Rockford Fosgate SSC-500 Installation Manual

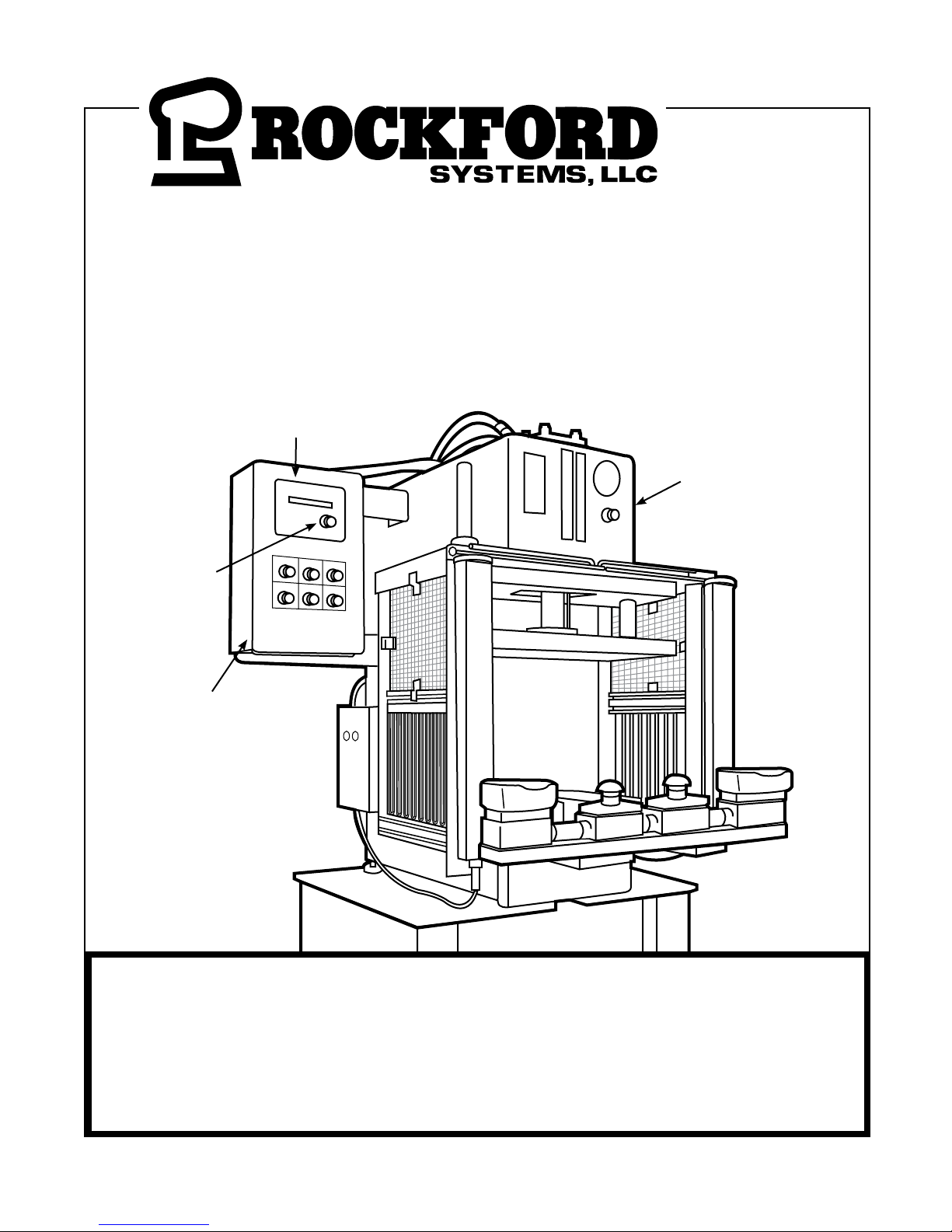

INSTALLATION MANUAL FOR

SSC-500 CONTROL SYSTEMS

ON HYDRAULIC PRESSES

Operator Interface

Keypad/Display

SSC-500 Control Box

Program/Run

Selector Switch

(Not Shown)

Remote Operator

Station (Optional)

IMPORTANT: PLEASE REVIEW THIS ENTIRE

PUBLICATION BEFORE INSTALLING, OPERATING OR

MAINTAINING THE SOLID-STATE HYDRAULIC PRESS

ELECTRICAL CONTROL SYSTEM.

5795 Logistics Parkway • Rockford, Illinois 61109 • Toll Free 1-800-922-7533 (USA only) • Phone (815) 874-7891

Fax (815) 874-6144 • Web Site: www.rockfordsystems.com • E-Mail: sales@rockfordsystems.com

Manual No. KSL-249

TABLE OF CONTENTS

SSC-500 Hydraulic Press Solid-State Control

SECTION 1—IN GENERAL ..................................................3 - 9

SE CTION 2—INTRODUCTION .........................................10 - 14

SE CTION 3—INSTALLATION OF SSC-500 CONTROL SYSTEM

COMPONENTS ............................................................14 - 24

Literature Packetr ...................................................... 14 - 15

Control Box ............................................................... 15 - 18

P alm Button Assembly ............................................... 18 - 20

Foot Switch (Optional) ........................................................20

Supervisory Control Station ................................................21

Presence Sensing Device ...................................................21

Main Power Disconnect Switch ..........................................22

Motor Starter ....................................................................22

Custom or Special Control Box ...........................................22

Flywheel and Gear Covers ..................................................22

Collateral Equipment ..........................................................22

Point-of-Operation Safeguards ...........................................22

Other Installation Considerations .................................23 - 24

SECTION 4—PROGRAMMING ........................................24 - 33

Setup of Control System .......................................................24

Initial Setup Procedure ........................................................24

Programming Overview .........................................................25

Clear Stroke ......................................................................26

Clear Batch .......................................................................27

Batch Preset .....................................................................27

Bottom Dwell ....................................................................28

Decompress Timerl ...........................................................28

Anti-tiedown ms ................................................................29

Single Return Mode ...........................................................28

Asing tmr sec ....................................................................29

PSDI Timer........................................................................30

Asing Mode.......................................................................30

Asing Timer ......................................................................31

User Inputs ...............................................................31 - 32

Options edit ......................................................................33

SECTION 5—PSDI ....................................................................34

SECTION 6—OPERATING CONSIDERATIONS ..............................35

SECTION 7—FAULT MESSAGES ....................................36 - 37

SECTION 8—MAINTENANCE & INSPECTION ..................... 38 - 39

SE CTION 10—LAYOUT SKETCH ...............................................42

SE CTION 11—RETURN AUTHORIZATION FORM ......................43

SE CTION 12—ORDER FORM ....................................................44

FIGURES, PHOTOS, AND TABLES

Figure 2.1 Block Diagram ........................................................12

