© ROBOTIQ INC. 2012

Get the latest version of the manual at support.robotiq.com

1

Table of Contents

Revisions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1. General Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Environmental and operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Mechanical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3 Power supply specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.4.1 Power connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.4.2 Communication connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

DeviceNet communication protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

CANopen communication protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Real-time Ethernet communication protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Serial communication protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4. Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1 Generalities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2 Status overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3 Control overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.4 Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.4.1 Supply LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.4.2 Communication LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.4.3 Fault LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.5 Gripper register mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.6 Robot output registers & functionalities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.7 Robot input registers & status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.8 Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.9 MODBUS RTU communication protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.9.1 Connection setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.9.2 Read holding registers (FC03) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.9.3 Preset single register (FC06) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.9.4 Preset multiple registers (FC16) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.10 MODBUS TCP communication protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.10.1 Connection Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.10.2 Read Input Registers (FC04) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.10.3 Preset Multiple Registers (FC16) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5. User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.1 Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.3 UI Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.4 Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.4.1 Modbus RTU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.4.2 Modbus TCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.5 Control of the Adaptive Gripper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.5.1 Initialization & Gripper Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.5.2 Interface Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.5.3 Operation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.5.4 Control Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.5.5 Gripper Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.6 Configuration of the Adaptive Gripper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.6.1 Ethernet IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.6.2 Modbus TCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.6.3 DeviceNet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.7 Menu Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.1 Technical dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.2 Mechanical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.3 Moment of inertia and center of mass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6.4 Electrical ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6.5 Faceplates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6.5.1 Blank faceplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6.5.2 Yaskawa SDA-5D_10D faceplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7. Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8. Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Robotiq inc. © 2011 2

Robotiq Adaptative Gripper, S model Instruction Manual

Revisions

Robotiq may modify this product without notice, when necessary, due to product improvements, modifications or changes in specifications. If such

modification is made, the manual will also be revised, see revision information. See the latest version of this manual online at

. http://support.robotiq.com/

Revision 120209

Update for Robotiq Adaptive Gripper S model 5.1

Revision 120118

Update for Robotiq Firmware 3.0

Revision 111031

Sections added: User Interface and MODBUS TCP communication protocol

Revision 110515

Manual release

Copyright

© 2011 Robotiq Inc. All rights reserved.

This manual, and the product it describes, are protected by the Copyright Act of Canada, by laws of other countries, and by international treaties,

and therefore may not be reproduced in whole or in part, whether for sale or not, without prior written consent from Robotiq. Under copyright law,

copying includes translation into another language or format.

Information provided by Robotiq in this document is believed to be accurate and reliable. However, no responsibility is assumed by Robotiq for its

use. There may be some differences between the manual and the product if the product has been modified after the edition date.

The information contained in this document is subject to change without notice.

Robotiq inc. © 2011 3

Robotiq Adaptative Gripper, S model Instruction Manual

1. General Presentation

The terms "Gripper", "Adaptive Gripper", "Robotiq Gripper" and "Robotiq Adaptive Gripper" used in the following manual all refer to the Robotiq

Adaptive Gripper . The Robotiq Adaptive Gripper S model is a robotic peripheral that is designed for industrial applications. Its designS model

makes it a unique robotic end-of-arm tool to pick, place and handle a large range and volume of parts of varying sizes and shapes.

The Adaptive Gripper has three articulated fingers, i.e. finger A in front of finger B and finger C, that each have three joints (three phalanxes per

finger), as shown in Figure 1.1. The Gripper can engage up to ten points of contact with objects (three on each of the phalanges plus the palm).

The fingers are under-actuated, meaning they have fewer motors than the total number of joints. This configuration allows the fingers to

automatically adapt to the shape of object they grip and it also simplifies the control of the Gripper.

Figure 1.1 – The Adaptive Gripper S model.

Two different types of movements can be performed with the Gripper. The first one simultaneously changes the orientation of fingers B and C as

shown in Figure 1.2. That movement is referred to as changing Operation Modes. The Operation Mode is determined by the user prior to the grip

in function of the size or the shape of the object and for the task that has to be done.

Robotiq inc. © 2011 4

Robotiq Adaptative Gripper, S model Instruction Manual

1.

2.

3.

4.

Figure 1.2 – First type of movement of the Adaptive Gripper S model: changing the Operation Mode

The is the most versatile Operation Mode. It is best suited for objects that have one dimension longer than the two othersbasic mode

but can grip a large variety of objects.

The is optimal for gripping round or large objects.wide mode

The is used for small objects that have to be picked precisely. This Operation Mode can only grip objects between the distalpinch mode

phalanxes of the fingers.

The is used primarily for tiny objects. This mode is not very powerful but is precise. In scissor mode, it is not possible toscissor mode

surround an object. Here, fingers B and C move laterally towards each other while finger A remains still.

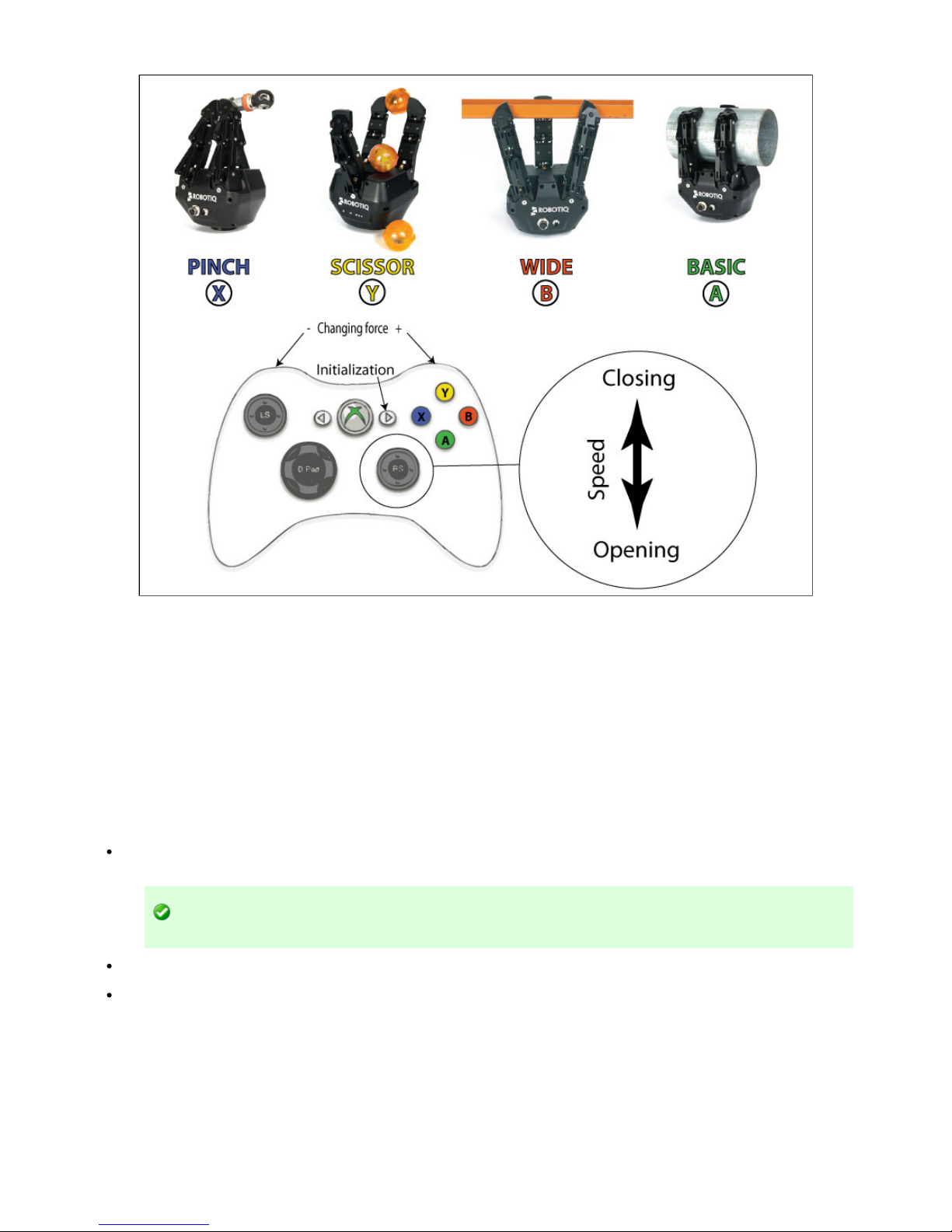

The four pre-set Operation Modes can be chosen by the user (see Figure 1.3).

Figure 1.3 – The four Operation Modes of the Adaptive Gripper.

Robotiq inc. © 2011 5

Robotiq Adaptative Gripper, S model Instruction Manual

The second movement of the Gripper is the closing and opening of the fingers as shown in Figure 1.4. This action is performed with a single input

from a user. Each finger is not controlled independently; the Gripper itself closes each finger until it reaches a stable configuration, on an object or

against the Gripper palm. Note that a user can specify the relative speed at which the fingers will close and the relative force that will be applied to

an object.

Figure 1.4 – Second movement of the Adaptive Gripper S model: closing and opening the fingers.

Two types of grips occur when closing the Adaptive Gripper S model on an object: Fingertip Grip or Encompassing Grip.

The is when an object is only held by the distal phalanxes. This type of grip is similar to what is done with conventionalFingertip Grip

industrial parallel grippers. In this situation, the stability of the grip is mainly related to the friction between the fingers and the object.

The is when the fingers surround an object. The object is encompassed within the fingers and the stability of theEncompassing Grip

grip is no longer related to friction. We suggest using the Encompassing Grip whenever possible to increase grip stability. Figure 1.5

shows the two types of grips.

Robotiq inc. © 2011 6

Robotiq Adaptative Gripper, S model Instruction Manual

Figure 1.5 – The Two Types of Grip: Encompassing and Fingertip Grips.

It is important to note that a Fingertip Grip can only be performed when the fingers touch the object with the distal phalanxes first. Inversely, for an

Encompassing Grip, the fingers must touch the object with the proximal or medial phalanxes first. Also, to ensure stability, the object should be

held against the Gripper palm before doing an Encompassing Grip.

Note that the Encompassing Grip cannot occur in all Operation Modes. Thereby, in Pinch and Scissor modes, it is only possible to do Fingertip

Gripping. On the other side, the Fingertip Grip can occur in all four Operation Modes. Figure 1.6 summarizes the Types of Grip possible for each

Operation Mode.

Info

Operation Modes are inputs to the Gripper. Whether the fingers close to produce an Encompassing or Fingertip grip is

. It will depend on:decided at the Gripper level automatically

The Operation Mode;

The part's geometry;

The relative position of the part with respect to the Gripper.

In other words, picking the same part using the same Operation Mode could result in either an encompassing or fingertip grip

based on a part's position and geometry.

Robotiq inc. © 2011 7

Robotiq Adaptative Gripper, S model Instruction Manual

Figure 1.6 – Operation Modes vs. Types of Grip.

Robotiq inc. © 2011 8

Robotiq Adaptative Gripper, S model Instruction Manual

2. Safety

Warning

Read this section carefully before installation, operation, maintenance or inspection of the Robotiq Adaptive Gripper.

This documentation explains the various components of the Adaptive Gripper S and general operation. Read this documentation and be sure to

understand its contents before handling the Adaptive Gripper S.

The drawings and photos in this documentation are representative examples and differences may exist between them and the delivered product.

2.1 Warning

Warning

The Gripper needs to be properly secured before operating the robot.

Do not install or operate a Gripper that is damaged or lacking parts.

Never supply the gripper with an alternative current source.

Make sure all cord sets are always secured at both ends, at the Gripper and at the robot.

Always respect the recommended keying for electrical connections.

Be sure no one is in the robot and Gripper path before initializing the robot's routine.

Always respect the Gripper payload.

Set the Gripper pinch force and speed accordingly, based on your application.

Keep fingers and clothes away from the Gripper while the power is on.

Do not use the Gripper on people or animals.

For welding applications, make sure there are no Gripper parts on the ground path of the welding power source.

Any usage of the Gripper beyond these definitions is inappropriate and may cause injury or damage.

2.2 Intended use

The Gripper unit is designed for gripping and temporary secure holding of parts.

Caution

The Gripper is NOT intended for applying force against objects or surfaces.

The unit may be used only within the range of its technical data. Any other use of the product is deemed improper and unintended use. Robotiq

will not be liable for any damages resulting from improper use.

Robotiq inc. © 2011 9

Robotiq Adaptative Gripper, S model Instruction Manual

1.

2.

3.

3. Installation

Warning

Be sure to read and understand the related to the Adaptive Griper S model prior to installation.safety instructions

Warning

Do not operate the Gripper, or even turn on the power supply, before it is firmly anchored. The Gripper fingers may move and

cause injury or damage.

