V

1610 West 1600 South Springville, UT 84663

Phone: 801-489-4466 FAX: 801-489-8241

Robotronics.com

Vehicle Robot Operating Manual

ersion 6.6

i

Vehicle Operating Manual

Congratulations on your purchase of a ROBOTRONICS, Inc. robot.

Your robot has been carefully constructed of the highest quality components. Its

design is the result of years of experience building robots. You will find it an

extremely effective spokesperson for safety and your organization. It is built for

ease of operation, maintenance and repair. It is built so that you can easily expand

its functions making its value grow as your needs grow.

Please read this manual carefully. It will help you make the most of your

robot. Attention to maintenance and proper training will greatly prolong the life of

your robot. Train users to take care of the robot and keep the robot covered and

indoors. Most problems you encounter will be minor and the manual will provide

an answer. Please feel free to contact us if you have unanswered questions relating

to operation, maintenance, and repair. Call 801-489-4466. Also, if you have

technical questions relating to expanding the functions of your robot, we would be

happy to help.

Sincerely,

ROBOTRONICS, Inc.

ROBOTRONICS INC.

Springville, Utah 84663

www.Robotronics.com

Robotronics Inc., 2009.

Robotronics

ii

Contents

Warranty Information ..............................................................................................1

PART 1 General Operating Instructions..........................................3

Chapter 1 Getting Started......................................................................3

Operating Tips and Safety Information ................................................................. 3

Setup and How to Operate The Robot..................................................................4

Transporting the Robot ......................................................................................... 7

PART 2 Subsystems of the Robot......................................................8

Chapter 2 Radio Control System...........................................................9

Radio Control Operating Instructions.................................................................... 9

Radio Control Transmitter (Diagram).................................................................. 10

Radio Control Transmitter Controls..................................................................... 11

NI-MH R.C. Transmitter Battery.......................................................................... 13

Charging of the NI-MH R.C. Transmitter Battery (Diagram)................................ 14

Adapter for Charging...........................................................................................14

Chapter 3 Voice System Overview......................................................15

Location of Voice Units ....................................................................................... 15

Belt Transmitter...................................................................................................16

Robot Receiver ................................................................................................... 17

151 System (Robot TX and Belt 151 Receiver) ..................................................18

Voice System Troubleshooting ........................................................................... 19

Mouth Operation................................................................................................. 21

Operator’s Voice Headset, Transmitter, and Receiver........................................ 22

Chapter 4 Audio Amplifier...................................................................23

Chapter 5 MP3 Player...........................................................................24

Chapter 6 Cassette Tape Player System............................................26

Chapter 7 Siren.....................................................................................27

Chapter 8 Robot Battery Systems.......................................................28

Robot Battery......................................................................................................28

Robot Battery Charger ........................................................................................29

Chapter 9 Drive Motor System ............................................................31

Chapter 10 Character Head Turning Motor System...........................33

Chapter 11 Eyelids and Eyes Left and Right......................................34

Contents

iii

Chapter 12 Optional Accessories

Water Squirter System........................................................................................ 36

Water Squirter System Diagrams........................................................................ 36

Pitch Shifter (Voice Modifier)............................................................................... 37

Stop Arm Option – Bus ....................................................................................... 39

Crossing Arm Option – Bus................................................................................. 40

PART 3 Assembly & Disassembly................................................41

Chapter 13 Assembly & Disassembly.................................................41

PART 4 Maintenance................................................................................ 43

Chapter 14 Maintenance ......................................................................43

Regular Maintenance Checklist ..........................................................................43

Recommended Tool Kit....................................................................................... 44

Care of Character Fur.........................................................................................45

Painting of the Body............................................................................................ 46

Repair of the Body .............................................................................................. 47

Storage................................................................................................................ 48

Appendices

Appendix A..............................................................................................49

QUICK REFERENCE TROUBLESHOOTING .............................................50

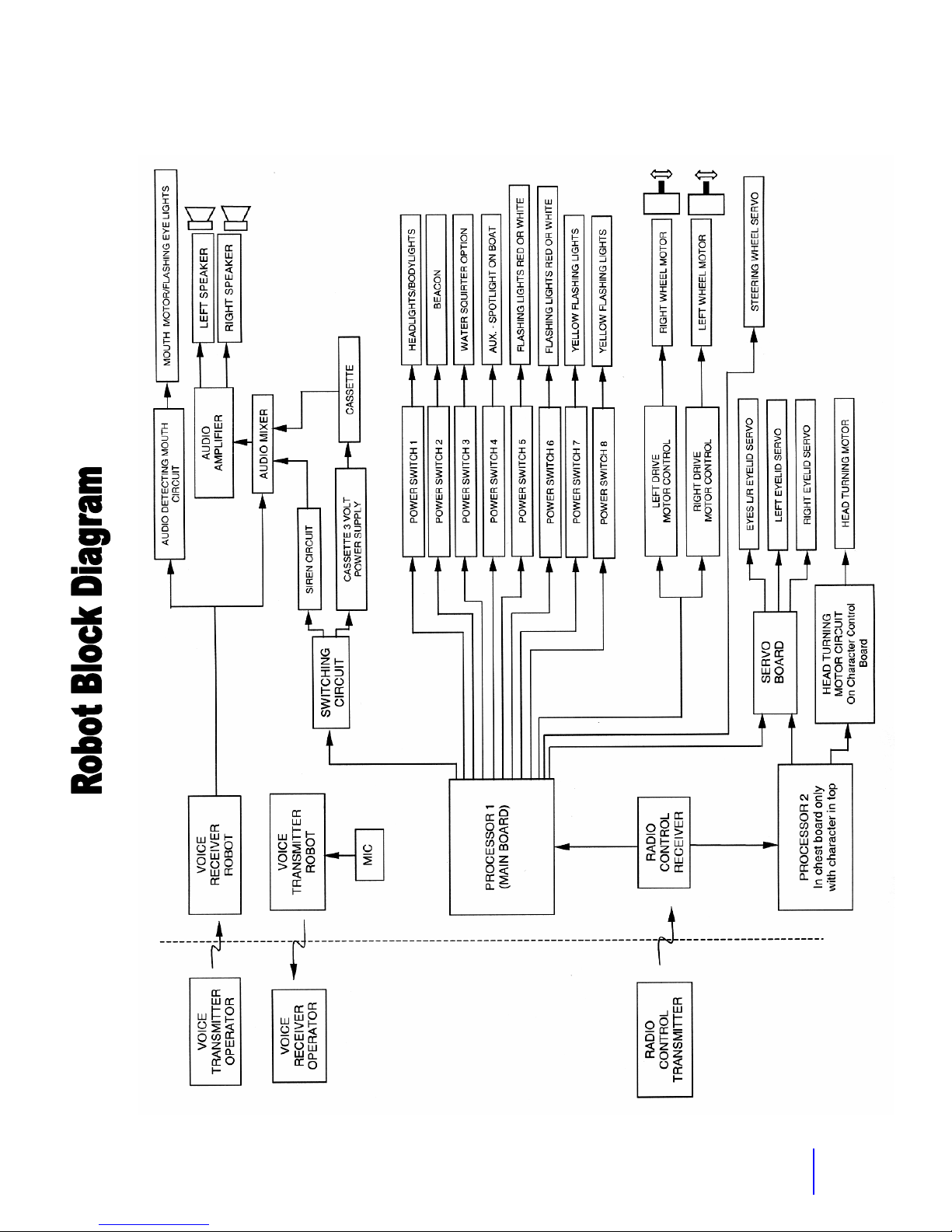

Robot Circuit Block Diagram............................................................................... 53

Appendix B Robot Parts Identification...............................................54

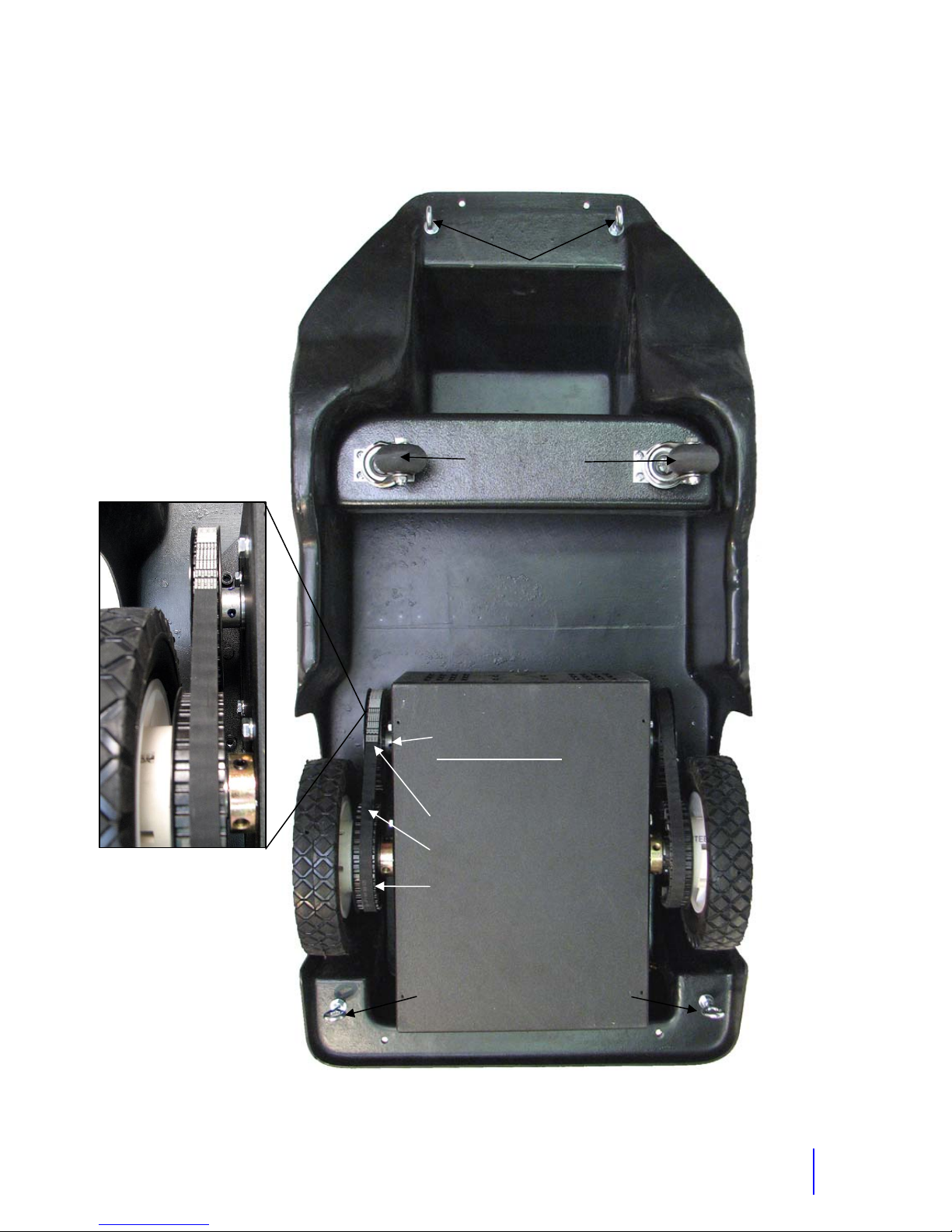

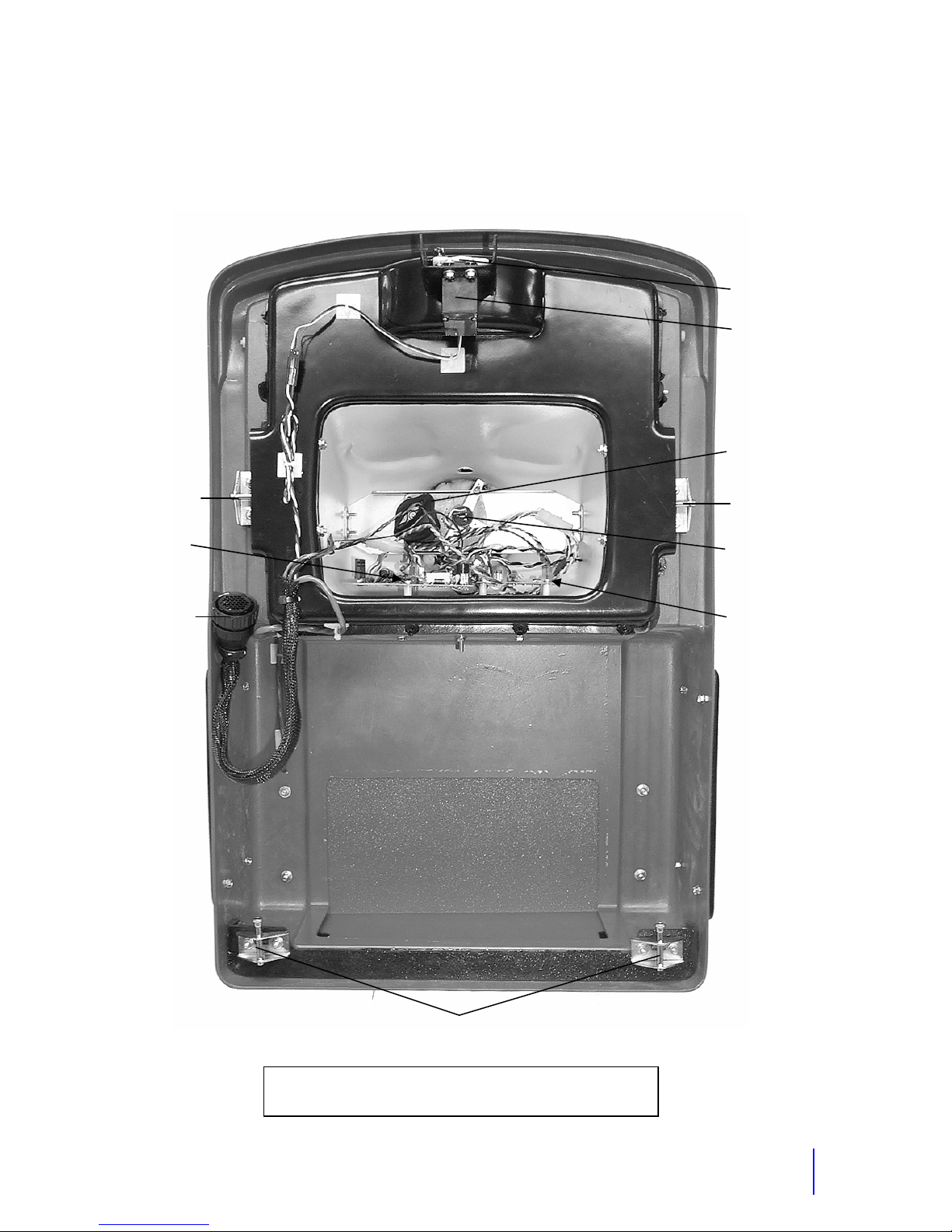

Robot Frame Top View 1 ....................................................................................55

