SUMMARY OF CONTENTS

SECTION 1 GENERAL WARNINGS...........................................................................2

1.1 GENERAL INFORMATION.............................................................................3

SECTION 2 QUICK GUIDE FOR THE USER..............................................................7

2.1 GENERAL CHARACTERISTICS OF THE DIRECT DIGITAL CONTROLLER............7

2.2 MAIN SCREEN................................................................................................................ 8

2.3 USING THE

ENCODER..............................................................................10

2.4 COOLING/HEATING SERVICE CONTROL MENU........................................................11

2.5 BASE AND SEPARABLE DHW SERVICE CONTROL MENU

................................15

2.6 ALERTS MENU

............................................................................................16

2.7 ERROR RESET

............................................................................................17

2.8 FLAME CONTROL UNIT RESET

.....................................................................18

SECTION 3 FUNCTIONS OF THE DIRECT DIGITAL CONTROLLER.......................19

3.1 MAIN MENU................................................................................................19

3.2 FUNCTIONAL DATA

....................................................................................20

3.3 UNITS MANAGEMENT

..................................................................................27

3.4 USER SETTINGS

.........................................................................................31

SECTION 4 INSTALLATION.......................................................................................52

4.1 CONNECTING THE DIRECT DIGITAL CONTROLLER ........................................52

4.3 DESCRIPTION OF THE REGULATION WATER TEMPERATURE ALGORITHM AND

OF THE RELATIVE PARAMETERS

.................................................................57

4.4 SYSTEM INSTALLATION

..............................................................................66

4.5 INSTRUCTIONS FOR DDC-PLANT CONFIGURATION................................................124

4.6 MANAGEMENT AND DISPLAY OF WARNINGS AND ANOMALIES

......................146

SECTION 5 GENERAL INDEX...................................................................................156

Read the warnings contained in this manual carefully; they give important information regarding safe

installation, operation and maintenance: keep this manual safe for all further consultation.

The manufacturer may not be held responsible for any damage arising from improper, incorrect or

unreasonable use of the appliance.

NOTE

Direct Digital Controller

2 Direct Digital Controller fw 4.013 – Ed. 01/2013

1 GENERAL WARNINGS

This manual is an integral and essential part of the product and must be delivered to the end user.

The installation of the Direct Digital Controller must be carried out by professionally qualified

personnel, in compliance with current regulations and according to the manufacturer’s instructions, as

incorrect installation may cause damage to persons, animals or things (or directly to the component), for which

the manufacturer cannot be held responsible.

“Professionally qualified personnel” is defined as those possessing specific technical competence in the sector

of electrical systems.

This device must be used only for the purposes for which it has been expressly designed. Any other use must

be considered inappropriate and therefore dangerous.

The manufacturer is exempt from any contractual or extra-contractual responsibility for damage caused by

errors of installation, use and in any case the non-observance of the instructions supplied by the manufacturer

itself.

In the event of failure and/or poor operation of the Direct Digital Controller, do not attempt to repair it under

any circumstances; any repair must be carried out solely by a ROBUR Technical Assistance Centre, using

only original replacement parts.

The non-observance of the foregoing warnings may compromise the safety of the device.

It is not possible to install the Direct Digital Controller and the GA – GAHP and Prontoclima series of gas

absorption units correctly without consulting the Installation Manual included with the UNIT and the

Installation and Programming Instructions which follow.

Direct Digital Controller

Direct Digital Controller fw 4.013 – Ed. 01/2013 3

1.1 GENERAL INFORMATION

The Direct Digital Controller is a device that is applicable as a

panel, and which is able to show, on a backlit graphical LCD

display of 128x64 pixels, all the status, operating and error

conditions of each individual unit to which it is linked. The DDC

(Direct Digital Controller) controls water thermostating by

controlling the switch-on and switch-off of the units connected to it.

The Digital Panel can support and manage up to 32 modules (16

for heating and 16 for cooling) where module refers to the ability of

a machine to produce cooled or hot water;

therefore the ACF 60-

00 comprises a module for the production of chilled water, and the

AY 00-120 and GAHP-A each comprise a module for the

production of hot water; on the other hand, the GAHP-AR and the

GAHP-GS/WS comprise two modules, one for the production of

chilled water, the other for hot water (see table below).

The Direct Digital Controller, on the other hand, is able to manage

a single prontoclima heater/heater-chiller.

The Direct Digital Controller is, in addition, able to manage several

plant configurations for the production of hot and/or chilled water,

in particular:

1. 1 plant for the production of chilled water (cold plant). For example it is possible to connect up to a

maximum of 16 ACF 60-00 which correspond to a maximum of 16 chilling modules; OR:

2. 1 plant for the production of hot water (hot plant). For example it is possible to connect up to a maximum

of 16 GAHP-A or ACF 00-120 which correspond to a maximum of 16 heating modules; OR:

3. 2 independent plants, one to product chilled water, the other to produce hot water (4-line configuration)

able to run simultaneously (one cold plant and one hot plant, independent). It is therefore possible to

manage both plants described in points 1 and 2, for a maximum of 16 modules for heating; for example,

this is useful for installations with AHU fitted with a post-heating exchanger which works at the same time

as the cooling OR:

4. 1 plant for alternate production (summer/winter) of hot or chilled water (2-line hot-cold plant). This is a

two-line plant that, for example, in the winter serves the heating network and in the summer serves the

cooling network. For example it is possible to connect up to a maximum of 16 GAHP-AR or AYF 60-119/2

which correspond to a maximum of 16 heating modules for chilling and 16 modules for heating.

To create high output plants it is also possible to connect two or three DDCs together in order to control up to

64 or 96 modules (up to 32 units may be linked to each DDC).

Direct Digital Controller

4 Direct Digital Controller fw 4.013 – Ed. 01/2013

The Direct Digital Controller can manage modules of the ACF60 and AY00-119 type equipped with S61 and

S70 electronic boards respectively.

- GAHP-A = 1 “hot” module

- GAHP-AR = 2 modules (1 “cold” + 1 “hot”)

- GAHP-GS/WS = 2 modules (1 “cold” + 1 “hot”)

- GA HR = 1 "cold" module (the "hot" module of the recuperator is not managed by the control

system)

- ACF 60-00 = 1 "cold" module

- AYF 60-119/2 = 2 modules (1 “cold” + 1 “hot”)

- AYF 60-119/4 = 2 modules (1 “cold” + 1 “hot”)

- AY 00-120 = 1 "hot" module

Domestic hot water (DHW) production plant control

The DDC is also capable of controlling a plant including the production of hot domestic water, by installing one

or more optional RB100 or RB200 devices (Robur Box).

Definitions

Generator: general term indicating machines for the production of hot and/or chilled water. In the text they are

also referred to as machines or units.

Robur generator: generator (heat pump, boiler or refrigerator) produced by Robur. All types of Robur

generator can be directly managed from the Robur Direct Digital Controller (DDC) using the CANBus

communication bus.

Third party generator: generator (usually a boiler or refrigerator) not produce d by Robur, which cannot be

directly managed from the DDC via the CANBus and thus requires an additional interface device (Robur Box

RB200).

Network ID: unique identification number identifying a Robur generator o n the CANBus BUS, a Direct Digital

Controller (DDC), the valve service of an RB100 device, or each of the services provided by an RB200. It acts

as an address for the data communication network; it must be set to a different value for each generator, DDC

or RB100/RB200 device present. For RB200 devices a base network ID is set, then the system automatically

assigns from this a network ID for each configured service.

In the documentation it is also referred to as a CAN ID or, when referred to Robur generators, unit ID or

machine ID.

Base plant part: this term refers to the portion of the plant including all generators, excluding those which can

be hydraulically separated via a specific three-way valve.

Separable plant part: this term refers to the part of the plant which can be hydraulically separately from the

base plant part and run independently to provide a type of service for Domestic Hot Water (DHW).

This part of the system can be in two distinct states, on the basis of the position of the hydraulic separation

motorised valve:

• Separate: in this status, the generators from the separable part of the plant are managed together with

those of the base plant, in order to satisfy the request for the separable DHW service.

• Included: in this state the generators from the separable part of the plant are managed together with those

of the base part, to satisfy heating and/or base DHW services; in particular the generators are made

available if at least the heating request is active; in the presence of only the base DHW request, the

generators on the separable part of the plant are not used.

Separate plant part: variant of the separable part of the plant, which has no three-way separation valve; it is

therefore permanently sectioned off from the base plant part.

Base DHW service: domestic hot water service obtained with the base plant part.

Separable/separate DHW service: domestic hot water service obtained with the separable/separate plant

part.

Base group: set of generators on the base plant part.

NOTE

Direct Digital Controller

Direct Digital Controller fw 4.013 – Ed. 01/2013 5

Separable/separate group: set of generators on the separable/separate plant part.

Plant ID: identification number between 0 and 15, set by a specific parameter in the Robur generators to

indicate that they belong to a given plant, understood as the hydraulic circuit they are connected to. One or

more plant IDs (cold plant ID and/or hot plant ID) must be set on the RB200 device if this manages third party

generators.

NOTE

: The plant ID does not vary between the base and separable/separate plant parts. To indicate on

which part of the plant a Robur generator is found we use another parameter to be set on it (group to

which the unit belongs); to indicate on which part of the plant a Third Party generator managed via an

RB200 device is found, we use a parameter to be set on that device.

The RB100 and RB200 devices are used to interface requests for different types of services from one or more

external control systems with the DDC.

The inputs for the service requests available on each RB100 and RB200 interface device are the following:

Cooling service request: when this input signal is enabled, the equipment sends a request to the DDC so

that the latter can drive the switching on of the cold modules present on the plant and can manage them in

order to meet the request appropriately;

Heating service request: when this input signals is enabled, the equipment sends a request to the DDC so

that the latter can drive the switching on of the hot modules present on the plant and can manage them in

order to meet the request appropriately;

DHW0 and DHW1 service request: when one of these input signal is enabled, the equipment sends a

request to the DDC so that the latter can drive the switching on of the hot modules present on the plant and

can manage them in order to meet the domestic hot water request appropriately. In particular, each of these

inputs can be configured to make separable or base domestic water requests; it is also possible to enable both

inputs and therefore manage two DHW service requests at the same time.

The basic DHW service is normally used to provide a DHW service at circuit temperatures that are compatible

with Robur GAHP high efficiency heat pumps.

The separable or separate DHW service is normally used to provide a DHW service (complete or integrating

the base DHW service) which requires higher circuit temperatures, which are not compatible with the GAHP

heat pump units, therefore delivered by conventional heat generators (boilers) installed on the separable or

separate part of the plant.

RB100 and RB200 devices can also control the three-way valve used to hydraulically separate the separable

plant part from the base part.

Control of alternate hot/cold 2 line production plant with generation side or 4-line user side manifolds

Using the RB100 or RB200, the DDC is also able to control a three-way valve used to hydraulically commute

the plant for operation in either heating or cooling. The valve is useful in the following two cases:

• Plant with two line generation (for example in the case of GAHP-AR units) and distribution to four-line

services (for example underfloor heating and fan coil cooling).

• Plant with four line generation (use of only cold and only hot units mounted on separate manifolds) and

distribution to two-line services (for example heating and cooling both served by the sam e fan coils).

NOTE

: installation of only cold or only hot units on separate manifolds is not compulsory, but can be done

for specific reasons: for example, during the summer to allow the production of domestic hot water with

heat pumps and at the same time the production of cold water for cooling.

NOTE

: RB100 has only one valve control output, while RB200 has two outputs. Therefore, if you need to

manage both the separation valve and the cooling/heating commutation valve using an RB100 device, you

will need two; if you use the RB200 on the other hand, you will need only one device.

Direct Digital Controller

6 Direct Digital Controller fw 4.013 – Ed. 01/2013

Control of plant with third party boilers and/or chillers

Using the optional device RB200, the DDC can also control plants which include not only Robur units, but also

third party generators (boilers and/or chillers). The RB200 is used to interface these generators through

specific input and output signals; at this point, the DDC can control the system by switching on or off all the

available units, including third party ones.

NOTE

: these functions are not available on the RB100.

Control of other plant parts

Again thanks to the use of the optional RB200, the DDC can control the operation of different types of water

pump needed to implement different plant layouts, as well as acquire the temperature of the manifolds on the

different branches of the plant through temperature probes connected to the RB200. The use of manifold

probes makes the system configurations supported by the control system more flexible.

NOTE

: these functions are not available on the RB100.

Control system expandability using RB200 devices

When one or more RB200 devices are added to a system comprising DDCs and Robur heating or chilling

modules, the following rules apply:

1. On any system, also with maximum expansion (three DDCs, 48 heating modules and 48 chilling

modules) it is possible to add an RB200 device used fully, i.e.:

• with the heating, cooling and DHW requests enabled

• with all water pump, temperature probe and valve services enabled

• with both the third party generator service enabled; however it must be considered that every

third party generator occupies a heating or chilling module, which must therefore be included

in the calculation of the total number of modules

2. It is also possible to add up to seven more RB200 devices, used only to manage other third party

generators, again considering that every generator occupies a heating or chilling module, to be

included in the calculation of the total.

For further information concerning:

• Domestic hot water (DHW) production plant control

• Control of alternate hot/cold 2 line production plant with generation side or 4-line user side manifolds

• Control of plant with third party boilers and/or chillers

• Control of other plant parts

• Control system expandability using RB100 or RB200 devices

• Installation and use of RB100 or RB200 devices

Please consult the installation and user booklet of the RB 100 (code D-LBR468) and the RB 100

applications booklet (code D-LBR467), or RB 200 device (code D-LBR632) and the Applications Manual

(code D-LBR630), according to the type of device used.

NOTE

Direct Digital Controller

Direct Digital Controller fw 4.013 – Ed. 01/2013 7

2 QUICK GUIDE FOR THE USER

2.1 GENERAL CHARACTERISTICS OF THE DIRECT DIGITAL CONTROLLER

The Direct Digital Controller is a device that is applicable as a panel, and which is able to show, on a backlit

graphic LCD display of 128x64 pixels, all the status, operating and error conditions of each individual unit to

which it is linked. The DDC (Direct Digital Controller) controls water thermostating by controlling the switch-on

and switch-off of the units connected to it.

The following elements are present on the front of the panel:

Graphic display on which all the parameters necessary to control, program and configure the plants

managed by the DDC are shown (see detail A in Figure 1).

Selector knob (Encoder): the instrument with which it is possible to interact with the DDC. It allows the

operator to select options, set parameters etc. (see detail B in Figure 1).

RS 232 serial port for connecting the DDC to a PC (see detail C in Figure 1).

Figure 1 – FRONT VIEW OF DIRECT DIGITAL CONTROLLER.

A

B

C

KEY

A GRAPHIC DISPLAY

B SELECTOR KNOB (ENCODER)

C RS232 SERIAL PORT

Direct Digital Controller

8 Direct Digital Controller fw 4.013 – Ed. 01/2013

2.2 MAIN SCREEN

The Direct Digital Controller is equipped with a backlit LCD graphic display (128x64 pixels), able to display the

operating conditions of the plants and each individual unit to which it is linked.

The Direct Digital Controller’s display, during normal operation, allows the following parameters to be viewed:

Zone 1 The upper zone of the display which shows,

upon activation, the time, day and symbol of the unit of

measurement used to display inlet and outlet water

temperatures of each plant controlled.

In case services for the production of domestic hot

water are configured, the

icon is shown on top right

side; its selection/press permits to display the

operation parameters of the heating/cooling plant (

)

or of the domestic hot water plant (

).

Zone 2 This zone contains the symbol

, to indicate

that it refers to the plant operating parameters for the

production of chilled water. In the initial screen, upon

first activation of the DDC, the message “PLANT NOT

CONFIG” appears. During the operation, the water

inlet/outlet temperature values and the set point value

are shown (if the plant is ON).

appears on the

right, allowing access to the “Plant control” menu; A:

plant status ON/OFF; B: plant ID code (0-15).

Zone 3 This zone contains the symbol

, indicating

that it refers to the plant operating parameters for the

production of hot water as concerns the heating plant.

In the initial screen, upon first activation of the DDC,

the message “PLANT NOT CONFIG” appears.

During operation, inlet/outlet water temperatures of the

plant and the set point value are displayed (if the plant

is ON). The

icon on the right of the display allows

access to the “Plant control” menu;

A: ON/OFF status of plat; B: plant identification code

(0-15).

Zone 4 The last row displays a message that briefly

describes the icon on which the cursor is positioned.

The

icon allows access to the “error” menu; the

icon permits to access to the “Main menu”.

Zone 5 The symbol is shown to indicate that the zone contains the displaying of the operation

parameters of the hot water production plant for the base DHW service (production of domestic hot water

making use of the units on the base plant part with possibility of carrying out the production at the same

time with the heating service). During the operation, the water inlet/outlet temperature values and the set

point value are shown (if the plant is ON). appears on the right, allowing access to the “Base DHW

Plant control” menu; A: plant status ON/OFF; B: plant ID code (0-15).

If this kind of DHW service is not configured, caption “SERV. NOT CONFIGURED” is shown.

Zone 6 The symbol is shown to indicate that the zone contains the displaying of the operation

parameters of the hot water production plant for the separable DHW service (production of domestic hot

water making use of the units on the splitting plant part with alternating DHW/heating service or with DHW

service only). During the operation, the water inlet/outlet temperature values and the set point value are

shown (if the plant is ON).

appears on the right, allowing access to the “Separable DHW Plant

control” menu; A: plant status ON/OFF; B: plant ID code (0-15).

Figure 2 - EXAMPLES OF MAIN SCREEN

ZONE 1

ZONE 2

ZONE 3

ZONE 4

VISUALISATION OF DISPLAY UPON FIRST

ACTIVATION OF DIRECT DIGITAL CONTROLLER

ZONE 1

ZONE 2

ZONE 3

ZONE 4

VISUALIZATION OF OPERATING CONDITIONS

FOR “BASE DHW” AND “SEPARABLE DHW”

PLANTS

A B

VISUALIZATION OF OPERATING CONDITIONS

FOR 4 PIPE HEATING/COOLING PLANT

ZONE 1

ZONE 2

ZONE 3

ZONE 4

A B

Direct Digital Controller

Direct Digital Controller fw 4.013 – Ed. 01/2013 9

If this kind of DHW service is not configured, caption “SERV. NOT CONFIGURED” is shown.

The symbols used to represent the heating and/or cooling plant are the following:

Sun: represents the chilled water production plant (COOLING);

Snowflake: represents the hot water production plant (HEATING).

The main screen of the DDC, according to the type of plant configured, may appear as follows:

ONLY CONDITIONING PLANT

CONFIGURED

COOLING AND HEATING PLANTS

CONFIGURED FOR CONTEMPORARY

OPERATION ; DHW SYSTEM CONFIGURED

COOLING AND/OR HEATING PLANTS

CONFIGURED FOR ALTERNATING

OPERATION

PLANTS NOT CONFIGURED

ONLY HEATING PLANT CONFIGURED

HEATING AND DOMESTIC HOT WATER

PLANTS CONFIGURED

COOLING AND HEATING PLANTS

CONFIGURED FOR CONTEMPORARY

OPERATION (4 pipes)

COOLING AND HEATING PLANTS

CONFIGURED FOR ALTERNATING

OPERATION

ONLY DOMESTIC HOT

WATER PLANT CONFIGURED

NOTE

Direct Digital Controller

10 Direct Digital Controller fw 4.013 – Ed. 01/2013

If the set point is configured on inlet water, the inlet water set point is displayed below it (In).

In the event of errors occurring in the units of the plant(s), the following signals are given:

The

symbol flashes;

The display illumination flashes;

The device (if ON) emits an intermittent beep (see Paragraph 3.4.2.4 - “Alarm Beeper” on page 49).

1 – The DDC’s display reverts to the main screen after 30 minutes of inactivity (no operation of encoder).

2 – The backlighting of the display is switched off after 15 minutes of inactivity (see also Paragraph 3.4.2.5

- "Display Options", on page 50).

3 – If the encoder is turned or pressed while the display’s backlight is flashing, it stops flashing, and starts

flashing again after 25 seconds of inactivity, if the error conditions persist.

In all other screens the display’s illumination flashes.

2.3 USING THE ENCODER

The main user interface for management, programming and control of the DDC is the knob located on the

front of the Direct Digital Controller (the encoder).

The operations that may be performed with the encoder can be summarised as follows:

1 - Rotate the encoder in a clockwise or anticlockwise direction to position the cursor on the icons to be

selected on the display or to modify the value of a numerical field.

2 - Press the encoder to access the menu selected or to confirm the operation being carried out.

Each time instructions in this manual indicate that an icon, parameter etc. should be selected, it is necessary

to carry out the two operations described above.

NOTE

WARNING

ROTATING THE ENCODER

PRESSING THE ENCODER

Direct Digital Controller

Direct Digital Controller fw 4.013 – Ed. 01/2013 11

2.4 COOLING/HEATING SERVICE CONTROL MENU

Select the icon from the main screen, concerning the service to be controlled, to access the “Plant

control” menu. In this screen, on the basis of the configuration carried out, it is possible to select and manage

the buttons that switch on the cooling/heating plants.

The figure below shows how the “Plant control” menu screen appears to give an example of configuration.

