Page 1

Robotiq FT 300 Force Torque Sensor

Original Notice

© 2018 Robotic Inc.

Instruction Manual

robotiq.com | leanrobotics.org

Page 2

Page 3

1. General Presentation 9

1.1. Main features 10

1.1.1. FT 300 Force Torque Sensor 10

1.1.2. Force Copilot 12

2. Safety 13

2.1. Warning 14

2.2. Intended Use 15

3. Installation 16

3.1. Scope of Delivery 16

3.1.1. Options 16

3.2. Environmental and Operating Conditions 17

3

3.3. Mechanical Connections 17

3.4. Power Supply Specifications 19

3.5. Wiring 20

3.5.1. Wiring with USB to RS485 Converter 21

3.5.2. Wiring with RS232 to RS485 Converter 22

3.6. Installation for Universal Robots 23

3.6.1. Force Copilot URCap Package 24

Installation 24

Calibration Procedure 28

Calibration Procedure with Universal Robots 29

Calibration Procedure for the Visual Demo Software (PC) 33

Payload/CoG 34

ActiveDrive Toolbar Installation 35

Firmware upgrade 36

Uninstalling the URCap Package 37

License Agreement 38

3.6.2. UR Package without URCaps 42

Driver Package Installation 42

Calibration 42

Testing the software package 43

Removing the Package 43

FT300 Force Torque Sensor - Instruction Manual

Page 4

4

3.7. Status LED 44

4. Software 45

4.1. Control with Universal Robots 46

4.1.1. ActiveDrive Toolbar 47

Overview 47

Toolbar collapsed 47

Toolbar expanded 47

ActiveDrive modes expanded 47

Features 48

Error Messages Overview 50

4.1.2. Using the force and torque values 52

4.1.3. Path Recording 54

Overview 55

Features* 57

4.1.4. Insertion nodes 58

Child nodes 59

Features (Spiral) 60

Features (Rotational) 61

Features (Linear) 62

4.1.5. Find Surface node 63

4.1.6. Using the Force Torque Sensor's Data in Force Nodes 66

4.1.7. Force ControlNode 66

Overview 66

Features 68

Reference frame 68

Parameters 69

Test 72

4.1.8. Multipoint Path Node 73

How to set up a Multipoint Path 74

Step 1 74

Step 2 75

4.2. Development Package 77

4.2.1. Distribution License 77

FT300 Force Torque Sensor - Instruction Manual

Page 5

4.2.2. Linux 79

Package Files – Description 79

Procedure to Compile and Test the Provided Source Code 79

Adapt to a User Application 80

4.2.3. Windows 81

Package Files – Description 81

Procedure to Compile and Test the Provided Source Code 81

Adapt to a User Application 82

4.3. Visual Demo Software 83

4.3.1. Software Package Installation 83

4.4. Serial Communication 85

4.4.1. Modbus RTU 85

Connection Setup 86

5

Read Holding Register (FC03) 88

4.4.2. Data Stream 89

Preset Multiple Registers (FC16) 89

5. Specifications 91

5.1. Technical Dimensions 91

5.1.1. Tool Side Bolt Pattern 92

5.2. Mechanical Specifications 93

5.2.1. Moment of Inertia and Center of Mass 94

5.2.2. Overload Capacity 95

5.3. Signal Specifications 96

5.4. Electrical Ratings 98

5.5. Couplings 99

5.5.1. Blank Coupling 100

6. Maintenance 101

6.1. Maintenance Intervals 101

7. Spare Parts, Kits and Accessories 102

8. Troubleshooting 103

8.1. General troubleshooting 103

8.1.1. An offset has appeared in the Sensor data 103

FT300 Force Torque Sensor - Instruction Manual

Page 6

6

8.1.2. Procedure to determine if the Sensor is functional 103

8.2. Troubleshooting on Universal Robots 104

8.2.1. ActiveDrive Toolbar troubleshooting – Error messages overview 104

8.2.2. Monitoring the Sensor state 105

8.3. Troubleshooting on other platforms 107

8.3.1. USB converter detected as a mouse by Windows 107

8.3.2. Data frequency under 100 Hz in Windows 107

8.3.3. In Linux, the serial port cannot be opened 107

9. Warranty 109

9.1. Exclusions 110

10. Contact 111

Appendix A – Translation of Original EC Declaration of Incorporation 113

Appendix B – Applied Standards 114

FT300 Force Torque Sensor - Instruction Manual

Page 7

Revisions

Robotiq may modify this product without notice, when necessary, due to product improvements, modifications or changes in

specifications. If such modification is made, the manual will also be revised, see revision information. See the latest version of this

manual online at: support.robotiq.com.

Revision 2018/10/09

Major update:all reference to the software compatible with UR(URCap)have been renamed Force Copilot

Updated Sofware section to include the Multipoint Path node and rename the FTMode node to Force Control node

Revision 2018/06/18

Updated Software (subsections 4.1.2 and 4.1.5) to include Robotiq FTMode node and corresponding script functions

Revision 2018/03/26

Removed all references to FT 150 Force Torque Sensor

Revision 2018/02/13

Removed reference to ROSpackage (section 4.3)

7

Revision 2017/12/11

Updated control with Universal Robots (section 4.1 and subsections)

Revision 2017/10/30

Updated mechanical specifications (section 5.2)

Updated signal specifications (section 5.3)

Revision 2016/11/18

Updated FT 150 signal specifications (section 5.3)

Updated installation for Universal Robots (section 3.8 and sub sections)

Updated Control with Universal Robots (section 4.1 and sub sections)

Revision 2016/04/26

Update for ActiveDrive toolbar, added calibration instructions

Revision 2016/01/18

Update for FT 300

Revision 2014/09/08

Official release

FT300 Force Torque Sensor - Instruction Manual

Page 8

8

Copyright

© 2016, 2018 Robotiq Inc. All rights reserved.

This manual and the product it describes are protected by the Copyright Act of Canada, by laws of other countries, and by

international treaties, and therefore may not be reproduced in whole or in part, whether for sale or not, without prior written consent

from Robotiq. Under copyright law, copying includes translation into another language or format.

Information provided by Robotiq in this document is believed to be accurate and reliable. However, no responsibility is assumed

by Robotiq for its use. There may be some differences between the manual and the product if the product has been modified after

the edition date.

The information contained in this document is subject to change without notice.

FT300 Force Torque Sensor - Instruction Manual

Page 9

1. General Presentation

The terms ''Sensor'', ''Robotiq Sensor'', ''Force Sensor'', ''Torque Sensor'', ''FT300 Force Torque Sensor'' used in the following

manual refer to the Robotiq Force Torque Sensor FT 300 unless specified. The Robotiq FT300 Force Torque Sensor is a robotic

peripheral designed for force and torque data acquisition.

The term "Force Copilot" used in the following manual refer to the Robotiq Force Copilot unless otherwise specified. The Robotiq

Force Copilot is a software package designed for using the force and torque values read by a force torque sensor in the framework

of robotic applications. The software interface provides force and torque feedback that can be used for robot hand guiding, force

control processes, assembly tasks, product testing,etc.

Info

The following manual uses the metric system, unless specified, all dimensions are in millimeters.

Info

The following section presents the key features of the Sensor and must not be considered as being related to Sensor

operation, each feature is detailed in the appropriate section of the manual. Safety guidelines must be read and

understood before any operation is attempted with theSensor.

9

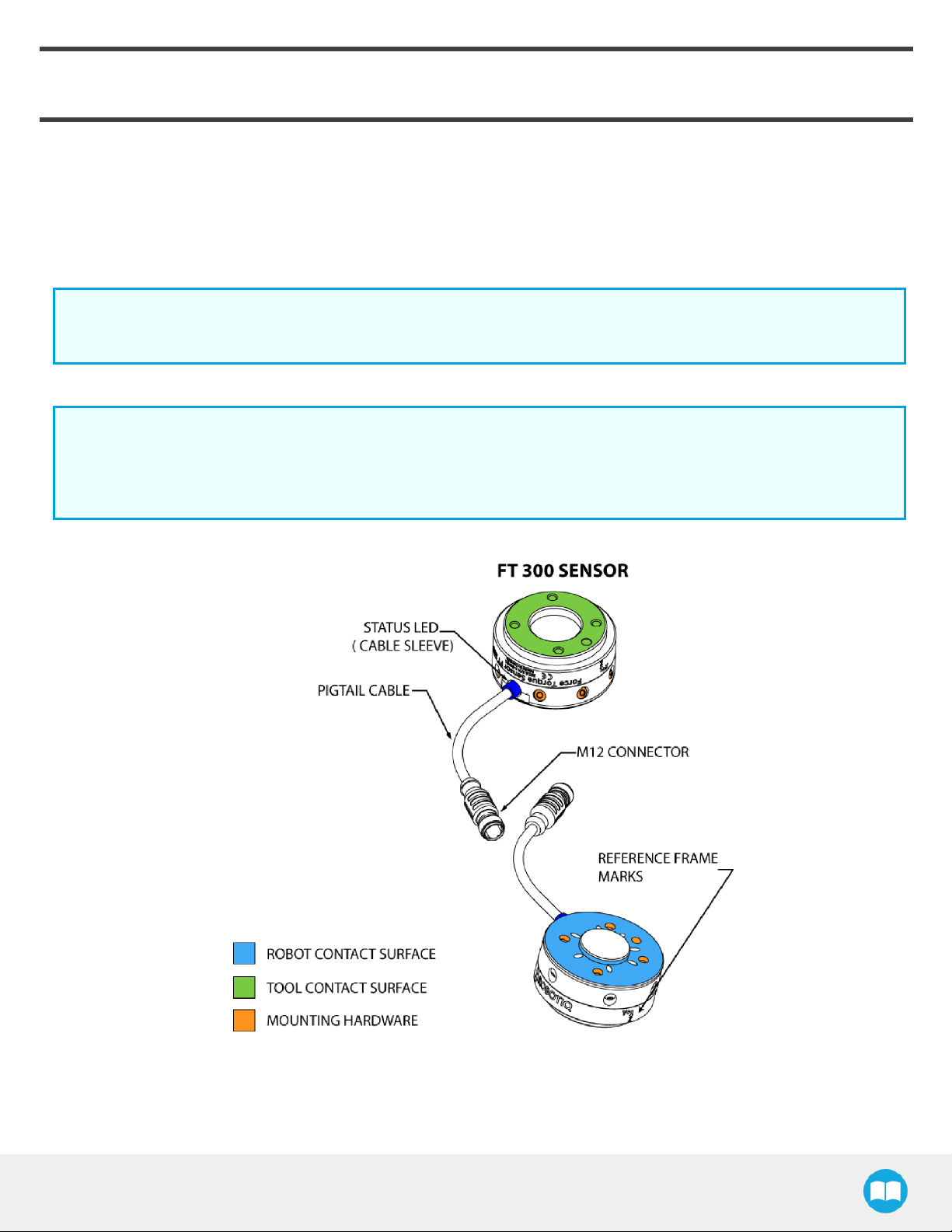

Fig. 1.1: General presentation of the Robotiq Force Torque Sensors with main features.

FT300 Force Torque Sensor - Instruction Manual

Page 10

10

1.1. Main features

1.1.1. FT 300 Force Torque Sensor

l The end-of-arm tool contact surface (in green) is the only point of contact allowed between the Sensor and the tool to ensure cor-

rect force and torquefeedback.

l The robot contact surface (in blue) is the only contact point allowed between the Sensor and the robot for fastening the sensor to

the robot. Note that the inside ring must not touch the robot.

Info

Details on the bolt pattern and indexing pin for the tool side and the robot side can be found in the Specifications

section.

l The screw positioning for the coupling and the robot mountings are shown in orange. See the Spare Parts section for a list of

available Couplings.

l M12 connector (pigtail or mounted) allows for both power and data transfer for the Sensor.

l Status LED provides visual information on the status of the Sensor, see Section 3.7 for details.

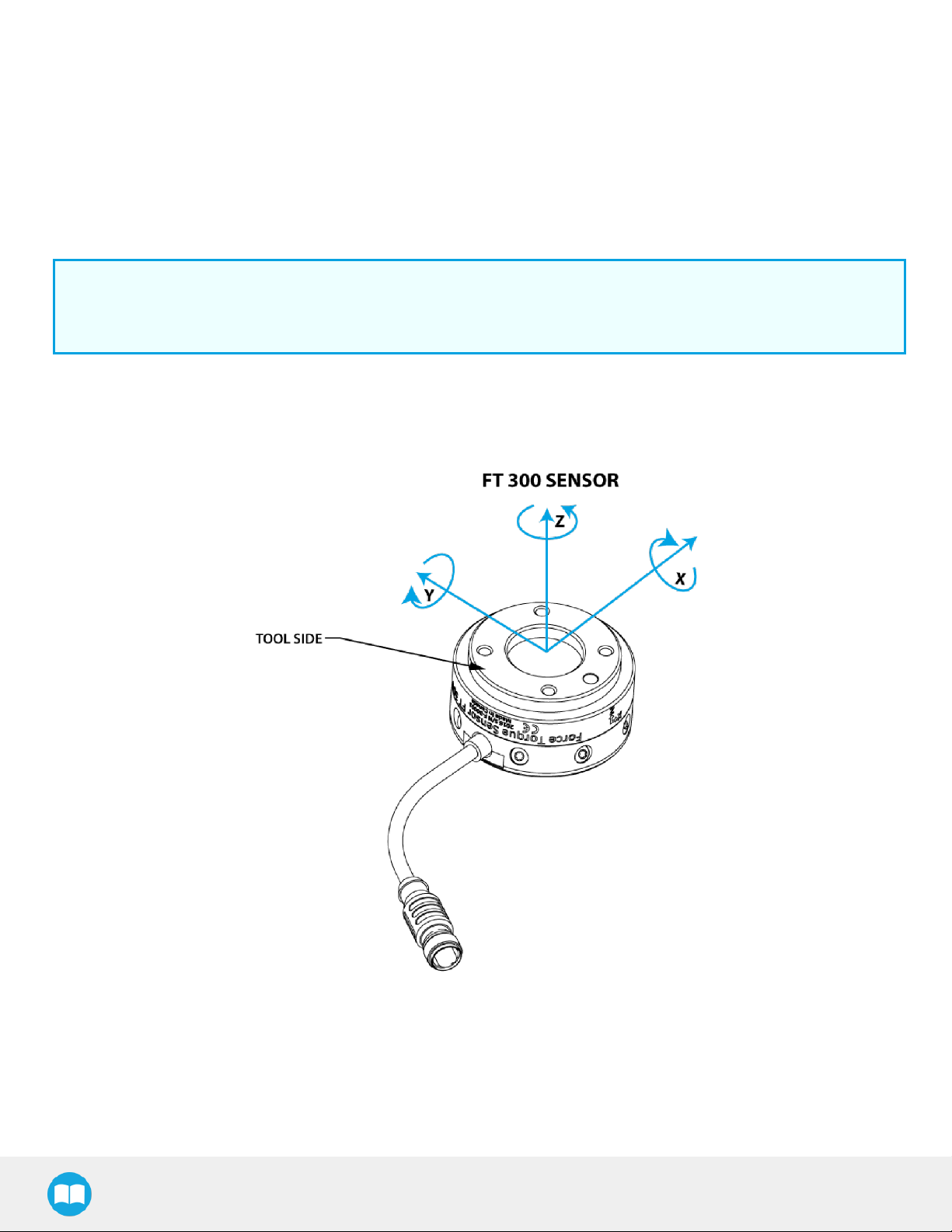

Fig. 1.2: FT300 Force Torque Sensor force and torque diagrams.

FT300 Force Torque Sensor - Instruction Manual

Page 11

The figure above represents the various force and torques that the FT300 Force Torque Sensor can measure. Reference frame is

centered on the Sensor as shown above and visual inscriptions are also represented on it.

l The Z axis passes through the center of the depression with positive direction in the tool direction.

l The X axis traces a symmetric line centered on the connector;the positive direction points the opposite way away from the con-

nector.

l The Y axis uses the right hand thumb rule according to X-Z.

11

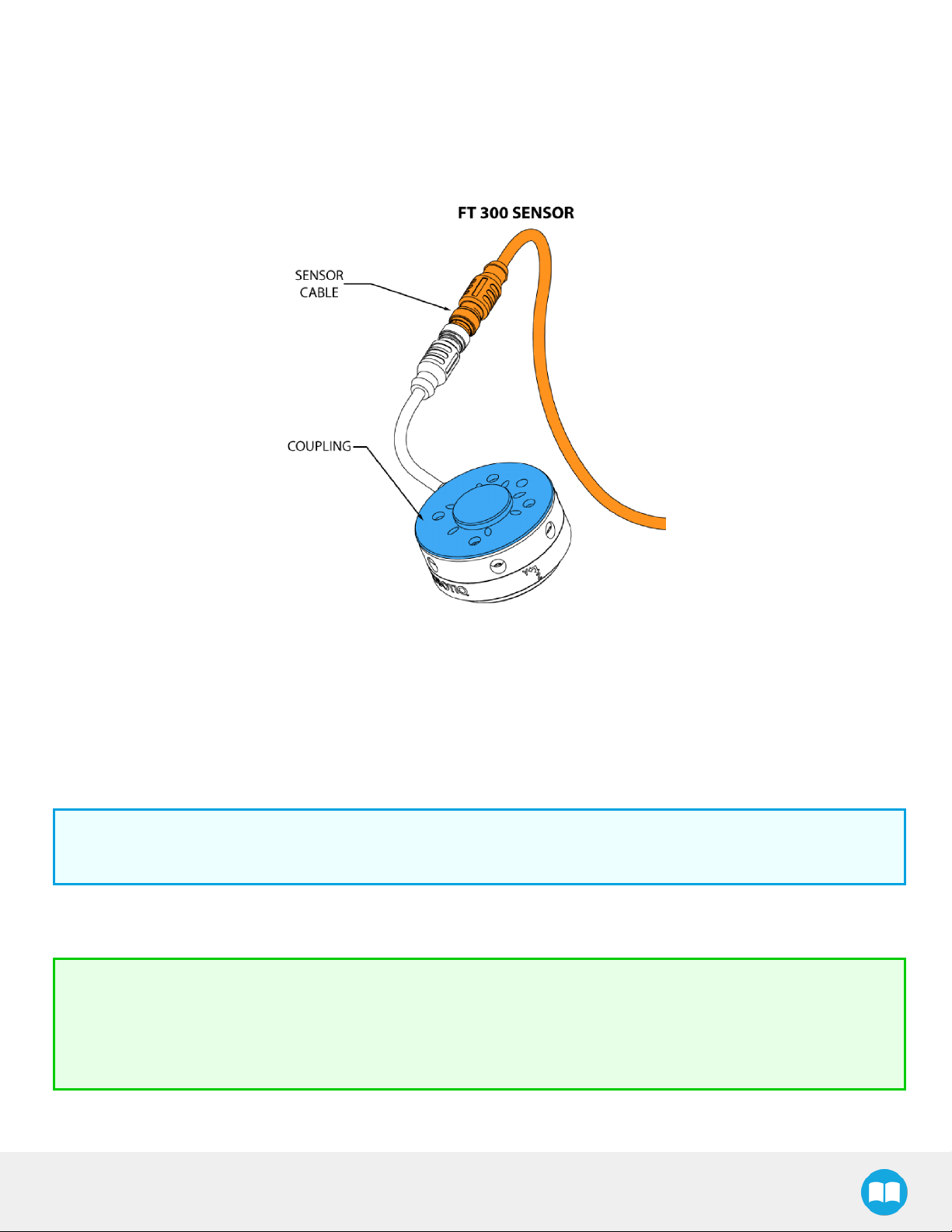

Fig. 1.3: FT300 Force Torque Sensor options.

