Rockford Fosgate Fanatic P FNP1414, Fanatic P FNP1514, Fanatic P FNP1614F, Fanatic P FNP1614 Operating & Installation Manual

Page 1

component systems

® ®

car audio

fanatics

for

operation &operation &

operation &operation &

operation &

installationinstallation

installationinstallation

installation

Page 2

Dear Customer,

Congratulations on your purchase of the world's finest brand of car audio speakers. At

Rockford Fosgate we are fanatics about musical reproduction at its best, and we are

pleased you chose our product. Through years of engineering expertise, hand craftsmanship and critical testing procedures, we have created a wide range of products that

reproduce music with all the clarity and richness you deserve.

For maximum performance we recommend you have your new Rockford Fosgate

product installed by an Authorized Rockford Fosgate Dealer, as we provide specialized

training through Rockford Technical Training Institute (RTTI). Please read your

warranty and retain your receipt and original carton for possible future use.

Great product and competent installations are only a piece of the puzzle when it comes

to your system. Make sure that your installer is using 100% authentic installation

accessories from Connecting Punch in your installation. Connecting Punch has

everything from RCA cables and speaker wire to Power line and battery connectors.

Insist on it! After all, your new system deserves nothing but the best.

To add the finishing touch to your new Rockford Fosgate image order your Rockford

wearables, which include everything from T-shirts and jackets to hats and sunglasses.

To get a free brochure on Rockford Fosgate products and Rockford accessories, in the

U.S. call 602-967-3565 or FAX 602-967-8132. For all other countries, call +001-602967-3565 or FAX +001-602-967-8132.

If, after reading your manual, you still have questions regarding this product,

we recommend that you see your Rockford Fosgate dealer. If you need further

assistance, you can call us direct at 1-800-669-9899. Be sure to have your serial

number, model number and date of purchase available when you call.

PRACTICE SAFE SOUND™

CONTINUOUS EXPOSURE TO SOUND PRESSURE LEVELS OVER 100dB

MAY

CAUSE PERMANENT HEARING LOSS. HIGH POWERED AUTOSOUND

SYSTEMS

MAY PRODUCE SOUND PRESSURE LEVELS WELL OVER

130dB. USE COMMON SENSE AND PRACTICE SAFE SOUND.

The serial number can be found on the outside of the box. Please record it in

the space provided below as your permanent record. This will serve as

verification of your factory warranty and may become useful in recovering your

product if it is ever stolen.

Serial Number: ________________________________

Model Number:________________________________

Page 3

Welcome to Rockford Fosgate! This manual is designed to provide information

for the owner, salesperson and installer. For those of you who want quick

information on how to install this product, please turn to the

Installation

Section

of this manual or refer to the icons listed below. Other information can

be located by using the Table of Contents. We, at Rockford Fosgate, have

worked very hard to make sure all the information in this manual is current. But,

as we are constantly finding new ways to improve our product, this information

is subject to change without notice.

G

ETTING

S

TARTED

Sections marked

TROUBLESHOOTING

include recommendations for

curing

installation problems

I

N

S

T

A

L

L

A

T

I

O

N

® ®

TROUBLE-

S

H

O

O

T

I

N

G

T

ABLE OF

C

ONTENTS

Introduction................................................................................................1

Package Contents ....................................................................................... 1

Design Features .......................................................................................... 2

Installation Considerations ...........................................................................4

Mounting Location ...................................................................................... 5

Installation ................................................................................................. 6

Troubleshooting.......................................................................................... 9

Specifications ........................................................................................... 10

Warranty Information ................................................................................ 11

International Information............................................................................12

Sections marked

INSTALLATION

include “slam dunk”

wiring connections

Page 4

I

NTRODUCTION

This manual provides information on the features and installation of the

Fanatic P Systems. We suggest you save this manual for future reference.

We strongly recommend you have your Authorized Rockford Fosgate Dealer

install the Fanatic P System. If you do choose to install the system yourself,

please be sure to read the entire manual before beginning.