3.1 Environmental and operating conditions

The Gripper is designed for industrial applications. Always respect the specified storage and operating environment conditions:

Minimum storage/transit temperature -22°F [-30°C]

Maximum storage/transit temperature 140°F [60°C]

Minimum operating temperature 14°F [-10°C]

Maximum operating temperature 122°F [50°C]

Humidity (non-condensing) 20-80% RH

Vibration < 0.5G

Others

Free from dust, soot or water

Free from corrosive gases, liquids or explosive gases

Free from powerful electromagnetic interference sources

3.2 Mechanical connections

You must use a faceplate to attach the Gripper to the robot. Be sure to use the faceplate related to your robot model. If there is no faceplate for

your robot, you can modify a blank faceplate model or Robotiq can create a custom version for you. (Please refer to the Faceplate Specification

for details on different faceplate models or see Robotiq support ) Section Options and Spare Parts section

Here are the steps to follow for the installation of the Gripper (see Figure 3.2.1). Note that all screws must be locked in place using medium

strength thread locker (Loctite 248).

Screw the faceplate to your robot arm (if your cables are running through the robot, be sure to use a faceplate with a groove).

Insert the Gripper in the faceplate and align the indexing dowel pin with the associated hole.

Secure the Gripper with the radial screws.

Robotiq inc. © 2011 10

Robotiq Adaptative Gripper, S model Instruction Manual

Figure 3.2.1 – Attaching the Adaptive Gripper S model to a robot arm with the Faceplate.

3.3 Power supply specifications

The Gripper needs to be supplied by a DC voltage source. This power supply is not included with the Gripper. The following table shows the

specifications regarding the power supply required to operate the Gripper properly.

Output voltage 24 V DC

Output current 2 A

Ripple 2-3 % peak-peak

Output regulation 2% maximum

Overcurrent

4 A fuse at 77°F [25 C]

o

Maximum fuse I t factor2100 A s at 77°F [25 C]

2 o

Overvoltage protection

Not required

1

1 The Gripper has built-in overvoltage protection.

3.4 Wiring

Two connections are needed for the Adaptive Gripper S model, one for the power and one for the communication. On the Gripper, both are

located on the Connection Panel shown in Figure 3.4.1.

Robotiq inc. © 2011 11

Robotiq Adaptative Gripper, S model Instruction Manual

Figure 3.4.1 – Power and Communication receptacles and connectors.

Warning

Use proper cabling management. Be sure to have enough forgiveness in the cabling to allow movement of the Gripper along all

axes without pulling out the connectors.

3.4.1 Power connection

Here is the way the Gripper should be connected to a power source (Figure 3.4.1.1).

Figure 3.4.1.1 – Power connection diagram of the Adaptive Gripper S model.

Caution

The 4A fuse is external to the Gripper. It is not provided by Robotiq and the user is responsible for proper installation.

The pin-out of the power connectors is detailed in Figure 3.4.1.2.

Robotiq inc. © 2011 12

Robotiq Adaptative Gripper, S model Instruction Manual

Figure 3.4.1.2 – Gripper Power Inlet and Power Connector.

The Adaptive Gripper S model should be supplied with cables that have the following specifications:

approximate length of 5 m.

#22 AWG TEW, 300 V or 600 V.

3 Conductors, 2 for the supply and one for the protective ground.

Shielding, depending on the application. Shield must be grounded in robot controller.

3.4.2 Communication connection

The following table summarizes the communication protocols available for the Gripper. Note that only one protocol option is available in a given

Gripper unit. The Gripper that you have was configured before shipment with only one of the following protocols.

Family Protocol

Real-Time-Ethernet

EtherNet/IP

Modbus TCP/IP

EtherCAT

Fieldbus

DeviceNet

CANopen

Serial Modbus RTU

The communication cable and connectors provided with the Robotiq Adaptive Gripper S model vary with the communication protocol option

choice. Each protocol has its own pin-out and cable, provided cable have an approximate length of 5m. See details in the following sections for

your communication pinout.

Warning

Be sure to use the appropriate cables and pin-outs for your communication protocol as any other setup may damage the

gripper.

Robotiq inc. © 2011 13

Robotiq Adaptative Gripper, S model Instruction Manual

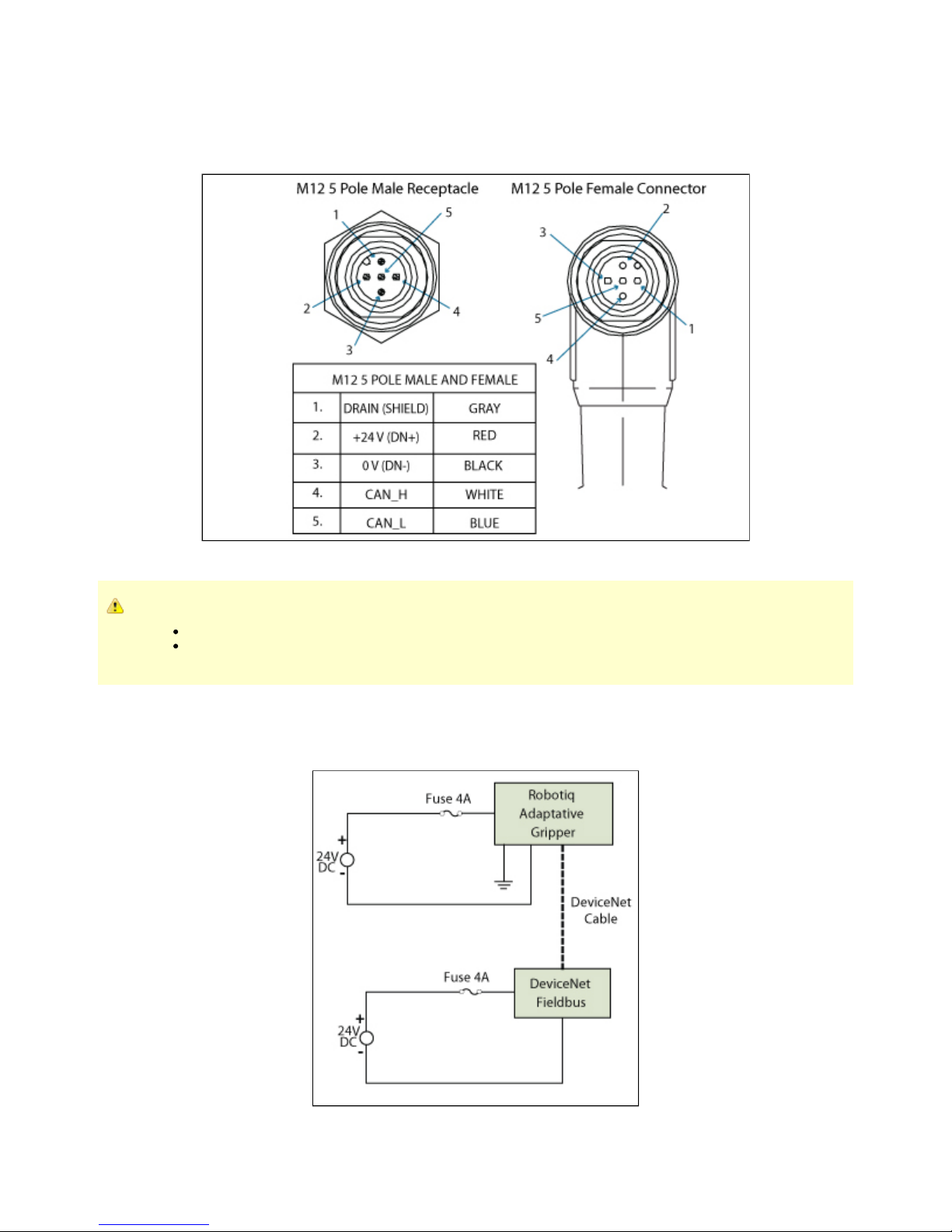

DeviceNet communication protocol

Figure 3.4.2.1 shows the pin-out for the DeviceNet communication protocol for the receptacle (male) present on the Adaptive Gripper S model

and the cable (female) provided with your Gripper.

Figure 3.4.2.1 – DeviceNet communication pinout.

Caution

There is no terminating resistor mounted in the Gripper.

The shield of the cable must be grounded in the robot controller.

The DeviceNet communication and the Adaptive Gripper S model use 24 V supply. Robotiq suggests to separate power supplies as shown in

Figure 3.4.2.2.

Figure 3.4.2.2 – Power connection diagram of the Adaptive Gripper S model using DeviceNet Fieldbus.

Robotiq inc. © 2011 14

Robotiq Adaptative Gripper, S model Instruction Manual

Factory settings for DeviceNet protocol:

IDENTIFICATION SETTINGS

Info Decimal value (base 10) Hexadecimal value (base 16)

Vendor ID : 283 0x0000011B

Product Code : 35 0x00000023

Serial Number : 0 0x00000000

Product Type : 12 0x0000000C

Major Revision : 1

Minor Revision : 1

Product Name : AG-DNS

BUS SETTING

MAC ID : 11

Baud Rate : 250 kBaud

DATA SETTINGS

Prod. Data Length : 16

Cons. Data Length : 16

Robotiq inc. © 2011 15

Robotiq Adaptative Gripper, S model Instruction Manual

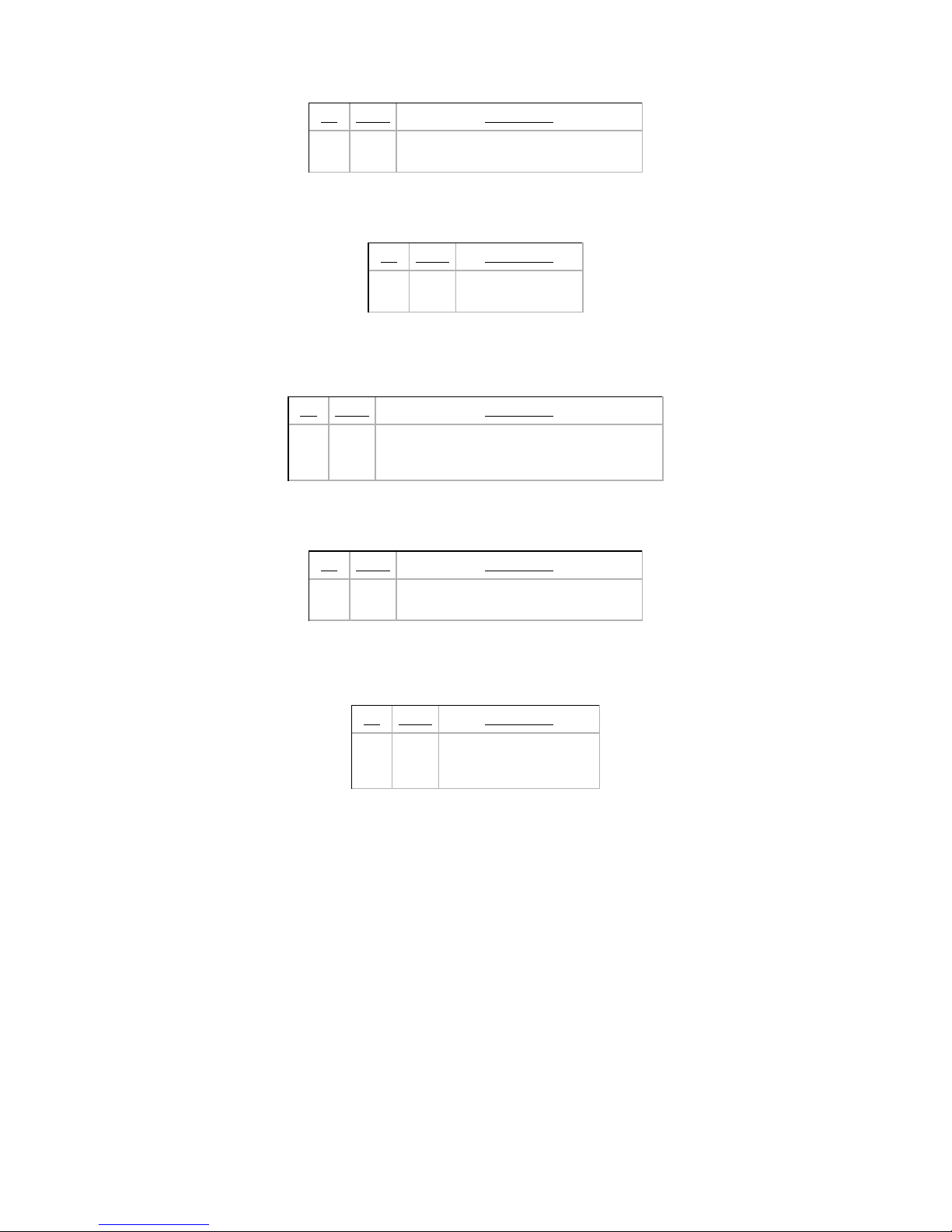

CANopen communication protocol

Figure 3.4.2.3 shows the pin-out for the CANopen communication protocol for the receptacle (male) present on the Adaptive Gripper S model and

the cable (female) provided with your Gripper.

