Page 1

h

trans•

ana

® ®

trans•

trans•

trans•

ana

ana

ana

car audio

for

fanatics

2-Channel Amplifiers

Operation & Installation

®

punc

Page 2

Dear Customer,

Congratulations on your purchase of the world's finest brand of car audio amplifiers.

At Rockford Fosgate we are fanatics about musical reproduction at its best, and we are

pleased you chose our product. Through years of engineering expertise, hand craftsmanship and critical testing procedures, we have created a wide range of products that

reproduce music with all the clarity and richness you deserve.

For maximum performance we recommend you have your new Rockford Fosgate

product installed by an Authorized Rockford Fosgate Dealer, as we provide specialized

training through Rockford Technical Training Institute (RTTI). Please read your

warranty and retain your receipt and original carton for possible future use.

Great product and competent installations are only a piece of the puzzle when it comes

to your system. Make sure that your installer is using 100% authentic installation

accessories from Connecting Punch in your installation. Connecting Punch has

everything from RCA cables and speaker wire to Power line and battery connectors.

Insist on it! After all, your new system deserves nothing but the best.

To add the finishing touch to your new Rockford Fosgate image order your Rockford

wearables, which include everything from T-shirts and jackets to hats and sunglasses.

To get a free brochure on Rockford Fosgate products and Rockford accessories, in the

U.S. call 602-967-3565 or FAX 602-967-8132. For all other countries, call +001-602967-3565 or FAX +001-602-967-8132.

PRACTICE SAFE SOUND™

CONTINUOUS EXPOSURE TO SOUND PRESSURE LEVELS OVER 100d B

CAUSE PERMANENT HEARING LOSS. HIGH POWERED AUTOSOUND

MAY

SYSTEMS

MAY PRODUCE SOUND PRESSURE LEVELS WELL OVER

130dB. USE COMMON SENSE AND PRACTICE SAFE SOUND.

If, after reading your manual, you still have questions regarding this product,

we recommend that you see your Rockford Fosgate dealer. If you need further

assistance, you can call us direct at 1-800-669-9899. Be sure to have your serial

number, model number and date of purchase available when you call.

The serial number can be found on the outside of the box. Please record it in

the space provided below as your permanent record. This will serve as

verification of your factory warranty and may become useful in recovering your

amplifier if it is ever stolen.

Serial Number: ________________________________

Model Number:________________________________

Page 3

T

ABLE OF

C

ONTENTS

Introduction................................................................................................1

Punch Amplifier Accessory Pack ................................................................... 1

Technical Design Features............................................................................2

Design Features .......................................................................................... 5

Installation Considerations ........................................................................... 7

Mounting Location ...................................................................................... 8

Battery and Charging .................................................................................. 9

Wiring the System....................................................................................... 9

Using Passive Crossovers........................................................................... 12

Table of Component Values........................................................................13

Using the XCard........................................................................................ 14

Resistor Chart ........................................................................................... 15

Installation ............................................................................................... 16

System Diagrams......................................................................................20

Rockford Fosgate Accessories ..................................................................... 24

Troubleshooting........................................................................................ 26

Dynamic Power Measurements...................................................................29

Specifications ........................................................................................... 31

Warranty Information ................................................................................ 33

International Information............................................................................ 34

GETTING STARTED

Welcome to Rockford Fosgate! This manual is designed to provide information

for the owner, salesperson and installer. For those of you who want quick

information on how to install this product, please turn to the

Section

of this manual or refer to the icons listed below. Other information can

be located by using the Table of Contents. We, at Rockford Fosgate, have

worked very hard to make sure all the information in this manual is current. But,

as we are constantly finding new ways to improve our product, this information

is subject to change without notice.

I

a

O

p

d

e

v

r

a

a

n

t

c

i

e

o

d

n

Sections marked

ADVANCED OPERATION

include in-depth

technical information

® ®

N

S

T

A

L

L

A

T

I

O

N

Sections marked

INSTALLATION

include “slam dunk”

wiring connections

include recommendations for

curing installation problems

Installation

TROUBLE-

S

H

O

O

T

I

N

G

Sections marked

TROUBLESHOOTING

Page 4

I

NTRODUCTION

Rockford engineers designed the Punch 55.2, 75.2, 125.2 and 225.2

amplifiers to withstand the rugged automotive environment while delivering

superior sound quality in a flexible, reliable, and efficient package. TRANS•ANA

is a low voltage circuit in the preamp stage of all Punch .2 amplifiers that

lets the music sound crystal clear and very real, even when played at high

volume levels. This is matched with TOPAZ, a unique grounding circuit used

to eliminate noise problems associated with car audio systems and their

installation. Flexibility is accomplished with the use of a built-in XCard.

Reliability is all but guaranteed with the use of a protection circuit called

NOMAD, while MOSFET and DSM (Discrete Surface Mount) technology

improve amplifier efficiency. The result of these components give the Punch

amplifier awesome sound quality in a “Bullet Proof” package. An explanation of these technologies, most of which are exclusively designed and

patented by Rockford, are described in the Technical Design Features.

P

UNCH

A

MPLIFIER

The accessory pack shipped with the Punch 2-channel amplifiers includes

the mounting hardware necessary to secure the amp to the vehicle and to

attach the end caps to the amplifier.

A

CCESSORY PACK

Installation & Operation Manual

Punch Verification Certificate

(4) Amplifier mounting screws (#8 x 3/4" Phillips)

(6) Speaker & power connector screws (3/32" Allen)

(4) End cap mounting screws (9/64" Allen)

(1) Allen Wrench 9/64"

(1) Allen Wrench 3/32"

(1) ATC Inline Fuseholder (Punch 55.2, 75.2, 125.2)

(1) AGU Inline Fuseholder (Punch 225.2)

(1) ATC 20 Amp Fuse (Punch 55.2)

(1) ATC 30 Amp Fuse (Punch 75.2)

(1) ATC 40 Amp Fuse (Punch 125.2)

(1) AGU 50 Amp Fuse (Punch 225.2)

– 1 –

Page 5

T

ECHNICAL

◆ TRANS•ANA

(TRANSconductance Active Nodal Amplifier)

The

TRANS•ANA

that allows the audio signal to pass through the amplifier at low voltage. The

signal is directly level-shifted to the fixed high voltage rails via a pair of driver

transistors. Signal linearity is assured by an active node formed by the drive

transistors at ultrasonic frequencies. This allows amplifier performance

similar to trans•

advantages of a non-floating power supply.

THE RESULT: An extended frequency bandwidth accurately supplied to the

output stages of the amplifier.

◆ MEHSA (Maximum Efficiency Heat Sink Application)

The

MEHSA

process that yields up to 5 times better heat transfer than traditional FET

mounting techniques using the exact same components. A multi-layer

insulated metal substrate operating with minimal thermal resistance spreads

heat both downward & outward to quickly dissipate heat from each device

across the heat sink. This process combined with our DSM technology and

MOSFET devices allow us to squeeze more watts per cubic inch from every

output device as well as provide consistent thermal stability.

D

ESIGN FEATURES

(TRANSconductance Active Nodal Amplifier) is a circuit

nova

which is highly stable and linear while utilizing the

(Maximum Efficiency Heat-Sink Application) is a proprietary

THE RESULT: Optimized power output, enhanced thermal stability, and

maximum component reliability.

◆ TOPAZ (Tracking Operation Pre-Amplifier Zone)

The

TOPAZ

(Tracking Operation Pre-Amplifier Zone) circuitry solves ground

loop noise problems common to automotive amplifier design. This innovative

new development allows vastly improved isolation of the input signal grounds

from the power supply ground of the amplifier. This is accomplished by

allowing the source unit to control the potential “environment” of the entire

input structure or “zone” of the amplifier. This process improves the noise

rejection of the amplifier by 30-40dB – an astounding 30-100 times better

than amplifiers without TOPAZ.

THE RESULT: Elimination of troublesome ground loop noise between source

and amplifier.

