Page 1

ICS Regent

®

PD-6033

Monitored Guarded Output Modules

24 VDC, 110 VAC and 120 VDC

(T3481/T3481A, T3484 and T3488/T3488A)

Issue 2,

Monitored Guarded output modules provide Guarded control

and line monitoring for sixteen field loads. Three typ

modules are available for interfacing to outputs powered from

24 VDC, 110 VAC, or 120 VDC field power supplies. These

modules are called Guarded because each module's dual

redundant design ensures that no single fault within the

module will inadvertently apply power to an output. These

modules also monitor the output field wiring for open and

short circuit faults. Individual output line status is available

to application programs.

March, 06

es of

-

Features

·

Sixteen Guarded outputs (in two groups of eight).

•

Fault tolerant operation when connected in parallel with

another module of the same type.

•

Hot-replaceable.

•

Complete, automatic testing of all output circuits.

•

Automatic line monitoring detects open and short field wiring

circuits.

•

Individual front panel indicators on each module show module

fault/active status and shutdown state; addi

show output status and load/fuse fault for each point.

·

Fuses accessible from front panel.

•

2500 minimum electrical isolation between field and logic

circuits.

·

TÜV certified, Risk Class 5.

Each module's triplicated Safetybus interface ensures that no

Regent system failure will inadvertently apply power to an

tional indicators

Industrial Control Services

(Issue 2)

1

Page 2

Monitored Guarded Output Modules

(T3481/81A, 84, and 88/88A)

output. E

circuits ensure that each module operates in a fail-safe

manner.

Two monitored Guarded output modules can be connected in

parallel to obtain fault tolerant control of power to loads. In

this parallel module configuration, either module can be

removed and replaced while the other Guarded module

continues to control the loads without interruption.

Module Operation

A block diagram of a typical monitored Guarded digital output

module is shown in Figure 1.

xtensive fault detection and redundant critical

Figure 1. Block Diagram of a Monitored Guarded Digital Output Module.

2

(Issue 2)

Industrial Control Services

Page 3

Monitored Guarded Output Modules

Case

Commanded

Output State

Switch

Failed

State

Actual

Output

to Load

Remarks

1 On

On On

Continued correct control.

Automatic testing detects

stuck-on switch. If output is

subsequently commanded

off, output will turn off.

2 On

Off Off

Fail-safe output. Automatic

testing detects stuck-off

switch.

3 Off

On

Off

Continued correct control.

Automatic testing detects

stuck-on

switch. If output is

subsequently commanded

on, output will turn on.

4 Off

Off Off

Fail-safe output. Automatic

testing detects stuck-off

switch. If output is subse

quently commanded on,

output will remain off.

The processor modules send triplicated write data commands

over the I/O Safetybus to the monitored Guarded output

module. Onboard the output module the triplicated data are

routed to two independent voters which provide voted data to

associated field programmable gate arrays (FPGA). Each

FPGA independently operates one of the two output control

switches. The two out

the load.

put switches are connected in series with

When both output switches are on, current will flow through

the output and energize a field load. If either switch is off,

current will not flow through the output and the load will be

de-energized. This combination of series output switches and

independent drive signals produces fail-safe activation of the

load. Single failures can only affect one of the output drive

signals or switches. A single failure will result in either

continued correct control

Table 1.

(T3481/81A, 84 and 88/88A)

or a fail-safe output as shown in

Table 1. Output States After Switch Failure.

PD-6033

Mar-06

To achieve fault tolerance, two monitored Guarded output

modules are used with their outputs connected in parallel.

This configuration provides for continued correct control even

(Issue 2)

3

Page 4

Monitored Guarded Output Modules

when one output switch fails off (cases two and four in Table

1

). The module failure is automatically detected and the

module can be removed and replaced without interrupting

output control.

(T3481/81A, 84, and 88/88A)

Testing and Diagnostics

Automatic testing is performed on the monitored guarded

output modules as well as the field load connections.

Module Testing

Each voter and FPGA logic section of the Guarded output

modules are automatically tested by the processor modules.

Discrepant data are sent through one of three legs of the I/O

Safetybus to determine whether the module’s voters are able

to outvote the incorrect data. A failure to return the correct

majority-voted result to the processors produces an I/O

module error indication at the processor modules and a

module fault indication at the I/O module.

Each type of module has a unique identification code that is

read by the controller. This code lets the controller know

which type of module is installed in each I/O chassis slot and

how to address that module and its points specifically. If a

module is removed, or is replaced with a module of a different

type, the

processor modules will indicate an I/O module error.

4

Loopback logic tests periodically write data to the module and

then read it back to determine whether the module’s I/O bus

interface logic is functioning correctly.

Output Circuit Testing

The output circuits of the monitored guarded output module

are automatically tested to detect failures in the redundant

output switch circuits on-board the module and also to detect

open and short circuits in the output field wiring and load

devices.

Output Switch Testing

To detect a failure in the redundant output switch circuits,

each output switch is checked for turn-on and turn-off

capability. Periodically, each output switch circuit on the

module is tested for its ability to change its current state.

