www.cel-robox.com

User Guide

including AutoMaker

™

Version 1.1

22

www.cel-robox.com

Contents

1.0 Introduction ..........................................................................6

1.1 Welcome ................................................................................................ 7

1.2 Learn More ............................................................................................. 7

1.3 Using This Guide ................................................................................... 8

1.4 Instructional Icons ............................................................................... 9

1.5 Typography ..........................................................................................10

1.6 Important Safety Information ...........................................................10

Electrical Safety ...................................................................................................10

Operation Safety ................................................................................................. 11

Safety Guidelines ................................................................................................ 12

1.7 Safety Symbols and Definitions ........................................................13

1.8 Legal Notice ......................................................................................... 14

1.9 Copyright .............................................................................................14

1.10 Declaration of Conformity ...............................................................15

1.11 Limited Warranty Statement ........................................................... 16

1.12 Regulatory and Environmental Information .................................17

2.0 Overview ..............................................................................19

2.1 Features ............................................................................................... 20

2.2 Specifications ...................................................................................... 20

2.3 Minimum Hardware Requirements ..................................................21

2.4 How It Works .......................................................................................22

2.5 At A Glance ........................................................................................... 23

3.0 Getting Started ..................................................................25

3.1 Package Contents ...............................................................................26

3.2 Unpacking Robox® ..............................................................................27

3.3 Soware Installation ..........................................................................29

3.4 Starting AutoMaker™ .......................................................................... 31

3.4.1 On Windows ............................................................................................... 31

3.4.2 On MacOS ................................................................................................... 31

3.4.3 On Linux ...................................................................................................... 31

33

www.cel-robox.com

Contents

3.5 Setting Up Your Robox® Account ....................................................... 32

3.6 Attaching the USB Cable .................................................................... 33

3.7 Attaching the Power Cable and Powering On .................................. 33

4.0 Using Robox® ...................................................................... 34

4.1 Loading Filament ...............................................................................35

4.1.1 Preparing the Filament ........................................................................... 35

4.1.2 Feeding to the Head ................................................................................ 35

4.1.3 Installing the Reel ..................................................................................... 36

4.2 Unloading Filament ............................................................................ 37

4.2.1 Pause / Resume / Eject Button ............................................................. 37

4.2.2 Removing The Reel .................................................................................. 38

4.3 Filament Storage .................................................................................38

4.4 The HeadLock™ System .....................................................................39

4.4.1 Removing a Head ..................................................................................... 39

4.4.2 Installing a Head ....................................................................................... 40

4.5 Removing the Bed ...............................................................................41

4.6 Installing the Bed ................................................................................41

5.0 AutoMaker Soware ........................................................42

5.1 User Interface ......................................................................................43

5.2 Print Workflow ....................................................................................44

5.3 Status Screen .......................................................................................45

5.3.1 Connected Printers .................................................................................. 45

5.3.2 Installed Filament ..................................................................................... 46

5.3.3 Temperature Display ............................................................................... 46

5.3.4 Projects Tabs..............................................................................................47

5.3.5 Current Printer Status .............................................................................. 47

5.3.6 Advanced Settings.................................................................................... 48

5.3.7 Advanced Settings - SmartReel™ Programming .............................49

5.3.8 Advanced Settings - Head Programming .......................................... 49

5.3.9 Advanced Settings - Calibration and Maintenance ........................ 50

44

www.cel-robox.com

Contents

5.3.10 Advanced Settings - Diagnostics ........................................................ 52

5.4 Layout Screen ......................................................................................53

5.4.1 Arranging Items on the Bed ...................................................................54

5.5 Settings Screen ...................................................................................56

5.5.1 Starting Production ................................................................................. 56

5.5.2 Filament Settings...................................................................................... 57

5.5.3 Print Settings ............................................................................................. 58

5.5.4 Advanced Settings - Material ................................................................. 60

5.5.5 Advanced Settings - Print Profile .......................................................... 63

5.5.6 Advanced Settings - Extrusion .............................................................. 64

5.5.7 Advanced Settings - Nozzles ................................................................. 67

5.5.8 Advanced Settings - Support ................................................................ 70

5.5.9 Advanced Settings - Speed .................................................................... 72

5.5.10 Advanced Settings - Cooling ............................................................... 75

6.0 Finishing Parts ....................................................................78

6.1 Removing Breakaway Support Material ...........................................79

6.2 Removing Soluble Support Material .................................................80

6.2.1 Polyvinyl Alcohol (PVOH) ........................................................................ 80

6.2.2 High Impact Polystyrene (HIPS) ........................................................... 80

6.2.3 Polylactic Acid (PLA) ................................................................................ 80

6.3 Vapour Finishing .................................................................................81

7.0 Calibration and Maintenance .......................................82

7.1 Calibration ...........................................................................................83

7.1.1 Nozzle Opening ......................................................................................... 83

7.1.2 Nozzle Height............................................................................................. 86

7.1.3 X and Y Oset ............................................................................................. 88

7.2 Maintenance ........................................................................................ 91

7.2.1 Purge Nozzles ............................................................................................ 91

7.2.2 Eject Stuck Material ................................................................................. 92

7.2.3 Speed Test .................................................................................................. 92

55

www.cel-robox.com

Contents

7.2.4 Cleaning ...................................................................................................... 92

7.2.5 Print Bed ..................................................................................................... 92

7.2.6 Build Chamber .......................................................................................... 93

7.2.7 Extruder ....................................................................................................... 93

7.2.8 Lubrication ................................................................................................. 94

7.3 Troubleshooting ..................................................................................95

8.0 Supplementary Information .......................................100

8.1 GCode Commands ............................................................................101

8.2 Frequently Asked Questions ............................................................105

8.2.1 Hardware ..................................................................................................105

8.2.2 Soware ....................................................................................................107

8.2.3 Printing ......................................................................................................108

8.3 Glossary of Terms ..............................................................................109

8.4 Contact Us .........................................................................................121

1.0

1.0

Introduction

77

www.cel-robox.com

1.0 Introduction

1.1 Welcome

Thank you for purchasing the Robox® micro-manufacturing platform and

welcome to the future of custom manufacturing!

Robox® provides you with the capability to produce three-dimensional models in

a variety of thermoplastic materials and with our HeadLock™ easy replacement

system, you can begin to explore a whole range of personal manufacturing

possibilities.

1.2 Learn More

Refer to the following sources for additional information and for product and

soware updates.

• Quick Start Guide

You will find this in the product packaging along with the warranty

registration card and safety information booklet. It contains a brief setup

guide for Robox® to get you printing as easily as possible.

• Safety Information Guide

You will also find this in the product packaging - it contains essential

information relating to safety and certification. Please read carefully before

using Robox®.

• Oicial Robox® website - www.cel-robox.com

The Robox® website provides up to date information on available hardware

and soware products compatible with the system. It also contains contact

details, warranty information and support.

• Optional Documentation

Your product packaging may include optional documentation, such as

warranty flyers, that may have been added by your dealer. These documents

are not necessarily part of the standard package.

88

www.cel-robox.com

1.0 Introduction

1.3 Using This Guide

This user guide contains the information you need to setup and use your Robox®

micro-manufacturing platform.

1.3.1 How This Guide Is Organised

This guide contains the following parts:

• Section 1 - Welcome

This section outlines all the important safety considerations, international

certifications and information on this user guide and accompanying

documentation.

• Section 2 - Overview

This section describes the features and specifications of the product, along

with a brief introduction of the printing process and overview diagrams of

the major hardware features.

• Section 3 - Getting Started

This section explains how to begin producing items with your new

micro-manufacturing platform. It includes how to unpack your new product,

soware installation and connectivity.

• Section 4 - Using Robox®

This section describes in detail how to use Robox® to produce items,

including loading and unloading filament, replacing the print head and

removing / replacing the print bed.

• Section 5 - AutoMaker™ Soware

This section explains how to use the included AutoMaker™ soware to set up

your production run. In includes detailed information on printer settings and

advanced options.

• Section 6 - Finishing Parts

This section explains how you can improve the quality of your parts aer

production.

• Section 7 - Troubleshooting and Maintenance

This section includes essential maintenance procedures to keep your

Robox® running smoothly, along with a troubleshooting guide to help you to

fine tune and diagnose any problems.

99

www.cel-robox.com

1.0 Introduction

• Section 8 - Supplementary Information

This final section contains a variety of extra information for your reference. It

includes a GCode reference, glossary of terms, FAQs and contact details.

1.4 Instructional Icons

The following classifications are used throughout this guide:

• DANGER/WARNING: Important information to prevent injury or

damage to yourself, people or property when trying to complete a task.

• CAUTION: Information to prevent damage to product components

when trying to complete a task.

• IMPORTANT: Instructions that you must follow to complete a task.

• NOTE: Tips and additional information to help you complete a task.

• GLASSES: Wear safety glasses to avoid injury to your eyes.

• GLOVES: When performing certain procedures, the machine may be

hot and gloves are required to avoid burns.

1010

www.cel-robox.com

1.0 Introduction

1.5 Typography

Bold text Indicates a menu or item to select.

Italics Used to emphasise a word or phrase.

<Key> Keys enclosed in the less-than and greater-than sign

means that you must press the enclosed key.

Example: <Enter> means that you must press the

Enter or Return key.

<Key1>+<Key2> If you must press two or more keys simultaneously,

the key names are linked with a plus sign (+).

Example: <Ctrl>+<Alt>+<R>

Indicates a mouse button click (le, wheel, right).

1.6 Important Safety Information

The following precautions should be made to ensure the safety of yourself and

your environment and to protect the product from damage. Please follow these

precautions at all times:

Electrical Safety

• To prevent electrical shock hazard, disconnect the power cable from the

electrical outlet before relocating the system or performing any maintenance.

• Seek professional assistance before using an adapter or extension cord. These

devices could interrupt the grounding circuit.

• Use the power supply voltage specified on the rating label. Avoid overloading

an electrical outlet with multiple devices.

• Use only the power cable supplied with the product. Do not damage, cut

or repair the power cable. A damaged power cable carries a risk of fire

and electric shock. Replace a damaged power cable with a manufacturer

approved power cable.

• Please do not disassemble the product, there are no user serviceable parts

inside. If you experience any problems, please contact your local Service

Representative or CEL Technology. See the ‘Contact Us’ section of the User

Guide / Warranty Card.

• Ensure the product is well-grounded. Failure to ground the product may result

in electrical shock, fire and susceptibility to electromagnetic interference.

1111

www.cel-robox.com

1.0 Introduction

Operation Safety

• Before using the product, ensure all cables are correctly connected to a power

supply that matches the rating label and the power cables are not damaged. If

you detect any damage, contact your retailer immediately.

• Do not place the product in any area where it may become wet or damp

and avoid dusty, humid and high temperature environments which could

negatively aect product performance. The printer is designed to work

properly at an ambient temperature of between 15°C and 25°C and humidity

of between 20% and 50%; Operating outside these limits may result in low

quality models.

• Place the product on a stable surface away from flammable substances.

• Do not allow metal or liquids to touch the internal parts of the product. Doing

so may cause damage, fire, electric shock or other serious hazards.

• Always use the product in a well-ventilated area.