Figure 3 – EXAMPLE OF COOLING/HEATING PLANT CONTROL SCREEN

Main ON/OFF switch of cooling/heating services. It permits to switch on/off the

controlled service(s) (cooling and heating or 2-pipe cooling/heating).

To sw itch on the service(s) , turn the knob and position the cursor on

and then

press the same. The button will appear thus

to indicate that the switch has been

closed (ON).

To sw itch off the service(s), turn the knob and position the cursor on

and then

press the same. The button will appear thus

to indicate that the switch has been

opened (OFF).

The symbol

indicates that the button has been disabled and that it is not possible

to select it. The switch will not affect the switching on of the plant.

Group ON/OFF switch. Use this button to switch on or off only the units that are directly

managed by the specific DDC. This button is enabled only for Multi DDC plants (i.e.

plants that are managed by several Direct Digital Controllers); the activation of those units

requires, however, that the main ON/OFF switch present only on the master DDC is

enabled.

To enable on the units controlled by the DDC, turn the knob to position the cursor on

, and press the knob. The button will appear thus to indicate that the switch

has been closed (ON).

To disable the units controlled by the DDC, turn the knob to position the cursor on

, and press the knob. The button will appear thus , indicating that the switch

has been opened (OFF).

The symbol

indicates that the button has been disabled and that it is not possible

to select it.

The switch does not affect the switching on of the units.

KEY:

A Main ON/OFF switch;

B Partial ON/OFF switch (enabled only on Multi

DDC systems)

C Button for enabling General water T timer;

D Button for enabling Partial water T timer (Multi

DDC plants only)

E Button for enabling chronothermostat;

F Heating-cooling switching button (only for the 2-

line heating/cooling systems)

G Exit menu.

A

B C D

E F G

Direct Digital Controller

12 Direct Digital Controller fw 4.013 – Ed. 01/2013

Button for enabling/disabling General water T timer. It enables/disables the use of the

switching-on timing for all the units.

To disable the general water T timer turn the knob and position the cursor on

then press the knob. The button will appear thus

, indicating that the water T timer

has been disabled and that the corresponding switch will be closed (ON status).

To enable the general water T timer turn the knob and position the cursor on

and

then press the knob. The button will appear thus

, indicating that the water T timer

has been enabled. The corresponding switch will be closed or opened according to

whether the time falls within a programmed timer cycle (see Paragraph 3.4.1.1.1.3 ,

programming the general water T timer).

The symbol

indicates that the button has been disabled and that it is not possible

to select it (switch with ON status).

Button for enabling/disabling Partial water T timer (button enabled only for Multi DDC

plants). This button allows the user to choose whether to program a switch-on time or not

only for the units managed by the individual DDC.

To disable the partial water T timer, turn the knob to position the cursor on

and

press the knob. The button will appear thus

, indicating that the partial water T

timer has been disabled and the corresponding switch will be closed (ON status). The

partial water T timer is in any case disabled if the General water T timer is disabled.

To enable the partial water T timer, turn the knob and position the cursor on

then

press the knob. The button will appear thus

, indicating that the Partial water T

timer has been enabled. The corresponding switch will be closed or opened according

to whether the time falls within a programmed Partial water T timer cycle (see

Paragraph 3.4.1.1.1.4 for the programming the Partial water T timer).

The symbol

indicates that the button has been disabled and that it is not possible

to select it (switch with ON status).

Chronothermostat activation/deactivation button;

This button is enabled in one of the following due cases and assumes different functions,

described below:

1- The room chronothermostat is active depending on the internal room probe (ambT

mode or equivalent, CUSTOM mode and "ChronT" active).

In this case:

• To disable the chronothermostat, turn the knob and position the cursor on

and then press the same. The button takes on the following aspect

indicating

that the chronothermostat has been deactivated and the corresponding switch is

closed (ON status), i.e. the system DOES NOT regulate the internal room

temperature).

• To enable the chronothermostat, turn the knob and position the cursor on

and then press the same. The button will appear thus , indicating that

the chronothermostat is enabled. The corresponding switch will be opened or

closed depending whether the room temperature satisfies the active room setpoint on the basis of chronothermostat programming. This means the system

regulates the internal room temperature on the basis of chronothermostat

programming (for further information see paragraph 3.4.1.2.3 “Chronothermostat”)

.

Direct Digital Controller

Direct Digital Controller fw 4.013 – Ed. 01/2013 13

2- The room thermostat is active based on the climatic curve and external temperature

probe (WCmp mode or equivalent equivalent, CUSTOM mode and “WCmp” function

active) and the climatic curve function is enabled in the user level menu “Enabling of

climatic curve” (see paragraph 3.4.1.1.1.2).

In this case, by pressing the knob repeatedly with the cursor positioned on the

chronothermostat activation/deactivation button, the symbol assumes the different

aspects in sequence to which the following modes correspond:

•

the room temperature set-point is that active on the bases of the

programming set on the chronothermostat.

•

o : the room temperature set-point is always T3 (maximum level of the

heating or cooling service)

•

the room temperature set-point is always T2 (average level of the heating or

cooling service)

•

o : the room temperature set-point is always T1 (minimum level of the

heating or cooling service)

NOTE: continuing to press the knob, the sequence is repeated.

Note that the climatic curve function remains active in all modes stated above; therefore in

this case the system ALWAYS regulates the internal room temperature, based on the

climatic curve. The change affects only the choice of the value of the room temperature

set-point value.

If neither of the two cases stated above exists, the button takes on the

aspect to

indicate that it is disabled. The system does not regulate the internal room temperature.

COOLING/HEATING switch button (button present for 2 line hot/cold plants only);

To change to Cooling turn the knob to position the cursor on

then press the

knob. The button will appear thus

, indicating that the plant will be enabled for

cooling operation.

To change to Heating mode turn the knob to position the cursor on

then press

the knob. The button will appear thus

, indicating that the plant will be enabled for

heating operation.

Heating/cooling priority selection button for GAHP-GS/WS module (button only present

on 4-line hot/cold plants with units of the GAHP-GS/WS type);

To give priority to Cooling turn the knob and position the cursor on

then press

the knob. The button will appear thus

, indicating that priority will be given to

cooling operation for the GAHP-GS/WS units.

To give priority to Heating turn the knob to position the cursor on

then press the

knob. The button will appear thus

, indicating that priority will be given to heating

operation for the GAHP-GS/WS Units.

For further information on the use of this button, consult the operation and maintenance

manual of the GAHP-GS/WS unit.

According to the configuration carried out, some of the buttons may be disabled. (status always ON). For

further details, consult Paragraph "On/off command configuration" on page 103.

NOTE

Direct Digital Controller

14 Direct Digital Controller fw 4.013 – Ed. 01/2013

As concerns the heating service, the switching off does not necessarily involve the switching off of the units.

In fact, if also one or more DHW production services are configured, the units can start to meet the DHW

requests. In order to ensure the real switching off of the plant, switch off also the DHW service(s), as

indicated in paragraph 2.5 “BASE AND SEPARABLE DHW SERVICE CONTROL MENU” on page 15.

NOTE

Direct Digital Controller

Direct Digital Controller fw 4.013 – Ed. 01/2013 15

2.5 BASE AND SEPARABLE DHW SERVICE CONTROL MENU

To access the “DHW Plant control” menu, follow the indications given below:

1 - Select the

icon from the initial screen and press the knob to gain access to the screen displaying the

base and separable DHW service operation parameters.

2 - Select the symbol positioned above to gain access to “Base DHW control” menu (see “Zone 5”

Figure 2 on page 6).

3 - Select the

symbol positioned below to gain access to “Separable DHW control” menu (see “Zone

6” Figure 2 on page 6).

4 - In both cases (“Base DHW control” and “Separable DHW control”) the screen shown in Figure 4 will be

displayed on the screen.

5 - The switching on of the Units of which use is made to produce domestic hot water requires also a request

coming from the RB100 or RB200; the button in position ON is not sufficient by itself to switch on the units

of the DHW group. The base or separable DHW services each require a specific request; for more

information please consult the installation and use booklet of the RB 100 (code D-LBR468) and the RB

100 applications booklet (code D-LBR467), or the installation and use booklet of the RB 200 (code DLBR632) and the applications manual (code D-LBR630), according to the type of device used.

Figure 4 – EXAMPLE OF BASE OR SEPARABLE DHW SERVICE CONTROL SCREEN

Base or separable DHW service ON/OFF switch. Used to switch the corresponding

DHW service ON/OFF.

To sw itch on the plant, turn the knob and position the cursor on

then press the

knob. The button will appear thus

to indicate that the switch has been closed

(ON).

To disable the plant, turn the knob and position the cursor on

and then press the

same. The button will appear thus

to indicate that the switch has been opened

(OFF).

The

symbol indicates that the button cannot be selected. The switch does not

affect the switching on of the units. The “milled” icon is shown only on the Slave DDC

in case of Multi-DDC configuration, and the switching On/Off of the corresponding

DHW service can occur only on the Master DDC. The “button” on the Slave DDC

reflect the status of the Master DDC button.

Switching off the DHW service does not necessarily imply that the units are switched off. If also the heating

service is configured, the units may come on to satisfy this request. In order to ensure the real switching off

of the plant, switch off also the heating service, as indicated in paragraph 2.4 “COOLING/HEATING

SERVICE CONTROL MENU” on page 11.

A

KEY

A General Power Switch

Direct Digital Controller

16 Direct Digital Controller fw 4.013 – Ed. 01/2013

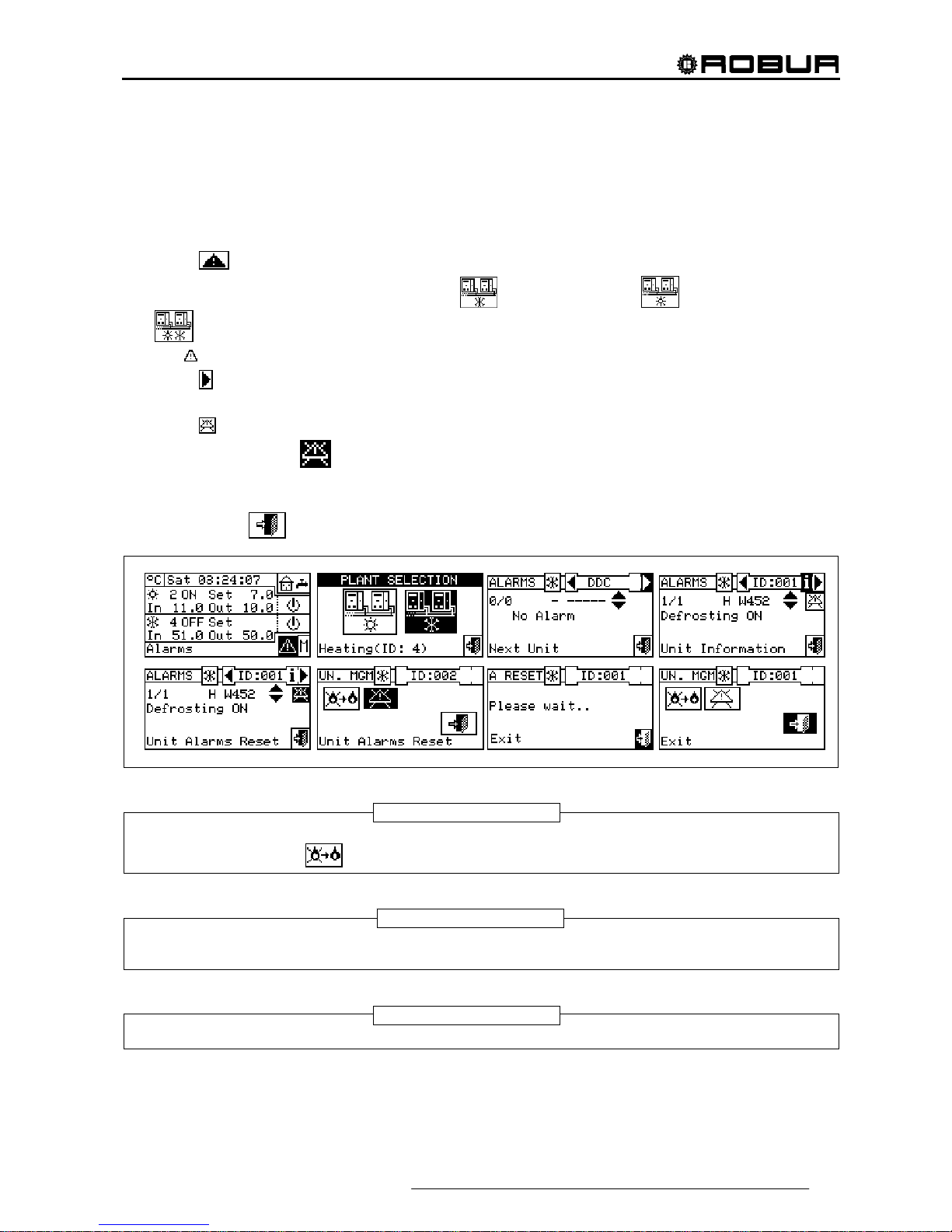

2.6 ALERTS MENU

This menu allows the user to visualise any anomalies in the units of the plant(s).

To access the alerts menu, select

from the main screen.

The figure below indicates the alerts menu screen.

Figure 5 – EXAMPLE OF ALERTS MENU SCREEN

The alerts menu shows the events underway: it is possible to view the type of event (warning or error) for

each machine type.

Instructions to access the alerts menu:

1 - Select from the initial screen to gain access to the main menu.

2 - From the main menu, select

.

3 - Select the plant in which the events occurred:

for two-line cooling/heating plants, for hot water

production plants, or

for chilled water production plants. The symbol that appears next to a plant

icon indicates that anomalies are present in that plant.

4 - To search for the unit in which errors have occurred select

(detail “D” in Figure 5). If no error has

occurred, the message “No error” appears.

5 - Use the vertical scroll arrows

(detail “E” in Figure 5) to view all the events present on the unit.

The key allows the user to access the “MACHINE MANAGEMENT” menu in order to perform an error

reset, if necessary.

The button

i allows to access the “INFORMATION MENU” related with the selected unit.

KEY:

A Sequential number of events in progress for selected unit;

B System identification symbol; for cooling plant, for

heating plant;

C Indication of machine ID;

D Scroll arrows to change which unit’s events are displayed;

E Vertical scroll arrows: these allow the user to view the

events that have occurred on the unit;

F Indication of event code (Error: E, Warning: W);

G String describing the position in which the cursor is;

I Text describing event;

H String describing the action to be carried out to solve the

event that occurred;

M Anomaly regards:

C: conditioning module;

H: heating module;

B: electronic board.

N Access to the “unit information” of the selected unit;

O Access to the “unit alarms reset” of the selected unit

NOTE: the letters C and H will not be displayed for GAHP-

GS/WS

D

B C

D

I

H

A

G M

F

E

N

O

Direct Digital Controller

Direct Digital Controller fw 4.013 – Ed. 01/2013 17

2.7 ERROR RESET

This option allows the user to reset the anomalies present in the unit selected (with the exception of flame

control unit arrest).

To carry out an error reset, follow the instructions below:

1 - Select from the initial screen to access the alerts menu.

2 - Select the plant in which the events occurred:

for the cooling plant, for the heating plant, or

if the DDC is configured to manage a 2 line hot/cold plant.

The

symbol that appears next to a plant icon indicates that anomalies are present in that plant.

3 - Select

to view the screen that relates to the unit where the error has occurred.

4 - Select i to access to the “INFORMATION MENU” related to the selected unit.

5 - Select

to access the MACHINE MANAGEMENT menu directly.

6 - Position the cursor on

and press the knob to carry out an error reset.

7 - Wait for the operation to be performed. If the operation is successful, the message “OK” appears on the

display.

8 - To exit, select

.

An error reset does not reset the flame control unit. To reset the flame control unit is necessary to

move with the cursor on

and press the knob.

Error resets for which the message “Contact Technical Assistance” appears must only be carried

out by qualified personnel

It is not possible to reset errors on third party machines.

WARNING

NOTE

NOTE

Direct Digital Controller

18 Direct Digital Controller fw 4.013 – Ed. 01/2013

2.8 FLAME CONTROL UNIT RESET

This option allows the user to reset the flame control unit of the unit selected in the event of arrest of the

burner.

To carry out a reset of the flame control unit if the burner ceases to function, follow the instructions below:

1 - Select

from the initial screen to gain access to the main menu.

2 - From the main menu, select

to enter the Machine Management menu.

3 - Select the plant (

, or if the DDC is configured to manage only one hot/cold plant).

4 - Select the unit by using

or . The unit’s identification number is shown between the arrows.

5 - Select i to access to the “INFORMATION MENU” related to the selected unit.

6 - Position the cursor on

and press the knob to carry out a reset of the flame control unit.

7 - Wait for the operation to be performed. If the operation is successful, the message “OK” appears on the

display.

8 - To exit, select

.

By law it is possible to execute max. 5 flame reset attempts within a 15 min period. If you exceed this

number, the function is disabled and further attempts can only be executed directly on the affected unit, as

described in the relative manual.

The flame control unit can be reset also by accessing the “Errors” menu

from the initial screen (for more

details see paragraph 2.7 ERROR RESET on page 17).

The errors reset can also be done from this menu: position the cursor on

then press the knob

to carry out the reset of the trouble of the selected unit.

It is not possible to reset the flame control unit on third party machines.

NOTE

NOTE

Direct Digital Controller

Direct Digital Controller fw 4.013 – Ed. 01/2013 19

3 FUNCTIONS OF THE DIRECT DIGITAL CONTROLLER

3.1 MAIN MENU

To access the main menu from the initial screen, select

.

The main menu consists of 5 sections, as indicated in the figure on

the right:

Functional data.

Machine Management

User Settings

Installation (see Installation” Section)

Exit

Direct Digital Controller

20 Direct Digital Controller fw 4.013 – Ed. 01/2013

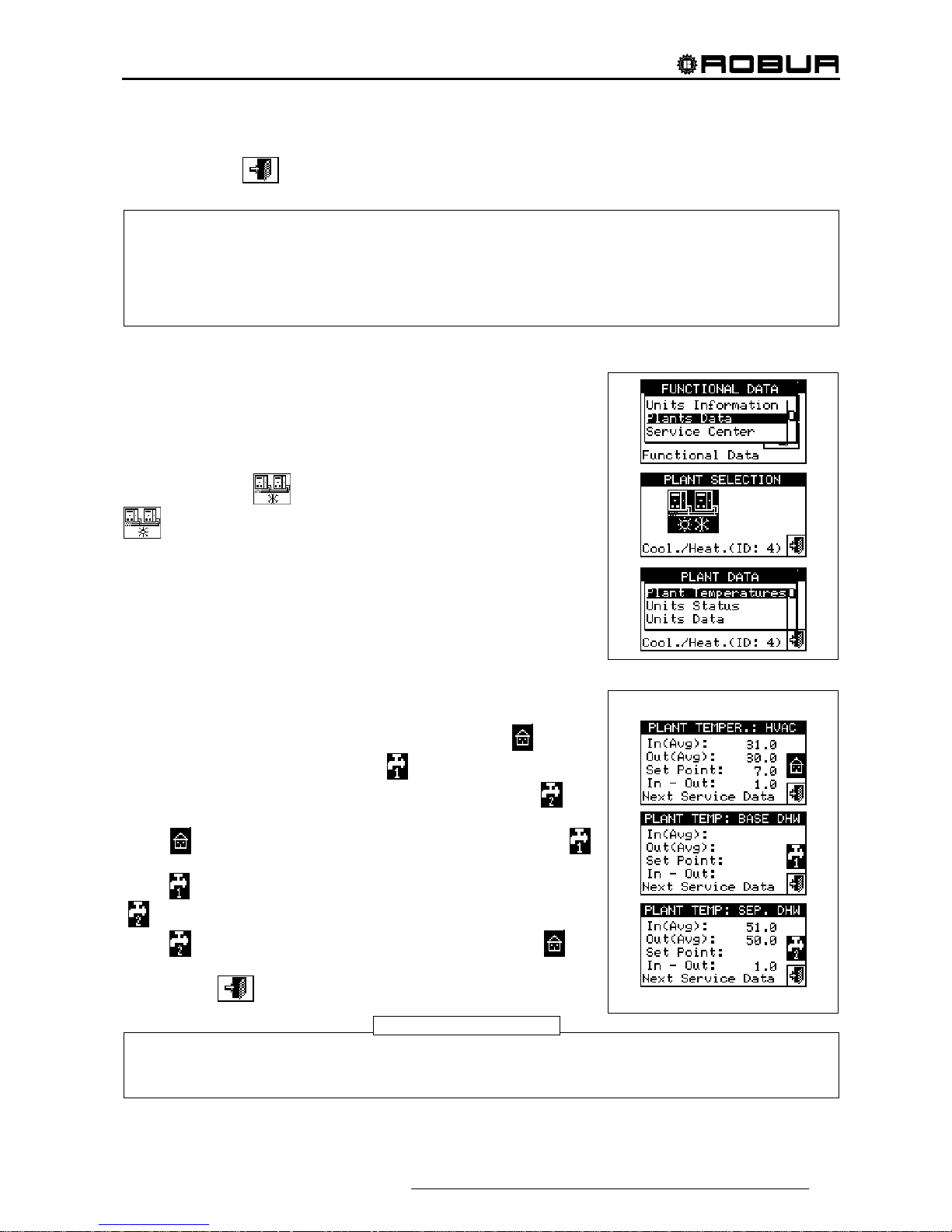

3.2 FUNCTIONAL DATA

The menu “Functional data” provides access to a scrolling menu that

allows the user to access all information regarding the plants and the

machines managed by the DDC. The options in this submenu are listed

below:

DDC information

Units information

Plants data

Service Centre

Alarms Log

Exit

3.2.1 DDC INFORMATION

By gaining access to two screens, some data concerning the DDC can

be displayed: Network ID assigned to the DDC, environmental

temperature (displayed if an environmental sensor is connected), power

supply voltage, serial ID. The second screen contains HW revision,

revision of Boot Loader FW, revision of application FW.

