Page 1

PUNCH

AUDIOPHILE

SYSTEM

RFA-414

RFA-514

RFA-614

INSTALLATION & OPERATION

®®

Page 2

Dear Customer,

Congratulations on your purchase of the world's finest brand of car audio speakers. At

Rockford Fosgate we are fanatics about musical reproduction at its best, and we are

pleased you chose our product. Through years of engineering expertise, hand craftsmanship and critical testing procedures, we have created a wide range of products that

reproduce music with all the clarity and richness you deserve.

For maximum performance we recommend you have your new Rockford Fosgate

product installed by an Authorized Rockford Fosgate Dealer, as we provide specialized

training through Rockford Technical Training Institute (RTTI). Please read your

warranty and retain your receipt and original carton for possible future use.

Great product and competent installations are only a piece of the puzzle when it comes

to your system. Make sure that your installer is using 100% authentic installation

accessories from Connecting Punch in your installation. Connecting Punch has

everything from RCA cables and speaker wire to Power line and battery connectors.

Insist on it! After all, your new system deserves nothing but the best.

To add the finishing touch to your new Rockford Fosgate image order your Rockford

wearables, which include everything from T-shirts and jackets to hats and sunglasses.

To get a free brochure on Rockford Fosgate products and Rockford accessories, in the

U.S. call 602-967-3565 or FAX 602-967-8132. For all other countries, call +001-602967-3565 or FAX +001-602-967-8132.

PRACTICE SAFE SOUND™

CONTINUOUS EXPOSURE TO SOUND PRESSURE LEVELS OVER

100dB MAY CAUSE PERMANENT HEARING LOSS. HIGH

POWERED

PRESSURE

AND

If, after reading your manual, you still have questions regarding this product,

we recommend that you see your Rockford Fosgate dealer. If you need further

assistance, you can call us direct at 1-800-795-2385. Be sure to have your serial

number, model number and date of purchase available when you call.

The serial number can be found on the outside of the box. Please record it in

the space provided below as your permanent record. This will serve as

verification of your factory warranty and may become useful in recovering your

product if it is ever stolen.

Serial Number: ________________________________

Model Number:________________________________

AUTOSOUND SYSTEMS MAY PRODUCE SOUND

LEVELS WELL OVER 130dB. USE COMMON SENSE

PRACTICE SAFE SOUND.

Page 3

TABLE OF CONTENTS

Introduction ...............................................................................................

Amplifier Accessory Pack.........................................................................1

Technical Design Features .......................................................................2

Design Features........................................................................................ 5

Installation Considerations ....................................................................... 7

Mounting Location...................................................................................8

Battery and Charging................................................................................ 9

Wiring the System .................................................................................... 9

Using the XCard.....................................................................................12

Resistor Chart.........................................................................................13

Installation ............................................................................................. 14

System Diagrams.................................................................................... 18

Rockford Fosgate Accessories................................................................. 22

Troubleshooting ..................................................................................... 26

Dynamic Power Measurements..............................................................29

Specifications.........................................................................................31

Warranty Information.............................................................................33

International Information........................................................................ 34

G

ETTING STARTED

Welcome to Rockford Fosgate! This manual is designed to provide

information for the owner, salesperson and installer. For those of you

who want quick information on how to install this product, please turn

to the

Installation Section

of this manual or refer to the icons listed

below. Other information can be located by using the Table of Contents.

We, at Rockford Fosgate, have worked very hard to make sure all the

information in this manual is current. But, as we are constantly finding

new ways to improve our product, this information is subject to change

without notice.

I

® ®

N

S

T

A

L

L

A

T

I

O

N

Sections marked

INSTALLATION

include “slam dunk”

wiring connections

include recommendations

TROUBLE-

Sections marked

TROUBLESHOOTING

for curing

installation problems

S

H

O

O

T

I

N

G

Page 4

INTRODUCTION

This manual provides information on the features and installation of

the Punch AUDIO

phile

Systems. We suggest you save this manual

for future reference.

We strongly recommend you have your Authorized Rockford Fosgate

Dealer install the Punch AUDIO

phile

System. If you do choose to

install the system yourself, please be sure to read the entire manual

before beginning.

PACKAGE CONTENTS

RFA-414 RFA-514

(1) Installation & Operation Manual (1) Installation & Operation Manual

(2) 4" Midrange Speakers (2) 5.25" Midrange Speakers

(2) 4" Speaker Grilles (2) 5.25" Speaker Grilles

(2) Speaker Grille Rings (2) Speaker Grille Rings

(2) Speaker Grille Gaskets (2) Speaker Grille Gaskets

(8 Tinnerman Clips (8) Tinnerman Clips

(2) RFA-142x Crossovers (2) RFA-142x Crossovers

(2) 20mm Tweeters (2) 20mm Tweeters

(2) Surface Mount Cups (2) Surface Mount Cups

(2) Surface Mount Baseplates (2) Surface Mount Baseplates

(2) Flush Mount Cups (2) Flush Mount Cups

(2) Flush Mount Baseplates (2) Flush Mount Baseplates

(2) Mounting Brackets (2) Mounting Brackets

(2) 6' 24 gauge speaker wire (2) 6' 24 gauge speaker wire

(16) #8 x .75 Phillips Mounting Screws (16) #8 x .75 Phillips Mounting Screws

(4) 8-32 x .50 Hex Head Bolts (4) 8-32 x .50 Hex Head Bolts

(4) 8-32 Nuts (4) 8-32 Nuts

(1) Installation & Operation Manual

(2) 6.5" Midrange Speakers

(2) 6.5" Speaker Grilles

(2) Speaker Grille Rings

(2) Speaker Grille Gaskets

(8 Tinnerman Clips

(2) RFA-142x Crossovers

(2) 20mm Tweeters

(2) Surface Mount Cups

RFA-614

(2) Surface Mount Baseplates

(2) Flush Mount Cups

(2) Flush Mount Baseplates

(2) Mounting Brackets

(2) 6' 24 gauge speaker wire

(16) #8 x .75 Phillips Mounting Screws

(4) 8-32 x .50 Hex Head Bolts

(4) 8-32 Nuts

– 1 –

Page 5

TECHNICAL DESIGN FEATURES

◆ Silk Dome

The silk dome used in the AUDIO

ment of the diaphragm and voice coil assembly. The linear movement

or “symmetrical control” of the assembly provides smooth and well

extended high frequency response.