• Do not use ABS plastic or its printed parts near any kind of heat source -

flames, fireworks, candles, incense, light bulbs etc. ABS will catch fire and burn

a thick black toxic smoke.

• Power o the product and disconnect the power cable from the power outlet

in any of the following cases:

• If there is any smoke coming from the product.

• If the product is making an unusual noise not heard during normal

operation.

• A piece of metal or a liquid touches the internal parts of the product.

• During an electrical (thunder/lightning) storm

• During a power failure

• When the 3D printing head is installed in the product, there are moving parts

which can cause injury and heater elements which generate temperatures in

the region of 200-300°C. Never reach inside the product while it is in operation,

and never touch the print head while it is hot.

• Always allow the product to cool down completely before reaching inside.

• Never try to override the interlock on the door which protects the user from

these dangerous temperatures.

• Contact with extruded material from the 3D print head may cause burns. Wait

for printed objects to cool before removing them from the build plate.

• Do not leave Robox® unattended during operation.

1212

www.cel-robox.com

1.0 Introduction

Safety Guidelines

• Follow all safety rules in this section and observe all cautions and warnings in

this guide (and those from any additions and materials used in conjunction

with the product).

• Before using the product, carefully read and understand all the manuals that

were included with the package. Check for updated versions on our website.

• Do not modify any safety features or make modifications to Robox®. Doing so

is prohibited and may void your warranty and/or aect the safe operation of

the product.

• Use of print materials other than Robox® print materials and genuine Robox®

components may void warranty.

• Tie back long hair and loose clothing and keep fingers away from moving

parts.

• Adult supervision is required; observe children closely and intervene as

necessary to prevent potential safety problems and ensure the appropriate

use of the product. Ensure small 3D prints are not accessible to young

children.

• These 3D prints are potential choking hazards for young children.Protective

glasses should always be worn when removing support material, especially

PLA.

• Do not use the product to create items which may be in contravention of laws

or regulations applicable in your area.

• If you encounter technical problems with the product, contact a qualified

service technician, your retailer or CEL Technology.

1313

www.cel-robox.com

1.0 Introduction

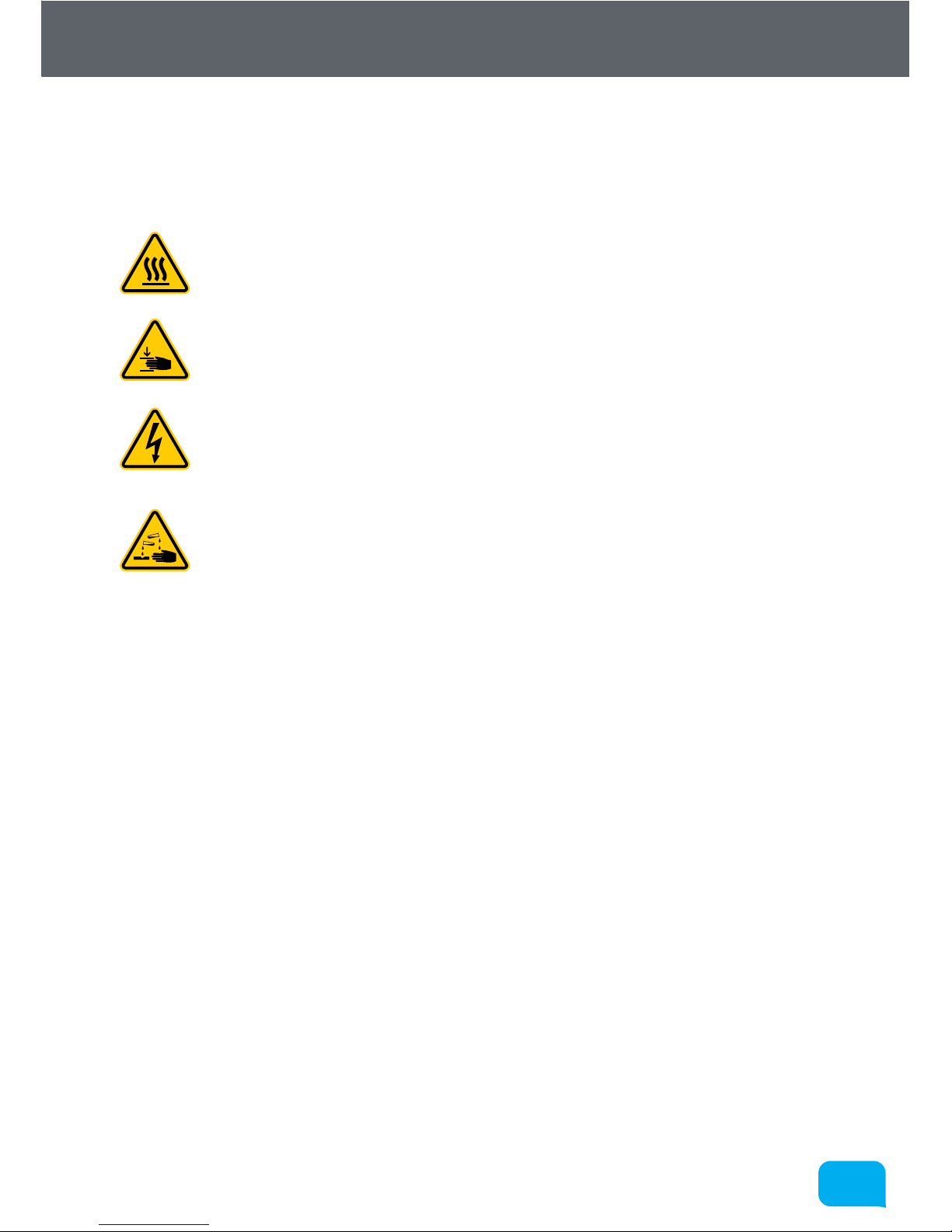

1.7 Safety Symbols and Definitions

The safety symbols are used throughout this guide and on product warning

labels:

• Hot Surface Hazard: Information to prevent injury to yourself when

trying to complete a task.

• Caution: Indicates a pinch point hazard that could cause person injury.

• Caution: Indicates an area which carries risk of electric shock -

disconnect from the power outlet before accessing.

• Corrosive: Used on materials which may be corrosive and cause harm

to skin and/or eyes. Wear protective eyewear and gloves.

1414

www.cel-robox.com

1.0 Introduction

1.8 Legal Notice

The only warranties for CEL Technology products and services are set forth in

the express warranty statement accompanying such products and services.

Nothing herein should be construed as constituting an additional warranty.

CEL Technology shall not be liable for technical or editorial errors or omissions

contained herein.

1.9 Copyright

© 2014 CEL Technology Ltd. All rights reserved.

Robox is a registered trademark of CEL Technology Ltd. HeadLock and AutoMaker

are trademarks of CEL Technology. All other trademarks are the property of

their respective owners, and CEL Technology assumes no responsibility with

regard to the selection, performance, or use of these non-CEL products. Product

specifications are subject to change without notice.

This document is protected by copyright. All rights reserved. Its use, disclosure,

and possession are restricted by an agreement with CEL Technology Ltd. per

soware copyright.

No part of this document may be photocopied, reproduced or translated into

another language without the prior written consent of CEL Technology.

Printed in China.

Imprimé en Chine.

1515

www.cel-robox.com

1.0 Introduction

1.10 Declaration of Conformity

Manufacturer: CEL Technology Ltd.

Unit 1604, 16/F Nan Fung Commercial Centre,

19 Lam Lok Street,

Kowloon Bay,

Hong Kong

UK Representative: C Enterprise (UK) Ltd.

Unit 3 Harbourmead, Harbour Road,

Portishead, North Somerset,

BS20 7AY, United Kingdom

Type of Equipment: Personal Manufacturing Robot

Model Number: RBX01

We declare under our sole responsibility that the devices mentioned above comply with the following EU Directives:

Electromagnetic Compatibility (EMC) 2004/108/EC

Machinery 206/42/EC

Low Voltage 2006/95/EC

Common Technical EN55022:2010

Specifications used EN60950-1: 2006 + Amendments A11: 2009 + A1: 2010 + A12: 2011

for demonstration EN55024:2010

of compliance: EN61000-4-2: 2009

EN61000-4-3: 2006 + Amendments A1: 2008 + A2: 2010

EN61000-4-4: 2004 + Corrigendum 2008

EN61000-4-5: 2006

EN61000-4-6: 2009

EN61000-4-8: 2010

EN61000-4-11 Second Edition: 2004

Date of Validity: 1st August 2014

Design and Technical CEL Technology Ltd. C Enterprise (UK) Ltd.

Construction File Unit 1604, 16/F Nan Fung Unit 3 Harbourmead, Harbour Road,

Maintained At: 19 Lam Lok Street, Portishead, North Somerset

Kowloon Bay, United Kingdom

Hong Kong BS20 7AY

Name of Authorised Signatory : Kenneth Tam Christopher Elsworthy

Position Held in Company: Chief Operating Oicer Chief Executive Oicer

Signatures:

1616

www.cel-robox.com

1.0 Introduction

1.11 Limited Warranty Statement

CEL Technology Ltd. (“CEL”) warrants its’ systems and associated peripheral devices and replacement parts (collectively,

the “Product”) purchased from CEL or an Authorised CEL Reseller to be free from defects in material and workmanship

according to the terms and conditions stated below:

Warranties extend only to the original purchaser of the Product. Unless otherwise specified, the warranty on the original

Product, as delivered, extends for two years starting on the date of delivery. Authorised distributors and/or resellers have

the rights to adjust and/or finalize the properties of the warranty, including but not limited to the duration of the warranty,

subject to local regulations. Your sole remedy as purchaser under this Limited Warranty shall be repair or replacement

as provided herein.

To preserve your warranty rights, Products must be installed in accordance with the then-current User Guide available at

www.cel-robox.com/downloads. During the Limited Warranty period, CEL or its’ designated representative will, at their

option, repair or replace a defective Product as set forth below. Service Parts and replacement Products will be furnished

on an exchange basis, and will be either new or refurbished. All replaced parts or replaced Products become the property

of CEL, and you will be invoiced for replacement parts if defective parts are not returned as directed by CEL under this

Limited Warranty.

CEL will bear the cost of returned parts, provided that you report the warranty claim within the Limited Warranty period

and obtain return instructions from CEL prior to return. CEL will not be responsible for any shipping costs or other

charges associated with these repairs. These terms only apply if CEL or its’ designated representative determines that

a fault is present. If no fault is found, the purchaser will bear the cost of all labour, materials and shipping. Replacement

parts independently carry a 90-day warranty from date of shipment from CEL or designated representative location.

Consumable parts are not covered by this Limited Warranty (these include the printing head, PEI bed sheet, filament,

and extruder). Warranty services may be provided by CEL, an Authorised Reseller, or a third party service provider

designated by CEL.

No coverage or benefits under this Limited Warranty will exist if any of the following conditions apply:

(a) The Product has been subjected to abnormal use, improper or inadequate maintenance, unauthorised modifications,

unauthorised repair, misuse, abuse, exposure to moisture, flooding, fire, electrical problems associated with incoming

power, or other acts which are not the fault of CEL Technology Ltd.