(Issue 2)

Industrial Control Services

Page 5

Monitored Guarded Output Modules

During testing, the output state is changed; outputs that are

on are turned off and outputs that are off are turned on.

When two monitored guarded output modules are wired in

parallel for fault tolerance, the output circuit testing of the

dual modules is coordinated. The test coordination is

automatically performed by the system when the modules are

properly configured for dual mode (see Configuration, starting

on page 17). When dual modules are tested, the second

module’s outputs are turned off momentarily while the first

module’s outputs are tested. Subsequently, the first module’s

outputs are turned off while second module’s outputs are

tested.

When an output switch is tested, the test pulse duration is

nominally 250 msec, and is insufficient to affect the state of

most field loads. With modules configured in dual mode, the

maximum test pulse may be 425 msec if one module has a

switch failure. The output circuit test interval will range from

1 to 60 seconds, depending on the quantity of I/O configured

in the system.

(T3481/81A, 84 and 88/88A)

If an output switch doesn’t change state when tested, an

output switch fault is detected. An output switch failure is

annunciated as a module fault. An I/O

module fault is

indicated by the module FAULT LED on the module, the red

I/O fault LEDs on the processor modules and the system

control relay fault bit for the module assembly and slot.

Load and Fuse Monitoring and Testing

During output switch testing, the module also monitors the

change in current flow in the field power for the outputs. The

sensed state changes of the output switches and the field

power current are reported back to the processor modules.

The triplicated processor modules use this inform

ation to

identify if an open load, shorted load or blown fuse condition

exists.

Any of these load/fuse fault conditions are annunciated via

the LOAD/FUSE fault LEDs on the face of the module and the

Fault Name variables configured for each point. Load/Fuse

faults are not reported as module faults and so do not turn on

the red Module FAULT LED or associated system variable

control relay fault bit. The Fault Name variables should be

PD-6033

Mar-06

(Issue 2)

5

Page 6

Note:

Monitored Guarded Output Modules

monitored by the application program or external operator

interface equipment to dispatch maintenance personnel to

correct the field connection problem.

Field faults such as open load, shorted load, blown fuse and

absence of field power, will mask an output switch fault. When

load/fuse faults are detected, they should be repaired as soon

as possible.

If the health of spare, unused output points is important, then

a minimum load device should be connected to these points.

(T3481/81A, 84, and 88/88A)