THE RESULT: Smooth response for “audiophile” sound quality.

phile

tweeter allows linear move-

◆ Neodymium Magnets

The high ionic compound of neodymium enables a smaller tweeter

magnet assembly to be used as opposed to the much larger ferrite

magnets that are commonly used in speaker manufacturing.

THE RESULT: An efficient magnet which allows smaller tweeter

construction.

◆ Magnetic Fluid Cooling

Magnetic fluid is a synthetic liquid consisting of microscopic magnetic particles. The fluid has four times the thermal conductivity as air

which makes it an ideal cooling agent. Magnetic fluid is injected into

the voice coil gap which helps dissipate heat generated by the voice

coil.

THE RESULT: A thermal conductor which allows increased power

handling.

◆ Swivel Mount Design

The tweeter is encapsulated in a variable swivel housing. This design

allows direct dispersion of the tweeter in order to accommodate

various mounting positions. The swivel mount design allows the

tweeter to maximize its sonic potential.

THE RESULT: Precise tweeter imaging regardless of mounting position.

– 2 –

Page 6

Midrange Features

◆ Nitrile Rubber Surround

The nitrile material is resilient to temperature variations and provides

a consistent support necessary of the linear motion of the speaker

cone, In addition, the inherent damping capabilities eliminates the

transmission of sonic disturbances between the cone and the frame of

the speaker. This greatly improves the clarity of the speaker's midrange

frequency response.

THE RESULT: Improves speaker's frequency response.

◆ Flat Spider

The speaker's linear compliance is balanced through the use of a

“proprietary” flat spider design. A flat spider provides symmetrical

control of the voice coil through its cone excursion. Linear cone

excursion reduces harmonic distortion for improved sound quality.

THE RESULT: Reduces mechanical distortion for better sound quality

.

◆ High Temperature Voice Coil

The voice coil is of a high temperature copper wire construction. The

wire is wound in two layers on a black, anodized, aluminum voice

coil former. The voice coil former dissipates heat away from the voice

coil improving the speaker's thermal stability and improving the

reliability of the speaker.

THE RESULT: Improves reliability by dissipating generated heat.

◆ Vented Pole Piece

The vented pole piece by design, ensures proper ventilation to cool

the voice coil and maintain lower operating temperatures. The vent

on the rear of the magnet reduces back pressure and allows cool air

to circulate in the voice coil gap. The air circulation increases the

thermal power handling of the speaker.

THE RESULT: Improves power handling by cooling the voice coil.

– 3 –

Page 7

◆ Powder Coat Finish

Powder coating has long been the industry standard for durability in

protective metal finishes. A dry powder (non-aerosol) is electrostatically applied to the metal and “baked” on to provide a hard “shell-

like” finish. As an additional benefit, powder coating is the only

finishing process that releases no toxic chemicals into our ozone.

THE RESULT: A durable and “earth friendly” metal finish.

Crossover Features

◆ Optical Compression Circuit

The speaker's linear compliance is balanced through the use of a

“proprietary” flat spider design. A flat spider provides symmetrical

control of the voice coil through its cone excursion. Linear cone

excursion reduces harmonic distortion for improved sound quality.

THE RESULT: Reduces mechanical distortion for better sound quality

.

◆ Series Notch Filter

The Series Notch Filter compensates for the inductive load presented

by the driver (speaker). The filter's primary function is to dampen and

eliminate the effect that driver resonance has on the crossover. The

Series Notch Filter flattens out the inductive load which greatly

improves driver performance by providing a “stable” crossover point.

THE RESULT: Improves driver performance by reducing resonant

peak.

– 4 –

Page 8

◆ Zobel Network

The Zobel network compensate for the impedance rise presented by

the driver (speaker). The network flattens out the gradual impedance

rise produced by the voice coil which typically results in high

frequency rolloff. The Zobel Network compensates for this natural

rolloff which allows the driver to produce a more linear response up

to the tweeter crossover point.

THE RESULT: Compensates for natural high frequency rolloff of

midrange.

◆ Adjustable Tweeter Level Matching

The RFA-142x utilizes a series power resistor for tweeter level

matching. The factory set tweeter output level is –0dB, however, can

be reduced –3dB to create a smoother transition between the midrange

and tweeter. The ability to level match allows the system to be custom

“tuned” for a particular listener or setup.

THE RESULT: Allows custom setup of tweeter output level.

