Rockford Fosgate Punch200 trans•ana 4-channel, Punch600 trans•ana 5-channel, Punch 200, Punch 400, Punch 600 Installation & Operation Manual

...

Punch200

trans•ana

4-channel

Punch400

trans•ana

4-channel

Punch600

trans•ana

4-channel

Punch800

trans•ana

4-channel

Punch600

trans•ana

5-channel

Installation

& Operation

Sections marked

TROUBLESHOOTING

include recommendations for

curing installation problems

Sections marked

INSTALLATION

include “slam dunk”

wiring connections

W elcome to Rockford Fosgate! This manual is designed to provide information for the owner, salesperson and installer. For those of you who want

quick information on how to install this product, please turn to the

Installation Section of this manual or refer to the icons listed below. Other

information can be located by using the Table of Contents. We, at Rockford

Fosgate, have worked very hard to make sure all the information in this

manual is current. But, as we are constantly finding new ways to improve

our product, this information is subject to change without notice.

GETTING STARTED

I

N

S

T

A

L

L

A

T

I

O

N

+ -

+ -

TROUBLE-

S

H

O

O

T

I

N

G

Visit our website for the latest information on all Rockford products.

If, after reading your manual, you still have questions regarding this product, we

recommend that you see your Rockford Fosgate dealer. If you need further assistance, you can call us direct at 1-800-669-9899. Be sure to have your serial number, model number and date of purchase available when you call.

The serial number can be found on the outside of the box. Please record it in the

space provided below as your permanent record. This will serve as verification of

your factory warranty and may become useful in recovering your amplifier if it is

ever stolen.

Serial Number: __________________________________

Model Number: __________________________________

–i–

Dear Customer,

Congratulations on your purchase of the world's finest brand of car audio amplifiers.

At Rockford Fosgate we are fanatics about musical reproduction at its best, and we

are pleased you chose our product. Through years of engineering expertise, hand

craftsmanship and critical testing procedures, we have created a wide range of products that reproduce music with all the clarity and richness you deserve.

For maximum performance we recommend you have your new Rockford Fosgate

product installed by an Authorized Rockford Fosgate Dealer, as we provide specialized training through Rockford Technical Training Institute (RTTI).

Please read your warranty and retain your receipt and original carton for possible

future use.

Great product and competent installations are only a piece of the puzzle when it

comes to your system. Make sure that your installer is using 100% authentic installation accessories from Connecting Punch in your installation. Connecting Punch

has everything from RCA cables and speaker wire to Power line and battery connectors. Insist on it! After all, your new system deserves nothing but the best.

To add the finishing touch to your new Rockford Fosgate image order your Rockford

wearables, which include everything from T-shirts and jackets to hats and sunglasses.

To get a free brochure on Rockford Fosgate products and Rockford accessories, in

the U.S. call 480-967-3565 or FAX 480-967-8132. For all other countries, call +001480-967-3565 or FAX +001-480-967-8132.

PRACTICE SAFE SOUND™

CONTINUOUS EXPOSURE TO SOUND PRESSURE LEVELS OVER 100dBMAY

CAUSE PERMANENT HEARING LOSS

. HIGH POWERED AUTOSOUND SYSTEMS

MAY PRODUCE SOUND PRESSURE LEVELS WELL OVER

130dB. USE COMMON

SENSE AND PRACTICE SAFE SOUND

.

