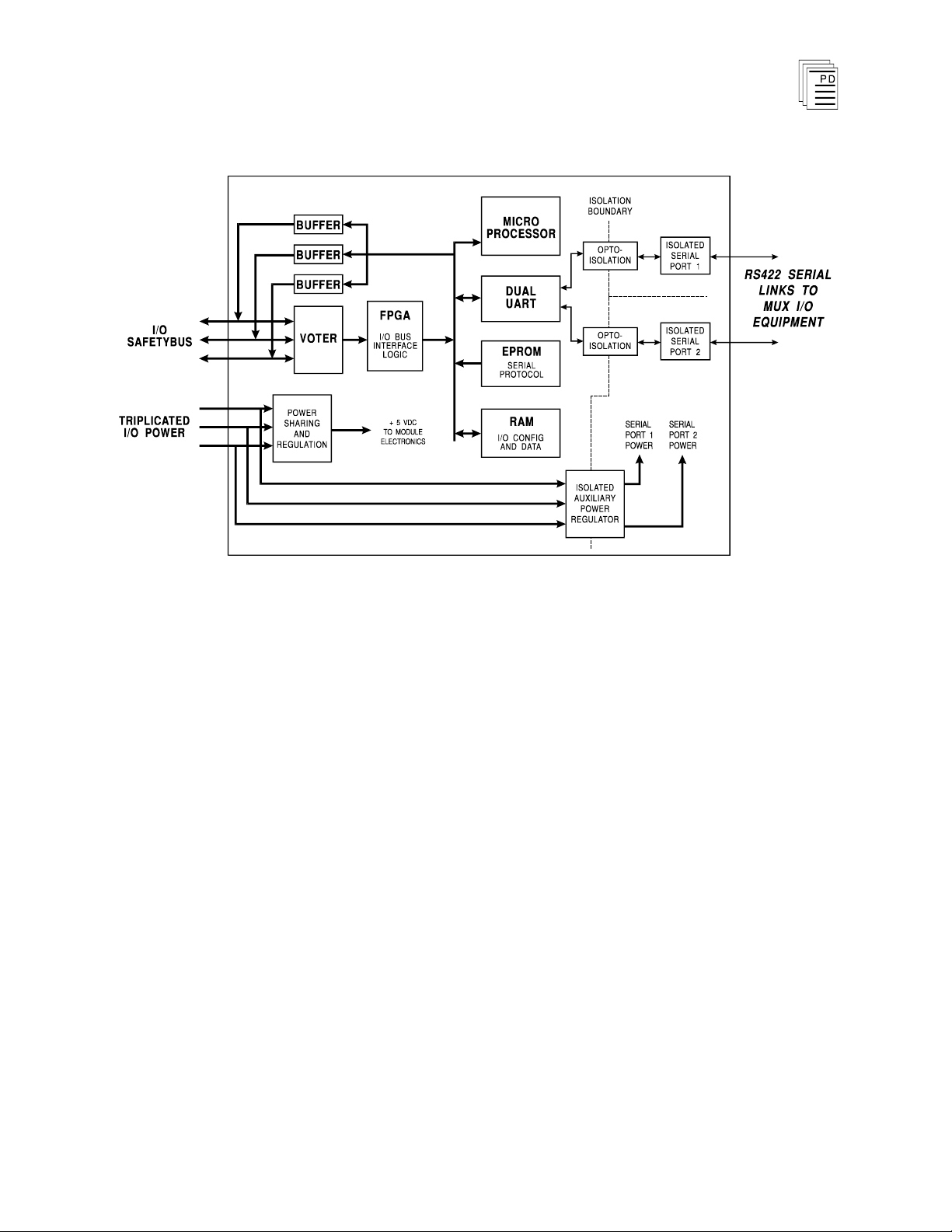

A block diagram of the multiplexed I/O module is shown in

Figure 2.

2

Industrial Control Services

Page 3

Multiplexed I/O Module (T3491)

Figure 2. Block Diagram of Multiplexed I/O Module.

The Voter, FPGA and triple buffers provide

an interface to the

triplicated I/O Safetybus. The Mux I/O module receives

configuration data over the I/O Safetybus from the processor

modules. This information defines the types of Multiplexed

I/O Unit equipment connected to the Mux I/O module. The

information is stored in the module’s dual ported RAM

memory.

The RAM memory is arranged into four blocks. One block is

used to download the Mux I/O equipment configuration. The

second block is used for reporting fault conditions. A third

block is used f

or writing output data, and the fourth block is

used for reading input data. The on-board microprocessor uses

this information to read and write I/O data via the two serial

ports.