– 5 –

Page 9

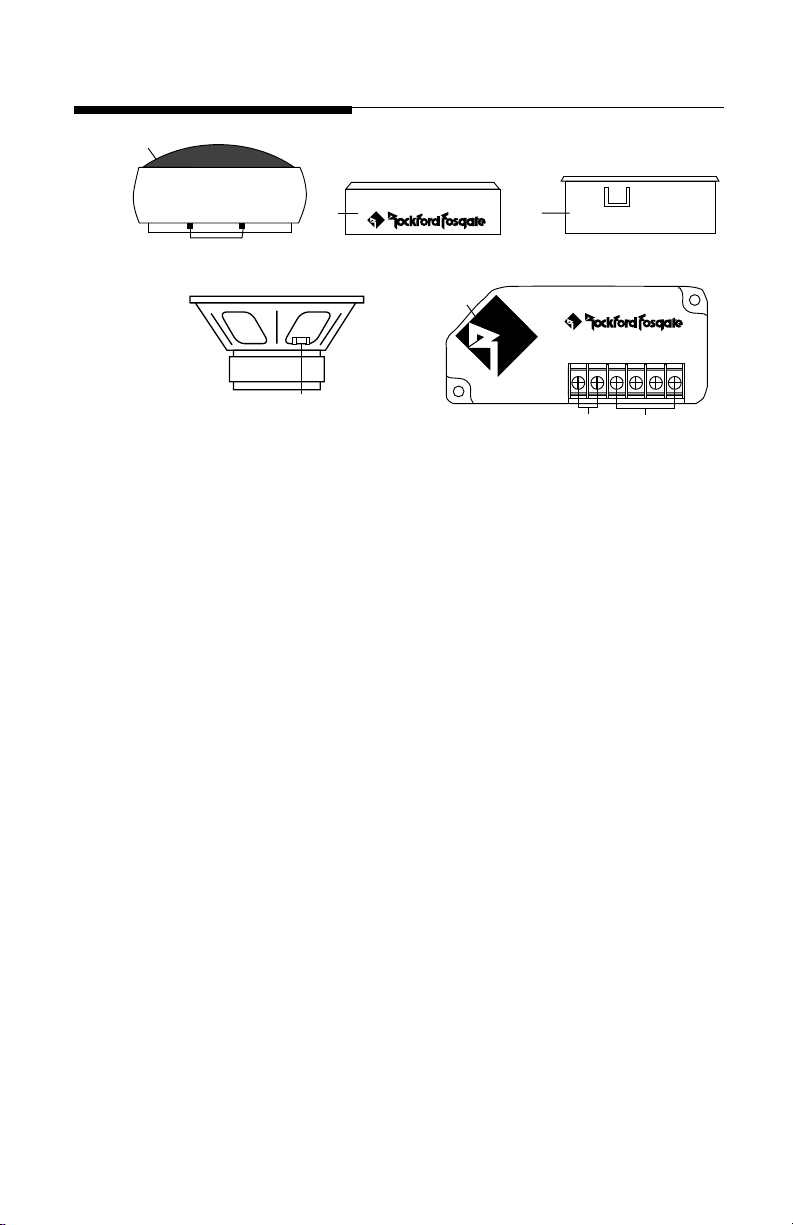

DESIGN FEATURES

1

6

®®

2

3

2

7

ACTIVE TWEETER PROTECTION

RFA-142x

®

®®

45

1. Wire Mesh Grille – The Wire Mesh Grille protects the tweeter

diaphragm from foreign objects and curious fingers.

2. Input Terminals – The “+” Terminal indicates the positive/plus

terminal of the speaker. The “–” Terminal indicates the negative/

minus terminal of the speaker. These terminals connect to the

corresponding output of the supplied crossover.

3. Variable Mount Logo – The Diamond “R” logo can be orientated

in its housing to accommodate vertical or horizontal crossover

mounting.

4. Input Screw Terminals – The Input Screw Terminals connect to

the outputs of the amplifier. These terminals accept bare wire or

1/4" spade lugs and are gold-plated to resist corrosion.

5. Output Screw Terminals – The Output Screw Terminals connect

to the input of the tweeter and midrange. These terminals accept

bare wire or 1/4" spade lugs and are gold-plated to resist corrosion.

6. Surface Mount Cup – This cup is used to “surface mount” the

tweeter on a panel.

7. Flush Mount Cup – This cup is used to recess or “flush mount” the

tweeter into a panel.

– 6 –

Page 10

INSTALLATION CONSIDERATIONS

Tools Needed

The following is a list of some of the tools necessary for the installation

of your speakers.

Power Drill with assorted bits #2 Phillips Screwdriver

Tape Measure Hole Saw (2")

Voltmeter

General

1. For safety, disconnect the negative lead from the battery prior to

beginning the installation.

2. Never run wires underneath the vehicle. Running the wires inside

the vehicle provides the best protection.

3. Avoid running wires over or through sharp edges. Use rubber of

plastic grommets to protect any wires routed through metal.

4. Mount the speakers/crossovers away from electrical sources (other

than the amplifier) i.e.., power cables, electronic fuel pumps,

vehicle computers, and other potential noise sources.

5. Mount the speakers/crossovers away from areas of extreme heat or

moisture.

Speakers

1. Make sure there is an area large enough of the speaker to mount.

Warning! Failure to do this can cause damage to the speaker if the

speaker frame is bent during installation.

2. Check to see that the location is deep enough for the speaker(s) and

the location does not interfere with the normal operation of the

vehicle.

3. When mounting the speaker(s) in the door of a vehicle, make sure

the speaker(s) do not interfere with either the door or window

operation.

4. When mounting the speaker(s) on the rear deck of the vehicle, check

the operation of the rear hatch or trunk lid. Make sure the torsion bars

and other moving parts are not obstructed by the speaker(s) installation.

• Please refer to the Specifications section of this manual for proper

mounting diameter and depth of the speaker(s).

Crossovers

1. Make sure there is a flat area large enough for the crossover to mount.

2. For best results, mount the crossover(s) next to the amplifier for a

decorative finish to the installation and provide an easy upgrade (no

new wires to run) for a bi-amp Rockford Fosgate system in the future.