– ii –

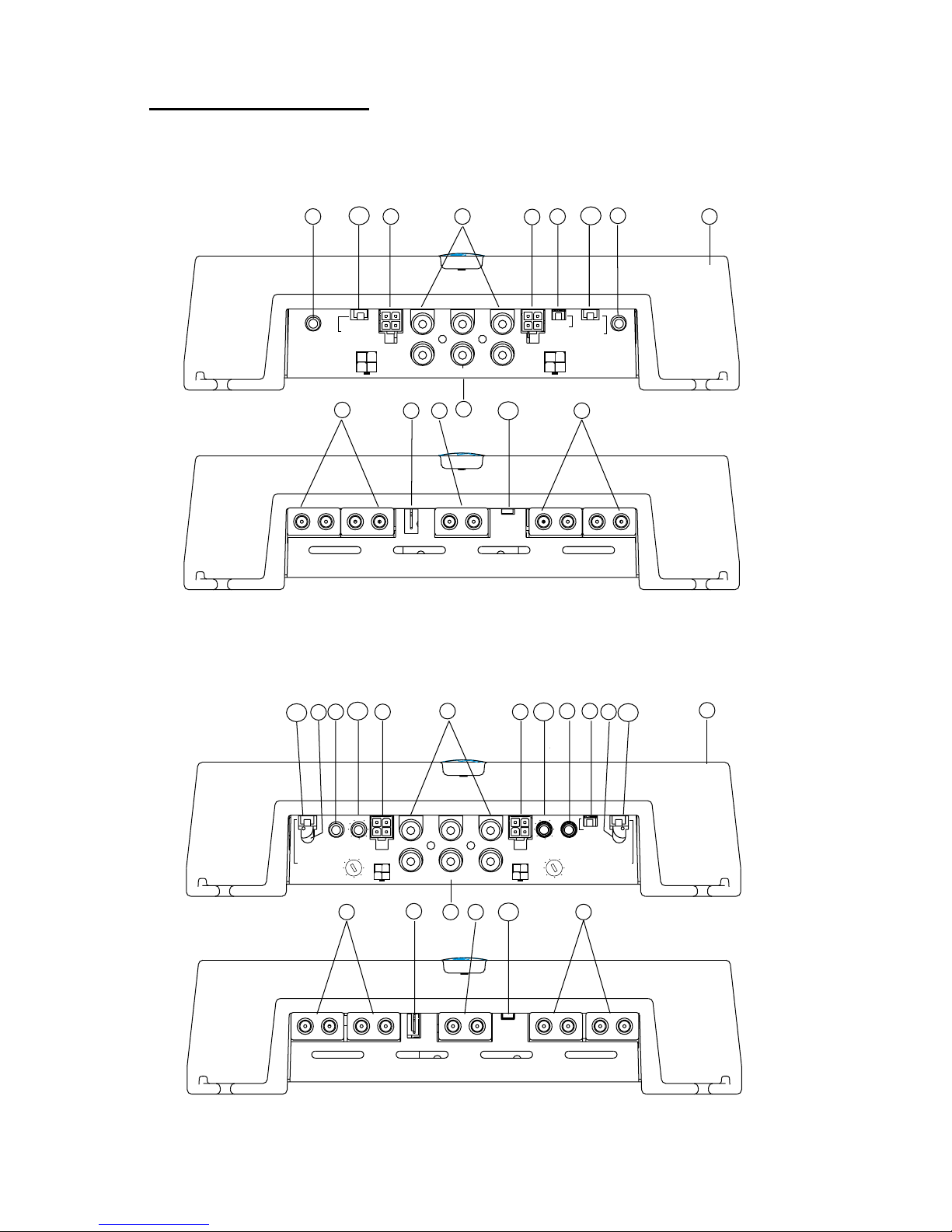

Specifications

PUNCH 200 PUNCH 400 PUNCH 600 PUNCH 800 PUNCH 600

4-channel 4-channel 4-channel 4-channel 5-channel

DynamicPowerRating (IHF-202 Standard)

- Measured at 14.4 Volts Front/Rear + Subwoofer

Bridged into a 4Ω Load

165 Watts x 2 220 Watts x 2 317 Watts x 2 525 Watts x 2 240 Watts x

2+ -

Per channel into a 2Ω Load

85 Watts x 4 130 Watts x 4 175 Watts x 4 270 Watts x 4 120 Watts x 4 + 240 Watts x 1

Per channel into a 4Ω Load

55 Watts x 4 85 Watts x 4 99 Watts x 4 150 Watts x 4 75 Watts x 4 + 115 Watts x 1

Continuous Power Rating (Competition Standard) - Measured at 13.8 Battery Volts

RMS continuous power per channel,

25 Watts x 4 50 Watts x 4 75 Watts x 4 100 Watts x 4 50 Watts x 4 + 100 Watts x 1

both channels driven into a 4Ω load

from 20 to 20,000 Hz with less than

0.05% Total Harmonic Distortion (THD+N)

RMS continuous power per channel,

50 Watts x 4 100 Watts x 4 150 Watts x 4 200 Watts x 4 100 Watts x 4 + 200 Watts x 1

both channels driven into a 2Ω load

from 20 to 20,000 Hz, with less than

0.1% Total Harmonic Distortion (THD+N)

RMS continuous power bridged into a

100 Watts x 2 200 Watts x 2 300 Watts x 2 400 Watts x 2 200 Watts x 2 + 4Ω load from 20 to 20,000 Hz, with

less than 0.1% Total Harmonic

Distortion (THD+N)

Signal-to-Noise Ratio >100dB A-weighted

Crossover Slope (Butterworth) 12dB/octave 12dB/octave 12dB/octave 12dB/octave 12dB/octave + 24dB/octave

Crossover Frequency 80Hz 80Hz

50Hz – 210Hz 50Hz – 210Hz 50Hz – 210Hz + 50Hz – 210Hz

Specifications are subject to change without notice.

– iii –

Dimensions PUNCH 200 PUNCH 400 PUNCH 600 PUNCH 800 PUNCH 600

4-channel 4-channel 4-channel 4-channel 5-channel

2.4” H 2.4” H 2.4” H 2.4” 2.4” H

(6.09cm) (6.09cm) (6.09cm) (6.09cm) (6.09cm)

9.9” W 9.9” W 9.9” W9.9” W9.9” W

(25.15cm) (25.15cm) (25.15cm) (25.15cm) (25.15cm)

13.4” L 13.4” L 14.4” L 18.4” L 18.4” L

(34.04cm) (34.04cm) (36.57cm) (46.74cm) (46.74cm)

Frequency Response 20Hz to 20kHz ±0.5dB

Bandwidth 20Hz to 200kHz ±3dB

Damping Factor @ 4Ω (at output connector ) >200

Slew Rate 30 Volts/ ms

IM Distortion (IHF) <0.05%

Source Unit Compatibility (+15dB gain overlap) All All All All All

Input Sensitivity (+0dB gain overlap) Variable from 250mV to 4V (low level in)

Variable from 650mV to 11V (high level in)

Protection NOMAD - Internal analog-computer output protection circuitry limits power in case of

overload. Thermal switch shuts down the amplifier in case of overheating.

Battery Fuse Rating (External to Amplifier) 30A 50A 50A 60A* 50A

Fuse Type ATC AGU AGU AGU AGU

Equalization (45Hz Punch Bass) Variable Variable Variable Variable Variable

(0 to +18dB) (0 to +18dB) (0 to +18dB) (0 to +18dB) (0 to +18dB)

Input Impedance 20k ohms 20k ohms 20k ohms 20k ohms 20k ohms

* recommended fuse not supplied with amplifier Specifications are subject to change without notice.