To access “DDC data”, follow the instructions below:

1 - Select from the initial screen to gain access to the main menu.

2 - Select

to gain access to the “Functional data” menu;

3 - Turn the knob to select the “DDC Information” menu, and press the

knob to access the menu.

4 - Select “1/2” to move to the second screen. To go back to the first

screen, select “2/2”.

5 - To exit, select

.

3.2.2 UNITS INFORMATION

By means of two or three screens some specific data concerning the

units can be displayed (machine type, serial ID of the unit board,

revisions of the HW and FW electronics) as well as other detailed data

concerning the module or the two modules that build up the unit (detailed

denomination of the module, its primary and secondary main codes,

separated by a “.”, then, the serial number).

To access to the “Units information” menu, follow the instructions

below:

1 - Select from the initial screen to gain access to the main menu.

2 - Select

to gain access to the “Functional data” menu;

3 - Turn the knob to select the “Units information” menu, then press the

knob to gain access.

4 - Select the unit making use of

or . The network ID of the

selected unit is indicated between the arrows; the first screen (“1/3”,

or “1/2”) containing the unit data is shown.

5 - Select “1/3” or “1/2” to move to the second screen, containing the data of the first module.

6 - If the unit consists of two modules, select “2/3” to move to the third screen, containing the data of the

second module.

Direct Digital Controller

Direct Digital Controller fw 4.013 – Ed. 01/2013 21

7 - Select “3/3” (or “2/2” in case of unit consisting of one module only) to go back to the first screen

8 - To exit, select

.

3.2.3 PLANTS

When the machines have been configured (see Section 4,

“INSTALLATION”), it is possible to view the functional data of the plants

managed. To enter the plants submenu, select “Plants” from the dropdown menu.

To view the operating data of the plants, select the desired icon. If two

plants have been configured, two icons will appear: one for the hot

plant, shown by the

icon, and one for the cold plant, shown by the

icon.

Select the plant for which the operating data is desired. A drop-down

menu will allow the user to select which data to view:

Plant temp.

Machine status

Machine data

Exit

3.2.3.1 Plant temperatures

The displaying concerns the temperature of water at inlet to/outlet from

the plant, the value of the set point temperature and the difference of

temperature between inlet and outlet of the cooling plant

or base

domestic hot water plant (base DHW)

(if configured) or separate

domestic hot water plant (separable/separated DHW)

(if

configured).

Select

to move to the screen concerning the base DHW plant (

will appear).

Select

to move to the screen concerning the separable DHW plant

(

will appear).

Select

to move to the screen concerning the cooling plant ( will

appear)

To exit, select

.

When viewing third party boilers or chillers managed via the Robur Box RB200, the first screen

shows the generic indication "Third Party Machine" and the serial ID, Hardware and Firmware

version of the RB200 device managing the boiler or chiller; the second screen shows a more

detailed description of the type of boiler or chiller (with or without water pump control, with or

without error reading) and the value of the corresponding configuration parameter set on the

RB200.

For a given temperature, if this is read by the manifold probe (managed via the RB200) rather than

by calculating the average of the machine probes, the indication between brackets will read

“(probe)” and not “(average)”.

NOTE

Direct Digital Controller

22 Direct Digital Controller fw 4.013 – Ed. 01/2013

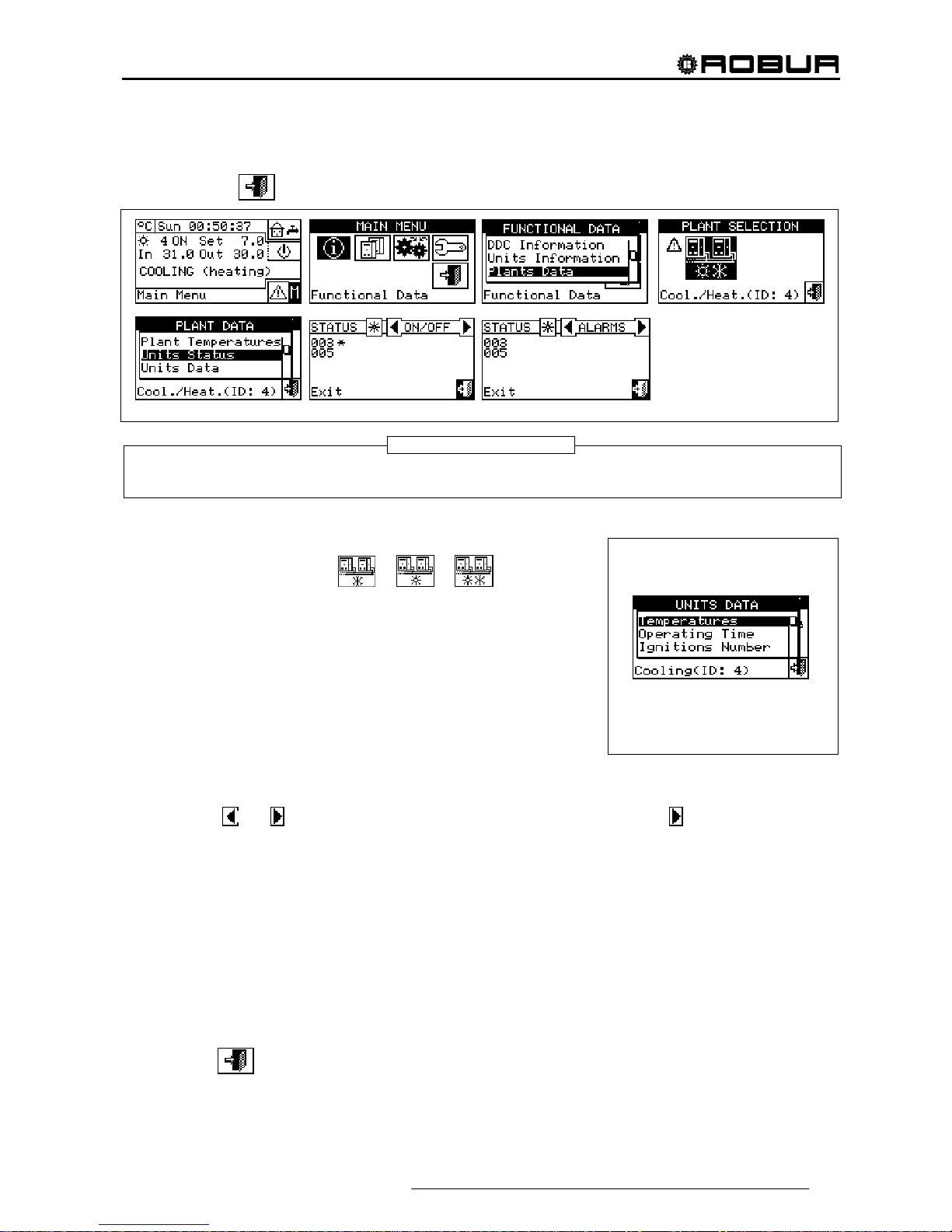

3.2.3.2 Machine status

The “Machine status” menu provides a complete overview of the units operating correctly and those where

errors have arisen. Each unit is identified by its network ID.

Two screens are present: “ACTIVATION” and “ERRORS”. Next to the machine ID, in the “ON” screen, the

following symbols appear:

1 - if the machine is on.

2 - If the unit is off, no symbol appears next to the machine ID.

3 -

if the machine has been excluded from the plant via the options

in the Units management menu.

4 -

if the unit is carrying out a Defrosting cycle. Option only for GAHP-

A and GAHP-AR units.

5 - if the unit is off because it has reached temperature or

thermostating limit values.

Select to visualise for which units errors or warnings have occurred. If an error has occurred in the machine,

the letter E will appear next to the unit’s ID.

In the “Error” screen next to the machine ID, the following symbols

appear:

1 -

if an error has occurred in the machine;

2 -

if a warning has occurred for the machine;

3 -

(“off-line”) if there are connection problems between the machine

and the DDC (the off-line may be due to various causes: the machine

is not powered, there are problems on the connection cable, the

machine board is malfunctioning and cannot communicate with the

DDC;

4 - If no error has occurred in the machine, no symbol will appear next to

the machine ID.

For two-line hot/cold plants, i.e. plants for the production of hot/chilled

water, the symbols

or apply.

Select

to view the screens relating to modules dedicated to the

production of chilled water (

is displayed).

Select

to view the screens relating to modules dedicated to the

production of hot water (

is displayed).

To access the menu, follow the instructions below:

1 - Select from the initial screen to gain access to the main menu.

2 - Select

to access the “Functional data” menu.

3 - Turn the knob to select the “Plants” menu, and press the knob to enter the menu.

4 - Select the plant for which to view the machine status:

for two-line cooling/heating plants, for

hot water production plants, or

for chilled water production plants. The symbol next to the plant

icon indicates an anomaly.

5 - Turn the knob to select the “Machine status” menu and press the knob to access the menu.

6 - Select

to move to the Errors screen: next to the identification number of each unit (ID = machine), the

letter E indicates that an error is present.

Direct Digital Controller

Direct Digital Controller fw 4.013 – Ed. 01/2013 23

7 - On both screens, a machine ID can be selected by turning the knob and, pressing it, access can be gained

directly to the “Machine information” menu.

8 - To exit, select

.

Warning: having carried out the machines configuration, each time it is switched on the DDC searches for

the configured units. Any units not found are considered to be “off-line”.

3.2.3.3 Machine data

In this menu the user may view typical machine operating data

according to the plant selected (

or or ).

The parameters that may be viewed are:

- Temperatures

- Operating time

- Ignitions Number

- Defrostings number

- Inversions Number

- Other data

Temperatures

An overview of all the operating temperatures of the machine selected. The machine’s ID is indicated between

the two arrows

and . To view the operating temperatures of another unit, select .

Which temperatures may be viewed depends on the type of machine selected (AY, ACF GAHP-GS/WS etc.).

A list of the temperatures that may be viewed on the screen is provided below.

1- In Unit inlet water temperature;

2- Out Unit outlet water temperature;

3- Ext External air temperature,

4- Cnd Condenser temperature;

5- Gen High generator temperature;

6- Eva Evaporator temperature;

7- TA1 TA2 Auxiliary probes.

8- Mix Air/gas mixture temperature

9- Fumi Temperature of the flue gas

10- GenF Temperature of the generator fins

To exit, select

.

NOTE

Direct Digital Controller

24 Direct Digital Controller fw 4.013 – Ed. 01/2013

It is not possible to view the operating temperatures of third party machines.

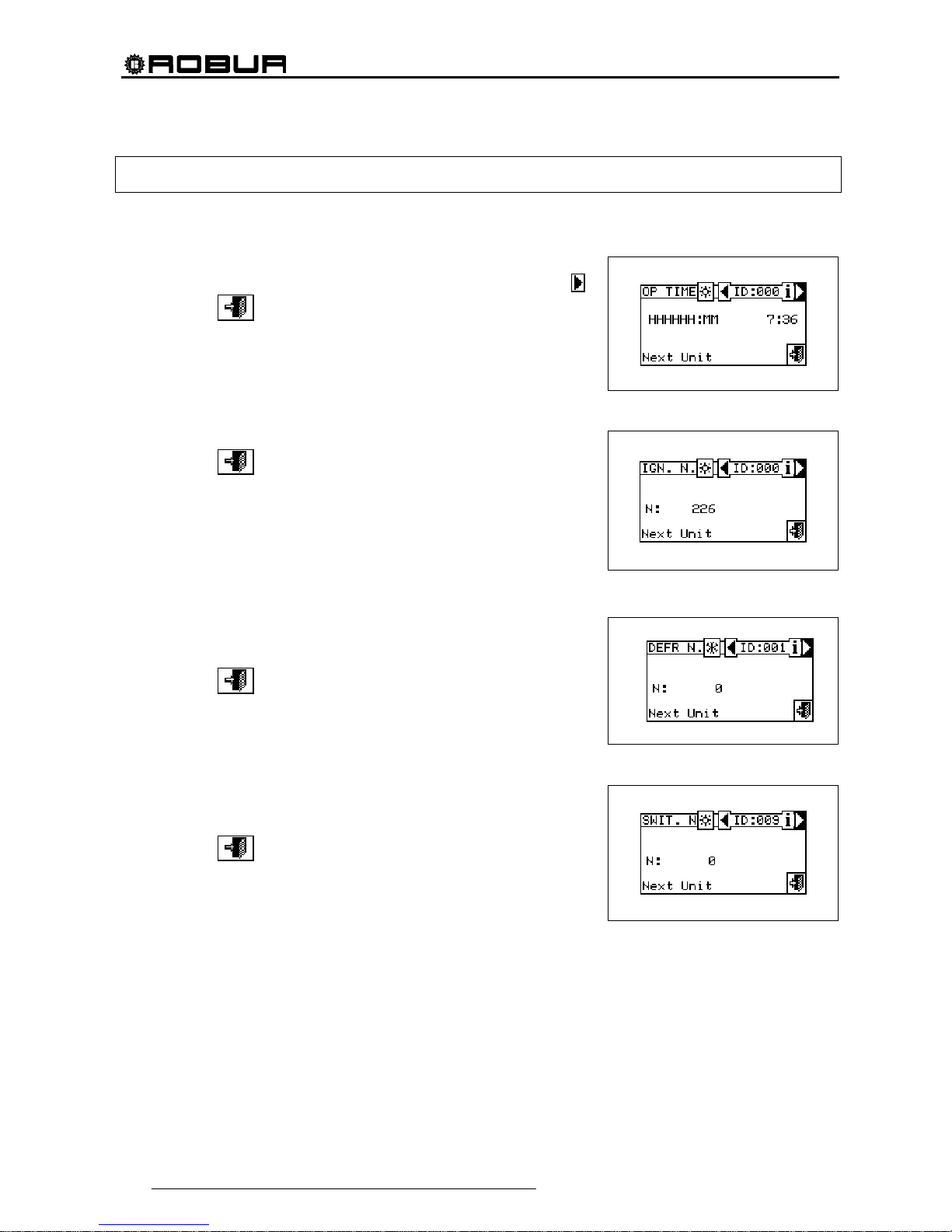

Operating Time

This screen shows the time that the machine has been operating in

hours and minutes. To view the operating time of another unit, select

.

To exit, select

.

Ignitions Number

This screen indicates the number of times the unit has been switched on.

To exit, select

.

Defrostings number

This screen indicates the number of defrosting cycles of the unit (GAHP

A-AR plants only).

To exit, select

.

Inversions number

Reports the number of times the unit has been inverted (GAHP-AR units

only).

To exit, select

.

Direct Digital Controller

Direct Digital Controller fw 4.013 – Ed. 01/2013 25

Other data

Indicates other data relative to the machine selected. To display the data

of another unit, select

to show the second screen 1/2; 2/2 to pass from

the second to the first screen.

To exit, select

.

It is not possible to view other data concerning third party

machines.

3.2.4 TECHNICAL ASSISTANCE

This screen gives information about the nearest Technical Assistance

Centre. See Paragraph 4.4.1.12 Technical assistance information

regarding the programming of technical assistance information.

To exit, select

.

Direct Digital Controller

26 Direct Digital Controller fw 4.013 – Ed. 01/2013

3.2.5 EVENT HISTORY

In this screen, it is possible to view all the parameters that characterise a warning or error event. All the events

are in chronological order from latest to earliest, and the times at which the event occurred and ended are

shown. For each event the following information is given, as shown in Figure 6: date, time, machine ID, error

or warning code, indication of which module (if required: “C” = Cooling, “H” = Heating) generated the event.

The ON indication regards the time the warning or error event arose, while the OFF indication regards the time

it ended. In addition, in the central area of the display there is a brief description of the type of event that

occurred.

All the events that occur are memorised in the Event history menu.

Figure 6 shows the Event history menu screen.

Figure 6 – EXAMPLE OF EVENT HISTORY MENU SCREEN

Instructions for accessing the event history

list follow:

1 - From the main menu, select

.

2 - Select

to access the “Functional data” menu.

3 - Turn the knob to select the “Event history” menu, and press the knob to access the menu.

4 - Position the cursor on the vertical scroll arrows (see detail “D” in Figure 6) to scroll through the events, from

latest to earliest.

5 - To exit, select

.

B

C

I

H

A

G

L

F

E

D

KEY:

A Date event detected;

B Time event detected;

C Indicator of number of events: the first number indicates the

chronological order of the event being viewed; the second

indicates the total number of events memorized by the DDC;

D Vertical scroll arrows. Use these to scroll through the events that

have occurred in the system in chronological order;

E Event status: ON refers to the moment that the event occurred;

OFF refers to the moment that it ended;

F Numerical code describing the type of event;

G Text describing the function highlighted by the cursor.

H Text describing the event.

I ID of machine or DDCs present where the event displayed

occurred;

L Origin of the anomaly:

C : cooling module;

H: heating module;

B: electronic board.

NOTE: the letters C and H are not displayed for GAHP-GS/WS units.

Direct Digital Controller

Direct Digital Controller fw 4.013 – Ed. 01/2013 27

3.3 UNITS MANAGEMENT

The menu allows the user to carry out certain operations upon the units controlled by the DDC.

Each machine has a screen associated with it in the “Units management” menu, which contains 5 icons that

allow the unit to be managed.

Flame control unit reset: this option allows the flame control unit of the selected machine to be

reset in the event of arrest.

Error reset: this option allows anomalies present in the selected unit to be reset (except in the

case of arrest of the flame control unit).

Machine exclusion: this option allows the selected machine to be excluded from the plant.

Modify set of parameters: this option allows the parameters set on the machine’s electronic

board to be modified. For a list of the parameters, consult the installation manual of the unit.

Default set of parameters: this option allows the default parameters memorised in the machine’s

electronic board to be reset.

Manual defrosting: The option allows the defrosting cycle to be carried out for the selected unit

(GAHP-a and GAHP-AR only).

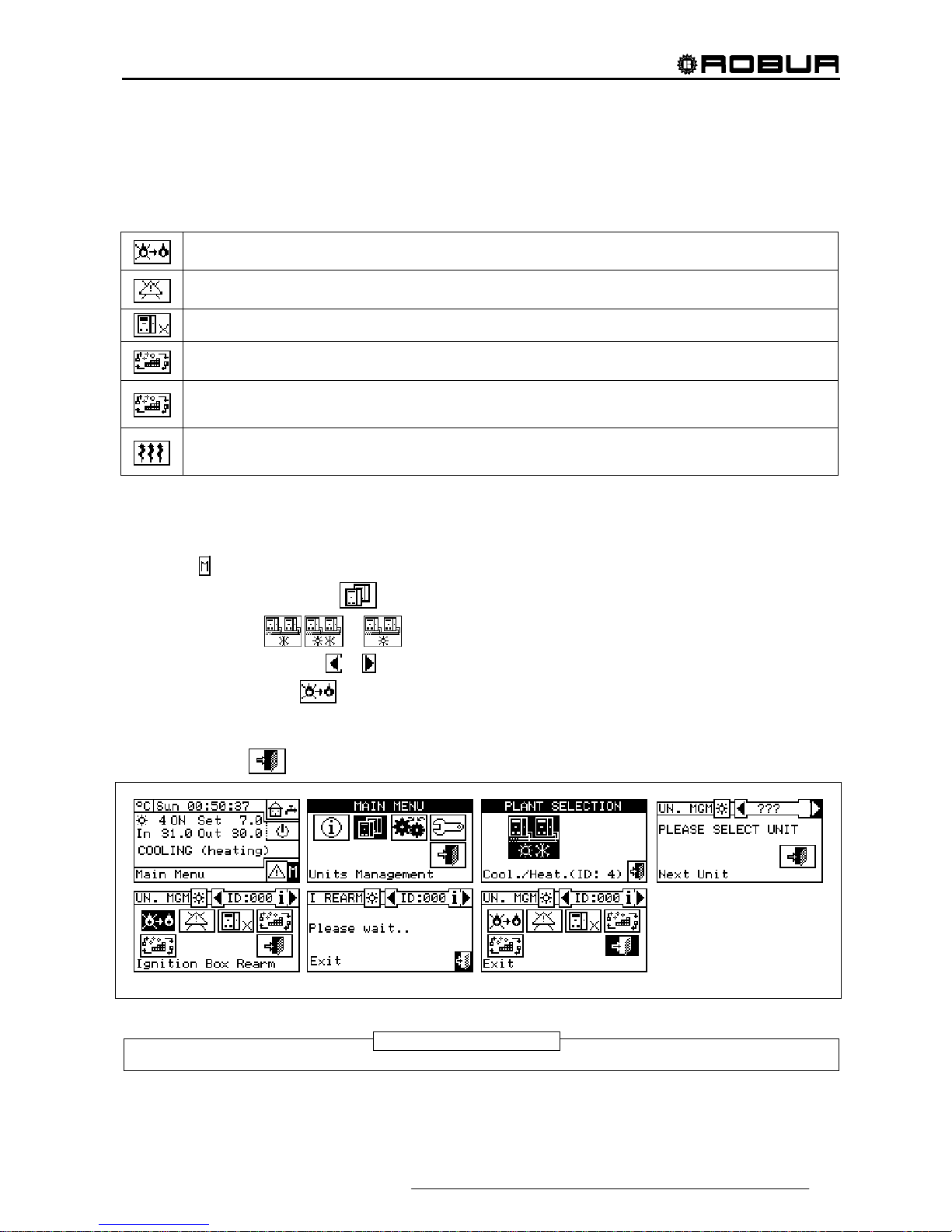

3.3.1 FLAME CONTROL UNIT RESET

To carry out a reset of the flame control unit if the burner ceases to function, follow the instructions below:

1 - Select

from the initial screen to gain access to the main menu.