Figure 3.4.2.3 – CANopen communication pinout.

Caution

There is no terminating resistor mounted in the Gripper.

The shield of the cable must be grounded in the robot controller.

Factory settings for CANopen protocol:

IDENTIFICATION SETTINGS

Info Decimal value (base 10) Hexadecimal value (base 16)

Vendor ID : 68 0x00000044

Product Code : 1541540 0x001785A4

Revision Number : 131072 0x00020000

Serial Number : 0 0x00000000

Robotiq inc. © 2011 16

Robotiq Adaptative Gripper, S model Instruction Manual

BUS SETTING

Node Adress : 11

Baud Rate : 1 MBaud

DATA SETTINGS

Index Size

Send Object 0x2000 128

Receive Object 0x2200 128

Output Databytes 512

Input Databytes 512

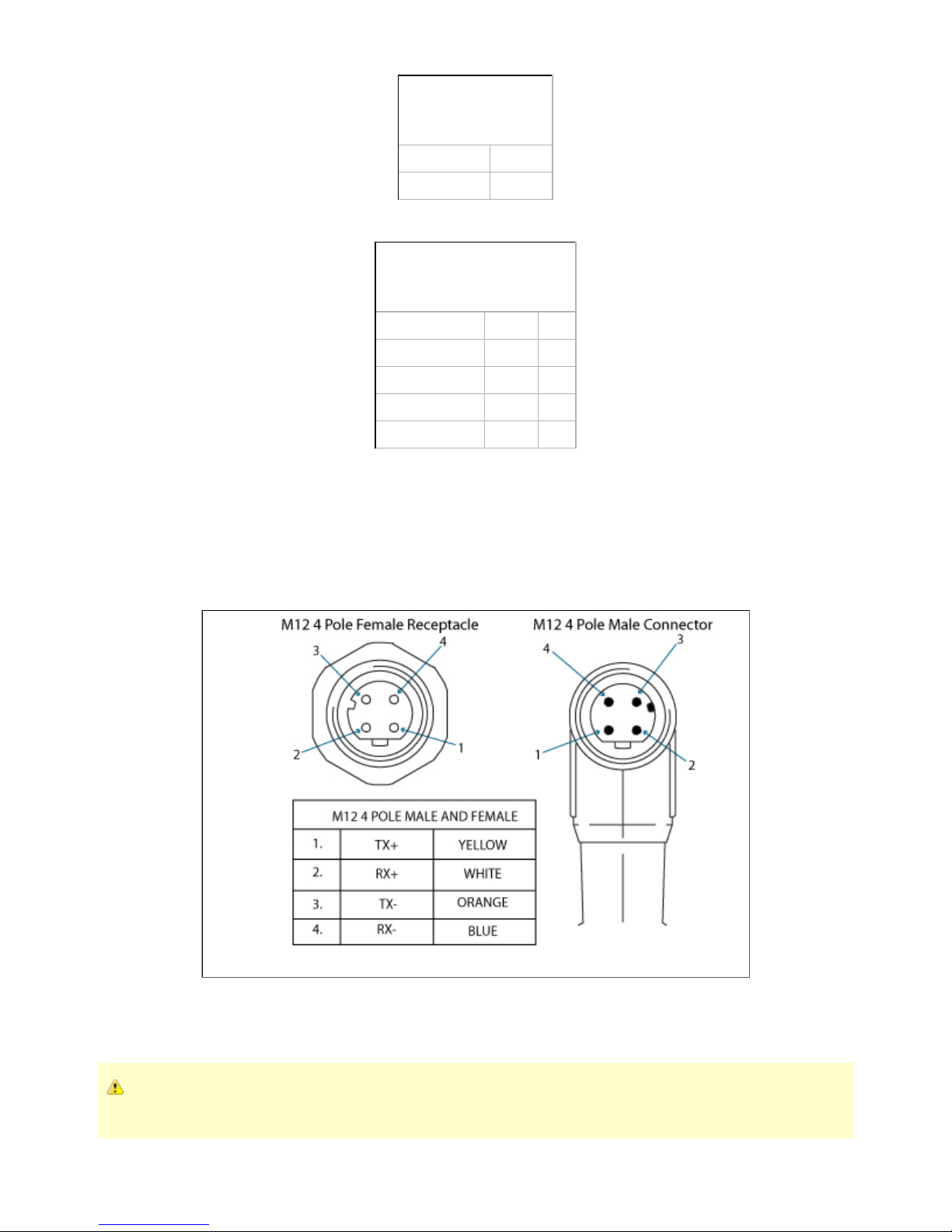

Real-time Ethernet communication protocol

Real-time Ethernet communication includes Ethernet/IP, EtherCAT and Modbus TCP/IP protocols.

See the Real-Time Ethernet pin-out diagram below (Figure 3.4.2.5) for the receptacle (male) present on the Adaptive Gripper S model and the

cable (female) provided with your Gripper.

Figure 3.4.2.5 – Real-time Ethernet communication pin-out.

Caution

The crossover on the RX/TX signals is made inside the Gripper.

Robotiq inc. © 2011 17

Robotiq Adaptative Gripper, S model Instruction Manual

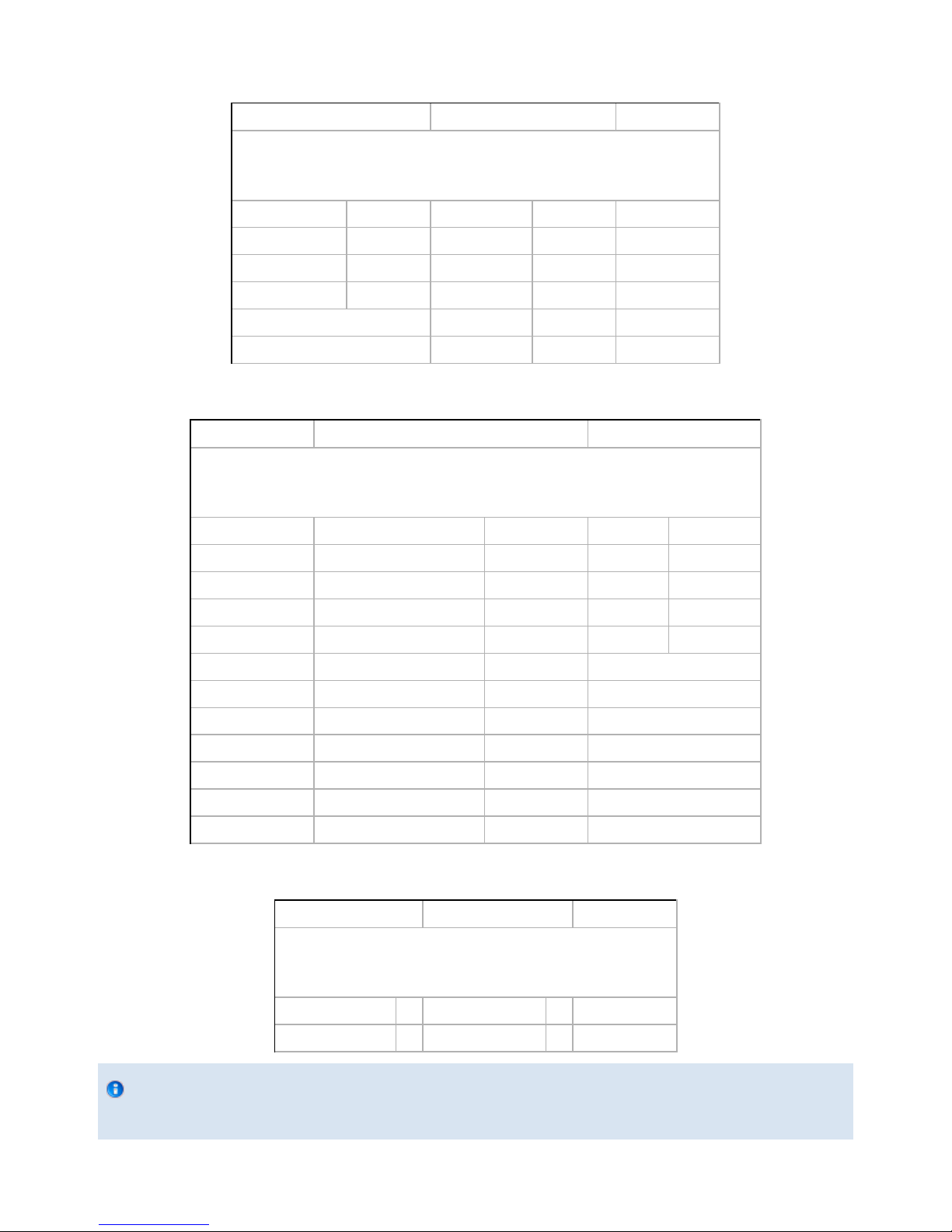

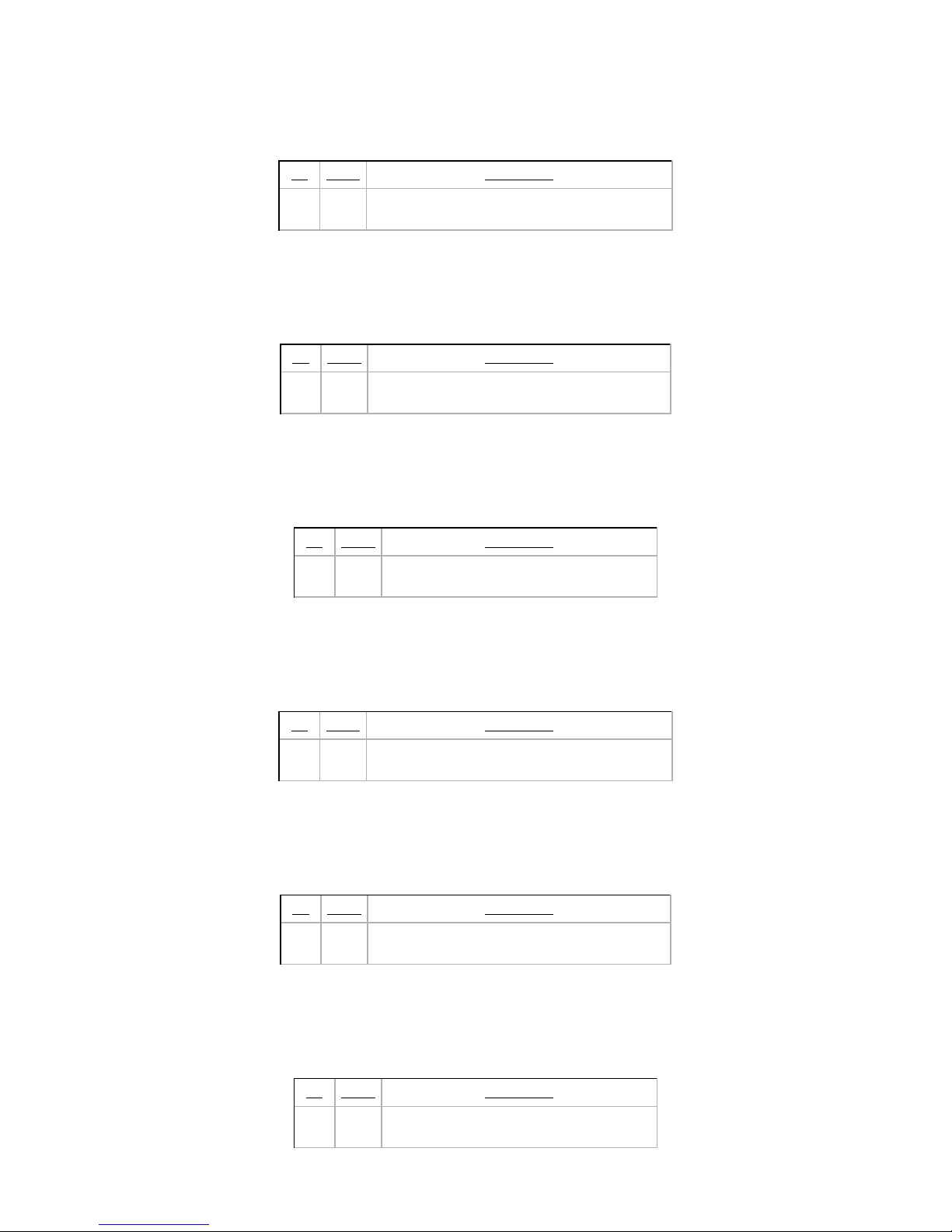

Factory settings for each Ethernet protocols:

EtherCat EtherNet/IP Modbus TCP/IP

IDENTIFICATION SETTINGS

Vendor ID : 0x0000FFFF Vendor ID : 0x0000011B N / A

Product Code : 0x0000000B Product Code : 0x0000010D

Serial Number : 0x00000000 Product Type : 0x0000000C

Revision Number : 0x00000000 Major Revision : 1

Minor Revision : 1

Device Name : AG-EIS

EtherCat EtherNet/IP Modbus TCP/IP

BUS SETTING

N / A (see info note) IP Address : 192.168.1.11 IP Address : 192.168.1.11

Netmask : 255.255.255.0 Netmask : 255.255.255.0

Gateway : Disabled Gateway : Disabled

BootP : Disabled BootP : Disabled

DHCP : Disabled DHCP : Disabled

100Mbit : Enabled 100Mbit always on

Full Duplex: Enabled Full Duplex always on

Auto-neg : Enabled Auto-neg always on

Assembly Instance (input) : 101

Assembly Instance (output) : 100

Configuraton Instance : 1

Connection Type : Run/Idle Header

EtherCat EtherNet/IP Modbus TCP/IP

DATA SETTINGS

Input Data Bytes : 16 Prod. Data Length : 20 N / A

Output Data Bytes : 16 Cons. Data Length : 20 N / A

Info

Ethercat protocol uses inherent dynamic addressing thus bus settings cannot be customized

Robotiq inc. © 2011 18

Robotiq Adaptative Gripper, S model Instruction Manual

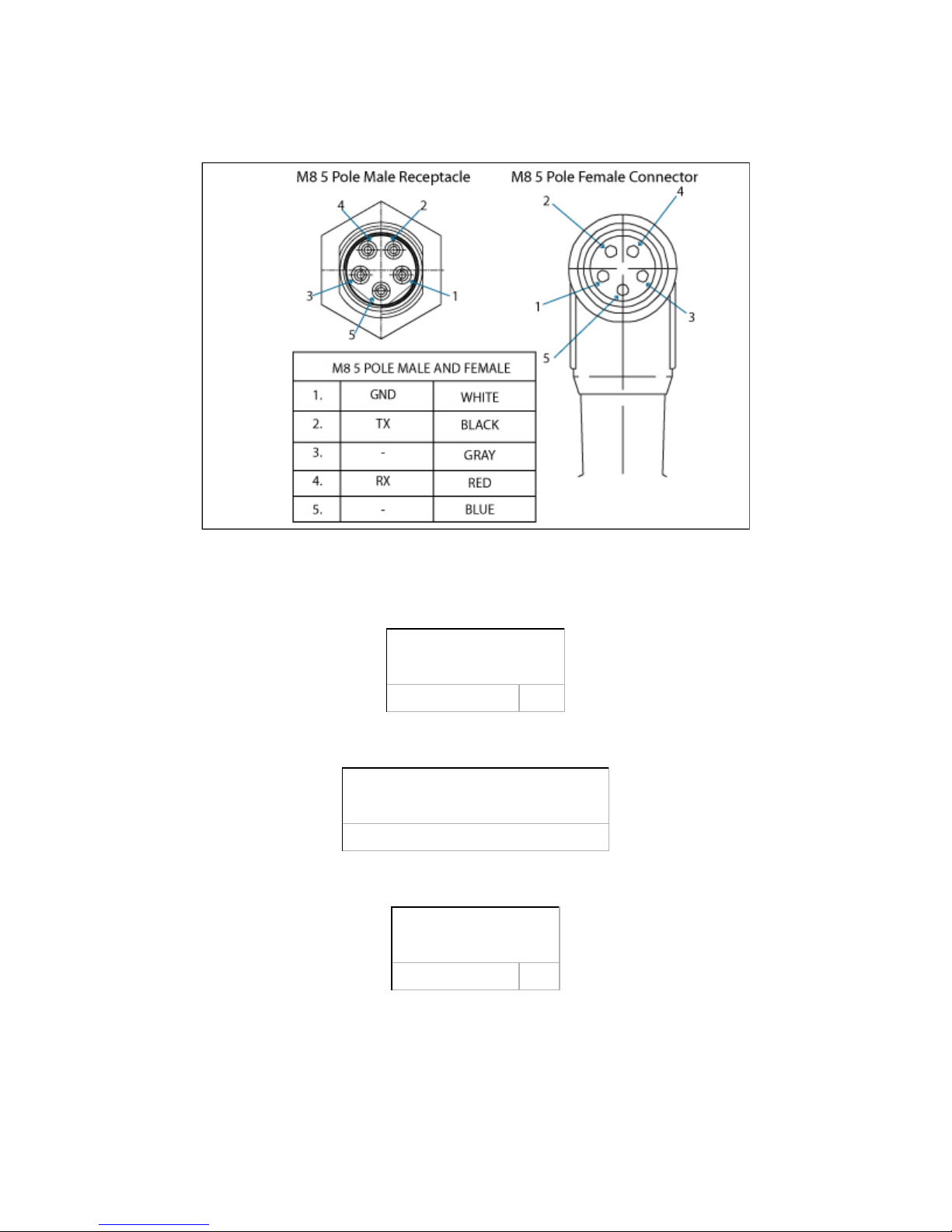

Serial communication protocol

Figure 3.4.2.6 shows the pin-out of the communication connectors when used in serial mode for the receptacle (male) present on the Adaptive

Gripper S model and the cable (female) provided with your Gripper.

Figure 3.4.2.6 – Serial communication pin-out.

Factory settings for Modbus RTU protocols:

IDENTIFICATION SETTINGS

Device : 9

BUS SETTING

See section for details4.9.1 Connection setup

DATA SETTINGS

Number of Register : 5000

Robotiq inc. © 2011 19

Robotiq Adaptative Gripper, S model Instruction Manual

4. Control

4.1 Generalities

Caution

This section applies to firmware 3.0 (grippers delivered after November 2011). For prior versions please see the documentation

archives.

The Robotiq Adaptive Gripper S model is controlled from the robot controller (see Figure 4.1) using an industrial protocol (EtherNet/IP, DeviceNet,

CANopen, EtherCat, etc.). The programming of the Gripper can be done with the of the robot or by offline programming.Teach Pendant

Info

For each Operation Mode, the operator can control the force and the speed of the fingers.

Unless individual control is selected, the fingers movement is always synchronized, movement is done with a single "Go

to requested position" command (the motion of each mechanical phalanx is done automatically).

Since the Robotiq Adaptive Gripper S model has its own internal controller, high-level commands such as "Go to requested position" are used to

control it. The embedded Robotiq Controller takes care of the regulation of the speed and the force prescribed, while the mechanical design of the

fingers automatically adapts to the shape of object(s).

Figure 4.1 – Adaptive Gripper S model connections.

4.2 Status overview

The Adaptive Gripper S-Model returns several registers of information to the robot controller:

Global Gripper Status - A global Gripper Status is available. This gives information such as which Operation Mode is currently active or

if the Gripper is closed or open.

Object Status - There is also an Object Status that let you know if there is an object in the Gripper and, in the affirmative, how many

fingers are in contact with it.

Fault Status - The Fault Status gives additional details about the cause of a fault.

Position Request Echo - The Gripper returns the position requested by the robot to make sure that the new command has been

received correctly.

Robotiq inc. © 2011 20

Robotiq Adaptative Gripper, S model Instruction Manual

1.

2.

Motor Encoder Status - The information of the encoders of the four motors is also available.

Current Status - The current of the motors can also be known. Since the torque of the motor is a linear function of the current, this gives

information about the force that is applied at the actuation linkage of the finger.

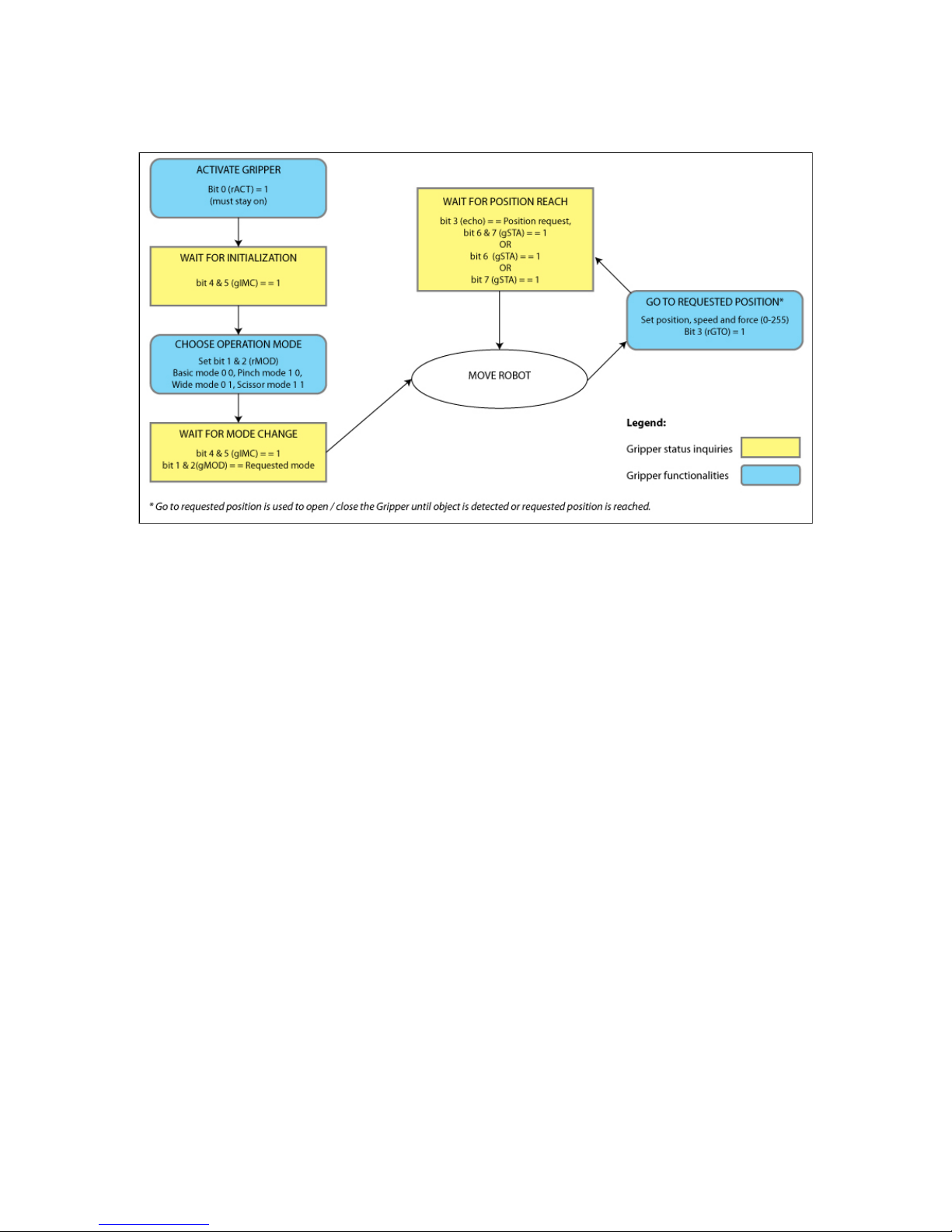

4.3 Control overview

The Gripper controller has an internal memory that is shared with the robot controller. One part of the memory is for the robot output, gripper

. The other part of the memory is for the robot input, (see Figure 4.3.1). Two types of actions can then be done byfunctionalities gripper status

the robot controller:

Write in the registers to activate ;robot output functionalities

Read in the registers to get the of the gripper. robot input status

Info

The Gripper must be initialized (activation bit) at power on. This procedure takes a few seconds and allows the gripper to be

calibrated against internal mechanical stops.

Figure 4.3.1 – Gripper memory shared with the robot controller.

4.4 Status LEDs

Three status LED lights provide general information about the Adaptive Gripper S model status. Figure 4.4.1 shows the LEDs and their locations.

Robotiq inc. © 2011 21

Robotiq Adaptative Gripper, S model Instruction Manual

Figure 4.4.1 – Status LEDs.