– 2 –

Page 6

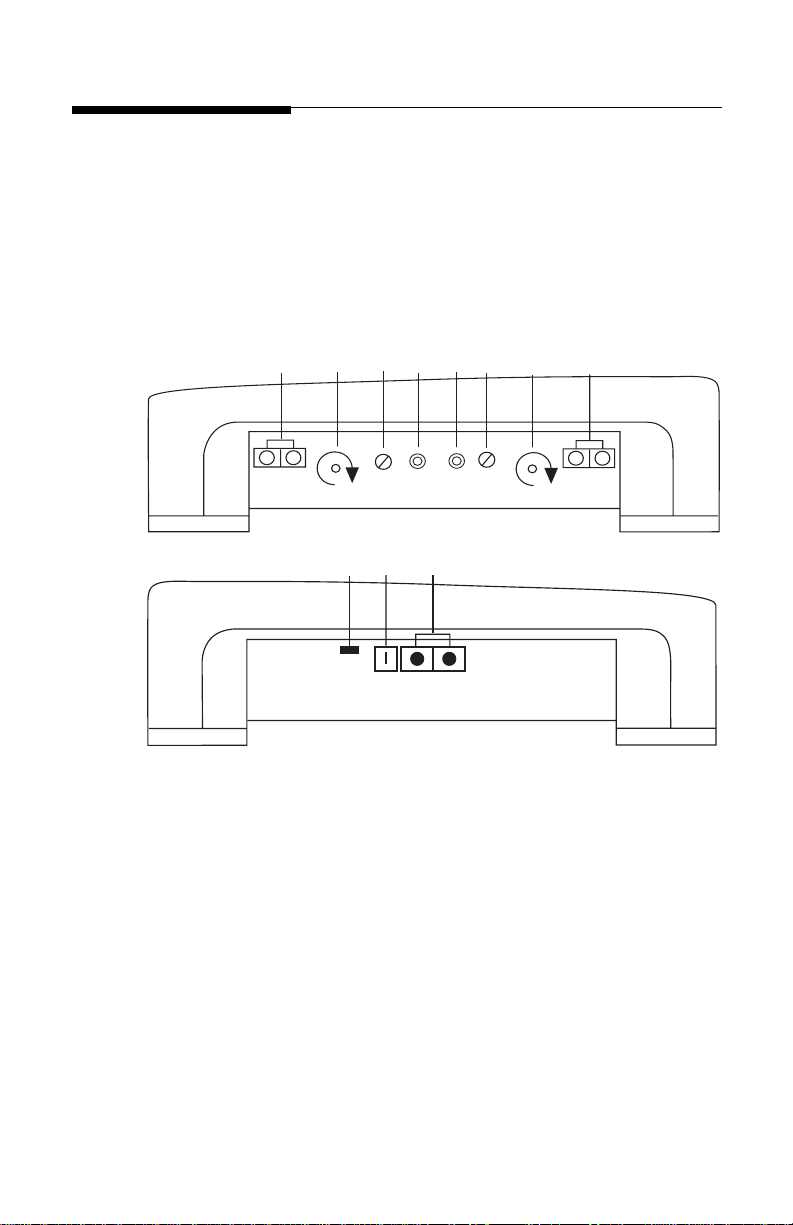

◆ DSM (Discrete Surface Mount) Technology

The

DSM

(Discrete Surface Mount) manufacturing process combines the

advantages of both discrete components and integrated circuitry. Rockford

Fosgate is the only American amplifier manufacturer to have invested millions

into this process. DSM components differ from conventional discrete components in different ways. They are more compact, more rugged, and they

efficiently dissipate generated heat. Using them wherever appropriate allows

the advantages associated with discrete circuitry to be retained while also

providing room for both highly advanced processing features and generous

PC board copper paths where needed. Their short lead-out structures allow

maximum audio performance and highest signal-to-noise ratios to be

obtained in amplifiers of desirable package size without resorting to “amplifier-on-a-chip” shortcuts. These advantages are shown below in Figure 1.

THE RESULT: Fewer connections, improved reliability, shorter signal paths,

superior signal-to-noise ratio and awesome sonic performance.

Figure 1

PC

Board

Thru-Hole Surface Mount

Solder

Component

Solder

PC

Board

◆ XCard (Internal Crossover)

The Punch amplifiers utilize internal active crossovers. These crossovers have

many performance advantages such as using discrete components for exact

frequency adjustments which are far superior to potentiometers. Additionally,

the

XCard

can be configured for high-pass, low-pass and full range

operation. With slight modifications, many crossover frequencies and slope

configurations can be achieved.

THE RESULT: Increased system design flexibility with a precise electronic

crossover without the limitations of conventional potentiometer designs.

– 3 –

Page 7

◆ MOSFET Devices

Rockford Fosgate is one of the few manufacturers in the sound community

to utilize MOSFET devices in both the

MOSFET

several important inherent advantages over the 30 year old technology of bipolar design. These advantages include: thermal stability, switching speed,

ultra low output impedance and wider bandwidth linearity. In addition,

MOSFETs operate very similarly to vacuum tubes in that they are more linear

than bi-polar transistors. However, MOSFETs can deliver the midrange clarity

without the limitations of transient response and high frequency phase

shifting normally associated with tube operation.

THE RESULT: Operational characteristics similar to vacuum tubes without

the performance limitations of tube design.

(Metal Oxide Semiconductor Field Effect Transistor) devices offer

power supply

and the

output stages

◆ NOMAD (NOn-Multiplying Advanced Decision)

.

The Punch amplifiers use an

output power under all operating conditions. The innovative

Multiplying Advanced Decision) system is the most sophisticated version of

this technique ever used, bringing previously unavailable levels of accuracy,

stability, temperature immunity and reliability to this critical process. NOMAD

makes advanced decisions based on device voltages to precisely control the

awesome levels of current available in the output MOSFETs to safe values –

but only when absolutely needed.

THE RESULT: Extremely fast protection system that always protects the

amplifier and never degrades the sound.

analog computer process

to maximize safe

NOMAD

(NOn-

◆ Punch EQ

The Punch EQ helps correct for acoustical deficiencies in the listening

environment. Two unique potentiometers that control bass and treble

compensate for the response errors present in most car environments. Unlike

conventional tone controls, Punch EQ corrects the specific problems of poor

low bass response and high frequency rolloff.

THE RESULT: Full range sound without excessive boost in areas where it is

not needed.

– 4 –

Page 8

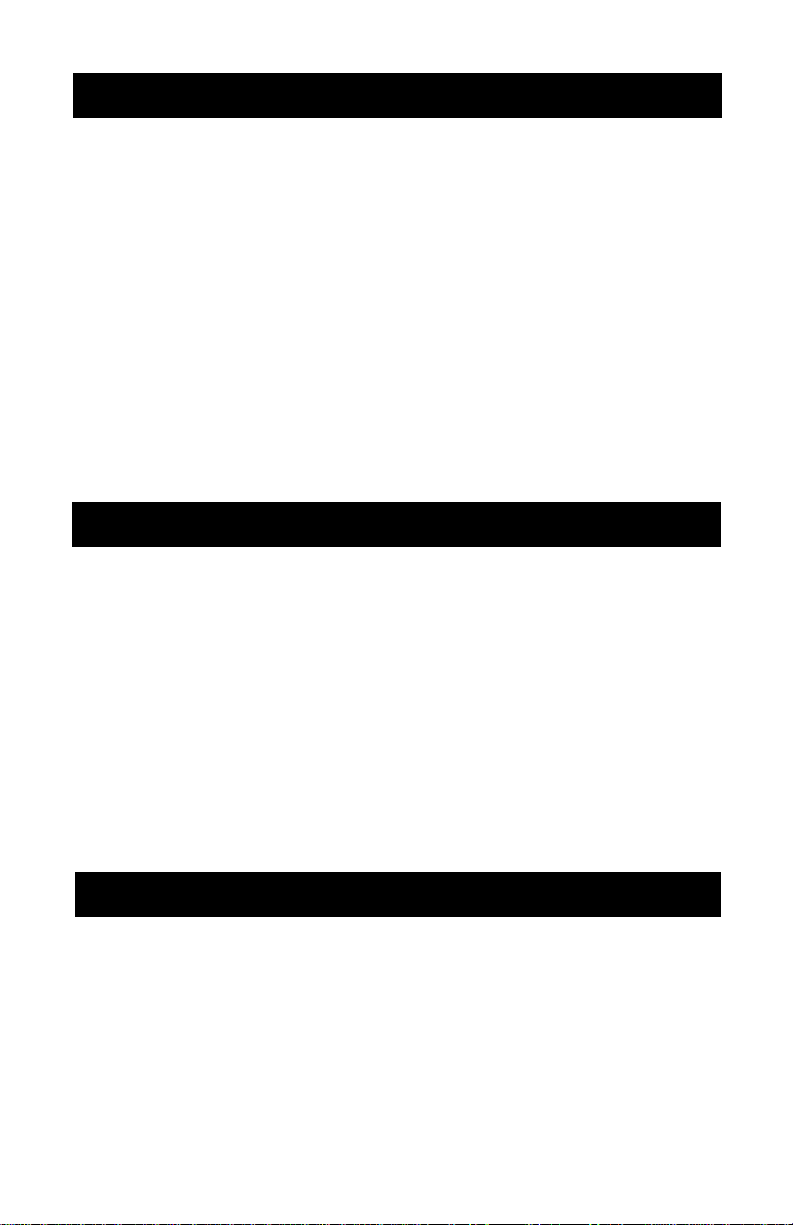

D

ESIGN FEATURES

1. Cast Aluminum Heatsink – The cast aluminum heatsink of the Punch

amplifier dissipates heat generated by the amplifier's circuitry. The

inherent advantage of casting provides a 30% improvement of cooling

over conventional extrusion heatsink designs.

2. End Caps – The unique end caps conceal the wiring and input cables,

giving the amplifier a clean “stealth” look.

Left

Gain

6 6

Left

Input

Right

Input

Right

Gain

Bass

3

8

+R–+L–

3 8 7 7

Speaker Speaker

Treble

49 5

LED

REM

GNDB+

3. Speaker Terminals – The heavy duty, gold-plated terminal block

connectors (+ and –) will accept wire sizes from 8 AWG to 18 AWG.

These gold-plated connectors are immune to corrosion that can cause

signal deterioration.

4. Power Terminals – The power and ground connectors on the Punch

amplifier are gold-plated and will accommodate up to 8 AWG wire

maximizing the input current capability of the amplifier.

5. REM Terminal – This gold-plated spade terminal is used for the auto

power/remote turn on of the Punch amplifier.

6. RCA Input Jacks – The industry standard RCA jacks provide easy

connections for signal level input. They are gold-plated to resist the

signal degradation caused by corrosion.

– 5 –

Page 9

7. Input Sensitivity Controls – The input level controls are preset to

match the output of most source units. They can be adjusted to match

output levels from a variety of source units.

8. Punch Equalization Controls – The Punch EQ helps correct for

acoustical deficiencies in the listening environment. The Bass control

allows a narrow band adjustment of up to 18dB centered at 45Hz. The

Treble control is a wide band hinged adjustment with a maximum of

12dB at 20kHz. The Punch EQ can be bypassed by turning the

controls to their minimum or counterclockwise position.

9. LED Power Indicator – The LED illuminates when the unit is turned on.

10. XCard (Internal Crossover) – This built-in crossover card is

configurable for a multitude of operating frequencies. The orientation

of the card in its socket determines the function of high-pass, low-pass,

or full range operation.

®

27.5 Watts RMS continuous power per

channel into 4 Ohms with less than 0.08%

Total Harmonic Distortion from 20-20kHz

High-Pass

AMPLIFIER

®

ROCKFORD CORPORATION

MADE IN THE USA

HP

LP

10

Low-Pass

LP

HP

Full Range

FULL

+

L+ R–

For Bridged Mono Wiring

Connect 4Ω mono woofer + to L+ of amplifier

and mono woofer – to R– of amplifier. Amplifier

will operate mono/stereo simultaneously.

