Page 1

Dynamixel

DX-116

User’s Manual 2004-04-02

Closer to Real,

Page 2

DYNAMIXEL

Contents

DX-116

1. Summary

1-1. Overview & Characteristics of DX-116 Page 2

1-2. Main Specification Page 4

2. Dynamixel Assembly

2-1. Mechanical Parts Assembly Page 5

2-2. Connector Assembly Page 5

2-3. Dynamixel Wiring Page 6

3. Communication Protocol

3-1. Communication Overview Page 9

3-2. Instruction Packet Page 10

3-3. Status Packet Page 10

3-4. Control Table Page 13

4. Instruction Set and Examples

4-1. WRITE _DATA Page 20

4-2. READ _DATA Page 21

4-3. REG_WRITE and ACTION Page 22

4-4. PING Page 23

4-5. RESET Page 24

5. Example Page 25

Appendix

Page 32

1

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 3

DYNAMIXEL

DX-116

1. Dynamixel DX-116

1-1. Overview & Characteristics of DX-116

Dynamixel DX-116 The Dynamixel is a smart actuator which incorporates a precision servo

motor and a control unit with networking functionality, all in a single unit.

Despite its compact size, it can produce high torque and has been

manufactured using high quality materials to provide the necessary strength

and structural resilience. It can also detect and act upon internal conditions

such as temperature and over-current .

The Dynamixel has many advantages over similar products:-

Precise Control Control position and speed with fine angular resolution (1024 divisions)

Compliance Driving Control the degree of elastic force in position control.

Feedback Feedback for angular position, speed and load size.

Alarm System Not only does the Dynamixel warn of a deviation from the user defined

ranges (e.g. internal temperatures, torques, voltages etc), but it also

automatically deals with the problems as they occur.

Communication Daisy chain connection with support for communication speeds of up to

1MBPS.

High Efficiency Motor Dynamixel uses the RE–MAX Series Coreless DC Motors from Swiss Maxon

Motor which boasts high output torque and excellent acceleration.

Distributed Control The main processor requires very few resources to control multiple

Dynamixels since the movement schedule requires only a single command

packet.

High Quality Enclosure The high quality plastic body ensures structural integrity under all

operational conditions

2

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 4

DYNAMIXEL

Metal Gears All the gear sets are made of metal to ensure extreme durability.

Axis Bearing A bearing is used on the final axis to ensure there is no loss of efficiency

Status LED A LED indicates error status.

DX-116

during heavily loaded conditions.

3

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 5

DYNAMIXEL

DX-116

1-2. Main Specification

Holding Torque 31.5kg·cm (18V) ~ 21 kg·cm (12V)

Reduction ratio 1/140

Speed 0.084sec/60° (18V) ~ 0.125sec/60° (12V)

Resolution 0.35°

Operating Angle 300°

Voltage 12V~18V (Recommended voltage: 14~15V)

Max. Current 1200mA

Operating Temp. -5℃ ~ +85℃

Weight 66g

Command Signal Digital Packet

Protocol Type Half duplex Asynchronous Serial Communication (8bit,1stop,No Parity)

Link (Physical) RS 485 Multi Drop (daisy chain configuration)

ID 254 ID (0~253)

Communication Speed 7343bps ~ 1 Mbps

Feedback Position, Temperature, Load, Input Voltage, etc.

Material Full Metal Gear, Engineering Plastic Body

Motor Swiss MAXON Motor RE-MAX (best level)

4

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 6

)

DYNAMIXEL

DX-116

2. Installation of Dynamixel

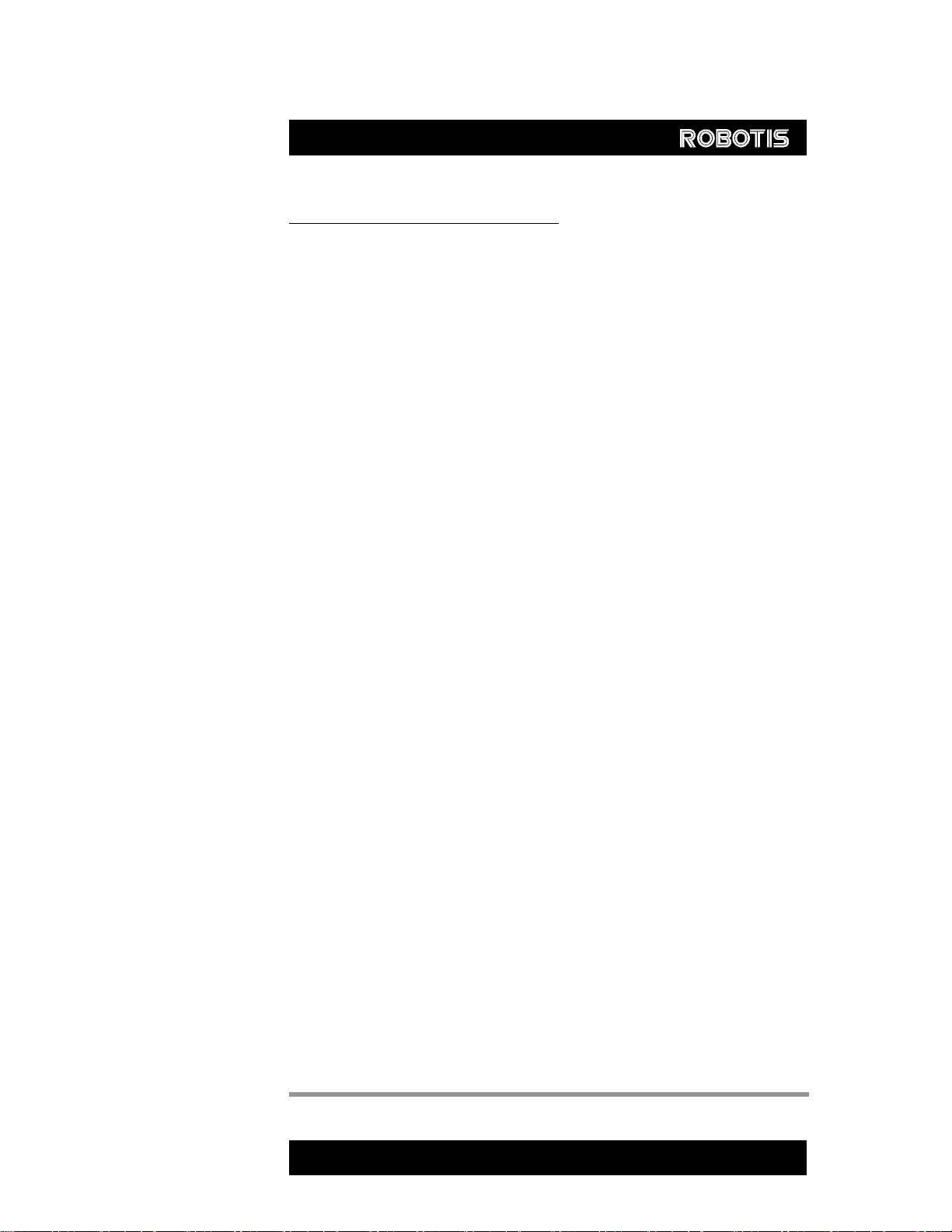

2-1. Mechanical Parts Assembly

Mechanical Parts of Dynamixel are assembled as follows:

Nut(8EA)

Screw for mount(8EA

The 8 sets of Nuts & Screws are only used when a Dynamixel is mounted to

other equipment.

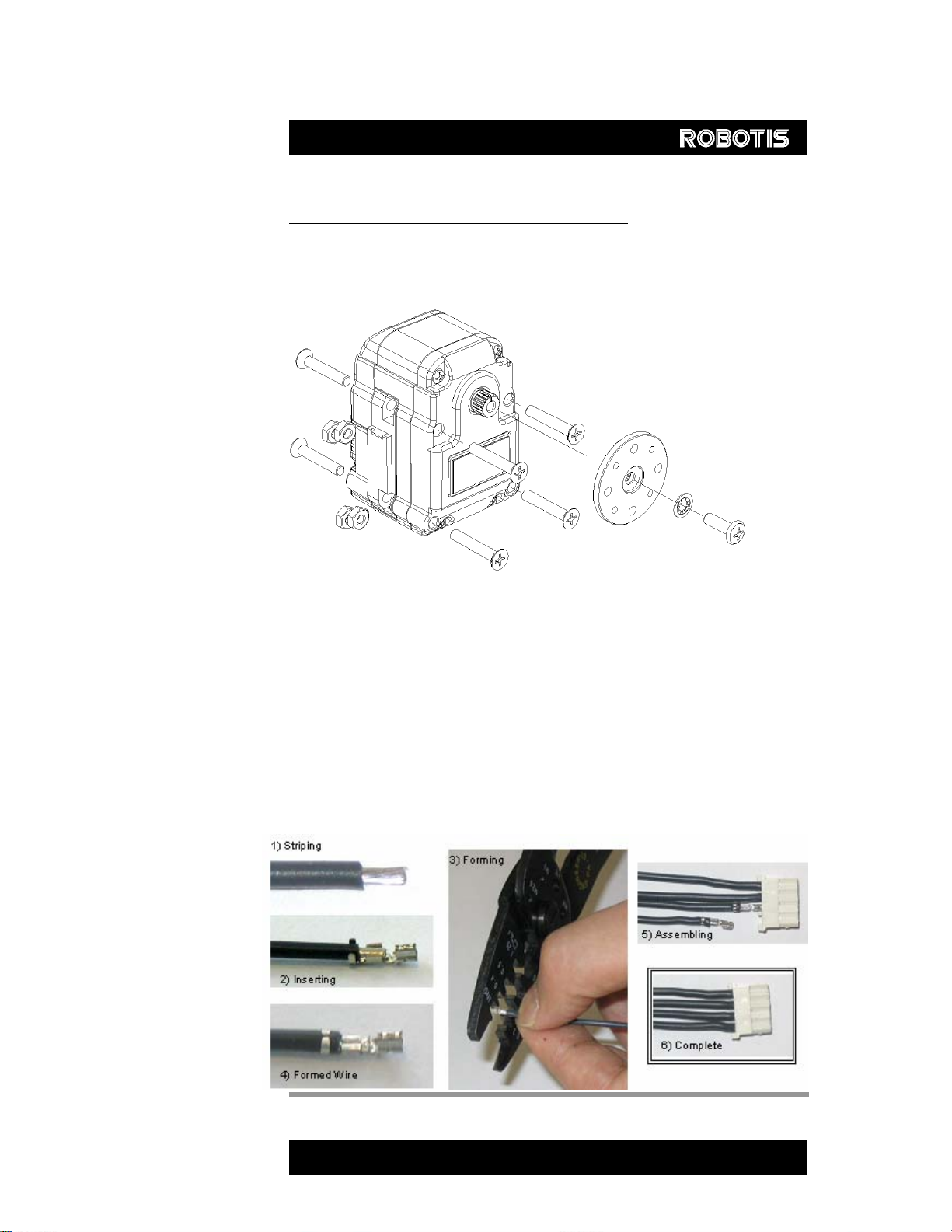

2-2. Connector Assembly

Assemble the connectors as shown below. Attach the wires to the terminals

using the correct crimping tool. If you do not have access to an appropriate

crimper, solder the terminals to the wires to ensure that they do not become

loose during operation.