(b) CEL’s Customer Service Department was not notified of the defect or malfunction of the system prior to expiration of

the warranty period that was oered.

(c) Parts or consumables were installed and used that were not certified or approved by CEL.

CEL will also not be liable under any circumstances for Product replacement or associated labour, loss of use, loss of

profits, or for any other indirect, incidental, collateral, exemplary, punitive, consequential or special damages, or losses

arising out of the purchase of the Product and/or out of this limited warranty, even if CEL or its’ designated representative

have been advised of the possibility of such damages or claims. To the extent such claims are not excludable as adjudged

by a court of competent jurisdiction; you agree to accept as sole and exclusive remedy, a payment equal to the original

purchase price for the product adjudged to be defective.

SOME COUNTRIES, REGIONS, STATES OR PROVINCES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF REMEDIES

OR OF INCIDENTAL, PUNITIVE, OR CONSEQUENTIAL DAMAGES, OR THE APPLICABLE TIME PERIODS, SO THE ABOVE

LIMITATIONS OR EXCLUSIONS MAY NOT APPLY TO YOU. EXCEPT TO THE EXTENT LAWFULLY PERMITTED, THIS LIMITED

WARRANTY DOES NOT EXCLUDE, RESTRICT OR MODIFY, AND IS IN ADDITION TO THE STATUTORY RIGHTS APPLICABLE

TO THE SALE OF THIS PRODUCT TO YOU.

This warranty gives you specific legal rights and you might also have other rights that vary from country/region to

country/region, state to state, or province to province.

EXCEPT FOR THIS LIMITED WARRANTY, AND TO THE FULLEST EXTENT ALLOWED BY LAW, NEITHER CEL NOR ANY

AUTHORISED RESELLER MAKES ANY OTHER WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. CEL TECHNOLOGY DOES NOT OFFER,

ASSUME OR AUTHORISE THE OFFER OR ASSUMPTION OF LIABILITY FOR IT OR FOR ANY OTHER WARRANTY, EITHER

EXPRESS OR IMPLIED BY ANY AUTHORISED RESELLER OR OTHER INDEPENDENT THIRD PARTY.

1717

www.cel-robox.com

1.0 Introduction

1.12 Regulatory and Environmental Information

1.12.1 Electromagnetic Interference

The normal functionality of the product may be disturbed by Strong Electro Magnetic Interference.

If you are experiencing problems, reset the product by cycling the power to resume normal

operation. If normal functionality does not resume, please try using the product in a dierent

location.

1.12.2 FCC Statements (U.S.A.)

The U.S. Federal Communications Commission (in 47 cfr1 5.105) has specified that the following

notices be brought to the attention of users of this product.

This device complies with part 15 of the FCC rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

Shielded cables: use of shielded data cables is required to comply with the Class A limits of Part 15

of the FCC Rules.

Caution: Pursuant to Part 15.21 of the FCC Rules, any changes or modifications to this equipment

not expressly approved by CEL Technology Ltd. may cause harmful interference and void the FCC

authorization to operate this equipment.

Note: This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a commercial environment. This equipment generates,

uses and can radiate radio frequency energy and, if not installed and used in accordance with

the instructions, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference, in which case the user will be

required to correct the interference at their own expense.

1.12.3 Canada Electromagnetic Compatibility (EMC)

• Normes de sécurité (Canada)

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites

applicables aux appareils numériques de Classe A prescrites dans le réglement sur le

brouillage radioélectrique édicté par le Ministère des Communications du Canada.

• DOC statement (Canada)

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital

apparatus set out in the Radio Interference Regulations of the Canadian Department of

Communications.

1.12.4 MSDS (Material Safety Data Sheets)

You can obtain current Material Safety Data Sheets for the materials used in the product at: www.

cel-robox.com/materials

1818

www.cel-robox.com

1.0 Introduction

1.12.5 Disposal of waste equipment by users in private households in the

European Union (WEEE)

This symbol on the product or on its packaging indicates that this product must not be disposed

of with your other household waste. Instead, it is your responsibility to dispose of your waste

equipment by handing it over to a designated collection point for the recycling of waste electrical

and electronic equipment. The separate collection and recycling of your waste equipment at the

time of disposal will help to conserve natural resources and ensure that it is recycled in a manner

that protects human health and the environment. For more information about where you can drop

o your waste equipment for recycling, please contact your local city oice, your household waste

disposal service or the shop where you purchased the product.

Overview

2.0

2020

www.cel-robox.com

2.0 Overview

2.1 Features

• QuickFill™ Dual Nozzle Technology

• Auto Z Height Calibration

• ‘TapeLess’ High Performance PEI Bed Material

• HeadLock™ quick change head system

• Single or Dual Extruders

• Automatic Material Recognition (SmartReel™) and Instant Loading

• Automatic Head Recognition

• Dra Blocking Build Chamber

• 2 minute Fast Heat-up Time

• Plug and Play - no set up or assembly required

2.2 Specifications

2.2.1 Physical Dimensions

• External Size (LxWxH): 370 x 340 x 240mm (14.5 x 13.4 x 9.4 in)

• Desk Footprint (LxW): 370 x 340mm (14.5 x 13.4 in)

• Shipping Box (LxWxH): 495 x 395 x 295mm (19.5 x 15.5 x 11.5 in)

• Product Weight: 8 kg (17.6 lbs)

• Shipping Weight: 9.8 kg (21.6 lbs)

2.2.2 Temperature

• Operation Temperature: 15°—25°C (60°—77°F)

• Storage Temperature: 0°—40°C (32°—104°F)

• Max. Bed Temperature: 150°C (302°F)

• Max. Nozzle Temperature: 300°C (572°F)

2.2.3 Electrical

• Power Requirements: AC 100-250V~, 50/60Hz, 3A max

• Connectivity: USB 2.0 and IEC C5 AC Cable

• microSD Compatibility: upto 32Gb (SDHC Version 2.0) Any Class

2.2.4 Mechanical

• Build Platform: Heated Polyetherimide (PEI)

• XYZ Bearings: Ball Raced Linear (6mm and 8mm ID)

• Stepper Motors: 1.8° Step Angle with 1/16 Micro Stepping

2121

www.cel-robox.com

2.0 Overview

2.2.5 3D Printing Head

• Print Technology: Fused Filament Fabrication (FFF)

• Build Size (LxWxH): 210 x 150 x 100mm (8.3 x 5.9 x 3.9 in)

• Layer Resolutions: Super (20 microns / 0.0008 in)

High (100 microns / 0.0039 in)

Standard (200 microns / 0.0078 in)

Low (300 microns / 0.0118 in)

• Positioning Precision: XY: 7.5 microns (0.0003 in)

Z: 0.15625 microns (0.000006 in)

• Filament Diameter: 1.75mm (0.069 in)

• Nozzle Diameters: 0.3mm (0.012 in) and 0.8mm (0.031 in)

• Model Materials: PLA, ABS, Nylon, PC, PET, PC-ABS + others

• Support Materials: PVA, HIPS, PLA

2.2.6 Soware

• Soware Bundle: Robox® AutoMaker™

• File Types: .stl, .obj, .robox

• Soware Compatibility: Windows (7, 8), Mac OS x (10.6 x64/10.7+),

Ubuntu Linux (12.04+)

2.3 Minimum Hardware Requirements

Processor Minimum:

Recommended:

Dual-core 2.0Ghz

Quad-core 3.0Ghz

System RAM Minimum:

Recommended:

2GB

4GB or greater

Hard Disk Installation:

Minimum:

Recommended:

256MB

2GB

4GB or greater

Graphics Card Minimum:

Recommended:

1024x768 or greater

128MB or greater memory

1680x1050 or greater

256MB or greater memory

or integrated Intel HD graphics

OpenGL v2.0 Support

2222

www.cel-robox.com

2.0 Overview

2.4 How It Works

2.4.1 3D Printing

When Robox® is using the 3D printer head, it uses a technology known as Fused

Filament Fabrication (FFF). This works in a similar way to a hot-melt glue gun using plastic filament instead of glue sticks.

The feedstock for the print head is 1.75mm thermoplastic filament which is

supplied on a reel for installing into the printer. This is then fed to the head via a

Bowden tube using the extruder, which contains two contra-rotating feedwheels

to grab hold of the filament, and push it along the tube to the head.

When the filament reaches the head, it is extruded out of a hot nozzle, which

melts the plastic and can control the diameter of the extrudate by using two

dierent size nozzles. This twin nozzle arrangement allows for highly detailed

outer surfaces of the print (those that are visible), alongside the larger nozzle

which is used for filling in parts quickly.

The printer head is mounted to a quick-release carriage, known as HeadLock™

which is constrained by a Cartesian axis system, allowing the head to move in 3

dimensions.

The included AutoMaker™ soware translates your 3D design files (in .stl or .obj

format) into machine coordinates that Robox® can understand. It does this by

‘slicing’ the 3D model into it’s individual layers, and then sending each slice (or

layer) to the printer, one at a time.

To produce a part, the molten plastic is laid down one layer at a time, and the

head moves up by a small amount (as little as 0.02mm!) at the end of each layer.

This allows fully-solid plastic parts to be constructed, with the quality of the

surface finish being determined by the height of the individual layers (quality

setting).

Robox® SmartReels are available in a variety of materials, finishes and colours

and they are automatically recognised by the machine, setting all of the

appropriate parameters for you. All you need to do is pick one, choose what

quality you’d like your model and hit print!

Welcome to the exciting world of custom desktop manufacturing!

