Delivery specification

COBAS-Reader 8000

Revision: 1.1.1

Delivery_Specification_COBAS_Reader_Roche_v1.1.1.odt 1 / 30

Delivery_Specification_COBAS_Reader_Roche_v1.1.1.odt 2 / 30

Document approval signatures

Responsible for definition and writing of specification:

Company Name Date Signature

Author TagStar Systems Michael Kober 17.02.2009

Reviewer maxsol Max Schneider

Reviewer etifix Heinz-Jörg Schröder

Reviewer Roche Helmut Jering

Approval and release of specification:

Company Name Date Signature

Approval RD S. Rosenblatt

Delivery_Specification_COBAS_Reader_Roche_v1.1.1.odt 3 / 30

Delivery_Specification_COBAS_Reader_Roche_v1.1.1.odt 4 / 30

Contents

1 General description......................................................................................................................................7

1.1 Supported RFID chips.........................................................................................................................................7

1.2 Functional description.........................................................................................................................................7

1.3 Model, Manufacturer..........................................................................................................................................8

1.4 Labelling..............................................................................................................................................................8

2 Applied standards and regulations............................................................................................................11

3 Specification...............................................................................................................................................12

3.1 Power supply.....................................................................................................................................................12

3.2 RFID data..........................................................................................................................................................13

3.3 Optical sensors..................................................................................................................................................15

3.4 Environmental conditions.................................................................................................................................16

3.5 Dimensions........................................................................................................................................................18

3.6 Dimensions of reader housing..........................................................................................................................18

3.7 Channel positions..............................................................................................................................................20

3.8 Connector..........................................................................................................................................................21

3.9 Serial interface parameters................................................................................................................................21

3.10 Host communication protocol.........................................................................................................................22

3.11 Life time..........................................................................................................................................................22

4 Packaging....................................................................................................................................................22

5 Embargoed countries.................................................................................................................................23

6 Installation notes........................................................................................................................................23

6.1 Recommended software algorithm for cassette position detection..................................................................24

7 Possible interactions between the COBAS-Reader 8000 and the host system......................................25

8 Product warranty.......................................................................................................................................26

9 List of appendixes.......................................................................................................................................27

10 Document revisions..................................................................................................................................28

Delivery_Specification_COBAS_Reader_Roche_v1.1.1.odt 5 / 30

Delivery_Specification_COBAS_Reader_Roche_v1.1.1.odt 6 / 30

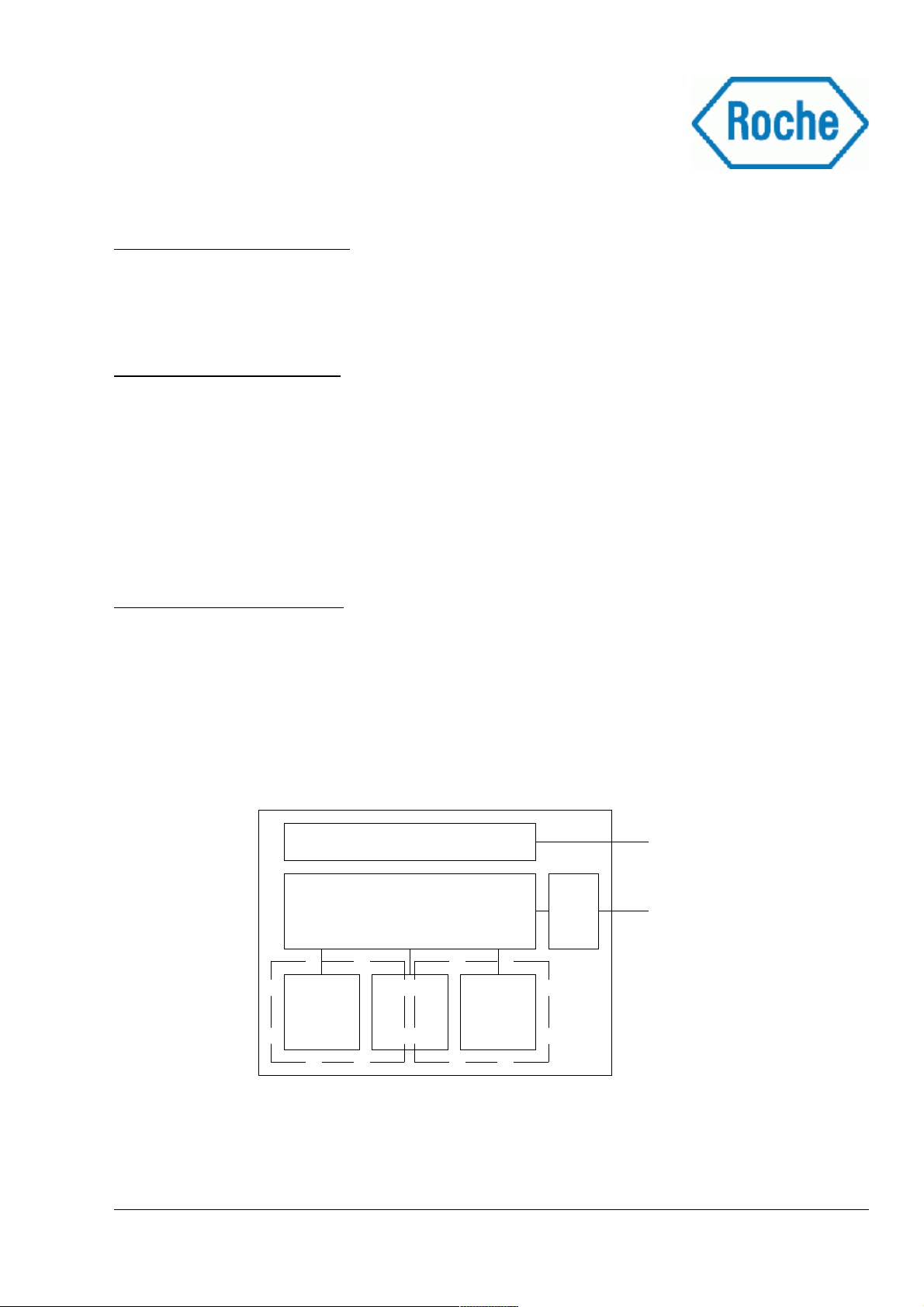

1 General description

Optical

Sensors

CH0

CH1

CH2

CH3

RFID

Channel 0

RFID

Channel 1

µC

Power regulator

RS232

driver

The COBAS-Reader 8000 is a customer specific adopted RFID reader based on TagStar's TS1415 reader

technology. It is designed for the use in a Roche / Hitachi C701/702 system.

1.1 Supported RFID chips

Following ISO 15693-3 compatible chips are supported by the COBAS-Reader 8000 RFID reader.

Due to the project definition the COBAS reader supports the following RFID chip:

● NXP I-Code SLI, the following documents are attached:

I-Code SLI SL2 ICS20, Smart Label IC, Short Form Specification, April 2002 (Appendix 1)

I-Code SLI SL2 ICS20, Smart Label IC, Functional Specification, January 2003 (Appendix 2)

1.2 Functional description

The COBAS-Reader 8000 has a two channel detection system consisting of a RFID antenna and two optical

sensors each. The optical sensors are used to detect the rotational orientation of a cassette placed below the

reader unit. Therefore the cassettes are labelled with a black/white coloured RFID label. At the detection

process the RFID reader reads the data of the transponder which is inserted into the RFID label. To control

the cassette orientation both optical sensors measure the reflected light, which indicates the black and white

label area. Depending on the reflection value the host system could decide if the cassette is inserted in the

correct orientation or turned at 180°.