Horn

Screw for Horn

5

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 7

evel

evel

DYNAMIXEL

DX-116

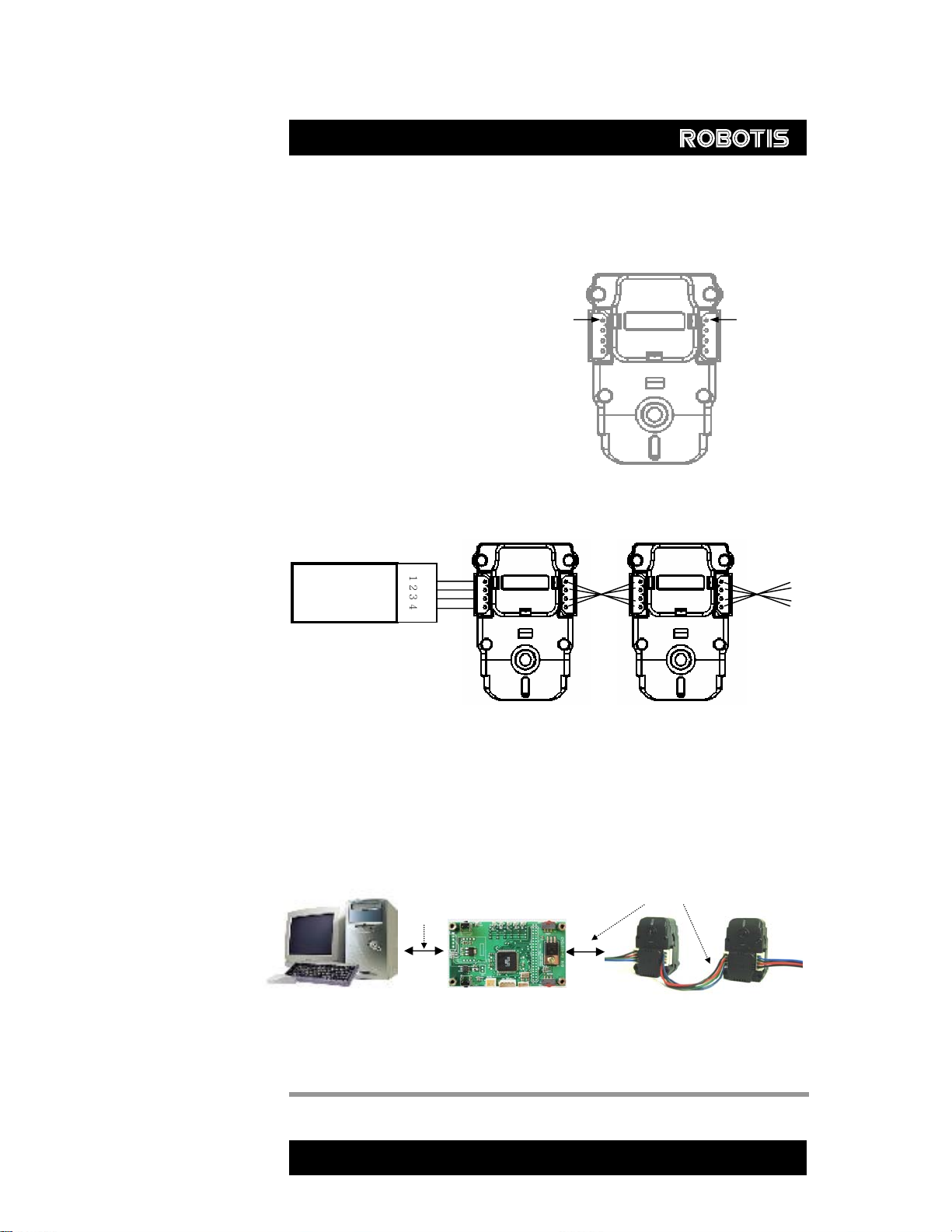

2-3. Wiring of Dynamixel

Pin Assignment Pin assignments of the connectors are as follows:-

Pin 1: GND

Pin 2: +12V~18V

Pin 3: D+ (RS485 Signal)

Pin 4: D- (RS485 Signal)

Pin 1

2

3

4

Wire Link Connect the same pin numbers as shown below.

Main

Controller

1

2

3

4

Main Controller The Main Controller must support RS485 to control the Dynamixel. A proprietary

Controller may be utilised but the Cycloid-M2 board is recommended.

PC LIMK A PC can be used to control the Dynamixel via the Cycloid-M2 Board.

PC

Stand Alone The Cycloid-M2 Board can be directly mounted on the robots.

RS232

L

Cycloid-M2

RS485

L

Dynamixels

Pin 4

3

2

1

6

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 8

DYNAMIXEL

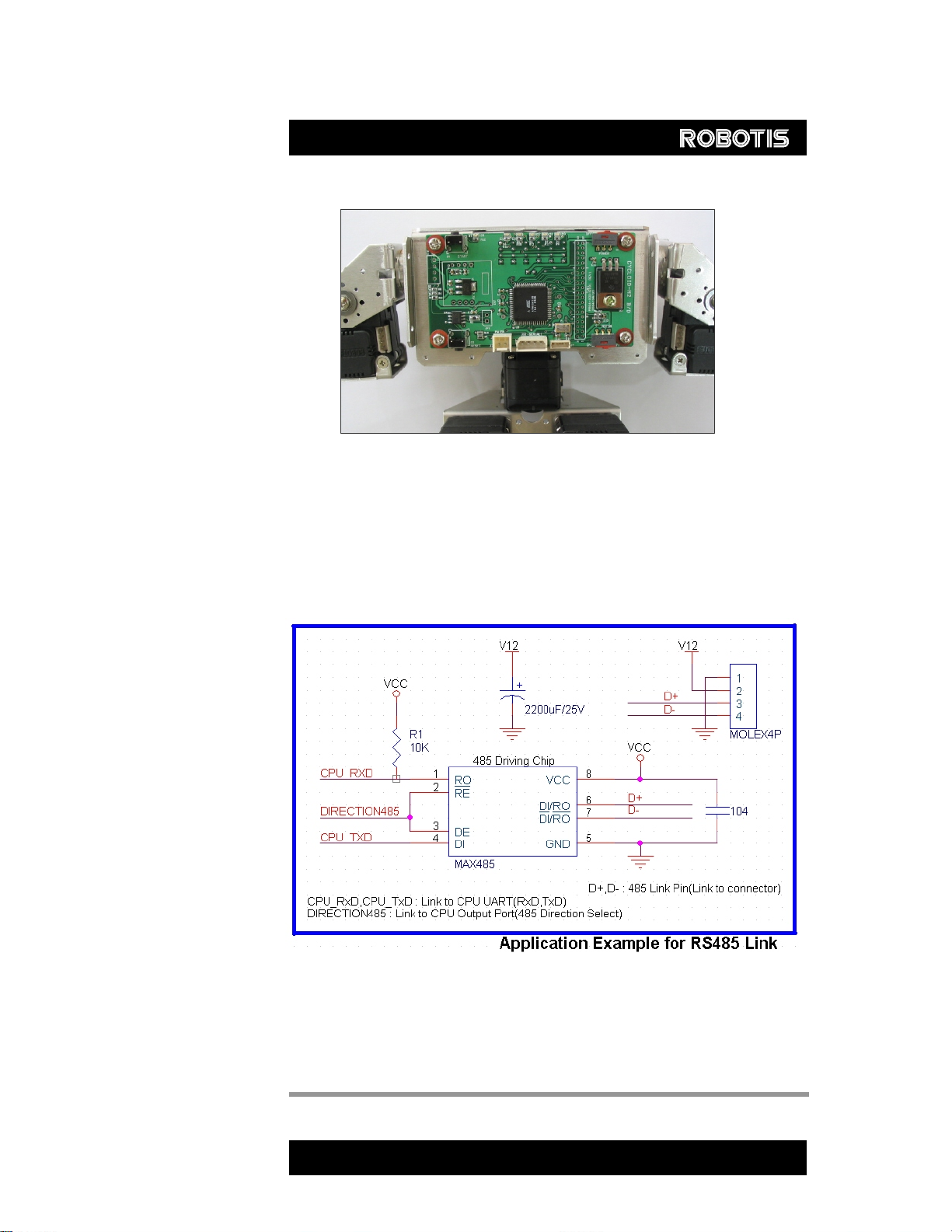

Please refer to the Cycloid-M2 Board manual for more details.

Connection to UART To control the Dynamixel, the main Controller needs to convert the signals to

전원은 Main Controller의 Molex4P Connector의 Pin1,Pin2를 통하여 Dynamixel로

Signal DIRECTION485 determines the data direction as follows:-

DX-116

Cycloid-M2 Board on Robot

RS485. The recommended schematic configuration is as follows:-

공급되어진다.

