Wrist Camera Vision System for CB-Series

Universal Robots

Instruction Manual

Get the latest version of the manual at support.robotiq.com

Original Notice

Wrist Camera Instruction Manual

Table of Contents

1. General Presentation 5

2. Safety 10

2.1. Warning 10

2.2. Intended Use 12

3. Installation 13

3.1. Scope of Delivery 14

3.1.1. Wrist Camera Kit for Universal Robots: 14

3.2. Required Tools and Equipment 15

3.3. Environmental and Operating Conditions 17

3.4. Mechanical Installation 18

3.4.1. Combo of 2-Finger Adaptive Gripper and Wrist Camera for Universal Robots 20

3.5. Electrical Setup 21

3.5.1. Power Supply 21

3.5.2. Cable Management 23

3.6. Software 23

3.6.1. Wrist Camera URCap Installation 24

3.6.1.1. Wrist Camera URCap Installation 24

3.6.2. Update and Uninstall 28

3.6.2.1. Version 1.1 and following 28

3.6.2.2. Version 1.0.2 and previous 30

4. Snapshot Position 31

4.1. Guidelines on Snapshot Position 33

4.2. Snapshot Position Wizard 34

4.3. Copy a Calibration 38

5. Object Teaching 39

5.1. Guidelines on Object Teaching 40

5.2. Teach Object Wizard 42

5.2.1. Automatic Method 44

5.2.1.1. Select Calibration 44

5.2.1.2. Select Model 45

5.2.1.3. Edit Model 56

5.2.1.4. Refine Model 61

5.2.1.5. Validate Model 62

5.2.1.6. Scan Model 63

5.2.2. Parametric Method 64

5.2.2.1. Circle 65

5.2.2.2. Ring 66

5.2.2.3. Rectangle 66

5.2.2.4. Square 67

5.2.3. Configure Model 68

5.2.3.1. Multiple objects detection 70

©Robotiq inc. 2016-2018

2

Wrist Camera Instruction Manual

5.2.3.2. Color Validation 71

5.2.3.3. Detection thresholds and scores 76

5.2.3.4. Camera settings 81

5.2.3.5. Save location 81

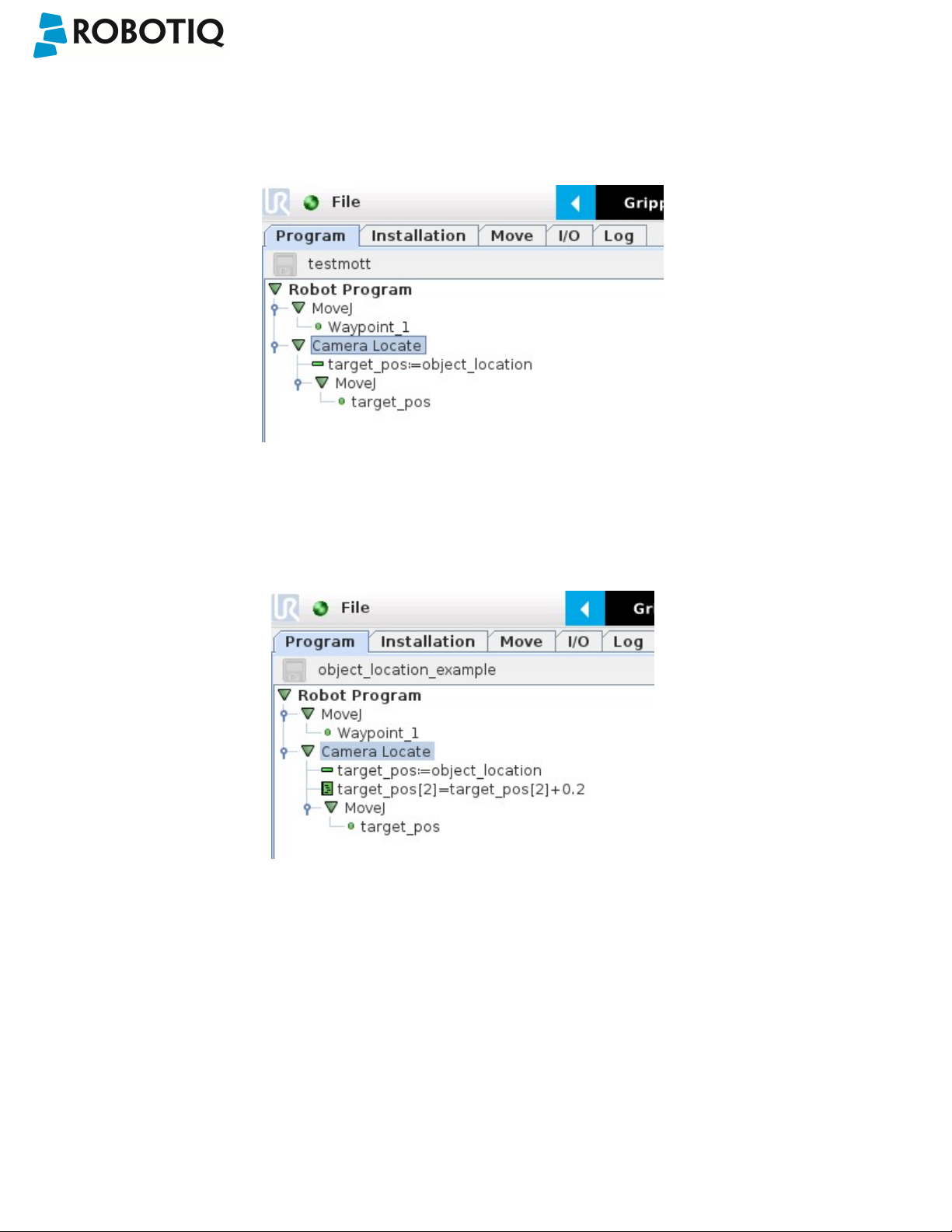

6. Programming with the Camera Locate Node 82

6.1. Linear Move with Feature – Pick and Place Template 85

6.2. object_location pose 86

6.3. Edit Detection Threshold and Object Location 89

6.4. Camera Locate node at a variable Snapshot position 90

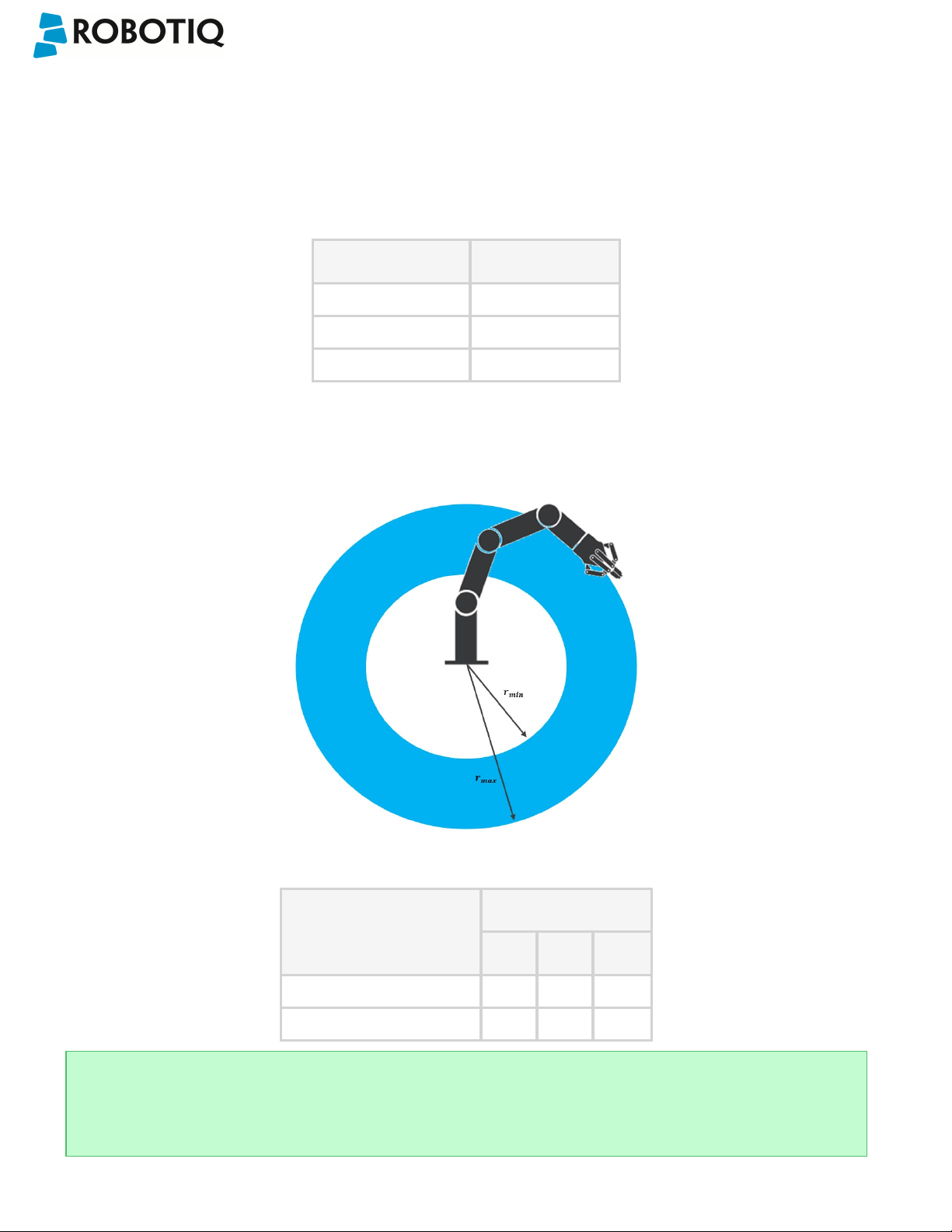

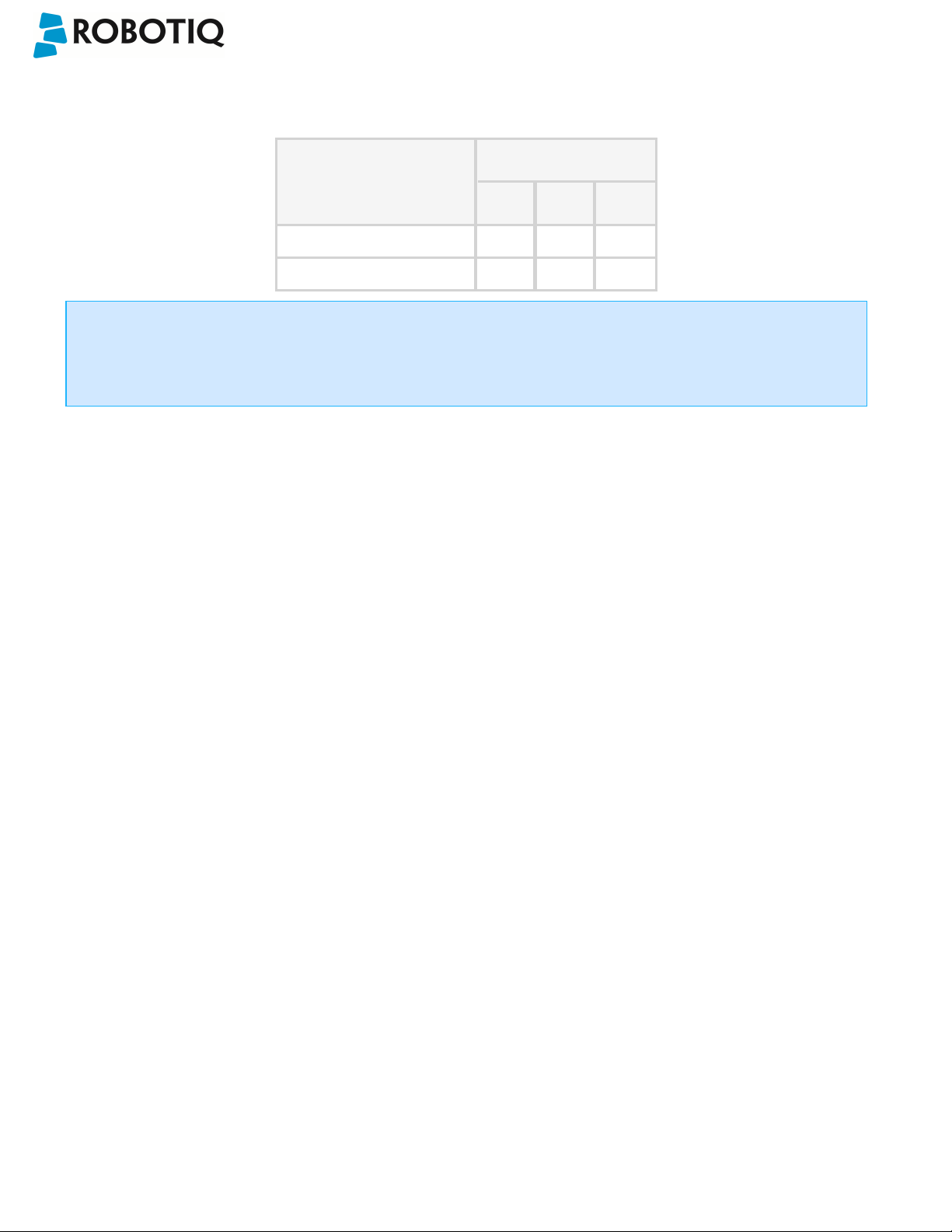

7. Specifications 92

7.1. Mechanical Specifications of Wrist Camera 93

7.1.1. Center of Mass and Moment of Inertia 94

7.2. Electrical rating & performance of Wrist Camera 96

7.3. Vision System Specifications 97

8. Maintenance 101

9. Spare Parts, Kits and Accessories 102

10. Troubleshooting 103

10.1. LED status 104

11. Warranty andPatent 105

12. Contact 107

A. Harmonized Standards, Declarations and Certificates DD

A1. Declaration of Incorporation DD

©Robotiq inc. 2016-2018

3

Wrist Camera Instruction Manual

Revisions

Robotiq may modify this product without notice, when necessary, due to product improvements, modifications or changes

in specifications. If such modification is made, the manual will also be revised, see revision information. See the latest

version of this manual online at: support.robotiq.com.

