Page 1

Ford Super Duty Step Slider Installation

BS-SS-100-SD

Installation Instruction RSEI 141

Page 2

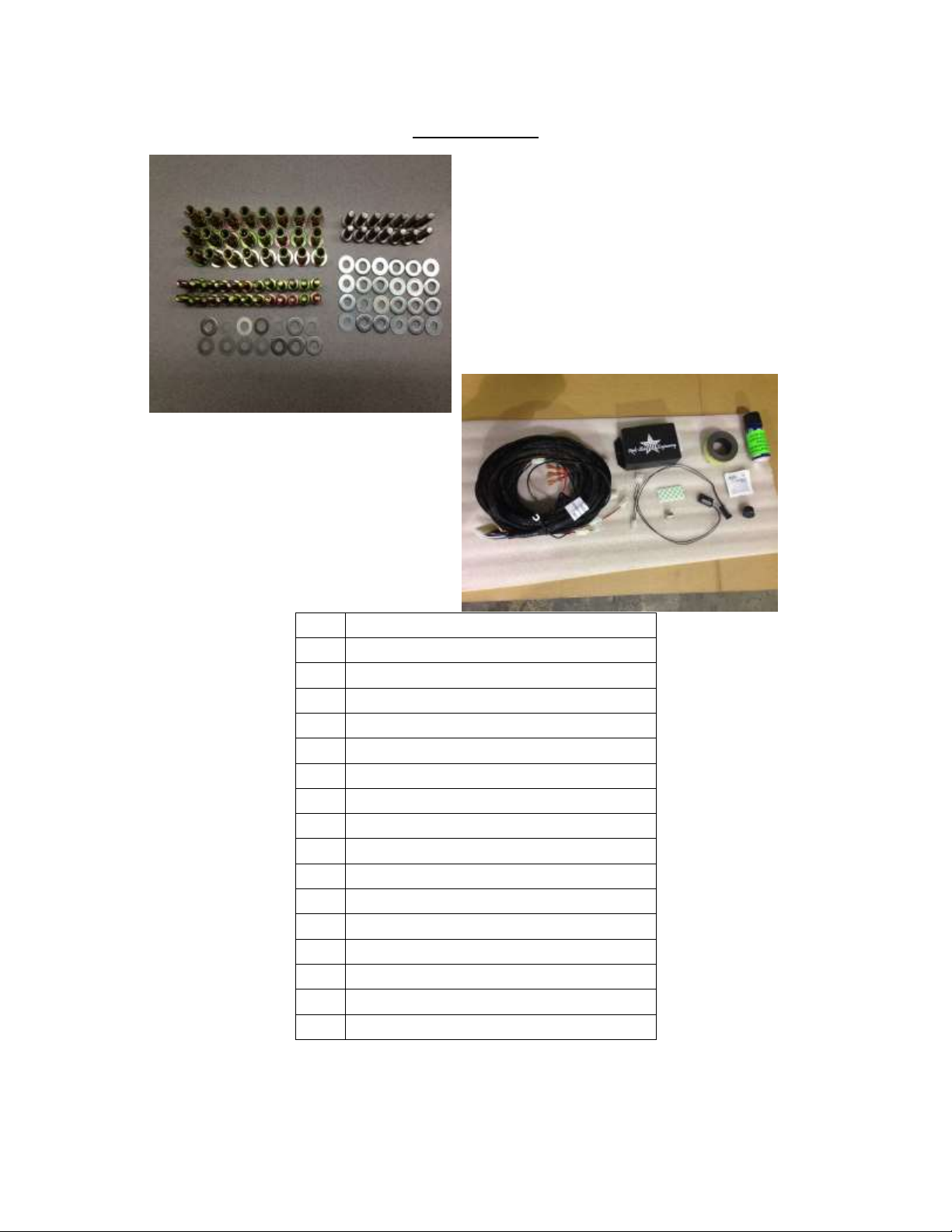

PARTS LIST

DESCRIPTION

1

Drivers Side Slider Assembly

1

Passenger Side Slider Assembly

1

Wiring Harness and Fuse

1

Double Sided Sticky Squares and Alcohol Pad

1

Cut Off Switch

1

Anti-Seize Packet

1

Control Box

2

Top Brackets

2

Back brackets

2

Grip Tape Strips

2

Stiffening Brackets

4

Actuating Magnets and Door Sensors

24

7/16” Washers

24

Aluminum Nutserts

14

5/16” SS Button Head Bolts

14

5/16” Stainless Steel Washers

*Optional: 2 LED Light Strips

*If any parts listed are missing or damaged please call Rock-Slide Engineering @ 435-752-4580 prior

