Page 1

AX2550

AX2850

Dual Channel

High Power

Digital Motor

Controller

User’s Manual

v1.9b, June 1, 2007

visit www.roboteq.com to download the latest revision of this manual

©Copyright 2003-2007 Roboteq, Inc.

Page 2

2 AX2550 Motor Controller User’s Manual Version 1.9b. June 1, 2007

Page 3

Revision History

Revision History

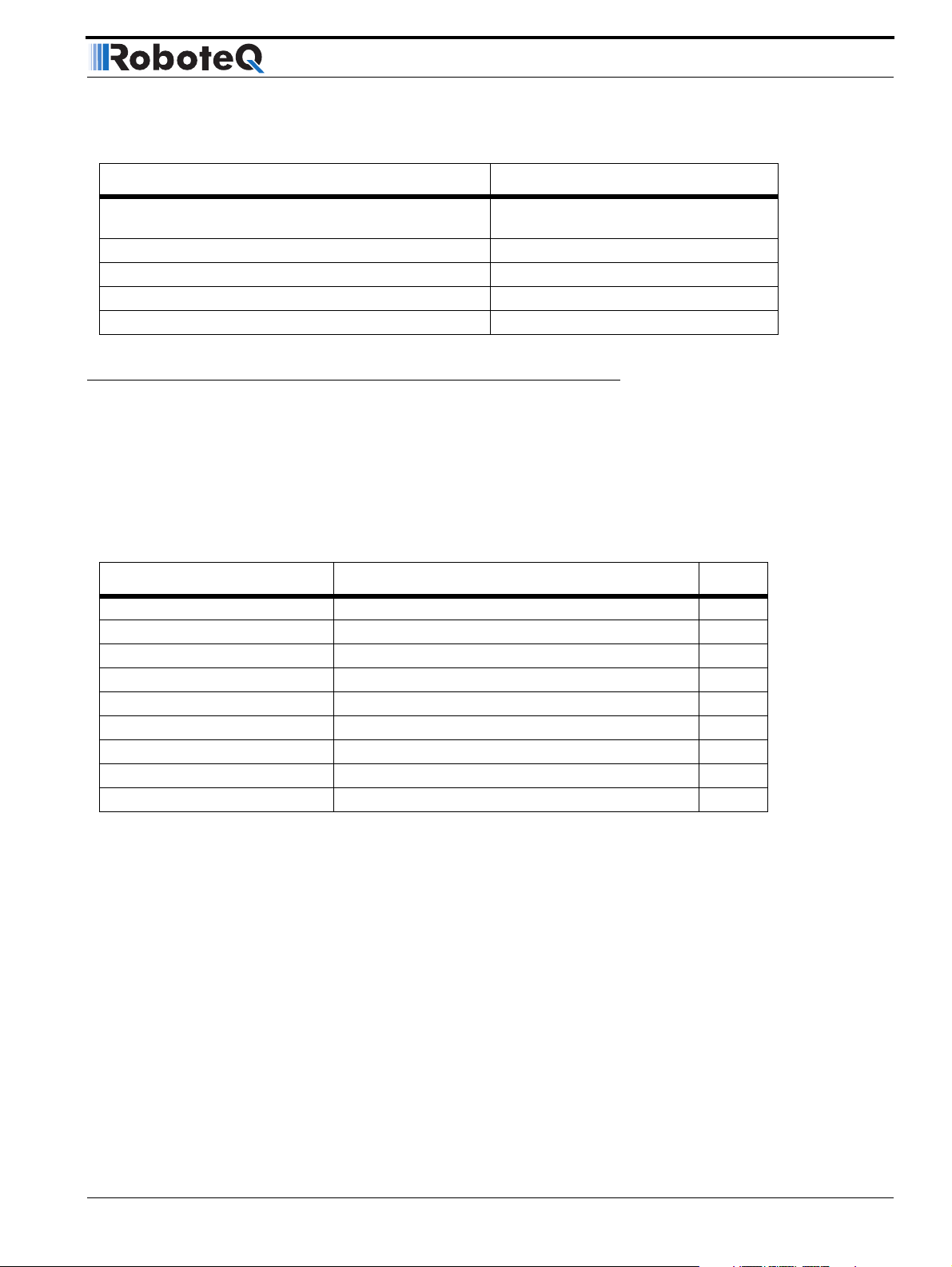

Date Version Changes

June 1, 2007 1.9b Added Output C active when Motors On

Fixed Encoder Limit Switches

Protection in case of Encoder failure in Closed Loop Speed

Added Short Circuit Protection (with supporting hardware)

Added Analog 3 and 4 Inputs (with supporting hardware)

Added Operating Mode Change on-the-fly

Changeable PWM frequency

Selectable polarity for Dead Man Switch

Modified Flashing Pattern

Separate PID Gains for Ch1 and C2, changeable on-the-fly

Miscellaneous additions and correction

Added Amps Calibration option

January 10, 2007 1.9 Changed Amps Limit Algorithm

Miscellaneous additions and correction

Console Mode in Roborun

March 7, 2005 1.7b Updated Encoder section.

February 1, 2005 1.7 Added Position mode support with Optical Encoder

Miscellaneous additions and corrections

April 17, 2004 1.6 Added Optical Encoder support

March 15, 2004 1.5 Added finer Amps limit settings

Enhanced Roborun utility

August 25, 2003 1.3 Added Closed Loop Speed mode

Added Data Logging support

Removed RC monitoring

August 15, 2003 1.2 Modified to cover AX2550 controller design

Changed Power Connection section

April 15, 2003 1.1 Added analog mode section

Added position mode section

Added RCRC monitoring feature

Updated Roborun utility section

Modified RS232 watchdog

March 15, 2003 1.0 Initial Release

The information contained in this manual is believed to be accurate and reliable. However,

it may contain errors that were not noticed at time of publication. User’s are expected to

perform their own product validation and not rely solely on data contained in this manual.