– 7 –

Page 11

MOUNTING LOCATION

A solid front stage with a good image is one of the most difficult tasks

to achieve in a vehicle. No car has the optimum listening environment.

This makes proper sound staging very difficult to accomplish. Most

speakers tend to be placed where they will fit easily, as opposed to

where they can perform the best.

speakers will have a great effect on the sound quality of your stereo

system. The special care taken to place the speakers will yield many

hours of listening enjoyment in return. Several important recommendations should be followed.

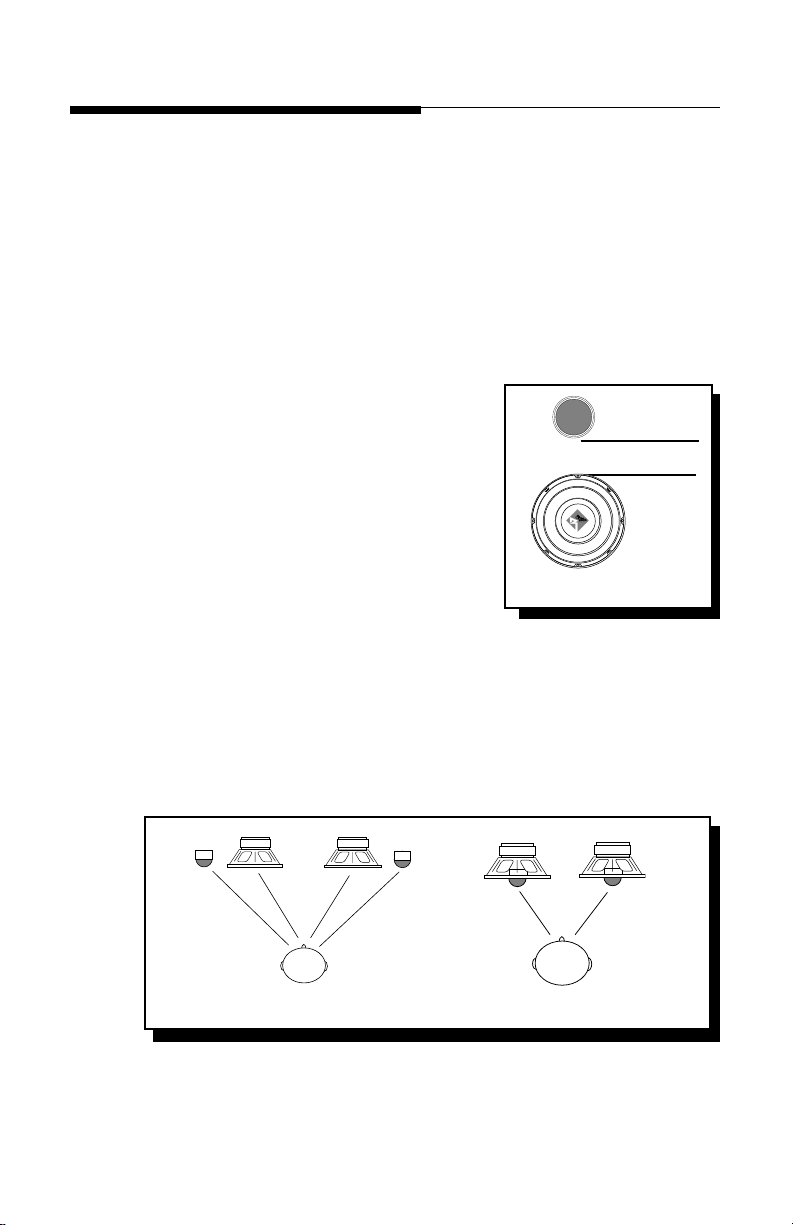

• Place the speakers where they have a

direct path to the listening area.

• For the best integration between the

midrange and tweeter, the tweeter should

be placed less than 2" from the midrange.

(Figure 1)

• If you cannot place the tweeter less than

2" from the midrange, then place the

tweeter more than 7" from the midrange.

Placing the tweeter 2"-7" from the

midrange can cause destructive interference (frequency response problems) which will affect the speaker's

ability to reproduce the frequency range around the crossover

frequency of the system.

• Whenever possible, place the tweeter directly above or below the

midrange as this maximizes the imaging (point source) capability of

the espeakrs. (Figure 2)

The mounting location of your

Figure 1

2" or less

Figure 2-A

Figure 2-B

– 8 –

Page 12

• Sound radiated from a “point source” has the most optimum stereo

imaging because the separation of the acoustical centers between

the midrange and tweeter for each channel is at the optimum. Figure

2-A describes a horizontal speaker alignment. In a closed environment such as an automobile, horizontal speaker alignment can

cause severe amplitude and phase differences which will degrade

not only the imaging, but also the frequency response. This is due to

the path length differences between the midrange and tweeter.

Figure 2-B displays a vertical alignment between the midrange and

tweeter. With a vertical alignment, the path length difference

between the midrange and tweeter are reduced to a minimum. The

result is a negligible difference in path lengths between the midrange

and tweeter regardless of the proximity of the listener to the

speakers. Mounting the speaker with minimum path length difference will ensure the best staging an imaging possible from your

audio system.

INSTALLATION

Mounting the Midrange

I

® ®

N

S

T

A

L

L

A

T

I

O

N

1. Cut the proper size hole for the midrange/woofer.

• For the RFA-44, cut a 4" (101.6mm) diameter hole

• For the RFA-54, cut a 415⁄16"

• For the RFA-64, cut a 527⁄32"" (148.4mm) diameter hole

2. Place the mounting ring over the mounting hole and mark the

location of the screw mounting holes.