2323

www.cel-robox.com

2.0 Overview

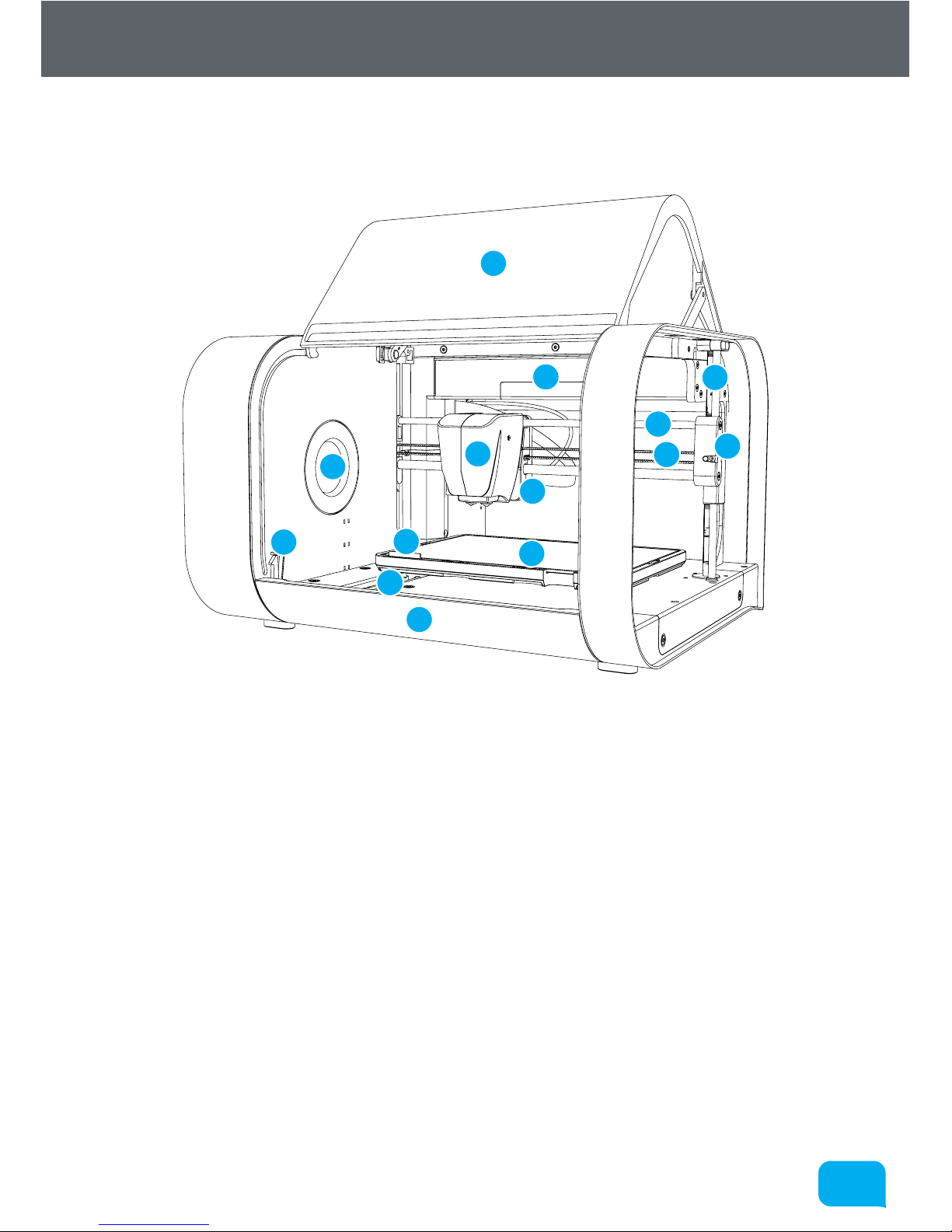

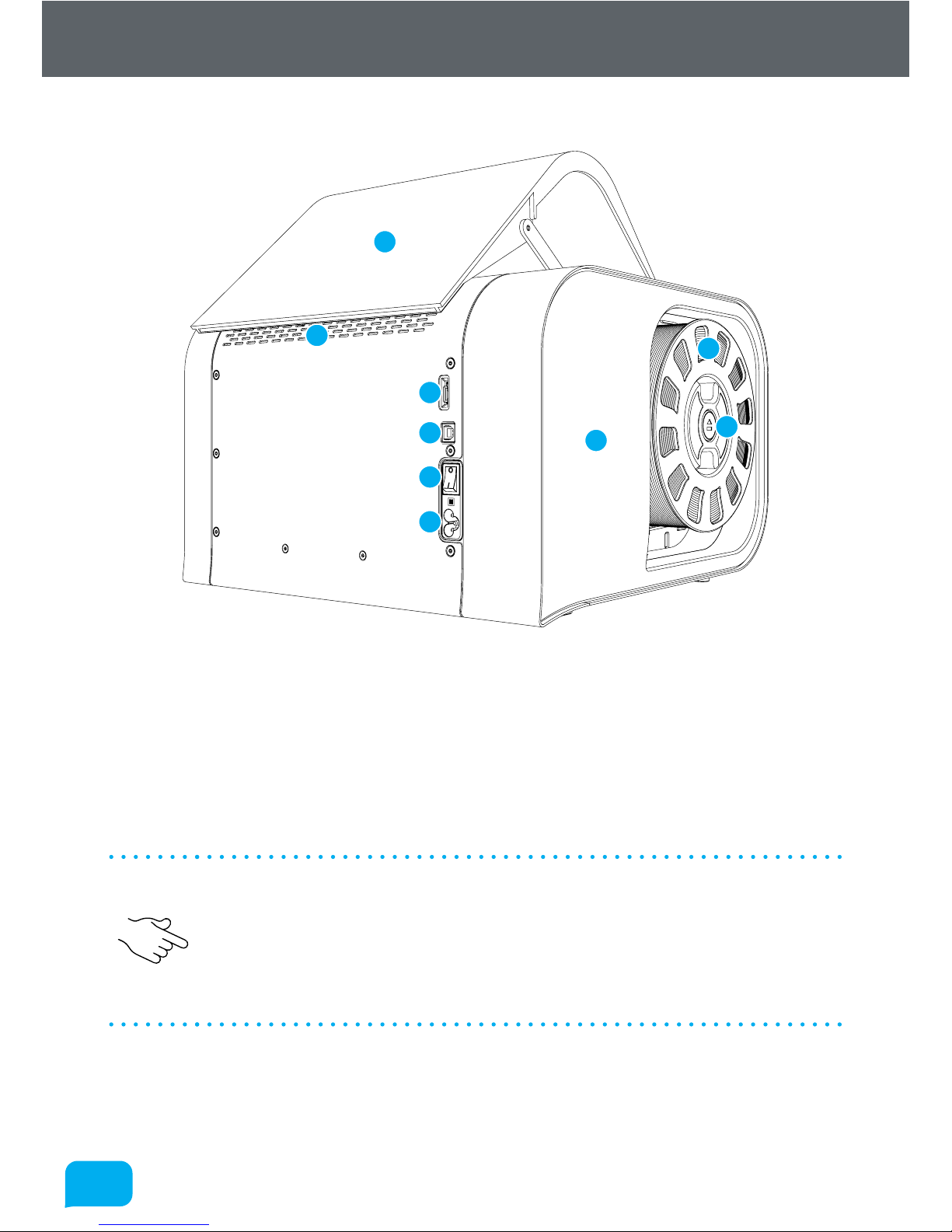

2.5 At A Glance

This section highlights all the major features of Robox®.

1

2

8

3

6

7

12

13

4

10

11

9

5

14

1 Print Head 8 X Axis Belt

2 X Carriage 9 Tip Wipe Blade

3 X Axis Rails 10 Reel Hub Cover

4 Print Bed 11 Door Interlock Latch

5 Y Axis Rail 12 Enclosure Door

6 Z Axis Rail and Drive Screw 13 Internal Ambient Lighting

7 Z Carriage (Right) 14 Front Tray Cover

2424

www.cel-robox.com

2.0 Overview

This view shows the rear connections of Robox® and the SmartReel™ location.

1

2

8

3

6

7

4

9

5

1 microSD Card Flash Storage 6 Pause/Resume/Eject Button

2 USB Type B Socket 7 Outlet Vents

3 Power Switch 8 Door

4 C5 ‘Cloverleaf’ Power Inlet 9 Side Cover

5 Robox® SmartReel™

• Although there is a microSD card accessible from the back of Robox®, this

cannot be read by any other machine and is only for use as internal flash

storage - access is provided only for diagnostic/repair purposes.

• Do NOT connect the USB cable until you have completed the installation of

AutoMaker™ - see section 3.3.

Getting Started

3.0

2626

www.cel-robox.com

3.0 Getting Started

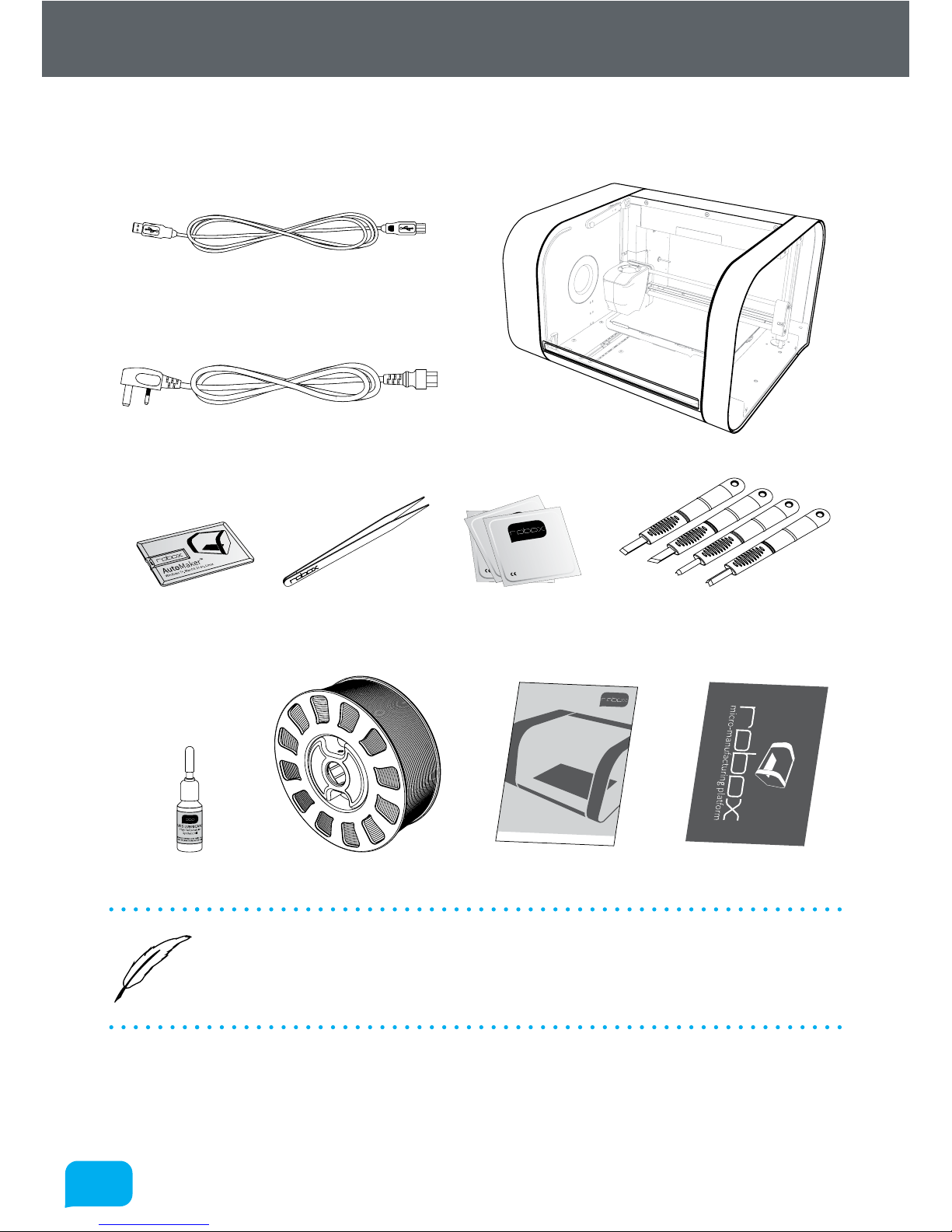

3.1 Package Contents

Check your product package for the following items.

Set of 4 Cleanup ToolsUSB Flash Drive Tweezers 10x Bed Wipes

Axis Lubricant

SmartReel™

2m USB A-B Cable

IEC C5 Power Cable

Safety Guide Warranty Card

Robox®

BED CLEANING WIPE

70% Isopropyl Alcohol

NOT FOR MEDICAL USE

0197

BED CLEANING WIPE

70% Isopropyl Alcohol

NOT FOR MEDICAL USE

0197

BED CLEANING WIPE

70% Isopropyl Alcohol

NOT FOR MEDICAL USE

0197

w

ww.cel-robox.com

Safety

Information

Versi

o

n

1

.0

• If any of the above items are damaged or missing, contact your retailer.