Figure 4.1 Initial Setup Procedure Flowchart .............................24

Figure 4.2 Initial Information on Display ....................................24

Figure 4.3 Main Program Menu Flowchart ................................25

Figure 4.4 Clear Stroke Flowchart ............................................26

Figure 4.5 Clear Batch Flowchart .............................................26

Figure 4.6 Batch Preset Flowchart ............................................27

Figure 4.7 Bottom Dwell Flowchart ...........................................27

Figure 4.8 Anti-tiedown Flowchart ............................................28

Figure 4.9 Asingle Mode Flowchart ..........................................28

Figure 4.10 Asingle Tmr Flowchart ...........................................29

Figure 4.11 User Input Fault Messages Chart ............................29

Figure 4.12 Input # 1 - 4 Flowchart .........................................30

Figure 4.10 Speed Change Flowchart .......................................31

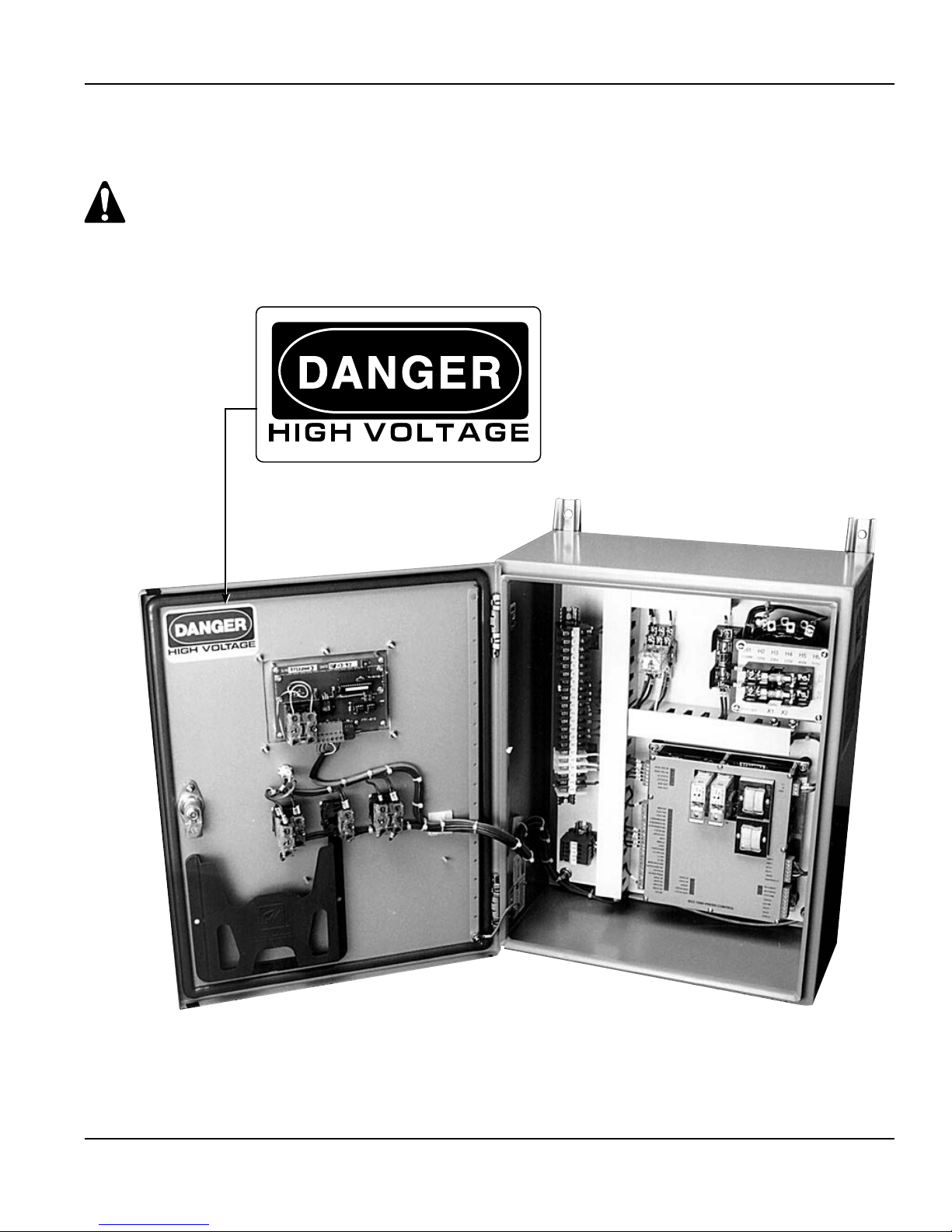

Photo 1.1 Inside view of Control box ...........................................8