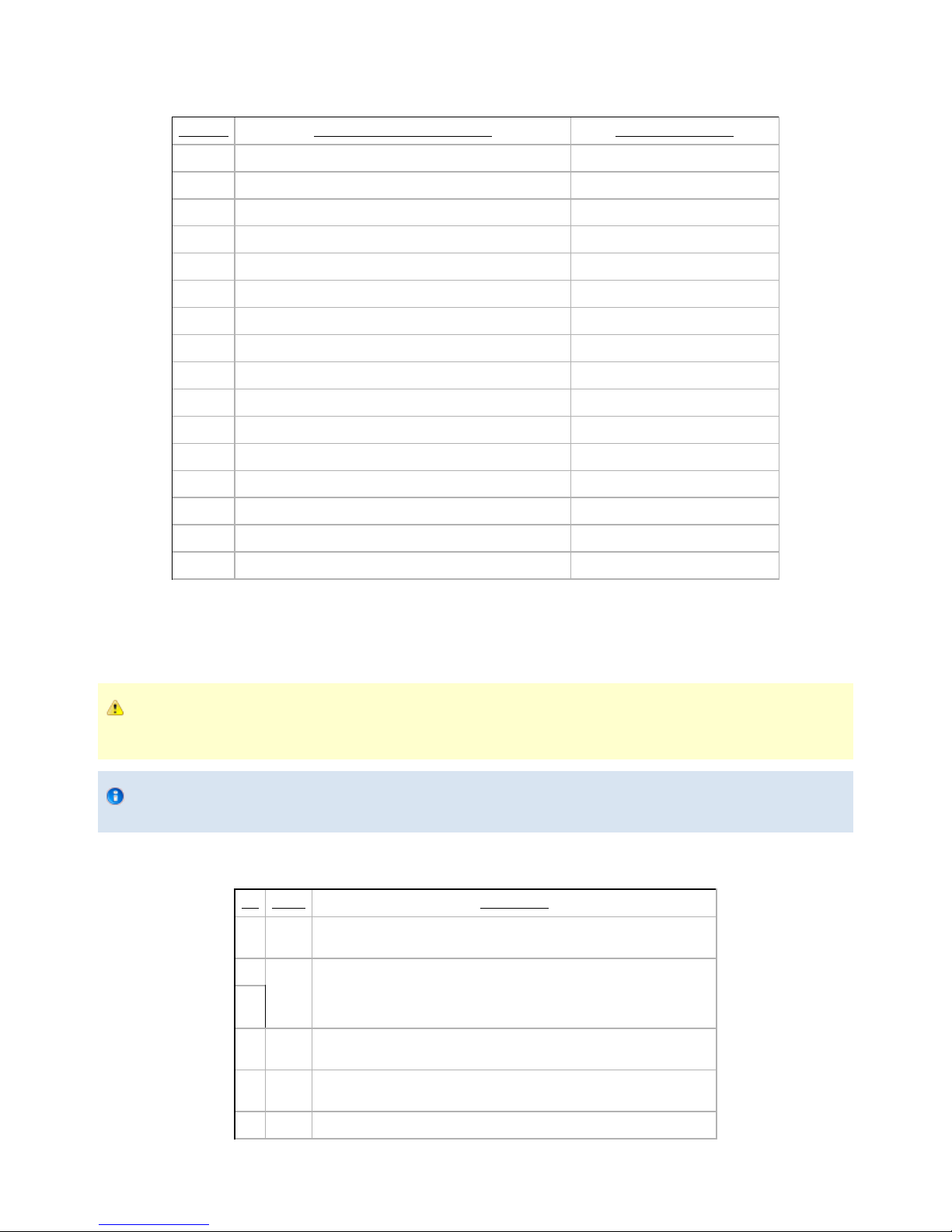

4.4.1 Supply LED

Color State Information

Blue Off Gripper is not power supplied

Blue On The Gripper is correctly supplied and the control board is running

4.4.2 Communication LED

Color State Information

Green Off No network detected

Green Blinking A network has been detected and no connection has been established

Green On A network has been detected and at least one connection is in the established state

4.4.3 Fault LED

Color State Information

Red Off No fault detected

Red On A minor fault occurred (or the Gripper si booting)

Red Blinking A major fault occurred

Info

A major fault refers to a situation where the Gripper must be reactivated.

Robotiq inc. © 2011 22

Robotiq Adaptative Gripper, S model Instruction Manual

4.5 Gripper register mapping

Caution

This section applies to firmware 3.0 (grippers delivered after November 2011). For prior versions please see the documentation

archives.

Info

Register format is Little Endian (Intel format), namely from LSB (Less Significant Bit) to MSB (Most Significant Bit).

Version 3 of the Adaptive Gripper S model firmware provides new functionalities such as the direct position control of the fingers via "go to"

commands. There is also additional advanced options such as the individual control of the fingers and scissor, the glove mode (when using the

Robotiq Glove) and the automatic centering of the fingers.

A Simplified Control Mode is available for users which do not intend to use the advanced option otherwise a register mapping for the Advanced

Control Mode containing all the gripper functionalities is also provided. From the gripper standpoint, there is no difference between the two

modes. The Simple Control Mode is only intended to ease the usage of the gripper for users who are only interested in the basic functionalities.

Warning

When using the Simplified Control Mode, it is important to fill the unused registers with zeros. Neglecting to do so would result in

the unwanted triggering of control options and could lead to a hazardous behavior of the Gripper.

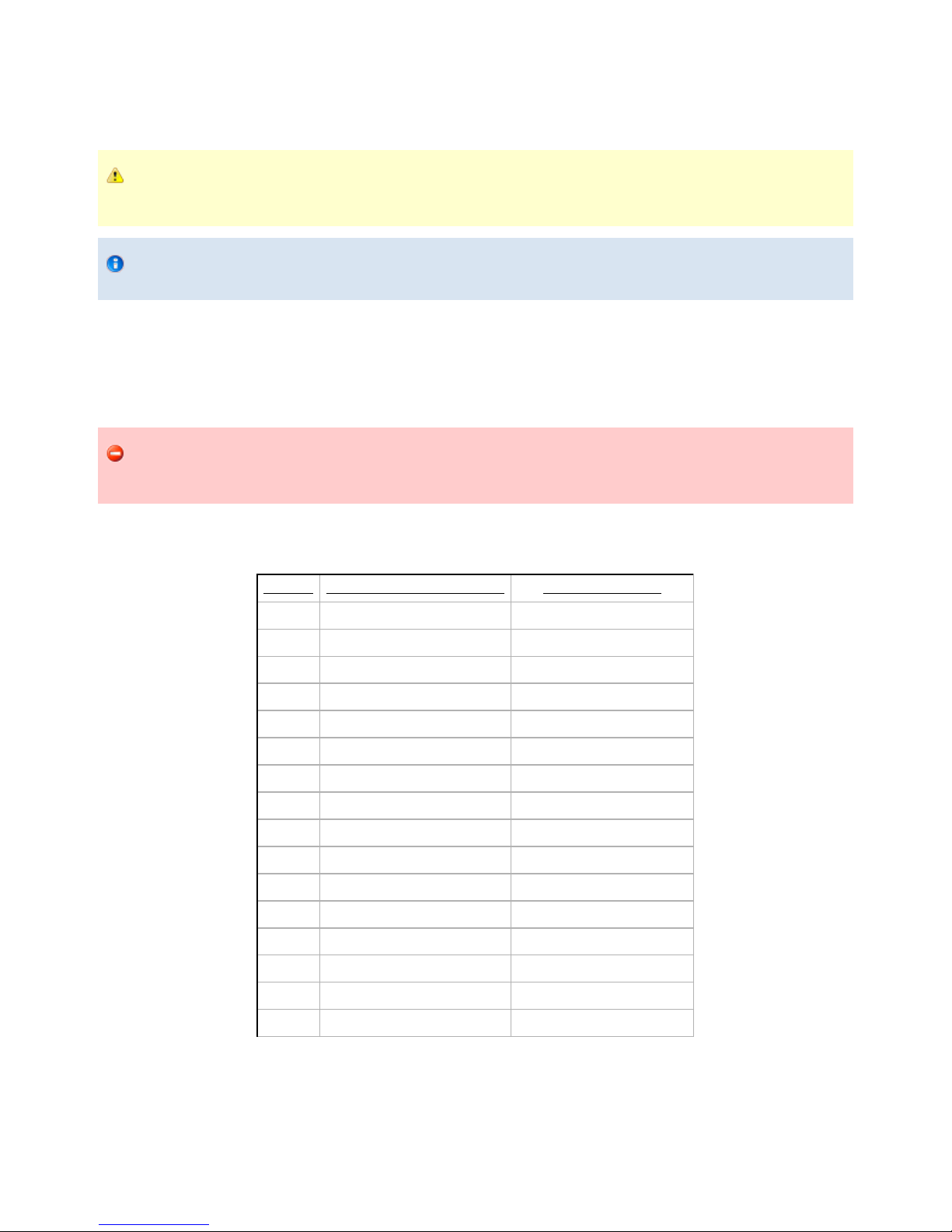

Register mapping for the Simplified Control Mode

Register Robot Output / Functionalities Robot Input / Status

Byte 0 ACTION REQUEST GRIPPER STATUS

Byte 1 00000000 OBJECT DETECTION

Byte 2 00000000 FAULT STATUS

Byte 3 POSITION REQUEST POS. REQUEST ECHO

Byte 4 SPEED FINGER A POSITION

Byte 5 FORCE FINGER A CURRENT

Byte 6 00000000 NOT USED IN SIMPLE MODE

Byte 7 00000000 FINGER B POSITION

Byte 8 00000000 FINGER B CURRENT

Byte 9 00000000 NOT USED IN SIMPLE MODE

Byte 10 00000000 FINGER C POSITION

Byte 11 00000000 FINGER C CURRENT

Byte 12 00000000 NOT USED IN SIMPLE MODE

Byte 13 00000000 SCISSOR POSITION

Byte 14 00000000 SCISSOR CURRENT

Byte 15 RESERVED RESERVED

Robotiq inc. © 2011 23

Robotiq Adaptative Gripper, S model Instruction Manual

Register mapping for the Advanced Control Mode

Register Robot Output / Functionalities Robot Input / Status

Byte 0 ACTION REQUEST GRIPPER STATUS

Byte 1 GRIPPER OPTIONS OBJECT DETECTION

Byte 2 GRIPPER OPTIONS #2 (EMPTY) FAULT STATUS

Byte 3 POSITION REQUEST (FINGER A IN INDIVIDUAL MODE) POS. REQUEST ECHO

Byte 4 SPEED (FINGER A IN INDIVIDUAL MODE) FINGER A POSITION

Byte 5 FORCE (FINGER A IN INDIVIDUAL MODE) FINGER A CURRENT

Byte 6 FINGER B POSITION REQUEST FINGER B POS. REQUEST ECHO

Byte 7 FINGER B SPEED FINGER B POSITION

Byte 8 FINGER B FORCE FINGER B CURRENT

Byte 9 FINGER C POSITION REQUEST FINGER C POS. REQUEST ECHO

Byte 10 FINGER C SPEED FINGER C POSITION

Byte 11 FINGER C FORCE FINGER C CURRENT

Byte 12 SCISSOR POSITION REQUEST SCISSOR POS. REQUEST ECHO

Byte 13 SCISSOR SPEED SCISSOR POSITION

Byte 14 SCISSOR FORCE SCISSOR CURRENT

Byte 15 RESERVED RESERVED

4.6 Robot output registers & functionalities

Caution

This section applies to firmware 3.0 (grippers delivered after November 2011). For prior versions please see the documentation

archives.

Info

Register format is Little Endian (Intel format), namely from LSB (Less Significant Bit) to MSB (Most Significant Bit).

Register: ACTION REQUEST

Address: Byte 0

Bit Name Description

0 rACT

0 – Reset Gripper

1 – Activate Gripper (Must stay on after activation routine is completed)

1

rMOD

00 – Go to Basic Mode

10 – Go to Pinch Mode

01 – Go to Wide Mode

11 – Go to Scissor Mode

2

3 rGTO

0 – Stop

1 – Go to Requested Position

4 rATR

0 – Normal

1 – Automatic release

5-7 rRS0 Reserved

Robotiq inc. © 2011 24

Robotiq Adaptative Gripper, S model Instruction Manual

: First action to be made prior to any other actions, bit will initialize the Adaptive Gripper. Clear to reset Gripper and fault status.rACT rACT rACT

Caution

rACT bit must stay on afterwards for any other action to be performed.

: Changes the Gripper . When the Grasping Mode is changed, the Gripper first opens completely to avoid interferencesrMOD Grasping Mode

between the fingers then go to the selected mode. This option is ignored if the bit is set (individual control of the scissor motion option). rICS

: The "Go To" action moves the Gripper fingers to the requested position using the configuration defined by the other registers and the rGTO

bits. The only motions performed without the bit are the activation, the mode change and the automatic release routines. rMOD rGTO

: Automatic Release routine action slowly open the Gripper fingers until all motions axes reach their mechanical limits. After the motion isrATR

completed, the Gripper sends a fault signal and needs to be reinitialized before any other motion is performed. The bit overrides all otherrATR

commands excluding the activation bit ( ).rACT

Caution

The Automatic Release is meant to disengage the Gripper after an emergency stop of the robot. The Automatic Release is not

intended to be used under normal operating conditions.

Register: GRIPPER OPTIONS

Address: Byte 1

Bit Name Description

0 rGLV

0 – Normal

1 – Enable Glove Mode (use only if a glove provided by Robotiq is installed on the Gripper)

1 rAAC

0 – Normal

1 – Enable Automatic Auto-Centering

2 rICF

0 – Normal

1 – Enable Individual Control of Fingers A, B and C

3 rICS

0 – Normal

1 – Enable Individual Control of Scissor. Disable Mode Selection.