Testing and Diagnostics

PD-6035

Mar-06

Comprehensive testing and diagnostics are used to determine

correct operation to the Mux I/O Module and connected MIU

equipment.

3

Page 4

Multiplexed I/O Module (T3491)

Standard Module Testing

Each module’s voter circuits are periodically tested by the

processor modules. Discrepant data are sent through one of

three legs of the I/O Safetybus to

determine whether the

module’s voter is able to outvote the incorrect data. A failure

to return the correct majority-voted result to the processors

produces an I/O module error indication at the processor

modules and a module fault indication at the I/O module.

Each type of module has a unique identification code that is

read by the controller. This code lets the controller know

which type of module is installed in each I/O chassis slot and

how to address that module and its points specifically. If a

mod

ule is removed, or is replaced with a module of a different

type, the processor modules will indicate I/O module errors.

Loopback logic tests periodically write data to the module and

then read it back to determine whether the module’s I/O bus

interface logic is functioning correctly.

Multiplexed I/O Module Testing

Additional tests are periodically performed to verify the

correct operations of the microprocessor, ROM, RAM and

serial interface to the remote MIU equipment. Detected

failures are reported back to the processor modules as either

fatal or non-fatal errors.

Fatal Errors

Fatal errors are reported when the diagnostics detect a failure

in the module’s electronics. For example, failures in the

microprocessor, RAM, or ROM are considered fatal errors. A

fatal error will result in a module fault indication.

Non-Fatal Errors

Non-fatal errors are reported when failures occur in

communications to the connected MIU equipment. These

failures would represent problems with the serial

communications cables, or the connected MIU processor.

These types of failures are indicated on the face of the module

as a Port fault.

4

Industrial Control Services

Page 5

Multiplexed I/O Module (T3491)