2018-09-10

Updated section 3, 5 and 6 according to the PolyScope version of the user (CB-Series vs. e-Series).

Updated section 5 and all pertaining subsections; major changes to the Teach object wizard (color validation layer masks,

multiple object detection, e-Series support).

2018-05-01

Updated section 5 and all pertaining subsections; major changes to the Teach object wizard

2018-03-26

Updated Section 3.6.2 for Update and uninstall

2017-06-07

Updated Section 3.6 for URCap package installation procedure

Updated Section 4.2 for calibration process

Updated Sections 5.2, 5.2.1, 5.2.2, 5.2.3 for new and improved teaching methods.

Added Section 6.2 to use advanced programming with the vision system.

Updated technical specifications (Section 7.3).

Updated calibration board for UR5 and UR10 robots (Section 4)

2016-11-16

Updated specifications (section 6)

Updated installations instructions (section 4)

Added Troubleshooting instructions (section 9.1)

2016-08-26

First release

©Robotiq inc. 2016-2018

4

Wrist Camera Instruction Manual

1. General Presentation

The terms "Camera" and "Wrist Camera" used in the following manual all refer to the Robotiq Wrist Camera, while the

term "Vision" and "Vision System" used in the following manual all refer to the Robotiq Wrist Camera Vision System for

Universal Robots.

The Vision System uses the Robotiq Wrist Camera and the Camera Locate software on Universal Robots to provide you

with a simple object teaching interface.

The interface allows to set up the Vision System so it can recognize object locations and orientations automatically. The

Vision System, using the Camera Locate feature, is only designed to locate one object at the time on a predefined

workplane. It gets the object's position (x, y) and orientation along the z-axis. It allows to operate the robot according to the

object location. The Camera is designed to work in industrial applications in combination with the Robotiq 2-Finger

Adaptive Gripper.

Note

The following manual uses the metric system. Unless specified, all dimensions are in millimeters.

Note

The following section presents the key features of the Vision System and must not be considered as appropriate

to complete operation, each feature is detailed in the appropriate section of the manual. Safety guidelines must

be read and understood before any operation is attempted with the system.

Vision System components:

The figure below describes the various components of the Robotiq Vision System for Universal Robots. This system will

use the Robotiq Wrist Camera, mounted on any of the Universal Robots (UR3, UR5, UR10) using a CB3.1 controller or

greater. For a list of provided components with your Robotiq Wrist Camera kit for UR, please refer to the Scope of Delivery

section.

Caution

Robotiq Vision System is only compatible with Universal Robots with controller version CB3 and later, to identify

your controller, please contact your Universal Robots representative.

©Robotiq inc. 2016-2018

5

Wrist Camera Instruction Manual

Fig. 1-1: Schematic representation of the Robotiq Wrist Camera Vision System hardware.

l Robotiq Wrist Camera: Described in details in sub-section Wrist Camera below.

l End effector: Any tool mounted on the robot for its application, the Wrist Camera is meant for direct integration of the

Robotiq 2-Finger Adaptive Gripper.

l Universal Robot Arm: Any of the UR3, UR5 or UR10 model from Universal Robots.

l Universal Robot Controller: Controller model CB3 from Universal Robots.

©Robotiq inc. 2016-2018

6

Wrist Camera Instruction Manual

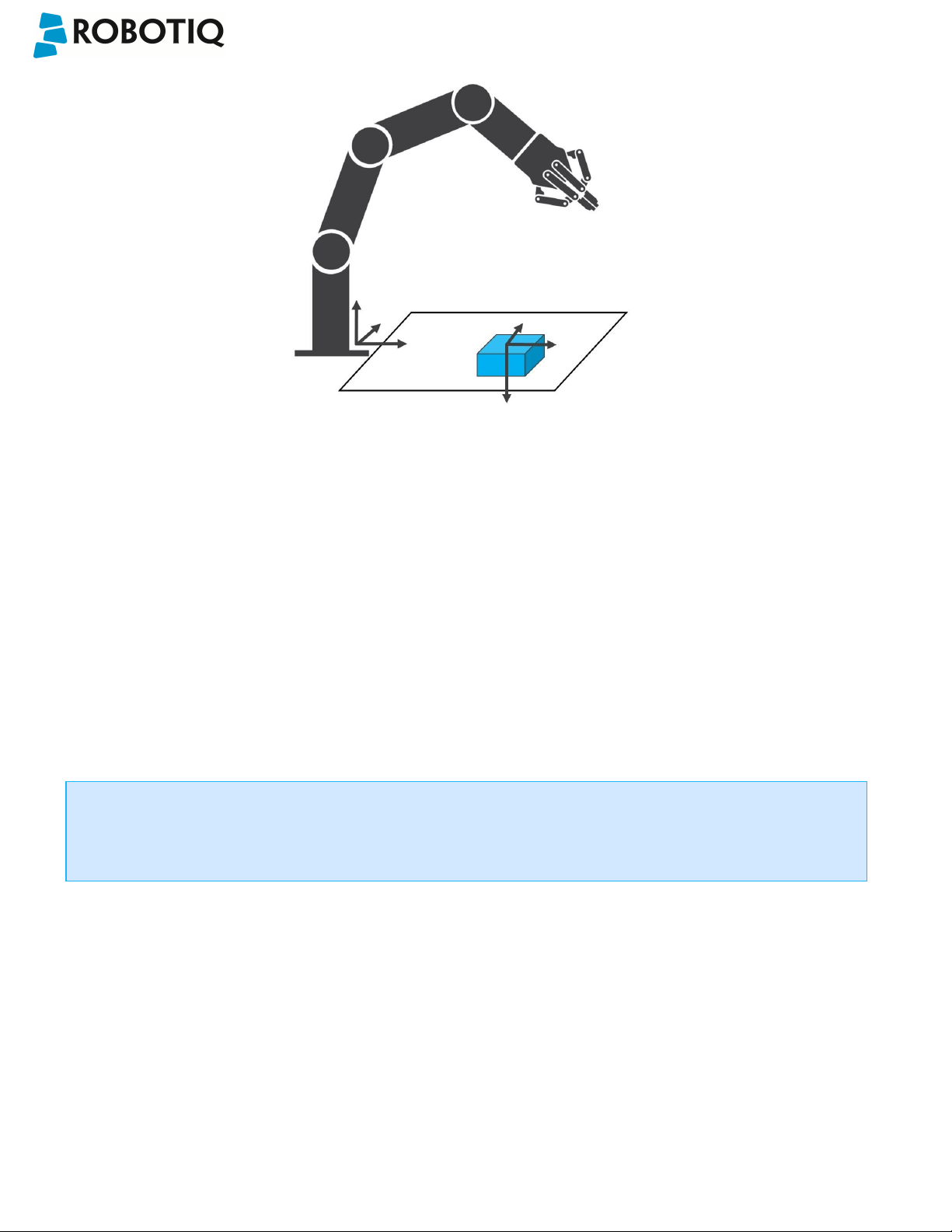

Snapshot Position & Workspace:

The figure below illustrates the various terms used in the following manual to describe the Vision System's Snapshot

Position and workspace. The object location process will always start at the Snapshot Position, that position will determine

the field of view of the Camera and thus the workspace. See the Snapshot Position section for details on how to teach the

Snapshot Position.

Fig. 1-2: Schematic representation of the Robotiq Vision System Snapshot Position and workspace concepts.

l Snapshot Position: the robot pose use to take snapshots from the Wrist Camera.

l Workspace: the area of interest for the Vision System,it is defined by the Camera's field of view.

l Object: the object you want to locate using the Vision System.

l Calibration board: a grid provided with your Camera UR Kit used during the calibration process of the Snapshot

Position.

©Robotiq inc. 2016-2018

7

Wrist Camera Instruction Manual

Object Location:

The System will use the Camera Locate node described in the Programming with the Camera Locate Node section to

locate the object. The figure below represents the object location process. Please refer to the Programming with the

Camera Locate Node section for details on the object location process.

Fig. 1-3: Object location process schematic representation.

l Object to locate: The object you want to locate with coordinates X & Y and rotation Rz.

l Camera Locate relative frame: The reference frame updated by the Vision System to provide you with the

objectlocation.

l Robot base frame: The reference frame of the Universal Robot. Coordinate [0,0,0].

©Robotiq inc. 2016-2018

8

Wrist Camera Instruction Manual

Wrist Camera:

The hardware at the center of the Vision System is the Robotiq Wrist Camera illustrated in the figure below. Steps on how

to install the Wrist Camera are explained in the Installation section.

Fig. 1-4: Main features of the Wrist Camera.

Main features of the Robotiq Wrist Camera:

l CMOS image sensor with liquid lens:

l Resolution: 0.3 to 5 Mpx;

l Frame rate: 2 to 30 FPS;

l Focus from 70 mm to infinity, automatic control.

l 2 sets of 3 LEDs:

l Integrated lighting with automatic control.

l Single high-flex 10 meter pigtail cable:

l USB 2.0;

l 24V DC power.

l ISO 9409-1-50-4M6 bolt pattern, both sides:

l Direct mounting on the UR;

l Direct mounting of the 2-Finger Adaptive Gripper on the Camera.

Info

The Robotiq Wrist Camera provides a direct mounting interface for the Robotiq 2-Finger Adaptive Gripper,

providing a mechanical interface, 24V power and communication to the Gripper.

©Robotiq inc. 2016-2018

9

Wrist Camera Instruction Manual

2. Safety

Warning

The operator must have read and understood all of the instructions in the following manual before handling the

Robotiq Wrist Camera Vision System for Universal Robots.

The term "operator" refers to anyone responsible for any of the following operations on the Wrist Camera Vision

System:

l Installation

l Control

l Maintenance

l Inspection

l Calibration

l Programming

l Decommissioning

This documentation explains the various components of the Vision System, as well as general operations regarding the

whole life-cycle of the product from installation to operation and decommissioning.

The drawings and photos in this documentation are representative examples and differences may exist between them and

the delivered product.

2.1. Warning

Note

Any use of the Vision System in noncompliance of these warnings is inappropriate and may cause injury or

damage.

Warning

The Wrist Camera Vision System used in human-robot collaboration must not be considered a complete safety

measure, additional dedicated safety device(s) must be considered. Vision System failure can occur and result in

danger for workers or machinery if not properly secured. See local or international safety measure for humanrobot collaboration.

Warning

©Robotiq inc. 2016-2018

10

Wrist Camera Instruction Manual

l The Camera needs to be properly secured before operating the robot.

l Do not install or operate a Camera that is damaged or lacking parts.

l Never supply the Camera with an alternative current.

l Make sure all cord sets are always secured at both ends, at the Camera and at the robot.

l Always respect the recommended keying for electrical connections.

l Be sure no one is in the robot and/or Camera path before initializing the robot's routine.

l Always respect the Camera payload.

l All local safety measures and/or laws on robot operation must be applied to the Vision System.

l

Avoid looking straight at the LEDs when they are turned on as this may cause dazzlement.

Any use of the Vision System in noncompliance with these warnings is inappropriate and may cause injury

ordamage.

©Robotiq inc. 2016-2018

11

Wrist Camera Instruction Manual

2.2. Intended Use

The Vision System is designed to locate objects laying flat on the defined workspace. The system can identify and locate

multiple kind of objects, each object will require its own object teaching process as explained in the Object Teaching

section. The Vision System gets the object's position (x, y) and orientation along the z axis. It allows to operate the robot

according to the object location.

Tip

The Guidelines on Snapshot Position section will give you advice on what workspace should be used or avoided.

Section 5 will give you advice on what objects can be located or not along with background recommendations.

Caution

The Vision System is NOT intended for:

l Metrology

l Bar-code / QR code reading

Note

Always comply with local and/or national laws, regulations and directives on automation safety and general

machine safety.

The unit may be used only within the range of its technical specifications. Any other use of the product is deemed improper

and unintended use. Robotiq will not be liable for any damages resulting from any improper or unintended use.

©Robotiq inc. 2016-2018

12

Wrist Camera Instruction Manual

3. Installation

The following subsections will guide you through the installation and general setup of your Robotiq Wrist Camera

Vision System:

l Section 3.1 details the scope of delivery for the Wrist Camera kit for UR, verify your package.

l Section 3.2 lists the required tools, parts and equipment for proper use of your Camera.

l Section 3.3 explains the operating conditions that must be met for the 2-Finger Gripper to operate normally.

l Section 3.4 guides you through the mechanical installation using the Wrist Camera and other optional parts.

l Section 3.5 describes the required electrical set up of the Gripper, its power source and cable management.

l Section 3.6 guides you through the software installation.

Warning

Before installing :

l Read and understand the safety instructions related to the Vision System.

l Verify your package according to the scope of delivery and your order.

l Have the required parts, equipment and tools listed in the requirements ready.

Warning

When installing :

l Meet the environmental conditions.

l Do not operate the Vision System, or even turn on the power supply, before the Camera is firmly

anchored and the danger zone iscleared.

©Robotiq inc. 2016-2018

13

3.1. Scope of Delivery

3.1.1. Wrist Camera Kit for Universal Robots:

RWC-UR-KIT

Standard upon delivery:

l Robotiq Wrist Camera with 10m High-Flex pigtail cable RWC-CAM-001;

l Universal Robots pattern tool plate RWC-TOOL-062;

l 16 Gb USB stick ACC-USB-16G;

l USB software license dongle ACC-USB-DONGLE;

l 4-port USB hub ACC-USB-4-HUB;

l Calibration board ACC-CALIB-BOARD;

l Colored background for object teaching ACC-TEACH-BACK;

l Hardware kit for fixing Wrist Camera on Universal Robots.