Delivery_Specification_COBAS_Reader_Roche_v1.1.1.odt 7 / 30

Drawing 1: Block diagram of COBAS RFID reader

1.3 Model, Manufacturer

The COBAS-Reader 8000 can be ordered at etifix at the following order code:

COBAS-Reader 8000

The reader electronic unit consists of a two channel RFID reader main board, with two external detection

units. These detection units carry an adopted RFID antenna and two optical sensors for the position detection

of labelled cassettes. The electronic unit is assembled into a housing provided by etifix.

The whole production of the COBAS-Reader 8000 unit will be done under the responsibility of etifix and a

subcontractor which are ISO 9001:2000 certified. The subcontractor is qualified and trained to meet the

special requirements of RFID reader production. (Appendix 12, 13)

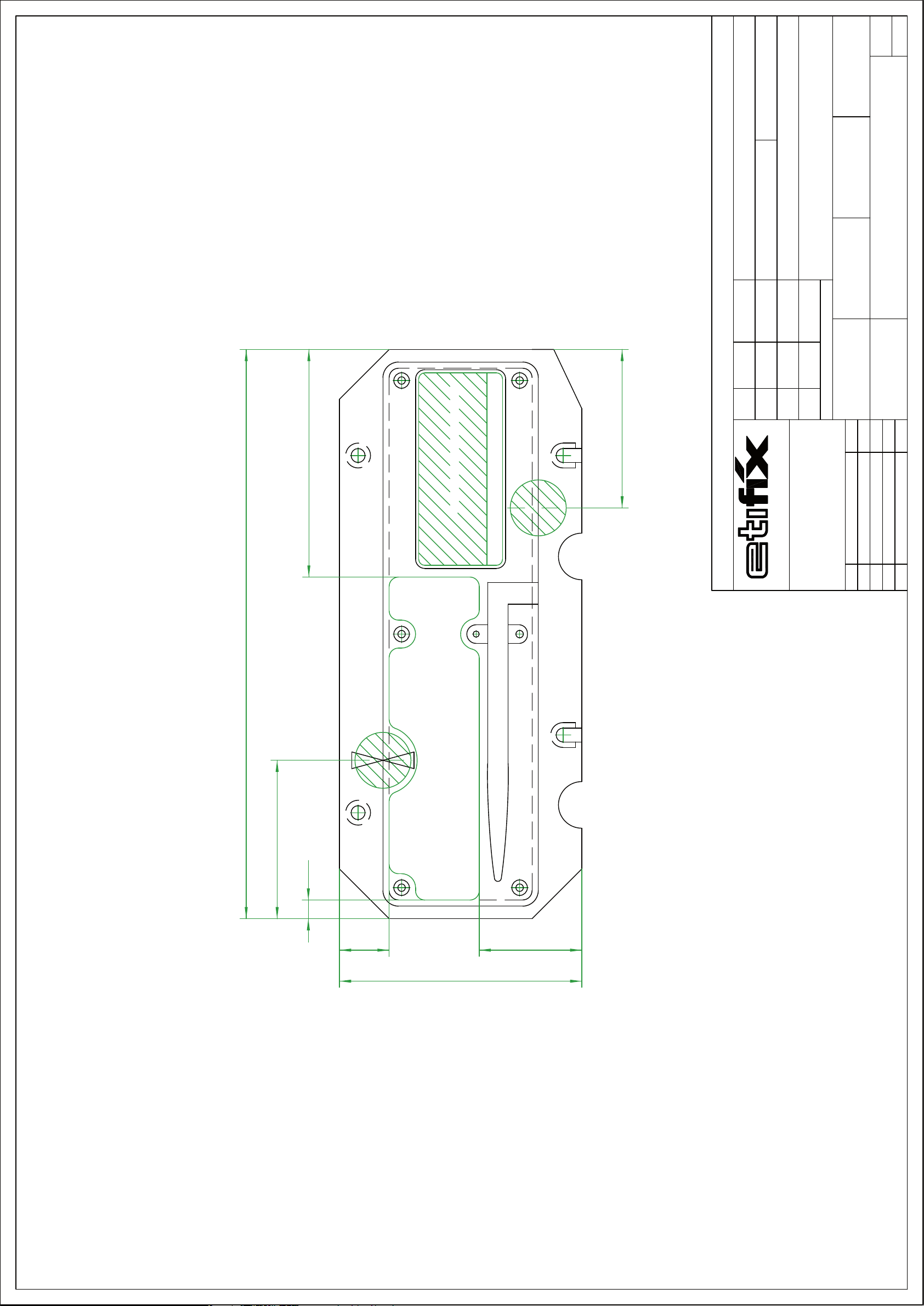

1.4 Labelling

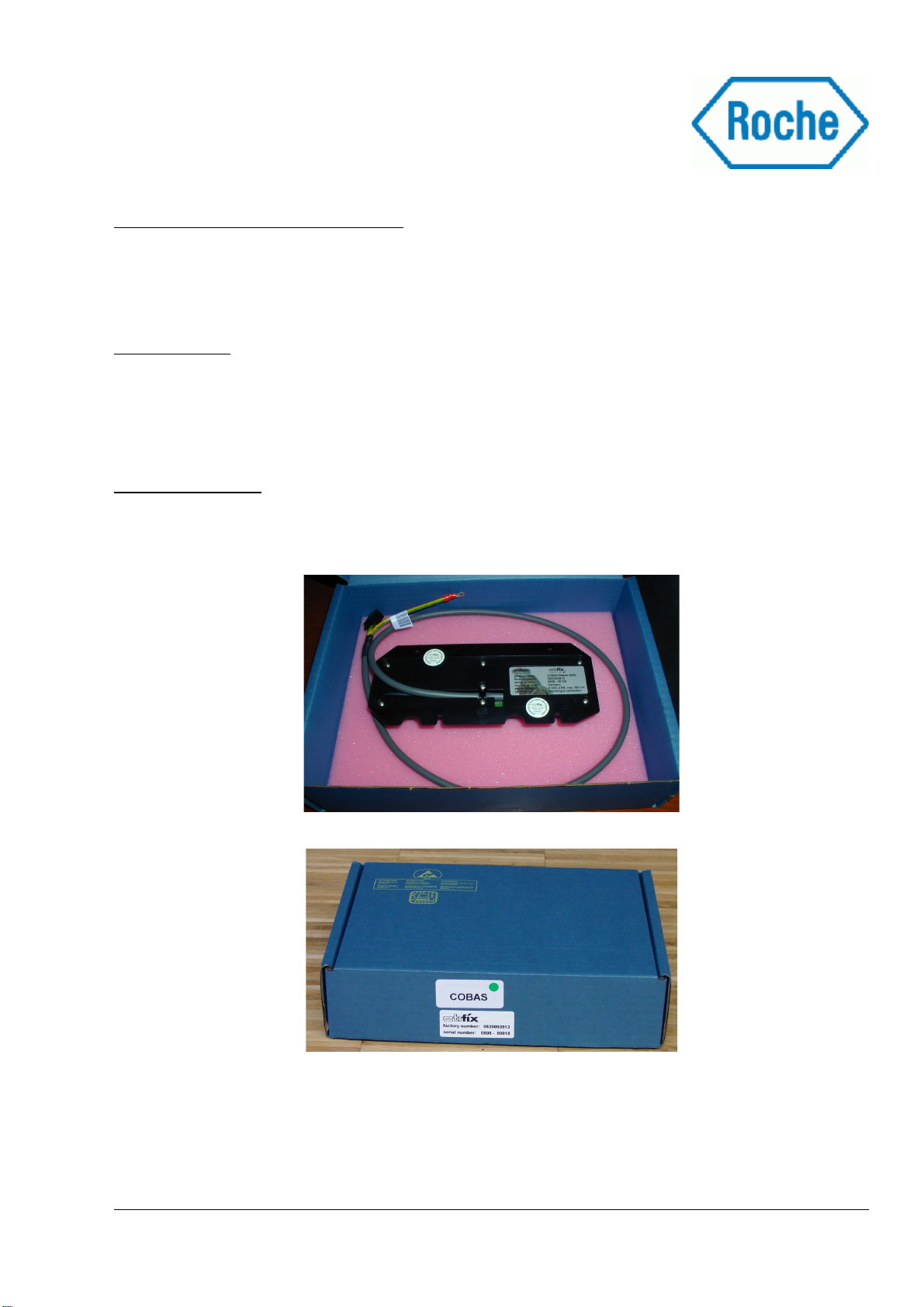

Each COBAS-Reader 8000 is labelled with different identification and security labels. The following picture

shows the position of each label:

Picture 1: Labelling of COBAS RFID reader

Position of labels on cassette:

The position of all labels on the cassette are shown on etifix drawing no. 7-50-1-1-2-1

Delivery_Specification_COBAS_Reader_Roche_v1.1.1.odt 8 / 30

position of labels on the top side of the RFID reader

identication plate

maximium size for

certication labels

to place certication symbols

78

183,27

36 ±3 19 ±3

76 ±3

9±3

51

51

alle Oberächen ohne

Rauhtiefenangabe

gemittelte Rz min. 2,5

Teile ohne Form- und

Lagetoleranzenangaben

nach DIN 7184 T1

Achtung:

bei eingepaBter Zeichnung

auf eine DIN A... Seite

dürfen die MaBstabsangaben

nicht berücksichtigt werden

Maße ohne

Toleranzangabe

nach DIN 7168 f

D-72661 Grafenberg

Riedericher StraBe 68

1

1

Werksto

Name

Änderungen nur bei gleichzeitiger Berichtigung im CAD-System zulässig.

CAD Zeichnung

Benennung

Typ

Bl.

Blatt

Zeichnungs-Nr.

verwendet in Zeichnung Nr.

Norm

Gepr.

Bearb.

Zust. Änderung Datum Name

Datum

MaBstab

Mat.-Nr.:

7-50-1-1-2-1

RFID - Gehäuse COBAS 8000

10.11.08 D. Wurster 1:1 eingepasst

>

Diese Zeichnung ist unser Eigentum und darf ohne

unsere Zustimmung weder vervielfÌltigt noch an

Dritte herausgegeben werden.

Wir behalten uns alle Rechte für den Fall der

Schutzerteilung vor.

etix GmbH; D-72661 Grafenberg

Identification label

Example of a label

The factory number is defined by etifix.

The serial number has the following syntax: JJMM-xxxx

JJ: Year of production

MM: Month of production

xxxx: Serial number of the reader, continuously increased

Security labels

Certification labels

Depending on national rules extra certification labels are applied on top of the reader housing.

Sample of a label:

Delivery_Specification_COBAS_Reader_Roche_v1.1.1.odt 10 / 30

2 Applied standards and regulations