Robot Frame Top View 2 ....................................................................................56

Main Electronics Box/Panel ................................................................................ 57

Vehicle Main Electronics Board .......................................................................... 58

Led Functions on the Main Board.......................................................................59

Vehicle Fuse Block Detail ................................................................................... 60

Robot Frame Bottom View-Motor Pulley Set Screws..........................................61

Vehicle Top 1 Underside View............................................................................ 62

Vehicle Top 2 Underside View............................................................................ 63

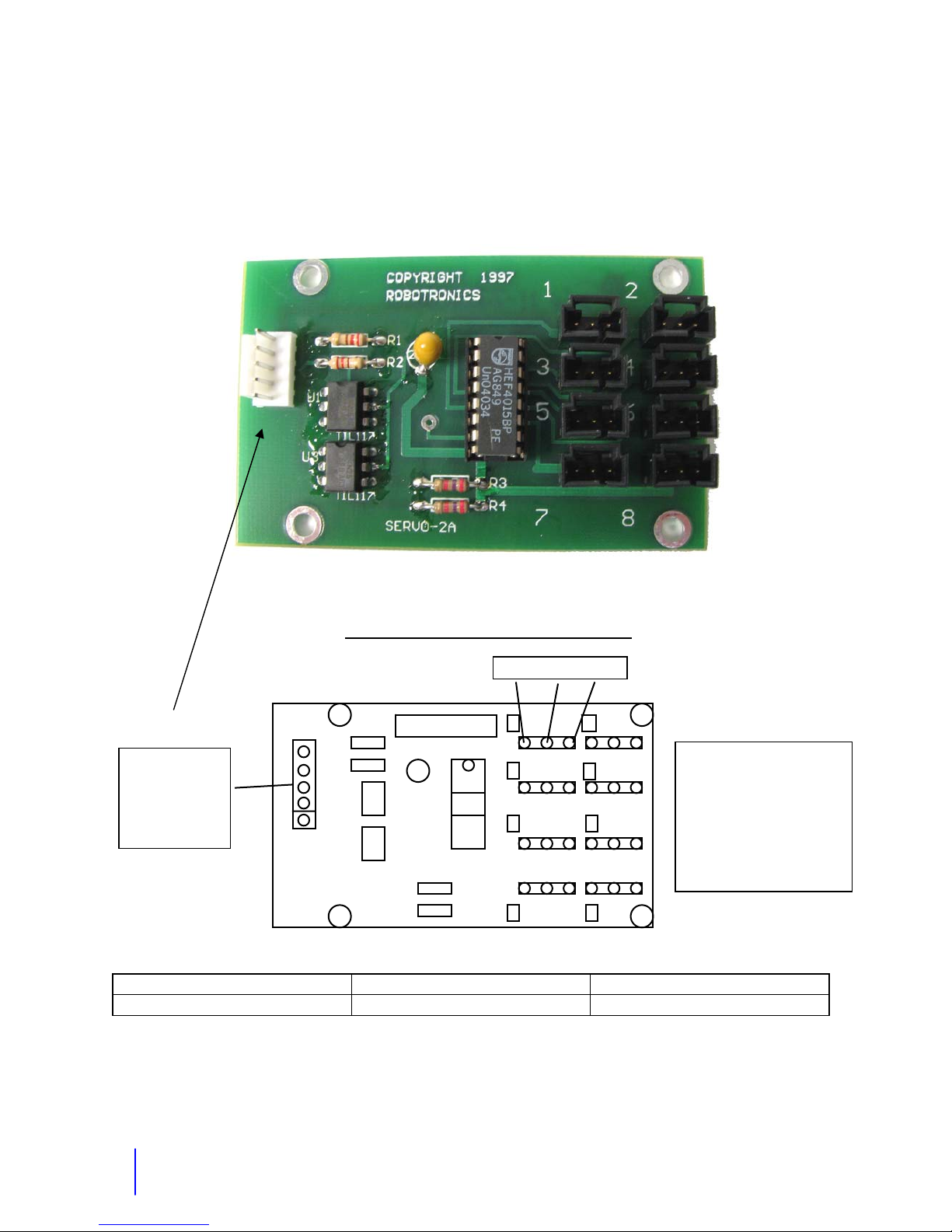

Eyes Servo Board ...............................................................................................64

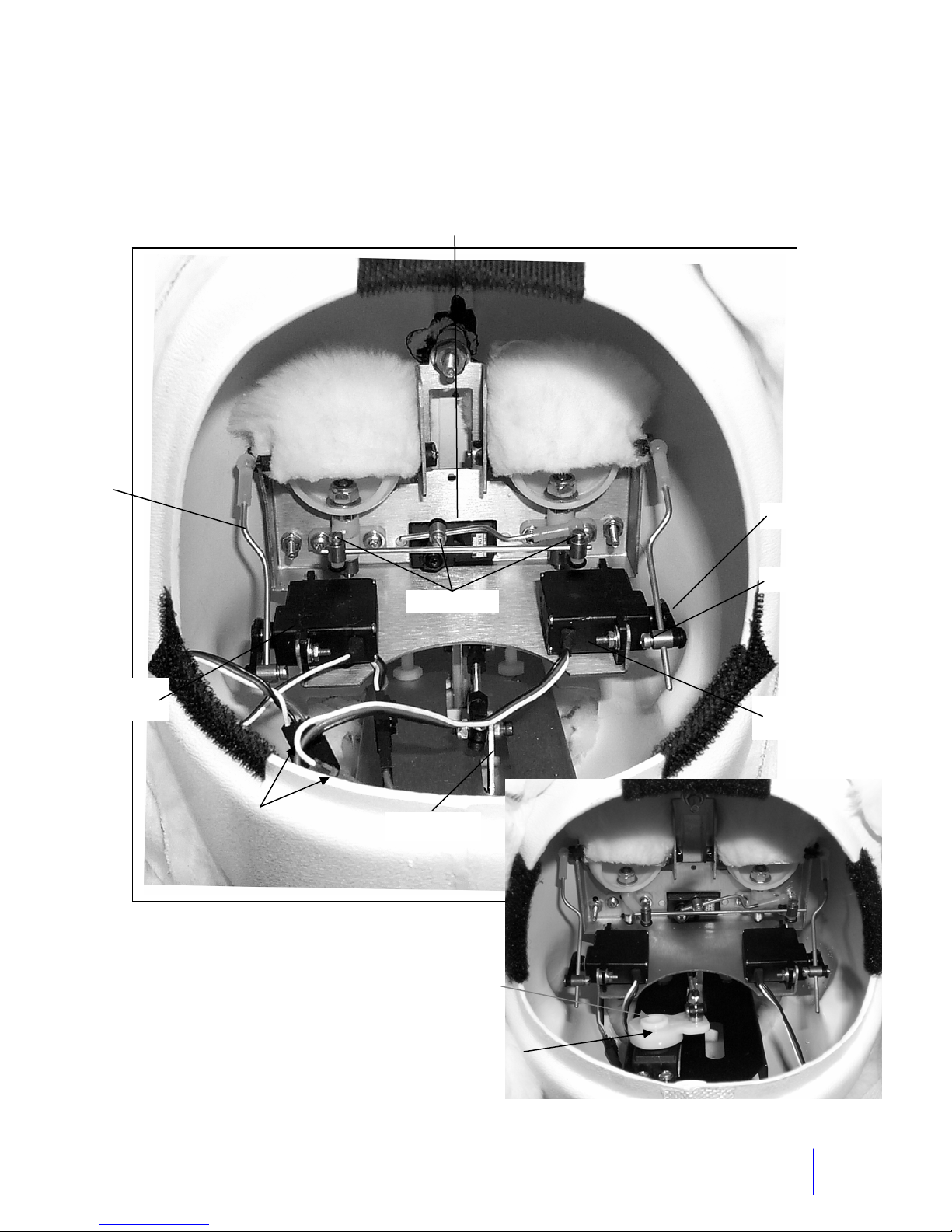

Character Head-Inside View...............................................................................65

Character Top Underside View........................................................................... 66

Character Top 2 Underside View........................................................................ 67

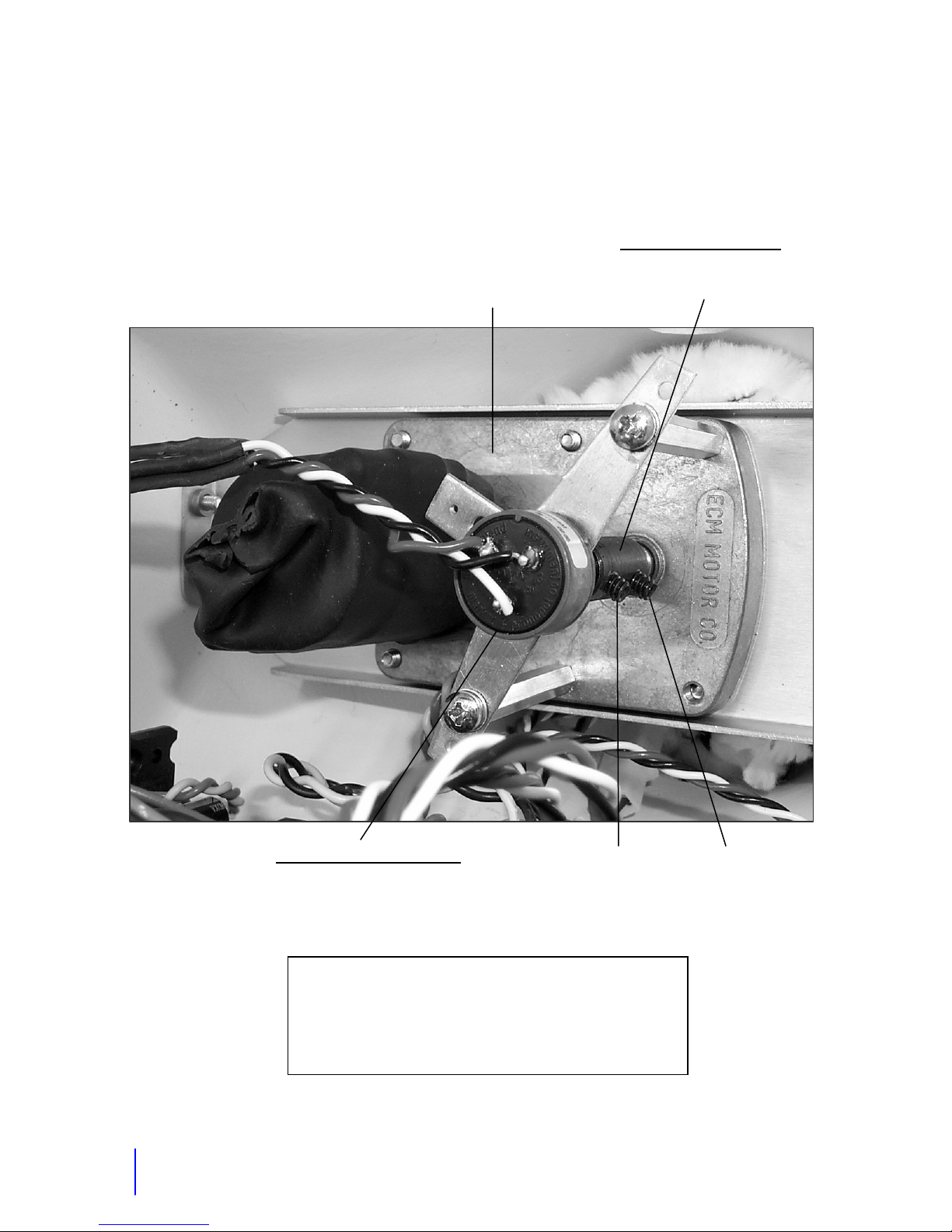

Character Head Turning Parts Detail.................................................................. 68

Character Control Board Type 1 .........................................................................69

Character Control Board Type 2 .........................................................................70

LED Light Bar (Available on certain robots)........................................................ 71

37 Pin Connector Pinout.....................................................................................72

Appendix C Maintenance Forms.........................................................73

Checklist Form....................................................................................................74

Maintenance Form..............................................................................................75

Notes Section......................................................................................................76

Contents

iv

Limited Warranty

All robots and accessories have a limited one year warranty, which covers all parts and labor.

This period covers the normal burn-in for electronic components. Experience has shown that

this warranty period catches most component defects and other possible flaws.

problem, we are anxious to help. Our desire is to be certain you receive a quality product and

excellent service.

Warranty work is specifically limited to correction of defects by repair or replacement of faulty

equipment or parts. The robot or part shall be repaired or replaced at Seller's option.

Equipment returned to the factory for repair must have pre-authorization from our service

department and must be sent freight pre-paid, and will be returned freight pre-paid by UPS

ground or common carrier. If you need parts returned by air shipment, you will be responsible to

pay the additional shipping charges. The end user is responsible to contact our service

department about any problem and install replacement parts or make adjustments if needed on

the robot.

In no event shall ROBOTRONICS, Inc. be liable for any incidental or consequential damages in

connection with or arising from the use of the robot, this manual or any procedures herein.

The buyer is further responsible to ensure that proper and complete training is given to those

operating the robot system as all aspects of such operation cannot be covered in a brief manual

such as this.

Date Received:

Customer Number:

Robot Model Number:

Robot Serial Number:

Brand of Radio Control:

Frequency of Radio Control:

Voice Frequencies

Operator Transmitter:

Operator Receiver:

Record the vital information from your robot here for future access

If You Have a Problem Call Service 801-489-4466

Call our service department and explain the problem. Most difficulties are minor and can

be solved easily over the phone. If possible, have the robot near the phone when you

call.

Important: Have the robot serial number and model number ready. This will help our

technician identify the model of robot you have. The serial and model number sticker is

located on the robot frame on the right side. In the Appendix, the Lower Robot - Top

View shows the location of the serial number sticker

Have the robot near the phone so that we can help you immediately.

If you have a

Warranty

1

If you need to send a part back to Robotronics for repairs

Go to our website, Robotronics.com

this out and send it back with the part or robot.

If you have saved the robot boxes and packaging this will make it easier to return the

robot.

Call the service dept. before shipping the robot or part back to the factory. Pack it

carefully and send it prepaid.

Parts of the robot are best sent by a carrier such as UPS, FedEx. or U.S. mail. A freight

company can be used to ship the entire robot. Be sure to insure the shipment for the

correct value.