The figure above represents various options available. They can be found in the Spare Parts, Kits and Accessories section.

l Couplings are meant to install the FT300 Force Torque Sensor on various robot models, see available models.

l Sensor Cable is used for power and communications with the FT300 Force Torque Sensor and is available in different lengths.

l Mechanical Protector is meant to protect the cable connector from collisions that can occur when operating the robot (especially

useful when in teach mode).

l Tool Plate is not shown, but might be required when certain end-of-arm tools are mounted on the FT300 Force Torque Sensor.

Info

Please refer to the Installation section for details on the installation of various options.

Several software packages are provided and detailed in the Software section of this manual.

Tip

It is important to understand that the FT300 Force Torque Sensor can be used either as a Modbus RTU slave or as a

streaming device. When use as a slave unit you will send status requests (read function) to get the force & moment

values, while when in data stream mode the Sensor will continuously stream data without responding to a master

request.Please refer to the Serial Communication section for details.

FT300 Force Torque Sensor - Instruction Manual

Page 12

12

1.1.2. Force Copilot

Force Copilot is the Robotiq software product that unlocks force control features and functionalities.

The Force Copilot software is used for the implementation of a force torque sensor's operational commands in a user interface.

FT300 Force Torque Sensor - Instruction Manual

Page 13

2. Safety

Warning

The operator must have read and understood all the instructions in this manual before handling the Robotiq Force

Torque Sensor and using Force Copilot.

Info

The term "operator" refers to anyone responsible for:

Any of the following operations with the FT300 and the associated robot or tools:

l Installation

l Control

13

l Maintenance

l Inspection

l Decommissioning

Any of the following usage of Force Copilot and the associated operational commands:

l Installation

l Control

l Calibration

l Programming

This documentation explains the various components of the Force Torque Sensor, as well as general operations regarding the

whole life-cycle of the product from installation to operation and decommissioning.

The drawings and photos in this documentation are representative examples and differences may exist between them and the

delivered product.

FT300 Force Torque Sensor - Instruction Manual

Page 14

14

2.1. Warning

Info

Any use of Force Copilot and/or the Force Torque Sensor in noncompliance of these warnings is inappropriate and may

cause injury or damage.

Warning

A force torque sensor used in human-robot collaboration must not be considered a complete safety measure, additional

dedicated safety device(s) must be considered. Sensor failure can occur and result in danger for workers or machinery.

See local or international safety measure for human-robot collaboration.

Warning

l The Sensor needs to be properly secured before operating the robot.

l Do not install or operate a Sensor that is damaged or lacking parts.

l Never supply the Sensor with an alternative current source.

l Make sure all cord sets are always secured at both ends, at the Sensor and at the robot.

l Always meet the recommended keying for electrical connections.

l Make sure no one is in the robot and/or Sensor path before initializing the robot's routine.

l Always meet the Sensor payload specifications.

l All local safety measures and/or laws on robot operation must be applied to the Sensor.

l Any use of the Sensor in noncompliance with these warnings is inappropriate and may cause injury or damage.

FT300 Force Torque Sensor - Instruction Manual

Page 15

2.2. Intended Use

The Sensor is designed for data acquisition (force and torque sensing) for an end-of-arm tool on a robot.

The Sensor is intended for installation on a robot or other automated machinery or equipment.

The software is used for the implementation of a force torque sensor's operational commands in a user interface.

Info

Always comply with local and/or national laws, regulations and directives on automation safety and general machine

safety.

The unit may be used only within the range of its technical specifications. Any other use of the product is deemed improper and

unintended use. Robotiq will not be liable for any damages resulting from any improper or unintended use.

15

FT300 Force Torque Sensor - Instruction Manual

Page 16

3. Installation

Warning

Be sure to read and understand the safety instructions related to the Robotiq Force Torque Sensor prior to installation.

3.1. Scope of Delivery

Standard delivery for an FT Sensor kit:

FTS-300-KIT-001

Robotiq Force Torque Sensor FT 300 unit

1 m pigtail cable (CBL-COM-2068-01)

10 m Robotiq Device Cable (CBL-COM-2065-10-HF)

16

USB Signal Converter (ACC-ADT-USB-RS485)

3.1.1. Options

l Couplings

Info

Coupling is mandatory for the FT 300.

l Adapter plates

l Tool plates

l Different cable lengths

Info

The following are not included in delivery unless specified in the purchase:

l Options such as couplings and adapters for mounting on divers industrial robots.

l Hardware required for options; accessories or fixtures for the FT Sensor unless specified.

l Power supply units, power supply wiring or fuses.

Please refer to the Spare Parts, Kits and Accessories section for a list of available parts.

FT300 Force Torque Sensor - Instruction Manual

Page 17

17

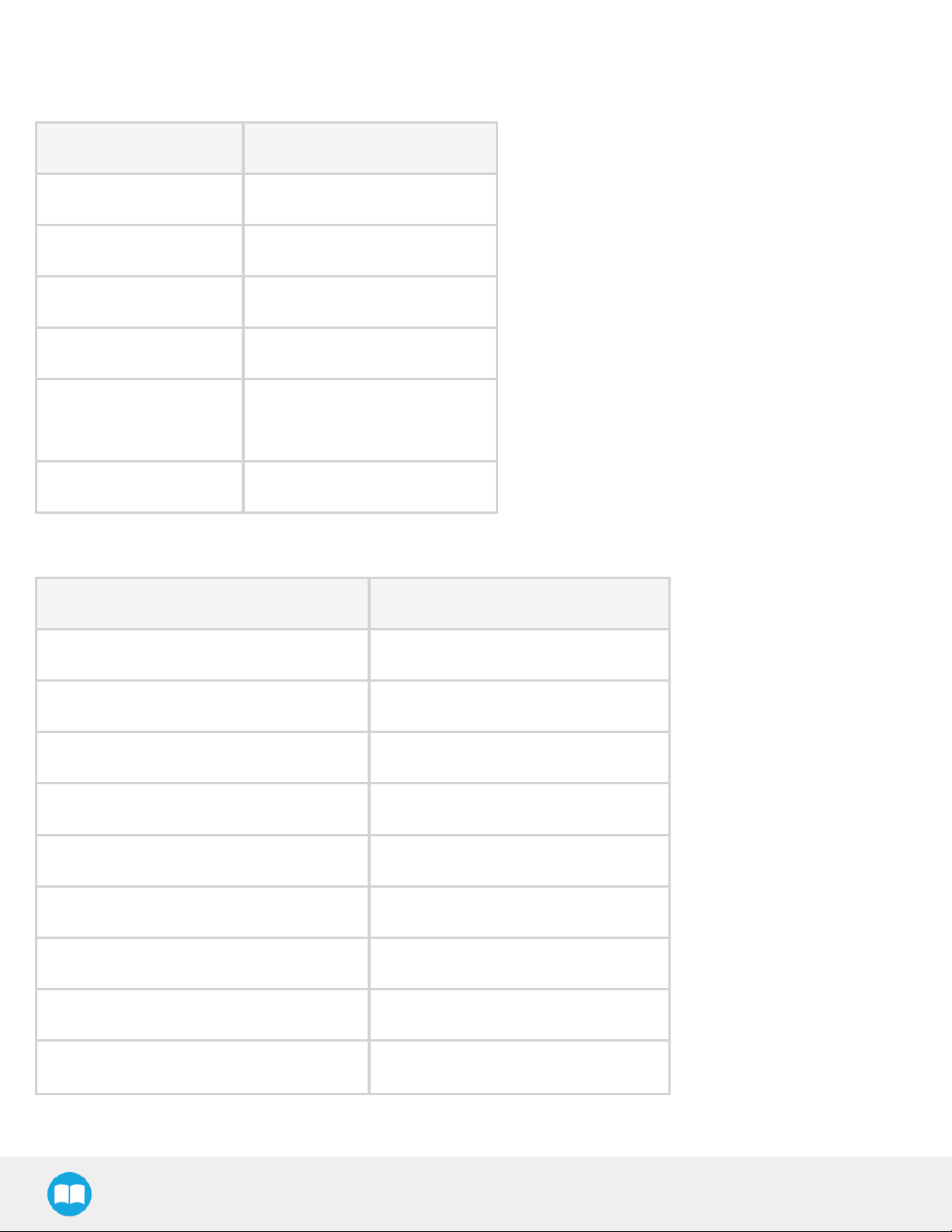

3.2. Environmental and Operating Conditions

The FT300 Force Torque Sensor is designed for industrial applications. Always respect the following specified storage, transport

and operating environmentalconditions:

CONDITION VALUE

Minimum storage/transit

temperature

Maximum storage/transit

temperature

-25°C

70°C

Minimum operating temperature 15°C

Maximum operating temperature 35°C

Humidity (non-condensing) 20-80% RH

Vibration (storage / transit) 5G

Vibration (operating) 2G

l Free from dust, soot or water

l Free from corrosive liquids or gases

Other

l Free from explosive liquids or gases

l Free from powerful

electromagneticinterference

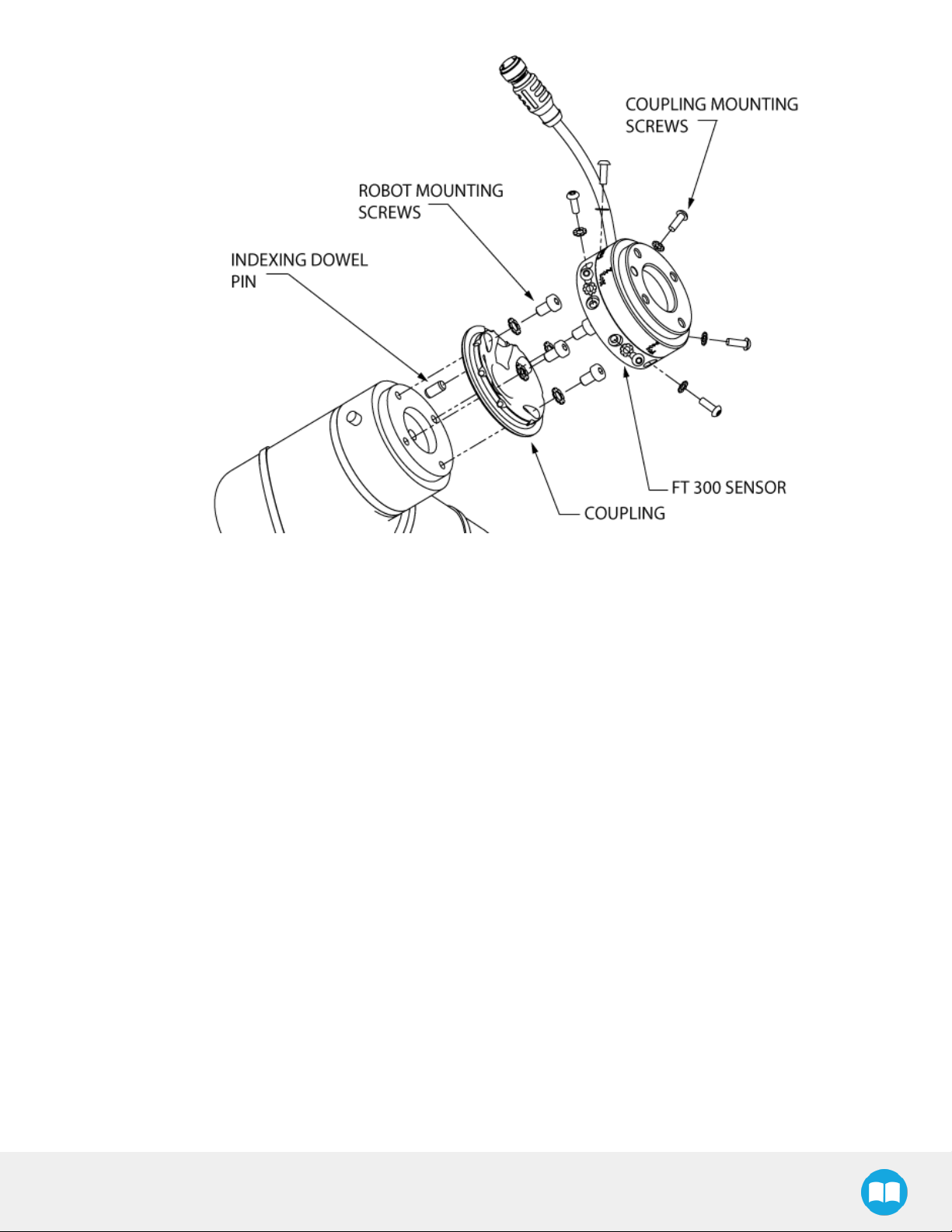

3.3. Mechanical Connections

You must use a coupling to attach the Sensor to a robot. Be sure to use the coupling related to your robot model. Our couplings

are listed according to ISO 9409-1 and this covers most bolt patterns. If there is no coupling for your robot, you can modify a blank

coupling or Robotiq can create a custom version for you. Some couplings may require an additional adapter plate. To create your

own coupling or adapter plate you can refer to the Technical Dimensions section. To see available couplings and adapter plates

and for details, refer to the Spare Parts, Kits and Accessories section.

Info

The FT 300 coupling is mandatory, you can customize yours from a blank provided by Robotiq.

Here are the steps to follow for the installation of the Sensor (see figure below). Note that all screws must be locked in place using

medium strength threadlocker, such as Loctite 248 or a similar product.

1. Align the indexing dowel pin between the coupling and the robot (usually press fitted to the robot).

2. Screw the coupling to the robot with the robot mounting screws (with lock washers if provided) and threadlocker.

3. Align the Sensor indexing dowel pins (prefixed to the Sensor) to the coupling.

4. Screw the Sensor to the coupling using the coupling mounting screws (with lock washers if provided) and threadlocker.

FT300 Force Torque Sensor - Instruction Manual

Page 18

18

Fig. 3.1: Attaching the FT 300 sensor to a robot arm using the mandatory coupling.

FT300 Force Torque Sensor - Instruction Manual

Page 19

19

3.4. Power Supply Specifications

The Sensor needs to be supplied by a DC voltage source. This power supply is not included with the Sensor.

POWER SUPPLY SPECIFICATIONS VALUE

Output voltage 5 to 24 V DC

Max power consumption 2 W

Overcurrent 1 A Fuse (Phoenix #0916604 (UT6-TMC M 1A))

Overvoltage protection

Info

Robotiq recommends the use of the following power supply:

TDK-Lambda DPP Series, 15W Single Output DIN Rail Mount Power Supply, DPP15-24

Warning

Maximum output voltage tolerance is 10%, exceeding this

limit, 26.4 V DC could damage the Sensor.

FT300 Force Torque Sensor - Instruction Manual

Page 20

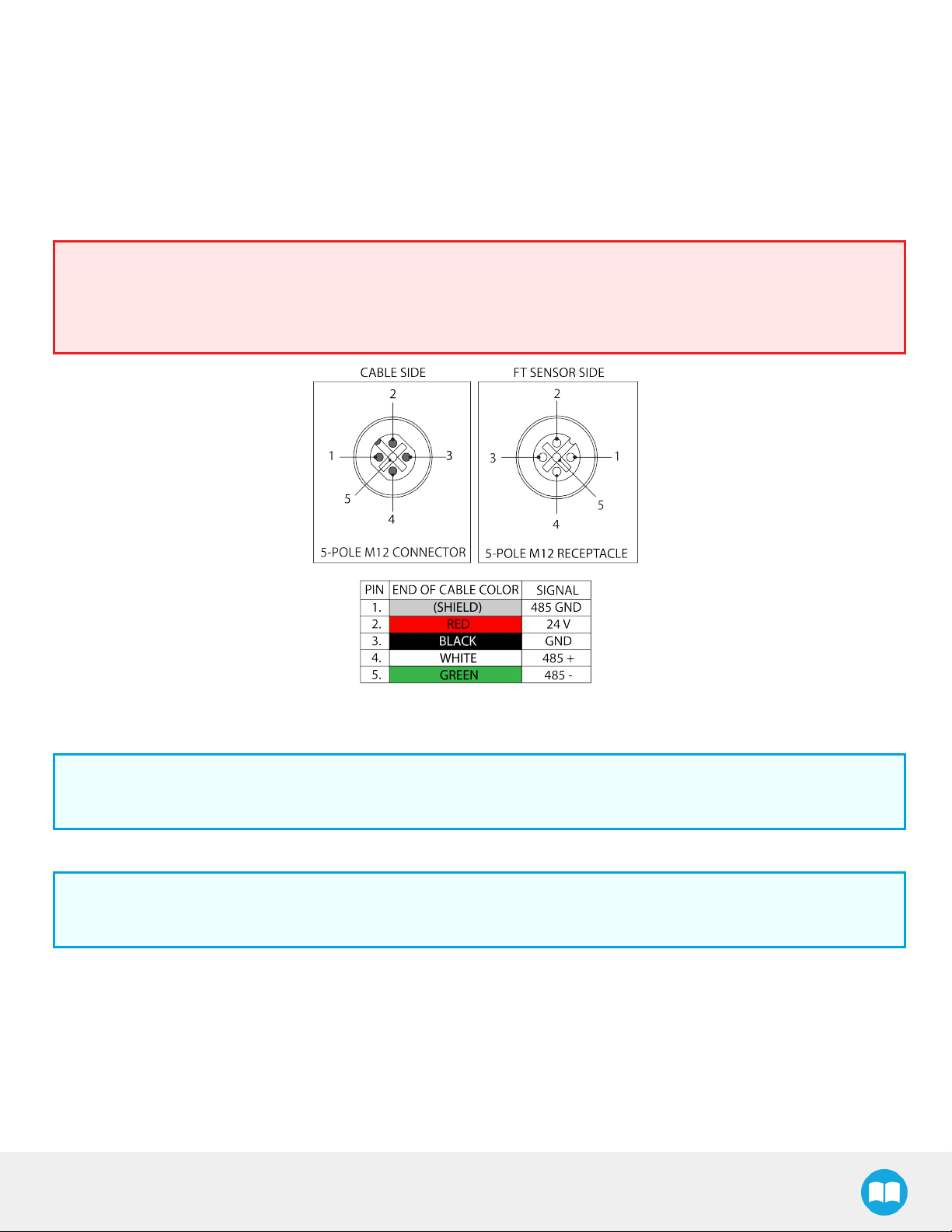

3.5. Wiring

Power and communications are established with the FT300 Force Torque Sensor via a single device cable. The FT 300 has a pigtail

cable.

The figure below represents the FT300 Force Torque Sensor receptacle (Sensor side) and connector (cable side) with associated

pinout. The M12 - 5 pin A-coded connector is used in accordance with IEC 61076-2-101.

Warning

Use proper cabling management. Be sure to have enough forgiveness in the cabling to allow movement of the Gripper

along all axes without pulling out the connectors. Always protect the controller side of the cable connection with a strain

relief cable clamp.

