Page 1

CANBus

CANOpen

RawCAN

MiniCAN

RoboCAN

User & Reference Manual

V2.0, July 8, 2019

visit www.roboteq.com to download the latest revision of this manual

©Copyright 2016-2019 Roboteq, Inc

1

Page 2

Brushless Motor Connections and Operation

Revision History

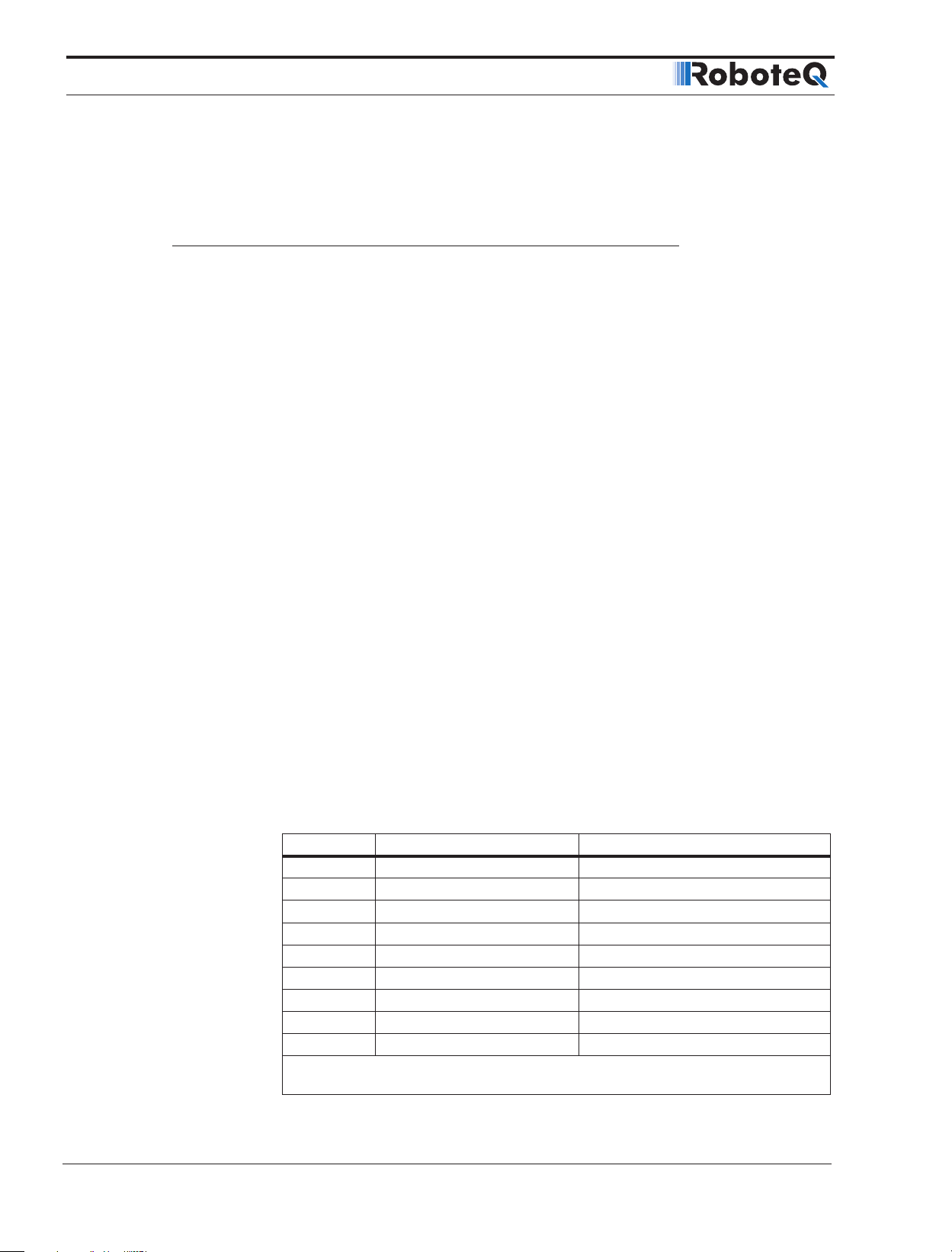

Date Version Changes

July 8, 2019 2.0 Extracted from main User Manual

The information contained in this manual is believed to be accurate and reliable. However, it may contain errors that were not noticed at the time of publication. Users are

expected to perform their own product validation and not rely solely on data contained

in this manual.

2 CANBus Networking Manual V2.0 July 8, 2019

Page 3

Revision History ......................................................................................... 2

Introduction ................................................................................................ 5

Refer to the Datasheet for Hardware-Specific Issues ................................ 5

User Manual Structure and Use ................................................................. 5

SECTION 1

Supported CAN Modes .............................................................................. 7

Connecting to CAN bus ............................................................................. 8

Introduction to CAN Hardware signaling .................................................... 9

CAN Bus Pinout ......................................................................................... 9

CAN and USB Limitations ........................................................................ 10

Basic Setup and Troubleshooting ............................................................. 10

Cable polarity, integrity and termination resistor ......................................11

Check CANbus activity using a voltmeter .................................................11

Check CANbus activity using a CAN sniffer ..............................................11

Mode Selection and Configuration ...........................................................11

Common Configurations .......................................................................... 12

MiniCAN Configurations .......................................................................... 12

RawCAN Configurations .......................................................................... 12

Using RawCAN Mode .............................................................................. 12

Checking Received Frames ...................................................................... 12

Reading Raw Received Frames ............................................................... 13

Transmitting Raw Frames ......................................................................... 13

Using MiniCAN Mode .............................................................................. 14

Transmitting Data ..................................................................................... 14

Receiving Data ......................................................................................... 14

MiniCAN Usage Example ........................................................................ 15

SECTION 2

Network Operation .................................................................................. 18

RoboCAN via Serial & USB ...................................................................... 18

Runtime Commands ................................................................................ 18

Broadcast Command ............................................................................... 18

Realtime Queries ..................................................................................... 19

Remote Queries restrictions .................................................................... 19

Configurations Read/Writes ..................................................................... 20

Remote Configurations Read restrictions ................................................ 20

Remote Maintenance Commands ........................................................... 20

Self Addressed Commands and Queries ................................................. 21

RoboCAN via MicroBasic Scripting .......................................................... 21

Sending Commands and Configuration ................................................... 21

Reading Operating values Configurations ................................................ 22

Continuous Scan ...................................................................................... 23

Checking the presence of a Node ............................................................ 25

Self Addressed Commands and Queries ................................................. 25

Broadcast Command ............................................................................... 25

Remote MicroBasic Script Download ...................................................... 25

SECTION 3

Use and benefits of CANopen ................................................................. 27

CAN Connection ...................................................................................... 27

CAN Bus Configuration ............................................................................ 28

Node ID .................................................................................................... 28

CAN Networking on Roboteq Controllers ................................................................7

RoboCAN Networking .............................................................................. 17

CANopen Interface ...................................................................................................27

CANBus Networking Manual 3

Page 4

Bit Rate .................................................................................................... 28

Heartbeat ................................................................................................. 28

Autostart .................................................................................................. 28

Commands Accessible via CANopen ....................................................... 29

CANopen Message Types ........................................................................ 29

Service Data Object (SDO) Read/Write Messages .................................. 29

Transmit Process Data Object (TPDO) Messages ................................... 29

Receive Process Data Object (RPDO) Messages .................................... 30

PDO Mapping .......................................................................................... 31

PDO Transmission Type ............................................................................ 32

Object Dictionary ..................................................................................... 33

Communication Profile ............................................................................. 33

Runtime Commands ................................................................................ 34

Runtime Queries ...................................................................................... 34

DS402 Profile ........................................................................................... 37

SDO Construction Details ........................................................................ 39

SDO Example 1: Set Encoder Counter 2 (C) of node 1 value 10 ............. 39

SDO Example 2: Activate emergency shutdown (EX) for node 12 .......... 40

SDO Example 3: Read Battery Volts (V) of node 1. .................................. 40

SECTION 4

Abbreviations ........................................................................................... 43

Introduction .............................................................................................. 43

What is DS402 ......................................................................................... 43

Implementation ........................................................................................ 44

Index Range & Channel Selection ............................................................ 44

Modes of Operation ................................................................................. 44

Supported SDOs ...................................................................................... 45

PDS FSA .................................................................................................. 45

SDO Description ...................................................................................... 47

0x6040 - Control Word ............................................................................. 47

0x6041 - Status Word .............................................................................. 49

0x6042 - VL Target Velocity ....................................................................... 51

0x6043 - VL Velocity Demand .................................................................. 51

0x6044 - VL Velocity Actual Value ............................................................. 51

0x6046 - VL Velocity Min Max Amount .................................................... 52

0x6048 - VL Velocity Acceleration ............................................................ 52

0x6049 - VL Velocity Deceleration ............................................................ 53

0x6060 - Modes of Operation .................................................................. 53

0x6061 - Modes of Operation Display ..................................................... 53

0x6064 - Position Actual Value (PP) .......................................................... 53

0x606C - Velocity Actual Value (PV) .......................................................... 54

0x6071 - Target Torque (TQ) ..................................................................... 54

