Page 1

Robotiq EPickVacuumGripper

forTM Robots

Original Notice

© 2019Robotiq Inc.

Instruction Manual

robotiq.com | leanrobotics.org

Page 2

Revisions 5

1.GeneralPresentation 7

1.1. Grippernomenclature 7

1.1.1. EPick Gripper 7

1.1.2. Suction Cup System 8

1.2. Object picking 9

1.2.1. Main unit suction cup 9

1.2.2. Auxiliarysystem with multiple suction cups 9

1.3. Setupandcontrol 9

2.Safety 11

2.1. Warning 12

2.1.1. Risk assessment and final application: 12

2.2. IntendedUse 13

2

3.Installation 14

3.1. ScopeofDelivery 14

3.1.1. Robotiq EPick Vacuum Gripper Kit 14

3.2. RequiredToolsandEquipment 16

3.2.1. EPick Gripper Add-On 16

3.2.2. Suction cup system 16

3.3. Environmentaland OperatingConditions 16

3.4. MechanicalInstallation 17

3.4.1. Installing the Vacuum Gripper onto the robot 17

Single Gripper 17

3.4.2. Air tubing 18

Connectionof the suction cup systems 18

3.4.3. Suction cup system 19

Manifold and mounting bracket 19

Suction cupsand airnodes 20

3.5. ElectricalSetup 21

3.5.1. Pinout interface 21

3.5.2. Coupling to controller 22

Single VacuumGripper 23

3.6. Testingthe GripperwiththeRobotiqUserInterface (RUI) 24

EPick- InstructionManual

Page 3

3

3.6.1. License Agreement 26

4.Software 29

4.1. Overview 29

4.1.1. Control using registers 29

4.2. Vacuum Gripperregistermapping 31

4.3. Robotoutputregisters&functionalities 31

4.4. Robotinput registers& status 35

4.5. Gripperbehavior 38

4.5.1. Control modes 38

Automaticmode 38

Advanced mode 39

Veryporousmaterialdetection 41

Objectlost/ drop behavior 41

Objectsecured behavior 41

Objectnot detected behavior 42

Objectreleasedelay 42

Emergencystop behavior 42

4.6. Controllogic 42

4.7. ModbusRTU communication 42

4.7.1. Connection setup 43

4.8. ControloverTM 44

4.8.1. TM Robots compatibilitywith Robotiq Vacuum Grippers 44

4.8.2. Getting Started 44

4.8.3. TM Vacuum Gripper Components 48

Installation 48

GripperButton 53

Programming 56

Advanced Mode 57

GRIPComponent 58

RELEASEComponent 58

SelectID Component 59

Changing theModbusSlaveID 59

5.UserInterface 62

Page 4

6.Specifications 63

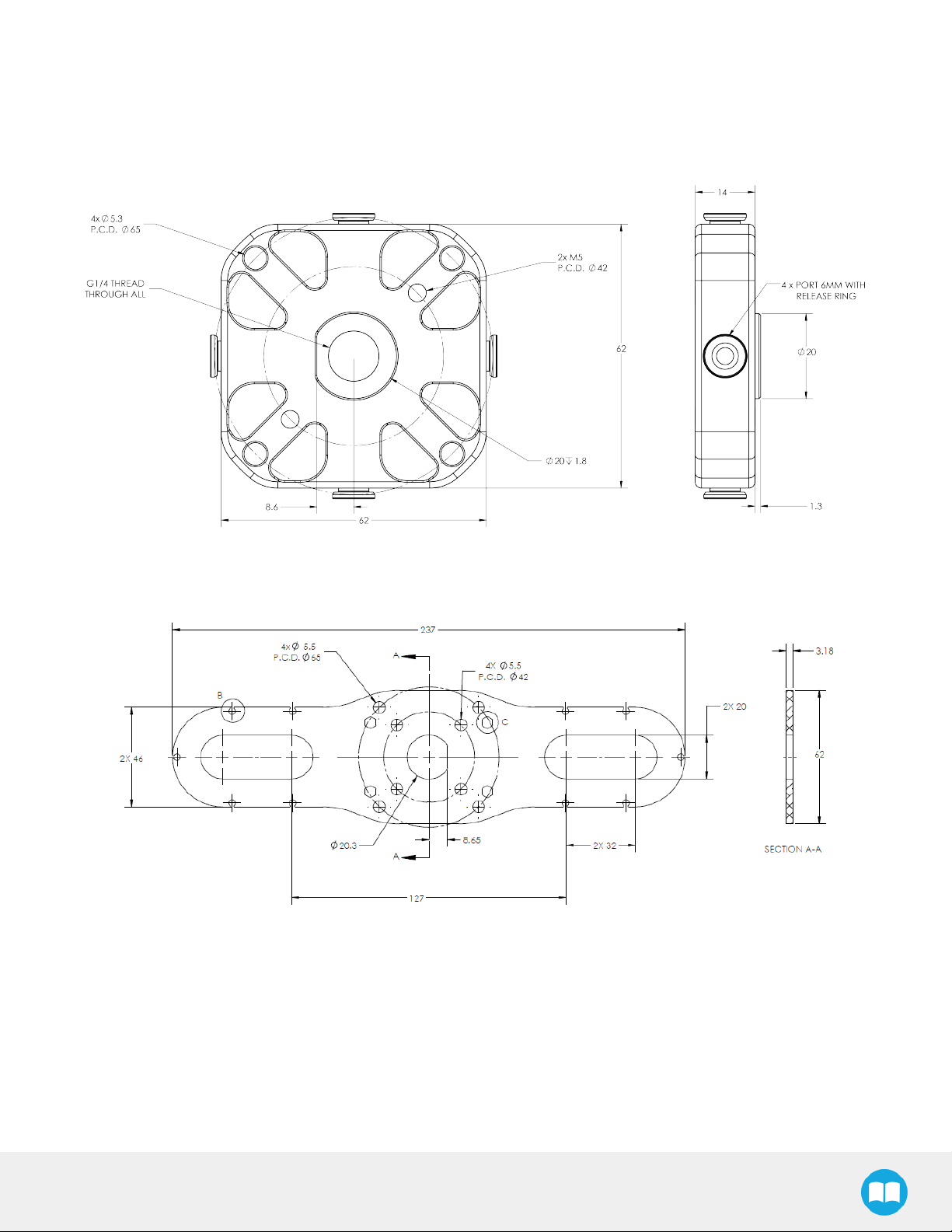

6.1. Technicaldimensions 64

6.1.1. Gripper 64

6.1.2. Suction Cup System 65

Manifold 65

Bracket for2 suction cups 65

Bracket for4 suction cups 66

6.1.3. Air nodes 68

6.1.4. Couplings 69

Blankcoupling 69

Coupling forISO 9409-1-50-4-M6 70

6.2. Mechanicalspecifications 71

6.2.1. Payload and force 72

4

Example1:Non-porousmaterial 75

Case#2 76

Example2:Porousmaterial 76

Case#1 78

6.2.2. Center of massand tool center point 79

6.2.3. Moment Limitation 80

6.3. Electricalspecifications 80

7.Maintenance 81

7.1. Vacuum Grippercleaning 82

7.2. Periodicinspection 83

Suction cupsand airnodes 84

8.Spare Parts, Kitsand Accessories 85

9.Troubleshooting 88

9.1. Vacuum Gripperverification 88

10. Warranty 89

11. Harmonized Standards, Declarationsand Certificates 91

11.1.OriginalECdeclarationofincorporation 91

11.2.Appliedstandards 92

12. Contact 93

EPick- InstructionManual

Page 5

5

Revisions

Robotiq maymodify thisproductwithout notice,whennecessary,due to product improvements,modificationsor changesin

specifications.If suchmodificationis made,themanual will also berevised,seerevision information.Seethelatest versionof this

manualonlineatsupport.robotiq.com.

2019/08/13

l Update of thelatestTMflow 1.72.3500

l Update of theversion V_002of thecomponents

2019/07/02

Initial release

Page 6

6

Copyright

© 2019Robotiq Inc.All rightsreserved.

Thismanualand theproduct it describesareprotected bytheCopyright Actof Canada,bylawsof othercountries,and by international

treaties,and thereforemaynot be reproduced in whole or inpart,whetherforsaleor not,without priorwrittenconsentfrom Robotiq.

Under copyright law,copying includestranslationinto anotherlanguage or format.

Information provided byRobotiq in thisdocument is believed to be accurate and reliable.However,no responsibility is assumed by

Robotiq for itsuse.Theremaybe somedifferencesbetweenthe manualand theproduct if theproduct hasbeenmodified afterthe

editiondate.

Theinformation contained inthisdocument issubject to change without notice.

EPick- InstructionManual

Page 7

7

1.GeneralPresentation

Theterms“ Gripper”,"EPickGripper", " EPickVacuumGripper" and "EPick" used in thefollowing manual allreferto the Robotiq EPick

VacuumGripper.TheRobotiq EPick VacuumGripperisa robotic peripheral designedfor industrialapplications. Thevacuum is

generated withanelectricvacuum pump. Itsdesignmakesit a uniquerobotic end-of-arm tool to quicklypick,placeand handlea large

range of partsof varying sizesand shapes.

Info

Thefollowing section presentsthekeyfeaturesof the Gripperand must not be considered asappropriateto theoperation of

theGripper.Eachfeatureis detailed inthe appropriatesection.

Info

Thefollowing manualusesthemetricsystem.Unlessspecified, alldimensionsareinmillimeters.

1.1. Grippernomenclature

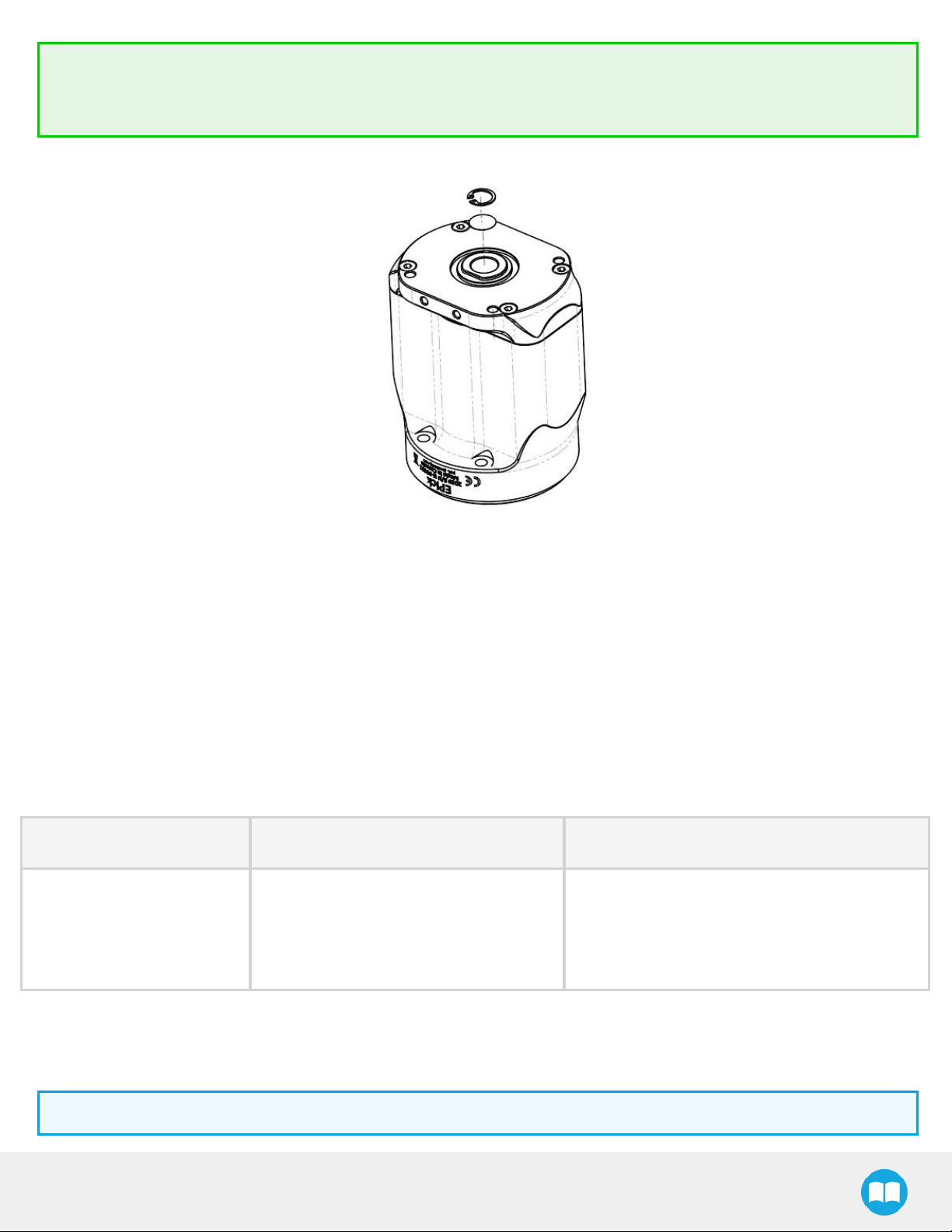

1.1.1.EPick Gripper

TheEPickGripperis avacuum Gripperthat generatesavacuum withanelectricvacuumpump..Itis equipped with oneormultiple

suction cups.Eachsuctioncup canbeadapted to your application and grasping needs.TheEPickGripperis compatible withthe

Robotiq standard coupling interface.

Fig. 1-1:Robotiq EPickGripper

EPick- InstructionManual

Page 8

8

Info

Pleasereferto theScope of Deliverysectionsubsection and the SpareParts, Kitsand Accessoriessection for detailson

standard andoptionalparts.

1.1.2.SuctionCupSystem

A Robotiq Suction Cup System can be installed directly under the Vacuum Gripper. Each Robotiq Suction Cup System includes a

bracket,a manifold, airnodes,port plugs,bumpers,tubing and additionalsuctioncups.

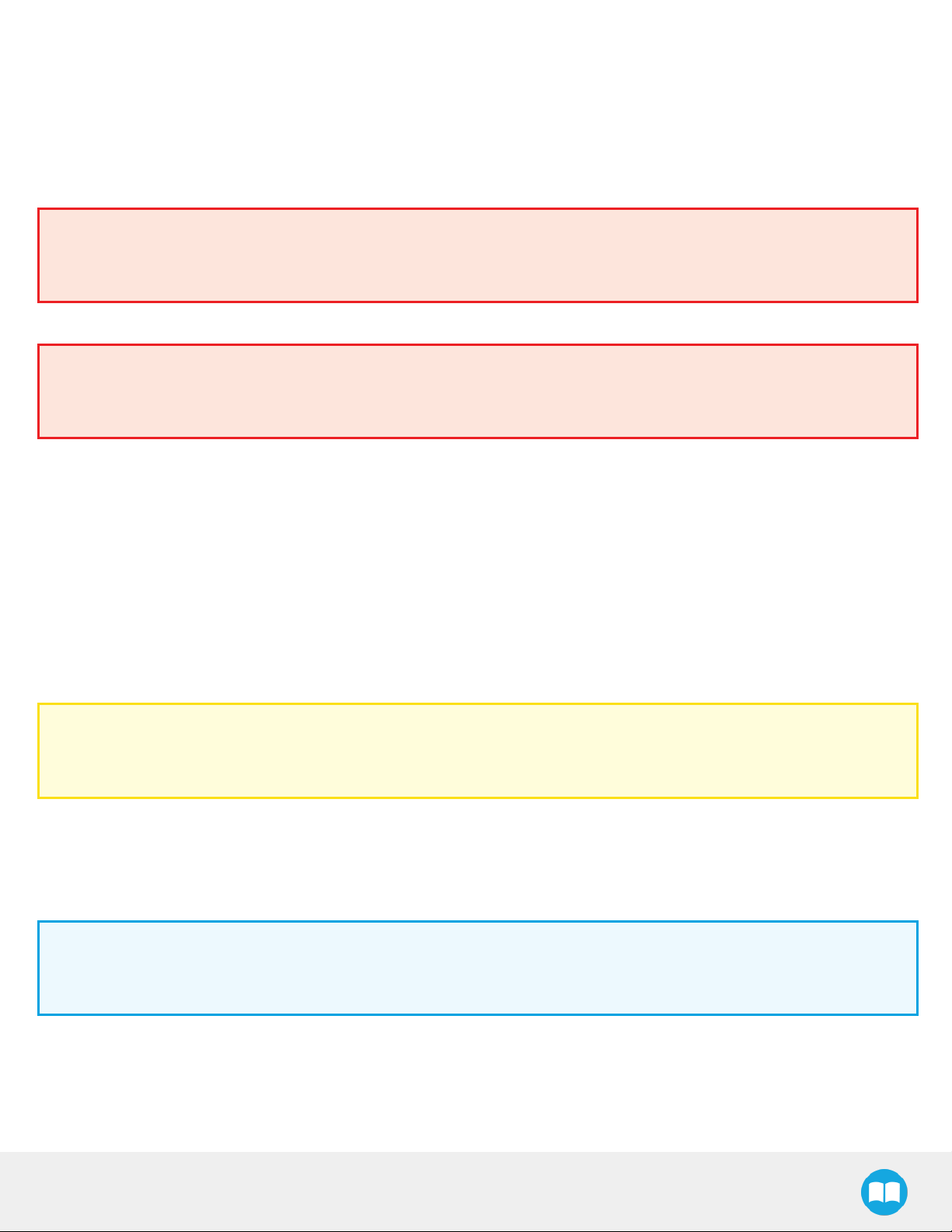

Fig. 1-2:Suction cup system

Info

Pleasereferto theInstallationsection for moreinformation on howto integratetheSuction Cup Systemto EPick.

Info

Pleasereferto theScope of Deliverysectionsubsection and the SpareParts, Kitsand Accessoriessection for detailson

standard andoptionalparts.

Tip

Theowner canusea custom bracketora mounting plate.Thebracketormounting plate canbeinstalled directlyunderthe

manifold.

Page 9

1.2.Object picking

TheEPickGripperallows:

1. Mainunitsuctioncup

2. Auxiliarysystem with multiple suctioncups

Warning

Objectpicking causesthecompression of thesuction cup(s),whichcanresultin pinching pointsbetweenthe gripperand the

load. Avoid presenceof bodypartsinthiszoneduring operation.

Warning

Before picking anynewobject or materialin autonomousmode,alwayscheckthat theresulting vacuumlevel issufficient to

ensuresafegripping,in order to prevent dropping or ejection of the load.

9

1.2.1.Mainunit suctioncup

Inorderto useonlyonesuction cup, thesinglecup canbe mounted right intheport of the vacuumgenerator.

1.2.2.Auxiliary systemwith multiplesuction cups

A standard Suction Cup Systemcanbe attached to theEPickVacuumGripper.Thebracket normallyholds two or foursuctioncups

(corresponding to thefourports of themanifold).

Anyunused manifold port should be blocked witha mating plug to avoid airleakage.

Othercustom mounting optionscanalso be used to benefit from a multiple suction cupssolution

Caution

Custom bracketsand platesmust meet therequired technical specifications(referto the Technicaldimensionssection

subsection).

1.3.Setupand control

TheVacuumGripper ispowered and controlled directlyviaa single devicecablethat carries24VDC powerand ModbusRTU

communication overRS-485.

Info

Pleasereferto theElectricalSetup section subsection for wiring information,and to the Softwaresection forthe control of the

VacuumGripper.

Inorderto be used,theEPickGripper hasto be connected to aGrippercoupling whichprovidesboth themechanicaland electrical

connectivityto the Gripper.

EPick- InstructionManual

Page 10

10

Info

Pleasereferto theMechanicalInstallationsection formoreinformation on mounting theVacuumGripperonto thecoupling.

Refer to the Technicaldimensionssectionfor thetechnical drawing,and referto theSpare Parts, KitsandAccessoriessection

for alist of theavailablecouplings.

TheEPickGripperboasts an embedded object detection featurewhichusesindirectsensing measurements.Thesystemthusindicates

if theworkpiecehasbeendropped or if theGripper failed to grasp theworkpiece.

Info

For moreinformation regarding theobject detection feature,please referto theSoftware section.

Page 11

2.Safety

Warning

Theoperatormusthaveread and understood all of theinstructionsinthe following manual beforeoperatingtheRobotiq

VacuumGripper.

Caution

Theterm“operator” refersto anyone responsiblefor anyof thefollowing operationson theRobotiq Vacuum Gripper:

l Installation

l Control

l Maintenance

11

l Inspection

l Calibration

l Programming

l Decommissioning

Thismanualcoversthevariouscomponentsof theRobotiq VacuumGripperand thegeneral operationsregarding thewholelife-cycle

of the product, from installation to operation and decommissioning.