4-7 rRS1 Reserved

rGLV: The Glove Mode option must be on when using the Robotiq Glove on the Adaptive Gripper. Using the Robotiq Glove without this option

could result in a hazardous behavior of the Gripper. . This option is not implemented in the beta version of the firmware

: The Automatic Centering option synchronizes the Gripper fingers in order to automatically center the object it seizes. This option requiresrAAC

that fingers B and C have the same position request and velocity. It is not intended to be used in the scissor mode. This option is currently in a

. beta version and might be modified in future versions of the firmware

: In Individual Control of Fingers mode each finger receives its own command (position request, speed and force) unless the Gripper is in therICF

Scissor Grasping Mode and the Independent Control of Scissor ( ) is not activated. Please refer to the (Position Request) registerrICS rPRA

description for information about the reachable positions of the fingers.

Caution

As soon as the bit is set, the fingers will move towards the target defined by the position request bytes. To avoid unwantedrICF

motion of the fingers, it is preferable to define the position requests before setting the bit. It is also possible to clear the rICF

bit, configure the registers according to the desired motion and then set the bit to start the motion.rGTO rGTO

: In Individual Control of Scissor the scissor axis moves independently from the Grasping mode. When this option is selected, the bitsrICS rMOD

(Grasping Mode) are ignored as the scissor axis position is defined by the (Position Request for the Scissor axis) register.rPRS

Robotiq inc. © 2011 25

Robotiq Adaptative Gripper, S model Instruction Manual

Caution

To avoid geometrical interference between fingers B and C, the reachable positions for the scissor axis is reduced if the

Individual Control of Scissor option is selected. Please refer to the (Position Request) register description for morerPRA

information about the reachable positions of the scissor axis.

Register: GRIPPER OPTIONS 2

Address: Byte 2

Bit Name Description

0 – 7 rRS2 Reserved

Register: POSITION REQUEST (FINGER A IN INDIVIDUAL MODE)

Address: Byte 3

Bit Name Description

0 – 7 rPRA

Set Position Request for the Gripper (finger A in individual mode).

0x00 (Minimum position) to 0xFF (Maximum position)

This register is used to set the Adaptive Gripper fingers target position (or finger A only if bit is set). The positions 0x00 and 0xFF correspondrICF

respectively to the fully opened and fully closed mechanical stops. Figure 4.6.1 represents the reachable workspace of the fingers and scissor

axis, values shown are valid only if the Glove Mode option is not selected and are shown as a reference only. Note that the finger position on the

figure represents the maximum value for the three fingers. Also, note that the fully opened and fully closed software limits are not shown on the

figure for simplicity.

Caution

In order to protect the Gripper from geometric interferences, several software limits are implemented and therefore some

positions are not reachable. When a finger reaches the software limit, the Gripper status will indicate that the requested position

was reached. This is because the requested position is internally replaced by the software limit.

Figure 4.6.1 Reachable workspace of the fingers and scissor axis.

Robotiq inc. © 2011 26

Robotiq Adaptative Gripper, S model Instruction Manual

Register: SPEED (FINGER A IN INDIVIDUAL MODE)

Address: Byte 4

Bit Name Description

0 – 7 rSPA

Set Grasping Speed of the Gripper (finger A in individual mode).

0x00 (Minimum velocity) to 0xFF (Maximum velocity)

This register is used to setup the Gripper closing or opening speed (or finger A only if bit is set) in real time, however, setting a speed will notrICF

initiate a motion.

Info

0x00 speed does not mean absolute zero speed. It is the minimum speed of the Gripper.

Register: FORCE (FINGER A IN INDIVIDUAL MODE)

Address: Byte 5

Bit Name Description

0 – 7 rFRA

Set Gripping Force

0x00 (Minimum force) to 0xFF (Maximum force)

The the force setting defines the final grasping force of the Adaptive Gripper (or finger A only if bit is set). The force will fix maximum currentrICF

sent to the motors while in motion. For each finger, if the current limit is exceeded, the finger stops and triggers an object detection notification.

Info

Force setting is overridden for a small distance when the motion is initiated. Also, note that 0x00 force does not mean zero

force; it is the minimum force that the Gripper can apply.

Register: FINGER B POSITION REQUEST

Address: Byte 6

Bit Name Description

0 – 7 rPRB

Set Position Request for finger B.

0x00 (Minimum position) to 0xFF (Maximum position)

This register is used to set the finger B target position. It is only considered if the Individual Control of Finger option is selected (bit is set).rICF

Please refer to (position request) register for more information.rPRA

Register: FINGER B SPEED

Address: Byte 7

Bit Name Description

0 – 7 rSPB

Set Grasping Speed for finger B.

0x00 (Minimum velocity) to 0xFF (Maximum velocity)

This register is used to set finger B speed. It is only considered if the Individual Control of Finger option is selected (bit is set). Please refer torICF

(speed) register for more information.rSPA

Register: FINGER B FORCE

Address: Byte 8

Bit Name Description

0 – 7 rFRB

Set Gripping Force for finger B.

0x00 (Minimum force) to 0xFF (Maximum force)

Robotiq inc. © 2011 27

Robotiq Adaptative Gripper, S model Instruction Manual

This register is used to set finger B force. It is only considered if the Individual Control of Finger option is selected (bit is set). Please refer to rICF

(force) register for more information.rFRA

Register: FINGER C POSITION REQUEST

Address: Byte 9

Bit Name Description

0 – 7 rPRC

Set Position Request for finger C.

0x00 (Minimum position) to 0xFF (Maximum position)

This register is used to set the finger C target position. It is only considered if the Individual Control of Finger option is selected (bit is set).rICF

Please refer to (position request) register for more information.rPRA

Register: FINGER C SPEED

Address: Byte 10

Bit Name Description

0 – 7 rSPC

Set Grasping Speed for finger C.

0x00 (Minimum velocity) to 0xFF (Maximum velocity)

This register is used to set finger C speed. It is only considered if the Individual Control of Finger option is selected (bit is set). Please refer torICF

(speed) register for more information.rSPA

Register: FINGER C FORCE

Address: Byte 11

Bit Name Description

0 – 7 rFRC

Set Gripping Force

0x00 (Minimum force) to 0xFF (Maximum force)

This register is used to set finger C force. It is only considered if the Individual Control of Finger option is selected (bit is set). Please refer to rICF

(force) register for more information.rFRA

Register: SCISSOR POSITION REQUEST

Address: Byte 12

Bit Name Description

0 – 7 rPRS

Set Position Request for the scissor axis.

0x00 (Minimum position) to 0xFF (Maximum position)

This register is used to set the scissor axis target position. It is only considered if the Individual Control of Scissor option is selected (bit isrICS

set). Please refer to (position request) register for more information.rPRA

Register: SCISSOR SPEED

Address: Byte 13

Bit Name Description

0 – 7 rSPS

Set Grasping Speed for the scissor axis.

0x00 (Minimum velocity) to 0xFF (Maximum velocity)

This register is used to set the scissor axis speed. It is only considered if the Individual Control of Scissor option is selected (bit is set).rICS

Please refer to (speed) register for more information.rSPA

Register: SCISSOR FORCE

Address: Byte 14

Bit Name Description

0 – 7 rFRS

Set Gripping Force for the scissor axis

0x00 (Minimum force) to 0xFF (Maximum force)

Robotiq inc. © 2011 28

Robotiq Adaptative Gripper, S model Instruction Manual

This register is used to set the scissor axis force. It is only considered if the Individual Control of Scissor option is selected (bit is set). PleaserICS

refer to (force) register for more information. rFRA

4.7 Robot input registers & status

Caution

This section applies to firmware 3.0 (grippers delivered after November 2011). For prior versions please see the documentation

archives.

Info

Register format is Little Endian (Intel format), namely from LSB (Less Significant Bit) to MSB (Most Significant Bit).

Register: GRIPPER STATUS

Address: Byte 0

Bit Name Description

0 gACT

Echo of the rACT bit (Activation bit):

0 – Gripper reset

1 – Gripper activation

1

gMOD

Echo of the rMOD bits (Grasping Mode request)

00 – Basic Mode

10 – Pinch Mode

01 – Wide Mode

11 – Scissor Mode

2

3 gGTO

0 – Stopped (or performing activation/grasping mode change/automatic release)

1 – Go to Position Request

4

gIMC

00 – Gripper is in reset (or automatic release) state. see Fault Status if Gripper is activated.

10 – Activation in progress.

01 – Mode change in progress.

11 – Activation an mode change are completed.

5

6

gSTA

00 – Gripper is in motion towards requested position (only meaningful if gGTO = 1)

01 – Gripper is stopped. One or two fingers stopped before requested position

10 – Gripper is stopped. All fingers stopped before requested position

11 --Gripper is stopped. All fingers reached requested position

7

Register: OBJECT STATUS

Address: Byte 1

Robotiq inc. © 2011 29

Robotiq Adaptative Gripper, S model Instruction Manual

Bit Name Description

0

gDTA

00 – Finger A is in motion (only meaningful if gGTO = 1)

10 – Finger A has stopped due to a contact while opening

01 – Finger A has stopped due to a contact while closing

11 – Finger A is at requested position

1

2

gDTB

00 – Finger B is in motion (only meaningful if gGTO = 1)

10 – Finger B has stopped due to a contact while opening

01 – Finger B has stopped due to a contact while closing

11 – Finger B is at requested position

3

4

gDTC

00 – Finger C is in motion (only meaningful if gGTO = 1)

10 – Finger C has stopped due to a contact while opening

01 – Finger C has stopped due to a contact while closing

11 – Finger C is at requested position

5

6

gDTS

00 – Scissor is in motion (only meaningful if gGTO = 1)

01 – Scissor has stopped due to a contact while opening

10 – Scissor has stopped due to a contact while closing

11 – Scissor is at requested position.

7

When a contact is detected, the corresponding axis will stop until one of these conditions is met: a new position request is commanded in the

opposite direction, the requested force level is increased or the bit is cleared and set again. rGTO

Warning

Resetting the contact detection repeatedly at high frequency using the bit may cause a major failure of the Gripper. ThisrGTO

is not considered a normal usage of the Gripper and it is not recommended by Robotiq.

Caution

The object detection is precise only to the order of a few mm. In some circumstances object detection may not detect an object

even if it is successfully grasped. For example, picking up a thin object in a fingertip grip may be successful without object

detection occurring. For such reasons, use this feature with caution. In such applications the "Gripper is stopped" status of

register is sufficient to proceed to the next step of the routine.gSTA

Register: FAULT STATUS

Address: Byte 2

Bit Name Description

0 – 3 gFLT

0x00 – No Fault

Priority Fault

0x05 – Action delayed, activation (reactivation) must be completed prior to action

0x06 – Action delayed, mode change must be completed prior to action

0x07 – The activation bit must be set prior to action

Minor Fault (red LED continuous)

0x09 – The communication chip is not ready (may be booting)

0x0A – Changing mode fault, interferences detected on Scissor (for less than 20 sec)

0x0B – Automatic release in progress

Major Fault (red LED blinking) – Reset is required

0x0D – Activation fault, verify that no interference or other error occured

0x0E – Changing mode fault, interferences detected on Scissor (for more than 20 sec)

0x0F – Automatic release completed. Reset and activation is required.

4 – 7 gRS1 Reserved (zeros)

Register: POSITION REQUEST ECHO (FINGER A IN INDIVIDUAL MODE)

Address: Byte 3

Robotiq inc. © 2011 30

Robotiq Adaptative Gripper, S model Instruction Manual

Bit Name Description

0 – 7 gPRA

Echo of the requested position for the Gripper (or finger A in individual mode)

0x00 (Full Opening) to 0xFF (Full Closing)

Register: FINGER A POSITION

Address: Byte 4

Bit Name Description

0 – 7 gPOA

Position of Finger A

0x00 (Fully opened) to 0xFF (Fully closed)

Register: FINGER A CURRENT

Address: Byte 5

Bit Name Description

0 – 7 gCUA

Current of Finger A

0.1 * Current (in mA)

Register: FINGER B POSITION REQUEST ECHO

Address: Byte 6

Bit Name Description

0 – 7 gPRB

Echo of the requested position for finger B

0x00 (Full Opening) to 0xFF (Full Closing)

Register: FINGER B POSITION

Address: Byte 7

Bit Name Description

0 – 7 gPOB

Position of Finger B

0x00 (Fully opened) to 0xFF (Fully closed)

Register: FINGER B CURRENT

Address: Byte 8

Bit Name Description

0 – 7 gCUB

Current of Finger B

0.1 * Current (in mA)

Register: FINGER C POSITION REQUEST ECHO

Address: Byte 9

Bit Name Description

0 – 7 gPRC

Echo of the requested position for finger C

0x00 (Full Opening) to 0xFF (Full Closing)

Register: FINGER C POSITION

Robotiq inc. © 2011 31

Robotiq Adaptative Gripper, S model Instruction Manual

Address: Byte 10

Bit Name Description

0 – 7 gPOC

Position of Finger C

0x00 (Fully opened) to 0xFF (Fully closed)

Register: FINGER C CURRENT

Address: Byte 11

Bit Name Description

0 – 7 gCUC

Current of Finger C

0.1 * Current (in mA)

Register: SCISSOR POSITION REQUEST ECHO

Address: Byte 12

Bit Name Description

0 – 7 gPRS

Echo of the requested position for the scissor axis

0x00 (Full Opening) to 0xFF (Full Closing)

Register: SCISSOR POSITION

Address: Byte 13

Bit Name Description

0 – 7 gPOS

Position of the scissor axis

0x00 (Fully opened) to 0xFF (Fully closed)

Register: SCISSOR CURRENT

Address: Byte 14

Bit Name Description

0 – 7 gCUS

Current for the scissor axis

0.1 * Current (in mA)

Robotiq inc. © 2011 32

Robotiq Adaptative Gripper, S model Instruction Manual

4.8 Example

Figure 4.8.1 : Example of Adaptive Gripper S model registers.