Do Not Chassis

Ground Any Speaker.

–

– 6 –

Page 10

I

NSTALLATION

The following is a list of tools you will need for installing the Punch amplifier:

Allen wrenches 9/64" & 3/32" (included) Voltmeter

Wire strippers Battery post wrench

Electric hand drill w/assorted bits Wire cutters

17' (518.16cm) Red Power Wire Assorted connectors

12' (365.76cm) Remote Turn-On Wire Wire crimpers

1.5' (45.72cm) Black Grounding Wire

This section focuses on some of the vehicle considerations for installing your

new Punch amplifier. Checking your battery and present sound system, as

well as pre-planning your system layout and best wiring routes will save

installation time. When deciding how to lay out your new system, be sure that

each component will be easily accessible for making adjustments.

Before beginning any installation, be sure to follow these simple rules:

1. Be sure to carefully read and understand the instructions before attempting to install the amplifier.

2. For safety, disconnect the negative lead from the battery prior to

beginning the installation.

3. For easier assembly, we suggest you run all wires prior to mounting your

amplifier in place.

4. Route all of the RCA cables close together and away from any high

current wires.

5. Use high quality connectors for a reliable installation and to minimize

signal or power loss.

6. Think before you drill! Be careful not to cut or drill into gas tanks, fuel

lines, brake or hydraulic lines, vacuum lines or electrical wiring when

working on any vehicle.

7. Never run wires underneath the vehicle. Running the wires inside the

vehicle provides the best protection.

8. Avoid running wires over or through sharp edges. Use rubber or plastic

grommets to protect any wires routed through metal, especially the

firewall.

9. ALWAYS protect the battery and electrical system from damage with

proper fusing. Install a fuseholder and appropriate fuse on the +12V

power wire within 18” (45.7 cm) of the battery terminal.

10. When grounding to the chassis of the vehicle, scrape all paint from the

metal to ensure a good, clean ground connection. Grounding connections should be as short as possible and always be connected to metal

that is welded to the main body, or chassis, of the vehicle.

C

ONSIDERATIONS

– 7 –

Page 11

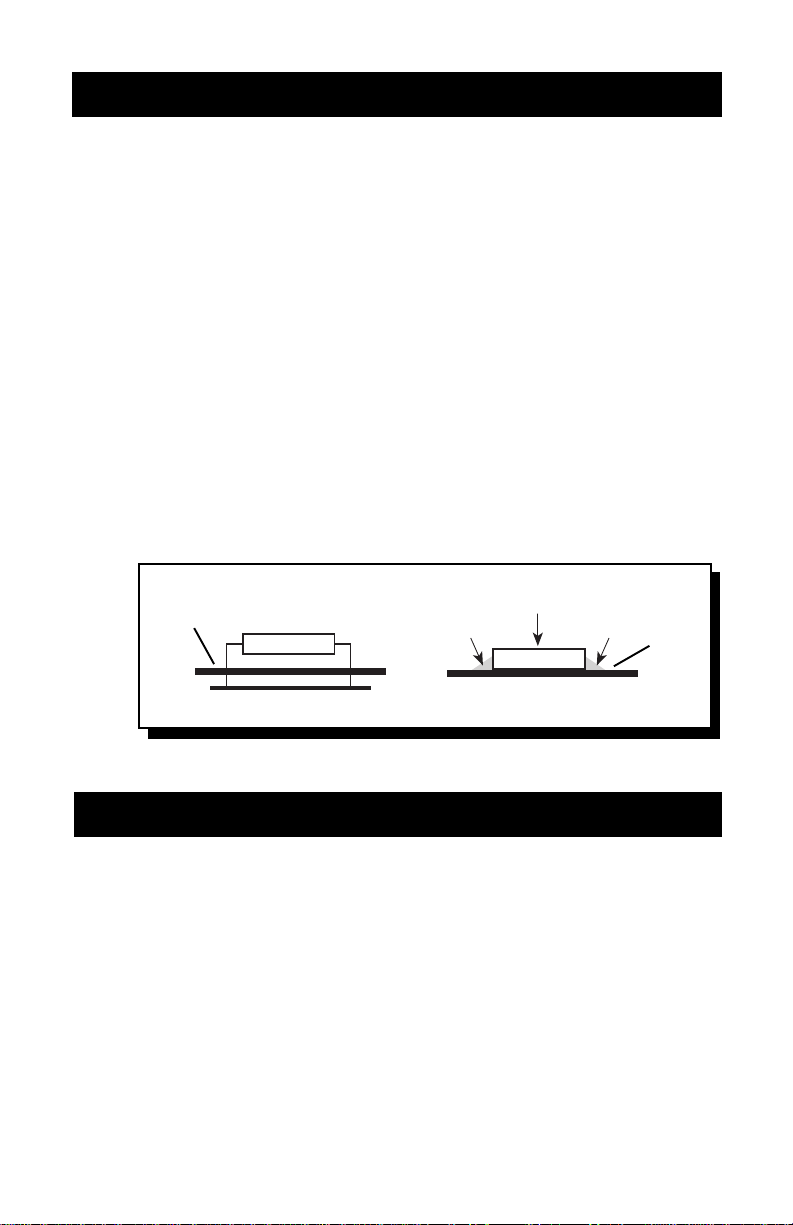

M

OUNTING LOCATION

The mounting location and position of your amplifier will have a great effect

on its ability to dissipate the heat generated during normal operation. The

design of our cast aluminum heatsink serves to easily dissipate the heat

generated over a wide range of operating conditions. However, to maximize

the performance of your amplifier, care should be taken to ensure adequate

ventilation.

Trunk Mounting

Mounting the amplifier vertically on a surface with the fin grooves running

up and down will provide the best cooling of the amplifier.

Mounting the amplifier on the floor of the trunk will work but provides less

cooling capability than vertical mounting.

Mounting the amplifier upside down to the rear deck of the trunk will not

provide proper cooling and will severely affect the performance of the

amplifier and is strongly

Passenger Compartment Mounting

Mounting the amplifier in the passenger compartment will work as long as

you provide a sufficient amount of air for the amplifier to cool itself. If you

are going to mount the amplifier under the seat of the vehicle, you must have

at least 1" (2.54cm) of air gap around the amplifier's heatsink.

not

recommended.

Mounting the amplifier with less than 1" (2.54cm) of air gap around the

amplifier's heatsink in the passenger compartment will not provide proper

cooling and will severely affect the performance of the amplifier and is

strongly

not

recommended.

Engine Compartment Mounting

Rockford Fosgate amplifiers should

compartment. Not only will this void your warranty but could create an

embarrassing situation caused by the ridicule from your friends.

– 8 –

never

be mounted in the engine

Page 12

B

ATTERY AND

C

HARGING

Amplifiers will put an increased load on the vehicle's battery and charging

system. We recommend checking your alternator and battery condition to

ensure that the electrical system has enough capacity to handle the

increased load of your stereo system. Stock electrical systems which are in

good condition should be able to handle the extra load of any Rockford

amplifier without problems, although battery and alternator life can be

reduced slightly. To maximize the performance of your Rockford Fosgate

amplifier, we suggest the use of a heavy duty battery and an energy storage

capacitor.

W

IRING THE SYSTEM

CAUTION:

Avoid running power wires near the low level input cables,

antenna, power leads, sensitive equipment or harnesses. The power

wires carry substantial current and could induce noise into the audio

system.

• For safety, disconnect the negative lead from the battery prior to beginning

the installation.

1. Configure the internal XCard crossovers prior to installation. Refer to

“Using the XCard” (page 14) for further information.

2. Plan the wire routing. Take care when running signal level RCA cables

to keep them close together but isolated from the amplifier's power cables

and any high power auto accessories, especially electric motors. This is

done to prevent coupling the noise from radiated electrical fields into the

audio signal. When feeding the wires through the firewall or any metal

barrier, protect them with plastic or rubber grommets to prevent short

circuits. Leave the wires long at this point to adjust for a precise fit at a

later time.