Front Panel Indicators

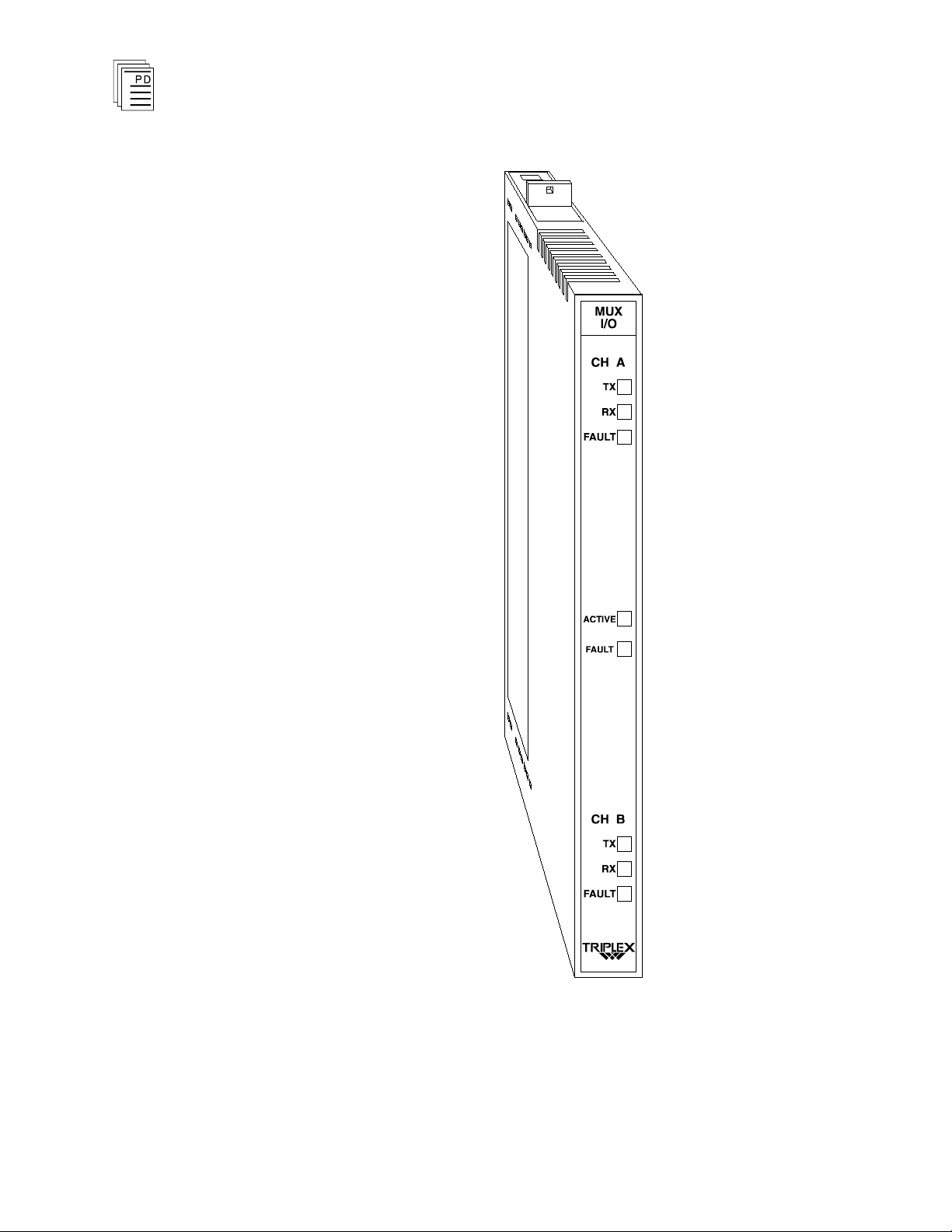

Figure 3 shows the physical features of the Mux I/O module.

The front panel of the module contains active, and fault status

indicators for the module as well as transmit, receive, and

communications fault status indicators for each port.

PD-6035

Mar-06

5

Page 6

Multiplexed I/O Module (T3491)

6

Figure 3. Multiplexed I/O Module.

Industrial Control Services

Page 7

Multiplexed I/O Module (T3491)

Application

Active and Fault Status Indicators

These green and red LEDs indicate the overall health of the

MUX I/O module. During normal operation the green

ACTIVE indicator flashes at the controller's scan rate. If a

fatal module fault is detected the red FAULT indicator

switches on and the green indicator switches off. Refer to page

4

for descriptions of fatal module faults.

Port Status Indicators

Both of the multiplexed I/O module’s ports have transmit,

receive and communications fault status indicators.

The green T

normal transmission and reception of communications data.

The communications fault indicator is normally off. When a

non-fatal communications fault occurs, the red LED switches

on. Refer to page 4 for descriptions of non-fatal faults.

X and RX indicators turn on and off reflecting

Simplex Configuration

Most often the Mux I/O module is used in simplex

configuration. In this configuration, each of the two serial

ports are used to individually connect to MIU equipment.

module uses the downloaded configuration information to

read inputs and write outputs for each serial port.

Dual Configurations

To protect against communications failures related to the

serial cables, the module can be configured for duplex

operation. When configured this way, the Mux I/O module

communicates to the connected equipment by reading from

and writing to both communications ports. Each port is cabled

to the same MIU processors.

The Mux I/O module reads inputs from each port and stores

the information in separate areas in RAM. The RAM data is

2oo2 voted, so that when both data areas agree, the input data

is updated for the Regent processor modules.

The

PD-6035

Mar-06

7

Page 8

Multiplexed I/O Module (T3491)

When output data changes state, the Mux I/O module writes

the output data to both ports. At the MIU processor, the

output data is 2oo2 voted, so that when the data agrees, the

outputs are updated.

When input data disagrees, the Mux I/O module reads the

input data three more times. If the disagreement persists, a

failure is reported.

Serial Port Cable Connections

The serial communications cables are connected to the screw

terminals located on the I/O chassis directly above and below

the slot where the module is installed. Figure 4 illustrates the

proper connections for the serial ports.

8

Industrial Control Services

Page 9

Multiplexed I/O Module (T3491)

PD-6035

Mar-06

Figure 4. MUX I/O Module Serial Cable Connections.

Keying

The I/O chassis can be physically keyed to prevent accidental

damage caused by inserting a module into a slot wired for a

9

Page 10

Multiplexed I/O Module (T3491)

different modu

le type. Figure 5 illustrates how the slot keys

are installed on the I/O chassis slot field wiring connectors.

The slot key positions for the multiplexed I/O module are

listed in Table 1.

10

Figure 5. Installing Slot Keys.

Industrial Control Services

Page 11

Multiplexed I/O Module (T3491)

Module

Upper

Connector

Lower

Connector

T3491

4

2

Note:

Table 1. Slot Key Positions.

Fault Mode Jumper

The fault mode jumper is located behind the ID switch cover

in the lower left-hand corner of each I/O ch

of the fault mode jumper determines the module's response to

system level faults. Normally, the fault mode jumper’s

position causes all output modules in the I/O chassis to either

shutdown (turn off all outputs) or to hold (hold the last state)

after a system level failure occurs. An example of a system

level failure is the failure of two processor modules.