Front Panel

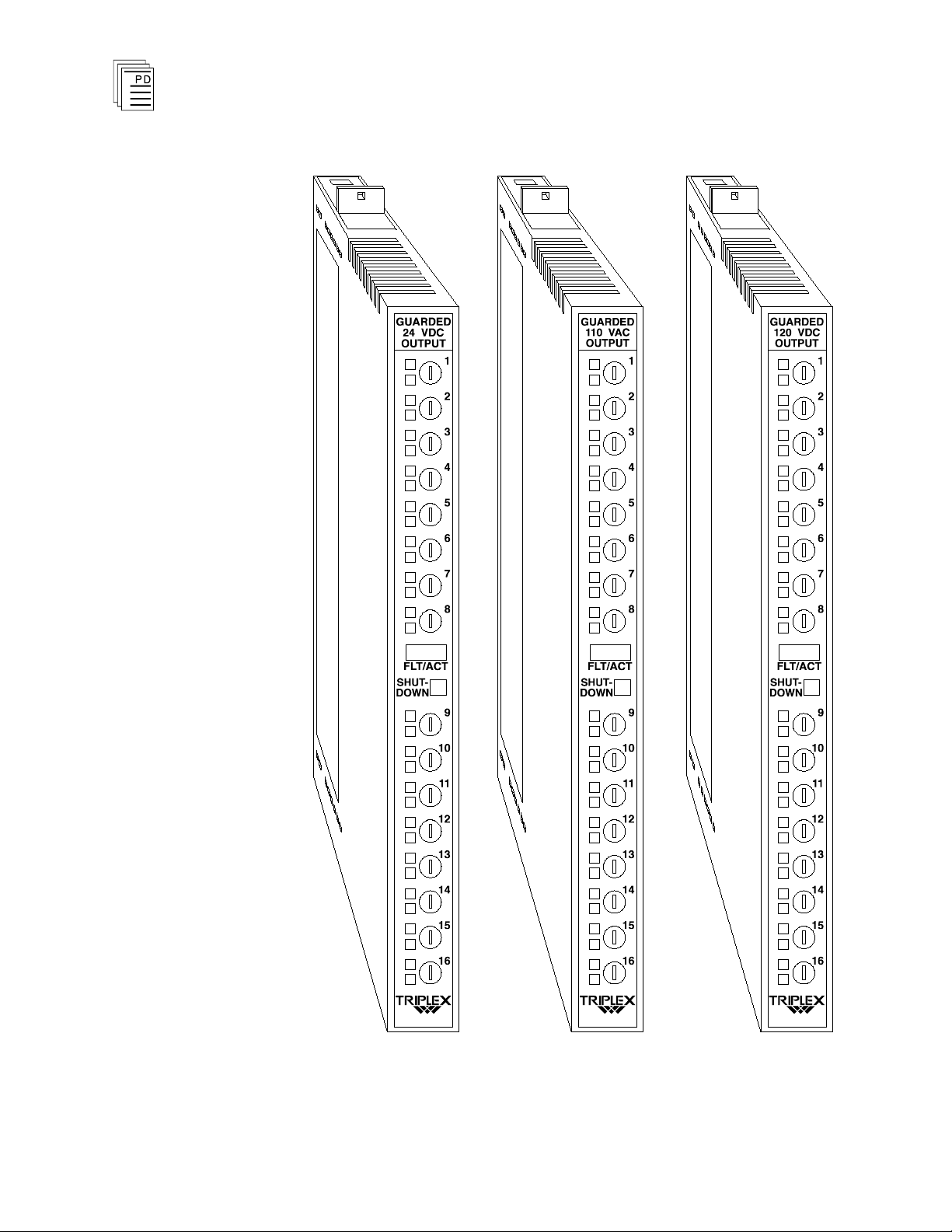

Figure 2 shows the physical features of the monitored

Guarded output modules. The front panel of each module

contains a module active and fault status indicator, a

shutdown indicator, as well as output fuses, output status

indicators and load/fuse fault indicators for the output

circuits.

Active/Fault Status Indicators

These green and red LEDs indicate the overall health of the

module and output circuits. During normal operation, the

green ACTIVE indicator flashes at the controller's scan rate.

If a module fault is detected, the red FAULT indicator turns

on and the green ACTIVE indicator turns off.

Shutdown Indicator

Upon loss of communications with the controller, output

modules enter either a shutdown or hold fault mode. If the I/O

unit is set to shutdown, the red SHUTDOWN indicator will

turn on when communications with the controller are lost. If

the I/O unit is set to hold, the SHUTDOWN indicator will

always be off (see page 16, Fault Mode Jumper).

6

(Issue 2)

Industrial Control Services

Page 7

Monitored Guarded Output Modules

Note:

When the module is installed in the I/O chassis or when logic

power (from the I/O power s

the module, it will be in the shutdown mode until the first

output scan, regardless of the fault mode jumper settings.

Also, removing two I/O transceiver modules, two I/O power

supply modules, or two power legs will cause the module to be

in the shutdown mode.

(T3481/81A, 84 and 88/88A)

upply modules) is first applied to

PD-6033

Mar-06

(Issue 2)

7

Page 8

Monitored Guarded Output Modules

(T3481/81A, 84, and 88/88A)

8

Figure 2. Monitored Guarded Output Modules.

(Issue 2)

Industrial Control Services

Page 9

Monitored Guarded Output Modules

(T3481/81A, 84 and 88/88A)

Application

Output Status Indicators

The output status indicators are yellow LEDs, located on the

front of the module. The state of

on the field side of the output circuit and optically coupled to

both of the FPGAs. The FPGAs logically drive the output

status LEDs. The indicator is on when the output circuit is

energized.

During output testing, the module monitors the current flow

to the load device. If no current is detected, or if an excessive

current is detected, the red load/fuse fault LED is energized.

This indicator annunciates a blown fuse or an open or short

circuit in the field wiring to the output field device.

the output circuit is sensed

Monitored Guarded digital output modules provide a suitable

interface to safety-critical output devices. These safety

critical devices typically include solenoids, actuators, or other

process interlock outputs. Monitored Guarded output modules

can be used for fail-safe or fault tolerant operation.