to installation

Installation Instruction RSEI 141

Page 3

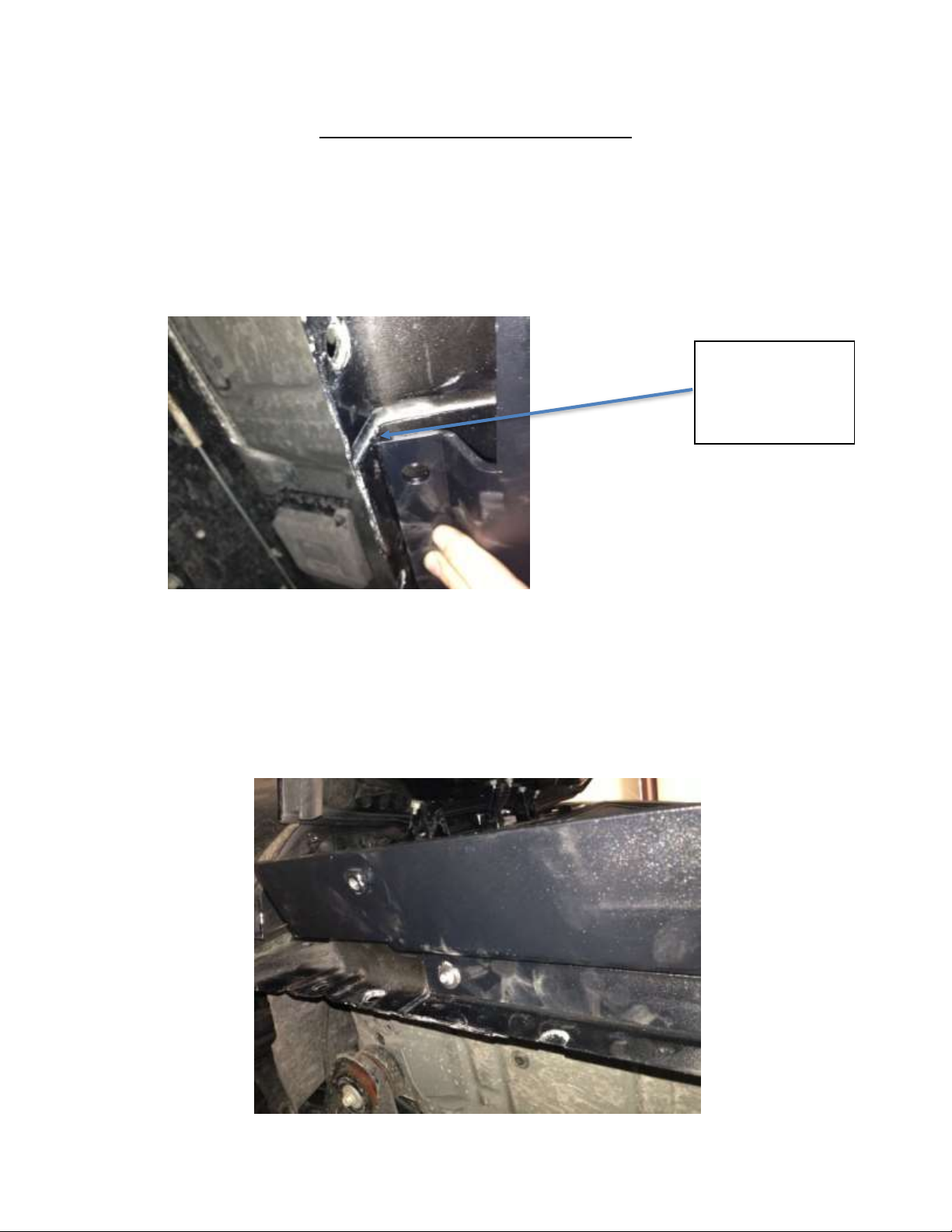

STEP SLIDER INSTALLATION

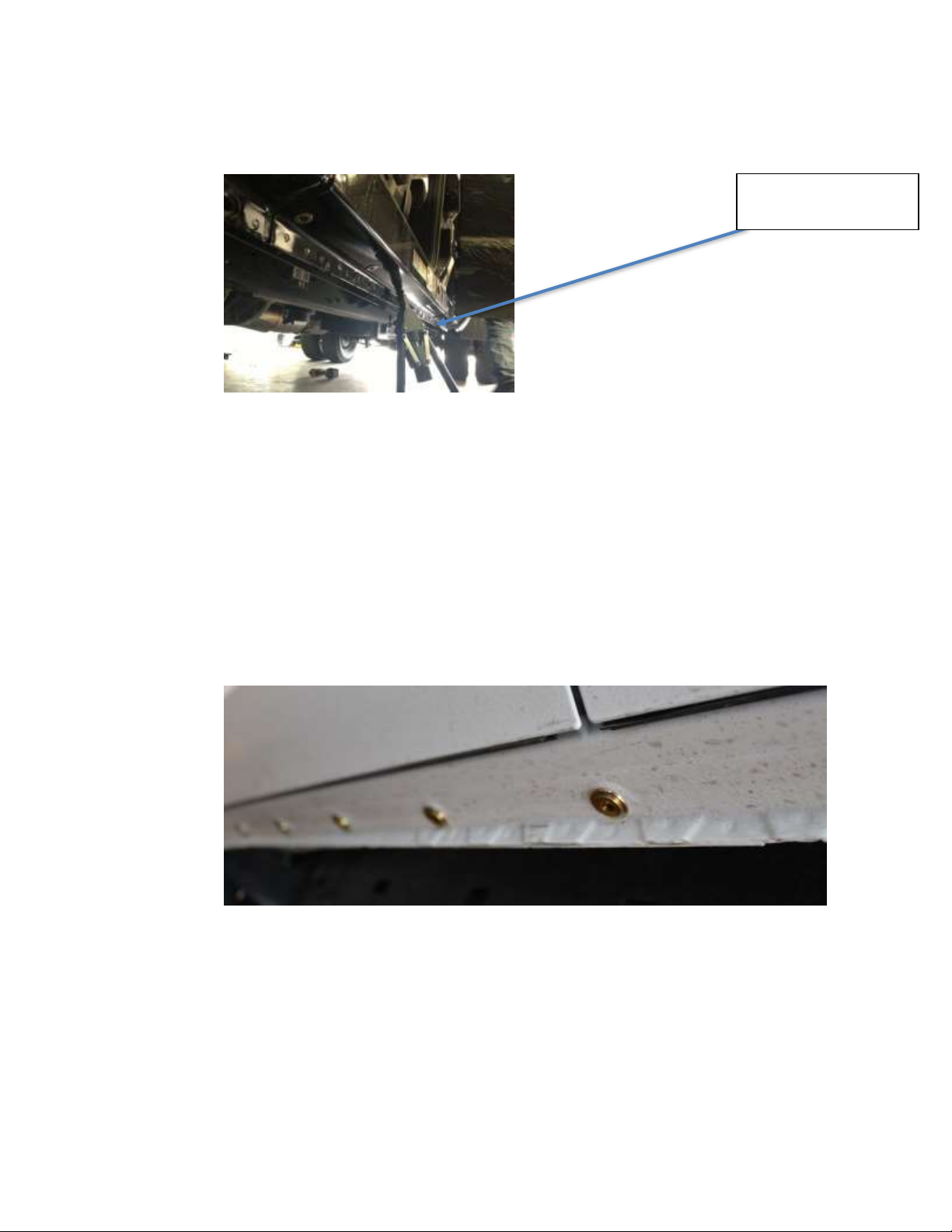

The front of the

bracket almost

touches the

seam

1. Remove the stock rocker panel guards or tube steps if equipped

2. The top bracket will be installed first (If the brackets are not symmetrical make sure

you install the correct bracket on the correct side)