3. Remove the ring. Drill the holes for the screws using a 1/8" drill bit.

4. Route the wire through the hole.

5. Install the screw clips (Tinnerman clips) over the screw holes. Place

the mounting ring over the hole.

6. Attach the wires and be sure to observe the proper speaker polarity.

7. Place the speaker into the hole and screw the speaker into place.

Be careful not to bend the speaker frame during this step.

8. Press the speaker grille into the mounting ring.

– 9 –

Page 13

Surface Mount Tweeter (Method #1)

Mounting

Baffle

Mounting

Screw

I

® ®

N

S

T

A

L

L

A

T

I

O

N

Surface

Mount

Baseplate

Exploded View

Surface

Mount

Cup

Front View

(twist clockwise to lock)

• Use when mounting tweeter to a solid surface (metal, wood, etc.)

Surface Mount Tweeter (Method #2)

Mounting

Baffle

Mounting

Surface

Mount

Baseplate

Bolt

Surface

Mount

Cup

Front View

(twist clockwise to lock)

Nut

Exploded View

• Use when mounting tweeter to a surface needing reinforcement

– 10 –

Page 14

Flush Mount Tweeter

Mounting

Bolt

Nut

Mounting

Baffle

2" Cutout

I

® ®

N

S

T

A

L

L

A

T

I

O

N

Bracket

Flush

Mount

Baseplate

Mount

Exploded View

Crossover Connections

HP CROSSOVER

LP CROSSOVER

®

– +

Input

OUTPUT

–

FROM

+

AMPLIFIER

Flush

Cup

TWEETER

PROTECTION

– + – +

Mid

Tweeter

Output

Output

Rear View

(twist clockwise to lock)

TWEETER

(Rear View)

“+”

“+”

Dot

• Striped Wire indicates “+”

terminal

of tweeter

• Be Sure to Maintain Speaker Polarity

– 11 –

Page 15

Bandpassing the Midrange

RFA-142x

Midrange

Output

–

I

® ®

N

S

T

A

L

L

A

T

I

O

N

+

+

–

400µf capacitor

• To bandpass the midrange, it is necessary to add a 400µf

capacitor in series with the speaker

Tweeter Level Matching

Cut jumper

wire for –3dB

• Factory set tweeter level is –0dB

• Cut jumper wire on bottom of crossover to reduce

tweeter level by –3dB

– 12 –

Page 16

Horizontal Logo Mounting

I

® ®

N

S

T

A

L

L

A

T

I

O

N

®®

ACTIVE TWEETER PROTECTION

®

RFA-142x

• Configure logo into desired position and snap into place

Vertical Logo Mounting

®

ACTIVE TWEETER PROTECTION

RFA-142x

®®

®®

ACTIVE TWEETER PROTECTION

RFA-142x

RFA-142x

ACTIVE TWEETER PROTECTION

®®

®

®

• Configure logo into desired position and snap into place

– 13 –

Page 17

TROUBLESHOOTING

Symptom Diagnosis Remedy

No sound from

speakers

Distorted sound

from speakers

Tweeters “burn

up” easily

Wires between amplifier,

crossover and speakers

not connected properly.

Amplifier has no output.

Speaker wires are shorted

to each other or to the

chassis of the vehicle.

Speakers are blown.

Incorrect wiring between crossover and

speakers

Excessive clipping from

amplifier

Equalizer in system (if

available) has excessive

boost in the high frequency range

Check and repair or replace

wiring as needed.

Check system with known

working amplifier and repair or replace as needed.

Check for shorts in the wiring with a volt/ohm meter

and repair or replace wires

as needed

Check system with known

working speaker and repair

or replace as needed.

Check wiring and repair or

replace as needed.

Check gain settings on amplifier and readjust as necessary

Check settings on equalizer

and readjust as necessary

– 14 –

Page 18

Symptom Diagnosis Remedy

TROUBLE-

S

H

O

O

T

I

N

G

Engi ne Noise

from One or

More Speakers

Speaker wires shorted to

chassis of vehicle.

Speaker wires are routed

near radiated noise

source. (Power cables,

vehicle computers, etc.)

Crossover is mounted

near radiated noise

source. (Power cables,

vehicle computers, etc.)

Check for shorts in the wiring with a volt/ohm meter

and repair or replace wires

as needed.

Re-route speaker wiring

away from noise sources.

(Refer to the Installation

Considerations section of

this manual.)

Move crossovers away from

noise sources. (Refer to the

Installation Considerations

section of this manual.)

– 15 –

Page 19

SPECIFICATIONS

Model RFA-14 RFA-44 RFA-54 RFA-64

Freq. Response 3kHz-20kHz 3kHz-20kHz 44Hz-6kHz 39Hz-6kHz

Power Handling 50 Watts* 30 Watts 50 Watts 80 Watts

(RMS)

Nom. Impedance 4Ω 4Ω 4Ω 4Ω

Sensitivity 92dB 86dB 86dB 89dB

1W/1M)

Fs (Hz) 2000Hz 94Hz 44Hz 39Hz

Mounting Diameter Refer to 4" 4

drawing (101.6mm) (122.8mm) (142.9mm)

Mounting Depth Refer to 1 25⁄8"3

drawing (45.2mm) 66.7mm) (78.6mm)

*Power ratings (PE) is established with recommended filter network.