• The illustrated items above are for reference only. Actual product

specifications may vary with dierent models.

2727

www.cel-robox.com

3.0 Getting Started

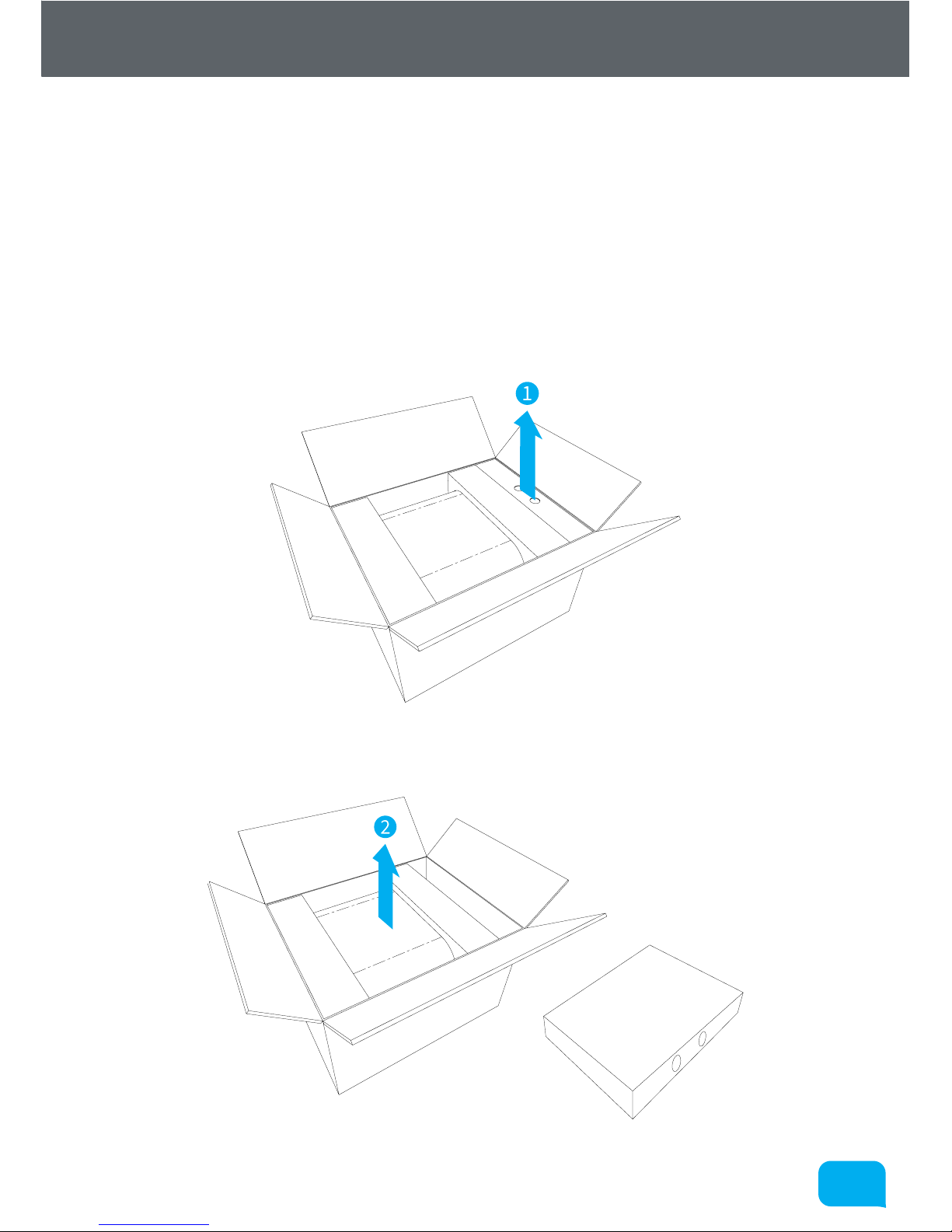

3.2 Unpacking Robox®

This section explains how to safely unpack your new Robox® and get it ready

for production! Your new micro manufacturing platform has been carefully

assembled and packaged at our factory to arrive with you in perfect condition.

Please follow the instructions below carefully to avoid causing any damage.

1. Carefully cut the tape along the top of the box, being careful not to cut too

deep, and open the box.

2. Remove the accessories box from the side by pulling on the plastic handle.

3. Li Robox® from the box using the two handles in the packing trays on either

side.

2828

www.cel-robox.com

3.0 Getting Started

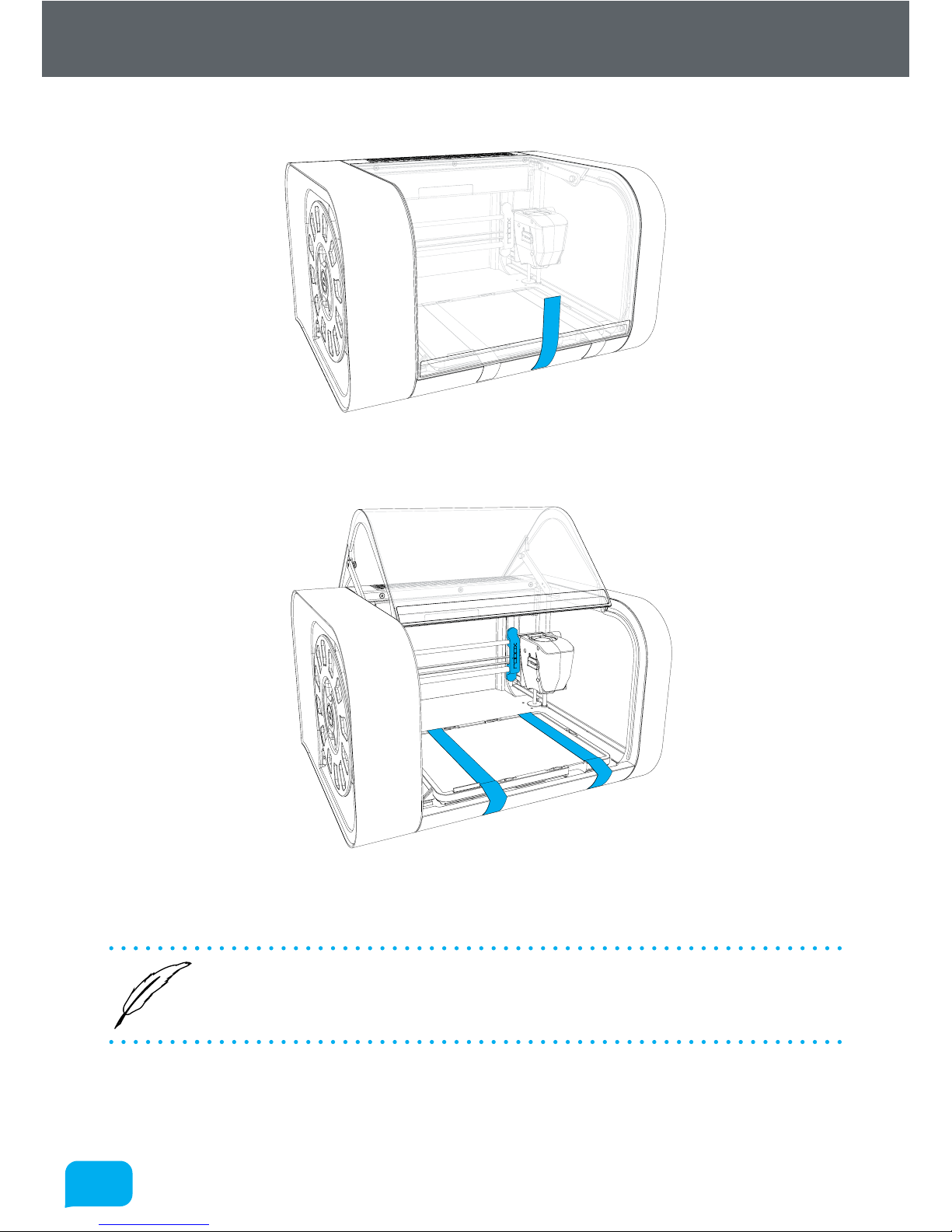

4. Remove the packing tape which is used to secure the door.

5. Remove the packing tape and warranty card which are secured to the bed and

the blue plastic packing clip used to secure the printhead.

6. Ensure that the head and bed are free to move before proceeding. You can

move them both by hand to check.

• We recommend that you keep hold of all of your packaging materials

should you need to return any parts to us.

2929

www.cel-robox.com

3.0 Getting Started

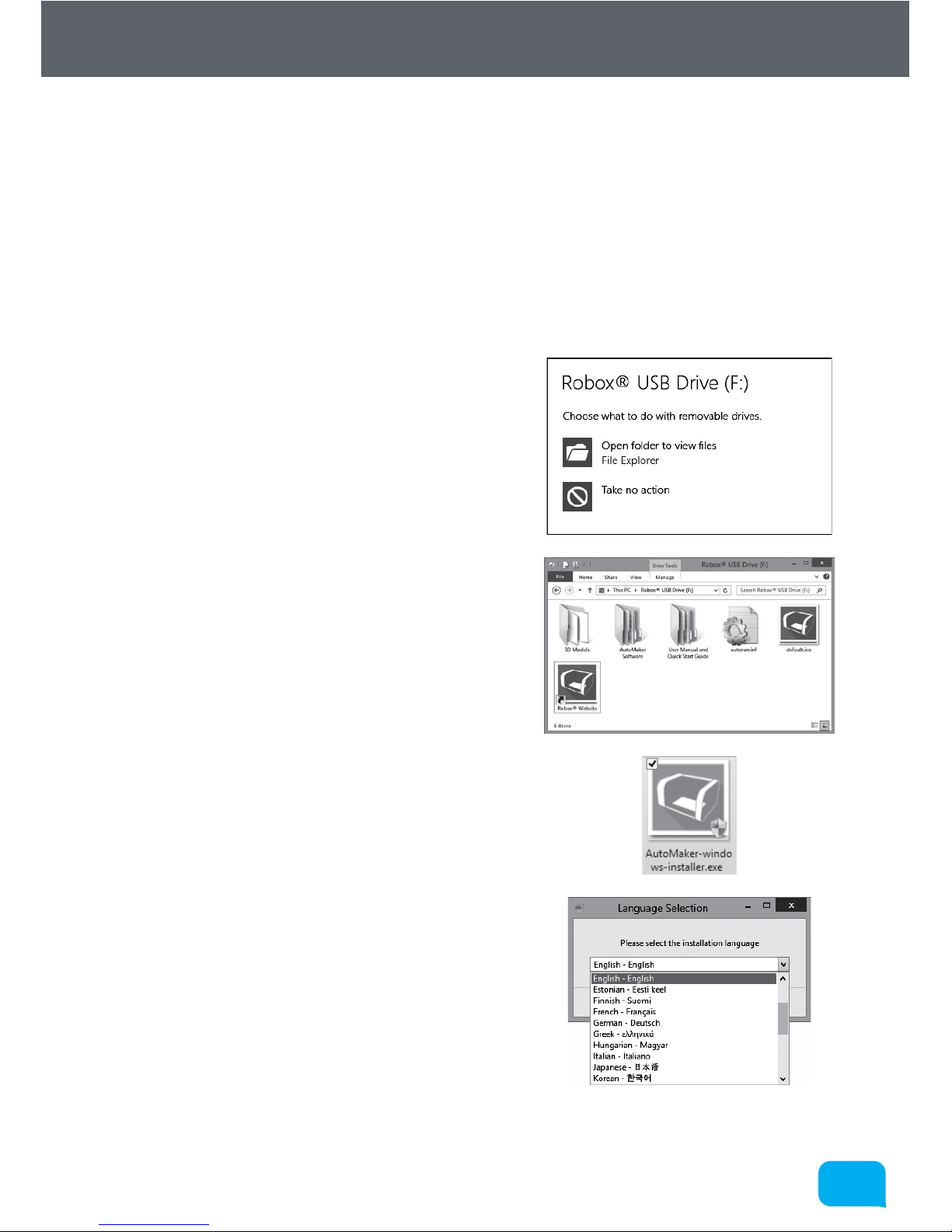

3.3 Soware Installation

This section explains in detail how to install the AutoMaker™ soware package for

controlling your Robox®. The included USB card drive contains this soware and

an electronic version of this document, as well as some sample .stl files for you to

print.