Thedrawings and photosin thismanualarerepresentativeexamples.However,discrepanciesmaybe observed betweenthevisual

supportsand theactual product.

EPick- InstructionManual

Page 12

12

2.1. Warning

Caution

Anyuseof theGripperin non-compliancewiththesewarningsis deemed inappropriate and maycause injuryor damage.

Warning

l Alwaysusethe suctioncup system and its components(airnodes,port plug, etc.)withtheRobotiq VacuumGripperonly.

l Neveroperatethe VacuumGripperwithleaking orwornparts.

l TheVacuumGripper needsto be properlysecured beforeoperating the robot.

l Do not installor operate aGripperthatis damaged or lacking parts.

l Neversupply theGripperwith an alternating current source.

l Makesureall cord setsarealwayssecured at both ends—Gripperand robot.

l Alwaysmeet therecommended keying for electricalconnections.

l Makesureno individualsor assetsareinthe vicinityof the robot and/orGripperpriorto initializing therobot.

l Alwaysmeet theGripper’spayload specifications.

l Set yourvacuum levelbased on yourapplication.

l Keep body partsand clothing awayfrom theGripperwhilethedeviceispowered on.

l Do not usetheGripperon people or animals.

l Neverstand undersuspended loadsheld by theVacuumGripper.

2.1.1.Riskassessment andfinal application:

TheRobotiq Vacuum Gripperismeantto be used on cobotsand industrial robots.

Therobot, theGripper and anyotherequipment used in thefinal application must go througha comprehensiveriskassessment

processbeforetheycanbe used.Special caremust be takenduring thisstep if custom mounting optionsareused for thesuction cups.

Caution

Itis therobot integrator’sresponsibilityto ensure thatall localsafetymeasuresand regulationsaremet.

Thefollowing non-exhaustivelistpresentsrisksthatmustbeassessedduringtheintegration process:

l Riskof contact betweenbodypartsand suction cups during gripping;

l Riskof load ejection resultingfrom lossof vacuum;

l Riskof load dropping resultingfrom lossof vacuum;

Page 13

l Riskof pinching betweenthe VacuumGripperand thepart(s)ortheenvironment;

l Riskof damageor breaking if using acustom suction cup bracket thatdoesnot meet thetechnicalrequirements.

Depending on theapplication,there maybe hazardsthat requireadditionalprotection and/or safetymeasures.Forinstance,the

workpiecehandled bythe Grippercould beinherentlydangerousto the operator.

Warning

Depending on thesupply sources,whenanemergencystop (e-Stop)button is pressed, thefollowing consequencesmay

occur.Therobot ownerhasthe responsibility to do a riskassessmentand choosetheappropriateoption.

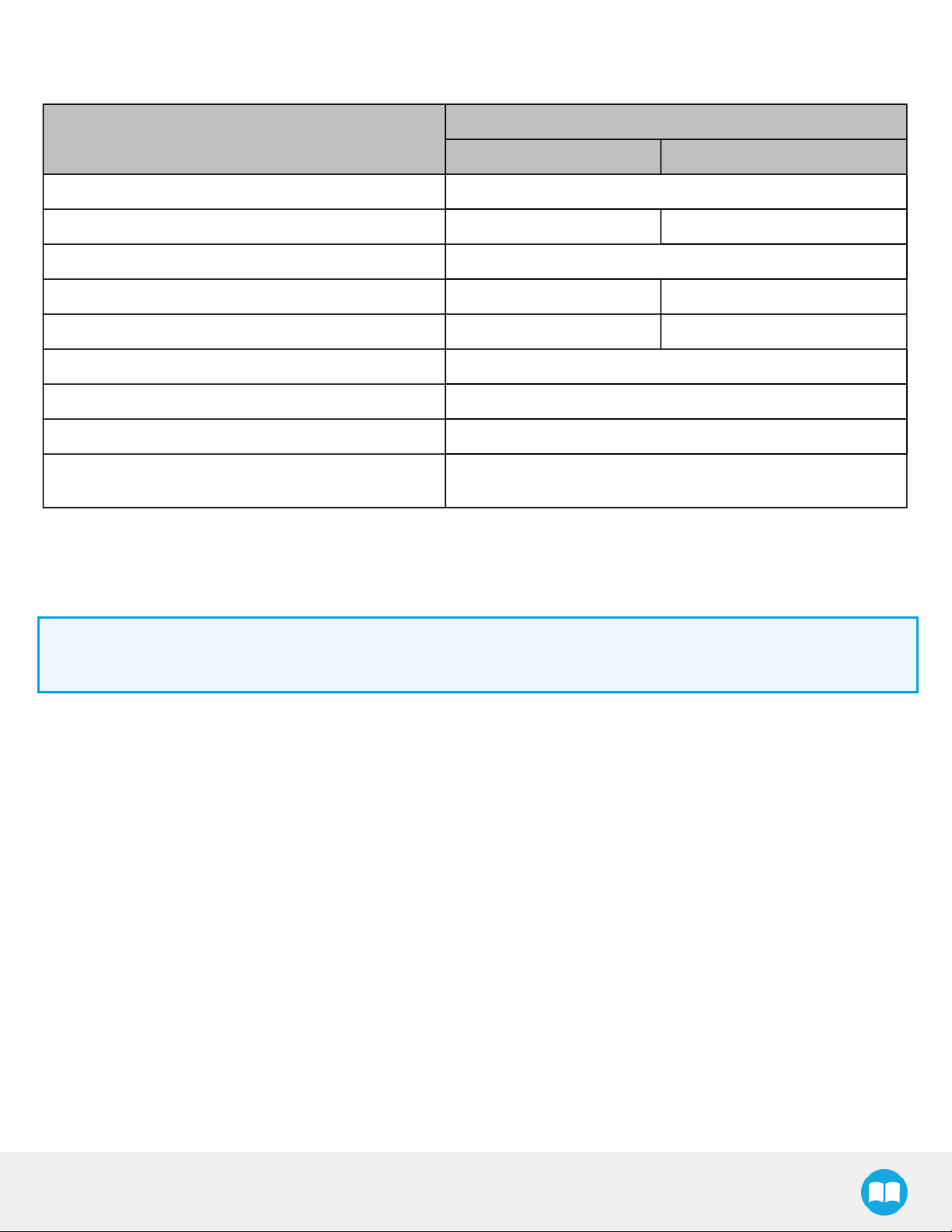

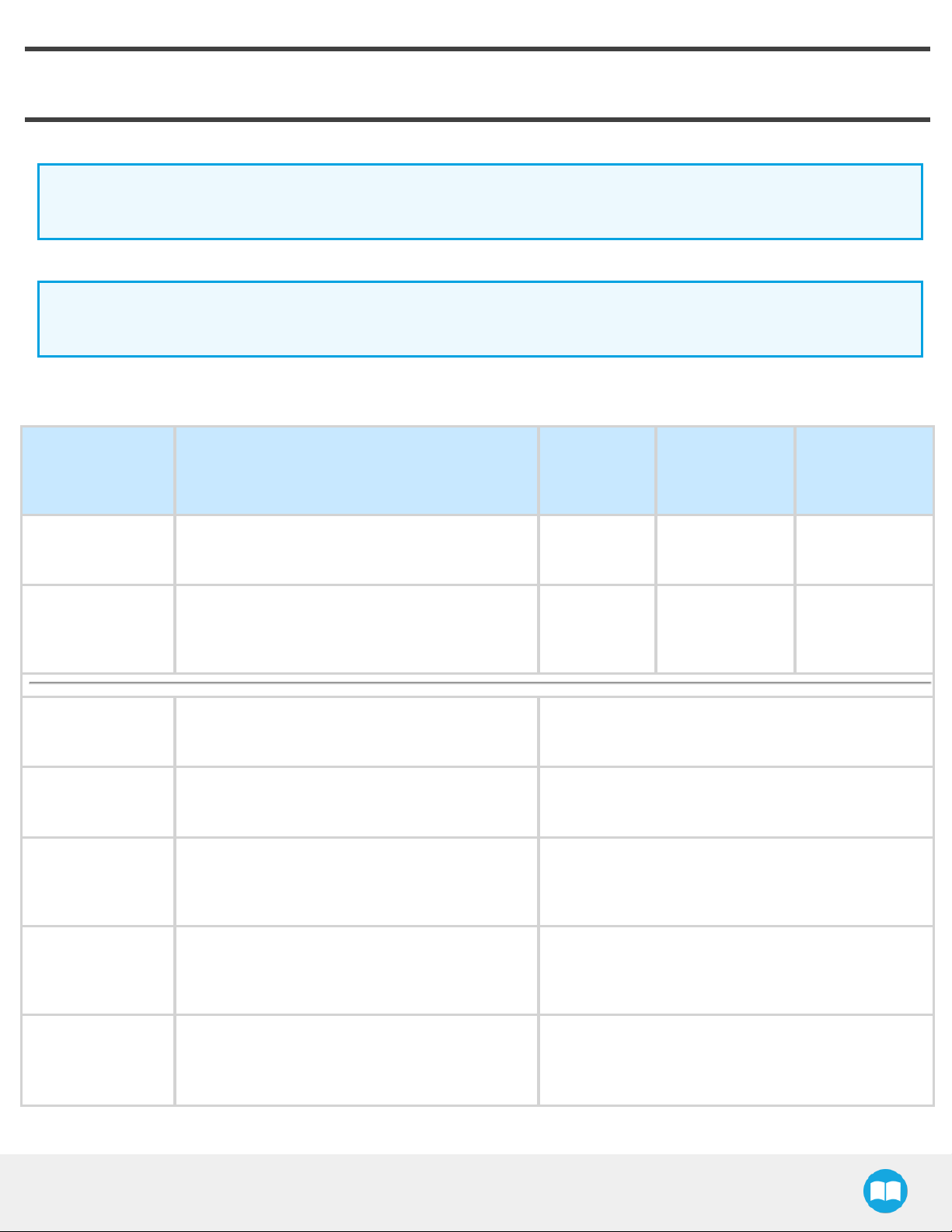

Supplysources e-Stop consequences

13

Robot tool supply

Powerfailureto theVacuum Gripper.Thevacuumlevelwilldrop to ambient pressureand the

objectwill be lost.

(tool connector)

VacuumGripper powered ON.

Robot controller supply

(Any24Vpin)

l Ifanobject isdetected: thevacuum levelwill continueto be regulated and theobject will

not be lost.

l Ifno object is detected:theVacuum Gripperwill go into astandby state 2 secondsafter

thee-Stop button ispressed.

Warning

Lossof vacuum canoccurdue to powerfailure.

2.2.Intended Use

TheGripperunit isdesigned for gripping and temporarilysecuring or holding objects.

Caution

TheGripperisNOT intended for applying forceagainstobjectsor surfaces.

Theproductis intended for installation on arobot or otherautomated machineryandequipment.

Info

Alwayscomplywith local,state,provinceand/or federallaws,regulation and directivesregarding automationsafetyand

generalmachinesafety.

Theunitshould be used exclusivelywithin therangeof itstechnicaldata.Anyotheruseof the productis deemed improperand

unintended.Robotiq will not be liablefor anydamagesresulting from anyimproperor unintended use.

EPick- InstructionManual

Page 14

3.Installation

Thefollowing subsectionswillguide you throughtheinstallation and generalsetup of yourRobotiq Vacuum Gripper.

Warning

Before installing:

l Read and understand thesafetyinstructionsrelated to theVacuumGripper.

l Verifyyourpackage according to the scope of deliveryandyourorder.

l Makesureto havetherequired parts,equipmentand toolslisted in Scope of delivery.

Warning

Wheninstalling:

14

l Meetthe recommended environmental conditions.

l Do not operate theVacuumGripper,oreventurnon thepowersupply,beforethedeviceisfirmlyanchored and themachine

areais cleared.Makesurethat theairsupply is secured.

3.1. Scope of Delivery

3.1.1.RobotiqEPickVacuumGripperKit

Standard upon delivery:

l Standard Kit

o

One(1)electricalvacuum generator

o

Two(2)standard suction cups(two different sizes)

o

One(1)End effectorcoupling kit

o

One(1)USBstick

o

One(1)USBto RS485signalconverter

o

One(1)RS485to RS232Converter

o

One(1)10-meterscommunicationcable

o

Required hardware

EPick- InstructionManual

Page 15

15

l 2SuctionCupsKit

o

One(1)Vacuumgenerator

o

One(1)suctioncup system for 2suction cups ( 1manifold,1 bracket, tubing, 2 airnodes,4 suctioncups)

o

Four(4)standard suction cups(two different sizes)

o

Four(4)port plugs (two alreadymounted on thesuction cup system)

o

One(1)End effectorcoupling kit

o

10-metercommunicationcable

o

One(1)USBto RS485signalconverter

o

One(1)RS485to RS232Converter

o

Required hardware

l 4SuctionCupsKit

o

One(1)Vacuumgenerator

o

One(1)suctioncup system for 4suction cups (1manifold, 1bracket,tubing,4 air nodes,8 suction cups)

o

Eight (8)standard suctioncups(two different sizes)

o

Four(4)port plugs

o

One(1)End effectorcoupling kit

o

10-metercommunicationcable

o

One(1)USBto RS485signalconverter

o

One(1)RS485to RS232Converter

o

Required hardware

Info

Pleasereferto theSpare Parts,Kitsand Accessoriessection for alist of available couplings.

Caution

Thefollowing are not included in thestandard delivery:

l Optionssuchascustom suction cup brackets/platesor couplingsfor mounting on variousindustrialrobots.

l Hardwarerequired for accessoriesor fixtures,unlessspecified.

Info

Whenpurchased asakit,theEPickVacuumGripperwill comein apackage withtheappropriatecoupling,suctioncupsand

cabling.

Page 16

Pleasereferto theSpare Parts,Kitsand Accessoriessection for additional components.

3.2. Required ToolsandEquipment

3.2.1.EPick Gripper Add-On

Thefollowing toolsarerequired to install theVacuum Gripper:

l Hexkeyto mount thecoupling onto therobot,according to yourcoupling

l 4mm hexkeyto mount theVacuum Gripperonto its coupling .

3.2.2.Suctioncupsystem

Thefollowing tool isrequired to install theSuction cup systemonthe VacuumGripper:

l 4mm hexkeyto assembletogetherthesuction cup systemand thevacuum generator.

16

3.3. Environmentaland Operating Conditions

CONDITION VALUE

Minimumstorage/transit

temperature

Maximumstorage/transit

temperature

Minimumoperating temperature 5°C[41°F]

Maximumoperating temperature 40°C[104°F]

Humidity (non-condensing) 20-80%RH

IPRating IP4X

Table3-1:Environmental and operating conditionsof the EPickVacuumGripper

-30°C[-22°F]

60°C[140°F]

Caution

Useof theVacuum Gripperis not recommended inpresence of chemicalsin theenvironment.

EPick- InstructionManual

Page 17

17

Info

Theinput filterprevents anydust larger than200 µm from getting insidethepump. Drydust will preventtheaccumulation on

filtersor inside thepump.Theuseof suction cups withintegrated filtercanbe used to reducedustaccumulation.

Theexhaustmustnot be blocked.

3.4.Mechanical Installation

3.4.1.InstallingtheVacuumGripperonto therobot

Single Gripper

For purposesof powerand communication,acoupling mustbeusedto attachtheVacuum Gripperto therobot.

Herearethestepsto follow to mount theGripper on therobot arm(exploded viewin figurebelow). Pleasenote thatall screwsshould

be secured using mediumstrengththreadlockers.

1. Mount thecoupling on therobot wristusing the provided M6 screwsand toothlockwashers.Alignproperlywith thedowelpin.

Thedowelpin ismeant to haveatight fit on therobot side and a slip fit on theeffector side of theassembly.

2. FastentheGripperto thecoupling usingtheprovided M5 screwsand tooth lockwashers.

3. Plug thedevicecableinto the gripper'spigtail andattachthecable along therobot armusing a cable routing system.

Page 18

18

Fig. 3-1:Installing the VacuumGripperonto therobot wrist

3.4.2.Air tubing

Connectionof the suctioncup systems

To ensurevacuumdistribution to the suction cups,connect theappropriatemanifold portswiththe pertaining airnodesusing the

provided plastictubing.

Info

To facilitatetheassemblyof theRobotiq Wrist Cameraon thesuction cup system,makesureto placethetubing asshownin

thefigureto be assured that therewill be no interferencewiththecamera'sfield of viewwhile preventing excessivetube

bending.

EPick- InstructionManual

Page 19

19

Fig. 3-2:Airtubesalignment

3.4.3.Suctioncupsystem

Manifold and mounting bracket

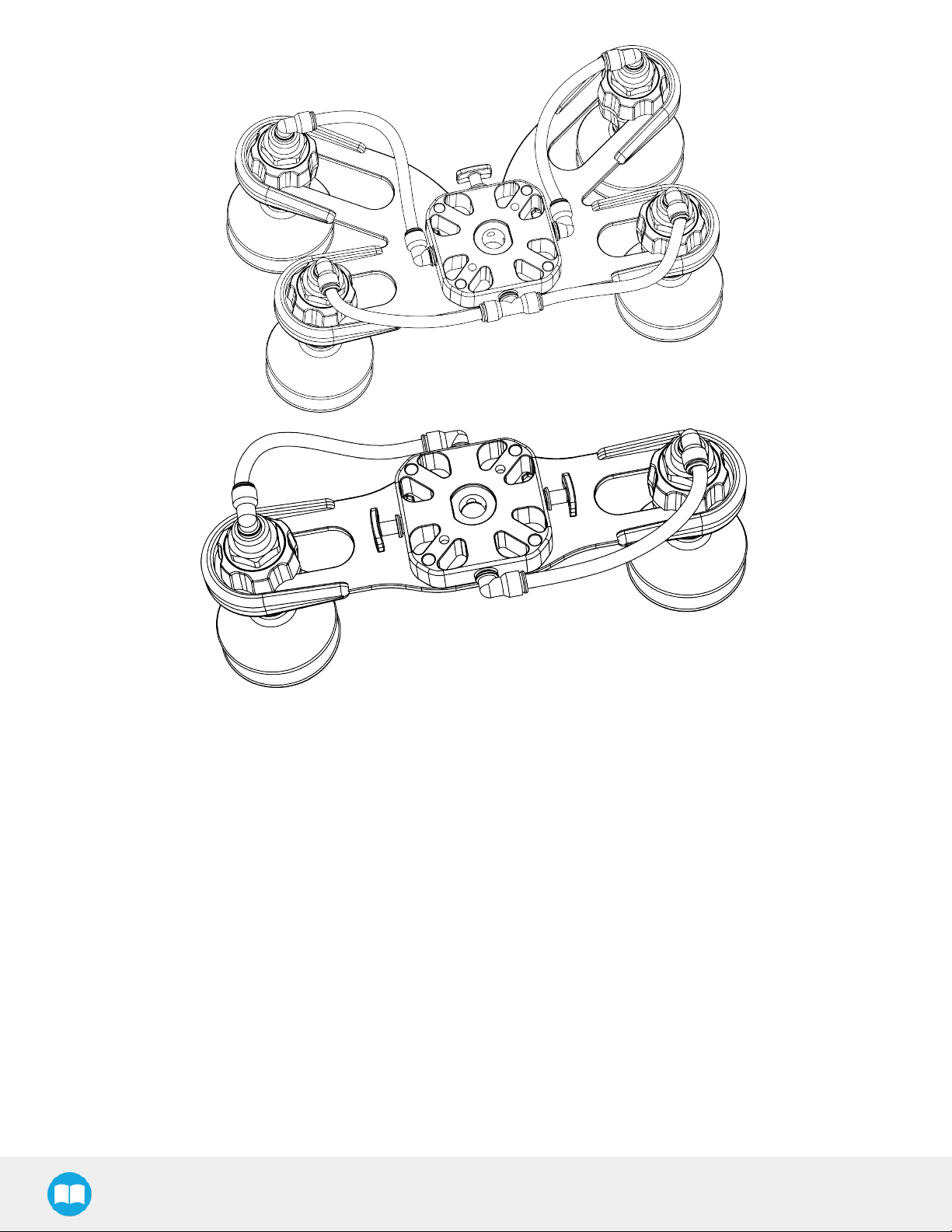

Inorderto usethetwo (2)or thefour(4)SuctionCupsSystem,assemble thevacuum generator to the suctioncup system,asshownin

thefigurebelow,using four(4)M5 socketheadcap screwsand four(4)M5 toothlockwashers.