2 - From the main menu, select

.

3 - Select the plant (

, or if the DDC is configured to manage only one hot/cold plant).

4 - Select the machine, using

or . The unit’s identification number is shown between the arrows.

5 - Position the cursor on

and press the knob to carry out a reset of the flame control unit.

6 - Wait for the operation to be performed. If the operation is successful, the message “OK” appears on the

display.

7 - To exit, select

.

It is not possible to reset the flame control unit on third party machines.

NOTE

Direct Digital Controller

28 Direct Digital Controller fw 4.013 – Ed. 01/2013

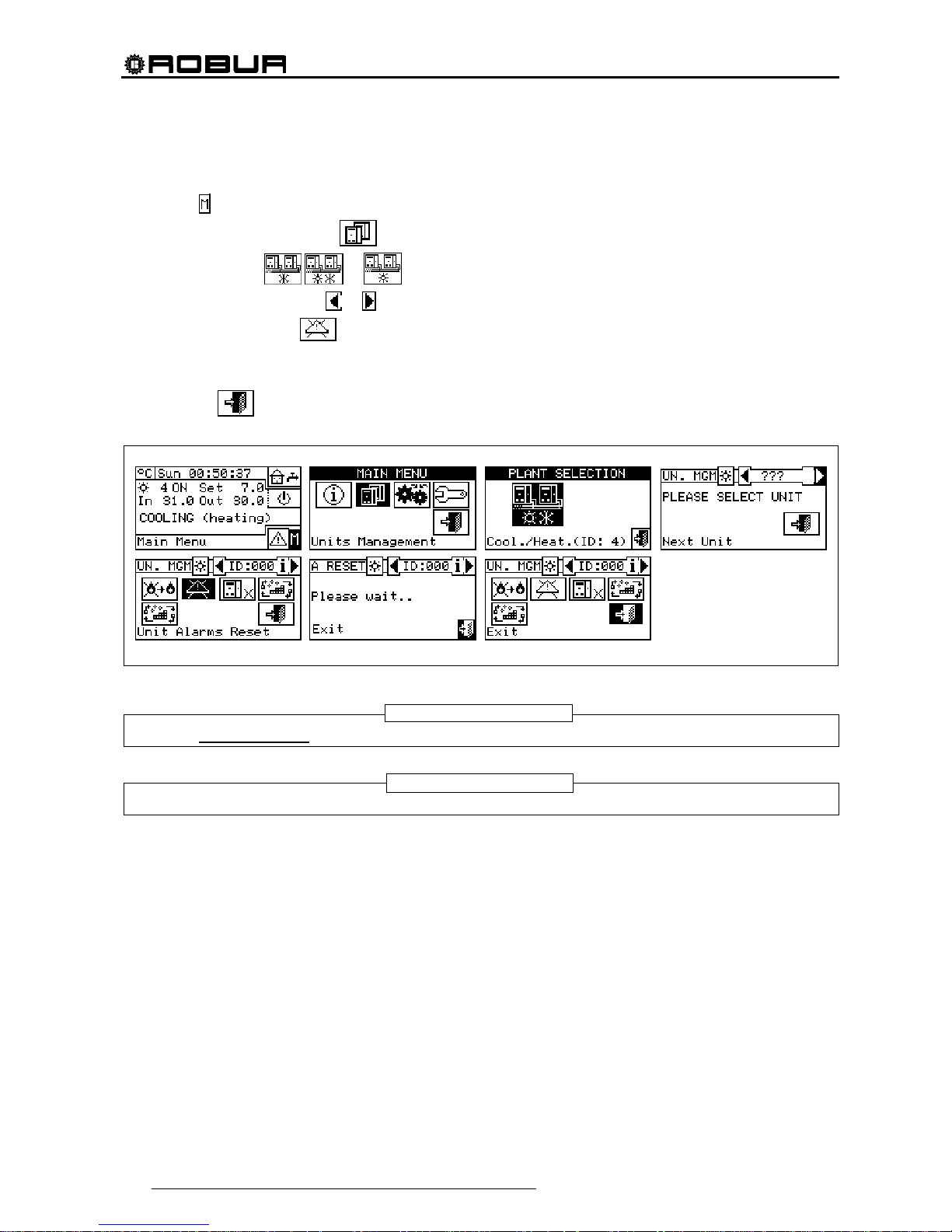

3.3.2 ERROR RESET

To carry out an error reset, follow the instructions below:

1 - Select

from the initial screen to gain access to the main menu.

2 - From the main menu, select

.

3 - Select the plant (

, or if the DDC is configured to manage only one hot/cold plant).

4 - Select the machine, using

or . The unit’s identification number is shown between the arrows.

5 - Position the cursor on

and press the knob to carry out an error reset.

6 - Wait for the operation to be performed. If the operation is successful, the message “OK” appears on the

display.

To exit, select

.

The reset does not perform a flame control unit reset.

It is not possible to reset errors on third party machines.

NOTE

NOTE

Direct Digital Controller

Direct Digital Controller fw 4.013 – Ed. 01/2013 29

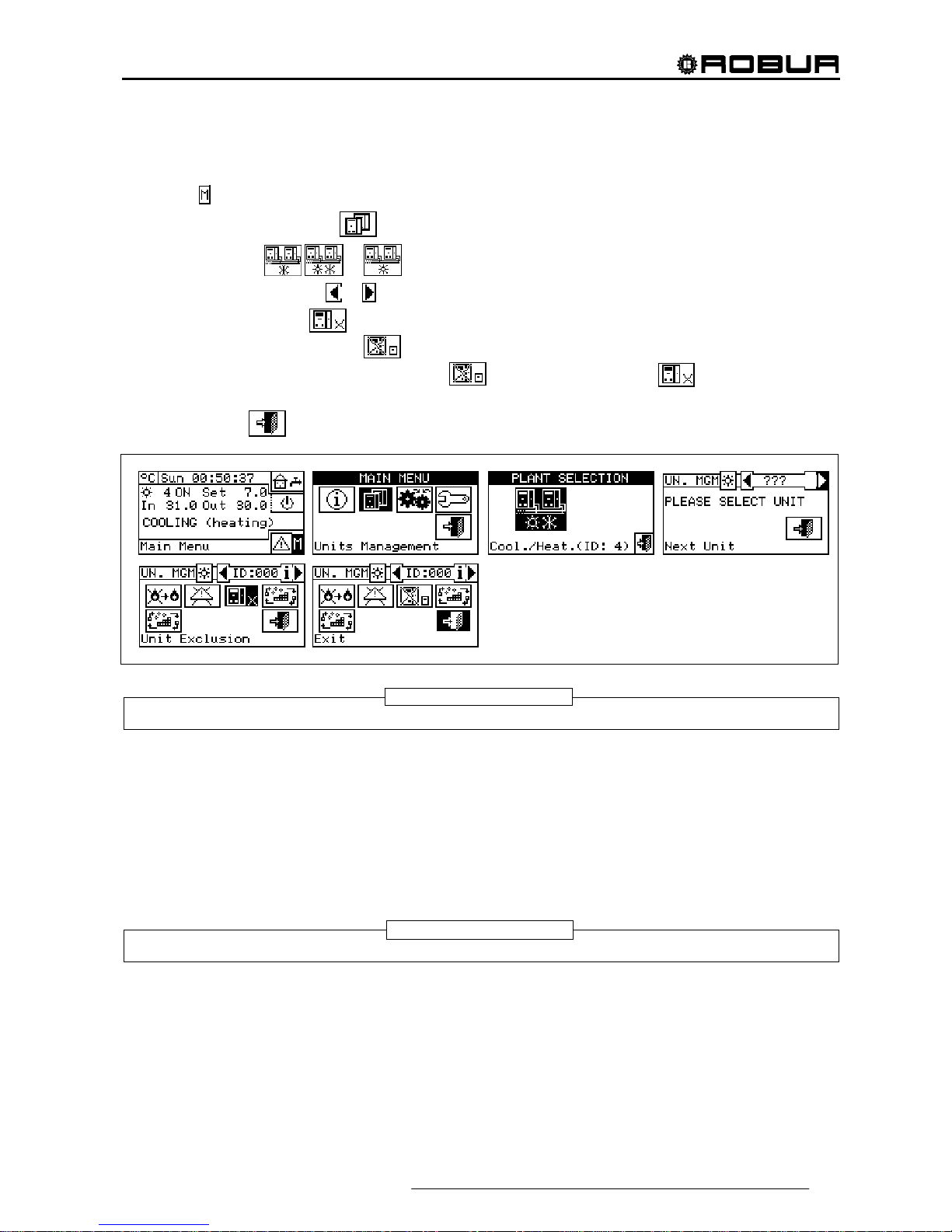

3.3.3 UNIT EXCLUSION

To exclude the unit from the plant, follow the instructions below:

1 - Select

from the initial screen to gain access to the main menu.

2 - From the main menu, select

.

3 - Select the plant (

, or if the DDC is configured to manage only one hot/cold plant).

4 - Select the machine, using

or . The unit’s identification number is shown between the arrows.

5 - Position the cursor on

and press the knob to exclude the machine from the plant. Wait for the

operation to be performed. The

symbol indicates that the machine is now excluded from the plant.

To include the unit in the plant again, select

and press the knob. The symbol indicates that

the machine is now excluded from the plant.

6 - To exit, select

.

When a machine is excluded, the DDC considers it unusable. In addition, any anomalies are not signalled.

3.3.4 EDIT SET PARAMETERS (Technical Assistance Centres only)

This option allows the modification of some parameters that are set on the machine’s built-in electronic boar d.

The Direct Digital Controller communicates with the machine’s electronic board and receives information

regarding the parameters set on it. Via the DDC, the operator may modify some of these parameters and

transmit them again to the machine’s built-in electronic board.

The option is protected by an installer password.

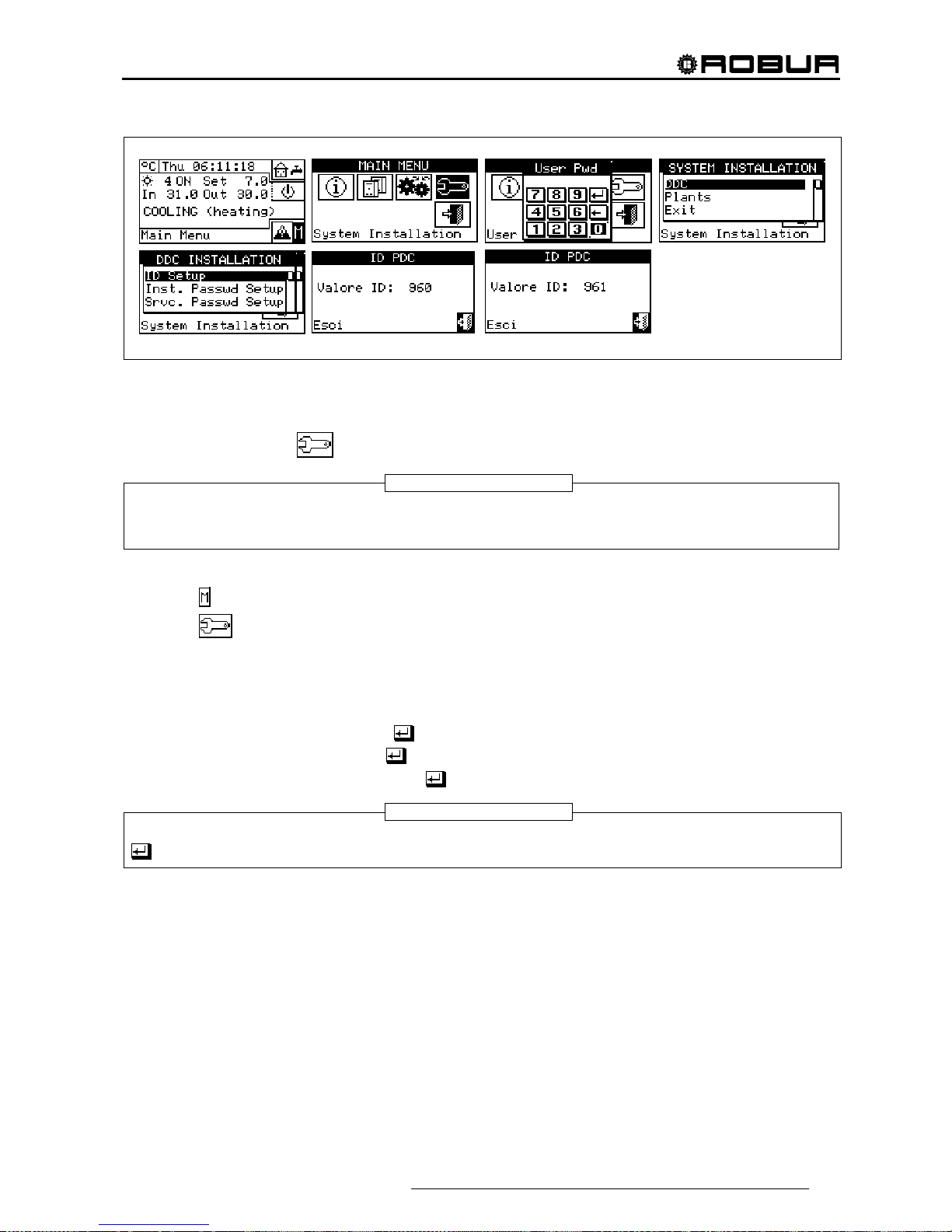

The figure below shows an example of a modification to the parameters, and the sequence of operations to

perform in relation to the screens shown on the display.

It is not possible to carry out the "modify set parameters" operation on third party machines.

NOTE

NOTE

Direct Digital Controller

30 Direct Digital Controller fw 4.013 – Ed. 01/2013

3.3.5 SET DEFAULT PARAMETERS (Technical Assistance Centres only)

The option allows the user to restore, via the DDC, the factory settings memorised on the built-in electronic

board of the machine.

The Direct Digital Controller communicates with the electronic board and receives information regarding the

default parameters (factory settings) set on it (warning: the default parameters are read-only, i.e. cannot be

modified). Via the DDC, the operator may modify some of these parameters and transmit them again to the

machine’s electronic board. The parameters transmitted are used by the board for operation of the unit but this

transmission will have no influence on the default settings memorised on board the machine.

The option is protected by an installer password.

It is not possible to carry out the "set default parameters" operation on third party machines.