Wrist Camera Instruction Manual

Caut ion

The hardware for fixing a tool on the Wrist Camera is not provided.

Combo of 2-Finger Adaptive Gripper and Wrist Camera for Universal Robots:

CUR-AGC-085-RWC or CUR-AGC-140-RWC

Standard upon delivery:

l Wrist Camera Kit for Universal Robots includes:

l Robotiq Wrist Camera with 10m High-Flex pigtail cable RWC-CAM-001;

l 16 Gb USB stick ACC-USB-16G;

l USB software license dongle ACC-USB-DONGLE;

l 4-port USB hub ACC-USB-4-HUB;

l Calibration board ACC-CALIB-BOARD;

l Colored background for object teaching ACC-TEACH-BACK;

l Hardware kit for fastening Wrist Camera to Universal Robots.

l Gripper parts:

l Basic Gripper unit (85 or 140) AGC-GRP-002 or -140 (depending on your combo);

l Screw kit for fixing Gripper on Wrist Camera.

©Robotiq inc. 2016-2018

14

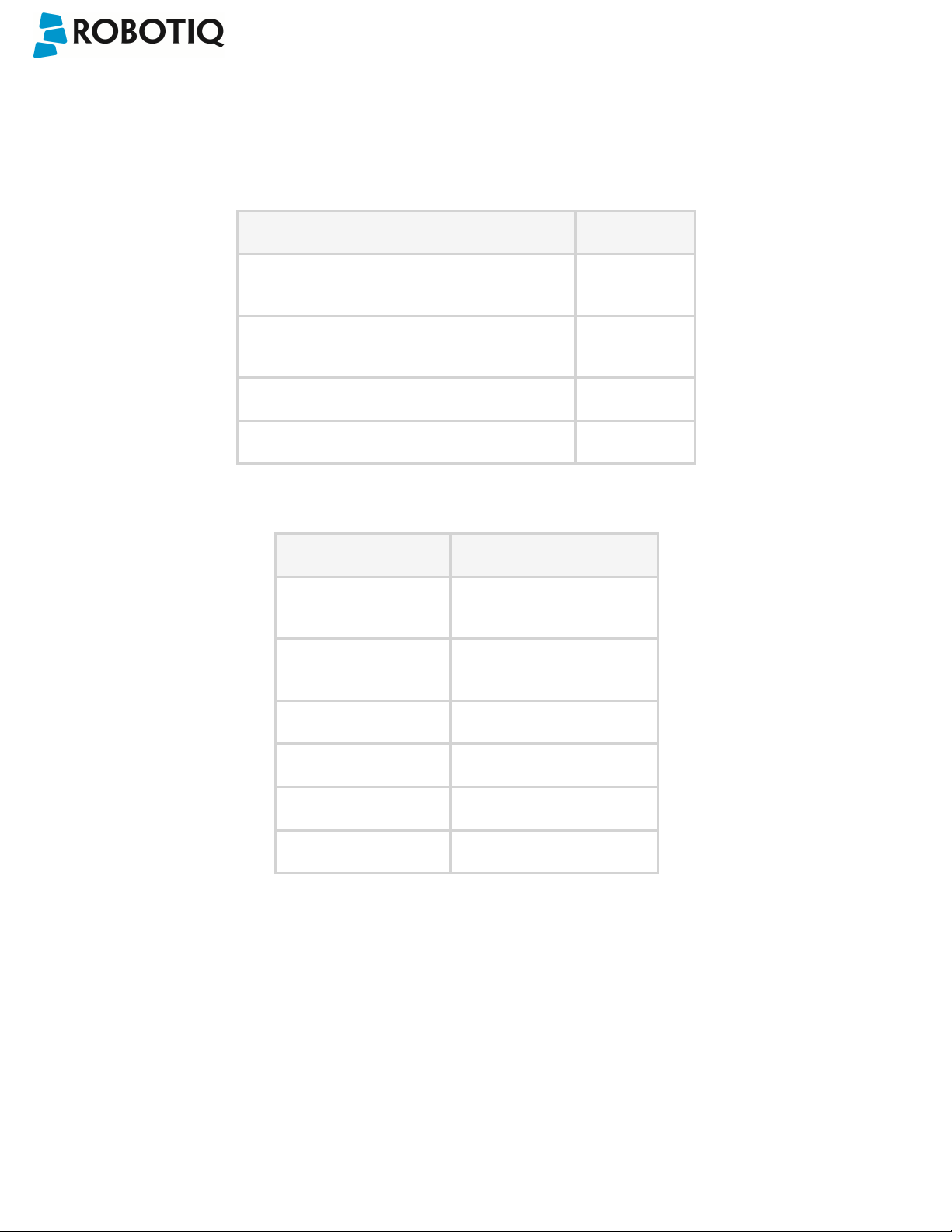

3.2. Required Tools and Equipment

The following tools are required to install the Wrist Camera:

l 2 mm slotted screwdriver to perform terminal block connections when wiring.

Provided tools with the Wrist Camera:

l 4 mm hex key to mount the Camera on the UR arm.

Optional tools if installing 2-Finger combo: CUR-AGC-085-RWC or CUR-AGC-140-RWC:

l none, use the provided 4 mm hex key.

The following parts are required for setup:

l Universal Robots UR3, UR5 or UR10 along with its controller;

Wrist Camera Instruction Manual

Warning

The system is only compatible with UR CB3.1 controller, check your controller version.

l Universal Robots' PolyScope version must be 3.5 or later in order to install the URCap.

l Power supply if not using Universal Robots controller supply (see below);

l Fuse, see information below.

The Camera needs to be supplied by a DC voltage source. This power supply is not included with the Camera kit for

UR. Required power supply must match the Robotiq device. The following table shows the specifications with

regards to the power supply required to operate the Camera and the optional RobotiqGripper.

SPECIFICATION VALUE

Output voltage 24 V DC ±10%

Output current 1 A

Overcurrent Recommended power supply with internal

protection, otherwise fusing is required.

2 A fuse at 25°C [77°F]

1

Info

1

Suggested fuse is a: Phoenix Contact # 0916605 2 A thermal; use AWG #20 wiring.

©Robotiq inc. 2016-2018

Table 3 - 1: Robotiq Wrist Camera and 2-Finger power supply requirements.

15

Wrist Camera Instruction Manual

Warning

If your power supply exceeds the specified regulation, over-voltage protection is required.

Robotiq recommends the use of the following power supplies:

l For the 1A output current: TDK-Lambda DPP Series, 100W Single Output DIN Rail Mount Power Supply: DPP30-

24.

©Robotiq inc. 2016-2018

16

Wrist Camera Instruction Manual

3.3. Environmental and Operating Conditions

The Wrist Camera is designed for industrial applications. Always respect the following specified operating

environmentalconditions:

CONDITION VALUE

Minimum storage/transit

temperature

Maximum storage/transit

temperature

Minimum operating temperature 0°C [32°F]

Maximum operating temperature 50°C [122°F]

Humidity (non-condensing) Non-condensing.

Others Lenses must be free from dust, soot and water.

Environment must be free from powerful electromagnetic

interference.

Environment must be free from corrosive or explosive liquids or

gases.

Table 3 - 2: Environmental and operating conditions for the Wrist Camera.

-30°C [-22°F]

70°C [158°F]

©Robotiq inc. 2016-2018

17

Wrist Camera Instruction Manual

3.4. Mechanical Installation

Wrist Camera kit for Universal Robots

For mechanical installation of a Wrist Camera on a UR robot along with an end-effector (other than Robotiq's 2Finger Gripper), follow these instructions and refer to the figure below:

l Place the Wrist Camera (RWC-CAM-001) on the robot arm. Align the camera's indexing (dowel) pin properly in

Universal Robots' bolt pattern.

l Place the tool plate (RWC-TOOL-062) on the camera. Align the tool plate's indexing (dowel) pin correctly in the

Wrist Camera.

l Fix the desired end-effector on the robot arm, through the tool plate and the camera, using M6 screws.

l Fix the cable along the robot arm, please refer to the Cable Management section.

The end-effector is not screwed in the camera or the tool plate, but directly in the robot arm. Both camera

and tool plate have through holes for thisassembly.

Warning

Make sure the Camera is oriented properly.

Do not offset the Camera from the tool center point on the X and Y axes, or around the Z axis.

©Robotiq inc. 2016-2018

Fig. 3-1: Mechanical installation of the Wrist Camera kit for Universal Robots.

18

Wrist Camera Instruction Manual

Hardware

M6 screws to mount an end-effector on the Wrist Camera are not provided. Use M6 screws of appropriate

length to secure the end-effector on the robot arm.

©Robotiq inc. 2016-2018

19

Wrist Camera Instruction Manual

3.4.1. Combo of 2-Finger Adaptive Gripper and Wrist Camera for Universal Robots

For mechanical installation of a Wrist Camera on a UR robot along with Robotiq's 2-Finger Gripper, follow these

instructions, and refer to the figure below:

l Place the Wrist Camera (RWC-CAM-001) on the robot arm. Align the camera's indexing (dowel) pin properly in

Universal Robots' bolt pattern.

l Fix the camera on the robot arm using the provided M6 X 12 LHCS screws and lock washers.

When mounting only the Wrist Camera on the robot, the spring pins that would ensure connection to a

Robotiq 2-Finger Gripper are exposed. Be careful not to harm them.

l Mount the gripper directly on the Wrist Camera using the provided M5 X 35 SHCS and lock washers.

l Fix the cable along the robot arm; please refer to the Cable Management section.

Fig. 3-2: Mechanical installation of the Combo of 2-Finger Gripper and Wrist Camera for Universal Robots.

©Robotiq inc. 2016-2018

20

Wrist Camera Instruction Manual

3.5. Electrical Setup

3.5.1. Power Supply

Caution

If mounting a 2-Finger Gripper on the Wrist Camera, the Camera replaces the gripper's coupling. Therefore,

only the Wrist Camera's device cable is required to provide power and communication to both the camera

and the gripper. The wiring for setups including only the camera or both the camera and the gripper is the

same.

Power and communication are established with the Wrist Camera via the high-flex device cable. The cable provides a

24V power supply to the Wrist Camera and enables USB 2.0 communication with the Universal Robots controller.

Follow these steps to correctly wire the Wrist Camera (or the camera and 2-Finger Gripper combo) to a Universal

Robots controller :

l With the controller turned off, connect the red (24V) and black (0V) wires of the device cable as shown in the figure

below. Use any available 24V and0V.

Fig. 3-3: Power supply wiring on CB3.1 Universal Robots controller.

l Connect the 4-port USB hub (ACC-USB-4-HUB) inside the robot controller.

l Connect the Wrist Camera's USB connector in the 4-port USB hub.

l Connect the license USB dongle (ACC-USB-DONGLE) in the 4-port USB hub.

Fig. 3-4: 4-port USB hub connection.

©Robotiq inc. 2016-2018

21

Wrist Camera Instruction Manual

Wrist Camera grounding is optional and is done via the robot ground. The camera's indexing pin (dowel) is the

groundconnector.

©Robotiq inc. 2016-2018

22

Wrist Camera Instruction Manual

3.5.2. Cable Management

Warning

Use proper cabling management. Be sure to have enough forgiveness in the cabling to allow movement of

the Gripper along all axes without pulling out the connectors. Always protect the controller side of the cable

connection with a strain relief cable clamp.

3.6. Software

Make sure the Wrist Camera is properly mounted on the robot arm and that all electrical wiring is correctly done (refer

to the Mechanical Installation section and the Electrical Setup section). Make sure your Universal Robots software is

up to date. PolyScope must be version 3.3 or later in order to install aURCap.

l Refer to the Wrist Camera URCap Installation section for the installation procedure.

l Refer to the Update and Uninstall section to update the version or uninstall.

Do not unplug the 16 Gb USB stick or the USB license dongle, even after the installation has been

completed.

Center of mass

Prior to use over Universal Robots, adjust the center of mass and payload from the Installation tab (refer to

the Mechanical Specifications of Wrist Camera section).

©Robotiq inc. 2016-2018

23

Wrist Camera Instruction Manual

3.6.1. Wrist Camera URCap Installation

Make sure the Wrist Camera is properly mounted to the robot arm and that all electrical wiring is correctly done (refer

to the Mechanical Installation section and the Electrical Setup section). Make sure your Universal Robots software is

up to date. The URCap pertaining to this product version has been tested in PolyScope 3.5.

Update

For the URCap update, refer to the Update and Uninstall section.

3.6.1.1. Wrist Camera URCap Installation

l From support.robotiq.com,visit the vision system page and download the latest UCC-X.X.X compressed file.

l Decompress the content of the latest UCC-X.X.X compressed file on the provided 16 Gb USB stick (ACC-USB-

16G).

l Make sure the .urcap file and the vision system folder are on the root of the USB drive, as shown in the figure

below.

Fig. 3-5: Files at the root of the 16 Gb USB stick.

l With the robot controller ON, insert the 16 Gb USB stick containing the latest URCap and vision server in the 4-

port USB hub.

Fig. 3-6: Connections on the 4-port USB hub.