Warning: Any changes or modifications not expressly approved by the party responsible for compliance could

void the user's authority to operate the equipment.

The COBAS-Reader 8000 is conformal to the following radio regulations and standards:

● Europe (CE): EN 300 330-1 V1.3.1 (2001-06), EN 300 330-2 V1.3.1 (2006-04), ETSI EN 301 489-1

V1.6.1 (2005-09), ETSI EN 301 489-3 V1.4.1 (2002-08), EN 60950-1:2006, EN 50364:2001

● US: FCC Code of Federal Regulations, CFR 47, Part 15, Sections 15.205, 15.207, 15.215, 15.225

● Canada: Industry Canada Radio Standards Specifications

RSS-Gen Issue 2, Section 7.2.2, RSS-210 Issue 7, Sections 2.2, 2.6, A2.6 (Category I Equipment)

● Japan: ARIB standard T82 V1.1

The COBAS-Reader 8000 will be compliant to the upper mentioned standards.

For the in appendix “Country list for registration RFID readers 0-series and series for c701/702” (see

Appendix 3) listed countries a compliance certification will be applied for. Therefore additional standards

will be applicable, but are not listed under this chapter. The compliance measurement and appliance will be

done by CETEOM ordered by etifix.

Additional applicable standards:

● compliant to the RoHS regulations (Appendix 4)

● relevant components of the COBAS-Reader 8000 are UL recognized (Appendix 5)

Compliance certifications for national regulations are in progress of application and are not appended to the

document.

Delivery_Specification_COBAS_Reader_Roche_v1.1.1.odt 11 / 30

3 Specification

The following reader parameters refer to the below shown coordinate system:

XY

Z

Drawing 2: Coordinate system for measurement values

3.1 Power supply

Value Symbol Min Max Unit

Supply voltage (at external connector) V 4,75 5,25 V

Max. ripple on supply voltage V

Current consumption, standby

Max. current consumption

1)

2)

Reader reset threshold voltage V

I

I

SS

standby

max

Thres

4,60 4,70 V

Table 1: Power supply ratings

1). .

Measurement conditions: V = 5V, both RF channels switched off, all 4 LED's of the optical sensors are

switched off

2). .

Measurement conditions: V = 5V, both RF channels switched on, all 4 LED's of the optical sensors

switched on

150 mV

70 mA

350 mA

DC

PP

DC

Attention: Supply voltages higher than 5,5 V might permanently damage the circuitry of the

COBAS-Reader 8000 and have to be avoided.

The COBAS-Reader 8000 has no internal fuses or any inrush current limitation. It is recommended to

integrate an appropriate protection circuit into the power supply line to protect the reader and surrounding

hardware against damage in case of failure or over voltage. A suppressor diode is integrated into the power

supply circuitry. Specific data of the suppressor diode see appendix “1.5SMC6.8AT3-D” (Appendix 6).

The circuitry is operates with an internally stabilized voltage for optimum and stable operation.

Behaviour of the COBAS-Reader 8000 at different supply voltages see at Appendix 7.