-

Fail-Safe Configuration

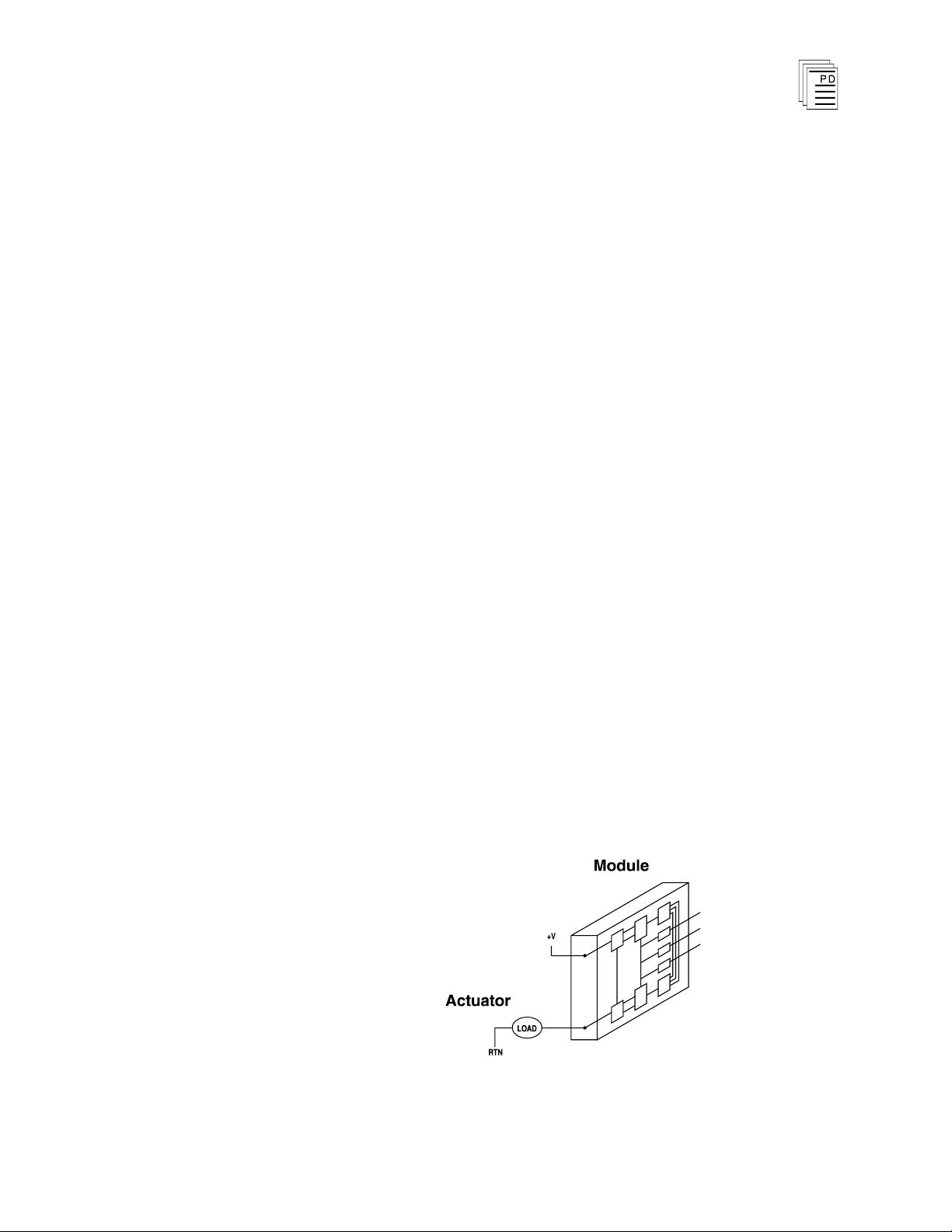

As shown in Figure 3, fail-safe configuration uses a single

monitored Guarded output module. In this configuration, the

worst case

In a fail-safe configuration, removing the module disables all

outputs.

failure will cause the output to fail to the off state.

Figure 3. Fail-Safe Configuration.

PD-6033

Mar-06

(Issue 2)

9

Page 10

Monitored Guarded Output Modules

(T3481/81A, 84, and 88/88A)

Fault Tolerant Configuration

For fault tolerant operation, two monitored Guarded output

modules are connected in parallel as shown in Figure 4. In

this configuration, operation continues even if one module

fails.

In the fault tolerant configuration, a failed module ca

n be

removed and replaced without interrupting operation of the

loads.

Figure 4. Fault Tolerant Configuration.

10

(Issue 2)

Industrial Control Services

Page 11

Monitored Guarded Output Modules

Fault Tolerant Configuration with Redundant

(T3481/81A, 84 and 88/88A)

Actuators

When redundant actuators are installed in the field, the level

of fault protection can be extended to include the field wiring

and actuators. Each actuator should be connected to an

individual monitored guarded output module as shown in

Figure 5.

In this configuration continuous operation can be maintained

even if a module, field wiring or load fault occurs.

PD-6033

Mar-06

Figure 5. Fault Tolerant Configuration with Redundant

Actuators.

Output Load Considerations

The monitored guarded output module will operate correctly

(no FAULT indication) with loads as small as 20 mA. The 81A

and 88A version will operate with loads as small as 5 mA.

(Issue 2)

11

Page 12

Load

OFF State Voltage (nominal field voltage and shorted switch)

Rating

T3481/81A

(24 Vdc)

T3484

(110 Vac)

T3488/88A (120 Vdc)

(mA) Single Dual

Single

Dual Single Dual

5 na 2.6 na 3.7 na na

na

12.8 na 18.3

10 na 1.4 na 2.0 na na

na

6.8 na 9.9

20 4.7 .71 6.4 1.0 23.5

31.8

na. 3.5 na 5.2

35 3.0 .41 4.1 .6 14.8

20.8

17.5 2.0 24.4 3.0

50 2.2 .29 3.1 .43 10.8

15.5

12.8 1.4 18.2 2.1

100

1.2 .15 1.7 .21 5.7 8.4

6.7. .71 9.8 1.0

Note

:

Monitored Guarded Output Modules

However, care should be exercised in applying the module to

small load devices.

(T3481/81A, 84, and 88/88A)

Off-state t

est current (Leakage current ) of the output circuit

may prevent some load devices from turning off completely.

Table 2 lists the off-state voltages (worst case) for various load

ratings and module configurations. These should be

compared to the “

being applied.

guaranteed off

Table 2. Off-

” voltage for the load device

State Voltage Ratings.

Field Wiring

Field wiring terminal blocks on the I/O chassis are used to

connect power sources and loads to the module. The terminal

blocks are located directly above and below the slot

where the

module is installed. Each terminal block consists of ten #6

wire clamp screw terminals capable of holding two 12 AWG

wires.