If DIRECTION485 is High: the signal TxD is output as D+,D-

If DIRECTION485 is Low: signal D+,D- is input as RxD

7

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 9

DYNAMIXEL

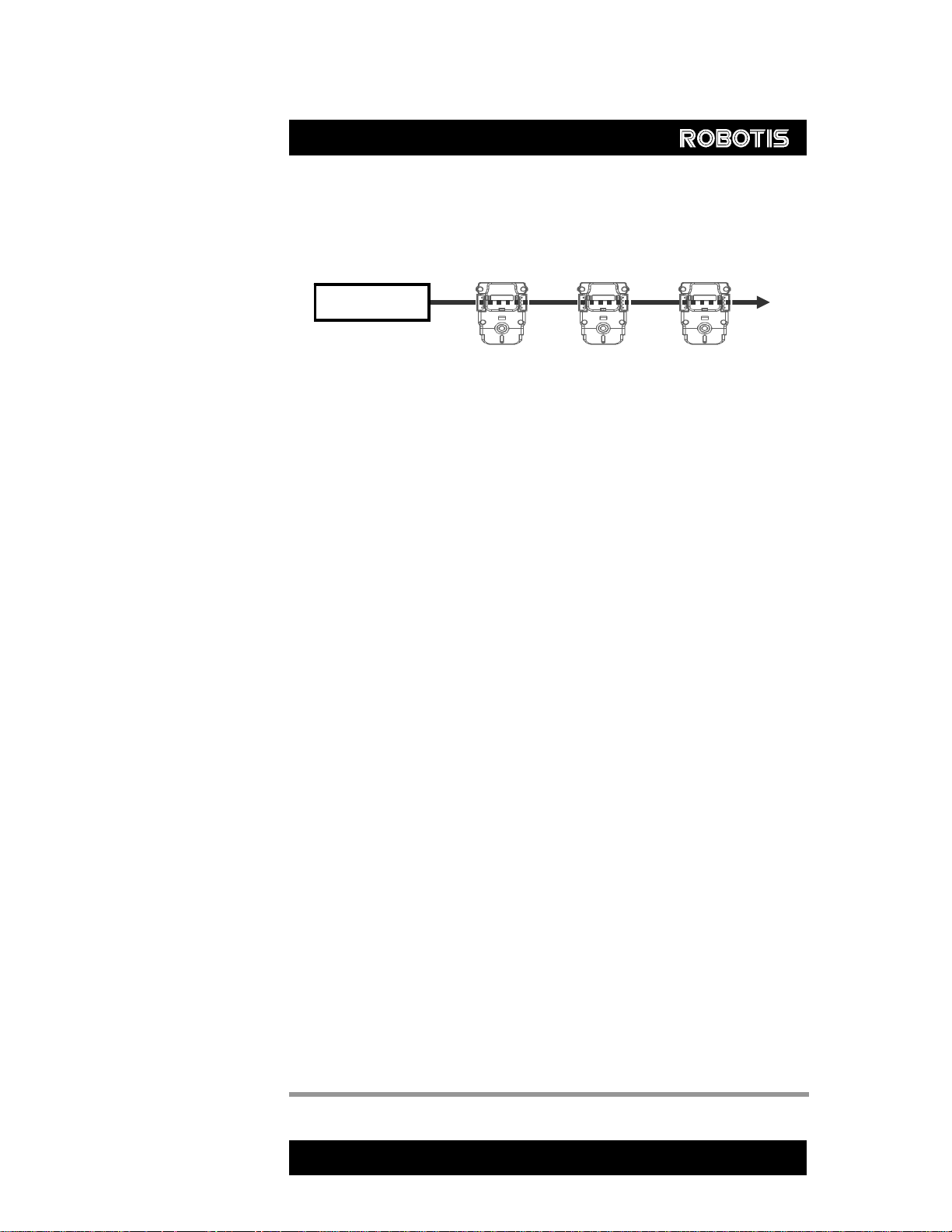

RS485 A multi-dropped RS485 (IEEE485) network is established from the main

DX-116

controller. Data Packets are then issued through this single portal.

Main

Controller

[RS485 Multi Drop Link]

Please note that caution should be applied when connecting the Dynamixel units to ensure that the pin

assignments are correct. Always check the current consumption. The standby current consumption of a

Dynamixel unit should be less than 50mA.

Connection Status When power is first applied the Dynamixel LED will blink twice to confirm its

healthy status.

Inspection If the above operation was not successful, then check the connector pin

assignment and the voltage/current limit of the power supply.

8

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 10

r

DYNAMIXEL

DX-116

3. Communication Protocol

3-1. Communication Overview

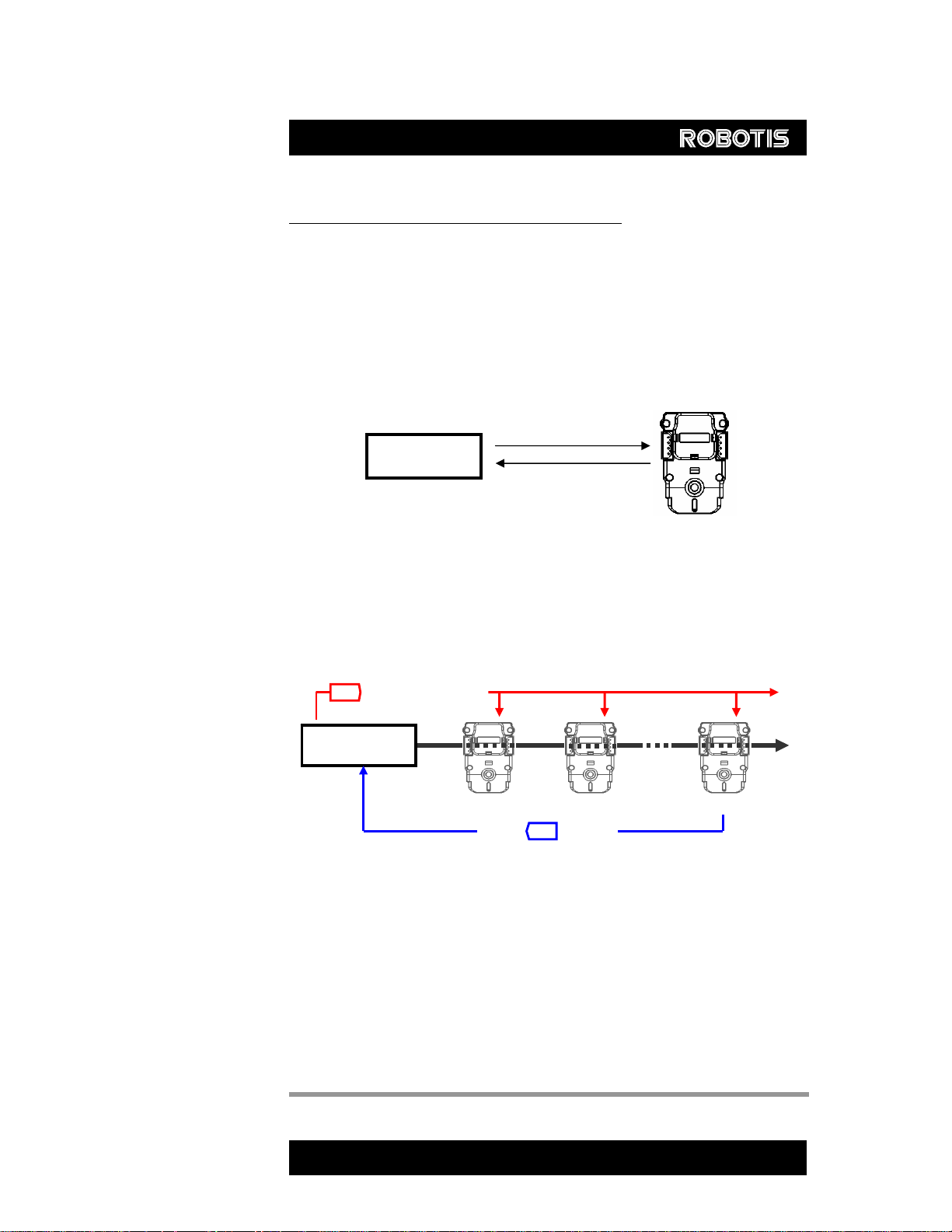

Packet The Main Controller communicates with the Dynamixel by sending and receiving

data packets. There are two types of packets, the Instruction Packet (Main

Controller to Dynamixel) and the Status Packet (Dynamixel to Main Controller)

Communication For the system connection below, if the main controller sends an instruction

packet with the ID set to N, only the Dynamixel with this ID value will return its

respective status packet and perform the required instruction.

Unique ID Communication problems will arise if multiple Dynamixel's have the same ID

value. This will cause multiple packets to be sent simultaneously resulting in

packet collisions. It is imperative that ID values are unique within each data

network.

Protocol The Asynchronous Serial Communication word consists of 8 bits, 1 Stop bit and

no parity.