These steps may vary slightly depending on your operating system, all provided

screenshots and instructions are from Windows 8 for reference.

1. Plug your included USB drive into an

available USB port (drive letter may vary) choose Open folder to view files:

If this is not displayed, you can access the

drive through My Computer.

2. The contents of the drive will be displayed

in File Explorer as shown (view mode

may vary).

3. Navigate to \AutoMaker Soware\

Windows and run the installer by

double-clicking on the icon - AutoMaker-

windows-installer.exe

4. Select the installation language from the

dropdown menu, and then click OK to

continue.

3030

www.cel-robox.com

3.0 Getting Started

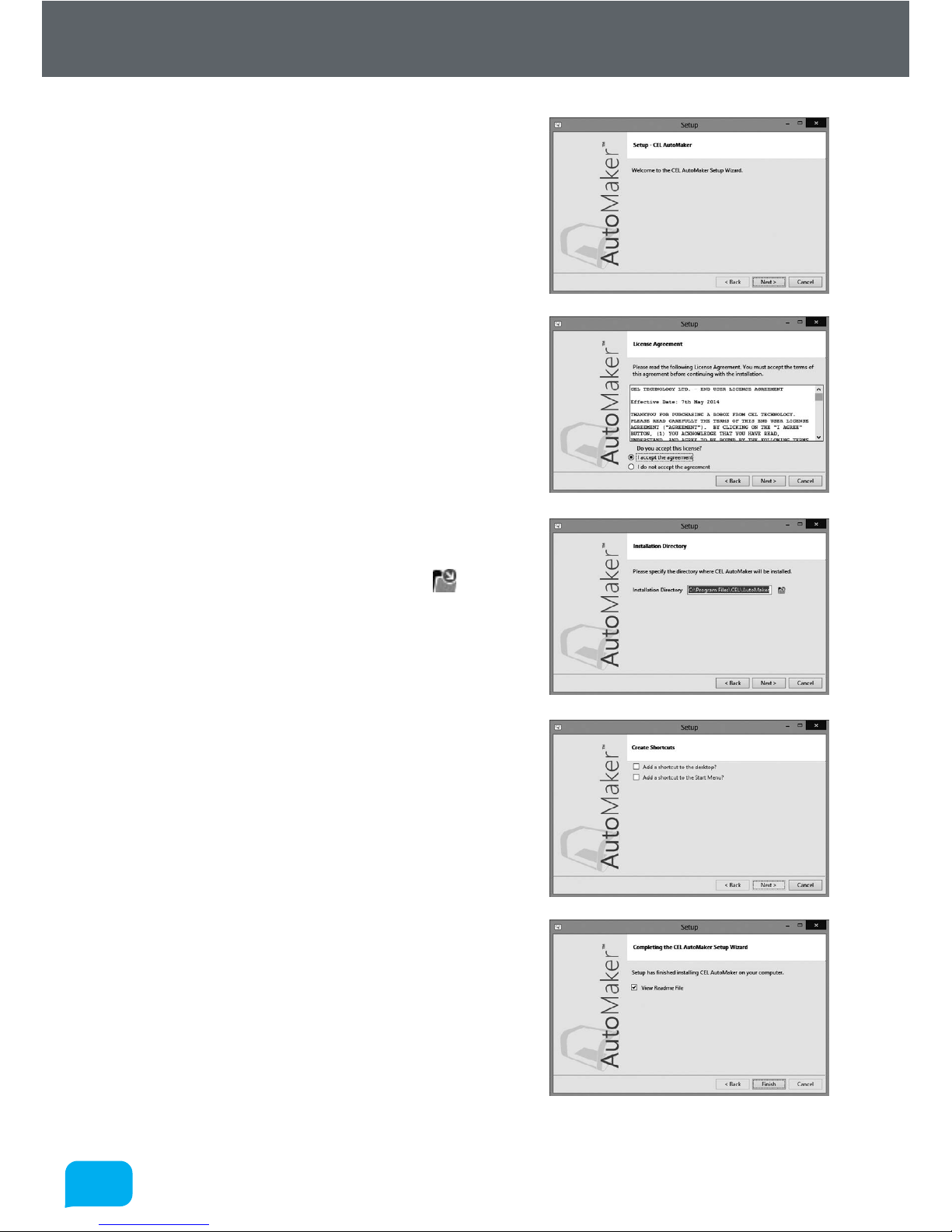

5. The installer will start, click Next > to

continue.

6. Please carefully read the Licence

Agreement and select ‘I accept the

agreement’, then select Next > to

continue.

7. Please choose where you would like to

install AutoMaker™ either by typing the

path directly, or by clicking the button.

Click Next > to continue and accept the

path and begin the installation. N.B. To

facilitate future support we recommend

using the default install location.

8. Choose whether you would like to add

Shortcuts to the Start Menu or Desktop.

Then click Next > and wait as AutoMaker™

is installed to your hard drive.

9. Installation is complete. Tick the checkbox

if you would like to read the ‘Readme’ file

aer clicking Finish.

3131

www.cel-robox.com

3.0 Getting Started

3.4 Starting AutoMaker™

This section explains how to start AutoMaker™ on all supported operating

systems.

3.4.1 On Windows

To start AutoMaker™, double click on the icon shown below on your desktop:

It can also be launched using the Start Menu in the normal way - it can be found

under ‘CEL’.

3.4.2 On MacOS

To start AutoMaker™, click the icon which has been added to your dock. It can

also be found under Applications in Finder.

3.4.3 On Linux

To start AutoMaker™, open a terminal window and navigate to the installation

directory (default is “CEL/AutoMaker”) and type “./AutoMaker.run” to start.

3232

www.cel-robox.com

3.0 Getting Started

3.5 Setting Up Your Robox® Account

This section guides you through registering your Robox® and setting up an

online account with us. When you start AutoMaker™ for the first time, the product

and customer registration screen will be displayed, allowing you to register for

product updates, support and warranty repairs.

• AutoMaker™ is continually being improved - please check our website for an

updated version of the user manual if you require further information.

• If you have completed the product registration within AutoMaker™, you do

NOT need to complete and return the included warranty card.

3333

www.cel-robox.com

3.0 Getting Started

3.6 Attaching the USB Cable

Robox® comes supplied with a 2 metre USB Type A-Type B cable for connecting

to your PC. Please connect as shown.

• DO NOT connect your Robox® until you have been through the soware

installation steps on the previous page and started AutoMaker™.

3.7 Attaching the Power Cable and Powering On

Connect the supplied AC power lead to Robox® and switch on using the rear

power switch.

1

2

This will install the necessary drivers for connecting your Robox® and could take

a few minutes. When correctly installed and switched on, it should appear in

Device Manager as a COM port called “Robox v1.0 (COM3)” (COM number may

vary). It should also appear on the Status Page of AutoMaker™, along with what

reel and head are installed.

Using Robox®

4.0

3535

www.cel-robox.com

4.0 Using Robox

4.1 Loading Filament

This section explains how to load your chosen 3D printing plastic filament

into Robox® ready to produce your first print! It is designed to be a very simple

process with most functions taking place automatically.

4.1.1 Preparing the Filament

Before attempting to load filament, it is advisable to cut the end at a shallow

angle using a knife or sharp scissors to produce a sharp tip as shown below. This

will allow the filament to enter the extruder and melt chamber more easily.

4.1.2 Feeding to the Head

Simply feed the end of the filament into one of the two extruder entrances

located in the bottom-le of the reel storage dock. If only one extruder is installed

in your machine, use the top path marked ‘1’. It is much easier to perform this

operation BEFORE installing the reel into the dock.

Once the filament reaches the extruder, you will hear the motor start; at this point

continue to feed in until you feel the filament has been grabbed. Robox® will then

automatically feed the material all the way to the head.

3636

www.cel-robox.com

4.0 Using Robox

4.1.3 Installing the Reel

Finally, install the SmartReel™ into the dock, you should hear a click when it

is correctly located, and it should appear as a recognised reel in AutoMaker™.

Congratulations! - you’re now ready to print.

3737

www.cel-robox.com

4.0 Using Robox

4.2 Unloading Filament

This section explains how to remove a reel of filament for storage or to change to

a dierent colour/material. This process has also been designed to be as simple

as possible, and can even be undertaken mid-print!

4.2.1 Pause / Resume / Eject Button

There is a button in the centre of the reel when installed which has three

functions - Pause, Resume and Eject. To pause the print, simply press this button

once, and to resume press the button again.

To eject filament, you must hold down this button for 3 seconds, at which point

you should hear the extruder motor start and the filament will start to reel back

onto the spool.

3838

www.cel-robox.com

4.0 Using Robox

4.2.2 Removing The Reel

Once the extruder motor has stopped, your filament has been fully ejected. Press

the two metal buttons on the top and bottom of the reel hub and pull the reel

away from the machine. Coil any extra material onto the reel - the loose end can

easily be held by weaving in and out of the holes in the rim.

1

2

1

4.3 Filament Storage

Most plastics, including ABS and PLA are ‘hygroscopic’ in nature i.e. they absorb

water from the surrounding environment. This oen has desirable eects, for

example in the case of Nylon, higher water content results in higher part strength.

However, when using plastic filament as a feedstock for 3D printing, higher water

content has a negative eect. As the plastic melts in the head, the water content

evaporates and turns into steam. As the molten plastic leaves the nozzle, the

reduction in pressure creates bubbles in the extrudate. This ‘outgassing’ of steam

can ruin the quality of the print, leaving pock marks in the surface finish where

the bubbles have popped.

It is therefore essential to store your filament somewhere very dry when your

Robox® is not in use for any extended period of time. SmartReels are packaged in

an airtight sealable bag with a sachet of silicagel, which should remove any water

from the bag and keep your filament dry. We recommend returning your filament

to its bag aer each print to ensure it stays print fresh!