20

Fig. 3.2: Pinout of the Robotiq Force Torque Sensor FT 300 and color code for the respective cable type.

Info

Power pins 2 & 3 are connected to the specified power supply.

Info

RS-485 signal pins 1, 4 & 5 are connected directly, to a RS-485 / USB converter or to a RS-485 / RS-232 converter.

FT300 Force Torque Sensor - Instruction Manual

Page 21

21

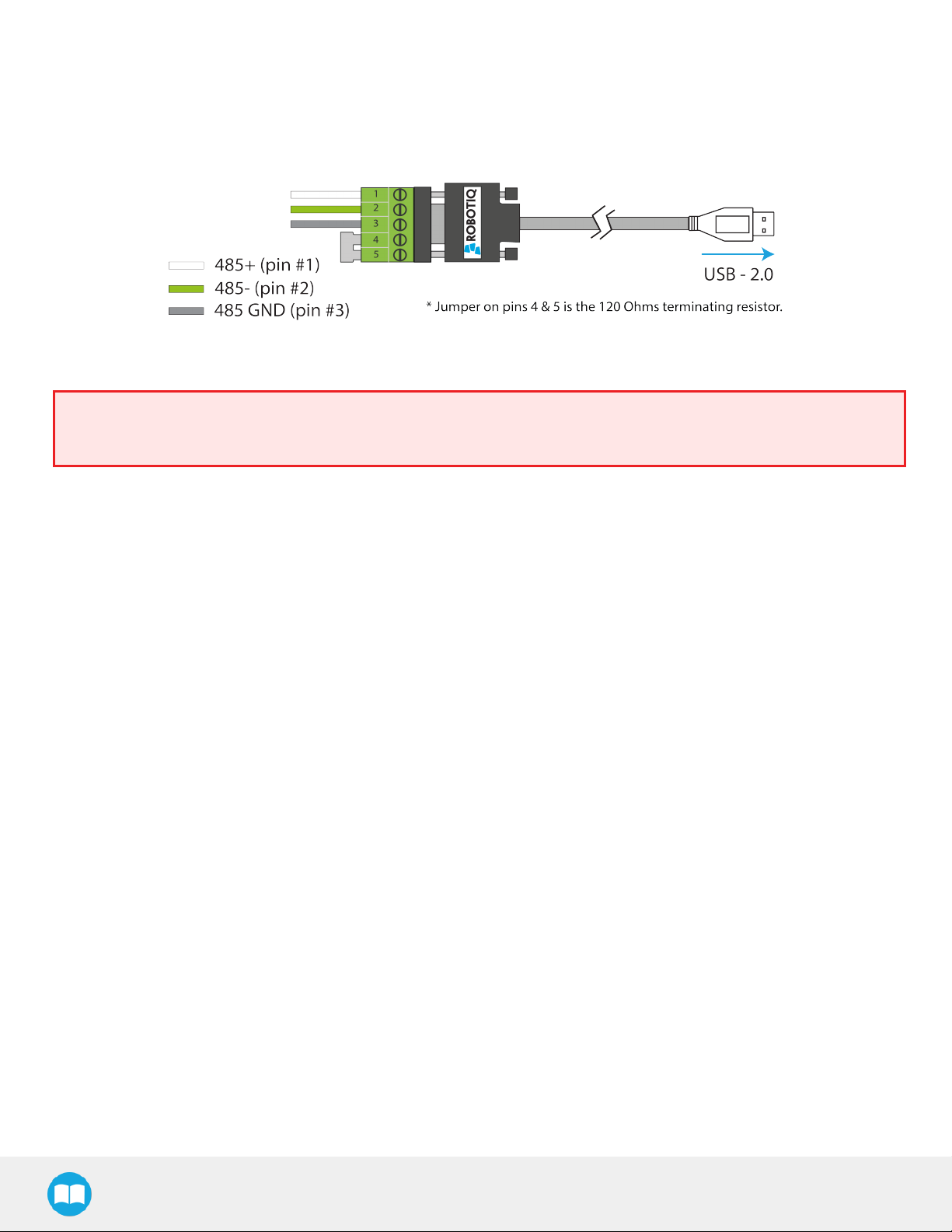

3.5.1. Wiring with USB to RS485 Converter

When using a RS485 to USB converter (refer to the Spare Parts, Kits and Accessories section), the wiring must respect the figure

below and subsequent directions. GND / 0V is wired to Sensor pin #1 as stated in the Wiring section.

The converter will provide you with a standard USB 2.0 male A connector.

Fig. 3.3: Wiring diagram for the RS485 to USB converter

Warning

Power is not delivered via the USB, do not plug 24V into the USB.

FT300 Force Torque Sensor - Instruction Manual

Page 22

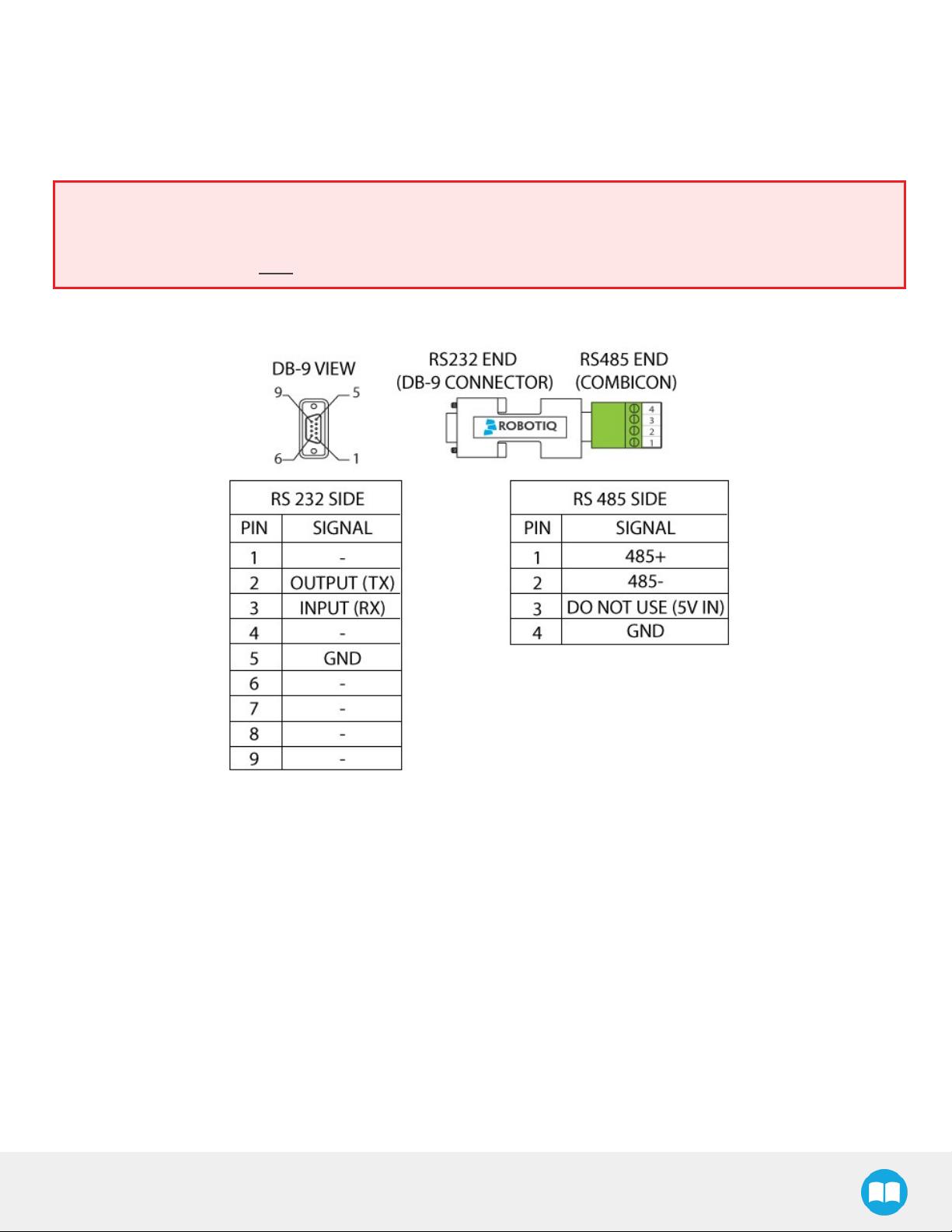

3.5.2. Wiring with RS232 to RS485 Converter

When using a RS232 to RS485 converter (refer to the Spare Parts, Kits and Accessories section), the wiring must respect the figure

below.

Warning

Do not wire converter pin #3 (5V) on the RS485.

The 24V power supply is NOT supplied via the converter.

The converted side will provide you with a standard DB - 9 female connector with signaling as shown in the figure below.

22

Fig. 3.4: Wiring diagram for RS232 to RS485 converter.

FT300 Force Torque Sensor - Instruction Manual

Page 23

23

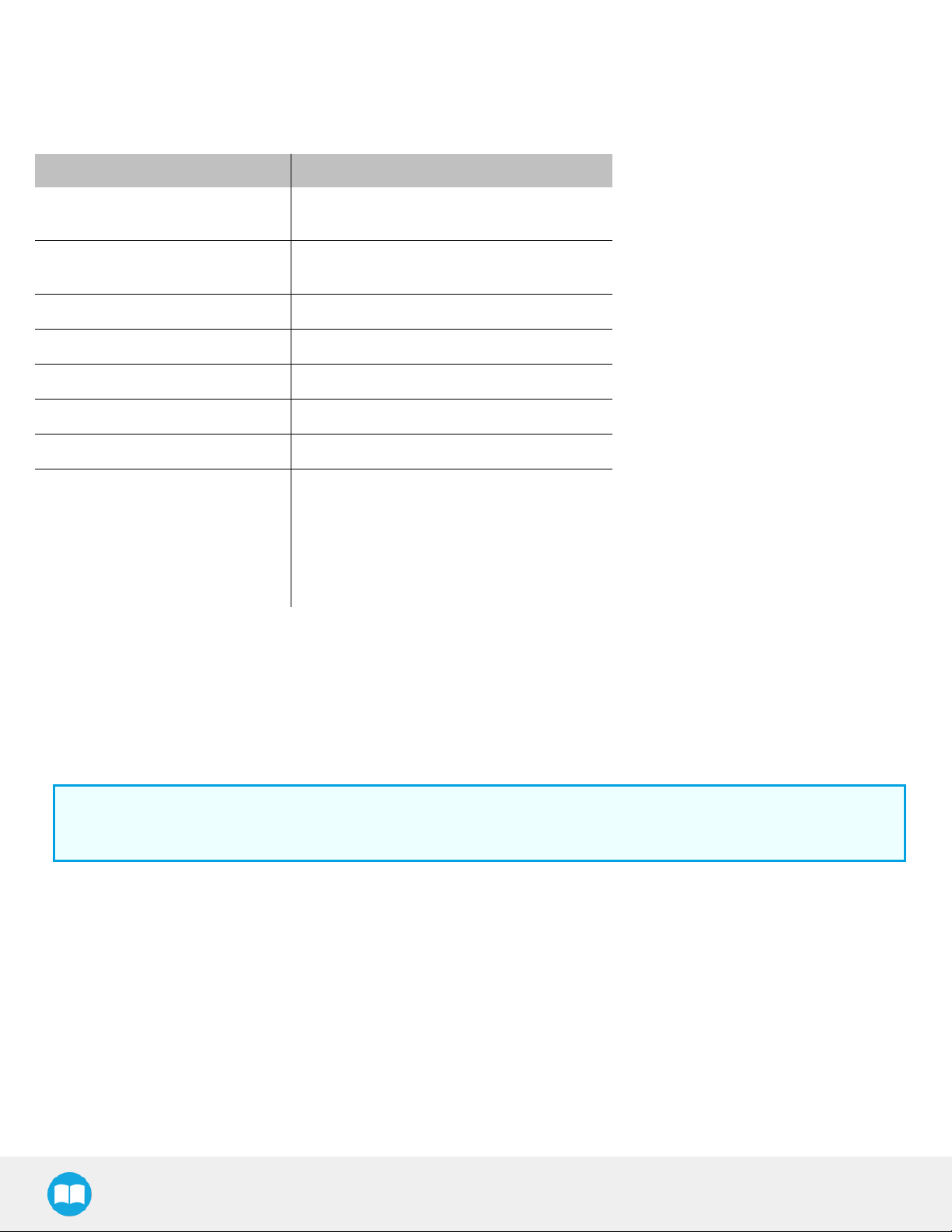

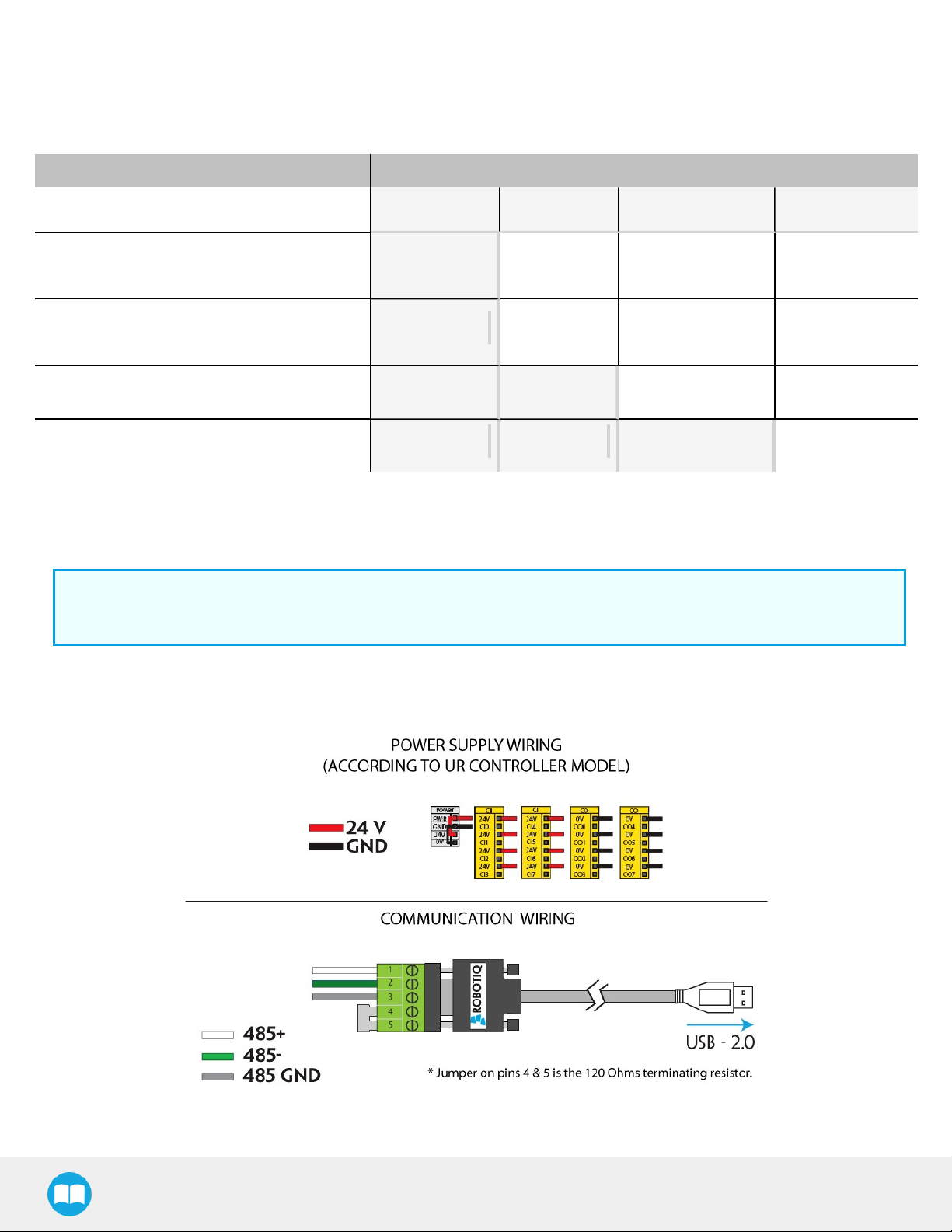

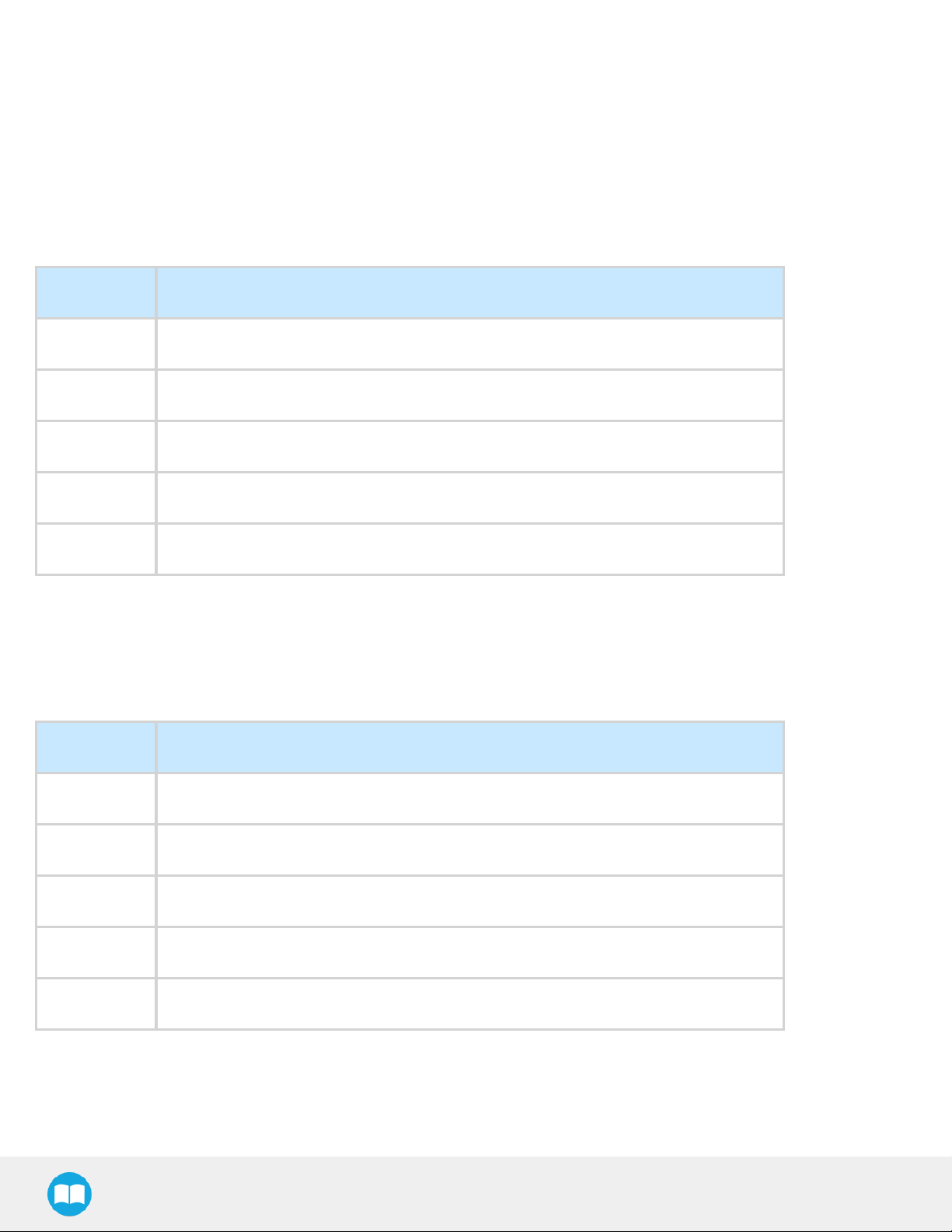

3.6. Installation for Universal Robots

The table below shows which Robotiq software to use with your version of Universal Robots’ controller. If you are using a CB3 or

CB3.1 controller, it is recommended to use the Force Copilot URCaps Package.