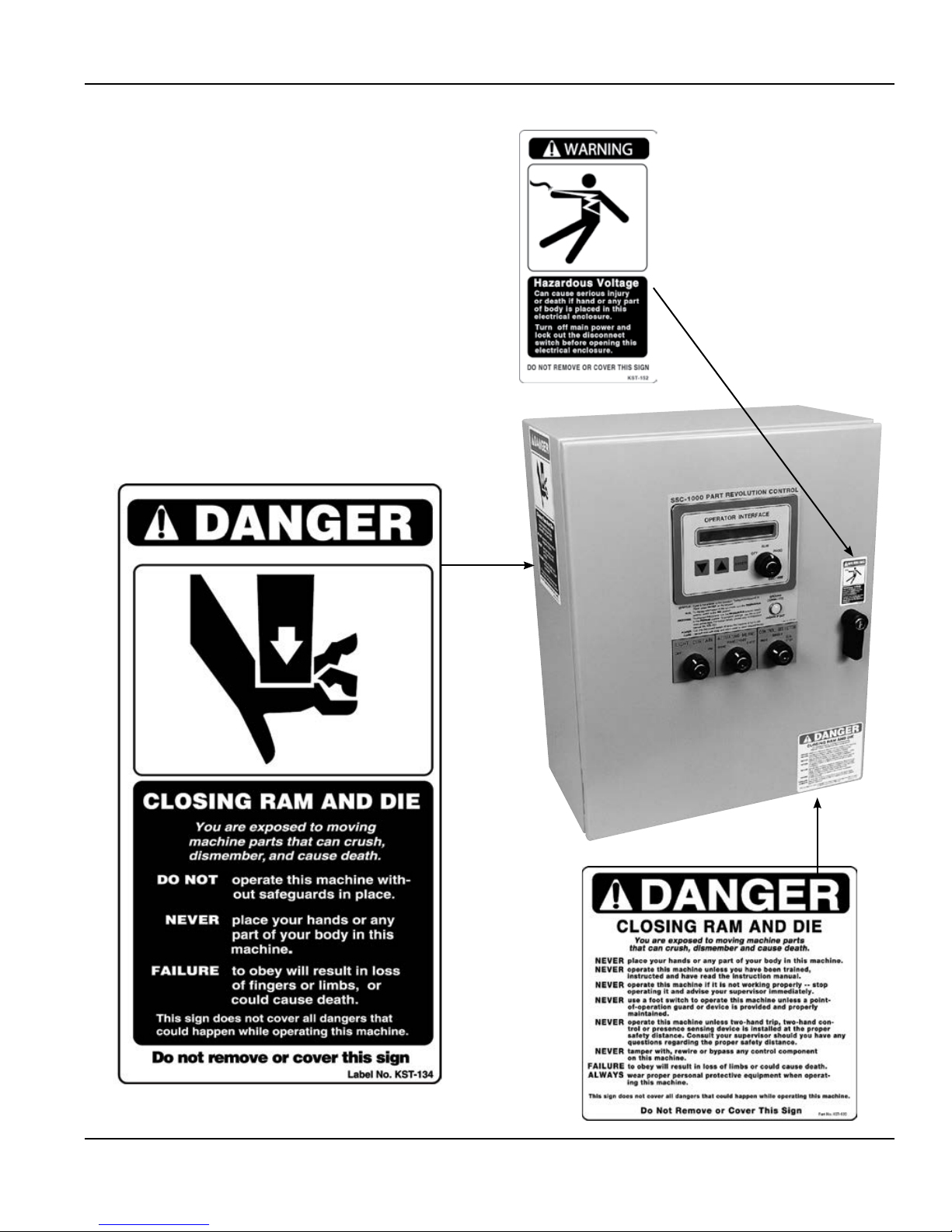

Photo 1.2 Control box with danger labels ....................................9

Photo 3.1 Standard control box with keypad/display .....................15

Photo 3.2 Inside view of standard control box ...........................15

Photo 3.3 Top view of control module with cover.......................16

Photo 3.4 Top view of control module without cover ....................16

Photo 3.5 Operator interface keypad .........................................17

Photo 3.6 Back side of keypad/display ......................................18

Photo 3.7 Palm button assembly ..............................................18

Photo 3.8 Red emergency stop palm button ..............................19

Photo 3.9 Yellow emergency return inch up ..............................20

Photo 3.10 Prior-action pushbutton stations ..............................20

Photo 3.11 Foot switch ............................................................20

Photo 3.12 Supervisory control station ......................................21

Photo 7.1 Main EPROM ...........................................................36

Table 3.1 Depth Penetration Factor ..........................................21

Table 4.1 Quick Reference Table ..............................................25

Table 6.1 Fatal Fault Messages ....................................... 33 - 34

Table 6.2 General Fault Messages ...........................................34

SECTION 9—METHODS OF SAFEGUARDING ...................... 40 - 41

© 2019 Rockford Systems, LLC All rights reserved. Not to be reproduced in whole or in part without written permission. Litho in U.S.A.

2 Call: 1-800-922-7533

Rockford Systems, LLC

DANGER

Safety Precautions

DANGER

SECTION 1 — IN GENERAL

SSC-500 Hydraulic Press Solid-State Control

“ ”

Danger is used to indicate the presence of a hazard which WILL cause SEVERE

personal injury if the warning is ignored.

“ ”

THIS SAFETY ALERT SYMBOL IDENTIFIES IMPORTANT SAFETY MESSAGES IN THIS MANUAL.

WHEN YOU SEE THIS SYMBOL , BE ALERT TO THE POSSIBILITY OF PERSONAL INJURY, AND

CAREFULLY READ THE MESSAGE THAT FOLLOWS.

Efficient and safe machine operation depends on the development, implementation and enforcement of a safety program. This program requires,

among other things, the proper selection of point-of-operation guards and safety devices for each particular job or operation and a thorough safety

training program for all machine personnel. This program should include instruction on the proper operation of the machine, instruction on the

point-of-operation guards and safety devices on the machine, and a regularly scheduled inspection and maintenance program.

Rules and procedures covering each aspect of your safety program should be developed and published both in an operator’s safety manual, as

well as in prominent places throughout the plant and on each machine. Some rules or instructions which must be conveyed to your personnel and

incorporated into your program include:

DANGER

Never place your hands or any part of your body in this machine.

Never operate this machine without proper eye, face and body protection.

Never operate this machine unless you are fully trained, instructed, and you have read the instruction manual.

Never operate this machine if it is not working properly—stop operating and advise your supervisor immediately.

Never use a foot switch to operate this machine unless a point-of-operation guard or device is provided and

properly maintained.

Never operate this machine unless two-hand trip, two-hand control or presence sensing device is installed at the proper

safety distance. Consult your supervisor should you have any questions regarding the proper safety distance.

Never tamper with, rewire or bypass any control or component on this machine.

A company’s safety program must involve everyone in the company, from top management to operators, since only as a group can any operational

problems be identified and resolved. It is everyone’s responsibility to implement and communicate the information and material contained in catalogs

and instruction manuals to all persons involved in machine operation. If a language barrier or insufficient education would prevent a person from

reading and understanding various literature available, it should be translated, read or interpreted to the person, with assurance that it is understood.

FOR MAINTENANCE AND INSPECTION ALWAYS REFER TO THE OEM’s (ORIGINAL EQUIPMENT

MANUFACTURER’S) MAINTENANCE MANUAL OR OWNER’S MANUAL. If you do not have an owner’s

manual, please contact the original equipment manufacturer.

Rockford Systems, LLC

Call: 1-800-922-7533 3

SECTION 1 — IN GENERAL

SSC-500 Hydraulic Press Solid-State Control

Safety References

OSHA’S ACT AND FEDERAL REGULATIONS

Since the enclosed equipment can never overcome a mechanical deficiency, defect or malfunction in the machine itself, OSHA (Occupational

Safety and Health Administration) has established certain safety regulations that the employers (users) must comply with so that the machines

used in their plants, factories or facilities are thoroughly inspected

and are in first-class operating condition before any of the enclosed

equipment is installed.

1. An Act – Public Law 91 - 596, 91st Congress, S. 2193,

December 29, 1970

Duties:

Sec. 5. (a) Each employer —

(1) shall furnish to each of his employees employ-

ment and a place of employment which are free from recognized hazards that are causing or are likely to cause death or

serious physical harm to his employees;

(2) shall comply with occupational safety and health standards

promulgated under this Act.

(b) Each employee shall comply with occupational safety and

health standards and all rules, regulations, and orders issued

pursuant to this Act which are applicable to his own actions

and conduct.

2. OSHA’s Code of Federal Regulations, Subpart O, that an

employer (user) must comply with include:

Section 1910.211 Definitions

Se ction 1910.212 (a) General Requirements for all Machines

Section 1910.217 Mechanical Power Presses

Se ction 1910.219 (b)(1) Mechanical Power-Transmission Apparatus

(Flywheel and Gear Covers)

3. OSHA’s 29 Code of Federal Regulations, Subpart J 1910.147

The Control of Hazardous Energy (Lockout / Tagout)

4. OSHA’s Publications

“General Industry Safety and Health Regulations Part 1910,” Code

of Federal Regulations, Subpart O

“Concepts and Techniques of Machine Safeguarding,” OSHA 3067,

Revised 1992

These publications can be obtained by contacting:

Superintendent of Documents

US Government Printing Office

P.O. Box 371954

Pittsburgh, PA 15250-7954

Phone: (202) 512-1800

Fax: (202) 512-2250

www.gpo.gov

ANSI SAFETY STANDARDS FOR MACHINES

The most complete safety standards for machine tools are published

in the ANSI (American National Standards Institute) B11 series. The

following is a list of each ANSI B11 Standard available at the printing

of this publication.