0x6077 - Torque Actual Value (TQ) ............................................................ 54

0x607A - Target Position (PP) ................................................................... 54

0x6081 - Profile Velocity (PP) ................................................................... 55

0x6083 - Profile Acceleration (PP) ............................................................ 55

0x6084 - Profile Deceleration (PP) ........................................................... 55

0x6087 - Torque Slope (TQ) ...................................................................... 55

0x60FF - Target Velocity (PV) .................................................................... 56

3.21 0x6502 - Supported Drive Modes .................................................... 56

3.22 0x67FE - Version Number ................................................................ 56

References ............................................................................................... 56

DS402 Implementation on Roboteq Motor Controllers ........................................43

4 CANBus Networking Manual V2.0 July 8, 2019

Page 5

User Manual Structure and Use

Introduction

Refer to the Datasheet for Hardware-Specific Issues

This manual is the companion to your controller’s datasheet. All information that is specific

to a particular controller model is found in the datasheet. These include:

• Number and types of I/O

• Connectors pin-out

• Wiring diagrams

• Maximum voltage and operating voltage

• Thermal and environmental specifications

• Mechanical drawings and characteristics

• Available storage for scripting

• Battery or/and Motor Amps sensing

• Storage size of user variables to Flash or Battery-backed RAM

User Manual Structure and Use

The user manual discusses issues that are common to all controllers inside a given product family. Except for a few exceptions, the information contained in the manual does not

repeat the data that is provided in the datasheets.

The manual is divided in 3 sections organized as follows:

SECTION 1 CAN Networking on Roboteq Controllers

This section describes the RawCAN and MiniCAN operating modes available on CAN-enabled Roboteq controllers.

SECTION 2 RoboCAN Networking

This section describes the RoboCAN protocol: a simple and efficient meshed network

scheme for Roboteq devices

CANBus Networking Manual 5

Page 6

Introduction

SECTION 3 CANopen Interface

This section describes the configuration of the CANopen communication protocol and the

commands accepted by the controller operating in the CANopen mode.

SECTION 4 DS402 Implementation on Roboteq Motor Controllers

This section will describe the implementation of CiA DS402 standard on Roboteq motor

controllers.

6 CANBus Networking Manual V2.0 July 8, 2019

Page 7

Supported CAN Modes

SECTION 1

CAN Networking

on Roboteq

Controllers

Some controller models are equipped with a standard CAN interface allowing up to 127

controllers to work together on a single twisted pair network at speeds up to 1Mbit/s.

Supported CAN Modes

Four CAN operating modes are available on Roboteq controllers:

1 - RawCAN

2 - MiniCAN

3 - CANopen

4 - RoboCAN

RawCAN is a low-level operating mode giving total read and write access to CAN frames.

It is recommended for use in low data rate systems that do not obey to any specific standard. CAN frames are typically built and decoded using the MicroBasic scripting language.

MiniCAN is greatly simplified subset of CANopen, allowing, within limits, the integration

of the controller into an existing CANopen network. This mode requires MicroBasic scripting to prepare and use the CAN data.

CANopen is the full Standard from CAN in Automation (CIA), based on the DS402 specification. It is the mode to use if full compliance with the CANopen standard is a primary requisite.

RoboCAN is a Roboteq proprietary meshed networking scheme allowing multiple Roboteq devices to operate together as a single system. This protocol is extremely simple and

lean, yet practically limitless in its abilities. It is the preferred protocol to use by users who

just wish to make multiple controllers work together with the minimal effort.

This section describes the RawCAN and MiniCAN modes.

Detailed descriptions of CANopen and RoboCAN can be found in specific sections of

this manual.

CANBus Networking Manual 7

Page 8

CAN Networking on Roboteq Controllers

CANH

CANL

120Ω

Microcomputer

Joysticks, Batteries

HMI’s and other CAN Accessories

Magnetic Guide Sensor

Motor Controllers

PLC

CAN

Adapter

120Ω

Connecting to CAN bus

A CAN bus network is made of a stretch of two wires. A device can be put on a CANbus

network by simply connecting it’s CAN-High and CAN-Low lines to those of other devices

on the network.

Figure 1-1: CAN Network topology

Resistors should be 120 ohm and located at each end of the cable. However, on a short

network communication will take place with a single resistor of 100 to 200 ohm located

anywhere on the network. Communication will not work if no resistor is present, or if its

value is too high.

No ground connection is necessary in between nodes. However, the ground potential of

each node must be within a few volts of each other. If all devices on the network are powered from the same power source, this can be expected to be the case.

CANbus will be operational upon enabling the desired CAN protocol and speed using the

PC utility.

Important Warning

A ground difference up to around 10V is acceptable. A difference of 30V or higher

can cause damage to one or more nodes. CANbus isolators must be used if a similar

ground level cannot be guaranteed between nodes.

8 CANBus Networking Manual V2.0 July 8, 2019

Page 9

Introduction to CAN Hardware signaling

0

2.5V

1.5V

3.5V

0V

00 0000 00000000011111111 11

1

13

14 25

Introduction to CAN Hardware signaling

CANbus uses differential signals, which is where CAN derives its robust noise immunity

and fault tolerance. The two signal lines of the bus, CANH and CANL, are biased to around

2.5 V. A logical “1” (also known as the dominant state) on the bus takes CANH around 1

V higher to around 3.5 V, and takes CANL around 1 V lower to 1.5 V, creating a typical 2V

differential signal as shown in Figure 1-2.

Figure 1-2: CANbus signaling

CAN Bus Pinout

FIGURE 1-3. DB9.Connector pin locations

TABLE 1-1. CAN Signals on DB9 connector

Pin Number Signal Description

2 CAN_L CAN bus low

7 CAN_H CAN bus high

Differential signaling reduces noise coupling and allows for high signaling rates over twisted-pair cable. The High-Speed CANbus specifications (ISO 11898 Standard) are given for

a maximum signaling rate of 1 Mbps with a bus length of 40 m with a maximum of 30

nodes. It also recommends a maximum unterminated stub length of 0.3 m.

Depending on the controller model, the CAN signals are located on the 9-pin, 15-pin or

25-pin DSub connector. Refer to datasheet for details.

69

15

The pins on the DB9 connector are mapped as described in the table below.

CANBus Networking Manual 9

Page 10

CAN Networking on Roboteq Controllers

18

915

1

13

14 25

FIGURE 1-4. DB15 Connector pin locations

The pins on the DB15 connector are mapped as described in the table below.

TABLE 1-2. CAN Signals on DB15 connector

Pin Number Signal Description

6 CAN_L CAN bus low

7 CAN_H CAN bus high

FIGURE 1-5. DB25 pin locations

The pins on the DB25 connector are mapped as described in the table below.

TABLE 1-3. CAN Signals od DB25 connector

Pin Number Signal Description

8 CAN_L CAN bus low

20 CAN_H CAN bus high

CAN and USB Limitations

On some controller models CAN and USB cannot operate at the same time. On controllers equipped with a USB connector, if simultaneous connection is not allowed, the controller will enable CAN if USB is not connected.

The controller will automatically enable USB and disable CAN as soon as the USB is connected to the PC. The CAN connection will then remain disabled until the controller is

restarted with the USB unplugged.

See the controller model datasheet to verify whether simultaneous CAN and USB is supported.

Basic Setup and Troubleshooting

CANbus is very easy to setup: Simply connect the CANH and CANL to a pair of wires with

at least one resistor somewhere along the cable. Enable the desired CAN protocol and

speed using the PC utility.

10 CANBus Networking Manual V2.0 July 8, 2019

Page 11

Basic Setup and Troubleshooting

If communication cannot be established, it can be difficult to determine the source of the

problem. Here are a few ways to diagnose:

Cable polarity, integrity and termination resistor

Verify that the controller’s CANH and CANL are connected to the CANH and CANL wire.

Check cable continuity to every node. Verify the presence of a least one resistor and that

its value is 120ohm (a value of 60 to 200 ohm would be acceptable)

Check CANbus activity using a voltmeter

The presence of CAN data traffic can be checked using a simple voltmeter and measuring

the voltage between GND and CANH, and between GND and CANL. When CAN is disabled, both lines should have approximately the same voltage around 2.5V. When CAN is

enabled with RoboCAN or MiniCAN protocol selected, the controller will send a continuous stream of data frames. This will cause the CANH voltage to rise above, and the CANL

voltage to drop below, the 2.5V midpoint. If the idle and active voltages do not match the

above, try again on the controller alone disconnected from the network but with a 100 to

200 ohm resistor across its CANH and CANL pins.

The CANOpen and RawCAN protocol should not be used for this test as these do not generate data traffic on their own and will not cause measurable voltage changes.

Check CANbus activity using a CAN sniffer

When working on a CAN system, it is highly recommended to make the acquisition of a

USB to CAN adapter such as the PCAN-USB from Peak Systems. Connect the adapter to

the CANH and CANL and run the sniffer software with the correct bit rate selected. The

figure below shows the expected received data when a Roboteq device is on the network

with MiniCAN protocol enabled.

Figure 1-6. USB to CAN adapter and MiniCAN frame capture

Mode Selection and Configuration

Mode selection is done using the CAN menu in the RoborunPlus PC utility.