Each module has separate power terminals for each output

group (group 1: channels 1-8, group 2: channels 9-16). The

two groups are electrically isolated from each other. Figure

6

shows the proper field wiring for a single module and Figure

shows the field wiring for fault tolerant modules connected in

parallel.

This module does not require a return connection from the

field power source. Do not connect any field wiring to

terminals A and D.

7

12

(Issue 2)

Industrial Control Services

Page 13

Monitored Guarded Output Modules

Note:

Output circuit testing monitors current flow to the outputs. If

the field power supply is not connected, then all of the outputs

in the associated group without power will indicate a load/fuse

fault condition.

(T3481/81A, 84 and 88/88A)

PD-6033

Mar-06

(Issue 2)

13

Page 14

Monitored Guarded Output Modules

(T3481/81A, 84, and 88/88A)

14

(Issue 2)

Figure 6. Fail-Safe Field Wiring.

Industrial Control Services

Page 15

Monitored Guarded Output Modules

(T3481/81A, 84 and 88/88A)

PD-6033

Mar-06

(Issue 2)

Figure 7. Fault Tolerant

Field Wiring.

15

Page 16

Module

Upper

Connector

Lower

Connector

T3481/81A

4

3

T3484

10

3

T3488

/88A

11 3

Monitored Guarded Output Modules

(T3481/81A, 84, and 88/88A)

Fault Mode Jumper

The fault mode jumper is located behind the ID switch cover

in the lower left-hand corner of each I/O chassis. The position

of the fault mode jumper determines the module's response to

system level faults. The fault mode jumper’s position will

cause all output modules in the I/O chassis to either shutdown

(turn off all outputs) or to hold (hold the last state) after a

system level failure occurs. An example of a system level

failure is the failure of two processor modules.

Keying

The I/O chassis can be physically keyed to prevent accidental

damage caused by inserting a module into a slot wired for a

different module type. Figure 8 illustrates how the slot keys

are installed on the I/O chassis slot field wiring connectors.

The slot key positions for the Monitored Guarded output

modules are listed in Table 3.

Table 3. Slot Key Positions.

16

(Issue 2)

Industrial Control Services

Page 17

Monitored Guarded Output Modules

(T3481/81A, 84 and 88/88A)

PD-6033

Mar-06

Figure 8. Installing Slot Keys.

Configuration

Each output module is configured using the

W

INTERPRET

Configuration Editor. In the editor you will perform the four

steps described below to configure the output module.

(Issue 2)

I/O

17

Page 18

Monitored Guarded Output Modules

(T3481/81A, 84, and 88/88A)

1) Set the Module Type:

Position the cursor on the module slot you wish to define.

Choose Set Module Type from the Edit Menu and select

the appropriate monitored guarded output module from

the list.