Page 20

20

Fig. 3-3:Mounting exampleof thefoursuctioncupsassemblyon thevacuumgenerator

Warning

Anyunused manifold port should be covered with aprovided port plug to avoid airleakage.Formoredetails,pleasereferto

theManifoldsection

Suctioncupsand air nodes

Whether you are using astandard or custom option,airnodesshould beusedto connect thesuction cups and the air tubing,and to

preventair leakage asmuchaspossible.Airnodesareeasyto assemble,asshownin thefiguresbelow.

1. Screwbyhand eachprovided vacuum cup to an airbolt.

Fig. 3-4:Screwinga vacuumcup and anairbolt

2. Passeachair bolt throughthemounting bracket,adjust thepositionof thenode along thebracket side,alignwith mating airnuts

andtightennode byhand.

EPick- InstructionManual

Page 21

21

Fig. 3-5:Mounting airnodes(vacuum cups,airbolts,airnuts)on thebracket

3.5. Electrical Setup

Powerand communicationareestablished withtheGripperviaasingle devicecable.Thedevicecableprovidesa24Vpowersupply

andenablesserialRS-485communication to therobot controller.

Info

RS-485signals(485+,485-and 485GND)areisolated from the main 24 Vpowersupply.GND canbe connected to anyother

ground referenceaslong asthe voltage potentialbetweenthe groundsdoesnot exceed 250V.Grounding referenceisat the

user’sdiscretion.

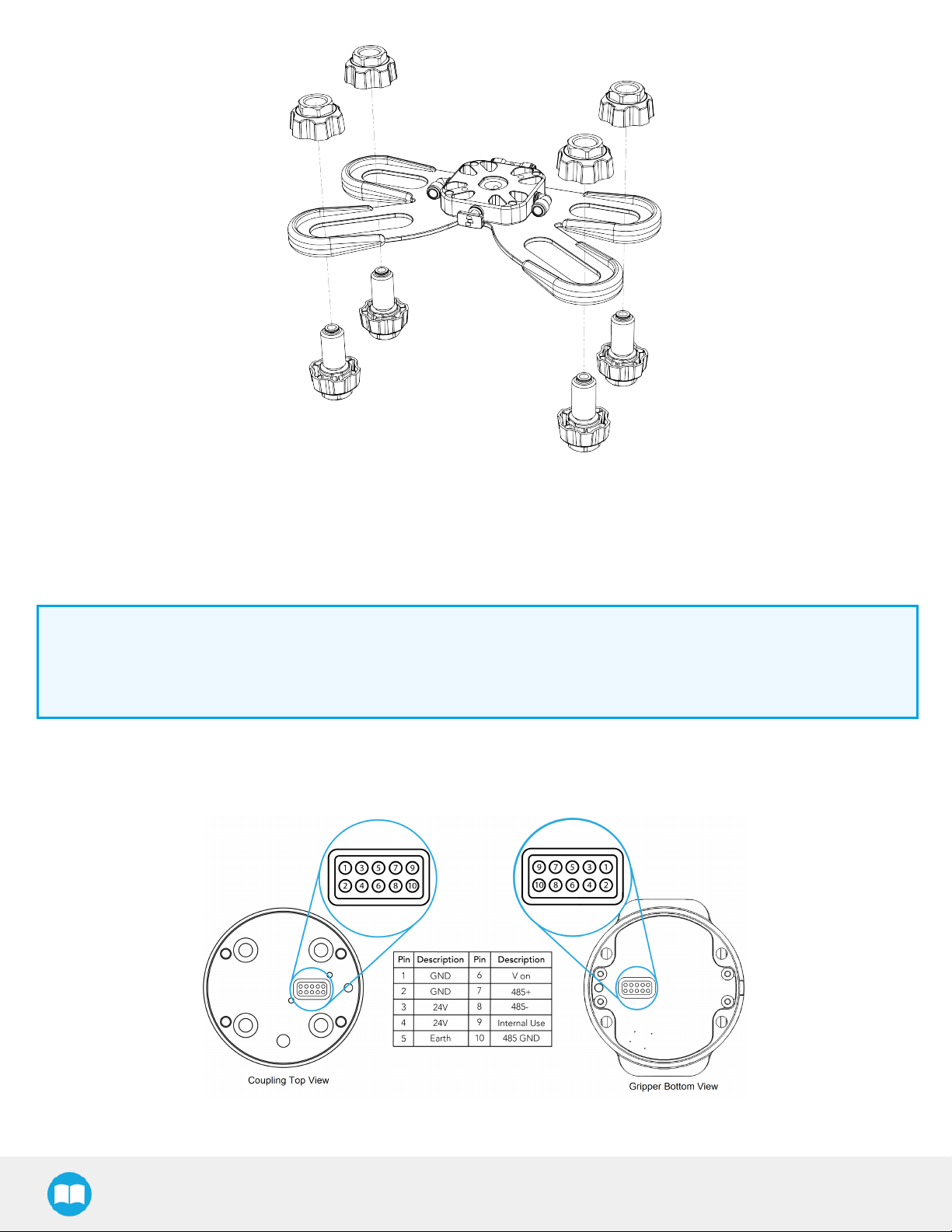

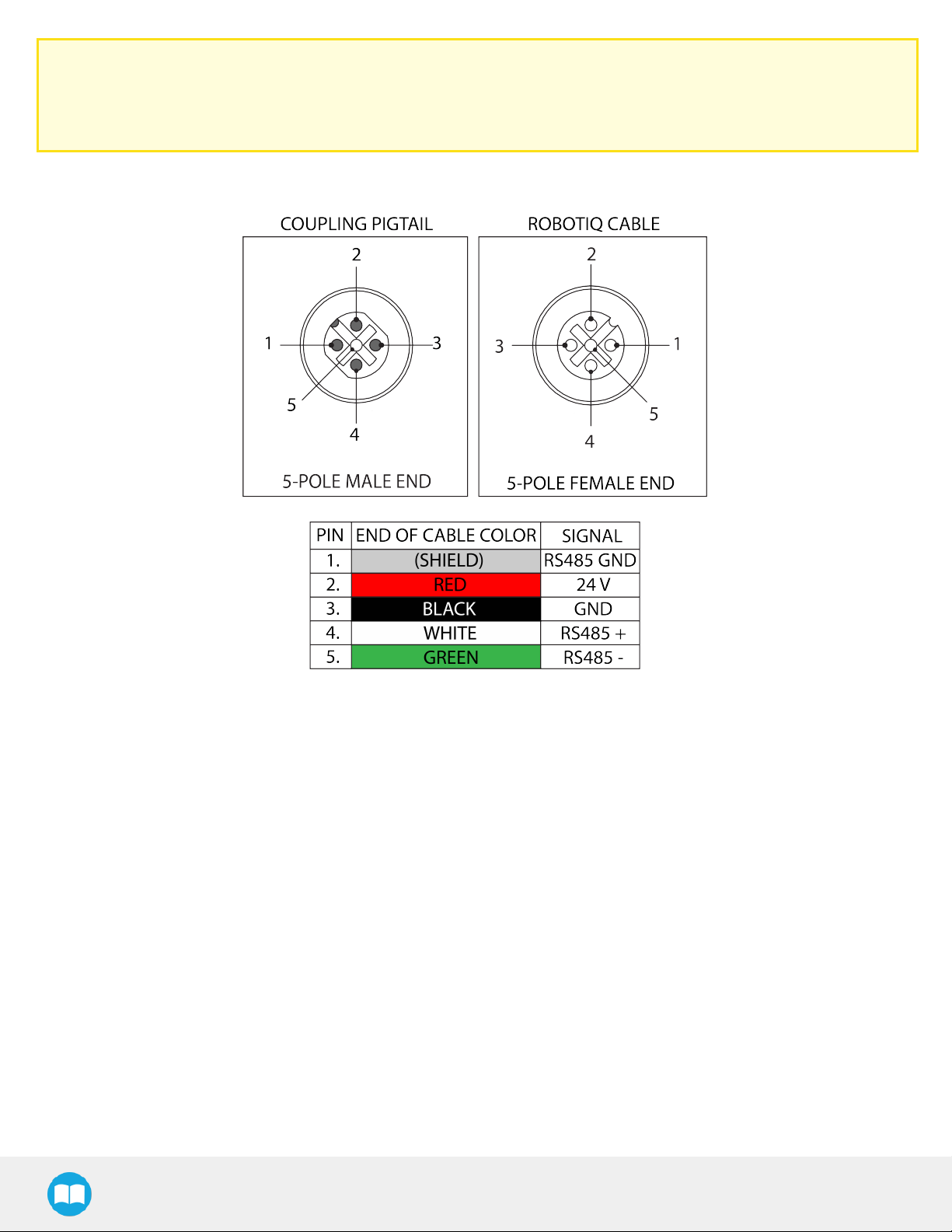

3.5.1.Pinout interface

TheGripperinterfaceswithitscoupling viaa 10-springpin connectorlocated on itsoutersurface.

Fig. 3-6:Pinout of the EPick cable-to-wristcoupling.

Page 22

22

Info

Thecoupling used inthe figureaboveisused for reference onlyand corresponds to bolt patternISO 9409-1-50-4-M6.

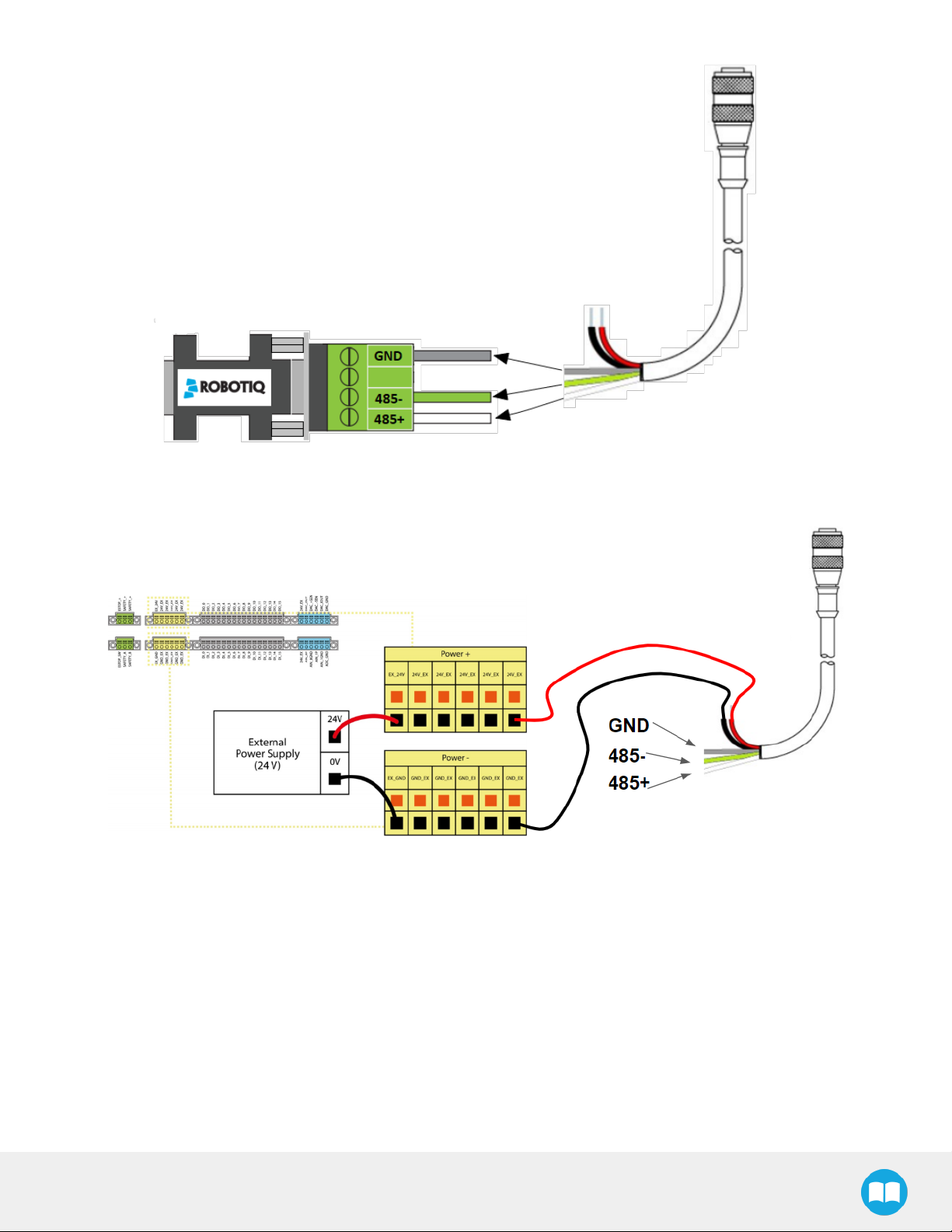

3.5.2.Couplingto controller

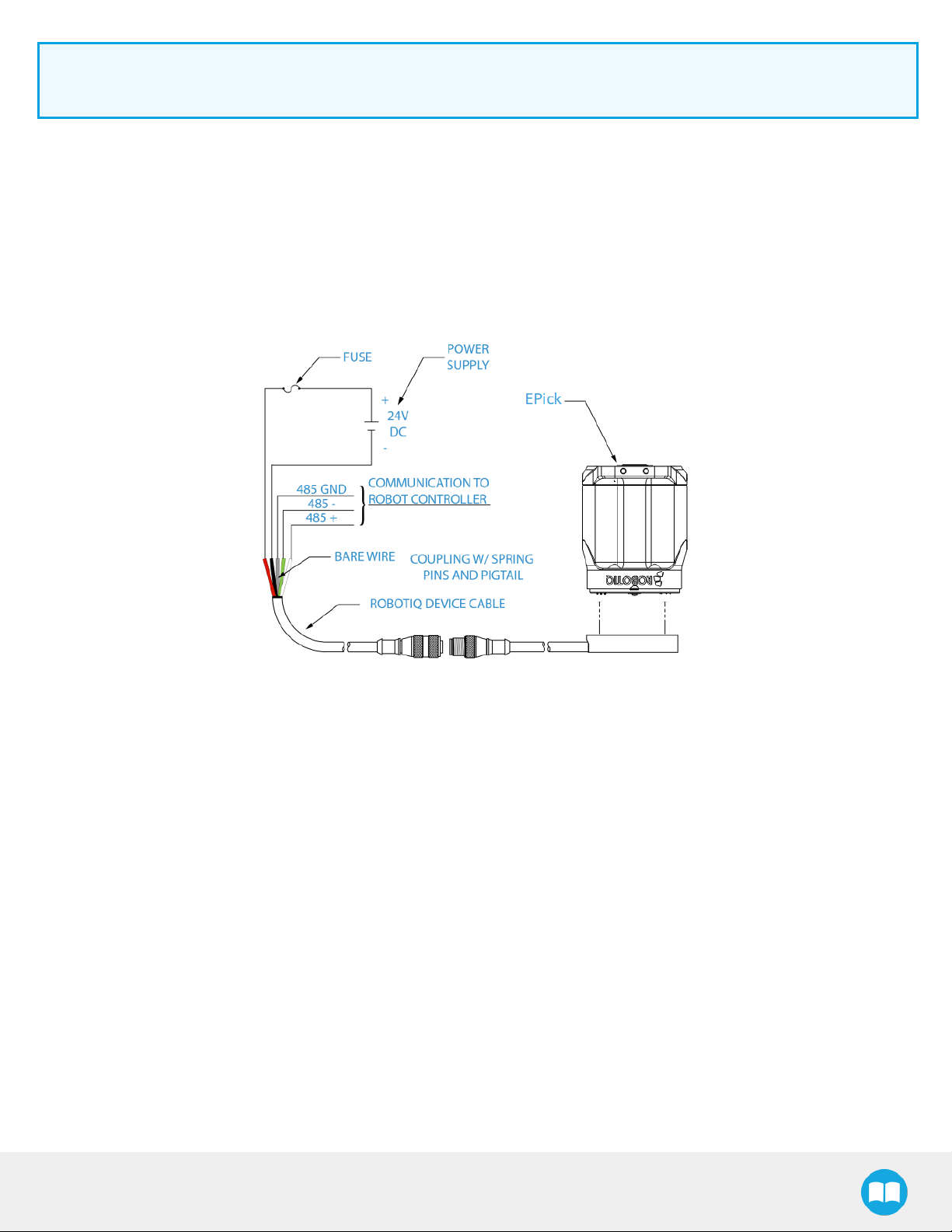

Anoptional Robotiq Universal Controllermaybe used betweenthe Gripperand thenetwork/robot controller if fieldbus

communication is required.

Ifa Robotiq Universal Controllerisused, pleasereferto theinstructionmanual of the Robotiq UniversalController.Thefigurebelow

representsthe wiring schemeof theVacuum Gripperwithdevicecable,powersupply,fuse (referto theRequiredToolsand Equipment

section)and grounding.

Fig. 3-7:Robotiq Vacuum Gripperwithpigtail cable and devicecable wiring scheme.

EPick- InstructionManual

Page 23

23

Caution

Useproper cabling management.Makesure to leave enough slackinthecabling to allowmovement of theGripperalong all

axeswithoutpulling out theconnectors.Alwaysprotect thecontrollerside (robot side)connector of the cable with astrain

relief cable clamp.

Thefigurebelowillustratesthe VacuumGripperpigtail connectorfrom thecoupling (GRP-CPL-062or AGC-CPL-XXX-002),the device

cable on therobot side (CBL-COM-2065-10-HF)and theirassociated pinout.

Fig. 3-8:Pinout of the VacuumGripperpigtail and devicecable

Ifadditionalcablesare used,suggested cable specificationsare:

Powersupply, fusing

l Minimum#22AWG TEW,300Vor 600V

RS485signal

l Minimum#24AWG TEW,300Vor 600V

l A and Bsignalsmust be balanced at 120Ohms

Single VacuumGripper

Connect the white, green and bare wires to the Robotiq RS485 to RS232 signal converter (ACC-ADT-RS232-RS485) as shown in the

figurebelow.

Page 24

24

Fig. 3-9:Grippercableto RS485/RS232converter

Also connectthe red (24V)and black(0V)wiresin thecontrolleraccording to the figurebellow.

Fig. 3-10:Grippercableto terminal connectoron thecontroller

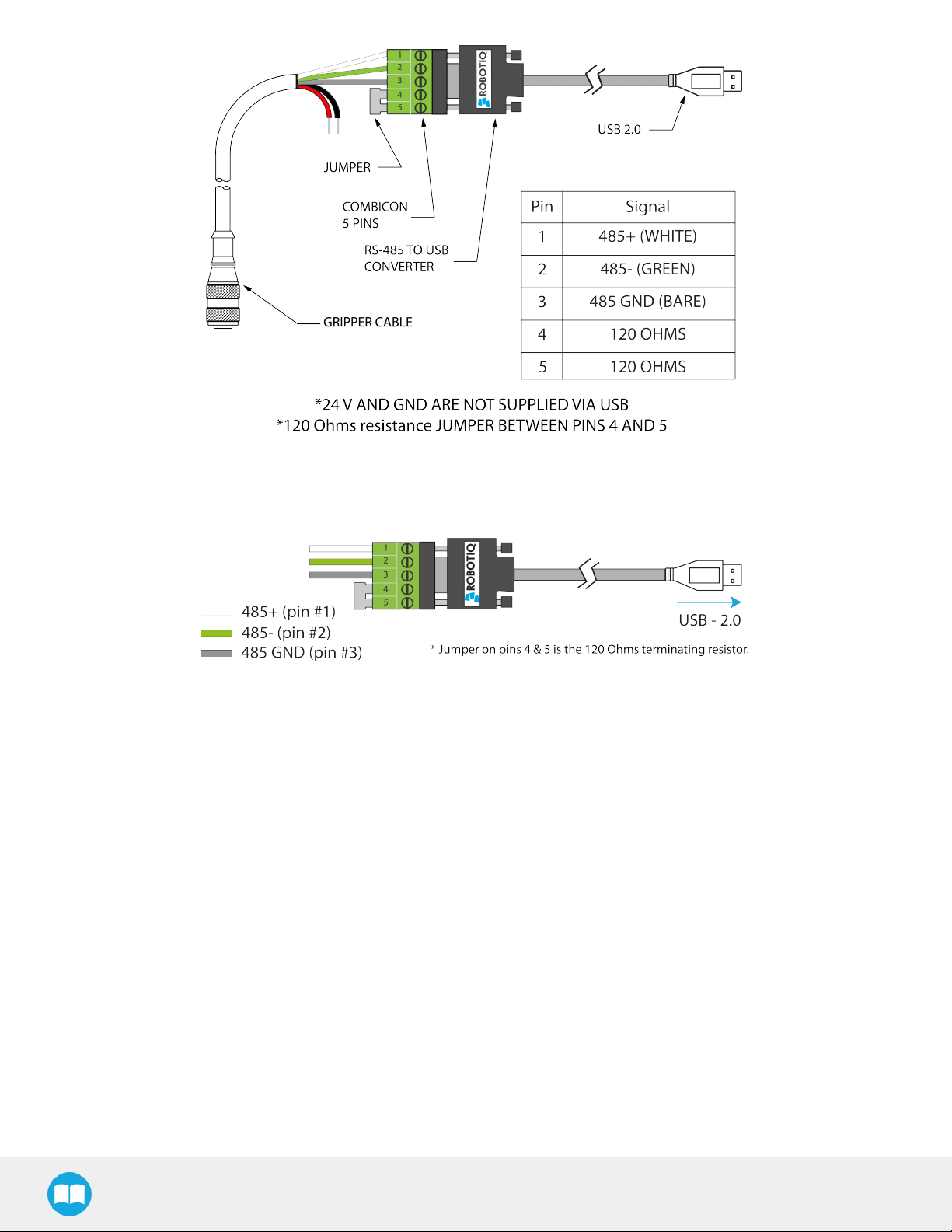

3.6.Testingthe Gripperwiththe Robotiq UserInterface (RUI)

Onceinstalled and properlysecured, yourRobotiq Vacuum Grippershould be tested with theRobotiq UserInterfacetestsoftware

using theprovided USBconverter.To do so :

EPick- InstructionManual

Page 25

25

Fig. 3-11:Wiring possibilitiesof theUSBto RS-485converter.