Robotiq Software Universal Robots' controller version

CB1 CB2 CB3 CB3.1

Legacy Driver Package (DFU-1.1.15)

Incompatible

Compatible Compatible Compatible

(includes Gripper toolbar)

ActiveDrive Toolbar (ADU-1.0.1)

FT300 Force Torque Sensor URCap Package

up to 1.1.1 (includes ActiveDrive toolbar)

Force Copilot URCap Package (includes

ActiveDrive toolbar)

Incompatible

Compatible Compatible Compatible

Incompatible Incompatible

Incompatible Incompatible

Compatible Compatible

Incompatible

Compatible

Refer to the appropriate section depending on your controller version:

l The Force Copilot URCap Package section covers the installation of the Force Copilot URCap Package.

l The UR Package without URCaps section goes through the software installation procedures when not using URCaps.

Info

The robot's PolyScope version must be 3.5 and higher in order to install and use the URCap.

Prior to any software installation, connect the white, green and bare wires to the Robotiq RS-485 signal converter (ACC-ADTRS485-USB) as shown in the figure below. Also connect the red (24V) and black (0V) wires in the controller according to the figure

below.

Fig. 3.5: Force Torque Sensor wiring to Universal Robots’ controller.

FT300 Force Torque Sensor - Instruction Manual

Page 24

Info

Prior to use over Universal Robots, adjust the payload and the center of gravity from the Installation tab (refer to the

Moment of Inertia and Center of Mass section).

3.6.1. Force Copilot URCap Package

Info

The robot's PolyScope version must be 3.5 and higher in order to install and use the URCap.

Installation

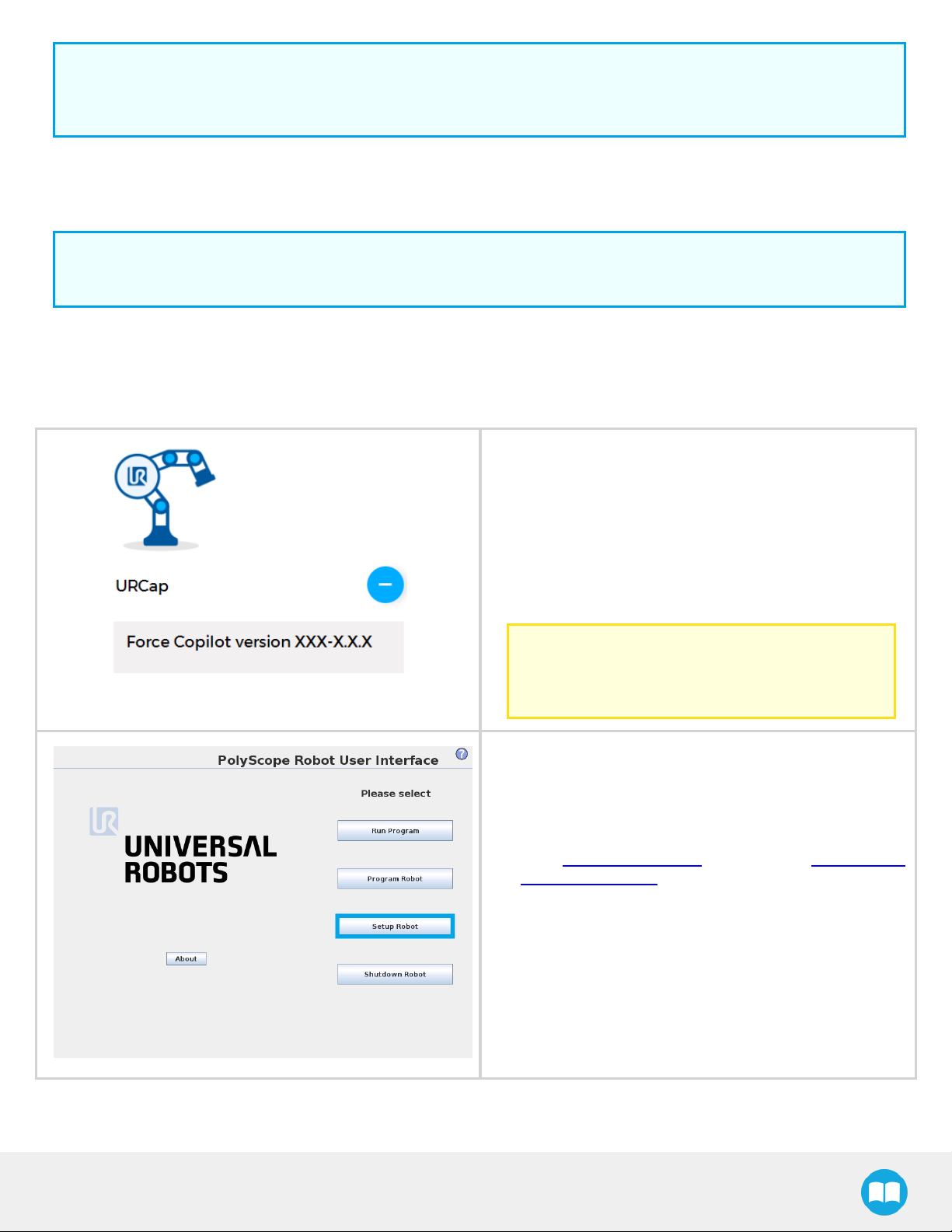

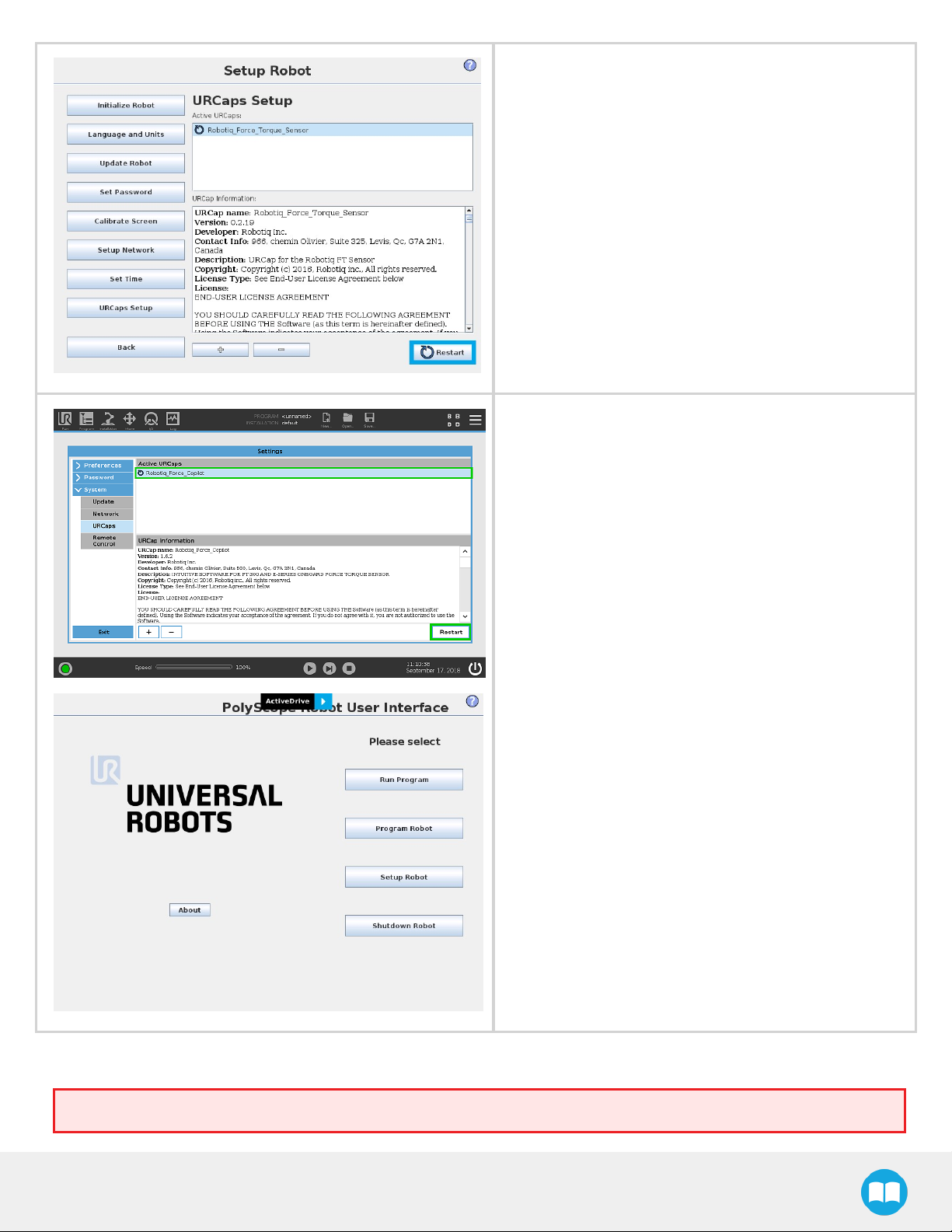

Follow this procedure to install the Force Copilot URCap Package.

24

l Browse to support.robotiq.com

l Select Force Copilot

l Download UCS-X.X.X.urcap

l Decompress the file on the USB license dongle

l Insert the USBlicense dongle in the robot teach pendant,

robot controller, or USBhub connected to the robot controller

Caution

Make sure that the license dongle stays

connected to the robot.

l Make sure that your PolyScope version is up-to-date and

that your Universal Robots controller is compatible with

the Force Copilot URCap package. Refer to the Control

with Universal Robots section for the UR controller compatibility.

l Go to support.robotiq.com and click on the product page

of the FT300 Sensor.

l Download the Robotiq_Force_Copilot-X.X.X.urcap file on

a blank USB stick.

l Insert the USB stick in the UR teach pendant or controller.

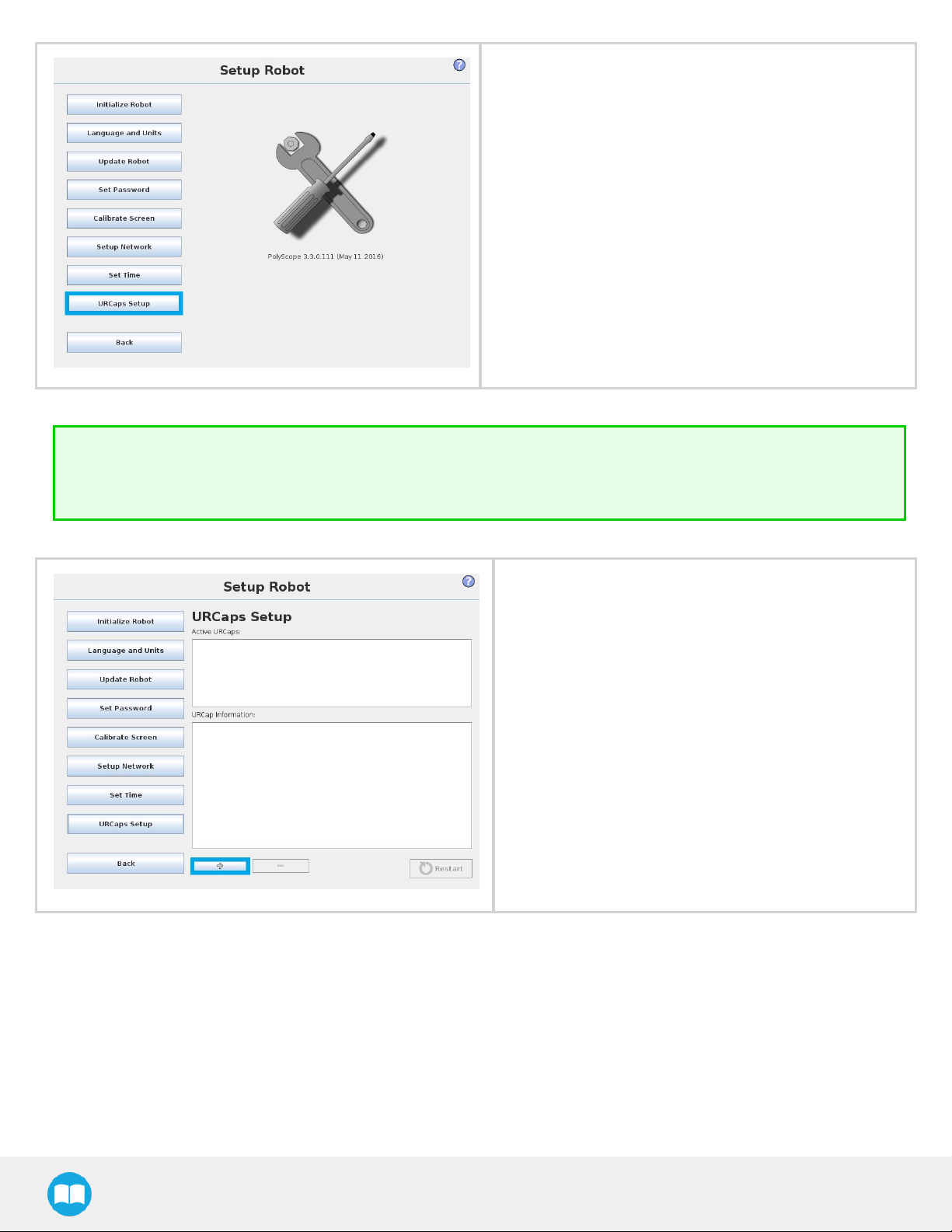

l Go to Setup Robot.

l Tap URCaps Setup.

FT300 Force Torque Sensor - Instruction Manual

Page 25

25

Tip

Go to the PolyScope home page and tap the About button. A window containing the Universal Robots software version

will pop up.

l Tap the plus button (+) to add the Sensor’s URCaps

package.

l Open Robotiq_Force_Copilot-X.X.X.urcap.

FT300 Force Torque Sensor - Instruction Manual

Page 26

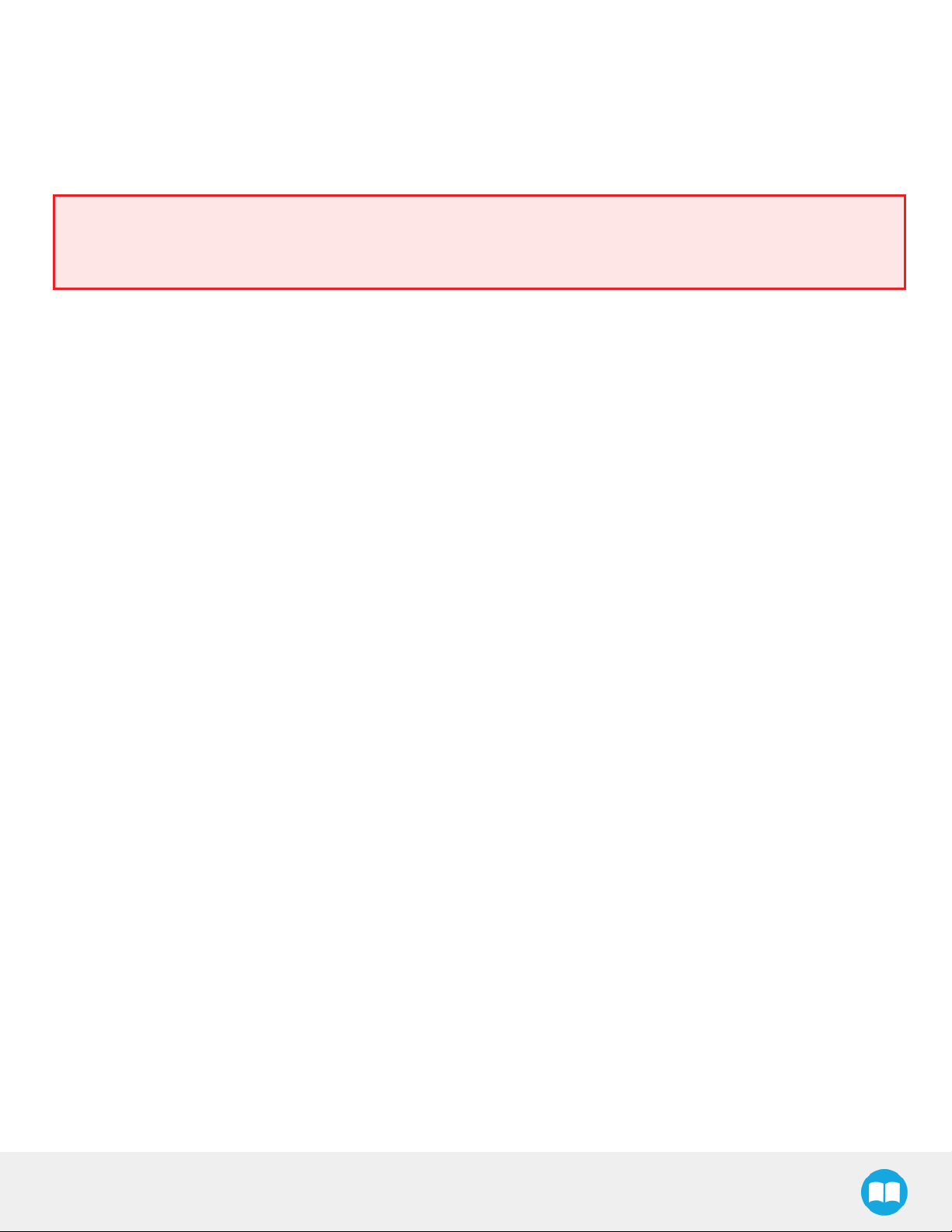

l Restart PolyScope to complete the URCap install-

ation.By doing so, you accept the License Agreement

that is detailed in the URCap Information text box (see

below for the LicenseAgreement).

l When PolyScope reopens, the ActiveDrive toolbar will

appear on thescreen.

26

If the Force Torque Sensor is mounted on the robot for the first time, the calibration must be performed. Refer to the Calibration

Procedure with Universal Robots section for the calibration procedure.

Warning

FT300 Force Torque Sensor - Instruction Manual

Page 27

27

The sensor must be recalibrated after each uninstall / install on the robot. Mounting screws will induce internal stress that

needs to be compensated for. Not doing so will significantly affect the sensor signal.

FT300 Force Torque Sensor - Instruction Manual

Page 28

Calibration Procedure

The sensor outputs the force and moment data according to a reference, i.e. a zero value. In order to compensate for any deviation

of this reference, Robotiq provides a feature which allows the sensor to automatically compute and compensate the installation

offset, the weight of the tool and its center ofmass.

Warning

The sensor must be re-calibrated after each uninstall / install on the robot. Mounting screws will induce internal stress

that needs to be compensated for. Not doing so will significantly affect the sensor signal.