Instruction Packet(ID=N)

Main

Main

Controlle

Instruction Packet

Status Packet

ID=0 ID=1 ID=N

Status Packet(ID=N)

9

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 11

DYNAMIXEL

DX-116

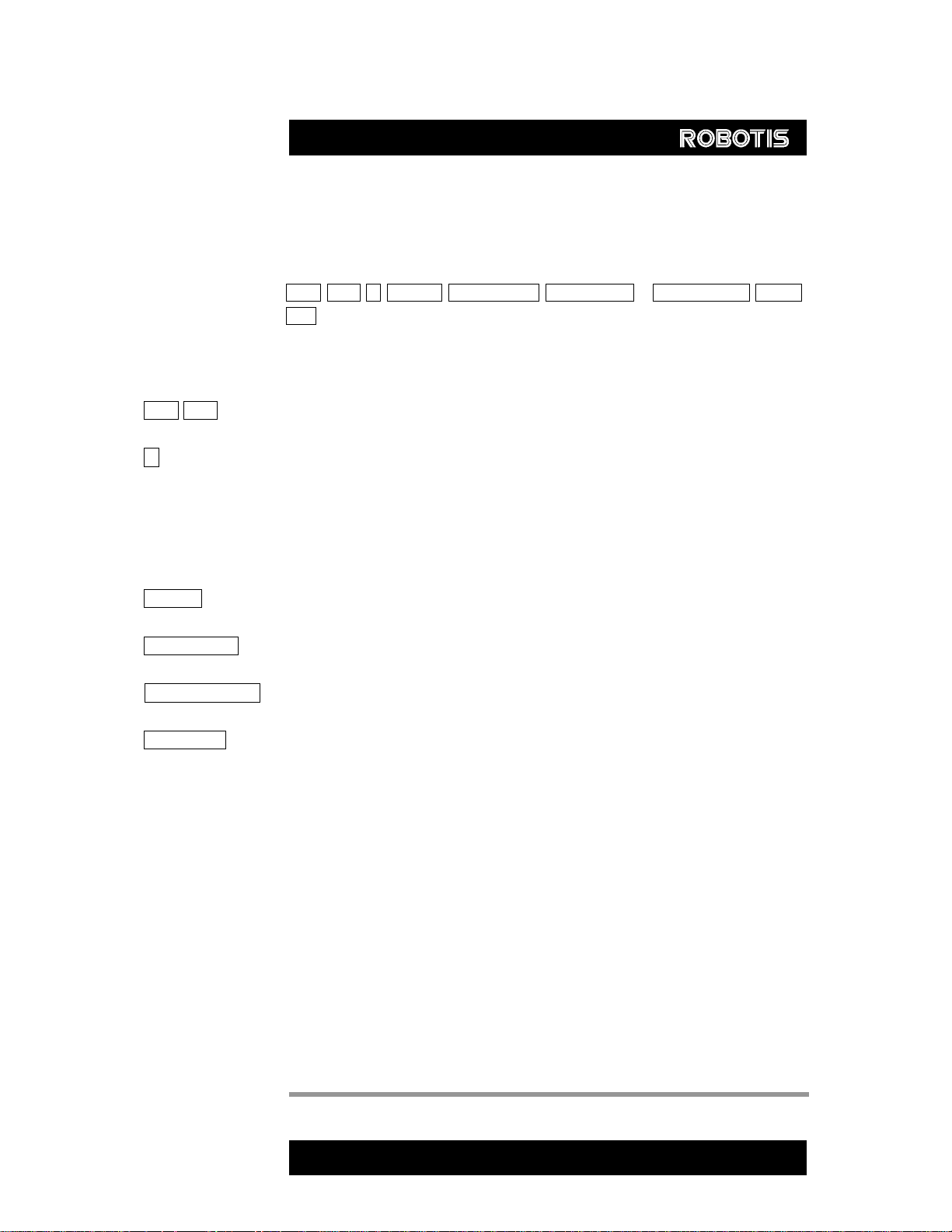

3-2. Instruction Packet

The structure of the Instruction Packet is as follows:

Instruction Packet

The packet byte definitions are as follows:-

0XFF 0XFF Two 0XFF bytes indicate the start of an incoming packet.

ID Unique ID of a Dynamixel. The ID can range from 0X00 to 0XFD (254 IDs are

Broadcasting ID ID 0XFE is the Broadcast ID which is assigned to all of the connected

LENGTH The length of the Status Packet. The value is “Parameter number (N) + 2”

INSTRUCTION The instruction for the Dynamixel to perform.

PARAMETER0…N Used if there is additional information to be sent other than the Instruction.

CHECK SUM The calculation method for the ‘Check Sum’ is as follows:

Check Sum = ~( ID + Length + Instruction + Parameter1 + … Parameter N )

If the calculated value is bigger than 255, the lower byte becomes the checksum.

~ represents the Not or complement operation

OXFF 0XFF ID LENGTH INSTRUCTION PARAMETER1 …PARAMETER N CHECK

SUM

available)

Dynamixel’s. Status packets will not be returned with a broadcasting ID.

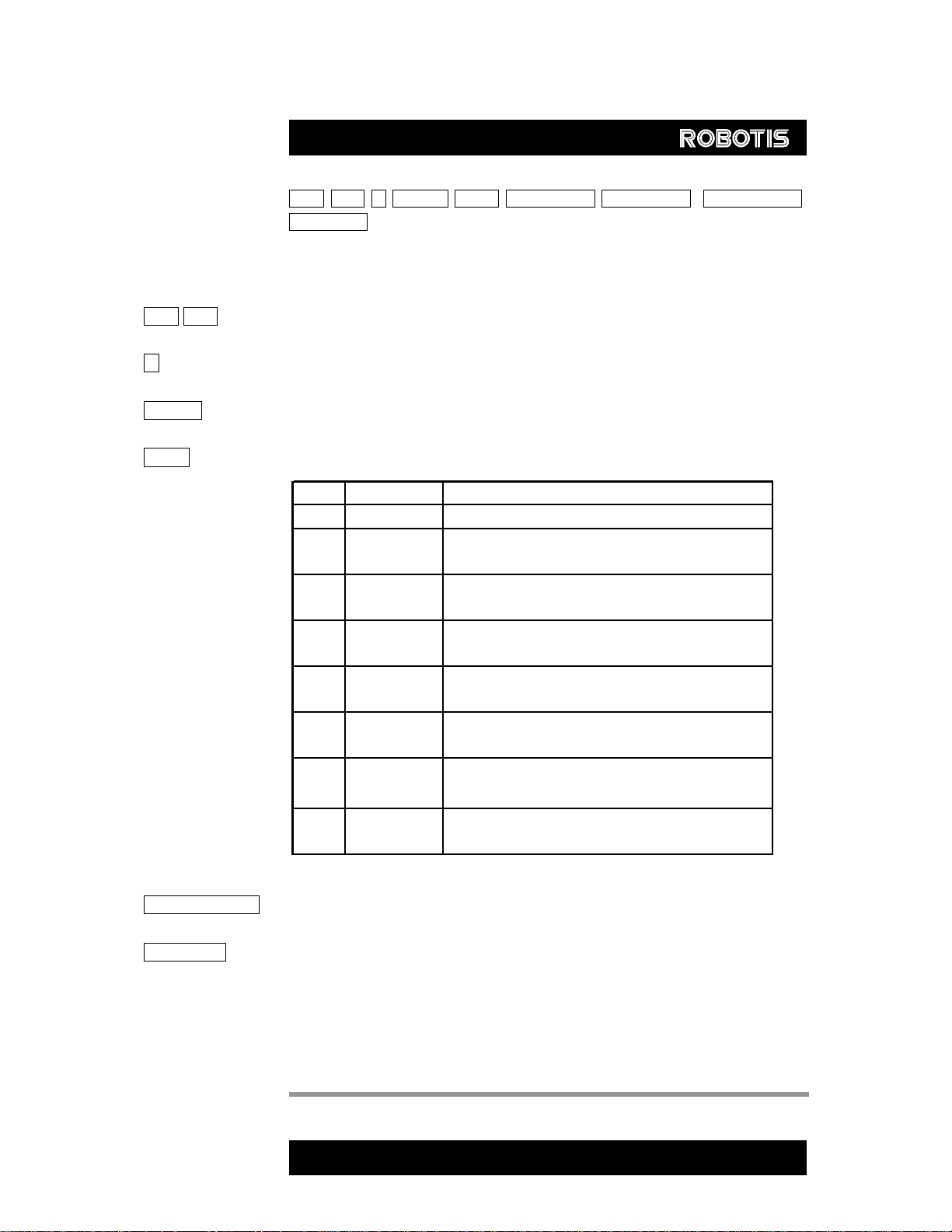

3-3. Status Packet

The Status Packet is the response packet from the Dynamixel to the Main

Controller after receiving an instruction packet. The structure of Status Packet

is as follows:-

10

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 12

DYNAMIXEL

OXFF 0XFF ID LENGTH ERROR PARAMETER1 PARAMETER2…PARAMETER N

The meaning of each byte within the packet is as follows:-

0XFF 0XFF Two 0XFF bytes indicate the start of a packet

ID ID of the Dynamixel which is returning the packet.

LENGTH The length of the Status Packet. The value is “Parameter number (N) + 2”.

ERROR Dynamixel communication error flags. The meaning of each bit is as follows:

PARAMETER0…N Used when additional information is required.

CHECK SUM Calculation method of ‘Check Sum’is as follows:

Check Sum = ~( ID + Length + Instruction + Parameter1 + … Parameter N )

If the calculated value is bigger than 255, the lower byte becomes the checksum.

~ represents the Not or complement operation

DX-116

CHECK SUM

Bit Name De tails

Bit 7 0 -

Bit 6

Bit 5

Bit 4

Bit 3 Range Error Set to 1 if the intruc tion is out of the usage r ange

Bit 2

Bit 1

Bit 0

Ins truction

Err or

Ove rload

Error

Che cks u m

Err or

Ove rheating

Err or

Ang le Lim it

Error

Input Voltage

Err or

Set to 1 if a n undefined instr uction is given without

the reg_write instruction.

Set to 1 if the spe cified torque c an't control the

load.

Set to 1 if the chec ksum of the intruction packe t is

incorrect

Set a s 1 if t h e in t e r n a l t e m p e r a t u r e o f Dy n a mix el is

out of the oper ative range as s et in the control

Set as 1 if the Goal Position is s et o utside of the

range between CW Angle Limit and CCW Angle

Limit.