Fig. 3-12:Wiring possibilitiesof theUSBto RS-485converter.

Page 26

3.6.1.License Agreement

END-USERLICENSEAGREEMENT

YOUSHOULD CAREFULLYREAD THEFOLLOWINGAGREEMENTBEFOREUSINGTHESoftware(asthistermis hereinafter

defined).Using theSoftwareindicatesyour acceptanceof the agreement. If youdo not agreewithit,youarenot authorized to usethe

Software.

IMPORTANT-READ CAREFULLY:ThisEnd-UserLicenseAgreement(the“ Agreement”)isa legalagreement betweenyou and the

Licensor (asthistermishereinafterdefined),thelicensor of the Software.ThisAgreement coverstheSoftware.The Softwareincludes

any“ on-line” orelectronicdocumentationand allmodificationsand upgradesrelated thereto.Byinstalling,or otherwiseusing the

Software,you agreeto bebound by thetermsof thisAgreement.Ifyou do not agreeto the termsof thisAgreement,theLicensor

cannot and doesnot license theSoftwareto you.Insuch event,you must not useor installtheSoftware.

1. Definition.

1. “TM” meansTechmanRobot,a corporation incorporated under thelawsof Taiwan,having its registeredofficeat 4F,

188Wenhua2nd Rd.,GuishanDist.TaoyuanCity,33383,Taiwan,whichspecializesinto theconception,advanced manufacturing and saleof roboticproducts;

2. “OMRON” isacorporation incorporated underthelawsof Japan,having itsregistered officeat HorikawaHigashiiru,

Shiokoji-Dori,Shimogyo-Ku,Kyoto,600-8530,Japan,whichspecializesinto the conception,advanced manufacturing

andsaleof automation components;

26

3. Theterm‘’OMRON-TM’’ isused to refer to bothTechmanRobot and Omron-TM SeriesRobot;

4. “Software” meansanyof theLicensor’ssoftwaresprovided to itscustomersfor thepurposesmentioned inSub-section

1.4hereof including theirmodificationsandupgradesand theirrelated materials;

5. “Licensor” meansRobotiq inc.,a corporation incorporated under thelawsof Quebec,having itsregistered officeat

500-966cheminOlivier,Lévis,Québec,Canada,G7A2N1,whichspecializesinto theconception,advancedmanufacturing and saleof roboticproducts(the“ Licensor’sBusiness”);

6. “End-User” meansacustomerauthorized pursuant to thisAgreement to installor use theSoftwarein orderto make a

specificproduct from theLicensor’sProductscompatible andfunctional with aspecificproductof the Omron-TM’scollaborativerobots;

7. “Licensor’sProducts” meansthoseproductsdeveloped bytheLicensorin thecourseof theLicensor’sBusiness;

8. “Omron-TM’s collaborative robots” means those products which are collaborative robots and are developed by

Omron-TM in thecourseof theOmron-TM’sBusiness;

9. “Licensor’sAuthorized Representatives” meansand includestheLicensor andLicensor’sauthorizedvendors,resellers,

distributorsand licensors;

10. “ PurchaseAgreement” meansan agreement betweentheEnd-Userand theLicensor pursuant to whichtheEnd-User

purchased oneormoreof theLicensor’sProducts.

2. License.Subjectto thetermsand conditionshereof,theLicensor grantsto the End-Userapersonal,temporary,non-exclusive,

non-assignable and non-transferableand revocablelicenseto usetheSoftwarein accordancewiththe termsand conditions

hereof.

3. Softwareand Documentation.TheLicensor mayprovide,if applicable,all documentation containing thedetailed specifications

for operationand useof theSoftware,whichSoftwareshallbeusedin accordancewithsuchdocumentation.Thisdocumentation,if applicable,willbe provided,whollyor inpart,within(i)thisAgreement,(ii)theLicensor’sWeb sitehttp://robotiq.com/ (iii)theLicensor’sProductsand thePurchase Agreement therewith,or(iv)anyotheragreement,document,support,

whatsoeverdecided by theLicensor.

Theuseof theSoftwarerequiresthe Licensor’sProducts,Omron-TM’s collaborativerobots,compatiblesystemsandcertain

EPick- InstructionManual

Page 27

27

software (whichmayrequiresomeexpenses), mayrequireperiodical updating and maybe affected by suchelements.Most

equipmentwill be compatiblewith theSoftware.However,theSoftwaremaynot functionon certaintypesof equipment.

4. Modificationsand Upgrades.TheLicensor shall be under no obligation to provide anyupgradeormodification to the Software.

However,theEnd-Usershallbe entitled to receivefreeof charge allmodificationsand upgradesof theSoftwareprovided bythe

Licensor if,at suchtime,theEnd-Userisnot in default inrespect of anyof its obligation contained herein.Suchmodificationsand

upgradesof theSoftwareshall be installed by theEnd-Useritself by consultingtheLicensor’sWebsitehttp://robotiq.com/ where

alinkto proceed to suchinstallation will be madeavailable thereof.A newversion of theSoftwareshall not be covered bythis

Section 4but shall requirethat anewEnd-UserSoftwareLicenseAgreementbeentered into betweentheLicensorand theEndUser.

5. Fees.ThegrantbyLicensorto theEnd-Userof thepresent licenseshallbefreeto theextent that theEnd-Useragreesand compliesto theterm and conditionshereinat alltime.

6. Maintenance.During thetermof thisAgreement,theLicensorwillmaintaintheSoftwarein anoperable conditionand willmake

availableanycorrectionsand improvementsasaregenerallyincorporated inthe Softwarebythe Licensorwithout additional

chargeto theEnd-User.TheLicensor maytemporarilyand without noticesuspend or limit accessto the Softwareif necessaryor

desirable inorderto maintain,restore,modifyorrepairanypart of theSoftwareorfor anyreason related to business.During

suchworks,theSoftwarewill not be availablebut theLicensor undertakesto deployitsbest effortsto perform such worksat

appropriatetimesand to limit anyinconveniencearisingtherefrom.

7. Titleto Software.Thelicensed Software is composed of confidentialdata and trade secretsand isproprietaryto and constitutes

tradesecretinformation and intellectualpropertyof theLicensor.Titleand ownership rights to the Software,including theintellectualpropertyrightsrelated thereto,shall remainwiththe Licensor.TheEnd-Useragreesto maintainthe confidentialnature of

theSoftwareand related materialsprovided for theEnd-User’sowninternaluseunderthisAgreement.Thelicensegranted

hereindoesnot include theright to sublicenseto others,andmaynot beassigned to others,in whole or in part,without theprior

written consent of theLicensor.TheEnd-Usermaynot orallow othersto modifyorprepare directiveworks,copy (except fornormalbackupsforrecoverypurposes),reproduce,republish,reverseengineer,upload,post,transmit,or distribute,inanymanner,

theSoftware.

8. Restricted Use.TheSoftwareshall be used solelyand exclusivelybytheEnd-Userand its employeesfor thepurposementioned

inSub-section 1.4hereof. Anyotheruseof the Software,including resellderivativemodificationsor extensions,isexpresslyprohibited.

9. Exclusionof Warrantyon Software.TheEnd-Userexpresslyacknowledgesand agreesthat useof theSoftwareisat theEnd-User

solerisk.TheSoftwareisprovided “ ASIS” and without warrantyof anykind. THELICENSORAND THELICENSOR’S

AUTHORIZED REPRESEN-TATIVESDO NOT WARRANT THAT SoftwareWILL BEFREEOFERRORSAND YOU

ACKNOWLEDGETHAT THEEXISTENCEOFANYSUCH ERRORSDOESNOT CONSTITUTEA BREACH OFTHIS

AGREEMENT. TO THEEXTENT PERMITTEDBYLAW LICENSORAND LICENSOR’SAUTHORIZED REPRESEN-TATIVES

EXPRESSLYDISCLAIM ALLWARRANTIES,EXPRESSORIMPLIED,INCLUDING,BUT NOT LIMITED TO,THEIMPLIED

WARRANTIESOFMERCHANTA-BILITYAND FITNESSFORA PARTICULARPURPOSEUNLESSOTHERWISESTATED

HEREIN.LICENSORAND LICENSOR’SAUTHORIZEDREPRESENTATIVESDO NOT WARRANT THAT THEFUNCTIONS

CONTAINED IN THESoftwareWILLMEET THEEND-USERREQUIREMENTSORTHAT THEOPERATION OFTHESoftware

WILLBECORRECT.FURTHERMORE,LICENSORAND LICENSOR’SAUTHORIZED REPRESEN-TATIVESDO NOT WARRANT

ORMAKEANY REPRESENTATIONSREGARDINGTHEUSEORTHERESULTSOFTHEUSEOFTHESoftwareIN TERMSOF

ITSCORRECTNESS,ACCURACY,RELIABILITY,OROTHERWISE.NO ORAL ORWRITTENINFORMATION ORADVICEGIVEN

BYLICENSORAND LICENSOR’SAUTHORIZED REPRESENTATIVESHALL CREATEA WARRANTYORINANYWAY

INCREASE THESCOPEOFTHISWARRANTY.SHOULD THESoftwarePROVEDEFECTIVEIN YOURTECHNOLOGY

ENVIRONMENT,YOUASSUME THEENTIRE COST OFALLNECESSARYSERVICING,REPAIRORCORRECTION TO YOUR

OWN TECHNOLOGYENVIRONMENT.

10. Limitation of liability.TO THEMAXIMUM EXTENTPERMITTED BYLAW,LICENSORAND LICENSOR’SAUTHORIZED

REPRESENTATIVESSHALLNOT BELIABLEFORANYINCIDENTAL ORCONSEQUENTIALDAMAGESFORBREACH OF

ANYEXPRESSORIMPLIED WARRANTY,BREACHOFCONTRACT,NEGLIGENCE,STRICT LIABILITYORANYOTHER

LEGALTHEORYRELATED TO THESoftware.SUCH DAMAGESINCLUDE,BUT ARE NOT LIMITED TO, LOSSOFPROFITS,

LOSSOFREVENUE,LOSSOFDATA, LOSSOFUSEOFTHEPRODUCT ORANYASSOCIATED EQUIPMENT,DOWN TIME

AND USER’STIME,EVEN IFTHELICENSORHASBEEN ADVISED OFTHEPOSSIBILITYOFSUCHDAMAGES. IN ANY CASE,

LICENSORENTIRELIABILITYUNDERANYPROVISION OFTHISAGREEMENTSHALLBELIMITED TO THEAMOUNT

ACTUALLYPAID IN RESPECT OFTHELICENSOR’SPRODUCTSPURCHASEDBYTHEEND-USERPURSUANT TO A

PURCHASEAGREEMENT.

Page 28

28

11. Training, Maintenanceand Support Thereisno entitlement to training,maintenanceand support underthislicenseunlessotherwise specified inthe PurchaseAgreement or anyotherwritten agreement betweentheEnd-Userand theLicensor.TheEndUsermayprovide theLicensor withdetailsregarding anybug,defect or failureinthe Software promptly and withno delayfrom

suchevent;theEnd-Usershall comply with theLicensor’srequest for information regarding bugs,defectsor failuresand furnish

himwithinformation,screenshots and tryto reproducesuchbugs,defectsor failuresuponLicensor’sdemand.

12. Expiration and Termination.TheLicensor mayterminatethisAgreementfor defaultbythe End-User.ThisAgreement willalsobe

automaticallyterminated upontheelection of suchbythe Licensoror theofficiallaunchof theSoftware,whichevereventcomes

first.Upon termination of thisAgreementfor anyreason,theEnd-Usershallpromptly uninstall theSoftwareon anyOmron-TM’s

collaborativerobots and Licensor’sProducts,computer,orserveron whichit hasbeeninstalled,deliverto theLicensor allCDs,

DVDs,magnetictapes,cards,and othertangibleitemsand materialsembodying theSoftware,and returnto theLicensorall copiesthereof or destroysuchcopiesand warrant inwriting thatall copiesthereof havebeendestroyed. In theevent of termination

of this Agreement,allobligationsof thepartiesunderthisAgreement duefor performanceon thedate of termination shallsurvivethe termination,and thepartyterminating shall not be liable to the otherpartyfor anydamagesarisingout of the termination.

13. Miscellaneous.

1. ThisAgreementconstitutestheentireunderstanding and agreementbetweentheLicensorand theEnd-Userand

replacesanyprior agreement relating to thesamesubject matter.

2. ThisAgreementshallbe governedand construed in accordancewith thelawsof theprovinceof Quebecand thefederal lawsof Canada applicable therein.Anylegalaction or proceeding betweentheLicensor and the End-Userfor any

purposeconcerning thisAgreement ortheparties'obligationshereundershallbe brought exclusivelyina court of competent jurisdiction sitting inthejudicial districtof Trois-Rivières,Quebec.

3. TheLicensor’sfailureto insist upon or enforcestrictperformanceof anyprovisionof thisAgreementshall not be construed asa waiverof anyprovisionorright. Neitherthecourseof conduct betweenthepartiesnor tradepracticeshall

act to modifyanyprovisionof thisAgreement.

4. TheLicensor mayassign itsrights and dutiesunder thisAgreement to anypartyat anytime withoutnoticeto the EndUser.TheEnd-Usermaynot assign thisAgreement without the prior written consent of the Licensor.

5. Ifanypart of thisAgreementisnull,illegal or non-enforceable,thisAgreement shallbe interpreted asif thispart was

neverpart of thisAgreement.

6. Theprovisionsof thisAgreementarefor thebenefit of the Licensorand itsofficers,directors,employees,agents,

licensorsand suppliers.Eachof theseindividualsor entitiesshallhavetheright to assert and enforcethoseprovisions

directly against theEnd-Useronitsownbehalf.ThisAgreementis also forthebenefit of, and binds,theEnd-Userand

itsheirs,successors,legal representativesand permitted assigns.

7. Anyrightsnot expresslygranted hereinarereserved.

8. Thepartiesconfirmthat theyhaveagreed that thisAgreement and all related documentsbe drafted inEnglishonly.Les

partiesauxprésentesconfirment qu’ellesont accepté quela présenteconvention et touslesdocumentsyafférentssoientrédigésenanglaisseulement.

EPick- InstructionManual

Page 29

4.Software

Info

Unlessspecified,all unitsin thissection arein hexadecimalvalues.

4.1. Overview

Info

Theoperatorcan:

l Control thevacuum level(continuousvacuumwhenmanual mode issetat 100%)

l Set theminimumvacuum level

29

l Theautomaticmode operationis set bydefault.Thecontinuousoperation mode can also be choose,when checked in the

Advanced settings.

l Benefit from asecuritymode if airleakageis detected

l Benefit from energysavingwith theautomaticmode.

l Applya timeout manually(ms)orbenefitfrom anautomatictimeout delay

4.1.1.Control usingregisters

The Vacuum Gripper has an internal memory that is shared with the robot controller. One part of the memory is for robot output

(Gripper functionalities). The otherpart of the memory is for robot input (Gripper status). Two types of actionscan thusbe performed

by therobot controller:

1. Write in therobot output registersto activatefunctionalities;

2. Read in therobot input registersto get thestatusof theGripper.

The Vacuum Gripper register mapping section will map the different registers used to control the Gripper or to read its status. The

Robot output registers & functionalities section will detail the output (write) register functions. The Robot input registers & status

section will detail the input (read) register status. The figure below is a representation of the memory and the control logic of the

Gripper.

EPick- InstructionManual

Page 30

30

Fig. 4-1:VacuumGripper control logic overview

Page 31

4.2.Vacuum Gripperregistermapping

Caution

Bytenumbering startsatzero.

Register Robot Output/Functionality Robot Input/Status

Byte0 ACTION REQUEST GRIPPERSTATUS

Byte1 RESERVED GRIPPERSTATUS

Byte2 RESERVED FAULTSTATUS

31

Byte3 MAXRELATIVEPRESSURE

LEVELREQUEST

Byte4 GRIPTIMEOUT/ RELEASEDELAY ACTUALRELATIVEPRESSURE

Byte5 MINIMUM RELATIVEPRESSURE LEVELREQUEST RESERVED

Byte6 to 15 RESERVED RESERVED

Table4-1:Registersof the VacuumGripper

MAXRELATIVEPRESSURE

LEVELREQUEST ECHO

4.3. Robot output registers& functionalities

Register:ACTION REQUEST

Address:Byte0

Bits 7 6 5 4 3 2 1 0

Symbols Reserved rATR rGTO rMOD rACT

EPick- InstructionManual

Page 32

32

rACT (Activate)

TherACT bit allowstheGripperto be operational.

l 0b0- ClearGripperfaultstatus.

l 0b1- Gripperisoperational.Muststay0x01at alltimeduring normaloperation of thegripper.

rMOD Grippermode

TherMOD bitsareused to select thegripping mode.

l 0b00- Automaticmode.Thegripper will automaticallydetect thepropervacuum level,timeout/delayand hysteresis.

l 0b01- Advancedmode.Theusercansetthe desired minimum and maximum vacuumlevel and the time-out.

l 0b10- Reserved

l 0b11- Reserved

rGTO (Regulate)

TherGTO bit allow gripperto follow thedesired vacuum parameters.

l 0b0- Stop thevacuum generator;valvesarein position to hold theworkpiece.

l 0b1- Followtherequested vacuumparametersin realtime.Whentimeout isreached,rGTO must be re-asserted (Set to 0b0 thento

0b1)

rATR(Automaticrelease)

TherATRbit is used to releasetheobject to ambient pressure(if possible)withoutanytimeout.TherATRbit overridesall other

commands excluding the activation bit (rACT).rACTmust be at 0b1during thisaction.

l 0b0- Normal operation

l 0b1- Openthevalveswithout anytimeout.Afteranautomatic release,rACTmustbe re-asserted(rACT=0b0 thenrACT=0b1).

Register:RESERVED

Address:Byte1

Bits 7 6 5 4 3 2 1 0

Symbols Reserved

Register:RESERVED

Address:Byte2

Bits 7 6 5 4 3 2 1 0

Symbols Reserved

Page 33

Register:MAXIMUM VACUUM/PRESSUREREQUEST

Address:Byte3

Bits 7 6 5 4 3 2 1 0

Symbols rPR

rPR( MaximumVacuum/Pressure request)

Thisregisterisused to setthe targetvacuumor pressureand isonlyvalid inmanual mode(rMOD=0x01).

rPR= 100+ Pmax

Where:

Pmaxisthe targetmaximum differentialpressurerelativeto ambientin KPa.

l 0x00(0d0)- Continuousgrip.Vacuum generator alwaysON.

33

l 0x16(0d22)-Grip to 78%of vacuum (Maximumdevice vacuum).

l 0x5A (0d90)- Grip to 10%of vacuum (Minimumdevicevacuum).

l 0x64(0d100)- Passiverelease.Releasing to ambient pressure.

l 0x65(0d101)- Activerelease.Releasing with minimum positivepressure.

l 0xFF(0d255)- Activerelease.Releasingwith maximumpositivepressure.

Example:

For agrip with78%of vacuum level,usePmax= -78kPain theformula.

For areleasewith155kPaof positiveair,usePmax= 155kPain theformula.

Register:GRIPTIMEOUT/ RELEASE TIME

Address:Byte4

Bits 7 6 5 4 3 2 1 0

Symbols rSP

rSP (Actiontimeout)

Whengripping (rPR<= 0d99),this registerisused to setthe timewindow (eachintegerbeing 100milliseconds)priorto agripping

error.Thevacuum generator will stop afterthetimeout period.Onlyvalid if rMOD=0x01.

l 0x00(0d0)- No timeout.

l 0x0A (0d10)- 1sectimeout period.

l 0xFF(0d255)- 25.5sectimeout period.

EPick- InstructionManual

Page 34

34

Whenreleasing (rPR>= 0d100), thisregisteris used to setthe timewindow (eachintegerbeing 100milliseconds)priorto setthe

vacuumactuatorsinholding mode.Onlyvalid if rMOD=0x01.

l 0x00(0d0)- Vacuumholding stateset whenambient pressureis detected.

l 0x01(0d01)-Vacuum holding stateset100msecafter ambientpressureisdetected.

l 0x0A (0d10)- Vacuumholding stateset 1000msecafterambientpressureisdetected.

Register:MINIMUM VACUUM/PRESSUREREQUEST

Address:Byte5

Bits 7 6 5 4 3 2 1 0

Symbols rFR

rFR(MinimumVacuum/Pressure request)

Thisregisterisused to setthe appropriateminimumacceptable vacuum/pressureon theworkpiece.Whentheminimumvacuum level

isreached, theobjectflag (gOBJ)will be set.Once theobjectis detected, thevacuum generatorwill keep thevacuum levelin between

theminimumand maximumvacuum level.Onlyvalid if rMOD=0x01.

rFR= 100+ Pmin.

Where:

P

isthetargetminimumdifferential pressurerelativeto ambient in kPa.

min

l 0x00(0d0)- Object willbedetected whenvacuumlevel reaches100%(Thisis impossible,so avoid using thisvalue)

l 0x1E(0d30)- Objectwill be detectedwhenvacuumlevel reaches70%.

l 0x50(0d80)-Object willbe detected whenvacuumlevelreaches20%.

l >0x64(>0d100)-Reserved value

Example:

For agrip withamaximum of 78%vacuumlevel and anobject detectionat 20%of vacuum level,use:

Pmax= -78kPa

Pmin = -20kPa

rFR= 100+ (-20)= 80

Warning

Setting thepressuretolerancetoo lowmight weartheproductprematurelyresulting in a shorterlifespan thanexpected.

Thewarrantyof theproduct is defined asthenumberof grip/releasevalvecyclesand not in termsof objectgrip/release

cycles.

Page 35

4.4.Robot input registers& status

Register:GRIPPERSTATUS

Address:Byte0

Bits 7 6 5 4 3 2 1 0

Symbols gOBJ gSTA gGTO gMOD gACT

gACT (Activateecho)

ThegACT bit is theecho of therACTbit in theACTION REQUEST register.

gMOD (Grippermodeecho)

ThegMOD bitsaretheechoof therMOD bitsin theACTION REQUEST register.

gGTO (Regulateecho)

35

ThegGTO bit istheecho of the rGTO bit in theACTION REQUEST register.Valid onlyif thevacuum/pressureisregulated,otherwiseit

returns0x0.

gSTA (Activationstatus)

TherSTA bits indicatesthestatusof the gripperactivation sequence.

l 0b00- Gripperisnot activated.

l 0b11- Gripperisoperational.

gOBJ(Objectstatus)

ThegOBJbits indicatesthe statusof theobjectdetection.

l 0b00- Unknownobject detection.Regulating towardsrequested vacuum/pressure.

l 0b01- Object detected.Minimumvacuumvaluereached.

l 0b10- Object detected.Maximumvacuumvaluereached.

l 0b11- No object detected. Object loss,dropped or gripping timeout reached.

Register:GRIPPERSTATUSEXTENSION

Address:Byte1

Bits 7 6 5 4 3 2 1 0

Symbols Reserved gVAS

EPick- InstructionManual

Page 36

36

gVAS(Vacuumactuatorstatus)

TherVASbitsindicatesthestatusof thegripperactuators.

l 0b00- Standby.Vacuum generator and valvesdeasserted (OFF).

l 0b01- Gripping.Vacuum generator ON.

l 0b10- Passivereleasing. Releasing to ambient pressure.

l 0b11- Activereleasing. Releasing withpositivepressure.

Register:FAULT STATUS

Address:Byte2

Bits 7 6 5 4 3 2 1 0

Symbols kFLT gFLT

gFLT (Gripperfaultstatus)

ThegFLT bits indicatespriority,minor or majorfault codesthat areuseful fortroubleshooting.

l No fault

o

0x0- No fault

l Priorityfaults(0x0 < gFLT <= 0x7)

o

0x5- Action delayed

o

0x3- Veryporousmaterial detected

o

0x6- Gripping timeout.rGTOmustbe re-asserted (rGTO=0 thenrGTO=1)or oneof thefollowing parametersmustbe changed

(rMOD,rPR,rSP,rFR).

o

0x7- TheActivation bit not set.Activationbit mustbesetprior to action(rACT=1).

l Minorfaults(0x8 <= gFLT <= 0x9)

o

0x8- Maximumoperating temperature exceeded,waitfor cool-down.

o

0x9- No communication duringat least 1second. Thisfaultwill onlybe returned once if thenext valid communication isa“ read

command” of theFAULTSTATUSregister.

l Majorfaults(0xA<= gFLT <= 0xF)- Resetisrequired(rising edge onactivationbitrACTrequired)

o

0xA -Underminimum operating voltage.

o

0xB-Automaticreleaseinprogress(Vacuum/pressuredetected).

o

0xC- Internalfault;contactsupport@robotiq.com.

o

0xF-Automaticrelease completed (Vacuum/pressurenot detected)

Page 37

kFLT

Pleasereferto theoptionalRobotiq Controller manual (input registers& status).

Register:MAXIMUM VACUUM/PRESSURELEVELREQUEST ECHO

Address:Byte3

Bits 7 6 5 4 3 2 1 0

Symbols gPR

gPR(Vacuum/Pressurerequestecho)

Thisregisteristheecho of theMAXIMUM VACUUM/PRESSURELEVELREQUEST register.

37

Register:ACTUALVACUUM/PRESSURE

Address:Byte4

Bits 7 6 5 4 3 2 1 0

Symbols gPO

gPO (ActualVacuum/Pressure)

ThegPO istheactual vacuum/pressuremeasured in thesuction cups.

Pdiff = gPO - 100.WherePdiff isthe differentialpressurerelativeto ambientin KPa.

l 0x00(0d00)-Maximum vacuum(Pdiff <= -100kPa).

l 0x64(0d100)- No differentialpressure(Pdiff = 0kPa).

l 0xFF(0d255)- Maximumpressure(Pdiff >= 155kPa).

EPick- InstructionManual

Page 38

38

4.5.Gripperbehavior

Workpiecegripping/releasing isperformed bychanging the valuesof thegripperinput registers.While thecontrol isverysimple,some

behaviorsdeservea betterexplanation.

4.5.1.Control modes

Thevacuumgrippercanworkin two different mode:theAutomaticand Advanced options.

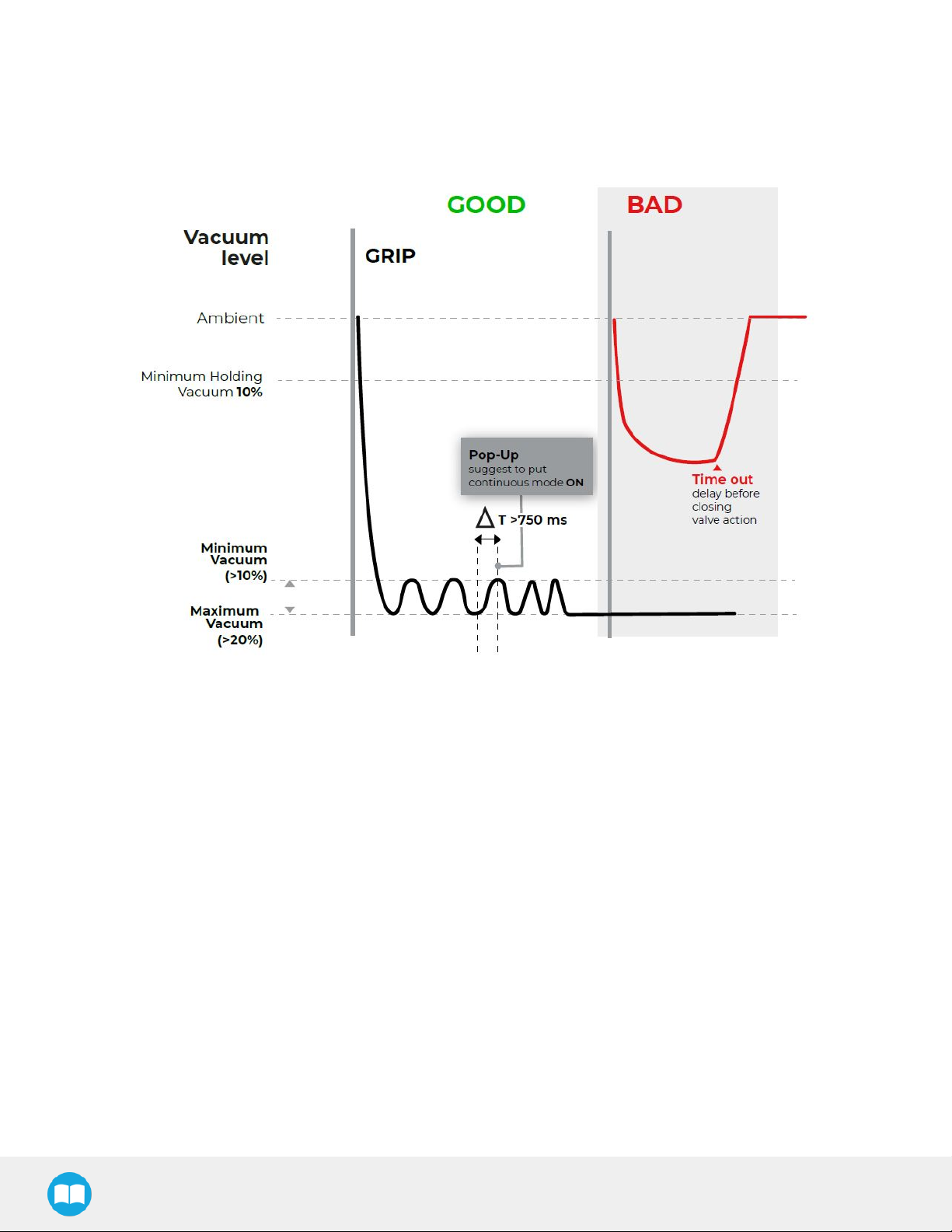

Automatic mode

Theautomaticmode is selected whenrMOD==0b00.Inthismode,the gripperwillautomaticallydetectthe propervacuum levelsand

timeout/delayrequired to grip or releasethe workpiece.Behavior of theautomatic modechangesdepending on theworkpiecesurface

material,thesuction cup condition and thefirmwarerevision.Thismode should be used whentheuserwants to makeaquicktest.Ifa

constant behavior isneeded,using theadvanced mode is amore suitable option.

Whengripping anobject intheautomatic mode,theVacuum Gripperwill:

1. Tryto reachthemaximum possible vacuumlevelfora maximumperiod of 2 seconds.

2. Automaticallydetermine a desired minimumand maximumvacuumlevelinorderto keep a good grip on theworkpiece,if a

vacuumlevelof morethan20%is detectedand thelevel seemsconstant.

3. Set theobject flag.

4. Vacuumgeneratorwill keep thevacuum levelin betweenmin and maxuntila releasecommand isreceived.

5. Objectlost/drop flag will be set if thevacuum leveldrops below 10%or if thevacuum levelfalls below theminimumvacuumlevel

for morethan2seconds.

Whenreleasing anobjectin theautomaticmode,the VacuumGripperwill:

1. Openthe releasevalve.

2. Objectdrop flag willbe set whenthe vacuumlevel fallsbelow0.5%.

3. Releasevalve will be kept open for 1second.

Page 39

39

Fig. 4-2:Vacuumlevel vstimein theautomaticmode

Advanced mode

Theadvanced mode isselected when rMOD==0b01.Inthismode,the usercansetthedesired vacuum levelsand timeout/delay

required to grip/releasetheobject.Behaviorof themanual mode onlydependsonthemaximumvacuumlevel,minimum vacuumlevel

andthetimeout/delayregisters.Thismode should beused when theuserwants to havea constantproductionbehavior.

Whengripping anobject inthemanual mode,withthemaximum vacuumlevel set below 100%,the VacuumGripperwill:

1. Tryto reachthedesired maximumvacuum levelfor amaximumperiod of thedesired timeout value.

2. Ifthe desired maximumvacuum levelisreachedand thevacuumlevel is higherthan20%,objectflag will be set to (gOBJ=0b10).

3. Vacuumgeneratorwill keep thevacuum levelin betweenmin and maxuntila releasecommand isreceived.Objectflag will

toggle in between (gOBJ=0b01)and (gOBJ=0b10).

4. Objectlost/drop flag will be set if thevacuum leveldrops below 10%or if thevacuum levelfalls below thedesired minimum

vacuumlevelformorethanthedesired timeout value.

Whengripping anobject inthemanual modewith themaximumvacuumlevel set to 100%,theVacuum Gripperwill:

1. Continuouslygeneratea vacuum

2. Whentheminimumvacuum levelis reached,objectflag willbe set (gOBJ=0b01). Object flag (gOBJ=0b10)will neverbe set

because100%of vacuum levelis impossible to reach.

3. Objectlost/drop flag will be set if thevacuum leveldrops below 10%or if thevacuum levelfalls below theminimumvacuumlevel

for morethanthedesired timeout value.

Whenreleasing anobjectin themanual mode,theVacuumGripperwill:

EPick- InstructionManual

Page 40

40

1. Openthe releasevalve.

2. Objectdrop flag willbe set whenthe vacuumlevel fallsbelow0.5%.

3. Releasevalve will be kept open for 1second.

Fig. 4-3:Vacuumlevel vstimein theAdvanced mode

Page 41

41

Fig. 4-4:Vacuumlevel vstimein thecontinuousmode

Very porousmaterial detection

Whenaveryporousmaterialis detected orwhenthesuction wearsout,the VacuumGripperwill detectit and reactaccording to the

grippermode.Whenthiscondition occurs,it isimportant to find the underlying reasonbecause it will makethe vacuumgeneratorstart

andstop veryrapidly.Thiscanlead to a prematurewearof thegripperinternalmechanics.

l Inautomaticmode,no fault willbeset,but thegripperwillcontinuouslyrunthevacuumgenerator untila releasecommand is

received.

l Inadvancedmode,afault flag willbe set (gFLT=0x3)and thegripperwillcontinueto runwiththe desired settings.

Object lost/ drop behavior

Whenanobjectis lost ordropped,thegripperwillset an object flag (gOBJ=0b11). Thismeansthatthe vacuumlevel hasfallenbelow

10%orbelow theminimumdesired vacuum levelfor athedesired timeout value.

Object secured behavior

Assoon asthegrip command isreceived bythegripper:

1. Theunknownobject flag will be set (gOBJ=0b00).

2. Ifthe vacuumlevel reachesthedesired maximum vacuumlevel,theobject secureto maxflag willbeset (gOBJ=0b10).

EPick- InstructionManual

Page 42

42

3. Thevacuumgenerator will stop until thevacuum reachthedesired minimumvacuum level.

4. Theobjectsecured to min flag willbeset (gOBJ=0b01)and thevacuum generator will tryto reachthemaximumvacuum again.

Object not detected behavior

When a grip command is received, the gripper will use the desired timeout value as a maximum period of time to detect an object.

When no object is detected after the timeout value, the timeout flag will be set (gFLT=0x6). To retry the same grip command, the

regulate bit needs to be re-asserted (rGTO=0b0,then rGTO=0b1). If newgripping settings are received (rMOD, rPR, rFR, rSP), thereis

no need to re-assertthe regulatebit.

Object release delay

When the release command is received, the vacuum gripper will open the releasevalve in order to let air enterthe suction cups.Once

the pressure inside the suction cup is equal or greater than the ambient pressure,the gripper will set the no object flag (gOBJ=0b11).

Therobot will then move awayfrom the workpiece. Depending on the suction type, thismotion might create a new vacuum inside the

suction cups.Therefore,theusercanset the distancefor therobot to moveawayfrom theworkpiece.Oncethisdistanceis reached,the

VacuumGripper valvewill close.

Emergency stop behavior

Depending on the robot, the behavior might be different when pushing an emergency stop. If the user wants to ensure a good grip

even in emergency stop, the vacuum gripper must be connected to a supply source that will not drop when pushing the emergency

stop. Aslong asthe gripperissupplied, it willalwaystryto keep the workpiece,evenif thecommunicationis stopped withthe robot.

4.6.Control logic

Fig. 4-5:Example of theVacuumGrippercontrol logicwithassociated registers.

4.7. ModbusRTU communication

TheVacuumGripper canbecontrolled byModbusRTUoverRS485.Thissection isintended to provideguidelinesfor setting up a

Modbusmasterthatwill adequatelycommunicatewiththeGripper.

For ageneralintroduction to ModbusRTUandfor detailsregarding theCRCalgorithm,thereaderisinvitedto read the Modbusover

seriallinespecification andimplementationguide availableat:http://www.modbus.org/docs/Modbus_over_serial_line_V1_02.pdf.

For debugging purposes,thereaderisalsoinvited to download one of manyfreeModbusmastersuch astheCASModbusScanner

from ChipkinAutomation Systemsavailable at:http://www.store.chipkin.com/products/tools/cas-modbus-scanner.

Page 43

Info

ModbusRTUisa communication protocol based on aBig Endianbyteorder.Therefore,the16-bit registeraddressesare

transmitted withthemostsignificantbytefirst.However,thedataport is,inthe caseof Robotiq products,basedon theLittle

Endianbyteorder.Assuch,thedata partsof ModbusRTUmessagesaresent withthe lesssignificant bytefirst.

Tip

ModbusRTUspecificationsand detailscanbe found at www.modbus.org.

4.7.1.Connection setup

Thefollowing table describestheconnection requirementsforcontrolling the Gripperusing the ModbusRTUprotocol.

Proprieties Value

Physical interface RS-485

43

Baud rate 1.2KBpsto 10500KBps;Default:115.2KBps

Data bits 8bits

Parity None,Odd, Even;Default:None

Stop bit 1or2 bit; Default:1bit

OtherModbusfunctions FC3,FC4,FC6,FC16,FC23,

Exception responses 0x03 (IllegalDataValue)

SlaveID 1to 9:Default:9

Robot output/Gripperinput registers 1000to 1007

Robot input/Gripper output registers 2000to 2007

Table4-2:ModbusRTUconnection setup for theVacuum Gripper

EPick- InstructionManual

Page 44

44

4.8.Control over TM

4.8.1.TM Robotscompatibility with RobotiqVacuumGrippers

Hardware Version TM FlowVersion TM GripperComponent RobotiqRS232Converter

HW1,HW2,HW3 1.68andlater VAC_V002_XXX Compatible

4.8.2.Getting Started

1

PowerON the robot

2

Tap thetriple baricon inthe upperleft cornerof thescreen

3

Clickon theLoginicon inthenavigation paneon theleft

Page 45

45

4

Enteryourlogin credentialsand clickonOK

5

Clickon GetControl

EPick- InstructionManual

Page 46

46

6

Clickon thetriplebariconin theupperleft cornerof thescreen and selectProject

7

Clickon theNewProject iconin theupperleft cornerof thescreen

Page 47

47

8

Entera namefor your programand clickon theOKbutton

9

EPick- InstructionManual

Page 48

48

4.8.3.TM Vacuum GripperComponents

Hereisthelist of thecurrent Robotiq Gripper TM Componentsto installon TM Robots:

l GRIPPER_ROBOTIQ_VAC_V002_SET.Component = SETtheVacuumGripper(Advanced mode,VacuumLevels,Timeout)

l GRIPPER_ROBOTIQ_VAC_V002_GRIP.Component = Grip a part(Action)

l GRIPPER_ROBOTIQ_VAC_V002_RELEASE.Component= Releaseapart(Action)

l GRIPPER_ROBOTIQ_VAC_V002_SELECTID.Component= Select theslaveID of thegripperwhenusing a dualgrippersetup

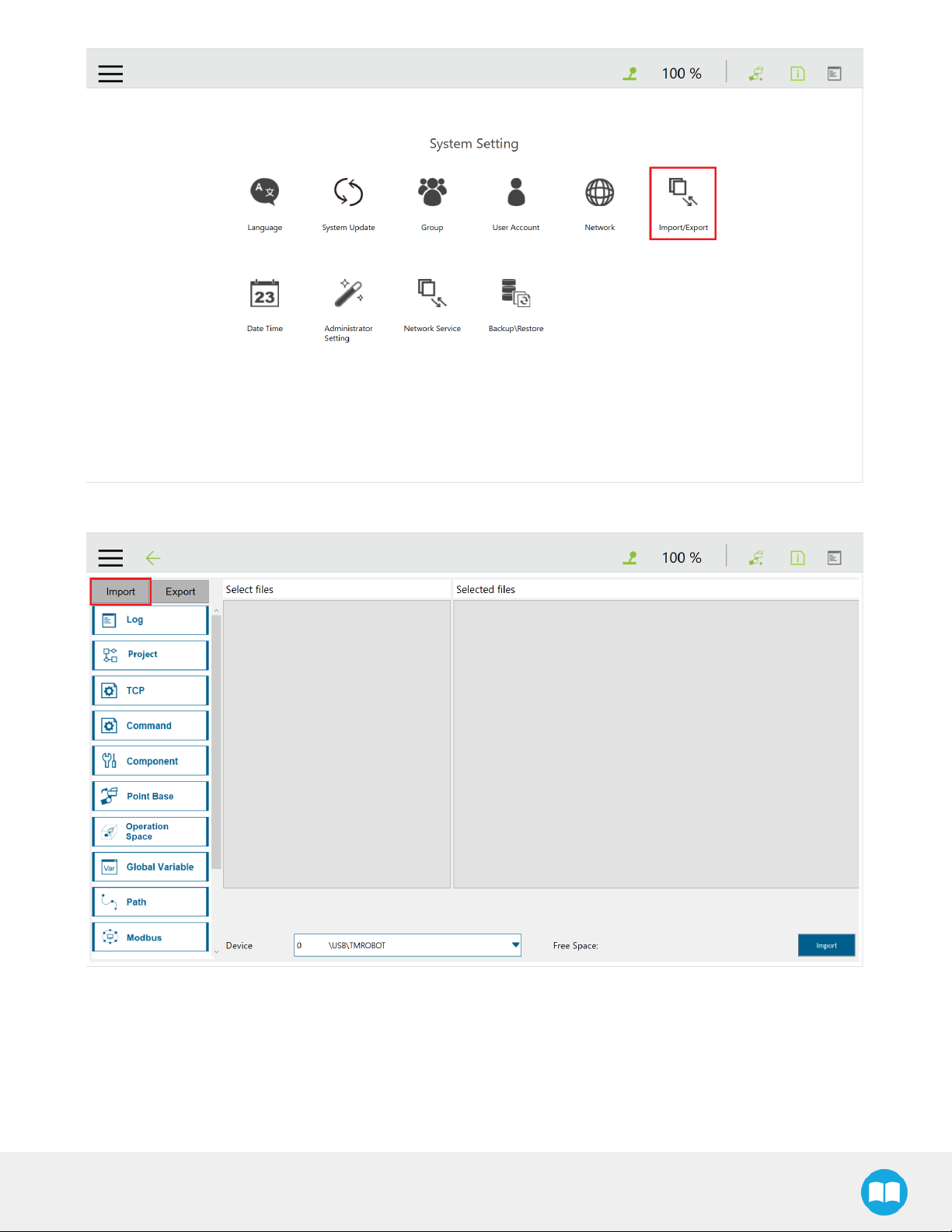

Installation

1

Download theTM Plug & PlaySoftwarePackage compressionfileson theofficialwebsite

2

RenametheUSBstorage device''TMROBOT''.Makesurethedrive format isNTFS.

3

Placethezipped componentfilesinthe USB with thefolder directoryTMROBOT:\TM_Export\TMComponent\ComponentObject\.

4

Insert theUSBstoragedevicein therobot controller

5

InTM Flow(robot software),tap thetriplebaricon and selectSystem

6

SelectImport/Export

Page 49

49

7

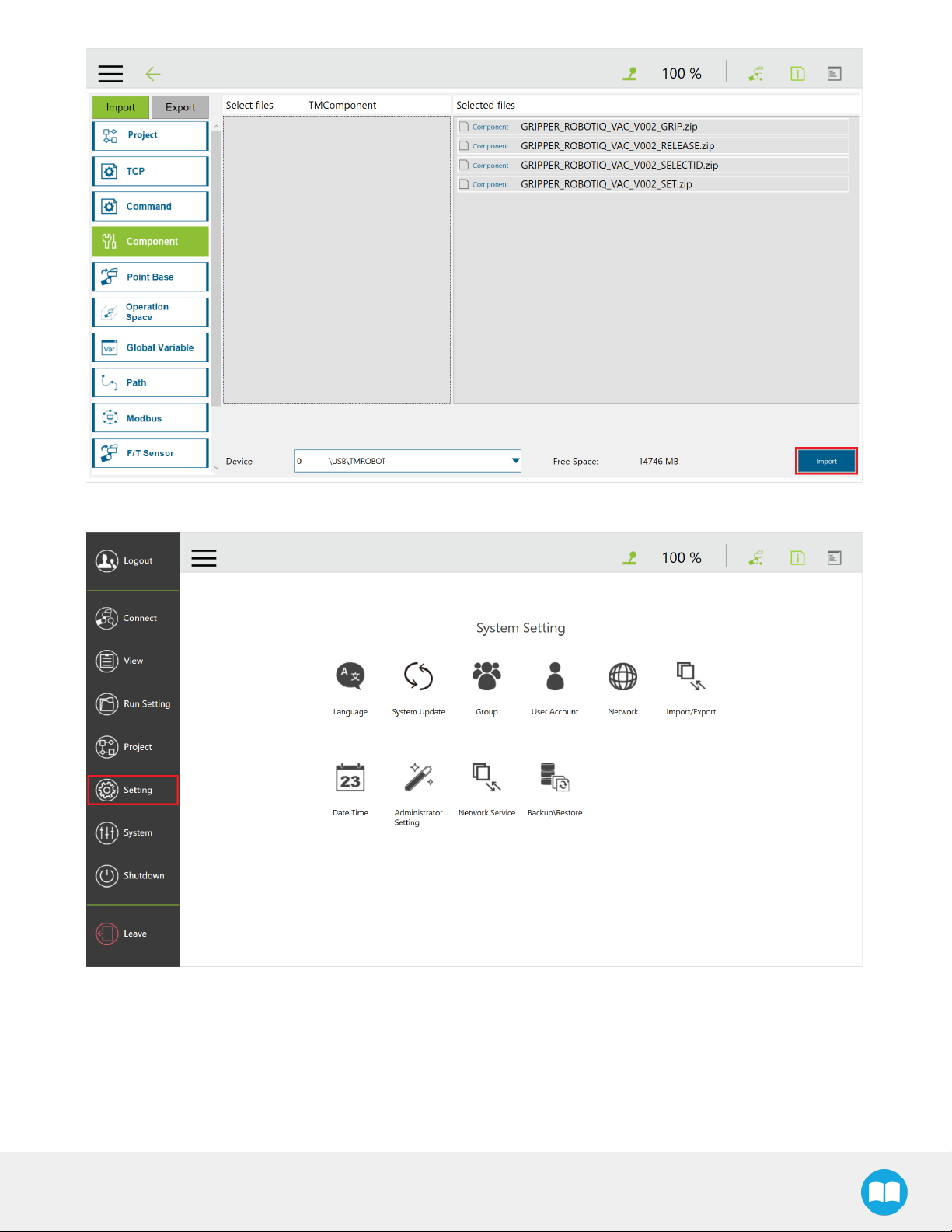

ClicktheImportbutton

8

Clickon TMComponentin theRobot Listwindowand clickon OK

EPick- InstructionManual

Page 50

50

9

Clickon theComponent button of the Import navigation pane

10

Selectthe Componentsyouwantto import and clickon theImportbutton

Page 51

51

11

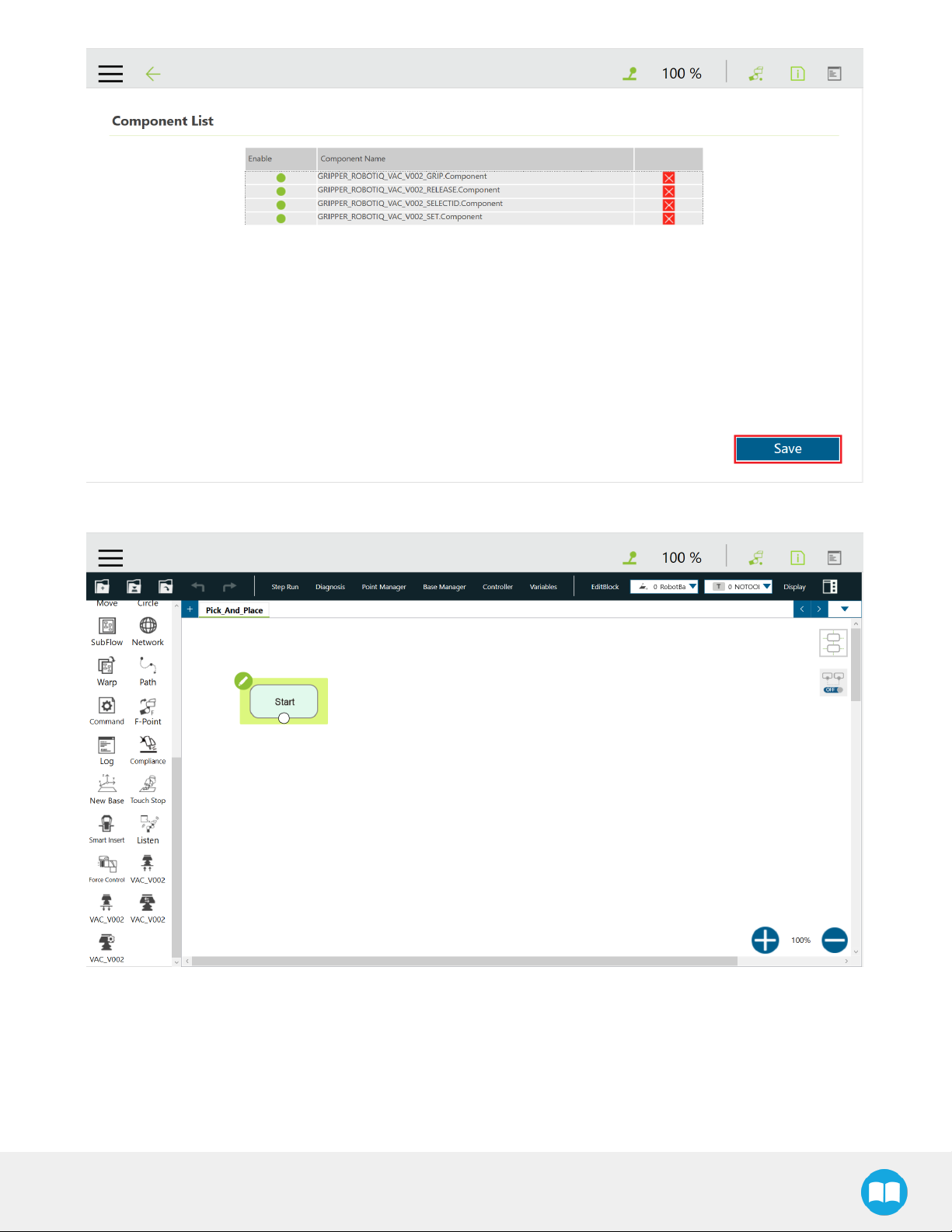

Tap thetriplebariconand select Setting to displaytheRobotSettingwindow

12

Clickon theComponent icon

EPick- InstructionManual

Page 52

52

13

EnablerequiredComponentsinthe Componentslist by ticking theradio buttonbesideeachof them

14

A Component thatis enabled displaysagreenradio button;oncetheComponentsareenabled,clickon theSave button

Page 53

53

15

Createanewproject or openanexisting project,and locatethe Grippercomponentsinthe navigation pane

GripperButton

Theusercan assignGripperComponentsto the Gripperbutton and usethelatter to open and closethefingersof theRobotiq

Gripper.

1

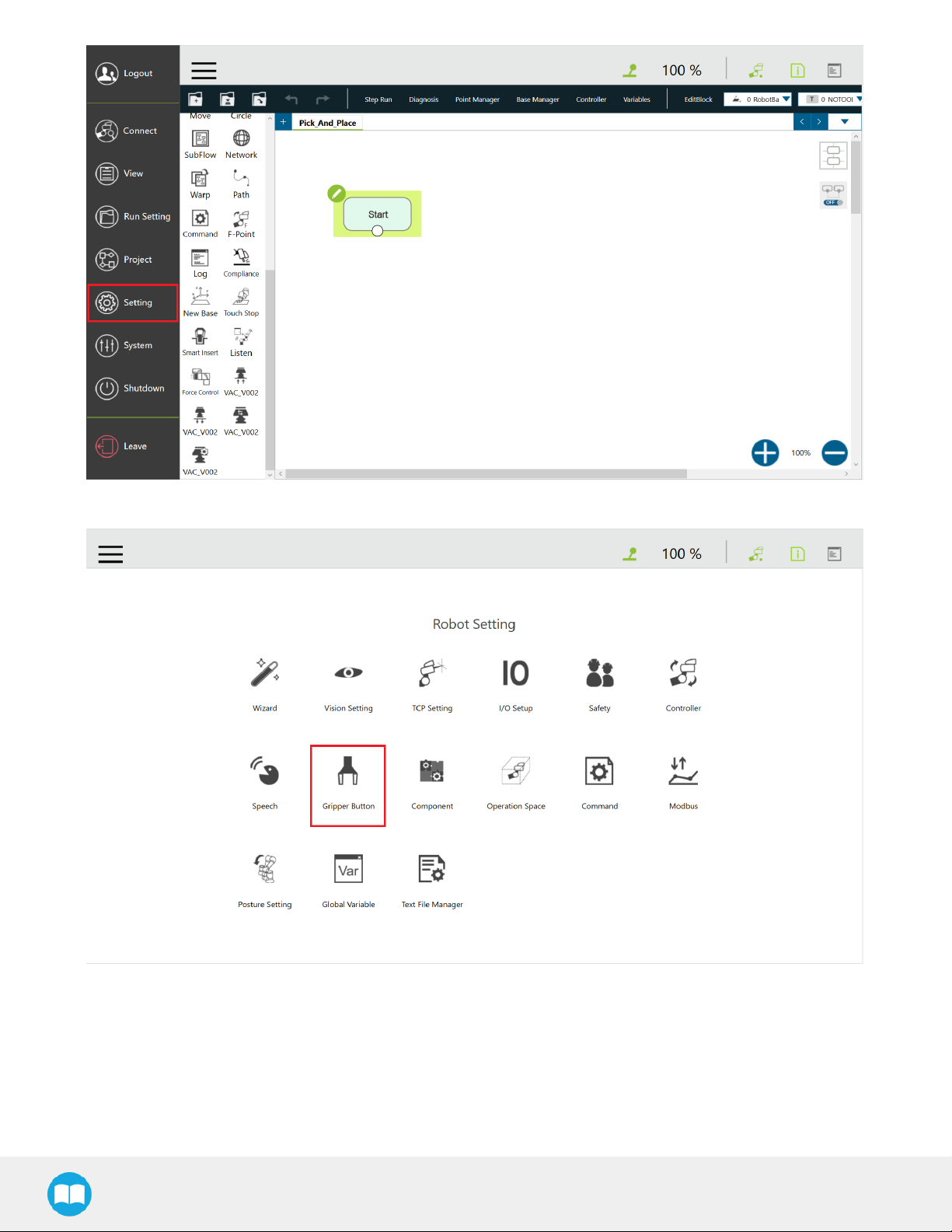

From theTM Flowhomepage,tap thetriplebariconand select theSettingicon

EPick- InstructionManual

Page 54

54

2

Clickon GripperButton

3

IntheGripperButtonwindow,ticktheUsingCustomizedComponent radio button and select theComponentyou want to assign

to eitherone of the Gripperactions

Page 55

55

4

Inthepop-up window,select or change theComponentyou wishto assignto theGripper action/button,andclickOK

EPick- InstructionManual

Page 56

56

Programming

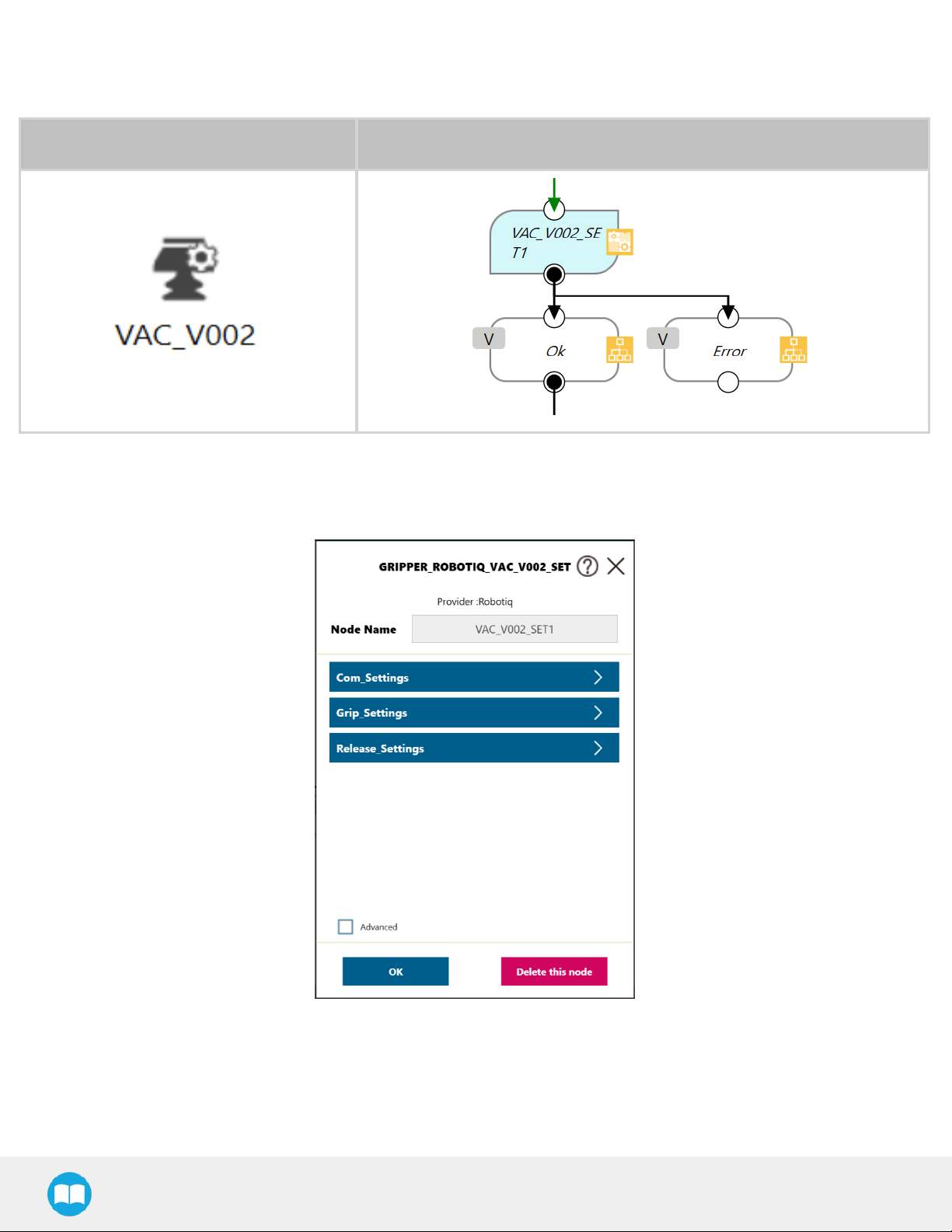

SETComponent

Component Icon Component Node

1

Drag and drop the SETComponent icon afteraprogramGatewayto place a SETprogramnode (VAC_V002_SET1)