– iv –

Table of Contents

Specifications............................................................................................ii

Introduction ..............................................................................................1

Amplifier Accessory Pack..........................................................................1

Feature Chart ............................................................................................2

Design Features ........................................................................................4

Installation Considerations........................................................................7

Mounting Location....................................................................................8

Battery and Charging ................................................................................9

Wiring the System ....................................................................................9

Using Passive Crossovers ........................................................................11

Table of Component Values ....................................................................12

Installation ..............................................................................................13

System Diagrams ....................................................................................25

Troubleshooting ......................................................................................29

Dynamic Power Measurements ..............................................................31

Warranty Information..............................................................................33

International Information ........................................................................35

Introduction

Rockford engineers designed the Punch multi-channel amplifiers to withstand the rugged automotive environment while delivering superior sound

quality in a flexible, reliable, and efficient package. TRANS•ana is a low

voltage circuit in the preamp stage of all Punch multi-channel amplifiers

that lets the music sound crystal clear and very real, even when played at

high volume levels. This is matched with TOPAZ, a unique grounding circuit used to eliminate noise problems associated with car audio systems

and their installation. Flexibility is accomplished with the use of high-level

inputs and a built-in crossover. The use of a protection circuit called

NOMAD, along with MOSFET and DSM (Discrete Surface Mount) and our

innovative MEHSA heat dissipating technology improves amplifier efficiency. The result of these components give the Punch amplifier awesome

sound quality in a “Bullet Proof” package.

– 1 –

Punch Amplifier Accessory Pack

The accessory pack shipped with the Punch multi-channel amplifiers

includes the mounting hardware necessary to secure the amp to the

vehicle.

Installation & Operation Manual

Punch Verification Certificate

(4) Amplifier mounting screws (#8 x 3/4" Phillips)

(4) Speaker/Power connector set screws (3/32" Allen)

(4) Endbell mounting screws (9/64" Allen)

(1) Allen wrench (3/32")

(1) Allen wrench (9/64")

(2) High Level Input harness (Punch 200/400/600/800, 4-channel)

- Replacement part #CC-1992 - 4 position molex

(1) High Level Input harness (Punch 600, 5-channel)

- Replacement part #CC-2347 - 8 pin mini-DIN

(1) Inline fuseholder (except Punch 800, 4-channel)

(1) ATC 30 amp fuse (Punch 200, 4-channel)

(1) ATC 50 amp fuse (Punch 400/600, 4-channel & Punch 600, 5-channel)

NOTE: Refer to the specifications section for recommended fuse size on

the Punch 800, 4-channel amplifier.