Set to 1 if the voltage is out of the operative range

se t in the control table

11

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 13

DYNAMIXEL

3-4. Control

Table

EEPROM

Area

RAM

Area

DX-116

Addres s Ite m Acc ess Initial Va lue

0(0X00) Model Number(L) RD

1(0X01) Model Number(H) RD

2(0X02) Version of Firmware RD

3(0X03) ID RD,WR

4(0X04) Baud Rate RD,WR

5(0X05) Return Delay Time RD,WR

6(0X06) CW Angle Limit(L) RD,WR

7(0X07) CW Angle Limit(H) RD,WR

8(0X08) CCW Angle Limit(L) RD,WR

9(0X09) CCW Angle Limit(H) RD,WR

10(0x0A) (Rese rve d) 11(0X0B) the Highest Limit Te mperature RD,WR

12(0X0C) the Lo west Limit Voltage RD,WR

13(0X0D) the Highest Limit Volta ge RD,WR

14(0X0E) Max Torque (L) RD,WR

15(0X0F) Max Torque(H) RD,WR

16(0X10) Status Re turn Level RD,WR

17(0X11) Alarm LED RD,WR

18(0X12) Alarm Shutdown RD,WR

19(0X13) (Re served) RD,WR

20(0X14) Down Calibration(L) RD

21(0X15) Down Calibration(H) RD

22(0X16) Up Calibration(L) RD

23(0X17) Up Calibration(H) RD

24(0X18) Torque Enable RD,WR

25(0X19) LED RD,WR

26(0X1A) CW Compliance Margin RD,WR

27(0X1B) CCW Compliance Margin RD,WR

28(0X1C) CW Compliance Slope RD,WR

29(0X1D) CCW Complia nce Slope RD,WR

30(0X1E) Goal Position(L) RD,WR

31(0X1F) Goal Position(H) RD,WR

32(0X20) Moving Speed(L) RD,WR

33(0X21) Moving Speed(H) RD,WR

34(0X22) Torque Limit(L) RD,WR

35(0X23) Torque Limit(H) RD,WR

36(0X24) Present Positio n(L) RD

37(0X25) Present Positio n(H) RD

38(0X26) Present Speed(L) RD

39(0X27) Present Speed(H) RD

40(0X28) Present Load(L) RD

41(0X29) Present Load(H) RD

42(0X2A) Present Voltage RD

43(0X2B) Present Temperature RD

44(0X2C) Registered Instruction RD,WR

45(0X2D) (Reserved) -

46[0x2E) Moving RD

47[0x2F) Loc k RD,WR

48[0x30) Punch(L) RD,WR

49[0x31) Punch(H) RD,WR

116(0x74)

0(0x00)

?

1(0x01)

34(0x22)

80(0x50)

0(0x00)

0(0x00)

255(0xFF)

3(0x03)

0(0x00)

100(0x64)

60(0X3C)

190(0xBE)

255(0XFF)

3(0x03)

2(0x02)

4(0x04)

4(0x04)

0(0x00)

?

?

?

?

0(0x00)

0(0x00)

0(0x00)

0(0x00)

32(0x20)

32(0x20)

[Addr36]value

[Addr37]value

0

0

[Ad d r 1 4 ] v a l u e

[Ad d r 1 5 ] v a l u e

?

?

?

?

?

?

?

?

0(0x00)

0(0x00)

0(0x00)

0(0x00)

32(0x20)

0(0x00)

12

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 14

DYNAMIXEL

Control Table The Control Table consists of data for conditions and movement of the

RAM and EEPROM The data values for the RAM Area will be set to the default initial values on

Initial Value The Initial Value column of the control table shows the Factory Default Values

Please note the following meanings for data assigned to each address in the

Address 0x00,0x01 Model Number

Address 0x02 Firmware Version

Address 0x03 ID

Address 0x04 Baud Rate

Speed(BPS) = 2000000/(Address4+1)

Note A maximum Baud Rate error of 3% is within the UART communication tolerance.

Address 0x05 Return Delay Time

DX-116

Dynamixel. By writing the values in the control table, you can move the

Dynamixel and detect the condition of the Dynamixel.

power on. The data values for the EEPROM Area are non-volatile and will be

available next power on.

for the case of EEPROM Area Data. For the RAM Area Data, the initial value

column gives the power on data values.

control table.

. In the case of the DX-116, the value is 0X0074(116).

.

. Unique ID number to identify the Dynamixel. Different ID’s are required to

be assigned to “linked” Dynamixels.

. Determines the Communication Speed. The Calculation method is:-

Data Value as per Major Baud Rate

Address 4

1 1000000.0 1000000.0 0.000%

3 500000.0 500000.0 0.000%

4 400000.0 400000.0 0.000%

7 250000.0 250000.0 0.000%

9 200000.0 200000.0 0.000%

16 117647.1 115200.0 - 2.124%

34 57142.9 57600.0 0.794%

103 19230.8 19200.0 - 0.160%

207 9615.4 9600.0 - 0.160%

BPS Set Ta rg et BPS Error

. The time taken after sending the Instruction Packet, to

13

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 15

DYNAMIXEL

Address 0x06,0x07,0x08,0x09

Operating Angle Limit

CW Angle Limit <= Goal Position <= CCW Angle Limit

An Angle Limit Error will occur if this relationship is not satisfied.

Address 0x0B the Highest Limit Temperature

Address 0x0C,0x0D the Lowest (Highest) Limit Voltage

If the present voltage (Address42) is out of the specified range, a Voltage Range

Address 0x0E,0x0F, 0x22,0x23

Max Torque

Address 0X10 Status Return Level

In the case of an instruction which uses the Broadcast ID (0XFE), regardless of

DX-116

receive the requested Status Packet. The delay time is given by 2uSec *

Address5 value.

. Set the operating angle to restrict the Dynamixel’s angular range. The Goal

Position needs to be within the range of:-

. The upper limit of the Dynamixel’s operative

temperature. If the Dynamixel’s internal temperature is higher than this value,

an Over Heating Error Bit (Bit 2 of the Status Packet) will be set. An alarm will

be set in Address 17,18. The values are in Degrees Celsius.

. Setting the operative upper and lower limits

of the Dynamixel’s voltages.

Error bit will be set in the Status Packet and an alarm executed will be set in

Address’s 17,18. The values are 10 times the actual voltages. For example, if

the Address 12 value is 80, then the lower voltage limit is set to 8V.

. The max torque output for the Dynamixel. When it is set to ‘0’,

the Dynamixel enters a Torque Free Run condition. The Max Torque (Torque

Limit) is assigned to EEPROM (Address 0X0E,0x0F) and RAM (Address

0x22,0x23) and a power on condition will copy EEPROM values to RAM. The

torque of a Dynamixel is limited by (Address0x22,0x23) of RAM.

. To determine whether the Dynamixel will return the Status

Packet after the transmission of an Instruction Packet.

Address16 Return of Status Pack e t

0 Do not respond to any instruction

1 Respond only to READ_DATA instructions

2 Respond to all instructions

the Address 0x10 value, the Status Packet will not be returned.

14

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 16

DYNAMIXEL

Address 0X11 Alarm LED

This function operates as the logical “OR”ing of all set bits. For example,

Address 0X12 Alarm Shutdown

This function operates as the logical “OR”ing of all set bits. However, unlike

Address 0x14~0x17 Calibration

DX-116

. When an Error occurs, if the corresponding Bit is set to 1, then the

LED blinks.

Bit F un c t io n

Bit 7 0

Bit 6 If set to 1, LED blinks whe n Instruction Error occurs

Bit 5 If set to 1, LED blinks whe n Overload Error occurs

Bit 4 If set to 1, LED blinks when Checksum Error occurs

Bit 3 If s et to 1 , LED blinks when Range Error occurs

Bit 2 If set to 1, LED blinks whe n Overheating Error occurs

Bit 1 If s et to 1 , LED blinks when Angle Limit Error occurs

Bit 0 If s et to 1 , LED blinks when Input Voltage Error occurs

when the register is set to 0X05, the LED will blink when a Voltage Error

occurs or when an Overheating Error occurs. Upon returning to a normal

condition from an error state, the LED stops blinking after 2 seconds.

. When an Error occurs, if the corresponding Bit is set to a 1,

then the Dynamixel will shut down (Torque off).

Bit F un c t io n

Bit 7 0

Bit 6 If set to 1, torque off when Instruction Error occurs

Bit 5 If set to 1, torque off when Overload Error occurs

Bit 4 If set to 1, torque off when Checksum Error occurs

Bit 3 If set to 1, torque off when Range Error occurs

Bit 2 If set to 1, torque off when Overheating Error occurs

Bit 1 If set to 1, torque off when Angle Limit Error occurs

Bit 0 If s et to 1 , torque off whe n Input Voltage Error oc curs

the Alarm LED, after returning to a normal condition, it maintains a torque off

status. To remove this restriction, Torque Enable (Address0X18) is required to

be set to 1.

. Data used for compensating for the differences between Robotis

products. Users cannot change this area.

15

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 17

DYNAMIXEL

DX-116

From Address 0x18 in the RAM area.

Address 0x18 Torque Enable

. When power is first applied the Dynamixel enters the Torque

Free Run condition. To allow torque to be applied Address 0x18 must be set to 1.

(Torque Enabled Condition)

Address 0x19 LED is on when set to 1 and LED is off if set to 0.

Address 0x1A~0x1D Compliance Margin and Slope

. The Dynamixel controls Compliance by setting the

Margin and Slope. If used well Compliance will absorb the shocks. The following

graph demonstrates the use of Compliance values (length of A,B,C & D) relative

to Position Error and applied torque.

CW

CCW

Goal Position

E

E

CCW

Y axis:Output Torque

A : CCW Compliance Slope(Address0x1D)

B : CCW Compliance Margin(Address0x1B)

C : CW Compliance Margin(Address0x1A)

D : CW Compliance Slope (Address0x1C)

E : Punch(Address0x30)

B A C D

Address 0X1E,0x1F Goal Position

. Requested Angular Position for the Dynamixel to move to. If this

is set to 0x3ff, then the goal position will be 300

CW

X axis:Position Error

°.

16

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 18

DYNAMIXEL

Address 0x20,0x21 Moving Speed

Address 0x24,0x25 Present Position

Address 0x26,0x27 Present Speed

Address 0x28,0x29 Present Load

Load Direction = 0 : CCW Load, Load Direction = 1: CW Load

Address 0x2A Present Voltage

Address 0x2B Present Temperature

Address 0x2C Registered Instruction

Address 0x2E Moving.