B11.1 Mechanical Power Presses

B11.2 Hydraulic Presses

B11.3 Power Press Brakes

B11.4 Shears

B11.5 Iron Workers

B11.6 Lathes

B11.7 Cold Headers and Cold Formers

B11.8 Drilling, Milling and Boring

B11.9 Grinding Machines

B11.10 Sawing Machines

B11.11 Gear Cutting Machines

B11.12 Roll Forming and Roll Bending

B11.13 Automatic Screw/Bar and Chucking

B11.14 Coil Slitting Machines

B11.15 Pipe, Tube and Shape Bending

B11.16 Metal Powder Compacting Presses

B11.17 Horizontal Hydraulic Extrusion Presses

B11.18 Coil Processing Systems

B11.19 Performance Criteria for the Design, Construc-tion, Care

and Operation of Safeguards as Referenced in the Other

B11 Machine Tool Safety Standards

B11.20 Safety Requirements for Manufacturing Sys-tems/Cells

B11.21 Lasers

B11.22 CNC Turning Machines

B11.23 Machining Centers

B11/TR1 Ergonomic Considerations for the Design, Installation and

Use of Machine Tools

B11/TR2 Mist Control

B11/TR3 Hazard ID and Control

B11/TR4 Control Reliability

R15.06 Robotic Safeguarding

These standards can be purchased by contacting:

American National Standards Institute, Inc.

11 West 42nd Street

New York, New York 10036

Phone: (212) 642-4900

Fax: (212) 302-1286

www.ansi.org

OR

Association of Manufacturing Technology (AMT)

7901 Westpark Drive

McLean, Virginia 22102

Phone: (703) 827-5211

Fax: (703) 893-1151

www.mfgtech.org

4 Call: 1-800-922-7533

(Continued on next page.)

Rockford Systems, LLC

SECTION 1 — IN GENERAL

SSC-500 Hydraulic Press Solid-State Control

NATIONAL SAFETY COUNCIL SAFETY MANUALS AND DATA

SHEETS

Other good references for safety on machine tools are the National

Safety Council’s Safety Manuals and Data Sheets. These manuals and

data sheets are written by various committees including the Power

Press, Forging and Fabricating Executive Committee. Copies of the

following publications are available from their library:

Manuals

Power Press Safety Manual - 4th Edition

Safeguarding Concept Illustrations - 6th Edition

Forging Safety Manual

Data Sheets

Bench and Pedestal Grinding Wheel Operations 12304-0705

Boring Mills, Horizontal Metal 12304-0269

Boring Mills, Vertical 12304-0347

Coated Abrasives 12304-0452

Cold Shearing Billets and Bars in the Forging Industry

12304-0739

Degreasing (Liquid), Small Metal Parts 12304-0537

Dies, Setup and Removal of Forging Hammer 12304-0716

Drill Presses, Metalworking 12304-0335

Drills, Portable Reamer 12304-0497

Drop Hammers, Steam 12304-0720

Electrical Controls for Mechanical Power Presses 12304-0624

Forging Hammer Dies, Setup and Removal of 12304-0716

Forging Presses, Mechanical 12304-0728

Gear-Hobbing Machines 12304-0362

Handling Materials in the Forging Industry 12304-0551

Kick (Foot) Presses 12304-0363

Lathes, Engine 12304-0264

Milling Machines, Metalworking 12304-0364

Planers, Metal 12304-0383

Power Press (Mechanical) Point-of-Operation Safeguarding, Concepts of

12304-0710

Power Press Point-of-Operation Safeguarding: Two-Hand Control and

Two-Hand Tripping Devices 12304-0714

Power Press Point-of-Operation Safeguarding: Type A and B Movable Barrier

Devices 12304-0712

Power Press Point-of-Operation Safeguarding: Point-of-Operation Guards

12304-0715

Power Press Point-of-Operation Safeguarding:

Presence Sensing Devices 12304-0711

Power Press Point-of-Operation Safeguarding:

Pullbacks and Restraint Devices 12304-0713

Power Presses (Mechanical), Inspection and

Maintenance of 12304-0603

Power Presses (Mechanical), Removing Pieceparts

from Dies in 12304-0534

Power Press, Setting Up and Removing Dies 12304-0211

Press Brakes 12304-0419

Robots 12304-0717

Saws, Metal (Cold Working) 12304-0584

Shapers, Metal 12304-0216

Shears, Alligator 12304-0213

Shears, Squaring, Metal 12304-0328

Upsetters, 12304-0721

Copies of these manuals and data sheets can be obtained by contacting:

National Safety Council

1121 Spring Lake Drive

Itasca, IL 60143-3201

1-800-621-7619 ext. 2199

Fax: (630) 285-0797

www.nsc.org

OTHER SAFETY SOURCES

National Institute of Occupational Safety and Health (NIOSH)

4676 Columbia Parkway

Cincinnati, OH 45226

Phone: (513) 533-8236

Robotic Industries Association (RIA)

P.O. Box 3724

Ann Arbor, MI 48106

Phone: (734) 994-6088

www.robotics.org

For additional safety information and assistance in devising,

implementing or revising your safety program, please contact the

machine manufacturer, your state and local safety councils, insurance

carriers, national trade associations and your state’s occupational

safety and health administration.

Warranty, Disclaimer and Limitation of Liability

Rockford Systems, LLC warrants that this product will be free from defects in material and workmanship for a period of 12 months from the date of shipment

thereof. ROCKFORD SYSTEMS LLC’S OBLIGATION UNDER THIS WARRANTY IS EXPRESSLY AND EXCLUSIVELY LIMITED to repairing or replacing such products

which are returned to it within the warranty period with shipping charges prepaid and which will be disclosed as defective upon examination by Rockford

Systems, LLC This warranty will not apply to any product which will have been subject to misuse, negligence, accident, restriction and use not in accordance

with Rockford Systems, LLC’s instructions or which will have been altered or repaired by persons other than the authorized agent or employees of Rockford

Systems, LLC Rockford Systems, LLC’s warranties as to any component part is expressly limited to that of the manufacturer of the component part.

DISCLAIMER

The foregoing Warranty is made in lieu of all other warranties, expressed or

implied, and of all other liabilities and obligations on the part of Rockford

Systems, LLC, including any liability for negligence, strict liability, or otherwise,

and any implied warranty of merchantability or fitness for a particular purpose

is expressly disclaimed.

Rockford Systems, LLC

Call: 1-800-922-7533 5

WARRANTY

LIMITATION OF LIABILITY

Under no circumstances, including any claim of negligence, strict liability, or otherwise,

shall Rockford Systems, LLC be liable for any incidental or consequential damages, or

any loss or damage resulting from a defect in the product of Rockford Systems, LLC

(Continued on next page.)