CANBus Networking Manual 11

Page 12

CAN Networking on Roboteq Controllers

Common Configurations

CAN Mode: Used to select one of the 4 operating modes. Off disables all CAN receive

and transmit capabilities.

Node ID: CAN Node ID used for transmission from the controller. Value may be be-

tween 1 and 126 included.

Bit Rate: Selectable bit rate. Available speeds are 1000, 800, 500, 250, and 125 kbit/s.

Default is 125kbit and is the recommended speed for RawCAN and MiniCAN modes.

Heartbeat: Period at which a Heartbeat frame is sent by the controller. The frame is

CANopen compatible 0x700 + NodeID, with one data byte of value 0x05

(Status: Operational). The Heartbeat is sent in any of the selected modes. It

can be disabled by entering a value of 0.

MiniCAN Configurations

ListenNodeID: Filters to accept only packets sent by a specific node.

SendRate: Period at which data frames are sent by the controller. Frames are struc-

tured as standard CANopen Transmit Process Data Objects (TPDOs). Transmission can be disabled by entering a value of 0.

RawCAN Configurations

In the RawCAN mode, incoming frames may be filtered or not by changing the ListenNodeID parameter that is shared with the MiniCAN mode. A value of 0 will capture all

incoming frames and it will be up to the user to use the ones wanted. Any other value will

cause the controller to capture only frames from that sender.

Using RawCAN Mode

In the RawCAN Mode, received unprocessed data packets can be read by the user. Likewise, the user can build a packet with any content and send it on the CAN network. A

FIFO buffer will capture up to 16 frames.

CAN packets are essentially composed by a header and a data payload. The header is an

11 bit number that identifies the sender’s address (bits 0 to 6) and a packet type (bits 7 to

10). Data payload can be 0 to 8 bytes long.

Checking Received Frames

Received frames are first loaded in the 16-frame FIFO buffer. Before a frame can be read,

it is necessary to check if any frames are present in the buffer using the ?CF query. The

query can be sent from the serial/USB port, or from a MicroBasic script using the getvalue(_CF) function. The query will return the number of frames that are currently pending,

and copy the oldest frame into the read buffer, from which it can then be accessed. Sending ?CF again, copies the next frame into the read buffer.

The query usage is as follows:

Syntax: ?CF

Reply: CF=number of frames pending

12 CANBus Networking Manual V2.0 July 8, 2019

Page 13

Using RawCAN Mode

Reading Raw Received Frames

After a frame has been moved to the read buffer, the header, bytecount and data can be

read with the ?CAN query. The query can be sent from the serial/USB port, or from a MicroBasic script using the getvalue(_CAN, n) function. The query usage is as follows:

When the query is sent from serial or USB, without arguments, the controller replies by

outputting all elements of the frame separated by colons.

Syntax: ?CAN [ee]

Reply: CAN=header:bytecount:data0:data1: .... :data7

Where: ee = frame element

1 = header

2 = bytecount

3 to 10 = data0 to data7

Examples: Q: ?CAN

R: CAN=5:4:11:12:13:14:0:0:0:0

Q: ?CAN 3

R: CAN=11

Notes: Read the header to detect that a new frame has arrived. If header is dif-

Transmitting Raw Frames

RawCAN Frames can easily be assembled and transmitted using the CAN Send Command !CS. This command can be used to enter the header, bytecount, and data, one

element at a time. The frame is sent immediately after the bytecount is entered, and so it

should be entered last.

Syntax: !CS ee nn

Where: ee = frame element

ferent than 0, then a new frame has arrived and you may read the data.

After reading the header, its value will be 0 if read again, unless a new

frame has arrived.

New CAN frames will not be received by the controller until a ?CAN

query is sent to read the header or any other element.

Once the header is read, proceed to read the other elements of the

received frame without delay to avoid data to be overwritten by a new

arriving frame.

1 = header

2 = bytecount

3 to 10 = data0 to data7

nn = value

Examples: !CS 1 5 Enter 5 in header

!CS 3 2 Enter 2 in Data 0

!CS 4 3 Enter 3 in Data 1

!CS 2 2 Enter 2 in bytecount. Send CAN data frame

CANBus Networking Manual 13

Page 14

CAN Networking on Roboteq Controllers

Using MiniCAN Mode

MiniCAN is greatly simplified subset of CANopen. It only supports Heartbeat, and fixed

map Received Process Data Objects (RPDOs) and Transmit Process Data Objects (TPDOs). It does not support Service Data Objects (SDOs), Network Management (NMT),

SYNC or other objects.

Transmitting Data

In MiniCAN mode, data to be transmitted is placed in one of the controller’s available Integer or Boolean User Variables. Variables can be written by the user from the serial/USB

using !VAR for Integer Variables, or !B for Boolean Variables. They can also be written from

MicroBasic scripts using the setcommand(_VAR, n) and setcommand(_B, n) functions.

The value of these variables is then sent at a periodic rate inside four standard CANopen

TPDO frames (TPDO1 to TPDO4). Each of the four TPDOs is sent in turn at the time period defined in the SendRate configuration parameter.

Header:

TPDO1: 0x180 + NodeID

TPDO2: 0x280 + NodeID

TPDO3: 0x380 + NodeID

TPDO4: 0x480 + NodeID

Data:

TPDO1 VAR1 VAR2

TPDO2 VAR3 VAR4

TPDO3 VAR5 VAR6 VAR7 VAR8

TPDO4 BVar

Byte and Bit Ordering:

Integer Variables are loaded into a frame with the Least Significant Byte first. Example

0x12345678 will appear in a frame as 0x78 0x56 0x34 0x12.

Boolean Variables are loaded in a frame as shown in the table above, with the lowest

Boolean Variable occupying the least significant bit of each byte. Example Boolean Var 1

will appear in byte as 0x01.

Receiving Data

In MiniCAN mode, incoming frames headers are compared to the Listen Node ID number.

If matched, and if the other 4 bits of the header identify the frame as a CANopen standard

RPDO1 to RPDO4, then the data is parsed and stored in Integer or Boolean Variables according to the map below. The received data can then be read from the serial/USB using

the ?VAR or ?B queries, or they can be read from a MicroBasic script using the getvalue(_VAR, n) or getvalue(_B, n) functions.

Byte1 Byte2 Byte3 Byte4 Byte5 Byte6 Byte7 Byte8

1-8

BVar

9-16

BVar

17-24

BVar

25-32

14 CANBus Networking Manual V2.0 July 8, 2019

Page 15

Using MiniCAN Mode

Header:

RPDO1: 0x200 + NodeID

RPDO2: 0x300 + NodeID

RPDO3: 0x400 + NodeID

RPDO4: 0x500 + NodeID

Data:

Byte1 Byte2 Byte3 Byte4 Byte5 Byte6 Byte7 Byte8

RPDO1 VAR9 VAR10

RPDO2 VAR11 VAR12

RPDO3 VAR13 VAR14 VAR15 VAR16

RPDO4 BVar

33-40

Byte and Bit Ordering:

Integer Variables are loaded from frame with the Least Significant Byte first. Example, a

frame with data as 0x78 0x56 0x34 0x12 will load in an Integer Variable as 0x12345678.

BVar

41-48

BVar

49-56

BVar

57-64

Boolean Variables are loaded from a frame as shown in the table above, with the lowest

Boolean Variable occupying the least significant bit of each byte. Example a received byte

of 0x01 will set Boolean Var 33 and clear Vars 34 to 40.

MiniCAN Usage Example

MiniCAN can only be used with the addition of MicroBasic scripts that will give a meaning to the general variables in which the CAN data are stored. The following simple script

uses VAR1 that is transported in RPDO1 as the incoming motor command and puts the

Motor Amp VAR9 so that it is sent in TPDO1.

top:

speed = getvalue(_VAR, 9)

setcommand(_G, 1, speed)

motor_amp = getvalue(_A, 1)

setcommand(_VAR, 1, motor_amp)

wait(10)

goto top:

Note: This script does not check for loss of communication on the CAN bus. It is provided

for information only.

CANBus Networking Manual 15

Page 16

CAN Networking on Roboteq Controllers

16 CANBus Networking Manual V2.0 July 8, 2019

Page 17

RoboCAN Networking

CAN

USB or

RS232

Microcomputer

3rd Party CAN Accessory

Magnetic Guide Sensor

CAN

Adapter

SECTION 2

RoboCAN Networking

RoboCAN is a Roboteq proprietary meshed networking scheme allowing multiple Roboteq

products to operate together as a single system. This protocol is extremely simple and

lean, yet practically limitless in its abilities. It is the preferred protocol to use by a user who

just wishes to make multiple controllers work together with minimal effort.

In RoboCAN, every controller can send commands to, and can read operational data from,

any other node on the network. One or more controller can act as a USB to CAN or Serial

to CAN gateway, allowing several controllers to be thus managed from a single PC or microcomputer.

Using a small set of dedicated Microbasic function, scripts can be written to exchange

data between controllers in order to create automation systems without the need for a

PLC or external computer.