DX-116

(Goal Position = 0x1ff)

300°

(Goal Position = 0x3ff)

. The angular speed to move to the Goal Position. If set to the

maximum values of 0x3ff, it moves at 70RPM.

. Current position of the Dynamixel.

. Current Speed of the Dynamixel.

. Load size on the Dynamixel in action. Bit 10 is the direction of the

load.

BIT 15~11 10 9876543210

Value 0 Load Direction Load Value

. The voltage applied to the Dynamixel. The value is 10 times the

actual voltage. For example, 10V is read as 100(0x64).

. Current internal Dynamixel temperature (Degrees Celsius).

. Set to 1 when a REG_WRITE instruction is made. After an

Action instruction and an action it is reset to 0.

Set to 1 when the Dynamixel moves by its own power.

150°

330~360°

Invalid Angle

0°

(Goal Position = 0)

17

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 19

DYNAMIXEL

Address 0x2F Lock.

Address 0x30,0x31 Punch.

Range Each Register has an operative range. Write instructions made outside of these

DX-116

If set to 1, only Address 0x18 ~ Address 0x23 can be written to. Other

areas are not permitted. Once locked, it can only be unlocked by powering down.

Minimum current being supplied to the motor during an action. The

minimum value is 0x20 and the maximum value as 0x3ff.

ranges will return an error. The following table summarises the data range for

each register. 16 bit data registers are indicated as (L) and (H), two bytes. Each

byte of a two byte register can be written to independently.

Write

Ad d re s s

3(0X03) ID 1 0

4(0X04) Baud Rate 1 0

5(0X05) Return Delay Time 1 0

6(0X06) CW Angle Limit 2 0

8(0X08) CCW Angle Limit 2 0

11(0X0B) the Highest Limit Temperature 1 0

12(0X0C) the Lowest Limit Voltage 1 50(0x32)

13(0X0D) the Highest Limit Voltage 1 50(0x32)

14(0X0E) Max Torque 2 0

16(0X10) Status Return Level 1 0

17(0X11) Alarm LED 1 0

18(0X12) Alarm Shutdown 1 0

19(0X13) (Reserved) 1 0

24(0X18) Torque Enable 1 0

25(0X19) LED 1 0

26(0X1A) CW Co mpliance Ma rgin 1 0

27(0X1B) CCW Co mpliance Margin 1 0

28(0X1C) CW Compliance Slope 1 1

29 (0X1D) CCW Com plia nc e Slope 1 1

30(0X1E) Goal Position 2 0

32(0X20) Moving Speed 2 0

34(0X22) Torque Limit 2 0

44(0X2C) Re gistered Instruction 1 0

47(0X2F) Lock 1 1

48(0X30) Punch 2 0

Writing Item

Le n g t h

(byte s)

Min Max

253(0xfd)

254(0xfe)

254(0xfe)

1023(0x3ff)

1023(0x3ff)

150(0x96)

250(0xfa)

250(0xfa)

1023(0x3ff)

2

127(0x7f)

127(0x7f)

1

1

1

254(0xfe)

254(0xfe)

254(0xfe)

254(0xfe)

1023(0x3ff)

1023(0x3ff)

1023(0x3ff)

1

1

1023(0x3ff)

[Control Table Data Range and Length for Writing]

18

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 20

DYNAMIXEL

DX-116

4. Instruction Set and Examples

The following Instructions are available.

4-1. WRITE_DATA

Function Write data into the control table of the Dynamixel

Length N+3 (Writing Data is N)

Instruction 0X03

Parameter1 Start Address of the Area to write Data

Parameter2 1st Data to write

Parameter3 2

Parameter N+1 N

Example 1 Set ID of connected Dynamixel as 1

Write 1 into the Address 3 of the Control Table. The ID is transmitted using

Instruction

Name

PING

READ_DAT A Read the values in the Control Table. 0x02 2

WRITE_DATA Write the values to the Control Table. 0x03 2 ~

REG_WRITE

ACTION Start the action registered by REG_WRITE 0x05 2

RESET

nd

Data to write

th

Data to write

No action. Used to obtain a Dynamixel

Status Packet.

Simila r to WRITE_DAT A, but sta y in

standby mode until the write upon the

action instruction.

Change the values of the Dynamixel in the

control table back to the Factory De fault

Va lu es.

Function Value

Numbe r of

Parameter

0x01 0

0x04 2 ~

0x06 0

19

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 21

DYNAMIXEL

Instruction Packet : 0XFF 0XFF 0XFE 0X04 0X03 0X03 0X01 0XF6`

Because it was transmitted by Broadcast ID(0XFE), no return status packet.

DX-116

Broadcasting ID (0xFE).

ID LENGTH INSTRUCTION PARAMETERS CHECKSUM

4-2. READ_DATA

Function Read data from the Control Table of Dynamixel.

Length 0X04

Instruction 0X02

Parameter1 Starting Address of Data to Read

Parameter2 length of Data to Read

Example 2 Read the internal temperature of the Dynamixel with ID=1.

Read 1 byte from the Address 0x2B values of the Control Table.

Instruction Packet : 0XFF 0XFF 0X01 0X04 0X02 0X2B 0X01 0XCC`

The returned Status Packet will be as follows.

Status Packet : 0XFF 0XFF 0X01 0X03 0X00 0X20 0XDB

ID LENGTH ERROR PARAMETER1 CHECKSUM

The value read is 0x20.The current Dynamixel’s internal temperature is

ID LENGTH INSTRUCTION PARAMETERS .. CHECKSUM

approximately 32℃ (0X20).

4-3. REG_WRITE and ACTION

REG_WRITE

20

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 22

DYNAMIXEL

Function REG_WRITE instruction is similar to the WRITE_DATA instruction, but the

Length N+3 (The number of Write Data bytes is N)

Instruction 0X04

Parameter1 Start Address for Write Data

Parameter2 1

Parameter3 2

Parameter N+1 N

DX-116

execution timing is different. When the Instruction Packet is received the values

are saved into the Buffer and the Write instruction is under a standby status.

The Registered Instruction register (Address 0x2C) is set to 1. After an Action

Instruction Packet is received the registered Write instruction is executed.

st

Data to Write

nd

Data to Write

th

Data to Write

ACTION

Function Execute the WRITE instruction written by REG_WRITE

Length 0X02

Instruction 0X05

Parameter NONE

The ACTION instruction is useful when multiple Dynamixels needs to move

simultaneously. When controlling multiple units, slight time delays occur

between the 1

approach fixes this problem through the use of the ACTION instruction.

Broadcasting When sending ACTION instructions to move more than two Dynamixel units, the

Broadcast ID (0XFE) should be utilised.

st

unit to receive an instruction and the last one. The Dynamixel

4-4. PING

Function Used to request a specific Dynamixel status packet or to check the existence of

a Dynamixel with a particular ID

Length 0X02

Instruction 0X01

Parameter NONE

21

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 23

DYNAMIXEL

Example 3 To obtain the status packet of a Dynamixel with ID=1

Instruction Packet : 0XFF 0XFF 0X01 0X02 0X01 0XFB`

ID LENGTH INSTRUCTION CHECKSUM

The returned Status Packet is as follow;

Status Packet : 0XFF 0XFF 0X01 0X02 0X00 0XFC

ID LENGTH ERROR CHECKSUM

DX-116

4-5. RESET

Function Restore the condition of the Control Table of the Dynamixel back to the Factory

Default values.

Length 0X02

Instruction 0X06

Parameter NONE

Example 4 Reset Dynamixe with ID=0

Instruction Packet : 0XFF 0XFF 0X00 0X02 0X06 0XF7`

The returned Status Packet is as follows;

Status Packet : 0XFF 0XFF 0X00 0X02 0X00 0XFD

Please note that after a RESET instruction, the ID of the Dynamixel is changed

ID LENGTH INSTRUCTION CHECKSUM

ID LENGTH ERROR CHECKSUM

to 1.

22

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 24

DYNAMIXEL

DX-116

5. Example

Used to explain through example with the assumption that the Dynamixel has

been Reset (ID = 1, Baudrate = 57142BPS)

Example 5 Read the Model Number and Firmware Version of a Dynamixel with ID=1

Instruction Packet Instruction = READ_DATA, Address = 0x00, Length = 0x03

Communication ->[Dynamixel]:FF FF 01 04 02 00 03 F5 (LEN:008)

<-[Dynamixel]:FF FF 01 05 00 74 00

Status Packet Result Model Number = 116(0x74), Firmware Version = 0x08

Example 6 Change ID number of Dynamixel from 1 to 0.

Instruction Packet Instruction = WRITE_DATA, Address = 0x03, DATA = 0x00

Communication ->[Dynamixel]:FF FF 01 04 03 03 00

<-[Dynamixel]:FF FF 01 02 00 FC (LEN:006)

Status Packet Result NO ERROR

Example 7 Change Baud Rate of Dynamixel to 1M bps.

Instruction Packet Instruction = WRITE_DATA, Address = 0x04, DATA = 0x01

Communication ->[Dynamixel]:FF FF 00 04 03 04 01

<-[Dynamixel]:FF FF 00 02 00 FD (LEN:006)

Status Packet Result NO ERROR

Example 8 Reset Return Delay Time of Dynamixel with ID=0 to 4us.

A Return Delay Time Value of 1 corresponds to 2us.

Instruction Packet Instruction = WRITE_DATA, Address = 0x05, DATA = 0x02

Communication ->[Dynamixel]:FF FF 00 04 03 05 02

<-[Dynamixel]:FF FF 00 02 00 FD (LEN:006)

Status Packet Result NO ERROR

08 7D (LEN:009)

F4 (LEN:008)

F3 (LEN:008)

F1 (LEN:008)

23

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 25

DYNAMIXEL

The best approach is to set the Return Delay Time to the minimum value the

Example 9 Limit the the operative angles of a Dynamixel with ID=0 to 0~150°.

If CCW Angle Limit is 0x3ff, it is 300°, therefore the values for 150°is 0x1ff.