SECTION 1 — IN GENERAL

SSC-500 Hydraulic Press Solid-State Control

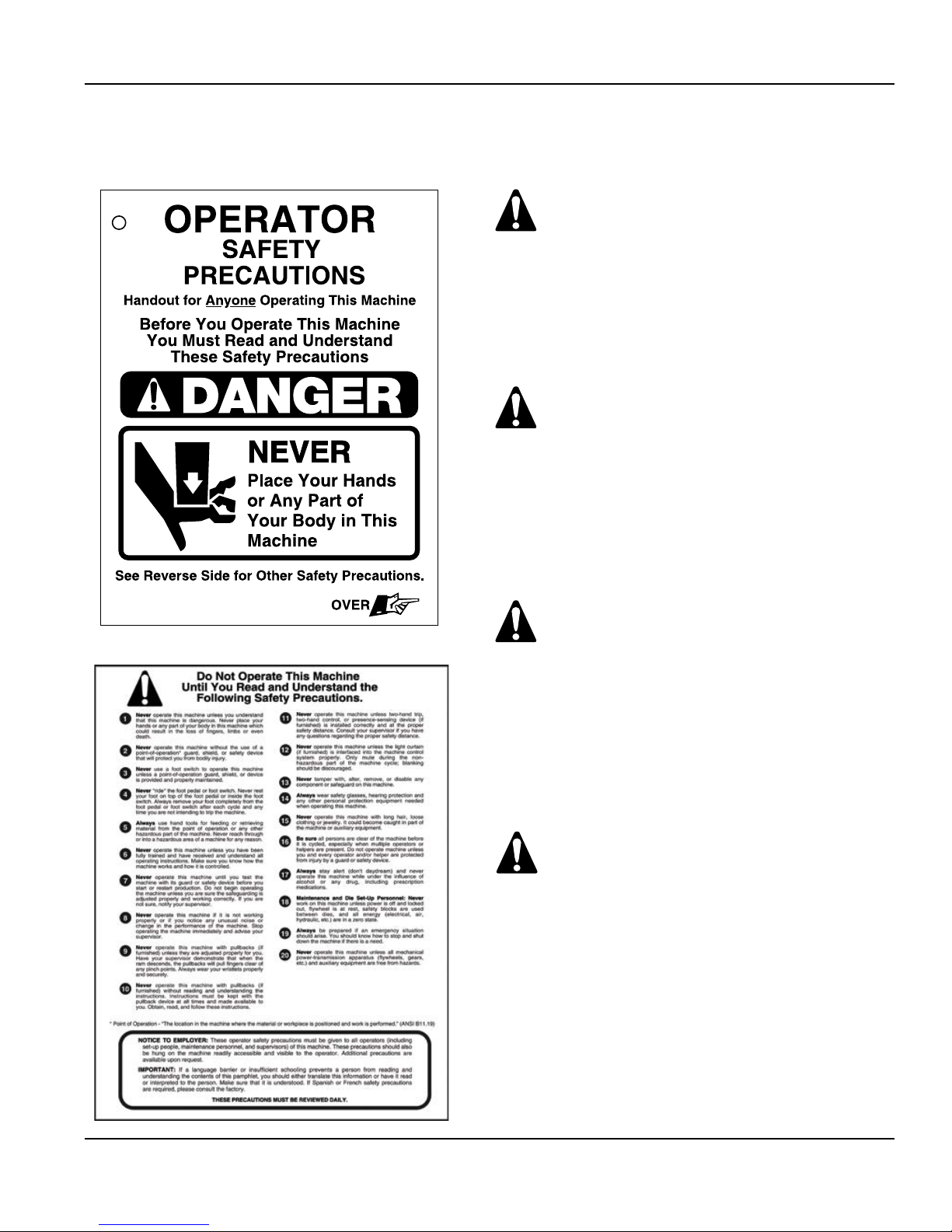

Operator Safety Precaution Pamphlet - (Attachment for machine operators)

Accompanying this equipment is an 8-1/2” x

11” operator safety precaution pamphlet, Part

No. KSC-000, for anyone operating the machine

where this equipment will be installed. This

precaution pamphlet is to be given to all operators, including setup people, maintenance

personnel and supervisors.

This pamphlet should also be attached to the

machine, readily accessible and visible to the

operator. (A hole in the corner of this precaution pamphlet is provided for attaching purposes.) Additional copies of this precaution

are available. Please call, e-mail, write, fax,

or use the order form found on a later page in

this manual.

Part No. KSC-000

Front

When a language barrier or insufficient education prevents a person from reading or

understanding the contents of this operator

safety precaution pamphlet, you should either

translate this information or have it read or

interpreted to the person. Make sure that the

person understands the information. To order

this pamphlet in Spanish, use Part No. KSC000S; in French, use Part No. KSC-000F.

This precaution pamphlet must be reviewed daily.

Back

6 Call: 1-800-922-7533

(Continued on next page.)

Rockford Systems, LLC

SECTION 1 — IN GENERAL

OPERATOR

SAFETY PRECAUTIONS

Handout for Anyone Operating This Machine

SSC-500 Hydraulic Press Solid-State Control

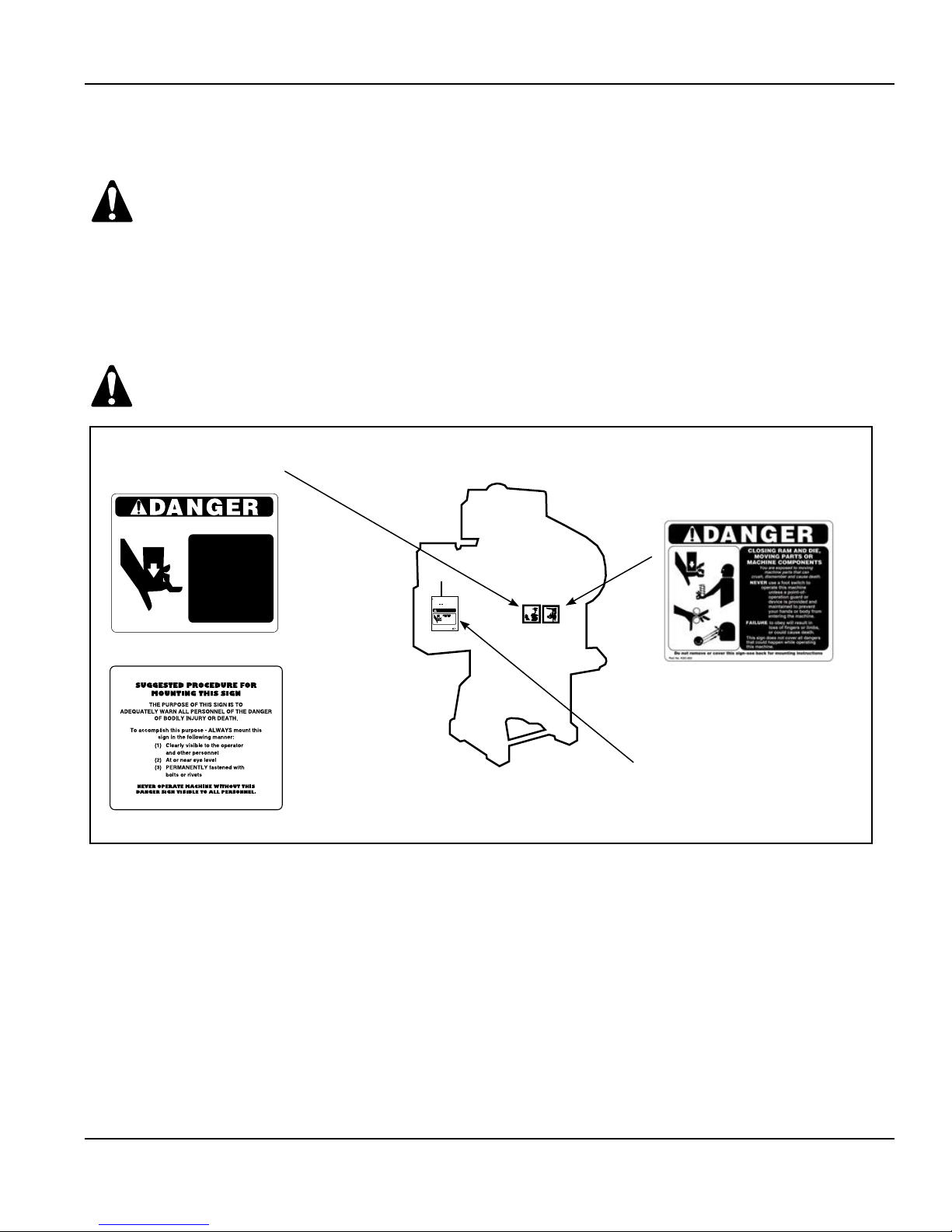

Danger Sign(s) to be Mounted on Machine

Accompanying this equipment is a 5” x 6” polyethylene danger sign, Part No. KSC-054. This sign MUST BE PERMANENTLY