The procedure requires moving the robot arm in three configurations for which each orientation of the tool is different. Using an

internal accelerometer, the sensor is then able to associate the measurements corresponding to the tool alone for each orientation.

After the procedure is completed, the sensor will output the force and moment values measured without the effect of the weight of

the tool and the installation offset.

28

FT300 Force Torque Sensor - Instruction Manual

Page 29

29

Calibration Procedure with Universal Robots

Info

You need the Universal Robots software package installed first.Please refer to the Installation for Universal Robots

section for the package download and installation.

1

On the teach pendant, tap the Installation button in the ribbon at the top of the screen.

2

Select URCaps in the navigation pane on the left of the screen.

3

Tap the Force Copilot button.

4

Select the Calibration tab

1

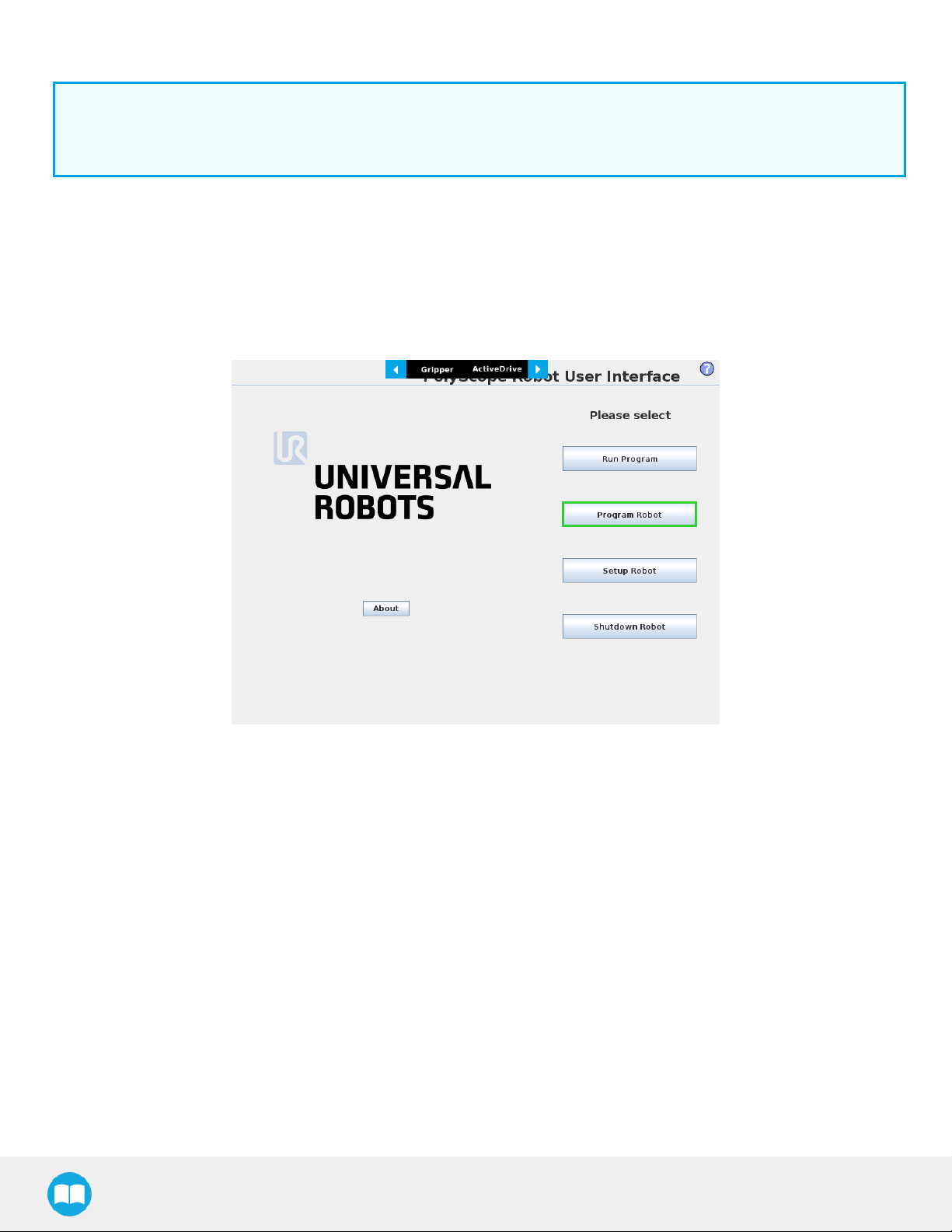

From the PolyScope home page, tap Program Robot.

2

Go to the Installation tab and tap FTSensor in the left pane. The FTSensor's Dashboard will be displayed. Tap the Calibration tab.

FT300 Force Torque Sensor - Instruction Manual

Page 30

30

FT300 Force Torque Sensor - Instruction Manual

Page 31

31

3

Tap the Start calibration wizard button to perform the calibration of the FTSensor. Make sure there are no external forces

applied to the Sensor while performing the calibration.

4

Step 1 consists in moving the robot arm so that the FTSensor's Xaxis points downward. Tap Continue when the action is

done.

FT300 Force Torque Sensor - Instruction Manual

Page 32

5

Step 2 consists in moving the robot arm so that the FTSensor's Yaxis points downward.Tap Continue when the action is

done

32

6

Step 3 consists in moving the robot arm so that the FTSensor's Zaxis points downward. Tap Continue when the action is

done

Info

Recalibration is recommended in the event of an error message displaying the incorrect orientation of the FTSensor

during at least one calibration step.

FT300 Force Torque Sensor - Instruction Manual

Page 33

33

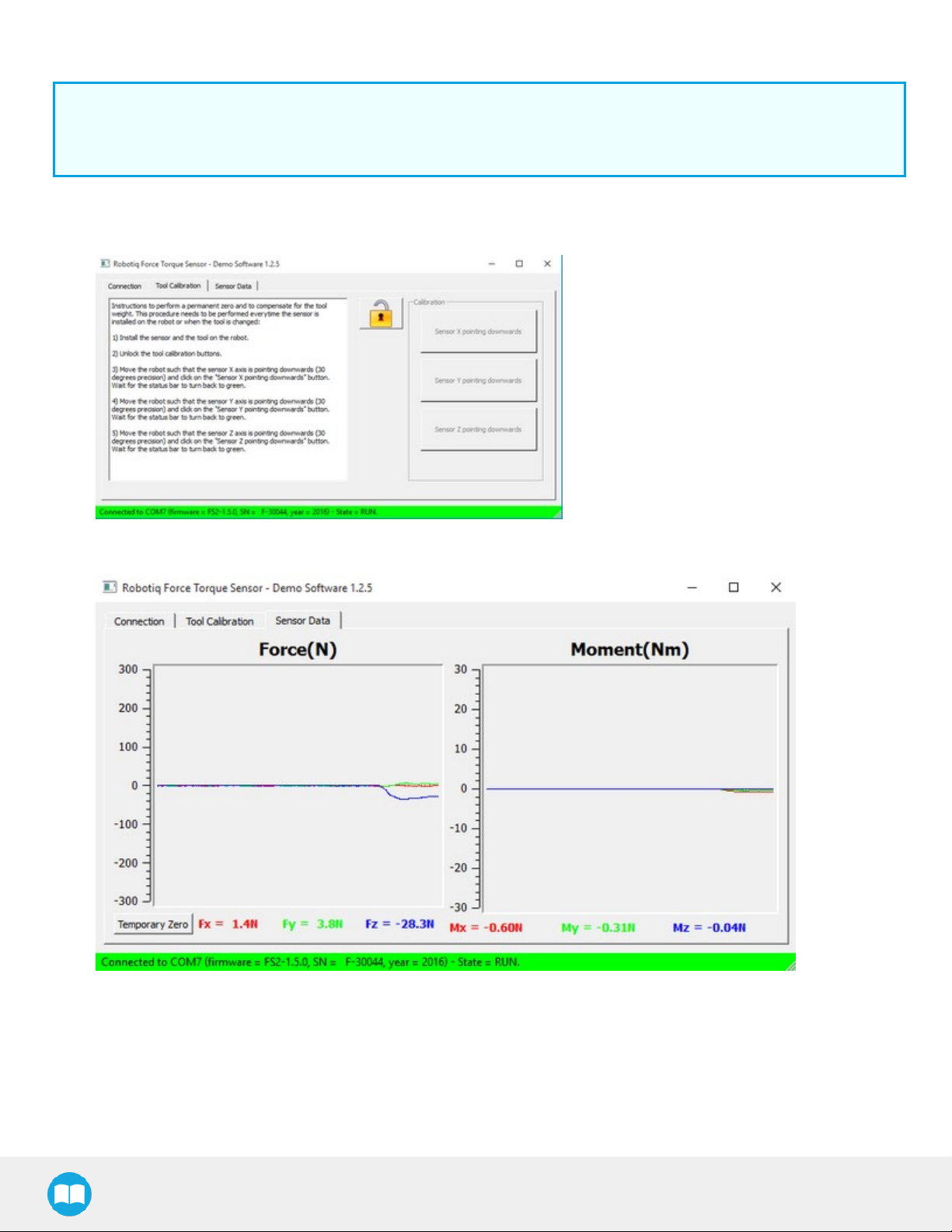

Calibration Procedure for the Visual Demo Software (PC)

Info

You need the Visual Demo Software installed first. Please refer to the Visual Demo Software section for download and

installation.

To calibrate your FT Sensor:

1

Go to the "Tool Calibration" tab and follow the instructions.

2

Once completed, go to the "Sensor Data" tab.

FT300 Force Torque Sensor - Instruction Manual

Page 34

Payload/CoG

The payload and center of gravity values can be accessed through the Calibration menu in the Installation tab, after the calibration

is completed. They include the mass and center of gravity of the Sensor.

Caution

The mass, payload or center of gravity of anything found under the Sensor (i.e. tool changer) will not be taken into

account in the calculation of the payload.

Warning

Make sure to save the installation file after performing the calibration. Saving will record the calibration date and

estimate tool parameters.

34

FT300 Force Torque Sensor - Instruction Manual

Page 35

35

ActiveDrive Toolbar Installation

Tip

Prior to installing the ActiveDrive toolbar, the Sensor Driver package should be installed.

Info

The URCaps package contains the ActiveDrive Toolbar. Therefore, installing the URCap package also installs the

toolbar. If you have installed the URCap, you do not need to install the ActiveDrive Toolbar. This section applies to

Robotiq’s software installation when not using the URCap. If you wish to install the URCap package, refer to the Force

Copilot URCap Package section.

Tip

Make sure your PolyScope version is up-to-date and that your controller is compatible with the driver package for UR

(refer to the Installation for Universal Robots section for controller compatibility). To view your PolyScope version, go to

the home page of the teach pendant and tap the About button. A window containing the Universal Robots software

version will pop up.

Warning

Verify that the Force Torque Sensor is aligned with the robot arm using the dowel pin, or at least make sure the holes are

aligned. This ensures that the Sensor’s axes are aligned with the robot’s and that the ActiveDrive will work correctly.

To install the ActiveDrive toolbar :

1

Visit support.robotiq.com and download the latest ActiveDrive toolbar installer (ADU-X.X.X) in the Documentation Archives

section.

2

Extract the files on a blank USB stick.

3

Connect the USB stick in the Universal Robots’ teach pendant or controller.

4

Installation is automatic. The pendant’s screen will show installation status.

5

Do not remove the USB stick before the installation is completed.

6

Once the installation is completed, the ActiveDrive Toolbar button will appear on the teach pendant’s screen after a short

delay.

Info

To get detailed information on how to use the ActiveDrive Toolbar, refer to the ActiveDrive Toolbar section.

FT300 Force Torque Sensor - Instruction Manual

Page 36

Firmware upgrade

A firmware upgrade might be necessary when updating the Force Copilot URCap. From the PolyScope home page, go to Program

Robot and tap the Installation tab. Select FT Sensor in the left pane and tap the Dashboard button. If an upgrade is needed, the

Upgrade firmware button will display. Tap the button and wait for the upgrade to be completed.

Warning

Do not disconnect the Sensor during firmware upgrade.

l Tap Upgrade firmware

36

Wait while the software is upgraded.

FT300 Force Torque Sensor - Instruction Manual

Page 37

37

Uninstalling the URCap Package

If you wish to uninstall the Force Copilot URCap, follow this procedure:

Go to Setup Robot.

Tap URCaps Setup.

l In the Active URCaps text box, tap the Force Copilot URCap.

l The Force Copilot URCap should be highlighted.

l Tap the minus button (-) to uninstall the URCap.

l Restart PolyScope to complete the uninstallation process.

FT300 Force Torque Sensor - Instruction Manual

Page 38

License Agreement

END-USER LICENSE AGREEMENT

YOU SHOULD CAREFULLY READ THE FOLLOWING AGREEMENT BEFORE USING THE SOFTWARE (as this term is hereinafter

defined). Using the Software indicates your acceptance of the agreement. If you do not agree with it, you are not authorized to use

the Software.

IMPORTANT, READ CAREFULLY: This End-User License Agreement (the “Agreement”) is a legal agreement between you and the

Licensor (as this term is hereinafter defined), the licensor of the Software. This Agreement covers the Software. The Software

includes any “on-line” or electronic documentation and all modifications and upgrades related thereto. By downloading, installing,

or otherwise using the Software, you agree to be bound by the terms of this Agreement. If you do not agree to the terms of this

Agreement, the Licensor cannot and does not license the Software to you. In such event, you must not download, use or install the

Software.

1. Definition.

1.1. “UR” means Universal Robots A/S, a corporation incorporated under the laws of Denmark, having its registered office at

Energivej 25, DK-5260 Odense S, which specializes into the conception, advanced manufacturing and sale of robotic products

(the “UR’s Business”);

1.2. “Software” means any of the Licensor’s software provided to its customers for the purposes mentioned in sub-section 2.2

hereof including their modifications and upgrades and their related materials;

38

1.3. “Licensor” means Robotiq inc., a corporation incorporated under the laws of Quebec, having its registered office at 500-966

chemin Olivier,Lévis, Québec, Canada, G7A 2N1, which specializes into the conception, advanced manufacturing and sale of

robotic products (the “Licensor’s Business”);

1.4. “End-User” means a customer authorized pursuant to this Agreement to install or use the Software with a specific product of

the UR’s Products;

1.5. “Licensor’s Products” means those robotic products developed by the Licensor in the course of the Licensor’s Business;

1.6. “UR’s Products” means those products developed by UR in the course of the UR’s Business;

1.7. “Licensor’s Authorized Representatives” means and includes the Licensor and Licensor’s authorized vendors, resellers,

distributors and licensors;

1.8. “Designated Equipment” means a personal computer that has a functional USB port and an operating system that is an

equivalent or a more recent version of one of the following:

l Windows 7;

l Mac OSX;

l Linux Ubuntu 16.

1.9. “Purchase Agreement” means an agreement between the End-User and the Licensor pursuant to which the End-User

purchased one or more of the Licensor’s Products;

1.10. “Trial Period” means the limited period during which the Software may be installed on the UR’s Product and used without

any charge by the End-User in order to be used without a Licensor’s Product.

2. License and Object of the Agreement.

2.1. License. Subject to the terms and conditions hereof, the Licensor grants to the End-User a personal, temporary, nonexclusive, non-assignable and non-transferable and revocable license to use the Software in accordance with the terms and

conditions hereof.

2.2. Object of the Agreement. The object of this Agreement is the grant of a license for the use of software that enables control

functionalities of UR’s Products devices or Licensor’s Products (the “Purpose”).

FT300 Force Torque Sensor - Instruction Manual

Page 39

39

3. Software and Documentation.

3.1. Download. The Software shall be downloaded from the Licensor’s website or provided to the End-User through a USB flash

drive, according to the instructions set forth in the order summary sent to the End-User by email or by other means of

communication, as decided by the Licensor (the “Order Summary”). The download of the Software shall be made with the EndUser’s Designated Equipment.

3.2. Installation. The installation on the UR’s Product shall be done with a USB flash drive inserted into the UR’s Product. If the

Software was downloaded from the Licensor’s website, it shall be uploaded on a USB flash drive device for the purpose of

installation on the UR’s Product.

3.3. Utilisation. Two scenarios are possible according to the modalities set forth in the Order Summary:

a) The use of the Software is made with a Licensor’s Product. In this case, the End-User may start using the Software upon

completed installation.

b) The use of the Software is made without a Licensor’s product. In this case,a Trial Period is granted to the End-User. At the

end of the Trial Period, which shall be set forth in the Order Summary, the use of the Software requires the software protection

dongle (the “Dongle”). The Dongle will be provided to the End-User for a fee as per section 5 of this Agreement, either by the

Licensor or by a Licensor’s Authorized Representative.

3.4. Documentation. The Licensor may provide, if applicable, all documentation containing the detailed specifications for

operation and use of the Software, which Software shall be used in accordance with such documentation. This documentation, if

applicable, will be provided, wholly or in part, within (i) this Agreement, (ii) the Licensor’s Web site http://robotiq.com/ (iii) the

Licensor’s Products and the Purchase Agreement therewith, or (iv) any other agreement, document, support, whatsoever decided

by the Licensor.

4. Modifications and Upgrades. The Licensor shall be under no obligation to provide any upgrade, modification or patch to the

Software. However, the End-User shall be entitled to receive free of charge the upgrades and patches of the Software provided by

the Licensor if, at such time, the End-User is not in default in respect of any of its obligations contained herein. Modifications that

create new functionalities may be offered to the End-User at a price set by the Licensor at its sole discretion.

Such modifications, upgrades and patches of the Software shall be installed by the End-User itself by consulting the Licensor’s

website http://robotiq.com/ where a link to proceed to such installation will be made available thereof.

5. Fees. The End-User shall pay the Licensor for using the software as per the Order Summary. The fees shall cover upgrades and

patches of the Software provided by the Licensor if, at the time of the upgrade or patch, the End-User is not in default in respect of

any of its obligations contained herein.

New End-Users not using the Licensor’s Products will be entitled to a Trial Period, which shall begin on the date of the first

installation on the UR’s Product and which shall end after the Trial Period as determined in the Order Summary.

6. Maintenance. During the term of this Agreement, the Licensor will maintain the Software in an operable condition and will make

available any corrections and improvements as are generally incorporated in the Software by the Licensor without additional

charge to the End-User.

7. Title to Software. The licensed Software is composed of confidential data and trade secrets and is proprietary to and constitutes

trade secret information and intellectual property of the Licensor. Title and ownership rights to the Software, including the

intellectual property rights related thereto, shall remain with the Licensor. The End-User agrees to maintain the confidential nature

of the source code and libraries.

The license granted herein does not include the right to sublicense to others, and may not be assigned to others, in whole or in

part, without the prior written consent of the Licensor. The End-User may not or allow others to modify or prepare derivative works,

copy (except for normal backups for recovery purposes), reproduce, republish, reverse engineer, upload, post, transmit, or

distribute, in any manner, the Software.

8. Restricted Use. The Software shall be used solely and exclusively by the End-User and its employees for the Purpose mentioned

in sub-section 2.2 hereof. Any other use of the Software, including resell derivative modifications or extensions, is expressly

prohibited.