Instruction Packet Instruction = WRITE_DATA, Address = 0x08, DATA = 0xff, 0x01

Communication ->[Dynamixel]:FF FF 00 05 03 08 FF 01

<-[Dynamixel]:FF FF 00 02 00 FD (LEN:006)

Status Packet Result NO ERROR

Example 10 Reset the upper limit temperature of the Dynamixel with ID=1 to 80°.

Instruction Packet Instruction = WRITE_DATA, Address = 0x0B, DATA = 0x50

Communication ->[Dynamixel]:FF FF 00 04 03 0B 50

<-[Dynamixel]:FF FF 00 02 00 FD (LEN:006)

Status Packet Result NO ERROR

Example 11 Set the operative voltage of a Dynamixel with ID=0 to 10V ~ 17V.

10V is expressed as 100(0x64) and 17V as 170(0xAA).

Instruction Packet Instruction = WRITE_DATA, Address = 0x0C, DATA = 0x64, 0xAA

Communication ->[Dynamixel]:FF FF 00 05 03 0C 64 AA

<-[Dynamixel]:FF FF 00 02 00 FD (LEN:006)

Status Packet Result NO ERROR

Example 12 Make the Dynamixel with ID=0 perform only 50% of the maximum torque.

Set the max torque values within the EEPROM area to 50% (0x1ff) of the

DX-116

Main Controller will allow.

EF (LEN:009)

9D (LEN:008)

DD (LEN:009)

maximum value (0x3ff)

24

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 26

DYNAMIXEL

Instruction Packet Instruction = WRITE_DATA, Address = 0x0E, DATA = 0xff, 0x01

Communication ->[Dynamixel]:FF FF 00 05 03 0E FF 01 E9 (LEN:009)

<-[Dynamixel]:FF FF 00 02 00 FD (LEN:006)

Status Packet Result NO ERROR

After a power off and on, you can check the effect of the changes in max torque.

Example 13 Stop the Dynamixel with ID=0 from returning a Status Packet.

Instruction Packet Instruction = WRITE_DATA, Address = 0x10, DATA = 0x00

Communication ->[Dynamixel]:FF FF 00 04 03 10 00 E8 (LEN:008)

<-[Dynamixel]:FF FF 00 02 00 FD (LEN:006)

Status Packet Result NO ERROR

The Status Packet will not be returned for the next instruction.

Example 14 If temperature values are higher than those defined operative temperatures, set

Overheating Error is Bit 2, therefore set the alarm value to 0x04.

Instruction Packet Instruction = WRITE_DATA, Address = 0x11, DATA = 0x04, 0x04

Communication ->[Dynamixel]:FF FF 00 05 03 11 04 04

<-[Dynamixel]:FF FF 00 02 00 FD (LEN:006)

Status Packet Result NO ERROR

Example 15 Turn on the LED of the Dynamixel with ID=0 and enable the torque.

Instruction Packet Instruction = WRITE_DATA, Address = 0x18, DATA = 0x01, 0x01

Communication ->[Dynamixel]:FF FF 00 05 03 18 01 01

<-[Dynamixel]:FF FF 00 02 00 FD (LEN:006)

Status Packet Result NO ERROR

Physical confirmation of an enabled torque can be obtained by attempting to

DX-116

the alarm to make the Dynamixel blink and then shut down the Dynamixel

(Torque off).

DE (LEN:009)

DD (LEN:009)

rotate the motor with your hand.

25

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 27

DYNAMIXEL

DX-116

Example 16 Set the Dynamixel with ID=0 to have a Compliance Margin = 1 and Compliance

Slope=0x40

The following graph shows the Angle Error and Torque Output.

CW

Goal Position

CCW

CW

X:Angle Error

If the position is slightly deviated from the goal position, the motor will generate

CCW

a high torque to try to adjust its position to that of the goal position. The true

control method is different due to the inertia. The condition provided in the

above example can be shown in the graph below:-

CW

Goal Position

CCW

CW

Angle(Position)

Output Torque

CCW

B A C D

A : CCW Compliance Slope(Address0x1D) = 0x40(Approximately 18.8°)

B : CCW Compliance Margin(Address0x1B) = 0x01 (Approximately 0.29°)

C : CW Compliance Margin(Address0x01A) = 0x01(Approximately 0.29°)

D : CW Compliance Slope(Address0x1C) = 0x40 (Approximately 18.8°)

Instruction Packet Instruction = WRITE_DATA, Address = 0x1A, DATA = 0x01, 0x01, 0x40, 0x40

Communication ->[Dynamixel]:FF FF 00 07 03 1A 01 01 40 40 59 (LEN:011)

<-[Dynamixel]:FF FF 00 02 00 FD (LEN:006)

Status Packet Result NO ERROR

The effect of a Compliance Slope changes at the boundary of 2

n

(n is positive

26

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 28

DYNAMIXEL

Example 17 Position Dynamixel with ID=0 at Position 180°after moving it at the speed of

Set Address 0x1E(Goal Position) = 0x200, Address 0x20(Moving Speed) =

Instruction Packet Instruction = WRITE_DATA, Address = 0x1E, DATA = 0x00, 0x02, 0x00, 0x02

Communication ->[Dynamixel]:FF FF 00 07 03 1E 00 02 00 02 D3 (LEN:011)

<-[Dynamixel]:FF FF 00 02 00 FD (LEN:006)

Status Packet Result NO ERROR

Example 18 Set the position of a Dynamixel (ID=0) to an angular Position of 0°and another

If you use WRITE_DATA instruction, two Dynamixel can not start at the same

Instruction Packet ID=0, Instruction = REG_WRITE, Address = 0x1E, DATA = 0x00, 0x00

ID=1, Instruction = REG_WRITE, Address = 0x1E, DATA = 0xff, 0x03

ID=0xfe(Broadcasting ID), Instruction = ACTION,

Communication ->[Dynamixel]:FF FF 00 05 04 1E 00 00 D8 (LEN:009)

<-[Dynamixel]:FF FF 00 02 00 FD (LEN:006)

->[Dynamixel]:FF FF 01 05 04 1E FF 03 D5 (LEN:009)

<-[Dynamixel]:FF FF 01 02 00 FC (LEN:006)

->[Dynamixel]:FF FF FE 02 05 FA (LEN:006)

<-[Dynamixel]: //No return packet against broadcasting ID

Status Packet Result NO ERROR

Example 19 Prevent the Dynamixel with ID=0 from changing values other than within the

Set Address 0x2F(Lock) to 1.

DX-116

number), that is, the effect of the values of Compliance between 0x11 and 0x20

are the same.

35RPM.

0x200

Dynamixel (ID=1) to an angular Position of 300°. Make sure both Dynamixels

start at the same time.

time, therefore use REG_WRITE and ACTION.

range between Address 0x18 and Address 0x23.

27

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 29

DYNAMIXEL

Instruction Packet Instruction = WRITE_DATA, Address = 0x2F, DATA = 0x01

Communication ->[Dynamixel]:FF FF 00 04 03 2F 01

<-[Dynamixel]:FF FF 00 02 00 FD (LEN:006)

Status Packet Result NO ERROR

If Locked, it can only be unlocked by removing power.

If trying to access other data areas whilst locked, an error will be returned.

->[Dynamixel]:FF FF 00 05 03 30 40 00 87 (LEN:009)

<-[Dynamixel]:FF FF 00 02 08 F5 (LEN:006)

Example 20 Set the minimum punch (output) in the Dynamixel with ID=0 to 0x40.

Instruction Packet Instruction = WRITE_DATA, Address = 0x30, DATA = 0x40, 0x00

Communication ->[Dynamixel]:FF FF 00 05 03 30 40 00

<-[Dynamixel]:FF FF 00 02 00 FD (LEN:006)

Status Packet Result NO ERROR

DX-116

C8 (LEN:008)

Range Error

87 (LEN:009)

28

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 30

DYNAMIXEL

DX-116

Appendix

RS485 Direction The Main Controller sets the RS485 communication direction to be an input at all

times other than when specifically sending an instruction packet.

Return Delay Time The Default Value is 160us and can be changed via the Control Table at Address

0x05. The Main Controller needs to change the RS485 communication direction

after sending an instruction packet within the Return Delay time range.

485 Direction The CPU normally indicates the UART_STATUS and the bit definitions within the

register have the following meanings:-

TXD_BUFFER_READY_BIT : Transmission DATA can be loaded into the Buffer.

Note that the SERIAL TX BUFFER is not necessarily completely empty.

TXD_SHIFT_REGISTER_EMPTY_BIT : Set when a Transmission byte has

completed its transmission.

The TXD_BUFFER_READY_BIT is used when a byte is to be transmitted via the

serial communication channel and an example is as follows:-

TxDByte(byte bData)

{

while(!TXD_BUFFER_READY_BIT); //wait until data can be loaded.

SerialTxDBuffer = bData; //data load to TxD buffer

}

When changing the RS485 Direction, check the

RS485 Direction Output Duration

Instruction Packet Status Packet

Return Delay Time

29

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 31

DYNAMIXEL

An example program to send an Instruction packet:-

LINE 1 PORT_485_DIRECTION = TX_DIRECTION;

LINE 2 TxDByte(0xff);

LINE 3 TxDByte(0xff);

LINE 4 TxDByte(bID);

LINE 5 TxDByte(bLength);

LINE 6 TxDByte(bInstruction);

LINE 7 TxDByte(Parameter0); TxDByte(Parameter1); …

LINE 8 DisableInterrupt(); // interrupt should be disabled

LINE 9 TxDByte(Checksum); //last TxD

LINE 10 while(!TXD_SHIFT_REGISTER_EMPTY_BIT); //Wait till last data bit has been

LINE 11 PORT_485_DIRECTION = RX_DIRECTION; //485 direction changed to RXD

LINE 12 EnableInterrupt(); // enable interrupt again

Please note the important lines (LINE 8 to LINE12).

Line 8 is necessary since an interrupt here may cause a delay longer than the

Byte to Byte Time The delay time between bytes when sending the instruction packet. If the delay

DX-116

TXD_SHIFT_REGISTER_EMPTY_BIT.

sent

return delay time and corruption to the front of the status packet may occur

time is over 100ms, then recognise it as a communication problem and wait for

header(0xff 0xff) of the packet again.