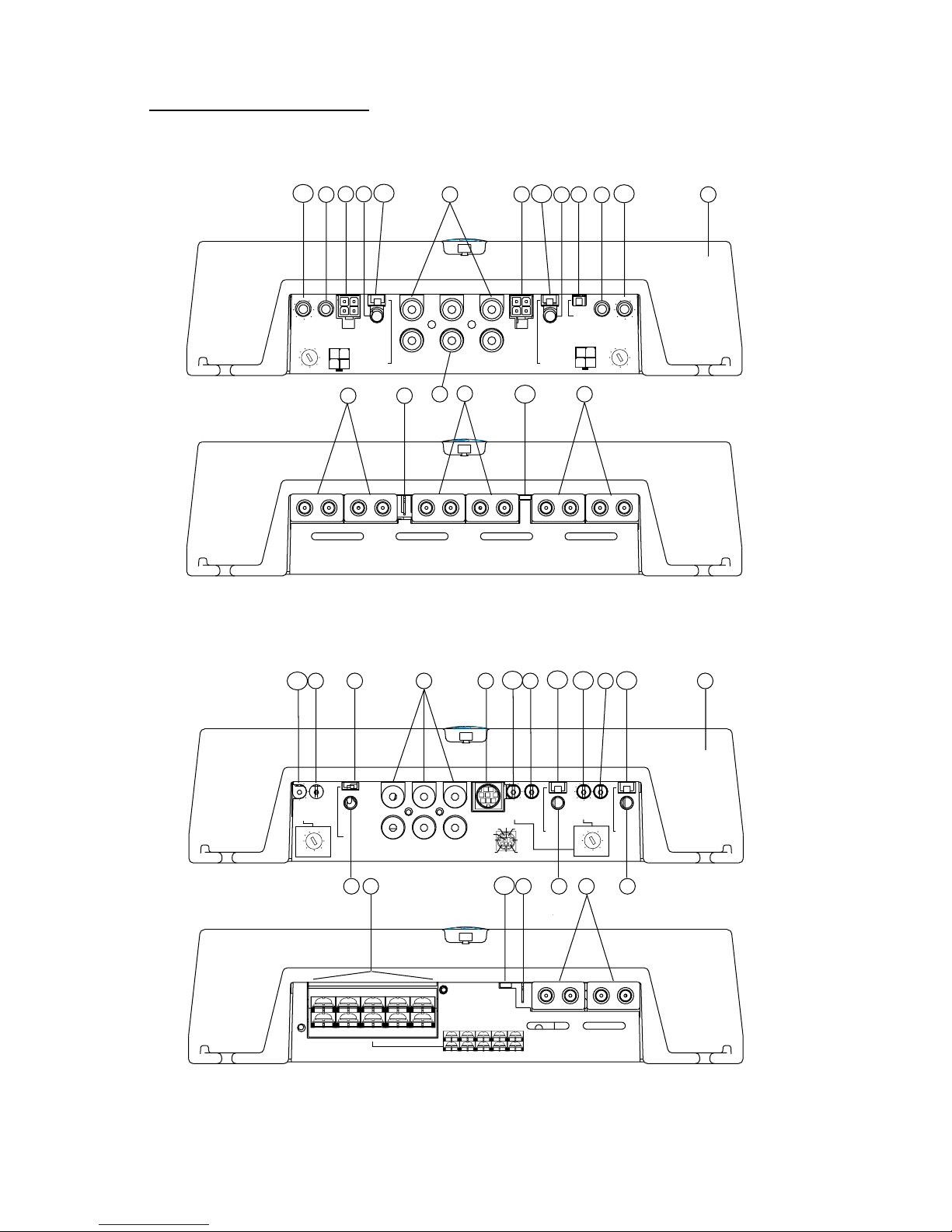

Punch Multi-Channel Amplifier Feature Chart

PUNCH AMPLIFIER MODEL 200 400 600 800 600

F/R + SUB

# of CHANNELS 44 4 4 5

RMS Power Stereo (4Ω) 25x4 50x4 75x4 100x4 50x4 + 100x1

RMS Power Stereo (2Ω) 50x4 100x4 150x4 200x4 100x4 + 200x1

RMS Power Bridged (4Ω) 100x2 200x2 300x2 400x2 200x2 + –

Stable Into: (each channel) 2Ω 2Ω 2Ω 2Ω 2Ω +2Ω

Stable into: (bridged) 4Ω 4Ω 4Ω 4Ω 4Ω + –

CIRCUITRY

1

TRANS•ana – circuit topology xx x x x

TRANS•nova – patented circuit topology2

–– – – –

Class-G – high efficiency topology –– – –SUB only

MEHSA – heat dissipating technology – xxx x

TOPAZ – patented noise eliminating circuitry

3

xx x x x

DSM – discrete surface mount xx x x x

MOSFETs – power supply & output devices xx x x x

NOMAD – protection circuit xx x x x

FEATURES

Die Cast Heatsink xx x x x

Hi-Level Inputs – for factory radios x x x x F/R only

RCA Inputs – for aftermarket radios xx x x x

Balanced Inputs –– – – –

Input Switches – eliminates “Y” adaptors xx x x x

Pass-Thru – feeds signal to aux. amp xx x x –

Pwr/Spk Screw Terminals –– – – Spk

Pwr/Spk Block Terminals x x x x Pwr

4 Gauge PWR/GND –– – – –

– 2 –

PUNCH AMPLIFIER MODEL 200 400 600 800 600

Adjustable Punch Bass –––– –

(0dB/+6dB/+12dB @ 45Hz)

Variable Punch Bass ––xx x

(0dB ~+18dB @ 45Hz)

Adjustable Xover (80Hz) –––– –

Variable Xover (50Hz ~ 210Hz)

HP/FULL/LP4HP/FULL/LP4HP/FULL/LP4HP/FULL/LP4HP/FULL/LP

4

Crossover Slope (Butterworth) 12dB 12dB 12dB 12dB 12dB + 24dB

5

Phase Warp (0 ~ 180) –––– –

GENERAL

B+ Fuse Size 30A ATC 50A AGU 50A AGU 60A AGU

6

50A AGU

Dimensions (H x W x L)

– 3 –

1 Additional information on features, specifications and system designs can be

found at: www.rockfordfosgate.com

2 Trans•nova is patented under "U.S. Patent No. 4,467,288"

3 TOPAZ is patented under "U.S. Patent No. 5,751,823"

4 HP = 12dB/octave High-Pass / LP = 12dB/octave Low-Pass / FULL = Full Range

5 Front/Rear = 12dB/octave + Sub = 24dB/octave Low-Pass

6 Recommended fuse not supplied with amplifier

--INTERNAL USE ONLY--

Heatsink Type #4 #4 #5 #6 #6

2.4” H 2.4” H 2.4” H 2.4”H 2.4” H

(6.09cm) (6.09cm) (6.09cm) (6.09cm) (6.09cm)

9.9” W9.9” W 9.9” W 9.9” W9.9” W

(25.15cm) (25.15cm) (25.15cm) (25.15cm) (25.15cm)

13.4” L 13.4” L 14.4” L 18.4” L 18.4” L

(34.04cm) (34.04cm) (36.57cm) (46.74cm) (46.74cm)

