Page 1

R-SE JK BOMBSHELL KIT

AX-BS-100-D44

*If any parts listed are missing or damaged please call Rock-Slide Engineering @

435-752-4580 prior to installation.

JK DANA 30 axle. The outer sleeve kit will need some minor trimming to allow for

install.

JK DANA 30 axle. The inner sleeve kit will work as per the instructions.

JK DANA 44. The inner and outer kits will work as per the instructions.

It is easier to install the kit with the axle removed or with the vehicle on a hoist. It is

possible to install the kit with the axle installed in the Jeep, but some welds may be

harder to do without being able to move the housing. If the housing is assembled or

has the axle seals in place, welds near the differential housing will need to be done

incrementally in order to keep the heat down so the seals are not damaged. If done

slowly, 1.5”-2” at a time, and cooled in between welds, the seals will be fine.

Installation of the inner sleeve kit

1. Remove the necessary hardware to allow the inner sleeve to slide over the

axle.

2. Pre-drill ½” holes in the axle housing prior to installing the inner sleeve kit. Drill

approximately 10-15 holes in appropriate places to allow a plug weld to take

Installation Instruction RSEI 117

Page 2

place. Be sure to distribute the holes appropriately to receive the maximum

strength.

3. Plug weld the inner sleeve kit into place

4. Weld the end of the inner sleeve to the shaft on the end.

5. Remove any excess weld if needed

Installation of the outer sleeve kit

1. First step is to clean up the axle. Place the Bombshell kit around the axle

and hold in place while you scribe around the perimeter of the shell. Use

these marks to clean up the axle with a flapper disc (or similar) in order to

obtain a clean strong weld.

2. Once you have it cleaned up place the Bombshell kit around the axle

housing and clamp in place.

3. Proceed by welding the kit to the housing. Weld all circular edges fully in

order to gain the strength advantage of the kit. These include the ends of

the pieces and any cutout that wraps around a bracket. On the straight or

axial edges, weld at least 50% of the length in 1.5”-2” sections. These edges

are not as critical to gain the strength. Fully weld the slots between the

upper and long lower piece.

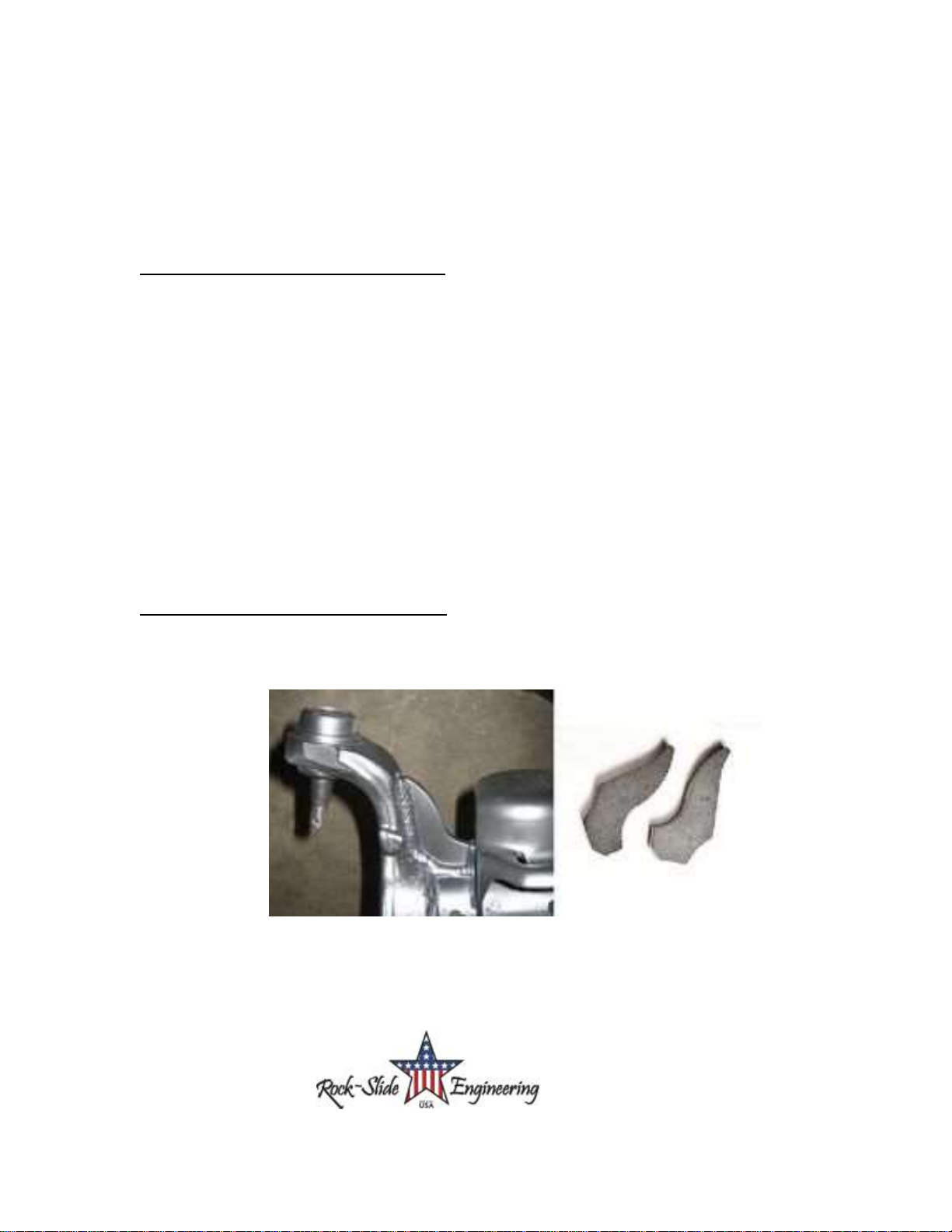

Installation of the knuckle gussets

1. Weld the knuckle gussets in place as shown in the picture below.

Thank you for choosing Rock-Slide Engineering products. We value your business and welcome your

feedback/suggestions. If you have any concerns please contact us directly @ 435-752-4580. We are

here to help you!

Installation Instruction RSEI 117

Loading...

Loading...