Model RFA-142x

Crossover Frequency 6kHz @ 4Ω

Crossover Slope 18dB/octave High-Pass

12dB/octave Low-Pass

Protection Circuitry Optical Compression

Crossover Alignment Butterworth

Zobel Network Effective @ 6.5kHz

Series Notch Filter Effective @ 2kHz

Tweeter Level Matching Factory set –0dB

User selectable –3dB

7

⁄8"5

5

⁄8"

3

⁄32"

1

1

⁄16"

(27mm)

®

Flush MountSurface Mount

1

2

⁄8" (50.8mm)

®®

ACTIVE TWEETER PROTECTION

RFA-142x

(Specifications are subject to change without notice)

2" (54mm)

25⁄16"

(58.4cm)

(End View)

– 16 –

7

⁄16" (11.1mm)

3

⁄4" (19mm)

3

1

⁄32"

(28.3mm)

Page 20

LIMITED WARRANTY INFORMATION

Rockford Corporation offers a limited warranty on Rockford Fosgate products on the

following terms:

• Length of Warranty

1 year on speakers 30 days on speaker B-stock (receipt required)

3 years on electronics 90 days on electronic B-stock (receipt required)

2 years on source units

• What is Covered

This warranty applies only to Rockford Fosgate products sold to consumers by

Authorized Rockford Fosgate Dealers in the United States of America or its

possessions. Product purchased by consumers from an Authorized Rockford

Fosgate Dealer in another country are covered only by that country’s Distributor

and not by Rockford Corporation.

• Who is Covered

This warranty covers only the original purchaser of Rockford product purchased

from an Authorized Rockford Fosgate Dealer in the United States. In order to

receive service, the purchaser must provide Rockford with a copy of the receipt

stating the customer name, dealer name, product purchased and date of purchase.

• Products found to be defective during the warranty period will be repaired or

replaced (with a product deemed to be equivalent) at Rockford's discretion.

• What is Not Covered

1. Damage caused by accident, abuse, improper operations, water, theft

2. Any cost or expense related to the removal or reinstallation of product

3. Service performed by anyone other than Rockford or an Authorized Rockford

Fosgate Service Center

4. Any product which has had the serial number defaced, altered, or removed

5. Subsequent damage to other components

6. Any product purchased outside the U.S.

7. Any product not purchased from an Authorized Rockford Fosgate Dealer

• Limit on Implied Warranties

Any implied warranties including warranties of fitness for use and merchantability

are limited in duration to the period of the express warranty set forth above. Some

states do not allow limitations on the length of an implied warranty, so this

limitation may not apply. No person is authorized to assume for Rockford Fosgate

any other liability in connection with the sale of the product.

• How to Obtain Service

Please call 1-800-669-9899 for Rockford Customer Service. You must obtain an

RA# (Return Authorization number) to return any product to Rockford Fosgate. You

are responsible for shipment of product to Rockford.

Ship to: Electronics

Rockford Corporation

Warranty Repair Department

2055 E. 5th Street

Tempe, AZ 85281

RA#:_________________

Ship to: Speakers

Rockford Acoustic Design

(Receiving-speakers)

609 Myrtle N.W.

Grand Rapids, MI 49504

RA#:_________________

– 17 –

Page 21

NTERNATIONAL

I

I

NFORMATION

– 18 –

Page 22

LEA DETENIDAMENTE LAS SIGUIENTES INSTRUCCIONES DE

INSTALACIÓN DEL PRODUCTO.

INTRODUCCIÓN

Este manual contiene información sobre la construcción, installación y

funcionamiento de los sistemas Punch AUDIO

que conserve el manual para futuras consultas.

phile

. Le recomendamos

Es preferible que la instalación de sistema Punch AUDIO

realizada por un distribuidor autorizado Rockford Fosgate. Si prefiere

realizar la instalación usted mismo, asegurese de leer el manual en su

totalidad antes de comenzar.

MONTAJE

• Le mejor interacción entre tweeter y

medio se consigue si no están separados

entre si más de 5 cenimetros. (Figura 1)

no superior a 5cm

Figura 1

IN S TALACIÓN

Montaje del altavoz de medios

phile

sea

® ®

I

N

S

T

A

L

L

A

T

I

O

N

1. Corte el agujero para el medio/woofer.

• Par el RFA-44, corte un circulo de 101.6mm de diámetro

• Par el RFA-54, corte un circulo de 125.4mm de diámetro

• Par el RFA-64, corte un circulo de 148.4mm de diámetro

– 19 –

Page 23

2. Use los anillos de montaje de plástico como plantilla. Marque la

posición de los tornills de anclaje.

3. Quite el anillo y perfore los agujeros con una broca de 1/8".

4. Pase el cable de altavoz a través del agujero.

5. Instale los clips para tornillo. Monte el anillo de montaje sobre el

agujero.

6. Conecte los cables observando la polaridad. Mantenga los cables

alejados pe partes móviles o cortantes.

7. Asegure el altavoz en la abertura con los tornillos. Tenga la precaución

de no doblar el marco del altavoz en este proceso.

8. Presione la rejilla en el anillo de montaje.

Montaje en Superficie

Mounting

Baffle

Mounting

Nut

Bolt

E

SPAÑOL

Surface

Mount

Baseplate

Seccion

Surface

Mount

Cup

Vista Frontal

(Gire en el sentido contrario a las

agujas del reloj para fijar)

• Use la base extra cuando monte el tweeter en una superficie que

necesite refuerzo.

Montaje Empotrado

Nut

Bracket

Mounting

Flush

Mount

Baseplate

Bolt

Mounting

Baffle

Flush

Mount

Cup

2" Cutout

Vista de Atrás

Seccion

(Gire en el sentido contrario a las

agujas del reloj para fijar)

– 20 –

Page 24

Paso Banda Para del Medio

RFA-142x

Midrange

Output

–

I

® ®

N

S

T

A

L

L

A

T

I

O

N

+

+

–

400µf capacitor

• Para hacer un paso banda para el medio se ha de añadir un

condensador de 400µf en serie con el altavoz

Ajuste de Nivel del Tweeter

(Vista inferior del RFA-142x)

Cut jumper

wire for –3dB

• El ajuste de origen es –0dB

• Corte el hilo en la parte inferior del tweeter para una

reduccion del nivel del tweeter de –3dB

– 21 –

Page 25

Veuillez lire les instrucitons suivantes pour l'installation de ces produits.