– 4 –

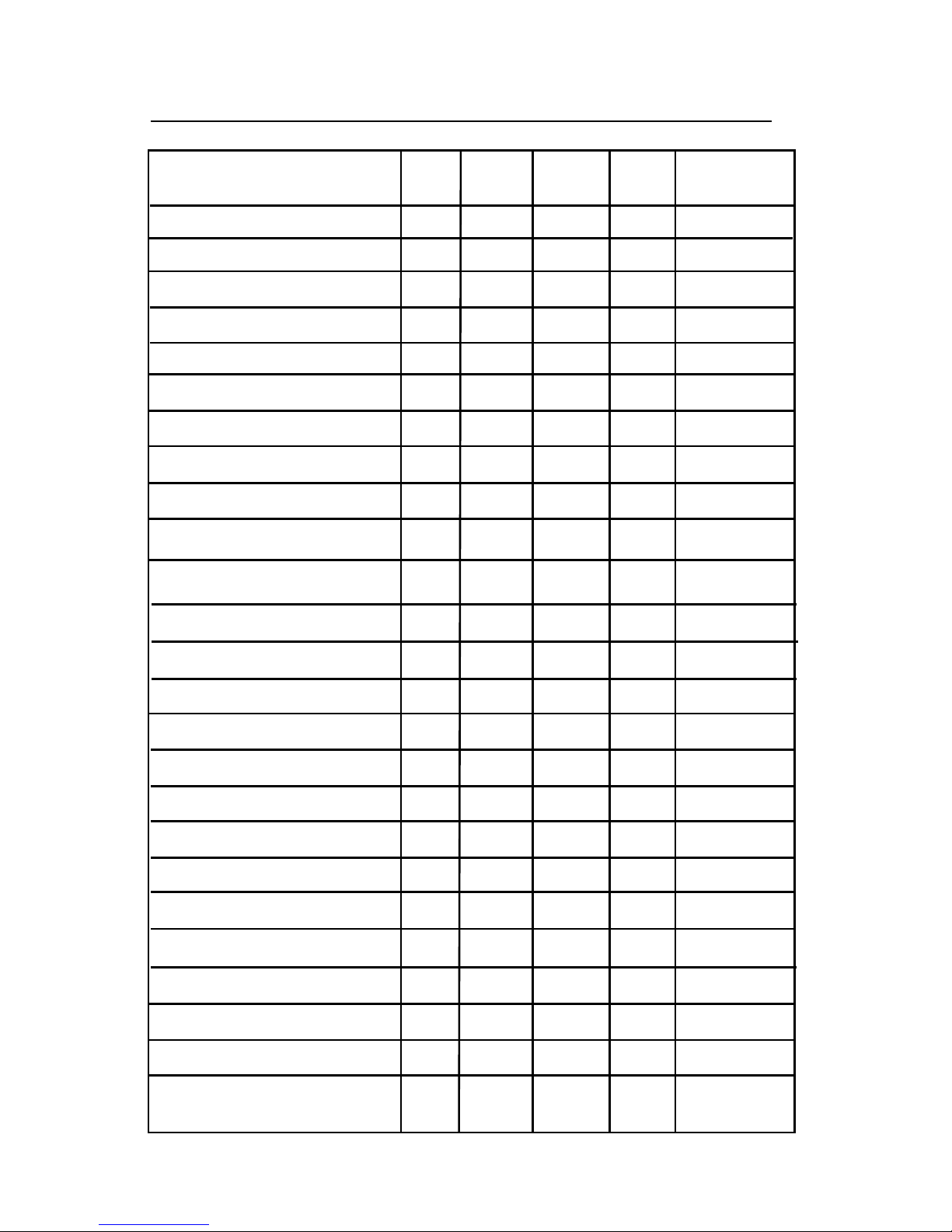

Design Features

Punch 200, 4-channel

Punch 400, 4-channel

Punch 600, 4-channel

10

Front High

Level Inputs

Gain

Gain

Crossover

Frequency

Front

R

L

R

L

RearPass-Thru

4-2

Input

Punch

Bass

HP-FULL-LP

Crossover

Front

Rear High

Level Inputs

Crossover

Frequency

Punch

Bass

Rear

L+

L–

R+

R–

Hz

65

80

55

50

110

210

Hz

145

190

Hz

L+

L–

R+

R–

65

80

55

50

110

210

Hz

145

190

HP-FULL-LP

Crossover

REM

B+ GND

LED

LR+ LR– RR+ RR– LF– LF+ RF– RF+

2

3

211

2

56

109

810 6 10 84

9

7

1

L+

L–

R+

R–

L+

L–

R+

R–

8

10

465610

8

7

2

3 2 11 2

1

Front

Gain

HP–Full–LP

Front 80Hz

Crossover

Front

High

Level

Input

Front

Pass-Thru

Rear

RR

LL

Rear

High

Level

Input

4 – 2

Input

HP-Full-LP

Rear 80Hz

Crossover

Rear

Gain

REM

LED

LR+ LR–

RR+ RR–

B+

GND

LF– LF+ RF– RF+

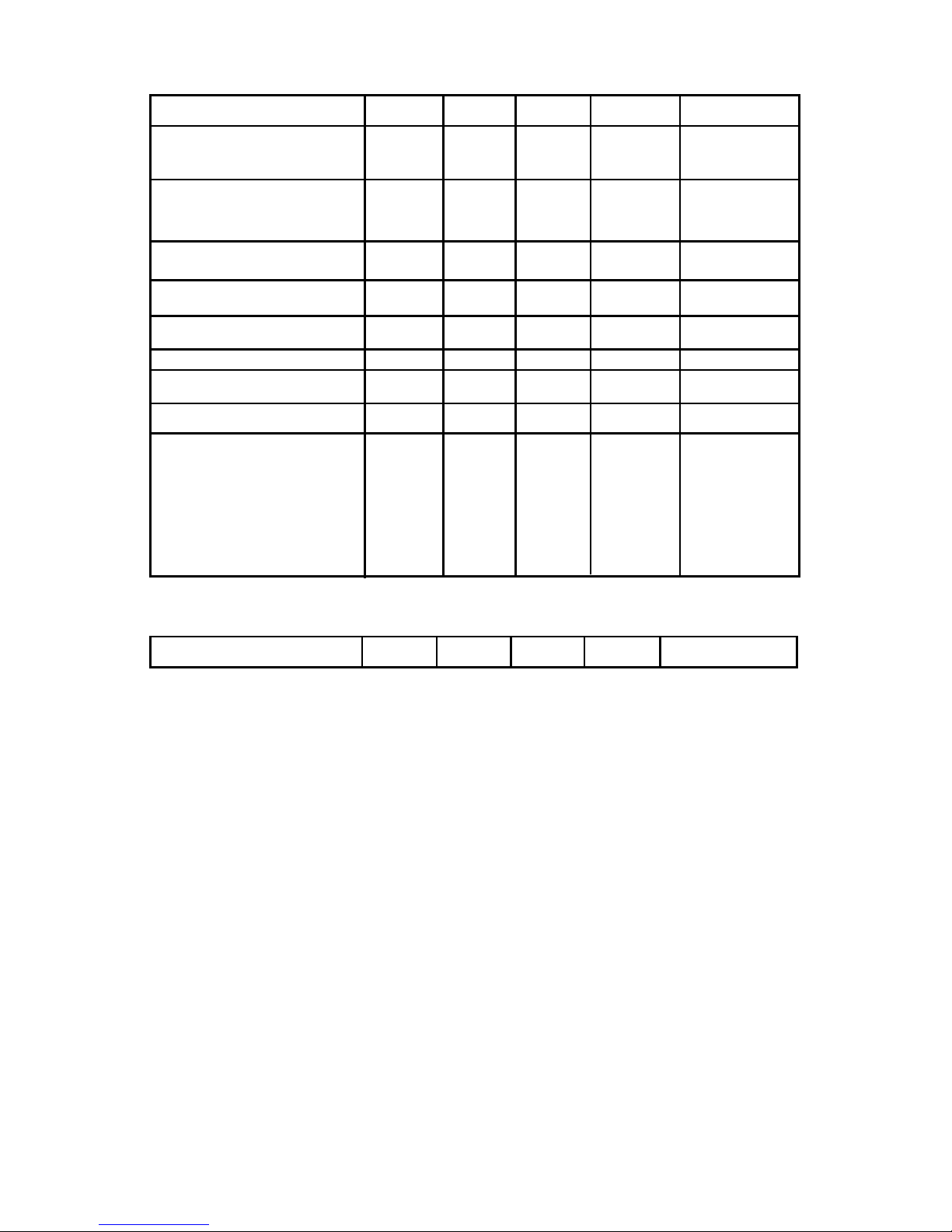

Design Features

– 5 –

Punch 800, 4-channel

10

2

3

11

2

5

8

10

7

1

LR+ LR- RR+ RR-

REM

B+ GND

LED

LF- LF+ RF+RF-

Hz

Front

Crossover

Frequency

Front

Gain

Front High

Level Input

L+

L–

R+

R–

Front

Punch

Bass

Front Pass-Thru Rear

RR

LL

Rear

High

Level

Input

Rear

Punch

Bass

Crossover

HP-Full-LP

Crossover

HP-Full-LP

4-2

Input

Rear

Crossover

Frequency

Rear

Gain

L+

L–

R+

R–

65

80

55

50

110

210

Hz

145

190

Hz

65

80

55

50

110

210

Hz

145

190

2

10

6 9

10

6

9

4

8

Punch 600, 5-channel

549 6

10

9 9

10

10

10 10

1

Sub LP

Crossover

Frequency

Sub

Gain

65

80

55

50

110

210

Hz

145

190

6/4/2

Input

Sub Rear Front

R

L

R

L

Sub

Punch

Bass

Rear

Crossover

Frequency

Rear

Punch

Bass

Rear

Gain

High Level

Input

Front

Crossover

Frequency

Front

Punch

Bass

Front

Gain

HP-Full-LP

Front

Crossover

HP-Full-LP

Rear

Crossover

65

80

55

50

110

210

Hz

145

190

GND

LF-LF+

RF+

RF-

LR+

RR-

RR+

LR-

LR+

LR-

RR+

RR-

RF- LF+ Sub-

RF+ LF- Sub+

REM

B+

GND

LED

LR+

LR-

RR+

RR-

RF- LF+ Sub-

RF+ LF- Sub+

11

232 888

– 6 –

1. Cast Aluminum Heatsink – The cast aluminum heatsink of the Punch

amplifier dissipates heat generated by the amplifier's circuitry. The

inherent advantage of casting provides a 30% improvement of cooling

over conventional extrusion heatsink designs.

2. Speaker/Power Terminals – The heavy duty, gold-plated terminal block

connectors (+ and –) will accept wire sizes from 8 AWG to 18 AWG

and are immune to corrosion that can cause signal degradation. The

Punch 600, 5-channel also utilizes a barrier strip that will accept #8

spade lugs or bare speker wires sized from 12-18 AWG.

3. REM Terminal – This spade terminal is used to remotely turn on and

turn off the amplifier when +12V DC is applied.

4. Signal Input Switch – This switch allows the amplifier to be driven with

either 2 or 4 pairs of inputs. The Punch 600, 5-channel allows the

amplifier to be driven with either 2, 4, or 6 pairs of inputs.

5. RCA Input Jacks – The industry standard RCA jacks provide an easy

connection for signal level input. They are gold-plated to resist the signal degradation caused by corrosion.

6. High Level Inputs – The high level inputs use a detachable connector

terminated with 20 AWG leads. These inputs should be used if the

source unit has only speaker line (high level) outputs and not RCA outputs.

7. RCA Pass-Thru Jacks – The Pass-Thru provides a convenient source for

daisy-chaining an additional amplifier without running an extra set of

RCA cables from the front of the vehicle to the rear amplifier location.

8. Gain Control – The input gain control is preset to match the output of

most source units. It can be adjusted to match output levels from a variety of source units.

9. Punch Bass – The Punch Bass helps correct for acoustical deficiencies

in the listening environment by helping reproduce full range sound

without adding excessive boost. The Punch Bass control is a narrow

band adjustment centered at 45Hz variable from 0dB to +18dB.

10. Internal Crossover – The internal crossover is a 12dB/octave

Butterworth filter selectable for High-Pass (HP), Full Range (FULL), or

Low-Pass (LP) operation. The Punch 200/400, 4-channel amplifiers

utilize a fixed 80Hz crossover. The Punch 600/800, 4-channel and

Punch 600, 5-channel amplifiers utilize a crossover variable from

50Hz to 210Hz with the Sub channel operating at 24dB/octave.

11. LED Power Indicator – The LED illuminates when the unit is turned on.

Installation Considerations

The following is a list of tools you will need for installing the Punch

amplifier:

Voltmeter Wire strippers

Electric hand drill w/assorted bits Battery post wrench

17' (5 m) Red Power Wire Wire cutters

12' (4 m) Remote Turn-On Wire Assorted connectors

1.5' (45 cm) Black Grounding Wire Wire crimpers

– 7 –

This section focuses on some of the vehicle considerations for installing

your new Punch amplifier. Checking your battery and present sound system, as well as pre-planning your system layout and best wiring routes, will

save installation time. When deciding how to lay out your new system, be

sure that each component will be easily accessible for making adjustments.

Before beginning any installation, be sure to follow these simple rules:

1. Be sure to carefully read and understand the instructions before

attempting to install the amplifier.

2. For safety, disconnect the negative lead from the battery prior to begin-

ning the installation.

3. For easier assembly, we suggest you run all wires prior to mounting

your amplifier in place.

4. Route all of the RCA cables close together and away from any high current wires.

5. Use high quality connectors for a reliable installation and to minimize

signal or power loss.

6. Think before you drill! Be careful not to cut or drill into gas tanks, fuel

lines, brake or hydraulic lines, vacuum lines or electrical wiring when

working on any vehicle.

7. Never run wires underneath the vehicle. Running the wires inside the

vehicle provides the best protection.

8. Avoid running wires over or through sharp edges. Use rubber or plastic grommets to protect any wires routed through metal, especially the

firewall.

9.

ALWAYS protect the battery and electrical system from damage with

proper fusing. Install a fuseholder and appropriate fuse on the +12V

power wire within 18” (45 cm) of the battery terminal.

10. When grounding to the chassis of the vehicle, scrape all paint from the

metal to ensure a good, clean ground connection. Grounding connections should be as short as possible and always be connected to metal

that is welded to the main body, or chassis, of the vehicle.

Mounting Location

The mounting location and position of your amplifier will have a great

effect on its ability to dissipate the heat generated during normal operation.

The design of our cast aluminum heatsink serves to easily dissipate the heat

generated over a wide range of operating conditions. However, to maximize the performance of your amplifier, care should be taken to ensure

adequate ventilation.

Trunk Mounting

Mounting the amplifier vertically on a surface with the fin grooves running

up and down will provide the best cooling of the amplifier.

Mounting the amplifier on the floor of the trunk will work but provides less

cooling capability than vertical mounting.

Mounting the amplifier upside down to the rear deck of the trunk will not

provide proper cooling and will severely affect the performance of the

amplifier and is strongly not recommended.

Passenger Compartment Mounting

Mounting the amplifier in the passenger compartment will work as long as

you provide a sufficient amount of air for the amplifier to cool itself. If you

are going to mount the amplifier under the seat of the vehicle, you must

have at least 1" (2.54cm) of air gap around the amplifier's heatsink.

Mounting the amplifier with less than 1" (2.54cm) of air gap around the

amplifier's heatsink in the passenger compartment will not provide proper

cooling and will severely affect the performance of the amplifier and is

strongly not recommended.

Engine Compartment Mounting

Rockford Fosgate amplifiers should never be mounted in the engine compartment. Not only will this void your warranty but could create an embarrassing situation caused by the ridicule from your friends.

– 8 –

Battery and Charging

– 9 –

Amplifiers will put an increased load on the vehicle's battery and charging

system. We recommend checking your alternator and battery condition to

ensure that the electrical system has enough capacity to handle the

increased load of your stereo system. Stock electrical systems which are in

good condition should be able to handle the extra load of any Rockford

amplifier without problems, although battery and alternator life can be

reduced slightly. To maximize the performance of your Rockford Fosgate

amplifier, we suggest the use of a heavy duty battery and an energy storage

capacitor.

Wiring the System

CAUTION: Avoid running power wires near the low level input cables,

antenna, power leads, sensitive equipment or harnesses. The power wires

carry substantial current and could induce noise into the audio system.

1. Plan the wire routing. Take care when running signal level RCA cables

to keep them close together but isolated from the amplifier's power

cables and any high power auto accessories, especially electric motors.

This is done to prevent coupling the noise from radiated electrical fields

into the audio signal. When feeding the wires through the firewall or

any metal barrier, protect them with plastic or rubber grommets to prevent short circuits. Leave the wires long at this point to adjust for a precise fit at a later time.