For international shipments

other fees. The shipment must be labeled on the paperwork and on the outside of the

container that it is “For Educational Purposes”. If it is a “warranty replacement” or a

“repair return” this also must be indicated both ways on the customs documentation.

Contact your customs agency on how to document the shipment correctly to avoid

unnecessary customs charges.

, you will be responsible for paying customs duties, taxes and

and under the service tab find the return form. Fill

After The Warranty Repair and Help

Our technical staff is always available to help with your questions. Again, most problems are

easily solved. The robot design is very modular to make removal of a part of the robot very

easy. For example the main electronics box, which houses most of the electronic circuitry, can

be removed from the frame of the robot. If you do need technical help or replacement parts, call

our Service Dept. We can usually ship them the following day you call.

Service Department phone number: 801-489-4466.

What’s Available on our Website

Parts for your robot: Our website contains a parts listing with pricing for some of the parts of

the robot such as batteries, chargers, wireless voices, headsets, RC, lights, plastic parts, servo

motors, drive motors etc. For any other parts, give us a call.

Maintenance and repair information: If your robot ever needs maintenance work to be done,

you can send a part or the complete robot to Robotronics. The website contains information

about packaging and shipping. There is a return form on the internet to fill out to print and send

with your part.

Photo gallery of other robots: You can look at other robots and how they have been painted,

customized and decaled.

Program Support Material: Educational material to handout and reinforce your safety

message as well as music that can be used in the robot.

Warranty

2

Part 1 General Operating Instructions

CHAPTER 1 Getting Started

Operating Tips and Safety Information

ROBOTRONICS, Inc. robots are a unique and exciting tool in the hands of a skilled and trained operator.

The operator provides much of the excitement the robot conveys. The selection and training of the

operator should be done carefully, so as to provide a person with good judgment and an outgoing

personality. Nevertheless, with a little practice anyone can learn to operate the robot and even those with

a shy personality can be very effective using the robot. It is important that you observe the following

safety guidelines

outline or script will help you have success the first few times out.

The operator must have the radio control in their hands when the robot is on. If you need to

set the radio control down, turn the robot off first.

Always have a trained person (escort) near the robot for safety purposes

control, and to protect the robot from vandalism. This person is also available to answer questions

and interact with the robot.

When using the robot on a stage, the area just in front of the stage should be clear of children

for at least 10 feet.

Neck Strap. There is a hook on the RC that you can attach a neck strap to. This will help prevent

drops.

Keep the robot indoors with the cover on when not in use. This will keep the robot clean and the

color at its best. Direct sunlight/UV light can fade the plastic over time.

You can paint the body if it fades or if you want to change the color of the body/trim. See the painting

instructions for tips.

Operate the robot with charged batteries in the transmitter and robot.

Never operate the robot out of line-of-sight.

Make sure trims (sliders) on the RC are centered prior to turning on the RC and the robot.

Operating distance should never exceed 100 feet. When moving the robot through crowds, the robot

should be operated slowly and smoothly without any sudden changes of direction. Walls, turns, and

other obstacles are hazards to be avoided. Never leave the robot "ON" when unattended or in direct

sunlight for extended periods of time.

The robot is designed to be operated on hard, smooth surfaces and carpet. Avoid extra deep shag

carpet, dirt, gravel, or grass surfaces. Avoid steep inclines or large uneven surfaces such as curbs,

gutters, or uncovered electrical lines.

If there are other radio controlled robots at the same event, confirm that they are not on the same

frequencies. See the diagrams showing your RC and wireless voices to locate these frequencies.

When attempting to operate the robot for the first time, do so in a large flat area without obstacles.

The operation of the controls should be done in a smooth, fluid manner. Avoid jerking starts and

stops or overreacting to the controls. When first practicing movement, it is sometimes helpful to

follow behind the robot, as robot movement will match stick movement. (Controls respond opposite

when the robot is facing the operator.)

The robot can be a highly successful tool for education and entertainment. Appropriate jokes, stories and

general conversation can be very effective. Children of all ages are strongly attracted to the robot. They

will talk to it, hug it, kiss it, and generally treat it as a good friend. The smaller sized robots are very

effective with children. They are light in weight and just the right size to communicate with children. The

most important ingredient to the use and effective operation of the robot is common sense. The following

instructions will help you get set up and start using the robot.

. Include this in any operator training. Practicing with the robot and having a program

, to help in crowd

Getting Started

3

Setup and How to Operate the Robot

1 Read the manual

Read and study this manual completely before operating the robot. If you have any questions

about operation of the robot, call our service group.

2 Charge the batteries

Be certain that the robot battery and radio control transmitter battery are fully charged before

operating the robot.

Install the robot battery. Open the rear door or trunk to gain access.

1. Put the robot battery in the compartment in the back.

2. Connect the robot battery connector to the robot connector. Red will go to red and black to

black. This connection is polarity protected and can be connected only the correct way.

3. The battery is secured in place with a battery strap. Tighten the strap very tight.

CAUTION

The robot battery posts should never contact the metal of the main electronics box or the

metal of the drive base. This will result in damage to electronic components especially

inside the main electronics box.

3 Attach the upper robot to the lower

1. Set the upper robot on the lower robot body.

2. As you put the top on, connect the 37-pin connector, which is a round connector and wire

bundle running from the upper robot to the lower robot. When connecting this rotate it until it

sits down into its mate connection and turn the plastic ring

3. Locate the four body latches (just two on certain robots) and push

the pins into the body to secure the upper robot to the lower. If you

have a Character driving, two of the latches are located in the

compartment where the Character sits. The pins are to the left and

right of Character. The other two are at the back of the robot. To

latch these you will need to reach in through the back trunk or

door. If you want to see a picture of the latches see page 5.

until it is secure.

Getting Started

4

CAUTION

Before operating the robot or transporting the robot on the cart or in a vehicle, the upper

robot must be properly latched to the lower by pushing the latch pins in. Failure to do

this could cause damage to the upper robot if it fell off.

Body Latches

Body Latches

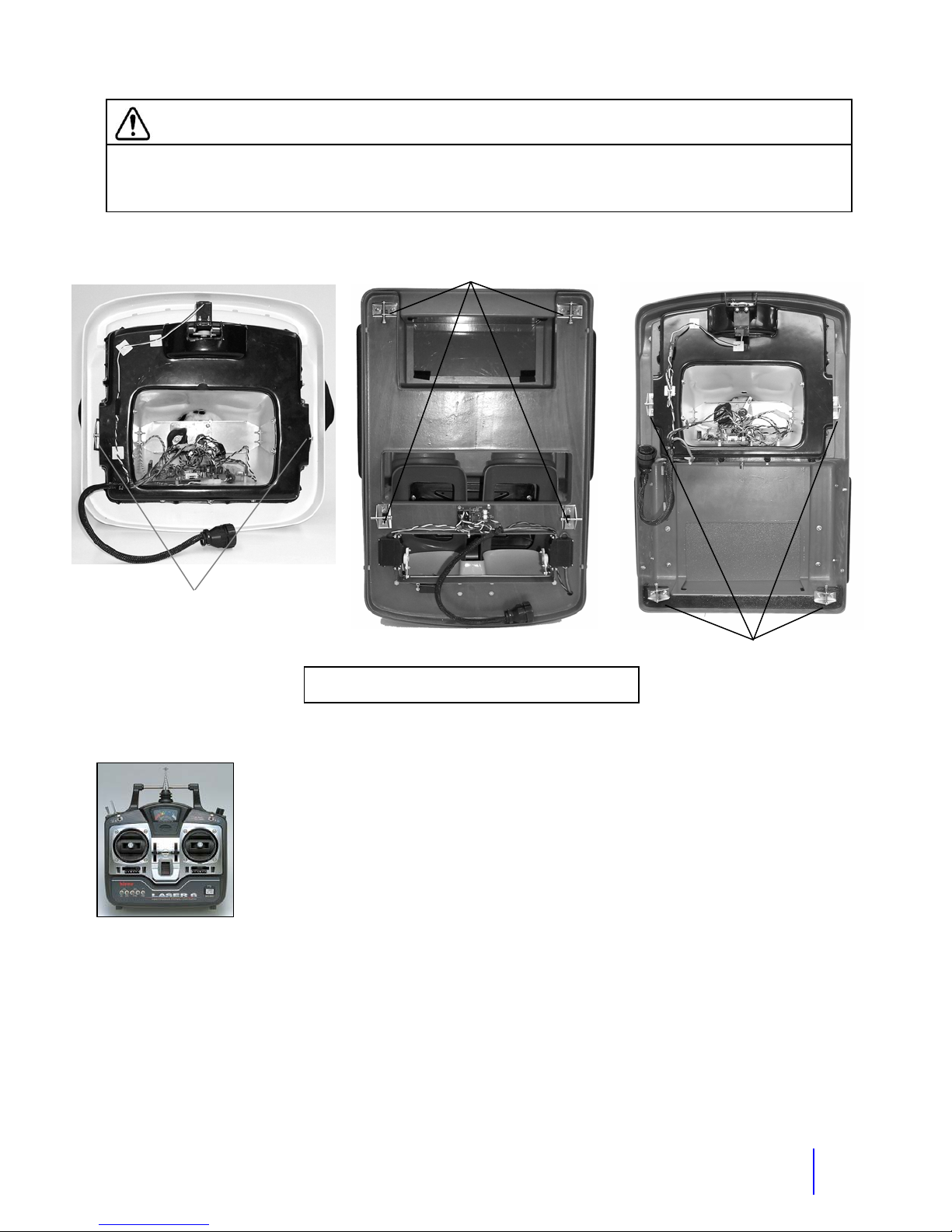

Location of Body Latches for each style of top

Body Latches

4 Powering up

The radio control transmitter will be referred to as the “RC” in this manual.

Turn the RC "ON" first and then turn the robot "ON". Check that the RC

battery level meter reads to the right. The "ON/OFF" switch for the robot is

located inside the rear door or trunk on the main electronics panel. Push the

switch up to turn the robot on. On some robots there is a hinged rear door to

access this switch. Tip: There is a hook on the RC that you can attach a

neck strap to. You can use a RC or camera type neck strap.

5 Set the volumes

Check that the volume of the voice and MP3 player are at the level that your want. The volume

for the robot’s voice is can be adjusted on the UHF Wireless Receiver in the robot or on the

level adjustment on the Nady UB4 transmitter. If you have the tape player, adjust the volume on

the player itself.

Tip: If you want to change your voice volume quickly, move the mic closer or further from your

mouth.

Getting Started

5

Tip: To change the volume of the MP3 player hold the mp3 switch on while moving the left

joystick. There is a master volume on the Road Rage Amp. This amp is located on the main box

in the lower robot. This acts as a master volume, so after changing it you may have to re-adjust

the voice volume on the UHF Receiver in the robot. Do not go above the 1:00 position on the

amp level adjustment.

6 Test all the functions

Test all of the robot's functions: Character’ voice both ways, head turning, mouth, steering

wheel, eyelids, eyes, tape, siren, lights, and drive movement for proper operation. The robot is

now ready to operate.

Note: Keep the sliders on the RC centered and be sure they are centered before turning

on the robot.

7 Optional accessories setup

For information about these, see the optional accessories section. This includes options such

as the voice modifier and water squirter. These sections will give you step by step instructions

for setup and related diagrams. You can put your own music and even sound effects on the

MP3 player SD card. See the MP3 player section for details.

8 Powering down

1. Turn off the voice units that you wear on your belt before turning off the robot.

2. Turn off the robot.

3. Finally turn off the Radio Control Transmitter.

9 Charge the batteries again

Connect the Robot battery to the charger and bring it back to a full charge before leaving the

robot. This battery should not be left with a partial charge. The transmitter battery should be

charged if it is low. Before a storage period, charge both batteries to a full charge.

All of the major functions of the robot each have a section in the manual with more

details and diagrams. Refer to these for more in depth information. The Appendix

has pictures and diagrams of where various parts are in the robot. These will help

you become familiar with where the parts are located and their function.

For parts that you need for the robot, go to Robotronics.com. This includes radio

controls, voice units, headsets, batteries and chargers.

When doing programs in large open locations you may want to use a separate

wireless mic with a portable amp or the PA system. You can play music through the

main system and even do the voice of the robot if you have at least two mics. This

will take some practice to get it set up.

It is possible to use a cell phone headset with the two way voice system if you get an

adapter that goes from a 2.5 mm jack to two 3.5mm(1/8”) plugs. This will give some

added flexibility in choosing what type of headset that you can use.

Getting Started

6

Transporting the Robot

Before transporting the robot, remove the robot battery from the robot. The vehicle that you use

to transport the robot should have adequate shock absorption. Vans and cars used for

passengers would be the best. Transporting the robot in a trailer is not recommended

trailers typically do not have the same level of shock absorption as a car or van. A good rule of

thumb to follow is that if the vehicle is adequate for transporting a computer it should also be

fine for the robot.

Double check that the upper robot is latched and secure. There are four latches (two on certain

robots) that must be latched to secure the upper robot to the lower robot (See the diagram

below). These pins must be pushed in to secure the upper robot. Reach in through the trunk to

access these latches.

because

CAUTION If the upper robot is not properly latched, it could come off while

moving the robot, causing damage to the upper robot.

To strap the robot on the cart, roll the robot on with the back wheels first. The back wheels will

drop in to the recesses. Put the cart’s wheels against a wall if necessary. There are four eye

bolts under the front and rear bumpers. Attach the hooks from the cart to the eye bolts. Loosen

the straps if you need to reach the eye. Tighten the straps.

To lift the cart there is a strap-handle that is used to lift the cart off the ground and set it back

down. There is a foam covered handle for moving the cart. Have the robot cover on the robot

to keep the body from getting scratched. The cover can also help hold the top on if the string is

tightly pulled around the bottom of the robot. Use elevators for upper levels when possible. You

can simply drive the robot in to some locations, especially if the location does not have stairs.

Use two people to move the robot upstairs.

7

Part 2 Subsystems of the Robot

Functionally, the robot is made up of the following basic subsystems:

A. Radio Control System

B. Voice System

C. Cassette Tape Player

D. Siren

E. Robot Battery Systems

F. Drive Motors

G. Eyelids and Eyes Left and Right

Following are explanations of each subsystem, some operating instructions, and trouble

shooting hints where appropriate.

8

CHAPTER 2 Radio Control System

The Radio Control System consists of the control transmitter unit held by the operator and the

receiver with its associated components in the robot.

The Radio Control Transmitter converts movements of the control sticks and switches into a

coded radio signal, which is transmitted by radio to the Radio Control Receiver within the robot.