3. The bracket start point is at the body seam near the front door. (see picture below) The

bracket has a lower piece with holes which almost touches the seam. The longer top

part will go beyond the seam.

4. Find your starting point and hold the bracket up against the truck. Hold the bracket up

against the truck panel matching the body angles. Position the bracket so that the back

edge of the bracket is up against the pinch seam. This should leave the top of the

bracket in approximately a level position when installed on the truck. Providing a level

bracket for the slider to sit on in the next step

Installation Instruction RSEI 141

Page 4

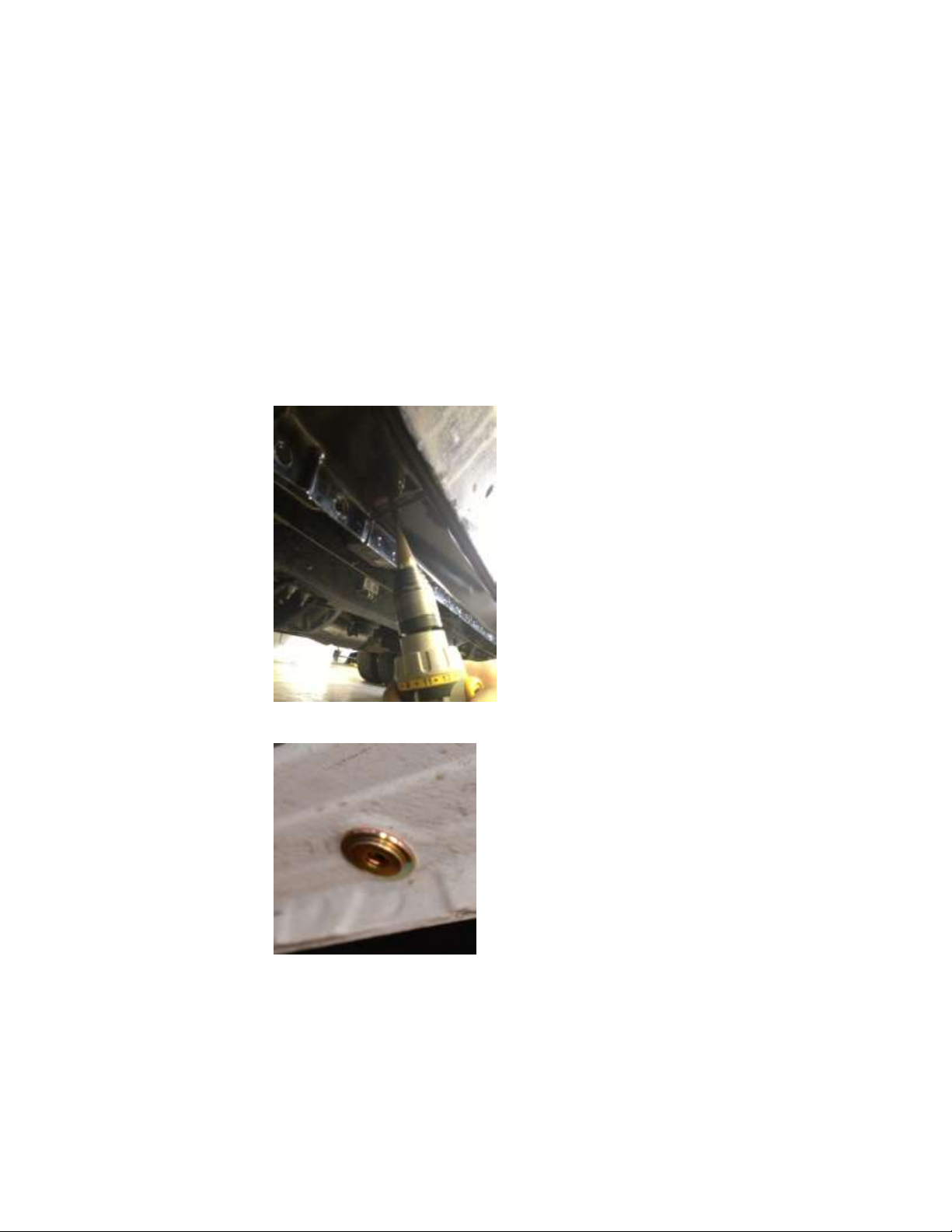

Make sure to get the front of the bracket positioned as described in step 3.

a. This works best with two people holding the bracket and a third person marking

the holes

b. With bracket in the correct location, mark the location of the holes with a

marker on the panel of the truck. These will be the locations for the nutserts to

be installed in the body.

5. Carefully drill a 7/32’’ pilot hole into the center of the marked points into the truck’s

rocker side

a. **It is extremely important these holes are drilled precisely to insure the

slider will fit properly once the nutserts have been installed

6. From the center of the pilot hole, step up the hole size using a ½” bit to create a finish

hole that will be used to install the nutserts

7. Install nutserts and 1/2” washer in the holes that were just drilled into the body of the

truck

Installation Instruction RSEI 141

Page 5

a. We suggest using a crimping tool to optimize the integrity of the nutserts to

We use a Marson

nutsert tool

support the slider

b. If no crimping tool is available, follow these instructions

i. Install by using a 5/16’’x1.125’’ minimum length bolt with a 3/8’’ nut

ii. Put a small amount of grease on the bolt to reduce friction

iii. Hold the nut steady with an end wrench so the flange of the insert is flush

against the body panel

iv. Tighten the bolt against the nut to crimp the nutsert into place

v. If the nutsert is rotating, place a star-lock washer between the 3/8’’ nut