MOUNTED IN A PROMINENT LOCATION on the machine where this equipment is installed. This sign must be in a LOCATION

THAT IS EASILY VISIBLE to the operator, setup person, or other personnel who work on or around this machine. ALWAYS

mount this sign with screws or rivets when installing the enclosed equipment. If a foot switch is ordered, a 5” x 6”

polyethylene danger sign, Part No. KSC-055 is provided. This sign must also be mounted according to the above instructions.

If any danger sign becomes destroyed or unreadable, the sign must be replaced immediately. Contact factory for replacement danger sign(s).

Never operate this machine unless the danger sign(s) is in place.

Part No. KSC-054 Danger Sign - Standard

Part No. KSC-054S - Spanish

Part No. KSC-054F - French

CLOSING RAM AND DIE

Do not remove or cover this sign–see back for mounting instructions

Part No. KSC-054

You are exposed to moving

machine parts that can crush,

dismember and cause death.

DO NOT operate this machine with out safeguards in place.

NEVER place your hands or any

part of your body in this

machine.

FAILURE to obey will result in loss

of fingers or limbs, or

could cause death.

This sign does not cover all dangers that

could happen while operating this machine

.

Front Side

Reverse Side

OPERATOR

SAFETY PRECAUTIONS

Handout for Anyone Operating This Machine

Before You Operate This Machine

You Must Read and Understand

These Safety Precautions

DANGER

Place Your Hands

or Any Part of

Your Body in This

Machine

See Reverse Side for Other Safety Precautions.

SIGN NO. KSC-000

Part No. KSC-055 Danger Sign

(Foot) - Standard

Part No. KSC-055S - Spanish

Part No. KSC-055F - French

OVER

Front Side

See page 6 for

details on this

pamphlet.

“Mechanical Power Press Safety” Booklet

A copy of Booklet No. MPPS (“Mechanical Power Press Safety”) is available upon request. This booklet is copied verbatim from the CFR (Code

of Federal Regulations) and contains all relevant sections of the OSHA Regulations concerning power presses with which an employer (user) must

comply. The enclosed equipment must be installed, used and maintained to meet these regulations. Specifically, any time a foot switch is used,

a suitable point-of-operation safeguard or device must be used to prevent bodily injury. In addition, every press must be provided with

a point-of-operation safeguard! Please review this booklet and the appropriate ANSI (American National Standards Institute) Safety Standard

before installing the enclosed equipment. If you are unfamiliar with these detailed safety regulations, which include regulations on safeguarding the

point of operation properly, you may want to attend our regularly scheduled machine safeguarding seminar. To obtain detailed information about

this training seminar, please call, fax, write, or check our web site. Our address, telephone, fax number, and web site address are on the front

cover of this manual.

Rockford Systems, LLC

Call: 1-800-922-7533 7

(Continued on next page.)

SECTION 1 — IN GENERAL

SSC-500 Hydraulic Press Solid-State Control

Danger and Warning Labels Provided on Control Box

The illustrated danger and warning labels are affixed to all control boxes provided. All personnel operating or

working around the machine, where this control box is installed, must be required to read, understand and

adhere to all dangers and warnings. If any of these labels become destroyed or unreadable, labels MUST be

replaced. Contact factory immediately for replacement labels and do not operate the machine until the danger

and warning labels are all in place.

KSS - 027

Photo 1.1

Inside View of

SSC-500 Control Box

8 Call: 1-800-922-7533

(Continued on next page.)

Rockford Systems, LLC

FOR REPLACEMENT SIGNS

CALL, FAX, E-MAIL, OR FACTORY OR USE ORDER

FORM ON A LATER PAGE OF THIS MANUAL.

Rockford Systems, LLC

5795 Logistics Parkway

Rockford, Illinois 61109

SECTION 1 — IN GENERAL

SSC-500 Hydraulic Press Solid-State Control

Toll Free: 1-800-922-7533 (USA only)

Phone: (815) 874-7891

Fax: (815) 874-6144

Web Site: www.rockfordsystems.com

E-Mail: sales@rockfordsystems.com

Photo 1.2

SSC-500 Control Box

Rockford Systems, LLC

Call: 1-800-922-7533 9

SECTION 2 — INTRODUCTION

SSC-500 Hydraulic Press Solid-State Control

General Description of Components in the System

A complete control package for hydraulic machines includes the following:

1. Literature folder (see page 14) containing installation manuals, “Operator Safety Precaution” Pamphlet, danger sign(s), electrical control

schematics, and our latest catalog

2. Control box - standard (custom or special includes motor controls and/or disconnect switch) with danger and warning signs

3. Palm button assembly (Includes two black palm buttons, two palm button guards, one red emergency-stop button, and mounting boxes. When

the “automatic” mode of operation is included, one yellow return/inch-up button with mounting box is furnished.) If multiple operator stations

are on a machine, more than one assembly is furnished.

4. Foot switch (optional) - If multiple operator stations are on a machine, more than one foot switch is furnished

5. Supervisory control station (Required when multiple operator stations are used on the machine; one station is required for each operator.)

6. Other required components and safeguarding that may be necessary for machine (See packing list for details.)

Individual packages may vary in contents. However, a packing list is always enclosed showing exactly what material was shipped on this order.

Please check the components actually received against this packing list immediately. In most cases, this control package system includes two-hand

control which can be used as a point-of-operation safeguarding device provided the palm buttons are mounted correctly and at the proper safety

distance (see formula on page 19 of this manual). If the optional foot switch is provided, a safeguard must always be used. Examples of safeguards

include barrier guards, presence sensing devices, pullbacks, restraints, gates, or two-hand control. The hands or any other part of the body of an

operator, maintenance person, setup person, etc., must never be put into the point-of-operation hazard for any reason, at any time.

These controls can neither cure nor overcome a malfunctioning machine. They cannot compensate for or prevent

a mechanical defect or failure of a machine part. These controls cannot prevent a repeat or unintended stroke

(cycle) resulting from a mechanical or hydraulic component malfunction, defect or failure of the machine itself.

Preliminary Steps Before Installation

Before proceeding with the installation of the enclosed equipment, you should undertake the following preliminary steps.

1. Read and make sure you understand this entire Installation Manual.

2. Refer to the front cover, other line drawings and photos, then make a rough sketch of your installation to plan the location of the enclosed

equipment on the machine.

3. This may be an opportunity to strip down the entire machine by removing all components, piping, wire,etc. Clean, paint and check the entire

electrical, hydraulic, and mechanical systems of the machine for proper adjustment and required replacement parts before proceeding with the

installation of the furnished equipment.