The signal is received and then decoded by the micro-controller, which is on the main circuit

board in the vehicle. The micro-controller controls functions based on what was sent from the

radio control transmitter.

Radio Control Operating Instructions

Refer to the diagram showing the radio control transmitter for the location of controls. Check all

of the trim adjustments on the transmitter and make sure they are in their center position.

Extend the Radio Control Transmitter Antenna 1/4 to 1/2 way. Turn the Radio Control

Transmitter on first and then turn on the main robot power switch. It is necessary for the robot to

always have an operating signal when it is on, if there is no signal you will not have full control

of the robot.

The right hand joystick controls movement of the robot's drive wheels. Pushing the stick

forward will cause the robot to move forward. Pulling the stick back will cause the robot to move

backward. Moving the stick to the right or left will cause the robot to turn to the right or left

respectively. Movement is fully proportional so any variation or combination of movement is

possible. The horizontal and vertical trim tabs to the left and below the joystick are for centering

and should be typically left in the center. The only time that you would need to move these

trims is if the robot started moving slightly on its own. In this case move them slightly until the

robot stops.

Control of the left and right eyelids is on the left joystick. The left and right eyelids are controlled

in the corners forward and blink to the back. The eyes left and right move when you turn the

head. The eyes will look in the direction that you are turning, adding animation to the robot.

The left joystick left and right moves the Character’ head on robots with a Character driving it.

On other robots this stick controls the eyes left and right. The slider control below the stick

should be left in the center so that the head stays in the center.

For a detail of other functions, see the radio control diagram on the next page. All of these

functions are labeled on the radio control itself.

A charge plug is provided on the transmitter for recharging its internal battery. The transmitter

power switch must be in the off position before charging the batteries. A charge light on the

charger will come on while charging.

There is a RC battery (NiMH) provided with all robots. There is an extra Ni-MH battery provided

with the package. These will give you about 5 hours operation each.

9

(

)

Radio Control Transmitter

1

Tape or MP3

Player Option

RC Frequency

on back of RC

Siren

Eyes & Head

13

12

11

10

Squirt

14

2

9

4

Flashing Lights

Not used on all robots

15

16

Lights/Beacon

Drive

3

5

Drive Trim

Charge

8

10

7

Power On/Off

RC Receiver located in

the robot

RX Crystal

6

RC

Frequency

on crystal

Power/Signal Wire Plugs

in to B/8.

RC Transmitter Controls

Note: The following information on the transmitter controls includes information for a variety of

similar robots.

1. Telescopic Transmitter Aerial.

2. Transmitter Battery Voltage Meter (Expand Scale Voltmeter)

3. Right control Stick-

Up and Down – Robot drive motors, forward and reverse.

Right and Left – Robot drive motors steering. Left and right turns.

Tip: Speed adjust- To reduce the drive speed you can adjust the ATV adjustments, AIL

and ELEV, down. You will need to adjust them proportionally to maintain straightness of

drive. You may want to add a label that this has been adjusted so that the future

operators are aware of this change. Note: This can make the robot slower for easier

operation indoors but will limit your speed for outdoor or large space use.

4. Forward/Reverse Trim lever for right control stick. Normal = Center. Neutrals the drive

motors. If the robot is moving slightly slide this a few clicks until robot stops moving.

5. Left and right Trim lever for right control stick. Normal = Center. Neutrals the drive

motors. If the robot is moving slightly slide this a few clicks until robot stops moving.

6. Crystal. Transmitter Crystal. Has RC frequency channel on label.

7. On/Off Switch.

8. Recharge jack. Plug the RC battery charger in here to recharge the internal battery.

The charge light will come on, on the charger.

9. Forward and reverse trim lever for the left control stick. Normal = Center. Unused.

10. Left and right Trim lever for left control stick. Normal = Center. Centers the head on

robots with head movement (Character in Vehicle).

11. Left Control Stick

Left and right movement - Turning of the head left and right (Character in Vehicle) and

eyes left and right.

Up – Left lid and Right lid

Down – Blink

11

p

Top Switch Functions

12. Tape player

13. Voice and Siren

14. Squirter

15. Up- Flashing Lights- Red (Buster and Andy) or Red & Blue(K.C./McGruff Cruisers)

Down- Flashing Lights- Yellow (Buster)

16. Beacon and Lights

Controls for the Integrated MP3 Player Option

The MP3 player is located in the robot and has a SD or MM memory card that you can load

music onto. If you have the MP3 player option then your switches will take on other functions

when the MP3 mode switch is held on. Two of the switches are for sound effects on the SD

memory card. The other two are for playing and selecting songs that you load on to the SD

card. You can also change the volume on the remote with the left joystick.

12

Hold the MP3 switch on to use MP3 Player and

to change volume with the left stick.

Battery Compartment View of Switches

Switches must stay in the normal position

exce

tfor mixing which should be off.

The NiMH (Nickel Metal Hydride) RC Battery

The NI-MH RC transmitter battery will last about 5-6 hours on a full charge. Charge the battery

for about 14 hours. A charge jack is provided on the transmitter for recharging its internal

batteries. This round jack is located on the right side of the radio control. (See the radio control

diagram) The RC power switch must be in the off position when the charger is plugged into it

and must remain in the off position while charging. A light on the charger will be on, when

charging.

Charging Jack for

the RC Battery

Caution: Do not overcharge the batteries as this could cause permanent damage to the

transmitter batteries. (Doubling the normal charging time is the type of over charging that is

meant here, and the battery getting hot.) When the battery level needle goes in the red, the

robot should be turned off because the robot could act erratic without the transmitter signal.

To avoid a RC battery going dead during a presentation, start the program with a fully charged

battery or be aware of how much charge there is left in the battery. If you have an extra battery

you can change batteries and keep going.

To install the NI-MH battery pack you need to take the battery cover off the RC. Disconnect the

RC battery and put the NI-MH battery in its place.

NI-MH RC Battery and Charger Specifications

NI-MH RC transmitter battery 9.6 Volts 1500mAH

NI-MH RC transmitter battery charger 11.6 Volts 130mA

13

ger

Adapter for Charging an Extra NI-MH RC Transmitter Battery

If you have an extra NI-MH RC battery, you can charge this outside the RC. You may need to

do this while you are using the robot or if you need to charge both batteries at the same time.

The adapter needed to do this is in the control case or it is on your charger. It has a white

connector on one side and a connection on the other end that will go directly to your battery. If

the barrel adapter is currently on the charger, disconnect it and connect the other adapter. The

charging time is still about 14 hours.

Radio Control System

No robot operations

1. Switches in RC battery compartment moved in to the

middle.

2. Crystal bad 2. Replace transmitter and receiver crystal or send RC in for

3. Wire is not plugged in correctly to the receiver. This is

typically a red-black-white wire.

One or two functions on the robot not working.

1. Typically not the RC unless a switch or wire is broken.

RC not maintaining power. Power meter will not go up.

1. Bad RC battery.

2. Charger not working. 2. Make sure your charger light is coming on.

3. If power goes on and off, could be a bad connection in RC. 3. Send your RC in for repair or replace it.

Joystick functions not working correctly.

1. Trim adjustments not in the center.

NiMH RC Battery

Char

Charging Adapter

Problem/Cause Action

1. Put all switches in normal position except for mixing which

should be off. See the battery compartment picture below.

repair.

3. Hitec Receiver has a channel labeled B/8. This is the

correct position.

1. Look for any broken or loose wiring inside the RC.

1. Try a new RC battery.

1. Put trims (sliders) in the middle.

14

Switches must stay in the normal

position except for mixing which

should be off.

CHAPTER 3 Wireless Voice System

The Voice System consists of two separate communication links. One link transmits the

operator's voice to the robot. When you speak into the headset mic, this audio goes to a

transmitter on your belt. This audio is transmitted to a receiver in the robot. The audio signal

then goes from the receiver through a mixing circuit on the main board. It is then is fed into the

amplifier which amplifies the signal through the robot's speakers.

The second voice link transmits the audio detected by the Mic element (located in the front of

the robot) to the 151 receiver (which is worn by the operator). This is amplified and sent to the

speaker in the operator's headset. When putting the headset on, adjust the earphone so that

you can hear well and the mic so that the volume is good.

Note:

you can use a belt pack. The 151 Receiver antenna can be put out of view, in your pocket.

Location of Voice Units

Voice Transmitter- Operator wears

Voice Receiver- On the main electronics box in the lower robot.

151 Transmitter- On the frame in the robot. The robot mic connects to it.

151 Receiver- Operator wears

Note: For the location of the transmitter and receiver in the robot, see the robot top view

diagram in the appendix.

The operator’s transmitter and receiver can be worn next to each other. If you want

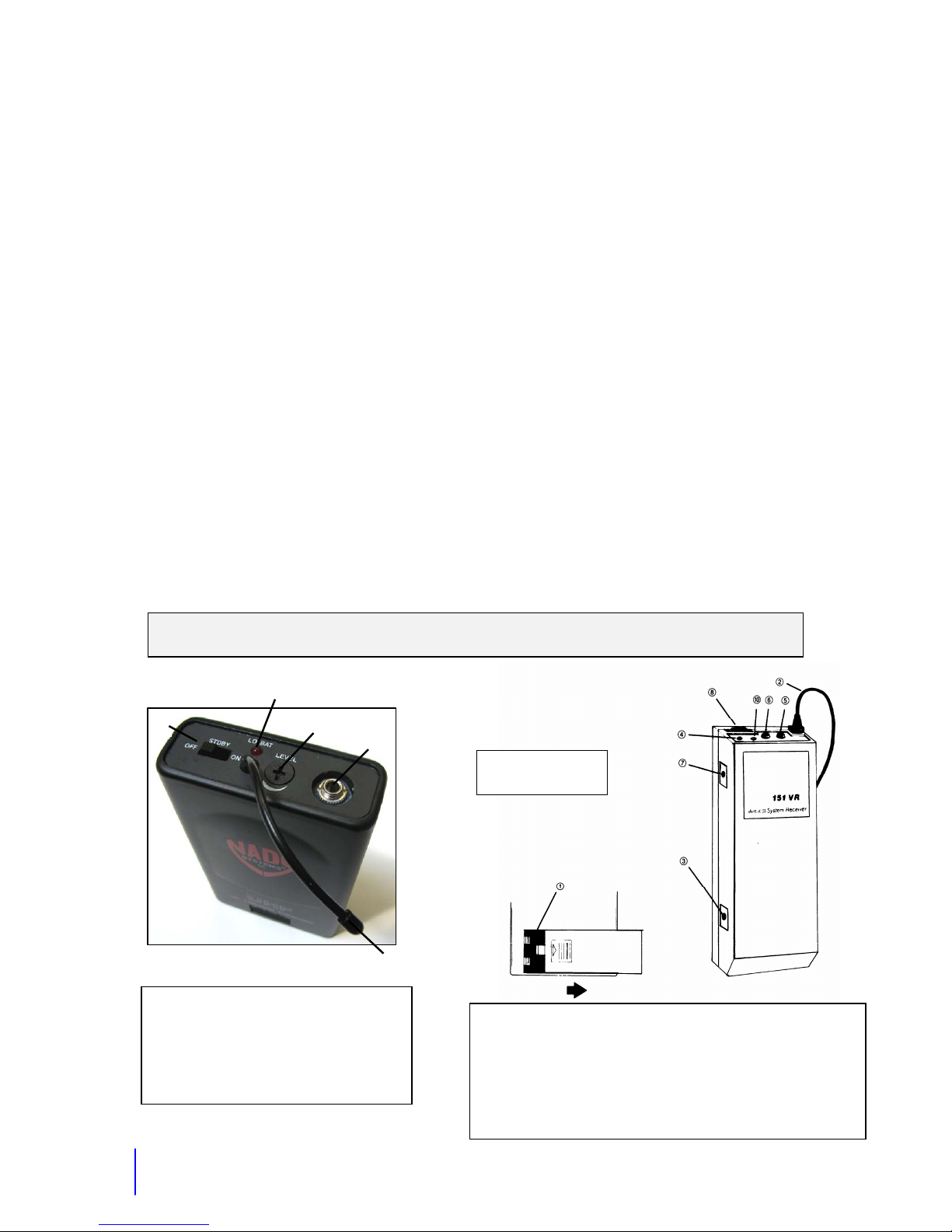

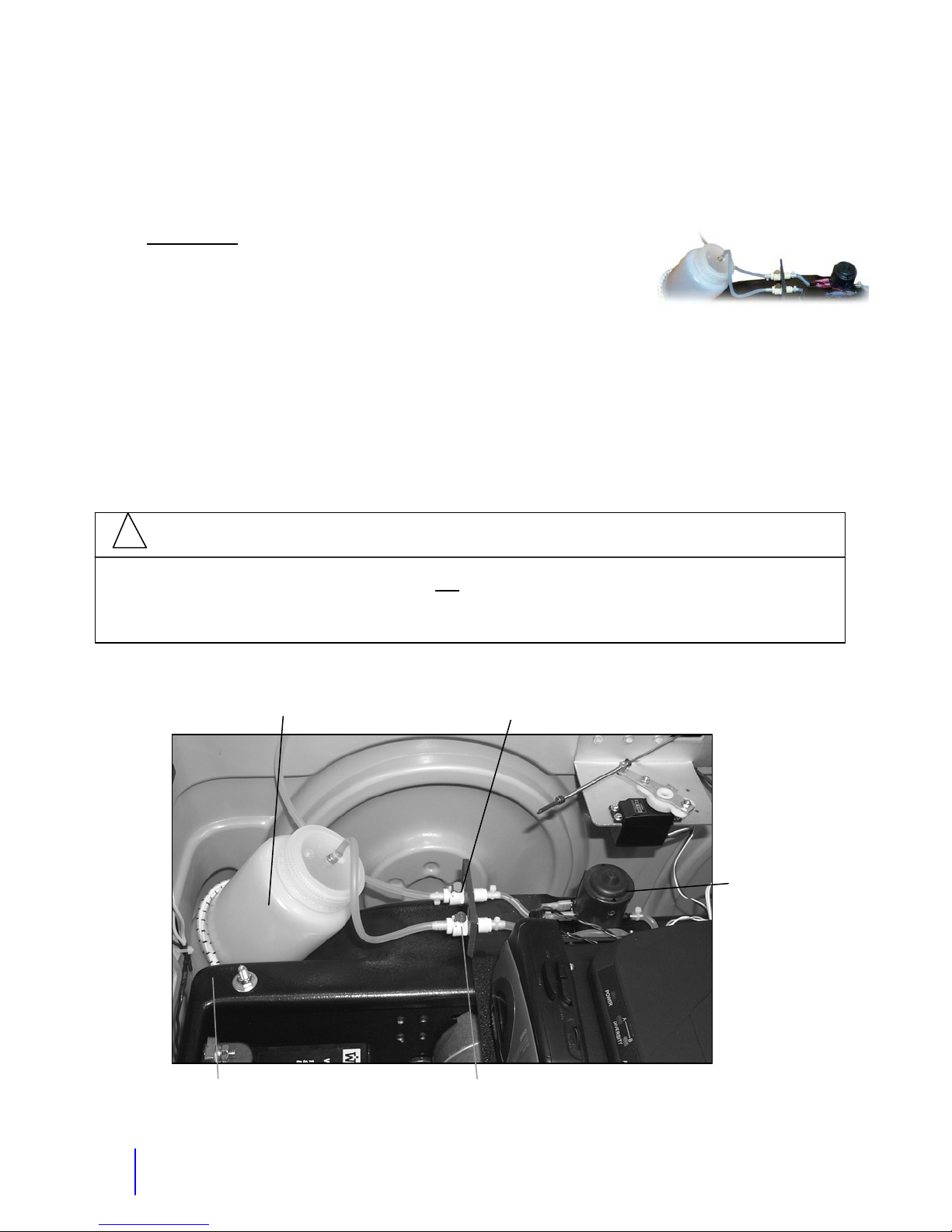

This headset

style is available

3.5 mm headphones

Plug

151 Receiver

Operator’s Voice Transmitter, Receiver, and Headset

3.5 mm mic

plug

Transmitter

This is the headset style that

comes with the robot.

