Page 1

Ford Raptor/F-150 Slider Installation

SL-F150-4DR, SL-F150-4DRA

SL-F150-2DR-EX, SL-F150-2DR-EXA

Installation Instruction RSEI 137

Page 2

PARTS LIST

DESCRIPTION

1

Drivers Side Slider Assembly

1

Passenger Side Slider Assembly

2

Top Brackets

2

Back brackets

24

7/16” Washers

24

Aluminum Nutserts

14

5/16” SS Button Head Bolts

14

5/16” Stainless Steel Washers

*If any parts listed are missing or damaged please call Rock-Slide Engineering @ 435-752-4580 prior

to installation

SLIDER INSTALLATION

1. Remove the stock rocker panel guards

2. The top bracket will be installed first (If the brackets are not symmetrical make sure

you install the correct bracket on the correct side)

3. The bracket start point is approximately 4 3/8 inches back from the front door seam.

4. Find your starting point and hold the bracket up against the truck. Hold the bracket up

against the truck panel matching the body angles. Position the bracket so that the back

of the bracket is up against the panel seam. This should leave the top of the bracket in

approximately a level position when installed on the truck. Providing a level bracket for

the slider to sit on in the next step:

Installation Instruction RSEI 137

Page 3

Make sure to get the front of the bracket positioned as described in step 3.

a. This works best with two people holding the bracket and a third person marking

the holes

b. With bracket in the correct location, mark the location of the holes with a

marker on the panel of the truck. These will be the locations for the nutserts to

be installed in the body.