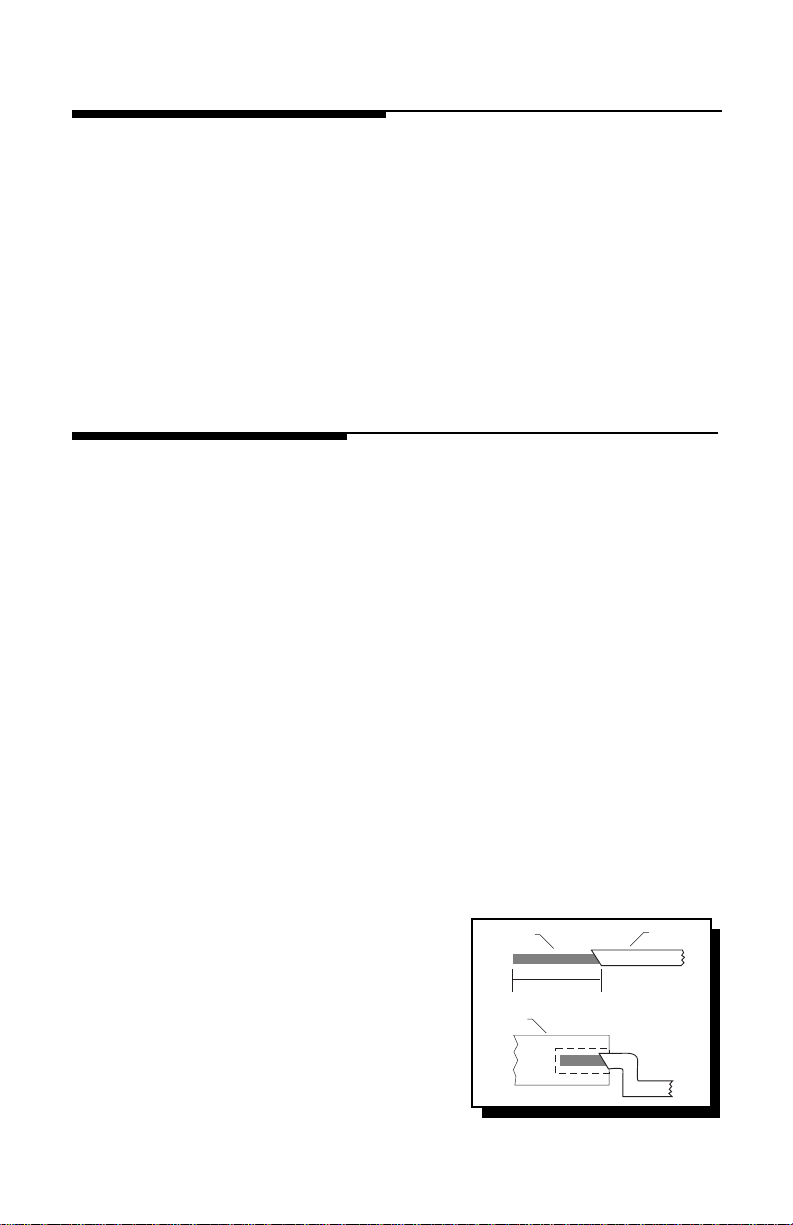

3. Prepare the Power cable for attach-

ment to the amplifier by stripping 5/8"

of insulation from the end of the wire.

To prevent the wire from fraying, strip

the insulation at a 45° angle. Insert

the bared wire into the B+ terminal

STRIP WIRE

AMP

>

5/8"

>

INSULATION

>

><

with the long side of the insulation on

the top. Bend the cable down at a 90°

angle. Tighten the set screw to secure

the cable in place.

– 9 –

Page 13

Punch 55.2, 75.2, 125.2

Trim the power cable to within 18" of the battery and install the protective

rubber boot, which is packed with the fuseholder, over the end of the wire.

Strip 3/8" of insulation from the wire and insert into the end of the

fuseholder, then crimp it in place. Slide the rubber boot into place to cover

the connection. Use the section of cable that was trimmed earlier and

connect it to the other end of the fuseholder.

Punch 225.2

Mount the fuseholder within 18" of the battery using two (2) #8 screws.

Disassemble the fuseholder. You should have 2 black plastic end caps,

2 gold-plated fuse clips, a plastic spacer and the fuseholder body. Trim

the amplifier power cable to reach the fuseholder and strip the wire 3/8".

Slide one of the end caps over the wire (narrow end first) and insert the

wire into one of the fuse clips. Tighten the set screw. Screw the black end

cap to the fuseholder body to secure the cable. Use the section of cable

that was trimmed earlier and connect it to the other end of the fuseholder.

Install the plastic spacer in the fuseholder and attach the cable to the

fuseholder body.

NOTE: The B+ cable MUST be fused 18" or less from the vehicle's

battery. Install the fuseholder under the hood and prepare the cable

ends as stated above. Connections should be water tight.

4. Strip 3/8" from the battery end of the power cable and crimp a large ring

terminal to the cable. Use the ring terminal to connect to the battery

positive terminal. Do not install the fuse at this time.

5. Prepare a length of cable to be used for the ground connection. Strip

5/8" of insulation from the end of the cable as described previously

and connect to the appropriate terminal of the amplifier. Prepare the

chassis ground by scraping any paint from the metal surface and

thoroughly clean the area of all dirt and grease. Strip the other end of the

wire and attach a ring connector. Fasten the cable to the chassis using a

non-anodized screw and a star washer.

6. Prepare the REM turn-on wire for connection to the amplifier by stripping

1/4" of insulation from the wire end and crimping an insulated spade

connector in place. Slide the connector over the REM terminal on the

– 10 –

Page 14

amplifier. Connect the other end of the REM wire to a switched 12 volt

positive source. The switched signal is usually taken from the source

unit's auto antenna or the accessory lead. If the source unit does not have

these outputs available, the recommended solution is to wire a mechanical switch in line with a 12 volt source to activate the amplifier.

7. Securely mount the amplifier (with supplied screws) to the vehicle or

amp rack. Be careful not to mount the amplifier on cardboard or plastic

panels. Doing so may enable the screws to pull out from the panel due

to road vibration or sudden vehicle stops.

8. Connect the source signal to the amplifier by plugging the RCA cables

into the input jacks at the amplifier.

9. Connect the speakers. Strip the speaker wires 5/8". Insert the bared wire

into the speaker terminal and tighten the set screw to secure into place.

Be sure to maintain proper speaker polarity.

DO NOT chassis ground

any of the speaker leads as unstable operation may result.

10. Perform a final check of the completed system wiring to ensure that all

connections are accurate. Check all power and ground connections for

frayed wires and loose connections which could cause problems.

11. After the final inspection is complete, install the power fuse and enjoy

listening. During the initial listening period, you may need to “fine tune”

any phasing and level settings within your particular vehicle. To aid in

this procedure, play a track with high musical content and cruise around

your neighborhood. After fully evaluating the transient response of your

system and making any final adjustments, all your neighbors within a

1 mile radius will assume that you have just successfully completed

another upgrade to your audio system for which they will probably spill

thumbtacks on your driveway.

– 11 –

Page 15

U

SING PASSIVE CROSSOVERS

A passive crossover is a circuit that uses capacitors and/or coils and is placed

on speaker leads between the amplifier and speaker. The crossover delegates

a specific range of frequencies to the speaker for optimum driver performance.

A crossover network can perform one of three functions: High-Pass (capacitors), Low-Pass (inductors or coils) and Bandpass (combination of capacitor

and coil).

The most commonly used passive crossover networks are 6dB/octave

systems. These are easy to construct and require one component per filter.

Placing this filter in series with the circuit will reduce power to the speaker by

6dB/octave above or below the crossover point depending on whether it is a

high-pass or low-pass filter. More complex systems such as 12dB/octave or

18dB/octave can cause impedance problems if not professionally designed.

Passive crossovers are directly dependent upon the speaker's impedance and

component value for accuracy. When passive crossover components are

used in multiple speaker systems, the crossover's effect on the overall

impedance should be taken into consideration along with the speaker's

impedance when determining amplifier loads.

fiers are not recommended for impedance loads below 2Ω stereo and 4Ω

bridged (mono) loads.

CAUTION: The Punch ampli-

a

O

p

d

e

v

r

a

a

n

t

c

i

e

o

d

n

– 12 –

Page 16

T

ABLE OF CROSSOVER COMPONENT VALUES

a

O

p

d

e

v

r

a

a

n

t

c

i

e

o

d

n

C

6dB/Octave High-Pass

8 OHMS

C

L C

Freq.

Hertz

L

6dB/Octave Low-Pass

2 OHMS

L

C L

Speaker Impedance

4 OHMS

80 4.1mH 1000µF 8.2mH 500µF 16mH 250µF

100 3.1mH 800µF 6.2mH 400µF 12mH 200µF

130 2.4mH 600µF 4.7mH 300µF 10mH 150µF

200 1.6mH 400µF 3.3mH 200µF 6.8mH 100µF

260 1.2mH 300µF 2.4mH 150µF 4.7mH 75µF

400 .8mH 200µF 1.6mH 100µF 3.3mH 50µF

600 .5mH 136µF 1.0mH 68µF 2.0mH 33µF

800 .41mH 100µF .82mH 50µF 1.6mH 26µF

1000 .31mH 78µF .62mH 39µF 1.2mH 20µF

1200 .25mH 66µF .51mH 33µF 1.0mH 16µF

1800 .16mH 44µF .33mH 22µF .68mH 10µF

4000 .08mH 20µF .16mH 10µF .33mH 5µF

6000 51µH14µF .10mH 6.8µF .20mH 3.3µF

9000 34µH 9.5µF68µH 4.7µF .15mH 2.2µF

12000 25µH 6.6µF51µH 3.3µF 100µH 1.6µF

L = Low-Pass (Inductor)

C = High-Pass (Capacitor)

For more information, see your Authorized Rockford Fosgate Dealer.

– 13 –

Page 17

U

SING THE

The crossover functions are controlled through the use of an XCard and can

be set for high-pass, low-pass or full range operation. The XCard shipped with

your amplifier is set for Full Range. Each crossover card has two faces: one

face operates Full Range, the other has arrows to indicate the edge for

selecting HP (high-pass) or LP (low-pass) operation. Orient the card with the

desired operating edge, indicated by the arrow, toward the socket terminals

inside the amplifier. Firmly, but carefully, plug the card into the socket.