©Robotiq inc. 2016-2018

24

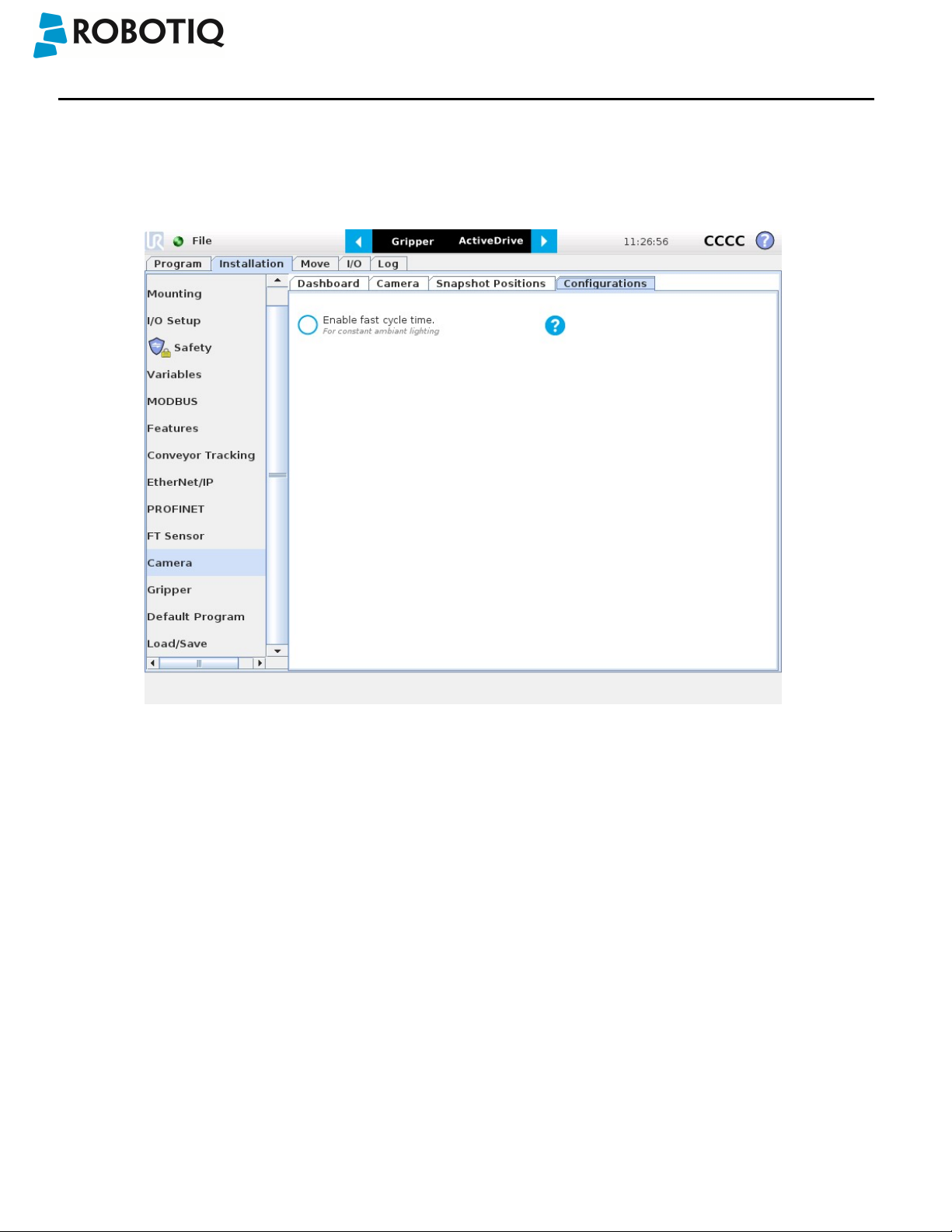

PolyScope 3.6

l From PolyScope's home page, tap Setup Robot and go to URCaps Setup.

l Tap the plus ( + ) sign and open Robotiq_Wrist_Camera-X.X.X.urcap from the USB stick.

l Tap Restart and wait for PolyScope to reopen.

l Go to Program Robot and then to the Installation tab.

l Choose Camera and go to the Dashboard tab.

l Verify the Vision system's status.

Wrist Camera Instruction Manual

l Tap Install and wait for the vision server to be installed.

l If the firmware has to be updated, tap Upgrade Camera firmware to upgrade it before continuing (refer to the

figure below).

©Robotiq inc. 2016-2018

Fig. 3-7: Camera dashboard ready to install the vision server.

25

Wrist Camera Instruction Manual

Fig. 3-8: Camera dashboard with camera firmware upgrade.

l Wait for the vision system to start.

l The installation is completed.

l In order to use another USB drive on the controller, reboot the robot controller.

Do not unplug the 16 Gb USB stick or the USB license dongle, even after the installation has been

completed.

Dashboard

The Dashboard tab contains helpful information for troubleshooting the vision system.

Test the Installation

After the installation has been completed, verify that the vision system works properly.

©Robotiq inc. 2016-2018

26

Wrist Camera Instruction Manual

PolyScope 3.6

1. From a robot program, go to the Installation tab and choose Camera.

2. Go to the Dashboard tab and verify the system's status. Make sure the vision system is running.

3. Go to the Camera tab. The output image will appear.

Center of Mass

Prior to use over Universal Robots, adjust the center of mass and payload from the Installation tab (refer to

the Mechanical Specifications of Wrist Camera section).

©Robotiq inc. 2016-2018

27

Wrist Camera Instruction Manual

3.6.2. Update and Uninstall

Warning

Updating the Wrist Camera software, unplugging the USBstorage device and/or switching USBports must

always be done while the robot is initialized and running.

3.6.2.1. Version 1.1 and following

PolyScope 3.6

1. From a robot program, go to the Installation tab.

2. Tap on Camera and go to Dashboard.

3. Tap Stop camera.

4. Tap Uninstall.

5. Remove the 16 Gb USB stick containing the older URCap and vision server from the 4-port USBhub.

6. Go to Setup Robot.

7. Tap URCaps Setup.

8. In the Active URCaps text box, tap the Camera URCap.

9. The Camera URCap should be highlighted.

10. Tap the minus button (-) to uninstall the URCap.

11. Restart PolyScope to complete the uninstall process.

12. Turn off or reboot the controller.

13. Connect the 16 Gb USB stick containing the older URCap and vision server to a PC.

14. Format it using FAT32.

15. Follow the procedure from theWrist Camera URCap Installation section to install the newest software.

©Robotiq inc. 2016-2018

28

Wrist Camera Instruction Manual

©Robotiq inc. 2016-2018

29

Wrist Camera Instruction Manual

3.6.2.2. Version 1.0.2 and previous

1. On a blank USB stick, add the following file : urmagic_uninstall.sh .

2. From a Robot Program, go to the Installation tab. Choose Camera and go to the Camera tab.

3. Tap Stop camera to stop the Vision server.

4. With the controller on, insert the USB stick containing the urmagic file in the UR teach pendant. Automatic

uninstall will begin.

5. Wait for the uninstall to be completed. Remove the USB stick containing the urmagic file.

6. Remove the 16 Gb USB stick containing the vision server.

7. From the home page, go to Setup Robot.

8. Tap URCaps Setup.

9. In the Active URCaps text box, tap the Camera URCap.

10. The Camera URCap should be highlighted.

11. Tap the minus button (-) to uninstall the URCap.

12. Turn off or reboot the controller

13. Connect the 16 Gb USB stick to a PC.

14. Format it using FAT32.

15. Follow the procedure from theWrist Camera URCap Installation section to install the latest software.

©Robotiq inc. 2016-2018

30

Wrist Camera Instruction Manual

4. Snapshot Position

Prior to teaching object with the Camera Locate URCaps node (refer to the Programming with the Camera Locate Node

section), the operator must define a Snapshot Position using the SnapshotPosition wizard. The following section and sub-

sections will guide you through this process.

Requirements:

l You must have completed the installation steps of the Installation section.

l Robot must set up to reach the desired workspace.

l You must have the correct calibration board in hand.

Reminders:

l You can teach as many Snapshot Positions as you want.

l Snapshot Position is where the robot is positioned to search for objects.

l One Snapshot Position can be used to search many objects.

l When the object teaching process of the Object Teaching section is done, it is linked to the Snapshot Position and you

cannot change that position.

l Each Snapshot Position along with the workplane will define a workspace according to the field of view of the Camera.

Refer to theSpecifications section for details on the field of view.

Calibration Boards:

Tip

If you are viewing a printed version of this manual, please visit support.robotiq.com to download the file.

l For UR5 and UR10

Along with your kit you will have the calibration board used for UR5 and UR10 on one side of the board, part number

ACC-CALIB-BOARD.

If you lose or damage your board, you can print the following file:

Note

If you are viewing the PDF version of the manual, please visit the online version of this manual at

support.robotiq.com to get the calibration board files. If you have printed this manual, please stop doing so, save

some trees and visit the website.

Info

UR5 and UR10 calibration board must be printed on Letter (11'' x 17'') or A3 paper, make sure scale is at 100%.

You can validate that your calibration board had the good scale by measuring the scale on your sheet.

l For UR3

©Robotiq inc. 2016-2018

31

Wrist Camera Instruction Manual

Along with your kit you will have the calibration board used for UR3 robots on one side the the board, part number

ACC-CALIB-BOARD. The color balance circles are not used yet with the vision system and are for future use. If you loose or

damage your board, you can print the following file:

Info

UR3 calibration board must be printed on Letter (8.5'' x 11'') or A4 paper, make sure scale is at 100%. You can

validate that your calibration board had the good scale by measuring the scale on your sheet.

©Robotiq inc. 2016-2018

32

Wrist Camera Instruction Manual

4.1. Guidelines on Snapshot Position

Caution

During the snapshot position definition, the ambient light must be of approximately 500 lux. At run-time, this

condition is not required.

The following must be considered when choosing your Snapshot Position:

l Choosing the workspace:

l Mostly uniform color;

l Planar;

l Provide contrast to your part; refer to theVision System Specifications section for details.

l Distance to the workplane:

l Your Snapshot Position will determine the field of view of the camera and thus the workspace used afterwards.

l See specifications in the Vision System Specifications section for details on the field of view & part size;

l Getting closer to the workplane, will reduce your workspace but allow you to locate smaller objects;

l Getting away from the workplace will increase the workspace but will increase the minimum size of objects to

locate.

Tip

During the Snapshot Position define step, use the "Show Grid" button, a grid will appear. Your

object should be larger than one grid cell.

l Angle of the camera:

l Snapshot position should consider the Camera angle:

l Robotiq greatly recommends to have the Camera perpendicular to the surface:

l Be as close as possible to perpendicular, avoid reflections.

l Object should be seen from the top view, not from the side.

l Calibration board:

l Snapshot position does not need to see the full calibration board, calibration step does.

Tip

The Snapshot position and Calibration pose are decoupled, they do not need to be the same.

l Use the appropriate calibration board.

l Board must be fully visible by the Camera.

l Refer to theVision System Specifications section for Calibration board position specifications.

©Robotiq inc. 2016-2018

33

Wrist Camera Instruction Manual

4.2. Snapshot Position Wizard

Feature Point:

Prior to defining the Snapshot Position, the operator must define a feature point.To do so, from the Universal Robots

Polyscope interface:

l Start a new program or open yours, then go to the Installation tab.

l Go to Features.

l Tap Point to insert a new point feature.

l Select that point, check the Variable checkbox.

l Define that point position anywhere by tapping Set this waypoint, then tap OK, actual position does not mater.

l Tap Rename to give a significant name to your feature, that name will be used as a reference frame later on in your

program.

Info

Each Snapshot Position you teach will require its own Feature point.

Snapshot Position Wizard:

Snapshot Position is define using the Snapshot Position Wizard, from the Universal Robots Polyscope interface, still within

the Installation tab:

l Go to Camera.

l Go to the Snapshot Positions tab.

l In the drop-down list, select the Feature you wish to use.

l Tap Define to launch the wizard.

Wizard step 1: Define Snapshot Position

l Move the robot arm using the Freedrive to place the Wrist Camera.

l Remember the guidelines from the Guidelines on Snapshot Position section:

l Distance will determine field of view and size of objects to be located.

l Use the Show Grid to help you choose distance (object at least one cell).

l Camera view should be quasi perpendicular to surface.

l Once the robot arm is in a proper position, tap Save position. Wizard will go to next step.

Wizard step 2: Calibrate

l Place the appropriate calibration board in the field of view of the camera

l Remember to use the appropriate board, according to your robot model

l The board orientation should match the screen - landscape orientation

©Robotiq inc. 2016-2018

34

l Make sure the Camera see the whole board

Tip

Snapshot Position will determine the field of view, notice that the calibration step position does not

have to be the same as Snapshot position. Thus, you can have a small field of view, then move back for

calibration step.

l Tap Calibrate to begin calibration

Warning

Calibration is an automatic process, the robot will move in order to perform calibration. Make sure the

robot workspace is clear. You can tap Cancel to stop the process. Operator should watch the robot at

all time and have emergency stop button at hand.

l The Vision System will center on the board and take 27 poses of the board.

l After the 27 poses, it will take 9 more photos for validating.

Wrist Camera Instruction Manual

l When the process is done, you will be asked to Accept or Re-Calibrate.

l Accept if the calibration board grid is match on all pose (first 27 poses)

l Re-Calibrate if the grid is not matched

l The wizard will show the 9 validating poses.

l Verify that the accuracy on the validation poses according to the color chart.

l Dark blue: local accuracy of +/-0mm.

l Dark red: local accuracy of +/-4mm and over.

©Robotiq inc. 2016-2018

Fig. 4-1: Validating poses.

35

Wrist Camera Instruction Manual

l If the accuracy is larger than +/- 4mm, an message will inform you that you should perform the calibration again.

l When you tap Accept, you will exit the wizard and the process is completed.

Once the calibration has been accepted, the Snapshot Position will appear in the Snapshot Positions tab with the name of

the Feature Point previously created. You can define other Snapshot positions, as long as you define new Feature Points.

To delete a Snapshot Position, tap the bin.

Tip

Make sure you save the Installation file (tap Load/Save from the Installation tab) in order to save the Snapshot

positions created.

©Robotiq inc. 2016-2018

36

Features

Wrist Camera Instruction Manual

Icon Feature Description

Define Launches the Snapshot Position definition wizard.

Show grid Displays a grid on the camera's field of view.