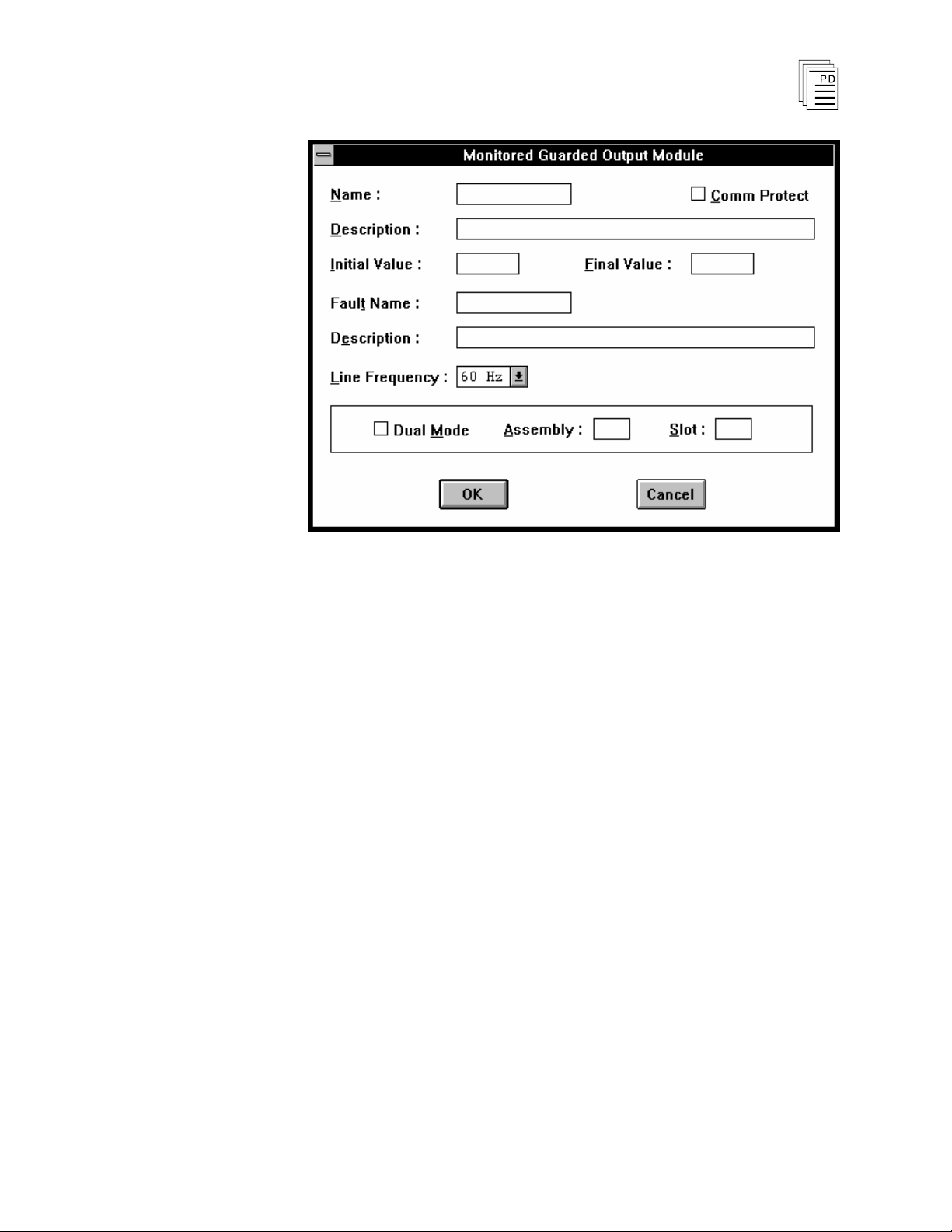

2) Edit the Module Definition:

Choose Edit Module Definition from the Edit Menu. A

dialog box will open where you can define the output point

definitions.

Figure 9. Monitored Guarded Output Module Definition.

3) Configure the module for single or dual mode.

With the cursor at the top of the list in the Module Definition

dialog shown in Figure 9, open the Monitored Guarded

Output Module Definition dialog by pressing Enter or double

clicking on the “(Module)” selection.

If the output module i

s to be used in dual mode (wired in

parallel with another similar module for fault tolerance), then

you must check the Dual Mode selection in the dialog box

shown in Figure 10. Also, you must enter the I/O Assembly

number (1-16) and I/O Slot number (1-10) of the redundant

module. This must be done for each of the two modules that

will operate in dual mode.

18

(Issue 2)

Industrial Control Services

Page 19

Monitored Guarded Output Modules

Note:

Note:

(T3481/81A, 84 and 88/88A)

Figure 10. Defining the Guarded Output Module Definition.

If you do not configure the modules for Dual Mode then the

output testing performed on the modules will not be

coordinated and each of the modules wired in parallel will

report a fault.

For the T3484, 110 VAC Monitored Guarded Output Module

you must also select the line frequency of the field power

supply. In the Line Frequency drop-down list, select either

50 Hz or 60 Hz.

4) Edit each point:

Choose Edit from the Module Definition dialog box to define a

name and description for each output point. In the Monitored

Guarded Output Point dialog, enter names and values for the

configuration fields as described below.

PD-6033

Mar-06

(Issue 2)

19

Page 20

Monitored Guarded Output Modules

(T3481/81A, 84, and 88/88A)

Figure 11. Defining a Guarded Digital Output Point.

Name

Also called the tag name, this is the name used in the

application program to reference the output point. The name

can be up to 12 characters long.

Description

This 40-character field provides a place to describe the output

point definition. The description is used to help document

your system (it does not affect application program operation).

Comm Protect

Marking the Comm Protect check box protects the point from

changes by communications functions such as data write,

forcing, and load initial value when Comm Protect is enabled.

Initial Value

The initial value for the output is loaded to the Regent when

you load the I/O configuration and also when you load the

application program that controls the output.

20

Final Value

The final value for the output is loaded to the Regent when

the application program that controls the output is deleted.

Unless special circ

(Issue 2)

umstances exist, you should always enter

Industrial Control Services

Page 21

Monitored Guarded Output Modules

zero, so that the output is turned off when you delete the

application program that controls it.

(T3481/81A, 84 and 88/88A)

Fault Name

This is the name used in the application program to reference

the output point line fault status. The name can be up to 12

characters long.

During operations the output module is regularly tested for

open load, shorted load and blown fuse conditions. If any of

these conditions occur, the Fault Name variable will turn on.

Fault Name Description

This 40-character field provides a place to describe the output

point fault name definition. The description is used to help

document your system (it does not affect application program

operation).

Disable Fault LED

Marking the Disable Fault LED check box disables the

load/fuse fault LED for this output point on the face of the

output module. Marking this box does not stop the module

from performing load monitoring and blown fuse detection, it

only stops the module from displaying load/fuse faults on the

face of the out

put module. Load/fuse faults are still reported

to the Regent and are available to the application program

through the fault name variable.

PD-6033

Mar-06

This box can be checked for those output points that are spare

and have no field loads connected. In this configuration the

load/fuse fault LED will always be off. If you do not check this

box for unconnected spare points, the load/fuse fault will

always be on.

Output Module Definition

In addition to configuring output point definitions, you can

configure the output module definition to represent the

combined state of all 16 output points. This configuration is

done in the Monitored Guarded Output Module dialog shown

in Figure 10.