and nutsert

vi. Once the nutsert is crimped into place completely back out the bolt

vii. If the nutsert ever breaks loose and spins, repeat the process and crimp it

tighter to prevent spinning

Installation Instruction RSEI 141

Nutserts properly installed

8. Attach the top bracket to the truck

a. Hang bracket on truck and bolt through bracket into the nutserts. Leave bolts

loose until all bolts are installed. Go back and tighten bolts until the bracket is

firm against side of truck

9. Set step slider onto installed top bracket

Page 6

10. Place step slider in place and put two countersunk bolts in the matching holes to hold

the slider in place. BE SURE TO TIGHTEN THESE BOLTS. DO NOT OPEN THE DOOR

WITH THESE PARTICIALLY INSTALLED IT COULD DAMAGE YOUR DOOR.

a. Make sure you put included anti-seize on bolt, since it is stainless steel and when

stainless steel is bolted into steel it can be hard to remove

11. Attach the back bracket to step slider body with two or three bolts and position it in

place as to where to secure it to the truck. Tighten the bolts to hold it in the desired location.

12. Make sure wires are run from the step slider body through the hole in the back bracket

13. Mark location of holes from back bracket into body of truck

14. Drill 5/16” holes into the pinch seam of the body

15. Remove the step slider to enable you to bolt the back bracket onto the truck

16. Bolt back bracket onto truck with provided bolts, nuts and washers. Bolt through the

bracket and pinch seam and put the nuts on the back side of the pinch seam

17. Tighten all the bolts on the back bracket

Installation Instruction RSEI 141

Page 7

18. Attach the slider to the top bracket using the stainless steel bolts. Don’t forget to use

the anti-sieze on each stainless steel bolt

19. Tighten the bolts from the back bracket to the step slider body

20. These holes are elongated to allow for any adjustments that need to me made.

21. When the slider is mounted make sure that you have not twisted or manipulated the

shape of the slider with you tightening sequence. THIS WILL CAUSE THE STEP TO NOT

WORK PROPERLY.