In addition, RoboCAN includes support for processing raw can data as defined in the

RawCAN specification (See page 154), in order to incorporate simple CAN compatible 3rd

party devices in the network.

CANBus Networking Manual 17

Page 18

RoboCAN Networking

Network Operation

RoboCAN requires only that a controller has a unique node number (other than 0)

assigned and that the RoboCAN mode is selected and enabled. All nodes must be

configured to operate at the same bit rate. Each enabled node will emit a special

heartbeat at a set and unchangeable rate of 128ms so that each node can create and

maintain a map of all nodes alive in the network.

RoboCAN via Serial & USB

Important notice: On many controller models, CAN and USB cannot be operated at the

same time. Please see product datasheet to verify if this is the case on the model used.

In case USB is not available, this section only applies to RS232 connections.

RoboCAN commands and queries can be sent from a USB or serial port using a modified syntax of the normal serial protocol: By simply adding the @ character followed by

the node as a 2 digit hex address, a command or query is sent to the desired node. This

scheme works with every Command (! Character), Query (?), Configuration setting (^),

Configuration read (~), and most Maintenance commands (%)

Runtime Commands

Below is a Command example:

!G 1 500

This is the normal command for giving a 50% power level command to motor 1 of the

controller that is attached to the computer.

@04!G 1 500

This will send the same 50% command to motor 1 of the controller at node address 4.

The reply to a local command is normally a + or - sign when a command is acknowledged

or rejected in normal serial mode.

When a command is sent to a remote node, the reply is also a + or – sign. However, in

addition, the reply can be a * sign to indicate that the destination node does not exist or is

not alive. Note that the + sign only indicates that the command syntax is valid and that the

destination node is alive.

Broadcast Command

Node address 00 is used to broadcast a command simultaneously to all the nodes in the

network. For example

@00!G 1 500

Will apply 50% power to all motor 1 at all nodes, including the local node

18 CANBus Networking Manual V2.0 July 8, 2019

Page 19

Realtime Queries

Queries are handled the same way but the reply to a query includes the responding

node’s address. Below is a Query example:

?V 2

This is the normal query for reading the battery voltage of the local controller. The controller will reply V=123

@04?V 2

This will send the same query to node address 4

The reply of the remote node is @04 V=123

Replies to remote nodes queries are identical to these to a local controller with the exception of an added latency. Since the reply must be retrieved from the remote node depending on the selected bit rate, the reply may come up to 10ms after the query was sent.

RoboCAN via Serial & USB

Remote Queries restrictions

Remote queries can only return a single value whereas local queries can be used to read

an array of values. For example

?AI

Is a local query that will return the values of all analog capture channels in a single string

as

AI=123:234:345:567

@04?AI

Is a remote query and it will return only the first analog capture channel as

@04 AI=123

Remote queries are not being added in the Query history.

Broadcast remote queries are not supported. For example @00?V 1 will not be executed.

Queries that return strings, such as ?FID or ?TRN are not supported. They will return the

value 0

See the Command Reference section in the manual for the complete list and description

of available queries

CANBus Networking Manual 19

Page 20

RoboCAN Networking

Configurations Read/Writes

Configuration settings, like Amp Limit or Operating Modes can be read and changed on a

remote node via the CAN bus. For example

@04^ALIM 1 250 will set the current limit of channel 1 of node 4 at 25.0A

@04~OVL will read the Overvoltage limit of node 4.

Note that changing a configuration via CAN only makes that change temporary until the

remote controller is powered down. The %EESAV maintenance command must be send

to the remote node to make the configuration change permanent.

A configuration write can be broadcast to all nodes simultaneously by using the node Id

00. For example

@00^OVL 250

Will set the overvoltage limit of all nodes at 25.0 Volts

Configuration reads cannot be broadcast.

See the Commands Reference section for the complete list and description of available

configurations

Remote Configurations Read restrictions

Remote Configuration Reads can only return a single value whereas local Configuration

Reads can be used to read an array of parameters. For example

~AMOD

Will return the operating mode of all analog capture channels in a single string as

AI=01:01:00:01:02

@04~AMOD

Will return only the mode first analog capture channel as

@04 AI=01

Configuration reads cannot be broadcast.

Remote Maintenance Commands

Maintenance Commands are not supported in RoboCAN.

20 CANBus Networking Manual V2.0 July 8, 2019

Page 21

RoboCAN via MicroBasic Scripting

Self Addressed Commands and Queries

For sake of consistency commands sent to the local node number are executed the same

way as they would be on a remote node. However the no CAN frame is sent to the network. For example if node 04 receive the command

@04!G 1 500

No data will be sent on the network and it will be interpreted and executed the same way as

!G 1 500

RoboCAN via MicroBasic Scripting

A set of functions have been added to the MicroBasic language in order to easily send

commands to, and read data from any other node on the network. Functions are also

available to read and write configurations at a remote node. Maintenance commands are

not supported.

Sending Commands and Configuration

Sending commands or configuration values is done using the functions

SetCANCommand(id, cc, ch, vv)

SetCANConfig(id, cc, ch, vv).

Where:

id is the remote Node Id in decimal

cc is the Command code, eg _G

ch is the channel number. Put 1 for commands that do not normally require a channel

number

vv is the value

Example:

SetCANCommand(04, _G, 1, 500)

Will apply 50% power to motor 1 of node 4

SetCANConfig(0, _OVL, 1, 250)

CANBus Networking Manual 21

Page 22

RoboCAN Networking

Will set the overvoltage limit of all nodes to 25.0V. Note that even though the Overvoltage

is set for the controller and does not normally require that a Channel, the value 1 must be

put in order for the instruction to compile.

Script execution is not paused when one of these function is used. The frame is sent on

the CAN network within one millisecond of the function call.

Reading Operating values Configurations

When reading an operating value such as Current Counter or Amps, or a configurations

such as Overvoltage Limit from another node, since the data must be fetched from the

network, and in order to avoid forcing a pausing of the script execution, data is accessed

in the following manner:

1. Send a request to fetch the node data

2. Wait for data to be received

3. Read the data

The wait step can be done using one of the 3 following ways

1. Pause script execution for a few milliseconds using a wait() instruction in line.

2. Perform other functions and read the results a number of loop cycles later

3. Monitor a data ready flag

The following functions are available in microbasic for requesting operating values and

configurations from a remote node.

FetchCANValue(id, cc, ch)

FetchCANConfig(id, cc, ch)

Where:

id is the remote Node Id in decimal

cc is the Command code, eg _G

cc is the channel number. Put 1 for commands that do not normally require a channel number

The following functions can be used to wait for the data to be ready for reading:

IsCANValueReady()

IsCANConfigReady()

These functions return a Boolean true/false value. They take no argument and apply to the

last issued FetchCANValue or FetchCANConfig function

The retrieved value can then be read using the following functions:

ReadCANValue()

ReadCANConfig()

These functions return an integer value. They take no argument and apply to the last issued FetchCANValue or FetchCANConfig function

22 CANBus Networking Manual V2.0 July 8, 2019

Page 23

Below is a sample script that continuously reads and print the counter value of node 4

Request value to be issued at

every t ms, to buffer location n

[Check if new value arrived]

Read from Scan buffer

Remote node

Local Scan Buffer

top:

FetchCANValue(4, _C, 1) ‘ request data from remote node

while(IsCANValueReady = false) ‘ wait until data is received

end while

Counter = ReadCANValue() ‘ read value

print (Counter, “\r”) ‘ print value followed by new line

goto top ‘ repeat forever

Continuous Scan

In many applications, it is necessary to monitor the value of an operating parameter on a

remote node. A typical example would be reading continuously the value of a counter. In

order to improve efficiency and reduce overhead, a technique is implemented to automatically scan a desired parameter from a given node, and make the value available for reading without the need to send a Fetch command.

A function is provided to initiate the automatic sending of a value from the remote node,

at a specific periodic rate, and to be stored to user selected location in a receive buffer.

RoboCAN via MicroBasic Scripting

The remote node will then send the data continuously without further commands.

A function is then provided to detect the arrival of a new value in that buffer location, and

another to read the value from that location.

Since the scan rate is known, the execution of the script can be timed so that it is not

necessary to check the arrival of a new value.

A scan is initiated with the function:

ScanCANValue(id, cc, ch, tt, bb)

Where:

id is the remote Node Id in decimal

CANBus Networking Manual 23

Page 24

RoboCAN Networking

cc is the Query code, eg _V

ch is the channel number. Put 1 for queries that do not normally require a channel number

tt is the scan rate in ms

bb is the buffer location

The scan rate can be up to 255ms. Setting a scan rate of 0 stops the automatic sending

from this node.

Unless otherwise specified, the buffer can store up to 32 values.

The arrival of a new value is checked with the function

IsScannedCANReady(aa)

Where

aa is the location in the scan buffer.

The function returns a Boolean true/false value

The new value is then read with the function

ReadScannedCANValue(aa)

Where

aa is the location in the scan buffer.

The function returns an integer value. If no new value was received since the previous

read, the old value will be read.