Meant to test the camera’s height relative to the workplane : a

part should be at least as large as a square of the grid.

Hide grid Hides the grid of the camera's field of view.

Save

position

Saves the robot position for the Snapshot Position.

This is the position from which the robot will do the part

detection.

Calibrate Starts the calibration procedure.

The robot will move automatically to defined positions for the

calibration.

Cancel Cancels the calibration procedure while it is running.

Re-calibrate Restarts the calibration procedure.

©Robotiq inc. 2016-2018

Accept Accepts the calibration process.

Delete Deletes a defined Snapshot position.

37

Wrist Camera Instruction Manual

4.3. Copy a Calibration

When defining a snapshot position, it is possible to copy the calibration from another snapshot position. This allows for a

faster snapshot position modification when using the same work plane.

Work Plane

To ensure proper precision, the work plane surface of both (new and copied) snapshot positions should be the

same.

To copy a calibration, you need to have a snapshot position already defined from which you want to copy the calibration.

l Create a new Snapshot feature point on the same plane as the existing Snapshot point you want to copy.

l Move the robot to this position.

l Go to the Installation tab, select Camera from the menu on the left and tap the Snapshot tab

l Choose the new Snapshop position.

l Select the existing Snapshot position you want to copy and select Copy.

l In the Wizard, select Save This Position.

l The calibration from the previously selected snapshot position will be used for this new one.

©Robotiq inc. 2016-2018

38

Wrist Camera Instruction Manual

5. Object Teaching

Once the snapshot position is defined (see section 4), the operator can use the Camera Locate node within a Universal

Robot program to teach an object to locate. The following section and sub-sections will guide you through this process.

Requirements

l You must have completed the installation steps of section 3.

l Snapshot position is defined as per steps of section 4.

l Have the object to teach in hand:

l Have a few samples to test during the last step of the object teaching process.

Reminder

l A Camera Locate node will be used for a single model.

l Object teaching is linked to the snapshot position, if you want to change snapshot position, you will have to perform

the object teaching again.

l You can teach many objects; each one will use a Camera Locate node.

Background

l Have a background that provides a maximum of contrast with your object, see section 4.1 for guidelines.

Tip

A colored background is provided with the camera kit. Use either the yellow or pink side to ensure a good color

contrast with the object.

©Robotiq inc. 2016-2018

39

5.1. Guidelines on Object Teaching

Info

During the object teaching, the ambient light must be approximately 500 lux, and stable.

At runtime, this condition is not required.

The following must be considered when going through the object teaching process :

l Objects criteria for reliable localization:

l Object is quasi-flat, respecting a maximum ratio of 1:1 between its height and its smallest dimension; please refer

to the Vision System Specifications section for more details.

l Top surface is mostly flat.

l Object has a distinctive shape and distinctive features.

Info

Wrist Camera Instruction Manual

Distinctive shape would mean an object contour that displays a sharp contrast with the background, and that

is ideally not symmetric. Distinctive features are shapes present within the contour of the object that the

vision system will be able to identify, such as holes, drawings, color contrasts,etc.

l Object is not highly reflective

l Object is not transparent

Tip

When teaching reflective objects, the user can turn the LEDs OFFto avoid bright spots contrasting with the actual

color of the object.

l Choosing the appropriate background:

l Workplane around the object must be planar, mostly uniform and clear of any other objects.

l At runtime, the work space conditions can change, the object detection threshold can be used to adjust

detection settings according to those conditions; refer to the Detection thresholds and scores section for

details.

l The background around the object must be a uniform, continuous shape with a single color.

Caution

From the vision system's point of view, white, gray and black are all gradients of gray. Avoid using a black

background to teach metal objects. The model would be a pale gray object on a dark gray background and

would therefore result in errors.

©Robotiq inc. 2016-2018

40

Wrist Camera Instruction Manual

The Machine edge view feature shows edges seen by the camera in greyscale format. Please refer to the Teach Object

Wizard section for more details. Refer to the Vision System Specifications section for specifications on color contrast.

Tip

At runtime, make sure you have the simplest and most uniform background possible for your application. Also

have as few objects and object types as possible. This will decrease the cycle time.

Tip

The ambient light should be diffuse. Avoid high light intensity spots on your background. This will result in a faster

object detection by the Wrist Camera and a lesser risk of false detection.

©Robotiq inc. 2016-2018

41

Wrist Camera Instruction Manual

5.2. Teach Object Wizard

Camera Locate Node

To insert a Camera Locate node in the robot program, from the Universal Robots PolyScope interface:

l Start a new program or open yours, then go to the Program tab.

l Select the Structure tab.

l Go to the URCaps tab and tap Cam Locate to insert the node inside your program.

Teach Object Wizard

Info

Snapshot position must be defined to launch the object teaching wizard. If not, go to section 4.

The Teach object wizard will guide you through the process of teaching an object for locating with the camera. Select the

Cam Locate node, go to the Command and tap Teach object to launch the wizard.

Fig. 5-1: Launch the object teaching wizard.

Choose teaching method

The first step is to choose the teaching method. Choose between either the automatic or parametric method:

l Automatic method: builds a model based on photos and a scan of the object. Best for complex and irregular shapes.

Use this method if the object orientation has to be detected with one of its features. Please refer to the Automatic

Method section for more details.

l Parametric method: builds a model based on parameters of a basic 2D shape (circle, ring, square or rectangle). This

method is faster and allows the vision system to recognize and locate with high robustness objects that have few

distinctive features such as raw material blanks. Usually gives best results than the Automatic method for simple

geometry and highly reflective objects. Please refer to the Parametric Method section for more details.

©Robotiq inc. 2016-2018

42

Wrist Camera Instruction Manual

Tip

At any moment during the teaching process, the user can access contextual help videos with the Play button.

Play button that displays contextual help videos for

visual support in going through the teaching steps

Question mark button that displays an HTML version

of the Wrist Camera's instruction manual directly on the

teach pendant (feature to be implemented in the

nearfuture)

©Robotiq inc. 2016-2018

Fig. 5-2: Selection of the teaching method.

43

Wrist Camera Instruction Manual

5.2.1. Automatic Method

Caution

A Snapshot position must be defined to launch the object teaching wizard. If no Snapshot position has been

defined, please refer to the Snapshot Position section.

5.2.1.1. Select Calibration

Tip

At any moment during the teaching process, the user can access contextual help videos with the Play button.

Tap the Snapshot position you want to use.

Info

If the robot is not at the Snapshot position, you will be prompted to move to the position.

Tap and hold the Move button to do so.

©Robotiq inc. 2016-2018

Fig. 5-3: Select Calibration step

44

Wrist Camera Instruction Manual

5.2.1.2. Select Model

Tip

At any moment during the teaching process, the user can access contextual help videos with the Play button.

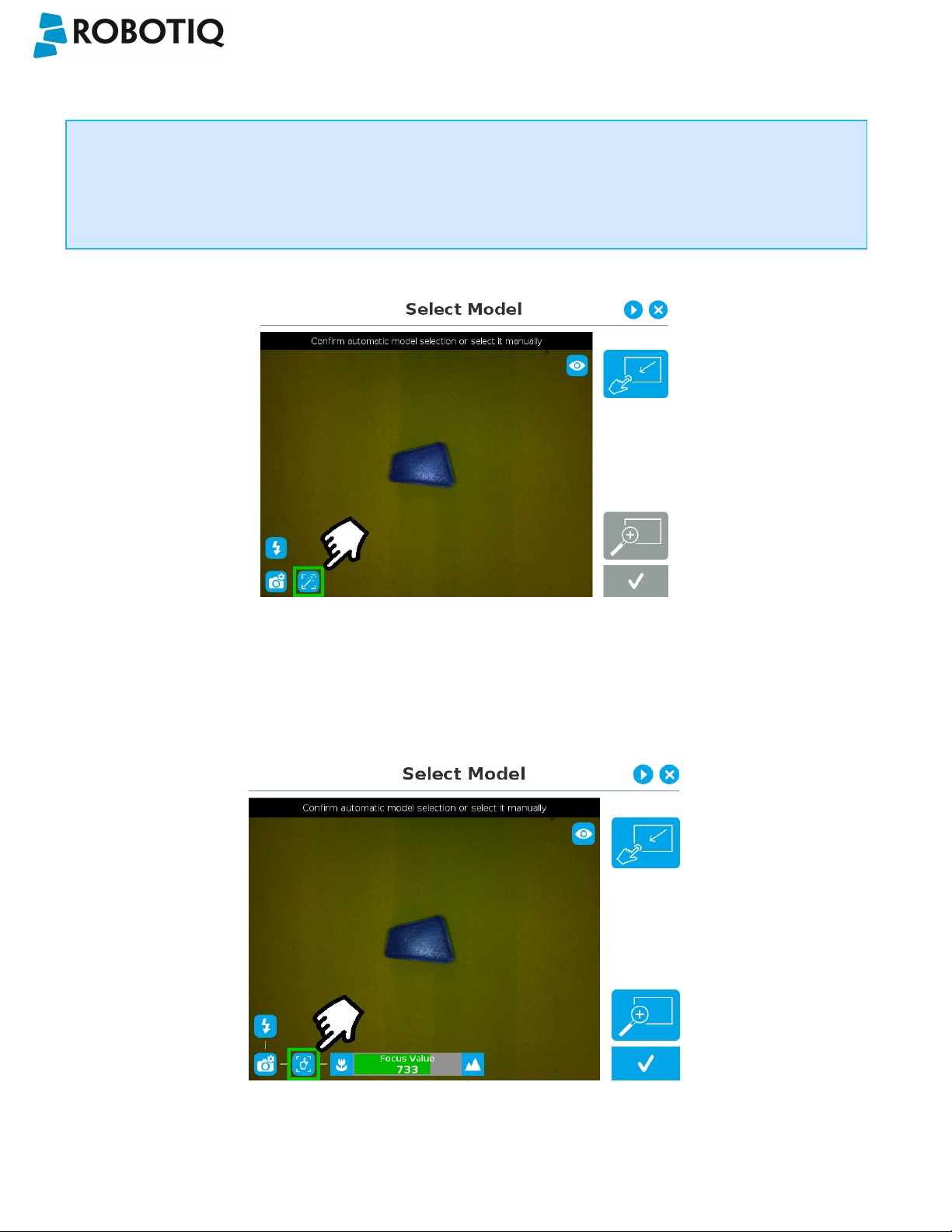

Prior to selecting a model, the user will place a background on the workplane and then position the object on the

background. By default, the Select Model step displays the object to teach, automatically selected by the software,

meaning a green selection rectangle overlaps the shape of the object.

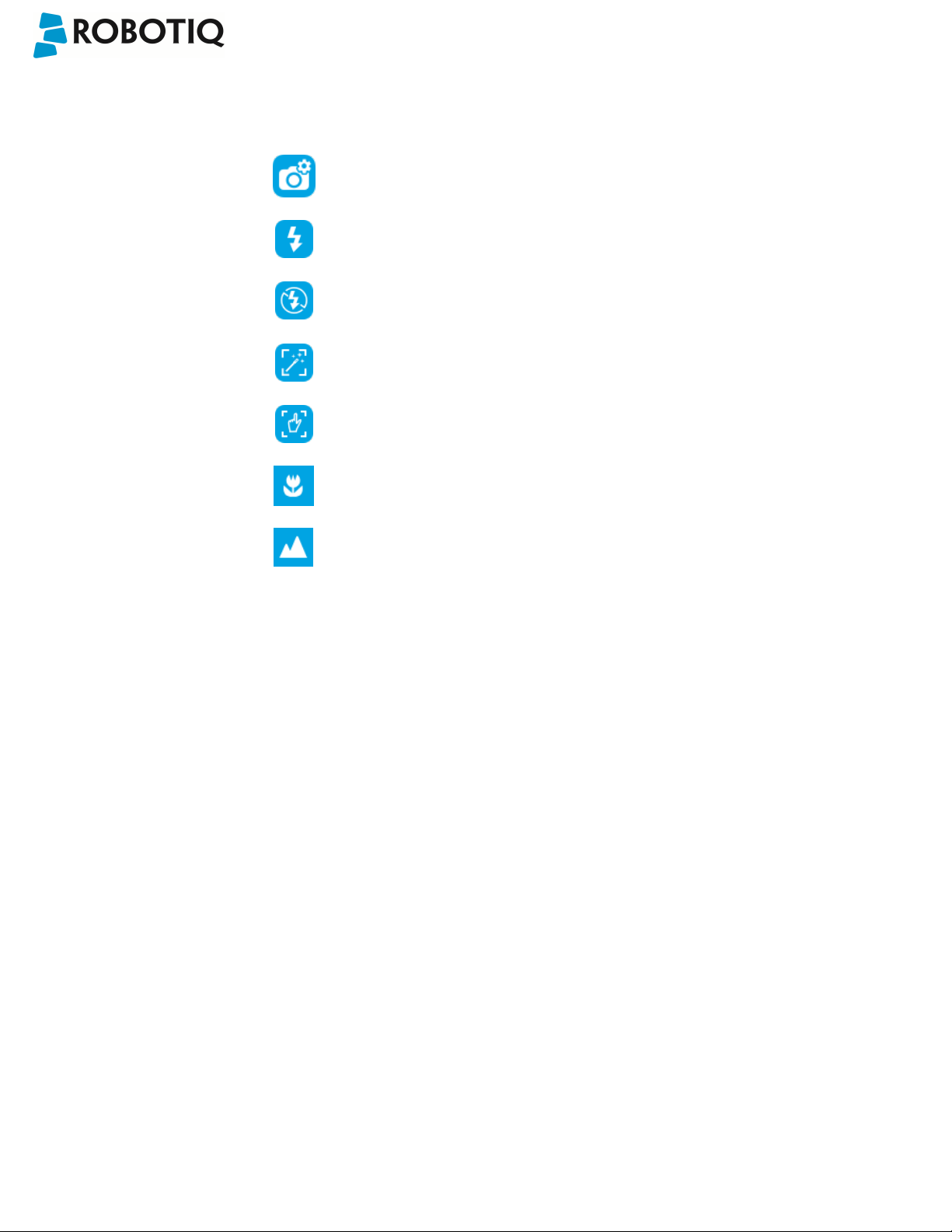

Magic Wand tool; please refer to the Automatic

area selection section for more details.