AX2550 Motor Controller User’s Manual 3

Page 4

4 AX2550 Motor Controller User’s Manual Version 1.9b. June 1, 2007

Page 5

Revision History 3

SECTION 1 Important Safety Warnings 13

This product is intended for use with rechargeable batteries 13

Do not Connect to a RC Radio with a Battery Attached 13

Beware of Motor Runaway in Improperly Closed Loop 13

SECTION 2 AX2550

Quick Start 15

What you will need 15

Locating the Switches, Wires and Connectors 15

Connecting to the Batteries and Motors 17

Connecting to the 15-pin Connector 18

Connecting the R/C Radio 19

Powering On the Controller 20

Button Operation 20

Default Controller Configuration 21

Connecting the controller to your PC using Roborun 22

Obtaining the Controller’s Software Revision Number 23

Exploring further 24

SECTION 3 AX2550 Motor Controller Overview 25

Product Description 25

Technical features 26

SECTION 4 Connecting Power and Motors to the Controller 29

Power Connections 29

Controller Power 30

Controller Powering Schemes 32

Powering the Controller from a single Battery 32

Powering the Controller Using a Main and Backup Battery 33

Connecting the Motors 34

Single Channel Operation 35

Converting the AX2550 to Single Channel 35

Power Fu ses 36

Wire Length Limits 37

Electrical Noise Reduction Techniques 37

Power Regeneration Considerations 37

Overvoltage Protection 38

Undervoltage Protection 38

Using the Controller with a Power Supply 39

AX2550 Motor Controller User’s Manual 5

Page 6

SECTION 5 General Operation 41

Basic Operation 41

Input Command Modes 41

Selecting the Motor Control Modes 42

Open Loop, Separate Speed Control 42

Open Loop, Mixed Speed Control 42

Closed Loop Speed Control 43

Close Loop Position Control 43

User Selected Current Limit Settings 44

Temperature-Based Current Limitation 44

Battery Current vs. Motor Current 45

Regeneration Current Limiting 46

Programmable Acceleration 47

Command Control Curves 48

Left / Right Tuning Adjustment 49

Activating Brake Release or Separate Motor Excitation 51

Emergency Shut Down Using Controller Switches 51

Emergency Stop using External Switch 51

Inverted Operation 52

Special Use of Accessory Digital Inputs 52

Using the Inputs to Activate the Buffered Output 52

Using the Inputs to turn Off/On the Power MOSFET

transistors 52

Self-Test Mode 53

SECTION 6 Connecting Sensors and Actuators to Input/Outputs 55

AX2550 Connections 55

AX2550’s Inputs and Outputs 57

I/O List and Pin Assignment 58

Connecting devices to Output C 59

Connecting Switches or Devices to Input E 60

Connecting Switches or Devices to Input F 61

Connecting Switches or Devices to EStop/Invert Input 62

Analog Inputs 63

Connecting Position Potentiometers to Analog Inputs 63

Connecting Tachometer to Analog Inputs 64

Connecting External Thermistor to Analog Inputs 66

Using the Analog Inputs to Monitor External Voltages 67

Connecting User Devices to Analog Inputs 67

Internal Voltage Monitoring Sensors 68

Internal Heatsink Temperature Sensors 68

Temperature Conversion C Source Code 69

6 AX2550 Motor Controller User’s Manual Version 1.9b. June 1, 2007

Page 7

SECTION 7 Installing, Connecting and Using the Encoder Module 71

Optical Incremental Encoders Overview 71

Recommended Encoder Types 72

Installing the Encoder Module 73

Connecting the Encoder 75

Cable Length and Noise Considerations 76

Motor - Encoder Polarity Matching 76

Voltage Levels, Thresholds and Limit Switches 76

Wiring Optional Limit Switches 78

Wiring Limit Switches Without Encoders 79

Effect of Limit Switches 79

Using the Encoder Module to Measure Distance 80

Using the Encoder to Measure Speed 80

Using the Encoder to Track Position 81

RS232 Communication with the Encoder Module 82

Encoder Testing and Setting Using the PC Utility 83

SECTION 8 Closed Loop Position Mode 85

Mode Description 85

Selecting the Position Mode 85

Position Sensor Selection 86

Sensor Mounting 86

Feedback Potentiometer wiring 87

Feedback Potentiometer wiring in RC or RS232 Mode 87

Feedback Potentiometer wiring in Analog Mode 88

Analog Feedback on Single Channel Controllers 89

Feedback Wiring in RC or RS232 Mode on Single Channel

Controllers 89

Feedback Wiring in Analog Mode on Single Channel

Controllers 89

Using Optical Encoders in Position Mode 90

Sensor and Motor Polarity 90

Encoder Error Detection and Protection 91

Adding Safety Limit Switches 91

Using Current Limiting as Protection 93

Control Loop Description 93

PID tuning in Position Mode 94

SECTION 9 Closed Loop Speed Mode 97

Mode Description 97

Selecting the Speed Mode 97

Using Optical Encoder for Speed Feedback (AX2850 only) 98

AX2550 Motor Controller User’s Manual 7

Page 8

Tachometer or Encoder Mounting 98

Tachometer wiring 98

Speed Sensor and Motor Polarity 99

Adjust Offset and Max Speed 100

Control Loop Description 100

PID tuning in Speed Mode 10 2

SECTION 10 Normal and

Fault Condition LED Messages 103

Use of the LED Display 103

Motor Direction Status 104

Fault Messages 105

No Control 105

Tem po ra r y F a u lt s 106

Permanent Faults 106

Self-Test Display 106

SECTION 11 R/C Operation 109

Mode Description 109

Selecting the R/C Input Mode 110

Connector I/O Pin Assignment (R/C Mode) 110

R/C Input Circuit Description 111

Supplied Cable Description 111

Powering the Radio from the controller 11 2

Connecting to a Separately Powered Radio 114

Operating the Controller in R/C mode 11 4

Reception Watchdog 115

R/C Transmitter/Receiver Quality Considerations 116

Joystick Deadband Programming 117

Command Control Curves 11 8

Left/Right Tuning Adjustment 118

Joystick Calibration 11 8

Automatic Joystick Calibration 119

Activating the Accessory Outputs 120

Data Logging in R/C Mode 121

SECTION 12 Analog Control and Operation 123

Mode Description 123

Connector I/O Pin Assignment (Analog Mode) 124

Connecting to a Voltage Source 125

Connecting a Potentiometer 125

Selecting the Potentiometer Value 126

8 AX2550 Motor Controller User’s Manual Version 1.9b. June 1, 2007

Page 9

Analog Deadband Adjustment 127

Power-On S afet y 128

Under Voltage Safety 128

Data Logging in Analog Mode 128

SECTION 13 Serial (RS-232) Controls and Operation 131

Use and benefits of RS232 131

Connector I/O Pin Assignment (RS232 Mode) 132

Cable configuration 133

Extending the RS232 Cable 133

Communication Settings 134

Establishing Manual Communication with a PC 134

RS232 Communication with the Encoder Module 135

Entering RS232 from R/C or Analog mode 136

Data Logging String in R/C or Analog mode 136

RS232 Mode if default 137

Commands Acknowledge and Error Messages 137

Character Echo 137

Command Acknowledgement 137

Command Error 137

Watchdog time-out 137

RS-232 Watchdog 138

Controller Commands and Queries 138

Set Motor Command Value 139

Set Accessory Output 139

Query Power Applied to Motors 140

Query Amps from Battery to each Motor Channel 140

Query Analog Inputs 140

Query Heatsink Temperatures 141

Query Battery Voltages 141

Query Digital Inputs 142

Reset Controller 142

Accessing & Changing Configuration Parameter in Flash 143

Apply Parameter Changes 143

Flash Configuration Parameters List 144

Input Control Mode 145

Motor Control Mode 145

Amps Limit 146

Acceleration 147

Input Switches Function 147

RC Joystick or Analog Deadband 148

Exponentiation on Channel 1 and Channel 2 148

Left/Right Adjust 149

Default Encoder Time Base 1 and 2 149

Default Encoder Distance Divider 150

AX2550 Motor Controller User’s Manual 9

Page 10

Default PID Gains 150

Joystick Min, Max and Center Values 150

Reading & Changing Operating Parameters at Runtime 151

Operating Modes Registers 152

Read/Change PID Values 152

PWM Frequency Register 153

Controller Status Register 153

Controller Identification Register 154

Current Amps Limit Registers 154

RS232 Encoder Command Set 155

Read Encoder Counter 155

Set/Reset Encoder Counters and Destination Registers 155

Read Speed 156

Read Distance 157

Read Speed/Distance 157

Read Encoder Limit Switch Status 157

Read / Modify Encoder Module Registers and Parameters 158

Register Description 160

Encoder Hardware ID code 160

Switch Status 160

Speed or Distance 1 or 2 160

Counter Read/Write Mailbox 161

Counter 1 and 2 161

Destination Register 1 and 2 161

Distance 1 and 2 162

Speed 1 and 2 162

Time Base 1 and 2 162

Encoder Threshold 162

Distance Divider 162

Counter Read Data Format 163

Encoder Testing and Setting Using the PC Utility 163

Automatic Switching from RS232 to RC Mode 165

Analog and R/C Modes Data Logging String Format 166

Data Logging Cables 166

Decimal to Hexadecimal Conversion Table 167

SECTION 14 Configuring the Controller using the Switches 171

Programming Methods 171

Programming using built-in Switches and Display 171

Entering Programming Mode 172

Changing parameters 173

The Special Case of Joystick Calibration 173

Restoring factory defaults 173

Exiting the Parameter Setting Mode 174

Programmable Parameters List 174

10 AX2550 Motor Controller User’s Manual Version 1.9b. June 1, 2007

Page 11

SECTION 15 Using the Roborun Configuration Utility 177

System Requirements 177

Downloading and Installing the Utility 177

Connecting the Controller to the PC 178

Roborun Frame, Tab and Menu Descriptions 179

Getting On-Screen Help 180

Loading, Changing Controller Parameters 181

Control Settings 181

Power Settings 182

Analog or R/C Specific Settings 183

Closed Loop Parameters 184

Encoder Setting and Testing 184

Encoder Module Parameters Setting 185

Exercising the Motors 186

Viewing Encoder Data 186

Running the Motors 186

Logging Data to Disk 189

Connecting a Joystick 190

Using the Console 191

Viewing and Logging Data in Analog and R/C Modes 192

Loading and Saving Profiles to Disk 192

Operating the AX2550 over a Wired or Wireless LAN 193

Updating the Controller’s Software 194

Updating the Encoder Software 195

Creating Customized Object Files 195

SECTION 16 Mechanical Specifications 197

Mechanical Dimensions 197

Mounting Considerations 198

Thermal Considerations 199

Attaching the Controller Directly to a Chassis 199

Wire Dimensions 199

Weight 200

AX2550 Motor Controller User’s Manual 11

Page 12

12 AX2550 Motor Controller User’s Manual Version 1.9b. June 1, 2007

Page 13

SECTION 1 Important Safety

Warnings

Read this Section First

The AX2550 is a high power electronics device. Serious damage, including fire,

may occur to the unit, motors, wiring and batteries as a result of its misuse.

Please review the User’s Manual for added precautions prior to applying full

battery or full load power.

This product is intended for use with rechargeable batteries

Unless special precautions are taken, damage to the controller and/or power supply

may occur if operated with a power supply alone. See“Power Regeneration Considerations” on page 37 of the Users Manual. Always keep the controller connected

to the Battery. Use the Power Control input to turn On/Off.

Do not Connect to a RC Radio with a Battery Attached

Without proper protection, a battery attached to an RC Radio may inject its voltage

directly inside the controller’s sensitive electronics. See

Beware of Motor Runaway in Improperly Closed Loop

Wiring or polarity errors between the feedback device and motor in position or

closed loop position mode may cause the controller to runaway with no possibility

to stop it until power is turned off.

AX2550 Motor Controller User’s Manual 13

Page 14

Important Safety Warnings

14 AX2550 Motor Controller User’s Manual Version 1.9b. June 1, 2007

Page 15

SECTION 2 AX2550

Quick Start

This section will give you the basic information needed to quickly install, setup and

run your AX2550 controller in a minimal configuration. The AX2850 is a version of

the AX2550 controller with the addition of Optical Encoder inputs.

What you will need

For a minimal installation, gather the following components:

• One AX2550 Controller and its provided cables

• 12V to 40V high capacity, high current battery

• One or two brushed DC motors

• One R/C to DB15 connector (provided)

• Miscellaneous wires, connectors, fuses and switch

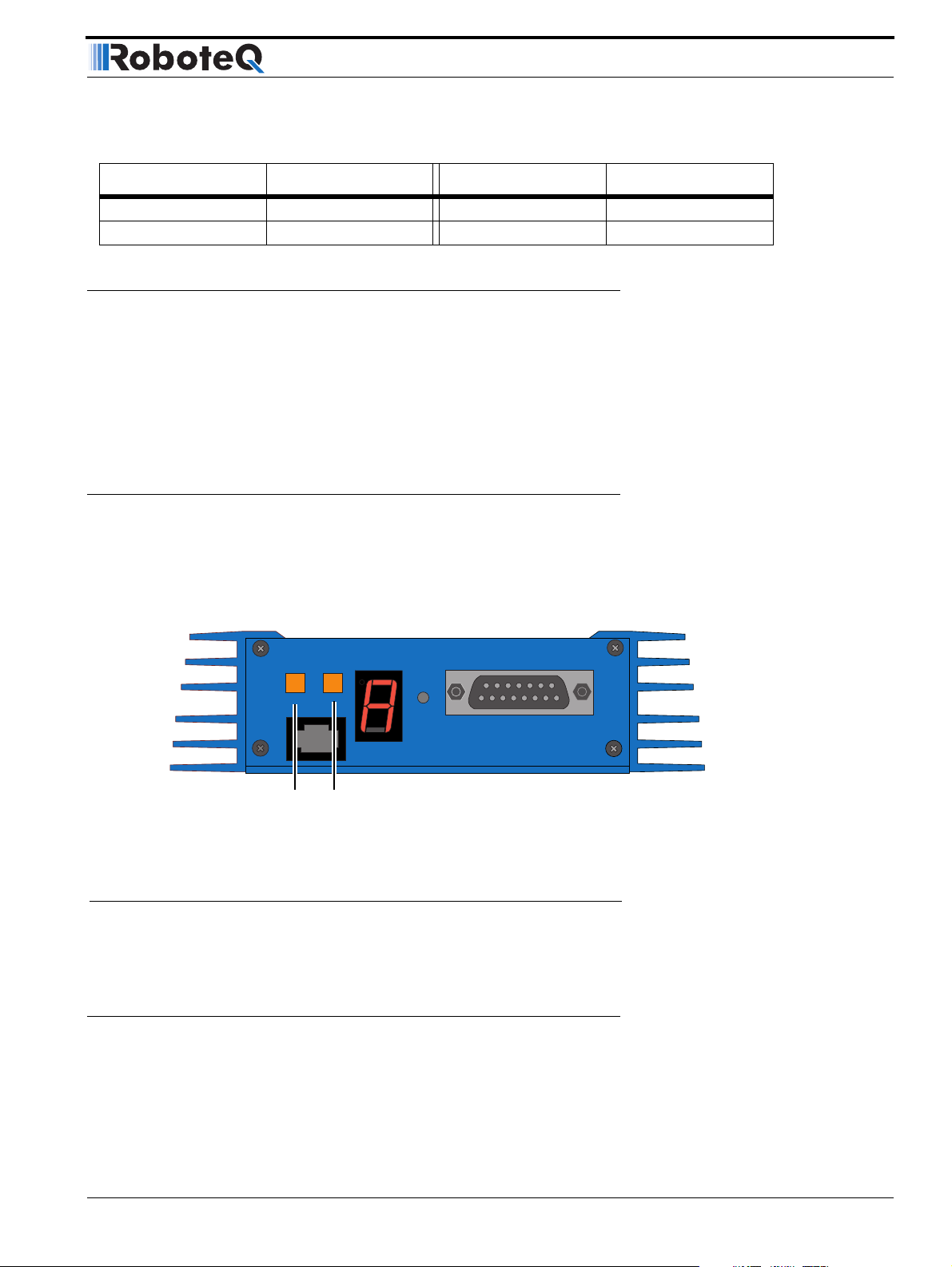

Locating the Switches, Wires and Connectors

Take a moment to familiarize yourself with the controller’s wires, switches and con-

nectors.

AX2550 Motor Controller User’s Manual 15

Page 16

AX2550 Quick Start

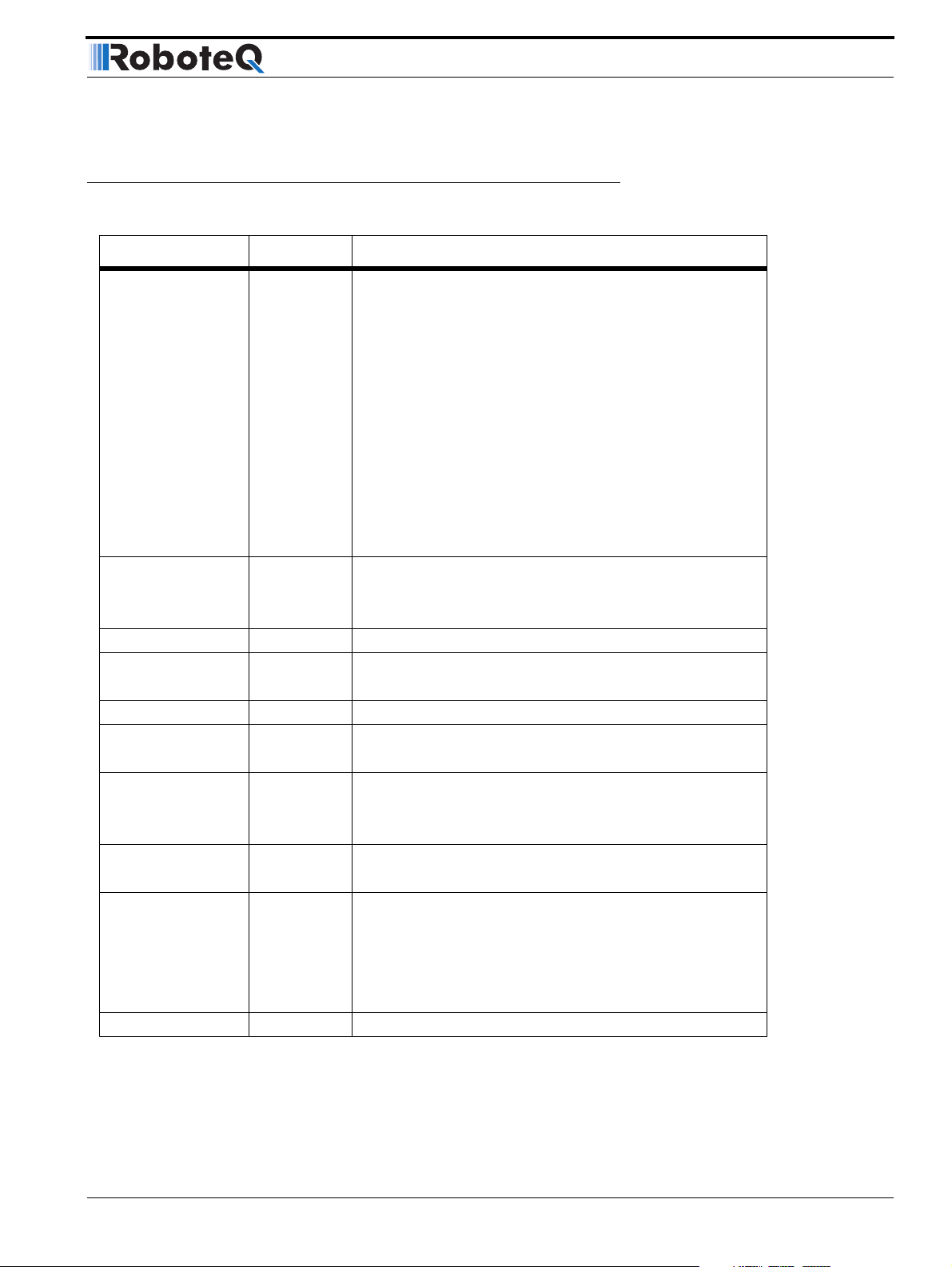

The front side (shown in Figure 1) contains the buttons and display needed to operate and

monitor the controller. The 15-pin connector provides the connection to the R/C radio, joystick or microcomputer, as well as connections to optional switches and sensors.