If you already have ‘wet’ filament, it can be dried using an o-the-shelf dessicant

or dehumidifier - look out for colour indicating silicagel which changes from

orange to green to indicate it has become saturated. It can then be dried in a

conventional oven to ‘recharge’ it - refer to it’s accompanying instructions.

3939

www.cel-robox.com

4.0 Using Robox

4.4 The HeadLock™ System

This section explains how to change the head on Robox® allowing you to change

its functionality. The base model comes supplied with the Dual Nozzle, Single

Material head for FFF 3D printing. All future head designs will make use of the

same interface, and the HeadLock™ system has been designed to make head

replacement quick and easy. A microchip in each head also allows AutoMaker™

to automatically identify what head is installed, and set itself up appropriately.

4.4.1 Removing a Head

To remove the head, click the ‘Head Change’ button in AutoMaker™ and you will

see the head move into position to allow easy access to the locking screw.

Turn o your Robox® using the power switch on the back or at the wall

outlet.

This screw is located behind the head on the back of the X Carriage and is used

to firmly constrain and fix the head to the carriage. Reach over the top of the

head and rotate this screw counterclockwise to unlock, as shown in the diagram

below:

Head Change

Continue to rotate the locking wheel until you feel it turning freely.

4040

www.cel-robox.com

4.0 Using Robox

Once unscrewed, pull down the head as shown in the diagram below - you will

hear a ‘snap’ as the head disconnects.

1

2

4.4.2 Installing a Head

To install a new head into Robox®, the process is essentially the same in reverse.

First, push the bottom of the head into the carriage until you hear/feel a ‘snap’

- this signifies the head is correctly aligned and located, then simply tighten the

locking wheel until fully tight. You should see the head recognised in AutoMaker™

when you switch the power back on.

1

2

4141

www.cel-robox.com

4.0 Using Robox

4.5 Removing the Bed

To remove the PEI bed from your Robox®, simply slide the handle on the front of

the bed (highlighted in blue) to the le to release. Then li up the front edge of

the board using the finger recess (shown by the hand) and slide the bed towards

you.

4.6 Installing the Bed

To re-install the bed, simply slide the sheet towards the back of the tray, ensuring

the tabs are aligned beneath the 4 metal clips on the sides, and then push all the

way to the back until it slides under the rear clip and stops. Then simply slide the

handle on the front to the right, securing it in position.

AutoMaker Soware

5.0

4343

www.cel-robox.com

5.0 AutoMaker Soware

5.1 User Interface

This section outlines the major elements which make up the AutoMaker™ user

interface. There are basically 3 separate screens - Status, Layout and Settings.

• Status Screen - This page displays the current status of the selected printer. It

shows what it’s doing, what filament and head are installed, as well as extra

information on temperatures etc.

• Layout Screen - This page is used for laying out the 3D models of objects

you’d like to print. They can be moved, scaled, duplicated and rotated using

simple controls.

• Settings Screen - This page allows you to choose print settings, for example

materials, quality/speed, fill density and support.

The soware is designed to be as simple to use as possible, so we have removed

a lot of the more advanced settings from plain sight, but don’t worry there’s

plenty of room for you tinkerers too!

The diagram below shows the main screen elements of AutoMaker™.

1 Side Bar 4 Toolbar

2 Advanced Tray 5 Program Window

3 Tab Bar

1

2

3

4

5

4444

www.cel-robox.com

5.0 AutoMaker Soware

5.2 Print Workflow

• AutoMaker™ is continually being improved - please check our website for an

updated version of the user manual if you require further information.

4545

www.cel-robox.com

5.0 AutoMaker Soware

5.3 Status Screen

This section explains the status screen in more detail.

1 Connected Printers 6 Current Printer Status

2 Installed Filament 7 Unlock Door

3 Temperature Display 8 Eject Filament

4 Projects Tabs 9 Display Advanced Settings

5 Preferences 10 Go To Settings Screen

5.3.1 Connected Printers

This area of the screen displays the status of all printers which are currently

attached to your PC.

Ready

Printing

Paused

Notification

Error

1

2

3

4 5

6

7 8 10

9

4646

www.cel-robox.com

5.0 AutoMaker Soware

Each Robox® connected to AutoMaker™ has its own icon which displays the

name and current status of the printer, as well as an indicator which shows the

progress of the current print (if available).

The status icons can be summarised as follows:

• Ready - When Robox® is available and ready to print.

• Printing - When Robox® is currently printing an object.

• Paused - When Robox® has been paused during a print.

• Notification - When a message is available in the printer status.

• Error - When Robox® has a problem which must be resolved before

continuing.

5.3.2 Installed Filament

AutoMaker™ will automatically recognise the material installed on the reel using

data stored on a chip inside the reel. Depending on the type of filament on the

reel, they are displayed in dierent ways, as shown below:

Chroma Green

™

110m / 372g remaining

1: PLA

Robox® SmartReel™

This will be displayed as a reel symbol.

Generic/Custom 1

50m / 125g remaining

1: ABS

Generic/Custom Material

This will be displayed as a gear symbol.

Unrecognised Reel

Not Available

1: ERROR

Unrecognised/Unformatted Reel

This will be displayed as a crossed circle.

Some of this information is also displayed in the ‘Current Printer Status’ area of

the screen, where the reel is shown installed on the le of the printer.

5.3.3 Temperature Display

This area of screen displays a historical graph of the bed, nozzle(s) and ambient

temperature over time.

4747

www.cel-robox.com

5.0 AutoMaker Soware

5.3.4 Projects Tabs

This part of the screen shows the currently available print jobs. On starting,

AutoMaker™ will create an empty project and load any projects which weren’t

closed on the previous run. Other functions are summarised below:

- Creates a new project file

- Displays the context menu explained below

Export

Rename

Upload

Email

- Change the name of the project

- Export the selected project as a .robox file

- Email the selected project

- Upload the selected project to your Robox® Account.

5.3.5 Current Printer Status

This part of the display provides an overview of the selected Robox®. It shows you

what filament, bed and head is installed and also displays warning and status

messages.

For example when installing a new filament reel, you will see the reel appear on

the status screen. As the bed and head are heating up, you will see a warning

message appear once the temperature exceeds 60°C (140°F):

WARNING!

Hot Surfaces

4848

www.cel-robox.com

5.0 AutoMaker Soware

5.3.6 Advanced Settings

This part of the screen allows you to perform more advanced functions relating

to the overall printer - print job settings are accessed from the Settings Screen see section 5.5. Its functions are summarised below:

1 GCode Console Output 5 Head Programming

2 GCode Text Entry 6 Calibration and Maintenance

3 Send GCode to Robox® 7 Diagnostics

4 SmartReel™ Programming

• GCode Console

This console allows you to manually send GCode commands to Robox® over

the USB cable. Simply type the command in the text entry box (2) and then

click Send GCode (3). A list of all GCode commands applicable to Robox®

can be found in the Supplementary Information section at the back of this

manual - section 8.1.

1

2 3

4 5 6 7

4949

www.cel-robox.com

5.0 AutoMaker Soware

5.3.7 Advanced Settings - SmartReel™ Programming

This page is for writing custom material parameters to a Robox® SmartReel™.

Simply choose which reel to apply the settings to, choose a material from the list

- custom or oicial, then click the Program Reel button.

1 Apply to Reel Hub 1 3 Material Selection

2 Apply to Reel Hub 2 4 Program Reel

5.3.8 Advanced Settings - Head Programming

This page is for programming the print head with the correct settings based on

CEL supplied defaults. Simply click the type of head you have, and click Reset

to Defaults. It also displays the unique serial number for your printhead which is

useful when contacting CEL support.

1 Select Head Type 3 Reset Head Defaults

2 Head Serial Display

1 2

3

4

1

2

3

5050

www.cel-robox.com

5.0 AutoMaker Soware

5.3.9 Advanced Settings - Calibration and Maintenance

This page is for executing a wide range of ‘macros’ (small GCode programs that

execute sequentially) and for access to machine calibration - see section 7.1.

1 Send SD GCode 9 Y Test Routine

2 Stream GCode USB 10 Speed Test

3 Clean Fine Nozzle 11 Level X Gantry

4 Clean Fill Nozzle 12 Level Y Axis

5 Purge Material 13 Calibrate Nozzle Opening

6 Eject Stuck Material 14 Calibrate Nozzle Height

7 X Test Routine 15 Load Firmware

8 Z Test Routine

• Send GCode Manually

AutoMaker™ can be used to send GCode manually to Robox® by one of two

methods - SD (1) or USB (2) i.e. sending data to the onboard SD flash storage

before executing, or transmitting each command one by one over the USB

1 2

3 4

5 6

7 8

9 10

11 12

15

13

14

5151

www.cel-robox.com

5.0 AutoMaker Soware

cable as they are executed.

• Clean Nozzles

This executes a short GCode ‘macro’ that makes use of the Tip Wipe blade

at the front of the bed, and as such should only be executed when the bed is

clear of objects. You can choose to clean either the fill or the fine nozzle.

• Purge Material

This executes the purge routine, which is used when changing between two

dissimilar materials - see section 7.2.1.

• Eject Stuck Material

If you are having diiculty ejecting your filament, this routine may be able to

rectify the problem. If you are still unsucessful, please contact CEL support.

• Test Routines

These routines are for checking the performance of all the motor axes - X,

Y and Z. Speed test gradually ramps up the speed as the test progresses,

allowing you to isolate any issues with motion.

• Level X Gantry

This button executes the automatic bed levelling algorithm. By probing the

bed in multiple locations, Robox® is able to determine the level of the bed

and independently adjust the Z motors to ensure the X gantry is parallel.

• Level Y Axis

This is currently an experimental feature which can further improve

the quality of bed levelling. Rather than just levelling the gantry, it can

continuously adjust the Z height as the bed moves forwards and backwards,

ensuring the nozzle is always the same distance from the bed.

• Calibrate Nozzle Opening

This routine is used to calibrate the point at which the needle valves in the

head operate - see section 7.1.1.

• Calibrate Nozzle Height

This routine is used to calibrate the nozzle li height - see section 7.1.2.

• Load Firmware

You shouldn’t require this function, unless directed by CEL support - it is used

for manually flashing the onboard firmware.

5252

www.cel-robox.com

5.0 AutoMaker Soware

5.3.10 Advanced Settings - Diagnostics

This page is really only intended for diagnosing possible faults with your Robox®.

It displays the serial numbers of the printer and the head which will be required

when contacting CEL support. It also displays the state of all of the microswitches

in the printer so that you can verify they are functioning correctly.

1 Printer Serial Number 3 Switch Diagnostics

2 Head Serial Number

• Switch Diagnostics

When any of these switches are triggered on the hardware, they will light up

on screen, so you can verify if they are working. There are lights for all limit

switches, the door open switch (located in the top le of the build chamber,

where it interacts with the door arm), the reel eject button, and the feedback

from both extruders. Each extruder has two outputs - ‘loaded’ is the extruder

output switch which detects when filament leaves the extruder, and index is

the output from the indexing wheel which measures the passage of filament

- you will see it toggle on and o as you move filament back and forth.