Tap and drag tool; please refer to the Manual

area selection section for more details.

Zoom in button; please refer to the Zoom in

section for more details.

Zoom out button; please refer to the Zoom out

section for more details.

Accept model button for finalizing the model

selection step; please refer to the Accepting the

model section for more details.

Camera settings button; please refer to the

Camera settings section for moredetails.

Standard view button; please refer to the

Standard view section for more details.

Machine edge view button; please refer to the

Machine edge view section for more details.

©Robotiq inc. 2016-2018

Machine color view;please refer to the Machine

color view section for more details.

45

Wrist Camera Instruction Manual

Automatic area selection

The object is selected since the Magic Wand tool is enabled by default. The Magic Wand feature allows to locate objects

on the background without user intervention.

Info

For the automatic area selection feature to function properly, the user has to employ a uniform background, and a

single object with well defined edges.

Tip

Tapping the Magic Wand tile in the right pane of the PolyScope interface switches the area selection mode to

Manual.

©Robotiq inc. 2016-2018

Fig. 5-4: Select Model step with object automatically selected by the Magic Wand tool

46

Wrist Camera Instruction Manual

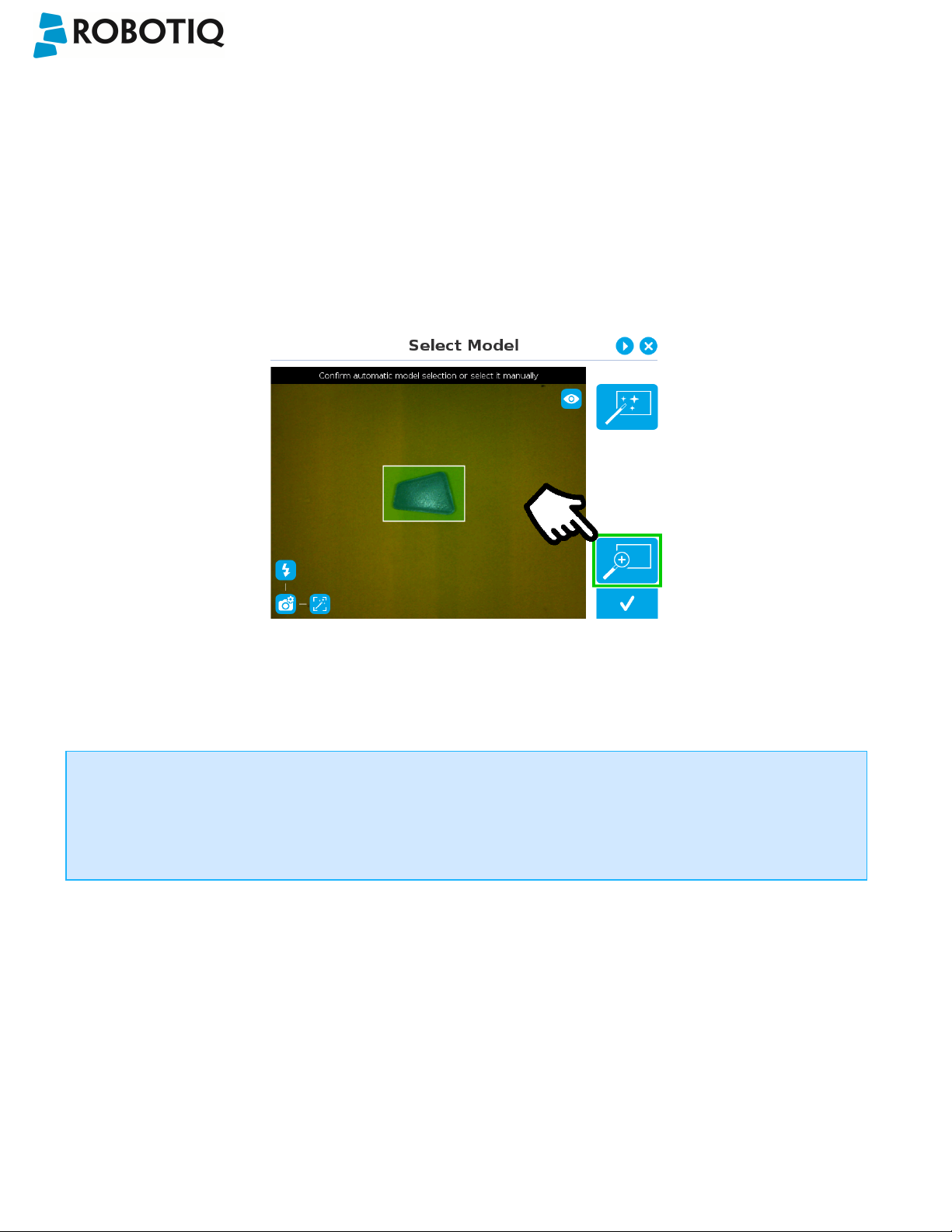

Manual area selection

The user then selects an area by tapping the screen and dragging his/her finger to contain the desired object in the

selection area.

Fig. 5-5: Select Model step with Manual area selection feature

Tip

The manual area selection is useful for careful inspection of specific features using the zoom function.

Refer to the Zoom section for more details.

The manual area selection can also be used for partial custom object selection (i.e. for selecting standalone

features or components of an object).

Tip

Tapping the Manual selection button in the right pane will bring back the Automatic area selection mode.

©Robotiq inc. 2016-2018

47

Wrist Camera Instruction Manual

Camera views

Standard view

When in standard view mode, the camera feed displays a reasonably faithful image based on what is normally perceived

by the human eye (colored object on colored background).

Fig. 5-6: Select Model step with standard view enabled

Tip

Tapping the eye button in the upper right corner of the camera feed window will bring up the machine view.

©Robotiq inc. 2016-2018

48

Wrist Camera Instruction Manual

Machine edge view

The user can access the machine view by tapping the Color view button in the upper right corner of the camera feed

window. The machine view makes no discrimination between colors; it rather highlights the contour of the selected object.

Fig. 5-7: Select Model step with Machine edge view enabled

Tip

The Machine edge view is a convenient tool that can be used to better understand the quality of the image and

the object contrast, and to improve adjustments made to the selection.

Tip

Tapping the cube button in the upper right corner of the camera feed window will bring up the Machine color

view.

©Robotiq inc. 2016-2018

49

Wrist Camera Instruction Manual

Machine color view

The user can access the Machine color view by tapping the Machine edge view button in the upper right corner of the

camera feed window. The Machine color view displays the elementary colors perceived by the vision system.

Fig. 5-8: Select Model step with Machine color view enabled

Tip

The Machine color view is a convenient tool that can be used to better understand the color signature and scale

used by the system.

Tip

Tapping the drop button in the upper right corner of the camera feed window will bring up the standard view.

©Robotiq inc. 2016-2018

50

Wrist Camera Instruction Manual

Camera settings

In order to access the advanced camera settings, tap the camera/gear icon in the lower left corner of the camera feed.

Camera settings

Camera LEDs are ON; please refer to the Camera

LEDs section for more details.

Camera LEDs are OFF; please refer to the Camera

LEDs section for more details.

Automatic focus is enabled; please refer to the

Focus section for more details.

Manual focus is enabled; please refer to the Focus

section for more details.

Shallow focus button; please refer to the Focus

section for more details.

Deep focus button; please refer to the Focus

section for more details.

©Robotiq inc. 2016-2018

51

Camera LEDs

Wrist Camera Instruction Manual

Camera LEDs ON Camera LEDs OFF

Tip

The LEDs, when turned ON, sometimes highlight undesirable features or create reflections that distort the

teaching process. It is recommended to try both settings when teaching the object in order to select the most

conclusive result.

Warning

The flash and focus settings selected will be used at runtime unless changes are made at the Configure Model

step at the end of the teaching process.

Please refer to the Configure Model section for more details.

©Robotiq inc. 2016-2018

52

Wrist Camera Instruction Manual

Focus

Info

Focus features can be used to sharpen or diminish the contrast between the object and the background, and

adjust the depth of field. The settings will be captured at runtime except if changes are made to the model during

the Configure Model step. Please refer to the Configure Model section for more details.

Automatic focus

Fig. 5-9: Select Model step with automatic focus option enabled

To some extent, the automatic focus feature detects sharpness in the overall image. If the image is blurry, the autofocus

system will adjust the focus until sharpness and/or contrast is achieved. This type of automatic focus requires enough

contrast between the object and the background for it to render an appropriate image.

Manual fo cus

©Robotiq inc. 2016-2018

Fig. 5-10: Select Model step with manual focus option enabled

53

Wrist Camera Instruction Manual

The manual focus feature allows the user to adjust the depth of field. Tapping the flower button reduces the focus value,

making the depth of field narrower, while tapping the mountain button increases the focus value, making the depth of field

deeper.

Zoom

The zoom-in/zoom-out tool is used to toggle between a high-level view and a more explicit view of the selection area

(andobject).

Zoom in

Fig. 5-11: Select Model step with Zoom in button highlighted

In order to zoom in on the selection area, the user has to tap the magnifier with a plus symbol in the lower right corner of

the teach pendant interface.

Once zoomed in, the user can perform focus adjustments to improve the recognition of edges in the model.

Info

Note that when zoomed in, the user can neither change the area selection mode nor accept the model selected

(the buttons are greyed out). The zoom in feature is therefore solely used for inspecting the model in details and

for adjusting the depth of field via the manual focus settings.

©Robotiq inc. 2016-2018

54

Zoom out

Wrist Camera Instruction Manual

Fig. 5-12: Select Model step with Zoom out button highlighted

In order to zoom out from the selection area, the user has to tap the magnifier with a minus symbol in the lower right corner

of the teach pendant interface.

Accepting the model

When the view of the model selected is satisfactory and you wish to carry on with the teaching wizard steps, tap the button

with the check mark in the lower right corner of the teach pendant interface.

©Robotiq inc. 2016-2018

Fig. 5-13: Select Model step with Accept button highlighted

55

Wrist Camera Instruction Manual

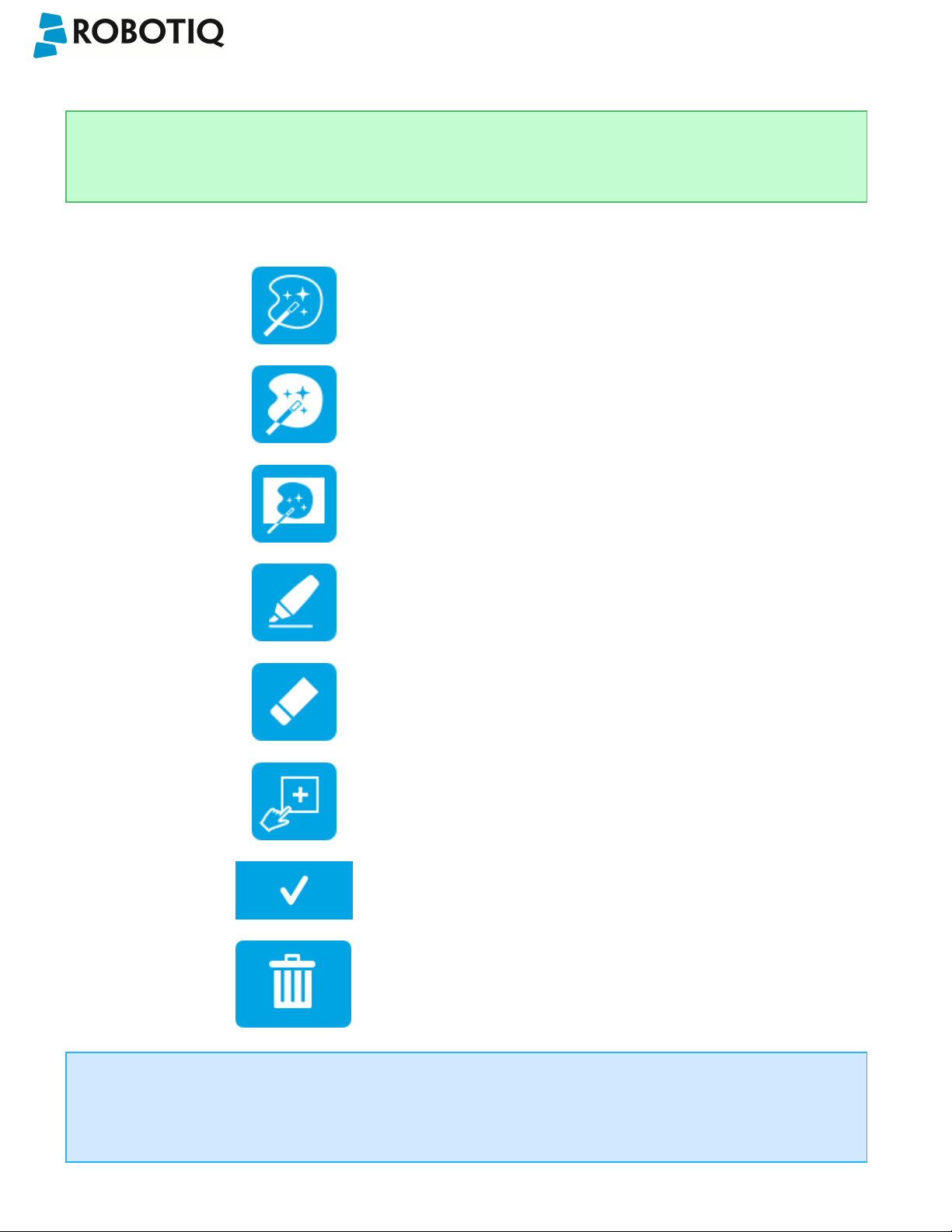

5.2.1.3. Edit Model

Tip

At any moment during the teaching process, the user can access contextual help videos with the Play button.