Program Set

Controller Configuration buttons

Connector to

Optical Encoders

(AX2850 only)

FIGURE 1. Front Controller Layout

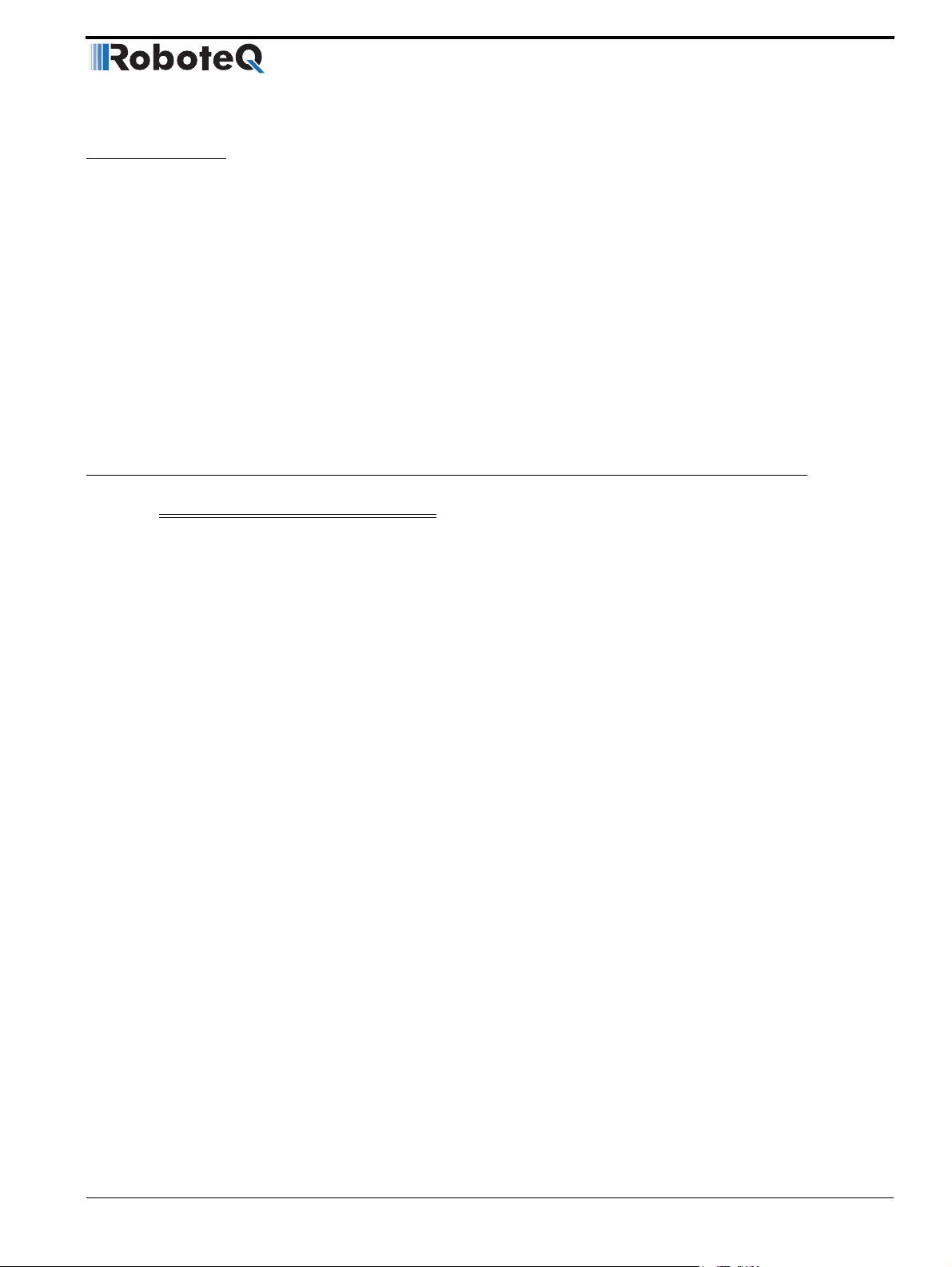

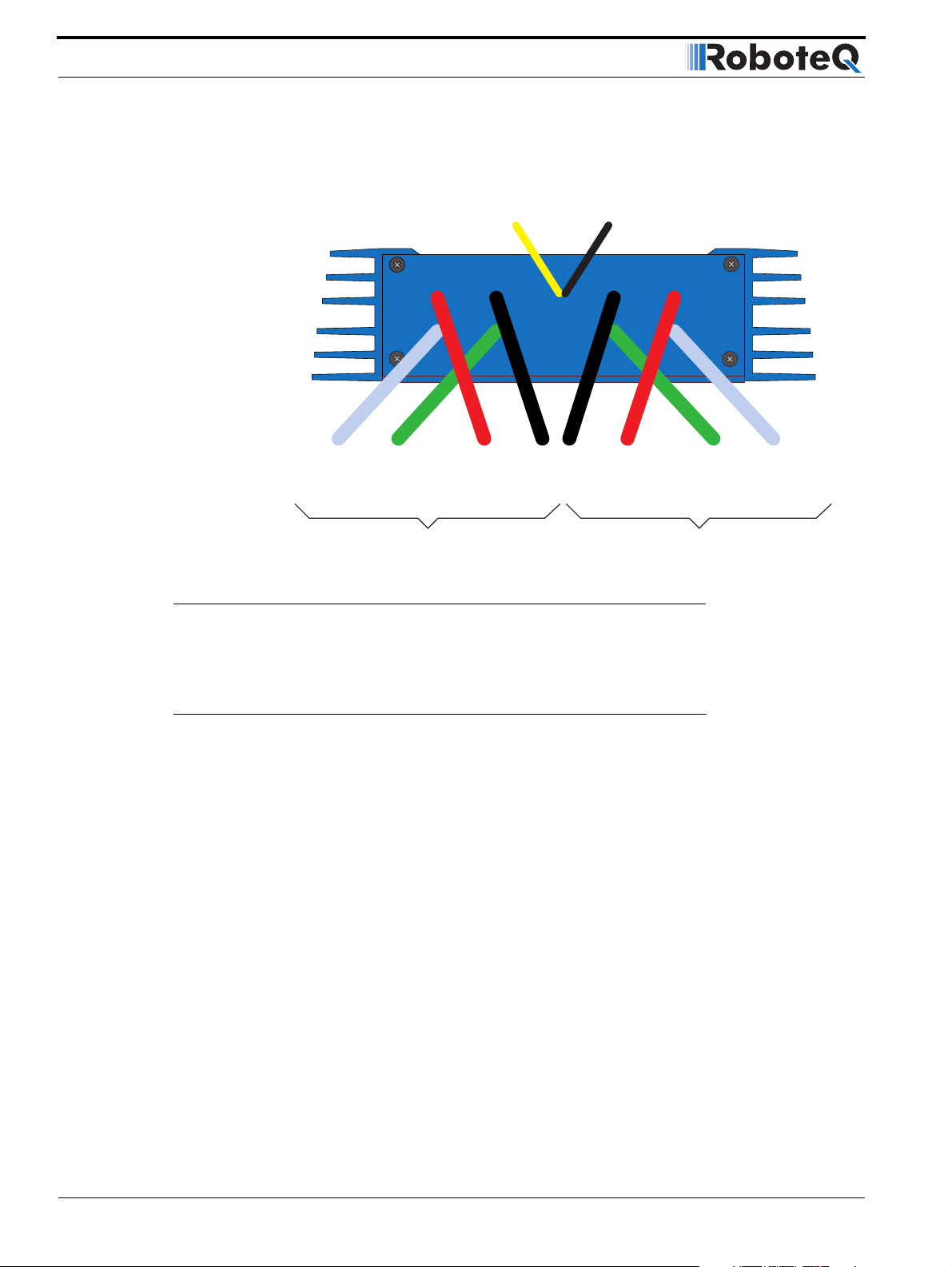

At the back of the controller (shown in the figure below) are located all the wires that must

be connected to the batteries and the motors.

Controller Power

Power Control

Yellow

Reset

Operating Status

and Program LED

Display

Ground (-)

Black

Connector to Receiver/Controls

and sensors

(top)

Motor (+)

White

Motor (-)

Green

Motor 1

12 to 40V (+)

Red

Ground (-)

Black

12 to 40V (+)

Red

Motor 2

Motor(+)

Yellow or

White

Motor (-)