NOTE

Direct Digital Controller

Direct Digital Controller fw 4.013 – Ed. 01/2013 31

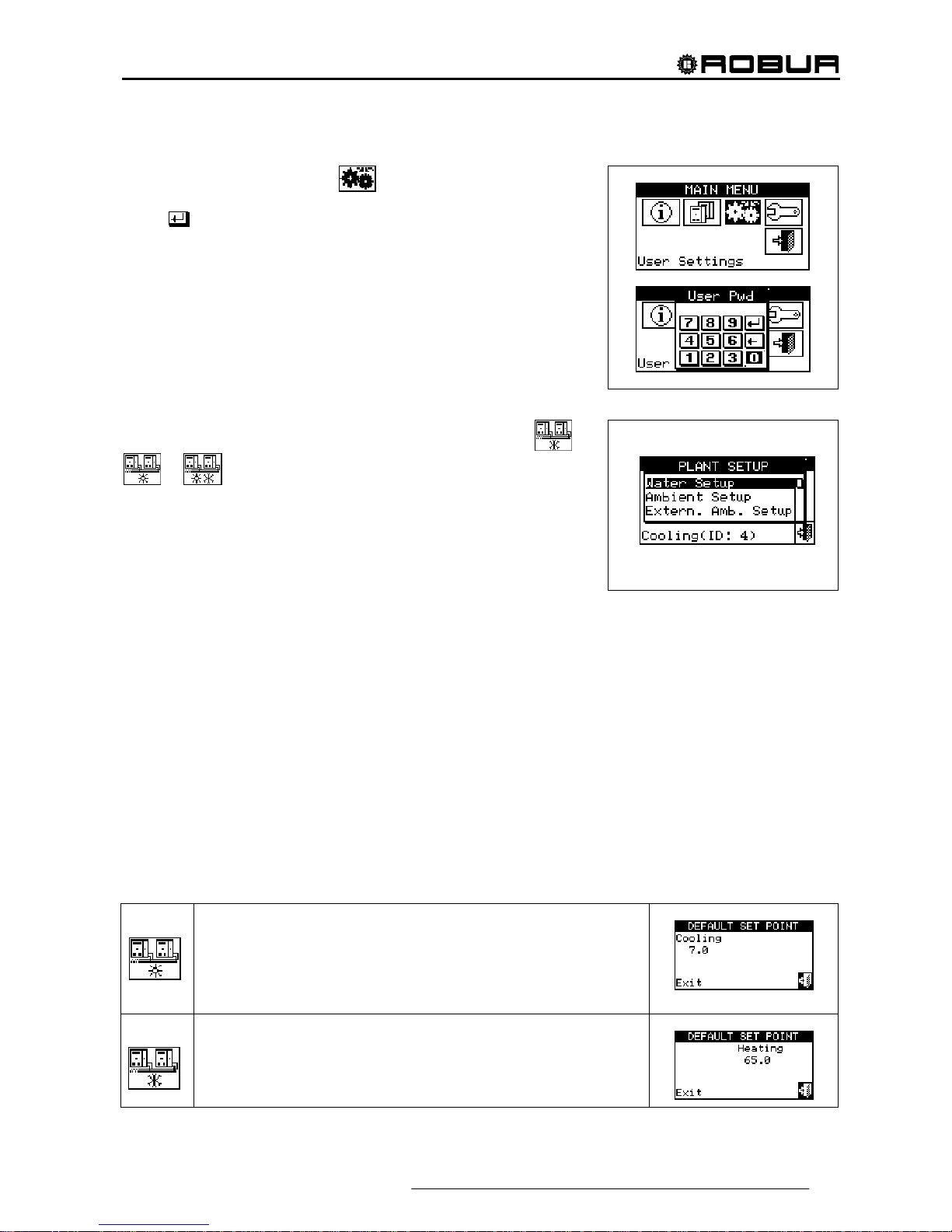

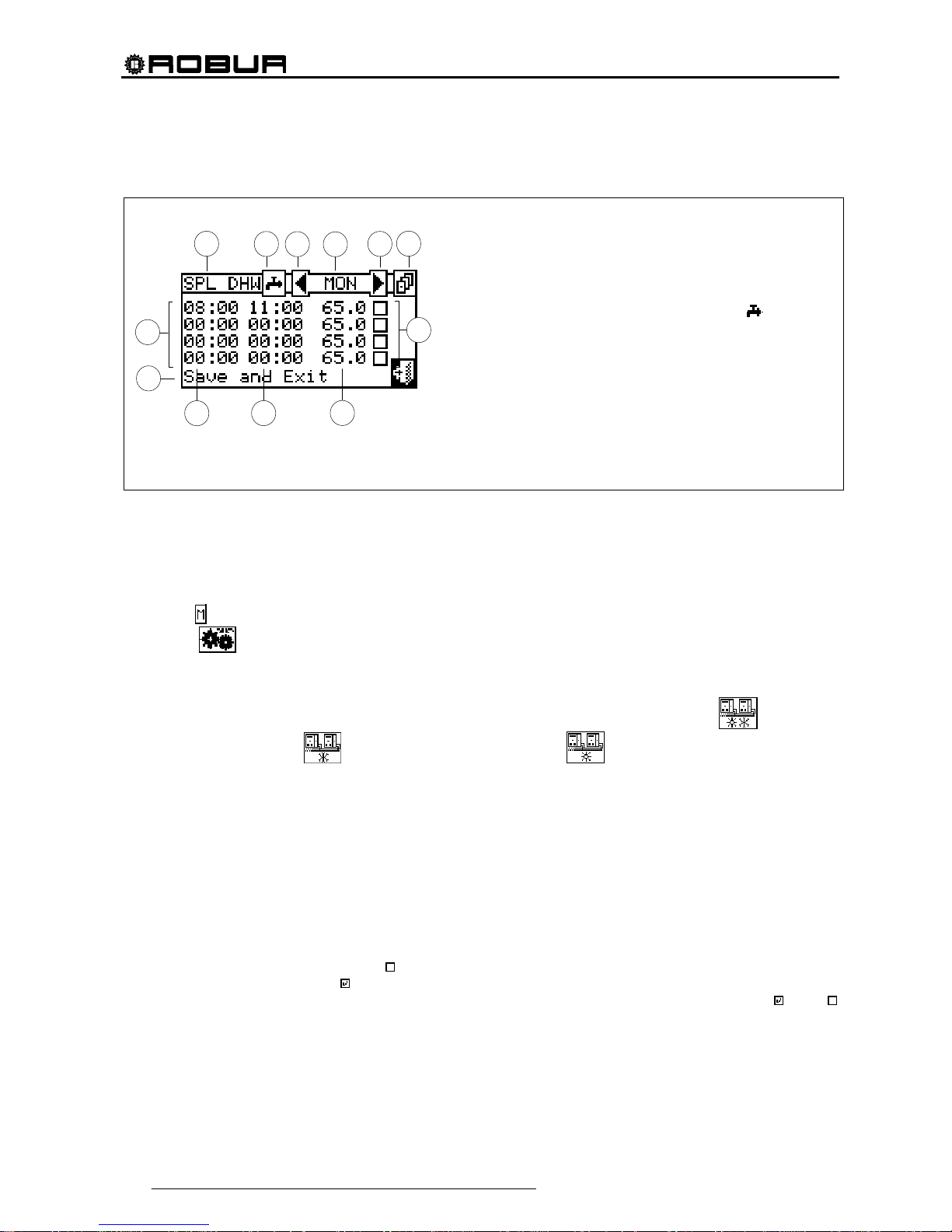

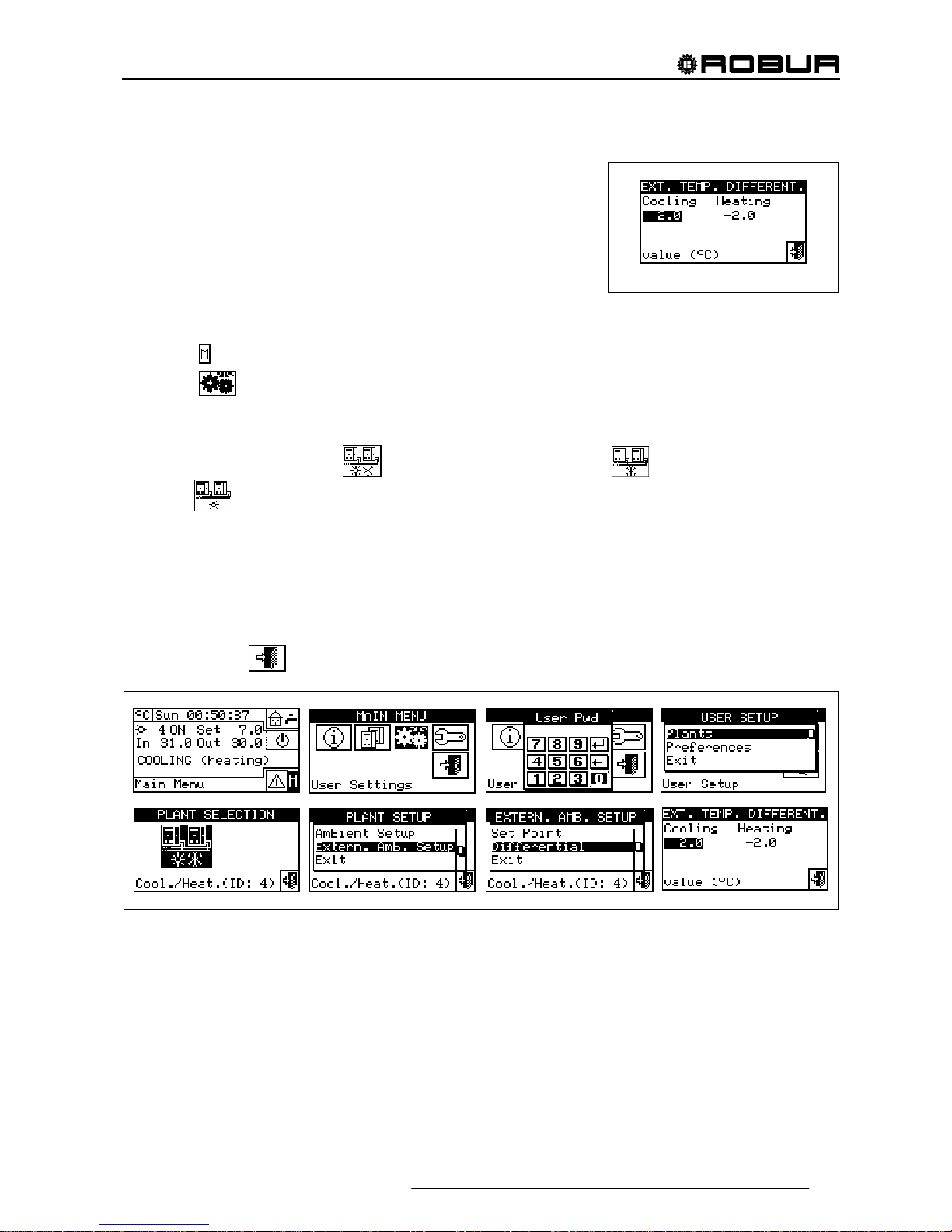

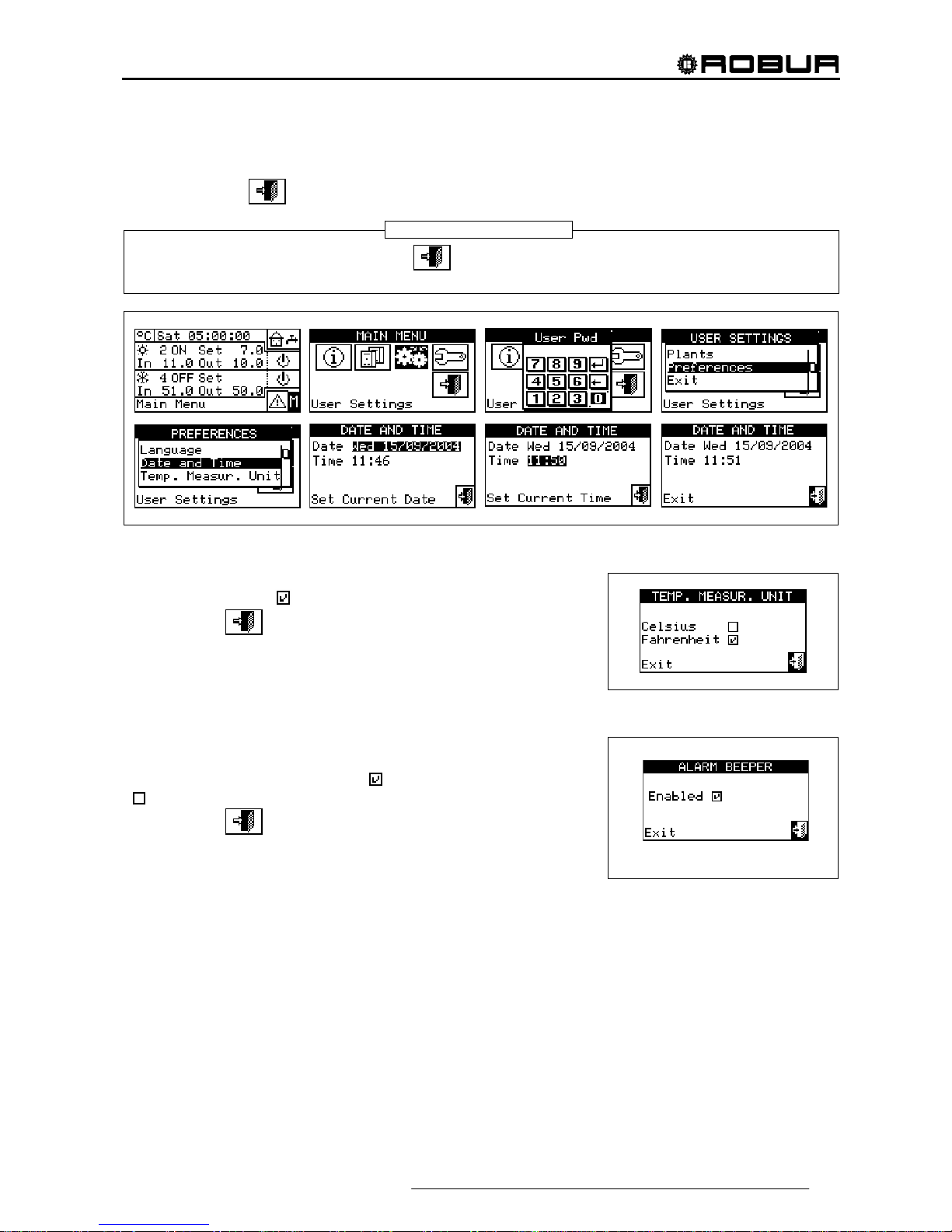

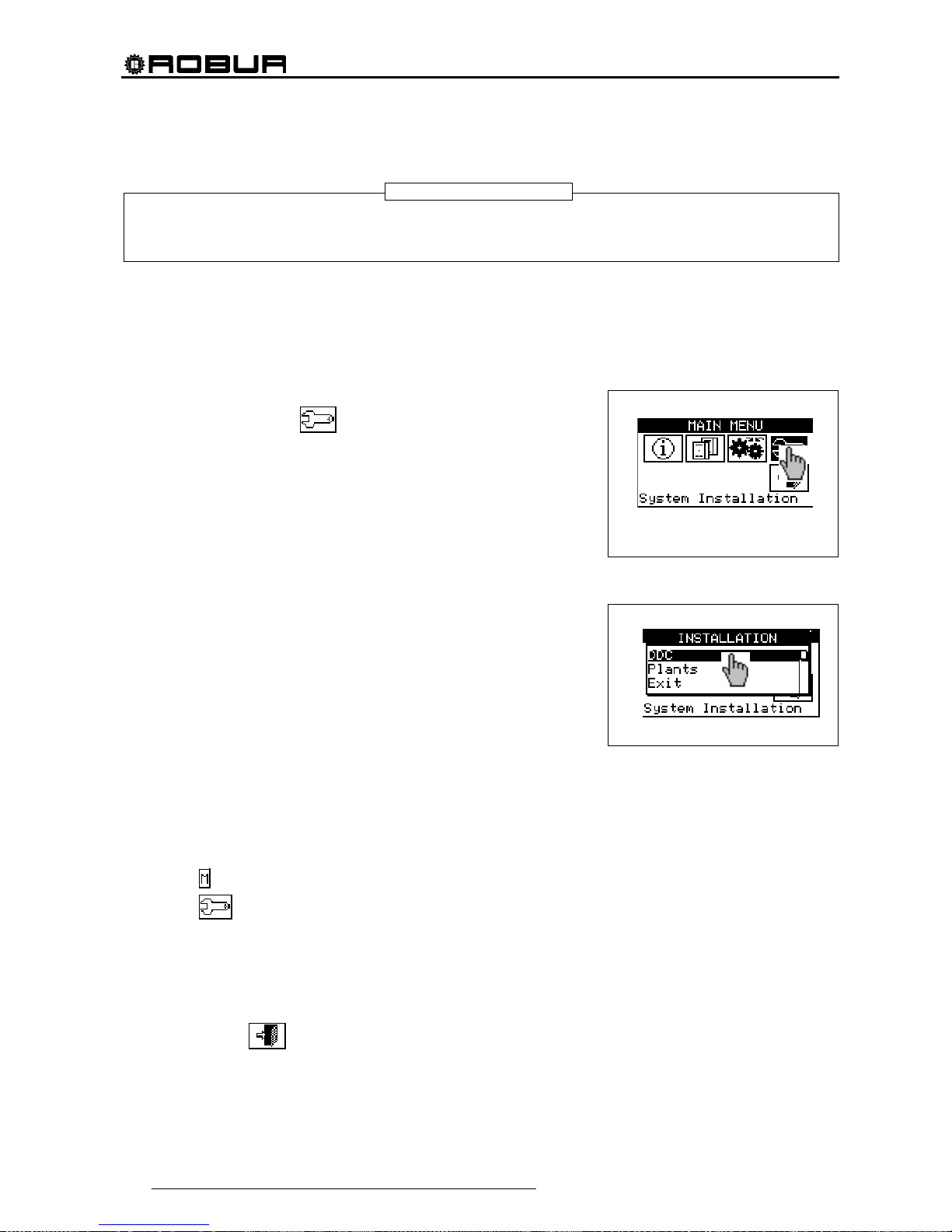

3.4 USER SETTINGS

From the main menu, select . If requested, enter the user

password on the numerical keypad that appears on the screen and then

select

to confirm. If the wrong password is entered, the display

reverts to the main menu screen.

Accessing this menu allows the following parameters to be

consulted/set:

3.4.1 plants

3.4.2 PREFERENCES

3.4.3 Exit

3.4.1 PLANTS

PLANTS Select “Plants” from the dropdown menu. Select the

or

or plant in function of the type of configured plant. Access

is gained to a scroll menu containing the parameters that can be set:

3.4.1.1 Water Setup

3.4.1.2 Ambient Setup

3.4.1.3 External ambient setup

3.4.1.1 Water Setup

The following paragraphs describe the operating logic of the Direct Digital Controller to allow the operator to

set the water parameters correctly, such as set point temperature, differential, and number of steps.

3.4.1.1.1 Cooling/Heating

The options that may be set in this menu, for the cooling/heating services, are:

3.4.1.1.1.1 Default set point

3.4.1.1.1.2 Enabling of climatic curve

3.4.1.1.1.3 General water T timer

3.4.1.1.1.4 Partial water T timer

3.4.1.1.1.1. Default set point

This screen displays the water set point temperatures for cooling and/or heating operation according to the

type of plant configured.

Plant for production of chilled water. The set point represents the desired

temperature for water leaving the machine if, in the System installation,

thermostating has been set on the outlet water; if the opposite applies, the

temperature set point represents the desired temperature for the machine’s inlet

water.

Plant for production of hot water. The set point represents the desired temperature

for water leaving the machine if, in the System installation, thermostating has been

set on the outlet water; if the opposite applies, the temperature set point represents

the desired temperature for the machine’s inlet water.

Direct Digital Controller

32 Direct Digital Controller fw 4.013 – Ed. 01/2013

Plant for alternate production of hot or chilled water.

Cooling set point: water temperature when the plant produces chilled water.

Heating set point: water temperature when the plant produces hot water.

The two set points described above may refer to outlet or inlet water, according to

the settings, which may be different from one another, configured in the installer

menu.

Configuring set point temperature.

In order to set the set point temperature for the heating and/or cooling services, follow the instructions below:

1 - Select

from the initial screen to gain access to the main menu.

2 - Select

to access the “User settings” menu.

3 - If requested, enter the user password on the numerical keypad that appears on the display.

4 - Select “Plants” from the drop-down menu.

5 - Select the plant for which the set point temperature is to be set:

for two-line cooling/heating plants,

for hot water production plants, or for chilled water production plants.

6 - Select “Water setup” from the drop-down menu.

7 - Select “Cooling” or “Heating” from the drop-down menu

8 - Select “Default set point” from the drop-down menu.

9 - Position the cursor on the temperature value to modify: for cold-only plants

, only the value of the

set point temperature in cooling mode appears (Cooling). For hot-only plants

, only the value of the

set point temperature in heating mode appears (Heating).For two-line hot-cold plants

, set point

temperatures for both heating and cooling mode appear (Cooling and Heating).

10 - Press the knob to allow the change of the selected value.

11 - Turn the knob to modify the value.

12 - Press the knob to confirm the set value.

13 - To exit, select

.

The default set point is used when the general water T timer cycles are disabled. Otherwise the set point

used at any given moment is that defined in the active water T timer cycle (see Paragraph 3.4.1.1.1.3 "General water T timer" ).

NOTE

Direct Digital Controller

Direct Digital Controller fw 4.013 – Ed. 01/2013 33

3.4.1.1.1.2. Enabling of climatic curve

To enable the climatic curves for the heating and/or cooling services, follow the instructions given:

1 - Select

from the initial screen to gain access to the main menu.

2 - Select

to access the “User settings” menu.

3 - If requested, enter the user password on the numerical keypad that appears on the display.

4 - Select “Plants” from the drop-down menu.

5 - Select the plant for which the climatic curve is to be enabled:

for two-line cooling/heating plants,

for hot water production plants, or for chilled water production plants.

6 - Select “Water setup” from the drop-down menu.

7 - Select “Cooling” or “Heating” or "Cool./Heat" from the drop-down menu.

8 - Select "Enab. Clim. Curve" from the drop down menu. Turn the knob and select the desired item.

9 - Turn the knob and select the desired item. Press the knob to enable/disable the climatic curve. The

symbol indicates that the climatic curve is enabled; the symbol indicates that the climatic curve has

been disabled.

10 - To exit, select

.

The climatic curve can only be enabled if an operating mode has been chosen that allows it (see paragraph

“On/off command configuration” on page 103).

If the climatic curve is enabled, the water set point is variable and is calculated by the DDC according to the

set climatic curve, the external temperature and the requested room temperature.

If the climatic curve is disabled, the corresponding default water set point will be used (see paragraph

3.4.1.1.1.1).

NOTE

Direct Digital Controller

34 Direct Digital Controller fw 4.013 – Ed. 01/2013

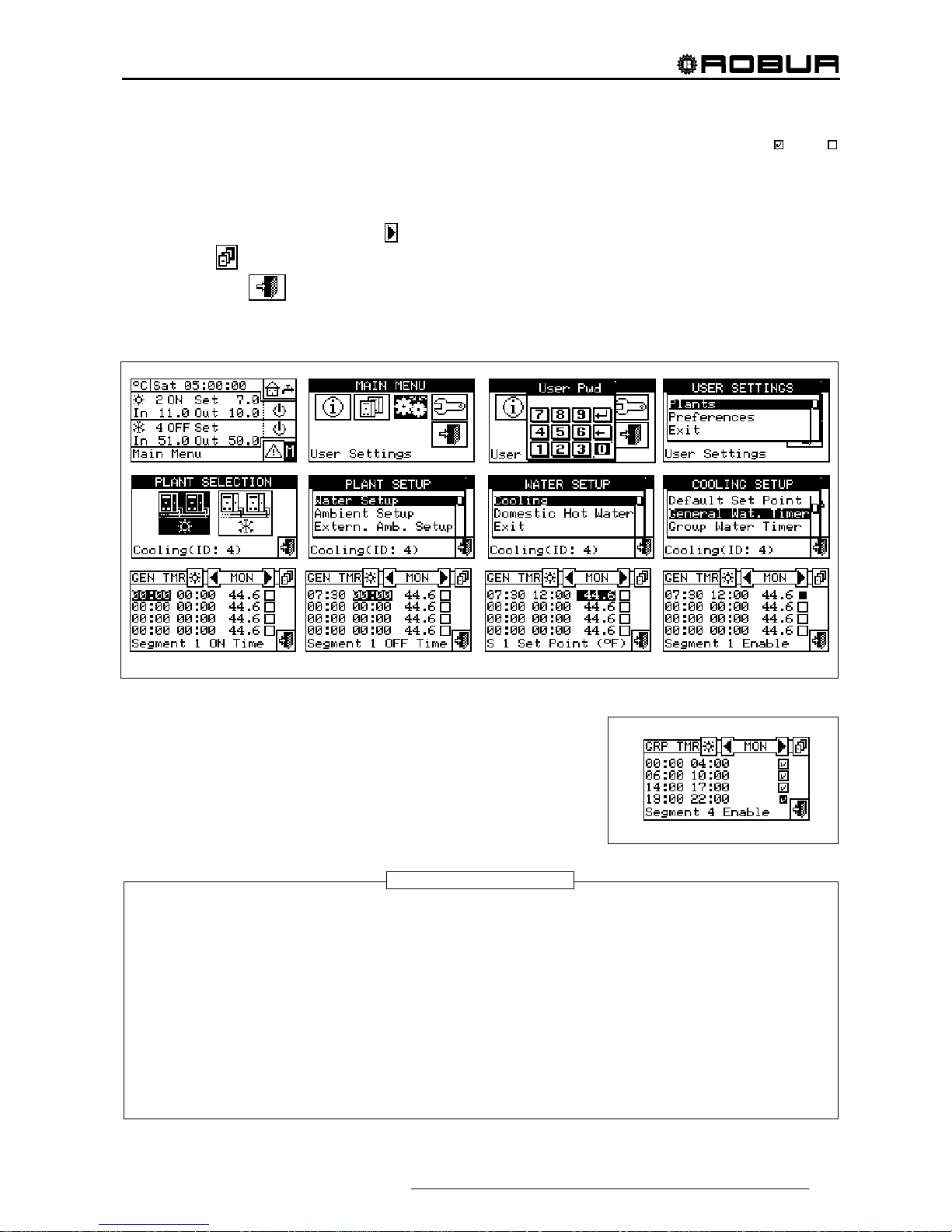

3.4.1.1.1.3. General water T timer

This option allows the user to manage the “General water T timer” operating mode of the plant as concerns

the heating and cooling services. It allows the user to select up to 4 plant activation time intervals, within which

it is possible to define a water set point temperature. Up to 4 daily water T timer cycles can be programmed, to

which it is possible to associate 4 different temperature levels. It is possible to enable/disable each water T

timer cycle programmed without cancelling it by operating on the

fields as described below. This

programming may be different for each of the seven days of the week and for the cooling and heating

services.

