Page 1

VSPFEXT

VSP ENCLOSURE

Vehicle Specific Punch

Ford Extended Cab ’97+

FEATURES

Specification

Reference

Sheet

• Vehicle Specific – Custom molded to fit under the rear bench seat.

• Acoustic Suspension Enclosure – The VSP enclosure uses an

acoustic suspension design (sealed) for optimum performance. The

enclosure is matched to the woofer for deep bass output while requiring

minimal operating space.

• Roto-Molded Urethane Construction – The use of Roto-Mold

manufacturing produces a composite enclosure with seamless construction.

This greatly increases rigidity to prevent the enclosure from flexing and

allows custom designs to be fabricated. The result is a radical, stronger,

more reliable enclosure.

PUNCH WOOFER

• PVA Cone – The cone material used is spruce pulp paper and provides

the necessary combination of weight and strength to allow high levels of

output without cone break up. The cone is also treated with a water

resistant PolyVinyl Acetate (PVA) Emulsion which increases cone rigidity

and lowers distortion.

SPECIFICATIONS

VSP Enclosure

Frequency Response ..............................................24Hz-400Hz

Overall Dimensions ................................ 61⁄4”H x 343⁄4”W x 11”D

(15.87cm x 88.26cm x 27.94cm)

Weight (woofer supplied) ............................... 24 lbs. (10.88kg)

Punch Woofers

Speaker Model ................................................... (2) RFP-1808

Nominal Impedance.............................................................8Ω

Fs ...............................................................................32Hz

RE ...............................................................................7.2Ω

• Aluminum Voice Coil Former – The voice coil is made of multiple

layers of copper wound on a black, anodized aluminum former. This

improves the speaker’s power handling by efficiently dissipating heat from

the voice coil.

• Hyper-Extended Pole Piece – The pole piece has been extended to

provide a more linear magnetic field for the operation of the woofer. This

lowers distortion and provides the woofer with better low frequency

response.

• Vented Bumped Back Plate – The back plate has been stepped

deeper to allow the woofer more excursion for harder hitting bass.

Additionally, the back plate is vented with a radiused aerodynamic vent that

efficiently and quietly keeps the voice coil cool.

LE.......................................................................... 4mH

QMS....................................................................... 5.00

QES ....................................................................... 0.33

QTS........................................................................ 0.31

VAS (ft3/liter) .................................................. .883 (25L)

XMAX (in/mm) ............................................ 0.31” (8mm)

SPL (dB @ 1w/1m) .................................................86dB

Power Handling (RMS/Peak) ........................ 200W/400W

Speaker Displacement (ft3/liter) .................... 0.05(1.416L)

ACCESSORY PACK

(1) Input Terminal Cup (16) #10-32 x 3/4” Allen Screws (4) Phillips Screws

(8) Foam Woofer Gaskets (2 x 24”) Red/Black 16 gauge Speaker Wire

®®

–1–

Specifications subject to change without notice

Page 2

VSPFEXT

The Vehicle Specific Punch (VSP) enclosure is supplied in kit form to allow custom finishing techniques. The unfinished surface

enables matching paint or carpet to be applied to the enclosure for seamless integration into the vehicle’s interior. In addition, the

input terminal cup can be positioned in the desired location where speaker wires can be conveniently routed from the amplifier to

the enclosure.

Ford Extended Cab ’97+

Vehicle Specific Punch

Installation

Reference

Sheet

IMPORTANT – Please follow these instructions carefully!!

The VSP enclosure is specially molded to fit particular vehicles. Be sure to attach the enclosure to the vehicle as

specified in this installation sheet for optimized bass output. Failure to install the enclosure as specified in this document may allow the enclosure to become detached from the vehicle and possibly cause personal injury.

Always use eye protection when drilling.

Never run wires underneath the vehicle. Run wires inside the vehicle and use rubber or plastic grommets

!