9. Audit. During the term of this Agreement and for six (6) months after the termination, the Licensor shall have the right, during

normal business hours and upon reasonable advance notice to the End-User, to visit the End-User’s premises for the purpose of

FT300 Force Torque Sensor - Instruction Manual

Page 40

auditing the End-User’s use of the Software to confirm that such use is in accordance with this Agreement or to confirm that the

End-User has ceased the use of the Software after the termination of the Agreement.The costs of such audit shall be borne by the

Licensor unless it determines that the End-User has underpaid it for any twelve-month period by five per cent (5%) or more or that

the use of the Software is not in accordance with the Agreement; in such case, the End-User shall pay the costs of the audit and

such underpayment.

10. Exclusion of Warranty on Software. The End-User expressly acknowledges and agrees that use of the Software is at the EndUser sole risk. The Software is provided “as is”. The Licensor warrants that, during the term of this Agreement and except if

modified by the End-User, the Software will meet in all material respects the specifications provided for in the Licensor’s website.

11. Limitation of liability. To the maximum extent permitted by law, the Licensor and Licensor’s Authorized Representatives shall

not be liable for any indirect, incidental or consequential damages for breach of any express or implied warranty,breach of

contract, negligence, strict liability or any other legal theory related to the Software. Such damages include, but are not limited to,

loss of profits, loss of revenue, loss of data, loss of use of the product or any associated equipment, down time and user’s time,

even if the Licensor has been advised of the possibility of such damages. In any case, the Licensor’s entire liability under any

provision of this agreement shall be limited to the amount actually paid in respect of the Licensor’s products purchased by the enduser pursuant to a purchase agreement.

12. Indemnification. The End-User shall indemnify and hold the Licensor harmless from any liability, loss, claim and from any

judgment, damage and cost (including, without limitation, the costs and fees of a dispute and reasonable legal fees), fine, penalty

and interest whatsoever arising from any defence, dispute, compensation, claim or counterclaim as a result of the use of the

Software by any third party authorized by the End-User.

13. Training, Maintenance and Support. There is no entitlement to training, maintenance and support under this license unless

otherwise specified in the Purchase Agreement or any other written agreement between the End-User and the Licensor. The EndUser may provide the Licensor with details regarding any bug, defect or failure in the Software promptly and with no delay from

such event; the End-User shall comply with the Licensor’s request for information regarding bugs, defects or failures and furnish

him with information, screenshots and try to reproduce such bugs, defects or failures upon Licensor’s demand.

40

14. Expiration and Termination. The Licensor may terminate this Agreement for default by the End-User by sending a ten (10) day

notice to the End-User.

Upon the termination of this Agreement for any reason, the End-User shall promptly uninstall the Software on any UR’s Products

and Licensor’s Products, computer, or server on which it has been installed, deliver to the Licensor all CDs, DVDs, USB flash drives,

and other tangible items and materials embodying the Software, and return to the Licensor all copies thereof or destroy such

copies and warrant in writing that all copies thereof have been destroyed or deleted. In the event of the termination of this

Agreement, all obligations of the parties under this Agreement due for performance on the date of termination shall survive the

termination, and the party terminating shall not be liable to the other party for any damages arising out of the termination.

15. Miscellaneous.

15.1. This Agreement constitutes the entire understanding and agreement between the Licensor and the End-User and replaces

any prior agreement relating to the same subject matter.

15.2. This Agreement shall be governed and construed in accordance with the laws of the province of Quebec and the federal

laws of Canada applicable therein. Any legal action or proceeding between the Licensor and the End-User for any purpose

concerning this Agreement or the parties' obligations hereunder shall be brought exclusively in a court of competent jurisdiction

sitting in the judicial district of Québec, Québec.

15.3. The Licensor’s failure to insist upon or enforce strict performance of any provision of this Agreement shall not be construed

as a waiver of any provision or right. Neither the course of conduct between the parties nor trade practice shall act to modify any

provision of this Agreement.

15.4. The Licensor may assign its rights and duties under this Agreement to any party at any time without notice to the End-User.

The End-User may not assign this Agreement without the prior written consent of the Licensor.

15.5. If any part of this Agreement is null, illegal or non-enforceable, this Agreement shall be interpreted as if this part was never

part of this Agreement.

15.6. The provisions of this Agreement are for the benefit of the Licensor and its officers, directors, employees, agents, licensors

and suppliers. Each of these individuals or entities shall have the right to assert and enforce those provisions directly against the

FT300 Force Torque Sensor - Instruction Manual

Page 41

41

End-User on its own behalf. This Agreement is also for the benefit of, and binds, the End-User and its heirs, successors, legal

representatives and permitted assigns.

15.7. The Licensor hereby confirms that there is no relationship of agency between the Licensor and UR, and that they are

independent contractors.

15.8. Any rights not expressly granted herein are reserved.

15.9. The parties confirm that they have agreed that this Agreement and all related documents be drafted in English only. Les

parties aux présentes confirment qu’elles ont accepté que la présente convention et tous les documents y afférents soient rédigés

en anglais seulement.

FT300 Force Torque Sensor - Instruction Manual

Page 42

3.6.2. UR Package without URCaps

If your Universal Robots controller is not compatible with the URCaps package (refer to the Installation for Universal Robots section

for compatibility), you can install the driver package and ActiveDrive Toolbar separately.

The ActiveDrive Toolbar allows to easily move the robot by hand guiding it. This section applies to Robotiq’s software installation

when not using URCaps.

Info

The driver package and the ActiveDrive toolbar have separate installation processes. The driver package is independant

from the ActiveDrive toolbar, but has to be installed beforehand if you wish to install the ActiveDrive toolbar.

Driver Package Installation

Info

The URCap package contains the driver package. Therefore, installing the URCap package also installs the driver

package. If you have installed the URCap, you do not need to install the driver package. This section applies to

Robotiq’s software installation when not using the URCap. If you wish to install the URCap package, refer to the Force

Copilot URCap Package section.

42

Caution

Make sure your PolyScope version is up-to-date and that your controller is compatible with the driver package for UR

(refer to the Installation for Universal Robots section for controller compatibility). To view your PolyScope version, go to

the home page of the teach pendant and tap the About button. A window containing the Universal Robots software

version will pop up.

To install the driver package, follow this procedure:

1

Download the Robotiq Force Torque Sensor software driver package (DFU-X.X.X) from the Documentation Archives.

2

Extract the content of the .zip file on a blank USB flash drive.

3

Plug the flash drive into the robot controller or teach pendant.

4

Installation is automatic. The pendant screen will show installation status. Do not unplug the flash drive until the operation is

completed.

5

When a green "USB" text is shown, unplug the USB drive.

Calibration

If the Force Torque Sensor is mounted on the robot for the first time, calibration must be performed. Refer to the Calibration

Procedure section for details.

Warning

The Sensor must be calibrated after each uninstall / install on the robot. Mounting screws will induce internal stress that

needs to be compensated for. Not doing so will significantly affect the Sensor signal.

FT300 Force Torque Sensor - Instruction Manual

Page 43

43

Testing the software package

l In PolyScope, load the program test_sensor.urp located in the Sensor folder and execute it. The program will display pop-ups

with the following information: Sensor firmware version, production year and serial number. The force and torque readings for Fx,

Fy, Fz, Mx, My and Mz are displayed in the Variables tab.

Info

To get detailed information on how to program in PolyScope using the Force Torque Sensor signals, refer to the Using

the force and torque values section.

Removing the Package

1

Locate the uninstall.sh file provided in the driver package.

2

Copy the file on a blank USB stick.

3

Rename the file to urmagic_uninstall.sh.

4

Plug the USB stick into the UR controller or teach pendant.

5

Uninstallation is automatic.

FT300 Force Torque Sensor - Instruction Manual

Page 44

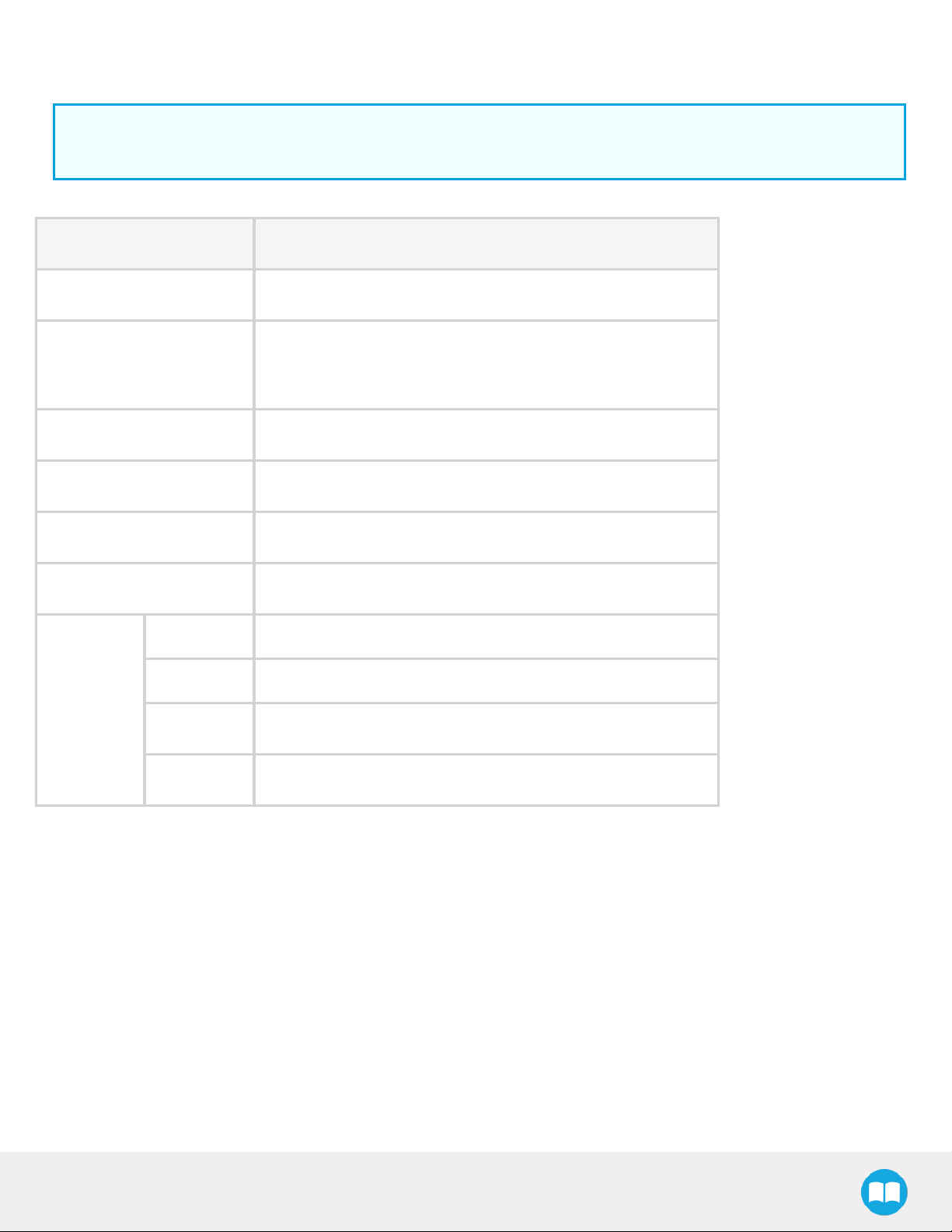

3.7. Status LED

A single status LED provides information on both Sensors, detailed information can be found in the tables below, while a

representation of both Sensor status LEDs is shown in the figure below.

On the FT 300 Sensor, the cable sleeve is the LED conductor:

COLOR LED STATE INFORMATION

- off No power

Blue / red on FT 300 Sensor is booting

Red on FT 300 Sensor is functional, no

communication detected

Red blinking FT 300 Sensor fault detected

44

Blue on FT 300 Sensor is functional,

communication established

Fig. 3.6: FT Sensor status LED.

FT300 Force Torque Sensor - Instruction Manual

Page 45

4. Software

The following sub-sections provide instructions for the installation of the Force Copilot software package. This allows you to get

data from a force torque sensor.

l Section 4.1 and subsections refers to the control and programming for Universal Robots.

l Section 4.2 and subsections detail the installation of an open source development package, which can be adapted according to

the users' needs. It currently functions with Windows and Linux.

l Section 4.3 links to ROS.

l Section 4.4 explains the Demo Software

l Section 4.5 will detail the use of serial communication in generic applications

45

FT300 Force Torque Sensor - Instruction Manual

Page 46

46

4.1. Control with Universal Robots

Force Copilot contains many features to program and control the robot’s arm using a sensor’s force and torque readings. The

packageprovides:

l ActiveDrive toolbar;

l Path recording node;

l Zero FTSensor node

l Insertion node

l Find Surface node

l Force Control node

l Multipoint Path node

l Driver package.

FT300 Force Torque Sensor - Instruction Manual

Page 47

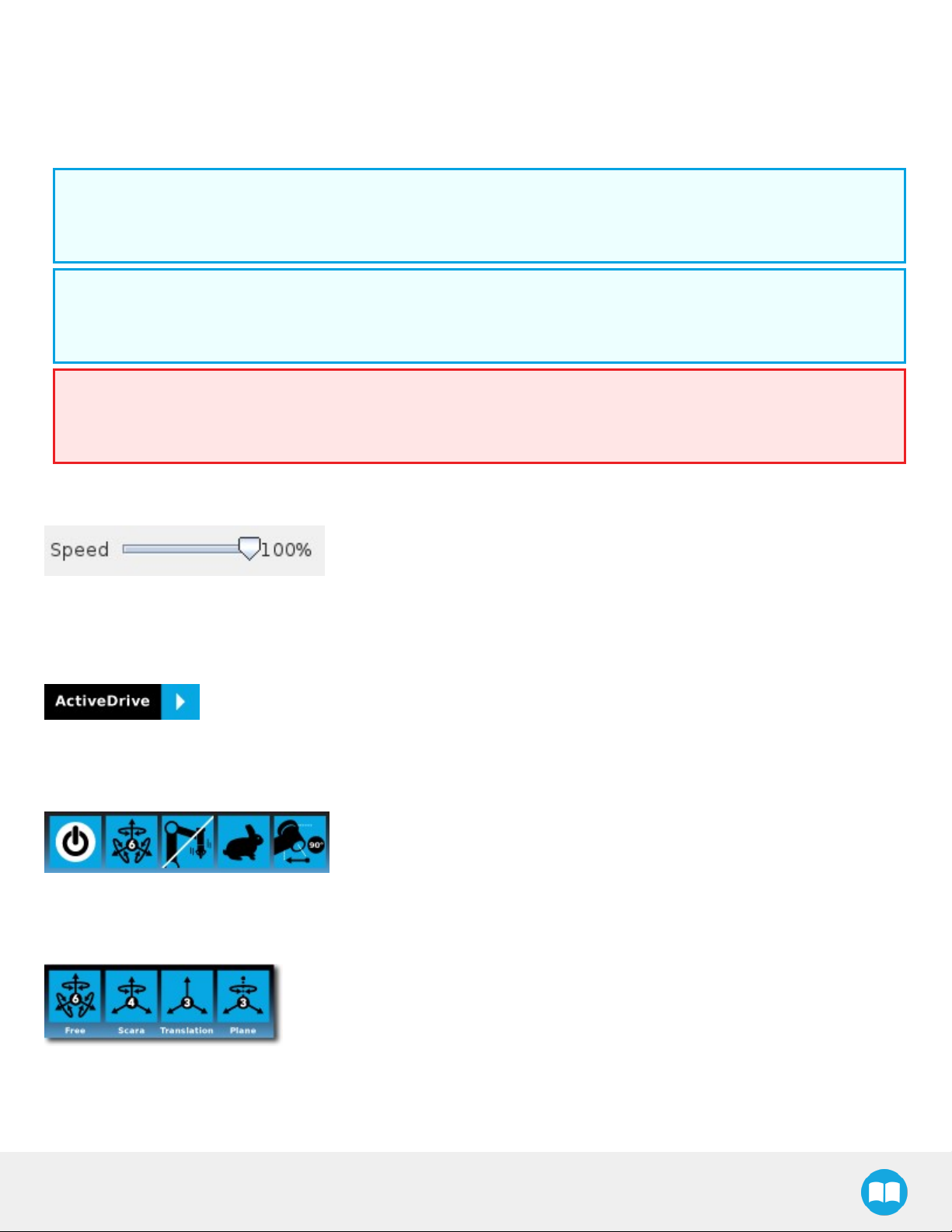

4.1.1. ActiveDrive Toolbar

The ActiveDrive Toolbar is automatically installed with the Force Copilot software Package. It enhances the guiding mode on

Universal Robots by allowing the robot to be hand guided smoothly and easily towards a waypoint. The ActiveDrive feature is a

great way to assist the Path recording described in the Path Recording section, by hand guiding the robot while recording a path.

Info

The Force Copilot software Package contains the ActiveDrive Toolbar. Therefore, the toolbar is automatically installed

with the URCap Package.

Info

The ActiveDrive Toolbar can be installed and used without the URCap Package (refer to the UR Package without

URCaps section for information on how to install the toolbar without the URCap).

Warning

Verify that the Force Torque Sensor is aligned with the robot arm using the dowel pin. This ensures that the Sensor’s axes

are aligned with the robot and that the ActiveDrive feature will work correctly.

47

The robot speed set with the Speed slider will affect the speed at which the robot moves in the ActiveDrive mode. Verify and adjust

the speed slider to the desired speed. It has to be greater than 50%.

Overview

Toolbar collapsed

Tap the ActiveDrive button to expand the toolbar.

Toolbar expanded

(Tap the mode selector to expand.)

ActiveDrive modes expanded

FT300 Force Torque Sensor - Instruction Manual

Page 48

48

Features

Primary icon Functionality

name

ActiveDrive Tap to toggle between the expanded and collapsed ActiveDrive Toolbar. When

Start / Stop Tap to start or stop ActiveDrive. ActiveDrive will automatically turn off after 30s of

Modes Shows the current ActiveDrive mode. When tapping the icon, the available modes

Description

grey, the functionality is not available. Tap the button to see why it is not available.

inactivity.

When started, ActiveDrive allows you to move the robot freely by applying forces

on robot’s end-effector. This is different from the Free Drive feature on the robot,

where you can move the robot arm.

will appear and you can change to a different mode. ActiveDrive modes allow you

to restrain the robot to specific movements.

Free Free motion: all translations and rotations are allowed.

Scara SCARA-style motion: all translations and horizontal rotation (twist) are allowed.

Translation Translation motion: only translations are allowed. No rotation of the robot is

possible in this mode.

Plane Plane motion: horizontal translations and horizontal rotations (twist) are allowed (no

vertical motions are allowed).

Drift Control Tap this button to stop the robot from drifting (resets the sensor’s offset).

FT300 Force Torque Sensor - Instruction Manual

Page 49

49

Primary icon Functionality

name

Speed Motion speed control is toggled between fast and slow, allowing precise

Square robot Aligns the tool center point (TCP) orientation with the robot base. Tap and hold this

Description

movement in slow motion.

The force torque sensor will switch to slow speed automatically whenever high

forces are detected, for example, during an impact with an object.

button to automatically move the end-effector to the closest orthogonal orientation

of the base axis system (just try it, you will see!).