4.9 MODBUS RTU communication protocol

The Robotiq Adaptive Gripper S model can be controlled over RS232 using the Modbus RTU protocol. This section is intended to provide

guidelines for setting up a Modbus scanner that will adequately communicate with the gripper.

For a general introduction to Modbus RTU and for details regarding the CRC algorithm, the reader is invited to read the Modbus over serial line

specification and implementation guide available . http://www.modbus.org/docs/Modbus_over_serial_line_V1.pdf

For debug purposes, the reader is also invited to download one of many free Modbus scanners such as the from CAS Modbus Scanner Chipkin

available .Automation Systems http://www.chipkin.com/cas-modbus-scanner

Robotiq inc. © 2011 33

Robotiq Adaptative Gripper, S model Instruction Manual

4.9.1 Connection setup

The following table describes the connection requirement for controlling the Robotiq Adaptive Gripper S model using the Modbus RTU protocol.

Physical Interface RS232

Baud Rate 115,200 bps

Data Bits 8

Stop Bit 1

Parity None

Number Notation Hexadecimal

Supported Functions

Read Holding Registers (FC03)

Preset Single Register (FC06)

Preset Multiple Registers (FC16)

Exception Responses Not supported

Slave ID 0x0009 (9)

Robot Output / Gripper Input First Register 0x03E8 (1000)

Robot Input / Gripper Output First Register 0x07D0 (2000)

Each register (word - 16 bits) of the Modbus RTU protocol is composed of registers (bytes – 8 bits) from the Robotiq Adaptive Gripper S. The2

first Gripper output Modbus register (0x07D0) is composed from the first Robotiq Adaptive Gripper S registers (byte 0 and byte 1).2

4.9.2 Read holding registers (FC03)

Function code 03 (FC03) is used for reading the status of the Gripper (robot input). Examples of such data are Gripper status, object status, finger

position, etc.

Ex: This message asks for register 0x07D0 (2000) and register 0x07D1 (2001) which contains Gripper Status, Object Detection, Fault Status and

Position Request Echo.

Request is:

09 03 07 D0 00 02 C5 CE

where

09 SlaveID

03 Function Code 03 (Read Holding Registers)

07D0 Address of the first requested register

0002 Number of registers requested (2)

C5CE Cyclic Redundancy Check (CRC)

Response is:

09 03 04 E0 00 00 00 44 33

where

Robotiq inc. © 2011 34

Robotiq Adaptative Gripper, S model Instruction Manual

09 SlaveID

03 Function Code 03 (Read Holding Registers)

04 Number of data bytes to follow (2 registers x 2 bytes/register = 4 bytes)

E000 Content of register 07D0

0000 Content of register 07D1

4433 Cyclic Redundancy Check (CRC)

Note

The Adaptive Gripper register values are updated at a 200Hz frequency. It is therefore recommanded to send FC03 commands

with a minimum delay of 5ms between them.

4.9.3 Preset single register (FC06)

Function code 06 (FC06) is used to activate functionalities of the Gripper (robot output). Examples of such data are action request, velocity, force,

etc.

Ex: This message requests to initialize the Gripper by setting register 0x03E8 (1000), which contains Action Request and Gripper Options, to

0x0100.

Request is:

09 06 03 E8 01 00 09 62

where

09 SlaveID

06 Function Code 06 (Preset Single Register)

03E8 Address of the register

0100 Value to write

0962 Cyclic Redundancy Check (CRC)

Response is an echo:

09 06 03 E8 01 00 09 62

where

09 SlaveID

06 Function Code 06 (Preset Single Register)

03E8 Address of the register

0100 Value written

0962 Cyclic Redundancy Check (CRC)

4.9.4 Preset multiple registers (FC16)

Function code 06 (FC16) is used to activate functionalities of the Gripper (robot output). Examples of such data are action request, speed, force,

etc.

Ex: This message requests to set position request, speed and force of the Gripper by setting register 0x03E9 (1001) and 0x03EA.

Request is:

09 10 03 E9 00 02 04 60 E6 3C C8 EC 7C

Robotiq inc. © 2011 35

Robotiq Adaptative Gripper, S model Instruction Manual

where

09 SlaveID

10 Function Code 16 (Preset Multiple Registers)

03E9 Address of the first register

0002 Number of registers to write

04 Number of data bytes to follow (2 registers x 2 bytes/register = 4 bytes)

00E6 Value to write to register 0x03E9

3CC8 Value to write to register 0x03EA

EC7C Cyclic Redundancy Check (CRC)

Response is:

09 10 03 E9 00 02 91 30

where

09 SlaveID

10 Function Code 16 (Preset Multiple Registers)

03E9 Address of the first register

0002 Number of written

9130 Cyclic Redundancy Check (CRC)

4.10 MODBUS TCP communication protocol

The Robotiq Adaptive Gripper S model can be controlled using the Modbus TCP protocol. This section is intended to provide guidelines for setting

up a Modbus TCP communication to adequately send commands and read inputs from the gripper.

For a general introduction to Modbus TCP and to understand its differences from Modbus RTU, the reader is invited to read the information

provided on the following website:

http://www.simplymodbus.ca/TCP.htm

4.10.1 Connection Setup

The following table describes the connection requirement for controlling the Robotiq Adaptive Gripper S using the Modbus TCP protocol.

Required protocol TCP/IP

Port 502

Gripper IP address Configurable (most grippers are shipped with the 192.168.1.11 address)

Supported Functions

Read Input Registers (FC04)

Preset Multiple Registers (FC16)

UnitID 0x0002 (2)

Robot Output / Gripper Input First Register 0x0000 (0000)

Robot Input / Gripper Output First Register 0x0000 (0000)

Each register (word - 16 bits) of the Modbus TCP protocol is composed of registers (bytes – 8 bits) from the Robotiq Adaptive Gripper. The first2

Gripper output Modbus register (0x0000) is composed from the first Robotiq Adaptive Gripper registers (byte 0 and byte 1).2

Robotiq inc. © 2011 36

Robotiq Adaptative Gripper, S model Instruction Manual

4.10.2 Read Input Registers (FC04)

Function code 04 (FC04) is used for reading the status of the Gripper (robot input). Examples of such data are Gripper status, object status, finger

position, etc.

Ex: This message asks for registers 0x0000 (0000) to 0x0006 (0006) which contain all the robot input statuses except for the scissor axis.

Request is:

01 00 00 00 00 06 02 04 00 00 00 06

where

01 00 Transaction identifier

00 00 Protocol identifier

00 06 Length

02 UnitID

04 Function 04 (Read input registers)

00 00 Address of the first register

00 06 Word count

Response is:

01 00 00 00 00 0f 02 04 0c e9 00 00 00 06 06 06 8a 00 00 00 00

where

01 00 Transaction identifier

00 00 Protocol identifier

00 0f Length

02 UnitID

04 Function 04 (Read input registers)

0c The number of data bytes to follow

e9 00 00 00 06 06 06 8a 00 00 00 00 Data

Note

The Adaptive Gripper register values are updated at a 200Hz frequency. It is therefore recommanded to send FC04 commands

with a minimum delay of 5ms between them.

4.10.3 Preset Multiple Registers (FC16)

Function code 06 (FC16) is used to activate functionalities of the Gripper (robot output). Examples of such data are action request, position

request, speed, force, etc.

Ex: This message requests to set several options of the Gripper by setting registers from 0x0000 (0000) to 0x0003.

Request is:

01 00 00 00 00 0d 02 10 00 00 00 03 06 09 00 64 64 00 ff

Robotiq inc. © 2011 37

Robotiq Adaptative Gripper, S model Instruction Manual

where

01 00 Transaction identifier

00 00 Protocol identifier

00 0d Length

02 UnitID

10 Function 16 (Preset multiple registers)

00 00 Address of the first register

00 03 The number of registers to write

06 The number of data bytes to follow

09 00 00 64 00 ff Data

Response is:

01 00 00 00 00 06 02 10 00 00 00 03

where

01 00 Transaction identifier

00 00 Protocol identifier

00 06 Length

02 UnitID

10 Function 16 (Preset multiple registers)

00 00 Address of the first register

00 03 The number of registers written

Robotiq inc. © 2011 38

Robotiq Adaptative Gripper, S model Instruction Manual

5. User Interface

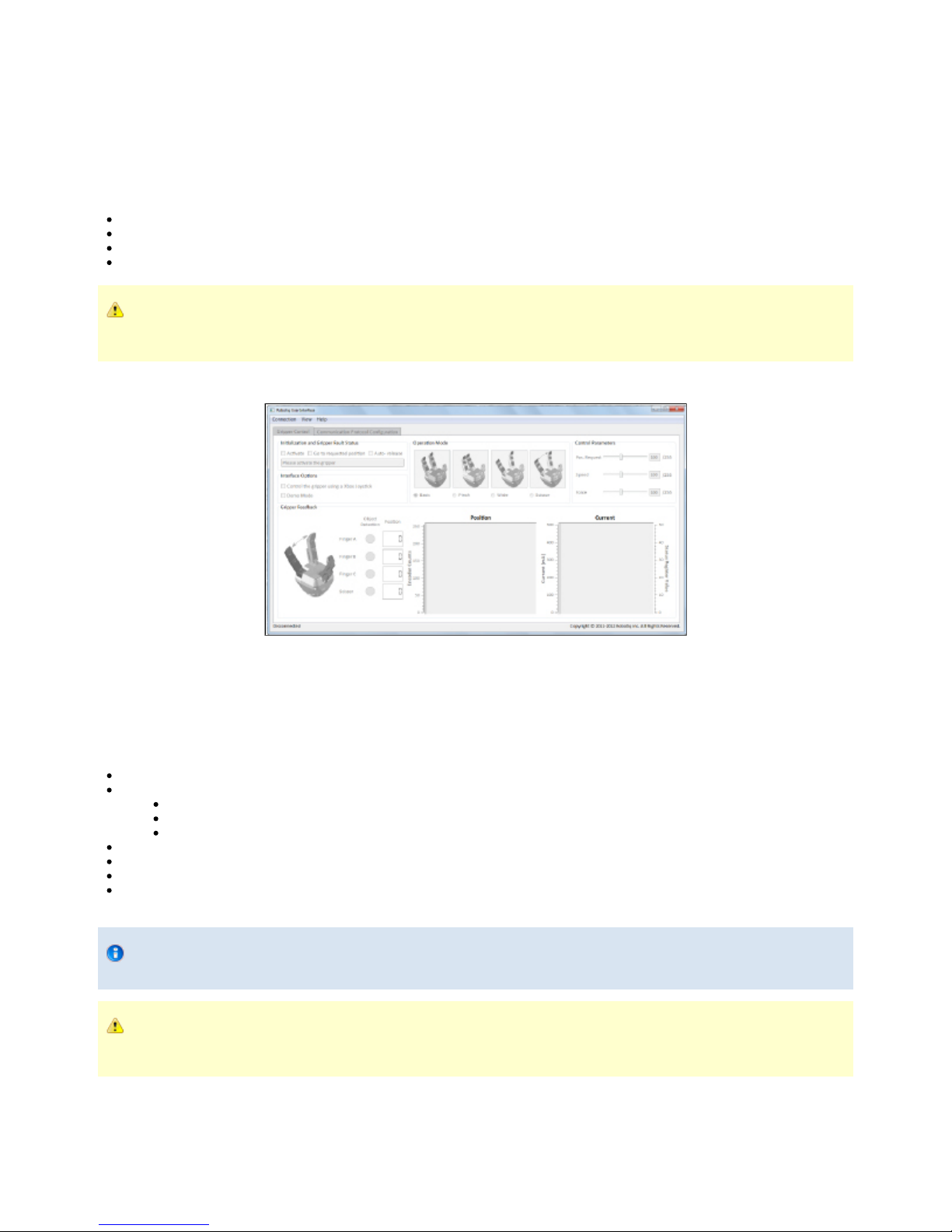

The following section describes the Robotiq User Interface software provided with the Adaptive Gripper S-Model.

The User Interface is designed to allow Adaptive Gripper S:

Testing.

Demo mode.

Xbox Remote control mode.

Communication options configuration.