5. Carefully drill a 7/32’’ pilot hole into the center of the marked points into the truck’s

rocker side

a. **It is extremely important these holes are drilled precisely to insure the

slider will fit properly once the nutserts have been installed

6. From the center of the pilot hole, step up the hole size using a ½” bit to create a finish

hole that will be used to install the nutserts

7. Install nutserts in the holes that were just drilled into the body of the truck

a. We suggest using a crimping tool to optimize the integrity of the nutserts to

support the slider

b. If no crimping tool is available, follow these instructions

i. Install by using a 5/16’’x1.125’’ minimum length bolt with a 3/8’’ nut

ii. Put a small amount of grease on the bolt to reduce friction

iii. Hold the nut steady with an end wrench so the flange of the insert is flush

against the body panel

iv. Tighten the bolt against the nut to crimp the nutsert into place

v. If the nutsert is rotating, place a star-lock washer between the 3/8’’ nut

and nutsert

vi. Once the nutsert is crimped into place completely back out the bolt

Installation Instruction RSEI 137

Page 4

vii. If the nutsert ever breaks loose and spins, repeat the process and crimp it

tighter to prevent spinning

Nutserts properly installed

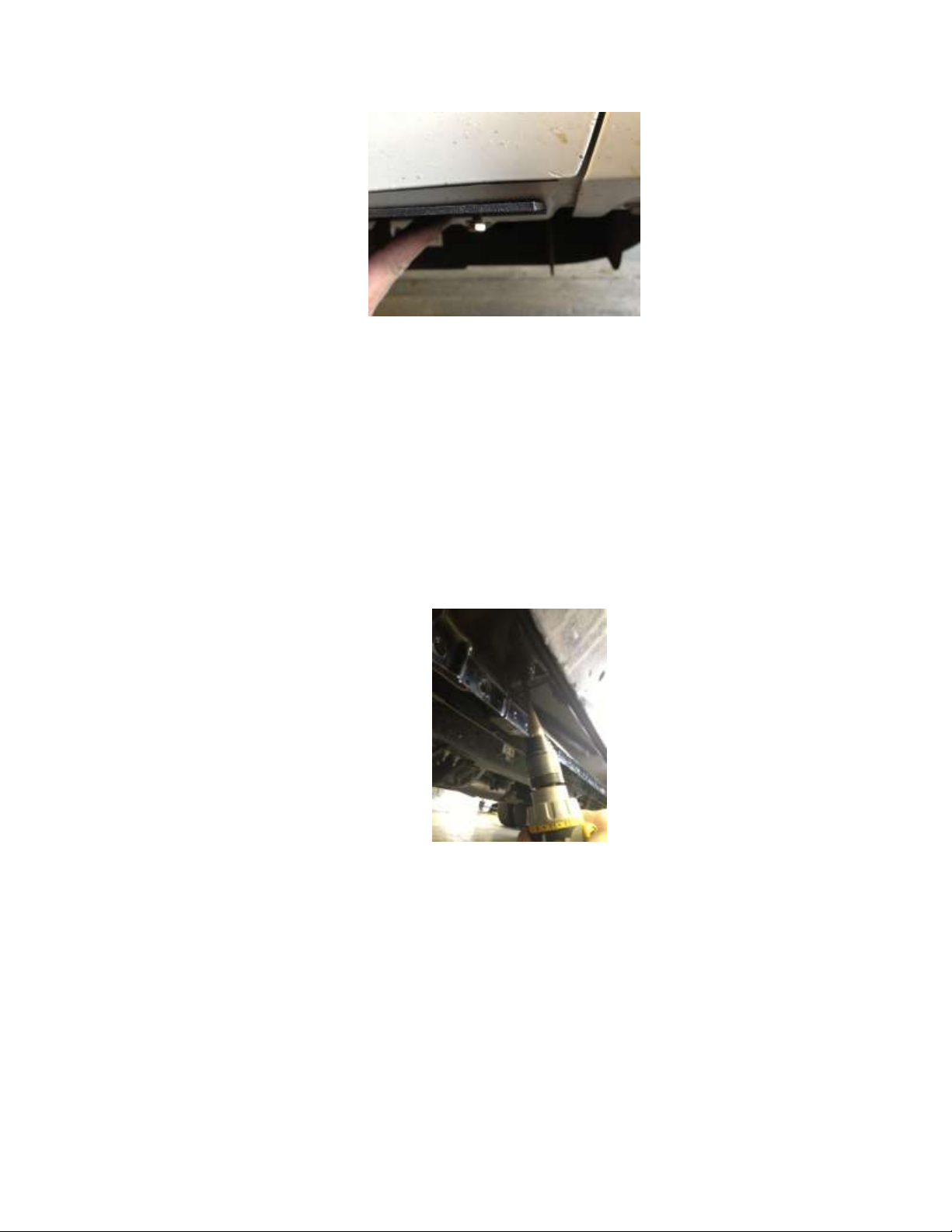

8. Attach the top bracket to the truck

a. Hang bracket on truck and bolt through bracket into the nutserts. Leave bolts

loose until all bolts are installed. Go back and tighten bolts until the bracket is

firm against side of truck

9. Set slider onto installed top bracket

10. Place slider in place and put two countersunk bolts in the matching holes to hold the

slider in place. BE SURE TO TIGHTEN THESE BOLTS. DO NOT OPEN THE DOOR WITH

THESE PARTICALLY INSTALLED IT WILL SCREWUP YOUR DOOR.

a. Make sure you put included anti-seize on bolt, since it is stainless steel and when

stainless steel is bolted into steel it can be hard to remove

11. Attach the back bracket to step slider body with two or three bolts and position it in

place as to where to secure it to the truck. Tighten the bolts to hold it in the desired location.

12. Mark location of holes from back bracket into body of truck

13. Drill 5/16” holes into the pinch seam of the body

14. Remove the slider to enable you to bolt the back bracket onto the truck

15. Bolt back bracket onto truck with provided bolts, nuts and washers. Bolt through the

bracket and pinch seam and put the nuts on the back side of the pinch seam

Installation Instruction RSEI 137

Page 5

16. Tighten all the bolts on the back bracket

17. Attach the slider to the top bracket using the stainless steel bolts. Don’t forget to use

the anti-sieze on each stainless steel bolt

18. Tighten the bolts from the back bracket to the slider body

19. These holes are elongated to allow for any adjustments that need to me made.

20. When the slider is mounted make sure that you have not twisted or manipulated the

shape of the slider with you tightening sequence. THIS WILL CAUSE THE STEP TO NOT

WORK PROPERLY.

21. Double check all bolts to verify components and hardware are installed correctly and

securely to the truck

***Please note: Expect some variance in parts that may require you to adjust the

tension of bolts to make parts fit correctly and properly. Once all parts are installed,

we suggest then fully tightening all bolts again to fit securely***

Thank you for choosing Rock-Slide Engineering products. We value your business and

welcome your feedback/suggestions. If you have any concerns please contact us directly @

435-752-4580. We are here to help you!

Installation Instruction RSEI 137

Loading...

Loading...