4. Please make sure the machine is in first-class condition. Before starting any installation, it is essential that the machine is thoroughly

inspected. Be sure that all mechanical components and all collateral equipment are in first-class operating condition. Your inspection should be

done according to the machine manufacturer’s installation and maintenance instruction manual. If you have any doubts or questions concerning

the condition of the machine, contact the machine manufacturer for assistance. Repair or replace all parts not operating properly before

proceeding.

Inspection and maintenance programs must be established and implemented to keep machines in first-class

condition. Programs must include thorough inspections of each machine on a weekly basis and records kept of

these inspections. Any part of the machine that is worn, damaged or is not operating properly must be replaced

immediately or repaired before the machine is used.

5. Verify that the machine is in first-class condition and operating properly; shut off all power to the machine. All trapped hydraulic pressure must be

released in areas of the systems that are being updated or retrofitted before proceeding. Padlock the disconnecting means in the “off” position

and do not actuate the machine again until the installation of all package components has been completed. Lockout/tagout energy isolation

procedures must always be practiced and enforced.

10 Call: 1-800-922-7533

(Continued on next page.)

Rockford Systems, LLC

SECTION 2 —INTRODUCTION

SSC-500 Hydraulic Press Solid-State Control

Safeguard Interlocks and Other Types Of Interlocks

Safeguard Interlocks

The machine will not operate or must not be operated until you either: (1) Electrically interlock or (2) Mechanically guard the machine’s point of

operation with a safeguarding system or device.

When an electrically interlocked method of safeguarding the point of operation is chosen, connect the interlock to the safeguard interlock terminals

(P7-5 and P7-6) in the control box (see page 16), and as shown on the control wiring schematic (wire numbers 82 and 83).

Point-of-operation electrically interlocked safeguards, when opened, prevent or stop normal machine operation during operator cycling modes.

Examples of these types of interlocks are barrier guard interlocks and gate device interlocks.

When a mechanical guard or device (nonelectrically interlocked) is chosen, the safeguard interlock terminals (P7-5 and P7-6) are not used. In order

for the machine to operate with the use of a mechanical guard or device, the safeguard interlock terminals must be connected.

The mechanical guard or device must be properly installed, used and maintained and must always prevent all

personnel from bodily injury.

If the mechanical guard or device is not used, is removed, or is defeated, an electrically interlocked method of

safeguarding must be used and connected to the safeguard interlock terminals (P7-5 and P7-6).

Never operate this machine without point-of-operation safeguarding.

OTHER ELECTRICAL INTERLOCKS

There are basically two types of electrical interlocks as applied to machine control circuitry:

• Interlocks for the purpose of personnel protection, as explained previously.

• Interlocks intended for the purpose of protecting the machine and its control components.

There are other locations for interlocks that, when opened, prevent all machine functions. Examples of these types of interlocks are safety block

electrical cut-off systems, lubricating systems, die protection equipment, and tonnage monitoring systems.

Be sure to connect the various electrical interlocks to the proper terminals (in the control box) according to the machine wiring schematics. If your

schematics do not include these electrical interlocks, please send this information to the factory and they can be added to your drawings. There is

an additional charge for this service.

Features of the SSC-500 Control - Hydraulic Press

• Redundant/cross-checking microprocessors

from different manufacturers

• Two-hand anti-tiedown and concurrent operation

• 1 x 16-character LCD display/membrane keypad

operator interface

• Two-speed solenoid valve support

• Four (4) user programmable diagnostic inputs

• Interface provided for light curtain(s)

• Provisions for electrically interlocking safety devices

• Redundant logic system microprocessor

• Isolated microprocessor logic power supply

• Redundant monitored SSR (Solid-State Relay)

with captive contact master safety relay

Rockford Systems, LLC

Call: 1-800-922-7533 11

• Unpluggable saddle-clamp circuit board terminal strips

• Supports redundant solenoid valves (self-checking)

• Fused SSR (Solid-State Relay) outputs eliminate

costly relay replacement (field-replaceable fuses)

• Seven-digit stroke counter and batch counter with preset

• LCD display choices while in run mode: Mode,

Stroke Counter, or Batch Counter

Modes of Operation

Standard Optional

• Two-Hand Inch

• Foot-Single Stroke • PSDI

• Automatic (hand only)

• Auto Single

• One-Hand Trip (used in

conjunction with a light curtain)

(Continued on next page.)

SECTION 2 — INTRODUCTION

SSC-500 Hydraulic Press Solid-State Control

SSC-500 Control Box

The SSC-500 Press Control is a full-featured, dual-microprocessor based control for hydraulic presses. This control system is designed to comply

with current ANSI Standard B11.2. It is a replacement for existing relay-based or PLC control systems, found in user’s plants or can be furnished

for new or rebuilt hydraulic presses.

The basic control consists of a multi-tap voltage control transformer, color-coded terminal strips, ground indicator light, selector switches, keypad/

display, a master control relay, and the SSC-500 control module assembly. As standard, this is furnished in a NEMA 12 enclosure. The master-control relay is used to provide a hard-wired emergency-stop function.

When this control box is to be wired to an existing main motor starter, the starter must have a 120 volt coil. If the starter does not have this component and it is not readily available, please contact Rockford Systems, LLC for a replacement magnetic starter.

The system uses redundant inputs from devices such as palm buttons, foot switches, and light curtain(s). The system output to the down solenoid

valve(s) is provided by redundant monitored solid-state relay/captive contact relay outputs for trip solenoid(s). These output relays are independently

controlled and cross-checked by the microprocessors. This allows control-reliable operation of the outputs in the event of a single control component

failure. Each microprocessor also has its own logic power supply. This decreases the possibility of simultaneous control failure because of a fault within

the power supply system. All inputs and outputs are optically isolated for electrical noise immunity. The operator provides setup information through the

use of the keypad/display and messages are shown on the 16-character LCD display.

Overview of Sequence of Operation

GENERAL

”

If the ram is not at the “TOS

be displayed until the return is depressed. The “TOS,” “BOS” (bottom of stroke), and speed change limit switch inputs can be either N.O. or N.C. as

required. (See OPTIONS EDIT programming on page 33.)

OFF

The machine is inoperable in this mode of operation. To initiate any of the following modes of operation, turn the Off/On Selector Switch from the

“Off” to the “On” position.

INCH

To initiate this mode of operation, set the Control Selector to “Inch” and set the Actuating Means Selector to the “Hand” position. In this mode of

operation, the ram moves down when both palm buttons are depressed concurrently and remain depressed. Ram motion will stop when either

button is released; however both buttons must be released and then depressed again in order to reinitiate ram motion. The ram will continue to

inch to the “BOS” limit switch. Return the ram to the “TOS” limit switch by depressing the return/inch-up palm button.

TWO-HAND SINGLE STROKE

To initiate this mode of operation, set the Control Selector to “Single” and set the Actuating Means Selector to the “Hand” position. In this mode of

operation, depressing and holding the run/inch buttons concurrently causes the ram to make one stroke from the “TOS” limit switch to the “BOS”

limit switch and back to the “TOS

Both buttons will have to be released and depressed again in order to reinitiate the cycle. Once the machine has reached the “BOS” limit switch,

the buttons may be released and the control will provide bottom dwell if programmed (see page 28), and return the ram to the “TOS” limit switch. If

the single stroke return mode is enabled, the ram will return to the “TOS” limit switch if either palm button is released prior to reaching the “BOS”

limit switch.