Green

FIGURE 2. Rear Controller Layout

16 AX2550 Motor Controller User’s Manual Version 1.9b. June 1, 2007

Page 17

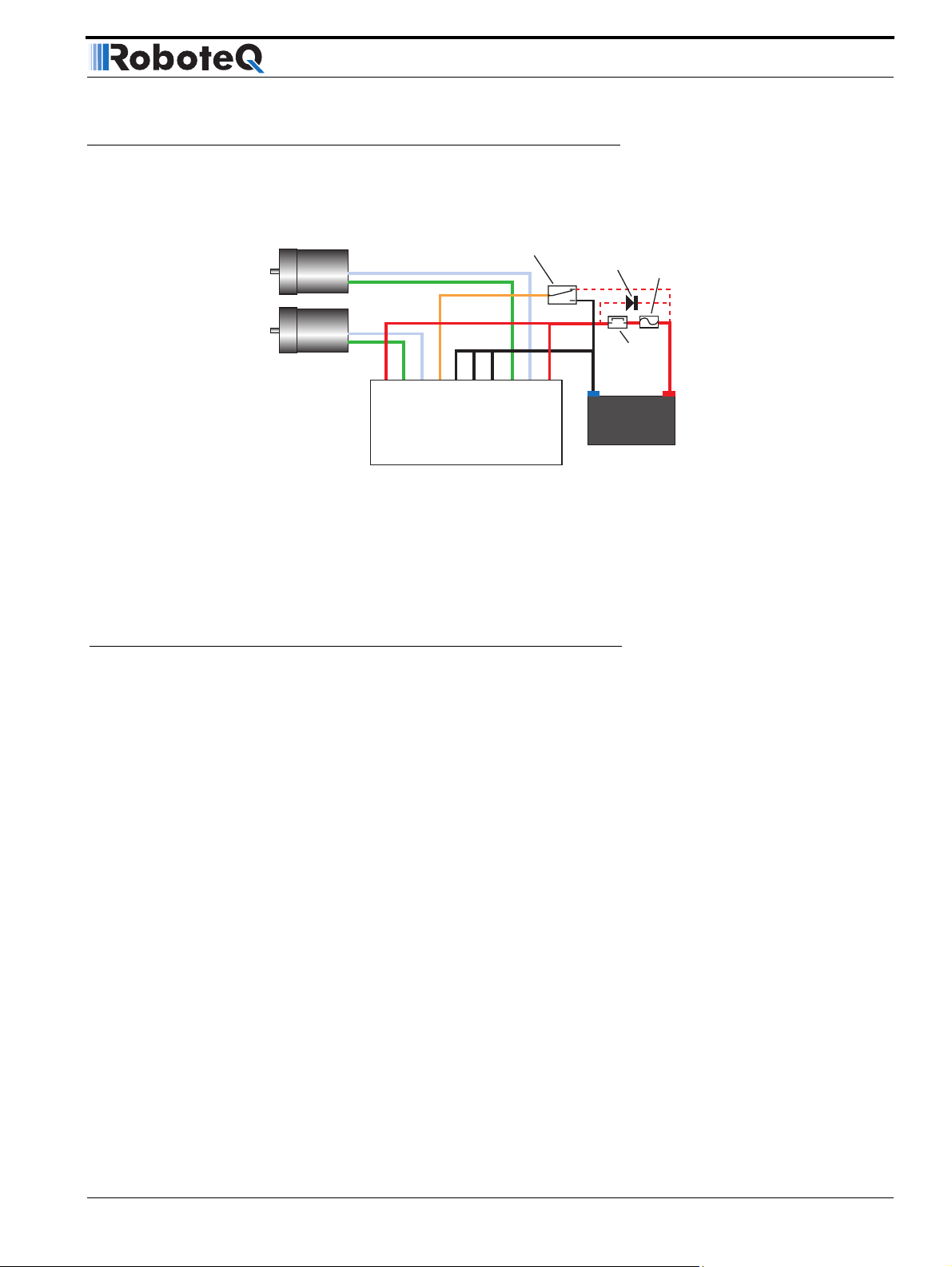

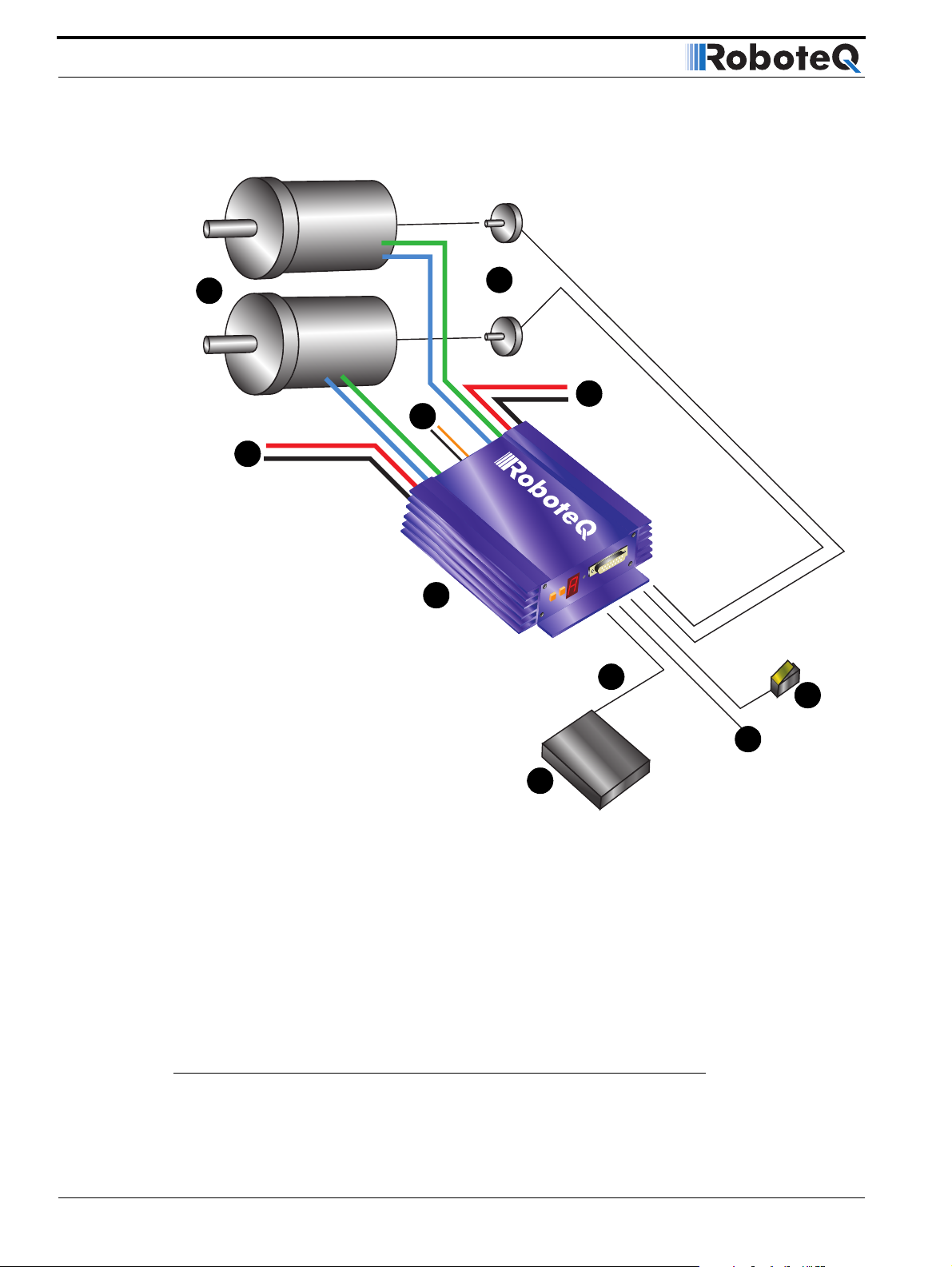

Connecting to the Batteries and Motors

Connecting to the Batteries and Motors

Connection to the batteries and motors is shown in the figure below and is done by connecting the set of wires coming out from the back of the controller.

Motor2

Motor1

Power switch

+

-

+

-

VMot

M1-

M1+

PwrCtrl

Controller

GND

GND

GND

M2-

M2+

VMot

Optional

Diode

On

Off

Optional

Emergency

Disconnect

12V to 24V

Motor Battery

Fuse

Notes:

- The Battery Power connection are doubled in order to provide the maximum current to the controller. If

only one motor is used, only one set of motor power cables needs to be connected.

- Typically, 1, 2 or 3 x 12V batteries are connected in series to reach 12, 24 or 36V respectively.

- The Power Control wire MUST be used to turn On and Off the controller.

FIGURE 3. AX2550 Electrical Power Wiring Diagram

1- Connect each motor to one of the two M+ and M- cables pairs. Make sure to respect

the polarity, otherwise the motor(s) may spin in the opposite direction than expected

2- Connect the two thick black wires to the minus (-) terminal of the battery that will be

used to power the motors. Connect the two thick red wires the two VMot terminals to the

plus (+) terminal of the battery. The motor battery may be of 12 to 40 Volts. There is no

need to insert a separate switch on Power cables, although one is suggested for Emergency disconnect. See “Controller Power” on page 30 for a detailed discussion and more

wiring options.

Avoid extending the length of wires from the battery to the controller as the added inductance may cause damage to the controller when operating at high currents. Try extending

the motor wires instead since the added inductance on the motor side of the controller is

not harmful.

The two red wires are connected to each other inside the controller. The same is true

for the black wires. You should wire each pair together as shown in the diagram

above.

3- The yellow Power Control wire and the thin black wire MUST be connected to Ground to

turn the Controller Off. For turning the controller On, even though the Power Control may

be left floating, whenever possible pull it to an unfused12V or higher voltage to keep the

controller logic solidly On. You may use a separate battery to keep the controller alive as

the main Motor battery discharges. Refer to the chapter “Connecting Power and Motors to

AX2550 Motor Controller User’s Manual 17

Page 18

AX2550 Quick Start

the Controller” on page 29 for more information about batteries and other connection

options.

Important Warning

Do not rely on cutting power to the controller for it to turn off if the Power Control is

left floating. If motors are spinning because the robot is pushed are pushed or

because of inertia, they will act as generators and will turn the controller, possibly in

an unsafe state. ALWAYS ground the Power Control wire to turn the controller Off

and keep it Off.

Important Warning

The controller includes large capacitors. When connecting the Motor Power Cables,

a spark will be generated at the connection point. This is a normal occurrence and

should be expected.

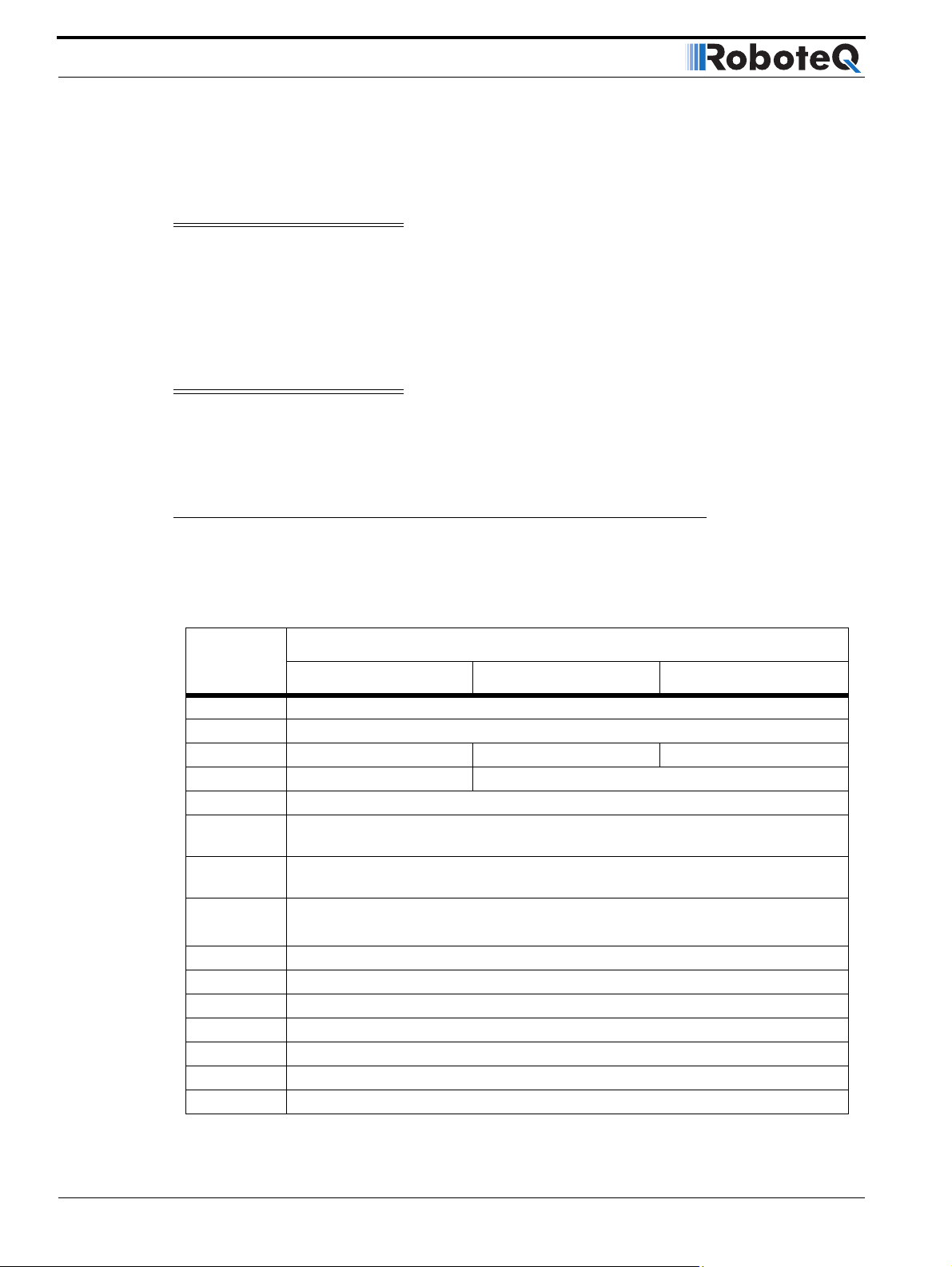

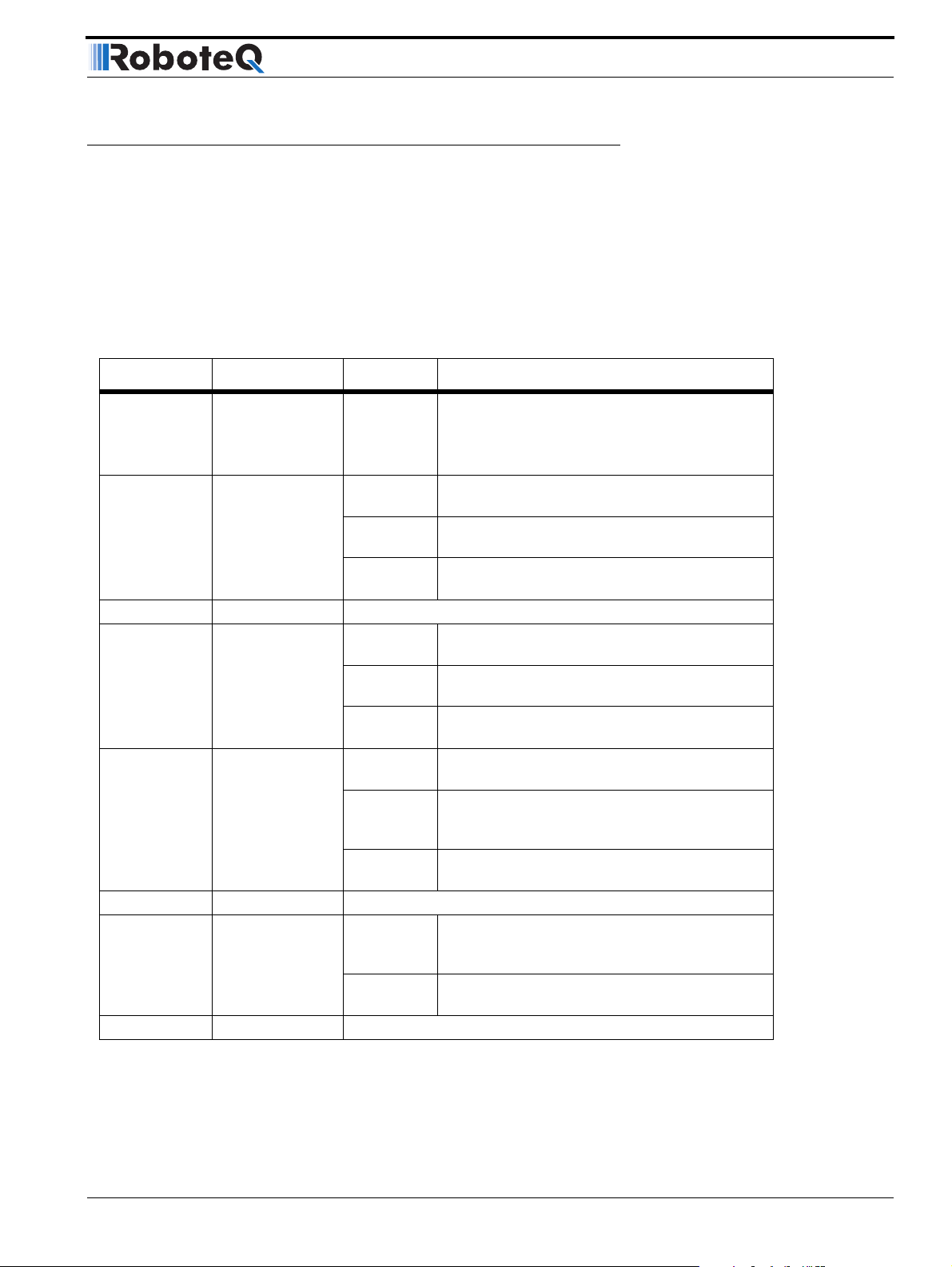

Connecting to the 15-pin Connector

The controller’s I/O are located on it’s standard 15-pin D-Sub Connector. The functions of

some pins varies depending on controller model and operating mode. Pin assignment is

found in the table below.

Signal

Pin

1 2A Digital Output C (same as pin 9)

2TxData

3 RC Ch1 RxData Unused

4 RC Ch 2 Digital Input F

5 Ground Out

6 Ground In

7 +5V In

8 Digital Input E (Not available when Encoder module is present)

9 2A Digital Output C (same as pin 1)

10 Analog Input 2

11 Analog Input 1

12 Analog Input 3 (on RevB hardware)

13 Ground Out

14 +5V Out (100mA max.)

15 Emergency Stop or Invert Switch input

RC Mode RS232 Mode Analog Mode

(Unused on RevB Hardware)

(Unused on RevB Hardware)

and Analog Input 4 (on RevB hardware only)

18 AX2550 Motor Controller User’s Manual Version 1.9b. June 1, 2007

Page 19

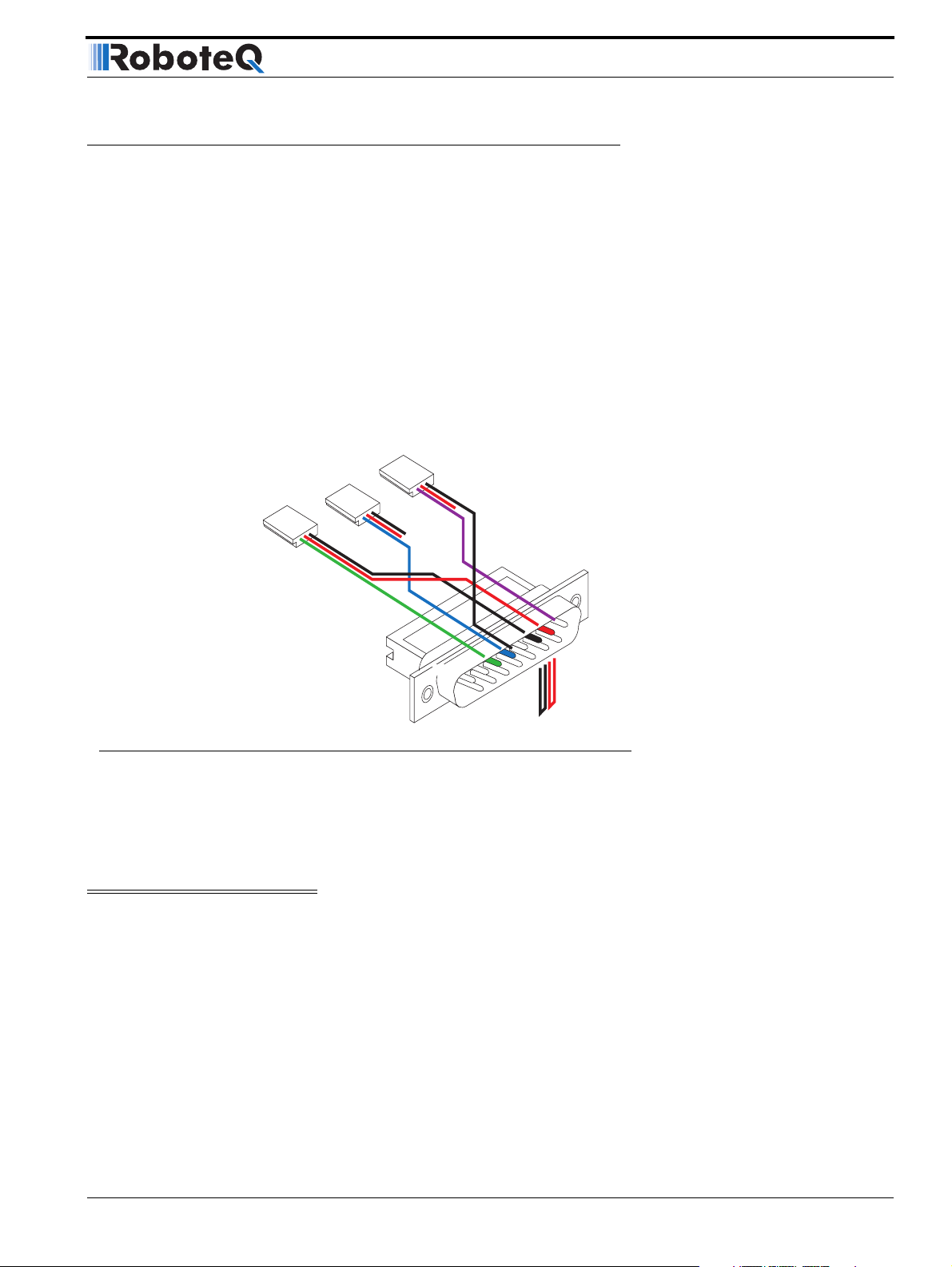

Connecting the R/C Radio

Connecting the R/C Radio

Connect the R/C adapter cables to the controller on one side and to two or three channels

on the R/C receiver on the other side. If present, the third channel is for activating the

accessory outputs and is optional.

When operating the controller in “Separate” mode, the wire labelled Ch1 controls Motor1,

and the wire labelled Ch2 controls Motor2.

When operating the controller in “Mixed” mode, Ch1 is used to set the robot’s speed and

direction, while Ch2 is used for steering.

See “R/C Operation” on page 109 of the User’s Manual for a more complete discussion on

R/C commands, calibration and other options.

Channel 3

Channel 2

Channel 1

Pin 1

15

FIGURE 4. R/C connector wiring for 3 channels and battery elimination (BEC)

This wiring - with the wire loop uncut - assumes that the R/C radio will be powered by the

AX2550 controller. Other wiring options are described in “R/C Operation” on page 109 of

the User’s Manual.

Important Warning

Do not connect a battery to the radio when the wire loop is uncut. The RC battery

voltage will flow directly into the controller and cause permanent damage if its voltage is higher than 5.5V.

3: Channel 1 Command Pulses

4: Channel 2 Command Pulses

6: Radio battery (-) Ground

7: Radio battery (+)

8: Channel 3 Command Pulses

8

9

Wire loop bringing power from

controller to RC radio

Connecting the optional channel 3 will enable you to turn on and off the accessory output.

See “Connecting Sensors and Actuators to Input/Outputs” on page 55 and “Activating the

Accessory Outputs” on page 120 of the User’s Manual.

AX2550 Motor Controller User’s Manual 19

Page 20

AX2550 Quick Start

Powering On the Controller

Important reminder: There is no On-Off switch on the controller. You must insert a switch

on the controller’s power wire as described in section“Connecting to the Batteries and

Motors” on page 17.

To power the controller, center the joystick and trims on the R/C transmitter. In Analog

mode, center the command potentiomenter or joystick.Then turn on the switch that you

have placed on the on the Power Control input.

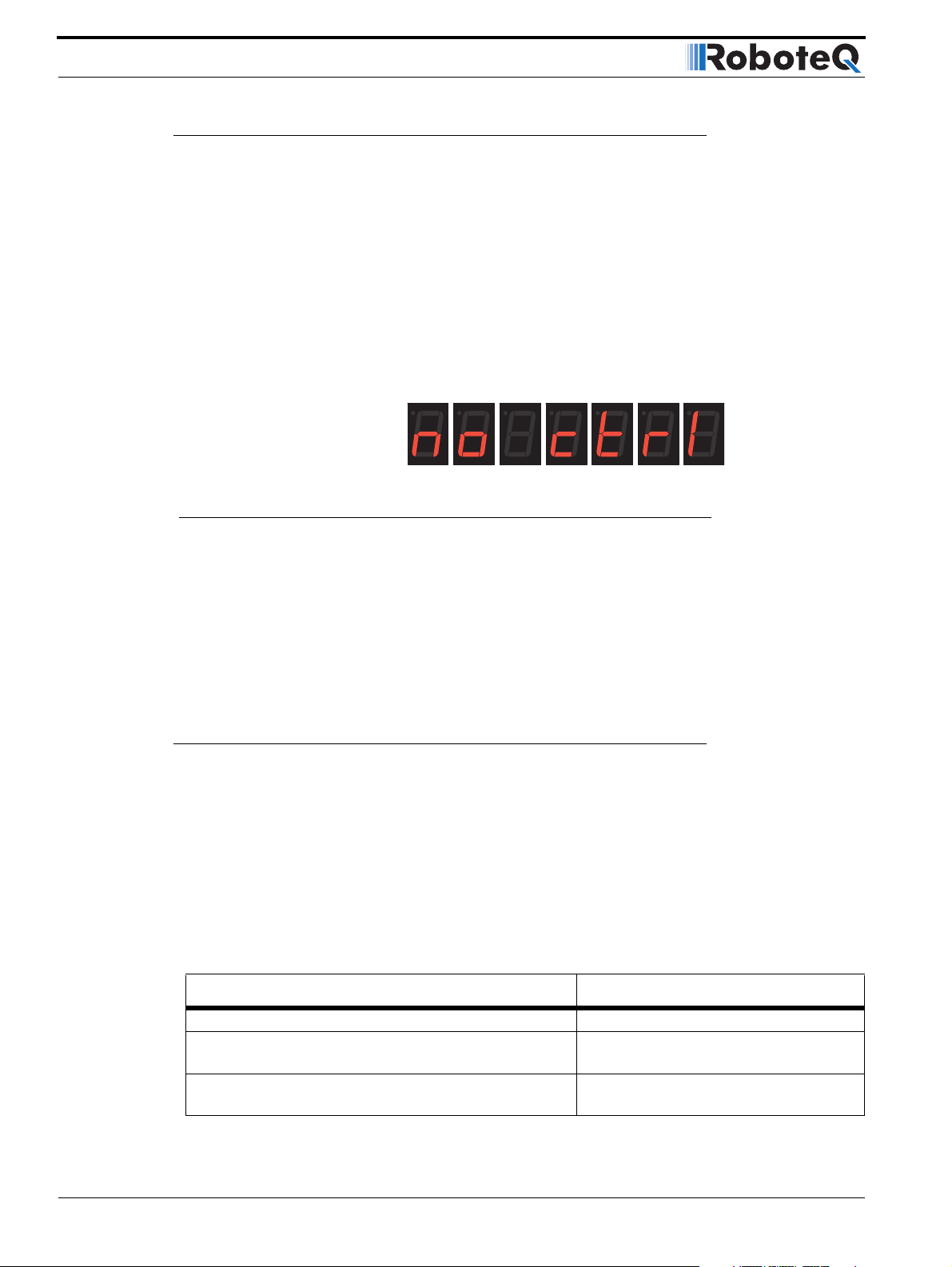

If the R/C transmitter and/or receiver is powered off, the display on the controller will alternate the letters spelling “no ctrl” to indicate that it is On but is not receiving a control signal.

FIGURE 5. “no control” scroll message indicates no valid R/C signal is present

Turn the R/C transmitter On. The “no ctrl” scrolling message will disappear and the display

will show steady patterns depending on the motor’s selected direction.

Move the joystick on the transmitter to activate the motors to the desired speed and direction.

See “R/C Operation” on page 109 of the User’s Manual for a detailed description of the

many features and options available in the R/C mode.

Button Operation

The AX2550 has three buttons: Set, Program and Reset. These buttons are not needed

for normal operation, as the controller is immediately operational upon power up.

The Reset button will restart the controller. This button is recessed and you will need a

paper clip to press it. Reset is also accomplished by turning the controller’s power Off and

back On.

The Set and Program buttons have the following functions depending how and when they

are pressed:

TABLE 1. AX2550 Buttons Function

Prog and Set button status Function

Press and hold Program alone during reset or power up Enter the Programming Mode.

Press and hold Set alone during reset of power up Enter Self-Test mode. See “Self-Test

Mode” on page 53 of the User’s Manual

Press and hold Program and Set together during reset or

power up

Reset configuration parameters to factory

default

20 AX2550 Motor Controller User’s Manual Version 1.9b. June 1, 2007

Page 21

Default Controller Configuration

TABLE 1. AX2550 Buttons Function

Prog and Set button status Function

Press Program while Programming Mode Accept previous parameter change and

select next parameter

Press Set while in Programming mode Change value of selected parameter

Press Program pressed alone during normal operation No effect

Press Set alone during normal operation No effect

Press Program and Set together during normal operation Emergency stop

Default Controller Configuration

Version 1.9b of the AX2550 software is configured with the factory defaults shown in the

table below. Although Roboteq strives to keep the same parameters and values from one

version to the next, changes may occur from one revision to the next. Make sure that you

have the matching manual and software versions. These may be retrieved from the

Roboteq web site. See “Configuring the Controller using the Switches” on page 171 of the

User Manual for a complete configuration parameter list and their possible values.

TABLE 2. AX2550 Default Settings

Parameter Default Values Letter

Input Command mode: (0) = R/C Radio mode I

Motor Control mode (0) = Separate A, B, speed control, open loop C

Amp limit (5) = 105A A

Acceleration (2) = medium-slow S

Input switch function (3) = no action U

Joystick Deadband (2) = 16% d

Exponentiation on channel 1 (0) = Linear (no exponentiation) E

Exponentiation on channel 2 (0) = Linear (no exponentiation) F

Left / Right Adjust (7) = no adjustment L

Any one of the parameters listed in Table 2, and others not listed, can easily be changed

either using the controller’s buttons or the PC with the Roboteq Configuration Utility. See

“Using the Roborun Configuration Utility” on page 177.

The example below shows how to use the buttons to select and change the Motor Control

mode from “separate” to “mixed”. See “Configuring the Controller using the Switches” on

page 171 of the User’s Manual for a complete list of all the AX2550’s parameters and their

meanings.

AX2550 Motor Controller User’s Manual 21

Page 22

AX2550 Quick Start

Press & hold Prog

Program mode entered

Press Prog to select

Press Set to select

next value for parameter

Press Prog to store change

and select next parameter

Restart

after 10 seconds

next parameter

Reset controller

to exit

Press and hold the Prog button for 10 seconds while

resetting or powering on the controller

After 10 seconds, the controller will enter the programming mode and flash alternatively the current parameter (I= Input Mode) and its value (0= R/C mode).

Press the Prog button to move to the next parameter

(C= Motor Control Mode) and its value (0= Separate)

Press the Set button to change the parameter’s value

(1= Combined)

Press the Prog button record the change and move to

the next parameter (A= Amps limit) and it’s value (2=

75A)

Press the Reset button or power off/on the control to

restart the controller using the new parameters.

Connecting the controller to your PC using Roborun

Connecting the controller to your PC is not necessary for basic R/C operation. However, it

is a very simple procedure that is useful for the following purposes:

• to Read and Set the programmable parameters with a user-friendly graphical inter-

face

• to obtain the controller’s software revision and date

• to send precise commands to the motors

• to read and plot real-time current consumption value

• Save captured parameters onto disk for later analysis

• to update the controller’s software

22 AX2550 Motor Controller User’s Manual Version 1.9b. June 1, 2007

Page 23

Obtaining the Controller’s Software Revision Number

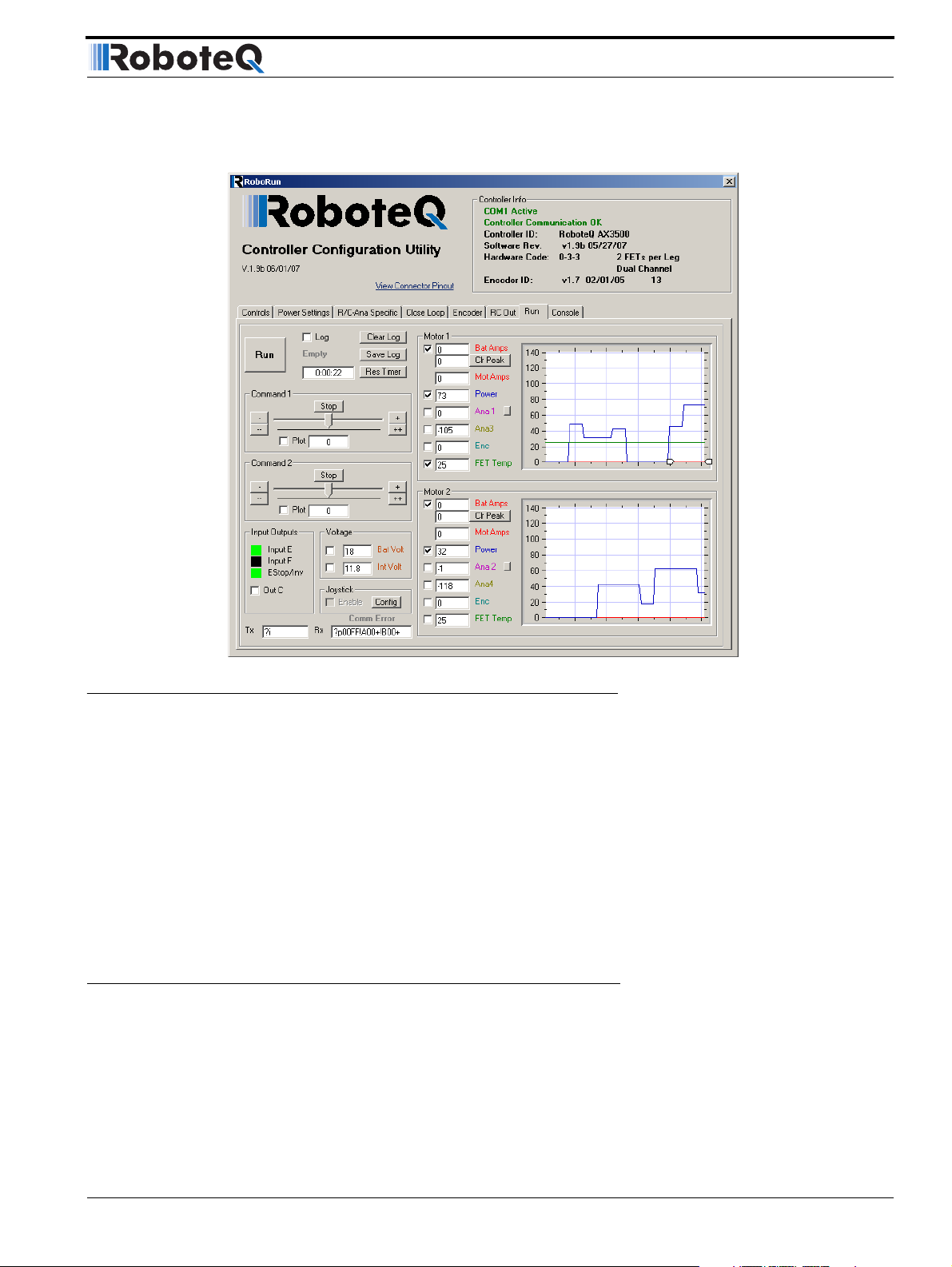

FIGURE 6. Roborun Utility screen layout

To connect the controller to your PC, use the provided cable. Connect the 15-pin connector

to the controller. Connect the 9-pin connector to your PC’s available port (typically COM1) -

use a USB to serial adapter if needed. Apply power to the controller to turn it on.

Load your CD or download the latest revision of Roborun software from

www.Roboteq.com, install it on your PC and launch the program. The software will automatically establish communication with the controller, retrieve the software revision number and present a series of buttons and tabs to enable its various possibilities.

The intuitive Graphical User Interface will let you view and change any of the controller’s

parameters. The “Run” tab will present a number of buttons, dials and charts that are used

for operating and monitoring the motors.

Obtaining the Controller’s Software Revision Number

One of the unique features of the AX2550 is the ability to easily update the controller’s

operating software with new revisions downloaded from Roboteq’s web site at

www.roboteq.com. This is useful for adding features and/or improving existing ones.

Each software version is identified with a unique number. Obtaining this number can be

done using the PC connection discussed previously.

AX2550 Motor Controller User’s Manual 23

Page 24

AX2550 Quick Start

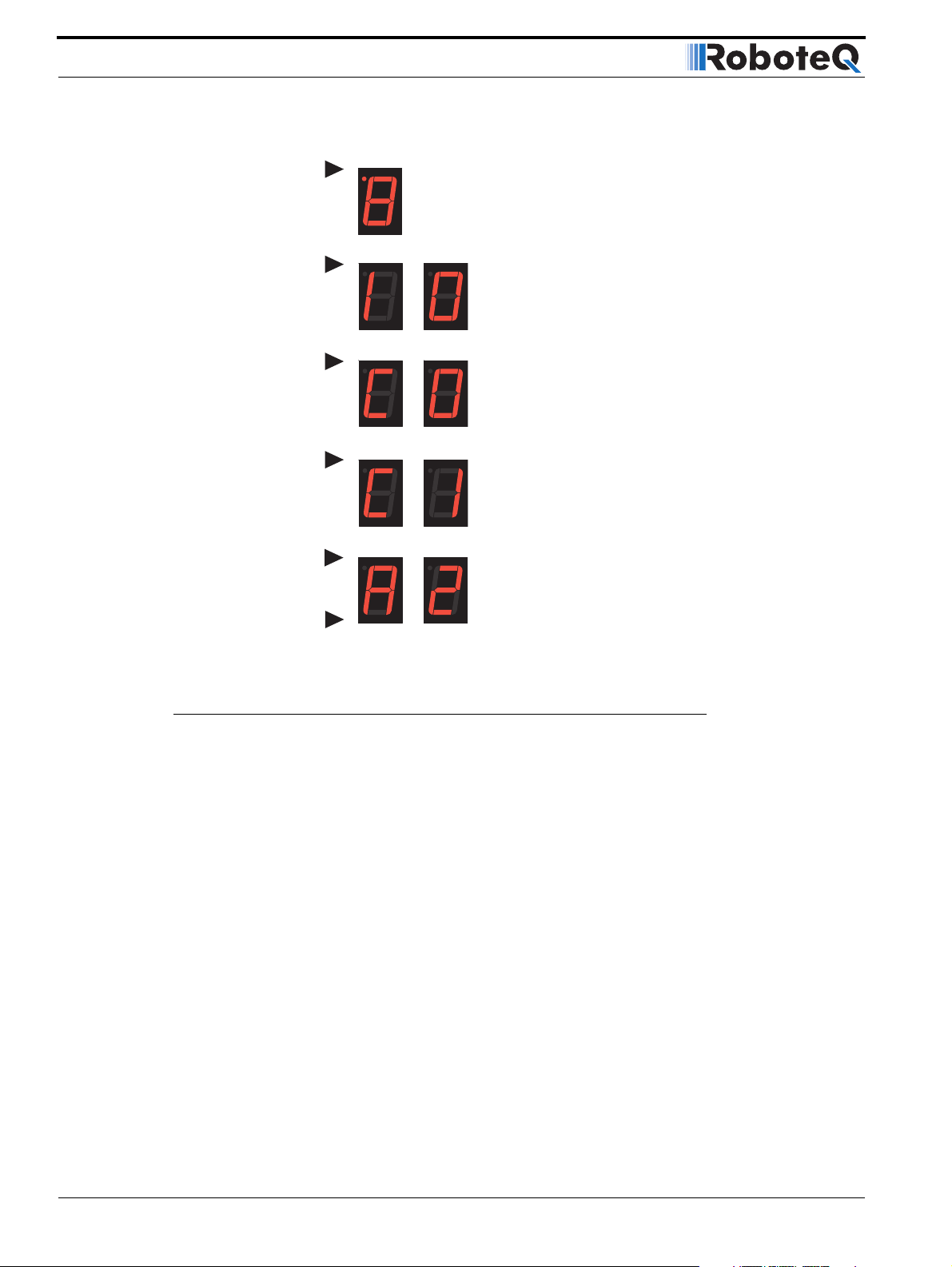

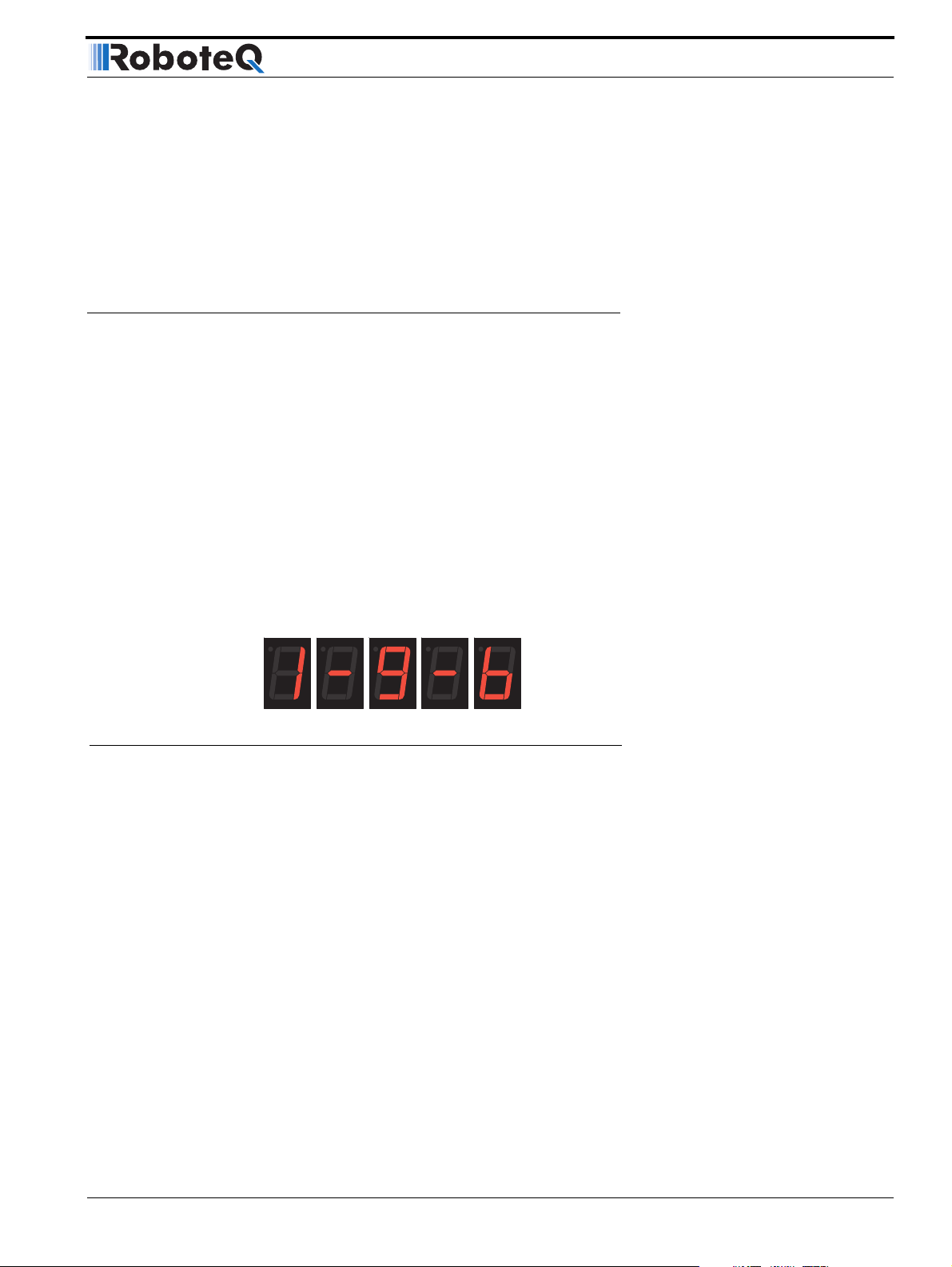

FIGURE 7. Press and hold “Set” to display version number and enter self-test

It is also possible to get the controller to display the software version number by following

these simple steps

• Disconnect the power from the motor batteries. Power the controller only via the

Power Control input.

• Press and hold the Set button while powering or resetting the controller.

The LED will display a sequence of two numerical digits and an optional letter separated by

dashes as shown in the examples below.

= Software version 1.9b

After these digits are displayed, the controller will attempt to power the motors as part of

the self test mode (see “Self-Test Mode” on page 53 of the User’s Manual for a more

detailed explanation). This is why the motor’s battery must be disconnected. After about

30 seconds, the software revision number will be displayed again the cycle will repeat.

You will need to reset, or power down and up, the controller to exit and resume normal

operation.

Now that you know your controller’s software version number, you will be able to see if a

new version is available for download and installation from Roboteq’s web site and which

features have been added or improved.

Installing new software is a simple and secure procedure, fully described in “Updating the

Controller’s Software” on page 194 of the User’s Manual.

Exploring further

By following this quick-start section, you should have managed to get your controller to

operate in its basic modes within minutes of unpacking.

Each of the features mentioned thus far has numerous options which are discussed further

in the complete User’s Manual, including:

• Self test mode

• Emergency stop condition

• Joystick calibration

• Using Inputs/Outputs

• Current limiting

• Closed Loop Operation

• Software updating

• and much more

24 AX2550 Motor Controller User’s Manual Version 1.9b. June 1, 2007

Page 25

SECTION 3 AX2550 Motor

Controller

Overview

Congratulations! By selecting Roboteq’s AX2550 you have empowered yourself

with the industry’s most versatile, powerful and programmable DC Motor Controller

for mobile robots. This manual will guide you step by step through its many possibilities.

Product Description

The AX2550 is a highly configurable, microcomputer-based, dual-channel digital

speed or position controller with built-in high power drivers. The controller is

designed to interface directly to high power DC motors in computer controlled or

remote controlled mobile robotics and automated vehicle applications.

The AX2550 controller can accept speed or position commands in a variety of ways:

pulse-width based control from a standard Radio Control receiver, Analog Voltage

commands, or RS-232 commands from a microcontroller or wireless modem.

The controller's two channels can be operated independently or can be combined to

set the forward/reverse direction and steering of a vehicle by coordinating the

motion on each side of the vehicle. In the speed control mode, the AX2550 can

operate in open loop or closed loop. In closed loop operation, actual speed measurements from tachometers or optical encoders are used to verify that the motor is

rotating at the desired speed and direction and to adjust the power to the motors

accordingly.

The AX2550 can also be configured to operate as a precision, high torque servo controller. When connected to a potentiometer coupled to the motor assembly, the

controller will command the motor to rotate up to a desired angular position.

Depending on the DC motor's power and gear ratio, the AX2550 can be used to

move or rotate steering columns or other physical objects with very high torque.

The AX2550 is fitted with many safety features ensuring a secure power-on start,

automatic stop in case of command loss, over current protection on both channels,

and overheat protection.

AX2550 Motor Controller User’s Manual 25

Page 26

AX2550 Motor Controller Overview

The motors are driven using high-efficiency Power MOSFET transistors controlled using

Pulse Width Modulation (PWM) at 16kHz. The AX2550 power stages can operate from 12

to 40VDC and can sustain up to 120A of controlled current, delivering up to 4,800W

(approximately 6 HP) of useful power to each motor.

The many programmable options of the AX2550 are easily configured using the supplied

PC utility or one-touch Program and Set buttons and a 7-segment LED display. Once programmed, the configuration data are stored in the controller's non-volatile memory, eliminating the need for cumbersome and unreliable jumpers.

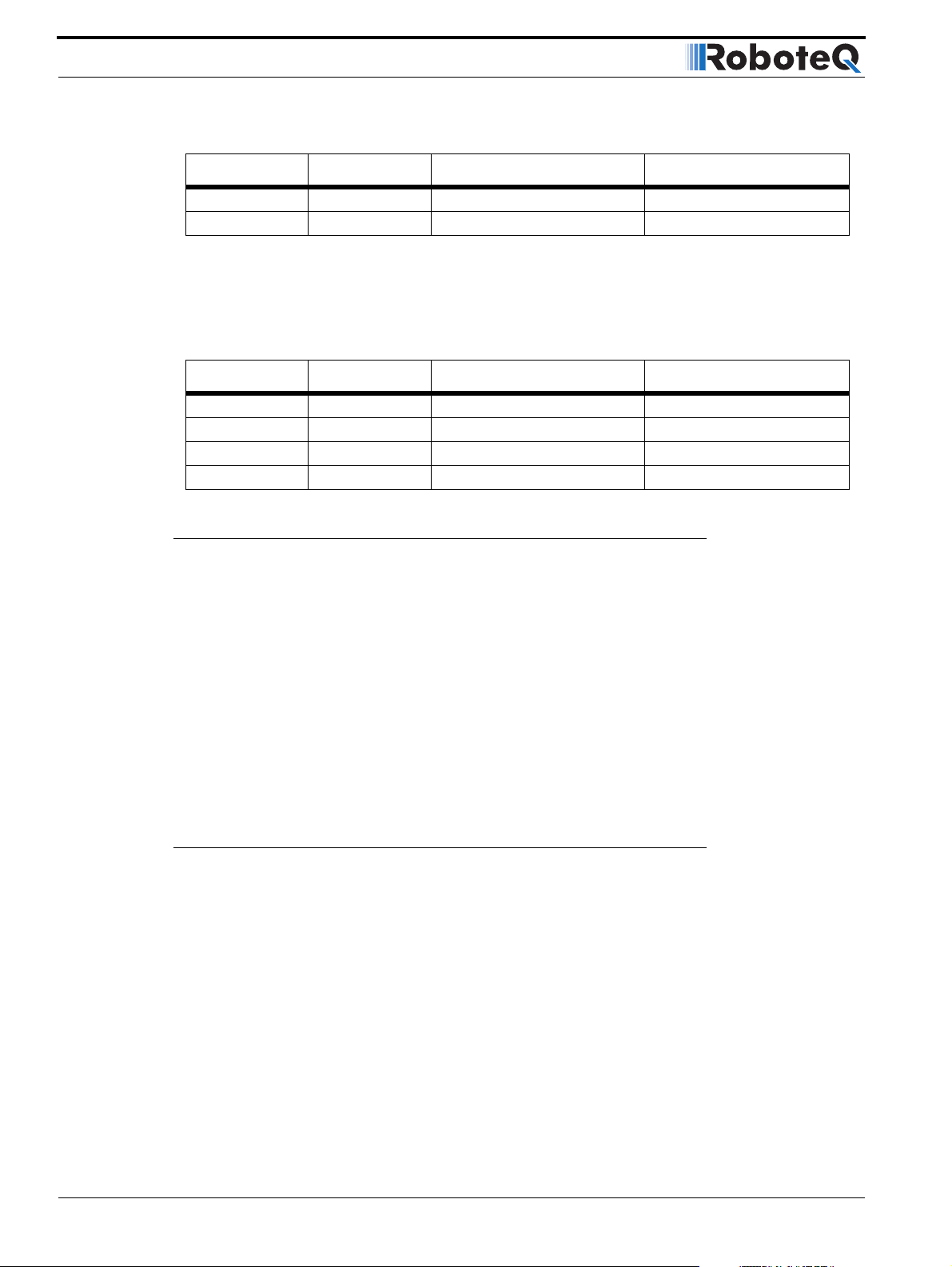

The AX2850 is the AX2550 controller fitted with a dual channel optical encoder input module. Optical Encoders allow precise motor speed and position measurement and enable

advance robotic applications.

Technical features

Fully Digital, Microcontroller-based Design

• Multiple operating modes

• Fully programmable using either built-in switches and 7 segment display or through

connection to a PC

• Non-volatile storage of user configurable settings

• Simple operation

• Software upgradable with new features

Multiple Command Modes

• Radio-Control Pulse-Width input

• Serial port (RS-232) input

• 0-5V Analog Command input

Multiple Advanced Motor Control Modes

• Independent operation on each channel

• Mixed control (sum and difference) for tank-like steering

• Open Loop or Closed Loop Speed mode

• Position control mode for building high power position servos

• Modes selectable independently for each channel

Automatic Joystick Command Corrections

• Joystick min, max and center calibration

• Selectable deadband width

• Selectable exponentiation factors for each joystick

• 3rd R/C channel input for accessory output activation (disabled when encoder mod-

ule present)

Special Function Inputs/Outputs

• 2 Analog inputs. Used as:

26 AX2550 Motor Controller User’s Manual Version 1.9b. June 1, 2007

Page 27

Technical features

• Tachometer inputs for closed loop speed control

• Potentiometer input for position (servo mode)

• Motor temperature sensor inputs

• External voltage sensors

• User defined purpose (RS232 mode only)

• 2 Extra analog inputs (on RevB hardware). Used as:

• Potentiometer input for position while in analog command mode

• User defined purpose (RS232 mode only)

• One Switch input configurable as

• Emergency stop command

• Reversing commands when running vehicle inverted

• General purpose digital input

• One general purpose 24V, 2A output for accessories

• Up to 2 general purpose digital inputs

Optical Encoder Inputs (AX2850 only)

• Inputs for two Quadrature Optical Encoders

• up to 250khz Encoder frequency per channel

• two 32-bit up-down counters

• Inputs may be shared with four optional limit switches per channel

Internal Sensors

• Voltage sensor for monitoring the main 12 to 40V battery system operation

• Voltage monitoring of internal 12V

• Temperature sensors on the heat sink of each power output stage

• Sensor information readable via RS232 port

Low Power Consumption

• On board DC/DC converter for single 12 to 40V battery system operation

• Optional backup power input for powering safely the controller if the motor batteries

are discharged

• Max 200mA at 12V or 100mA at 24V idle current consumption

• Power Control wire for turning On or Off the controller from external microcomputer

or switch

• No power consumed by output stage when motors are stopped

• Regulated 5V output for powering R/C radio. Eliminates the need for separate R/C

battery

High Efficiency Motor Power Outputs

• Two independent power output stages

• Optional Single Channel operation at double the current

• Dual H bridge for full forward/reverse operation

• Ultra-efficient 2.5mOhm (1.25mOhm on HE version) ON resistance (RDSon) MOS-

FET transistors

• Synchronous Rectification H Bridge

AX2550 Motor Controller User’s Manual 27

Page 28

AX2550 Motor Controller Overview

• 12 to 40 V operation

• High current 8 AWG cable sets for each power stages

• Temperature-based Automatic Current Limitation

• 120A up to 15 seconds (per channel)

• 100A up to 30 seconds

• 80A extended

• High current operation may be extended with forced cooling

• 250A peak Amps per channel

• 16kHz Pulse Width Modulation (PWM) output

• Auxiliary output for brake, clutch or armature excitation

• Heat sink extruded case

Advanced Safety Features

• Safe power on mode

• Optical isolation on R/C control inputs

• Automatic Power stage off in case of electrically or software induced program fail-

ure

• Overvoltage and Undervoltage protection

• Regeneration current limiting

• Watchdog for automatic motor shutdown in case of command loss (R/C and RS232

modes)

• Large, bright run/failure diagnostics on 7 segment LED display

• Programmable motor acceleration

• Built-in controller overheat sensor

• Emergency Stop input signal and button

Data Logging Capabilities

• 13 internal parameters, including battery voltage, captured R/C command, tempera-

ture and Amps accessible via RS232 port

• Data may be logged in a PC, PDA or microcomputer

Sturdy and Compact Mechanical Design

• Built from aluminum heat sink extrusion with mounting brackets

• Efficient heat sinking. Operates without a fan in most applications.

• 7” (178mm) long (excluding mounting brackets) by 5.5” wide (140mm) by 1.8”

(40mm) high

• -20o to +85o C case operating environment

• 3.3 lbs (1500g)

28 AX2550 Motor Controller User’s Manual Version 1.9b. June 1, 2007

Page 29

Power Connections

SECTION 4 Connecting

Power and

Motors to the

Controller

This section describes the AX2550 Controller’s connections to power sources and motors.