The module definition represents the 16 output point

definitions as signed, 16-bit integers. The Module Output

name represents the 16 output names and the Module Fault

(Issue 2)

21

Page 22

Monitored Guarded Output Modules

Name represents the 16 output fault names. In each module

variable, output 1 is the least significant bit (LSB) and output

point 16 is the

The module definition names are not normally used for

control purposes. However, they do provide convenient single

name references to all 16 outputs points when reporting

status information to operator interface equipment.

most significant bit (MSB).

(T3481/81A, 84, and 88/88A)

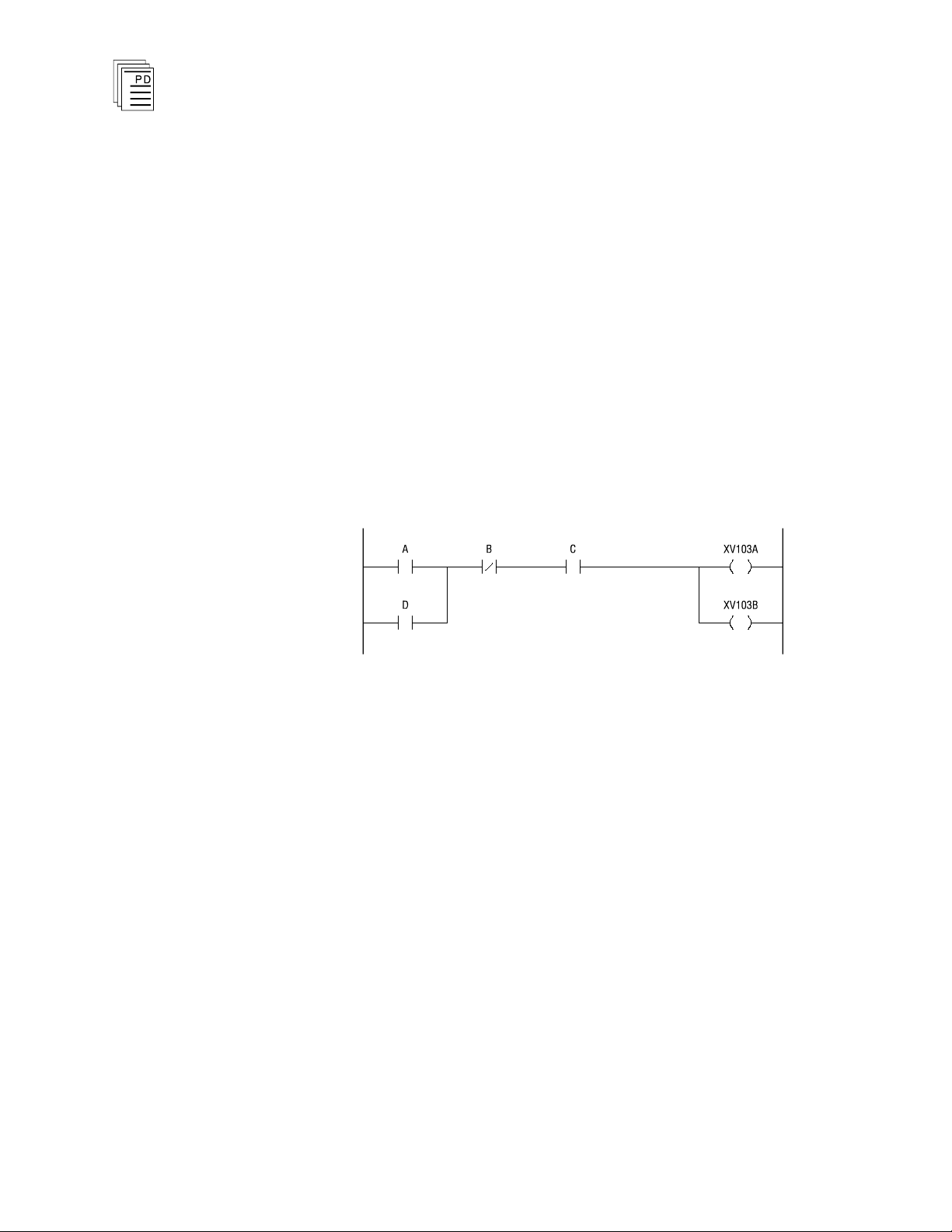

Programming

Outputs are controlled by writing application programs that

solve for output values. For example, placing an output tag

name on a coil in ladder logic will cause the output to turn on

when there is power flow to the coil in the ladder logic rung.

To program fault tolerant outputs two output coils driven by

the same control logic are used as shown in Figure 12.

Figure 12. Programming Fault Tolerant Outputs.

In this illustration A, B, C, D represent various logic elements

used to drive the outputs; XV103A represents the output on

one Guarded output module; and XV103B represents the

output on the other Guarded output module.

Maintenance

22

No periodic maintenance or calibration

module.

Fuses can be removed and replaced without removing the

module from the I/O chassis. Turning the fuse holder one

quarter turn from its locked position releases the fuse holder,

extending the fuse and allowing it to be removed.