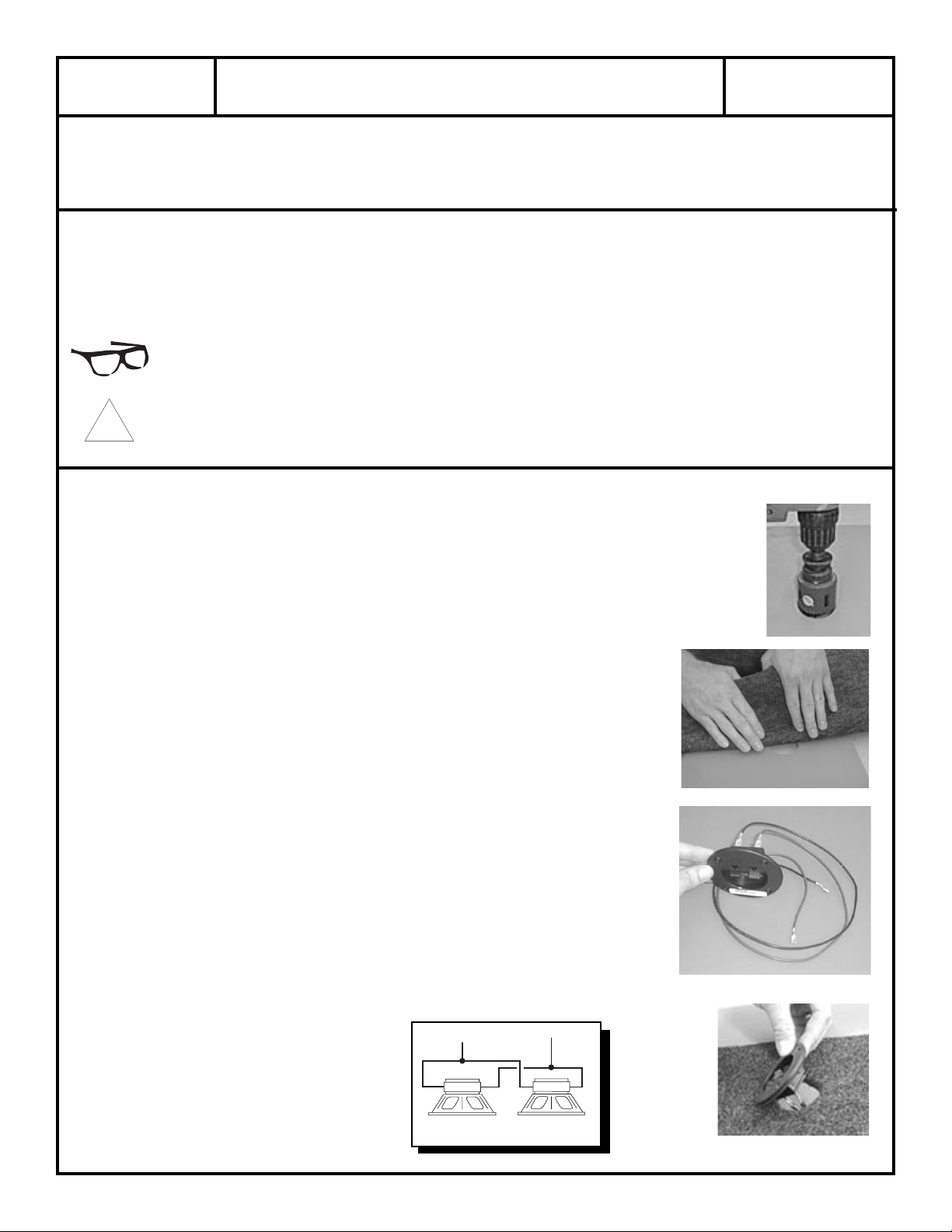

VSP ENCLOSURE PREPARATION

to protect wires routed through metal.

1. Select the desired location for the speaker terminal cup, and with a hole saw, cut a 2” diameter hole.

2. Using the speaker terminal cup as a template, mark the holes used to secure the cup to the enclosure.

Remove the cup and drill pilot holes using a 3/32” drill bit.

3. Carpet or paint the enclosure(s) to your desired color theme.

4. Connect the supplied speaker wire to the appropriate (+) and (–) terminals of the speaker

cup. Connect the RED wire to the (+) terminal and the BLACK wire to the (–) terminal.

5. Secure the speaker terminal cup to the enclosure using the (4) supplied Phillips screws.

Connect the speaker wires as shown in the diagram and secure the woofers to the enclosure.