XC

ARD

Low-Pass Full RangeHigh-Pass

➝

LP

HP

➝

➝

HP

LP

➝

FULL

↕

The crossover point can be altered by changing all 4 resistor values. Use the following

formula to select the appropriate resistor value to be placed on the XCard.

a

O

3386

f

o

7234

f

o

= R (in kΩ) for .047µf cap

= R (in kΩ) for .022µf cap

p

d

e

v

r

a

a

n

t

c

i

e

o

d

n

The actual formula is:

R =

1

2πfoc

Crossover Card

High Pass

R1

Low Pass

Full Range

R2

R1

FULL

R2

Where: R = Ω

fo = desired crossover frequency

c = capacitor in farads

ex: .047 x 10-6 for .047µf cap

– 14 –

Page 18

R

ESISTOR

C

HART

Our tests have shown that using 0.047µf capacitors for frequencies below 100Hz, and 0.022µf

capacitors for frequencies above 100Hz, result in more linear crossover control. Refer to the

Specifications page to determine the capacitor value of each supplied XCard.

a

O

p

d

e

v

r

a

a

n

t

c

i

e

o

d

n

Butterworth Alignment Q = .707

1% resistors used with 0.047µF caps

Frequency R1 R2

20Hz 169k

25Hz 133kΩ 133kΩ

30Hz 110kΩ 110kΩ

35Hz 95.3kΩ 95.3kΩ

40Hz 84.5kΩ 84.5kΩ

45Hz 75kΩ 75kΩ

50Hz 68.1kΩ 68.1kΩ

55Hz 61.9kΩ 61.9kΩ

60Hz 56.2kΩ 56.2kΩ

65Hz 52.3kΩ 52.3kΩ

70Hz 48.7kΩ 48.7kΩ

75Hz 45.3kΩ 45.3kΩ

80Hz 42.2kΩ 42.2kΩ

85Hz 40.2kΩ 40.2kΩ

90Hz 37.4kΩ 37.4kΩ

200Hz 16.9kΩ 16.9kΩ

300Hz 11.3kΩ 11.3kΩ

400Hz 8.45kΩ 8.45kΩ

500Hz 6.65kΩ 6.65kΩ

600Hz 5.62kΩ 5.62kΩ

700Hz 4.75kΩ 4.75kΩ

800Hz 4.22kΩ 4.22kΩ

900Hz 3.74kΩ 3.74kΩ

1kHz 3.40kΩ 3.40kΩ

1.2kHz 2.80kΩ 2.80kΩ

2kHz 1.69kΩ 1.69kΩ

3kHz 1.10kΩ 1.10kΩ

4kHz 845Ω 845Ω

5kHz 665Ω 665Ω

6kHz 562Ω 562Ω

7kHz 487Ω 487Ω

8kHz 422Ω 422Ω

Ω 169kΩ

Butterworth Alignment Q = .707

1% resistors used with 0.022µF caps

Frequency R1 R2

20Hz 357kΩ 357kΩ

25Hz 287kΩ 287kΩ

30Hz 237kΩ 237kΩ

35Hz 205kΩ 205kΩ

40Hz 178kΩ 178kΩ

45Hz 162kΩ 162kΩ

50Hz 143kΩ 143kΩ

55Hz 130kΩ 130kΩ

60Hz 121kΩ 121kΩ

65Hz 110kΩ 110kΩ

70Hz 102kΩ 102kΩ

75Hz 95.3kΩ 95.3kΩ

80Hz 90.9kΩ 90.9kΩ

85Hz 84.5kΩ 84.5kΩ

90Hz 80.6kΩ 80.6kΩ

200Hz 35.7k

300Hz 23.7kΩ 23.7kΩ

400Hz 17.8kΩ 17.8kΩ

500Hz 14.3kΩ 14.3kΩ

600Hz 12.1kΩ 12.1kΩ

700Hz 10.2kΩ 10.2kΩ

800Hz 9.9kΩ 9.9kΩ

900Hz 8.6kΩ 8.6kΩ

1.0kHz 7.15kΩ 7.15kΩ

1.2kHz 6.04kΩ 6.04kΩ

2.0kHz 3.57kΩ 3.57kΩ

3.0kHz 2.37kΩ 2.37kΩ

4.0kHz 1.76kΩ 1.76kΩ

5.0kHz 1.43kΩ 1.43kΩ

6.0kHz 1.21kΩ 1.21kΩ

7.0kHz 1.02kΩ 1.02kΩ

8.0kHz 909Ω 909Ω

Ω 35.7kΩ

– 15 –

Page 19

I

NSTALLATION

Power Connections

I

® ®

N

S

T

A

L

L

A

T

I

O

N

LED

Connect to remote

turn-on lead of

source unit

Less than 18"

*Keep grounds as short as possible

REM

Connect to B+ of battery with

GNDB+

Connect to chassis

ground of vehicle*

appropriate fuse value

P75

P125

P225.

P55

.

2

- 20A

.2

- 30A

.2

- 40A

2

- 50A

– 16 –

Page 20

Stereo Operation

RCA Input

I

® ®

N

S

T

A

L

L

A

T

I

O

N

Speaker

+L–

Treble

Gain

Left

Left

Input

Right

Input

Right

Gain

–

2Ω min.

2Ω min.

+

• RCA inputs are connected to

both left and right

• Gain for left and right channels operate

• Impedance for each channel should be

independently

2Ω minimum

Bass

+

–

Speaker

+R–

channels

• XCard can be set for High-Pass, Low-Pass or Full Range

– 17 –

Page 21

Mono Operation

RCA Input

I

® ®

N

S

T

A

L

L

A

T

I

O

N

Speaker

+L–

Treble

• RCA inputs are connected to

Left

Left

Input

Gain

+–

4Ω min.

both left and right

• Gain for left and right channels are

Right

Right

Gain

Input

set equally

Speaker

+R–

Bass

channels

to balance

the subwoofer

• Impedance for mono channel should be

4Ω minimum

• XCard can be set for High-Pass, Low-Pass or Full Range

– 18 –

Page 22

Stereo/Mono Operation

RCA Input

I

® ®

N

S

T

A

L

L

A

T

I

O

N

Speaker

+L–

Treble

–

+

Left

Left

Input

Gain

2Ω min. 2Ω min.

+–

4Ω min.

• RCA inputs are connected to both

• Gain for left and right channels are

Right

Right

Gain

Input

left and right channels

set equally

Speaker

+R–

Bass

+

–

to balance the

subwoofer

• Impedance for each channel should be

• Impedance for mono channel should be

• XCard is set for

Full Range

2Ω minimum

4Ω minimum

• Passive Crossovers are needed for proper stereo/mono operation

– 19 –

Page 23

S

YSTEM

2-Way System

D

IAGRAMS

80Hz

12dB/octave HP

Crossover

Tweeter

Midrange

AUD

DISC

FM

ST

AM

PWR

VOL

® ®

Ch

RPTLD

RDM

CLOCK

ILLUM

AUTO

P.SCN LOUDDSPL

RDM

RPT

SCAN

D.SCN

1 2 3 4 5 6

DIM

R

SEL

TUNE

PAUSE

80Hz HP

XCard

Crossover

Tweeter

Midrange

– 20 –

Page 24

3-Way System

80Hz

12dB/octave HP

80Hz HP

XCard

Tweeter

Midrange

Crossover

Front

AUD

DISC

FM

AM

PWR

VOL

® ®

ST

Ch

RPTLD

RDM

CLOCK

AUTO

P.SCN LOUDDSPL

RDM

RPT

SCAN

D.SCN

1 2 3 4 5 6

R

SEL

ILLUM

TUNE

DIM

PAUSE

Rear

80Hz

12dB/octave LP

80Hz LP

XCard

Crossover

Tweeter

8Ω

Woofer

8Ω

Midrange

Woofer

– 21 –

Page 25

4-Way System

80Hz HP

12dB/octave HP

80Hz HP

24dB/octave HP

Tweeter

Midrange

AUD

PWR

VOL

3

Crossover

DISC

FM

AM

® ®

®

ST

Ch

RPTLD

RDM

®

CLOCK

ILLUM

AUTO

P.SCN LOUDDSPL

RDM

RPT

SCAN

D.SCN

1 2 3 4 5 6

Front

Crossover

DIM

SEL

PAUSE

Midbass

R

TUNE

4Ω

80Hz HP

XCard

80Hz HP

24dB/octave HP

Tweeter

Midrange

80Hz

24dB/octave HP

12dB/octave LP

275Hz LP

XCard

275Hz

80Hz LP

XCard

30Hz

12dB/octave HP

– 22 –

Woofer

8Ω

30Hz

12dB/octave HP

12dB/octave LP

80Hz

Page 26

4-Way System w/Fadable Rear Stage

80Hz HP

12dB/octave HP

80Hz HP

24dB/octave HP

30Hz

12dB/octave HP

Tweeter

Midrange

3

Crossover

AUD

DISC

FM

ST

AM

PWR

VOL

® ®

Ch

RPTLD

RDM

CLOCK

ILLUM

AUTO

P.SCN LOUDDSPL

RDM

RPT

SCAN

D.SCN

1 2 3 4 5 6

Front

®

®

DIM

Rear

R

SEL

TUNE

PAUSE

80Hz HP

XCard

Crossover

80Hz HP

24dB/octave HP

Tweeter

Midrange

275Hz LP

XCard

Midbass

4Ω

275Hz

80Hz

24dB/octave HP

12dB/octave LP

80Hz LP

XCard

Woofer

8Ω

30Hz

80Hz

12dB/octave HP

12dB/octave LP

80Hz HP

12dB/octave HP

Tweeter

Midrange

Crossover

– 23 –

80Hz HP

XCard

Crossover

Tweeter

Midrange

Page 27

R

OCKFORD FOSGATE

Energy Storage Capacitors

®

Energy storage capacitors are used to provide extra current needed by

amplifiers to reproduce musical transients. The capacitors also have the

natural ability to filter AC ripple caused by the alternator, reducing the chance

of noise in the system. The Punch Caps are available in a variety of values and

will maximize both the sound quality and performance that Rockford Fosgate

amplifiers can deliver.

A

CCESSORIES

LED

Battery +

REM

B+ GND

® ®

the connecting

1.0

1.0

punch

cap

1 farad • 20 VDC • 95°C

®

• Recommended capacitance is 1 farad per 1000 watts

ATTENTION: We recommend your Authorized Rockford Fosgate Dealer

install your new accessory.

– 24 –

Page 28

XCard Crossovers

®

Additional crossover card frequencies are available for specialized requirements. You can get the following XCards from your Authorized Rockford

Fosgate Dealer.

XM50 = 50Hz XM200 = 200Hz

XM70 = 70Hz XM275 = 275Hz

XM80 = 80Hz XM400 = 400Hz

XM100 = 100Hz XM4.5k = 4,500Hz

XM150 = 150Hz XM6.5k = 6,500Hz

XM00 = Blank card for

custom crossover

Crossover Card

High Pass

R1

R2

Low Pass

Full Range

R1

FULL

R2

ATTENTION: We recommend your Authorized Rockford Fosgate Dealer

install your new accessory.