If needed, adjust the headset

frame so that the earphone and

the frame fit comfortably and the

earphone is against your ear.

15

How to Operate the Operator’s Transmitter

1. Open the battery door. This may be the front cover of the case that slides open.

2. Use a 9 Volt alkaline battery and insert it according to the diagram inside the battery

compartment.

3. Place the headset on your head and adjust the microphone to approximately 1 inch from

your mouth. If needed, adjust the headset frame so that the earphone and the frame fit

comfortably and the earphone is against your ear.

4. Plug the mic plug from the headset into the top of the transmitter.

5. Move slide switches to the "ON" position.

6. On the UB4 there is a Volume input level adjust on the unit.

Frequency channel- Located on the back of the transmitter.

Function of the LED

When turning on the power switch, with a fresh alkaline 9-Volt, the battery light will blink on

momentarily and go out. This indicates that it is powering up and that the battery is good.

Because the light is a low battery indicator, when the light is on constant, this indicates the

battery is too low-below 7 Volts. Replace with a new alkaline battery.

Tip: The operator’s voice units both have metal clips that contact the posts of the 9volt battery. These must be bent out from time to time to keep this contact good.

22. Sliding door

23. 9 V Alkaline Battery

24. Front Cover

25. 3.5 mm jack

26. Off/Standby/On switch

27. Antenna

28. Volume- Input Level Control

29. Belt Clip

Frequency is listed on the back.

16

How to Operate the Receiver (in Robot)

There are two adjustments on the receiver. The volume is on the back of the receiver, which

you may set to the desired volume. The other adjustment is the sensitivity. This is factory

preset to maximum sensitivity. This effects how sensitive the receiver is to the transmitter

signal. Typically you would never need to adjust this. The only exception would be if you get

squelch when the transmitter is off. You can deal with this by simply turning on the belt

transmitter whenever the robot is turned on. You could turn the sensitivity down slightly but turn

the adjustment as little as possible, because adjusting it will affect the range.

Frequency label- Located on the side of the receiver.

Function of the LEDs

TX LED- This indicates that you are receiving a signal from the transmitter. On some units it is

a single TX light. On other units it may have an A or B that it will alternate between.

AF LED- This light indicates that audio is going through the receiver. It will flash as you speak

into your headset mic.

Tip: For best range extend the receiver antenna(s) as much as possible, not allowing it

to touch metal.

6

4

1

5

2 3

1. Power On LED Indicator

2. Diversity LED Indicators

3. AF Peak LED Indicator

4. Antennas

5. Power Switch (Leave On)

6. Frequency Label

7. Audio Output

8. DC Input Jack 12V

9. Aux. Volume Control

10. Balanced Mic Audio Output XLR

7

8

9

10

11

17

How to Operate the 151 Transmitter (in Robot)

Located in the front left of the lower robot. The wire from the hood mic connects to it. No

adjustment is needed. The switches will be preset to on at the factory. It receives its power

from the robot. No 9 Volt battery is needed.

Function of the LED

When the robot is turned on, this light flashes and then goes out. This indicates that the

transmitter is getting power.

How to Operate the 151 Receiver (Operator)

1. Remove the battery door. Use a 9-Volt alkaline battery and insert it according to the

diagram in the battery compartment.

2. Plug the small round connector from the headset into the headphone jack on the top of the

151 receiver.

3. Turn the volume knob clockwise to the desired volume (if volume is too loud you will hear a

loud high-pitched feedback noise. Turn the volume down until the feedback is gone.

Frequency label- Located on the back of the receiver.

Function of LEDs

When turning the volume knob on with a fresh alkaline battery, the red light will blink on

momentarily and go out. This indicates that it is powering up and that the battery has enough

charge on it. As labeled, the light is a low battery indicator. When the light is on constant, this

indicates that the battery is below 7 Volts. It then would need to be replaced.

Tip: The operator’s voice units both have metal clips that contact the posts of the 9Volt battery. These must be bent out from time to time to keep this contact good.

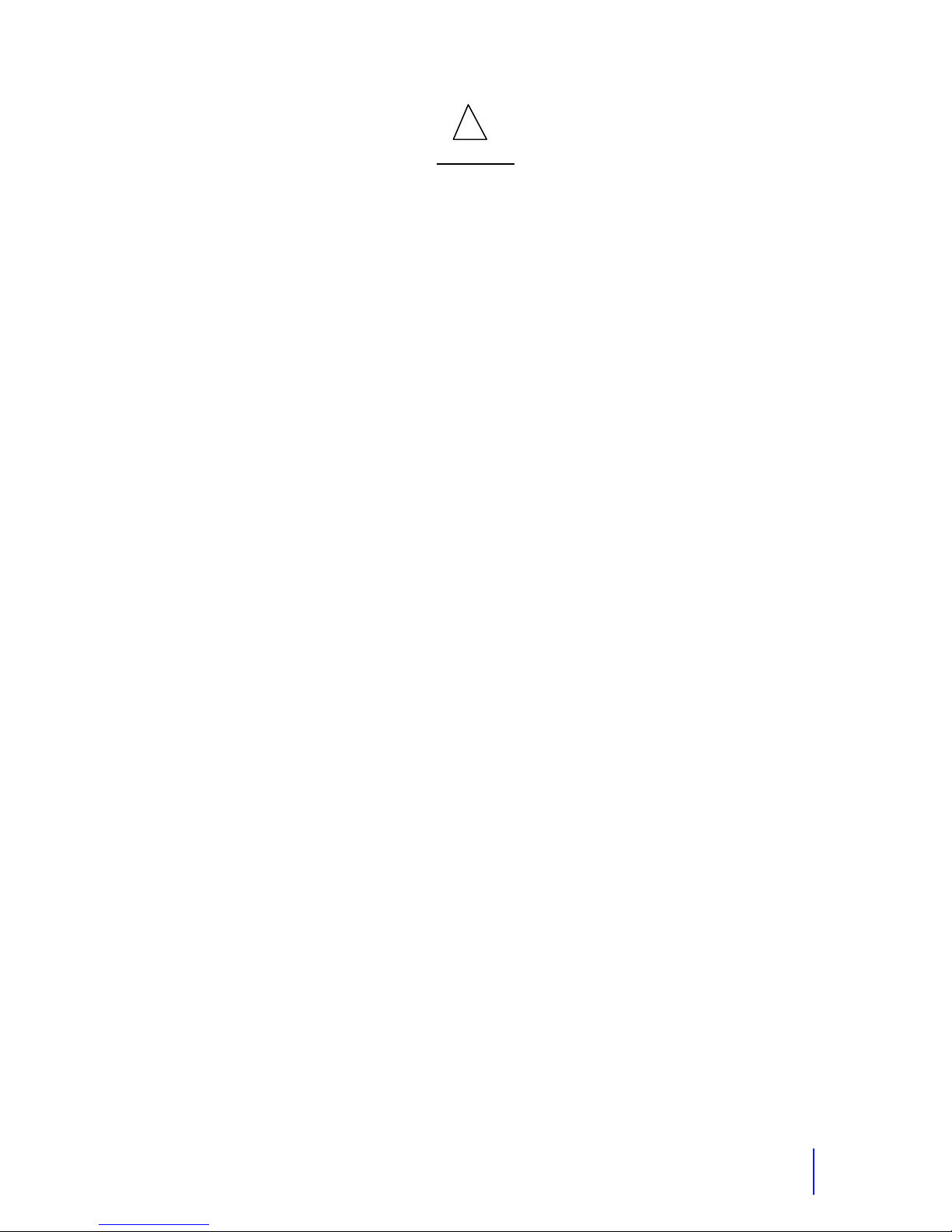

2

1

1. Off/Mute/On Switch

2. Low Battery Indicator

3. Audio Level Trim

4 Audio Jack for mic

5. Antenna

9 Volt Battery not needed in robot.

3

4

Frequency listed

on back

5

1. Battery door

2. Antenna

3. Mute control- Used if RF causes squelch. Leave Fully

counter-clockwise for best range and reception.

4. Green TX LED- Indicates signal being received.

6. Headphones jack

8. Volume On/Off

-

18

!

Warnings

1. Do not unplug or plug in the DC power plug on the robot receiver with the robot

power on. If the power is left on, the plug will short out and could damage the receiver.

The fuse in line on the power wire that is plugged into this receiver may blow. This fuse is a

round black fuse holder. If this fuse is not blown but no RX power light is on, check the

audio fuse on the main fuse block in the electronics box.

2. Do not leave the voice units in direct sunlight or in a damp place for any length of time.

3. Remove batteries if voices will not be used for an extended period of time.

4. Keep voices and headset in the carrying case when not in use.

5. Generally when the robot is on, the operator's transmitter should be on. This will avoid the

receiver on the robot picking up radio frequency interference and putting out static (see

intermittent static problem of Voice System Troubleshooting).

6. Turn off the 151 receiver or remove the headset before turning off the robot. You can get a

squelch in your headset when you turn off the robot.

Troubleshooting the Voice

For any voice problem, perform the following steps first:

1. Check to see that the batteries are good in the operator's transmitter and in the 151

receiver. Normally when you turn the 151 receiver on, the low battery light should blink on

and go off. When turning on the power switch of the transmitter, the light should blink on

and go off. If either of these lights stays on constant, the 9-volt battery is too low and must

be replaced.

2. Check that the battery is in the correct polarity and confirm that the battery contacts are

making a solid connection to the spring clips inside the compartment. Bend them out

slightly if necessary. If the battery is making intermittent contact in the Transmitter, try a

different brand battery. Certain brand batteries are bigger than others.

3. Check all switch positions both on the operator and robot voice units. This includes the

audio and the power switches. See the Voice Unit Diagrams for details about the correct

position of these switches.

4. Check all plugs to and from the voices for proper connection.

5. Check the LED lights. When operating normally, the Receiver in the robot has a red TX light

on. The UHF10 or UHF4 Receiver has two LEDs, A and B to indicate that a signal is being

received. The 151 Receiver has a green TX light. These lights indicate that a signal is

being sent from the respective transmitter and that the receiver is receiving this signal.

See the next page for specific problems and their solutions.