Delivery_Specification_COBAS_Reader_Roche_v1.1.1.odt 12 / 30

3.2 RFID data

5 10 15 20

-20 -15 -10 -5

0

5

10

15

-5

-10

-15

0

X-displacement

[mm]

20 mm

15 mm

10 mm

Operation ranges

Y-displacement

[mm]

Value Symbol Min Max Unit

RFID Frequency (typical) 13,56 MHz

Modulation degree according to ISO 15693 100% %

Data transfer rate Tag <–> Reader according to

ISO 15693

RFID Output power @ 50 Ω termination

Read distance

1)

Minimum distance between two labels

Data coding 1 out of 4

26,48 kBit/sec

P

HF

d

Peak

d

LL

70 90 mW

0 20 mm

40 mm

(centre to centre of label) to avoid cross talking

Table 2: RFID measurement values

1)

Measurement conditions: V = 5V, Transponder size = 20x10mm, Chip I-Code SLI

Transponder is converted to a label and placed on top of cassette

Read distance is measured from housing of reader to top surface of cassette

The transponder is readable over the whole operation distance between reader housing and the

specified maximum read distance

Delivery_Specification_COBAS_Reader_Roche_v1.1.1.odt 13 / 30

Diagram 1: Typical operation distance depending on label displacement from reader

antenna centre

The typical field strength of the COBAS-Reader 8000 in a distance of 13 mm from the reader housing has the

24

20

16

12

8

4

0

-4

-8

-12

-16

-20

16

12

8

4

0

-4

-8

-12

-16

0

500

1000

1500

2000

2500

3000

3500

4000

4500

Field strength

[mA/m]

X-Displacement

[mm]

Y-Displacement

[mm]

Field strength COBAS RFID reader

following characteristic:

Diagram 2: Typical field strength in dependence of position under the reader measured at a distance of 13 mm measured

from bottom of reader housing

Delivery_Specification_COBAS_Reader_Roche_v1.1.1.odt 14 / 30

3.3 Optical sensors

Value Symbol Min Max Unit

Current consumption per Sensor channel I

Wave length of sensor light

Response value “white”

Response value “black”

max. displacement in X-axis

max. displacement in Y-axis

1)

2)

3)

3)

Settling time of sensors (measurement delay

RV

RV

Sensor

λ

white

black

d

X

d

Y

25 35 mA

629 661 nm

250 Digits

100 Digits

3 mm

5 mm

5 ms

after LED is switched on)

Table 3: Optical sensor values

1)

Measurement conditions: V = 5V, distance between sensor and white reference surface = 13 mm

2)

Measurement conditions: V = 5V, distance between sensor and black reference surface = 13 mm

3)

Measurement conditions: V = 5V, distance between sensor and cassette = 13 mm;

transponder label applied 2,5mm out of cassette centre (white area at cassette border)

All values are measured with both channels at one detection position switched on simultaneously. The following

commands are used: WriteOutput and ReadAnalogInput according to the document “COBAS interface protocol

v1.5”

Delivery_Specification_COBAS_Reader_Roche_v1.1.1.odt 15 / 30

3.4 Environmental conditions

Value Symbol Min Max Unit

Operation temperature range T

Storage temperature range T

Requested Relative humidity for storage and

Operation

Storage

5 +35 °C

-20 +75 °C

5 95 %

operation (not condensing)

Requested protection against mechanical

2,5 m/s

2

vibration in X/Y/Z direction at full

operation

Normal operation after single shock in X/Y/Z

direction

Housing protection class against intrusion of

1)

1,

294 m/s

2

IP 20

rigid particles and liquids (DIN EN 60529)

Table 4: Environmental conditions

1)

Exact specification of mechanical vibration and shock tests see below

Note: The COBAS-Reader 8000 housing is only sealed against condensing of water at the bottom of the

reader housing at normal assembly orientation in the rotor housing. No special protection against water

intrusion from all other sides is provided.

Because Hitachi has confidential internal standards the environmental tests are specified as follows:

● Rapid Change of Temperature according to EN 60068-2-14

-20°C / +75°C test temperatures

2h exposure time for upper and lower temperature

5 cycles

<10 sec. transportation time from one chamber to the other

COBAS-Reader 8000 off during test

● Cold storage according to EN 60068-2-1

+5°C exposure time

16h exposure time

1 K/min temperature changing speed from RT to test temperature

COBAS-Reader 8000 on during test

● Dry heat according to EN 600068-2-2

+35°C exposure temperature

16h exposure time

1 K/min temperature changing speed from RT to test temperature

COBAS-Reader 8000 on during test

Delivery_Specification_COBAS_Reader_Roche_v1.1.1.odt 16 / 30

● Damp heat, steady state, according to EN 60068-2-78

30°C exposure temperature

5% relative humidity

16h exposure time

1 K/min temperature changing speed from RT to test temperature

COBAS-Reader 8000 on during test

● Damp heat, steady state, according to EN 60068-2-78

30°C exposure temperature

95% relative humidity, non condensing

16h exposure time

1 K/min temperature changing speed from RT to test temperature

COBAS-Reader 8000 on during test

● Vibration (sinusoidal) according to EN 60068-2-6

5 Hz lower frequency

200 Hz upper frequency

0,75 mm displacement amplitude

0,25 g acceleration

9,2 Hz cross-over frequency

1 octave/minute frequency sweep

10 cycles per axis, 3 axis tested (X;Y,Z)

COBAS-Reader 8000 on during test (normally off, on requested by HHT)

● Vibration (sinusoidal) according to EN 60068-2-6

5 Hz lower frequency

200 Hz upper frequency

3,5 mm displacement amplitude

1,6 g acceleration

10,8 Hz cross-over frequency

1 octave/minute frequency sweep

10 cycles per axis, 3 axis tested (X;Y,Z)

COBAS-Reader 8000 on during test (normally off, on requested by HHT)

● Shock according to EN 60068-2-27

30 g acceleration

11 ms shock duration, half-sine pulse shape

3 shocks per direction, 6 directions tested (±X, ±Y, ±Z)

COBAS-Reader 8000 off during test

● Free fall according to EN 60068-2-32

1 procedure

300 mm fall height

1 tests per defined orientation (5 fall tests)

COBAS-Reader 8000 without packaging

COBAS-Reader 8000 off during test

Delivery_Specification_COBAS_Reader_Roche_v1.1.1.odt 17 / 30

3.5 Dimensions

The PCB-Board of the COBAS-Reader 8000 has the following dimensions:

Drawing 3: Final assembly of COBAS RFID reader electronic

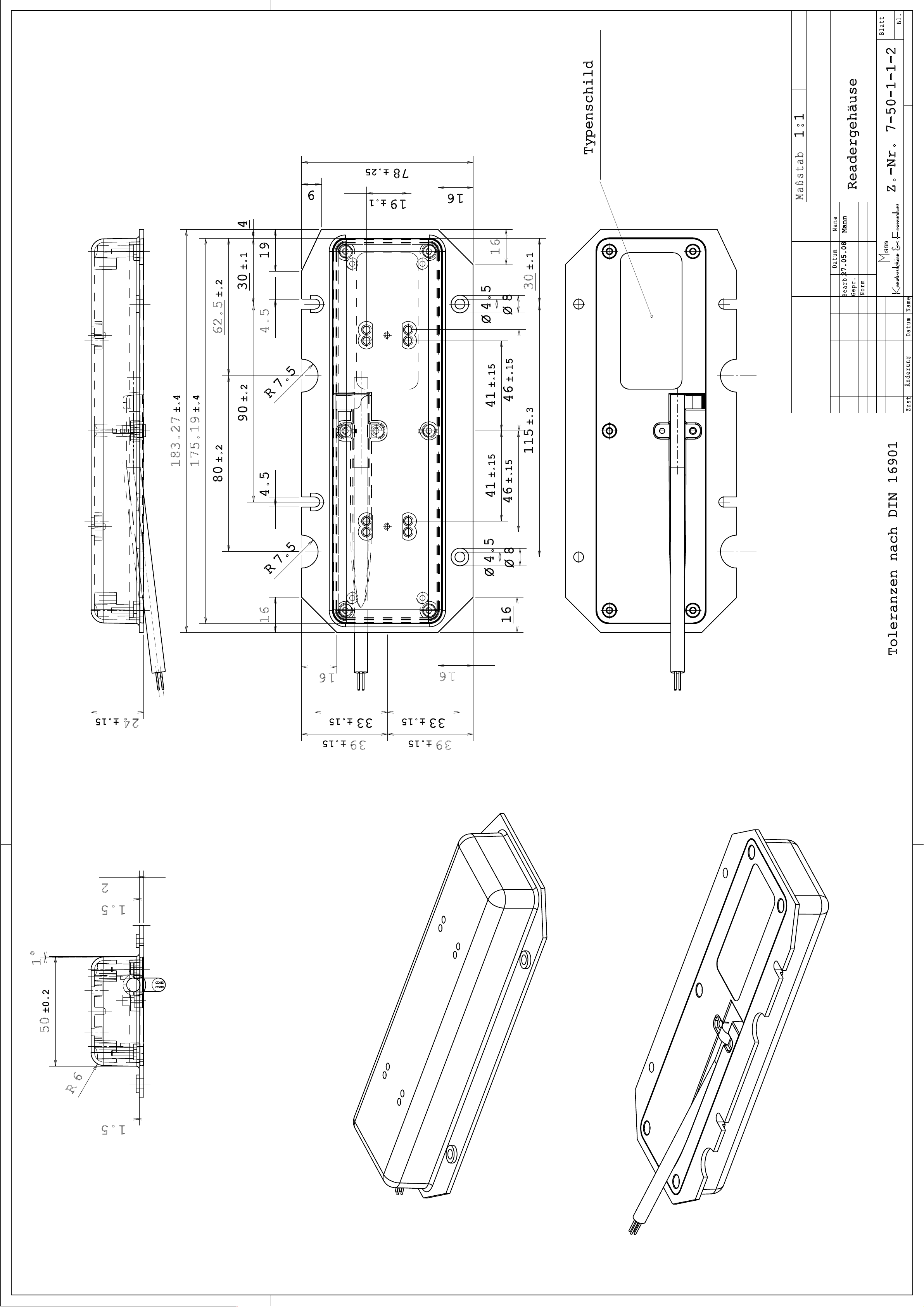

3.6 Dimensions of reader housing

The reader housing is specified in drawing no. 7-50-1-1-2 (Document “Reader housing”) .

Delivery_Specification_COBAS_Reader_Roche_v1.1.1.odt 18 / 30

3.7 Channel positions

For correct addressing of the RFID-channels and optical sensor channels please pay attention to the following

drawing:

Opt. Sensor 0

RFID channel 1

RFID channel 1

RFID channel 0

Opt. Sensor 1

Opt. Sensor 1

Opt. Sensor 3

Drawing 4: Side view of COBAS RFID reader (red dots indicate position of LED)

RFID channel 0

Opt. Opt.

Sensor 2

Opt. Sensor 3

Opt. Sensor 2

Delivery_Specification_COBAS_Reader_Roche_v1.1.1.odt 20 / 30

3.8 Connector

The COBAS-Reader 8000 comes with a 800 mm long cable for the connection to the external host.

Cable type: UNITRONIC LiYCY UL/CSA 4x AWG22/7,

Manufacturer LAPPKABEL, order code 0044704

fire-retardant according to IEC 60332-1-2, UL VW1, CSA FT1

see Appendix 8, 9

Connector type: AMP D-2100, Product code 1318119

Drawing of cable: see attachment “Cable_v1.6.pdf” (Appendix 10)

Pin assignment:

Pin Name Direction Description

A1 +5V PWR Positive supply voltage

B1 GND PWR Reference voltage level for power

supply and serial communication

A2 RxD In Receive signal from host

B2 TxD out Transmit signal to Host

A3

Shorted with cable

B3

Table 5: Pin assignment cable connector

Maximum pull force at the cable: 40 N

3.9 Serial interface parameters

The data between the COBAS-Reader 8000 and a host system are transmitted via a serial interface. The

voltage levels at the serial interface is fixed to V24-level standard, e.g. for communication with a PC.

Interface parameters:

Baud rate 19.200

No of Bits 8

Stop bit 1

Parity N

Handshake No hardware or software handshake

Delivery_Specification_COBAS_Reader_Roche_v1.1.1.odt 21 / 30

3.10 Host communication protocol

The communication protocol between a host system and the COBAS-Reader 8000 is defined in the document

“COBAS Interface Protocol v1.5” (Appendix 11)

3.11 Life time

The analysis of the critical components and the corresponding circuitry of the COBAS-Reader 8000 resulted

in an expected life time of more than 16.000 hours of operation.