– 25 –

Page 29

T

ROUBLESHOOTING

Symptom Diagnosis Remedy

TROUBLE-

S

H

O

O

T

I

N

G

Amplifier does not

turn on

(Power LED is off)

Amplifier has no

sound

(Power LED is on)

Voltage applied to the REM

terminal of the amplifier is

not between 10.5 and

15.5 volts or there is no

voltage present.

Voltage to the B+ terminal

of the amplifier is not between 10.5 and 15.5 volts

or there is no voltage

present.

Amplifier is not properly

grounded.

RCA Input from source unit

is not connected or not

functioning properly.

XCard is missing or not

placed properly in crossover slots.

Speaker leads are shorted

to each other or to the chassis of the vehicle.

Check the alternator, battery,

fuse, and wiring and repair as

necessary. If the voltage is

above 15.5 volts, have the electrical system inspected by an

authorized car service center.

Check the alternator, battery,

fuse, and wiring and repair as

necessary. If the voltage is

above 15.5 volts, have the electrical system inspected by an

authorized car service center.

Check wiring and repair as necessary.

Check connections, substitute

with known working source and

cables and repair or replace as

necessary.

Check XCard position and repair or replace as necessary.

Disconnect existing speakers

and test with known working

speakers and wires. If amplifier

plays, check and repair wiring

and installation of speakers as

necessary.

Speakers are defective.

– 26 –

Disconnect existing speakers

and test with known working

speakers. If amplifier plays,

check and repair speakers as

necessary.

Page 30

Symptom Diagnosis Remedy

TROUBLE-

S

H

O

O

T

I

N

G

Speaker Output

Low or Distorted

Amplifier Noise

(Turn-on Pop)

Input gain signal for amplifier

is incorrectly set.

Source unit output too low or

source unit has no output.

XCard is missing or not placed

properly in crossover slots.

Low battery voltage or large

voltage drops to the amplifier

under load.

Voltage spike from output of

preceding component is entering amplifier through input signal.

Voltage spike from remote

turn-on lead is entering

through REM input terminal.

Readjust input gains of amplifier.

Check system with known working source and repair or replace

original source as needed.

Check XCard position and repair

or replace as necessary.

Check the alternator, battery,

fuse, and power and ground

wiring. Repair as necessary.

Disconnect input signal to

amplifier and turn amplifier

on and off. If noise is eliminated, connect REM lead of

amplifier to source unit with

a delay turn-on module.

Use a different 12 volt source

for REM lead of amplifier.

(i.e., battery direct) If noise

is eliminated, use a relay to

isolate amplifier from noisy

turn-on output.

– 27 –

Page 31

Symptom Diagnosis Remedy

TROUBLE-

S

H

O

O

T

I

N

G

Engine Noise

Noise is radiating into RCA

signal cable.

Bad component in the signal chain.

Noise is radiating into

speaker cables.

Multiple grounds in the

audio system.

Check connections, run the

RCA cables on a different route

away from sources of high

current.

Check connections, bypass

additional components (crossovers and equalizers) between

the source unit and the amplifier. Connect one component

at a time to determine the

culprit. Repair or replace components as necessary.

Disconnect existing speakers

and connect a test speaker to

the output terminals of the

amplifier. If noise is gone, reroute the speaker cables away

from sources of high voltage.

Check ground connections and

connect amplifiers, signal processors, and other components

to a central location or try a

different grounding point on

the chassis.

Ground loop between source

unit and antenna.

Check connections, disconnect

antenna from source unit. If

noise is gone, install an antenna ground loop isolator.

• If noise persists, see your Authorized Rockford Fosgate Dealer.

– 28 –

Page 32

D

YNAMIC POWER

About the Dynamic Power Measurements

The Audio Graph PowerCube is a test instrument used to measure the output of

an amplifier in accordance with IHF-202 industry standards. The IHF-202

standard is a dynamic power measurement and was developed as a means of

measuring power in a manner that best represents the Real World operation of an

amplifier. Many manufacturers, including Rockford Fosgate, at times will measure

amplifier power into a fixed resistor (4 ohm, 2 ohm). While this method is useful

in some types of evaluation and testing, it is not representative of an amplifier that

is connected to a speaker and playing music.

Music

Music is dynamic; the sound waves are complex and constantly changing. In

order to simulate this, the IHF-202 standard calls for the input signal to the

amplifier to be a 1kHz bursted tone. This signal is input (on for 20 milliseconds)

and reduced 20dB for 480 milliseconds. The signal is gradually increased in level

until the amplifier's output exceeds 1% Total Harmonic Distortion (THD). At 1%

distortion becomes audible, therefore, any power produced above that level is

considered

power in excess of 10% distortion. They use many names for this measurement,

such as Total Maximum Power or Maximum Output Power. This is not indicative

of the

unusable

actual usable output power

M

EASUREMENTS

. Many manufacturers represent their amplifiers' output

.

Listening to Loudspeakers - Not Resistors

A loudspeaker is not a resistor. A resistor's value (resistance measured in ohms)

is fixed. A loudspeaker's impedance is dynamic. It is constantly changing in value,

dependent upon the frequency of the input signal. Therefore, measuring power

with the amplifier loaded into a 4 ohm resistor is not the same as measuring power

with the amplifier connected to a 4 ohm speaker. Most people do not listen to

music through a resistor.

A 4 ohm speaker may experience a drop in impedance 4-6 times lower than its

nominal (printed) impedance. A speaker will also create phase shifts in the signal

that is passed through it. These phase shifts happen because a speaker is an

inductor (voice coil) and a capacitor (compliance of the surround/spider), as well

as a resistor (voice coil wire).

To simulate a speaker the Audio Graph PowerCube measures output power into

20 different loads. It tests at 8 ohms, 4 ohms, 2 ohms and 1 ohm. Each of these

impedances is also tested at –60°, –30°, 0°, +30° and +60° phase angles.

These different impedances and phase angles represent the shifts in impedance

and phase that can occur in a typical loudspeaker.

– 29 –

Page 33

Information Cubed

The data acquired in the testing procedure is then graphed in the form of a

3-dimensional cube, hence the name PowerCube.

The

Phase Angle

presented on the vertical axis and the

Output Power,

is expressed on the horizontal axis, the

Impedance

is displayed on the Z axis.

Output Voltage

is

in watts, is listed on the left hand side for each impedance at

each phase angle.

Audio Graph – The PowerCube™

MODEL BEING

TESTED

Amplifier:

PUNCH 200.2 14.4V x 2

Serial No:

Owner :

ROCKFORD CORPORATION

85 W

8Ω –60°

*

84 W

–30°

84 W

0°

84 W

30°

86 W

60°

162 W

4Ω –60°

*

157 W

–30°

156 W

0°

157 W

30°

162 W

60°

273 W

2Ω –60°

*

IMPEDANCE

258 W

–30°

251 W

0°

256 W

30°

271 W

60°

390 W

1Ω –60°

*

356 W

–30°

346 W

0°

352 W

30°

390 W

60°

VOLTAGE FROM

BATTERY

POWER

IN

WATTS

{

–60° (Cap)

• Example of a Punch 200.2 PowerCube

MONO = BRIDGED MONO

0°

{

PHASE ANGLES

x2 = STEREO

Rated Power : 100 W @ 4 Ohms

(Ind) +60°

50V

30V

10V

OUTPUT VOLTAGE

8Ω

4Ω

2Ω

1Ω

{

Impedance

What is an Amplifier?

An amplifier by definition is a voltage generating device, recreating the signal

which is input to it identically but with increased volume. It will be connected

to a reactive load (the speaker). The impedance of this load and phase of the

signal passing through the load will vary, dependent upon the frequency of

the input signal (music).

Therefore, a perfect amplifier will be able to maintain the same output voltage

regardless of load characteristics and will not alter the signal it is reproducing.

A perfect amplifier when measured by the Audio Graph PowerCube would

present data that forms a perfect cube. Unfortunately, amplifiers are not

perfect. The laws of physics generally prevent it. A great amplifier is about the

best one can hope to attain.

As you can see by the PowerCube and as you will experience by listening,

your Punch amplifier is a GREAT AMPLIFIER!

– 30 –

Page 34

2

2 PUNCH 225.

PUNCH 75.2 PUNCH 125.

PUNCH 55.2

Dynamic Power Rating (IHF-202 Standard) - Measured at 14.4 Volts

PECIFICATIONS

S

Mono into a 4Ω Load 240 Watts 320 Watts 440 Watts 690 Watts

Per channel into a 2Ω Load 120 Watts 160 Watts 220 Watts 345 Watts

Per channel into a 4Ω Load 85 Watts 105 Watts 145 Watts 220 Watts

Continuous Power Rating (Competition Standard) - Measured at 13.8 Battery Volts

RMS continuous power per channel,

both channels driven into a 4Ω load 27.5 Watts 37.5 Watts 62.5 Watts 112.5 Watts

from 20 to 20,000 Hz with less than

0.05% Total Harmonic Distortion (THD)

RMS continuous power per channel,

both channels driven into a 2Ω load 55 Watts 75 Watts 125 Watts 225 Watts

from 20 to 20,000 Hz, with less than

0.1% Total Harmonic Distortion (THD)

RMS continuous power mono into a

4Ω load from 20 to 20,000 Hz, with 110 Watts 150 Watts 250 Watts 450 Watts

less than 0.1% Total Harmonic

Distortion (THD)

Signal-to-Noise Ratio > 100dB A-weighted

Crossover Slope 12dB/octave Butterworth

Factory Default Crossover Frequency 80Hz adjustable (.047µf)

– 31 –

Page 35

2

/8" (24.4cm) W

⁄32" (33.70cm) L

5

9

2 PUNCH 225.

PUNCH 125.