Be sure to maintain proper speaker polarity.

+ –

4Ω load

+ – + –

8Ω load 8Ω load

–2–

Page 3

VSPFEXT

VEHICLE PREPARATION

6. The VSP enclosure will be located under the rear bench seat. Be sure to remove any

obstructions for proper installation.

7. Remove the (8) screws holding the rear seat panel in place using a T-30 Torx driver

(there are 3 screws on each end of the seat and 2 in the middle).

8. Remove the (2) 18mm bolts that secure the rear seat to the wall of the cab.

Ford Extended Cab ’97+

Vehicle Specific Punch

Installation

Reference

Sheet

9. Temporarily remove the rear bench seat from the vehicle.

VSP ENCLOSURE INSTALLATION

10. Run the speaker wire from the amplifier to the desired location.

11. Install the enclosure between the rear seat mounting brackets with the woofers facing

down. Push the enclosure all the way back (the front of the enclosure should be flush

with the front of the seat brackets).

12. Replace the rear seat by re-installing the (8) screws and the (2) 18mm bolts previously

removed in steps 7 & 8. NOTE: The VSP enclosure will remain in place by “sandwiching” it between the floorboard and the rear bench seat.

13. If necessary, fine tune the system to find the proper bass level for your new VSP woofer

enclosure.

–3–

Page 4

L

IMITED

Rockford Corporation offers a limited warranty on Rockford Fosgate products on the following terms:

• Length of Warranty

1 year on VSP speakers (not the entire enclosure)

• What is Covered

This warranty applies only to Rockford Fosgate products sold to consumers by Authorized Rockford Fosgate Dealers in the United States

of America or its possessions. Product purchased by consumers from an Authorized Rockford Fosgate Dealer in another country are covered

only by that country’s Distributor and not by Rockford Corporation.

• Who is Covered

This warranty covers only the original purchaser of Rockford product purchased from an Authorized Rockford Fosgate Dealer in the United

States. In order to receive service, the purchaser must provide Rockford with a copy of the receipt stating the customer name, dealer name,

product purchased and date of purchase.

• Products found to be defective during the warranty period will be repaired or replaced (with a product deemed to be equivalent) at

Rockford's discretion.

• What is Not Covered

1. Damage caused by accident, abuse, improper operations, water, theft

2. Any cost or expense related to the removal or reinstallation of product

3. Service performed by anyone other than Rockford or an Authorized Rockford Fosgate Service Center

4. Any product which has had the serial number defaced, altered, or removed

5. Subsequent damage to other components

6. Any product purchased outside the U.S.

7. Any product not purchased from an Authorized Rockford Fosgate Dealer

W

ARRANTY

I

NFORMATION

• Limit on Implied Warranties

Any implied warranties including warranties of fitness for use and merchantability are limited in duration to the period of the express warranty

set forth above. Some states do not allow limitations on the length of an implied warranty, so this limitation may not apply. No person is

authorized to assume for Rockford Fosgate any other liability in connection with the sale of the product.

• How to Obtain Service

Please call 1-800-669-9899 for Rockford Customer Service. You must obtain an RA# (Return Authorization number) to return any product

to Rockford Fosgate. You are responsible for shipment of product to Rockford.

Ship to: Electronics

Rockford Corporation

Warranty Repair Department

2055 E. 5th Street

Tempe, AZ 85281

RA#:_________________

Ship to: Speakers

Rockford Acoustic Design

(Receiving-speakers)

609 Myrtle N.W.

Grand Rapids, MI 49504

RA#:_________________

MADE IN THE USA

This product is designed, developed and assembled in the USA by a dedicated group of American

workers. The majority of the components used in the construction of this product are produced by

American companies. However, due to the global nature of their manufacturing facilities and the

electronics parts industry in general, some parts may be manufactured in other countries.

Rockford Fosgate

Rockford Corporation

546 South Rockford Drive

Tempe, Arizona 85281 U.S.A.

In U.S.A., (602) 967-3565

In Europe, Fax (49) 850-3934-014

LIT10029

4/98

In Japan, Fax (81) 559-79-1265

www.rockfordfosgate.com

Loading...

Loading...