FNP1414

(2) FNP1401 Tweeters

Includes 3/4" [20mm] mylar dome tweeter,

flush mount housing, surface mount housing,

wedge mount housing

(2) Tweeter Mounting Brackets

(4) #8 32 x .500 Screws

(4) #8 32 Black Nuts

(8) #8 x .75 Phillips Screws

(2) .110 Female Fast-on Connectors

(2) .110 Male Fast-on Connectors

(2) FNP1404 4" Midrange Speakers

(2) 4" Speaker Grilles

(2) 4" Speaker Grille Rings

(2) “RF” Speaker Grille Logos

(2) FNP142x 2-Way Crossovers

(8) #8 x 1.25 Phillips Screws

(20) 18 Gauge Speaker Wire

P

ACKAGE

C

ONTENTS

– 1 –

FNP1514

(2) FNP1401 Tweeters

Includes 3/4" [20mm] mylar dome tweeter,

flush mount housing, surface mount housing,

wedge mount housing

(2) Tweeter Mounting Brackets

(4) #8 32 x .500 Screws

(4) #8 32 Black Nuts

(8) #8 x .75 Phillips Screws

(2) .110 Female Fast-on Connectors

(2) .110 Male Fast-on Connectors

(2) FNP1405 51⁄4" Midrange Speakers

(2) 51⁄4" Speaker Grilles

(2) 51⁄4" Speaker Grille Rings

(2) “RF” Speaker Grille Logos

(2) FNP142x 2-Way Crossovers

(8) #8 x 1.25 Phillips Screws

(20) 18 Gauge Speaker Wire

FNP1614F

(2) FNP1401 Tweeters

Includes 3/4" [20mm] mylar dome tweeter,

flush mount housing, surface mount housing,

wedge mount housing

(2) Tweeter Mounting Brackets

(4) #8 32 x .500 Screws

(4) #8 32 Black Nuts

(8) #8 x .75 Phillips Screws

(2) .110 Female Fast-on Connectors

(2) .110 Male Fast-on Connectors

(2) FNP1406F 6" Midrange Speakers

(2) 6" Speaker Grilles

(2) 6" Speaker Grille Rings

(2) “RF” Speaker Grille Logos

(2) FNP142x 2-Way Crossovers

(8) #8 x 1.25 Phillips Screws

(20) 18 Gauge Speaker Wire

FNP1614

(2) FNP1401 Tweeters

Includes 3/4" [20mm] mylar dome tweeter,

flush mount housing, surface mount housing,

wedge mount housing

(2) Tweeter Mounting Brackets

(4) #8 32 x .500 Screws

(4) #8 32 Black Nuts

(8) #8 x .75 Phillips Screws

(2) .110 Female Fast-on Connectors

(2) .110 Male Fast-on Connectors

(2) FNP1406 61⁄2" Midrange Speakers

(2) 61⁄2" Speaker Grilles

(2) 61⁄2" Speaker Grille Rings

(2) “RF” Speaker Grille Logos

(2) FNP142x 2-Way Crossovers

(8) #8 x 1.25 Phillips Screws

(20) 18 Gauge Speaker Wire

Page 5

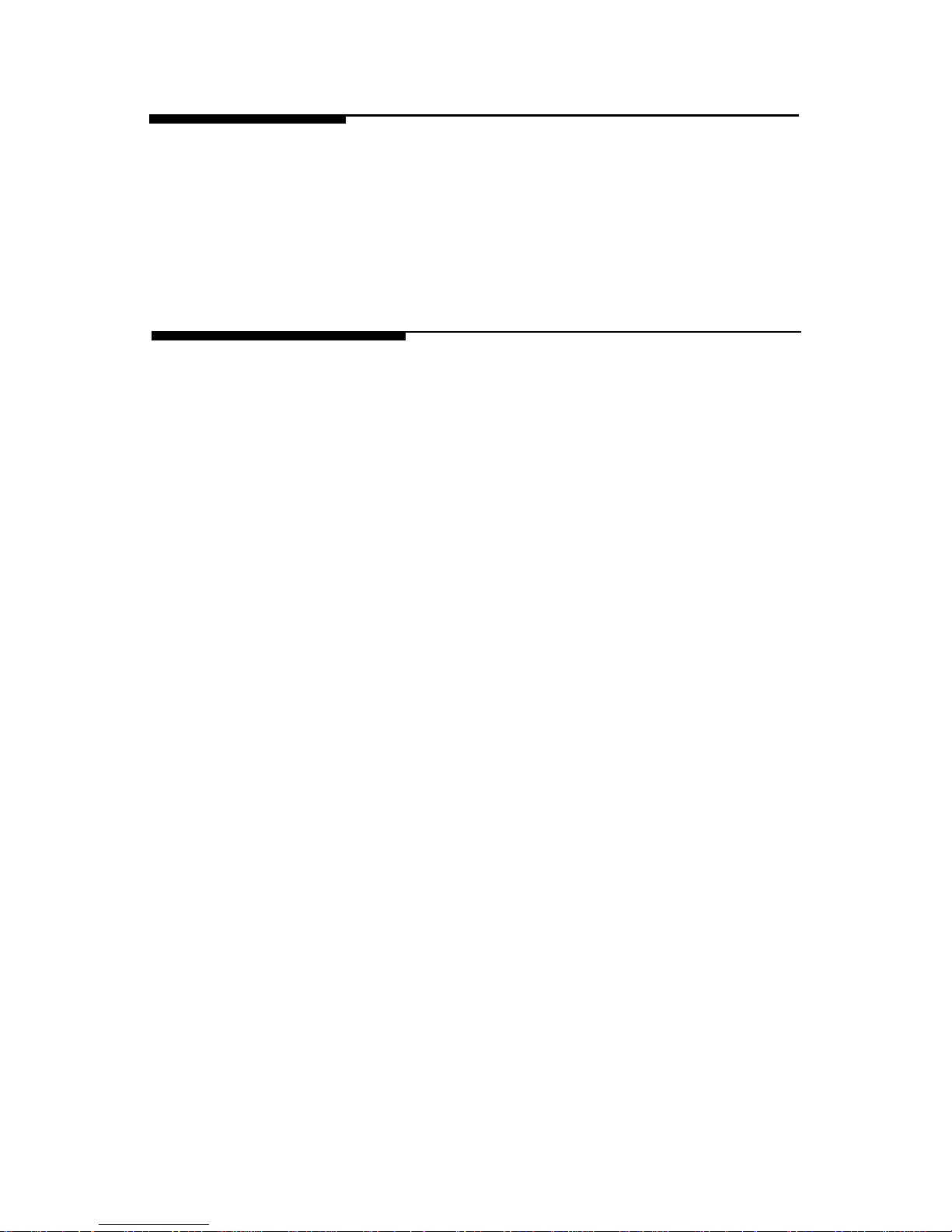

D

ESIGN

F

EATURES

Tweeter

1. 3/4" Mylar Dome Tweeter – To ensure accurate high frequency reproduction,