19

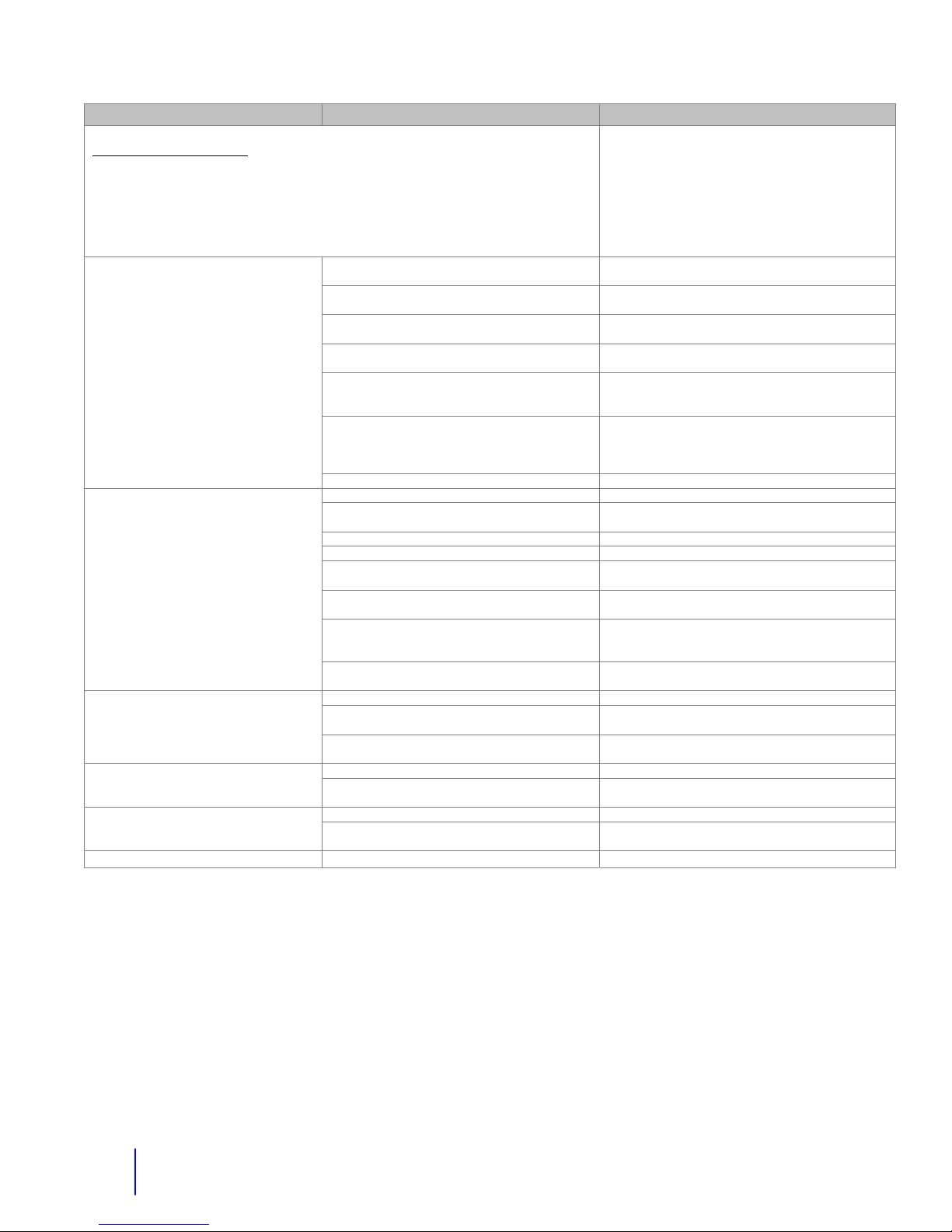

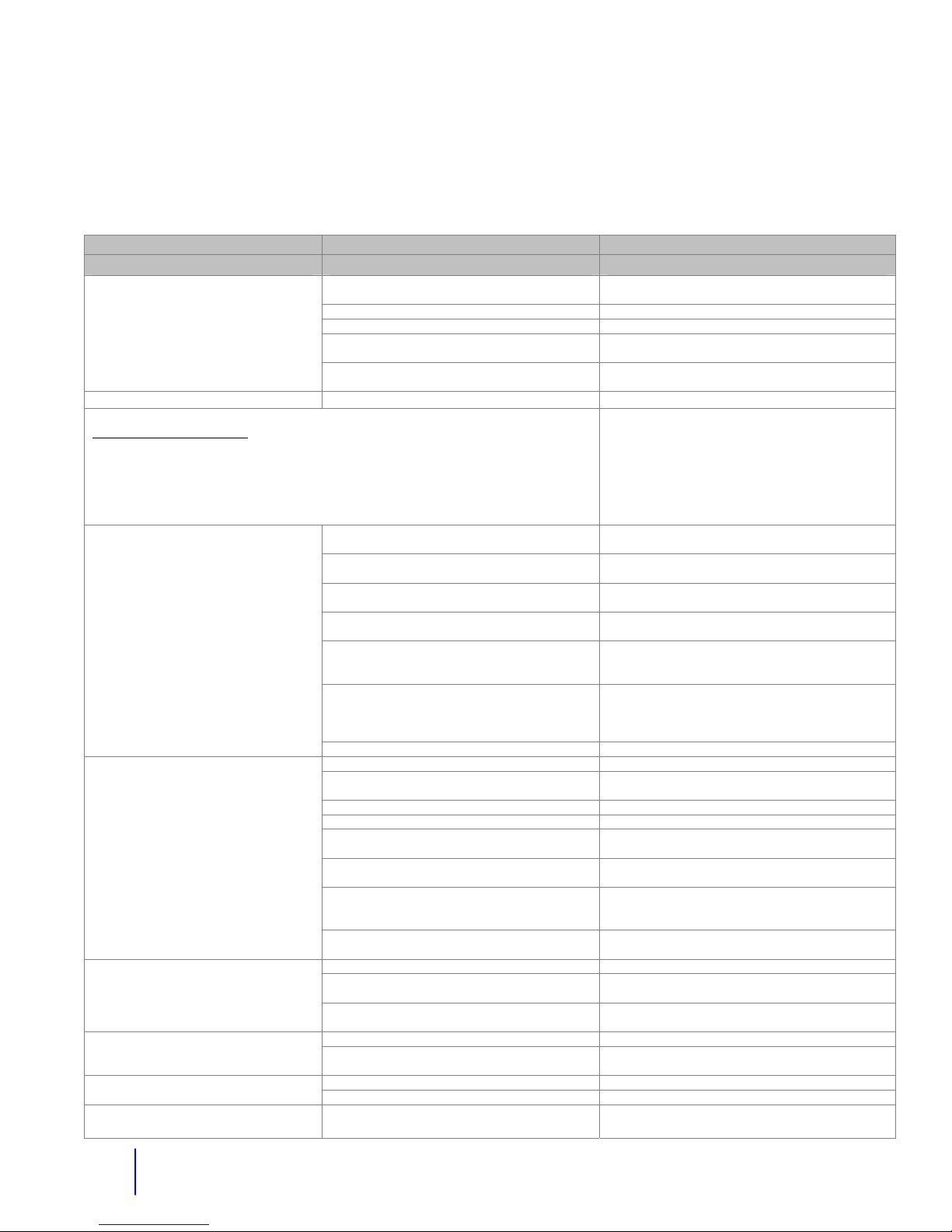

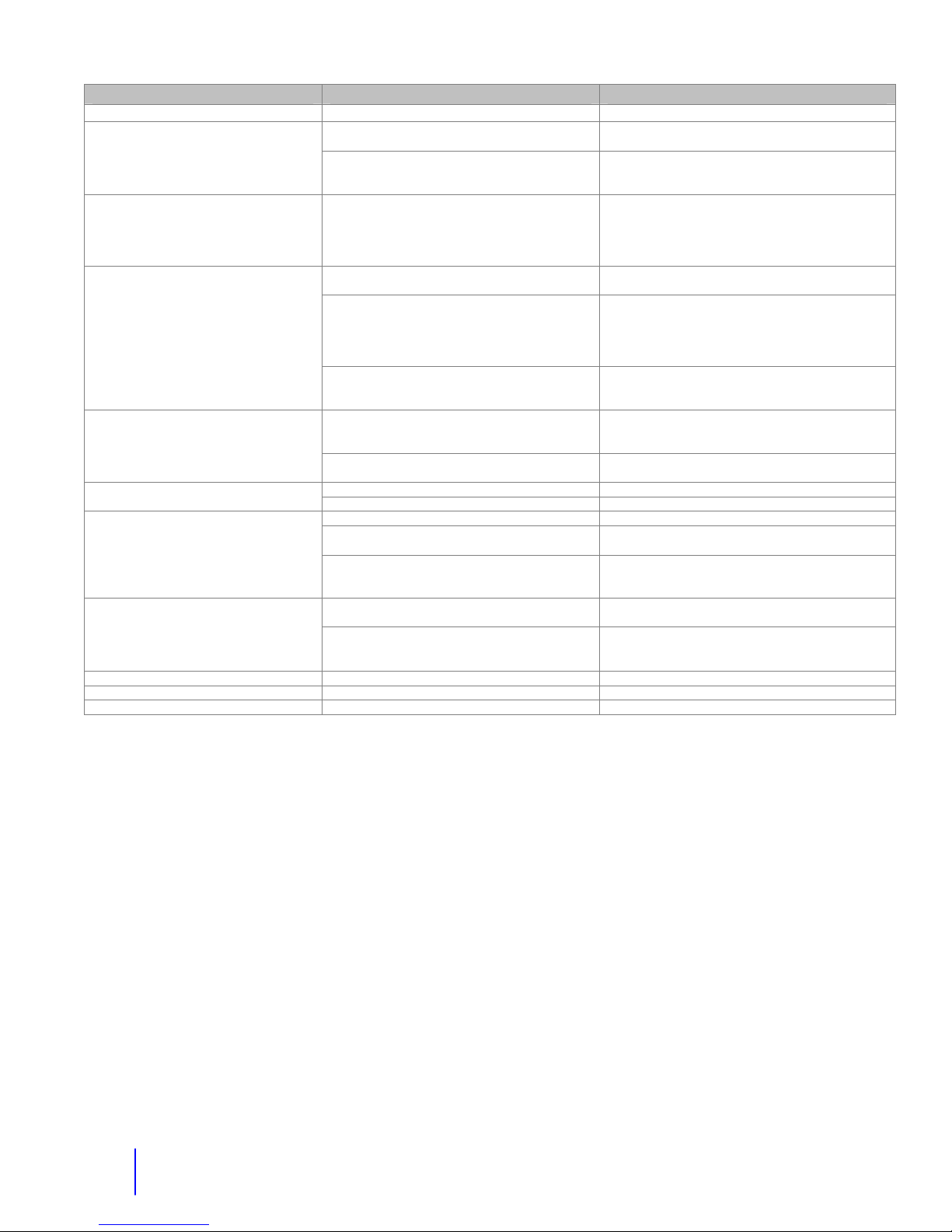

Problem Cause Solution

Voice System

Always do the following first:

1. Replace the 9 Volt batteries with new ones. USE ALKALINE!

2. Bend the battery contact out for better contact with the post of the 9 Volt battery.

3. Check power and audio switches, and lights on all voice units.

4. Check plugs to and from the voices for proper connection. Some plugs have covers

that can be opened. Look for a broken wire.

5. Check if the transmit (TX) lights are coming on.

Operator cannot talk

Operator cannot hear

Voice Operates but cuts out.

Should get 50 feet without any cutouts.

off.

1. Low Battery. LED on steady or no LED

flash.

2. Battery posts not touching the metal clips in

the operator’s transmitter.

3. No power to the UHF10 or UHF4 Receiver.

If yes, continue.

4. No TX light on the Receiver. If yes,

continue.

5. Audio wires going through pitch shifter

connected wrong.

6. Headset plug to transmitter broken. 6. Take apart and look for broken wire or solder

7. Still not working. Call Robotronics. Send transmitter, receiver, and headset in.

1. Low Battery. LED on steady or no LED flash. 1. Replace the 9 Volt battery.

2. Battery posts not touching the metal clips in

the operator’s receiver

3. Headset plug to 151 RX has a broken wire. 3. Unscrew cover of plug and look for broken wire.

4. Robot 151 transmitter not turned on. 4. Turn on audio and power.

5. Power plug to robot 151 transmitter

unplugged.

6. If you have no TX light on 151 RX mute

could be out of adjustment

7. Robot microphone in robot is bad. 7. Order a replacement. TEST- Plug your

8. Still not working. Call Robotronics. 8. Send robot mic, transmitter, receiver, and

1. Low Battery. 1. Replace the 9 Volt battery.

2. Sensitivity Adjustment down too far. 2. Sensitivity adjustments should be at max. on

3. Broken, loose or retracted antenna 3. Extend robot receiver antenna or replace

1. No signal being sent to the robot 1. Turn on the operator’s transmitter. Squelch coming from robot

2. Sensitivity is too sensitive. 2. Very slightly adjust sensitivity down from max.

1. 151 Receiver slightly too sensitive. 1. Adjust 151 RX mute slightly CW Squelch in headset when turning robot

2. 151 RX picking up interference in your area. 2. Always turn off 151 RX and remove headset

1. Replace the 9 Volt battery. Is battery inserted in

correct polarity?

2. Bend out the metal clips. Put foam under clips.

3. Check the in line fuse to the Receiver in robot

and audio fuse on main fuse block.

4. Check Sensitivity adjustment on back of

Receiver. It should be on Max. Sens.

5. The wire should go from audio out of receiver

to input of pitch shifter, then from output A into

the main box and plug on to the main board.

joint. TEST- Connect robot mic to transmitter. If it

now works, problem is in headset. Repair or

replace.

2. Bend out the metal clips. Put foam under clips.

5. Find wire and plug it back in.

6. Adjust the mute on the 151 RX to max. which is

fully CCW.

headset into the robot transmitter in place of the

robot microphone and test.

headset.

the 151 Receiver and robot receiver.

broken antenna.

(This will decrease your range)

before you turn off robot.

20

Moving Mouth

Function

Adjustment-

Location of the Adjustment

Main Electronics Box in Vehicle.

- The moving mouth is a feature where the mouth moves as the operator speaks

through the robot. The amount of the movement is affected by the level of volume of the

voice. This level is affected by the Receiver volume level and the position of the headset

microphone to the operator's mouth. The sensitivity is set based on a typical voice

volume and the headset microphone being about 1 inch from the operator’s mouth.

The adjustment is preset at the factory and should not need any adjustment. If an

adjustment is necessary, see the Main Circuit Board diagram in the Appendix for the

location of it. It is labeled Moving Mouth sensitivity. When this pot is adjusted clockwise

this makes the mouth more sensitive to your voice and turning it counter-clockwise

makes it less sensitive.

21

Operator’s Voice Transmitter and Receiver

3.5mm Headphones Plug

Mic Plug - 3.5mm

Headset style that comes with

the robot.

22

CHAPTER 4 Audio Amplifier System

The audio amplifier boosts the all audio from the main circuit board and drives the speakers.

The level adjustment adjusts the volume for any audio projected from the speakers. There are

individual volumes for the voice, mp3 player, and siren. Set the Filter to middle because this

gives you the best mid-range sound. If your sound is bassy or too high pitched, check this

switch position. Set the level at about 2:00. If this is too high you will get some distortion.

Audio In - Left/Right

Filter- Lo/Hi

Set Filter to Off

Speakers Power 12V

Problem/Cause Action

Siren

No audio

1. Audio fuse blown

2. Speaker wires are disconnected

One speaker not working

1. One channel of booster bad.

2. Speaker wire broken or disconnected.

3. Speaker bad.

Audio Sounds muffled and low

1. Filter is in low position.

Level Adjustment

Master Volume

1. Replace fuse. See fuse block diagram.

2. Re-connect speaker wires.

1. Replace booster.

2. Connect or replace wire.

3. Replace speaker.

1. Switch to off position.

23

CHAPTER 5 MP3 Player Option

Integrated MP3 Player Features

Ability to play MP3 files through the robot.

Memory Storage Card: SD Card.

Four sound effects stored on the card varies with

robot type.

Space on the card to load your own music.

Selection of songs is done with the RC.

New feature: Adjust the volume of the music and effects from the RC.

The Integrated MP3 player will only play mp3 format

best choice for this player for best cueing speed. File names cannot be more then 20 characters

long. Abbreviate your file names to accommodate this. When loading music it is important that

you load your songs outside the soundfx folder

To use the MP3 player you will need access to software that converts audio files to the mp3

format and a card reader or slot on your computer for SD memory cards.

Important

Play Music

When you first turn on the robot, the MP3 player will take a few seconds to start up before you

can operate it. To play a song, hold the MP3 mode switch and push the play switch shown on

the diagram below.

files. The 128kbps compression rate is the

on the card or they will not play.

MP3 Switch

MP3 Functions

Snd4

Snd3

Snd2

Snd1

Fwd. Track

Back Track

Play

Pause

Hold the MP3 switch on to use MP3 Player

and to change volume with the left stick.

Tips

After you move forward or back to a new track, the music will start right when you release

the switch.

When you scroll to the last track it will stop there. If you want to go to the first track you

need to back track.

If you stop on a song, it will remember that position when you start the mp3 player again,

unless you turn off the robot.

24

There is an additional way to change the volume of the music/effects. It is to go to the Road

Rage audio amp and adjust the volume. When you do this, you may also need to adjust the

volume of the voice on the voice receiver. Do not turn the amp up too high; not much past

1:00, because you may get some audio distortion.