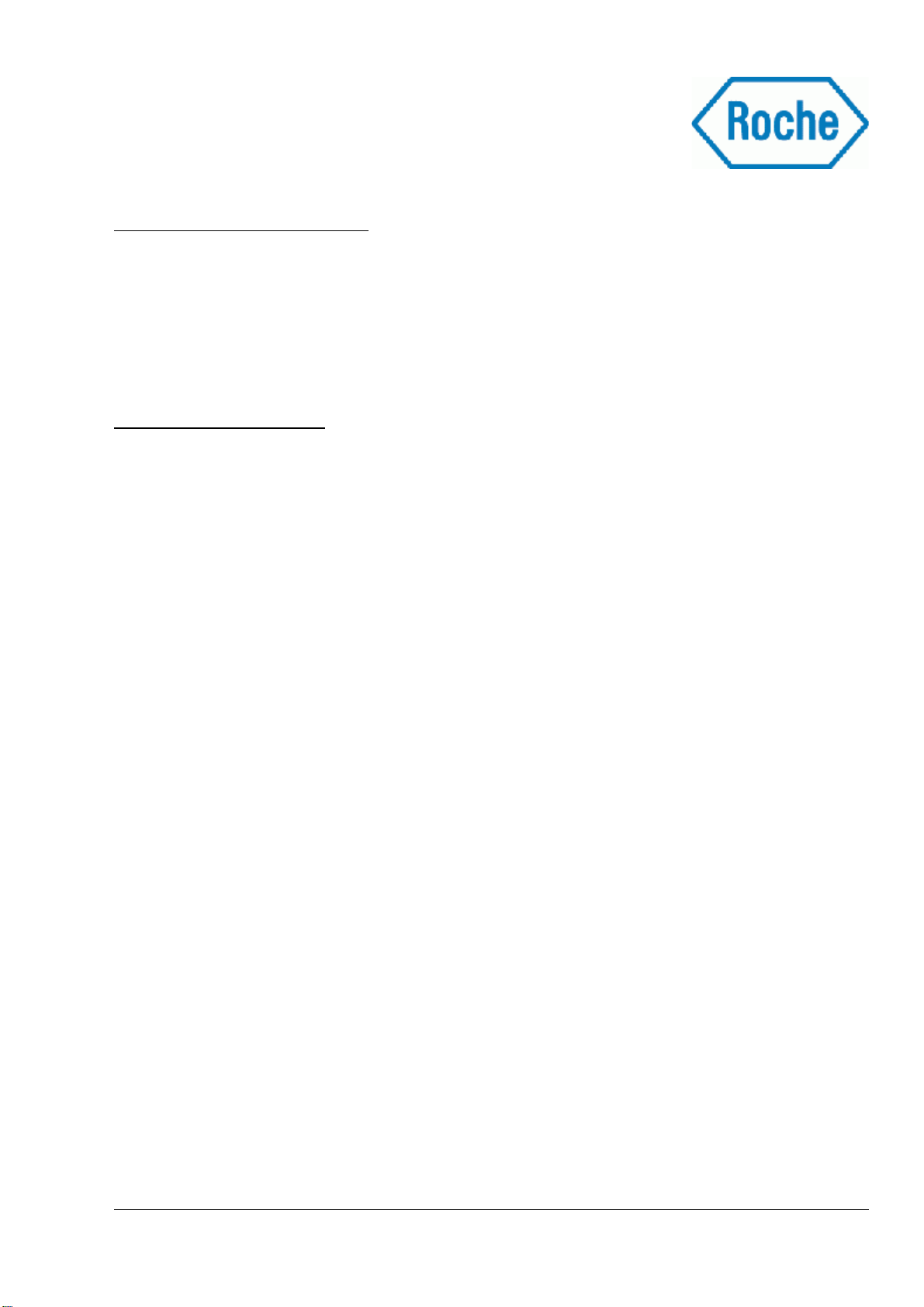

4 Packaging

Every COBAS-Reader 8000 is packed into an ESD proof carton box, protected with ESD save foam against

mechanical shocks. Each carton box is labelled with a label showing the product name and the serial number.

Picture 2: Packaging of COBAS RFID reader

Picture 3: Carton box with labelling

Delivery_Specification_COBAS_Reader_Roche_v1.1.1.odt 22 / 30

5 Embargoed countries

According to the information given from Mr. Martin, Head of division for Electronics, Optics and Sensors

(phone: 06196 / 908 – 788) at the Federal Office of Economics and Export Control in Germany are the

COBAS-Reader 8000 not restricted in any countries if they are used for medical applications as they are

designed for. The end user has to ensure that the COBAS-Reader 8000 are only used for their intent

application in the COBAS 8000 systems.

6 Installation notes

No special ESD prevention is required to assemble the COBAS-Reader 8000. It is recommend to use a ESD

wristband when you unpack the reader and connect it to the host system. The system power has to be

switched off prior to the assembly.

Be aware of the following possible environmental effects when your are installing the COBAS-Reader 8000

into a device. Also the transponders might be effected by:

• Nearby existing metal objects like housings, shielding and also PCB-boards with large ground

plates.

• EMC effects from cables

• EMC effects from magnetic fields.

Metal surface in direct vicinity of the active internal antenna will detune the antenna and thus have a direct

influence to the operating distance. Increase the distance between the antenna and the metal layer to the

possible maximum for least influence.

Communication between the reader and a transponder can never pass through a metal layer.

The optical sensors might be influenced (reduced) by condensed water on the housing of the LED / detector

components. A transparent medium should be placed on the rotor jacket cover for preventing water

condensing at the optical sensor area. The medium should be selected carefully and has to be transparent for

red light emitted by the LEDs.

Contamination by deposition of reactants on the optical sensors will reduce the reflection values for the white

and black label surface until no distinction can be made. Please take care that the sensors are periodically

cleaned.

The COBAS-Reader 8000 housing is designed to protect the reader electronics against humidity and water

condensation from the reagent rotor side. Please take care for a good sealing of the COBAS housing against

the rotor cover to prevent moisture / condensed water getting into the housing through the cable outlet.

Delivery_Specification_COBAS_Reader_Roche_v1.1.1.odt 23 / 30

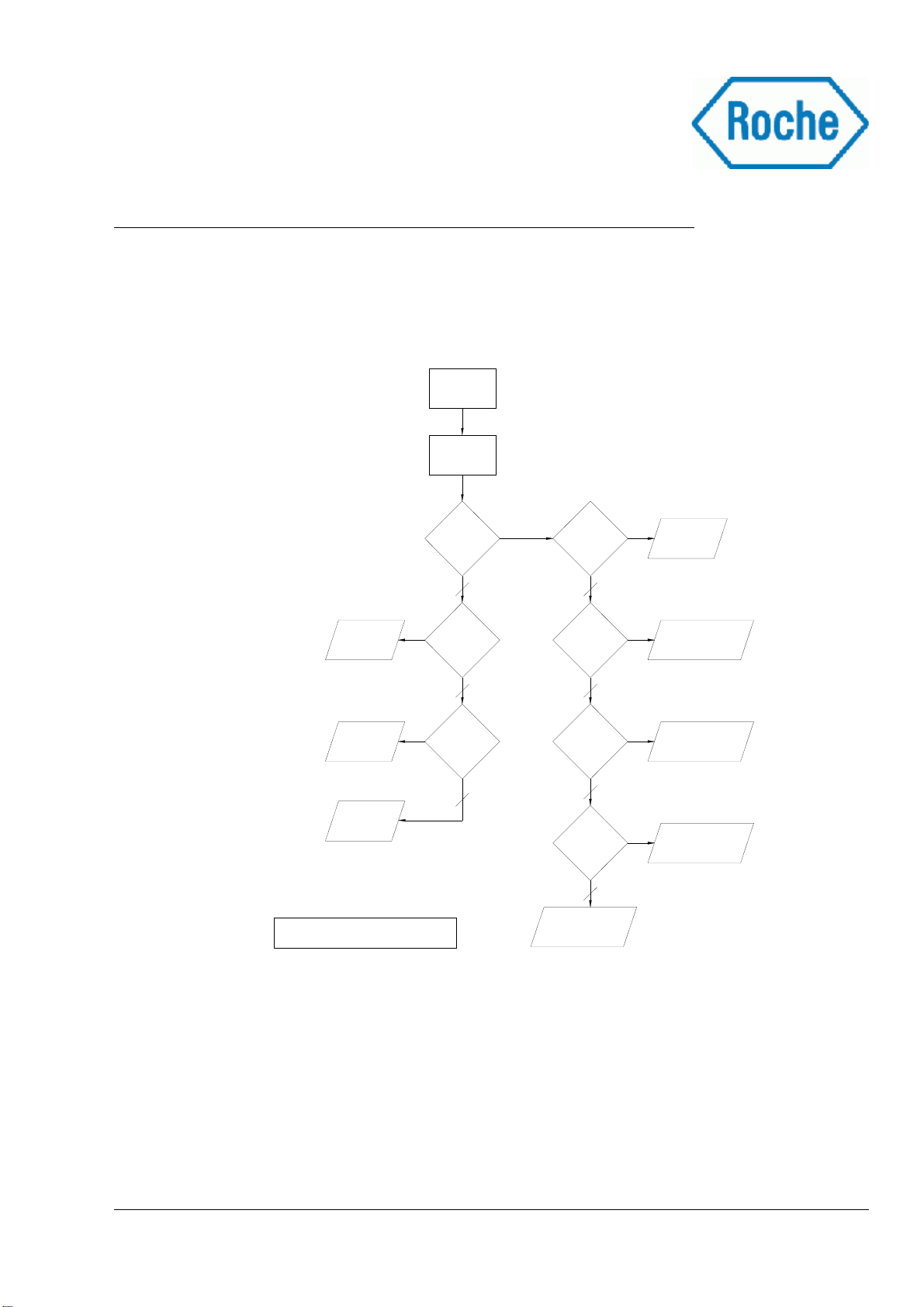

6.1 Recommended software algorithm for cassette position detection

Read RFID tag

Tag readable

?