2

Tap theSETnode to highlight it and clickon thepencilto edit thesettings

Fig. 4-6:SETNodeSettingsMenu

Page 57

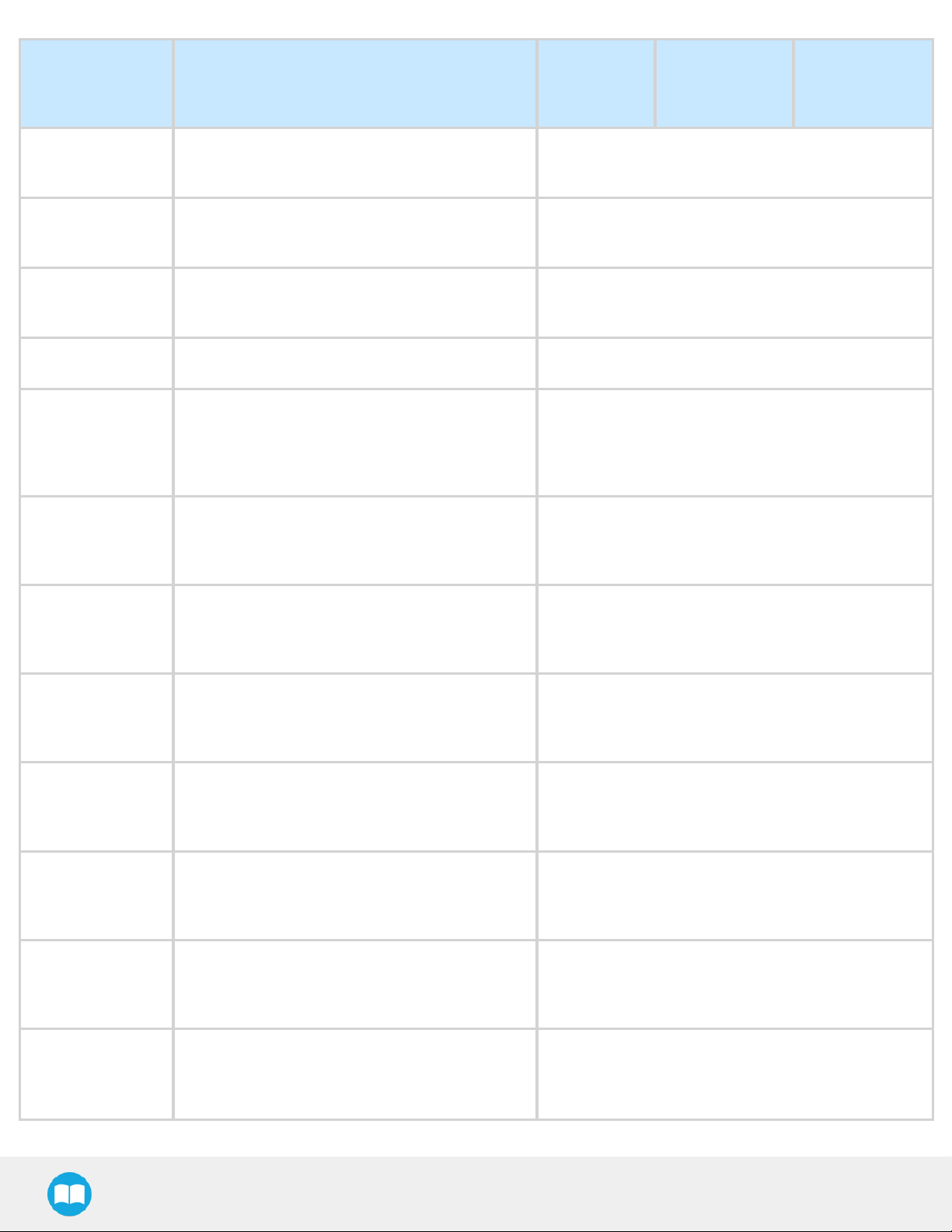

Settings Variable Type Default Description

var_grip_

advanced_

mode

bool False Set to trueto usetheAdvanced mode of thegripper

57

Grip_Settings

Release_

Settings

var_grip_

max_vacuum

var_grip_min_

vacuum

var_grip_

timeout

var_grip_

wait_for_

oject_

detected

var_release_

advanced_

mode

var_release_

shutoff_time

var_release_

wait_for_

object_

released

byte 60

byte 40

int 3000 Timeinmillisecond (ms)until no partis detected

bool True

bool False Set to trueto usetheAdvanced mode of thegripper

int 1000

bool True

Whenset to true,theprogramwillwait for anobjectdetection

Whenset to true,theprogramwillwait for anobjectdetection

20~100whichrepresentsthe vacuumpercentage

10~maxwhichrepresentsthe vacuumpercentage

beforeexiting thecomponent

EPickTimefor thevalveto shut off

beforeexiting thecomponent

var_slave_id int 9 Theslave ID of thegripperusedfor modbuscommunication

var_com_port byte 1 Thenumberof theCOM port on whichthegripper is connected

Table4-3:SETComponent Variables

Advanced Mode

TheAdvanced modeis set to falsebydefault,whichmeansthatthe vacuumvaluesand the timersaresetautomatically.Whenthe

Advanced modeis set to true,thegripper will usethe vacuumlevel parametersand thetimerset by theuserto grip and release.

EPick- InstructionManual

Page 58

58

GRIPComponent

Component Icon Component Node

Thegrip componentis used to activatethegrippersuctionand to pickanobject.Thegrip component hasthreepossibleexits:

1. Detected:Whenan object isdetected bythegripper

2. Not Detected:Whenno object is detectedbythe gripper

3. Error:Whenagripper erroroccurs

1

Drag and drop the GRIPComponent icon aftera programGatewayto placea GRIPprogramnode(VAC_V002_GRIP1)

2

Tap theGRIPnode to highlight it and clickon thepencilto edit thesettings

RELEASEComponent

Component Icon Component Node

TheReleasecomponentisusedto releasethepart byopening a valve.TheRelease componenthastwo possibleexits:

1. Ok:theobjecthasbeenreleased

2. Error:communication error

Page 59

1

Drag and drop the RELEASEComponent icon aftera programGatewayto placea RELEASEprogramnode (VAC_V002_GRIP1)

2

Tap theRELEASEnode to highlight it and clickon thepencil to edit thesettings

SelectIDComponent

TheSelectID component isused to change theSlaveID for themodbuscommunication whenusing adualgripper setup.

Component Icon ComponentNode

59

Info

Usethe Robotiq UserInterfaceto change theModbusSlaveIDAddressof the second VacuumGripperwhen using a dual

gripper(Default = 9).

Changing the ModbusSlave ID

Theusercan change theModbusSlaveID of a Robotiq VacuumGripperviatheRobotiq UserInterface.

Installer

Browseto the support pageof theGripperintheSoftwaresection to download theRUIinstaller (.exe).

1

First,clickon theModbusRTUParameterstab

EPick- InstructionManual

Page 60

60

2

Changethe SlaveID of theVacuumGripperby typing inthe corresponding box

3

Clickon theApplybutton

4

Performa powercycle(24V)whiletheUSBdeviceremainsconnected

Page 61

61

EPick- InstructionManual

Page 62

5.UserInterface

Visit support.robotiq.com to get thelatestinstaller of the Robotiq UserInterfacealong withappropriate documentation.

Seetheinstructionmanual of theRobotiq UserInterfaceformoredetails.

62

EPick- InstructionManual

Page 63

6.Specifications

Caution

Thismanualusesthemetricsystem,unlessspecified, alldimensionsareinmillimeters.

Thefollowing subsectionsprovide data on thevariousspecificationsfor theRobotiq EPickGripper.

l Section 6.1liststhetechnicaldimensionsof theGripper

l Dimensionsfor custom (blank)coupling

l Dimensionsof all available couplings

l Section 6.2presentsthemechanical specificationsof theGripper.

l Section 6.3giveselectrical specificationsforthe Gripper.

63

EPick- InstructionManual

Page 64

64

6.1. Technical dimensions

6.1.1.Gripper

ThefigurebelowrepresentstheGripper’sdimensions.

Fig. 6-1:EPickgeneral dimensions

Page 65

6.1.2.SuctionCupSystem

Thefiguresbelow represent thedimensionsof thecomponents of the suction cup systems.

Manifold

65

Bracket for 2 suctioncups

Fig. 6-2:Manifold general dimensions

EPick- InstructionManual

Page 66

66

Bracket for 4 suctioncups

Fig. 6-3:Two airnodesbracket's dimensions

Fig. 6-4:Fourairnodesbracket's dimensions

Page 67

67

Fig. 6-5:Minimumand maximumarrangement possibilitiesof theairnodesposition.

EPick- InstructionManual

Page 68

68

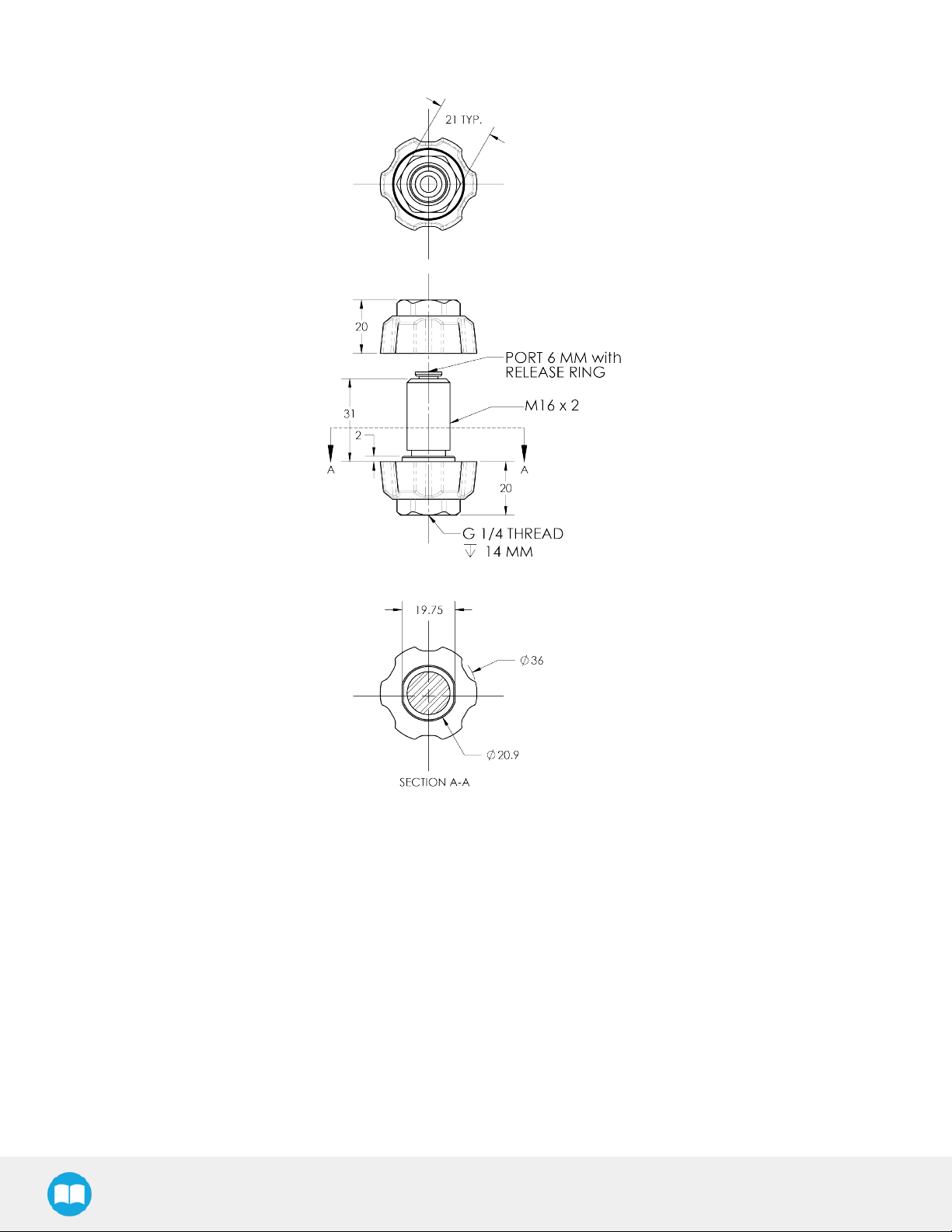

6.1.3.Airnodes

Fig. 6-6:Airnodesdimensions

Page 69

69

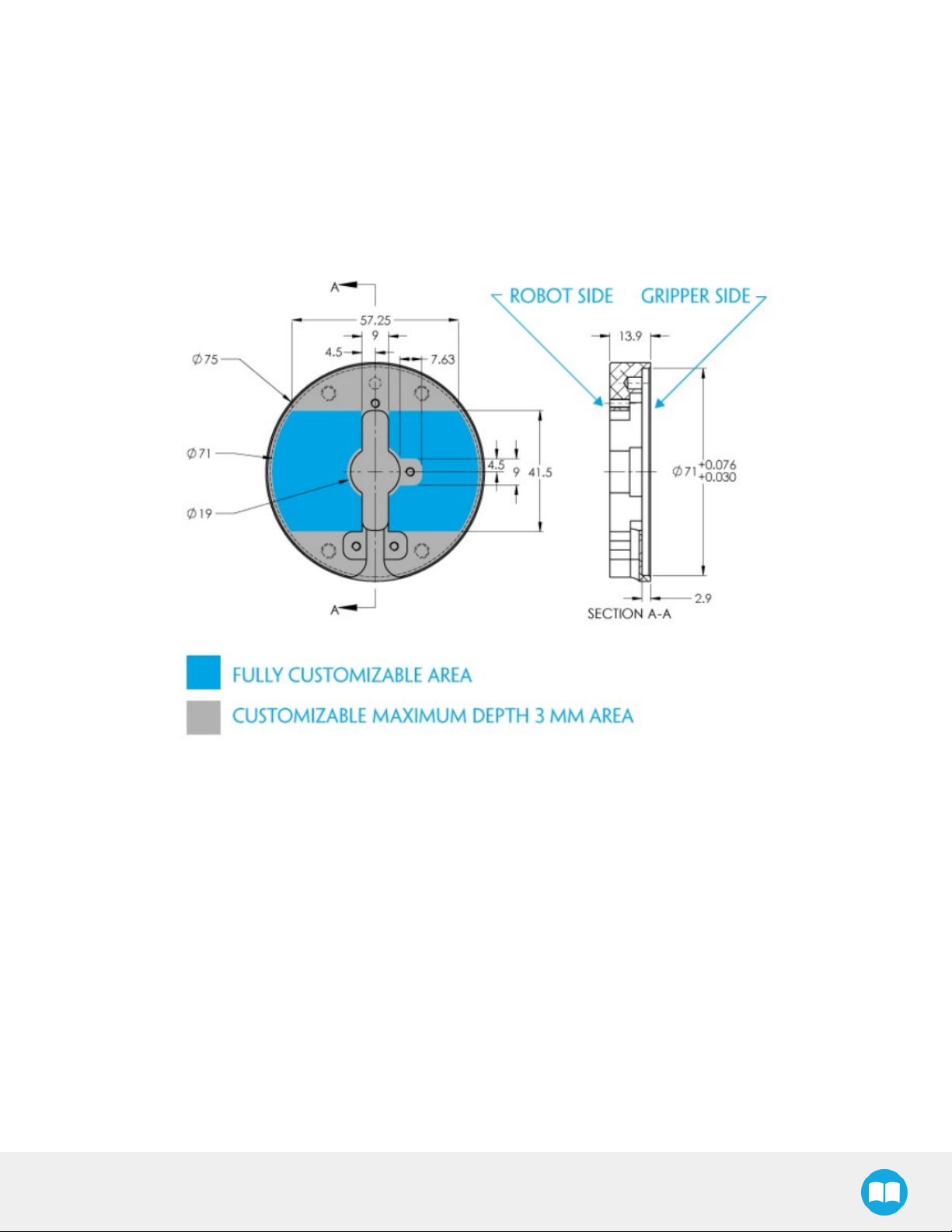

6.1.4.Couplings

Operating the VacuumGripperrequiresa coupling provided byRobotiq. Thecoupling ismandatorysinceit integrateselectronicsand

electrical contacts.

Blank coupling

Below arethe dimensionsof theblankcoupling,AGC-CPL-BLANK-002(referto theSpare Parts,Kitsand Accessoriessection),available

to createa custom bolt pattern.Bluesectioncanbe fullycustomized (holescanbeplaceinanypart of thissection)whilethegrey

section canonlybe worked to a depthof 3 mm.

Fig. 6-7:Workableareadimensionsof blankcoupling AGC-CPL-BLANK-002

EPick- InstructionManual

Page 70

70

CouplingforISO 9409-1-50-4-M6

Bolt patternfor coupling GRP-CPL-062 (referto the SpareParts, KitsandAccessoriessection)iscompatible with:

l 50mm pitchcirclediameter:

l (4)M6-1.0lowhead socket cap screwclearance

l (1)M6indexing pin

l ISO 9409-1standard 50-4-M6

Fig. 6-8:Coupling for ISO 9409-1-50-4-M6.

Page 71

6.2.Mechanicalspecifications

Specifications

71

EPickVacuumGripper

MetricUnits ImperialUnits

Energy source

Grippermass(including coupling)

720g 1.58lbs

Electricity

Maximumvacuum level 80 %

Maximummeanflow 12L/min 3.17gal/min

Payload range

Gripping time

Releasetime

1 0-10kg 0-22lbs

2 150ms

2 180ms

Noiselevel 64dBa

Maximumtorquepermissiblebycustom suction cup

bracket

1

The payload range isfor anon-porous surface with four suction cups of 55mm diameter at 80%of vacuum level.

2

The Gripping and Release time is the time for one suction cup of 40mm and can vary according to the suction cups configuration and

vacuum level.

150Nm / 110lbf-ft

Table6-1:Specificationsof the EPickGripper

Info

All specificationsaremeasuredwith coupling GRP-CPL-062.

EPick- InstructionManual

Page 72

72

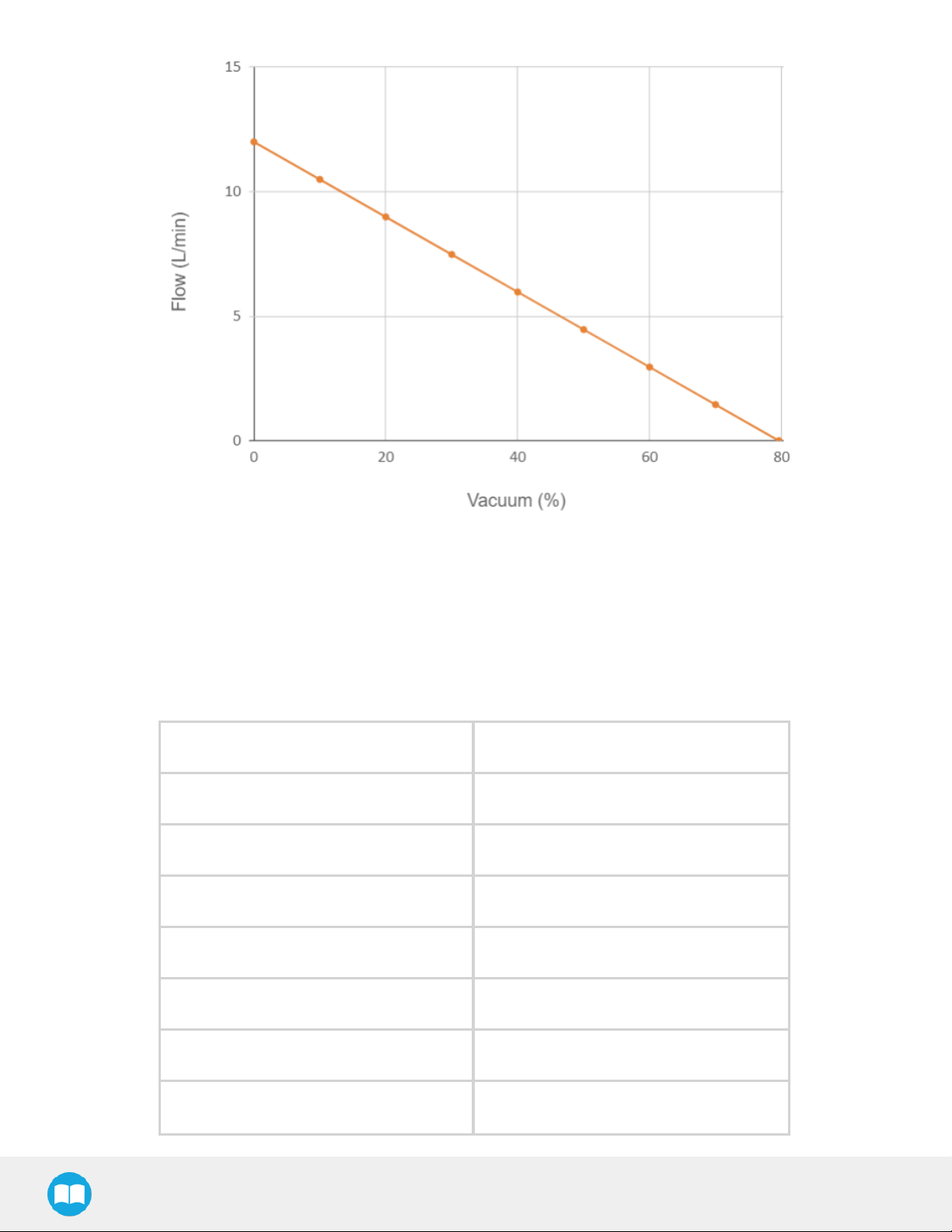

Chart6-2:Flow(L/min)vsVacuum(%)

6.2.1.Payloadandforce

Whena load is to be picked by a Vacuum Gripper,several factorshave to be considered. One of themis the vacuum level percentage

selected. This value represents the pressure difference between the inside of the system and the ambient pressure. This table is valid

for anominal atmosphericpressureof 101,3kPa.