Programming general water T timer cycles

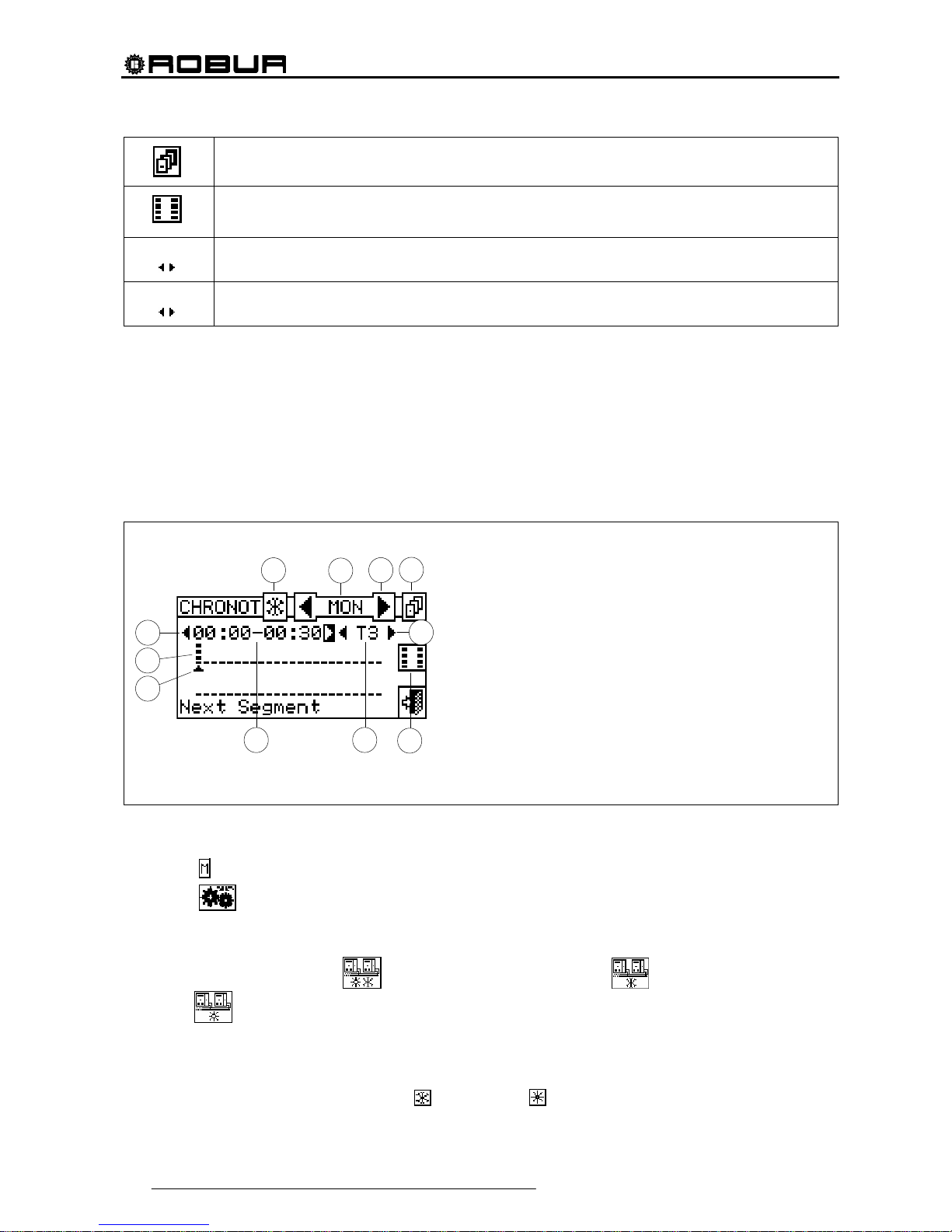

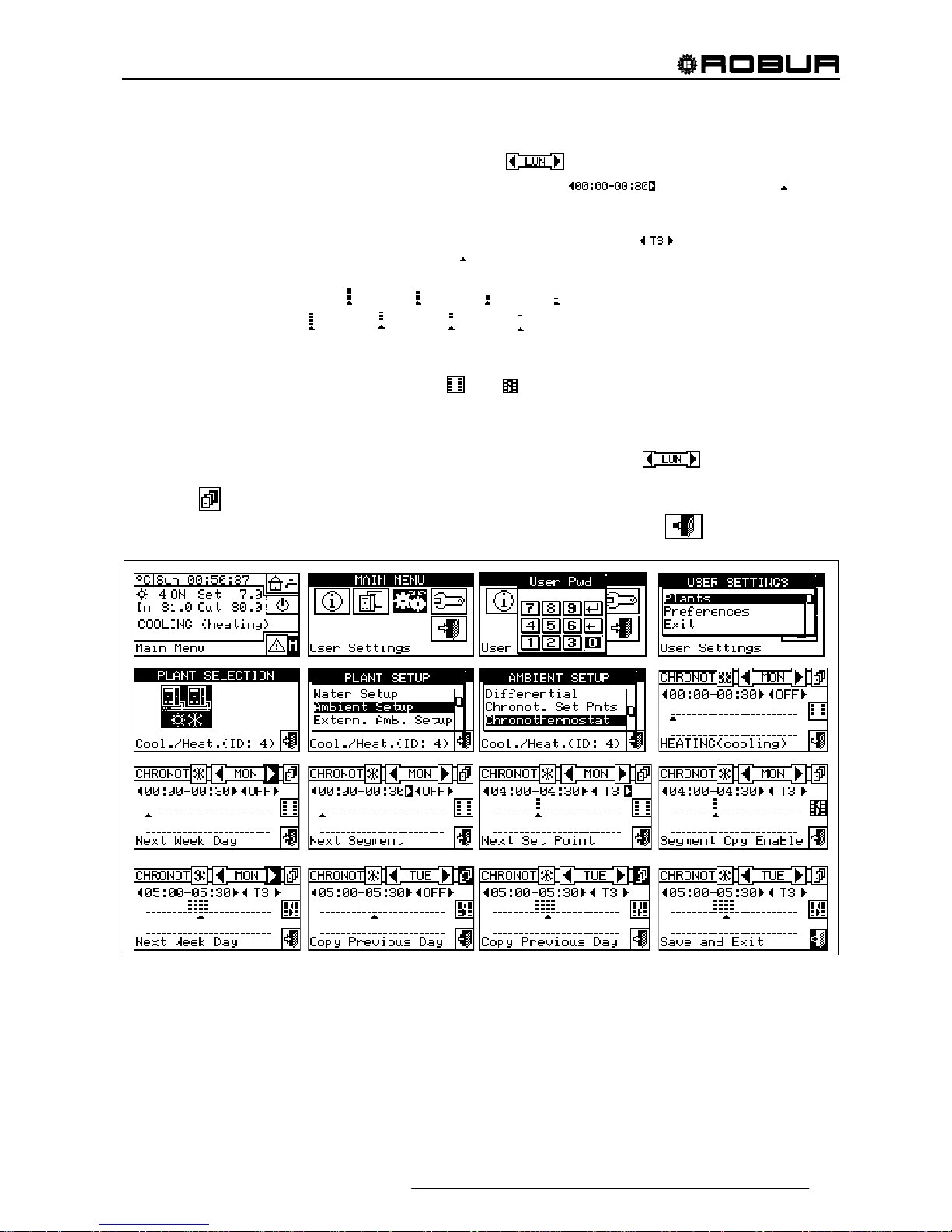

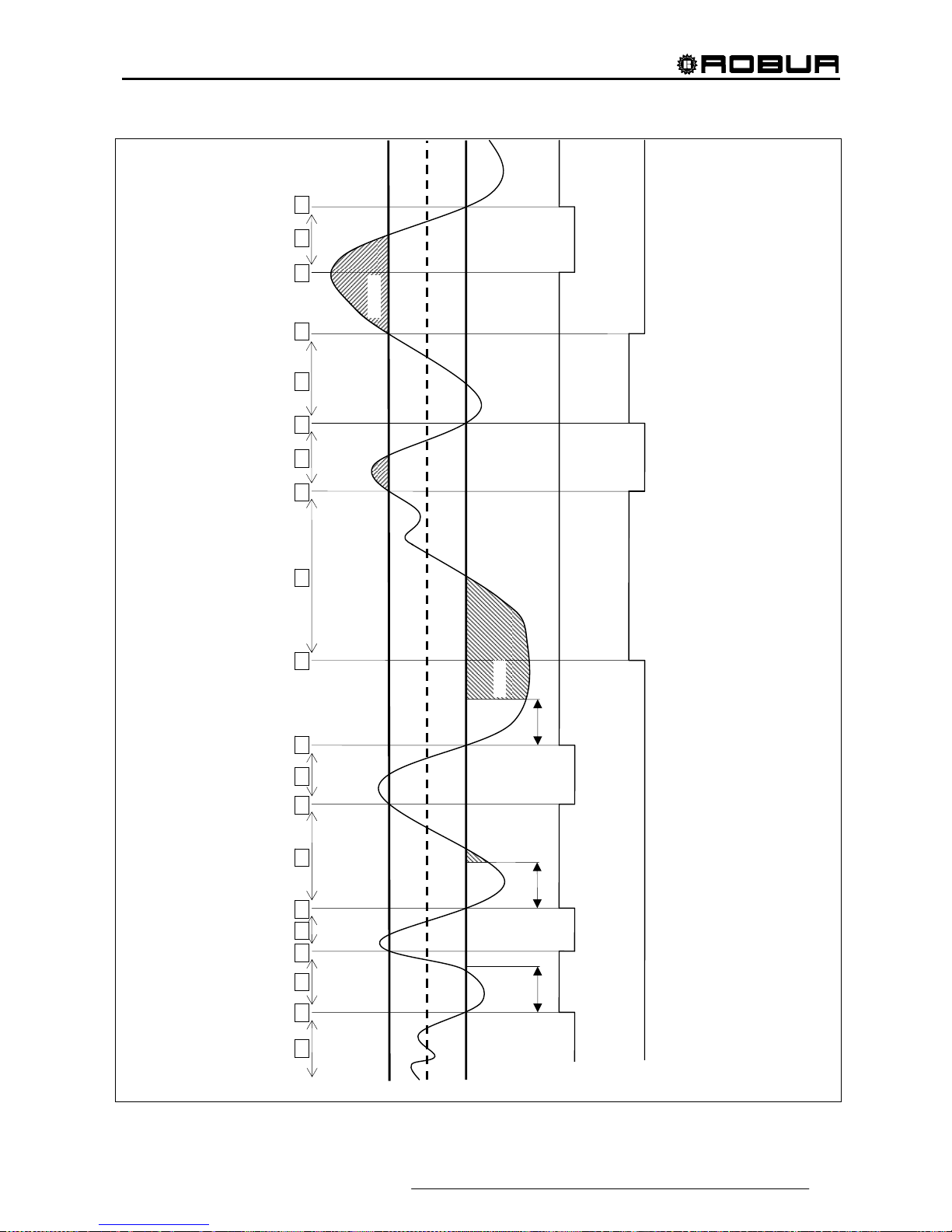

Figure 7 shows how the DDC’s display appears while the general water T timer cycles are programmed.

Figure 7 – PROGRAMMING SCREEN FOR GENERAL WATER T TIMER CYCLES

For plants managed by several Direct Digital Controllers, it is only possible to program the General water T

timer cycles from the DDC designated as the Master DDC.

In order to program the switching-on T timer cycles for a typical day, follow the instructions below:

1. Select

from the initial screen to gain access to the main menu.

2. Select

to access the “User settings” menu.

3. If requested, enter the user password on the numerical keypad that appears on the display.

4. Select “Plants” from the drop-down menu.

5. Select the plant for which the partial water T timer cycles are to be programmed:

for two-line

cooling/heating plants,

for the heating plant, for the cooling plant.

6. Select “Water setup” from the drop-down menu.

7. Select “Cooling” or “Heating” from the drop-down menu

8. Select “General Water Timer” from the drop-down menu.

9. Position the cursor on the activation time of the first water T timer cycle and press the knob. Turn the

knob to select the activation time of the first timer cycle and press the knob to confirm. The cursor moves

automatically to the deactivation time of the first timer cycle. Proceed in the same way to program the

deactivation time of the first timer cycle.

10. Set the water set-point temperature for the programmed timer cycle. Press the knob to modify the

temperature value once the cursor is positioned on the number. Turn the knob to modify the value. Press

the knob to confirm.

11. The cursor moves automatically to

for the activation of the timer cycle programmed. Press the knob to

enable the timer cycle. The symbol indicates that the timer cycle that has just been programmed has

KEY:

A Gene ral water T timer;

B T timer cycle switching –on time;

C Water T timer cycle switching-off time;

D Identification symbol of the system for which the water T timer

cycles are being programmed;

for the heating plant; for the

cooling plant. For two-line hot/cold systems it is a button that

allows the user to pass from programming one system to the

other;

E Day for which water T timer cycles are being programmed;

F Scroll arrows to change day;

G Button for copying previous day’s settings to current day;

H Checkbox for activation of programmed water T timer cycle;

I Set point temperature for the programmed period;

L Text describing the function highlighted by the cursor;

M Activation/deactivation times of water T timer cycles.

D

F

H

M

I

A

F

E

G

C

B

L

Direct Digital Controller

Direct Digital Controller fw 4.013 – Ed. 01/2013 35

been enabled. NOTE: a water T timer cycle may be disabled at any moment by pressing . The

symbol indicates that the water T timer cycle programmed has been disabled.

12. Proceed in the same way, repeating steps 9 – 10 - 11 for the programming of any further timer cycles

required.

13. Once the desired timer cycles have been programmed, it is possible to pass to the following day by

selecting the arrow at the top right

. The previous day’s program may be copied for the current day by

selecting

, or the water T timer cycles required for the new day may be programmed.

14. To exit, select

.

If a programming anomaly occurs, appropriate alert messages are displayed:

Water T timer cycle with zero (or “negative”) duration.

Water T timer cycle in conflict with another timer cycle.

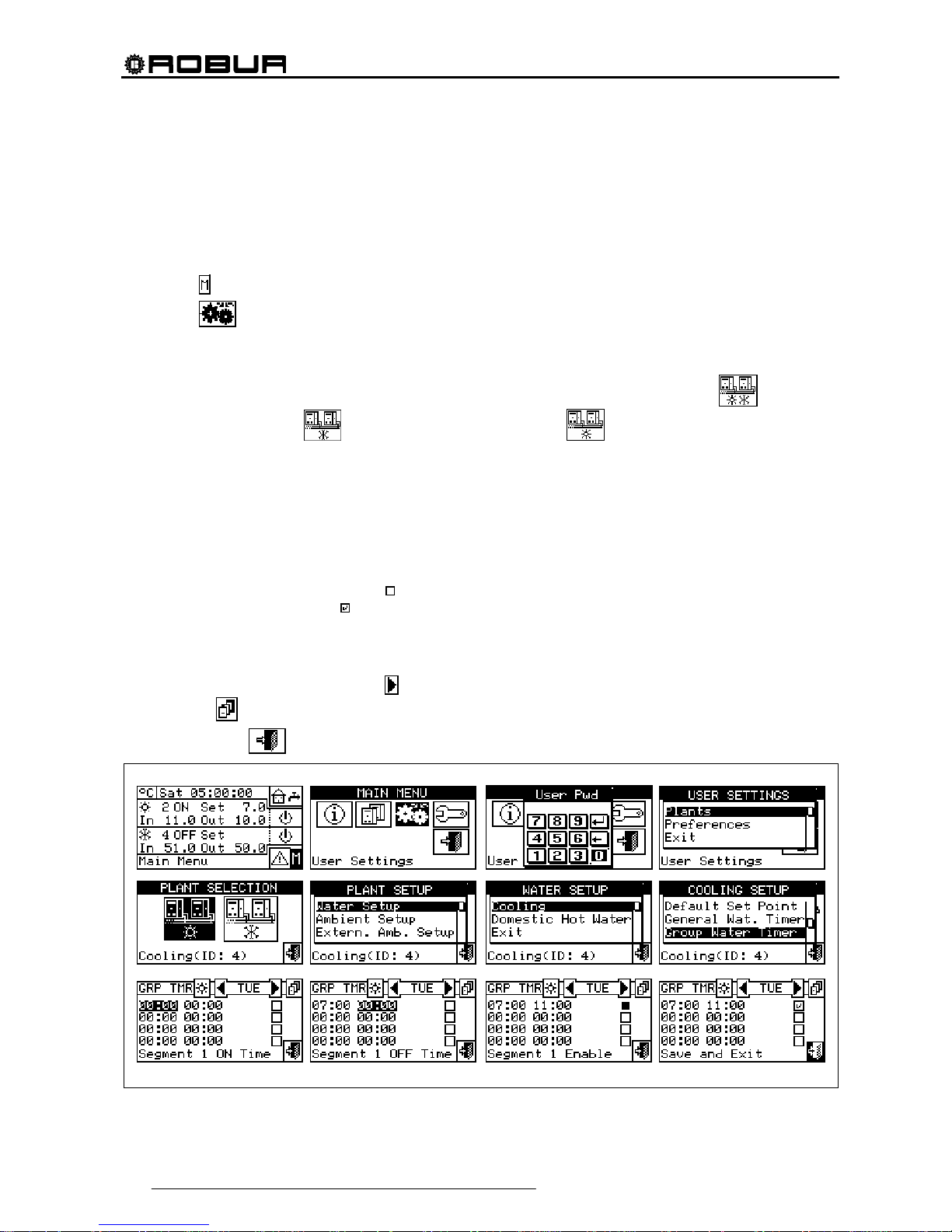

3.4.1.1.1.4. Partial water T timer

Partial water T timer This option may be programmed for Multi DDC

plants only, and allows the user to select up to 4 operating timer cycles

for each day of the week. This programming may be different for each of

the seven days of the week, and for the cooling and heating services.

The partial water T timers control only the machines directly managed by a specific DDC. Therefore,

according to the number of DDCs present in the plant, two situations may arise:

The plant is controlled by a single DDC. The DDC is defined as Master DDC by default and it is

possible to use ONLY the general water T timer.

The plant is controlled by more than one DDC (MASTER and SLAVE). In this case only one of the

DDCs installed is defined as the Master DDC. Via this DDC it is possible to program the general water T

timer to control the entire plant, and the partial water T timer to control the units that are managed

directly by the Master DDC. On the Slave DDCs it is possible to program the partial water T timer for the

purposes of controlling only the machines connected to the DDC in question. The group of machines

managed by any given DDC operates at the intersection between the general water T timer cycles and

partial water T timer cycles set on it. If, for example, a 0-10 general water T timer cycle has been set on

the Master DDC, and on a Slave DDC a 6-12 partial water T timer cycle, the units managed by the Slave

DDC may have ON status only between 6 and10.

WARNING

Direct Digital Controller

36 Direct Digital Controller fw 4.013 – Ed. 01/2013

Programming partial water T timer cycles

Programming of the partial water T timer cycles affects only plants managed by several Direct Digital

Controllers.

In this case, on the Master plant DDC it is possible to program the general water T timer cycles of the overall

plant and the partial water T timer cycles of all the units directly managed by the same Master DDC. On each

Slave DDC it is possible to program the partial water T timer cycles from that Slave DDC.

To program the water T timer cycles for a typical day, follow the instructions below.

1 - Select

from the initial screen to gain access to the main menu.

2 - Select

to access the “User settings” menu.

3 - If requested, enter the user password on the numerical keypad that appears on the display.

4 - Select “Plants” from the drop-down menu.

5 - Select the plant for which the partial water T timer cycles are to be programmed:

for two-line

cooling/heating plants,

for hot water production plants, or for chilled water production plants.

6 - Select “Water setup” from the drop-down menu.

7 - Select “Cooling” or “Heating” from the drop-down menu.

8 - Select “Group Water Timer” from the drop-down menu.