Read

optical sensors

No

-20<C<20

?

No

Empty position

Defect RFID

reader

0<R<10

?

Optical sensor

defect

C<-20

?

-20<C<20

?

No

20<C<50

?

No

Wrong cassette

orientation

No optical detection

cleaning required

Cassette orientation

correct,

cleaning required

Cassette orientation

correct

C: Contrast value (CH1-CH0 or CH3-CH2)

R: Return value of each optical sensor

No RFID

signal at all

cassettes?

No

No

Defect

RFID label

No

Based on several tests done at Roche Mannheim and Roche Penzberg the following procedure for cassette

position detection is recommended. This algorithm is able to distinguish between different states.:

Picture 4: Program flow for analysis of optical sensor output

Depending on further evaluation the decision criteria for valid sensor signals and valid differences might

have to be adopted.

Delivery_Specification_COBAS_Reader_Roche_v1.1.1.odt 24 / 30

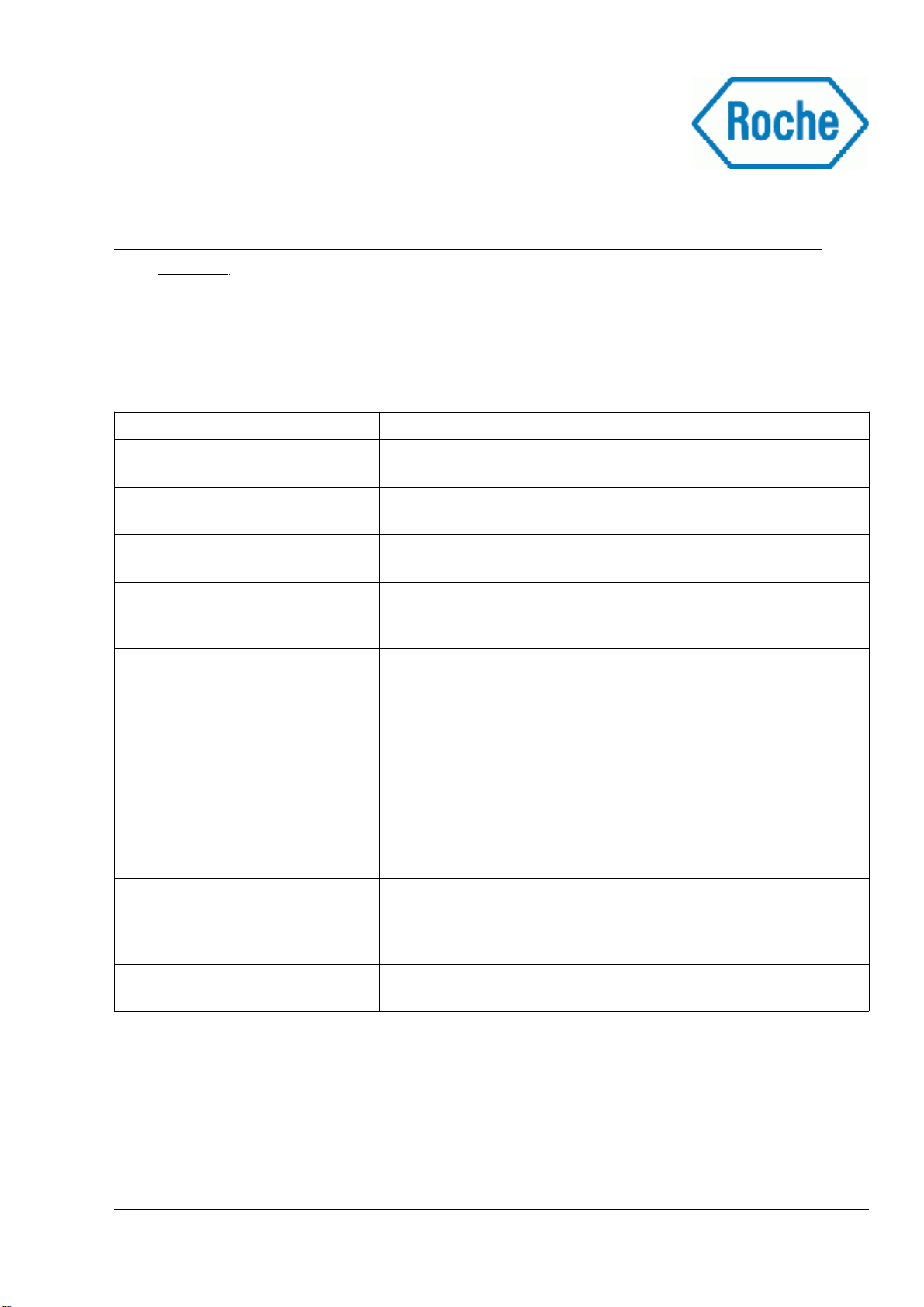

7 Possible interactions between the COBAS-Reader 8000 and the host

system

Several different failure modes could have an impact on the functionality of the host system. The COBASReader 8000 is designed according to best knowledge to avoid any negative interactions with an host system.

All electrical interfaces to the host system are designed in conformance to existing standards. The following

table lists possible failure modes and methods to prevent defects on the host system.

Failure mode / possible influence Protective measures

Short circuit on reader board at the

power supply

Failure at the RS232 interface, like

short or open wires

Data failure inside the COBAS

machine due to EMC / EMV

Impact of the emitted RFID field to

the measurements

Malfunction of the optical detection

due to humidity condensation

Malfunction of the optical detection

due to contamination by reactants

Malfunction of the optical detection

due to HF field

Integration of an appropriate protection circuit into the power supply

which limits the supply current to 350mA during operation

The COBAS-Reader 8000 uses an RS-232 interface driver which is

according to industrial specifications

The reader will be qualified according to international standards as

listed in chapter 2 to minimize the risk of potential influences.

This effect can't be estimated and depends strongly on the

measurement methods used. Switch off the RFID antennae of the

reader before starting the measurements

Condensed humidity reduces the responses values of the black and

white label area. Therefore software could distinguish between both

colours by measuring the relation/difference of both responses

values.

Threshold values for contrast and absolute sensor values for black

and white label areas have to be defined.

Periodical manual cleaning of the optical sensors by service personal

or operators

Threshold values for contrast and absolute sensor values for black

and white label areas have to be defined.

