Page 1

Robotiq 2F-85 & 2F-140

for CB-Series Universal Robots

Original Notice

© 2019 Robotic Inc.

Instruction Manual

robotiq.com | leanrobotics.org

Page 2

Revisions 7

1. General Presentation 10

1.1. Gripper nomenclature 11

1.2. 2F-85 vs. 2F-140 12

1.3. Object picking 13

1.4. Setup and control 16

2. Safety 17

2.1. Warning 18

2.1.1. Risk assessment and final application: 18

2.2. Intended Use 19

3. Installation 20

3.1. Scope of Delivery 21

2

3.1.1. UR Kit 21

3.2. Required Tools and Equipment 21

3.3. Environmental and Operating Conditions 22

3.4. Mechanical Installation 23

3.4.1. Installing fingers on the Gripper 23

3.4.2. Installing the fingertips on the Gripper 24

3.4.3. Installing a Protector Kit on the Gripper Fingers 25

3.4.4. Installing the Gripper onto the robot 25

Single Gripper 25

Multiple Grippers 27

3.5. Electrical Setup 28

3.5.1. Pinout Interface 29

3.5.2. Coupling to controller 29

Single Gripper 30

Multiple Grippers 31

3.6. Testing the Gripper with the Robotiq User Interface (RUI) 32

3.7. Installation for Universal Robots 33

3.8. URCap Package 34

3.8.1. Installing URCap Package 35

Single Gripper 35

Multiple Grippers 36

2F-85 &2F-140 - Instruction Manual

Page 3

3

3.8.2. Uninstalling URCap Package 39

3.8.3. License Agreement 40

3.9. URPackage without URCaps 43

3.9.1. Installation 43

4. Control 45

4.1. Overview 45

4.2. Gripper Register Mapping 47

4.3. Robot Output Registers &Functionalities 48

4.4. Robot Input Registers &Status 51

4.5. Picking Features 54

4.5.1. Force control 54

4.5.2. Re-Grasp 59

4.5.3. Object detection 60

4.6. Control Logic 61

4.7. Modbus RTUCommunication 62

4.7.1. Connection Setup 63

4.7.2. Read holding registers (FC03) 64

4.7.3. Read input registers (FC04) 65

4.7.4. Preset multiple registers (FC16) 66

4.7.5. Master read & write multiple registers FC23 67

4.7.6. Modbus RTU example 69

4.8. Control over Universal Robots with URCap 78

4.8.1. Gripper Dashboard 79

Overview 79

Single Gripper 79

Multiple Grippers 81

Features 81

4.8.2. Gripper Calibration menu and wizard 82

Features 84

4.8.3. Gripper Toolbar 86

Overview 86

Single Gripper 87

Multiple Grippers 88

Features 89

2F-85 &2F-140 - Instruction Manual

Page 4

Gripper activation 89

Gripper operation window 90

Show/hide Gripper Toolbar 92

4.8.4. Gripper Node 92

Command window 92

Features 94

Edit action screen 96

Single Gripper 96

Multiple Grippers 97

Features 98

Grip Check node 99

About 99

Error messages overview 100

4

Gripper Program Template 102

Advanced Gripper Functions 103

Single Gripper 103

Multiple Grippers 106

4.8.5. Retro-compatibility of URCaps with legacy driver programs 109

4.9. Control over Universal Robots without URCaps 110

4.9.1. Gripper Toolbar 110

Overview 110

Features 110

Toolbar collapsed 110

Toolbar expanded 111

4.9.2. Demo Scripts 112

4.9.3. Custom Programs 113

4.9.4. Provided Variables and Functions 114

5. User Interface 117

6. Specifications 118

6.1. Technical dimensions 119

6.1.1. Couplings 123

Blank coupling 123

Coupling for ISO 9409-1-50-4-M6 124

2F-85 &2F-140 - Instruction Manual

Page 5

5

Coupling for ISO 9409-1-31.5-4-M5 125

Coupling for ISO 9409-1-40-4-M6 126

Coupling for PCD 56 with 8 x M4 127

Coupling for PCD 56 with 6 x M4 128

Coupling for PCD 60 with 4 x M5 129

Coupling for PCD 63 with 6 x M6 130

6.1.2. Fingertips 131

Flat silicone fingertip 132

Grooved fingertip 133

6.2. Mechanical specifications 134

6.2.1. Payload and force 135

Friction grasp and form-fit grasp 137

Maximum payload by grasp type 137

6.2.2. Equilibrium Line 138

6.2.3. Center of mass, tool centere point and moment of inertia 139

6.2.4. Moment and force limits 141

6.3. Electrical specifications 142

7. Maintenance 143

7.1. Gripper cleaning 144

7.2. Periodic inspection 146

7.3. Fingertip replacement 147

7.4. Overhaul 148

8. Spare Parts, Kits and Accessories 149

9. Troubleshooting 152

10. Warranty andPatent 155

11. Contact 158

12. Harmonized Standards, Declarations and Certificates 159

12.1. Translation of original EC declaration of incorporation 159

12.2. Applied standards 160

2F-85 &2F-140 - Instruction Manual

Page 6

6

2F-85 &2F-140 - Instruction Manual

Page 7

Revisions

Robotiq may modify this product without notice, when necessary, due to product improvements, modifications or changes in

specifications. If such modification is made, the manual will also be revised, see revision information. See the latest version of this

manual online at support.robotiq.com.

Revision 2019/03/13

Updated mechanical specifications (section 6.2)

Revision 2018/11/07

New major revision of the Gripper hardware

l All external visual supports changed to reflect the hardware changes

l Updated Section 1

l Updated Section 3

l Updated Section 4

l Updated Section 6

7

l Updated Section 7

l Updated Section 8

l Updated Section 9

Revision 2018/09/11

l Updated Section 3 according to the robot used (CB-Series vs. e-Series)

l Updated Section 4

l Input &Output Registers

l Control over Universal Robots depending on the robot software used (PolyScope 3.6 and later version vs. PolyScope 5.0 and

later versions)

l Added LEDand move functions to the list of available functions

l Updated Section 8 with new spare parts, kits and accessories

Revision 2018/05/23

l Major update following the release of UCG-1.2.0

l New subsections in Section 4: Control

l Gripper Dashboard

l Gripper Calibration menu and Calibration wizard for object validation

Revision 2017/06/06

Added section:

l 4.8.2.1 Multiple Grippers

Revised sections:

2F-85 &2F-140 - Instruction Manual

Page 8

8

l 3.8.1 Installation procedure for URCaps

l 4.8.1 Gripper Toolbar

Revision 2016/07/04

Major revision : Updated for URcaps release Section added :

l 3.8 URCaps Package

l 3.9 UR Package without URCaps

l 4.8 Control over Universal Robots with URCaps

l 4.9 Control over Universal Robots without URCaps

Revision 2015/09/15

Major revision : Updated for 2-Finger 140

Revision 2015/07/21

Section added :

l 4.5 Picking features : Force control, re-grasp and object detection.

l A. Harmonized standards, declarations and certificates

Minor modifications :

l Section 1. General Presentation

l Section 3.7 Universal Robots package

Revision 2014/11/05

Modification for Robotiq 2-Finger 85 Adaptive Robot Gripper version 3

Revision 2014/07/22

Modification for use on Robotiq Universal Controller

Minor modifications : User Interface section, maintenance section

Revision 2013/02/06

Section added : Couplings ISO models and Baxter robots Minor modifications

Revision 2013/02/06

Section added : Communication with UR robots Minor modifications

Revision 2012/10/18

Official release

Revision 2012/03/02

Beta release

2F-85 &2F-140 - Instruction Manual

Page 9

9

Copyright

© 2016-2019 Robotiq Inc. All rights reserved.

This manual and the product it describes are protected by the Copyright Act of Canada, by laws of other countries, and by international

treaties, and therefore may not be reproduced in whole or in part, whether for sale or not, without prior written consent from Robotiq.

Under copyright law, copying includes translation into another language or format.

Information provided by Robotiq in this document is believed to be accurate and reliable. However, no responsibility is assumed by

Robotiq for its use. There may be some differences between the manual and the product if the product has been modified after the

edition date.

The information contained in this document is subject to change without notice.

2F-85 &2F-140 - Instruction Manual

Page 10

10

1. General Presentation

The terms "Gripper", "Adaptive Gripper", "Robotiq Gripper", "Robotiq Adaptive Gripper", "2-Finger 85", "2-Finger 140", "2F-85" and "2F140" used in the following manual all refer to the Robotiq 2-Finger Adaptive Robot Gripper. The Robotiq 2-Finger Adaptive Gripper has

two versions, 85 and 140. The 2-Finger version will change finger opening dimensions, which will be 85 mm (2F-85) or 140mm (2F-140).

Both versions use the same base, installation and control will be exactly the same. The 2-Finger Gripper is a robotic peripheral that is

designed for industrial applications. Its design makes it a unique robotic end-of-arm tool to quickly pick, place and handle a large range

of objects of varying sizes and shapes.

Info

Unless specified, information in this manual applies to both the 85 and the 140 mm version of the 2-Finger Adaptive Robot

Gripper.

Info

The following manual uses the metric system, unless specified, all dimensions are in millimeters.

Info

The following section presents the key features of the grasp-type gripper and must not be considered as appropriate to the

gripper operation, each feature is detailed in the appropriate section of the manual. Safety guidelines must be read and

understood before any operation is attempted with thegrasp-type gripper.

2F-85 &2F-140 - Instruction Manual

Page 11

11

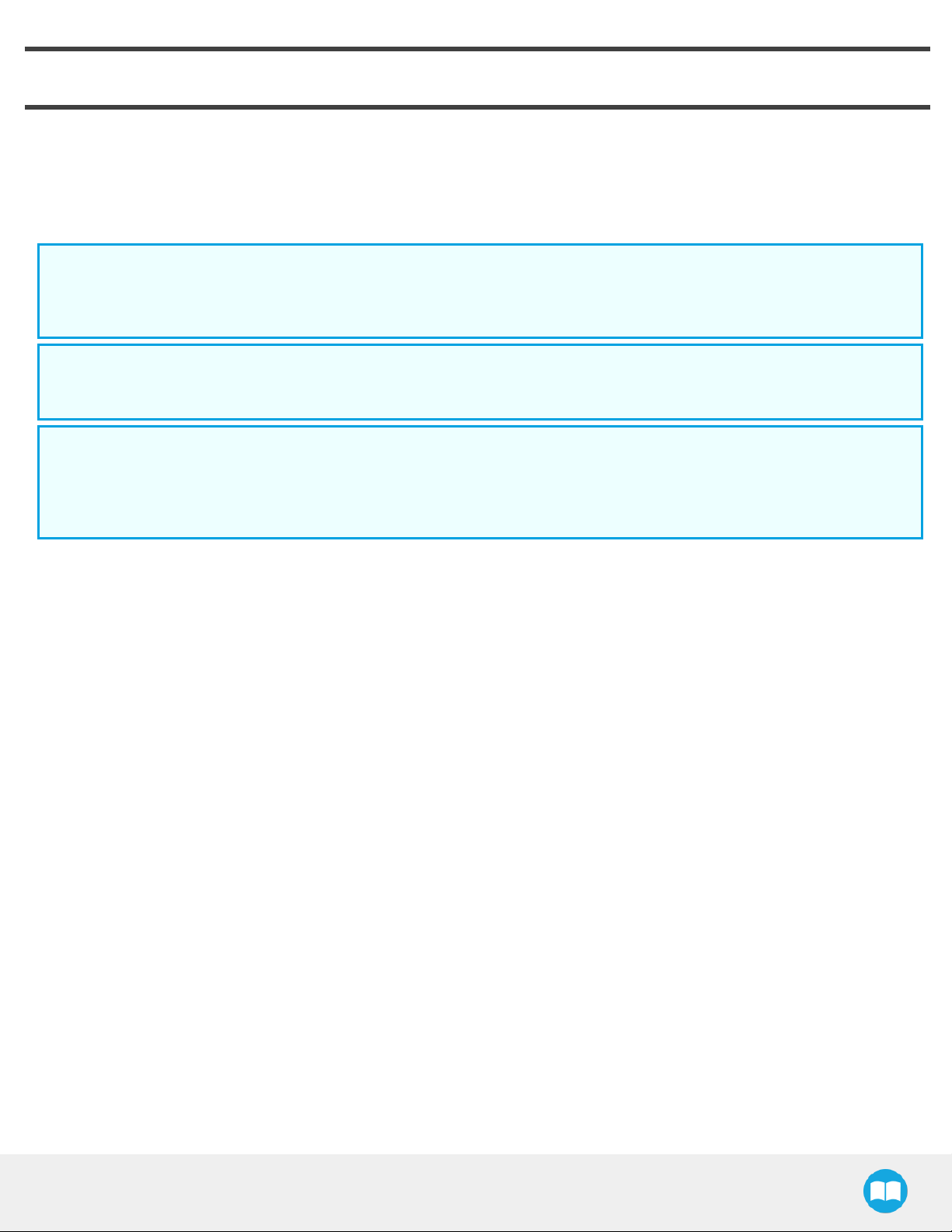

1.1. Gripper nomenclature

The 2-Finger Gripper has two articulated fingers that each have two joints (two phalanxes per finger), as shown in the figure below. The

grasp-type gripper can engage up to five points of contact with an object (two on each of the phalanges plus the palm). The fingers are

under-actuated, meaning they have fewer motors than the total number of joints. This configuration allows the fingers to automatically

adapt to the shape of the object they grasp and it also simplifies the control of the grasp-type gripper.

Fig. 1-1: Robotiq 2-Finger Adaptive Gripper.

Please refer to the for details on standard and optional parts.

The status LED presented in the figure above will be :

l solid blue/red when booting

l solid blue when powered with no errors (while communication is active)

l solid red if minor fault occurs, see status details in the Control section.

l blinking red/blue if major fault occurs, see status details in the Control section.

2F-85 &2F-140 - Instruction Manual

Page 12

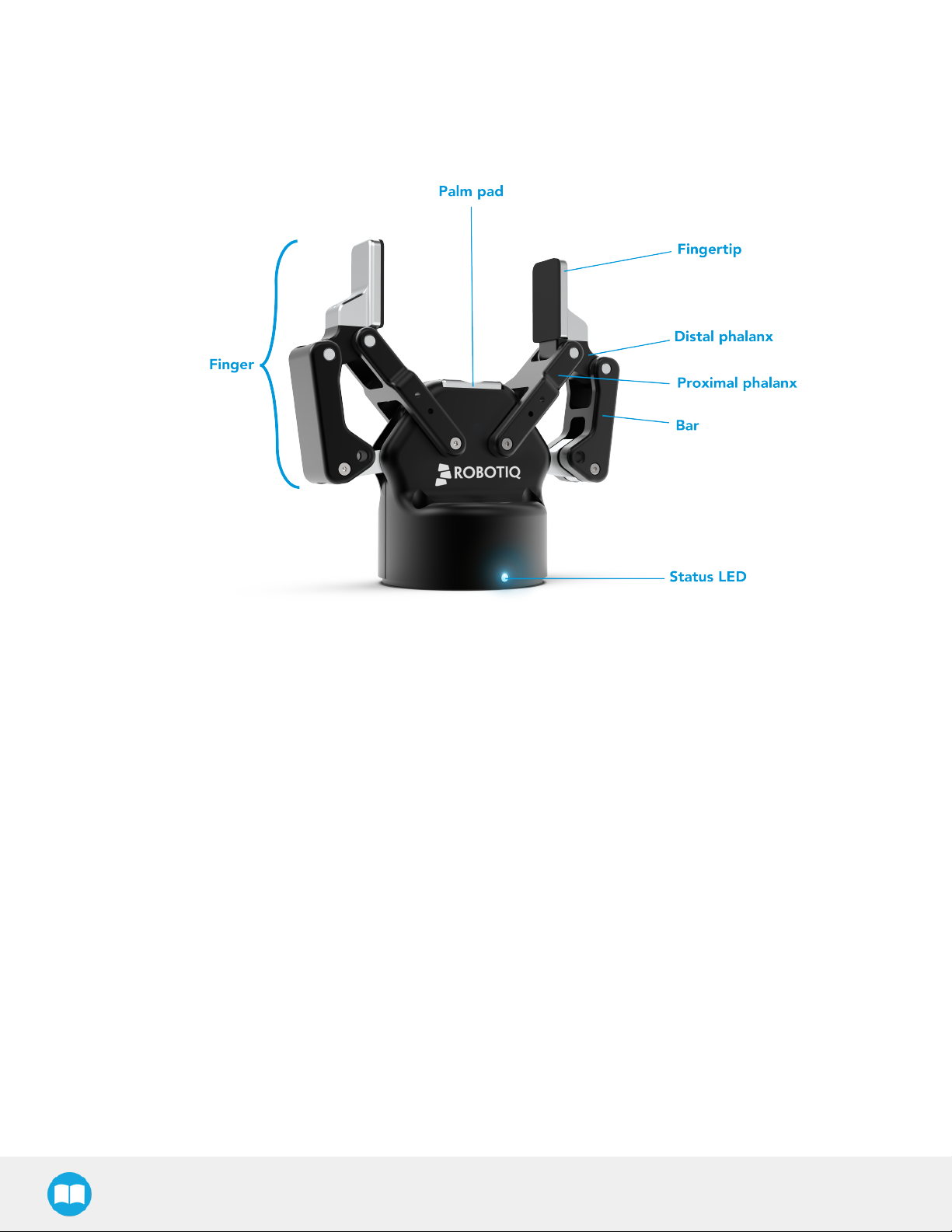

1.2. 2F-85 vs. 2F-140

The 2-Finger Gripper comes with either 85 mm opening (2-Finger 85) or 140 mm opening (2-Finger 140) according to the figure below.

The chassis will remain the same, only the fingers will change. Please refer to the Mechanical Installation section for installation

instructions. Finger kits are available in the Spare Parts and Accessories section.

Info

Details on the 2-Finger 85 and 2-Finger 140 (dimensions and specifications) can be found in the Specifications section.

12

Fig. 1-2: The 2-Finger 85 and 140 mm versions.

2F-85 &2F-140 - Instruction Manual

Page 13

13

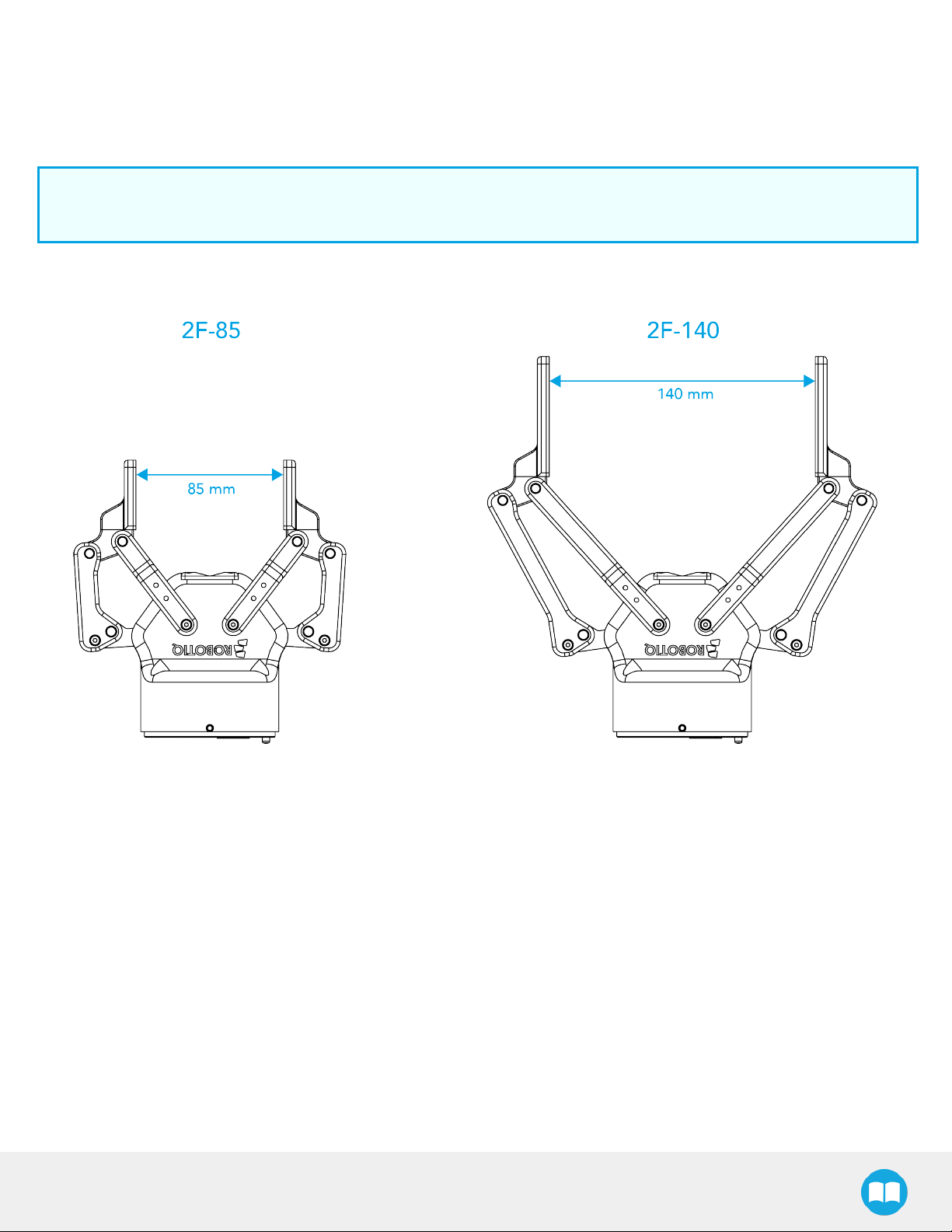

1.3. Object picking

The 2-Finger Gripper has a single actuator for opening and closing the fingers, the fingers automatically adapt to the shape of the object

manipulated.

Fingers will adopt either a parallel grasp or encompassing grasp as shown in the figure below.

Info

Closing or opening is done via the "Go to requested position" command and is input to the Gripper Whether the fingers

close to produce an emcompassing or fingertip grasp is decided at the Gripper level automatically. It will depend on:

l The objects's geometry;

l The relative position of the object with respect to the Gripper.

In other words, picking the same object could result in either an emcompassing or fingertip grasp based on an object's

position and geometry.

Fig. 1-3: 2-Finger parallel and encompassing grips.

Info

It is important to note that a fingertip grasp can only be performed when the fingers touch the object with the upper section of

the distal phalanxes first. Inversely, for an encompassing grip, the fingers must touch the object with the proximal or the

lower section of the distal phalanxes first. Also, to ensure stability, the object should be held against the Gripper palm while

performing an encompassing grip. Refer to the figure below for a visual representation of the parallel and encompassing

grasp regions on the distal phalanx of the 2-Finger Gripper.

2F-85 &2F-140 - Instruction Manual

Page 14

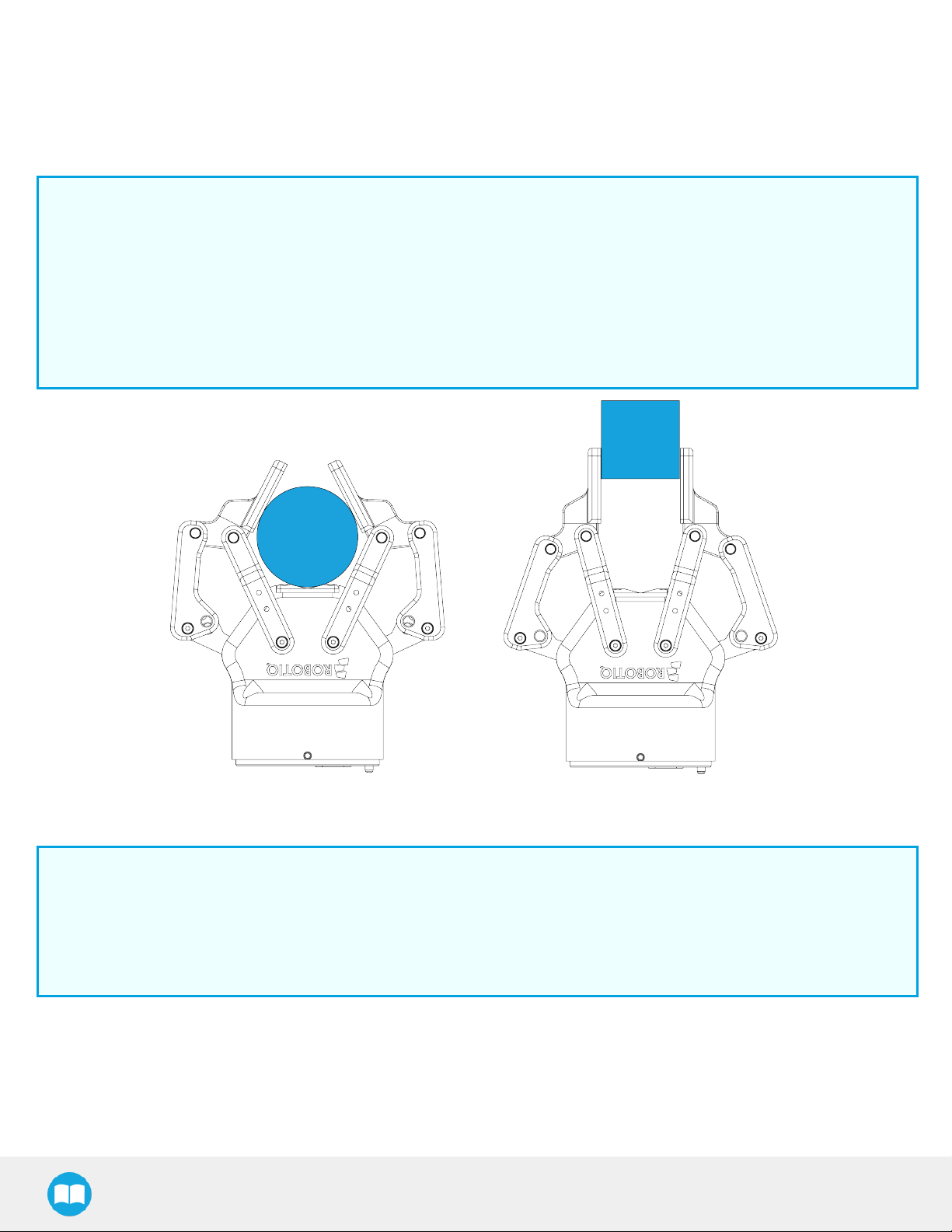

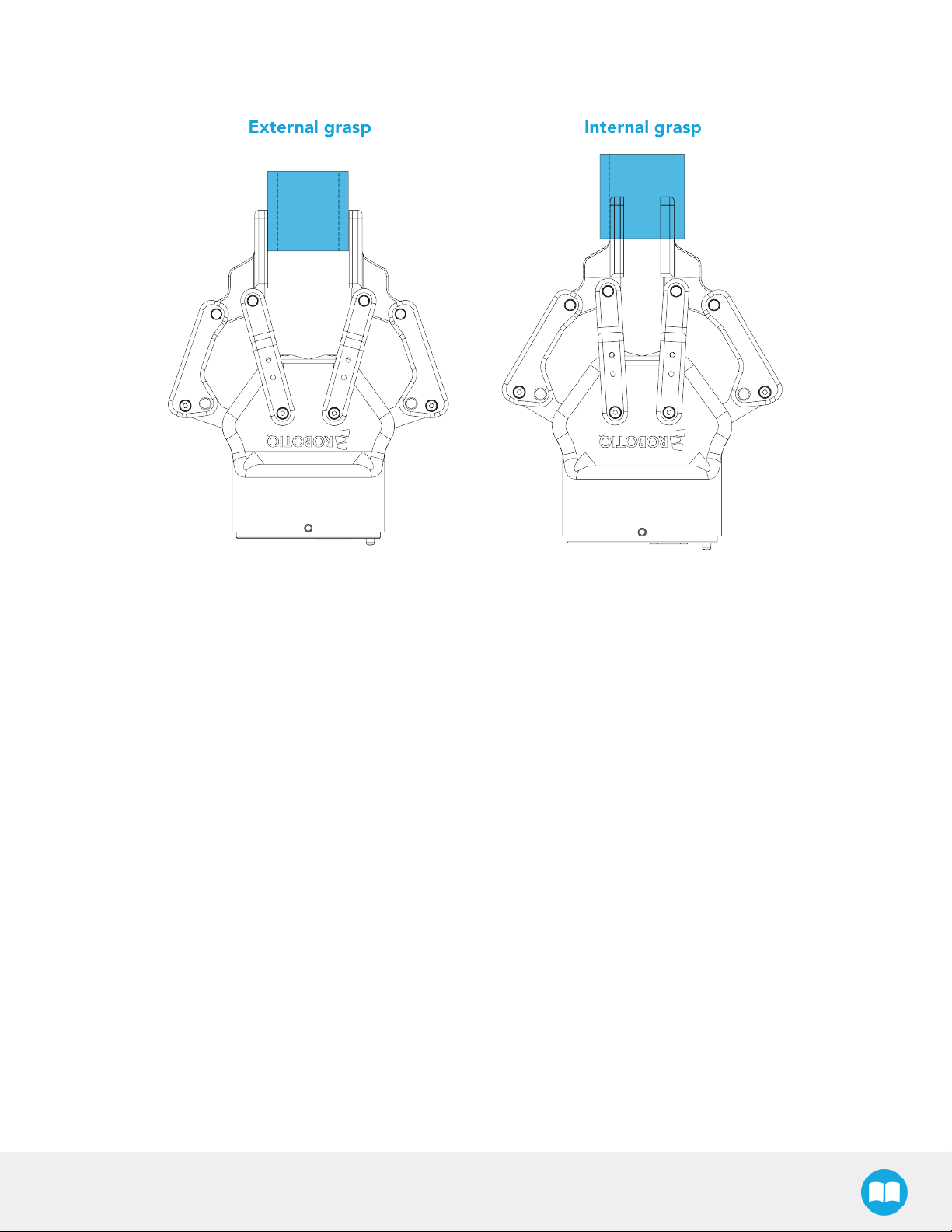

The 2-Finger Adaptive Robot Gripper also allows for internal grasping. The fingers can pick hollow objects from the inside by applying

pressure with the outside of the fingers. Refer to the figure below for a visual representation and to the Picking Features section for

details on the possible position commands of your Gripper.

14

Fig. 1-4: Finger internal and external grasping.

2F-85 &2F-140 - Instruction Manual

Page 15

15

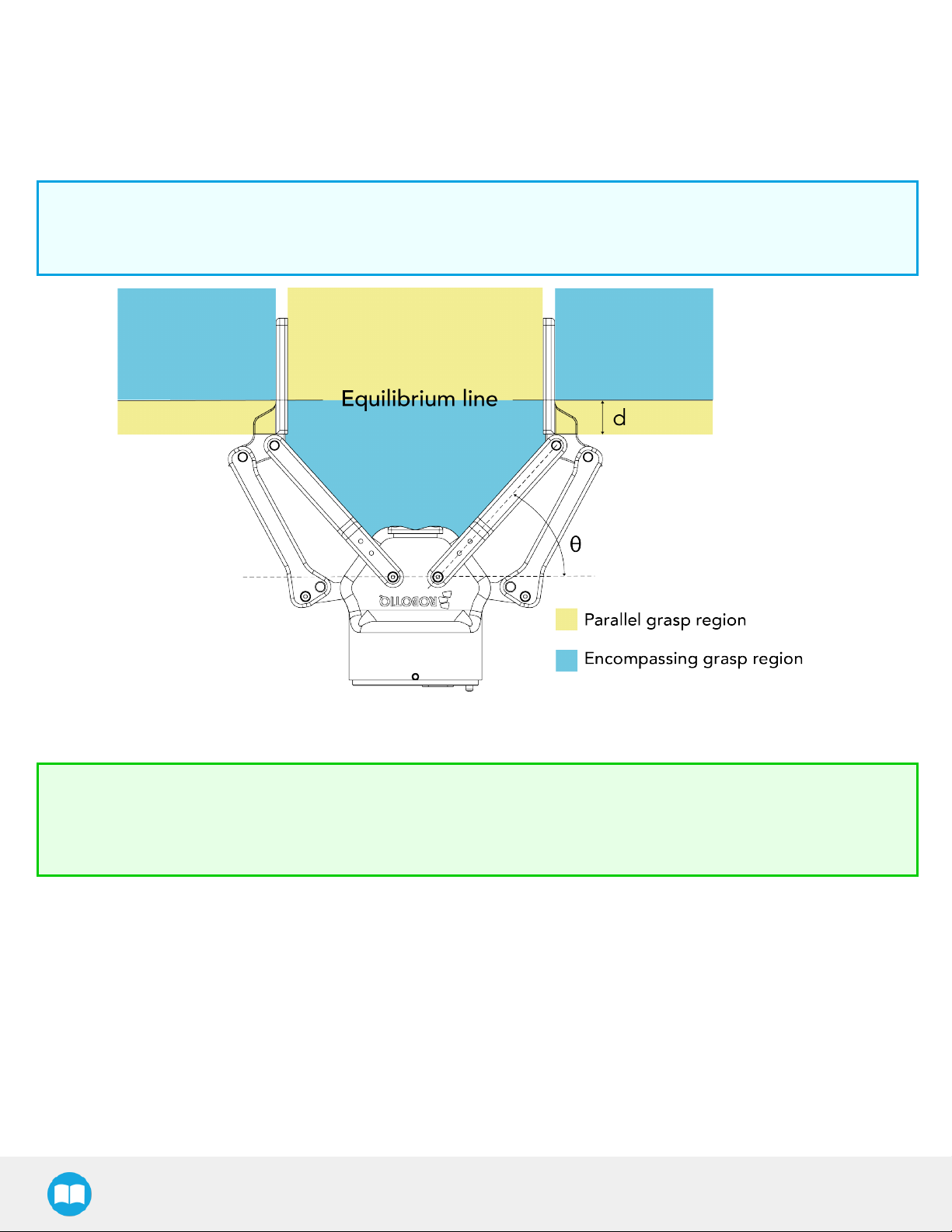

The Gripper equilibrium line is the grasping region that separates the encompassing grasp from the parallel grip. When grasping an

object close enough to the inside (palm) of the Gripper, the encompassing grasp will occur (unless the object size or shape is not

adequate) and the fingers will close around theobject.

If grasped above the equilibrium line, the same object will be picked up in a parallel grasp by the fingertips and the fingers will close with

a parallel motion. The figure below shows the encompassing grasp region, the equilibrium line, and the parallel grasp region on

the2-Finger Adaptive Robot Gripper.

Info

The details of the equilibrium line relation between opening angle and the related position d can be found in the Mechanical

specifications section.

Fig. 1-5: Equilibrium line on the 2-Finger, shown with no fingertip pads.

Tip

Grasping an object that could be grasped by an encompassing grasp (a cylinder for example) on the equilibrium line is not

recommended, as slight variations on the position will switch the grasp from parallel to encompassing and vice versa. Robot

programming should be done so that the grasping mode will be predetermined.

2F-85 &2F-140 - Instruction Manual

Page 16

16

1.4. Setup and control

The Gripper is powered and controlled directly via a single Device Cable that carries a 24V DC supply and Modbus RTU

communication over RS-485, see Section 3.5 for wiring information and Section 4 for control of the Gripper (various software packages

are available for control via various robotcontrollers).

Info

Robotiq Universal Controller is available when industrial communication protocols are required (other then Modbus RTU over

serial).

Gripper Coupling is required for 2-Finger usage, the Coupling will provide mechanical and electrical connectivity. Please refer to the

Mechanical Installation section for installation of the Coupling, to the Specifications section for technical drawings, and to the Spare

Parts, Kits and Accessories section for available couplings.

The 2-Finger has an embedded object detection feature using indirect sensing methods. When picking an object via the "go to"

command, the Gripper status will allow you to know if an object is picked or not via a simple object detection bit (0 or 1). When an

object is detected, the Gripper will stop. If the object is being dropped, the Gripper will automatically close to keep the object until the

''go to'' command limit is attained. For details on object detection, see Control section.

2F-85 &2F-140 - Instruction Manual

Page 17

2. Safety

Warning

The operator must have read and understood all of the instructions in the following manual before handling the Robotiq

2-Finger Adaptive Robot Gripper.

Caution

The term "operator" refers to anyone responsible for any of the following operations on the 2-Finger Adaptive Robot Gripper:

l Installation

l Control

l Maintenance

l Inspection

l Calibration

17

l Programming

l Decommissioning

This documentation explains the various components of the 2-Finger and general operations regarding the whole life-cycle of the

product from installation to operation and decommissioning.

The drawings and photos in this documentation are representative examples and differences may exist between them and the delivered

product.

2F-85 &2F-140 - Instruction Manual

Page 18

18

2.1. Warning

Caution

Any use of the Gripper in noncompliance of these warnings is inappropriate and may cause injury or damage.

Warning

l The Gripper needs to be properly secured before operating the robot.

l Do not install or operate a Gripper that is damaged or lacking parts.

l Never supply the Gripper with an alternative current source.

l Make sure all cord sets are always secured at both ends, at the Gripper and at the robot.

l Always satisfy the recommended keying for electrical connections.

l Be sure no one is in the robot and/or Gripper path before initializing the robot's routine.

l Always satisfy the Gripper payload.

l Set the Gripper pinch force and speed accordingly, based on your application.

l Keep fingers and clothes away from the Gripper while the power is on.

l Do not use the Gripper on people or animals.

l For welding applications, make sure there are no Gripper parts on the ground path of the welding power source.

Any use of the Gripper in noncompliance of these warnings is inappropriate and may cause injury or damage.

2.1.1. Risk assessment and final application:

The Robotiq 2-Finger Adaptive Gripper is meant to be used on an industrial robot. The robot, Gripper and any other equipment used in

the final application must be evaluated with a risk assessment. It is the robot integrator's duty to ensure that all local safety measures

and regulations are respected. Depending on the application, there may be risks that need additional protection/safety measures, for

example, the work-piece the Gripper is manipulating may be inherently dangerous to the operator.

2F-85 &2F-140 - Instruction Manual

Page 19

2.2. Intended Use

The Gripper unit is designed for grasping and temporarily securing or holding objects.

Caution

The Gripper is NOT intended for applying force against objects or surfaces.

The product is intended for installation on a robot or other automated machinery and equipment.

Info

Always comply with local and/or national laws, regulations and directives on automation safety and general machine safety.

The unit may be used only within the range of its technical data. Any other use of the product is deemed improper and unintended use.

Robotiq will not be liable for any damages resulting from any improper or unintended use.

19

2F-85 &2F-140 - Instruction Manual

Page 20

3. Installation

The following subsections will guide you through the installation and general setup of your Robotiq 2-Finger Adaptive Robot Gripper.

l The Scope of Delivery section

l The Required Tools and Equipment section

l The Environmental and Operating Conditions section

l The Mechanical Installation section

l The Electrical Setup section

l The Testing the Gripper with the Robotiq User Interface (RUI) section.

l The Installation for Universal Robots section

l The URCap Package section

Warning

20

Before installing:

l Read and understand the safety instructions related to the 2-Finger Adaptive Robot Gripper.

l Verify your package according to the Scope of delivery and your order.

l Have the required parts, equipment and tools listed in the requirements readily available

Warning

When installing:

l Satisfy the environmental conditions.

l Do not operate the Gripper, or even turn on the power supply, before it is firmly anchored and the danger zone is cleared.

The fingers of the Gripper may move and cause injury or damage.

2F-85 &2F-140 - Instruction Manual

Page 21

21

3.1. Scope of Delivery

3.1.1. UR Kit

Robotiq 2-Finger Adaptive Gripper 85 (AGC-UR-KIT-002) Robotiq 2-Finger Adaptive Gripper 140 (AGC-UR-KIT-140)

Standard upon delivery:

l Robotiq 2-Finger Adaptive Gripper 85 complete unit:

AGC-GRP-002

l 85 mm opening fingers without fingertips or pads (these are

bought separately unless specified)

l Palm pad

l USBto RS485 signal converter: ACC-ADT-USB-RS485

l Coupling according to your robot bolt pattern:

GRP-CPL-062

Info

Please refer to the Spare Parts, Kits and

Accessories section for a list of availablecouplings.

l Robotiq device cable:

l CBL-COM-2065-10-HF for 10 meters cable

Standard upon delivery:

l Robotiq 2-Finger Adaptive Gripper 140 complete unit:

AGC-GRP-140

l 140 mm opening fingers without fingertips or pads (these

are bought separately unless specified)

l Palm pad

l USBto RS485 signal converter: ACC-ADT-USB-RS485

l Coupling according to your robot bolt pattern:

GRP-CPL-062

Info

Please refer to the Spare Parts, Kits and

Accessories section for a list of availablecouplings.

l Robotiq device cable:

l CBL-COM-2065-10-HF for 10 meters cable

Info

The following are not included in standard delivery:

l Options such as adapter plates or couplings for mounting on various industrial robots, fingertips or finger pads.

l Hardware required for options; accessories or fixtures for the 2-Finger Adaptive Robot Gripper, unless specified.

l Power supply units, power supply wiring or fuses.

Info

When bought as a kit, the 2-Finger 85 or 140 will come in a package with the appropriate coupling, fingertips or finger pads

and cabling. Please refer to the Spare Parts, Kits and Accessories section.

3.2. Required Tools and Equipment

The following tools are required to install the 2-Finger Adaptive Gripper:

l 4 mm hex key to mount the Gripper onto its coupling.

l Metric hex key according to your coupling to mount the coupling onto the robot.

Optional tools if installing finger kits: AGC-FIN-KIT-085 or AGC-FIN-KIT-140:

l 2 mm hex key

2F-85 &2F-140 - Instruction Manual

Page 22

Optional tools if installing other fingertips: AGC-TIP-204-085, AGC-TIP-205-085, AGC-TIP-420-140, AGC-TIP-420-140

l 4 mm hex key

The following parts are required for setup :

l Power supply (see below).

l Fuse (if applicable), see information below.

l Emergency stop is not provided, but its use is strongly advised.

The Gripper needs to be supplied by a DC voltage source. This power supply is not included with the Gripper. Required power supply

must match the Robotiq device. The following table shows the specifications with regards to the power supply required to operate the

Gripper and the optional Robotiq Controller.

SPECIFICATION VALUE

Output voltage 24 V DC ±10%

Output current 1 A

Recommended power supply with internal protection, otherwise fusing is

Overcurrent

2 A fuse at 25°C [77°F]

required.

1

Table 3-1: 2-Finger power supply requirements.

22

Info

1

Suggested fuse is a: Phoenix Contact # 0916605 2 A thermal, use AWG #20 wiring.

Warning

If your power supply could exceed the specified regulation, over-voltage protection is required.

Robotiq recommends the use of the following power supplies:

l For the 1A output current: TDK-Lambda DPP Series,

100W Single Output DIN Rail Mount Power Supply

Tip

Optional Robotiq Universal Controller can use the same power supply.

3.3. Environmental and Operating Conditions

CONDITION VALUE

Minimum storage/transit

temperature

Maximum storage/transit

temperature

-30°C [-22°F]

60°C [140°F]

: DPP30-24.

Minimum operating temperature -10°C [14°F]

2F-85 &2F-140 - Instruction Manual

Page 23

23

CONDITION VALUE

Maximum operating temperature 50°C [122°F]

Humidity (non-condensing) 20-80% RH

Vibration < 0.5G

Other

Table 3-2: Environmental and operating conditions of the 2-Finger Adaptive Gripper.

3.4. Mechanical Installation

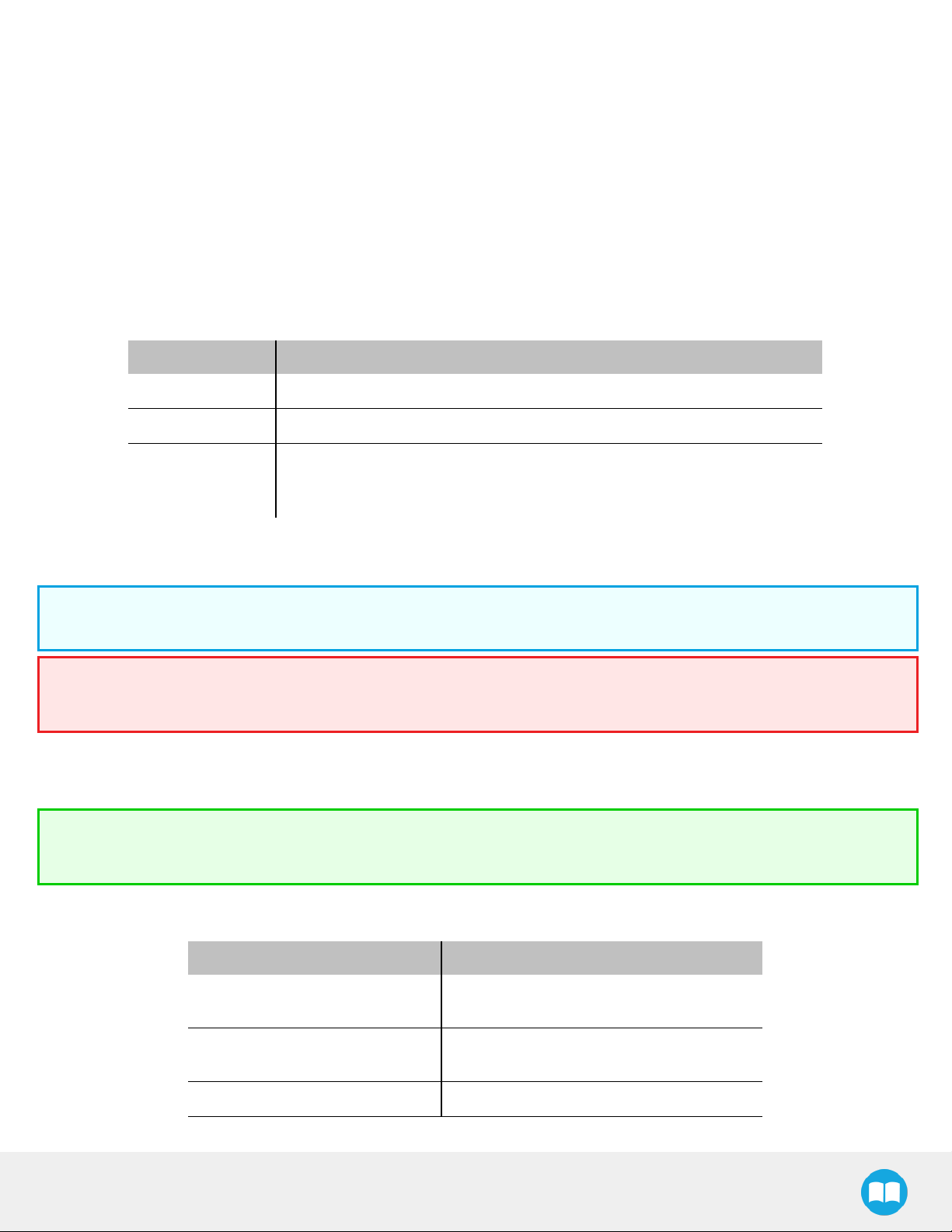

3.4.1. Installing fingers on the Gripper

l Free from dust, soot or fluids

l Free from corrosive liquids or gases

l Free from explosive liquids or gases

l Free from powerful electromagnetic inter-

ference

Depending on your order, you may or may not have fingers already mounted on the Gripper. The first step of installation should be to

install the fingers. Refer to the figure below for finger placement. To do so :

1. Align fingers with chassis axes. To do so, the slot on the finger bar should be aligned correctly with the corresponding chassis

axis.

2. Insert the finger shaft in the finger bar bracket hole and through the chassis axis (top hole is for parallel locking while bottom hole

is for finger installation)..

3. Apply medium strength threadlocker on the provided screws, align the finger bar and fasten to the chassis/chassis axis.

Fig. 3-1: 2-Finger Adaptive Gripper installation.

2F-85 &2F-140 - Instruction Manual

Page 24

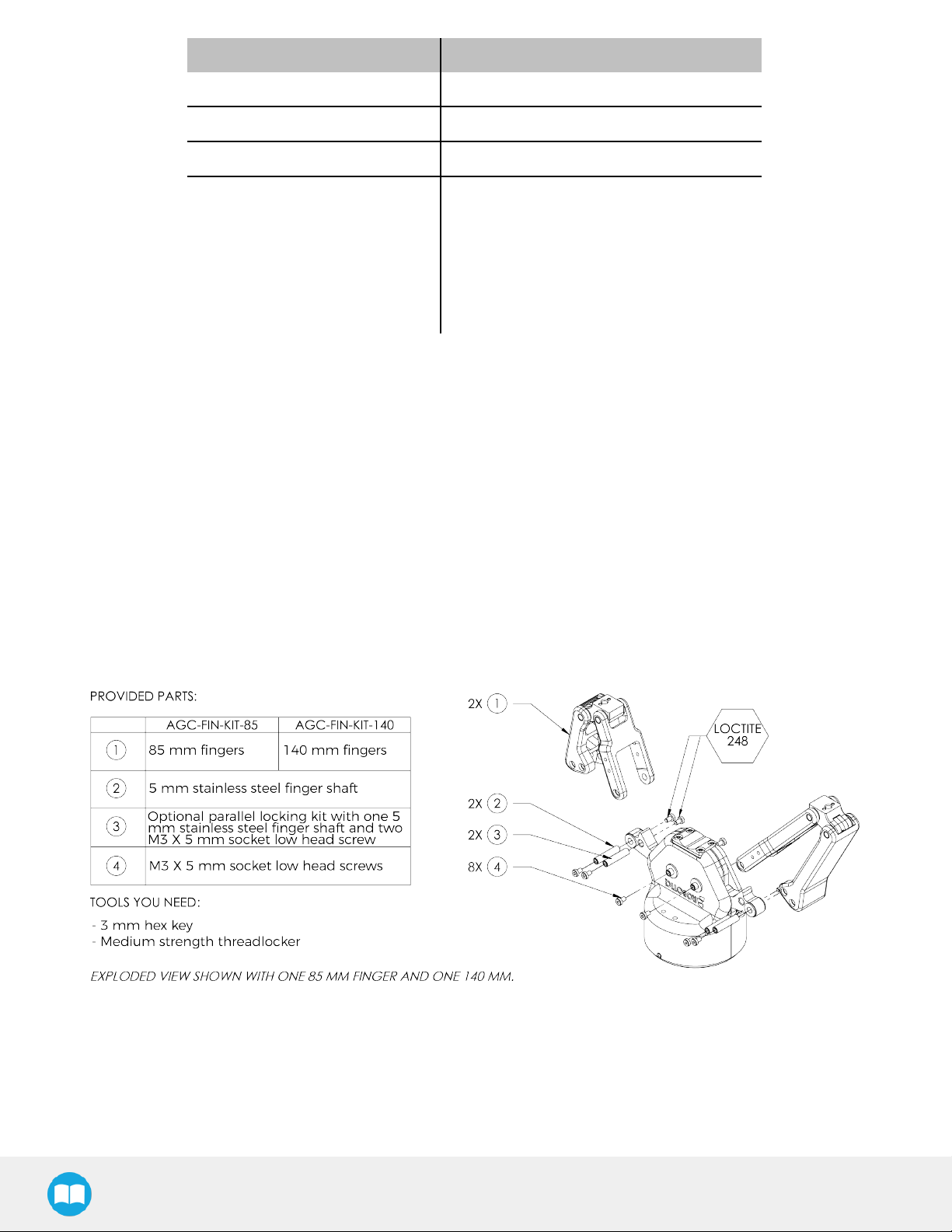

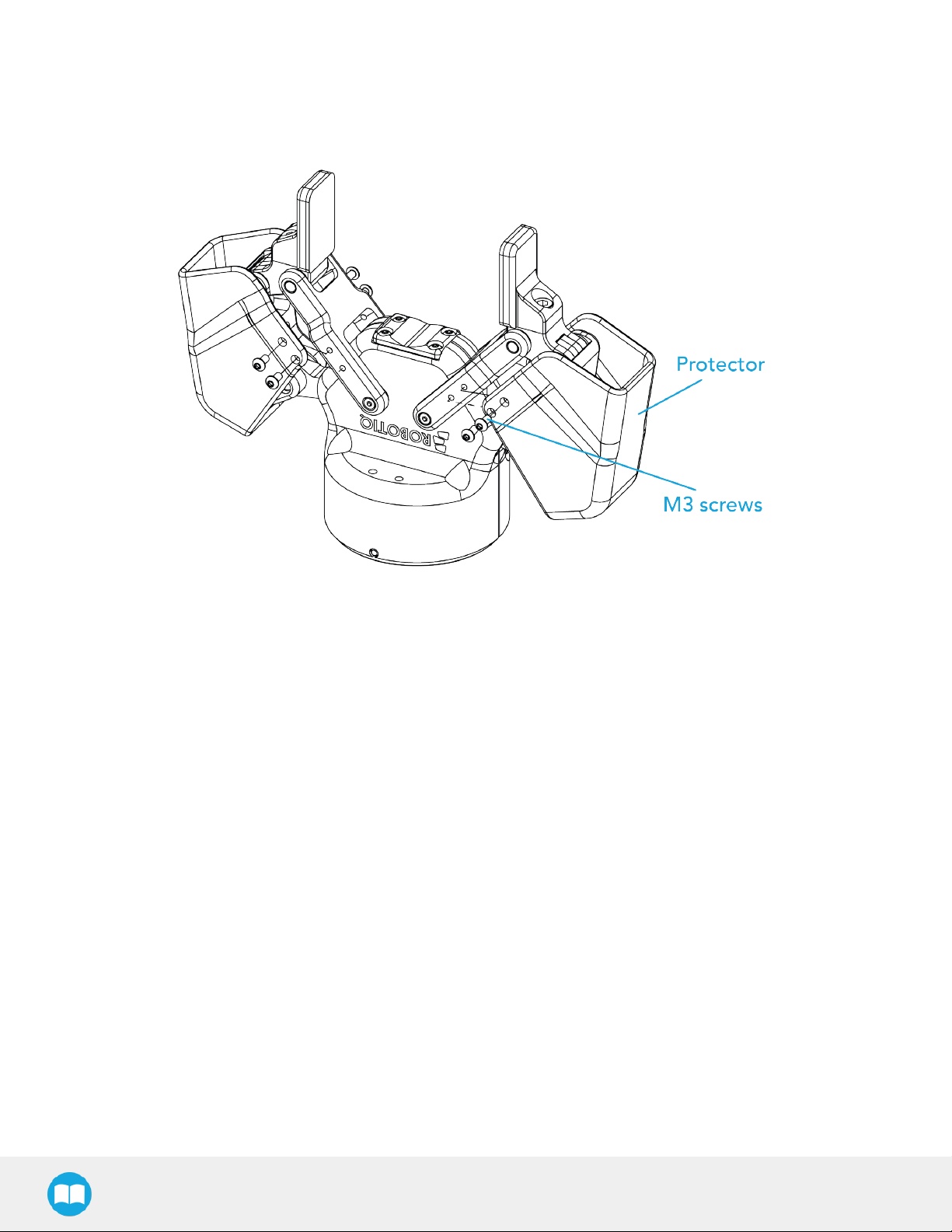

3.4.2. Installing the fingertips on the Gripper

Depending on your options, you may have fingertips to install. The second step of the installation should be to install the fingertips. To

do so:

1. Align the fingertip indexing pins with the finger dowel holes.

2. Insert the M5 X 10 low head cap screws and screw on after applying low strength threadlocker.

24

Fig. 3-2: Installing the fingertips on the Gripper

2F-85 &2F-140 - Instruction Manual

Page 25

25

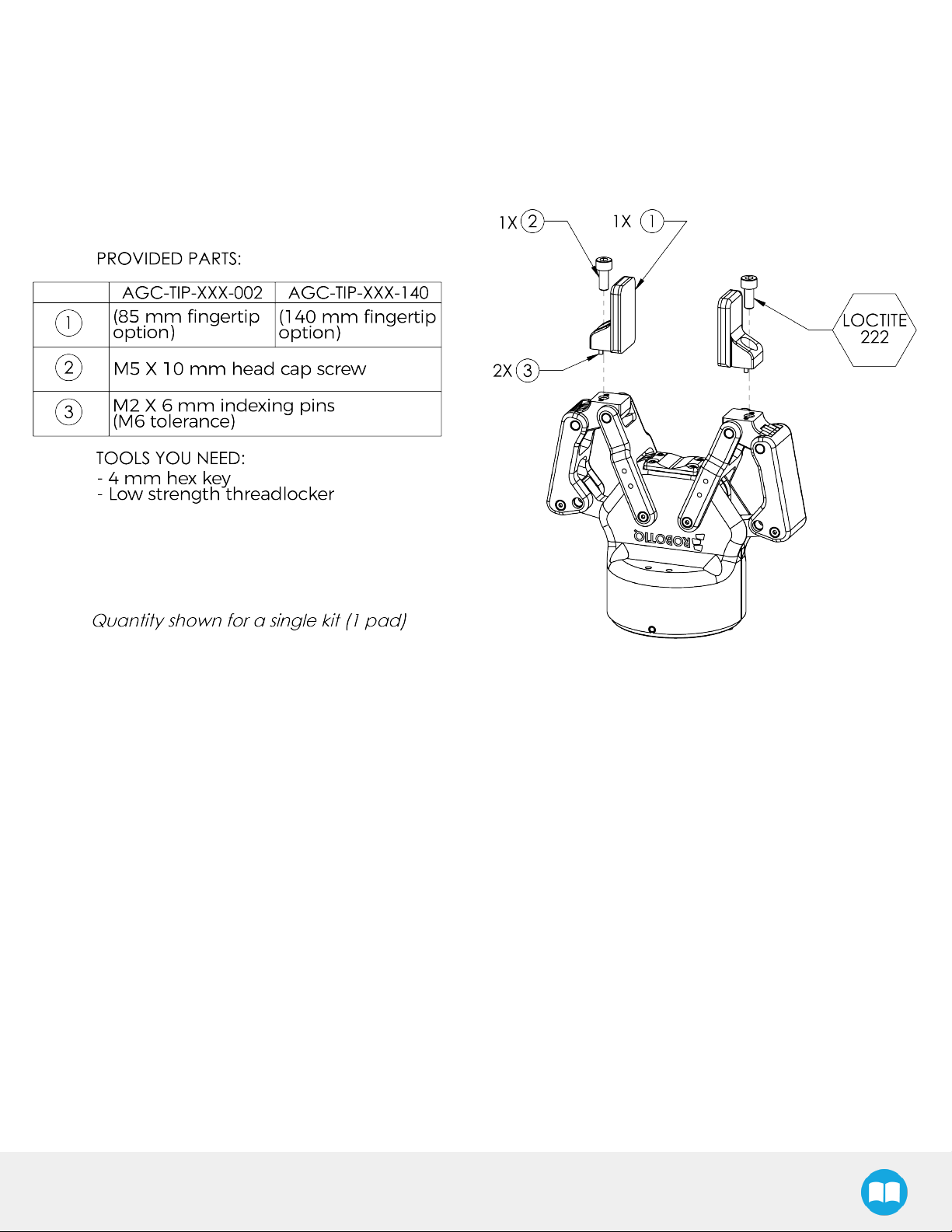

3.4.3. Installing a Protector Kit on the Gripper Fingers

An optional protector kit (AGC-PRO-KIT-V4) can be ordred to cover the fingers of the 2F-85 and therefore protect users and assets

against pinch points.

You can install them using eight (8) M3 screws.

Fig. 3-3: Protector Kit Installation

3.4.4. Installing the Gripper onto the robot

Single Gripper

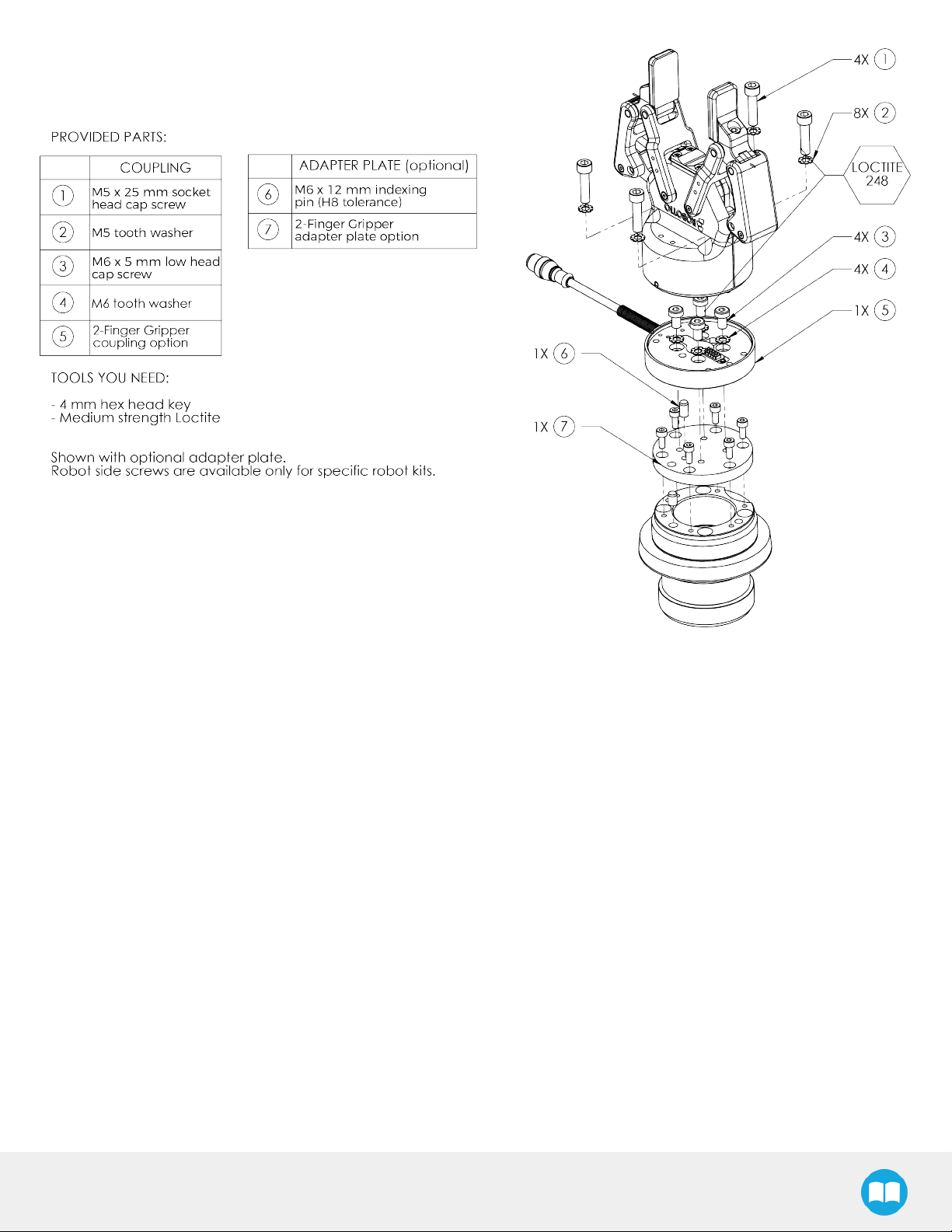

You must use a coupling to attach the Gripper to the robot. Be sure to use the coupling related to your robot model. If there is no

coupling for your robot, you can modify a blank coupling or Robotiq can create a custom version for you. Some couplings may require

an additional adapter plate. To create your own coupling or adapter plate you can refer to the Coupling section. To see the details of the

available couplings and adapter plates, please refer to the Spare Parts, Kits and Accessories section.

Here are the steps to follow to mount the Gripper to your robot (exploded view in the figure below). Note that all screws must be locked

in place using medium strength threadlocker.

1. Screw the adapter plate or the coupling to the robot (if adapter plate is required).

2. Screw the coupling to the adapter plate (if applicable).

3. Screw the Gripper onto its coupling.

2F-85 &2F-140 - Instruction Manual

Page 26

26

Fig. 3-4: Installing the Gripper to a robot using an adapter plate and coupling.

2F-85 &2F-140 - Instruction Manual

Page 27

27

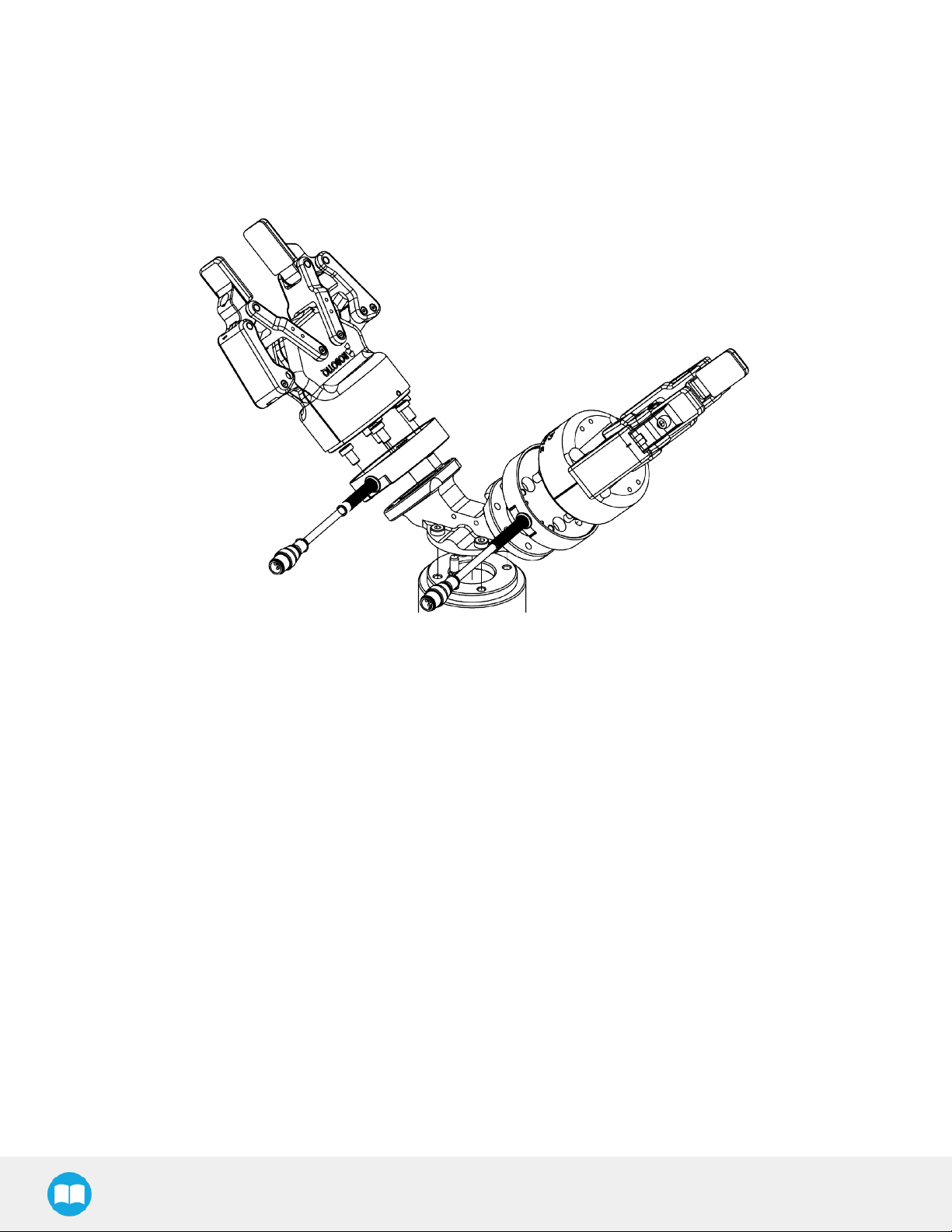

Multiple Grippers

When installing multiple grippers on one robot, every gripper must have its own coupling.

1. Install a mounting plate (not provided) first on the robot arm (AGC-APL-159-02).

2. Mount the gripper couplings on the mounting plate using the provided M6 X 10 mm screws.

3. Mount the grippers onto their coupling using the provided M5 X 35 mm screws.

Fig. 3-5: Exploded View of a Dual Gripper Setup

2F-85 &2F-140 - Instruction Manual

Page 28

3.5. Electrical Setup

Power and communication are established with the 2-Finger Adaptive Robot Gripper via a single Device Cable. The Device Cable

provides a 24V power supply to the Gripper and enables serial RS485 communication to the robot controller. An optional Robotiq

Universal Controller may be used between the Gripper and the network / robot controller if fieldbus communication is required.

Info

RS485 signals (485+, 485- and 485 GND) are isolated from the main 24V power supply. 4 GND can be connected to any

other ground reference as long as the voltage potential between the grounds does not exceed 250V. Grounding reference is

at the user's discretion.

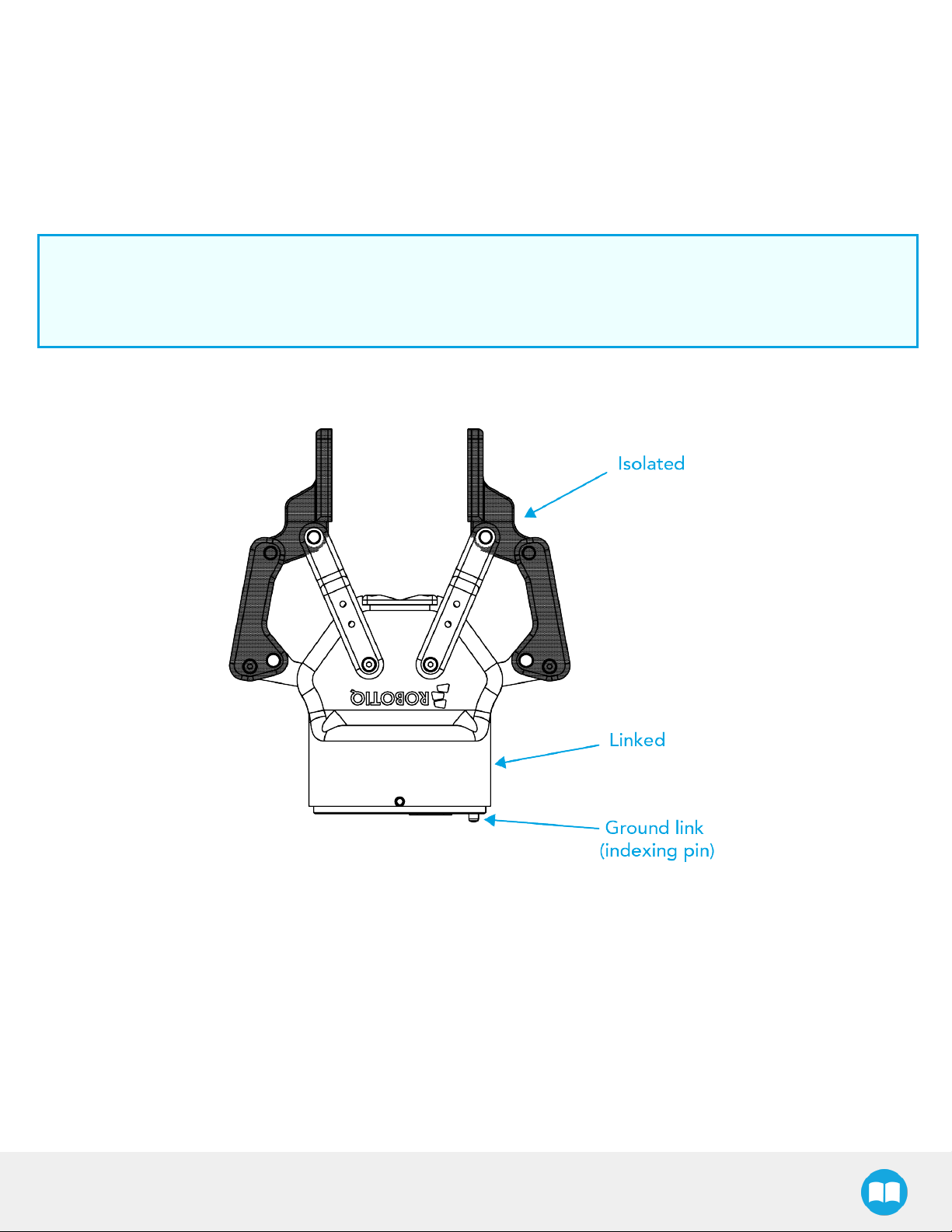

Gripper grounding is optional and is done via the robot ground. The coupling indexing pin (dowel) is the ground connector. Gripper

coupling, chassis and proximal phalanx are linked as illustrated in the figure below. They link through the coupling indexing pin to the

robot ground. Proximal bars, distal phalanx, fingertip base and fingertips are isolated.

28

Fig. 3-6: Robotiq 2-Finger electrical isolation / grounding.

2F-85 &2F-140 - Instruction Manual

Page 29

29

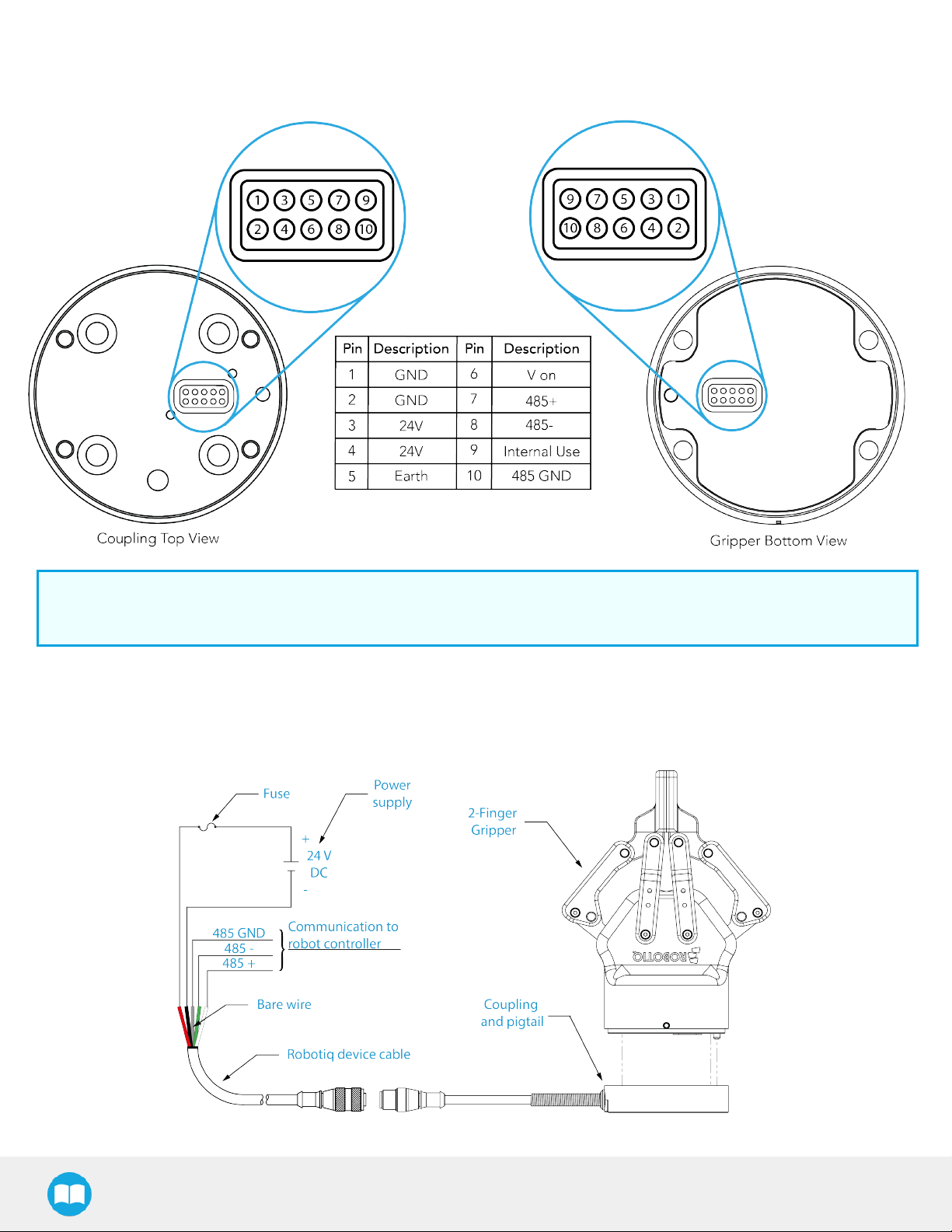

3.5.1. Pinout Interface

The Gripper interfaces with its coupling via a 10-spring pin connector located on its outer surface.

Info

The coupling used in the figure above is used for reference only and corresponds to bolt pattern ISO 9409-1-50-4-M6.

3.5.2. Coupling to controller

If a Robotiq Universal Controller is used, please refer to the Robotiq Universal Controller manual. The figure below represents the

wiring schematic of the 2-Finger with device cable, power supply, fuse (please refer to the Required Tools and Equipment section)

and grounding.

Fig. 3-7: Robotiq 2-Finger with pigtail cable and device cable wiring schematic.

2F-85 &2F-140 - Instruction Manual

Page 30

Warning

Use proper cabling management. Be sure to have enough forgiveness in the cabling to allow movement of the Gripper along

all axes without pulling out the connectors. Always protect the controller-side (robot side) connector of the cable with a strain

relief cable clamp.

The figure below represents the 2-Finger pigtail connector from the coupling (AGC-CPL-XXX), device cable - robot side

(CBL-COM-2065-XX) and their associated pinout.

30

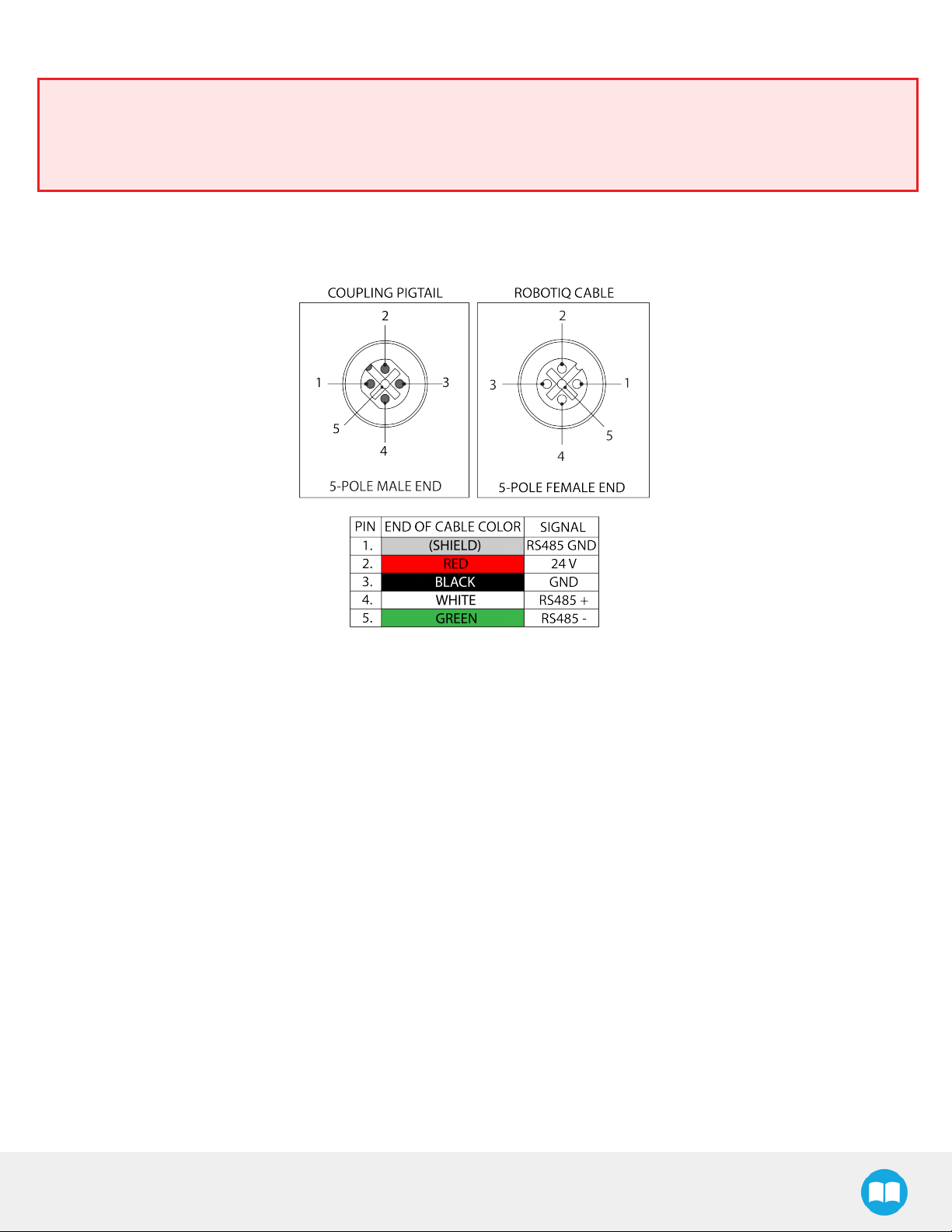

Fig. 3-8: Pinout of the 2-Finger pigtail and device cable.

If additional cable is used, suggested cable specifications are as follows:

Power supply, fusing:

l minimum #22 AWG TEW, 300 V or 600 V

RS485 signals :

l minimum #24 AWG TEW, 300 V or 600 V

l A and B signals must be balanced at 120 Ohms

Single Gripper

Prior to any software installation on Universal Robots, connect the white, green and bare wires to the Robotiq RS-485 signal converter

(ACC-ADT-USB-RS485) as shown in the figure below. Also connect the red (24V) and black (0V) wires in the controller according to

that same figure.

2F-85 &2F-140 - Instruction Manual

Page 31

31

Fig. 3-9: 2-Finger Adaptive Robot Gripper wiring to robot controller.

Multiple Grippers

It is possible to connect and control up to four grippers on the same UR robot. Only one RS485 to USB converter (ACC-ADT-USBRS485) must be used. Use M12 splitters (ACC-SPLIT-M12-2:1) to connect all the grippers pigtails to one 10m cable (CBL-COM-206510-HF) that connects to the RS485 to USB converter.

Fig. 3-10: Multiple grippers wiring on CB-Series Universal Robots.

2F-85 &2F-140 - Instruction Manual

Page 32

3.6. Testing the Gripper with the Robotiq User Interface (RUI)

Once installed and properly secured, your Robotiq 2-Finger Adaptive Gripper should be tested with the Robotiq User Interface test

software using the provided USB converter. To do so:

1. Follow the instructions to install the Robotiq User Interface.

Use the provided RS-485 to USB converter ACC-ADT-USB-RS485 (see the schematic in the figure below) to plug into a PC

with the Robotiq User Interface installed.

2. Power up your Gripper with the previously recommended power supply.

3. Execute the R.U.I. software and select ''auto-connect'' on the connection screen.

4. You are now connected to your Gripper, you can click "activate" to begin using the Gripper.

Info

The Activate command will initiate movement of the Gripper for auto-calibration procedures. Do not interfere with the

Gripper. Be sure you have satisfied robot safety measures.

32

Fig. 3-11: RS-485 to USB converter ACC-ADT-USB-RS485 pinout.

Fig. 3-12: Wiring of the USB to RS-485 converter.

2F-85 &2F-140 - Instruction Manual

Page 33

33

Tip

With the R.U.I. controlling the Gripper, you can go to the "view" menu to see input and output register values to further your

understanding on how to command the Gripper. You can also test grasping objects with various speed and force settings.

See the Control section for details.

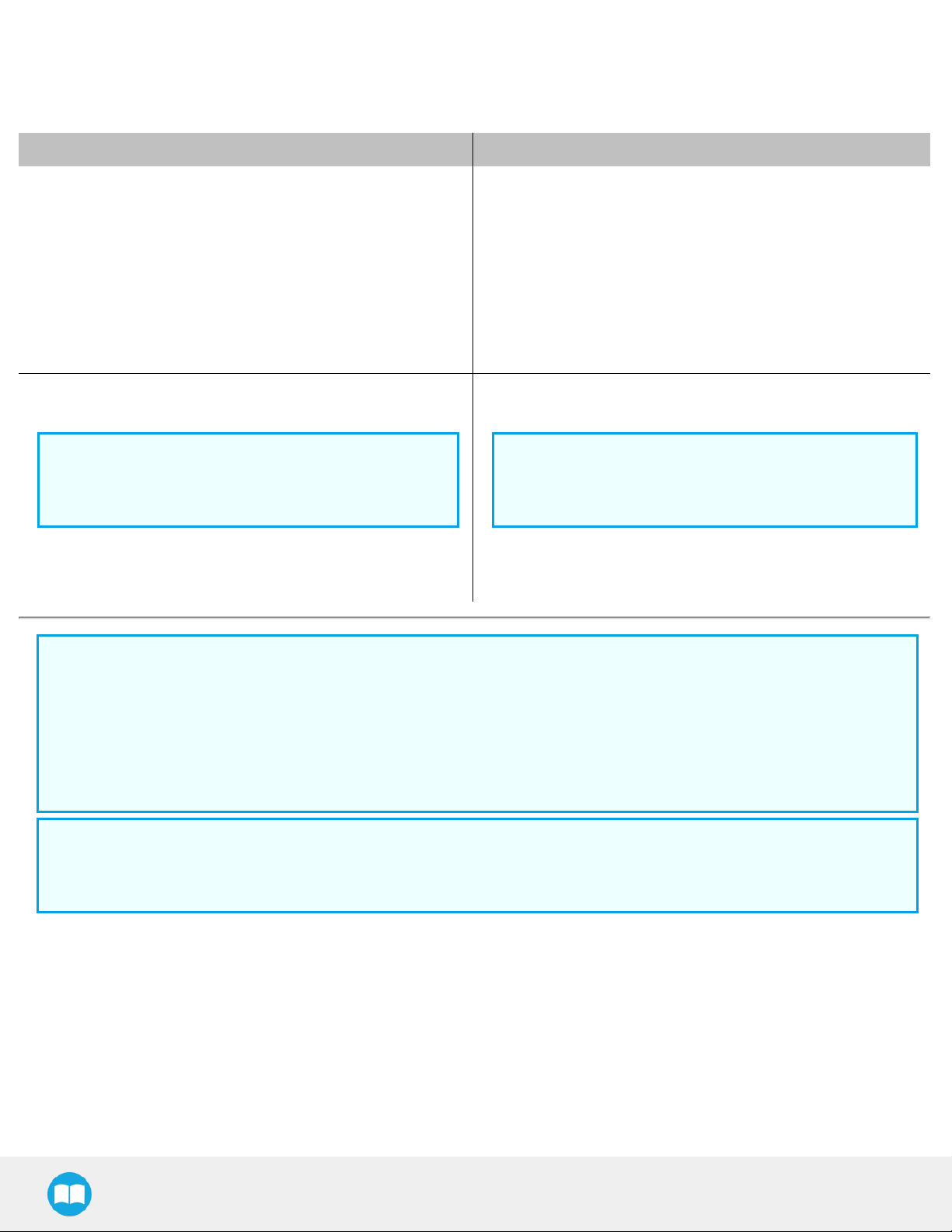

3.7. Installation for Universal Robots

The table below shows which Robotiq software to use with your Universal Robots’ controller. If you are using a CB3, CB3.1 or e-Series

controller, it is recommended to use a Robotiq Grippers URCap Package.

Robotiq Software

Driver Package

(includes Gripper toolbar)

Robotiq Grippers URCap Package 1.2.1

and earlier versions

Robotiq Grippers URCap Package 1.3.0

Robotiq Grippers URCap Package 1.3.1

and later versions

Controller

CB1

Incompatible

Incompatible Incompatible

Incompatible Incompatible

Incompatible Incompatible

Controller

CB2

Compatible Compatible Compatible Incompatible

Table 3-3: Compatibility between Robotiq software and Universal Robots controller

Refer to the appropriate section depending on your controller version:

l Section 3.8 covers the installation of the Robotiq Grippers URCap Package.

l Section 3.9 covers the software installation when not using a URCap.

Caution

Controller

CB3

Controller

CB3.1

e-Series

Controller

Compatible Compatible Incompatible

Incompatible Compatible Incompatible

Incompatible Compatible Compatible

The robot's PolyScope version must be 3.5 and later in order to install the URCap.

Caution

Prior to use over

Universal Robots

, adjust the payload and the center of gravity from the Installation tab (refer to the

Mechanical specifications section.

Caution

Make sure to refer to the Installing URCap Package section to configure the grippers properly before controlling and

programming them.

2F-85 &2F-140 - Instruction Manual

Page 34

3.8. URCap Package

Robotiq provides you with a Universal Robots URCap package that enables direct serial communication to your UR controller.

Info

To get the URCaps package for your UR controller, visit support.robotiq.com.

Make sure the 2-Finger Adaptive Gripper is properly mounted to the robot arm. Refer to the Mechanical Installation section for

detailed information on the mechanical installation. Before proceeding with the installation of the URCap package, make sure your

Universal Robots controller is compatible with the package (refer to the Installation for Universal Robots section).

Info

The robot's PolyScope version must be 3.5 and later in order to install the URCap.

The Gripper’s URCap package contains:

34

l The URCap for the Gripper;

l The Gripper toolbar;

l The Gripper nodes.

Tip

For other robots, where no driver package is available, we recommend the use of the Robotiq Universal Controller which

allows fieldbus communication. Available communication protocols with this Universal Controller are:

l Modbus TCP

l EtherNet IP

l EtherCAT

l PROFINET

l DeviceNET

l CANopen

For details on controlling the Gripper, please refer to the Control section.

Info

Visit support.robotiq.com for detailed information on how to program using the URCap package (please refer to the Control

section).

2F-85 &2F-140 - Instruction Manual

Page 35

35

3.8.1. Installing URCap Package

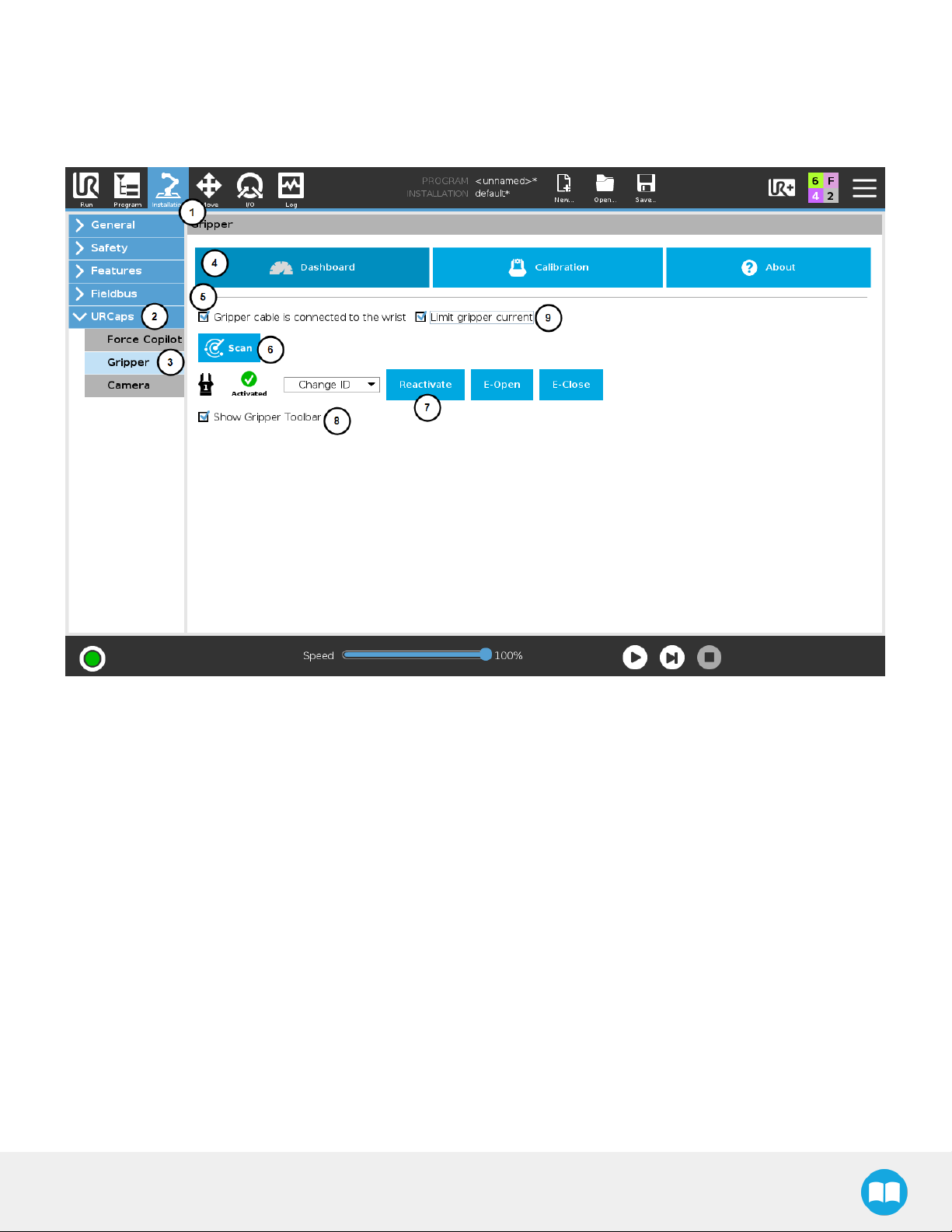

Single Gripper

Make sure the 2-Finger Adaptive Gripper is properly mounted to the robot arm. Refer to the Mechanical Installation section for

detailed information on the mechanical installation. Before proceeding with the installation of the URCap package, make sure your

Universal Robots’ controller is compatible with the package (refer to the Installation for Universal Robots section).

Follow this procedure to install the 2-Finger Adaptive Gripper URCap package:

l Make sure that your PolyScope version is up-to-date and that your

Universal Robots controller is compatible with the Gripper’s URCap

package.

l Go to support.robotiq.com and click on the 2-Finger Adaptive Gripper

product page.

l Download the UCG-X.X.X and extract on the root of a blank USB

stick.

l Insert the USB stick in the UR teach pendant or controller.

Tip

l Go to Setup Robot.

l Tap URCaps Setup.

In PolyScope, go to the Home page and tap the About button. A window containing the Universal Robots software version

will pop up.

2F-85 &2F-140 - Instruction Manual

Page 36

l Tap the plus button (+) to add the Gripper’s URCap package.

l Open Robotiq_Grippers-X.X.X.urcap.

l Restart PolyScope to complete the URCap installation. By doing

so, you accept the License Agreement that is detailed in the

URCap Information text box (see below for the

LicenseAgreement).

36

l When PolyScope reopens, the Gripper toolbar will appear on

thescreen.

Multiple Grippers

It is possible to connect and control up to four grippers on the same UR robot.

Only one USB to RS485 converter (ACC- ADT-USB-RS485) must be used. Use M12 splitters (ACC-SPLIT-M12-2:1) to connect all

the grippers pigtails to one 10m cable (CBL-COM-2065-10-HF) that connects to the USB to RS485 converter.

2F-85 &2F-140 - Instruction Manual

Page 37

37

Fig. 3-13: Wiring for multiple grippers.

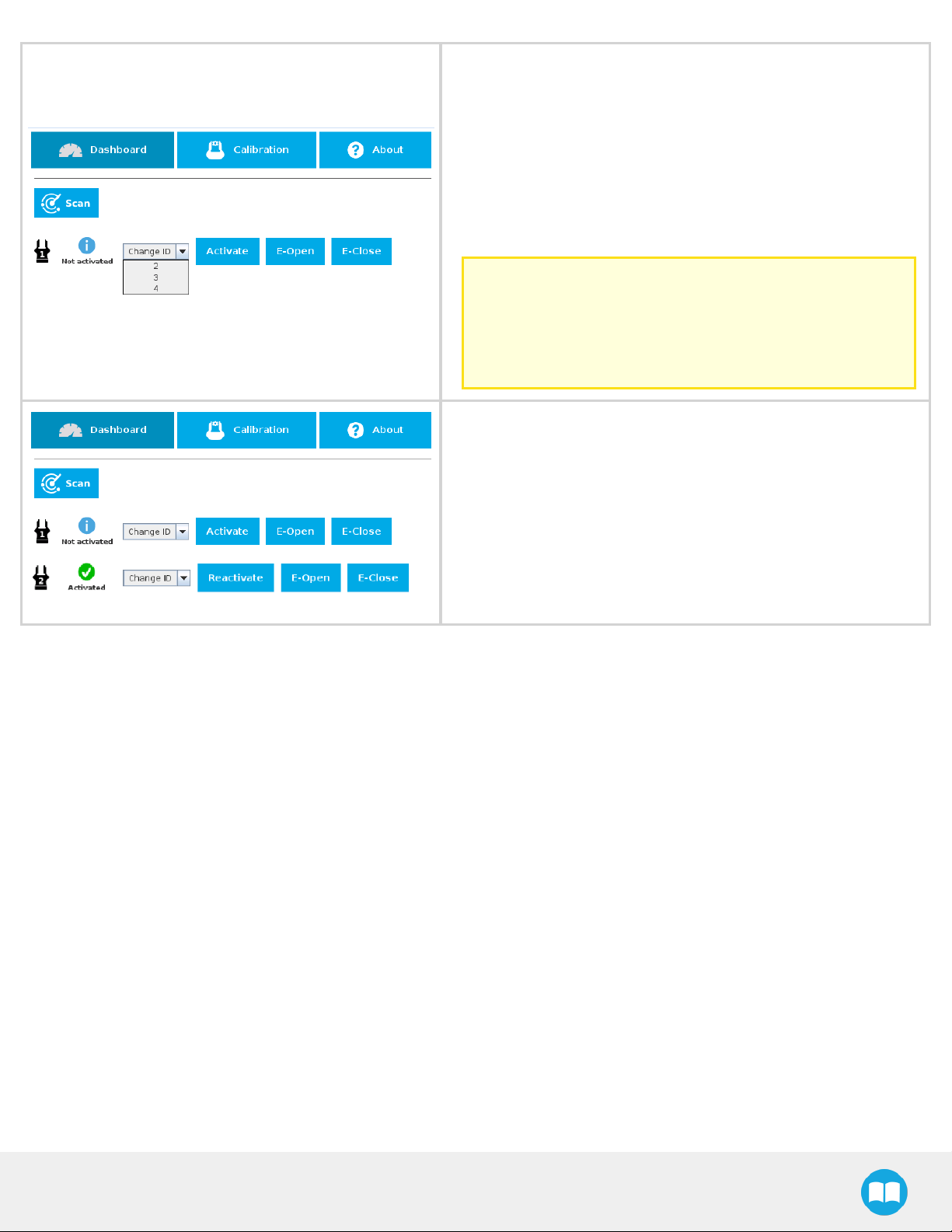

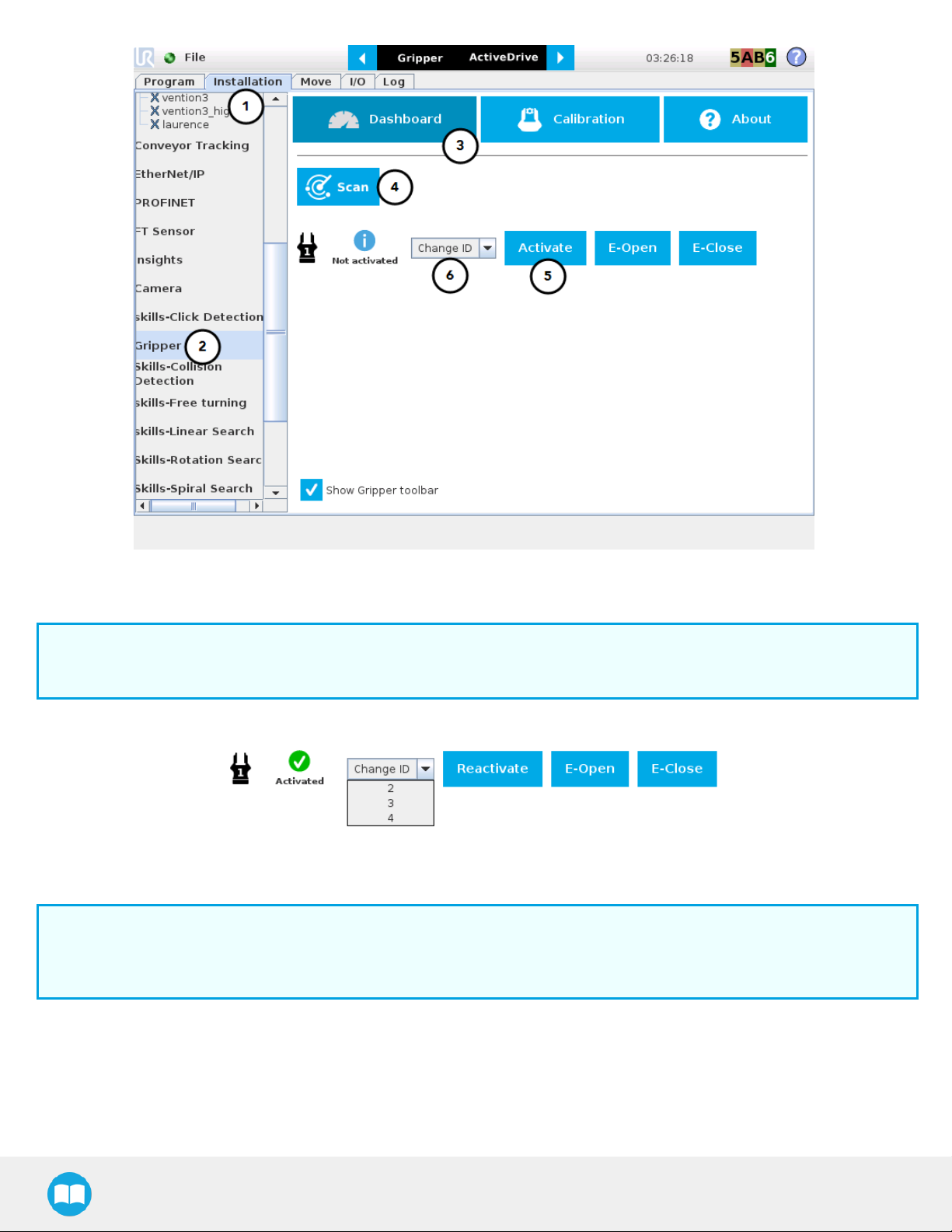

When installing multiple grippers on one UR robot, their gripper ID must be set properly. To do so, perform the following steps for each

gripper:

l Connect only one gripper at a time using the M12 splitter.

2F-85 &2F-140 - Instruction Manual

l From the PolyScope home page, go to Program Robot and then tap

the Installation tab.

l Tap on Gripper.

l Select the Dashboard menu.

l Tap the Scan button to detect Grippers.

Page 38

38

l Change the Gripper ID to the desired one.

l Make sure it is different from the other Gripper IDs.

l Gripper ID is saved to the Gripper's internal memory. ID will be kept

at all time.

l Click on Activate to activate the Gripper.

l Perform the same routine for all grippers, if applicable, connecting

only one at a time.

Caution

Make sure all grippers have different IDs. With their factory

settings, all grippers have Gripper IDset to 1. If you have

more than one gripper connected with the same ID,

communication issues will arise.

l Once all grippers IDs have been set, connect them all to the

M12splitter.

l Go back to the Dashboard tab and confirm that all grippers are

recognized and can be controlled.

2F-85 &2F-140 - Instruction Manual

Page 39

39

3.8.2. Uninstalling URCap Package

If you wish to uninstall the 2-Finger Gripper URCap, follow this procedure:

l Go to Setup Robot.

l Tap URCaps Setup.

2F-85 &2F-140 - Instruction Manual

l In the Active URCaps box, tap the URCap to uninstall.

l Tap the minus (-) button to uninstall the URCap.

l Restart PolyScope to complete the uninstallation process.

Page 40

40

3.8.3. License Agreement

END-USER LICENSE AGREEMENT

YOU SHOULD CAREFULLY READ THE FOLLOWING AGREEMENT BEFORE USING THE Software (as this term is hereinafter

defined). Using the Software indicates your acceptance of the agreement. If you do not agree with it, you are not authorized to use the

Software.

IMPORTANT-READ CAREFULLY: This End-User License Agreement (the “Agreement”) is a legal agreement between you and the

Licensor (as this term is hereinafter defined), the licensor of the Software. This Agreement covers the Software. The Software includes

any “on-line” or electronic documentation and all modifications and upgrades related thereto. By installing, or otherwise using the

Software, you agree to be bound by the terms of this Agreement. If you do not agree to the terms of this Agreement, the Licensor

cannot and does not license the Software to you. In such event, you must not use or install the Software.

1. Definition.

1. “UR” means Universal Robots A/S, a corporation incorporated under the laws of Denmark, having its registered office

at Energivej 25, DK-5260 Odense S, which specializes into the conception, advanced manufacturing and sale of

robotic products (the “UR’s Business”);

2. “Software” means any of the Licensor’s softwares provided to its customers for the purposes mentioned in Sub-section

1.4 hereof including their modifications and upgrades and their related materials;

3. “Licensor” means Robotiq inc., a corporation incorporated under the laws of Quebec, having its registered office at 325966 chemin Olivier, Lévis, Québec, Canada, G7A 2N1, which specializes into the conception, advanced manufacturing

and sale of robotic products (the “Licensor’s Business”);

4. “End-User” means a customer authorized pursuant to this Agreement to install or use the Software in order to make a

specific product from the Licensor’s Products compatible and functional with a specific product of the UR’s Product;

5. “Licensor’s Products” means those products developed by the Licensor in the course of the Licensor’s Business;

6. “UR’s Products” means those products developed by UR in the course of the UR’s Business;

7. “Licensor’s Authorized Representatives” means and includes the Licensor and Licensor’s authorized vendors,

resellers, distributors and licensors;

8. “Purchase Agreement” means an agreement between the End-User and the Licensor pursuant to which the End-User

purchased one or more of the Licensor’s Products.

2. License. Subject to the terms and conditions hereof, the Licensor grants to the End-User a personal, temporary, non-exclusive,

non-assignable and non-transferable and revocable license to use the Software in accordance with the terms and conditions

hereof.

3. Software and Documentation. The Licensor may provide, if applicable, all documentation containing the detailed specifications

for operation and use of the Software, which Software shall be used in accordance with such documentation. This documentation, if applicable, will be provided, wholly or in part, within (i) this Agreement, (ii) the Licensor’s Web site http://robotiq.com/ (iii) the Licensor’s Products and the Purchase Agreement therewith, or (iv) any other agreement, document, support,

whatsoever decided by the Licensor.

The use of the Software requires the Licensor’s Products, UR’s Products, compatible systems and certain software (which may

require some expenses), may require periodical updating and may be affected by such elements. Most equipment will be compatible with the Software. However, the Software may not function on certain types of equipment.

4. Modifications and Upgrades. The Licensor shall be under no obligation to provide any upgrade or modification to the Software.

However, the End-User shall be entitled to receive free of charge all modifications and upgrades of the Software provided by the

Licensor if, at such time, the End-User is not in default in respect of any of its obligation contained herein. Such modifications

and upgrades of the Software shall be installed by the End-User itself by consulting the Licensor’s Website http://robotiq.com/

where a link to proceed to such installation will be made available thereof. A new version of the Software shall not be covered by

2F-85 &2F-140 - Instruction Manual

Page 41

41

this Section 4 but shall require that a new End-User Software License Agreement be entered into between the Licensor and the

End-User.

5. Fees. The grant by Licensor to the End-User of the present license shall be free to the extent that the End-User agrees and complies to the term and conditions herein at all time.

6. Maintenance. During the term of this Agreement, the Licensor will maintain the Software in an operable condition and will make

available any corrections and improvements as are generally incorporated in the Software by the Licensor without additional

charge to the End-User. The Licensor may temporarily and without notice suspend or limit access to the Software if necessary or

desirable in order to maintain, restore, modify or repair any part of the Software or for any reason related to business. During such

works, the Software will not be available but the Licensor undertakes to deploy its best efforts to perform such works at appropriate times and to limit any inconvenience arising therefrom.

7. Title to Software. The licensed Software is composed of confidential data and trade secrets and is proprietary to and constitutes

trade secret information and intellectual property of the Licensor. Title and ownership rights to the Software, including the intellectual property rights related thereto, shall remain with the Licensor. The End-User agrees to maintain the confidential nature of

the Software and related materials provided for the End-User’s own internal use under this Agreement. The license granted

herein does not include the right to sublicense to others, and may not be assigned to others, in whole or in part, without the prior

written consent of the Licensor. The End-User may not or allow others to modify or prepare directive works, copy (except for normal backups for recovery purposes), reproduce, republish, reverse engineer, upload, post, transmit, or distribute, in any manner,

the Software.

8. Restricted Use. The Software shall be used solely and exclusively by the End-User and its employees for the purpose mentioned in Sub-section 1.4 hereof. Any other use of the Software, including resell derivative modifications or extensions, is

expressly prohibited.

9. Exclusion of Warranty on Software. The End-User expressly acknowledges and agrees that use of the Software is at the EndUser sole risk. The Software is provided “AS IS” and without warranty of any kind. THE LICENSOR AND THE LICENSOR’S

AUTHORIZED REPRESEN-TATIVES DO NOT WARRANT THAT Software WILL BE FREE OF ERRORS AND YOU

ACKNOWLEDGE THAT THE EXISTENCE OF ANY SUCH ERRORS DOES NOT CONSTITUTE A BREACH OF THIS

AGREEMENT. TO THE EXTENT PERMITTED BY LAW LICENSOR AND LICENSOR’S AUTHORIZED REPRESENTATIVES EXPRESSLY DISCLAIM ALL WARRANTIES, EXPRESS OR IMPLIED, INCLUDING , BUT NOT LIMITED TO,

THE IMPLIED WARRANTIES OF MERCHANTA-BILITY AND FITNESS FOR A PARTICULAR PURPOSE UNLESS

OTHERWISE STATED HEREIN. LICENSOR AND LICENSOR’S AUTHORIZED REPRESENTATIVES DO NOT

WARRANT THAT THE FUNCTIONS CONTAINED IN THE Software WILL MEET THE END-USER REQUIREMENTS OR

THAT THE OPERATION OF THE Software WILL BE CORRECT. FURTHERMORE, LICENSOR AND LICENSOR’S

AUTHORIZED REPRESEN-TATIVES DO NOT WARRANT OR MAKE ANY REPRESENTATIONS REGARDING THE USE

OR THE RESULTS OF THE USE OF THE Software IN TERMS OF ITS CORRECTNESS, ACCURACY, RELIABILITY, OR

OTHERWISE. NO ORAL OR WRITTEN INFORMATION OR ADVICE GIVEN BY LICENSOR AND LICENSOR’S

AUTHORIZED REPRESENTATIVE SHALL CREATE A WARRANTY OR IN ANY WAY INCREASE THE SCOPE OF THIS

WARRANTY. SHOULD THE Software PROVE DEFECTIVE IN YOUR TECHNOLOGY ENVIRONMENT, YOU ASSUME

THE ENTIRE COST OF ALL NECESSARY SERVICING, REPAIR OR CORRECTION TO YOUR OWN TECHNOLOGY

ENVIRONMENT.

10. Limitation of liability. TO THE MAXIMUM EXTENT PERMITTED BY LAW, LICENSOR AND LICENSOR’S AUTHORIZED

REPRESENTATIVES SHALL NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES FOR BREACH

OF ANY EXPRESS OR IMPLIED WARRANTY, BREACH OF CONTRACT, NEGLIGENCE, STRICT LIABILITY OR ANY

OTHER LEGAL THEORY RELATED TO THE Software. SUCH DAMAGES INCLUDE, BUT ARE NOT LIMITED TO, LOSS

OF PROFITS, LOSS OF REVENUE, LOSS OF DATA, LOSS OF USE OF THE PRODUCT OR ANY ASSOCIATED

EQUIPMENT, DOWN TIME AND USER’S TIME, EVEN IF THE LICENSOR HAS BEEN ADVISED OF THE POSSIBILITY

OF SUCH DAMAGES. IN ANY CASE, LICENSOR ENTIRE LIABILITY UNDER ANY PROVISION OF THIS AGREEMENT

SHALL BE LIMITED TO THE AMOUNT ACTUALLY PAID IN RESPECT OF THE LICENSOR’S PRODUCTS PURCHASED

BY THE END-USER PURSUANT TO A PURCHASE AGREEMENT.

11. Training, Maintenance and Support There is no entitlement to training, maintenance and support under this license unless otherwise specified in the Purchase Agreement or any other written agreement between the End-User and the Licensor. The EndUser may provide the Licensor with details regarding any bug, defect or failure in the Software promptly and with no delay from

such event; the End-User shall comply with the Licensor’s request for information regarding bugs, defects or failures and furnish

him with information, screenshots and try to reproduce such bugs, defects or failures upon Licensor’s demand.

2F-85 &2F-140 - Instruction Manual

Page 42

42

12. Expiration and Termination. The Licensor may terminate this Agreement for default by the End-User. This Agreement will also be

automatically terminated upon the election of such by the Licensor or the official launch of the Software, whichever event comes

first. Upon termination of this Agreement for any reason, the End-User shall promptly uninstall the Software on any UR’s

Products and Licensor’s Products, computer, or server on which it has been installed, deliver to the Licensor all CDs, DVDs,

magnetic tapes, cards, and other tangible items and materials embodying the Software, and return to the Licensor all copies

thereof or destroy such copies and warrant in writing that all copies thereof have been destroyed. In the event of termination of

this Agreement, all obligations of the parties under this Agreement due for performance on the date of termination shall survive

the termination, and the party terminating shall not be liable to the other party for any damages arising out of the termination.

13. Miscellaneous.

1. This Agreement constitutes the entire understanding and agreement between the Licensor and the End-User and

replaces any prior agreement relating to the same subject matter.

2. This Agreement shall be governed and construed in accordance with the laws of the province of Quebec and the federal

laws of Canada applicable therein. Any legal action or proceeding between the Licensor and the End-User for any purpose concerning this Agreement or the parties' obligations hereunder shall be brought exclusively in a court of competent jurisdiction sitting in the judicial district of Trois-Rivières, Quebec.

3. The Licensor’s failure to insist upon or enforce strict performance of any provision of this Agreement shall not be construed as a waiver of any provision or right. Neither the course of conduct between the parties nor trade practice shall

act to modify any provision of this Agreement.

4. The Licensor may assign its rights and duties under this Agreement to any party at any time without notice to the EndUser. The End-User may not assign this Agreement without the prior written consent of the Licensor.

5. If any part of this Agreement is null, illegal or non-enforceable, this Agreement shall be interpreted as if this part was

never part of this Agreement.

6. The provisions of this Agreement are for the benefit of the Licensor and its officers, directors, employees, agents,

licensors and suppliers. Each of these individuals or entities shall have the right to assert and enforce those provisions

directly against the End-User on its own behalf. This Agreement is also for the benefit of, and binds, the End-User and

its heirs, successors, legal representatives and permitted assigns.

7. Any rights not expressly granted herein are reserved.

8. The parties confirm that they have agreed that this Agreement and all related documents be drafted in English only. Les

parties aux présentes confirment qu’elles ont accepté que la présente convention et tous les documents y afférents soient rédigés en anglais seulement.

2F-85 &2F-140 - Instruction Manual

Page 43

43

3.9. URPackage without URCaps

Robotiq provides you with a Universal Robots driver package that enables direct serial communication (via USB) to your UR controller.

Info

To get the driver package for your UR controller, visit the Documentation Archives.

If your Universal Robots’ controller is not compatible with the URCaps package (refer to the Installation for Universal Robots section

for compatibility), you can install the driver package. This package allows programming of the Gripper with scripts in a PolyScope

program. It includes program templates and examples to help you get started with your own custom program. It also contains the

Gripper toolbar for jogging and controlling the Gripper.

Info

The URCap package also contains a driver package that is different from this section’s. If you have already installed the

URCaps, you do not need to install the driver package. This section applies to Robotiq’s software excluding the URCap

package. If you wish to use the URCaps package, refer to the Control section.

Tip

Make sure your PolyScope version is up-to-date and that your controller is compatible with the driver package for UR (refer to

the Installation for Universal Robots section for controller compatibility). To view your PolyScope version, go to the

PolyScope home page and tap the About button. A window containing the Universal Robots software version will pop up.

Tip

For other robots, where no driver package is available, we recommend the use of the Robotiq Universal Controller which

allows fieldbus communication. Available communication protocols with this Universal Controller are :

l Modbus TCP

l EtherNet IP

l EtherCAT

l PROFINET

l DeviceNET

l CANopen

For details on controlling the Gripper, refer to the Control section.

3.9.1. Installation

To install the driver package, follow this procedure:

2F-85 &2F-140 - Instruction Manual

Page 44

l Download the Robotiq 2-Finger Gripper software driver package (DCU-X.X.X) from the Documentation Archives.

l Extract the content of the .zip file onto a blank USB flash drive.

l Plug the flash drive into the robot controller or teach pendant.

l Installation is automatic. The pendant screen will show installation status. Do not unplug the flash drive until the operation is com-

pleted.

l When a green "USB" text is shown, unplug the USB drive.

Testing the Gripper:

l When the installation is completed, the Gripper toolbar button will appear on the teach pendant’s screen after a short delay.

l Use the toolbar to jog and test the Gripper. Refer to the Control over Universal Robots without URCaps section to get detailed

information on how to use the Gripper toolbar.

Removing the package

l Locate the uninstall.sh file provided in the driver package.

44

l Copy the file on a blank USB stick.

l Rename the file to urmagic_uninstall.sh.

l Plug the USB stick into the UR controller or teach pendant.

l Uninstallation is automatic.

2F-85 &2F-140 - Instruction Manual

Page 45

45

4. Control

Info

Unless specified, all values in this section are hexadecimal values.

4.1. Overview

The Robotiq 2-Finger Adaptive Gripper is controlled directly via Modbus RTU using a RS 485 signal. It can also be controlled via an

optional Robotiq Universal Controller using an industrial protocol. The programming of the Gripper can be done with the Teach Pendant

of the robot or by offline programming. Communication method used to control the 2-Finger Gripper does not change the control logic or

the registers setup described in the following subsections.

Tip

Robotiq suggests using the Robotiq User Interface test software to explore the various features of the Gripper, like object

detection and forcecontrol.

Since the Robotiq 2-Finger has its own embedded controller, high-level commands, such as "Go to requested position" are used to

control it.

Info

The operator can:

l Control force, speed and position of the Gripper fingers.

l Finger movement is always synchronized, movement is initiated via a single "Go to requested position" command.

l Parallel or encompassing grasp is done automatically.

l A built in object detection feature is available, the user can be notified after an object is picked once the "Go to" command

has been initiated. The feature also works for lost or dropped objects, and the user can be alerted if an object is dropped

after being detected.

l Engage directional (open or close ) auto-release for emergencies.

Control using registers

The Gripper has an internal memory that is shared with the robot controller. One part of the memory is for the robot output; gripper

functionalities. The other part of the memory is for the robot input; gripper status. Two types of actions can then be done by the robot

controller :

1. Write in the robot output registers to activate functionalities;

2. Read in the robot input registers to get the status of the Gripper.

The Gripper Register Mapping section will map the different registers used to control the Gripper or to read its status while the Robot

Output Registers &Functionalities section will detail the output (write) register functions, and the Robot Input Registers &Status

section will detail the input (read) register status. The figure below is a representation of the memory and the control logic of the Gripper.

2F-85 &2F-140 - Instruction Manual

Page 46

46

Fig. 4-1: 2-Finger control logic overview

2F-85 &2F-140 - Instruction Manual

Page 47

4.2. Gripper Register Mapping

Register mapping

Caution

Byte numeration starts at zero and not at 1 for the functionalities and status registers.

47

Register

Byte 0 ACTIONREQUEST GRIPPERSTATUS

Byte 1 RESERVED RESERVED

Byte 2 RESERVED FAULTSTATUS

Byte 3 POSITIONREQUEST POSREQUESTECHO

Byte 4 SPEED POSITION

Byte 5 FORCE CURRENT

Byte 6 to 15 RESERVED RESERVED

Robot Output /

Functionalities

Table 4-1: Registers of the 2-Finger Gripper.

Robot Input / Status

2F-85 &2F-140 - Instruction Manual

Page 48

48

4.3. Robot Output Registers &Functionalities

Register: ACTIONREQUEST

Address: Byte 0

Bits 7 6 5 4 3 2 1 0

Symbols Reserved rARD rATR rGTO Reserved rACT

rACT: First action to be made prior to any other actions, rACT bit will activate the Gripper. Clear rACT to reset the Gripper and clear

fault status.

l 0x0 - Deactivate Gripper.

l 0x1 - Activate Gripper (must stay on after activation routine is completed).

Warning

When setting rACT to one, the Gripper will begin movement to complete its auto-calibration feature.

Info

Power loss will set rACT; rACT bit must then be cleared, then set to allow operation of the Gripper.

Caution

rACT bit must stay on afterwards for any other action to be performed.

rGTO: The "Go To" action moves the Gripper fingers to the requested position using the configuration defined by the other registers,

rGTO will engage motion while byte 3, 4 and 5 will determine aimed position, force and speed. The only motions performed without the

rGTO bit are activation and automatic release routines.

l 0x0 - Stop.

l 0x1 - Go to requested position.

rATR: Automatic Release routine action slowly opens the Gripper fingers until all motion axes reach their mechanical limits. After all

motion is completed, the Gripper sends a fault signal and needs to be reactivated before any other motion is performed. The rATR bit

overrides all other commands excluding the activation bit (rACT).

l 0x0 - Normal.

l 0x1 - Emergency auto-release.

Caution

The automatic release is meant to disengage the Gripper after an emergency stop of the robot.

The automatic release is not intended to be used under normal operating conditions.

Automatic release will require rACT to be cleared (rACT == 0) then set (rACT == 1).

2F-85 &2F-140 - Instruction Manual

Page 49

49

rARD: Auto-release direction. When auto-releasing, rARD commands the direction of the movement. The rARD bit should be set prior

to or at the same time as the rATR bit, as the motion direction is set when the auto-release is initiated.

l 0x0 - Closing auto-release

l 0x1 - Opening auto-release

Register: GRIPPER OPTIONS

Address: Byte 1

Bits 7 6 5 4 3 2 1 0

Symbol Reserved

Register: GRIPPER OPTIONS 2

Address: Byte 2

Bits 7 6 5 4 3 2 1 0

Symbol Reserved

Register: POSITIONREQUEST

Address: Byte 3

Bits 7 6 5 4 3 2 1 0

Symbol rPR

This register is used to set the target position for the Gripper's fingers. The positions 0x00 and 0xFF correspond respectively to the fully

opened and fully closed mechanical stops. For detailed finger trajectory, please refer to the Specifications section.

l 0x00 - Open position, with 85 mm or 140 mm opening respectively

l 0xFF - Closed

l Opening / count: 0.4 mm (for 85 mm stroke) and 0.65 mm (for 140 mm stroke)

Info

The activation feature of the Robotiq Adaptive Gripper will allow the Gripper to adjust to any fingertips. No matter what is the

size and shape of the fingertips used, 0 will always be fully opened and 255 fully closed, with a quasi-linear relationship

between 0 and 255.

Register: SPEED

2F-85 &2F-140 - Instruction Manual

Page 50

50

Address: Byte 4

Bits 7 6 5 4 3 2 1 0

Symbol rSP

This register is used to set the Gripper closing or opening speed in real time, however, setting a speed will not initiate a motion.

l 0x00 - Minimum speed

l 0xFF - Maximum speed

Register: FORCE

Address: Byte 5

Bits 7 6 5 4 3 2 1 0

Symbol rFR

The force setting defines the final gripping force for the Gripper. The force will fix the maximum current sent to the motor while in

motion. If the current limit is exceeded, the fingers stop and trigger an object detection notification. Please refer to the Robot Input

Registers &Status section for details on force control.

l 0x00 - Minimum force

l 0xFF - Maximum force

Info

Register bytes 6 to 15 are reserved and should be set to zero.

2F-85 &2F-140 - Instruction Manual

Page 51

4.4. Robot Input Registers &Status

Register: GRIPPERSTATUS

Address: Byte 0

Bits 7 6 5 4 3 2 1 0

51

Symbol

s

gOBJ gSTA gGTO Reserved gACT

gACT: Activation status, echo of the rACT bit (activation bit).

l 0x0 - Gripper reset.

l 0x1 - Gripper activation.

gGTO: Action status, echo of the rGTO bit (go to bit).

l 0x0 - Stopped (or performing activation / automatic release).

l 0x1 - Go to Position Request.

gSTA: Gripper status, returns the current status & motion of the Gripper fingers.

l 0x00 - Gripper is in reset (or automatic release ) state. See Fault Status if Gripper is activated.

l 0x01 - Activation in progress.

l 0x02 - Not used.

l 0x03 - Activation is completed.

gOBJ: Object detection status, is a built-in feature that provides information on possible object pick-up. Ignore if gGTO == 0.

l 0x00 - Fingers are in motion towards requested position. No object detected.

l 0x01 - Fingers have stopped due to a contact while opening before requested position. Object detected opening.

l 0x02 - Fingers have stopped due to a contact while closing before requested position. Object detected closing.

l 0x03 - Fingers are at requested position. No object detected or object has been loss / dropped.

Caution

In some circumstances object detection may not detect an object even if it is successfully grasped. For example, picking up

a thin object in a fingertip grasp may be successful without object detection occurring. For such reasons, use this feature

with caution. In these applications when the "Fingers are at requested position" status of register gOBJ, this is sufficient to

proceed to the next step of the routine.

Tip

Checking for the correct position of the fingers (byte 4), as well as object detection (byte 0, bit 6 & 7) before proceeding to

the next step of a routine is a more reliable method than object detection or finger position alone.

Register: RESERVED

2F-85 &2F-140 - Instruction Manual

Page 52

52

Address: Byte 1

Bits 7 6 5 4 3 2 1 0

Symbol Reserved

Register: FAULTSTATUS

Address: Byte 2

Bits 7 6 5 4 3 2 1 0

Symbols kFLT

gFLT

gFLT: Fault status returns general error messages that are useful for troubleshooting. Fault LED (red) is present on the Gripper

chassis, LED can be blue, red or both and be solid or blinking.

l 0x00 - No fault (LED is blue)

l Priority faults (LED is blue)

l 0x05 - Action delayed, activation (reactivation) must be completed prior to perfmoring the action.

l 0x07 - The activation bit must be set prior to action.

Minor faults (LED continuous red)

l 0x08 - Maximum operating temperature exceeded, wait for cool-down.

l 0x09 No communication during at least 1 second.

Major faults (LED blinking red/blue) - Reset is required (rising edge on activation bit rACT needed).

l 0x0A - Under minimum operating voltage.

l 0x0B - Automatic release in progress.

l 0x0C - Internal fault; contact support@robotiq.com.

l 0x0D - Activation fault, verify that no interference or other error occurred.

l 0x0E - Overcurrent triggered.

l 0x0F - Automatic release completed.

Info

While booting, status LED will be solid blue / red.

kFLT : See your optional Controller Manual (input registers & status).

2F-85 &2F-140 - Instruction Manual

Page 53

Register: POSITIONREQUESTECHO

Address: Byte 3

Bits 7 6 5 4 3 2 1 0

Symbol gPR

gPR: Echo of the requested position for the Gripper, value between 0x00 and 0xFF.

l 0x00 - Full opening.

l 0xFF - Full closing.

Register: POSITION

Address: Byte 4

Bits 7 6 5 4 3 2 1 0

Symbol gPO

gPO: Actual position of the Gripper obtained via the encoders, value between 0x00 and 0xFF.

53

l 0x00 - Fully opened.

l 0xFF - Fully closed.

Register: CURRENT

Adress: Byte 5

Bits 7 6 5 4 3 2 1 0

Symbol gCU

gCU: The current is read instantaneously from the motor drive, value between 0x00 and 0xFF, approximate current equivalent is 10 *

value read inmA.

Tip

Built-in features like object detection and force control use the finger's electrical current readings. The user does not need to

create thesefeatures.

2F-85 &2F-140 - Instruction Manual

Page 54

54

4.5. Picking Features

As stated in previous sections, object picking is done via a simple "Go To" command, rGTO bit calls for movement, while rPR byte is

the aimed position, rSP and rFR will be the desired speed and force settings respectively. This section describes key features in object

picking applications:

l Force control

l Re-grasp

l Object detection

4.5.1. Force control

The 2-Finger Gripper gripping force is controlled via the rFR byte (refer to the Gripper Register Mapping section).The Gripper

behavior will change according to the rFR forcerequested.

l rFR = 0 : Very fragile objects or deformable objects mode

l Lowest force

l Re-grasp feature is off

l 1 rFR 127 : Solid & fragile objects

l Low torque mode

l Re-grasp feature is on

l 128 rFR 255 : Solid & strong objects

l High torque mode

l Re-grasp feature is on

The table below shows the expected applied force according to the payload material hardness, speed setting rSP and force setting

rFR. All tests were done with the 2-Finger Gripper with firmware GC3-1.3.9. Data was obtained with a Load Cell from

model 3138

.

Phidget,S Type

,

2F-85 &2F-140 - Instruction Manual

Page 55

FINGERPAD PAYLOAD MEASURED FORCE MIN / MAX (N)

TYPE HARDNESS TYPE HARDNESS 2-Finger 85 2-Finger 140

55

Steel 4340 220 HV Steel 4340

95 HV Aluminium 6061 95 HV 25 - 220 15 - 120

Aluminium 6061

Aluminium 6061

Aluminium 6061

Aluminium 6061

Aluminium 6061

1

Available with V-Groove fingertip AGC-TIP-205-0085 / AGC-TIP-421-140.

2

Available with flat silicone fingertip AGC-TIP-204-085 / AGC-TIP-420-140.

3

HV refers to Vickers hardness test.

1

95 HV

1

95 HV Silicone rubber

1

95 HV Neoprene rubber 10 A Durometer 25 - 115 15 - 75

1

95 HV Polyurethane rubber 30 OO Durometer 25 - 115 15 - 75

1

Silicone (TIP-204)

220 HV

60 A Durometer 25 - 220 15 - 120

2

40 ADurometer

4 Durometer refers to Shore durometer hardness, scale A or scale OO.

3

4

25 - 220 15 - 120

25 - 155 15 - 100

2F-85 &2F-140 - Instruction Manual

Page 56

56

Fig. 4-2: grasp force on hardness 220 HV (4340 annealed carbon steel).

Fig. 4-3: grasp force on hardness 95 HV (6061-T6 aluminium).

2F-85 &2F-140 - Instruction Manual

Page 57

Fig. 4-4: grasp force on hardness 60A (silicone).

57

Fig. 4-5: grasp force on hardness 40 A (silicone).

2F-85 &2F-140 - Instruction Manual

Page 58

58

Fig. 4-6: grasp force on hardness 10 A (neoprene).

Fig. 4-7: grasp force on hardness 30 OO (polyurethane).

2F-85 &2F-140 - Instruction Manual

Page 59

59

4.5.2. Re-Grasp

Re-grasp feature is a built-in feature meant to prevent object lost due to slipping or inaccurate initial grip. The Re-grasp feature will

allow the Gripper to initiate movement when an object is slipping or dropped. When Re-grasping, the Gripper will attempt to close until it

reaches the position (rPR) request.

l This feature is automatically set according to the force request rFR.

Info

Feature is off at force request rFR = 0, otherwise it is on.

l Re-grasp will keep the position setting:

l Finger motion will stop when rPR position is reached, even if there is no object.

l Force and speed settings are not used, Re-grasp force and speed will automatically adjust to keep the object from being lost /

dropped.

Info

While your initial settings for force and speed are not used for Re-grasp, they will never be exceeded to prevent damaging the

object grasped.

Info

The rOBJ status is cleared when a motion is detected.

2F-85 &2F-140 - Instruction Manual

Page 60

60

4.5.3. Object detection

When the Gripper grabs an object, gOBJ status will allow you to know if object retention was successful. This is a built-in feature for

the 2-Finger Grippers meant to be used by the robot controller (or PLC) commanding the overall application. The Object detection

feature will change the gOBJ status and can be used inside your robot program. As stated in the previous section:

gOBJ: Only valid if gGTO = 1.

l 0x00 - Fingers are in motion towards requested position. No object detected.

l 0x01 - Fingers have stopped due to a contact while opening before requested position. Object detected.

l 0x02 - Fingers have stopped due to a contact while closing before requested position. Object detected.

l 0x03 - Fingers are at requested position. No object detected or object has been lost / dropped.

Object detection exemple:

1. Set position, speed and force at maximum (full closing):

a. rPR == 0xFF, rSP == 0xFF, rFR ==0xFF,

2. Set ''go to requested'' will initiate movement :

a. rGTO == 0x01

3. Then object detection status will be "in motion"

a. gOBJ = 0x00

4. Until an object is picked, object detection status will then be "stopped due to contact while closing"

a. gOBJ = 0x02

5. The user can now assume it is holding the payload, and proceed to the next step.

Object lost example:

1. From previous example, after an object is picked, gOBJ = 0x02

2. If gOBJ = 0x03 after it was 0x02, user can assume the object as been lost.

2F-85 &2F-140 - Instruction Manual

Page 61

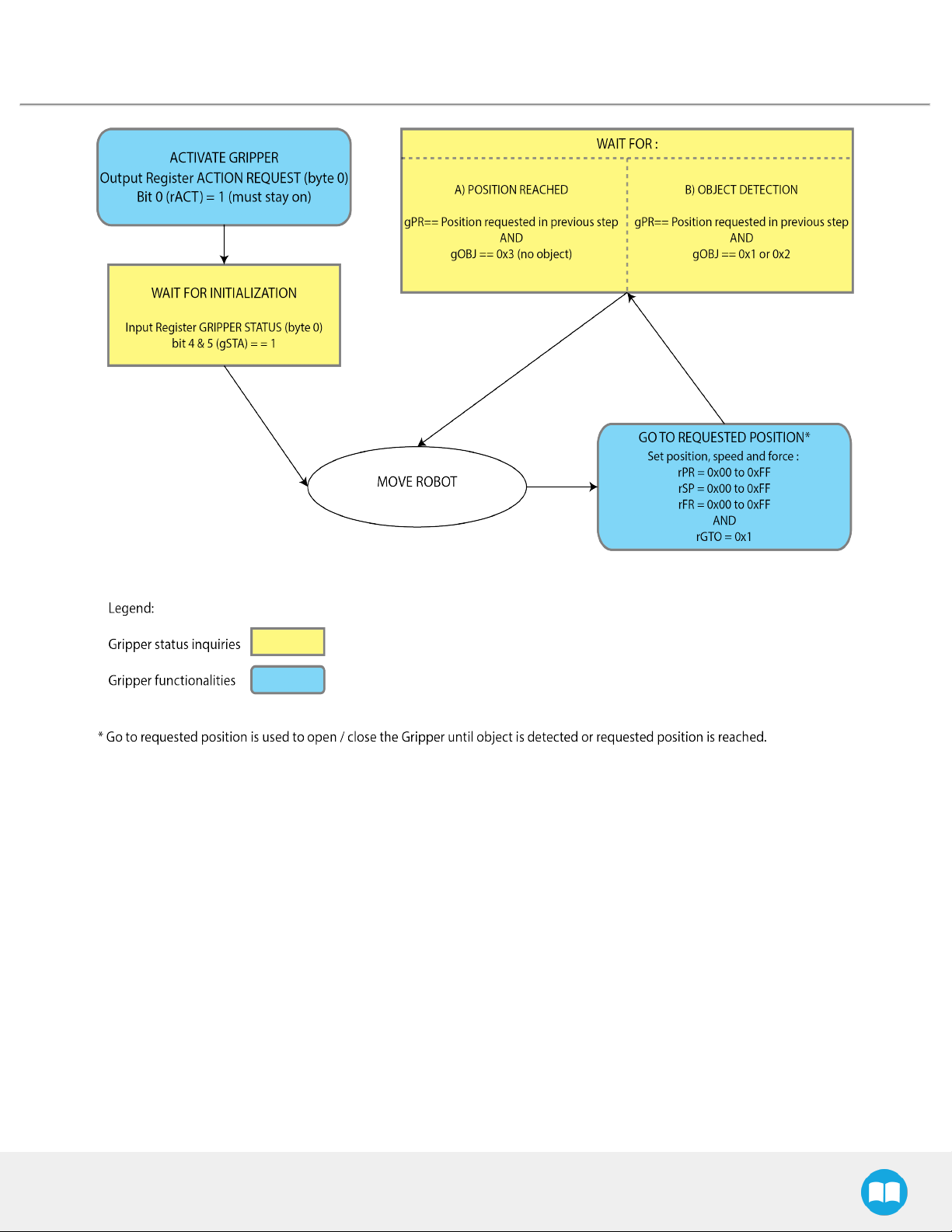

4.6. Control Logic

61

Fig. 4-8: Example of the 2-Finger control logic with associated registers.

2F-85 &2F-140 - Instruction Manual

Page 62

62

4.7. Modbus RTUCommunication

The Gripper can be controlled by Modbus RTU directly with RS485-RS232 using the ACC-ADT-RS232-RS485, or over USB using the

ACC-ADT-USB-RS485. This section is intended to provide guidelines for setting up a Modbus scanner that will adequately

communicate with the Gripper.

For a general introduction to Modbus RTU and for details regarding the CRC algorithm, the reader is invited to read the Modbus over

serial line specification and implementation guide available at: http://www.modbus.org/docs/Modbus_over_serial_line_V1_02.pdf.

For debugging purposes, the reader is also invited to download one of many free Modbus scanners such as the

from Chipkin Automation Systems

Info

Modbus RTU is a communication protocol based on a Big Endian byte order. Therefore, the 16-bit register addresses are

transmitted with the most significant byte first. However, the data port is in the case of Robotiq products based on the Little

Endian byte order. As such, the data parts of Modbus RTU messages are sent with the less significant byte first.

Tip

Modbus RTU specification and details can be found at www.modbus.org.

available at: http://www.store.chipkin.com/products/tools/cas-modbus-scanner.

CAS Modbus Scanner

2F-85 &2F-140 - Instruction Manual

Page 63

4.7.1. Connection Setup

The following table describes the connection requirements for controlling the Gripper using the Modbus RTU protocol.

PROPRIETY VALUE

63

Physical Interface

Baud Rate

2

RS-485

115,200 bps

1

Data Bits 8

Stop Bit

Parity

2

2

1

None

Read Holding Register (FC03)

Read Input Registers (FC04)

Supported Functions

Preset Multiple Register (FC16)

Master read & write multiple registers (FC23)

Exception Responses Not supported

Slave ID

2

0x0009 (9)

Robot Output / Gripper Input First Register 0x03E8 (1000)

Robot Input / Gripper Output First Register 0x07D0 (2000)

1

Various converters are available in the Spare parts section.

2

These parameters can be adjusted using the Robotiq User Interface.

Each register (word - 16 bits) of the Modbus RTU protocol is composed of 2 bytes (8 bits) from the Gripper. The first Gripper output

Modbus register(0x07D0) is composed from the first 2 Robotiq Gripper bytes (byte 0 and byte 1).

Info

200 Hz is the usual speed when commanding / reading from the Robotiq Gripper. It is therefore recommended to send

commands with a minimum delay of 5 ms between them.

Info

Maximum baud rate of ACC-ADT-USB-RS485 is 115200 bps.

120 Ohms termination resistor is already present on the converter.

2F-85 &2F-140 - Instruction Manual

Page 64

64

4.7.2. Read holding registers (FC03)

Function code 03 (FC03) is used for reading the status of the Gripper (robot input). Examples of such data are Gripper status, object

status, finger position, etc.

Example of FC03 Read function:

This message asks for register 0x07D0 (2000) and register 0x07D1 (2001) which contains Gripper Status, Object Detection, Fault