0xFF 0xFF ID

Byte To Byte Time

Length

30

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 32

DYNAMIXEL

DX-116

C Language Example

#include <stdio.h>

#include <stdlib.h>

#include <conio.h>

#include <dos.h>

#include <mem.h>

#define MCS80

#include "..\..\base.h"

#include "..\lib188es.c"

#define RS485_DIRECTION_BIT 0x2000

#define RS485_TXD (SET_PORT1(RS485_DIRECTION_BIT))

#define RS485_RXD (RESET_PORT1(RS485_DIRECTION_BIT))

#define BROADCASTING_ID 0xfe

#define MEMORY_SPARE 10

#define ADDRESS_TORQUE_ENABLE 20

#define ADDRESS_OPERATING_MODE 19

#define ADDRESS_ID 3

#define ADDRESS_GOAL_POSITION 26

#define INST_PING 0x01

#define INST_READ 0x02

#define INST_WRITE 0x03

#define INST_SET_SCHEDULE 0x04

#define INST_DO_SCHEDULE 0x05

#define INST_RESET 0x06

#define DIGITAL_MODE 0

//Global variable number

byte gbpInterruptRxBuffer[256+MEMORY_SPARE]; //485 RxD Data Buffer

byte gbRxBufferReadPointer,gbRxBufferWritePointer; //Pointers for access the gbpInterruptRxBuffer

void static interrupt far Serial0Interrupt(void);

void PrintBuffer(byte *bpPrintBuffer, byte bLength);

byte TxPacket(byte *bpTxBuffer, byte bID, byte bInstruction, byte *bpParameter, byte bParameterLength);

byte RxPacket(byte *bpRxBuffer);

void main(void)

{

byte bID,bPacketLength;

byte bpTxBuffer[20+MEMORY_SPARE];

byte bpRxBuffer[256+MEMORY_SPARE];

byte bpParameter[256+MEMORY_SPARE];

CLI; //Disable Interrupt

//PortInitialize();

InitPort(OUT, PDATA1, 0xe000); //Set Out(Port30,31:LED,Port29:485Direction)

InitPort(IN, PDATA1, 0x0004); //Set In(Port2:Push SW)

InitPort(NORMAL_USE, PDATA1, 0x00c0); //

RS485_RXD; //Set 485 Direction Select Port to 0

//UartInitialize();

outpw(SP0BAUD,5); //.2MBPS = 16MHz/16/5

outpw(SP1BAUD,17); //57600

outpw(SP0STS,0);

outpw(SP1STS,0);

//InterruptInitialize();

Definition area

CPU dependent Initialize

Major

Function

31

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 33

DYNAMIXEL

SetInterrupt(INUM_SERIAL0,Serial0Interrupt,INT_ENABLE|INT_RX, 7/*Priority*/);

//Memory Initialize

gbRxBufferReadPointer = gbRxBufferWritePointer = 0;

STI; //Interrupt Enable

/*

*

* Example For Driving Dynamixel DX-116

*

*/

TxDString("\r\n\n Dynamixel Driving Sample Program");

//Set ID to 3

bpParameter[0] = ADDRESS_ID;

bpParameter[1] = 3;

bPacketLength = TxPacket(bpTxBuffer, BROADCASTING_ID, INST_WRITE, bpParameter, 2/*Length of Parameter*/);

bID = 3;

TxDString("\r\n ->[Dynamixel]: "); PrintBuffer(bpTxBuffer,bPacketLength);

bPacketLength = RxPacket(bpRxBuffer);

TxDString("\r\n <-[Dynamixel]: "); PrintBuffer(bpRxBuffer,bPacketLength);

//Set Motor Torque Enable

bpParameter[0] = ADDRESS_TORQUE_ENABLE;

bpParameter[1] = 1;

bPacketLength = TxPacket(bpTxBuffer, bID, INST_WRITE, bpParameter, 2/*Length of Parameter*/);

TxDString("\r\n ->[Dynamixel]: "); PrintBuffer(bpTxBuffer,bPacketLength);

bPacketLength = RxPacket(bpRxBuffer);

TxDString("\r\n <-[Dynamixel]: "); PrintBuffer(bpRxBuffer,bPacketLength);

//Move to Position 0x0100 <-> 0x300

while(1)

{

bpParameter[0] = ADDRESS_GOAL_POSITION;

bpParameter[1] = 0x00; bpParameter[2] = 0x01;

bPacketLength = TxPacket(bpTxBuffer, bID, INST_WRITE, bpParameter, 3/*Length of Parameter*/);

TxDString("\r\n ->[Dynamixel]: "); PrintBuffer(bpTxBuffer,bPacketLength);

bPacketLength = RxPacket(bpRxBuffer);

TxDString("\r\n <-[Dynamixel]: "); PrintBuffer(bpRxBuffer,bPacketLength);

MiliSec(1000);

bpParameter[0] = ADDRESS_GOAL_POSITION;

bpParameter[1] = 0x00; bpParameter[2] = 0x03;

bPacketLength = TxPacket(bpTxBuffer, bID, INST_WRITE, bpParameter, 3/*Length of Parameter*/);

TxDString("\r\n ->[Dynamixel]: "); PrintBuffer(bpTxBuffer,bPacketLength);

bPacketLength = RxPacket(bpRxBuffer);

TxDString("\r\n <-[Dynamixel]: "); PrintBuffer(bpRxBuffer,bPacketLength);

MiliSec(1000);

}

//while(1);

}

void static interrupt far Serial0Interrupt(void) //Serial RxD Interrupt routine

{

STI; //Enable Interrupt

gbpInterruptRxBuffer[gbRxBufferWritePointer++] = RXD_DATA0; //Reading Arrival Data

outpw(EOI, 0x14); //End of Interrupt

}

byte RxPacket(byte *bpRxBuffer)

{

DX-116

32

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 34

DYNAMIXEL

#define RX_TIMEOUT_COUNT2 10000L //10mSec

#define RX_TIMEOUT_COUNT1 (RX_TIMEOUT_COUNT2*10L) //1Sec

unsigned long ulCounter;

byte bCount;

ulCounter = 0;

while(gbRxBufferReadPointer == gbRxBufferWritePointer)

{

if(ulCounter++ > RX_TIMEOUT_COUNT1)

{

return 0;

}

}

bCount = 0;

for(bCount = 0; bCount < 254; bCount++) //Maximum Data Length Limit : 255

{

ulCounter = 0;

while(gbRxBufferReadPointer == gbRxBufferWritePointer)

{

if(ulCounter++ > RX_TIMEOUT_COUNT2)

{

return bCount;

}

}

bpRxBuffer[bCount] = gbpInterruptRxBuffer[gbRxBufferReadPointer++];

}

return bCount;

}

byte TxPacket(byte *bpTxBuffer, byte bID, byte bInstruction, byte *bpParameter, byte bParameterLength)

{

byte bCount,bCheckSum,bPacketLength;

bpTxBuffer[0] = 0xff;

bpTxBuffer[1] = 0xff;

bpTxBuffer[2] = bID;

bpTxBuffer[3] = bParameterLength+2; //Length(Paramter,Instruction,Checksum)

bpTxBuffer[4] = bInstruction;

for(bCount = 0; bCount < bParameterLength; bCount++)

{

bpTxBuffer[bCount+5] = bpParameter[bCount];

}

bCheckSum = 0;

bPacketLength = bParameterLength+4+2;

for(bCount = 2; bCount < bPacketLength-1; bCount++) //except 0xff,checksum

{

bCheckSum += bpTxBuffer[bCount];

}

bpTxBuffer[bCount] = ~bCheckSum; //Writing Checksum with Bit Inversion

RS485_TXD; //Change 485 Direction to Transmission

for(bCount = 0; bCount < bPacketLength; bCount++)

{

TxD80(bpTxBuffer[bCount]);

}

while(!TXD_FINISH0); //Wait until TXD Shift register empty

RS485_RXD;

return(bPacketLength);

}

void PrintBuffer(byte *bpPrintBuffer, byte bLength)

{

byte bCount;

for(bCount = 0; bCount < bLength; bCount++)

DX-116

Should wait until last data bit transmission is

completed.

Note.: ‘Shift register empty’ is differ from ‘Tx

Ready’. Tx Ready just means you can load the

data to CPU UART TxD Register. There can be

several Tx Buffering registers as what kind of

33

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 35

DYNAMIXEL

{

TxD8Hex(bpPrintBuffer[bCount]);

TxD8(' ');

}

}

DX-116

Result

0xFE is BROADCAST_ID, so Dynamixel does not return status packet.(First 2 Instruction Packet)

Set ID to 3

Motor Torque Enable

34

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 36

DYNAMIXEL

Connector Company Name : Molex

Pin Number: 4

Model Number

Temperature range : -40°C to +105°C

Contact Insertion Force-max : 14.7N (3.30 lb)

Contact Retention Force-min : 14.7N (3.30 lb)

Female Connector

Male Connector

DX-116

Molex Part Number Old Part Number

Male 22-03-5045 5267-04

Female 50-37-5043 5264-04

www.molex.com

or www.molex.co.jp for more detail information

Pin No.1

35

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 37

DYNAMIXEL

Dimension

Motor Curve(No reduction gear state)

DX-116

36

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 38

DYNAMIXEL

Optional Frame Application Example

OF116H

OF116S

OF116B

Body to Body Mount

DX-116

37

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 39

DYNAMIXEL

Full Option frame

Cycloid M2 Board

DX-116

23Axis frame full Set 15Axis frame full set

Helmet and hands plastic is not included in frame set

- The Custom-Built Controller for Dynamixel

- Optional Part : Blue-tooth module, RS232 UART, and 6-button blue-tooth

remocon.

- Can be adapted multi-axis robot directly.

86

48

38

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Page 40

DYNAMIXEL

Application Example

DX-116

CYCLOIDⅡ

39

English Translation by: Tribotix Pty Ltd

www.tribotix.com

Loading...

Loading...