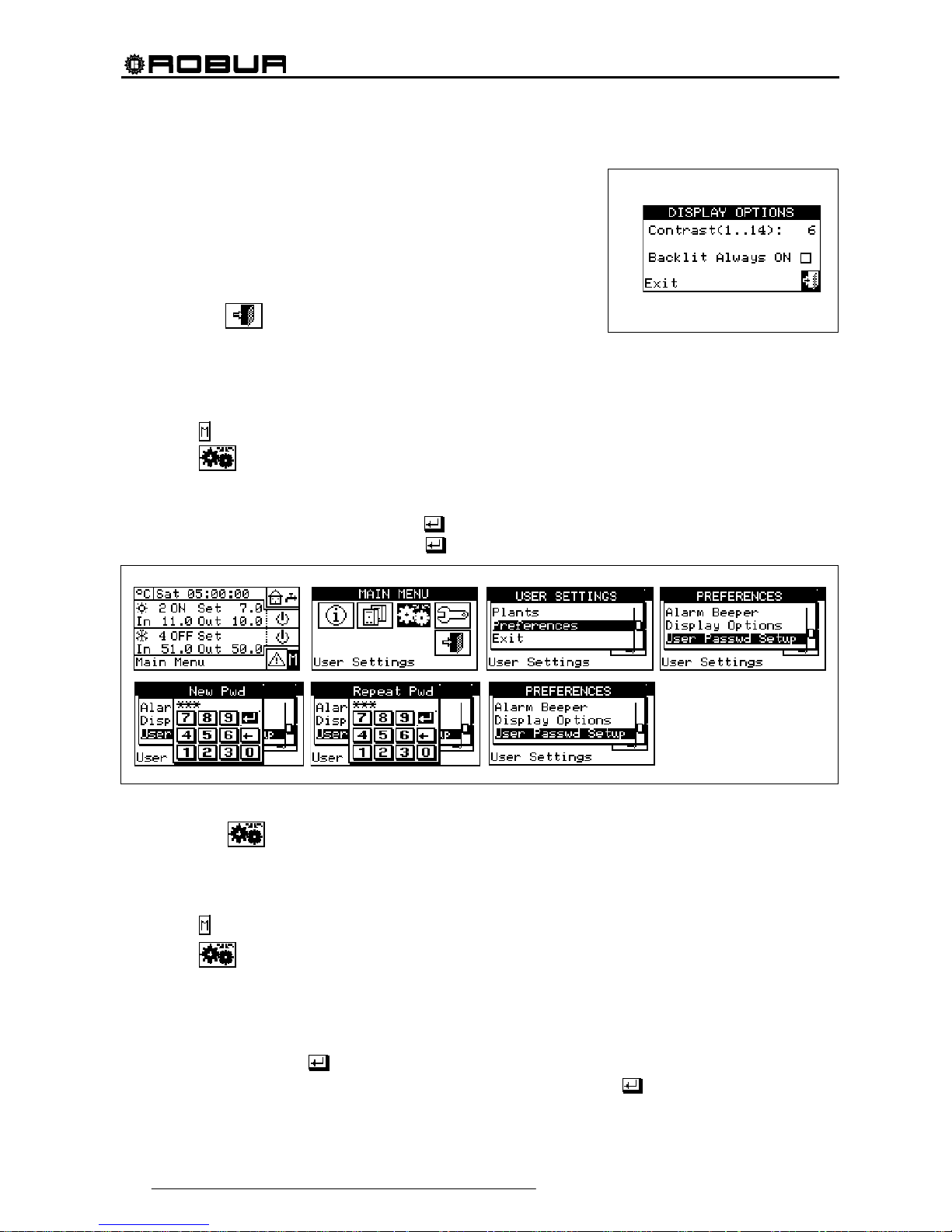

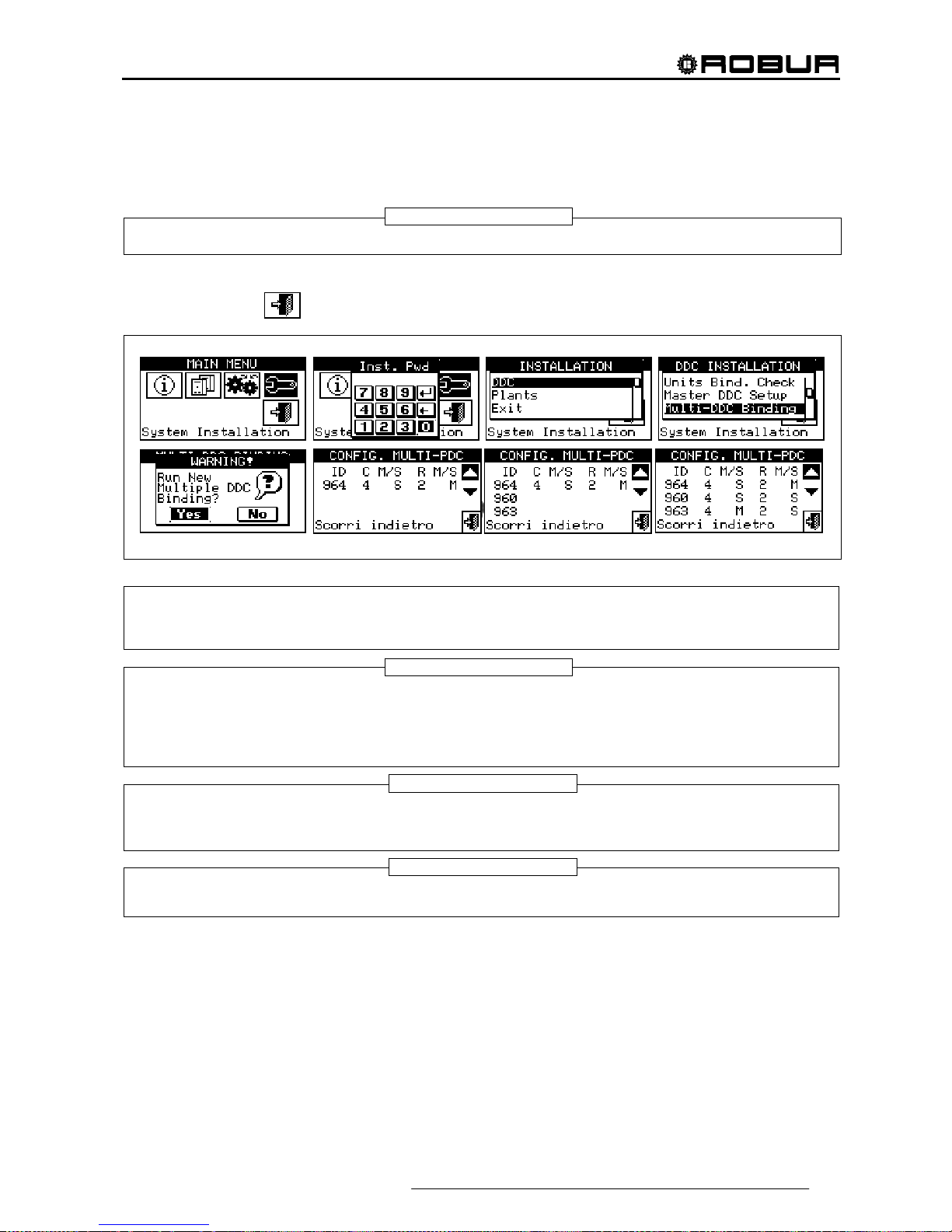

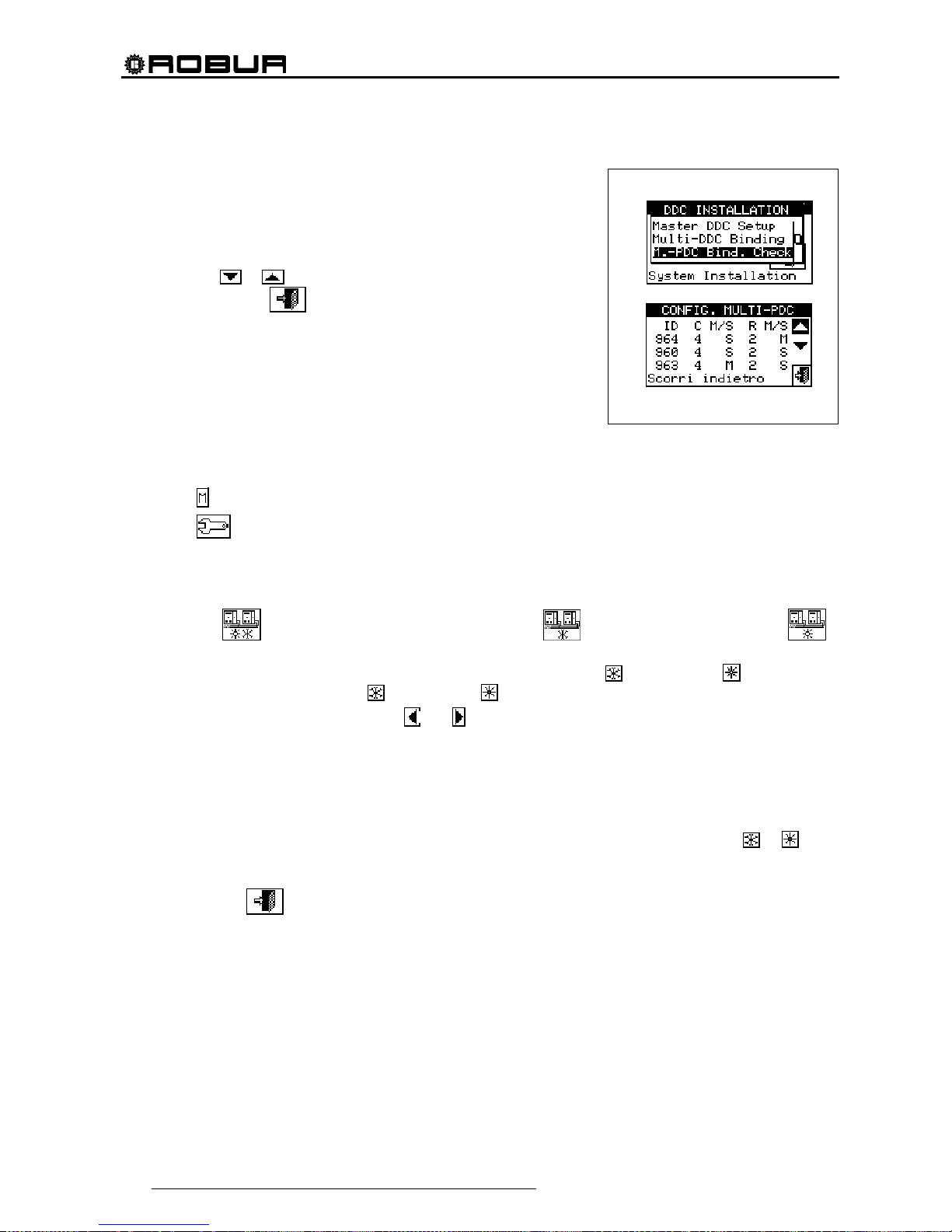

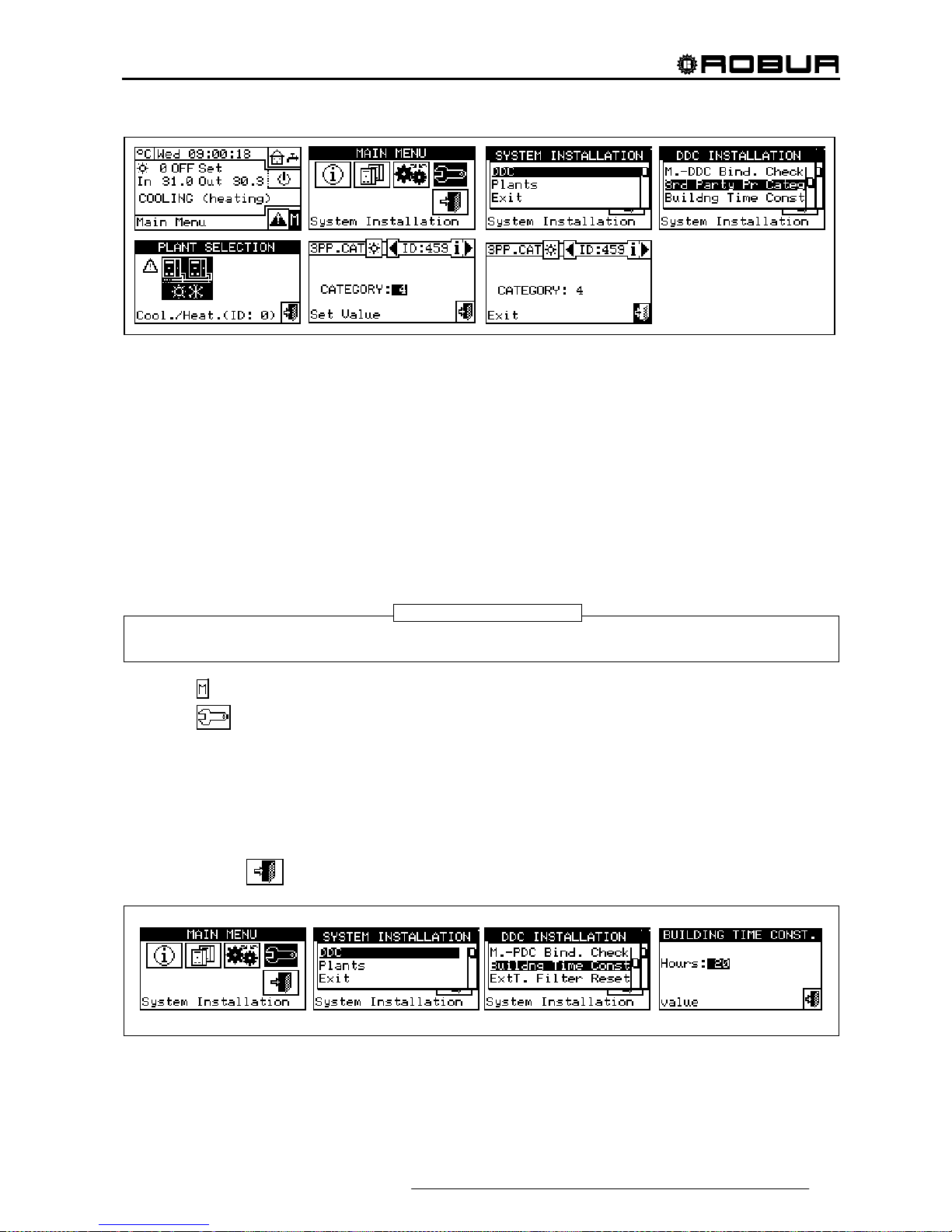

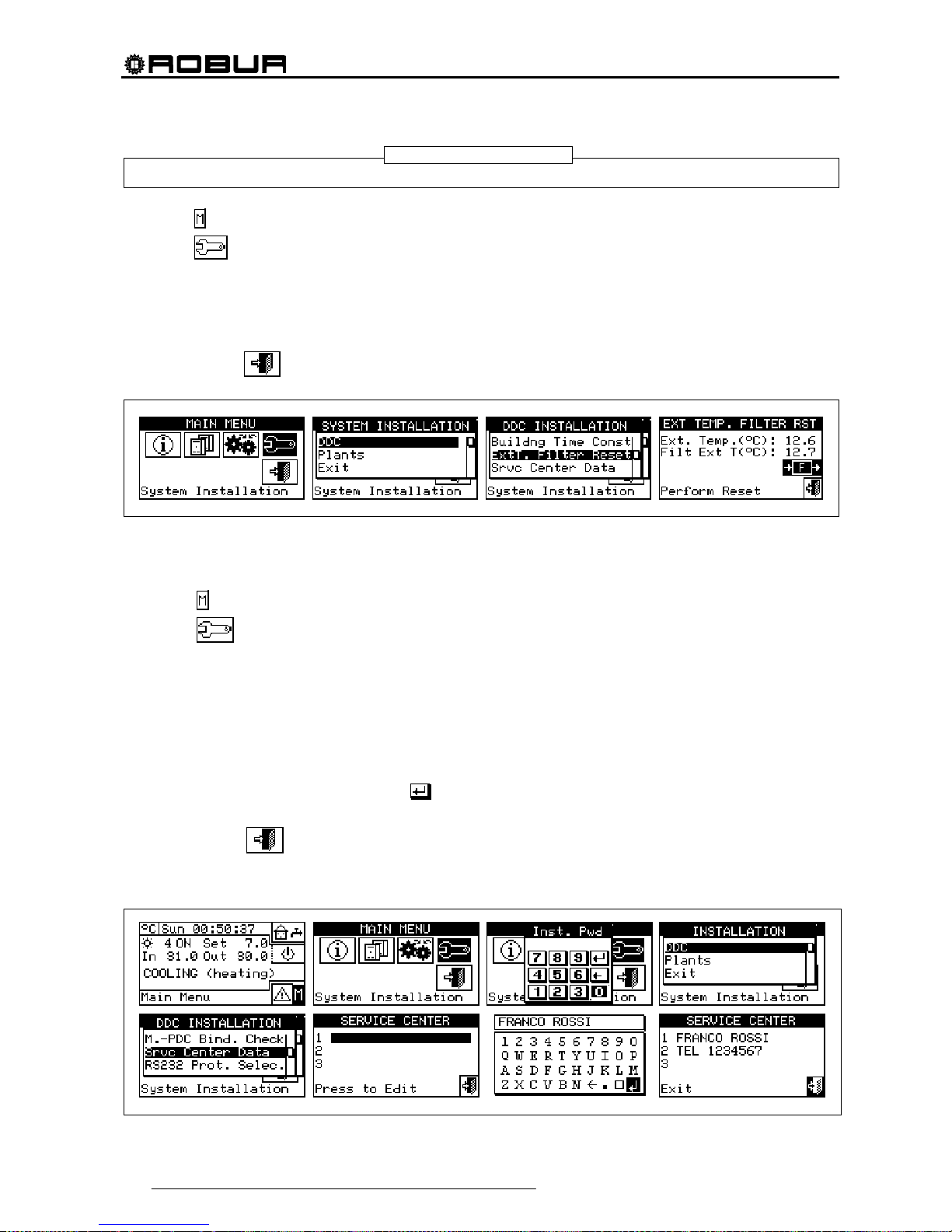

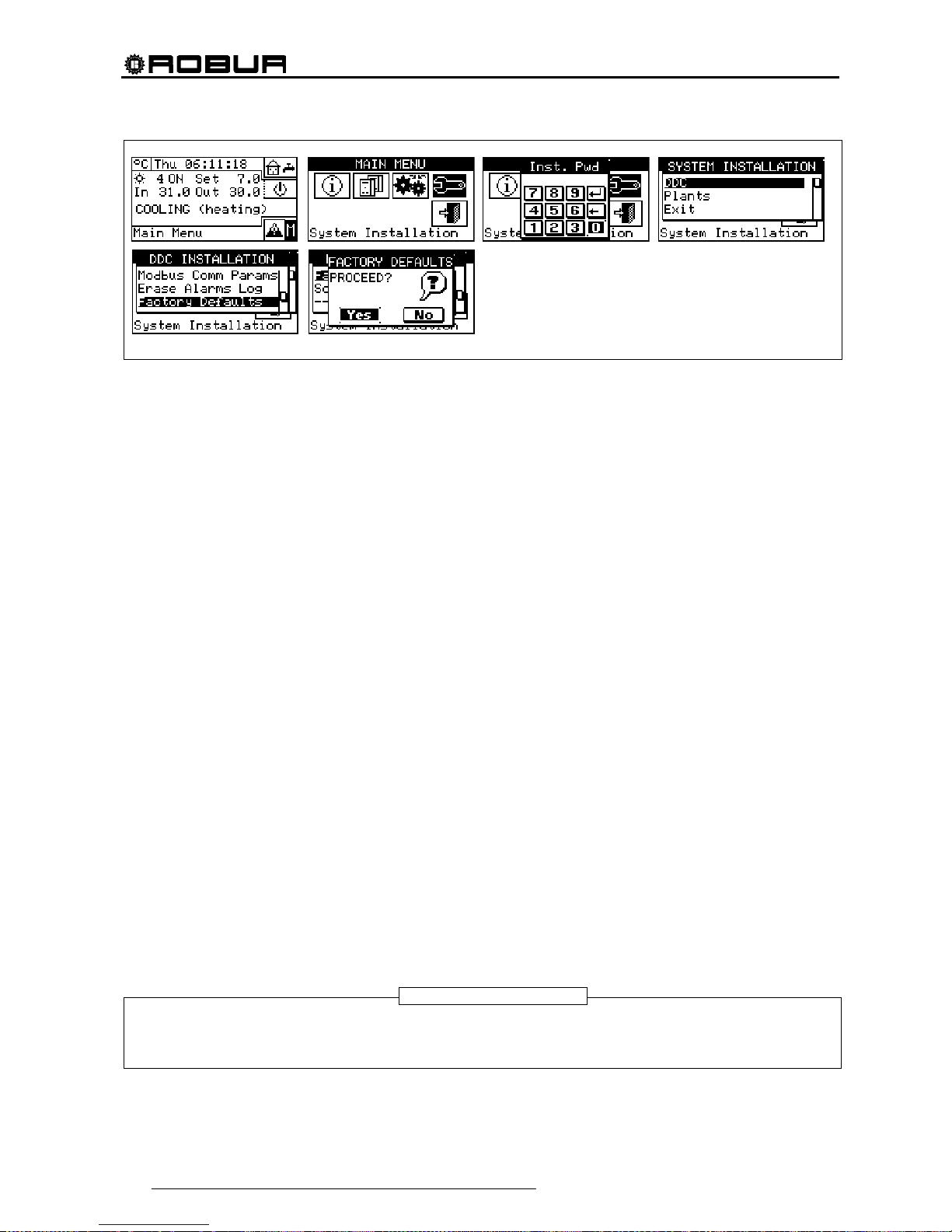

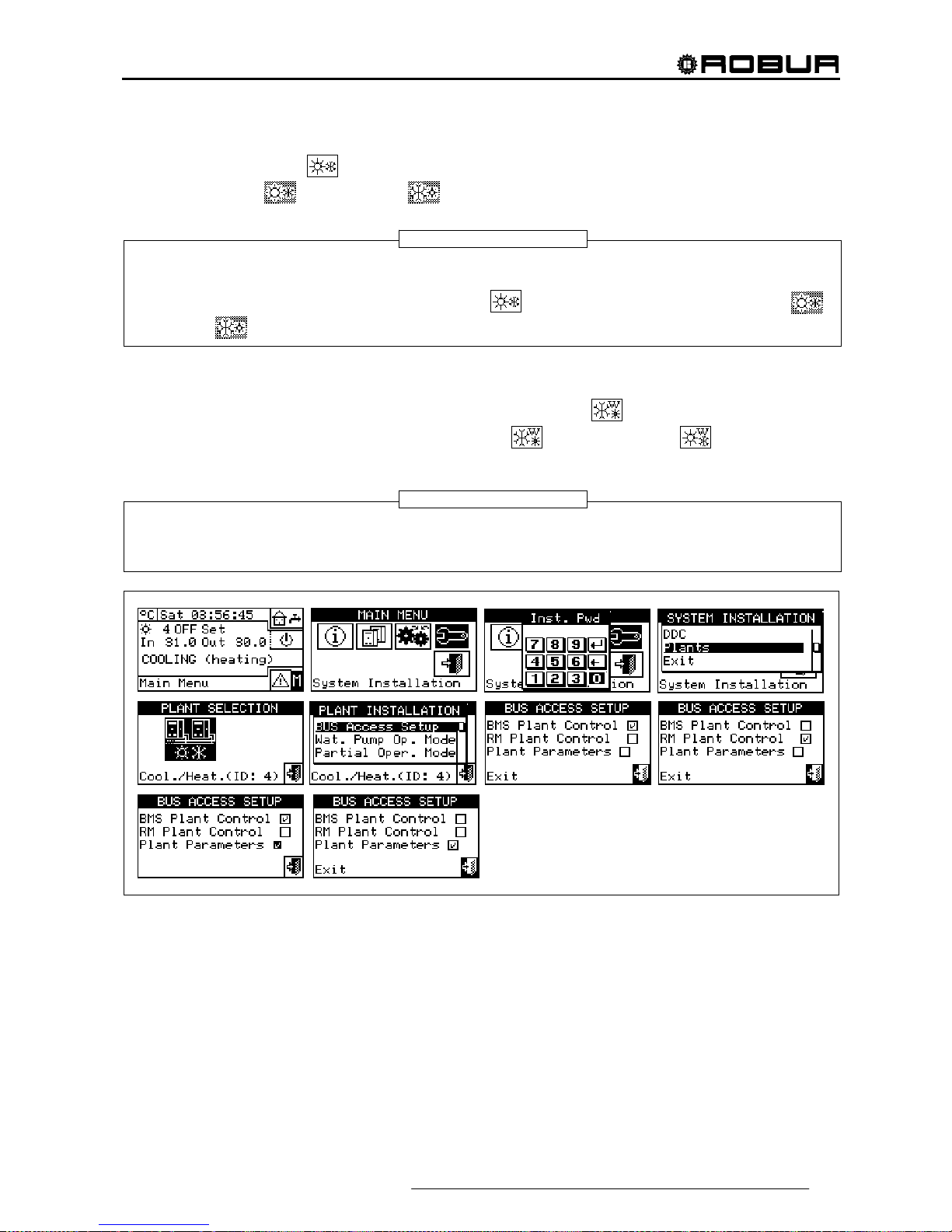