The following example shows the use of the Scan functions

‘ Initiate scan of counter every 10ms from node 4 and store to

buffer location 0

ScanCANValue(4, _C, 1, 10, 0)

‘ initiate scan of voltage every 100ms from node 4 and store to

buffer location 1

ScanCANValue(5, _V, 1, 100, 1)

top:

wait(10) ‘ Executer loop every 10 ms

‘ check if scanned volts arrived

if(IsScannedCANReady(1))

‘ read and print volts

Volts = ReadScannedCANValue(1)

print (Volts,”\r”)

end if

‘ No need to check if counter is ready since scan rate = loop cycle

Counter = ReadScannedCANValue(0)

print (Counter,”\r”)

goto top ‘ Loop continuously

24 CANBus Networking Manual V2.0 July 8, 2019

Page 25

RoboCAN via MicroBasic Scripting

Checking the presence of a Node

No error is reported in MicroBasic if an exchange is initiated with a node that does not exist. A command or configuration sent to a non-existent node will simply not be executed.

A query sent to a non existing or dead node will return the value 0. A function is therefore

provided for verifying the presence of a live node. A live node is one that sends the distinct RoboCAN heartbeat frame every 128ms. The function syntax is:

IsCANNodeAlive(id)

Where:

id is the remote Node Id in decimal

The function returns a Boolean true/false value.

Self Addressed Commands and Queries

Functions addressed to the local node have no effect. The following function will not

work if executed on node 4

SetCANCommand(04, _G, 1, 500)

The regular function must be used instead

SetCommand(_G, 1, 500)

Broadcast Command

Node address 00 is used to broadcast a command, or a configuration write simultaneously to all the nodes in the network.

The local node, however, will not be reached by the broadcast command.

Remote MicroBasic Script Download

RoboCAN includes a mechanism for loading MicroBasic scripts into any node in the network. Use the “To Remote” button in the Scripting Tab of the Roborun PC utility. A window will pop-up asking for the destination node Id. Details of the command used to enter

the download mode and transferring scripts is outside the scope of this manual.

CANBus Networking Manual 25

Page 26

RoboCAN Networking

26 CANBus Networking Manual V2.0 July 8, 2019

Page 27

Use and benefits of CANopen

Other

SECTION 3

CANopen

Interface

This section describes the configuration of the CANopen communication protocol and the

commands accepted by the controller using the CANopen protocol. It will help you to enable CANopen on your Roboteq controller, configure CAN communication parameters, and

ensure efficient operation in CANopen mode.

The section contains CANopen information specific to Roboteq controllers. Detailed information

on the physical CAN layer and CANopen protocol can be found in the DS402 documentation.

Use and benefits of CANopen

CANopen protocol allows multiple controllers to be connected into an extensible unified

network. Its flexible configuration capabilities offer easy access to exposed device parameters and real-time automatic (cyclic or event-driven) data transfer.

The benefits of CANopen include:

• Standardized in EN50325-4

• Widely supported and vendor independent

• Highly extensible

• Offers flexible structure (can be used in a wide variety of application areas)

• Suitable for decentralized architectures

• Wide support of CANopen monitoring tools and solutions

CAN Connection

Controller Controller

CANH

120 Ohm

CANL

CAN Device

120 Ohm

Termination

Resistor

FIGURE 3-1. CAN connection

CANBus Networking Manual 27

Page 28

CANopen Interface

Connection to a CAN bus is as simple as shown on the diagram above. 120 Ohm Termination Resistors must be inserted at both ends of the bus cable. CAN network can be up to

1000m long. See CAN specifications for maximum length at the various bit rates.

CAN Bus Configuration

To configure communication parameters via the RoborunPlus PC utility, your controller

must be connected to a PC via an RS232/RS485/TCP/USB port

Use the CAN menu in the Configuration tab in order to enable the CANopen mode. Additionally, the utility can be used to configure the following parameters:

• Node ID

• Bit rate

• Heartbeat (ms)

• Autostart

• TPDO Enable and Send rate

Node ID

Every CANopen network device must have a unique Node ID, between 1 and 127. The value of 0 is used for broadcast messaging and cannot be assigned to a network node.

Bit Rate

Heartbeat

Autostart

The CAN bus supports bit rates ranging from 10Kbps to 1Mbps. The default rate used in

the current CANopen implementation is set to 125kbps. Valid bit bates supported by the

controller are:

• 1000K

• 800K

• 500K

• 250K

• 125K

A heartbeat message is sent to the bus in millisecond intervals. Heartbeats are useful for detecting the presence or absence of a node on the network. The default value is set to 1000ms.

When autostart is enabled, the controller automatically enters the Operational Mode of

CANopen. The controller autostart is disabled by default. Disabling the parameter will prevent the controller from starting automatically after the reset occurs. When disabled, the

controller can only be enabled when receiving a CANopen management command.

28 CANBus Networking Manual V2.0 July 8, 2019

Page 29

Commands Accessible via CANopen

Commands Accessible via CANopen

Practically all of the controller’s real-time queries and real-time commands that can be accessed via Serial/USB communication can also be accessed via CANopen. The meaning,

effect, range, and use of these commands is explained in detail in Commands Reference

section of the manual.

All supported commands are mapped in a table, or Object Dictionary that is compliant

with the CANopen specification. See “Object Dictionary” on page 33 for a complete

set of commands.

CANopen Message Types

The controller operating in the CANopen mode can accept the following types of messages:

• Service Data Objects, or SDO messages to read/write parameter values

• Process Data Objects, or PDO mapped messages to automatically transmit param-

eters and/or accept commands at runtime

• Network Management, or NMT as defined in the CANopen specification

Service Data Object (SDO) Read/Write Messages

Runtime queries and runtime commands can be sent to the controller in real-time using

the expedited SDO messages.

SDO messages provide generic access to Object Dictionary and can be used for obtaining

parameter values on an irregular basis due to the excessive network traffic that is generated with each SDO request and response message.

The list of commands accessible with SDO messages can be found in the “Object Dictionary” on page 33.

Transmit Process Data Object (TPDO) Messages

Transmit PDO (TPDO) messages are one of the two types of PDO messages that are

used during operation.

TPDOs are runtime operating parameters that are sent automatically on a periodic basis

from the controller to one or multiple nodes. TPDOs do not alter object data; they only

read internal controller values and transmit them to the CAN bus.

TPDOs are identified on a CANopen network by the bit pattern in the 11-bit header of the

CAN frame.

4 bits 7 bits

}

Object Type NodeID

TPDO1: 0x180 + Node ID

TPDO2: 0x280 + Node ID

TPDO3: 0x380 + Node ID

TPDO4: 0x480 + Node ID

}

CANBus Networking Manual 29

Page 30

CANopen Interface

TABLE 3-1. Commands mapped on TPDOs

TPDO Object Index-Sub Size Default Object Mapped

TPDO1 0x2106-1 S32 User VAR 1

TPDO2 0x2106-3 S32 User VAR 3

TPDO3 0x2106-5 S32 User VAR 5

TPDO4 0x2106-7 S32 User VAR 7

S32: signed 32-bit word

CANopen allows up to four TPDOs for any node ID. Unless otherwise specified in the

product datasheet, by default, TPDO1 to TPDO4 are used to transmit up to 8 user variables which may be loaded with any operating parameters using MicroBasic scripting.

Each of the 4 TPDO can be mapped with any mappable SDO query. For more details see

chapter PDO Mapping below.

Each of the 4 TPDOs can be configured to be sent at user-defined periodic intervals. This

is done using the CTPS parameter (See “CTPS - CANOpen TPDO Send Rate” in “Roboteq

Controllers User Manual v2.0”).

0x2106-2 User VAR 2

0x2106-4 User VAR 4

0x2106-6 User VAR 6

0x2106-8 User VAR 8

Receive Process Data Object (RPDO) Messages

RPDOs are configured to capture runtime data destined to the controller.

RPDOs are CAN frames identified by their 11-bit header.

4 bits 7 bits

}

Object Type NodeID

RPDO1: 0x200 + Node ID

RPDO2: 0x300 + Node ID

RPDO3: 0x400 + Node ID

RPDO4: 0x500 + Node ID

Roboteq CANopen implementation supports RPDOs. Unless otherwise specified in the

product’s datasheet, by default, data received using RPDOs are stored in 8 user variables

from where they can be processed using MicroBasic scripting. Each of the 4 RPDO can

be mapped with any mappable SDO command. For more details see chapter PDO Mapping below.

TABLE 3-2. Commands mapped on RPDOs

RPDO Object Index-Sub Size Default Object Mapped

RPDO1 0x2005-9 S32 User VAR 9

0x2005-10 User VAR 10

RPDO2 0x2005-11 S32 User VAR 11

0x2005-12 User VAR 12

}

30 CANBus Networking Manual V2.0 July 8, 2019

Page 31

CANopen Message Types

RPDO Object Index-Sub Size Default Object Mapped

RPDO3 0x2005-13 S32 User VAR 13

0x2005-14 User VAR 14

RPDO4 0x2005-15 S32 User VAR 15

0x2005-16 User VAR 16

S32: signed 32-bit word

PDO Mapping

The Process Data Object (PDO) service allows exchanging one or several process variables in one single CAN message. The PDO mapping parameter describes which objects

in the CANopen object dictionary are transmitted by the sender. The PDO receiver uses

also a PDO mapping parameter, which specifies where to store the received process data

in the CANopen object dictionary. The PDO mapping parameter of the transmitter and

the sender may use different pointers (16-bit index and 8-bit sub-index) depending on the

CANopen profile.