22. Attach the strengthening bracket.

a. This bracket will stiffen the step slider. Loosen the body mount bolt at the

center of the truck behind the step slider

Installation Instruction RSEI 141

Page 8

b. Slide the bracket behind the washer of the body mount bolt and use the

provided bolt and washer to attach the bracket to the step slider

c. Attach the bottom of the bracket to the step slider assembly using the bolt and

washer provided

23. Double check all bolts to verify components and hardware are installed correctly and

securely to the truck

***Please note: Expect some variance in parts that may require you to adjust the

tension of bolts to make parts fit correctly and properly. Once all parts are installed,

we suggest then fully tightening all bolts again to fit securely***

If you have any questions please contact Rock-Slide Engineering @ 435-752-4580

Installation Instruction RSEI 141

Page 9

WIRING HARNESS INSTALL

Step Slider Wiring Diagram

Driver Side Wire Color Passenger Side Wire Color

Front Door Sensor Orange/Yellow Front Door Sensor Green/Gray

Rear Door Sensor Orange/Pink Door Sensor Blue/White

Driver LED Light Brown/Tan Passenger LED Light Pink/Tan

Driver Actuator Red/Black Passenger Actuator Red/Black

**WARNING**

REMOVE FUSE FROM WIRING HARNESS PRIOR TO INSTALLATION! CONNECTING

THE HARNESS TO THE POWER SOURCE WITH THE FUSE ATTACHED MAY SHORT

OUT THE WIRING HARNESS.

NEVER ALLOW THE DOOR SENSOR TO COME INTO DIRECT CONTACT WITH THE

ACTUATING MAGNET. THIS WILL DESTROY THE SENSOR MAKING IT UNUSABLE.

Installation Instruction RSEI 141

Page 10

1. Remove the sill plate covers on both driver and passenger rear doors

2. Lay out the wiring harness on the carpet in the back seat

3. Split the harness into the driver’s and passenger side as instructed above.

4. Position the control box under the rear seat or near the back of the cab, anywhere out of

the way where the wiring harness will fit to both sides of the truck.

a. Choose a location out of sight and in a secure spot so it will not come into contact

with anything or be kicked by a rear seat passenger

5. Plug the harness into the control box and lay the harness wire into position in the truck

starting on the rear passenger side

a. You will want to divide the harness between the rear seats, the front passenger

seat and finish with the driver door. This will reveal how you will be able to

conceal the harness under the carpet when your done

6. Once the harness is positioned in its proposed layout you will need to gain access to the

slider outside the truck to power the slider.

7. Starting on the rear passenger side, run the actuator wires up through the floor of the

vehicle. THIS MAY REQUIRE YOU TO DRILL AN ACCESS HOLE DEPENDING ON MODEL

AND YEAR. Connect the red/black connector on the wiring harness.

a. Secure wires to minimize slack so they are protected. We recommend zip ties

b. *Optional: The pink/tan wire is used if LED light package is being installed

8. Inside the truck, route the rear passenger door sensor wire along the doorframe; and

using a sticky pad, mount the sensor underneath the door latch

Installation Instruction RSEI 141

Page 11

a. Pull the rubber door seal away from near the latch and run the sensor wires

under the seal.

b. Connect the blue/white wire to the door sensor

c. Place a small piece of electrical tape on the sensor wire to secure the wire from

the truck and protect it on the metal seam

9. While moving to the front passenger door, run the harness under the door sill. Just as

for the back door, route the front passenger door sensor wire up near the latch and

under the door seal.

a. Connect the green/grey wire to door sensor

b. Place a small piece of electrical tape on the sensor wire to secure

10. Returning to the backseat, complete the driver’s side. Run the actuator wires from the

step slider through the floor of the vehicle and plug into the wiring harness. Plug into

the red/black connector into the wiring harness.