INTRODUCTION

Ce manuel contient des informations sur les caractéristiques et l'installation

des systèmes Punch AUDIOphile. Nous vous proposons de garder ce

manuel pour toute référence future.

Nous vous recommandons vivement de faire installaer votre système

punch AUDIOphile par un dealer agréé Rockford Fosgate. Si vous

choisissez d'installer le système vous même, assurez-vous de lire ce

manuel entièrement avant de commencer.

EMPLACEMENT DE MONTAGE

• Pour bénéficier d'une harmonie maximum entre le médium et l'aigu

l'éloignement entre ces deux hautparleurs devrait être de moins de 5 cm

entre les 2 chassis. (Figure 1)

INSTALLATION

Montage du haut-parleur médium

moins de 5cm

Figure 1

® ®

F

RANCAIS

I

N

S

T

A

L

L

A

T

I

O

N

1. Découper un trou adapté au haut-parleur médium/woofer.

• Pour le RFA-44, le diamètre du trou est de 101,6mm

• Pour le RFA-54, le diamètre du trou est de 125,4mm

• Pour le RFA-64, le diamètre du trou est de 148,4mm

2. Placer l'anneau de montage sur le trou et repérer l'emplamcement

des trous des vis.

– 22 –

Page 26

3. Retirer l'anneau. Percer les trous des vis en utilisant une mèche de 3mm.

4. Faire passer les fils dans le trou central.

5. Installer les clips (clips Tinnerman) sur les trous des vis. Placer l'anneau

de montage au-dessus du trou central.

6. Connecter les fils au haut-parleur en respectant les polarités. Eloigner les

fils de toute partie tranchante ou mobile du véhicule.

7. Placer le haut-parleur au-dussus du trou central. Visser le haut-parleur

dans son emplacement. Faire attention à ne pas tordre le chassis du

haut-parleur durant cette étape de montage.

8. Mettre la grille dans l'anneau de montage.

Montage en surface du tweeter

Surface de

Mounting

Montage

Baffle

Mounting

Vis

écrou

Nut

Bolt

Bague de

Surface

Mount

Montage

Baseplate

en Surface

Vue Explosée

Support de

Surface

Montage

Mount

Cup

en Surface

Vue de Face

(Tourner dans le sens horlogique

pour verrouiller)

• Ajouter une bague de montage supplémentaire lorsque la surface de

montage doit être renforcée

Montage en affleurement du tweeter

Vis

Bolt

Flush

Surface de

Mounting

Montage

Baffle

Flush

Support de

Mount

Montage en

Cup

Affleurement

Découpe

2" Cutout

de 5cm

Vue Arrière

(Tourner dans le sens horlogique

pour verrouiller)

écrou

Nut

Bracket

Plaque de

Fixation

Mounting

Bague de

Mount

Montage en

Baseplate

Affleurement

Vue Explosée

– 23 –

Page 27

Bandpassing the Midrange

RFA-142x

Midrange

Output

–

+

+

–

400µf capacitor

• To bandpass the midrange, it is necessary to adda 400µf

capacitor in series with the speaker

Compensation du Niveau Aigu

Vue d'en bas du PCH-142x

Cut jumper

Coupez le pontage au

wire for –3dB

verso du filtre pour –3dB

• Le niveau de défaut est de –0dB

• Coupez le pontage au verso du filtre our atténuer l'aigu de 3dB.

– 24 –

Page 28

Die folgende Bedienungsanleitung soll Ihnen beim Einbau eine Hilfestellung

geben.

ENLEITUNG

Diese Bedienungsanleitung enthält Informationen für den Gebrauch und

Einbau des Punch AUDIOphile Systems. Wire empfehlen, sie auch für

Fragen in der Zukunft sorgfältig aufzubewahren.

Es ist empfehlenswert, sich das Punch AUDIOphile System von einem

Autorisierten Rockford Fosgate Fachhändler einbauen zu lassen. Sollten

Sie den Einbau jedoch selber vornehmen wollen, so empfehlen wir Ihnen

diese Bedienungsanleitung sorgfälitg zu lesen.

EINBAUORT

• Für das optimale Zusammenspiel von

Mittel- und Hochtöner, sollte der

Hochtöner niemals weiter als 5cm vorn

Mitteltöner entfernt montiert werden.

(Abb. 1)

Abstand max. 5cm

(Abb. 1)

EINBAU

Montage des Mitteltöners

1. Schneiden Sie die richtige Lochgröβe für den Mitteltöner oder

Midbaβ aus.

• Für den RFA-44, schneiden Sie ein 101,6cm Ø Loch

• Für den RFA-54, schneiden Sie ein 125,4cm Ø Loch

• Für den RFA-64, schneiden Sie ein 148,4cm Ø Loch

2. Setzen Sie den Montagering auf das Loch und markieren Sie die

Löcher für die Schrauben.

– 25 –

I

® ®

N

S

T

A

L

D

L

A

T

I

O

EUTSCH

N

Page 29

3. Nehmen Sie den Ring wieder ab und bohren Sie dann, mit einem

passenden Bohrer, die Schraubenlöcher vor.

4. Führen Sie das Kabel durch das Loch.

5. Stecken Sie die Schraubenships über die Schraubenlöcher. Plazieren

sie den Montagering über dem Loch.