In some simple devices, the user does not have the possibility to configure the PDO

mapping parameters. This is called static PDO mapping, but our controllers provide variable PDO mapping. This means the system designer can re-configure the default PDO

mapping or generate new PDOs. Normally, this is done in the NMT pre-operational state,

when the PDOs are disabled. Of course, the user can also reconfigure the PDO mapping

in the NMT operational state, but then it is necessary to avoid inconsistencies in the PDO

mapping on the producer and the consumer side. To avoid this, the PDO must not be produced until the entire reconfiguration is finished.

The CiA 301 application layer specification requires a dedicated re-mapping procedure:

1. “Destroy” the PDO by setting the valid bit to 1b of sub-index 01h of the PDO communication parameter.

2. Disable PDO mapping by setting the sub-index 00h of the PDO mapping parameter to

00h.

3. Modify PDO mapping by changing the values of the corresponding sub-indices of the

PDO mapping parameters.

4. Enable PDO mapping by setting the sub-index 00h to the number mapped process

data.

5. “Create” a PDO by setting the valid bit to 0b of sub-index 01h of the PDO communication parameter.

If the controller detects that the index and subindex of the mapped object does not exist

or the object cannot be mapped during step 3, the controller responds with the SDO abort

transfer service (abort code: 06020000h or 06040041h). If the controller detects that the

RPDO mapping is not valid or not possible during step 4, the controller responds with the

SDO abort transfer service (abort code: 06020000h or 06040042h).

In the following example, we will show how to remap TPDO1 (0x1800) to transfer the following:

• 0x2100

• 0x2100

• 0x210D

• 0x210F

: Motor amps for channel 1 (U16).

01

: Motor amps for channel 2 (U16).

02

: Internal voltage (U16).

01

: MCU temperature (U8).

01

CANBus Networking Manual 31

Page 32

CANopen Interface

In this example, we suppose that the controller has node-id 01.

1. Destroy TPDO1 by setting the invalid bit of COB-ID (0x180001):

23 00 18 01 81 01 00 C0

2. Disable TPDO1 mapping by setting number of entries mapping parameter to 00

(0x1A0000).

2F 00 1A 00 00 00 00 00

3. Modify TPDO1 mapping by changing (0x1A00

• 0x210001: Motor amps for channel 1 (U16).

23 00 1A 01 10 01 00 21

• 0x2100

23 00 1A 02 10 02 00 21

• 0x210D

23 00 1A 03 10 01 0D 21

• 0x210F

23 00 1A 04 08 01 0F 21

4. Enable TPDO1 mapping by setting number of entries mapping parameter to 04

((0x1A0000).

2F 00 1A 00 04 00 00 00

5. Create TPDO1 by setting the invalid bit of COB-ID to 0 (0x180001).

23 00 18 01 81 01 00 40

PDO Transmission Type

The transmission type of a PDO can be set via the second sub-index.

: Motor amps for channel 2 (U16).

02

: Internal voltage (U16).

01

: MCU temperature (U8).

01

01-0 2

):

(1)

0

The Transmit PDO is synchronous. Which specific SYNC Object

occurrence triggers the transmission is given in the device profile.

1 – 240 The Transmit PDO is synchronous. It is transmitted after every nth

SYNC Object within the Synchronous Window Length, where n is the

transmission type. For example, when using transmission type 34, the

PDO is transmitted after every 34th SYNC Object.

241 – 25

252

1(1

(1)

) Reserved.

The data for the PDO is updated on reception of a SYNC Object, but

the PDO is not transmitted. The PDO is only transmitted on reception

of a Remote Transmission Request.

(1)

253

The data for the PDO is updated and the PDO is transmitted on

reception of a Remote Transmission Request.

(2)

254

The conditions that cause the Transmit PDO to be transmitted are

manufacturer specific.

255 The Transmit PDO is asynchronous. The transmission is triggered at

defined send rate.

32 CANBus Networking Manual V2.0 July 8, 2019

Page 33

Object Dictionary

(1)

Not supported in Roboteq controllers.

(2)

In Roboteq controllers, it behaves exactly like value 255.

First it is necessary to distinguish between synchronous and asynchronous PDOs:

Asynchronous PDOs are event-controlled and represent the normal transmission type of

PDOs. For this, the values 255 or 254 are to be entered as PDO type.

Synchronous PDOs are only transmitted after prior reception of a synchronization message (Sync Object). PDO transmission is thus carried out synchronously in the entire network, more or less at the same time. But what is much more important is that all device

inputs must be sampled on the arrival of the sync object, so that a uniform snapshot of

the process results. With the next sync-message, the recorded data are then sent in the

synchronous PDOs. Therefore, there is a delay here corresponding to the cycle time of

the Sync message, as the consumers receive the process variables at the time of the previous Sync message. In output direction the synchronous PDOs received by a node only

become valid on arrival of the next Sync message.

In order that the bus is not blocked up by a large number of synchronous PDOs, which

are all sent with every Sync message, the values 1-240 of the cyclic synchronous PDO

type are used as dividers for the transmission interval. Accordingly, [18xxsub02] = 4

means that the synchronous PDO is only sent with every fourth Sync message.

Object Dictionary

The CANopen dictionary shown in this section is subject to change. The CANopen EDS

file can be downloaded from the roboteq web site.

The Object Dictionary given in the table below contains the runtime queries and runtime

commands that can be accessed with SDO/PDO messages during controller operation.

Communication Profile

Index Sub (hex) Entry Name Type Access PDO Command

0x1000 00 Device Type U32 RO No

0x10 01 00 Error Register U8 RO No

0x1008 00 Manufacturer Device Name STR CONST No

0x1009 00 Manufacturer Hardware Version STR CONST No

0x100A 00 Manufacturer Software Version STR CONST No

0x100C 00 Guard Time U16 RW No

0x100D 00 Life Time Factor U8 RW No

0x1016 01-04 Consumer Heartbeat Time U32 RW No

0x1017 00 Producer Heartbeat Time U16 RW No

0x1018 01 Identity Object – Vendor ID U32 CONST No

CANBus Networking Manual 33

Page 34

CANopen Interface

Runtime Commands

Index Sub (hex) Entry Name Type Access PDO Command

0x2000 01-mm

0x2001 01-mm

0x2002 01-mm

0x2003 01-ee

0x2004 01-mm

0x2005 01-vv

0x2006 01-mm

0x2007 01-mm

0x2008 00 Set All Digital Out bits U8 WO Yes DS

0x2009 00 Set Individual Digital Out bits U8 WO Yes D1

0x200A 00 Reset Individual Digital Out bits U8 WO Yes D0

0x200B 01-ee

0x200C 00 Emergency Shutdown U8 WO Yes EX

0x200D 00 Release Shutdown U8 WO Yes MG

0x200E 00 Stop in all modes U8 WO Yes MS

0x200F 01-mm

0x2010 01-mm

0x2011 01-mm

0x2012 01-mm

0x2013 01-mm

0x2014 01-mm

0x2015 01-bb

0x2016 01-rr

0x2017 00 Save Config to Flash U8 WO Yes EES

0x2018 00 Run MicroBasic Script U8 WO Yes R

0x201F 01-si

(1) mm: Maximum number of motors.

(2) ee: Maximum number of encoders.

(3) vv: Maximum number of integer variables.

(4) bb: Maximum number of boolean variables.

(5) rr: Maximum number of RC pulse output.

(6) si: Maximum number of SSI encoders.

(1)

(1)

(1)

(2)

(1)

(3)

(1)

(1)

(2)

(1)

(1)

(1)

(1)

(1)

(1)

(4)

(5)

(6)

Set Motor Command S32 WO Yes CANGO

Set Position S32 WO Yes P

Set Velocity S16 WO Yes S

Set Encoder Counter S32 WO Yes C

Set Brushless Counter S32 WO Yes CB

Set User Integer Variable S32 WO Yes VAR

Set Acceleration S32 WO Yes AC

Set Deceleration S32 WO Yes DC

Load Home Counter U8 WO Yes H

Set Pos Relative S32 WO Yes PR

Set Next Pos Absolute S32 WO Yes PX

Set Next Pos Relative S32 WO Yes PRX

Set Next Acceleration S32 WO Yes AX

Set Next Deceleration S32 WO Yes DX

Set Next Velocity S32 WO Yes SX

Set User Boolean Variable U32 WO Yes B

Set RC Pulse Out S32 WO Yes RS

Set Absolute SSI Counter S32 WO Yes CSS

Runtime Queries

Index Sub (hex) Entry Name Type Access PDO Command

0x2100 01-mm(1) Read Motor Amps S16 RO Ye s A

0x2101 01-mm(1) Read Actual Motor Command S16 RO Yes M

0x2102 01-mm(1) Read Applied Power Level S16 RO Ye s P

34 CANBus Networking Manual V2.0 July 8, 2019

Page 35

Object Dictionary

Index Sub (hex) Entry Name Type Access PDO Command

0x2103 01-ee(2) Read Encoder Motor Speed S32 RO Ye s S

0x2104 01-ee(2) Read Absolute Encoder Counter S32 RO Ye s C

0x2105 01-mm(1) Read Absolute Brushless S32 RO Ye s CB

0x2106 01-vv(3) Read User Integer Variable S32 RO Ye s VAR

0x2107 01-ee(2) Read Relative Encoder Motor Speed S16 RO Ye s SR

0x2108 01-ee(2) Read Encoder Count Relative S32 RO Ye s CR

0x2109 0-mm(1) Read Brushless Count Relative S32 RO Ye s BCR

0x210A 01-mm(1) Read BL Motor Speed in RPM S16 RO Ye s BS

0x210B 01-mm(1) Read Relative BL Motor Speed S 16 RO Yes BSR

0x210C 01-mm(1) Read Battery Amps S16 RO Ye s BA

0x210D 01 Read Internal Voltages U16 RO Ye s V

02 Read Internal Voltages (Battery) U16 RO Ye s V

03 Read Internal Voltages (5Vout) U16 RO Ye s V

0x210E 00 Read All Digital Inputs U32 RO Ye s D

0x210F 01-tt(5) + 1 Read MCU temperature (01) and

each transistor temperature (02,

03, …).