Note

Robotiq User Interface Software is designed for the testing and demo control of the Adaptive Gripper S-Model. It is not a

production control software.

visit to get the latest installer of the Robotiq User Interface for S-Modelhttp://support.robotiq.com

Figure 5.1 Main screen of the Robotiq User Interface.

5.1 Requirements

To use this version of the Robotiq User Interface, you will need:

The Adaptive Gripper S model and its power cable (see section)Wiring

A computer with

Windows XP or newer

At least 50MB of main memory

A USB port and/or an Ethernet port

A 24V power source for the Gripper

A small Phillips screwdriver

A USB 2.0 Micro-B or a USB 2.0 Micro-A cable. (Connection via the USB use Modbus RTU)

Optional: An Ethernet communication connector for Modbus TCP provided by Robotiq. (Connection via Ethernet uses Modbus TCP), an

Xbox controller

Info

The USB cable that is needed for the configuration of the communication protocol is provided with the Adaptive Gripper.

Note

Ethernet Option: You will only have the Ethernet communication connector provided with your Gripper if you have the Modbus

TCP option.

5.2 Installation

Robotiq inc. © 2011 39

Robotiq Adaptative Gripper, S model Instruction Manual

1.

2.

3.

4.

1.

2.

3.

4.

To install the Robotiq User Interface software:

Launch the Robotiq User Interface installer from "Robotiq User Interface Setup.exe" provided by Robotiq.

Choose the installer language and click "Ok".

Follow the setup steps until you can click "Install".

Tip

You can leave the settings on default or choose an installation directory of your own.

After installation is completed you can launch the Robotiq User Interface, if you do not have the required drivers for the USB connection

of the Gripper, please select the box shown in figure 5.2.1.

Warning

To use the Modbus RTU communication via the USB port, you need to select the driver installation shown in figure

5.2.1

Figure 5.2.1 Completing the installation of Robotiq User Interface

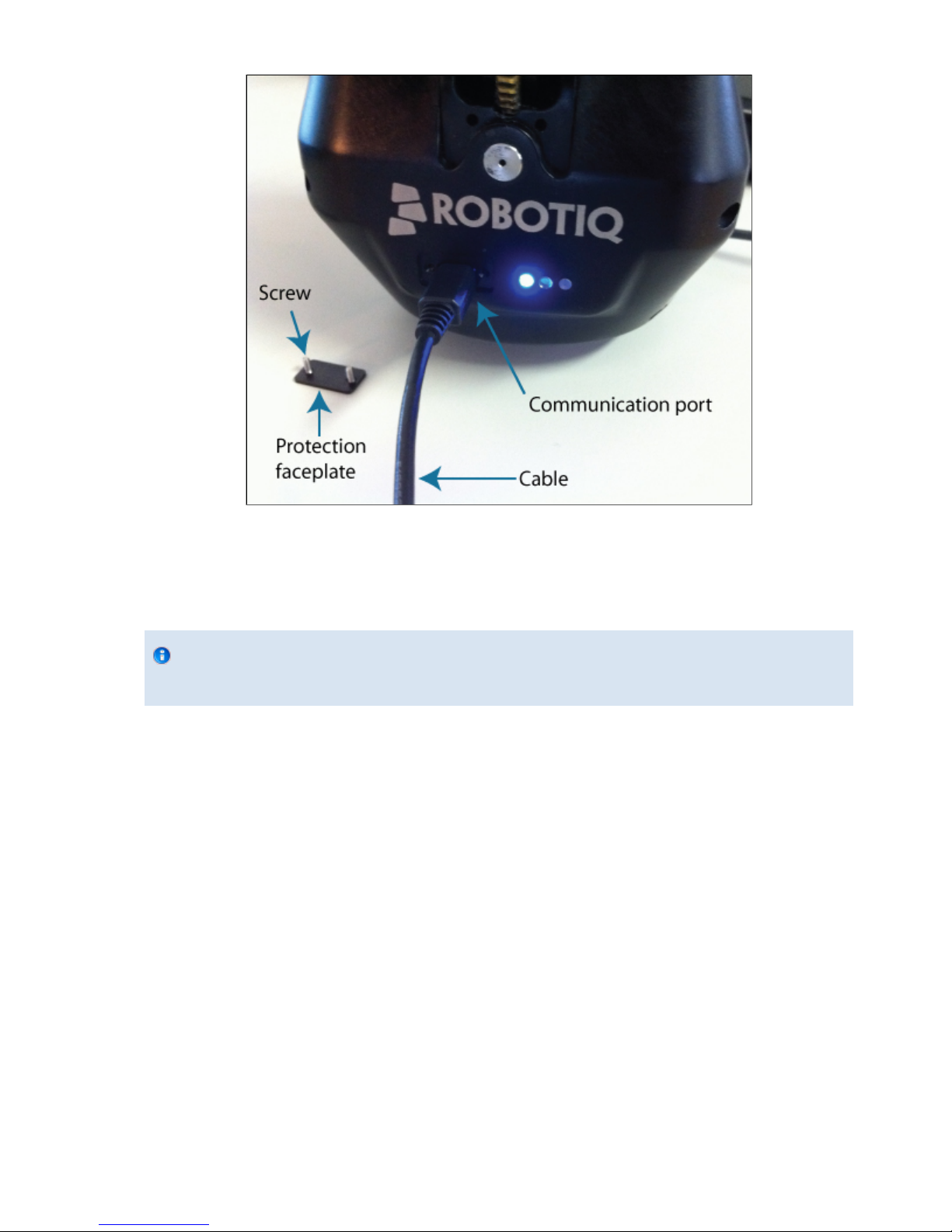

In order to connect the Adaptive Gripper via USB for Modbus RTU:

Unplug the Gripper from the power source by disconnecting the power cable from the Gripper.

Remove the USB port panel by unscrewing the two screws (shown in Figure 5.2.2). A Phillips screwdriver is needed.

Connect the Gripper to your computer with a USB 2.0 Micro-B or a USB 2.0 Micro-A cable.

Info

The USB cable needed is provided with the Adaptive Gripper.

Reconnect the power connector to the power receptacle and power up the Gripper with a 24V power source (not included) as described

in the section . Wiring

Robotiq inc. © 2011 40

Robotiq Adaptative Gripper, S model Instruction Manual

1.

2.

3.

1.

2.

3.

4.

5.

Figure 5.2.2: Unscrewing the USB port panel and connecting the USB 2.0 Micro cable.

To connect the Adaptive Gripper via Ethernet port for Modbus TCP or Modbus RTU:

Unplug the Gripper from the power source by disconnecting the power cable from the Gripper.

Connect the Gripper to your computer with the Ethernet communication connector.

Info

The Ethernet or Serial cable needed is provided with the Adaptive Gripper if the Gripper has the Modbus TCP or

Modbus RTU communication option.

Reconnect the power connector to the power receptacle and power up the Gripper with a 24V power source (not included) as described

in the section.Wiring

See the following sections for a description of the User Interface and its usage.

If you are connected through the USB port and the configuration is finished, follow these steps to acess the normal usage of the Gripper:

Disconnect the Gripper with the button found in the User Interface menu or simply quit the program.Disconnect

Unplug the Gripper from the power source by disconnecting the power cable from the Gripper.

Unplug the Gripper from your PC by removing the USB cable.

Replace the USB port panel by screwing back the two screws (shown in figure 5.2.2). A phillips screwdriver is needed.

Reconnect the power and communication cables to the Gripper as described in the section. Wiring

5.3 UI Description

When you first start the Robotiq User Interface you need to set the connection mode you will use (see Figure 5.3.1). Choose between Modbus

RTU or Modbus TCP according to your connection options. If you do not know what connection you will be using simply close the pop-up window

(you can connect later).

Robotiq inc. © 2011 41

Robotiq Adaptative Gripper, S model Instruction Manual

Figure 5.3.1 Connection options available on start-up of the Robotiq User Interface.

Once you choose the connection mode, the first tab becomes activated (see Figure 5.3.2).

The first tab is the Gripper Control tab (detailed in ), it can be split into the following:section 5.5

Initialization and Gripper Fault Status

Interface Options

Operation Mode

Control Parameters

Gripper Feedback

Menus: Connection, View and Help

Figure 5.3.2 Gripper Control tab description.

The Communication Protocol Configuration tab (detailed in ) will be split into :section 5.6

Device Identity

Protocol

Data

Robotiq inc. © 2011 42

Robotiq Adaptative Gripper, S model Instruction Manual

Figure 5.3.3 Communication Protocol Control configuration tab (shown with Ethernet/IP)

5.4 Connection

If the connection protocol was properly chosen using the pop-up window, the connection will be automatically established unless the status label

(lower left part of the main window) displays "Connection failed".

If a connection has not been established yet, you can manually connect to the Gripper via the connection menu.

The connection menu allows you to :

Connect via Modbus RTU

Connect via Modbus TCP

Disconnect

Note that you must choose the right connection option (see section 5.2) for your Gripper.

5.4.1 Modbus RTU

A connection via Modbus RTU can be established with all Robotiq Adaptive Grippers S models via the USB port panel or via the communication

connector for Grippers with Modbus RTU communication option.

To establish a connection simply select " " from the connection menu.Connect using modbus RTU

The Robotiq User Interface is programmed to automatically detect the port being used.

5.4.2 Modbus TCP

A connection via Modbus TCP can only be established via the communication connector for Grippers with Modbus TCP communication option.

To establish the connection simply select from the connection menu.Connect using modbus TCP

The Robotiq User Interface is programmed to automatically detect the Gripper address comprised in the range 192.168.1.11 to

192.168.1.13.

Robotiq inc. © 2011 43

Robotiq Adaptative Gripper, S model Instruction Manual

The Modbus TCP does not allow Communication Protocol Configuration. A connection using the Modbus RTU protocol is

required to perform the reconfiguration of the communication protocol.

5.5 Control of the Adaptive Gripper

This section guides you through the control of the Adaptive Gripper S model via the Gripper Control tab.

5.5.1 Initialization & Gripper Status

Activate

Once a connection to the Gripper has been established (see ), the Adaptive Gripper needs to be activated before being used. Simplysection 5.4

click the "Activate" button in the Initialization and Gripper Fault Status section. The Gripper will start its initialization procedure and once

completed the Gripper status text box located under the "Activate" button will display "No Fault".

Warning

Do not interfere with the Gripper during the initialization process.

After the initialization process is completed the Gripper is ready to be used.

Note

The Activate button must stay checked while using the Gripper.

Go to requested position

Commands the Adaptive Gripper to go to the selected "Position Request" slider in the Control Parameters section

Auto-release

Commands the Adaptive Gripper to slowly open, overrides all previous commands. After Auto-release is completed the Gripper must be

reactivated, the "Activate" button must be unchecked and rechecked.

Caution

Auto-release is only meant for emergency procedures, use the "Go to requested position" command for normal use.

5.5.2 Interface Options

"Interface Options" allows you to choose between two options:

Xbox Joystick control allows control of the Gripper using a remote Xbox controller (see Figure 5.5.2.1 for a summary of the available

controls).

Demo Mode command the Gripper to cycle through its operation modes with pauses after every move.

To disable any of the options simply uncheck the corresponding box.

Robotiq inc. © 2011 44

Robotiq Adaptative Gripper, S model Instruction Manual

Figure 5.5.2.1 Xbox Controls for the Adaptive Gripper S model

5.5.3 Operation Mode

You can select the operation mode of your Gripper in the "Operation Mode" section of the Robotiq User Interface. Simply check the corresponding

radio button or click on the corresponding picture to activate any mode.

For a description of the operation modes see the general presentation in section 1.

5.5.4 Control Parameters

The "Control Parameters" section of the UI can customize all the parameters for the Gripper:

Pos. Request slider sets the reach position of the Gripper when the "Go to requested position" button of the Initialization and Gripper

Fault Status sections are filled with a numeric value. The value can be set anywhere between 0 (fully open) and 255 (fully close).

Hint

You can fix the desired position with the slider or the numeric values.

Force slider will control the grasping force limit of the Gripper. The value can be set anywhere between 0 and 255 with 255 being the

maximum strength.

Speed slider will control the closing or opening speed of the Gripper. The value can be set anywhere between 0 and 255 with 255 being

the maximum speed.

Robotiq inc. © 2011 45

Robotiq Adaptative Gripper, S model Instruction Manual

Figure 5.5.4.1 Changing the control parameters of the Gripper

5.5.5 Gripper Feedback

The "Gripper Feedback" section provides you with information concerning the current status of the Adaptive Gripper.

Object Detection: If the Gripper detects a contact with an object when closing, the "Object Detection" display turns yellow on the

corresponding finger. Object detections are displayed independently for each of the three fingers and the scissor axis.

Figure 5.5.5.1 Positive object detection is registered when the object detection dot turns yellow.

Position (numeric): The digital display of "Position" shows the position of the associated finger as designated on a scale of 0 to 255 (see

for details).section 4.6

Position (graphic): The visual display of "Position" shows the real-time position of each finger graphically. Each axis has an associated

color.