Right after accepting the model at the end of the Select Model step, the camera automatically zooms in on the object

selected. Quick selection modes and tools are made available to the user.

Outline only selection mode; please refer to the

Object Teaching section for more details.

Outline & surface selection model please refer to

the section for more details.

Rectangle selection around object please refer to

the section for more details.

Marker tool; please refer to the Object Teaching

section for more details.

Eraser tool; please refer to the Object Teaching

section for more details.

Rectangle+ (add area) tool; please refer to the

section for more details.

Accept model button; please refer to the

Accepting the model section for more details.

Info

The user can alternate between color and machine view while editing the model. Please refer to the Camera views

section for more details.

©Robotiq inc. 2016-2018

Delete selection area button; please refer to the

Accepting the model section for more details.

56

Quick selection modes

Tap the arrow to the left of the quick selection tool to expand the selection modes menu.

Wrist Camera Instruction Manual

Fig. 5-14: Edit Model step with quick selection modes expanded

1

Outline only

The Outline only selection tool is used to highlight the contour of the object

Info

The selection area bleeds off the edge of the object to capture the background color.

Caution

The Outline only selection tool is not available for an object that has been selected manually at the Select Model

step. This prevents users from selecting the partial contour of an object,which could lead to faulty contrasts and

edge detection.

2

Outline & surface

The Outline &surface selection tool is used to highlight the contour and upper surface of the object. Tap the middle

button. This tool is selected by default when the user accepts a model selected automatically during the Select

Model step.

Info

The selection area bleeds off the edge of the object to capture the background color.

©Robotiq inc. 2016-2018

57

Wrist Camera Instruction Manual

Caution

The Outline & surface selection tool is not available for an object that has been selected manually at the Select

Model step.This prevents users from selecting the partial outline and/or surface of an object, which could lead to

faulty contrasts and edge detection.

3

Rectangle around object

The Rectangle around object selection tool generates a rectangular selection area surrounding the object.

Info

The Rectangle around object selection tool is automatically selected when the object has been manually selected

at the Select Model step. The other options are disabled. This prevents users from selecting a partial outline

and/or surface of the object, which could lead to faulty contrasts, and erroneous color signature and background

identification.

©Robotiq inc. 2016-2018

58

Tools

Tap the arrow to the left of the tools button to expand the tools menu.

Wrist Camera Instruction Manual

1

Marker

The marker tool can be used to highlight features and edges to include and keep in the selection area.

Slide your finger or pointing device on the desired area(s) on the teach pendant. A green object layer mask will be

applied to the highlighted portion of the model.

2

Eraser

The eraser tool can be used to ignore features and edges in the selection area.

Slide your finger or pointing device on the undesired area(s) on the teach pendant. The object layer mask will be

replaced by the background layer mask.

3

Rectangle+ (add area)

The rectangle+ (add area) tool can be used to quickly highlight desired areas.

Tap and drag your finger or pointing device to draw rectangular shapes that will highlight presently available

features.

Deleting the selection area

4

Garbage can

Tapping the garbage can icon will clear the object layer mask, thus deleting the selection area.

Accepting the model

5

Check mark

When the view of the model is satisfactory and you wish to carry on with the teaching wizard steps, tap the button

with the check mark in the lower right corner of the teach pendant interface.

©Robotiq inc. 2016-2018

59

Wrist Camera Instruction Manual

Caution

Tapping the Accept model button (check mark) takes a picture of the model that will act as the first step in the next

phase of the teaching process:Refine Model.

©Robotiq inc. 2016-2018

60

Wrist Camera Instruction Manual

5.2.1.4. Refine Model

The Refine Model step prompts the user to take photos of the model in four different orientations. The purpose of this

step is to remove shade effects associated with the edges of the object in order to refine the model.

Info

The first photo is automatically generated at the end of the Edit Model step.

Info

Tap the camera icon to take a photo between each step. An error will pop up if the object has not been rotated.

1. The user is prompted to turn the object 90 degrees

clockwise. Note that the first picture is already taken,

in the upper right corner.

3. Object turned another 90 degrees clockwise. The

user is prompted to take the third picture.

Tip

2. The user is prompted to take the second picture of the

object.

4. Object turned another 90 degrees clockwise. The user is

prompted to take the fourth picture.

Tap on any snapshot taken in the object teaching wizard to enlarge it.

©Robotiq inc. 2016-2018

61

Wrist Camera Instruction Manual

5.2.1.5. Validate Model

Tip

At any moment during the teaching process, the user can access contextual help videos with the Play button.

The Validate Model step will start right after the fourth picture is taken at the end of the Refine Model step.

Info

If the object is properly detected, it will display green and red outlines.

If the object has not been recognized, please refer to the Guidelines on Object Teaching section for instructions.

Accept button

Retake button

The Validate Model step is used to verify the contour selection of the model. If satisfactory, the user can accept the model

by pressing the Accept button, or go through the Refine Model step again by tapping the Retake button.

Main points to observe:

l Object contours and detected features are outlined in green

l Features from the model that cannot be located on the object in the field of view of the camera are outlined in red.

©Robotiq inc. 2016-2018

62

Wrist Camera Instruction Manual

5.2.1.6. Scan Model

Tip

At any moment during the teaching process, the user can access contextual help videos with the Play button.

Warning

Scanning is an automatic process; the robot will move in order to perform calibration. Make sure the robot's work

space is clear. You can tap Cancel to stop the process. The operator should watch the robot at all time and have

the emergency stop button at hand.

Scan button used to start the scanning process

Cancel button used to abort the scanning process

while it is running

Fig. 5-15: Scan Model step with Scan button highlighted

The vision system will run a scan of the object by taking 9 pictures.

When the process is completed, the wizard will bring up the Configure Model step. Please refer to the Configure Model

section for more information.

©Robotiq inc. 2016-2018

63

Wrist Camera Instruction Manual

5.2.2. Parametric Method

When teaching a simple geometry object, it is recommended to use the Parametric method. It builds a model based on

parameters of a basic 2D shape (circle, ring, square or rectangle). This method allows the vision system to recognize and

locate with high robustness objects that have few distinctive features such as raw material blanks. It usually gives best

results than the Automatic method for simple geometry and highly reflective objects.

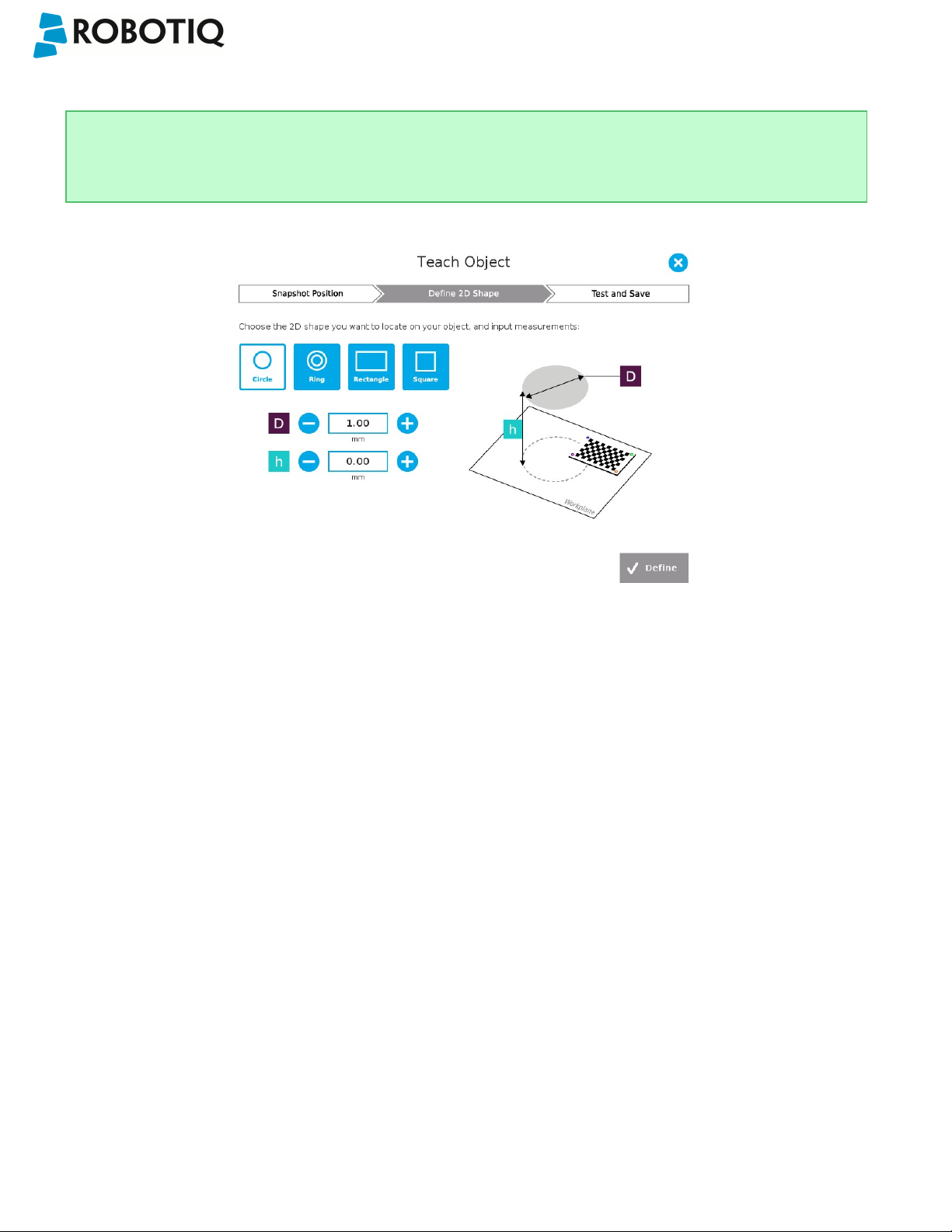

Choose the geometry that corresponds to the object to detect and define its parameters:

l Circle

l Ring

l Rectangle

l Square

Caution

In all cases, the height (h) is the distance between the workplane and the 2D shape. It considers and compensates

the thickness of the provided calibration board (roughly 3mm) that was used to calibrate the workplane.

Thus, if you calibrated the workplane using a printed version of the calibration board, you must add 3mm to the

height measurement.

Define button used to confirm the

dimensions of the object.

©Robotiq inc. 2016-2018

64

Wrist Camera Instruction Manual

5.2.2.1. Circle

Tip

At any moment during the teaching process, the user can access contextual help videos with the Play button.

Enter the circle diameter (D) and the height (h) at which the circle is located. Tap the Define button.

Fig. 5-16: Definition of a circle 2D shape.

©Robotiq inc. 2016-2018

65

Wrist Camera Instruction Manual

5.2.2.2. Ring

Enter the ring outer diameter (D), inner diameter (d) and the height (h) at which the ring is located. Tap the Define button.

Fig. 5-17: Definition of a ring 2D shape.

5.2.2.3. Rectangle

Enter the rectangle length (l),width (w) and the height (h) at which the rectangle is located. Tap the Define button.

Fig. 5-18: Definition of a rectangle 2D shape.

©Robotiq inc. 2016-2018

66

5.2.2.4. Square

Enter the square length (l) and the height (h) at which the square is located.

Wrist Camera Instruction Manual

Fig. 5-19: Definition of a square 2D shape.

When the process is done, the wizard will switch to the Configure Model step. Please refer to the Configure Model section

for more details.

©Robotiq inc. 2016-2018

67

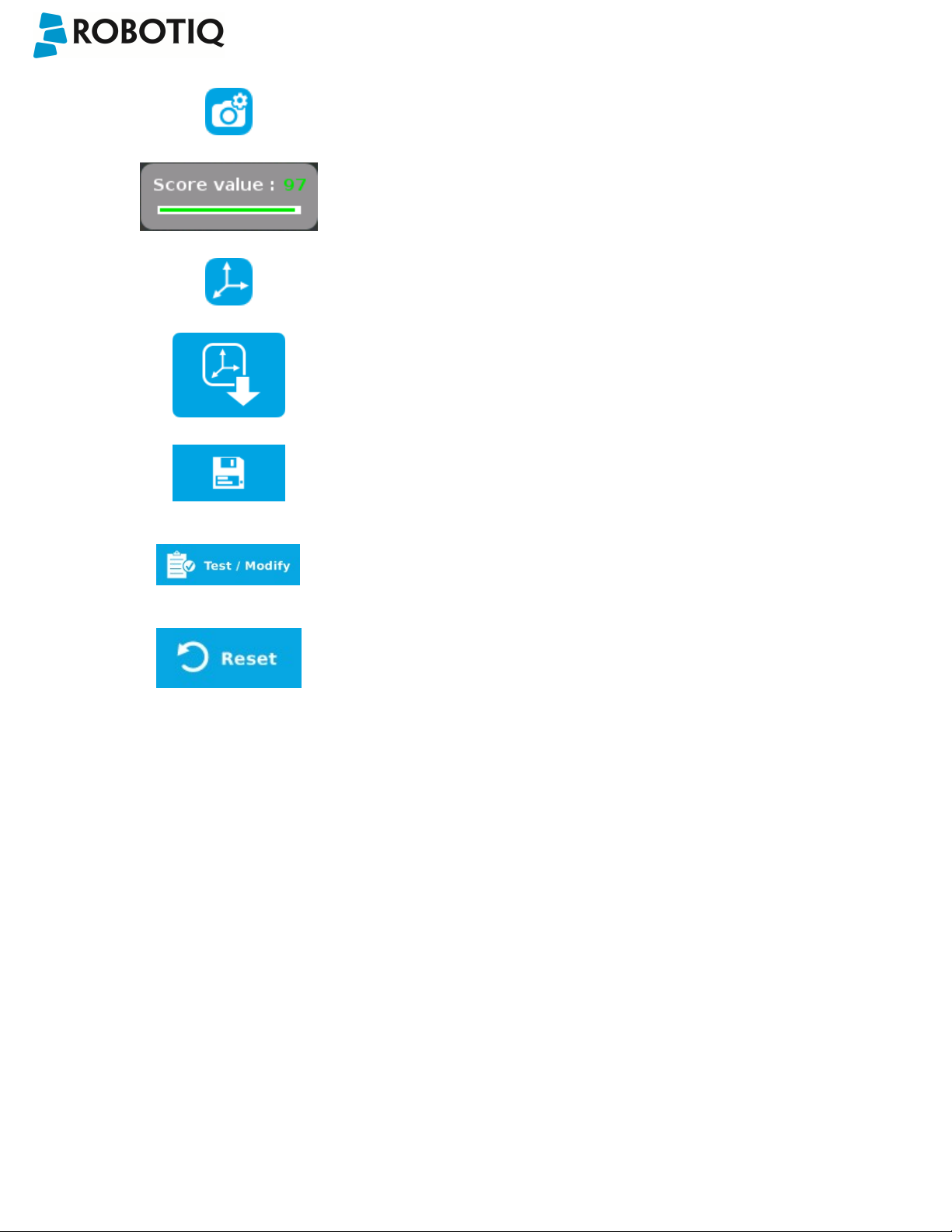

5.2.3. Configure Model

Wrist Camera Instruction Manual

Test locating object button; the Vision System will search for the

object in the field of view of the Wrist Camera.