the tweeter dome must be both light and strong. The Fanatic P Component

Systems use a mylar dome that has extremely low mass and high strength for

smooth high frequency reproduction.

2. Ferrofluid Cooling – This synthetic fluid is held in place in the magnetic gap. It

bathes the voice coil allowing higher power handling and greater reliability.

3. Neodymium Magnet – What good would a tweeter be if it was too big to mount

in your favorite spot? The Fanatic Component Systems use a highly efficient

neodymium magnet to enable a very small tweeter to have very big performance.

– 2 –

4

5

6

7

8

2

1

3

9

Page 6

D

ESIGN

F

EATURES

Midrange

4. Foam Surround – The specially treated foam surround withstands the

extremes of the automotive environment and “decouples” the cone from

the basket and the mounting surface for superior sound quality.

5. Mica Filled Polypropylene Cone – The ideal cone material would be

infinitely strong, very light and would have very high damping to ensure

great sound quality. The Fanatic P Series Component Systems use a

mica filled polypropylene cone that is strong, light and has high internal

damping to provide excellent reproduction of sound.

6. Cupped Spider – The spider has the job of centering the voice coil and

providing the rear suspension for the speaker. The Fanatic P Component

Systems use a durable cupped spider to ensure great sound with long

life and durability.

7. Large 1" Voice Coil with Anodized Aluminum Former – Just like all

Rockford Fosgate woofers, all Fanatic Component System midrange

drivers use an aluminum voice coil former for more efficient dissipation

of heat. Dissipating the heat is key to long life and high power handling,

so go ahead and crank it up!

Crossover

8. Butterworth Crossover – Features an 18dB per octave high-pass

crossover for the tweeter. The steeper slope of the tweeter crossover

gives better power handling.

9. Optical Compression – This built-in protection circuit limits power to the

tweeter when the “danger” threshold is exceeded. Because it simply

limits power and doesn't shut the tweeter off, this circuit is completely

inaudible.

– 3 –

Page 7

I

NSTALLATION

C

ONSIDERATIONS

Tools Needed

The following is a list of some of the tools necessary for the installation of your

speakers.