Vacuumlevel(%) Pressuredifference(kPa)

0 0

10 10.1

20 20.3

30 30.4

40 40.5

50 50.7

60 60.8

Page 73

70 70.9

80 81.1

90 91.2

100 101.3

Table6-3:Conversionof absolutepressureto vacuumlevel

73

EPick- InstructionManual

Page 74

74

Fig. 6-9:Suction cup withinsidediameter

Depending on theselected suctioncup,the maximumgrip strength can be determined withthefollowing equation:

Where:

l A= Suction cups internal surface(mm

l P= Vacuum Level (kPa)

l n= Quantity of suction cups to lift-off

2

)

For moredetails,pleasereferto the specificationsprovided bythe suctioncup manufacturer.

Thepayload isthemassto belifted according to an acceleration and an applied safetyfactor.Therearethreemaintypesof load

application thatarerepresented in thefollowing cases.Note thatthearrowsrepresent therobot movement.

Case#1 Case#2 Case #3

Where:

Page 75

l M = mass(kg)

75

l G= gravitational acceleration (m/s

l A = robot acceleration(m/s

l µ= friction coefficient

l S= safety factor

2

)

2

)

Themaximumgrip strength of the suctioncup must alwaysbebiggerthanthepayload (Fp> Fc)to guaranteethe good grip of the

piece.Robotiq recommends a minimum securityfactor of 2in everycase.However,afactor4 isrecommended for thenext situations:

l Lowfriction coefficient

l Importantrobot acceleration

l Non-uniform surface

l Poroussurface

l Unequaldistribution of the payload inregardsto thesuction cups

Twocategoriesof materialcanbe lifted bythevacuumgripper:porousand non-porous.A non-porousmaterial isdefined asamaterial

whereairleakagesarenegligible and whereit is possibleto preciselyattaina vacuumpercentage between 10 and 80%.

Example 1: Non-porousmaterial

Fig. 6-10:Non-porousmaterial

Initialdata:

l Material type:non-porous

l Application type:Case#2

l Suction cup diameter(d):40mm (r=20mm)

l Percentage of vacuum:60%(whichisequivalentto 60.8kPa,according to the conversiontableabove)

l Mass:2 kg

l Acceleration:1.2m/s

l n= 4

2

EPick- InstructionManual

Page 76

76

Case #2

l m = 2 kg

l g = 9.81m/s

l a= 1.2m/s

l S= 4 (recommended)

l µ= 0.5

2

2

ValidationthatFp> Fc:305.6N > 97.7N

Since305.6N > 97.7N ,theruleisrespected and wecanensurethe good grip of thepart.

Example 2: Porousmaterial

For porousmaterial,non-negligibleairleakagescanbe observed.Therefore,the useof theEPickis not recommended.Considering

that,theVacuum Gripperwill workin acontinuousmodeto compensate leakagesand thereached vacuum willdepend on 4main

factors:

1. Pump flowrate

2. Themodelof suction cups

3. Porosityof materials

4. Payload to lift

Page 77

Fig. 6-11:Porousmaterial

77

Info

Robotiq recommendsto do someteststo determinethemaximumgrip strength of the suctioncup,depending on the

selected material to lift.It isnot recommended to operatetherobot withvacuum levelslowerthan10%.

EPick- InstructionManual

Page 78

78

Initialdata:

l Material type:porous

l Application type:Case#1

Case #1

l m = 0.2Kg

l g = 9.81m/s

l a= 1.2m/s

l S= 4 (recommended)

2

2

A test hasbeenmade with thismaterialand it wasstatisticallypossible(without anyacceleration)to picka massof 1 kg.

Since,Fp>Fc(9.81N > 8.8N),it ispossibleto lift a massof 0.2kg,asrequired.

Page 79

6.2.2.Centerofmassandtoolcenterpoint

Couplingsareincluded inthecalculationswhenVacuumGrippersarenot mounted onthe Robotiq Wrist Camera.DualGripper

adapterplatesareincluded where appropriate

79

Fig. 6-12:Centerof massand tool centerpoint matrix.

Thecoordinatesystemused to calculate themoment of inertia and centerof massof theVacuum Gripperis shownin thefigurebelow.

Fig. 6-13:Inertiamatrixfor EPickGripper.

EPick- InstructionManual

Page 80

80

6.2.3.Moment Limitation

TheVacuumGripper hasa maximummoment.Thelisted momentis independent to theforceapplied bythe Gripperitself on it's

payload.Forpayload calculation,referto theMechanical specificationssection.

Warning

Thefollowing limitsmustberespected at all time.Calculationof maximum momentshould include therobot acceleration

anda safety factor.

Parameters MaximumValue

Total moment 150Nm

Table6-4:Momentlimitation of the VacuumGripper

6.3. Electricalspecifications

SPECIFICATION VALUE

Operating supply voltage 24VDC± 10%

Quiescent power(minimum

powerconsumption)

Peakcurrent 1.8A for 80 mswhenvacuum pump starts

Table6-5:VacuumGripperelectrical specifications

1W

Page 81

7.Maintenance

TheVacuumGripper onlyrequiresexternal maintenancewithlimited downtime.

Maintenanceisrequired afterspecified usage,measured incycles(workpiecepick-upand release)orusetime (hours).

Following themaintenanceintervalwillensure:

l Correctfunctioning of theVacuum Gripper.

l Validityof thewarranty.

l Properlifetime of theVacuum Gripper.

Warning

Unlessspecified,anyrepairsdoneonthe VacuumGripperwill be done byRobotiq.

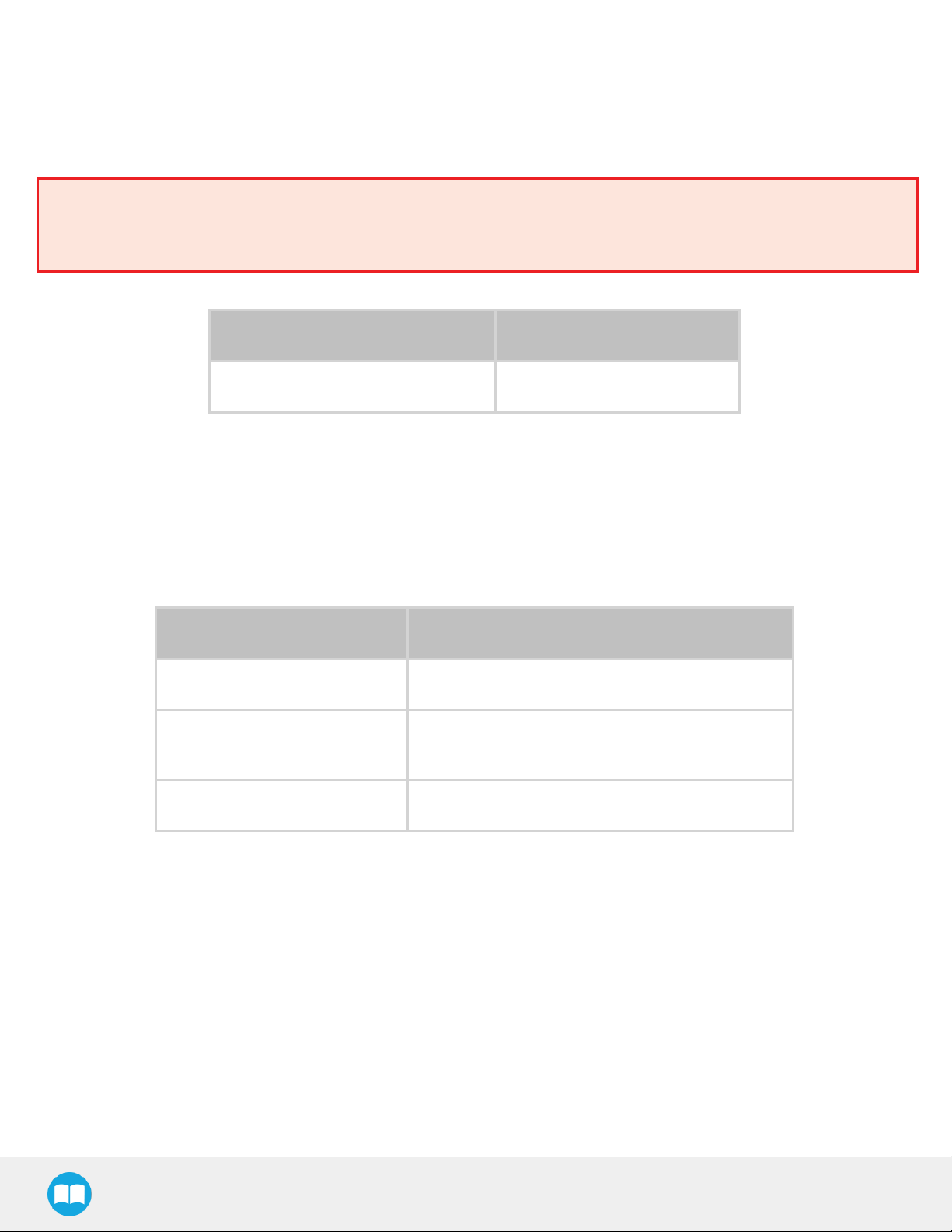

Operation Daily Monthly 1M cyclesor

1000hours

81

GripperCleaning Dirty

conditions

Normal

conditions

Periodic Inspection X

Table7-1:VacuumGrippermaintenanceintervals

Caution

Maintenanceoperationsare for theaveragenormalusage of theVacuumGripper,themaintenanceintervalsmust be

adjusted according to theenvironmentalconditionssuchas:

l Operating temperature

l Humidity

l Presenceof chemical(s)

l Presenceof physical objects (debris,scraps,dust,greaseetc.)

l Interaction withoperated parts(sharp orrough)

l Dynamicsof the operation(accelerations)

EPick- InstructionManual

Page 82

82

7.1. Vacuum Grippercleaning

Maintenance Interval Toolsyouneed Partsyouneed

l 4mm hexkey

Monthly

(or dailyin dirtyoperating conditions)

l Drytissueortowel

l Mediumstrengththread locker

l Retaining ring plier

Replacement filter

(if required)

Table7-2:VacuumGrippercleaning intervals

Caution

TheEPickVacuumGripperisnot waterproof orwaterresistant without additionalprotection,onlycleantheGripper with a

dry towel.

Caution

Alwaysturnoff therobot,theVacuum Gripperpowersupplybefore performing anymaintenanceoperation on it.

Caution

Maintenanceoperatormustbegrounded to preventelectrostaticdischarge thatcould damagetheVacuumGripper

electronics.

Caution

Do not usecompressed air to cleanthe VacuumGripper.Doing socanresultin adamageto thecheckvalveor therelease

valve.

1. RemovetheVacuumGripperfrom its coupling using the4 mmhexkeyto unscrewthe four(4)M5-0.8x25 mm socket head cap

screws.Note thateachscrewusesatooth lockwasher,do not discard.

2. CleantheVacuumGripperwitha drytowel,removeall debris,dirt anddustfrom itssurface.Cleanall suction cups.Drythoroughly.Inspect theinput filterto determineif it needsto be changed or not.

3. Ifthe inputfilterneedsto be changed,follow thesteps:

i. Removetheretaining ring.

ii. Removetheold input filter.

iii. Install thenewoneand put backtheretaining ring.

Page 83

Tip

Ifthe inputfilterneedsto be changed,werecommend you to get aretaining ring plierfor internalretaining ringsof 0.038'' tip

diameterto help youreplaceit.

83

Fig. 7-1:EPickinput filterchange

4. Cleanthecoupling withadrytowel andpayaparticularattention to the electricalcontact.

5. Visuallyinspect theVacuum Gripperand payattention to anyvisible damage.

6. Put thecoupling backonand secureusing the four (4)M5-0.8x 25 mmsocket head cap screws.Usethetooth lockwashers.

Applymedium strength thread lockerto theM5 screws.

Whencleaning the VacuumGripperverifythewearof thesuction cup. Ifwearis visible,changethe suctioncup.Pleasereferto the

Spare Parts,Kitsand Accessoriessection to orderEPick replacement parts.

7.2. Periodicinspection

Maintenance Interval ToolsYouNeed PartsYouNeed

l Flat head precision2 mmscrewdriver

Monthly

l Drytissueortowel

l Mediumstrengththread locker

None(unlessdamageis detected)

Info

Table7-3:EPickGripperinspection intervals.

EPick- InstructionManual

Page 84

84

Alwaysturnoff therobot and theVacuum Gripperpowersupply beforeperforming anymaintenance operations.

1. Removeand clean theVacuumGripperfollowing instructionsin theVacuumGrippercleaning section.

2. Inspect theVacuum Gripper:

a. Checkfor anycollision damage.If damage isvisible,contactsupport@robotiq.com.

b. Checkfor anysign of wearon theVacuum Gripperchassis.If wearispresentand mayaffect theVacuumGripper,con-

tactsupport@robotiq.com.

3. Put theVacuum Gripperbackin placeaccording to the instructionsfrom theVacuumGrippercleaning section.

Suctioncupsand airnodes

Depending on yoursetup, mountthe appropriatenumberof vacuumcups to theirmating airbolts.If you need more information about

thesuction cups installation,pleasereferto Suctioncup systemsection.

Warning

Anyunused manifold port should be covered with aprovided port plug to avoid airleakage.

Page 85

8.Spare Parts, Kitsand Accessories

Info

Thefollowing listis up to dateat print timeand issubject to change,checkonlineforupdates.

Info

Unlessspecified,screws,dowelpinsand otherhardwareareincluded onlyfortheGripperside,neverfortherobot side.

Spareparts,kitsand accessorieslist:

85

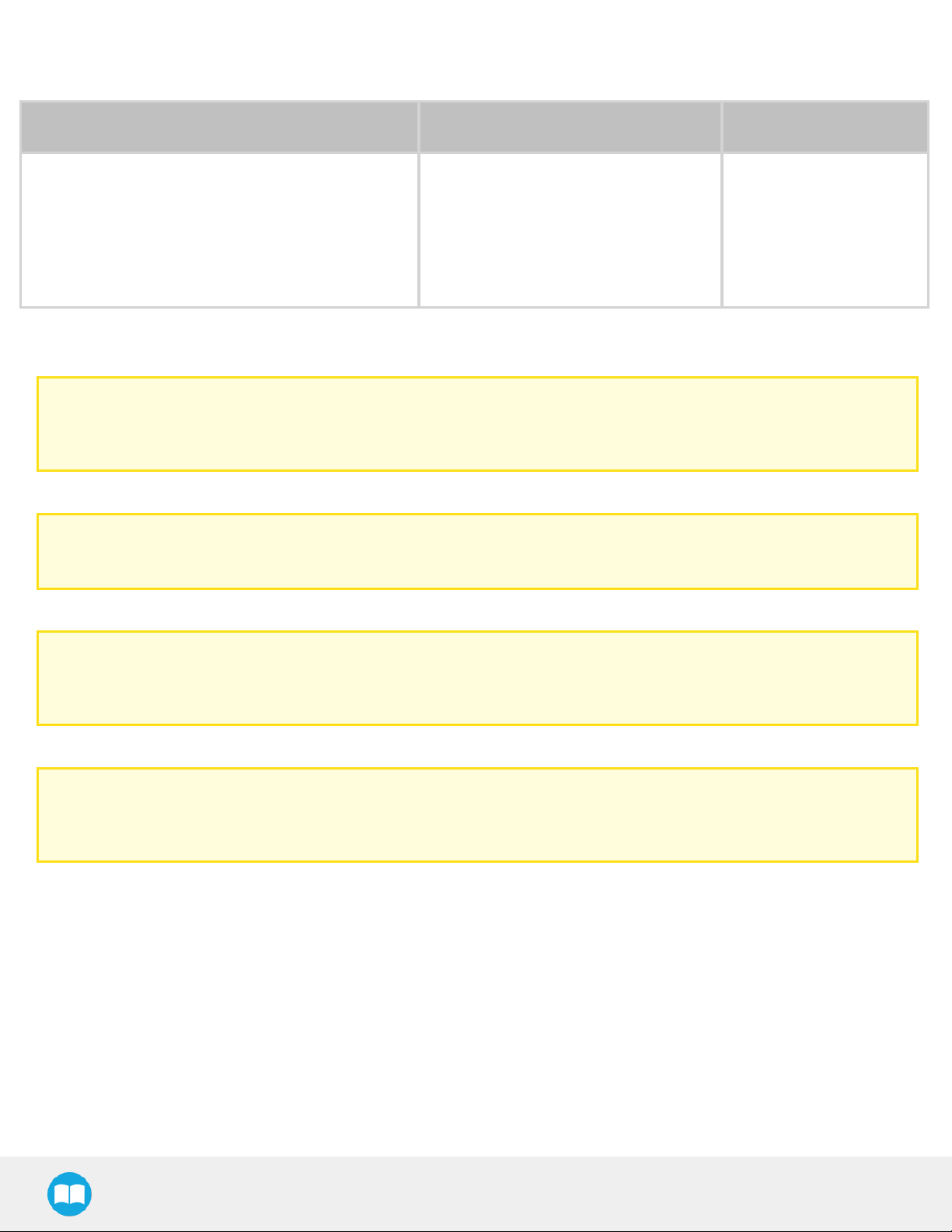

Item Description Ordering

Number

(1Cup)

Kit for TM Robot EPickKitfor TM VAC-TM-

EPICK-KIT1

Kit for Omron-TM EPickKitfor Omron-TM VAC-

OMRON-

EPICK-KIT1

Kit 2 Suction Cup

System

Kit 4 Suction Cup

System

Suction cup

configurationScrewing Kit

Kit 4 Suction Cup System-2 SuctionCups VAC-SCS-KIT2

Kit 4 Suction Cup System-4 SuctionCups VAC-SCS-KIT4

Suction cup configuration- Screwing Kit VAC-SCS-SCREW-KIT

Ordering

Number

(2Cups)

VAC-TM-

EPICK-KIT2

VAC-OMRON-

EPICK-KIT2

Ordering

Number

(4Cups)

VAC-TM-EPICK-

KIT4

VAC-OMRON-

EPICK-KIT4

VacuumSuction

Cup platefor 2

cups

VacuumSuction

Cup platefor 4

cups

VacuumSuction Cup platefor 2cups VAC-SCS-PLATE-2

VacuumSuction Cup platefor 4cups VAC-SCS-PLATE-4

EPick- InstructionManual

Page 86

86

Item Description Ordering

Number

(1Cup)

Airnode Plug and

Play

VacuumCup 1.5

Bellow 40 mm

VacuumCup 1.5

Bellow 55mm

Replacement filter Filterfor vacuumgenerator VAC-SCS-FILTER

ISO 9409-1-50-4M6coupling

(coupling to

controller)

Airnode Plug andPlay VAC-SCS-NODE

VacuumCup 1.5Bellow 40mm VAC-SCS-CUP40-2

VacuumCup 1.5Bellow 55mm VAC-SCS-CUP55-2

ISO 9409-1-50-4-M6coupling for 2-FingerRobot

Grippers,withscrewsfor Gripperfixation and 1 m

pigtail cable

Ordering

Number

(2Cups)

GRP-CPL-062

Ordering

Number

(4Cups)

ISO 9409-1-31.5-4M5coupling

ISO 9409-1-40-4M6coupling

56-8M4-1D4

coupling

56-6M4-1D6

coupling

60-4Ø5-1D5

coupling

63-6M6-2D6

coupling

ISO 9409-1-31.5-4-M5coupling for Adaptive

Robot Gripper2-Finger,with screwsfor Gripper

fixationand 1m pigtail cable

ISO 9409-1-40-4-M6coupling for AdaptiveRobot