Back button; after testing an object's location, tap to return to the

output image of the camera.

Color validation button; tap to open the color validation menu.

A colored button Indicates that the color validation mode is enabled.

Please refer to the Color Validation section for more details.

Multiple Object Detection button; a grey button means the feature is

not available at the moment.

Tap to open the multi-object detection menu.

Detection Threshold button; tap to expand the detection threshold

menu. Please refer to the Detection thresholds and scores section for

more details.

©Robotiq inc. 2016-2018

Minus button; tap to lower the Detection Threshold. Please refer to

the Detection thresholds and scores section for more details.

Plus button; tap to increase the Detection Threshold. Please refer to

the Detection thresholds and scores section for more details.

68

Wrist Camera Instruction Manual

Camera settings button; please refer to the Camera settings section

for more details.

Score value box; display section in which the detection score appears

after testing the object location.

Object location button; when an object is found, tap this button to

view its position relative to the robot base.

Set reference position button; tap to save the object's position for

programming linear move (MoveL) relative to the object's location.

Please refer to the Save location section for more details.

Save &finish button; tap to save the detection threshold, the

reference position and finish the wizard.

Test/Modify button; accessible via the Command tab of the Program

Robot interface in Polyscope, once the object teaching wizard is

completed. Tap to access the Test and Modify wizard. It allows the

user to modify the detection threshold and the saved object position.

Reset button; accessible via the Command tab of the Program Robot

interface in Polyscope, once the Teach object wizard is completed.

Tap to reset the whole process of the object teaching wizard.

©Robotiq inc. 2016-2018

69

Wrist Camera Instruction Manual

5.2.3.1. Multiple objects detection

In order to enable the multiple objects detection, tap the multi-object button from the Configure Model step.

Fig. 5-20: Configure Model with multi-object button highlighted.

Once in the multi-object menu, tap the plus (+) symbol to increase the maximum number of objects to detect, or tap the

minus (-) symbol to reduce that number.

©Robotiq inc. 2016-2018

Fig. 5-21: Configure Multiple Detection menu.

70

Wrist Camera Instruction Manual

5.2.3.2. Color Validation

Color validation adds reliability to the camera locate feature.

Whereas editing the model allows to select,configure and save the shape, outline and area of the model, the color

validation allows the system to save the color signature of objects or features.

Warning

Color validation is not intended for discriminating between two colors in the same Camera Locate node, no

matter what the purpose is. However, this action can be performed and programmed with two or more Camera

Locate nodes in the same program tree.

Color validation is not intended for eliminating all colors but one in a Camera Locate node, no matter what the

purpose is.

Automatic method

1

Tap the color validation button to access the color validation menu

©Robotiq inc. 2016-2018

Fig. 5-22: Configure Model with color validation button highlighted.

71

2

Turn on color validation by tapping the red button on the right side of the screen.

Wrist Camera Instruction Manual

Color sampling tools

Fig. 5-23: Configure Model Color model with ON/OFFbutton highlighted

1

Marker

The marker tool can be used to highlight features and edges to include and keep in the color sampling area.

Slide your finger or pointing device on the desired area(s) on the teach pendant. A green layer mask will be applied to

the highlighted portion of the model.

©Robotiq inc. 2016-2018

72

Wrist Camera Instruction Manual

2

Eraser

The eraser tool can be used to ignore features and edges in the color sampling area.

Slide your finger or pointing device on the undesired area(s) on the teach pendant.

3

Rectangle+ (add area)

The rectangle+ (add area) tool can be used to quickly highlight desired areas for color sampling.

Tap and drag your finger or pointing device to draw rectangular shapes that will highlight available features.

4

Garbage can

Tapping the garbage can icon will clear the object layer mask, thus deleting the selection area.

Info

The validation routine of the camera is performed in two steps:

1

Contour (edge) validation, with its own detection score

2

Color validation (if applicable), with its own detection score

Tip

Using the color validation helps to avoid false detections in your background.

©Robotiq inc. 2016-2018

73

Parametric method

1

Tap the color validation button to access the color validation menu.

Wrist Camera Instruction Manual

Fig. 5-24: Configure Model Step (Parametric method) with color validation button highlighted.

©Robotiq inc. 2016-2018

74

2

Turn on color validation by the tapping the red button on the right side of the screen.

Wrist Camera Instruction Manual

Fig. 5-25: Edit Color Validation menu (Parametric method) with ON/OFFtoggle button highlighted.

Color sampling tool

In the parametric method, given the inherent symmetry of the objects located by the system, color validation is supported

via an expendable/shrinkable color selection zone, on par with the contour of the object to be located.

Tap the plus icon to expand the color selection zone, and tap the minus button to shrink the selection zone.

Color selection zone (50% of object size) Color selection zone (80% of object size)

Caution

The size of the color selection zone ranges from 50% of the object size to 150% of the object size.

©Robotiq inc. 2016-2018

75

Wrist Camera Instruction Manual

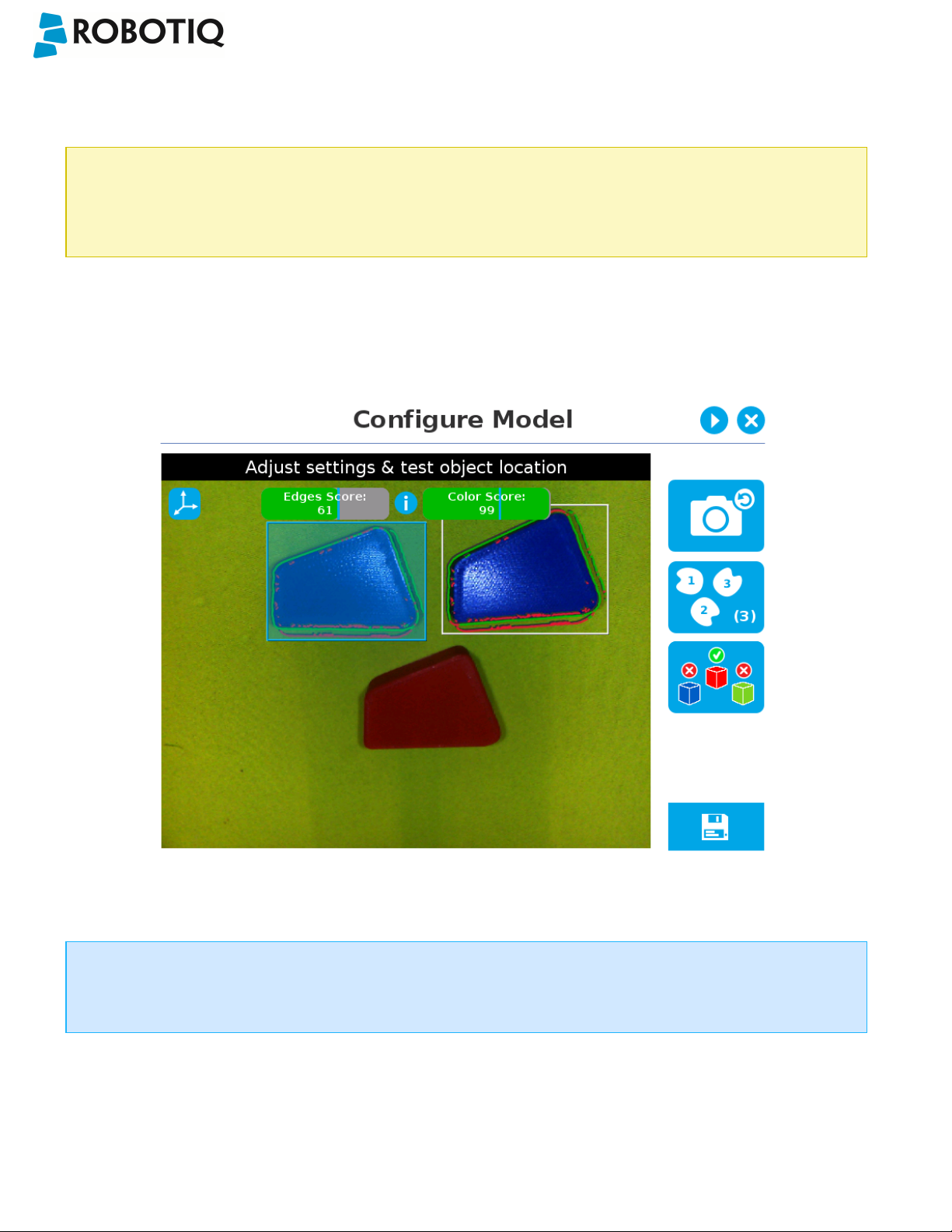

5.2.3.3. Detection thresholds and scores

At the Configure model step, the user can tap the Detection threshold button in the lower right corner to expand the

detection threshold settings.

Fig. 5-26: Configure Model Step with detection thresholds highlighted.

After adjusting the detection thresholds, if applicable, the user can test the location of the object(s)in the field of view by

tapping the camera icon.

©Robotiq inc. 2016-2018

Fig. 5-27: Configure Model Step with camera icon highlighted.

76

Wrist Camera Instruction Manual

Info

In the context of multiple objects detection, each object detected has its own set of detection score values (%).

©Robotiq inc. 2016-2018

77

Wrist Camera Instruction Manual

Edges detection threshold and score

If the object is found, you will see the object outlined, surrounded by a blue rectangle, with the detection score value (%).

Other objects detected will be surrounded by a white rectangle. Tap the other object(s) to display their own set of

detection score values.

Fig. 5-28: Object found with detection score.

l If no object is found, an error message will display, reading that the object was not found.

When testing the object(s) locating:

l Object contours and detected features are outlined in green

l Features from the model that cannot be located on the object in the field of view of the camera are outlined in red.

Info

In the context of multiple objects detection, each object detected has its own set of detection score values (%).

Info

When performing the localization test, place the whole object over the workplane. Due to the perspective effect,

some or all of the object features might not be recognized. If an important feature needs to be found for your

application (a hole for example), make sure it is found during all localization tests. Again, green contour should

match the object outlines at all times.

©Robotiq inc. 2016-2018

78

Wrist Camera Instruction Manual

Tip

To avoid false detections, remove the object from the workplane, decrease the detection threshold to 0% and try

to locate the object. If a false detection occurs on your workplane, you will see an object detected with the

detection score. Increase the detection threshold above this score to avoid false detection.

l Try all areas of the workplane on which the object might be found. Adjust the detection threshold properly for the

object and for the runtimeenvironment.

l Adjust the detection threshold with the plus (+) and minus (-) buttons.

Tip

Set the detection threshold at the highest value possible so the vision system detects the object on the whole

workplane. Tap the Test locating object button to test the threshold.

This ensures optimal robustness for object detection everywher on the workplane. If it is not possible to reach such a

success rate, the following should be considered:

l Redefine the Cam Locate node (go through the Teach object wizard again), make sure there are no reflections, or as

few as possible.

l Refer to the Guidelines on Object Teaching section for instructions

Tip

After completing the object teaching wizard, it is possible to edit the detection threshold. To do so, select the

Camera Locate node and go to the Command tab. Click on Test/Modify to edit the threshold and/or modify the

position of the object.

©Robotiq inc. 2016-2018

79

Wrist Camera Instruction Manual

Color detection threshold and score

Color detection can only happen following a successful edge detection.

Caution

Color validation must be enabled in order to go through the color detection step. Please refer to the Color

Validation section for more details on enabling color validation.

If the object goes through the 2-step detection successsfully, you will see the object(s) outlined,surrounded by a blue

rectangle, with the detection score values (%).

Other objects detected will be surrounded by a white rectangle. Tap the other object(s) to display their own set of

detection score values.

Fig. 5-29: Multiple objects found each with their selection rectangles and detection scores.

Info

In the context of multiple objects detection, each object detected has its own set of detection score values (%).

©Robotiq inc. 2016-2018

80

Wrist Camera Instruction Manual

5.2.3.4. Camera settings

Warning

Camera settings can be adjusted at the Select Model step of the Automatic teaching method and/or at the

Configure Model step of the Teach object wizard.

Editing the camera settings at the Configure Model step will override the settings selected at the Select Model