FOOT-SWITCH SINGLE STROKE

To initiate this mode of operation, set the Control Selector to “Single” and set the Actuating Means Selector to the “Foot” position. In this mode of

operation, depressing the foot switch causes the machine to function in the same manner as described for two-hand single stroke. Foot-switch single

stroke requires either a light curtain or the safeguard interlock connection to function. See page 11. If foot trip is enabled in the options edit menu,

depressing and releasing the foot switch causes the ram to make one stroke from the “TOS” limit switch to the “BOS” limit switch and back to the

“TOS

” limit switch

.

(top of stroke) limit switch at power up, or the control selector is changed in mid stroke, the message RETURN RAM will

” limit switch

. If either button is released before the machine reaches the “BOS” limit switch, the ram will stop.

12 Call: 1-800-922-7533

(Continued on next page.)

Rockford Systems, LLC

SECTION 2 —INTRODUCTION

SSC-500 Hydraulic Press Solid-State Control

Overview of Sequence of Operation (continued)

AUTOMATIC

To initiate this mode of operation, set the Control Selector to “Automatic” and set the Actuating Means Selector to the “Hand” position. In this mode

of operation, press the “Automatic Prior-Action” push button and then both run buttons concurrently (within five seconds). This causes the ram to

stroke continuously from the “TOS” limit switch to the “BOS” limit switch, and back to “TOS.” The ram may be stopped and returned to the “TOS”

limit switch by pressing the return/inch-up yellow palm button. The automatic mode of operation requires either a light curtain or the safeguard

interlock connection to function (see page 11).

LIGHT CURTAIN

The light curtain is active during the downstroke portion of the machine cycle in all modes of operation except inch. The light curtain is muted

during the ram-return portion of the cycle. The light curtain is muted when the ram reaches the “BOS” limit switch. If a mute point is required prior

to bottom of stroke, a light curtain mute limit switch may be used. This input should be set to come on when the upper die is at 1/4” above the

piecepart and must remain on until the “BOS” limit switch is reached. (See the schematic diagram supplied with the control for the mute switch

connection.) The LIGHT CURTAIN OFF/ON selector is provided so the light curtain can be turned off when another method of safeguarding is used.

LIGHT CURTAIN ACTIVE ON THE UPSTROKE (OPTIONAL)

This option allows the light curtain to be active on the upstroke portion of the machine cycle as well as the downstroke (no muting). This option is

enabled at the factory.

PRESSURE OR DISTANCE RETURN

A key-selector switch is provided for the selecting the method of returning the ram by PRESSURE, PRESSURE/DISTANCE, or DISTANCE. An

optional pressure switch can be connected to the return selector switch to facilitate pressure, pressure/distance, or distance return on machines

with “BOS” limit and pressure switches. The “BOS” limit switch input can be either N.O. or N.C. as required. (See the OPTIONS EDIT programming

on page 33.)

Optional Software and Overview

An options module is required with any of these software options:

• PSDI (Presence Sensing Device Initiation)

• User Inputs

• Speed Change

• Auto Single

• Block Valve Monitoring

PSDI (PRESENCE SENSING DEVICE INITIATION)—REQUIRES OPTIONS MODULE AND LIGHT CURTAIN

PSDI is an optional mode of operation for hydraulic presses. In this mode of operation, a stroke is initiated by an interruption in the sensing of a

light curtain when the light curtain is used as the point-of-operation safeguard. The operator can hand feed parts through the light curtain sensing

field, and when the hand(s) is removed from the sensing field, the press will single stroke. This interruption and withdrawal sequence is commonly

referred to as a “break.”

To initiate the PSDI mode of operation, set the control selector switch to “Single,” turn the light curtain “On,” and set the PSDI selector switch to

PSDI 1 (single break) or PSDI 2 (double break for loading and unloading of pieceparts). At this point, interruption of the light curtain sensing field

should not cause the press to stroke. First press the “PSDI Prior Action” push button, then begin PSDI. The press should start and run in the PSDI

mode until a stop signal is given or if time expires between breaks. The PSDI prior action push button must then be reinitiated to restart the PSDI

mode of operation. See the PSDI Section on page 34 for the sequence of operation and displayed messages.

PSDI TIMER—REQUIRES OPTIONS MODULE

The PSDI timer measures the time between breaks. The timer starts timing once the stroke is complete and the slide is at TOS limit switch. If time

expires before the next break occurs, the PSDI mode of operation will deactivate. To reactivate the PSDI mode of operation, depress the PSDI prior

action push button. The PSDI timer can be programmed from 2 to 30 seconds. See the PSDI TIMER programming section on page 30.

Rockford Systems, LLC

Call: 1-800-922-7533 13

(Continued on next page.)

SECTION 2 — INTRODUCTION

SSC-500 Hydraulic Press Solid-State Control

USER INPUTS

Up to four programmable user inputs are available to monitor and diagnose common problems with auxiliary equipment on the machine. See the

USER INPUT programming section on pages 31 - 32 for the user input choices. Refer to the wiring schematics for information on wiring the inputs

to the proper terminals.

Note: If block valve monitoring is enabled, only three (3) user inputs will be available.

SPEED CHANGE—REQUIRES OPTIONS MODULE

An optional speed change limit switch can be connected to the speed change selector switch to facilitate HIGH, HIGH/LOW, or LOW speed on

machines with speed change solenoid valves. (See the schematic diagram supplied with the control for switch connection.) The speed change

limit switch can be either N.O. or N.C. and the speed change solenoid valve can be energized for slow or fast as required. (See the OPTIONS EDIT

programming on page 33.) The speed change logic will work with either a momentary or maintained limit switch.

AUTOMATIC SINGLE STROKE—REQUIRES OPTIONS MODULE

The automatic single stroke mode of operation is used when a continuous stroke operation is desired but the press is faster than the material

feeding equipment. When this mode of operation is ON, each press cycle can be initiated by the material or material feeding equipment. This mode

of operation requires a prior-action pushbutton station. To initiate automatic single stroke, set the Mode Selector to “Single” and enable “Automatic

Single Stroke” in the programming menu (see ASINGLE MODE programming on page 30). Press the prior-action push button and then both run

buttons concurrently (within five seconds). The press will make one stroke and then continue to run in automatic single stroke as long as an input

signal is received. The press will operate in the automatic single stroke mode of operation until a signal is given to stop, or when the automatic

single stroke timer runs out before an input signal is received (see ASINGLE TMR programming on page 31). The prior-action pushbutton and the

palm buttons must be reinitiated to restart the automatic single stroke mode of operation.

BLOCK VALVE MONITORING—REQUIRES OPTIONS MODULE

This valve is used to monitor the state of the hydraulic block valve. When enabled, there must be a switch on the valve wired into User Input #4.

Refer to the wiring diagrams supplied with the control for wiring connection. This block valve monitor option uses User Input #4, which leaves only

three (3) programmable User Inputs available. (See the OPTIONS EDIT programming on page 33.)

14 Call: 1-800-922-7533

(Continued on next page.)

Rockford Systems, LLC

Loading...

Loading...