FT300 Force Torque Sensor - Instruction Manual

Page 50

50

Error Messages Overview

The ActiveDrive Toolbar will be automatically collapsed and be grayed whenever one of the following situations occurs. In such

cases, by tapping the ActiveDrive button, the following messages will appear:

l Message:

l Solution:

l Starting ActiveDrive while an excessive force is applied to the tool:

l Determine if an external force is applied to the end-effector. If it is the case, tap OK and move the robot away from the

obstacle (with Free Drive or Move tab), or remove any external forces and start ActiveDrive again.

l If no external forces are applied, tap Zero Sensor.

l Message:

l Solution:

l

Force Torque Sensor is detected: Check the Force Torque Sensor’s connection. Make sure the USB adapter and all the

wires are connected. Also, verify the Sensor’s LED status (refer to the Status LED section).

l Message:

l Solution:

l

The robot is not initialized: Tap OK and go to PolyScope’s home page. Tap Setup Robot and go to Initialize Robot to

start the robot.

FT300 Force Torque Sensor - Instruction Manual

Page 51

l Message:

l Solution:

l A program is already running: The ActiveDrive Toolbar cannot be used while a program is running. Stop the program to

enable the ActiveDrivefeature.

l Message:

51

l Solution:

l The speed setting of the robot is lower than 50%: The robot’s speed setting should be greater than 50%. Modify the speed

setting in the robot program using the slider.

l Message:

l Solution:

l

If the Freedrive button is pressed: The ActiveDrive mode cannot be used when the Free Drive mode is ON. Make sure

you are not pressing on the teach pendant’s Teach button when trying to use the ActiveDrive toolbar.

FT300 Force Torque Sensor - Instruction Manual

Page 52

52

4.1.2. Using the force and torque values

Force Torque Sensor functions are made available in the Universal Robots functions drop-down menu.

l The rq_zero_sensor() function can be called at any point in a robot program to zero the force and torque values of the Force

Torque Sensor.

l The get_sensor_Fx(), get_sensor_Fy(), get_sensor_Fz(), get_sensor_Mx(), get_sensor_My(), get_sensor_Mz() functions allow the

user to assign the sensor values to any variable.

l The get_applied_tcp_force(<index>) function returns the current wrench (force and torque vector) value currently applied at the

tool center point (TCP).

l The get_applied_base_force(<index>) function returns the current wrench (force and torque vector) value applied at the robot

arm base.

l The express_force_in_frame(<T_from_to>,<wrench_from>) function is used to convert the wrench (force and torque vector)

reading in a given reference frame into another (end-effector to robot base, and vice-versa, for example).

l T_from_to = relative pose of the reference frame into which the wrench reading is converted

l wrench_from = wrench to transform in pose or list format (Fx, Fy, Fz, Mx, My, Mz)

Fig. 4.1: Example of two reference frames for the express_force_in_frame(<T_from_to>,<wrench_from>) function

Info

Although displayed in real time in the Variables tab, the force and torque values can be seen in the Force Copilot

Dashboard.

After the calibration has been completed, go to the FT300 Dashboard to monitor the force and torque values in real time.

Prior to using the FTSensor's data in the framework of a robot program, it is recommended to zero the sensor using the Zero

sensor button.

FT300 Force Torque Sensor - Instruction Manual

Page 53

Fig. 4.2: Force Copilot Dashboard with force and torque values displayed in real time.

53

FT300 Force Torque Sensor - Instruction Manual

Page 54

54

4.1.3. Path Recording

The Force Copilot software package adds a Path feature in PolyScope which can be used to record paths directly by moving the

robot.The ActiveDrive Toolbar is a great tool to use while recording a path, as it is an easy way to hand guide the robot’s endeffector. Path recording can be used for specific processes requiring complex paths (polishing, gluing, etc.) or more generally for

any useful case that would require programming a high number of waypoints. The Path node offers options to modify the

recorded path to change its speed and play the path backwards or relative to a variable start position.

How to add and record a path

l On the PolyScope home page, tap Program Robot

l Create an empty program or load an existing program

l In the Program tab, select the Structure menu.

l Select the URCaps submenu.

l Tap the Path button

FT300 Force Torque Sensor - Instruction Manual

Page 55

Overview

55

Path recording and visualization.

Path speed box.

Path options.

Warning section. Displayed whenever a setting results in a duration

different than the original path duration.

FT300 Force Torque Sensor - Instruction Manual

Page 56

56

When a Path node is empty (no path recorded), the only available button is

the record button.

While recording a path, the only available button is the stop button.

When the speed of the original recording is modified using the speed slider,

a warning message appears and the path time and speed information is

updated.

FT300 Force Torque Sensor - Instruction Manual

Page 57

Features*

Primary icon Description

Starts and stops the path recording.

Press and hold in order to move the robot at the path’s start.

57

Press and hold in order to move the robot at the path’s end.

Press and hold in order to move the robot to the path’s start and play the path as it will be executed in

the program.

If selected, the path is modified to play at a constant tool speed (linear speed at the tool center point).

With this option, all pauses and hesitations (dead times) in the path will be removed.

If selected, the recorded path will be played backwards in the program. It can be useful if a path is

copied and played backwards, resulting in a path played back and forth.

If selected, the path will be played relative to the current robot position when the program enters the

path instruction.

This effectively offsets all the recorded path.

Displayed whenever a setting results in a duration different than the original pathduration.

* When an icon is greyed, it means it is unavailable.

If you tap the record button when a path is already recorded in a node, a warning pop-up will ask if you want to overwrite the path

(tap OK) or keep the previously recorded path (tap Cancel).

FT300 Force Torque Sensor - Instruction Manual

Page 58

58

4.1.4. Insertion nodes

The Force Copilot software Package includes Insertion nodes, which can be used to perform spiral, rotational and linear

movements to insert objects in holes or bores, or to make contact with a surface. It is an essential integration resource for

streamlining robot programs in the framework of precise assembly applications.

When the task is performed by a human operator, the operator's fingers provide valuable feedback through the sense of touch,

thus allowing the human to detect any resistance when trying to insert a pin in a hole, for instance. To a certain extent,Force Copilot

gives that kind of sensitivity to the end effector.

How to add an Insertion node

l From the PolyScope home page, tap Program Robot

l Create or load a robot program

l Go to the Structure tab and tap the URCaps submenu

l Select Insertion

l Tap the Insertion node in the robot program to edit it

Info

The parent Insertion node is automatically followed by a Zero Sensor child node.

FT300 Force Torque Sensor - Instruction Manual

Page 59

Child nodes

59

1

Spiral button to insert a Spiral child node

2

Rotational button to insert a Rotational child node

3

Linear button to insert a Linear child node

Spiral

Following a contact established

between the object grasped by the end

effector (or the end effector itself) and

the corresponding mating part or

surface, a spiral motion is engaged on a

specific plane to find the path of least

resistance according to the direction,

speed, force, radius increment per turn

and maximum radius parameters set by

the user.

Rotational

Following a contact established between

the object grasped by the end effector (or

the effector itself) and the corresponding

mating part or surface, a rotational

motion is engaged on a specific plane to

find the path of least resistance,

according to the direction, speed, force,

maximum torque and maximum rotation

angle parameters set by the user.

Linear

Following the successful spiral,

rotational or fortuitous location of a

mating hole or bore, a linear motion

is engaged at a certain speed until

the force threshold or maximum

travel distance is reached.

FT300 Force Torque Sensor - Instruction Manual

Page 60

60

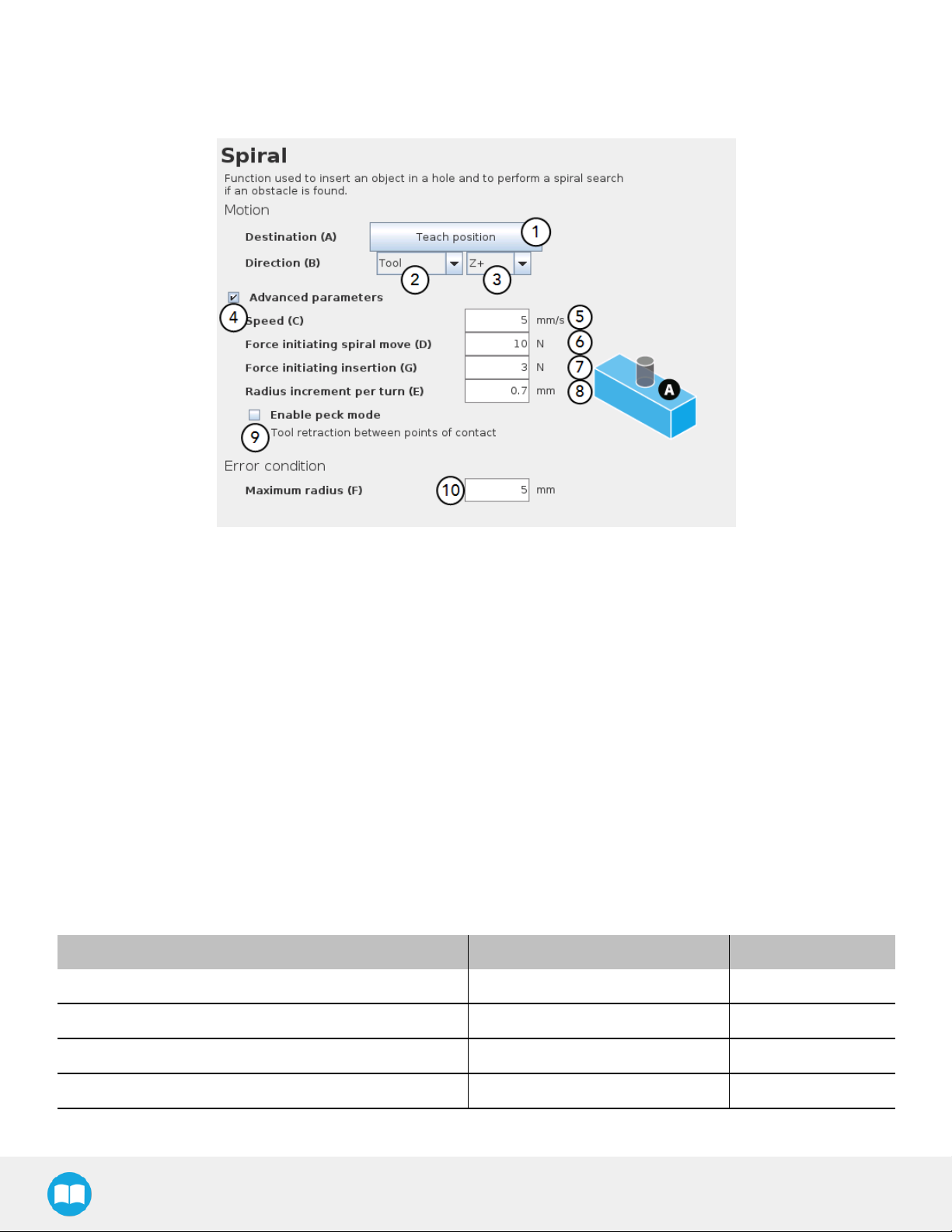

Features (Spiral)

The Spiral child node is packaged with an On error condition line to be populated with a program instruction when/if the error

condition occurs. The potential sequence after the Spiral instruction is followed by a program halt, by default.

1

Teach position button (Destination):Tapping this button saves the object's destination as a waypoint in the robot program

2

Reference frame dropdown menu (Direction):Menu used to select the frame according to which the tool will move in space

3

Axis dropdown menu (Direction): Menu used to select the direction in which the tool will go to reach the destination

4

Advanced parameters box: Box that expands the advanced parameters menu when ticked

5

Speed parameter: Textbox for the user to enter a speed value

6

Force initiating spiral move parameter:Textbox for the user to enter a force threshold value that triggers the spiral move,

after the part/tool has established contact with the mating part/surface

7

Force initiating insertion parameter: Textbox for the user to enter a force drop value indicating that the part/tool has found

the path of least resistance, prior to completing the insertion process

8

Radius increment per turn parameter: Textbox for the user to enter the distance between each spiral turn on the spiral radius

9

Enable peck mode box: Box that enables the retraction of the tool between points of contact

10

Maximum radius (Error condition): Textbox for the user to enter the maximum radius of the spiral, considering that no path of

least resistance has been found

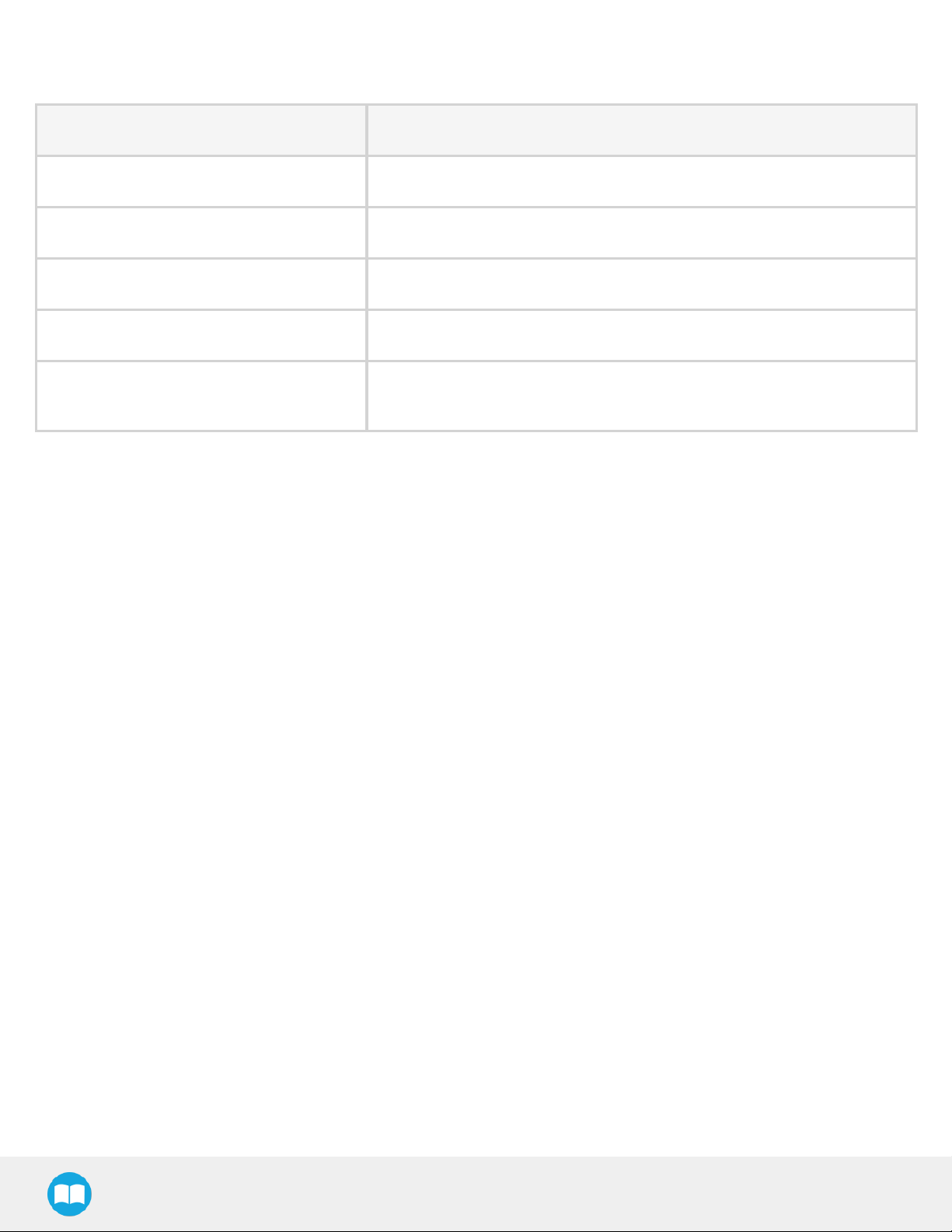

Default values and units of measurement

Parameter Unit of measurement Default value

Reference frame (Direction) N/A Tool

Axis (Direction) N/A Z+

Speed mm/s 5

Force initiating spiral move N 10

FT300 Force Torque Sensor - Instruction Manual

Page 61

Parameter Unit of measurement Default value

Force initiating insertion N 3

Radius increment per turn mm 0.7

Maximum radius (Error condition) mm 5

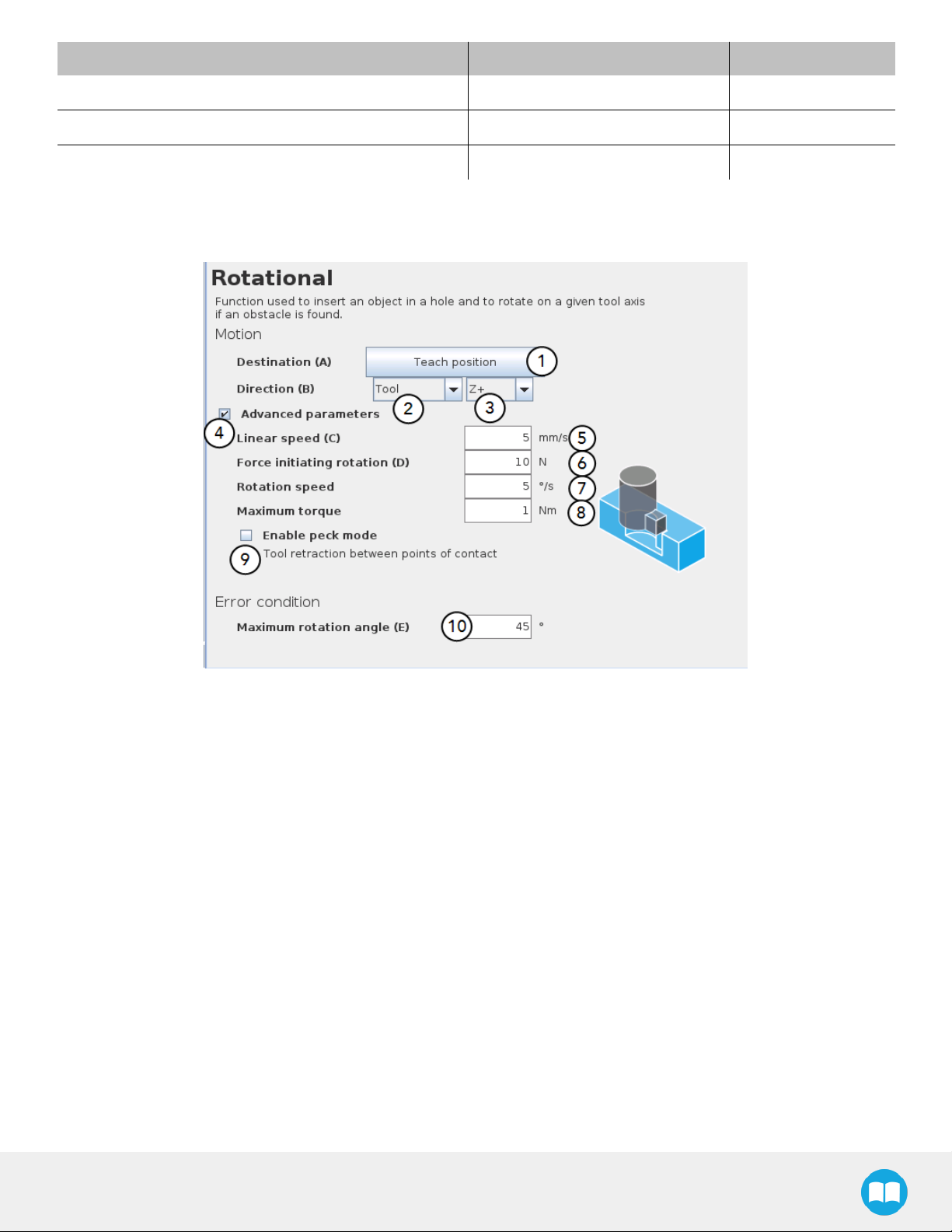

Features (Rotational)