To prevent damage to the module, replacement fuses must be

of the same rating and type (see Specifications, below).

(Issue 2)

Industrial Control Services

is required for this

-

Page 23

Monitored Guarded Output Modules

Safetybus Power

1.5 load units

Number of Outputs

16 circuits divided into two

groups of 8 circuits e

ach

T3481 (81A)

T3484

T3488 (88A)

Voltage Range

18 to 36 VDC

90 to 130 VAC

95 to 140 VDC

Frequency

N/A 47 to 63 Hz

N/A

Load Current

(0 to 40° C)

derating (at 60°

C)

2 amp

1.5 amp

0.7 amp

0.5 amp

1.0 amp

0.75 amp

Minimum Load

20 mA ( 5mA)

20 mA

35 mA (5mA)

On State Drop

1.0 V, maximum

2.5 V, maximum

2.0 V, maximum

Surge Current

incandescent,

capacitive loads:

inductive loads:

3.5 amps, peak

7 amps for

20 msec

3.5 amps, peak

3 amps for

20 msec

3.5 amps, peak

3 amps for 20 msec

Output Leakage

single, fail-safe

module:

dual, fault-tolerant

modules:

5 mA, ( 700ua)

maximum

7.5 mA, (1 mA)

maximum

5.5 mA,

maximum

8.5 mA,

maximum

5.5 mA, (700ua)

maximum

8.5 mA, (1 mA)

maximum

T3481/81A

T3484

T3488/88A

(T3481/81A, 84 and 88/88A)

Safety Considerations

Specifications

The Monitored Guarded output modules are TÜV certified to

Risk Class 5 for safety critic

al outputs. The modules are

approved for de-energize to trip safety critical outputs in

single or dual module configurations.

The modules are also approved for energize to trip safety

critical outputs in dual module configuration, but

only

if the

fault name variables are configured and used to automatically

alarm and annunciate the detection of load/fuse faults to plant

operations personnel.

PD-6033

Mar-06

(Issue 2)

23

Page 24

Fusing

(front mounted)

One 3 amp, 250

V, fast acting

(3AB), rectifier

type, per output

Littelfuse 322-003

One 2 amp, 250

V, fast acting

(3AB), rectifier

type, per output

Littelfuse

322-002

One 2 amp, 250 V,

fast acting (3AB),

rectifier type, per

output

Littelfuse 322-002

Turn-On Delay

0.5 msec

0.5 msec

0.5 msec

Turn-Off Delay

0.5 msec

0.5 msec

0.5 msec

Output Test

Duration

250 msec for

single or dual

modules, max of

425 msec if switch

fault (dual

modules only)

250 msec for

single or dual

modules, max of

425 msec if

switch fault

(dual modules

only)

250 msec for single

o

r dual modules,

max of 425 msec if

switch fault (dual

modules only)

Heat Dissipation

30 Watts,

101 BTUs/hour

27 Watts,

92 BTUs/hour

27 Watts,

92 BTUs/hour

Over Voltage

Protection

70 VDC,

continuous

100 VDC,

5 seconds

275 VAC,

continuous

450 VAC,

5 seconds

275 VAC,

continuous

450 VAC, 5 seconds

Isolation

2500 volts minimum (field

wiring to control logic)

2500 volts minimum (output

group 1-8 to output group 9

-

16)

Operating Temperature

0°

to 60° C

(32° to 140° F)

Storage Temperature

-40°

to 85° C

(-40°

to 185° F)

Operating Humidity

0 to 95% relative humidity,

non-condensing

Vibration

10 to 55 Hz:

±0.15mm

Shock

Operating:

15 g, ½ sine wave, 11 msec

Monitored Guarded Output Modules

(T3481/81A, 84, and 88/88A)

24

(Issue 2)

Industrial Control Services

Page 25

Monitored Guarded Output Modules

Electromagnetic

Interference

•

IEC 801 Part 2 - Electrostatic

Discharges

•

IEC 801 Part 3 - Radiated

Electromagnetic Fields

•

IEC 801 Part 4 - Transients

and Bursts

•

IEC 801 Part 5 - Surge

Immunity

•

ANSI/IEEE C37.90 - Surge

Withstand Capability

Level 3: Contact discharge of

6 kV

Level 3: 10 V/M, 27 MHz 500 MHz

Level 4: 2 kV, 2.5 kHz for

t=60 sec

Level 3: 2 kV

2.5 kV damped 1 MHz sine

wave,

4 kV bi-directional impulse,

10 nsec ri

se time, fast

transient

Safety

Certified to DIN V VDE

0801 for Risk Class 5. Also

designed to meet UL 508 and

CSA 22.2, No. 142-M1981

Dimensions

Height:

Width:

Depth:

12.6" (320 mm)

1.27" (32 mm)

10.12" (257 mm)

Weight

4.2 lbs (1.8 kg)

(T3481/81A, 84 and 88/88A)

PD-6033

Mar-06

(Issue 2)

25

Page 26

Monitored Guarded Output Modules

(T3481/81A, 84, and 88/88A)

26

(Issue 2)

Industrial Control Services

Loading...

Loading...