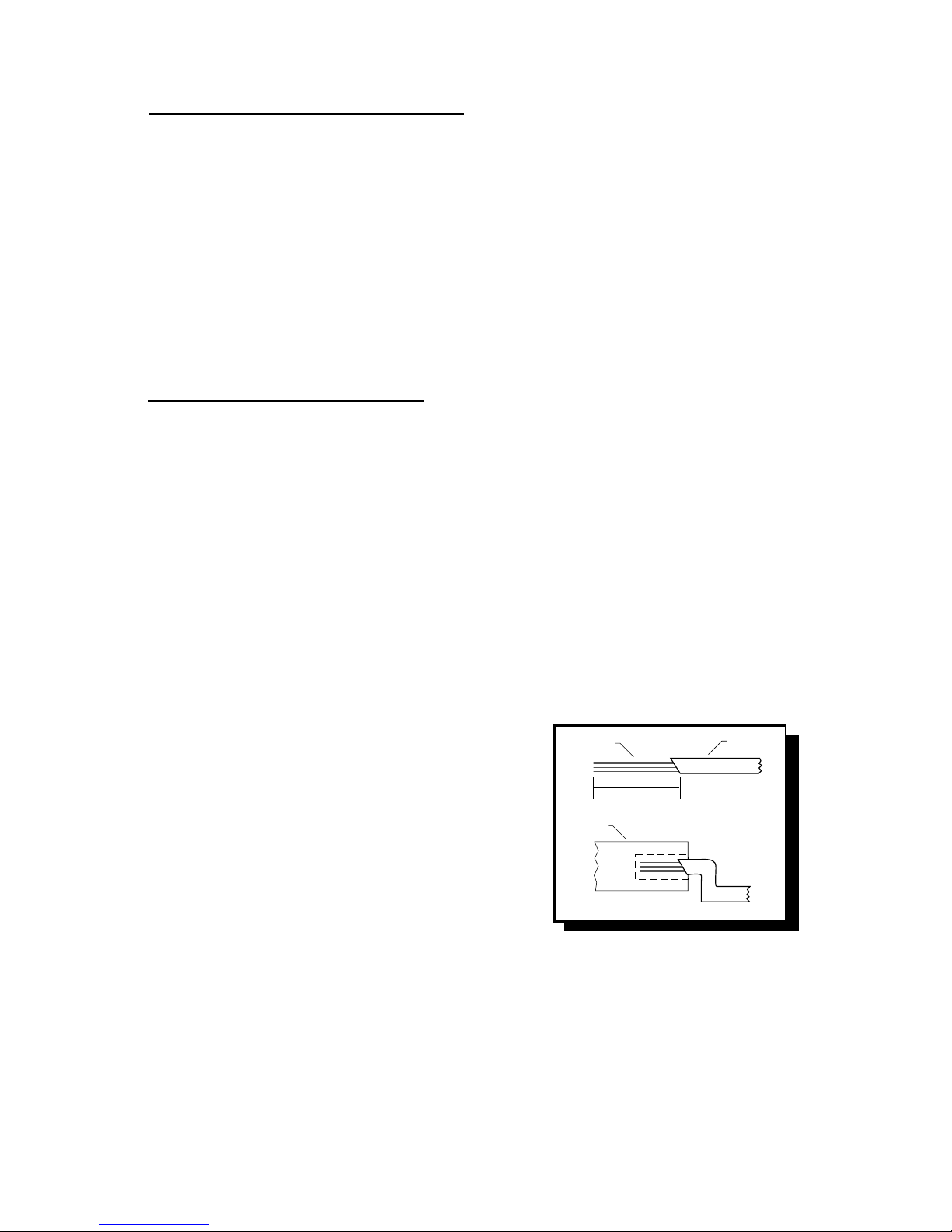

2. Prepare the

Power cable for attachment

to the amplifier by stripping 5/8" of

insulation from the end of the wire. The

use of 8 gauge power cable can interfere with the installation of the end

caps. Proper wire dress can prevent this

from occurring. To prevent the wire

from fraying, strip the insulation at a

45° angle. Insert the bared wire into the

B+ terminal with the long side of the insulation on the top. Bend the

cable down at a 90° angle. Tighten the set screw to secure the cable in

place.

3. Strip 3/8" from the battery end of the power cable and crimp a large

ring terminal to the cable. Use the ring terminal to connect to the battery positive terminal.

Do not install the fuse at this time.

><

5/8"

INSULATION

STRIP WIRE

>

>

AMP

>

– 10 –

4. Prepare a length of cable to be used for the ground connection. Strip

5/8" of insulation from the end of the cable as described above and

connect to the appropriate terminal of the amplifier. Prepare the chassis ground by scraping any paint from the metal surface and thoroughly clean the area of all dirt and grease. Strip the other end of the wire

and attach a ring connector . Fasten the cable to the chassis using a nonanodized screw and a star washer.

5. Prepare the REM turn-on wire for connection to the amplifier by stripping 1/4" of insulation from the wire end and crimping an insulated

spade connector in place. Slide the connector over the REM terminal

on the amplifier. Connect the other end of the REM wire to a switched

12 volt positive source. The switched signal is usually taken from the

source unit's auto antenna or the accessory lead. If the source unit does

not have these outputs available, the recommended solution is to wire

a mechanical switch in line with a 12 volt source to activate the amplifier.

6. Securely mount the amplifier (with supplied screws) to the vehicle or

amp rack. Be careful not to mount the amplifier on cardboard or plastic panels. Doing so may enable the screws to pull out from the panel

due to road vibrations or sudden vehicle stops.

7. Determine the number of inputs needed to drive the amplifier and

move the input switch to the desired setting.

8. Connect the source signal to the amplifier by plugging the RCA cables

or high level inputs into the input jack(s) at the amplifier.

9. Connect the speakers. Strip the speaker wires 5/8" and insert into the

appropriate terminal on the amplifier. Insert the bared wire into the

speaker terminal and tighten the set screw to secure into place. Be sure

to maintain proper speaker polarity.

DO NOT chassis ground any of

the speaker leads as unstable operation may result.

10. Perform a final check of the completed system wiring to ensure that all

connections are accurate. Check all power and ground connections for

frayed wires and loose connections which could cause problems from

road vibrations.

Loading...

Loading...