61

1

Teach position button (Destination):Tapping this button saves the object's destination as a waypoint in the robot program

2

Reference frame dropdown menu (Direction):Menu used to select the frame according to which the tool will move in space

3

Axis dropdown menu (Direction): Menu used to select the direction in which the tool will go to reach the destination

4

Advanced parameters box: Box that expands the advanced parameters menu when ticked

5

Linear speed parameter: Textbox for the user to enter a speed value for the approach motion towards the destination

6

Force initiating rotation parameter: Textbox for the user to enter a force threshold value that triggers the rotation move, after

the part/tool has established contact with the mating part/surface

7

Rotation speed parameter: Textbox for the user to enter a speed value for the rotational (indexing) motion

8

Maximum torque parameter: Textbox for the user to enter a torque threshold value used to prevent potential collision with

objects during the rotational motion

9

Enable peck mode box: Box that enables the retraction of the tool between points of contact

10

Maximum rotation angle (Error condition): Textbox for the user to enter the maximum angle of the rotation motion, considering that no path of least resistance has been found

FT300 Force Torque Sensor - Instruction Manual

Page 62

62

Default values and units of measurement

Parameter Unit of measurement Default value

Reference frame (Direction) N/A Tool

Axis (Direction) N/A Z+

Linear speed mm/s 5

Force initiating rotation N 10

Rotation speed °/s 5

Maximum torque Nm 1

Maximum rotation angle (Error condition) ° 45

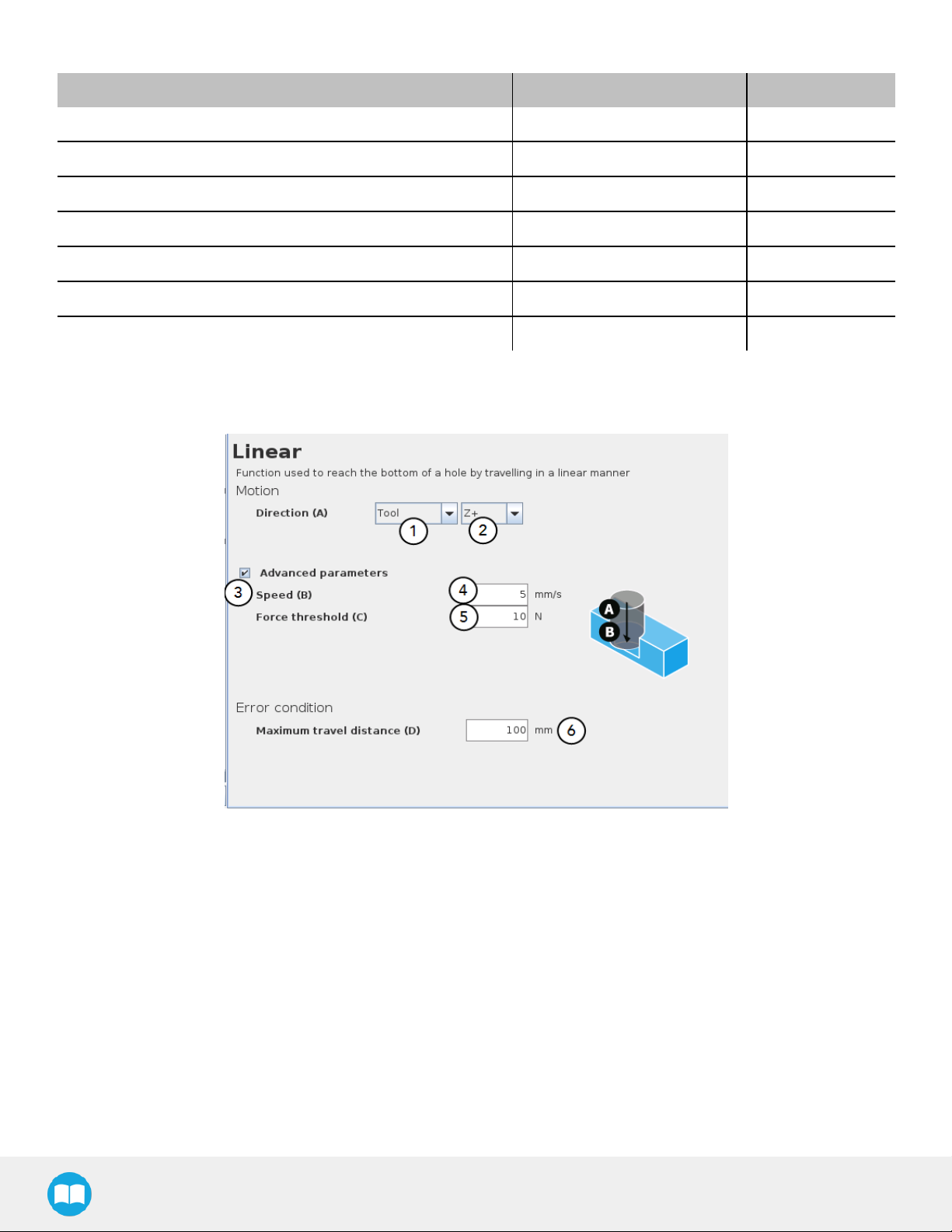

Features (Linear)

1

Reference frame dropdown menu (Direction):Menu used to select the frame according to which the tool will move in space

2

Axis dropdown menu (Direction): Menu used to select the direction in which the tool will go to reach the destination

3

Advanced parameters box: Box that expands the advanced parameters menu when ticked

4

Speed parameter: Textbox for the user to enter a speed value for the approach motion towards the destination

5

Force threshold parameter: Textbox for the user to enter a force threshold value that completes the linear motion

6

Maximum travel distance (Error condition):Textbox for the user to enter the maximum distance value which, upon being

reached, means the force threshold has never been reached in the linear motion

FT300 Force Torque Sensor - Instruction Manual

Page 63

Parameter Unit of measurement Default value

Reference frame (Direction) N/A Tool

Axis (Direction) N/A Z+

Speed mm/s 5

Force threshold N 10

Maximum travel distance (Error condition) mm 100

4.1.5. Find Surface node

The Force Copilot software package includes the Find Surface node, which is a great tool for machine tending and various other

applications that require repeated accurate positioning of objects.

The default parameters of the function allow for a versatile demo or a quick test of the features while the advanced parameters

make it a more customizable asset.

63

How to add a Find Surface node

l From the PolyScope home page, tap Program Robot

l Create or load a robot program

l Go to the Structure tab and tap the URCaps submenu

l Select the Find Surface node

l Tap the Find Surface node in the robot program to edit it

1

Direction relative to the tool dropdown menu:Menu used to select the direction of the linear motion, relative to the tool

2

Zero Sensor Before Execution box: Box that inserts a Zero FT Sensor command right before the Find Surface instructions

3

Advanced parameters box: Box that expands the advanced parameters menu when ticked

FT300 Force Torque Sensor - Instruction Manual

Page 64

64

4

Motion speed parameter: Textbox for the user to enter a speed value for the approach motion towards the destination

5

Maximum distance traveled (Stop condition):Textbox for the user to enter the maximum distance value which, upon being

reached, means the force threshold has never been reached in the linear motion

6

Insert instruction textbox: Checkbox that inserts the corresponding stop condition in the robot program when ticked; its main

function is to facilitate the programming and improve the user experience

7

Force threshold (Stop condition): Textbox for the user to enter a force thershold value that completes the linear motion

8

Insert instruction textbox: Checkbox that inserts the corresponding stop condition in the robot program when ticked; its main

function is to facilitate the programming and improve the user experience

Parameter Unit of measurement Default value

Direction relative to the tool N/A Z+

Motion speed mm/s 5

Maximum distance traveled (Stop condition) mm 100

Force threshold (Stop condition) N 10

FT300 Force Torque Sensor - Instruction Manual

Page 65

65

Fig. 4.3: Find Surface node with stop condition(s)

FT300 Force Torque Sensor - Instruction Manual

Page 66

66

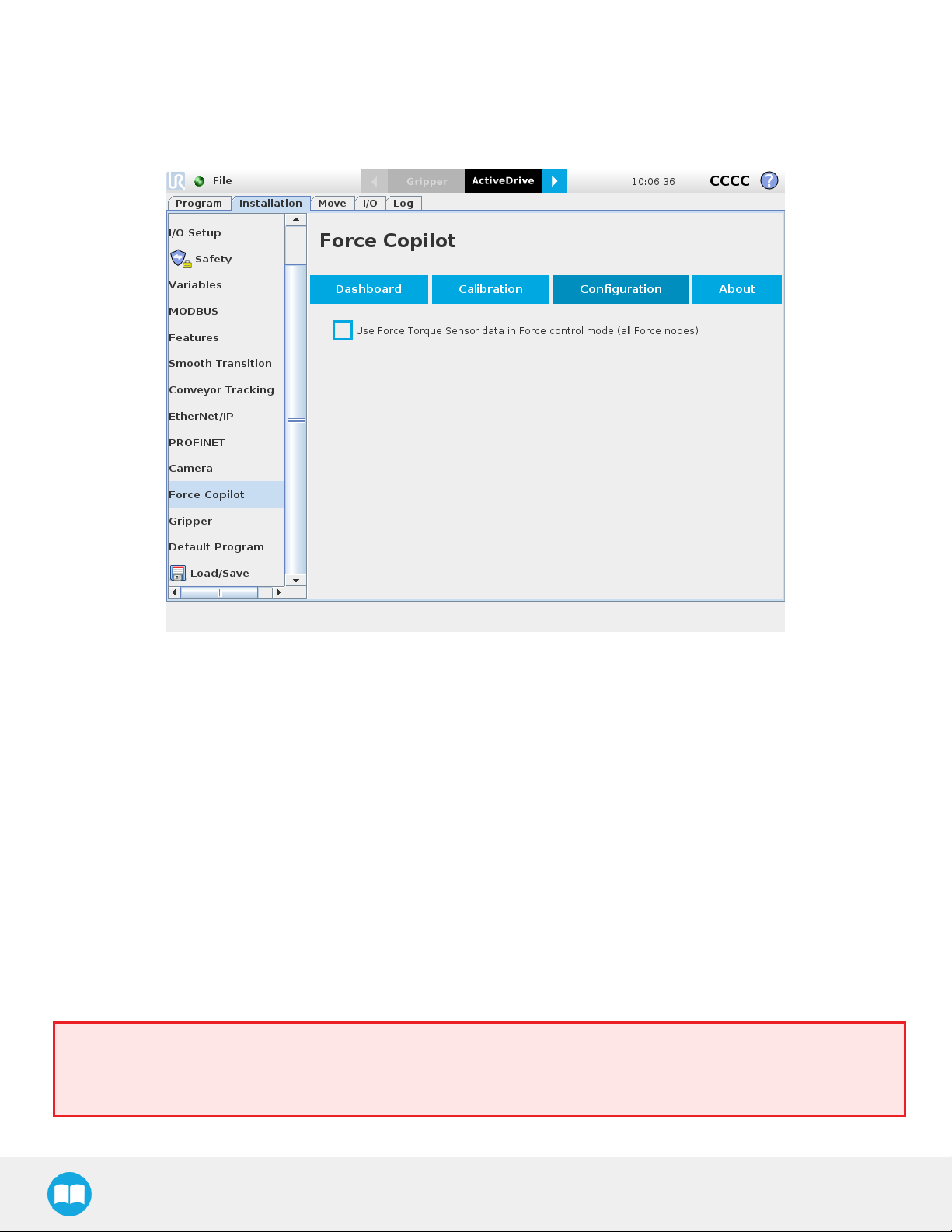

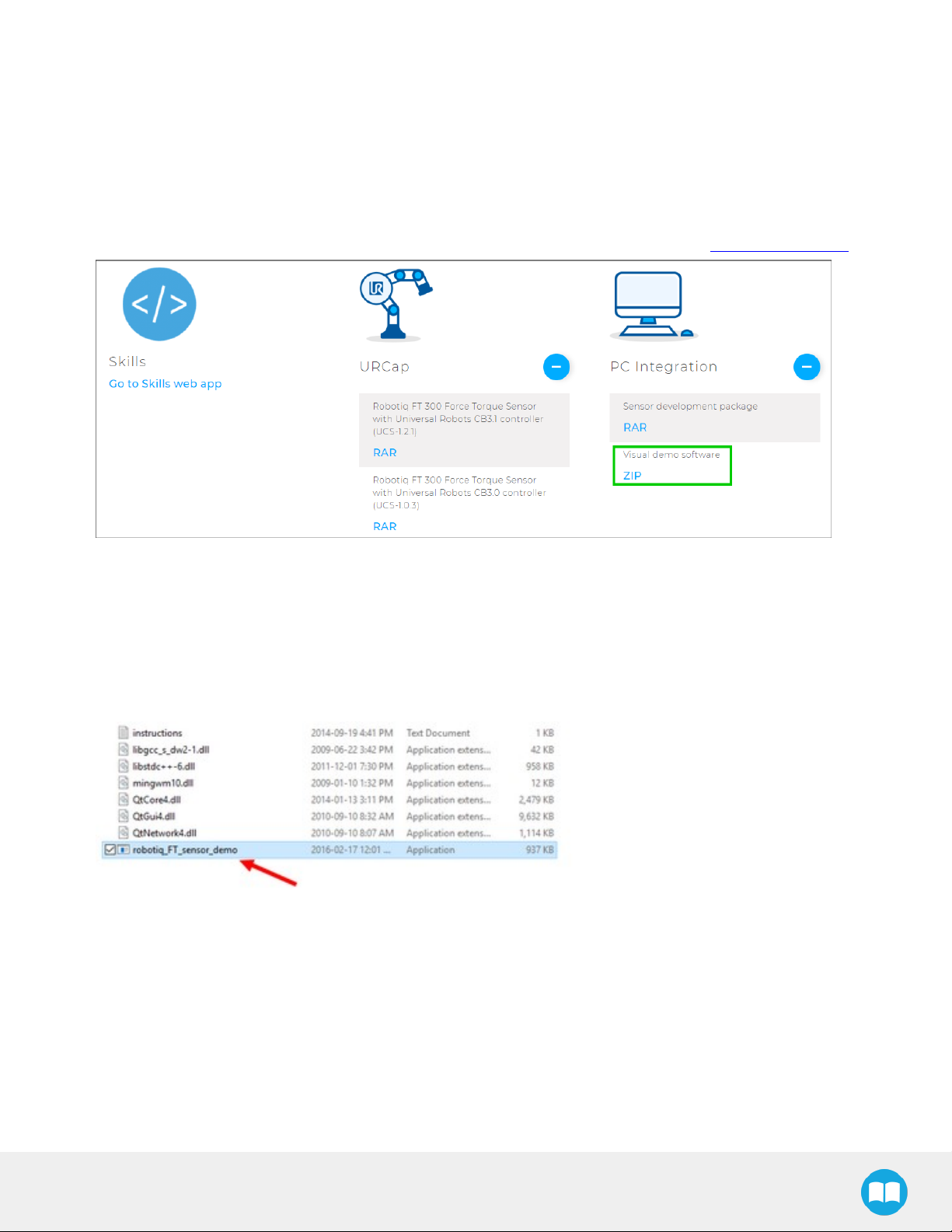

4.1.6. Using the Force Torque Sensor's Data in Force Nodes

In order to use the FTSensor's data in Force control mode for all Force nodes, go to the Configuration tab and check the

corresponding box. This will feed the Sensor's force values to the UR Force mode as an alternative to UR's embedded force

feedback.

4.1.7. Force ControlNode

Overview

The Robotiq Force Control node is used to apply force and torque values along and around axes.

How to add a Force Control node

l From the PolyScope home page, tap Program Robot

l Create or load a robot program

l Go to the Structure tab and tap the URCaps submenu

l Select the Force Control node

l Tap the Force Control node in the robot program to edit it

Warning

UR Move nodes (MoveL, MoveJ, MoveP)and Force nodes cannot be executed as child of the Robotiq Force Control

node.

FT300 Force Torque Sensor - Instruction Manual

Page 67

Tip

Where a URMove node would normally be used, the user shall record a Robotiq Path emulating the desired Move.

In a situation where the user wants to make contact with a surface in accordance with the user-defined settings, a Wait

instruction can be inserted as child of the Robotiq Force Control.

The Force Control node is primarily meant to be used with a Robotiq Path node.

With the various user-defined settings available, operators can use a force torque sensor to apply force/torque and thus follow

irregular shapes and/or surfaces for applications such as polishing, deburring, finishing, dispensing, etc.

67

FT300 Force Torque Sensor - Instruction Manual

Page 68

68

Features

Reference frame

The user can select a reference frame from a dropdown menu, as shown below.

The Tool reference frame uses the X, Y and Z axes of the end-effector to apply force and torque values in the appropriate direction.

On the other hand, the Base reference frame takes into consideration the X, Y and Z axes of the robot arm base.

Fig. 4.4: Force Control node with Reference Feature dropdown highlighted.

FT300 Force Torque Sensor - Instruction Manual

Page 69

Parameters

69

1

Enable control:each checkbox corresponds to the enablement of force feeding along an axis (upper three options) or torque

feeding around an axis (lower three options)

2

Force/Torque:depending on which options were checked at step 1, the corresponding textboxes here should be filled with

the desired force/torque values

a

Force values applied are in newtons (N) – the range allowed goes from -150 to +150 N

b

Torque values applied are in newton-metre (Nm) – the range allowed goes from -50 to +50 N.

Info

Tapping the text boxes brings up a numpad used to enter the values.

3

Stiffness:the stiffness settings act directly on the Sensor's directional compliance depending on the orientation of the endeffector and the axes selected at step 1.

a

A stiffness value closer to 0% will provide greater compliance along/around the corresponding axis

b

A stiffness value of 100% offers no compliance along/around the corresponding axis

4

Deviation range:the deviation range limits the flexibility allowed along/around the corresponding axis.

a

The deviation range along the X, Y and Z axes is measured in millimeters (mm) – the negative range allowed goes

from -1000 mm to 0 mm while the positive range allowed goes from 0 mm to 1000 mm.

b

The deviation range around the X, Y and Z axes is mesured in degrees (°) – the negative range allowed goes from

-179° to 0° while the positive range allowed goes from 0° to 179°.

Example

In a situation where 10 N are applied exclusively along the Z-axis, with 20% stiffness along the X and Yaxes, and a

deviation range that goes from -50 mm to +50 mm along all axes...

FT300 Force Torque Sensor - Instruction Manual

Page 70

70

l The end-effector will systematically point towards its Z-axis

l The end-effector will not rotate around Rx, Ry and Rz (no torque feeding)

l The end-effector will be moderately flexible to move along the X and Yaxes

l The movements along the X, Yand Z axes will be limited to -50 mm and +50 mm from the command position

Fig. 4.5: Deviation range - On the left, no deviation range has been entered. On the right, a deviation range of at least 15 degrees

has been entered around the corresponding axis.

5