/8" (24.4cm) W 9

⁄32" (31.16cm) L 13

5

9

PUNCH 75.2

/8" (24.4cm) W 9

⁄32" (28.65cm) L 12

5

9

/8" ( 6.6cm) H

5

/8" ( 6.6cm) H 2

5

/8" ( 6.6cm) H 2

5

Treble: +12dB Maximum at 20kHz

2

PUNCH 55.

⁄32" (26.1cm) L 11

9

/8" (24.4cm) W 9

5

10

Dimensions 9

Specifications are subject to change without notice.

/8" (6.6cm) H 2

5

2

Frequency Response 20Hz to 20kHz ±0.5dB

Bandwidth 10Hz to 200kHz ±3dB

Damping Factor @ 4Ω (at output connector ) >200

Slew Rate 30 Volts µs

IM Distortion (IHF) <0.05%

Source Unit Compatibility (+15dB gain overlap) 17V max.

overload. Thermal switch shuts down the amplifier in case of overheating.

Input Sensitivity (+0dB gain overlap) Variable from 150mV to 3V

Protection NOMAD - Internal analog-computer output protection circuitry limits power in case of

Battery Fusing Rates (External to Amplifier) 20 amps 30 amps 40 amps 50 amps

Fuse Type ATC ATC ATC AGU

Equalization Bass: +18dB Maximum at 45Hz

Input Impedance 20k ohms

– 32 –

Page 36

L

IMITED

Rockford Corporation offers a limited warranty on Rockford Fosgate products on the following

terms:

• Length of Warranty

3 years on electronics 90 days on electronic B-stock (receipt required)

2 years on source units 30 days on speaker B-stock (receipt required)

1 year on speakers

• What is Covered

This warranty applies only to Rockford Fosgate products sold to consumers by Authorized

Rockford Fosgate Dealers in the United States of America or its possessions. Product

purchased by consumers from an Authorized Rockford Fosgate Dealer in another country

are covered only by that country’s Distributor and not by Rockford Corporation.

• Who is Covered

This warranty covers only the original purchaser of Rockford product purchased from an

Authorized Rockford Fosgate Dealer in the United States. In order to receive service, the

purchaser must provide Rockford with a copy of the receipt stating the customer name,

dealer name, product purchased and date of purchase.

• Products found to be defective during the warranty period will be repaired or replaced

(with a product deemed to be equivalent) at Rockford's discretion.

• What is Not Covered

1. Damage caused by accident, abuse, improper operations, water, theft

2. Any cost or expense related to the removal or reinstallation of product

3. Service performed by anyone other than Rockford or an Authorized Rockford Fosgate

4. Any product which has had the serial number defaced, altered, or removed

5. Subsequent damage to other components

6. Any product purchased outside the U.S.

7. Any product not purchased from an Authorized Rockford Fosgate Dealer

W

Service Center

ARRANTY INFORMATION

• Limit on Implied Warranties

Any implied warranties including warranties of fitness for use and merchantability are

limited in duration to the period of the express warranty set forth above. Some states do not

allow limitations on the length of an implied warranty, so this limitation may not apply. No

person is authorized to assume for Rockford Fosgate any other liability in connection with

the sale of the product.

• How to Obtain Service

Please call 1-800-669-9899 for Rockford Customer Service. You must obtain an RA#

(Return Authorization number) to return any product to Rockford Fosgate. You are

responsible for shipment of product to Rockford.

Ship to: Electronics

Rockford Corporation

Warranty Repair Department

2055 E. 5th Street

Tempe, AZ 85281

RA#:_________________

Ship to: Speakers

Rockford Acoustic Design

(Receiving-speakers)

609 Myrtle N.W.

Grand Rapids, MI 49504

RA#:_________________

– 33 –

Page 37

INTERNATIONAL

I NFORMATION

– 34 –

Page 38

LEA DETENIDAMENTE LAS SIGUIENTES INSTRUCCIONES DE INSTALACION DEL

PRODUCTO. EVITARA POSIBLES DAÑOS A VD., AL VEHICULO O AL PRODUCTO.

I

NTRODUCCION

Los ingenieros de Rockford han diseñado los amplificadores Punch.2 para

ofrecer en el dificil entorno de un automóvil una calidad de sonido superior en

un producto flexible, fiable y eficiente. Trans•

en la etapa de preamplificación de los amplificadores Punch.2 que permite que

la musica suene limpia y cristalina y muy real, incluso a altos niveles de

audicion. Esto se complementa con el TOPAZ, un circuito exclusivo de masa

utilizado para eliminar los ruidos asociados con las instalaciones de car-audio.

La flexibilidad esta garantizada con el uso de la XCard incorporada. La

fiabilidad se refuerza con el uso de un circuito de proteccion llamado NOMAD,

mientras que los MOSFET y la tecnologia DSM (montaje discreto en superficie)

aumentan la eficiencia del amplificador. La combinacion de todos estos

componentes dan al amplificador Punch una impresionante calidad de sonido

en un chasis discreto. Mas adelante encontrará mas explicaciones de todas

estas tecnologías, la mayoria de ellas usados en exclusiva y patentadas por

Rockford.

ana

es un circuito de baja tensión

U

BICACIÓN PARA EL

M

ONTAJE

Montaje en el Malatero

Monte el amplificador verticalmente con las lineas del radiador orientadas de

arriba hacia abajo. De esta manera conseguira la mejor ventilacion.

Montaje en el Compartimento de Pasajeros

El montaje en el compartimento de pasajeros sera eficiente en funcion de la

ventilacion que tenga el amplificador. Si va a instalar el amplificador bajo un

asiento deberá dejar al menos 2.5cm libres sobre la carcasa del amplificador.

Instalacion

Por seguridad, desconecte el terminal negativo de la bateria antes de comenzar

la instalacion.

Terminal B+

El cable B+ debe ir provisto de un fusible a una distancia no mayor de 45cm

de la bateria. Prepare el cable e instale el portafusibles en el compartimento del

motor. Las conexiones han de ser impermeables.

– 35 –

Page 39

Terminal GND

Prepare un trozo de cable para usarlo como toma de masa. Prepare un

punto de masa en el chasis rascando y eliminando la pintura de la

superficie de metal y limpielo de toda suciedad asegure el cable al chasis

con un tornillo.

Terminal REM

Conecte el cable REM a un punto de +12V con mutable. La señal se suele

coger de la salida auto antena del radio cassette si este no tiene salida

remote.

Funcionamiento Estereo/Mono

RCA Input

ESPAÑOL

Speaker

+L–

Treble

–

+

Left

Left

Input

Gain

2Ω min. 2Ω min.

+–

• Las entradas RCA se conectan a ambos

4Ω min.

Right

Right

Gain

Input

canales izquierdo y derecho

• Las ganancias izquierda y derecha han de

ajustarse igual

Speaker

+R–

Bass

+

–

para ambos

canales

• La impedancia minima para cada canal debe ser

• La impedancia minima mono debe ser

• XCard en

Full Range

4Ω.

2Ω.

• Debe usarse un filtro pasivo para la configuracion estereo/mono

• No llevar a masa ningun cable de altavoz

• Crossovers pasivos se requieren para operar el amplificador en estereo/

mono

– 36 –

Page 40

ATTENTION: Veuillez lire les instructions suivantes pour l'installation de cet

amplifcateur. Ne pas les suivre pourrait causer des blessures ou endommager le

véhicule.

I

NTRODUCTION

Les ingénieurs de Rockford Fosgate ont conçu l'amplificateur Punch.2 pour

supporter l'environnement rude de l'automobile en délivrant une qualité de son

supérieure dans un ensemble efficace, fiable et flexible. Trans•

de bas voltage dans l'étage de préamplification de tous les ampificateurs

Punch.2 qui reproduit un son musical clair comme du cristal et très réel, même

à très haut volume. Ceci est accompagné du TOPAZ, un circuit unique employé

pour éliminer les problèmes de bruits parasites associés aux systémes audiomobile

et leur installation. La flexibilité est assurée par l'emploi d'une XCard incorporée.

La fiabilité est garantie grâce au circuit de protection NOMAD, la technologie

MOSFET et DSM (Composants Montés en Surface) améliorent l'efficacité de

l'amplificateur.

L'ensemble de ces atouts donne à l'amplificateur Punch une qualité de son

inégalable sous une carrosserie “pare-balles.”

Vous trouverez de plus amples informations sur ces technologies, exclusivement

conçues et brevetées par Rockford, dans la rubrique technique.

ana

est un circuit

M

ONTAGE

Montage dans le coffre

Monter l'amplificateur verticalement avec les rainures de haut en bas ce qui lui

permet de refroidir plus facilement.

Montage dans l'habitacle

Monter l'amplificateur dans l'habitacle ne pose aucun problème, du moment

qu'il y ait assez d'air pour le refroidir. Si vous montez l'ampli en dessous du

siège, prévoyez 3 cm d'air autour du radiateur.

Installation

Pour votre sécurité, déconnectez la borne négative de la batterie du véhicule

avant de commencer l'installation.

Terminal B+

Il est impératif qu'il y ait un fusible sur le câble pour la connexion à la masse.

Préparez le châssis en grattant la peinture de la surface métallique et nettoyez

la saleté et l'huile. Attachez le câble au châssis avec une vis.

– 37 –

Page 41

Terminal GND

Préparez une longueur de câble pour la connexion à la masse. Préparez le châssis

en grattant la peinture de la surface métallique et nettoyez la saleté et l'huile. Attachez

le câble au châssis avec une vis.

Terminal REM

Connectez le fil REM à une commande 12 volts positive de la source. La

commande 12 volts est habituellement prise sur la sortie antenne électrique

de la source ou la commande accessoire. Si la source ne dispose pas de

ces sorties, nous vous recommandons d'installer un interrupteur qui

fournira un positif 12 volts au REM de l'amplificateur.

Opération stéréo/mono (tri

mode)

RCA Input

Speaker

+L–

Treble

–

+

Left

Gain

2Ω min. 2Ω min.

Input

Input

+–

4Ω min.