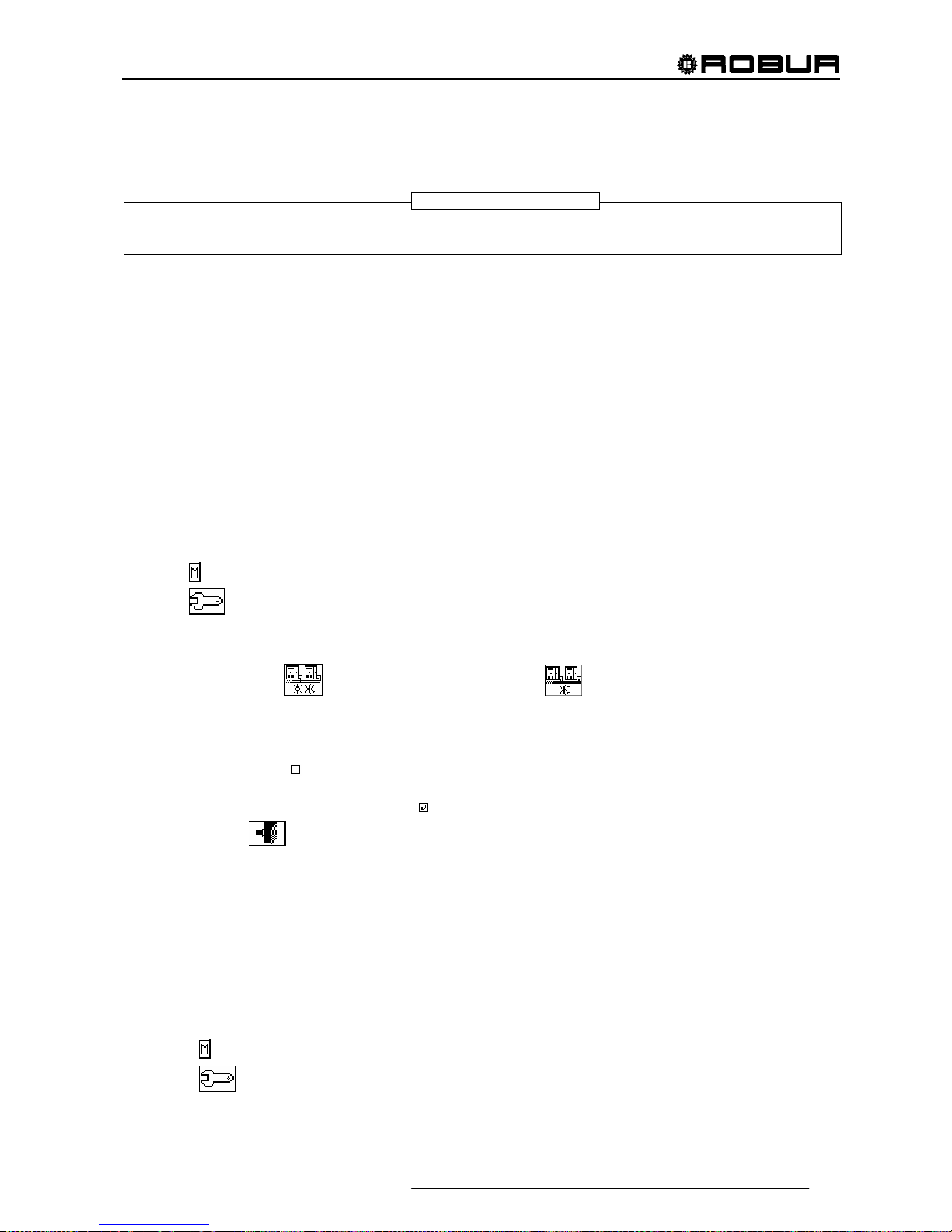

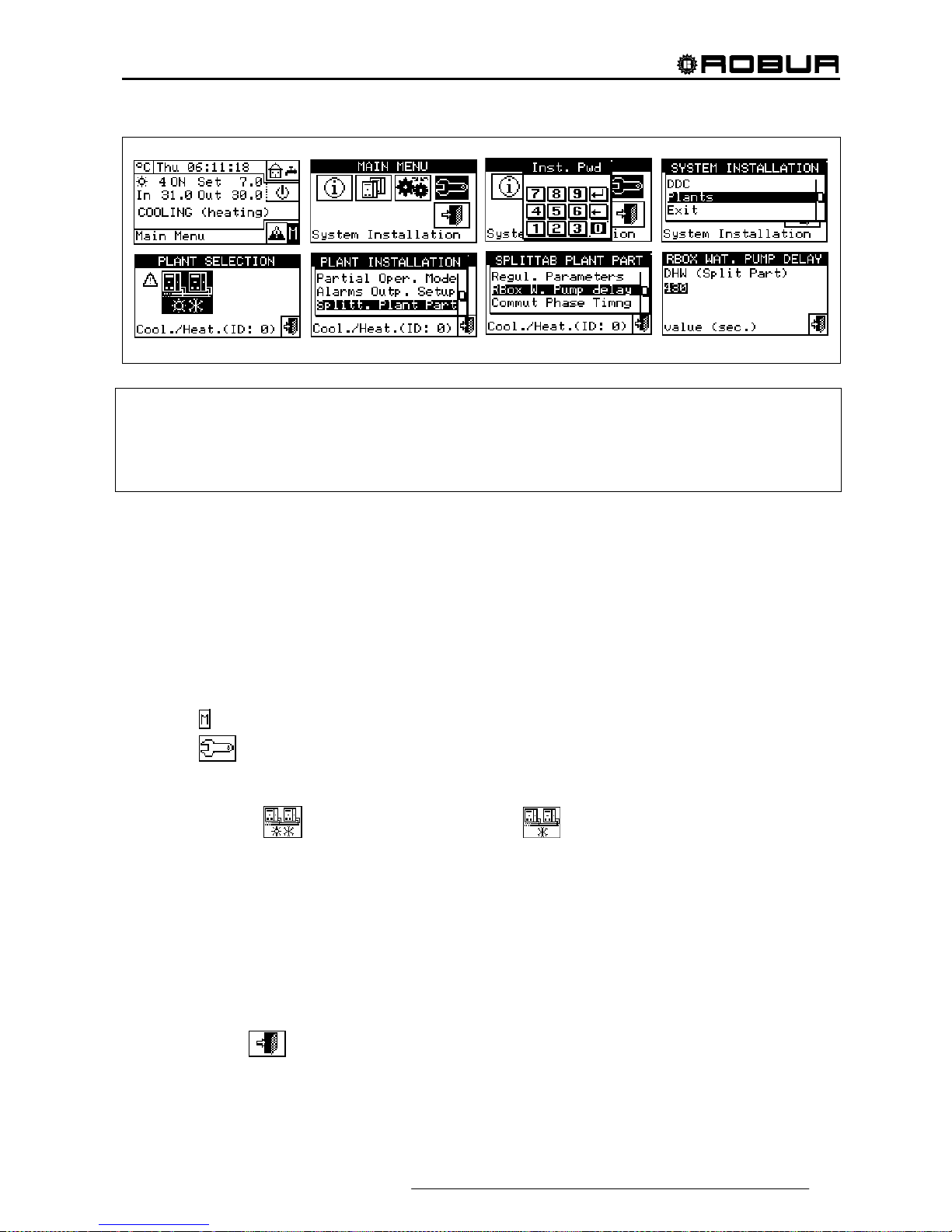

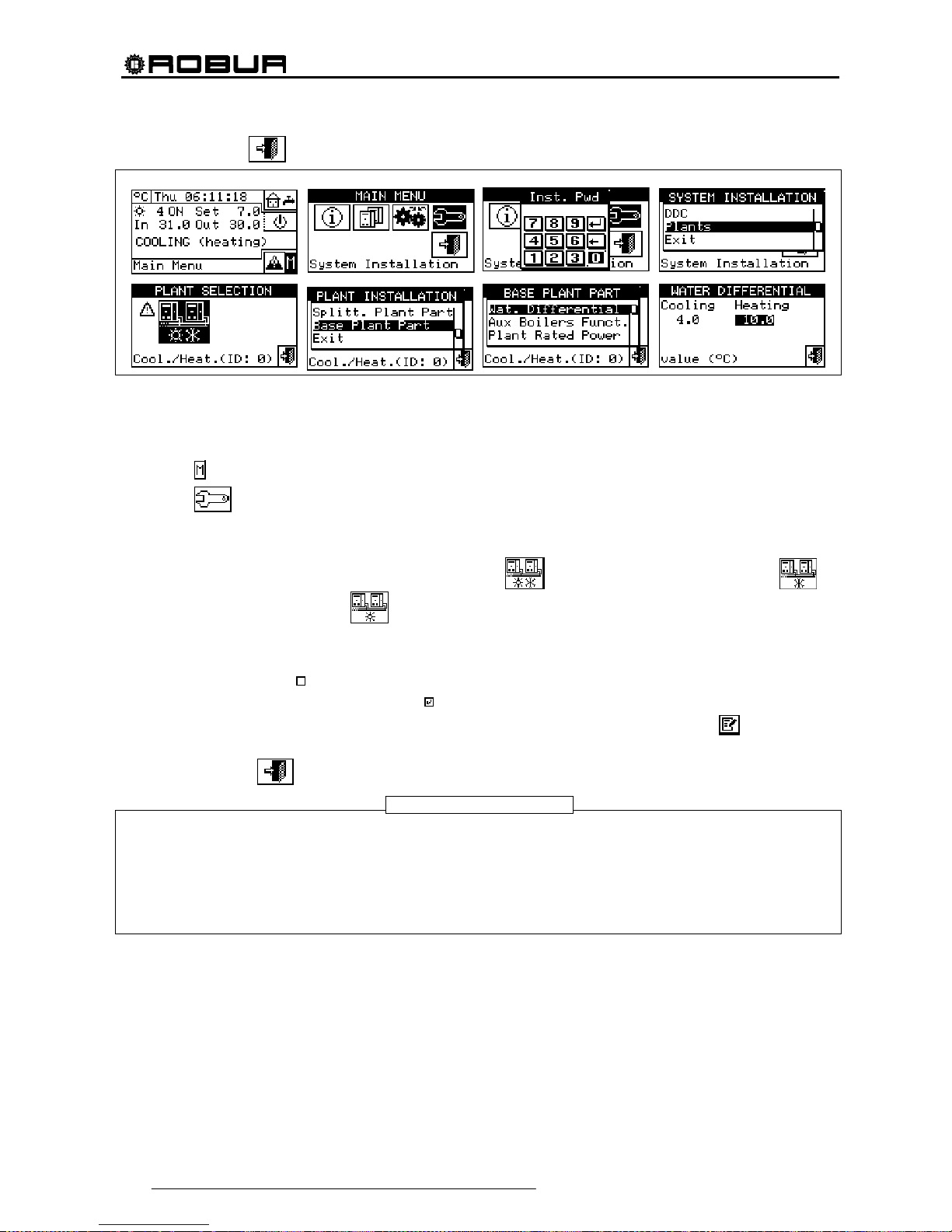

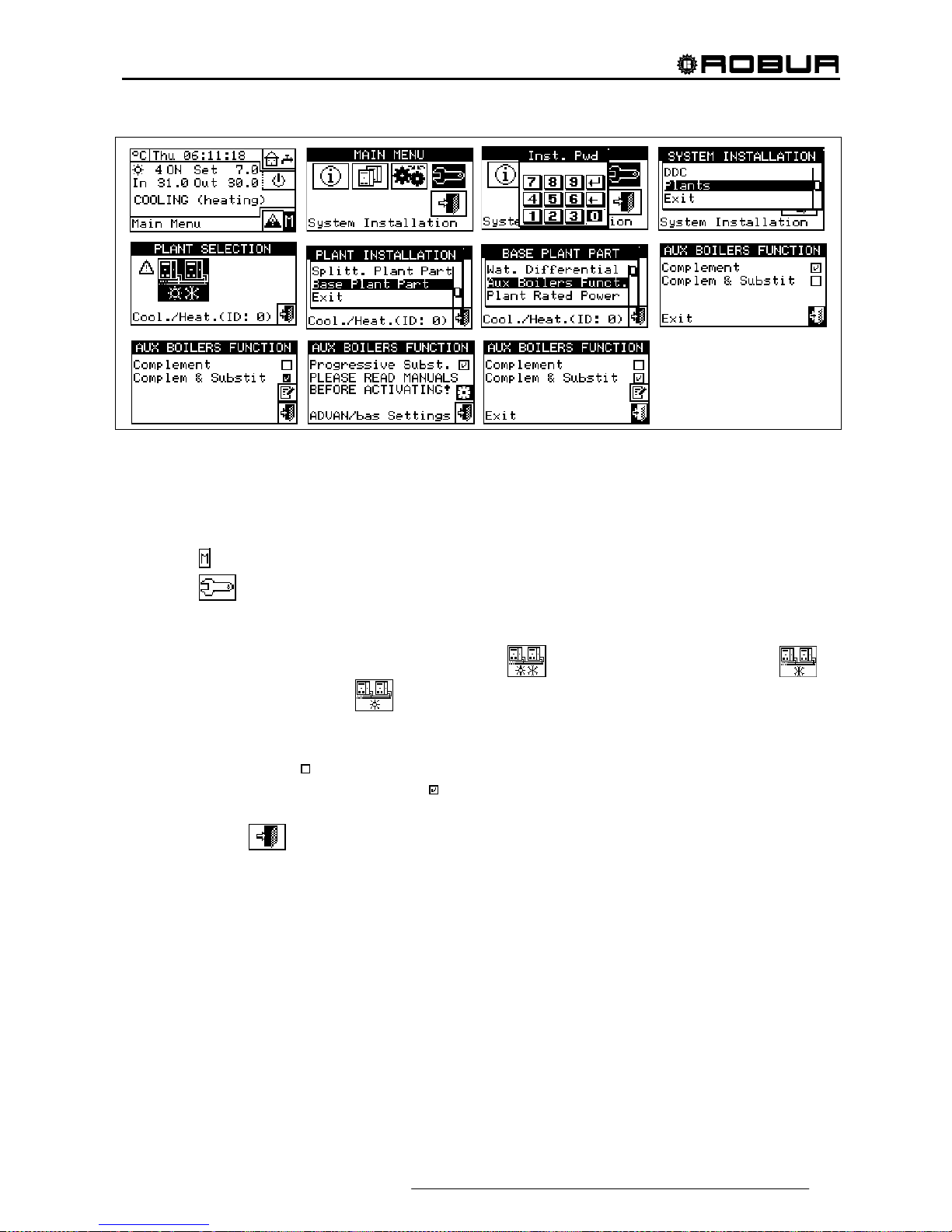

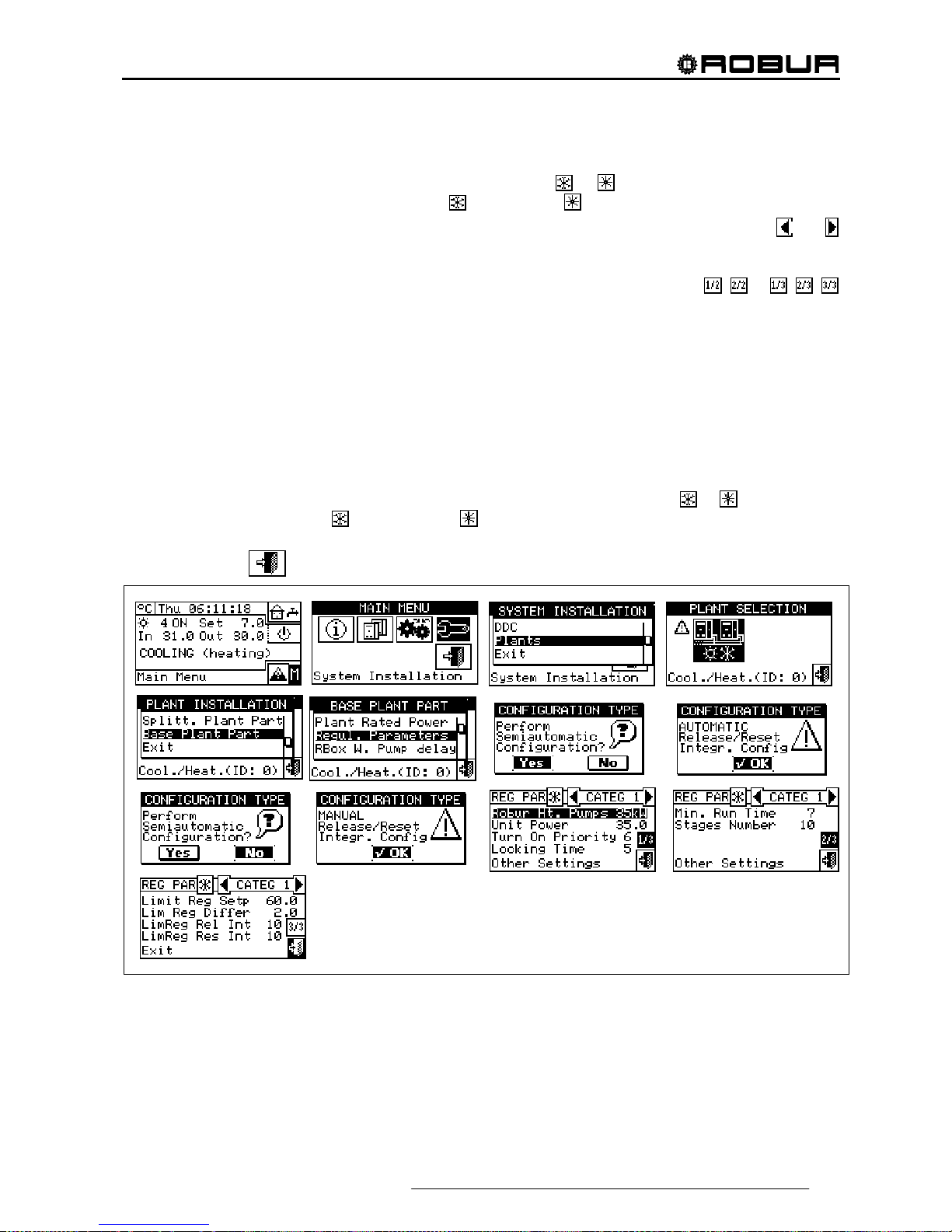

9 - Position the cursor on the activation time of the first water T timer cycle and press the knob. Turn the