Power Drill with assorted bits #2 Phillips Screwdriver

Tape Measure Voltmeter

General

1. For safety, disconnect the negative lead from the battery prior to beginning

the installation.

2. Never run wires underneath the vehicle. Running the wires inside the vehicle

provides the best protection.

3. Avoid running wires over or through sharp edges. Use rubber or plastic

grommets to protect any wires routed through metal.

4. Mount the speakers/crossovers away from electrical sources (other than the

amplifier), i.e., power cables, electronic fuel pumps, vehicle computers,

and other potential noise sources.

5. Mount the speakers/crossovers away from areas of extreme heat or

moisture.

Speakers

1. Make sure there is an area large enough for the speaker to mount. Warning!

Failure to do this can cause damage to the speaker if the speaker frame

is bent during installation.

2. Check to see that the location is deep enough for the speaker(s) and the

location does not interfere with the normal operation of the vehicle.

3. When mounting the speaker(s) in the door of a vehicle, make sure the

speaker(s) do not interfere with either the door or window operation.

4. When mounting the speaker(s) on the rear deck of the vehicle, check the

operation of the rear hatch or trunk lid. Make sure the torsion bars and other

moving parts are not obstructed by the speaker(s) installation.

• Please refer to the Specifications section of this manual for proper mounting

diameter and depth of the speaker(s).

Crossovers

1. Make sure there is a flat area large enough for the crossover to mount.

2. For best results, mount the crossover(s) next to the amplifier for a decorative

finish to the installation and to provide an easy upgrade (no new wires to

run) for a bi-amp Rockford Fosgate system in the future.

– 4 –

Page 8

M

OUNTING

L

OCATION

A solid front stage with a good image is one of the most difficult tasks to achieve

in a vehicle. No car has the optimum listening environment. This makes proper

sound staging very difficult to accomplish. Most speakers tend to be placed

where they will fit easily, as opposed to where they can perform the best.

The

mounting location of your speakers will have a great effect on the sound quality

of your stereo system. The special care taken to place the speakers will yield

many hours of listening enjoyment in return. Several important recommendations should be followed.

• Place the speakers where they have a direct

path to the listening area.

• For the best integration between the midrange

and tweeter, the tweeter should be placed

less than 2" from the midrange. (Figure 1)

• If you cannot place the tweeter less than 2"

from the midrange, then place the tweeter

more than 7" from the midrange. Placing

the tweeter 2"-7" from the midrange can

cause destructive interference (frequency

response problems) which will affect the

speaker's ability to reproduce the frequency range around the crossover

frequency of the system.

• Whenever possible, place the tweeter directly above or below the midrange

as this maximizes the imaging (point source) capability of the speakers.

(Figure 2)

Figure 1

2" or less

Figure 2-A

Figure 2-B

– 5 –

Page 9

• Sound radiated from a “point source” has the most optimum stereo imaging

because the separation of the acoustical centers between the midrange and

tweeter for each channel is at the optimum. Figure 2-A describes a

horizontal speaker alignment. In a closed environment such as an

automobile, horizontal speaker alignment can cause severe amplitude and

phase differences which will degrade not only the imaging, but also the

frequency response. This is due to the path length differences between the

midrange and tweeter. Figure 2-B displays a vertical alignment between the

midrange and tweeter. With a vertical alignment, the path length difference

between the midrange and tweeter are reduced to a minimum. The result

is a negligible difference in path lengths between the midrange and tweeter

regardless of the proximity of the listener to the speakers. Mounting the

speaker with minimum path length difference will ensure the best staging

and imaging possible from your audio system.

I

NSTALLATION

Mounting the Midrange

– 6 –

I

N

S

T

A

L

L

A

T

I

O

N

® ®

1. Cut the proper size hole for the midrange/woofer.

• For the FNP-1404, cut an 90.48mm (39⁄16") diameter hole

• For the FNP-1405, cut a 113.50mm (415⁄32") diameter hole

• For the FNP-1406F, cut a 127mm (5") diameter hole

• For the FNP-1406, cut a 139.06mm (51⁄2") diameter hole

2. Place the mounting ring over the mounting hole and mark the location of

the screw mounting holes.