Right

Left

Right

Gain

Speaker

+R–

Bass

+

–

• Les entrées RCA sont connectées aux canaux gauche et droit

• Les Gains des canaux gauche et droit sont réglés de la même manière

pour équilibrer le subwoofer

• L'impédance de chaque canal devrait être de minimum 2Ω

• L'impédance du canal mono devrait être de minimum 4Ω

• Les XCard sont introduites sur full range

• Il est conseillé d'utiliser les filtres passifs lorsqu'on fait fonctionner

l'amplificateur en tri-mode

•

NE connecter AUCUN des câbles HP à la masse au risque d'un

fonctionnement instable

• Des filtres passifs sont nécessaires pour un bon fonctionnement en

mode stéréo/mono

FRANÇAIS

– 38 –

Page 42

BITTE LESEN SIE DIESE GEBRAUCHSANLEITUNG ZUERST SORGFÄLTIG DURCH.

DAS KANN SIE VOR DEM FALSCHEN EINSATZ, AUSFALLEN ODER SOGAR

BESCHÄDIGUNG DES PRODUKTES ODER IHRES FAHRZEUGES SCHÜTZEN.

E

INLEITUNG

Rockford Ingenieure haben die Punch.2 Verstärker entwickelt. Mit höchstem

Technologie-Standart, hervorragender Klangqualität, einfacher Handhabung

und bester Servicefreundlichkeit Trans•

Vorverstärkerteil aller Pünch.2 Verstärker die für kristallklaren Klang auch bei

sehr hohen Lautstärken sorgt. TOPAZ, eine einzigartige Erdungsschaltung

verhindert und unterdrückt Einstreuungen und Störungen die nur allzu oft Car

Audio Systeme beeinträchtigen. Flexibilität durch die Vielfalt der Aktivweiche mit

ihren XCards, lange Lebensdauer durch die Schutzschaltung NOMAD und der

Einsatz von MOSFET Transistoren und DSM (Discrete Surface Mount), machen

diese Verstärker so effizient. Das Ergebnis all dieser Komponenten machen

Punch-Verstärker so einzigartig und in ihrer Klangqualität nahezu unschlagbar.

Eine genauere Beschreibung dieser Technologien, die gröbtenteils einzigartig

und von Rockford patentiert sind, finden Sie unter Technical Design Features.

E

INBAUORT

ana

ist eine Nieder-Volt Schaltung im

Im Fahrzeugkofferraum

Der vertikale Einbau der Endstufen, das bedeutet, dab die Kühlrippen von oben

nach unten verlaufen, gibt dem Verstärker die beste Kühlung.

Auf der Beifahrerseite

Sollte der Verstärker auf der Beifahrerseite montiert werden, so ist es sehr wichtig,

für eine ausreichende Kühlung zu sorgen. Sollte der Verstärker z.B. unter dem

Beifahrersitz montiert werden, sollte dem Kühlkörper mindestens ein Luftspalt

von 3 cm bleiben, um so für eine ausreichende Kühlung zu sorgen.

Einbau

Zur Sicherheit klemmen Sie den Negativ-Pol der Batterie während des gesamten

Einbaues ab.

B+ Anschluβ

Die Plus-Leitung MUβ ca. 40 cm nach dem Plus-Pol der Batterie abgesichert

sein. Preparieren Si die Kabellängen und montieren Sie den Sicherungshalter im

Motorraum. ALLE Verbindungen müssen wasserdicht sein.

– 39 –

Page 43

GND Anschluβ

Preparieren Sie Ihr Kabel für die Negativ Leitung (Erdung). Preparieren Sie

die Anschlubstelle des Erdungskabels, indem Sie das Metall gründlich

reinigen und vom Lack befreien. Befestigen Sie nun die Erdung an dieser

Stelle mit einer Schraube.

REM Anschluβ

Verbinden Sie das Ein-und Ausschaltungskontroll-Kabel mit Ihrem Radio

(12 Volt positiv). Normalerweise verwenden Sie hierfür die Ant.-Remote

Ihres Radios oder ein eigens dafür vorgesehenes Kabel (Amp-Remote).

Sollte Ihr Radio diesen Anschlub nicht besitzen, so verwenden Sie eine 12

Volt Spannung, die Sie durch einen Schalter ein- und ausschalten können.

Stereo/Mono Operation

Speaker

+L–

• Chinch Eingänge des

Treble

–

+

rechten- und linken-Kanales anschlieben

RCA Input

Right

Left

Left

Gain

2Ω min. 2Ω min.

Input

Input

+–

4Ω min.

Right

Gain

Speaker

+R–

Bass

+

–

• Gain -Kontrolle gleich stellen um das Signal des Subwoofer

anzugleichen

• Die Impedanz für jeden Kanal sollte

• Die Impedanz des Mono Kanales sollte

• Die Akltivweichen-Module sollten auf jeden

minimum 2 Ohm betragen.

minimum 4 Ohm betragen

Fall im Stereo/Mono Betrieb

verwendet werden

•

Vermeiden Sie auf jeden Fall eine Erdung der Lautsprecher-Kabel, da

sonst ein einwandfreier Betrieb nicht grantiert werden kann

• Passive Frequenzweichen werden für korrekte Stereo/Mono Operationen

benötigt

DEUTSCH

– 40 –

Page 44

ATTENZIONE: SI PREGA DI LEGGERE LE SEGUENTI ISTRUZIONI PER L'INSTALLAZIONE

DI QUESTO PRODOTTO. IL NON SEGUIRLE POTREBBE RISULTARE SERIAMENTE

DANNOSO PER LA PERSONA O PER IL VEICOLO.

I

NTRODUZIONE

Gli ingenieri Rockford hanno progettato la serie di amplificatori Punch.2 per

resistere all'ostico ambiente automobilistico mentre suonano con una musicalitá

superiore, offrendo un insieme versatile, affidabile ed efficiente. Trans•

circuito a bassa tensione dello stadio preamplificatore del Punch.2 che permette

al suono di essere cristallino e reale anche in presenza di volumi molto

elevati…tutto questo é accoppiato TOPAZ, un exclusivo circuito di massa

impiegato per eliminare i problemi di rumore comunemente presenti negli

impianti car audio. Il massimo della versatilitá é raggiunto con l'impiego delle

XCard. L'affidabilitá é completamente garantita dall'impiego di un circuito di

protezione chiamato NOMAD, mentre l'uso di MOSFET e della tecnologia DSM

(Discrete Surface Mount) permette di raggiungere efficienze elevatissime. Il

risultato finale di tutte queste tecnnologie moderne é che gli amplificatori Punch

suonano meravigliosamente e sono indistruttibili, a “prova di proiettile.” Una

spiegazione di queste tecnologie innovative, molte coperte da brevetti Rockford,

sono descritte in un'altra sezione di questo manuale.

ana

é un

D

OVE POSIZIONARLO

Nel Bagagliaio

Montando l'amplificatore su una superficie in verticale con le alette direzionate

dall'alto verso il basso si garantirá un miglior raffreddamento dell'amplificatore.

Nell'abitacolo

Montare l'amplificatore nell'abitacolo si avrá un funzionamento regolare se si

garantisce un flusso d'aria sufficiente. Per l'installazione sotto un sedile, é

necessario avere uno spazio di almeno 3 cm attorno a tutto l'amplificatore.

Installazione

Per sicurezza, scollegare il polo negativo della batteria dell'auto prima di

iniziare l'installazione.

Terminale B+ (cavo positivo)

Il cavo positivo deve essere protetto da un fusibile a non piú di 45 cm dalla

batteria. Terminare il cavo e installare il fusibile nel vano motore. Tutte le

connessioni devono essere a prova d'acqua.

– 41 –

Page 45

Terminale GND (cavo negativo)

Decidere la lunghezza del cavo e terminarlo. Preparare la massa grattando

la vernice dal telaio dell'auto ed eliminando tracce di olio o sporco. Fissare

il cavo di massa al telaio con una vite.

Terminale REM (Consenso di accensione)

Collegare il cavo REM ad un positivo presente solo ad autoradio accesa

(normalmente il cavo pilota dell'antenna elettrica o il cavo accessori

dell'autoradio). Se la sorgente non dovesse essere equipaggiata con

queste uscite, la soluzione raccomandabile é di inserire un interruttore su

un cavo positivo e connettersi all'amplificatore.

Stereo/Mono Operation

Speaker

+L–

Treble

–

+

RCA Input

Right

Left

Gain

Left

Input

Input

2Ω min. 2Ω min.

+–

4Ω min.

Right

Gain

Speaker

+R–

Bass

+

–

• Ingressi RCA collegati sia al canale destro sia al sinistro

• Gain (controllo di sensibilitá) regolati in modo identico per bilanciare il

subwoofer

• L'impedenza di ciascun canale deve essere minimo 2Ω

• L'impedenza per il canale mono deve essere minimo 4Ω

• La scheda XCard deve essere in posizione Full Range

• Nel funzionamento Stereo/Mono simultaneo devono essere impiegati i

crossover passivi

•

Non cortocircuitare a massa nessun cavo degli altoparlanti, potrebbe

portare ad un funzionamento irregolare

• Crossover passivi sono indispensabili per un corretto funzionamento

stereo/mono

ITALIANO

– 42 –

Page 46

N

OTES

Page 47

N

OTES

Page 48

MADE IN THE USA

This product is designed, developed and assembled in the USA by a dedicated group of

American workers. The majority of the components used in the construction of this product

are produced by American companies. However, due to the global nature of their

manufacturing facilities and the loudspeaker parts industry in general, some parts may be

10/97

MAN-1849-A

manufactured in other countries.

Rockford Fosgate

Rockford Corporation

546 South Rockford Drive

Tempe, Arizona 85281 U.S.A.

In U.S.A., (602) 967-3565

In Europe, Fax (49) 8503-934014

In Japan, Fax (81) 559-79-1265

Loading...

Loading...