6. Schlieβen Sie die Lautsprecherkabel an. Kontrollieren Sie, ob die

Polarität stimmt. Stellen Sie sicher, daβ das Lautsprecherkabel an

keinen scharfen oder sich bewegenden Teilen anliegt.

7. Plazieren Sie den Lautsprecher im Loch und befestigen ihn. Seien

Sie dabei vorsichtig daβ sich der Lautsprecherkorb nicht verzieht.

8. Drücken Sie das Lautsprechergitter im Montagering fest.

Hochtöner Aufbau-Montage

Surface de

Mounting

Montage

Baffle

Mounting

Vis

écrou

Nut

Bolt

Bague de

Surface

Mount

Montage

Baseplate

en Surface

Spreng Zeichnung

Support de

Surface

Montage

Mount

Cup

en Surface

Front-Ansicht

(Im Uhreigersinn drehen)

• Use when mounting tweeter to a solid surface (metal, wood, etc.)

Hochtöner Einbau-Montage

Vis

Bolt

Flush

Surface de

Mounting

Montage

Baffle

Flush

Support de

Mount

Montage en

Cup

Affleurement

Découpe

2" Cutout

de 5cm

Vue Arrière

(Tourner dans le sens horlogique

pour verrouiller)

écrou

Nut

Bracket

Plaque de

Fixation

Mounting

Bague de

Mount

Montage en

Baseplate

Affleurement

Spreng Zeichnung

– 26 –

Page 30

Bandpassing the Midrange

RFA-142x

Midrange

Output

–

+

+

–

400µf capacitor

• To bandpass the midrange, it is necessary to adda 400µf

capacitor in series with the speaker

Tweeter Level Matching

Bottom view of RFA-142x

Cut jumper

Cut jumper wire for –3dB

wire for –3dB

• Factory set tweeter level is –0dB

• Cut jumper wire on bottom of crossover to reduce tweeter level

by –3dB

– 27 –

Page 31

Leggere le istruzioni seguenti prima dell'installazione del prodotto.

INTRODUZIONE

Questo manuale fornisce informazioni sulle caratteristiche e sul

installazione dei sistemi Punch AUDIOphile. Vi suggeriamo di conservare

questo manuale come riferimento futuro.

Raccomandiamo fortemente che is sistema sia installato dal vostro

rivenditore Rockford Fosgate. Se scegliete di procedere con l'installazione

da soli, leggete attentamente tutto il manuale prima di proseguire.

POSIZIONAMENTO

• Per ottenere la miglior integrazione tra

tweeter e midrange, vi suggeriamo di

posizionare i due componenti a meno

meno di 5 cm

di 5 cm tra loro. (Figura 1)

Figura 1

INSTALLAZIONE

Installazione del Midrange

I

® ®

N

S

T

A

L

L

A

T

I

O

N

1. Practicate un foro del diametro corretto per il midrange/woofer

• 101,6mm per RFA-44

• 125,4mm per RFA-54

• 148,4mm per RFA-64

2. Posizionate l'anello della griglia sul foro e segnate la posizione

delle viti.

– 28 –

I

TALIANO

Page 32

3. Togliete l'anello e forate il pannello con una puna da 3,5mm.

4. Passate i cavi attraverso il foro.

5. Posizionate le clips di fissaggio sopra i fori delle viti e l'anello della

griglia sopra il foro dell'altoplarlante.

6. Collegate i cave assicurandovi di osservare la corretta polarità.

Assicuratevi di mantenere i cavi lontano da parti in movimento o

strutture taglienti.

7. Posizionate l'altoparlante nel foro ed avvitatelo. Assicuratevi di non

piegare il cestello dell'altoparlante.

8. Incastrate la griglia sull'anello di fissaggio.

Surface Mount Tweeter

Mounting

Mounting

Baffle

Baffle

Mounting

Mounting

Bolt

Nut

Nut

Bolt

Surface

Surface

Mount

Mount

Baseplate

Baseplate

Exploded View

Surface

Surface

Mount

Mount

Cup

Cup

Front View

(twist clockwise to lock)

• Use when mounting tweeter to a surface needing reinforcement

Flush Mount Tweeter

Mounting

Mounting

Baffle

Baffle

Flush

Flush

Mount

Mount

Cup

Cup

2" Cutout

2" Cutout

Front View

(twist clockwise to lock)

Nut

Bracket

Bracket

Nut

Mounting

Mounting

Bolt

Bolt

Flush

Flush

Mount

Mount

Baseplate

Baseplate

Exploded View

– 29 –

Page 33

Bandpassing the Midrange

RFA-142x

Midrange

Output

–

+

+

–

400µf capacitor

• To bandpass the midrange, it is necessary to adda 400µf

capacitor in series with the speaker

Tweeter Level Matching

Bottom view of RFA-142x

Cut jumper

Cut jumper wire for –3dB

wire for –3dB

• Factory set tweeter level is –0dB.

• Cut jumper wire on bottom of crossover to reduce tweeter level

by –3dB.

– 30 –

Page 34

MADE IN THE USA

This product is designed, developed and assembled in the USA by a dedicated

group of American workers. The majority of the components used in the

construction of this product are produced by American companies. However, due

to the global nature of their manufacturing facilities and the loudspeaker parts

industry in general, some parts may be manufactured in other countries.

Rockford Fosgate

Rockford Corporation

546 South Rockford Drive

Tempe, Arizona 85281 U.S.A.

In U.S.A., (602) 967-3565

In Europe, Fax (49) 4207-801250

In Japan, Fax (81) 559-79-1265

11/96

LIT9780

Loading...

Loading...