You can customize the songs and sound effects that you use for different programs by

getting additional cards and adding your own set of sound effects and music.

To Load Music on the Memory Card

Place the card in a card reader or in a SD card slot on your computer. Go into ‘My Computer’

on your desktop and find the drive that represents the card. Open this and you will see the

sound effects folder. Open the source folder where you have your MP3 music or sound effects

to transfer to the card. Drag and drop a copy of these files to the card. Make sure to put these

files separate from the sound effects folder. You can place the files in the order that you want to

use them. Put the memory card back in the MP3 player.

Play Sound Effects

If you want to play a sound effect, hold the MP3 mode switch while you hit the sound effect you

want (See the diagram above). You can play any of the sound effects: snd1, snd2, snd3, or

snd4 with the switch as shown. If you add sound effects or songs to be played in the place of

snd1-4 they must have the filename of snd1, snd2, snd3, snd4 to play in their place. The

sound effects files must be in the soundfx folder.

Removing the SD Card

Open the back door of the robot to locate the MP3 player. Push on the memory card and it will

slide out part way. Remove the card. Now you can load music on the card. If you need more

storage space, get a card with additional capacity. If you need to add the sound effects to a

new card, make a copy of the folder with the sound effects on and place it on the new card.

Tip: Have multiple cards with different music customized for the presentations.

Changing the Volume

While holding the MP3 switch, move the left stick right for volume up and left for volume down.

Order of songs playing

The songs will play in the order that you transfer them to the SD card. Transfer one song at a

time in the order that you want them to play.

25

CHAPTER 6 Cassette Tape System

If you have the MP3 Player Option on your robot, you will not have a cassette player.

The cassette tape system is located inside the robot on the metal electronics box. The system

is activated by remote control from the remote control box. (Additional instructions are on the

next page.)

How to Play a Cassette Tape

1. Insert a regular type cassette tape into the player.

2. Depress the play button on the cassette player.

3. Move the radio tape select switch to the tape position.

4. Activate the tape from the control box.

5. Adjust the volume to desired level.

6. Press F FWD to move the tape to the next song.

The tape head of the cassette player should be cleaned after

every 25 to 30 hours of use. Always remove the cassette tape

when not in use. This will prevent flat spots on the capstan roller.

Specifications

Output Jack- 3.5mm stereo

Power Input- DC 3V Center negative

Problem/Cause Action

Cassette Player

No tape operation

1. Tape player not on tape mode or volume not turned up.

2. Play button not pushed 2. Must push play button before hitting the switch on the radio

3. Bad Tape. 3. Check tape in other tape player.

4. Tape is too tight. 4. Loosen with a pencil by spinning tape.

5. Player is not getting power because power wire or plug is

broken.

6. Power or audio wire has come disconnected from the main

board.

7. Radio control or tape circuit not working 7. Contact Robotronics for help.

No siren, or voice either.

1. Audio fuse blown.

Poor quality sound or slow.

1. Belts worn out and slipping.

Troubleshooting - Cassette Player

1. Put mode select to tape and turn volume up.

control.

5. Check for 3 Volts at power plug. Replace plug or repair the

wire.

6. Open the main box and re-connect to board.

1. Replace the fuse. See fuse block diagram.

1. Replace cassette player or belts.

26

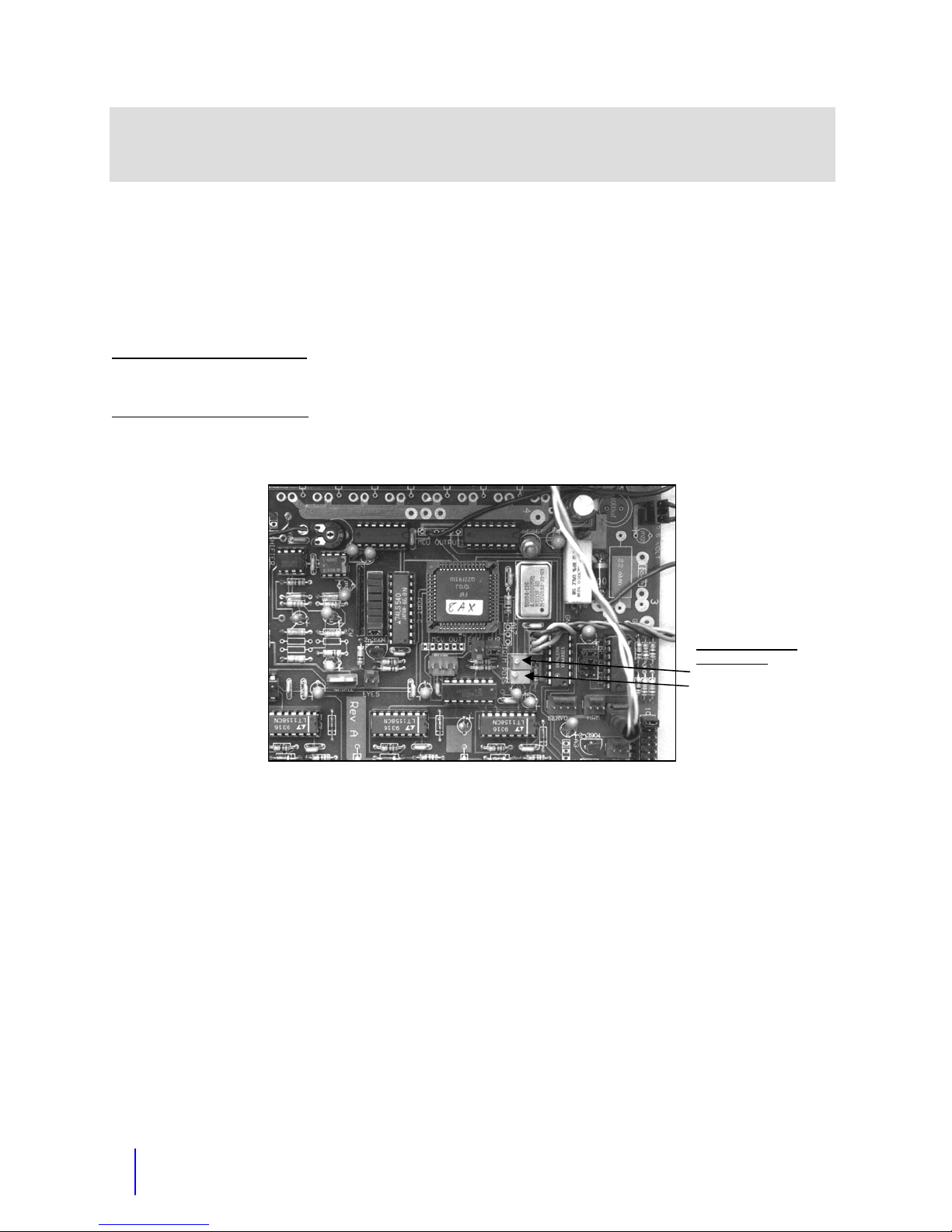

CHAPTER 7 Siren

The robot siren is operated by remote control from the Radio Control Transmitter. The siren

circuitry is located on the main circuit board. See the Main Circuit Board diagram, in the

Appendix, for the location of the siren volume, mode select and oscillation frequency adjust.

The volume of the siren is controlled by a trim pot on the main board. Turning the pot

clockwise will increase the volume of the siren. Turn the pot counterclockwise to decrease

volume. Three different sirens are available. Choose the siren you want by moving the jumper

located on the siren mode select. To control the oscillating speed, adjust the siren frequency

trim pot in the siren circuit. The siren mode select is set to the common siren for your robot. If

the siren mode select is changed, the siren frequency will very likely need to be adjusted.

NOTE: The volume and oscillation are preset at the factory and do not need to be adjusted

unless you want a different volume level or oscillation speed.

Siren Volume

Siren Frequency

Troubleshooting – Siren

Problem/Cause Action

Siren

No siren

1. Audio fuse blown

Siren volume not loud enough

1. Booster problem if tape and voice vol. also are not loud

enough.

2. Adjust siren volume if tape and voice okay.

Mouth Sensitivity

Siren mode select

1. Replace fuse. See fuse block diagram.

1. Replace or have booster repaired.

2. See siren volume adjust on main board.

27

CHAPTER 8 Robot Battery System

Robot Battery

The battery in the robot is a rechargeable sealed lead-acid Gel type battery 12 Volt 33AH. This

type of battery is very dependable and safe. It can be repeatedly charged and discharged.

How to Recharge

1. To recharge the robot battery, first open the trunk or rear door and

unplug the battery from the main component board. You could also

remove the battery from the robot.

2. Connect the charger wires to the battery, red to the red (POSITIVE

+) post and black to the black (NEGATIVE -) post.

3. Plug the line cord of the charger into a 110-volt AC outlet. Leave the

trunk cover off or open during charging for ventilation. Keep the AC

power connection as short as possible especially when using an

extension cord.

4. The red LED will come on during charging and the green when the battery is charged and

ready to use. Both red and green on indicates that you are in the middle stage of

charging.

The robot is supplied with an automatic type battery charger. This will recharge the battery full

in about 8-12 hours depending on how long you have operated the robot. It will not overcharge

the battery if left "ON" indefinitely. It goes to a float charge mode once the battery is fully

charged.

Taking Care of the Robot Battery

The number one rule for battery care is to keep the batteries fully charged at all times.

Like all batteries, there is some discharge that occurs every day. Because of this you

should charge up the battery monthly during periods when the robot is not being used.

Also, the automatic battery charger can be left connected for extended periods of time to

keep the batteries at full.

It is a good practice to rotate the batteries if you have two or more.

For a battery that is outside the robot, store the battery on a wood or rubber surface not

concrete floors.

If the wires to the battery have been removed, observe properly polarity when reconnecting. The red wire goes to the positive terminal and black wire to the negative

terminal. Damage to electronics could result if the polarity is wrong.

Charge the battery to a full charge right after each use of the robot and monthly when

not in constant use.

28

Caution

Important

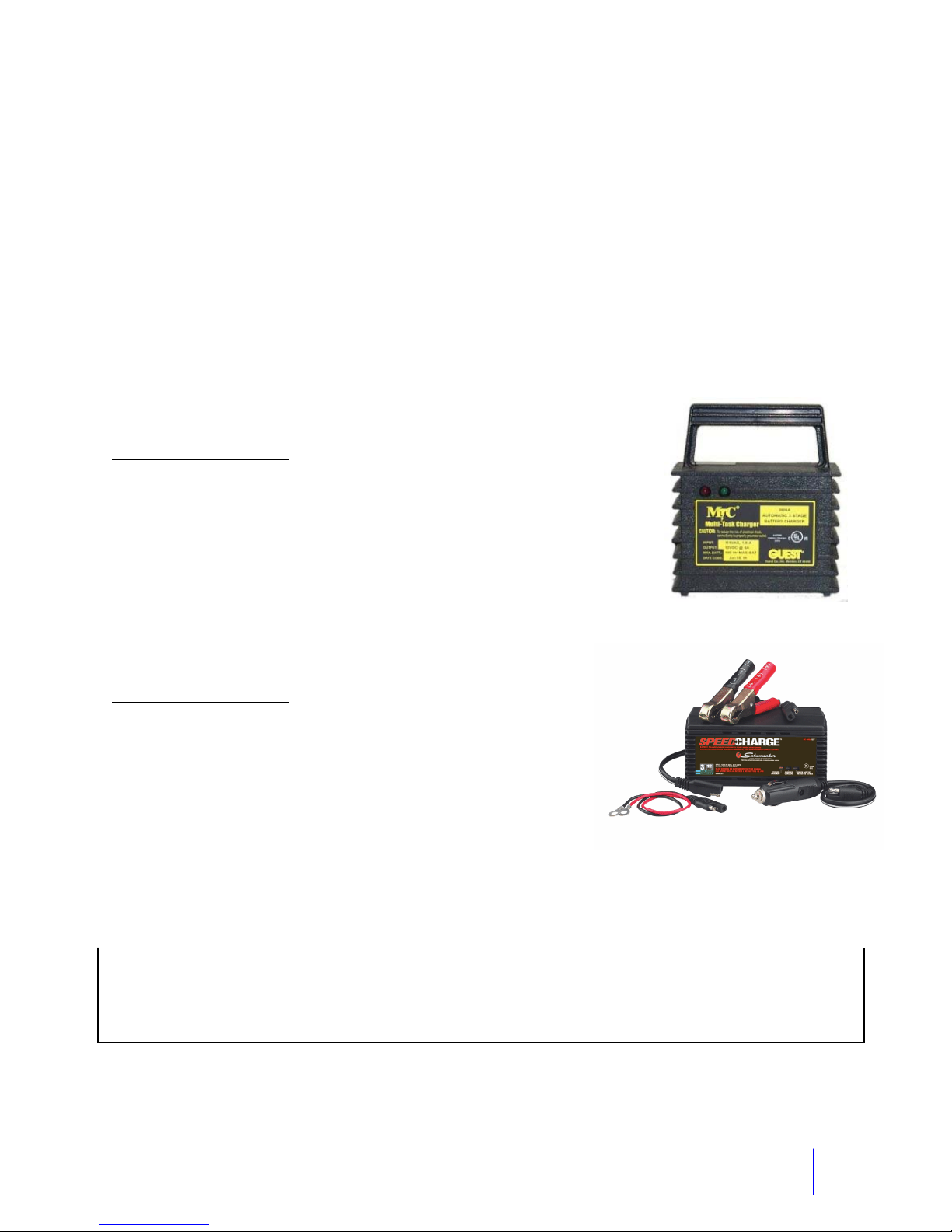

Robot Battery Charger

The charger supplied with the robot is designed to both recharge your battery, and extend your

battery’s life. It produces 12 Volts DC at a full 6/3 Amps. It will charge the battery in about 8-12

hours depending on how long you have used the robot. After the battery is charged, the green

LED will come on and the battery is ready to use. At this point the charger is charging at a

FLOAT or maintenance rate. At this rate you can leave the charger connected for extended

periods of time.

Robots with recharge jack: Certain robots have a recharge jack on the body for recharging. If

your robot does, then the on-off switch will have a recharge position also.

Charge Pro Model 2606A 6 Amp Battery Charger

Status Indicating Lights

Red on-The battery is discharged and is being recharged at the

maximum 6 Amp rate of the charger (stage 1).

Red and green both on-The battery is charging at the stage 2 rate of

1.5 to 5 Amps.

Green on-Your battery is charged and ready to use. It is now on float

charge (stage 3).

Schumacher 3 Amp Battery Charger

Status Indicating Lights

Amber- Charging

Green- Charged and is now in float charge.