3. Remove the ring. Drill the holes for the screws using a 1/8" drill bit.

4. Route the wire through the hole.

5. Attach the wires and be sure to observe the proper speaker polarity.

6. Place the speaker into the hole and screw the speaker into place. Be

careful not to bend the speaker frame during this step.

7. Press the speaker grille into the mounting ring.

Page 10

– 7 –

Flush Mount Tweeter

Tweeter

Surface Mount Tweeter

I

N

S

T

A

L

L

A

T

I

O

N

® ®

Trim Ring

Back

Plate

Flush

Housing

Tweeter

Trim Ring

Back

Plate

Surface

Housing

Wedge Mount Tweeter

Tweeter

Wedge

Housing

Page 11

Crossover Connections

• Be Sure to Maintain Speaker Polarity

– 8 –

Negative (Black Wire)

Positive (Black/White Stripe Wire)

Midrange Negative

Tweeter Negative

Tweeter Positive

Midrange Positive

(One channel of amplifier)

+

(Purple Dot)

–

+

–

+

–

High-passing the Midrange

I

N

S

T

A

L

L

A

T

I

O

N

® ®

• The Fanatic Component Systems are optimized for full range music

reproduction. In cases where a subwoofer is used, the midrange can be

high-passed in order to prevent overlapping frequencies from the

midrange into the subwoofer.

1.Determine the frequency range that the subwoofer will play (i.e.: 20Hz80Hz)

2.Use the low-pass crossover frequency of the subwoofer system (i.e.:

80Hz) as the high-pass crossover frequency for the midrange

3.Select the appropriate capacitor value (i.e.: 500µF) to properly high-pass

the midrange

4.Place the capacitor in series with the “+” terminal of the speaker

Frequency Speaker

Hertz (4 ohms)

C1

80Hz 500µF

100Hz 400µF

130Hz 300µF

200Hz 200µF

260Hz 150µF

400Hz 100µF

Midrange Negative

Midrange Positive

+

–

C1

0dB

–3dB

80Hz

Subwoofer Midrange Tweeter

6dB/octave High-Pass

Page 12

T

ROUBLESHOOTING

No sound from

speakers

Symptom Diagnosis Remedy

Check and repair or replace

wiring as needed.

Check system with known

working amplifier and repair

or replace as needed.

Check for shorts in the wiring

with a volt/ohm meter and repair or replace wires as needed.

Check system with known working speaker and repair or replace as needed.

Wires between amplifier,

crossover or speakers not

connected properly.

Amplifier has no output.

Speaker wires are shorted

to each other or to the chassis of the vehicle.

Speakers are blown.

Incorrect wiring between

crossover and speakers

Excessive power from amplifier

Equalizer in system (if

available) has excessive

boost in the high frequency

range

Check wiring and repair or replace as needed.

Check gain settings on amplifier and readjust as necessary

Check settings on equalizer and

readjust as necessary

Distorted sound

from speakers

Tweeters “burn

up” easily

– 9 –

Engine Noise from

One or More

Speakers

Check for shorts in the wiring

with a volt/ohm meter and repair or replace wires as needed.

Re-route speaker wiring away

from noise sources. (Refer to

the Installation Consider-

ations section of this manual.)

Move crossovers away from

noise sources. (Refer to the In-

stallation Considerations section of this manual.)

Speaker wires shorted to

chassis of vehicle.

Speaker wires are routed

near radiated noise source.

(Power cables, vehicle

computers, etc.)

Crossover is mounted near

radiated noise source.

(Power cables, vehicle

computers, etc.)

Page 13

System Model Number FNP1414 FNP1514 FNP1614F FNP1614

Midrange Model Number FNP1404 FNP1405 FNP1406F FNP1406

Nominal Diameter 4" 5

1

⁄4"6"6

1

⁄2"

Nominal Impedance 4Ω 4Ω 4Ω 4Ω

Frequency Response 100Hz-8kHz 60Hz-6kHz 61Hz-6kHz 55Hz-5kHz

Fs (Hz) 100Hz 60Hz 61Hz 55Hz

Qes .907 .705 .701 .926

Qms 3.372 2.896 2.58 3.558

Qts .715 .567 .551 .733

Vas (ft3/liter) .078/2.2 .29/8.1 .335/9.5 .59/16.7

Xmax (in/mm) .09/2.4 .11/2.9 .11/2.9 .11/2.9

Sensitivity 84.9dB 86.4dB 86.8dB 87.1dB

RMS Power Handling 50 Watts 50 Watts 50 Watts 50 Watts

Mounting Diameter 90.48mm 113.50mm 127mm 139.06mm

(39⁄16") (415⁄32") (5") (51⁄2")

Mounting Depth 48mm (1

29

⁄32") 60mm (23⁄8") 61mm (213⁄32") 63mm (21⁄2")

S

PECIFICATIONS

(Specifications are subject to change without notice)

– 10 –

Wedge

Mount

Surface

Mount

Flush

Mount

* Power Ratings (PE) is established with recommended filter network.