a. Secure wires to minimize slack so they are protected. We recommend zip ties

b. *Optional: The brown/tan wire is used if LED light package is being installed

11. Route the rear driver’s side door sensor wire along the doorframe; and using a sticky

pad, mount the sensor underneath the door latch

a. Connect the orange/pink wire to the door sensor

b. Place a small piece of electrical tape on the sensor wire to secure

12. Continue to route the harness wires along the door sill and just like performed on the

passenger side route the door sensor wire up the doorframe and using another sticky

pad, mount the sensor below the door hatch.

a. Connect the orange/yellow wire to the door sensor

b. Place a small piece of electrical tape on the sensor wire to secure

Installation Instruction RSEI 141

Page 12

13. Drill an 18 mm hole to mount the cutoff switch. We recommend above the emergency

break release (see picture below).

14. Mount the ground from the cutoff switch to a metal surface behind dash panel

15. Route the cutoff switch wires by running the POS+ and NEG- wires rom the wiring

harness plug them into the back of the cutoff switch

THE BRASS COLORED PRONG IS FOR THE GROUND THE SILVER COLORED IS FOR THE POWER

16. Route the remaining POS+ and NEG- wires through the firewall on the driver’s side into

the engine compartment. YOU MAY NEED TO DRILL A HOLE THROUGH THE FIREWALL

INTO ENGINE COMPARTMENT

a. Make sure there is NO INTERFERENCE with any of the pedal linkage under the

dash

17. Route these wires along the firewall up to the battery compartment

a. Secure the wires using the harness attached to the firewall

18. Attach the NEG- to the NEG- side of the battery

Installation Instruction RSEI 141

Page 13

19. Attach the POS+ to the POS+ side of the battery

20. Position the actuating magnets on the catch side of each door

a. Make sure the actuating magnets are in perfect line with the sensors

b. **DO NOT allow the magnet and sensor to come into direct contact. This

will destroy the sensor making it unusable**

c. Once that proper placement is achieved we recommend using a permanent

marker to outline the magnet on the door.

21. Re-check all wires to make sure they are completely secure and free from coming into

contact with any moving part to prevent system damage due to a cut wire

22. Reinstall all internal plastic and carpet pieces that were removed.

23. Make sure that all wires are tucked back and out of heavy traffic areas on the floor.

a. Route them toward the furthest back area underneath the rear seat

24. Close all doors

25. Insert the fuse into the holder on the POS+ side of the battery

26. Get in the vehicle. Start it and then turn the cutoff switch into the ON position. The red

Led light should come on. The system is now active. Wait for 10 seconds so the system

can check the system. Open your door and the step will actuate.

Installation Instruction RSEI 141

Page 14

MAINTENANCE OF THE STEP SLIDER

Please note the slider is a mechanical mechanism that requires maintenance to operate

properly. To keep the slider operating at an optimal level it needs to be maintained

with lubrication. We recommend using a Teflon based lubrication on the 7 indicated

points below to keep the slider operating smoothly. A good rule of thumb is every time

you change your engine oil. Heavy trail use will increase the frequency in lubrication.

TROUBLE SHOOTING/FRICTION POINTS

The slider is powered by the truck’s battery when engine is off and powered by the

Truck’s engine while the vehicle is running. This will cause the slider to operate at

different speeds depending on if the truck engine is running or not.

If you feel the slider is sticking at certain points or the motor is stressing it may be

possible a friction point has developed during the install due to a variance in the slider

or truck’s construction

o To identify a friction point that may be stressing the slider motor, look at the

slider from outside the truck and open and shut the truck door a couple of times

and study the way the slider operates. Look at the slider for wear in the powder

coating. The slider leaves our manufacturing facility with a perfect powder

coating so if you see a spot on the slider that has scratches or the powder coating

shows a blemish; that’s a good indication of a friction point. Using a file or other

grinding tool to smooth over a small area on the slider can alleviate this

problem.

Thank you for choosing Rock-Slide Engineering products. We value your business and

welcome your feedback/suggestions. If you have any concerns please contact us directly @

435-752-4580. We are here to help you!

Installation Instruction RSEI 141

Loading...

Loading...