Red- Check battery. The charge clips may be on wrong or

the battery may be bad.

Personal Safety Precautions

When charging, a lead acid battery gives off hydrogen gas. The Gel type battery is a lead acid

battery with pressure relief type vents. Although it only gives off a small percentage of the gas

that a wet lead acid battery does, the following precautions should be observed:

1. Connect the charger clips to the battery first, then connect the cord to an outlet.

2. Warning: Battery chargers get hot during operation and must have proper ventilation. Do

not set the charger on flammable materials like carpeting, upholstery, paper, cardboard,

etc.

Warnings

HAZARD OF EXPLOSIVE GAS MIXTURE

29

3. Charge the battery in a dry, well ventilated area. This is why it is important that you leave

the trunk or door open. You can also remove the battery from the robot.

4. Do not position your face over the battery, at any time while making connections.

5. Do not smoke, strike a match, or cause a spark in the vicinity of the battery during charging.

6. Always unplug the AC supply cord before connecting or

from the battery or arcing may result.

7. Do not drop a metal tool onto the battery.

8. Do not expose the charger to rain.

9. Replace defective cords and wires immediately.

10. Do not operate this charger with a two bladed adapter plug or extension cord. Doing so

can result in serious personal injury.

11. To reduce the risk of shock, connect only to a properly grounded outlet.

12. Remove personal metal items such as rings, bracelets, necklaces and watches when

working near a lead acid battery.

disconnecting the charger leads

If the Battery is not taking a Charge

Make sure that the charger is working by connecting it to a battery that is known to be good.

Leave the charger on for a few days and see if the battery starts taking a charge. Turn the robot

on and try to operate it. Connect to the charger again. If it still will not take a charge, it’s time to

replace the battery.

30

CHAPTER 9 Drive Motor System

Your robot is provided with two high quality industrial grade drive motors. Each

motor controls a drive wheel-left and right. Steering of the robot is

accomplished by varying the speed and direction of these motors. For

example, when the left motor runs faster than the right, the robot turns to the

right.

Each drive motor is connected to its drive wheel via pulleys and 1/2" wide

rubber timing belts. The pulley set screws and bolts should be kept tight.

Trouble-Shooting – Drive System

Perform the following steps first when trouble-shooting a drive problem:

1. Check drive belts and motor pulley set screws. Especially if you hear the motors

activate but the robot does not move. It may be a belt off or loose set screws on the

pulley.

2. Check connections to motor controls and motor leads. These are blue and yellow

wires coming from the electronics box and going to the drive motors. There is a white

connector in line. The joystick could be pushed in the on position while the connector is

being checked for an intermittent connection. If there is a bad connection, the connector

and/or pins should be replaced. While doing the test just explained, have the robot

wheels off the ground.

Note: Get the wheels off the ground to look at each wheel independently.

Neither drive operates

Check both fuses in the fuse block. Check set screws on the motor pulleys.

One drive motor does not operate either direction

Set screw is loose on the motor pulley. Tighten the Allen set screw(s) on the pulley on

the motor shaft.

Drive motor is bad- To test the motor for operation, swap the motor wires. Get the wheels

off the ground to see which motor and wheel are not working. The motor wires are

blue/yellow wires hanging down below the electronics box. You may have to remove the

robot battery, to make the swap. If now the wheel/motor on the side in question operates

and sounds fine then the motor is good.

Drive circuit problem (motor control)- If the drive motor is good, the drive circuit could be

the problem. Each motor has a drive circuit on the main board. If you have a Voltmeter you

can check that there is power (about 12 Volts) on the blue wire from the fuse block. Contact

Robotronics for additional help.

Fuse blown or bad wire. Check the drive fuse in the fuse block. See the fuse block detail.

One drive motor operates only in one direction

The motor control circuit is likely the cause of this. The problem is in the drive circuit. Send

the main electronics to Robotronics for repair or contact our Service Department.

The robot is not driving straight (Veering when you drive)

31

Note: Before making this adjustment, be sure that your motor pulley set screws are tight

and that both motors appear to be working forward and reverse. To check this prop the back

of the robot off the ground.

To locate the adjustment, see the Robot Main Electronics Box diagram in the Appendix.

They are labeled Forward Drive adjust and Reverse Drive adjust. You will need a small

flat head precision screwdriver to make the adjustment. The cover of the main electronics

box would need to be removed to access the adjustment. Take the cover of the box

completely off and set outside the robot so that it cannot touch the post(s) of the robot

battery.

Forward Drive Adjust Pot

- Effects forward straightness of drive.

Robot veering left- Adjust it counter-clockwise

Robot veering right- Adjust it clockwise

Reverse Drive Adjust Pot-

Effects reverse straightness of drive.

Robot veering left- Adjust it counter-clockwise

Robot veering right- Adjust it clockwise

Drive Straightness

Adjustments:

Forward

Reverse

If the robot veers, the reason is that one motor is going faster than the other at any given

position of the joystick. For example if at full speed, the robot veers to the right, this means that

the left motor is going faster than the right motor. To correct this you would adjust the forward

drive adjust pot clockwise. You may need to do some trial and error to get it just right. It is best

to use full speed during the adjusting, because this will act as a good reference point.

The robot is moving slightly even though the drive stick is at neutral

Move the sliders next to the drive stick until the robot neutrals out. This is called trimming

the stick.

The joystick is broken or a wire has broken off the potentiometer of the joystick. Send the

RC in for repair. We need the Hitec receiver out of the robot also.

32

CHAPTER 10 Character Head Turning System

Vehicle robots that have characters driving them will have this system. The main components

of this system consist of the head turning motor, motor control circuit, and the feedback pot.

When you move the joystick on the radio control, a signal is sent to the receiver in the Robot.

The receiver sends this signal to the microcontroller on the Character board. The motor control

circuit is on the Character board. The motor control circuit is directed by the signal to send 12

Volts to the motor and in what polarity. What polarity is sent to the motor will cause the motor to

move right or left.

The job of the feedback pot is to track the position of the head and continually relay information

to the motor control circuit and micro-controller so that when you release the joystick and it goes

back to center, the head also goes back to center.

Location of Parts

Motor control circuit-On the Character Board mounted on the inside the chest of Character.

Feedback potentiometer- directly below the motor.

Set screw- on the inside of the neck.

The head is out of position but operates

The head could have been hit out of position or the setscrew is loose. Try to move the head manually. If

you can, move it back into the correct position and make sure the setscrew is tight. The setscrew can be

accessed through hole in the plastic below the neck. If you cannot manually move the head, you may

need to loosen the setscrew, re-position the head and then tighten the setscrew. When re-positioning the

head, have the robot on so that the motor will maintain the motor center position.

The head motor is keeping the head position to the extreme left or right

The in line connector to the blue feedback potentiometer has come disconnected. Check if one of

the wires has broken off the pot.

The feedback pot could have slipped. The pot could be loose or the head needs to be re-centered.

There are two ways to re-center the head. Option1: Find the hole in the plastic just below the neck,

as you look at the neck from the front. You have to pull down the fur. To access the set screw the

head has to be looking straight forward. Loosen the set screw (3/16” Allen wrench). With the robot

on, position the head and tighten the set screw. Option 2: The feedback pot which is a blue pot just

below the head turning motor will need to be lowered clear of the tubing that joins its shaft to the shaft

of the head turning motor. Now you will have access to be able turn the shaft of the feedback pot

until the head comes back into center position. Bolt the pot back up into its correct position.

Feedback pot is bad and needs to be replaced. It is a 5K 360 degree single turn pot.

The head motor is not operating

Check the motor wire to see if it came disconnected at its in line connection (blue/yellow).

The Character board is not getting power- if this is the case you would not be getting eyelid

movement. Check the fuse inside the main electronics box. See the main electronics box diagram

for location of the fuse.

Look at the red and black wire bringing power to the Character board. If you have a

Voltmeter, check for 12 Volts going to the board. Is there 12 Volts; a broken wire?

Troubleshooting – Head Movement

33

CHAPTER 11 Eyelids and Eyes Left and Right

The eyelid and eyes left and right movement is accomplished by three servo motors in the

Character or upper robot. When the switch on the radio control is activated, this signal is sent

to the radio control receiver in the robot. The micro-processor in the robot decodes this signal

and a new signal is sent to the eyes servo board. The eyes servo board is located on the

underside of the top of the robot. To see it, the top would need to be removed and the top

turned on its side. The wires connected to this board take the signal to the servo itself and

operate the shaft of the servo motor to turn clockwise or counter-clockwise for opening or

closing. The rotation of the servo motor shaft is coupled to the eyelid and eyeballs with a servo

arm and then an eyelid rod.

Set Screw

(M2.5 x .45 x 8mm Phillips Pan

Head Machine Screw)

4-40 Ball Link

Troubleshooting - Eyes

An eyelid or the eyes left and right does not operate:

Linkage problem. Check the linkage from the servo motor. Look for the servo arm off the

servo shaft or the ball link off the eyelid. Put the servo arm back on and get a set screw to

hold it on.

Wire broken. Follow the wires from the specific servo motor with the problem. The wire will

run to the eye servo board. If it is disconnected, reconnect according to the eye servo board

diagram. If the servo does not work correctly (wrong direction), try one of the other outputs

on the eye servo board. See the diagram showing the eye servo board on the next page.

Bad servo. Replace the servo motor.

One of the eyelids is at a different level than the other:

Bent rod. If the eyelid rod is bent, bend it back into position or replace the threaded rod.

Adjust the level. The eyelid can be positioned to match the other eyelid. To remove the

servo saver arm, the set screw must be removed. The eyelid level can be changed by

altering the length of the eyelid rod or changing the position of the servo saver arm on the

servo motor shaft.

There is no operation of any of the eye functions:

Five pin wire disconnected, broken or in the wrong place. The wires that bring the

signal to the eyes servo board are gray and yellow. 5 Volts power is the black and red wires

that connect to the eyes servo board. You can check for 5 Volts here. If these wires are

connected, follow them back to the board that they originate. Typically these wires go to the

Futaba Servo Motor

Servo Arm Assembly

4-40 All Thread Rod

Large Vehicle Eyes Parts

34

37 pin connector. Check the wiring here to see if there is a broken wire. On robots with

characters driving, these wires go to the Character Control Board in the chest area. Check

these connections and look at the Character Control Board in the end of this manual for

correct placement on the circuit board.

Check the fuse on the fuse block.

The eyes work but not properly:

Check switches 3 and 4 in the battery compartment of the RC transmitter. They should be

in the normal (blue) position.

Put the joystick sliders in the middle.

Eye and Mouth Servo Board

Red + 5 V

Black Gnd

Gray

Yellow

Black

1 Left Eyelid

2 Left Eyelid Reverse

3 Right Eyelid

4 Right Eyelid Reverse

5 Eyes L/R

6 Eyes L/R Reverse

7 Mouth Servo

8

35

CHAPTER 12 OPTIONAL ACCESSORIES

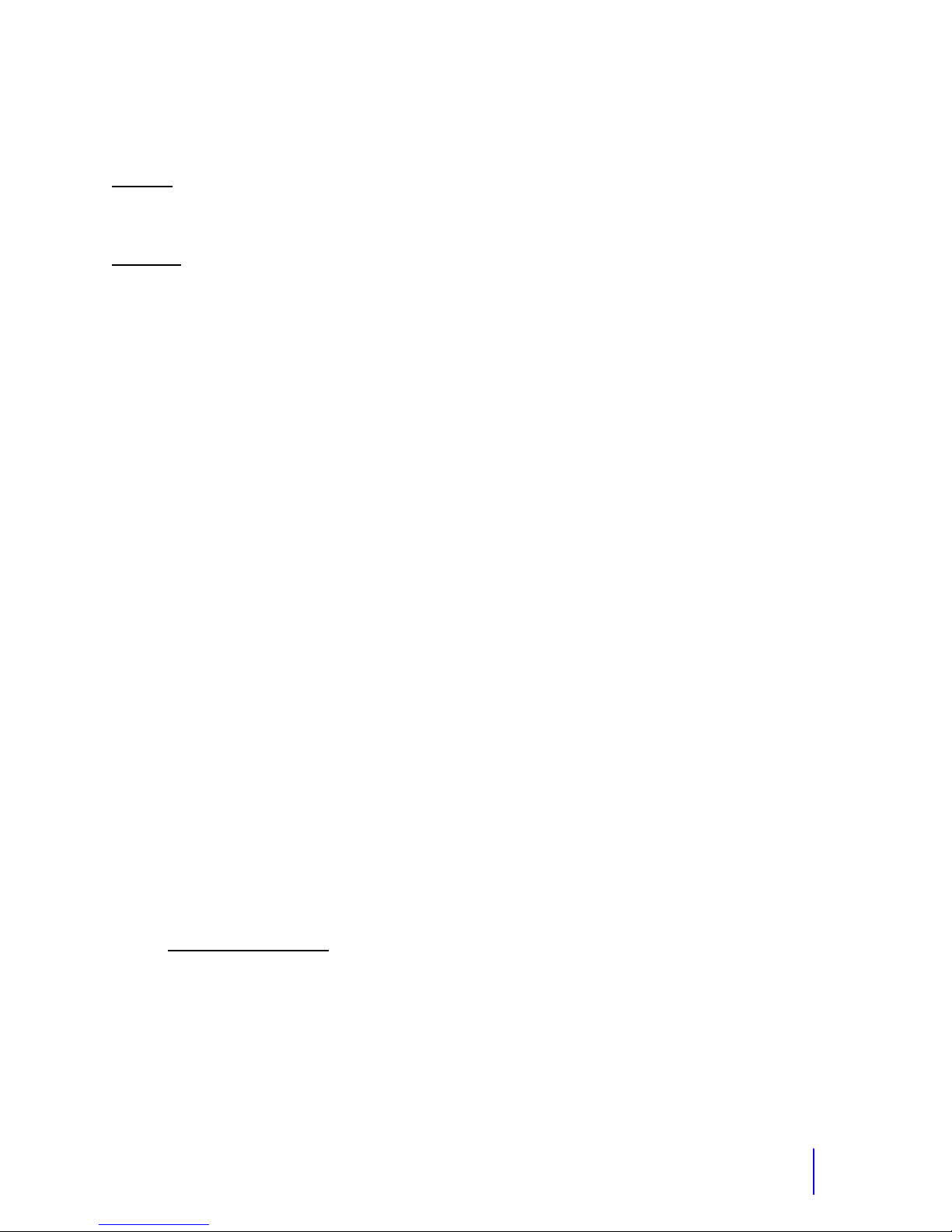

Water Squirter System

The new system

It is held by an elastic band.

Fill the Water Bottle