Due to the mechanical design of the detection channels a powered HF

field has a direct influence to the response values. For save

measurements it is strongly recommended to switch the appropriate

HF channel off before the optical sensors are read out.

Interference of optical sensors The interferences between the optical sensors CH0/CH1 or CH2/CH3

are at an absolute minimum and have no impact to the measurement.

Delivery_Specification_COBAS_Reader_Roche_v1.1.1.odt 25 / 30

8 Product warranty

etifix provides customer assistance in various technical areas, but does not have full access to data

concerning the use and applications of customer's products. Therefore, etifix assumes no liability and is not

responsible for customer applications or product or software design or performance relating to systems or

applications incorporating etifix products.

etifix assumes no liability and is not responsible for infringement of patents and/or any other intellectual or

industrial property rights of third parties, which may result from assistance provided by etifix. The electronic

circuitry and reader firmware has been checked for critical solutions and routines. etifix is not liable for

infringements of patents and/or any other intellectual or industrial property rights of third parties resulting

out of the usage in the COBAS analysis system.

etifix products are not designed, intended, authorized or warranted to be suitable for life support applications

or any other life critical applications which could involve potential risk of death, personal injury or severe

property or environmental damage. A critical component is a component used in a life-supporting device or

system whose failure can reasonably be expected to cause the failure of that life-support device or system, or

to affect its safety or effectiveness of that device or system. Life support devices or systems are intended (a)

to be implanted in the human body, or (b) to support and/or maintain and sustain human life. If they fail, it is

reasonable to assume that the health of the user may be endangered.

The product warranty is defined by governmental law and in etifix's “General Conditions for the supply of

products and services.

Delivery_Specification_COBAS_Reader_Roche_v1.1.1.odt 26 / 30

9 List of appendixes

Appendix No. Description

1 I-Code SLI SL2 ICS20, Smart Label IC, Short Form Specification, April 2002

2 I-Code SLI SL2 ICS20, Smart Label IC, Functional Specification, January 2003

3 Country list for registration RFID readers 0-series and series for c701/702

10

11

12

13

4

5

6

7

8

9

RoHS compliance certificate

UL Compliance certificate

Data sheet 1.5SMC6.8AT3-D

Behaviour of the COBAS-Reader 8000 at different supply voltages

Data sheet of cable

Ohmic resistance of cable

Cable_v1.6 specification

COBAS Interface Protocol v1.5

ISO 9001 certificate etifix

ISO 9001 certificate Zollner

Delivery_Specification_COBAS_Reader_Roche_v1.1.1.odt 27 / 30

10 Document revisions

Datum Version Status

27.11.07 0.1 1st draft version

31.03.08 0.2 Extension with additional requested information

0.3 Internal working paper

15.07.08 0.4

Purpose: Draft as appendix to the “Einzelentwicklungsvertrag”

§1: Changes in overall description of product, added block diagram and

identification plate layout

§2: Extension of applied standards

§3: General changes at all sub chapters

§4. Extensions

§5: Extensions

§6: Extensions

§7: Extensions

§8: Extension about raw material discontinuation

0.5 §1.4: Change of label samples, extended explanation

§3.1 Change of power supply data

§3.2 Change of RFID data

§3.3 Change of optical data

§3.4 Description of environmental tests

§3.5 Drawing of reader electronics assembly

§3.7: Correction of optical sensor position, additional 3D drawing

§3.8 Change of cable length to 800mm (future deliveries)

08.08.08 1.0 Public document for first shipment of COBAS-Reader 8000 (pre- production)

Delivery_Specification_COBAS_Reader_Roche_v1.1.1.odt 28 / 30

Datum Version Status

15.08.08 1.1 §1.4: Added picture of labelled reader

§2: Sentence about risks of third country certification removed, Canada

added

§3: Drawing with coordinate system showing axis of measurement values

added

§3.1: Change of data, change of recommended fuse

§3.2: Change of data, read area values at 80% of read range deleted

Diagram with operation range in dependence of position added

§3.3: Change of data, digram showing valid reflection values in dependence

on position above label added

§3.4: Standard for IP protection class added, editorial changes

§3.6: editorial changes

§3.8: Maximum pull strength of cable fixture added

§3.10:Release info of COBAS interface protocol document added

§4: Secondary packaging removed

§6: ESD handling precautions added

§7: Exchange TagStar with etifix

1.2 Working paper, not released

22.10.2008 1.3 Added Reviewer and Approval list

§1.2: Correction on position of label on cassette

§1.3: Correction of product name

§1.4: Change of picture of labelling

Added drawing about position of labels

§2.0: Intern. Compliance certifications are excluded to this document

§3.1: Added behaviour at different supply voltages

Added notice about over voltage

§3.2: Change of RF output power

Adding diagram of HF field strength

§3.3: Change of X/Y limits of acceptable label displacement

Adoption of black/white limits to new label surface

Sensor values measured simultaneously

§3.6: Implementation of housing drawing

§3.7: Removed drawing form bottom side, added LED position at optical

sensors

§3.8: Interface cable drawing changed from v1.2 to v1.4 (length tolerance,

mounting ring, additional pins A3, B3)

§3.10: Changed document version of interface protocol to 1.5

§3.11: Added topic Expected life time

§4: Added pictures about packaging

§5: Embargoed countries (none)

§6: Editorial change at water condensation protection

§7: Adopted value for recommended external fuse at power line

Definition of threshold values recommended

§8: Extension of intellectual property rights and exclusion of life supporting

devices

§9: Added topic Table of appendixes

Delivery_Specification_COBAS_Reader_Roche_v1.1.1.odt 29 / 30

Datum Version Status

05.02.2009 1.4 General name change of the reader to COBAS-Reader 8000 (change from

development project name to product name)

§1.2: Remove over voltage protection from block diagram

Wording misleading, see chapter 3.1

§1.4: Exchange of identification label to newer design

(corrected max. current consumption 300 → 350mA)

§2: Extension and correction of radio regulations and standards according to

granted certificates

§3.1: max. standby current consumption changed from 55mA to 70mA caused

by review of first 150 readers.

Change of wording for over voltage protection

§3.4: Change of Damp heat testing standard from sub part 30 (dynamic

humidity change during test) to sub part 78 (static humidity during test)

as qualification test have been done and certified.

§3.11:Change Expected life time → Life Time

§6.1: Added chapter: Recommended software algorithm for cassette position

detection

§7: Change of wording for protective measures against short circuit and

failures at communication interface

10.02.2009 1.4.1 §1.4: Correction of identification plate picture (same plate as shown in other

pictures used in this document)

§3.1: Removed annotation about Reader reset threshold voltage

Voltage will be measured at production testes

§3.2: Removed annotation “Not verified at mass production” at diagram 1 and

diagram 2

§3.8: Removed annotation “Not verified at mass production” at value for

maximum pull force applied to the cable

§ 8: Removed clause about discontinuation of raw material. Has to be

defined in delivery contract.

Removed misspelling in sentence about critical solutions and routines.

17.02 1.5 Removal of HHT from the list of document approvals

§3.1: Misleading wording about suppressor diode deleted

Delivery_Specification_COBAS_Reader_Roche_v1.1.1.odt 30 / 30

Loading...

Loading...