1.75"

.875"

3.687"

4.437"

1.74"

1.00"

1.94"

.375"

1.00"

.25"

1.795"

.965"

.675"

1.562"

1.24"

Model FNP142x

Crossover Type 2-Way

Crossover Frequency 6.3kHz @ 4Ω

Crossover Slope 18dB/octave High-Pass

Full Range Low-Pass

Filter Q 0.707 (Butterworth)

Tweeter Protection Optical Compression

Dimensions See drawings

Model FNP1401

Nominal Diameter 3/4" (20mm)

Nominal Impedance 4Ω

Frequency Response 2.8kHz-20kHz

Fs 2.8kHz

Sensitivity 91dB

RMS Power Handling 50 Watts*

Mounting Diameter See drawings

Mounting Depth See drawings

Page 14

– 11 –

L

IMITED

W

ARRANTY

I

NFORMATION

Rockford Corporation offers a limited warranty on Rockford Fosgate products on the following

terms:

• Length of Warranty

1 year on speakers 30 days on speaker B-stock (receipt required)

3 years on electronics 90 days on electronic B-stock (receipt required)

2 years on source units

• What is Covered

This warranty applies only to Rockford Fosgate products sold to consumers by Authorized

Rockford Fosgate Dealers in the United States of America or its possessions. Product

purchased by consumers from an Authorized Rockford Fosgate Dealer in another country

are covered only by that country’s Distributor and not by Rockford Corporation.

• Who is Covered

This warranty covers only the original purchaser of Rockford product purchased from an

Authorized Rockford Fosgate Dealer in the United States. In order to receive service, the

purchaser must provide Rockford with a copy of the receipt stating the customer name,

dealer name, product purchased and date of purchase.

• Products found to be defective during the warranty period will be repaired or replaced

(with a product deemed to be equivalent) at Rockford's discretion.

• What is Not Covered

1. Damage caused by accident, abuse, improper operations, water, theft

2. Any cost or expense related to the removal or reinstallation of product

3. Service performed by anyone other than Rockford or an Authorized Rockford Fosgate

Service Center

4. Any product which has had the serial number defaced, altered, or removed

5. Subsequent damage to other components

6. Any product purchased outside the U.S.

7. Any product not purchased from an Authorized Rockford Fosgate Dealer

• Limit on Implied Warranties

Any implied warranties including warranties of fitness for use and merchantability are

limited in duration to the period of the express warranty set forth above. Some states do not

allow limitations on the length of an implied warranty, so this limitation may not apply. No

person is authorized to assume for Rockford Fosgate any other liability in connection with

the sale of the product.

• How to Obtain Service

Please call 1-800-669-9899 for Rockford Customer Service. You must obtain an RA#

(Return Authorization number) to return any product to Rockford Fosgate. You are

responsible for shipment of product to Rockford.

Ship to: Electronics

Rockford Corporation

Warranty Repair Department

2055 E. 5th Street

Tempe, AZ 85281

RA#:_________________

Ship to: Speakers

Rockford Acoustic Design

(Receiving-speakers)

609 Myrtle N.W.

Grand Rapids, MI 49504

RA#:_________________

Page 15

INTERNATIONAL

INFORMATION

– 12 –

Page 16

2/98

LIT9943

Rockford Fosgate

Rockford Corporation

546 South Rockford Drive

Tempe, Arizona 85281 U.S.A.

In U.S.A., (602) 967-3565

In Europe, Fax (49) 8503-934014

In Japan, Fax (81) 559-79-1265

MADE IN THE USA

This product is designed, developed and assembled in the USA by a dedicated

group of American workers. The majority of the components used in the

construction of this product are produced by American companies. However,

due to the global nature of their manufacturing facilities and the loudspeaker

parts industry in general, some parts may be manufactured in other countries.

Loading...

Loading...