The MIU Output Units contain latching output circuits.

When a system level failure occurs, the MIU outputs will

remain in their last state. Configuring the I/O chassis fault

mode jumper for shutdown will not cause the MIU outputs to

turn off when a system level failure occurs.

assis. The position

Configuration

Each Mux I/O module is configured using the

I/O Configuration Editor. In the editor, you will perform the

steps described below to configure the module.

1) Set the Module Type:

Position the cursor on the module slot you wish to define.

Choose Set Module Type from the Edit Menu and select

T3491, 12x64 Matrix Interface Module f

2) Edit the Module Definition:

Choose Edit Module Definition from the Edit Menu. A

dialog box will open where you can begin to define the

Protocol (Single or Dual), the Baud Rate (19200 or 9600),

and the MIU Processors that will be connected to the Mux

I/O module.

W

INTERPRET

rom the list.

PD-6035

Mar-06

11

Page 12

Multiplexed I/O Module (T3491)

Figure 6. The Matrix Interface Module Dialog.

3) Define the MIU Processors:

After selecting the Protocol and Baud Rate in step 2,

choose Edit ( or Insert) from the Matrix Interface Dialog

Box. Another dialog box will open where you can define

the configuration for the MIU Processor.

12

Figure 7. Configuring a Mux I/O Processor Unit.

Select the Mux I/O module port that the MIU processor

will be connected (1 or 2 if single protocol, 1 if dual

protocol). Enter the ID number for the MIU processor (2

Industrial Control Services

Page 13

Multiplexed I/O Module (T3491)

Important!

Important!

through 15). You may also enter a description to annotate

the MIU processor definition.

Each MIU processor has an ID number that must be

unique from other processors connected to the same Mux

I/O mo

dule. This number should match the ID number set

by links on the MIU processor unit. Refer to the product

description for the MIU Processor for details on link

settings.

4) Define the MIU I/O Modules:

In the MIU Processor Definition Dialog Box, position the

cursor on one of the four possible Mux I/O Units and

choose Edit (or Insert). Choose Input Unit or Output Unit

from the New Multiplexed Unit Dialog Box.

If both Input Units and Output Units will be connected to

a single MIU processor, the

before the Input Units.

Output Units must be defined

Figure 8. The New Multiplexed Unit Dialog Box.

After selecting the type of I/O module a new dialog box will

open where you can enter a description to annotate the I/O

unit.

PD-6035

Mar-06

13

Page 14

Multiplexed I/O Module (T3491)

Important!

14

Figure 9. The Mux Input Unit and Mux Output Unit Dialog

5) Edit each point:

Boxes.

Choose Edit from the Mux I/O Unit dialog box to define a

name and description for each point. In the Mux Input (or

Output) Point dialog box, enter names and values for

of the point configuration fields described below.

each

The first I/O point on the first I/O Unit is unusable. Do not

enter a definition for this point. For example, if you

configure four, 64-point Input Units for a single MIU

processor, the first input unit has only 63 usable inputs.

Do not define the first input on the first input unit. The

remaining three input units may have 64 inputs defined.

Industrial Control Services

Page 15

Multiplexed I/O Module (T3491)

Figure 10. The Mux Input Point and Mux Output Point

Name

Dialog Boxes.

Also called the tag name, this is the name used in the

application program to reference an input point status or

control an output point. The name can be up to 12 characters

long.

Description

The 40-character field provides a place to describe the input or

output point definition. The description is used to help

document your system (it does not affect application program

operation).

Comm Protect

This field applies only to Mux output points. Marking the

Comm Protect check box protects the point from changes b

y

communications functions such as data write, forcing and load

initial value when Comm Protect is enabled.

PD-6035

Mar-06

Initial Value

This field applies only to Mux output points. The initial value

for the output is loaded to the Regent when you load the I/O

15

Page 16

Multiplexed I/O Module (T3491)

Desired Output

State

Coil

--

( )--

Mux Coil

--

( M )--

Off

Off Off

Flash Fast On Off

Flash Slow Off On

On

On On

configuration and also when you load the application program

that controls the output.

Final Value

This field applies only to Mux output points. The final value

for the output is loaded to the Regent when the application

program that controls the output is delete

d. Unless special

circumstances exist, you should always choose Off, so that the

output is turned off when you delete the application program

that controls the output. If you do not enter a final value, the

output will remain in its last state when you delete the

application that controls it.