0x2110 01-mm(1) Read Feedback S16 RO Ye s F

0x2111 00 Read Status Flags U16 RO Ye s FS

0x2112 00 Read Fault Flags U16 RO Yes FF

0x2113 00 Read Current Digital Outputs U16 RO Yes DO

0x2114 01-mm(1) Read Closed Loop Error S32 RO Ye s E

0x2115 01-bb(4) Read User Boolean Variable U32 RO Ye s B

0x2116 01-mm(1) Read Internal Serial Command S32 RO Ye s CIS

0x2117 01-mm(1) Read Internal Analog Command S32 RO Ye s CIA

0x2118 01-mm(1) Read Internal Pulse Command S32 RO Ye s CIP

0x2119 00 Read Time U32 RO Yes TM

0x211A 01-kk(6) Read Spektrum Radio Capture U16 RO Ye s K

0x211B 01-mm(1) Destination Pos Reached Flag U8 RO Yes DR

0x211C 01-ma(7) Read MEMS Accelerometer S32 RO Ye s M

0x211D 01-mg(8) Read Magsensor Track Detect U8 RO Ye s MGD

0x211E 01-3×mg(8) Read Magsensor Track Position

(Left, Right, and Active Track)

0x211F 01-2×mg(8) Read Magsensor Markers (Left

and Right)

0x2120 01-mg(8) Read Magsensor Status U 16 RO Ye s MGS

0x2121 01-mg(8) Read Magsensor Gyroscope S16 RO Ye s MGY

0x2122 01-mm(1) Read Motor Status Flags U16 RO Ye s FM

0x2123 01-mm(1) Read Hall Sensor States U8 RO Ye s HS

0x2124 00 Read Lock Status U8 RO Ye s LK

S8 RO Ye s T

S16 RO Ye s MGT

U8 RO Yes MGM

CANBus Networking Manual 35

Page 36

CANopen Interface

Index Sub (hex) Entry Name Type Access PDO Command

0x2125 01-mm(1) Read Destination Tracking S32 RO Ye s TR

0x2132 01-mm(1) Read Rotor Angle S16 RO Ye s ANG

0x2133 00 Read Script Checksum U32 RO Ye s SCC

0x2134 00 Read Node Is Alive U8 RO Ye s ICL

0x2135 01-mm(1) Read FOC Angle Correction S16 RO Yes FC

0x2136 01-ii(9) Read AC Induction Slip S16 RO Yes SL

0x2137 01 Read Firmware Version U16 RO Yes FIN

02 Read Firmware Month U16 RO Yes FIN

03 Read Firmware Day U16 RO Ye s FIN

04 Read Firmware Year U16 RO Ye s FIN

0x2138 01-mg(8) Read MagSensor Cross Tape U8 RO Ye s MGX

0x213A 00 Read BMS Battery’s State of

Charge

0x213C 01-si(10) Read SSI Sensor Motor Speed S32 RO Ye s SS

0x213D 01-si(10) Read Relative SSI Sensor Motor

Speed

0x213E 01-si(10) Read SSI Absolute Counter S32 RO Ye s CSS

0x213F 01-si(10) Read SSI Relative Counter S32 RO Ye s CSR

0x2141 00 Read BMS State of Charge U8 RO Yes BMC

0x2142 00 Read BMS Status Flags U8 RO Ye s BMF

0x2143 00 Read BMS Operational State U8 RO Ye s BMS

0x2145 01- 13 Read Digital Inputs BOOL RO Yes DI

0x2146 01-di(11) Read Analog Inputs S16 RO Ye s AI

0x2147 01-di(11) Read Analog Inputs Converted S16 RO Ye s AIC

0x2148 01-pi(11) Read Pulse Inputs U 16 RO Ye s PI

0x2149 01-pi(11) Read Pulse Inputs Converted S16 RO Ye s PIC

0x214A 01-fs(11) Read FlowSensor S32 RO Ye s F LW

(1) mm: Maximum number of motors.

(2) ee: Maximum number of encoders.

(3) vv: Maximum number of integer variables.

(4) bb: Maximum number of boolean variables.

(5) tt: Maximum number of internal temperature sensors.

(6) kk: Maximum number of spectrum radio.

(7) ma: Maximum number of MEMS accelerometers.

(8) mg: Maximum number of magnetic sensors.

(9) ii: Maximum number of AC induction motors.

(10) si: Maximum number of SSI sensors.

(11) di: Maximum number of digital inputs.

(12) pi: Maximum number of pulse inputs.

(13) fs: Maximum number of flow sensors.