1

2

3

5353

www.cel-robox.com

5.0 AutoMaker Soware

5.4 Layout Screen

This section explains how to lay out objects on the bed and prepare for printing.

1 Return to Status Screen 8 Auto Layout All Objects

2 Undo Previous Change 9 Group/Ungroup Objects

3 Redo Change 10 Preferences

4 Add New Model 11 Go To Settings Screen

5 Remove Selected Model 12 Model Display

6 Duplicate Selected Model 13 Advanced Settings

7 Lay Model Flat

• Preferences

This displays the AutoMaker™ preferences page - see section 5.6.

• Model Display

This displays a preview of the selected print job, showing the print bed and

any objects you have added, arranged as they will be printed. You can rotate

the view by clicking the right mouse button and dragging , pan around by

holding the <Alt> key and dragging with the right mouse, and zoom by rolling

the mouse wheel.

1

1

2 3 4 5 6 7 8 9

10

11

12

13

5454

www.cel-robox.com

5.0 AutoMaker Soware

Rotate View (click and drag)

+

Pan View (click and drag)

Zoom (scroll wheel)

Select and manipulate models

+

Select multiple models

5.4.1 Arranging Items on the Bed

This section explains the layout function of the soware which allows you to

arrange your 3D models on the bed ready for printing. It is designed to be very

simple, requiring only the following buttons:

Undo

Step back through the history of layout operations

you have completed i.e. undo the last command you

executed.

Redo

Step forward through the history of layout operations.

Add Model

This is used to add a new model (.stl/.obj) to the

build plate - clicking it reveals a file browser dialog to

choose your model from the local filesystem.

Remove Model

This is used to remove the selected model from the

build plate.

Duplicate

This is used to duplicate the currently selected item

and place it on the build plate.

5555

www.cel-robox.com

5.0 AutoMaker Soware

Lay Flat

This is for reorienting your model to the build plate.

Click the button, and then select a surface on the

model that you would like to lay flat to the bed.

Auto Layout

This automatically arranges all models on the bed

with suicient clearance between them and no

interference.

Group

This used to collect multiple objects together into one

selection. When a group is selected, this button will

toggle to ‘Ungroup’.

• AutoMaker™ is continually being improved - please check our website for an

updated version of the user manual if you require further information.

5656

www.cel-robox.com

5.0 AutoMaker Soware

5.5 Settings Screen

This section explains the basic settings page of the soware which allows you to

choose quality options and materials for your print.

1 Filament Settings 5 Start the production (Make!)

2 Print Settings 6 Return to Status Screen

3 Advanced Settings 7 Model Display

4 Return to Layout Screen

5.5.1 Starting Production

To start a print, simply choose a quality setting from the Print Settings box (2),

verify that your material has been selected in the Filament Settings box (1), and

press Make! (5).

AutoMaker™ will then begin to slice your 3D model and transfer to your Robox®

ready for printing. Due to the unstable nature of printing ‘by wire’ - sending data

over USB during a print, Robox® incorporates onboard flash storage for storing

print jobs once production has started. This means that when the print job

has been fully transferred, you can disconnect from the USB, and Robox® will

continue to print unattached.

1

2

4 5

6

7

3

5757

www.cel-robox.com

5.0 AutoMaker Soware

5.5.2 Filament Settings

This part of the screen displays what colour and type of filament is currently

installed in the machine and allows you to choose and create custom material

profiles. It will also show you how much material is remaining on each reel. A

brief description of its functions is shown below:

1 Extruder 1 Reel 4 Material Colour

2 Extruder 2 Reel 5 Filament Remaining

3 Material Type 6 Filament Type

• Material Type

This displays the material on the reel of filament which is currently

installed in Robox® - 1 for the primary reel and 2 for the secondary. A whole

range of dierent materials is available to purchase on SmartReels from

www.cel-robox.com.

• Material Colour

This displays the colour of the reel which is installed - click the dropdown

menu to define a custom filament - see section 5.5.4.

• Filament Remaining

This displays the amount of filament le on the reel in metres and grams.

• Filament Type

This icon denotes the type of reel installed in Robox® - SmartReel™, Custom,

Unkown or Unrecognised - see section 5.3.2.

1

2

3

4

5

6

5858

www.cel-robox.com

5.0 AutoMaker Soware

5.5.3 Print Settings

This allows you to adjust the quality and print profile for production.

1 Quality Setting 4 Fill Density

2 Custom Print Profile 5 Support Material Setting

3 Profile Summary 6 Brim Width

• Quality Setting

This allows you to select a basic quality setting from the list of options - Dra,

Normal or Fine. The final option - Custom allows you to create a new profile

or to select from a previously created one. To create a new profile, click the

selection box and choose Create New... - this will expand the Advanced Tray

to the right (see section 5.5.5).

• Profile Summary

This displays a brief summary of the currently selected print settings. The

information available is as follows:

• Layer Height in microns (µm).

• Perimeters use - which nozzle is used to print the outside surface of the

object.

• Infills use - which nozzle is used to print the inside fill of the object.

1

2

3

4

5

6

5959

www.cel-robox.com

5.0 AutoMaker Soware

• Fill Density

This setting allows you to choose how ‘solid’ you would like the finished

object to be. The fill pattern can also be changed using a custom profile - see

section 5.5.6.

90% Fill 80% Fill 70% Fill 60% Fill 50% Fill 40% Fill 30% Fill

• Support Material

This switch toggles the printing of support material. If you are printing a part

with large overhangs, you may wish to print structures at the same time

to support the object. Support settings (e.g. density and type) can also be

changed using a custom profile - see section 5.5.8.

• Brim Width

‘Brim’ is a term applied to FFF (Fused Filament Fabrication) which describes

a large flat area which is printed around the part to help with bed adhesion

and warping. It can be easily trimmed o aer printing, but may greatly

increase the success rate of prints with a small surface area at the base. This

number specifies the number of loops (and therefore the width) of the brim.

6060

www.cel-robox.com

5.0 AutoMaker Soware

5.5.4 Advanced Settings - Material

This section explains the advanced page, and it’s associated functions and

options.

1 Material Name 7 Bed Temperature

2 Material Type 8 Bed Temperature (1st Layer)

3 Material Colour 9 Nozzle Temperature

4 Filament Diameter 10 Nozzle Temperature (1st Layer)

5 Filament Multiplier 11 Ambient Temperature

6 Feed Rate Multiplier 12 Help Text

1

5

2

6

9

3

7

10

12

4

8

11

6161

www.cel-robox.com

5.0 AutoMaker Soware

• Material Name

This field can be used to name the material profile - this will be displayed on

the Status page when the reel is installed in the dock.

• Material Type

Pick the material type here from the list of available options, or type the

name of the material yourself.

• Material Colour

Pick the material colour here, or choose custom to define your own colour.

• Filament Diameter (mm)

Enter the diameter of your filament in mm - it is recommended to use digital

calipers / micrometer to obtain an accurate value for this field.

• Filament Multiplier

This value is used to compensate for the ‘squishyness’ of your material. As

filament passes through the extruder, it can be compressed by the feed

wheels causing to change shape slightly. This can aect the amount of

material that is fed to the head - the harder the material, the closer this value

should be to 1.

• Feed Rate Multiplier

This multiplier allows you to finely tune the extrusion rate of the material - it

can be adjusted during a print to obtain the optimum extrudate profile.

Increasing the value above 1 will cause more material to be extruded and

vice versa - 2 would be equivalent to 200% material flow. It varies the amount

of plastic proportionally and should be changed in very small steps (e.g. +/-

0.05) as the eects are very visible.

• Bed Temperature (°C)

This value sets the temperature of the print bed surface during a print. A

heated bed will help to reduce warping and improve adhesion of a wide

range of materials. ABS requires a bed temperature of approximately 110°C

for good adhesion, whereas PLA only requires 60-80°C.

• Bed Temperature (1

st

Layer) (°C)

This value sets the temperature of the print bed surface when printing the

very first layer of the object. This value is oen set higher to ensure good

adhesion when starting a print, however the temperature can be lower for

the remainder of the print, or it may cause the object to ‘sag’ at its base.

6262

www.cel-robox.com

5.0 AutoMaker Soware

• Nozzle Temperature (°C)

This value sets the temperature of the nozzle used for printing the material.

Dierent thermoplastics require dierent nozzle temperatures due to their

diering melting points (or more accurately, glass transition temperatures).

For example, most ABS requires a nozzle temperature of 240°C, whereas PLA

only requires 200°C to print successfully.

• Nozzle Temperature (1

st

Layer) (°C)

This value sets the temperature of the nozzle when printing the very first layer

of the object. This value is oen set higher to ensure good adhesion when

starting a print, however the temperature can be lower for the remainder of

the print.

• Ambient Temperature (°C)

This value sets the temperature of the enclosed build area. By maintaining

the temperature of the environment, it is possible to keep the printed object

warm, reducing its tendency to shrink and warp. The best results will be

obtained by maintaining the temperature of the object until the end of

the print when the whole object can be cooled simultaneously. Warp is

introduced when the part is cooling unevenly, with areas that are shrinking

exerting forces on areas that are still warm and so.

• Help Text

This box displays a brief explanation of the setting which is highlighted

(changes on mouseover).

6363

www.cel-robox.com

5.0 AutoMaker Soware

5.5.5 Advanced Settings - Print Profile

This section explains the advanced page, and it’s associated functions and

options:

1 Advanced Extrusion Settings 4 Advanced Speed Settings

2 Advanced Nozzle Settings 5 Advanced Cooling Settings

3 Advanced Support Settings

• Advanced Extrusion Settings

This allows you to adjust advanced printing profile parameters relevant to

extrusion e.g. layer height, fill density and fill pattern - see section 5.5.6.

• Advanced Nozzle Settings

This allows you to adjust advanced printing profile parameters relevant to

both nozzles and needle valve control - see section 5.5.7.

• Advanced Support Settings

This allows you to adjust advanced printing profile parameters relevant to

automatic support material generation e.g. angle threshold and support

pattern and density - see section 5.5.8.

• Advanced Speed Settings

This allows you to adjust advanced printing profile parameters relevant

to print speed e.g. perimeter speed, infill speed and bridging speed - see

section 5.5.9.

• Advanced Cooling Settings

This allows you to adjust advanced printing profile parameters relevant to

cooling e.g. fan speeds and minimum time per layer - see section 5.5.10.

3 41 52

6464

www.cel-robox.com

5.0 AutoMaker Soware

5.5.6 Advanced Settings - Extrusion

These settings allow you to adjust all the parameters which aect the

extrusion of plastic and generally relate to print quality and speed. By tuning

these values, users can control the appearance, strength and surface finish of

objects, as well as dramatically aecting print speed by varying layer height,

fill pattern, density and perimeters.

1 Layer Height 5 Top and Bottom Layers

2 Fill Density 6 Number of Perimeters

3 Fill Pattern 7 Brim Width

4 Infill Every ... Layers 8 Help Text

1

5

2

6

3

7

8

4

6565

www.cel-robox.com

5.0 AutoMaker Soware

• Layer Height (mm)

This setting defines the layer height (essentially the print resolution) of

the printed object. Users can select from any value between 20-400µm,

however this setting will dramatically aect print time as shown in the below

illustration: