Page 1

User Manual

ControlLogix Time Syncronization Module - Series B

Catalog Number 1756HP-TIME

Allen-Bradley Motors

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

t

o be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

aired.

imp

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

or application of this equipment.

use

The examples and diagrams in this manual are included solely f

or illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

tware described in this manual.

sof

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

nc., is prohibited.

I

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, ControlFLASH, ControlLogix, Logix5000, R SLogix, Studio 5000 Automation Engineering & Design Environment, Studio 5000, Studio 5000 Logix Designer, Rockwell S oftware, and Rockwell Automation

are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Table of Contents

Preface

Installation

Setup

Operation

Studio 5000 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1756HP-TIME Module Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

Chapter 1

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

GPS Antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 2

BOOTP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

ControlFLASH Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

The Logix Designer Application Configuration. . . . . . . . . . . . . . . . . . . . . 10

View the Satellite Status in the Logix Designer Application . . . . . . . . . . 12

Satellite Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Satellite Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1756HP-TIME Module AOP Configuration Parameters. . . . . . . . . . . . 13

Chapter 3

Logix5000 Controller Input Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Logix5000 Controller Output Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Web Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Time Synchronization

Specifications

Chapter 4

1588 Precision Time Protocol (CIP Sync). . . . . . . . . . . . . . . . . . . . . . . . . . 23

1756HP-TIME Module as a PTP Master. . . . . . . . . . . . . . . . . . . . . . . 23

Configure the Ethernet Module/Controller PTP/CIP

Sync Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PTP as a Time Source. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Network Time Protocol (NTP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1756HP-TIME Module as an NTP Server. . . . . . . . . . . . . . . . . . . . . .

1756HP-TIME Module as an NTP Client . . . . . . . . . . . . . . . . . . . . . 28

IRIG-B. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1756HP-TIME Module as an IRIG-B Master

1756HP-TIME Module as an IRIG-B Slave . . . . . . . . . . . . . . . . . . . . 30

CST and UTC Time Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . 29

24

26

26

29

30

Appendix A

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GPS Antenna Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31

33

Allen-Bradley Motors

Rockwell Automation Publication 1756-UM542A-EN-P - September 2014 3

Page 4

Table of Contents

Appendix B

1756HP-TIME Module Status

CST/UTC Conversion Message Blocks

Operating Modes

GPS Antenna Cable Extensions

Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Status Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

36

Appendix C

CST to UTC and Gregorian Time Conversion . . . . . . . . . . . . . . . . . . . . . 37

UTC to Gregorian Time Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Satellite Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Appendix D

GPS Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

IRIG-B Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

PTP Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

NTP Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Appendix E

Cable Extensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Determine the Length of the Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Determine the Attenuation Rate of the Cable . . . . . . . . . . . . . . . . . . . 43

Example – Determining Cable Requirements . . . . . . . . . . . . . . . . . . . 44

Cable Extension Kits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Lightning Protection Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Glossary

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4 Rockwell Automation Publication 1756-UM542A-EN-P - September 2014

Page 5

Top ic Page

Studio 5000 Environment 5

1756HP-TIME Module Overview 5

Additional Resources 6

Preface

Studio 5000 Environment

The Studio 5000 Automation Engineering & Design Environment™ combines

engineering and design elements into a common environment. The first element

is the Studio 5000 Logix Designer™ application. The Logix Designer application

is the rebranding of RSLogix™ 5000 software and will continue to be the product

to program Logix5000™ controllers for discrete, process, batch, motion, safety,

and drive-based solutions.

The Studio 5000® environment is the foundation for the future of Rockwell

A

utomation® engineering design tools and capabilities. The Studio 5000

environment is the one place for design engineers to develop all of the elements of

their control system.

1756HP-TIME Module Overview

Allen-Bradley Motors

This user manual describes the functionality, installation, configuration, and

operation of the 1756HP-TIME module, series B, firmware revision 3.001.

The 1756HP-TIME module provides accurate time synchronization on different

terfaces by using Global Positioning System (GPS) technology. The

in

1756HP-TIME module can obtain time from various sources, and provide time

synchronization on other devices by acting as a gateway between different time

synchronization methods and standards.

Rockwell Automation Publication 1756-UM542A-EN-P - September 2014 5

Page 6

Preface

Time synchronization is accomplished by using these methods, standards, and

protocols:

• The

ControlLogix® backplane for Coordinated System Time (CST) and

Coordinated Universal Time (UTC) conversion.

• Inter-range Instrumentation Group, code B (IRIG-B) standards.

• Precision Time Protocol (PTP) on Ethernet and the ControlLogix

backplane.

• Network Time Protocol (NTP) on Ethernet.

The 1756HP-TIME module provides GPS position in the form of latitude,

gitude, and altitude (LLA).

lon

The 1756HP-TIME module provides course and route information in the form

round speed (knots) with heading in the form of degrees from true north.

of g

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

Integrated Architecture and CIP Sync Configuration

Application Technique, publication IA-AT003

ControlLogix System User Manual, publication 1756-UM001 Describes the necessary tasks to install, configure,

EtherNet/IP Network Configuration User Manual,

publication

ControlFLASH® Firmware Upgrade Software User Manua l,

publication 1756-UM105

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Product Certifications website,

ENET-UM001

http://www.ab.com Provides declarations of conformity, certificates, and

This document explains CIP sync technology and how

you can synchronize clocks within the Rockwell

Automation Integrated Architecture.

program, and operate a ControlLogix system.

Provides Bootstrap Protocol/ Dynamic Host

Configuration Protocol (BOOTP/DHCP) information for

setting the IP address of the module.

Describes the necessary tasks to install, and use the

ControlFLASH software to update the module firmware.

Provides general guidelines for installing a Rockwell

Automation industrial system.

other certification details.

You can view or download publications at

http:/www.rockwellautomation.com/literature/. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

R

ockwell Automation sales representative.

6 Rockwell Automation Publication 1756-UM542A-EN-P - September 2014

Page 7

Installation

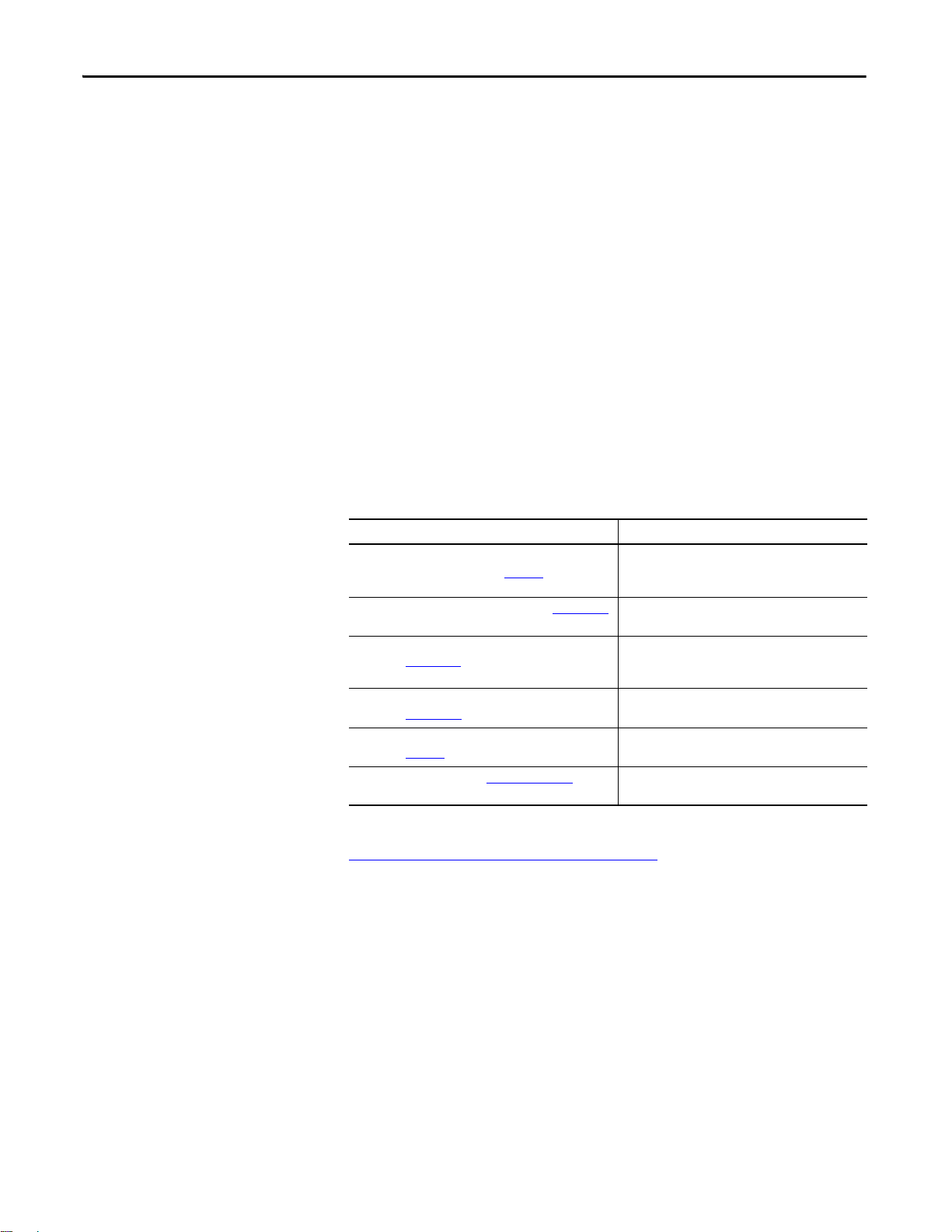

Status Indicators and Messages

Ethernet Connection 1

Ethernet Connection 2

GPS Subminiture Version A (SMA) Connector

IRIG-B Coaxial Connector

Top ic Page

Hardware 7

GPS Antenna 8

Software 8

Chapter 1

Hardware

The 1756HP-TIME module operates within the ControlLogix platform. All

power required for the operation of the module is supplied by the ControlLogix

backplane.

Figure 1 - 1756HP-TIME Module, Front View

Table 1 - 1756HP-TIME Module Hardware Descriptions

Hardware Description

Status indicators and messages Provides status and operational information for the 1756HP-TIME module.

Ethernet connector 1 and

Ethernet connector 2

(uses Rockwell Automation®

dual-port switch technology)

GPS SMA connector Connect the GPS b ullet antenna to this connector. See GPS Antenna on page 8.

IRIG-B coaxial connec tor Connect the IRIG-B network cable to this connector. The 1756HP-TIME module

See 1756HP-TIME Module Status on page 35.

PTP and NTP time synchronization uses the Ethernet connections.

Note: This connection is not a bridge to the backplane and cannot be used to

view m

odules on the backplane.

can be configured as a master clock or a slave clock on the IRIG-B network.

Allen-Bradley Motors

Rockwell Automation Publication 1756-UM542A-EN-P - September 2014 7

Page 8

Chapter 1 Installation

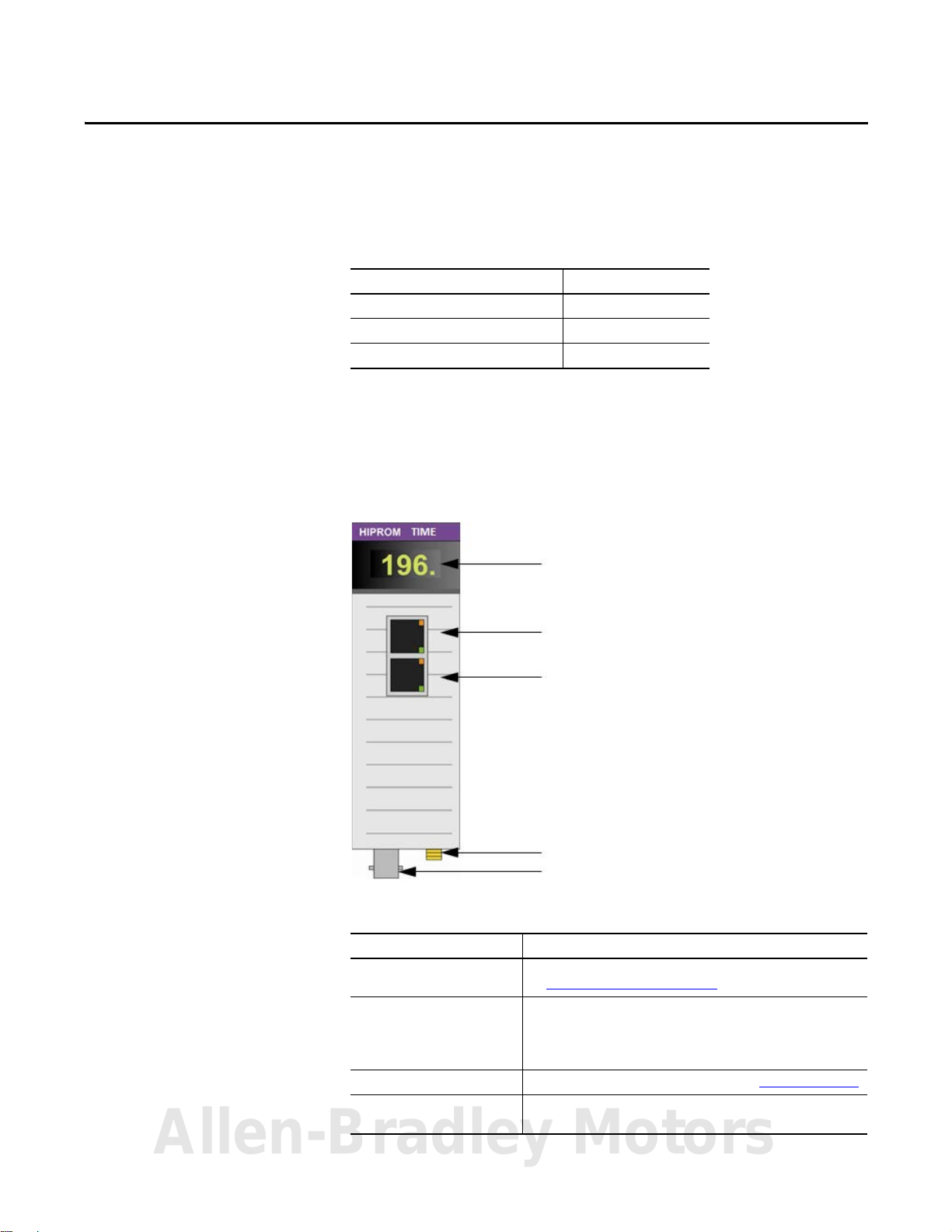

GPS Antenna

Install the GPS antenna with a clear view of the sky (do not install the antenna

where objects can obstruct the view of the antenna to the sky). If an antenna is

installed with a limited view of the sky, the GPS receiver can have a low satellite

lock count, or be unable to obtain a lock. A limited view of the sky can cause

inaccurate time synchronization.

Figure 2 - GPS Antenna Installation with Clear View of the Sky

Figure 3 - GPS Antenna Installation with Obstructed View of the Sky

Software

Use this software to configure and operate the 1756HP-TIME module:

• The Studio 5000 Logix Designer application

• The Add-on Profile (AOP) for the 1756HP-TIME module, available for

download at this link:

http://www.hiprom.com/Pages/Products/1756_CLX/1756HP-TIME/

web/1756HP-TIME.htm

8 Rockwell Automation Publication 1756-UM542A-EN-P - September 2014

Page 9

Setup

Top ic Page

BOOTP 9

Fac tory Defaul ts 9

ControlFLASH Software 10

The Logix Designer Application Configuration 10

View the Satellite Status in the Logix Designer Application 12

1756HP-TIME Module AOP Configuration Parameters 13

Chapter 2

BOOTP

Factory Defaults

Use BOOTP to set the initial IP address for the 1756HP-TIME module. The

module comes from the factory with BOOTP enabled.

The BOOTP/DHCP server is a standalone server that you can use to set an IP

s.

addres

Access the BOOTP/DHCP server from one of these locations:

rograms > Rockwell Software > BOOTP-DHCP Server

• P

• Tools directory on the Studio 5000 environment installation CD

If you have not installed the BOOTP/DHCP server, you can download and

ll it from

insta

To set the IP address of the module with a BOOTP/DHCP server, follow the

ps found in EtherNet/IP Network Configuration User Manual, publication

ste

ENET-UM001.

If the module fails or becomes inoperable, the module reboots with

factory-loaded boot software. The display informs you of the error and suggests a

method to fix the error. If there is a firmware error, use the ControlFLASH

software to restore the module to a working condition.

http://www.ab.com/linked/networks/ethernet/bootp.html.

Allen-Bradley Motors

Rockwell Automation Publication 1756-UM542A-EN-P - September 2014 9

Page 10

Chapter 2 Setup

IMPORTANT

IMPORTANT

ControlFLASH Software

The Logix Designer Application Configuration

Use the ControlFLASH software to upgrade the software to a newer version.

For more information on the ControlFLASH software and how to use it, see

C

ontrolFLASH Firmware Upgrade Software User Manual, publication

UM105.

The latest firmware can be found at this link:

Products/1756_CLX/1756HP-TIME/web/1756HP-TIME.htm.

Before you can program the 1756HP-TIME module, the AOP for the module

must be installed. You also need admin rights for the module to view and

configure the AOP.

The installer for the AOP can be found at this link:

http://www.hiprom.com/Pages/Products/1756_CLX/1756HP-TIME/web/

1756HP-TIME.htm.

Each 1756HP-TIME module is programmed to work with a single Logix5000

controller.

http://www.hiprom.com/Pages/

1756-

There is no direct communication between the 1756HP-TIME module Ethernet

ports and a Logix5000 controller. If the 1756HP-TIME module resides in a

remote Logix rack, it needs to communicate through an EN2T(R) module in the

same rack.

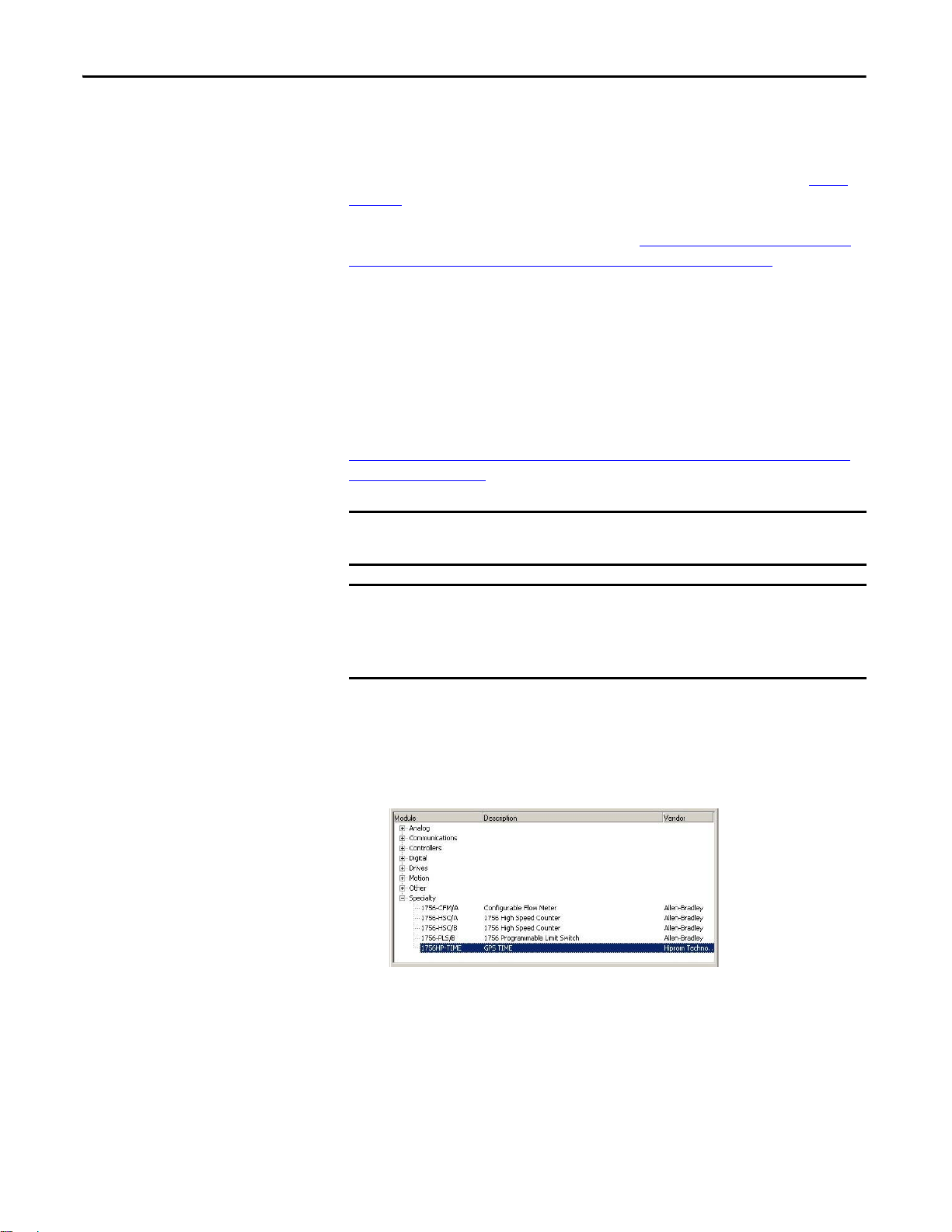

Follow these steps to configure the 1756HP-TIME module in the Logix

Designer application.

1. Doub

le-click the 1756HP-TIME module in the I/O tree in the Logix

Designer application.

The New Module dialog box appears.

10 Rockwell Automation Publication 1756-UM542A-EN-P - September 2014

Page 11

2. Enter a name for the module.

3. Enter a brief description for the module.

4. Enter the IP address for the module.

Setup Chapter 2

5. Click the Configuration tab.

6. From the Source Settings pull-down menu, choose the time source that

you want to use.

See Chapter 4

7. Select the Time Output format.

8. Enter the Advanced CIP Sync Settings.

9. Enter the Description Settings.

10. Click OK.

for more information on the source types.

The time properties of the 1756HP-TIME module are now configured.

Allen-Bradley Motors

Rockwell Automation Publication 1756-UM542A-EN-P - September 2014 11

Page 12

Chapter 2 Setup

View the Satellite Status in the Logix Designer Application

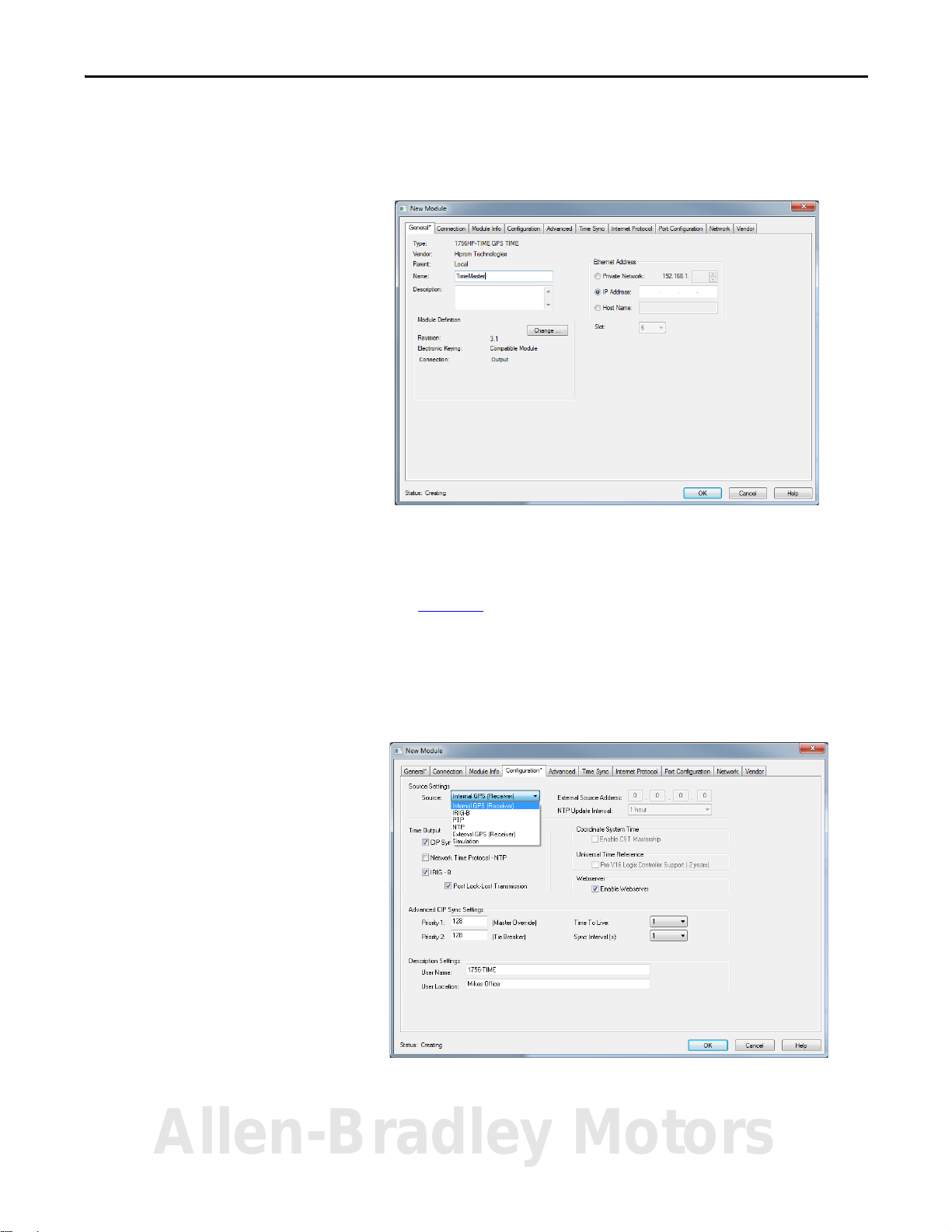

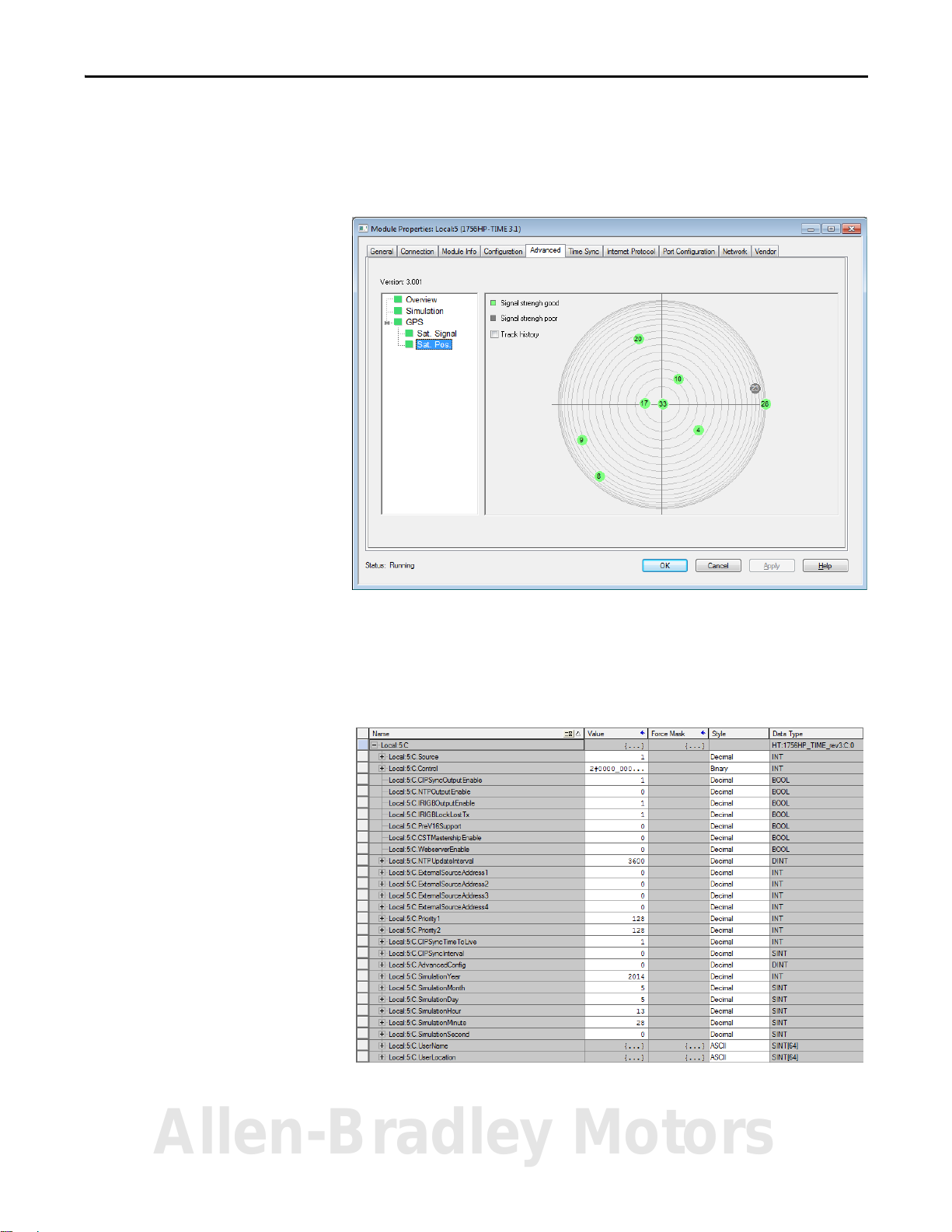

Click the Advanced tab to view the source of the time (Time Input), and see if

the time source is valid and available (green) or invalid (red). You can also view

the output type (Time Output), the UTC time of the 1756HP-TIME module,

and the GPS coordinates of the satellite (when a connection is locked).

Figure 4 - 1756HP-TIME Module Properties Dialogue Box, Advanced Tab

Satellite Signal

Click Sat. Signal to view the signal strength of the satellites.

Figure 5 - 1756HP-TIME Module Properties Dialogue Box, Sat. Signal Node

12 Rockwell Automation Publication 1756-UM542A-EN-P - September 2014

Page 13

Satellite Position

Click Sat. Pos. to view the position of the satellites in the sky.

Figure 6 - 1756HP-TIME Module Properties Dialogue Box, Sat. Pos. Node

Setup Chapter 2

1756HP-TIME Module AOP Configuration Parameters

This section describes the AOP configuration parameters for the 1756HP-TIME

module. This section is for information purposes. The AOP is used to configure

all the relevant module parameters.

Allen-Bradley Motors

Rockwell Automation Publication 1756-UM542A-EN-P - September 2014 13

Page 14

Chapter 2 Setup

Table 2 - AOP Configuration Parameters

Parameter Description Value

Source Indicates the time source that is used for the module. 1 = GPS

2 = IRIG-B

3 = PTP

4 = NTP

5 = External GPS (future)

6 = Simulation

CIPSyncOutputEnable When this bit is set, the module enables 1588 PTP (CIP sync) output. 0 = 1588 PTP (CIP sync) output is disabled

1 = 1588 PTP (CIP sync) output is enabled

NTPOutputEnable When this bit is set, the module enables NTP on Ethernet. 0 = NTP v3 RF(1305) output is disabled

1 = NTP v3 RF(1305) output is enabled

IRIGBOutputEnable When this bit is set, the module enables IRIG-B on the coaxial interface. 0 = IRIG-B-122 output is disabled

1 = IRIG-B-122 output is enabled

IRIGBLockLostTX When this bit is set, the module keeps sending an IRIG-B signal aft

PreV16Support If you are using RSLogix 5000 software, version 16.00.00 and later, or the Studio 5000

CSTMastershipEnable Indicates if the module is the CST master clock on the local rack (if no other CST master

WebserverEnable Allows you to access the web server from a web browser pointed to the IP address of the

NTPUpdateInterval The time (in seconds) when the module requests an update of the time from the NTP

ExternalSo urceAddress The external source address is used for one of two sources depending on how the

Priority1 This is the override for the Best Master Clock Algorithm (BMCA). The default is 128.

Priority2 This is used to break a tie between two modules with the same priority 1 value. The default is 128.

CIPSyncTimeToLive Limits the lifespan of data in a network. It

CIPSyncInterval The time interval when the module sends out a PTP sync packet. Allowed values:

AdvancedConfig These are various bits used to set c

time source.

If this bit is clear, the module stops sending a valid IRIG-B signal when it has lost lock

with the time source, as long as it has had lock at least once previously.

environment, version 21.00.00 and later, the UTC time base is different than earlier

versions of RSLogix 5000 software.

The setting syncs the time between Logix5000 controllers that use any version of

RSLogix 5000 software or the Studio 5000 environment.

clocks are currently active).

module.

server.

guration is set:

confi

• If the time source is set to NTP, this is the IP address of the source that is used.

• If the source is set to External GPS, this is the IP address of the GPS receiver.

indefinitely.

prevents the IP packet from circulating

ertain options in the module. Bit:

er it has lost lo ck to th e

0 = Module stops sending IRIG-B when lock is lost

1 = Module continues sending IRIG-B, even when a lock is

lost

0 = For all versions of RSLogix 5000 software or the Studio

5000 environment

1 = For RSLogix 5000 software, version 16.00.00 and earlier.

0 = Module does not attempt to be the CST master clock

1 = Module does attempt to be the CST master clock

0 = Module does not allow access to the web server

1 = Module allows access to the web server

Example:

5 = 5 seconds

30 = 30 seconds

300 = 5 minutes

3600 = 1 hour

86400 = 1 day

604800 = 1 week

In this example, the module uses external IP address:

192.168.1.100

Byte 0 = 192

Byte 1 = 168

Byte 2 = 1

Byte 3 = 100

Values lower than 128 indicate preference on the network.

Values lower than 128 indicate preference on the network.

Example:

1 = the packet circulates once

1/2 = 500 ms

1 = 1 second

2 = 2 seconds

0 =Simulation Mode

1…31 = Reserved

14 Rockwell Automation Publication 1756-UM542A-EN-P - September 2014

Page 15

Table 2 - AOP Configuration Parameters (Continued)

Parameter Description Value

SimulationYear When the module is in simulation mode, use this to set the initial year to be used by the

SimulationMonth When the module is in simulation mode, use this to set the initial month to be used by

SimulationDay When the module is in simulation mode, use this to set the initial day to be used by the

SimulationHour When the module is in simulation mode, use this to set the initial hour to be used by the

SimulationMinute When the module is in simulation mode, use this to set the initial minute to be used by

SimulationSecond When the module is in simulation mode, use this to set the initial second to be used by

UserName Use this parameter to identify the time module, visible in CIP sync synchronization. Example:

UserLocation Use this parameter to provide extra information to identify the location of the module. Example:

module.

the module.

.

module

module.

the module.

the module

.

Example:

29 April 2014

Year = 2014

Example:

29 April 2014

Month = 4

Example:

29 April 2014

Day = 29

Example:

11:14:23 AM

Hour =11

Example:

11:14:23 AM

Minute =14

Example:

11:14:23 AM

Second =23

1756HP-TIME

Basement

Setup Chapter 2

Allen-Bradley Motors

Rockwell Automation Publication 1756-UM542A-EN-P - September 2014 15

Page 16

Chapter 2 Setup

Notes:

16 Rockwell Automation Publication 1756-UM542A-EN-P - September 2014

Page 17

Operation

Top ic Page

Logix5000 Controller Input Image 17

Logix5000 Controller Output Image 20

Web Int erf ace 21

Chapter 3

Logix5000 Controller Input Image

Each 1756HP-TIME module consumes one connection from the Logix5000

controller. This section provides descriptions for the Logix5000 controller input

image parameters.

Allen-Bradley Motors

Rockwell Automation Publication 1756-UM542A-EN-P - September 2014 17

Page 18

Chapter 3 Operation

Table 3 - Logix5000 Controller Input Image Parameters

Parameter Description Value

CommStatus Reserved. –

Source Indicates the current time source. 1 = GPS

2 = IRIG-B

3 = PTP

4 = NTP

5 = External GPS (future)

6 = Simulation

ModuleStatus Reserved. –

WebserverEnable Allows you to access the web server from a web browser pointed to

Time.TimeValid Indicates if a valid time is being received from the time source. 0 = Time being received from source is invalid

Time.CIPSyncOutputEnable Indicates if the 1588 Output PTP is enabled in the configuration. 0 = 1588 PTP (CIP Sync) output is disabled

Time.NTPOutputEnable Indicates if the NTP Output is enabled in the configuration. 0 = NTP v3 RF(1305) output is disabled

Time.IRIGBOutputEnable Indicates if the IRIG-B Output is enabled in the configuration. 0 = IRIG-B-122 output is disabled

Time.CSTMasterEnabled Indicates if the module is enabled to be the CST master clock. 0 = Module does not attempt to be the CST master clock

Time.CSTMastership Indicates if the module is the CST master clock on the local rack. 0 = Module is not the CST master clock

Time.CSTDuplicateDetect Indicates if the module is attempting to be the CST master clock.

Time.SimulationModeActive Indicates if the module is operating in simulation mode. 0 = Simulation mode is inactive

Time.Year Displays the current year received from the time source. Example:

Time.Month Displays the current month received from the time source. Example:

Time.Day Displays the current day received from the time source. Example:

Time.Hour Displays the current hour received from the time source. Example:

Time.Minute Displays the current minute received from the time source. Example:

IP address of the module.

the

If there is another CST master clock on the local rack, the module sets

this bit and stops attempting to be the CST master clock.

0 = Module does not allow access to the web server

1 = Module allows access to the web server

1 = Time being received from source is valid

1 = 1588 PTP (CIP Sync) output is enabled

1 = NTP v3 RF(1305) output is enabled

1 = IRIG-B-122 output is enabled

1 = Module does attempt to be the CST master clock

1 = Module is the CST master clock

0 = There is no other CST master clock on the local rack

1 = There is another CST master clock on the local rack

1 = Simulation mode is active

27/04/2010

13:45:22 - 234567 μs

Year = 2010

27/04/2010

13:45:22 - 234567 μs

Month = 4

27/04/2010

13:45:22 - 234567 μs

Day = 27

27/04/2010

13:45:22 - 234567 μs

Hour = 13

27/04/2010

13:45:22 - 234567 μs

Minute = 45

18 Rockwell Automation Publication 1756-UM542A-EN-P - September 2014

Page 19

Table 3 - Logix5000 Controller Input Image Parameters (continued)

Parameter Description Value

Time.Second Displays the current second received from the time source. Example:

27/04/2010

13:45:22 - 234567 μs

Second = 22

Time.Microsecond Displays the current microsecond received from the time source. Example:

27/04/2010

13:45:22 - 234567 μs

Microsecond = 234567

Time.UTC This is the current UTC in microseconds since the time base. The time

Time.CST Displays the current CST of the local rack (depending on the CST

Time.CSTOffset Displays the difference between the UTC and CST in microseconds.

GPS.GPSLock Indicates if the GPS receiver has lock (if GPS is the time source). 0 = GPS receiver does not have lock

GPS.AntennaOK Indicates if the GPS antenna is connected and is operational (if GPS is

GPS.HDOPOk Horizontal Dilution of Precision (HDOP) occurs when there are

GPS.PPS The pulse per second toggles at the exact moment the second

GPS.FaultCode Reserved. –

GPS.Mode Reserved. –

GPS.SVCount Indicates the number of satellites that the GPS receiver is locked on. This is a number between 0…12

GPS.Latitude Displays the current position latitude in degrees. Example:

GPS.Longitude Displays the current position longitude in degrees. Example:

GPS.Altitude Displays the current positio

gin is based on all versions of RSLogix 5000 software or the Studio

ori

5000 environment. See the example code for how this is used to time

stamp events in sequence-of-events (SOE) modules in RSLogix 5000

software versions earlier than 18.00.00.

master clock) in microseconds.

Use this to set the wall clock in the Logix5000 controller in RSLogix

5000 software versions earlier than 18.00.00. Click this link to see

example code:

http://www.hiprom.com/Pages/Products/1756_CLX/1756HP-TIME/

web/1756HP-TIME.htm.

source).

the time

sufficient satellites in lock, but two or more satellites occupy similar

positions in the sky (therefore decreasing the number of effective

satellites).

changes and the microseconds are zero.

Note: because the actual RPI is 50 ms, the accuracy is lost in the input

image.

n altitude in meters. Example:

Example:

02 April 2014

14:12:41

UTC = 87277992127872

Example:

CST master clock running for 1 hour

CST = 3600000000

Example:

CSTOffset = UTC - CST

UTC = 87277992127872

CST = 3600000000

CSTOffset = 87274392127872

1 = GPS receiver has locked onto sufficient satellites

0 = The antenna is either not present or is faulty

1 = The antenna is connected correctly and is operational

0 = HDOP is currently active

1 = HDOP is not active

0 = It has been more than 100 ms since the rollover pulse of the

last second

1 = It has been less than 100 ms since the rollover pulse of the

last second

S26°05'17.0"

E28°00'21.3"

Elev: 1577m

Latitude = -26.088087

S26°05'17.0"

E28°00'21.3"

Elev: 1577m

Longitude = 28.00586

S26°05'17.0"

E28°00'21.3"

Elev: 1577m

Elevation = 1577

Operation Chapter 3

Allen-Bradley Motors

Rockwell Automation Publication 1756-UM542A-EN-P - September 2014 19

Page 20

Chapter 3 Operation

Table 3 - Logix5000 Controller Input Image Parameters (continued)

Parameter Description Value

GPS.GroundSpeed Displays the ground speed, in meters per second. Example: 10.2m/s

GPS.DegreeFromTrueNorth Displays the degrees from true north. Example:

279.12°

GPS.MagneticVariationFromTrueNorth Displays the magnetic variation from true north. Example:

-18.1°

GPS.RelativePositionX Reserved. –

GPS.RelativePositionY Reserved. –

GPS.RelativePositionZ Reserved. –

Logix5000 Controller Output Image

This section provides descriptions for the Logix5000 controller output image

parameters.

Table 4 - Logix5000 Controller Output Image Parameters

Parameter Description Value

IRIGYear When the module has an IRIG-B time source, the year is not passed

over IRIG-B. Enter the current year here in the output image.

UTC_Offset The UTC_Offset is used only when the time source is IRIG-B, and PTP

output is enabled.

IRIG-B provides the UTC time, while PTP requires International

Atomic Time (TAI). The difference between the two is the UTC offset.

ReferencePositionX Reserved. –

ReferencePositionY Reserved. –

ReferencePositionZ Reserved. –

Example:

30 April 2014

IRIGYear = 2014

Example:

30 April 2014

UTC_Offset = 35

Be sure to verify the current UTC offset. The UTC offset changes

ap

proximately every 18 months.

20 Rockwell Automation Publication 1756-UM542A-EN-P - September 2014

Page 21

Operation Chapter 3

Web Interface

The web interface is disabled by default. Follow these steps to enable the web

interface.

n the configuration tab, check Enable Webserver.

1. O

2. Click OK.

You can access the web interface from any computer that has a web browser.

Enter ht

bar of your web browser.

For example, enter the IP address as shown here.

The web interface provides diagnostics and statistics for the 1756HP-TIME

mo

tp:// and the IP address of the 1756HP-TIME module into the address

dule.

Allen-Bradley Motors

Rockwell Automation Publication 1756-UM542A-EN-P - September 2014 21

Page 22

Chapter 3 Operation

Notes:

22 Rockwell Automation Publication 1756-UM542A-EN-P - September 2014

Page 23

Time Synchronization

IMPORTANT

IMPORTANT

Top ic Page

1588 Precision Time Protocol (CIP Sync) 23

Network Time Protocol (NTP) 26

IRIG-B 29

CST and UTC Time Conversion 30

Chapter 4

1588 Precision Time Protocol (CIP Sync)

The 1756HP-TIME module supports 1588 PTP which enables high-precision

time synchronization over an Ethernet network or the chassis backplane. When

PTP is selected, both Ethernet and backplane synchronization is enabled. In the

case of PTP output, the module outputs time over both the backplane and

Ethernet (if connected). In the case of PTP as a time source, the module searches

for the best clock on both media.

See the Integrated Architecture and CIP Sync Configuration Application

Te

c hn i qu e, pu b l ic at io n

IA-AT003, for details on how to use this object.

RSLogix 5000 software, version 18.00.00 and later, or the Studio 5000

environment, version 21.00.00 and later, supports 1588 PTP.

RSLogix 5000 software, version 17.00.00 and earlier, does not support

1588 PTP.

The 1756HP-TIME module supports PTP software version 2.

1756HP-TIME Module as a PTP Master

When locked onto sufficient satellites, the 1756HP-TIME module can

synchronize devices to within 100 ns (by using 1588 PTP) when connected

directly to the device that is being synchronized. If these devices are connected via

a switch that does not support 1588 PTP (transparent and boundary clock

modes), the time synchronization degrades because there are more random delays

that can affect the mean-delay time calculation used for time synchronization.

Therefore, the more switches and interfaces between the 1756HP-TIME module

and the devices being synchronized, the bigger the spread of random time delays

that can result in lower time sync accuracy.

Allen-Bradley Motors

Rockwell Automation Publication 1756-UM542A-EN-P - September 2014 23

Page 24

Chapter 4 Time Synchronization

IMPORTANT

IMPORTANT

IMPORTANT

If you enable CIP Sync on a 1756-EN2T/1756-EN2TR module, the module

looks for other 1588 PTP devices and syncs to the device that has the highestquality clock.

1588 PTP uses a multicast address; therefore, set the switches to allow

multicast, or have IGMP enabled.

There is no direct communication between the 1756HP-TIME module Ethernet

ports and a Logix5000 controller. If the 1756HP-TIME module resides in a

remote Logix rack, it needs to communicate through an EN2T(R) module in the

same rack.

The 1756-EN2T/1756-EN2TR modules are boundary clocks that can be a slave

clock on one interface, and a master clock on another interface. The modules can

act as a transparent gateway when a Logix5000 controller uses the time

Grandmaster (the 1756HP-TIME module) on the network. The 1756-EN2T/

1756-EN2TR module must have CIP Sync and Motion enabled. See

Configure

the Ethernet Module/Controller PTP/CIP Sync Settings on page 24.

Most devices supporting 1588 PTP defaults to PTP Enabled: FALSE.

PTP must be enabled on the devices before time synchronization can begin.

Configure the Ethernet Module/Controller PTP/CIP Sync Settings

Follow these steps to configure the PTP/CIP Sync settings of the 1756-EN2T/

1756-EN2TR module and controller.

en the AOP for the Ethernet module.

1. Op

2. From the General tab, under Module Definition, click Change.

24 Rockwell Automation Publication 1756-UM542A-EN-P - September 2014

Page 25

Time Synchronization Chapter 4

3. From the Time Sync Connection pull-down menu, choose Time Sync and

Motion.

4. Click OK.

The 1756-EN2T/1756-EN2TR module is now configured for PTP

synchronization.

5. To enable synchronization on the controller, open the Controller AOP.

6. On the Date/Time tab, check the Enable Time Synchronization box.

The Logix5000 controller looks for the highest-quality clock on the

plane.

back

7. Click OK.

The settings of the Ethernet module and controller module are now configured

or time sync and motion.

f

Allen-Bradley Motors

Rockwell Automation Publication 1756-UM542A-EN-P - September 2014 25

Page 26

Chapter 4 Time Synchronization

IMPORTANT

IMPORTANT

IMPORTANT

IMPORTANT

PTP as a Time Source

The 1756HP-TIME module can be set to be a PTP slave. The module

synchronizes to the best PTP clock on either the backplane or the Ethernet

network, using the best master clock algorithm (BMC).

The TIME module cannot act as a boundary clock. If PTP is selected as the input

time source, then PTP output is disabled.

Using PTP as the time source enables NTP and IRIG-B as the output modes.

herefore, the accuracy is limited to the accuracy of the respective output modes.

T

The accuracy of the PTP time is dependent on the quality and reliability of the

Ethernet network. The PTP algorithm allows for network delays, but needs a

constant delay to synchronize accurately. PTP switches prioritize PTP messages

to keep the delay constant, and are preferred for PTP networks.

Network Time Protocol (NTP)

This section describes how to configure the 1756HP-TIME module as an NTP

server or an NTP client.

1756HP-TIME Module as an NTP Server

The 1756HP-TIME module supports NTP, which provides time

synchronization over an Ethernet network. NTP clients can be synchronized to

approximately 1ms of the NTP client, depending on the network configuration

and reliability.

NTP is typically used when synchronizing personal computers or domain

con

trollers. You can use the Hiprom Software Network Time Protocol

(HSNTP) application to set the Windows time service on a personal computer

to synchronize to the 1756HP-TIME module. Download the HSNTP

application from

www.hiprom.com.

The 1756HP-TIME module supports NTP version 3, RFC1305.

When a computer is on a domain, it tries to synchronize to the domain

controller. Therefore, you can set up the domain controller to synchronize to

the 1756HP-TIME module.

26 Rockwell Automation Publication 1756-UM542A-EN-P - September 2014

Page 27

Time Synchronization Chapter 4

Configure Windows NTP Settings

Follow these steps to configure the Windows time service to synchronize to the

1756HP-TIME module. Note that the time module and computer need to be on

the same Ethernet network to use NTP.

en the HSNTP application.

1. Op

nter the IP address of the NTP source (the 1756HP-TIME module).

2. E

3. Click Set to update the IP address.

4. From the Update Interval pull-down menu, choose an update interval

time.

5. Click Set to update the update interval time.

6. Click Stop to stop the time service and load the new settings.

7. Click Start to start the time service.

8. Click NTP Source Sync to synchronize the time with the NTP server.

The Windows time service is now configured to synchronize to the

1756H

defaults’.

P-TIME module. To reset the defaults, click Set next to ‘Resort to

Allen-Bradley Motors

Rockwell Automation Publication 1756-UM542A-EN-P - September 2014 27

Page 28

Chapter 4 Time Synchronization

TIP

TIP

1756HP-TIME Module as an NTP Client

You can configure the 1756HP-TIME module to connect to an external NTP

source, and then output the time as PTP or IRIG-B time.

You can also use the SNTP protocol for the source.

Follow these steps to configure the 1756HP-TIME module to an NTP source.

en the Time module AOP in RSLogix 5000 software.

1. Op

2. Click the Configuration tab.

3. From the Source Settings pull-down menu, choose NTP as the source.

The External Source Address and NTP Update Interval options become

available.

4. In the External Source Address field, enter the IP address of the NTP

source.

5. From the NTP Update Interval pull-down menu, choose the update

interval for the 1756HP-TIME module to adjust its internal clock to the

NTP source.

The update interval can range from 5 seconds to 1 week.

The frequency of the update interval affects the accuracy of the time from the

1756HP-TIME module. If the time is not adjusted by the NTP source, the time

can drift by up to 10 μs/s depending on external factors, such as temperature

and humidity.

6. Cl

ick OK.

The 1756HP-TIME module is now configured to an NTP source.

28 Rockwell Automation Publication 1756-UM542A-EN-P - September 2014

Page 29

Time Synchronization Chapter 4

IMPORTANT

IMPORTANT

IMPORTANT

Time Adjustments

To keep the time of the 1756HP-TIME module as smooth as possible, the time is

adjusted in small increments (ramp) until it is equal to the NTP source. If the

time of the 1756HP-TIME module drifts more than 1 second off of the source

time, the 1756HP-TIME module jumps to the time given by the NTP source.

The accuracy of the NTP time depends on the quality and reliability of the

Ethernet network. If the update time is set too high, the clock can drift and

jump. Rockwell Automation recommends a value of 30 seconds or less for

optimal accuracy.

Loss of Communication

If the 1756HP-TIME module loses its connection to the NTP source (if the

source does not reply after the update interval time has expired) then the PPS and

SYNC indicators illuminate red, the TimeValid bit is set to FALSE, and the

1756HP-TIME module runs on its internal oscillator until the NTP source

becomes available again. The 1756HP-TIME module tries to reconnect to the

NTP source every 10 seconds after a loss of communication.

IRIG-B

NTP time as a source is accurate to 10 ms; therefore, the synchronization

accuracy of the output 1588 PTP is limited to 10 ms.

The 1756HP-TIME module can be used as an IRIG-B master clock (outputs the

IRIG-B signal) or an IRIG-B slave clock (receives the IRIG-B signal from

another master clock). The time is transmitted over a coaxial cable, which plugs

into the BNC connector at the bottom of the 1756HP-TIME module.

The 1756HP-TIME module currently supports the IRIG-B-122 format.

1756HP-TIME Module as an IRIG-B Master

When the 1756HP-TIME module is an IRIG-B master clock, it sends the

current time over the IRIG-B network and synchronizes slave clocks to

approximately 1ms.

Note that the 1756HP-TIME module does not send the current year over the

-B network.

IRIG

Allen-Bradley Motors

Rockwell Automation Publication 1756-UM542A-EN-P - September 2014 29

Page 30

Chapter 4 Time Synchronization

IMPORTANT

IMPORTANT

IMPORTANT

IMPORTANT

1756HP-TIME Module as an IRIG-B Slave

The 1756HP-TIME module can synchronize to an external IRIG-B source using

coaxial cable. The source needs to output IRIG-B 122 format time.

The current year for the IRIG-B format is not supported by the 1756HP-TIME

module. Therefore, you need to supply the current year in the output image of

the module in RSLogix 5000 software. A simple rung of ladder logic increases

the year without your intervention.

You can also use the 1756HP-TIME module to output 1588 PTP and NTP

hile receiving time from an IRIG-B source.

w

If using PTP as an output, you must also supply the UTC offset in the output

image. The current value is 35, but this changes periodically. To keep up to

date, this page lists the current value.

http://en.wikipedia.org/wiki/Leap_second.

CST and UTC Time Conversion

If the 1756HP-TIME module has an IRIG-B time source that is accurate to 1 ms,

then the synchronization accuracy when using 1588 PTP is also limited to 1ms.

This process is not needed for RSLogix 5000 software version 18.00.00 or later.

The 1756HP-TIME module can also be used to convert CST or UTC time

fo

rmats to Gregorian time (year, day, month, and so on). The GPS module

accurately tracks the local CST and UTC time to the current Gregorian time.

Therefore, the different drifting rates of the CST are also compensated for.

In a sequence-of-events (SOE) solution, the SOE module (for example, the

1756-I

B16ISOE module) reports the event time in either CST or UTC time

formats.

One CST master clock must be present for a sequence-of-events solution.

Verify that there is no duplicate CST master clock. This is indicated in 1756HPTIME module and the Logix controller.

These values are passed to the 1756HP-TIME module (by using unconnected

ge blocks) and converted to Gregorian time. The 1756HP-TIME module

messa

tracks the last 12 hours of CST, UTC, and Gregorian time formats. If an event

has occurred, you have up to 12 hours to convert the event time. See

Conversion Message Blocks on page 37 for these message formats.

CST/UTC

The CST offset can also be used to adjust the wallclock by using a set system

v

alues (SSV) instruction to pass the CST offset.

30 Rockwell Automation Publication 1756-UM542A-EN-P - September 2014

Page 31

Specifications

Top ic Page

Technical Specifications 31

Cable Specifications 31

GPS Antenna Specifications 32

Dimensions 33

Appendix A

Technical Specifications

Cable Specifications

This table lists the technical specifications for the 1756HP-TIME module.

Attribute Value

Power requirements All power is derived from the 1756 backplane.

Power consumption

Operating temperature

Storage temperature

Relative humidity 5… 95% noncondensing

Enclosure type rating IP20

Ethernet conductor CAT5 STP

This table lists the cable specifications for the 1756HP-TIME module.

Attribute Value

Cable type Type RG58 or equivalent

Impedance 50 Ω

Shield Foil or copper braid (100% coverage)

Conne ctors SMA male to TNC male

Signal attenuation At 1.5 GHz < 10 dB (less than 6 dB recommended)

Current draw at 5V = 736 mA

Current draw at 24V = 1.64 mA

0…50 °C (32…122 °F)

Allen-Bradley Motors

Rockwell Automation Publication 1756-UM542A-EN-P - September 2014 31

Page 32

Appendix A Specifications

IMPORTANT

66.2 mm

2.61 in.

77.5 mm

3.05 in.

GPS Antenna Specifications

This section lists the specifications for the Trimble Bullet III 3.3V DC GPS

antenna, part number 57861-20.

Antenna Attribute Value

Vol tag e 3.3V DC

Environment Outside (weather proof)

Trimble Bullet III 3.3V DC GPS antenna

Trimble Par t Number 57861-20

(sold separately; not sold by Rockwell

Auto

mation)

Temperature range -40…85 °C (-40…185 °F)

Dimensions, W x H 77.5 x 66.2 mm (3.05 x 2.61 in.)

Wei ght 170.0 g (6.0 oz)

Connector TNC female

Mounting 3/4 in. pipe thread

For more information about the Trimble Bullet III 3.3V GPS antenna, part

umber 57861-20, visit the Trimble website at

n

http://www.trimble.com/.

Contact a Trimble sales representative to purchase the Trimble Bullet III 3.3V

GPS antenna.

Rockwell Automation does not provide GPS antennas.

32 Rockwell Automation Publication 1756-UM542A-EN-P - September 2014

Page 33

Specifications Appendix A

35 mm (1.37 in.)

140 mm (5.51 in.)

153 mm (6.02 in.)

1756HP-TIME Module

PTP, NTP, and IRIG-B Time Master

Dimensions

This drawing shows the dimensions of the 1756HP-TIME module.

Allen-Bradley Motors

Rockwell Automation Publication 1756-UM542A-EN-P - September 2014 33

Page 34

Appendix A Specifications

Notes:

34 Rockwell Automation Publication 1756-UM542A-EN-P - September 2014

Page 35

Appendix B

1756HP-TIME Module Status

Top ic Page

Status Indicators 35

Status Messages 36

The display on the front of the 1756HP-TIME module provides status indicators

and status messages.

Status Indicators

The 1756HP-TIME module provides three status indicators on the display.

Status Indicators Description

This indicator is toggled every second for 100 ms at the exact PPS.

PPS

SYNC

OK

Green = the module is locked on the time source.

Red = the module is not locked on the time source.

When the module is set to be an IRIG-IN or sl

time a reference frame is received.

Green = the module is locked on the time source.

Red = the module is not locked on the time source.

Green = the module has started successfully.

Red = the module has a hardware fault.

ave clock, this indicator is toggled every

Allen-Bradley Motors

Rockwell Automation Publication 1756-UM542A-EN-P - September 2014 35

Page 36

Appendix B 1756HP-TIME Module Status

Status Messages

The 1756HP-TIME module provides the following status messages on the

display.

Status Message Description

192.168.1.100 Indicates the IP address of the 1756HP-TIME module.

Source: X

BOOTP Enabled

Sat Count X The GPS receiver is locked onto X number

No Time Lock The time has not been received.

Time Locked The module is locked to the selected time source.

Firmware update in progress, do not power down! Indicates that a firmware upgrade is in progress.

OK Indicates that the module is operating correctly.

RESET Indicates the module has received a reset command.

TEST

PTP Source X

PTP Source Unreachable

NTP Source X Displays the IP address of the NTP Source

NTP Source Unreachable Indicates that there is no NTP

Please provide IRIG-B Year

BL. Err X - Y

Err X - Y

Indicates the current time source being used.

The sources are GPS, IRIG-B, NTP, and PTP.

Indicates that BOOTP is currently active on the module.

Use a BOOTP server to set the IP address.

of satellites.

The module displays this on startup when it is performing

sel

f-diagnostics to make sure the hardware is working properly.

Displays either the IP address (Ethernet CIP Sync) or slot number

(Back

plane CIP Sync) of the PTP source.

Indicates that there is no PTP source on either the backplane or

Ethernet network.

source on Ethernet network.

The Output image does not have a valid year for the IRIG-B

signal.

An error has occurred in initializing the module. X is the error

code, and Y is the description of the error.

An error has occurred during operation. X is the error code, and Y

is the

description of the error.

36 Rockwell Automation Publication 1756-UM542A-EN-P - September 2014

Page 37

CST/UTC Conversion Message Blocks

Top ic Page

CST to UTC and Gregorian Time Conversion 37

UTC to Gregorian Time Conversion 37

Satellite Info rmation 38

Appendix C

CST to UTC and Gregorian Time Conversion

UTC to Gregorian Time Conversion

This table shows the structure of the message block for the CST to UTC and

Gregorian time conversion.

Settings and Elements Attribute Value

Message type CIP generic

Service type Custom

Message settings

Date elements

(1) See the example code at http://ww w.hiprom.co m/.

Service code 36h

Class 72h

Instance 01h

Attribute 03h

Source element Event_CST [0]

Source length 8

Destination Event.Year

(1)

(1)

This table shows the structure of the message block for the UTC to Gregorian

time conversion.

Settings and Elements Attribute Va lue

Message type CIP generic

Service type Cust om

Message settings

Date elements

Service code 36h

Class 72h

Instance 01h

Attribute 04h

Source element Event_UTC[0]

Source length 8

Destination Event.Year

(1)

(1)

Allen-Bradley Motors

(1) See the example code at http://ww w.hiprom.co m/.

Rockwell Automation Publication 1756-UM542A-EN-P - September 2014 37

Page 38

Appendix C CST/UTC Conversion Message Blocks

Satellite Information

This table shows the structure of the message block for the satellite information.

Settings and Elements Attribute Valu e

Message type CIP generic

Service type Cust om

Message settings

Date elements

(1) See the example code at http://www.hiprom.com/.

Service code 36h

Class 72h

Instance 01h

Attribute 09h

Source element -

Source length 0

Destination SatInformation[0].PRN

(1)

38 Rockwell Automation Publication 1756-UM542A-EN-P - September 2014

Page 39

Operating Modes

IRIG-B

1588 PTP

NTP

GPS Antenna

Top ic Page

GPS Source 39

IRIG-B Source 40

PTP Source 40

NTP Source 41

Appendix D

GPS Source

The GPS source mode can have the following configurations:

urce: GPS

• So

• Outputs: IRIG-B, 1588 PTP/CIP Sync, NTP, and input/output

assemblies.

Allen-Bradley Motors

Rockwell Automation Publication 1756-UM542A-EN-P - September 2014 39

Page 40

Appendix D Operating Modes

IRIG-B

1588 PTP

NTP

IRIG-B

1588 PTP

NTP

IRIG-B Source

The IRIG-B source mode can have the following configurations:

• S

ource: IRIG-B 122

• Outputs: 1588 PTP/CIP Sync, NTP, and input/output assemblies

PTP Source

The PTP source mode can have the following configurations:

• S

ource: 1588 PTP/CIP Sync, either over Ethernet or the backplane

• Outputs: IRIG-B, NTP, and input/output assemblies

40 Rockwell Automation Publication 1756-UM542A-EN-P - September 2014

Page 41

Operating Modes Appendix D

IRIG-B

1588 PTP

NTP

NTP Source

The NTP source mode can have the following configurations:

• S

ource: NTP, over Ethernet

• Outputs: IRIG-B, 1588 PTP/CIP Sync, and input/output assemblies

Allen-Bradley Motors

Rockwell Automation Publication 1756-UM542A-EN-P - September 2014 41

Page 42

Appendix D Operating Modes

Notes:

42 Rockwell Automation Publication 1756-UM542A-EN-P - September 2014

Page 43

GPS Antenna Cable Extensions

Top ic Page

Cable Extensions 43

Lightning Protection Devices 45

Appendix E

Cable Extensions

The 1756HP-TIME module ships with a 5 m (16 ft) RG58 coaxial cable.

Rockwell Automation does not supply longer cables. If you need a longer cable

for your installation, follow the guidelines in this appendix to specify and

purchase extensions from a cable supplier.

Determine the Length of the Cable

Determine the length of the cable by measuring the cable path from the

1756HP-TIME module to a position that provides the antenna with a 360

degree clear view of the sky. Plan your installation so the length of the cable path

is as short as possible.

Determine the Attenuation Rate of the Cable

Determine the type and quality of cable and whether an amplifier is required. Use

the cable attenuation tables of the manufacture. Determine the over-signal

attenuation at 1.5 GHz. Keep the attenuation below 10 dB. Rockwell

Automation recommends no more than 6 dB for better performance.

Ta b l e

5 provides typical attenuation values (in dB) for common types of 50 Ω

coaxial cable at 1.5 GHz. Light green shading shows acceptable levels of

uation below 10 dB. Dark green shading is in the recommended range.

atten

Table 5 - - Typical Attenuation Values in dB for Cable Extension, m (ft)

5

(16)10(33)15(49)20(66)25(82)30(98)35(115)40(131)45(148)50(164)55(180)60(197)65(213)70(230)75(246)80(262)85(279)90(295)95(312)

Cable Type Typical Attenuation Values in dB

RG58 3.1 6.3 9.4 12.5 15.7 18.8 21.9 25.0 28.2 31.3 34.4 37 .6 40.7 43.8 47.0 50.1 53.2 56.3 59.5 62.6

LMR-240 1.6 3.2 4.9 6.5 8.1 9.7 11.3 13.0 14.6 16.2 17.8 19.4 21.0 22.7 24.3 25.9 27.5 29.1 30.8 32.4

LMR-400 0.8 1.7 2.5 3.4 4.2 5.0 5.9 6.7 7.6 8.4 9.2 10.1 10.9 11.8 12.6 13.5 14.3 15.1 16.0 16.8

LMR-600 0.5 1.1 1.6 2.2 2.7 3.3 3.8 4.4 4.9 5.4 6.0 6.5 7.1 7.6 8.2 8.7 9.2 9.8 10.3 10.9

(328)

Allen-Bradley Motors

Rockwell Automation Publication 1756-UM542A-EN-P - September 2014 43

100

Page 44

Appendix E GPS Antenna Cable Extensions

IMPORTANT

IMPORTANT

TIP

LMR-400 and LMR-600 cables are too stiff and heavy to connect directly to the

small SMA connector on the 1756HP-TIME module.

For these cables, use a fly lead to wire the connector.

If the attenuation from a lower loss cable (such as LMR 600) is greater than 10

dB, you need to use an amplifier. Rockwell Automation does not supply

amplifiers. If you need an amplifier for your installation, follow the guidelines in

this appendix to specify and purchase an amplifier from a cable supplier.

Amplifiers of 15 and 30 dB gain are typically available.

Verify that the signal gain through the amplifier, minus the attenuation from the

able, is in the range of +10 dB (gain) to -10 dB (loss). Mount the amplifiers as

c

close to the antenna as possible without exposing them to the weather.

Amplifiers must pass the 3.3V DC supplied by the GPS receiver to power the

internal antenna amplifier, or provide the 3.3V DC internally.

If the amplifier blocks the DC component, it also needs to supply a dummy load

to prevent the receiver from giving a false No Antenna fault.

Example – Determining Cable Requirements

Cable length required is 30 m (100 ft).

Fro m Ta b l e 5 on page

LMR-400 can be used with a 5 dB loss. Because LMR-400 cannot be connected

dir

ectly to the 1756HP-TIME module, a shorter length of RG58 can be used.

The antenna cable extension needs to connect to an SMA female connector on

he 1756HP-TIME module, and a TNC female connector on the antenna. So

t

the cable connectors need to be SMA male to TNC male.

43, LMR-240 has a 9.7 dB loss that is acceptable, or

Rockwell Automation recommends a TNC bulkhead connector for cable-tocable connections.

Cable Extension Kits

The cable extension kits inTa b l e 6 on page 45 can be purchased from Millimeter

Wave Technologies. For more information, visit the Millimeter Wave

T

echnologies website,

http://mmwavetech.com/, or call 1-480-941-2990.

44 Rockwell Automation Publication 1756-UM542A-EN-P - September 2014

Page 45

Table 6 - Cable Extension Kits

Power Ampl ifier

Enclosure

1756HP-TIME

Module

Bulkhead Connector

Earth Ground

Lightening Protection Device

GPS Antenna Cable Extensions Appendix E

Lightning Protection Devices

Part No. Cable Length

m (ft)

ACK33 10 (33) - - RG58-ST-33 - -

ACK50 15 (50) - - LMR240-ST-50 - -

ACK66 20 (66) - - LMR240-ST-66 - -

ACK10 0 30 (100) RG58-ST-6 BULKH-TT LMR400-TT-100 - -

ACK13 0 40 (130) RG58-ST-6 BULKH-TT LMR400-TT-130 - -

ACK15 0 46 (150) RG58-ST-6 BULKH-TT LMR400-TT-150 - -

ACK17 5 53 (175) RG58-ST-6 BULKH-TT LMR600-TT-175 - -

ACK20 0 61 (200) RG58-ST-6 BULKH-TT LMR600-TT-200 - -

ACK26 0 79 (260) RG58-ST-6 BULKH-TT LMR600-TT-260 A11-P110/3.3-TF

ACK30 0 300 (91) RG58-ST-6 BULKH-TT LMR600-TT-300 A11-P110/3.3-TF

ACK36 0 110 (360) RG58-ST-6 BULKH-TT L MR600-T T-360 A11-P110/3.3-TF

Fly Lead 1 Bulkhead

Connector

Main Cable Amplifier Fly Lead 2

RG58-TT-6

15 dB

RG58-TT-6

15 dB

RG58-TT-6

15 dB

Rockwell Automation recommends lightning protection devices that are capable

of receiving multiple strikes, with a clamping voltage above the 3.3V DC that is

required by the antenna (such as a Polyphaser DGXZ+06NFNF device). Mount

the lightning protection device outside, with an earth ground.

Allen-Bradley Motors

Rockwell Automation Publication 1756-UM542A-EN-P - September 2014 45

Page 46

Appendix E GPS Antenna Cable Extensions

Notes:

46 Rockwell Automation Publication 1756-UM542A-EN-P - September 2014

Page 47

Glossary

The following terms and abbreviations are used throughout this manual. For

definitions of terms not listed here, refer to the Allen-Bradley Industrial

Automation Glossary, publication

Add-On Instructions Add-on instructions are custom RSLogix 5000 software and the Logix Designer

app

lication instructions that you design and create. With add-on instructions,

you can create new instructions for sets of commonly-used logic, provide a

common interface to this logic, and provide documentation for the instruction.

Best Master Clock Algorithm The algorithm performed by each node to determine the clock that will become

t

he master clock on a subnet and the Grandmaster clock for the domain. The

algorithm primarily compares priority1, clock quality, priority2, and source

identity to determine the best master among available candidates.

Boundary Clock A boundary clock has more than one port, for example, a managed Ethernet

itch, and perform the duties as a master or slave clock.

sw

Common Industrial Protocol (CIP) The common industrial protocol (CIP) is an open industrial protocol for

dustrial automation applications.

in

AG-7.1.

CIP Sync CIP sync is the Open DeviceNet Vendors Association (ODVA) implementation

he Institute of Electrical and Electronics Engineers (IEEE) 1588-2008

of t

standard. The protocol provides a mechanism to synchronize clocks between

controllers, I/O devices, and other automation products.

Clock A node participating in the PTP protocol that is capable of providing a

mea

surement of the passage of time since a defined epoch. There are three types

of clocks in IEEE 1588-2008: boundary, transparent, and ordinary clocks.

Coordinated System Time (CST) In its simplest form, CST is a backplane clock propagated between all modules

n the ControlLogix backplane. Its presence is necessary whenever time

o

coordination between modules in the chassis is required.

Device Level Ring (DLR) A DLR network is a single-fault tolerant ring network intended for the

terconnection of automation devices. This topolog y is also implemented at the

in

device level. No additional switches are required.

Domain A logical grouping of clocks that synchronize to each other by using the PTP

p

rotocol, but that are not necessarily synchronized to clocks in another domain.

Greenwich Mean Time (GMT) GMT is the mean solar time of the longitude (0°) of the former Royal

bservatory at Greenwich, England, or Greenwich meridian. UTC replaced

O

GMT as the basis for the main reference time scale or civil time in various regions

on 1 January 1970.

Global Positioning System (GPS) GPS is a satellite-based navigation system made up of a network of 24 satellites

aced into orbit by the U.S. Department of Defense. GPS provides reliable

pl

timing services (as well as positioning and navigation) on a continuous basis in all

weather, day and night, anywhere on or near the Earth that has an unobstructed

view of four or more GPS satellites.

Allen-Bradley Motors

Rockwell Automation Publication 1756-UM542A-EN-P - September 2014 47

Page 48

Glossary

Grandmaster (GM) Within a domain, a clock that is the ultimate source of time for clock

synchronization by using the CIP sync protocol.

Local Clock The clock on a device.

Master Clock (M) In the context of a single CIP sync communication path, a clock that is the source

of

time to which all other clocks on that path synchronize on a local subnet.

Network Time Protocol (NTP) A protocol for synchronizing the clocks of computer systems over packet-

itched, variable-latency data networks.

sw

Priorities (P1 and P2) Parameters that can override the best master clock algorithm to choose a different

master.

Grand

Precision Time Protocol (PTP) The PTP protocol is a time-transfer protocol defined in the CIP sync IEEE

1588-2008

standard that allows precise synchronization of networks.

Slave Clock A clock that synchronizes its local clock to a master time.

Sequence of Events (SOE) Sequence of events is any events that need to be compared against a second event.

Synchronized Clocks Two clocks are synchronized to a specified uncertainty if they have the same

och and their measurements of the time of a single event at an arbitrary time

ep

differ by no more than that uncertainty.

System Time The absolute time value as defined by CIP sync in the context of a distributed

ime system where all devices have a local clock that is synchronized with a

t

common master clock. System time is a 64-bit integer value in units of

nanoseconds or microseconds with a value of 0 corresponding to an epoch of

January 1, 1970.

Time Sync Object The time sync object provides a Common Industrial Protocol (CIP) interface to

he IEEE 1588 (IEC 61588) standard for a precision clock synchronization

t

protocol for networked measurement and control systems. This information can

be collected to be used in diagnostics.

Transparent Clocks A device that measures the time taken for a PTP event message to transit the

de

vice and provides this information to clocks receiving this PTP event message.

Coordinated Universal Time (UTC) The time standard for 'civil time' that is time at the Prime Meridian (0 degrees

ngitude). The time does not include time zone or Daylight Saving Time offsets.

lo

System time is the same as UTC.

Wal lCl ockT ime (WC T) WallClockTime is the time of the controller based on UTC system time.

48 Rockwell Automation Publication 1756-UM542A-EN-P - September 2014

Page 49

Index

Numerics

1588 Output PTP 18

1588 PTP

23

A

accuracy of NTP time 29

Add-on Profile

amplifier

determine if needed

dummy load

mounting 44

signal gain

AOP

configuration parameters

download

attenuation values 43

8

44

44

descriptions

example

13

10

44

14

B

backplane 7

best master clock algorithm

26

BMC

BOOTP/DHCP server

9

access

download and install

set IP address of module 9

boundary clock

bulkhead connector

24, 26

26

9

44

C

cable extension kits 44

clock

7

master

slave

7

coaxial cable

communication loss

configure the 1756HP-TIME module

6

CST

current time source

43

attenuation

master clock

offset

30

43

29

14, 18

18

D

diagnostics 21

dimensions

1756HP-TIME module

GPS antenna

domain controller

33

32

26

10

E

Ethernet connectors 7

F

firmware

download

error

revision 5

10

9

G

GPS antenna

installation examples

GPS coordinates 12

GPS SMA connector

Grandmaster

Gregorian time

24

30

8

7

H

high-precision time synchronization 23

26

HSNTP

I

input image parameters

description

example 17

internal oscillator

IP packet

IRIG-B

coaxial connector

master clock

output

slave clock

IRIG-B-122 format

18

29

14

6

7

29

18

29

29

L

lightning protection 45

6

LLA

M

master clock 7

multicast address

24

N

NTP 6

26

client

output

18

14, 26

server

source

28

version 3, RFC1305

26

Allen-Bradley Motors

Rockwell Automation Publication 1756-UM542A-EN-P - September 2014 49

Page 50

Index

O

operating modes

GPS source

IRIG-B source

NTP source

PTP source

output image parameters

descriptions

example

39

40

41

40

20

20

P

PTP 6

as a time source

output

slave 26

sync packet

23

23

14

R

RG58 coaxial cable 43

S

satellite

GPS coordinates

position

signal strength 12

sequence-of-events solution

simulation mode

slave clock

SNTP protocol

SOE module

SSV instruction

statistics

status

synchronization accuracy

7

21

indicators

messages

view

7

12

13

15

28

30

30

35

36

29, 30

30

U

UTC 6

UTC offset

20, 30

W

web interface 21

Windows time service

27

T

TAI 20

time

adjustments

drift

Grandmaster

input

output

source 12

sync accuracy

synchronization

time format conversion

CST to Gregorian

CST to UTC

UTC to Gregorian

transparent gateway

50 Rockwell Automation Publication 1756-UM542A-EN-P - September 2014

29

28, 29

24

12

12

23

methods, standards, a

30, 37

37

30, 37

24

nd protocols 6

Page 51

Allen-Bradley Motors

Page 52

Rockwell Automation Support

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Rockwell Automation provides technical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support

software service packs. You can also visit our Support Center at https://rockwellautomation.custhelp.com/

updates, support chats and forums, technical information, FAQs, and to sign up for product notification updates.

In addition, we offer multiple support programs for installation, configuration, and troubleshooting. For more

information, contact your local distributor or Rockwell Automation representative, or visit

http://www.rockwellautomation.com/services/online-phone

Installation Assistance

If you experience a problem within the first 24 hours of installation, review the information that is contained in this

manual. You can contact Customer Support for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or Canada Use the Worl dwi de Locat or

Rockwell Automation representative.

at http://www.rockwellautomation.com/rockwellautomation/support/overview.page, or contact your local

New Product Satisfaction Return

you can find technical and application notes, sample code, and links to

for software

.

Rockwell Automation tests all of its products to help ensure that they are fully operational when shipped from the

manufacturing facility. However, if your product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number (call the phone number above to obtain one) to your

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this

document, complete this form, publication RA-DU002

Rockwell Automation maintains current product environmental information on its website at

http://www.rockwellautomation.com/rockwellautomation/about-us/sustainability-ethics/product-environmental-compliance.page

, available at http://www.rockwellautomation.com/literature/.

.

Publication 1756-UM542A-EN-P - September 2014

Copyright © 2014 Rockwell Auto mation, Inc. All rights reserved. Pr inted in the U.S.A.

Loading...

Loading...