Programming

Mux input points are used in application programs just like

any other simplex input. Contacts in ladder logic can be used

to examine the on or off status of the inputs.

Mux outputs have special programming considerations. The

Mux outputs can be programmed to any one of four possible

states: On, Off, Flash slow, and Flash fast. In order to control

the outputs in these four states a special Mux Coil instruction

is provided in ladder logic. This instruction is used along with

the standard coil instruction to control the Mux output. Table

2

illustrates which on/off combinations of the Coil and Mux

Coil instructions produce the four output states.

16

Table 2. Programmi

ng Mux Output States

Industrial Control Services

Page 17

Multiplexed I/O Module (T3491)

Maintenance

No periodic maintenance or calibration is required for the

multiplexed I/O module. There are no user replaceable parts

inside the module.

Troubleshooting

Most problems with the Mux I/O equipment relates to

improper configuration. For correct operation you should

carefully check the protocol configuration (single vs. dual) and

the MIU processor addresses. Verify the configuration

information with the link settings for the MIU processors.

Also you should carefully check the serial cable connections.

The Mux I/O module labels the serial cable connections with

‘A’ and ‘B’ designations although the MIU processors refer to

the connections as ‘+’ and ‘-’. The serial cable connection

diagram in Figure 4 properly illustrates the relationship

between these signal references.

Safety Considerations

The Multiplexed I/O module is TÜV certified as non

interfering and may be used for non-safety critical inputs and

outputs.

While the use of dual protocol configurations for 2oo2 voting

provides greater security for the communications link, it is not

sufficient to meet the requirements for Risk Class 5 safety

critical inputs and outputs. In applications of Mux I/O

equipment for maintenance override of safety critical inputs,

redundant Mux I/O Modules and MIU equipment is

recommended.

For additional safety considerations, please

Considerations section of the Regent User’s Guide.

-

refer to the Safety

PD-6035

Mar-06

17

Page 18

Multiplexed I/O Module (T3491)

Safetybus Power

1.0 load units

Mux I/O Capacity

Maximum 12 MIU

processors supporting a total

of 8 Mux Input Units (512

points) and 4 Mux Output

Units (256 points).

Compatible MIU Equipment

MIU 3201

: Multiplexed I/O

Processor Unit,

MIU 3202

: Multiplexed

Input Unit, 64-channel,

MIU 3204

: Multiplexed

Output Unit, 64-channel

Port Type

Two isolated RS-422 ports

Protocol

Subset of ICS2000 I/O

communications protocol

Operat

ing Modes

Two independent single

communications links, or

Dual voted communications

links (2oo2)

Baud Rate

9,600 or 19,200 baud

Maximum Distance

approximately 4000 feet

(1220 m) @ 19,200 baud,

8000 feet (2440 m) @ 9,600

baud

Isolation

1,000 volts minimum (serial

port to serial port)

1,000 volts minimum (serial

port to logic)

Heat Dissipation

4.5 Watts, 15 BTUs/hour

Operating Temperature

0°

to 60° C

(32° to 140° F)

Storage Temperature

-40°

to 85° C

(-40°

to 185° F)

Specifications

18

Industrial Control Services

Page 19

Multiplexed I/O Module (T3491)

Operating Humidity

0 to 95% relative humidity,

non-condensing

Vibration

10 to 55 Hz:

±0.15mm

Shock

Operating:

15 g, ½ sine wave, 11 msec

Electromagnetic

Interference

•

IEC 801 Part 2 - Electrostatic

Discharges

•

IEC 801 Part 3 - Radiated

Electromagnetic Fields

•

IEC 801 Part 4 - Transients

and Bursts

•

ANSI/IEEE C37.90 - Surge

Withstand Capability

Level 3: Contact discharge of

6 kV

Level 3: 10 V/M, 27 MHz 500 MHz

Level 4: 2 kV, 2.5 kHz for t =

60 seconds

2.5 kV damped 1 MHz sine

wave

4 kV bi-directional impulse,

10 nsec rise time, fast

transient

Safety

Certified to DIN V VDE

0801 for Risk Class 5, non

interfering. Also designed to

meet UL 508 and CSA 22.2,

No. 142-M1981

Dimensions

Height:

Width:

Depth:

12.6" (320 mm)

1.27" (32 mm)

10.12" (257 mm)

Weight

3.0 lbs (1.4 kg)

PD-6035

Mar-06

19

Loading...

Loading...