U8 RO Yes BSC

S16 RO Ye s SSR

36 CANBus Networking Manual V2.0 July 8, 2019

Page 37

Object Dictionary

DS402 Profile

Index Sub (hex) Entry Name Type Access PDO Command

0x6040 00 Control Word CH1 U16 RW Ye s CW

0x6041 00 Status Word CH1 U16 RO Ye s SW

0x6042 00 Target Velocity CH1 S16 RW Ye s S

0x6043 00 VL Velocity Demand CH1 S16 RO Ye s RMP

0x6044 00 VL Velocity Actual Value CH1 S16 RO Ye s F

0x6046 01 VL Velocity Min Amount CH1 U32 RW Ye s SPL

02 VL Velocity Max Amount CH1 U32 RW Ye s SPL

0x6048 01 Velocity Acceleration Delta Speed CH1 U32 RW Ye s SAC

02 Velocity Acceleration Delta Time CH1 U 16 RW Ye s SAC

0x6049 01 Velocity Deceleration Delta Speed CH1 U32 RW Ye s SDC

02 Velocity Acceleration Delta Time CH1 U 16 RW Ye s SDC

0x6060 00 Modes of Operation CH1 S8 RW Ye s ROM

0x6061 00 Modes of Operation Display CH1 S8 RO No AOM

0x6064 00 Position Actual Value CH1 S32 RO Ye s F

0x606C 00 Velocity Actual Value CH1 S32 RO Ye s F

0x6071 00 Target Torque CH1 S16 RW Ye s TC

0x6077 00 Torque Actual Value CH1 S16 RO Ye s TRQ

0x607A 00 Target Position CH1 S32 RW Ye s POS

0x6081 00 Profile Velocity CH1 U32 RW Ye s PSP

0x6083 00 Profile Acceleration CH1 U32 RW Ye s PAC

0x6084 00 Profile Deceleration CH1 U32 RW Ye s PDC

0x6087 00 Torque Slope CH1 U32 RW Ye s TSL

0x60FF 00 Target Profile Velocity CH1 U32 RW Ye s S

0x6502 00 Supported Drive Modes CH1 U32 CONST No SDM

0x67FE 00 Version Number CH1 U32 CONST No VNM

0x6840 00 Control Word CH2 U16 RW Ye s CW

0x6841 00 Status Word CH2 U16 RO Ye s SW

0x6842 00 Target Velocity CH2 S16 RW Ye s S

0x6843 00 VL Velocity Demand CH2 S16 RO Ye s RMP

0x6844 00 VL Velocity Actual Value CH2 S16 RO Ye s F

0x6046 01 VL Velocity Min Amount CH2 U32 RW Ye s SPL

02 VL Velocity Max Amount CH2 U32 RW Ye s SPL

0x6048 01 Velocity Acceleration Delta Speed CH2 U32 RW Ye s SAC

02 Velocity Acceleration Delta Time CH2 U 16 RW Ye s SAC

0x6049 01 Velocity Deceleration Delta Speed CH2 U32 RW Ye s SDC

02 Velocity Acceleration Delta Time CH2 U 16 RW Ye s SDC

0x6860 00 Modes of Operation CH2 S8 RW Ye s ROM

CANBus Networking Manual 37

Page 38

CANopen Interface

Index Sub (hex) Entry Name Type Access PDO Command

0x6861 00 Modes of Operation Display CH2 S8 RO No AOM

0x6864 00 Position Actual Value CH2 S32 RO Ye s F

0x686C 00 Velocity Actual Value CH2 S32 RO Ye s F

0x6871 00 Target Torque CH2 S16 RW Ye s TC

0x6877 00 Torque Actual Value CH2 S16 RO Ye s TRQ

0x687A 00 Target Position CH2 S32 RW Ye s POS

0x6881 00 Profile Velocity CH2 U32 RW Ye s PSP

0x6883 00 Profile Acceleration CH2 U32 RW Ye s PAC

0x6884 00 Profile Deceleration CH2 U32 RW Ye s PDC

0x6887 00 Torque Slope CH2 U32 RW Ye s TSL

0x68FF 00 Target Profile Velocity CH2 U32 RW Ye s S

0x6D02 00 Supported Drive Modes CH2 U32 CONST No SDM

0x6FFE 00 Version Number CH2 U32 CONST No VNM

0x7040 00 Control Word CH3 U16 RW Ye s CW

0x7041 00 Status Word CH3 U16 RO Ye s SW

0x7042 00 Target Velocity CH3 S16 RW Ye s S

0x7043 00 VL Velocity Demand CH3 S16 RO Ye s RMP

0x7044 00 VL Velocity Actual Value CH3 S16 RO Ye s F

0x6046 01 VL Velocity Min Amount CH3 U32 RW Ye s SPL

02 VL Velocity Max Amount CH3 U32 RW Ye s SPL

0x6048 01 Velocity Acceleration Delta Speed CH3 U32 RW Ye s SAC

02 Velocity Acceleration Delta Time CH3 U 16 RW Ye s SAC

0x6049 01 Velocity Deceleration Delta Speed CH3 U32 RW Ye s SDC

02 Velocity Acceleration Delta Time CH3 U 16 RW Ye s SDC

0x7060 00 Modes of Operation CH3 S8 RW Ye s ROM

0x7061 00 Modes of Operation Display CH3 S8 RO No AOM

0x7064 00 Position Actual Value CH3 S32 RO Ye s F

0x706C 00 Velocity Actual Value CH3 S32 RO Ye s F

0x7071 00 Target Torque CH3 S16 RW Ye s TC

0x7077 00 Torque Actual Value CH3 S16 RO Ye s TRQ

0x707A 00 Target Position CH3 S32 RW Ye s POS

0x7081 00 Profile Velocity CH3 U32 RW Ye s PSP

0x7083 00 Profile Acceleration CH3 U32 RW Ye s PAC

0x7084 00 Profile Deceleration CH3 U32 RW Ye s PDC

0x7087 00 Torque Slope CH3 U32 RW Ye s TSL

0x70FF 00 Target Profile Velocity CH3 U32 RW Ye s S

0x7502 00 Supported Drive Modes CH3 U32 CONST No SDM

0x77FE 00 Version Number CH3 U32 CONST No VNM

38 CANBus Networking Manual V2.0 July 8, 2019

Page 39

SDO Construction Details

SDO Construction Details

CANOpen SDO frames can easily be created manually and used to send commands

and queries to a Roboteq device. The directives below are a simplified description of the

CANOpen SDO mechanism. For more details please advise the CANOpen standard.

A CANOpen command/query towards a Roboteq device can be analyzed as shown below:

Payload

Byte0

Header DLC

0x600+nd 8 css n xx index subindex data

• nd is the destination node id.

• ccs is the Client Command Specifier, if 2 it is command if 4 it is query.

• n is the Number of bytes in the data part, which do not contain data

• xx not necessary for basic operation. For more details advise CANOpen standard.

• index is the object dictionary index of the data to be accessed

• subindex is the subindex of the object dictionary variable

• data contains the data to be uploaded.

Byte1-2 Byte 3 Bytes4-7bits 4-7 bits2-3 bits0-1

The Response from the roboteq device is as shown below:

Payload

Byte0

Header DLC

Byte1-2 Byte 3 Bytes4-7bits 4-7 bits2-3 bits0-1

0x580+nd 8 css n xx index subindex Data

• nd is the source node id.

• ccs is the Client Command Specifier, if 4 it is query response, 6 it is a successful

response to command, 8 is an error in message received.

• n is the Number of bytes in the data part, which do not contain data

• xx not necessary for the simplistic way. For more details advise CANOpen standard.

• index is the object dictionary index of the data to be accessed.

• subindex is the subindex of the object dictionary variable

• data contains the data to be uploaded. Applicable only if css=4.

SDO Example 1: Set Encoder Counter 2 (C) of node 1 value 10

• nd = 1, since the destination’s node id is 1.

• ccs = 2, since it is a command.

• n = 0 since all 4 bytes of the data are used (signed32).

• index = 0x2003 and subindex = 0x02 according to object dictionary.

CANBus Networking Manual 39

Page 40

CANopen Interface

Payload

Byte0

Header DLC

Byte1-2 Byte 3 Bytes4-7bits 4-7 bits2-3 bits0-1

0x600+1 8 2 0 0 0x2003 0x02 0x0A

601h 8 20 03 20 02 0A 00 00 00

The respective response will be:

Payload

Byte0

Header DLC

Byte1-2 Byte 3 Bytes4-7bits 4-7 bits2-3 bits0-1

0x580+1 8 6 0 0 0x2003 0x02 0x00

581h 8 60 03 20 02 00 00 00 00

SDO Example 2: Activate emergency shutdown (EX) for node 12

• nd = 12, since the destination’s node id is 12.

• ccs = 2, since it is a command.

• n = 3 since only one byte of the data is used (unsigned8).

• index = 0x200C and subindex = 0x00 according to object dictionary.

Payload

Byte0

Header DLC

0x600+12 8 2 3 0 0x200C 0x00 0x01

601Ch 8 2C 0C 20 00 01 00 00 00

Byte1-2 Byte 3 Bytes4-7bits 4-7 bits2-3 bits0-1

The respective response will be:

Payload

Byte0

Header DLC

Byte1-2 Byte 3 Bytes4-7bits 4-7 bits2-3 bits0-1

0x580+1 8 6 0 0 0x200C 0x00 0x00

58Ch 8 60 0C 20 00 00 00 00 00

SDO Example 3: Read Battery Volts (V) of node 1.

• nd = 1, since the destination’s node id is 1.

• ccs = 4, since it is a query.

• n = 2 since 2 bytes of the data are used (unsigned16).

• index = 0x210D and subindex = 0x02 according to object dictionary.

40 CANBus Networking Manual V2.0 July 8, 2019

Page 41

SDO Construction Details

Payload

Byte0

Header DLC

Byte1-2 Byte 3 Bytes4-7bits 4-7 bits2-3 bits0-1

0x600+1 8 4 2 0 0x210D 0x02 0x00

601h 8 48 0D 21 02 0A 00 00 00

The respective response will be:

• nd = 1, since the source node id is 1.

• ccs = 4, since it is a query response.

• n = 2 since 2 bytes of the data are used (unsigned16).

• index = 0x210D and subindex = 0x02 according to object dictionary.

• data = 0x190 = 400 = 40 Volts.

Payload

Byte0

Header DLC

Byte1-2 Byte 3 Bytes4-7bits 4-7 bits2-3 bits0-1

0x580+1 8 4 2 xx 0x210D 0x02 0x190

581h 8 48 0D 21 02 90 01 00 00

CANBus Networking Manual 41

Page 42

CANopen Interface

42 CANBus Networking Manual V2.0 July 8, 2019

Page 43

Abbreviations

SECTION 4

Abbreviations

C Constant

CiA CAN in Automation

FSA Finite State Automation

PDS Power Drive System

PP Profile Position Mode

PV Profile Velocity Mode

RO Read Only

RW Read Write

SDO Service Data Object

TQ Torque Mode

VL Velocity Mode

DS402 Implementation

on Roboteq Motor

Controllers

Introduction

This documentation will describe the implementation of CiA DS402 standard on Roboteq

motor controllers.

What is DS402

DS402 is an open standard, that is designed specifically for motion control. There are a

number of CANOpen SDOs with which one can control the motor by commanding the

motor controller.

CANBus Networking Manual 43

Page 44

CAN Networking on Roboteq Controllers

The standard describes all the required SDOs, as long as the actions the motor controller

should take upon receiving these SDOs. Additionally the standard describes a Finite State

Machine (FSA) which should run on motor controller.

Implementation

The implementation has been directed under standard version 4.1.0.

Index Range & Channel Selection

All the SDOs described in DS402 standard range from index 0x600 - 0x67FF. However

these are only for controlling one motor channel. For multi channel controllers the controller should be able to accept index ranges for the other channels as well. These index ranges are shifted ranges of the abovementioned one as shown below:

• 0x6000 - 0x67FF, for channel 1.

• 0x6800 - 0x6FFF, for channel 2.

• 0x7000 - 0x77FF, for channel 3.

There are Roboteq motor controllers with up to three channels available.

Modes of Operation

Roboteq Controllers support the following operation Modes:

A. Open Loop

B. Closed Loop Speed, controls Speed using Speed as feedback.

C. Closed Loop Speed Position, controls Speed using Position as feedback.

D. Closed Loop Count Position, controls Position.

E. Closed Loop Position Relative, controls Position within specific boundaries.