Important Warning

Please follow the instructions in this section very carefully. Any problem due to wiring errors may have very serious consequences and will not be covered by the product’s warranty.

Power Connections

The AX2550 has three Ground (black), two Vmot (red) power cables and a Power Control

wire (yellow). The power cables are located at the back end of the controller. The various

power cables are identified by their position, wire thickness and color: Red is positive (+),

black is negative or ground (-).

The power connections to the batteries and motors are shown in the figure below.

AX2550 Motor Controller User’s Manual 29

Page 30

Connecting Power and Motors to the Controller

Controller Power

Power Control

Ye l l o w

Motor (+)

White

Motor (-)

Green

12 to 40V (+)

Red

Motor 1

FIGURE 8. Controller rear plate and power wiring

Ground (-)

Black

Ground (-)

Black

12 to 40V (+)

Red

Motor(+)

Ye l l o w o r

Motor 2

(top)

Motor (-)

Green

White

Controller Power

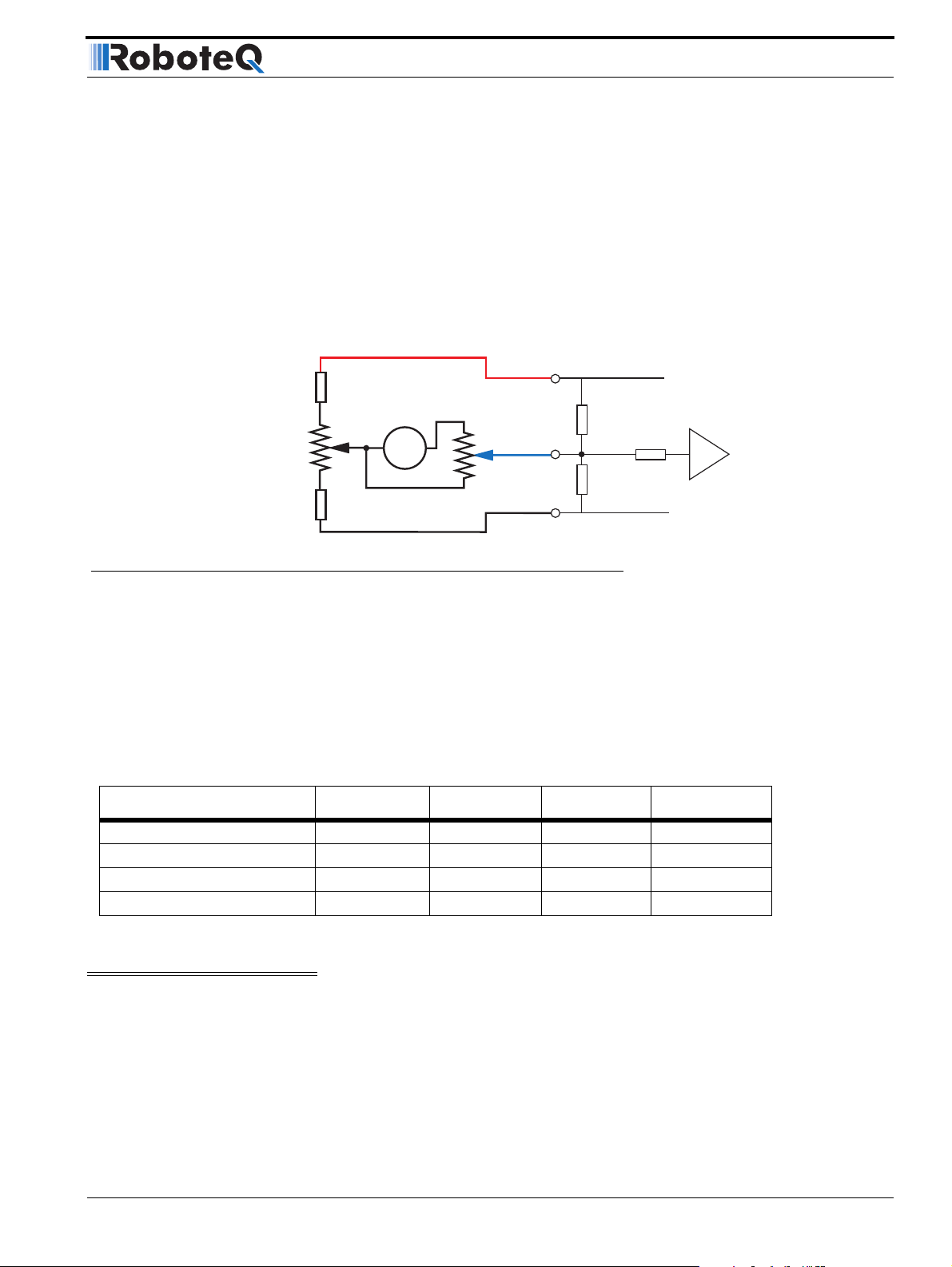

The AX2550 uses a flexible power supply scheme that is best described in Figure 9. In this

diagram, it can be seen that the power for the Controller’s microcomputer is separate from

this of the motor drivers. The microcomputer circuit is connected to a DC/DC converter

which takes power from either the Power Control wire or the VMot input. The diode circuit

is designed to automatically select one power source over the other, letting through the

source that is higher than the other.

30 AX2550 Motor Controller User’s Manual Version 1.9b. June 1, 2007

Page 31

Controller Power

Mot1(-)

Mot1(+)

Channel 1 MOSFET Power Stage

Microcomputer &

MOSFET Drivers

Channel 2 MOSFET Power Stage

9.5V min

13V max

DC/DC

ENABLE

10.5V min

40V max

FIGURE 9. Representation of the AX2550’s Internal Power Circuits

When powered only via the Power Control input, the controller will turn On but motors will

not be able to turn until power is also present on the VMot wires

The Power Control input also ser ves as the Enable signal for the DC/DC converter. When

floating or pulled to above 1V, the DC/DC converter is active and supplies the AX2550’s

microcomputer and drivers, thus turning it On. When the Power Control input is pulled to

Ground, the DC/DC converter is stopped and the controller is turned Off.

5Vmin

40V max

5Vmin

40V max

VBatt Vmot

GND

Power

Control

&Backup

GND

GND

VBatt Vmot

Mot2(+)

Mot2(-)

The yellow Power Control wire and the thin black wire MUST be connected to Ground to

turn the Controller Off. For turning the controller On, even though the Power Control may

be left floating, whenever possible pull it to an unfused12V or higher voltage to keep the

controller logic solidly On. You may use a separate battery to keep the controller alive as

the main Motor battery discharges.

The table below shows the state of the controller depending on the voltage applied to

Power Control and Vmot.

TABLE 3. Controller Status depending on Power Control and VMot

Power Control input is

connected to

And Main Battery

Voltage is Action

Ground Any Voltage from 0V to 40V Controller is Off

Floating 0V Controller is Off. Not Recom-

mended Off Configuration.

Floating Between 8V and 10.5V Controller Logic is On

Power Stage is Disabled (undervoltage condition)

Floating Between 10.5 and 40V Controller is On.

Power Stage is Active

AX2550 Motor Controller User’s Manual 31

Page 32

Connecting Power and Motors to the Controller

TABLE 3. Controller Status depending on Power Control and VMot

Power Control input is

connected to

And Main Battery

Voltage is Action

10.5V to 40V 0V Controller is On.

Power Stage is Off

10.5V to 40V 1V to 40V Controller is On.

Power Stage is Active

All 3 ground (-) are connected to each other inside the controller. The two main battery

wires are also connected to each other internally. However, you must never assume that

connecting one wire of a given battery potential will eliminate the need to connect the

other.

Controller Powering Schemes

Powering the Controller from a single Battery

The diagram on Figure 12 show how to wire the controller to a single battery circuit and

how to turn power On and Off.

Motor2

+

-

Power on/off

switch

Fuse

Optional

Emergency

Disconnect

12V to 24V

Motor Battery

Motor1

+

VMot

M1+

M1-

GND

VCon

Controller

GND

GND

M2-

M2+

VMot

Notes:

- The Battery Power connection are doubled in order to provide the maximum current to the controller. If

only one motor is used, only one set of motor power cables needs to be connected.

- Typically, 1, 2 or 3 x 12V batteries are connected in series to reach 12V, 24V or 36V respectively.

FIGURE 10. Powering the AX2550 from a single battery

Connect the two thick black wires to the minus (-) terminal of the battery that will be used

to power the motors. Connect the two thick red wires to the plus (+) terminal of the battery. The motor battery may be of 12 to 40 Volts.

32 AX2550 Motor Controller User’s Manual Version 1.9b. June 1, 2007

Page 33

There is no need to insert a separate switch on Power cables, although for safety reasons,

it is highly recommended that a way of quickly disconnecting the Motor Power be provided

in the case of loss of control and all of the AX2550 safety features fail to activate.

The two red wires are connected to each other inside the controller. The same is true

for the black wires. You should wire each pair together as shown in the diagram

above.

The yellow Power Control wire and the thin black wire MUST be connected to Ground to

turn the Controller Off. When the controller is Off, the output transistors are in the Off position and no power is drawn on VMot.

For turning the controller On, even though the Power Control may be left floating, whenever possible pull it to an unfused12V or higher voltage to keep the controller logic solidly

On. In applications where the motors could be made to run through external force (electric

vehicle going downhill, for example), and generate 40V or more, a diode should be placed

across the fuse & emergency switch to provide a path, under all circumstances, for the

regeneration current. See “Power Regeneration Considerations” on page 37.

Important Warning

Controller Powering Schemes

Do not rely on cutting power to the controller for it to turn off if the Power Control is

left floating. If motors are spinning because the robot is pushed are pushed or

because of inertia, they will act as generators and will turn the controller On, possibly in an unsafe state. ALWAYS ground the Power Control wire to turn the controller

Off and keep it Off.

Important Warning

On versions of the AX2550 with PCB revision number lower than 5.2, the backup

power supply applied on the Power Control wire must NEVER EXCEED 13V. Permanent damage may otherwise occur. The PCB revision number can be found on the

sticker on the case’s bottom.

Important Warning

Always connect the thick black wires to ground BEFORE connecting the red wires to

the battery. If the motors are activated while the connection to ground is done solely

via the thin black wire (or the ground wire in the RS232 cable), the ground wire will

overheat and/or melt .

Powering the Controller Using a Main and Backup Battery

In typical applications, the main motor batteries will get eventually weaker and the voltage

will drop below the level needed for the internal microcomputer to properly operate. For all

professional applications it is therefore recommended to add a separate 12V (to 40V)

power supply to ensure proper powering of the controller under any conditions. This dual

battery configuration is highly recommended in 12V systems.

AX2550 Motor Controller User’s Manual 33

Page 34

Connecting Power and Motors to the Controller

Motor2

Motor1

+

-

+

-

M1-

M1+

VMot

PwrCtrl

Controller

Power switch

GND

GND

GND

FIGURE 11. Powering the AX2550 with a Main and Backup Supply

Important Warning

Unless you can ensure a steady 12V to 40V voltage in all conditions, it is recommended that the battery used to power the controller’s electronics be separate from

the one used to power the motors. This is because it is very likely that the motor batteries will be subject to very large current loads which may cause the voltage to

eventually dip below 12V as the batteries’ charge drops. The separate backup power

supply should be connected to the Power Control input.

M2-

M2+

VMot

On

Off

12V to 40V

Motor Battery

12V to 40V

Backup Battery

Connecting the Motors

Connecting the motors is simply done by connecting each motor terminal to the M1+

(M2+) and M1- (M2-) wires. Which motor terminal goes to which of the + or - controller

output is typically determined empirically.

After connecting the motors, apply a minimal amount of power using the Roborun PC utility with the controller configured in Open Loop speed mode. Verify that the motor spins in

the desired direction. Immediately stop and swap the motor wires if not.

In Closed Loop Speed or Position mode, beware that the motor polarity must match this of

the feedback. If it does not, the motors will runaway with no possibility to stop other than

switching Off the power. The polarity of the Motor or off the feedback device may need to

be changed.

Important Warning

Make sure that your motors have their wires isolated from the motor casing. Some

motors, particularly automotive parts, use only one wire, with the other connected

to the motor’s frame.

34 AX2550 Motor Controller User’s Manual Version 1.9b. June 1, 2007

Page 35

Single Channel Operation

If you are using this type of motor, make sure that it is mounted on isolators and that

its casing will not cause a short circuit with other motors and circuits which may

also be inadvertently connected to the same metal chassis.

Single Channel Operation

The AX2550’s two channel outputs can be paralleled as shown in the figure below so that

they can drive a single load with twice the power. To perform in this manner, the controller’s Power Transistor that are switching in each channel must be perfectly synchronized.

Without this synchronization, the current will flow from one channel to the other and cause

the destruction of the controller.

The controller may be ordered with the -SC (Single Channel) suffix. This version incorporates a hardware setting inside the controller which ensures that both channels switch in a

synchronized manner and respond to commands sent to channel 1.

Warning:

Use this wiring only with

+

-

-SC versions (Single

Channel) of the controller

VMot

FIGURE 12. Wiring for Single Channel Operation

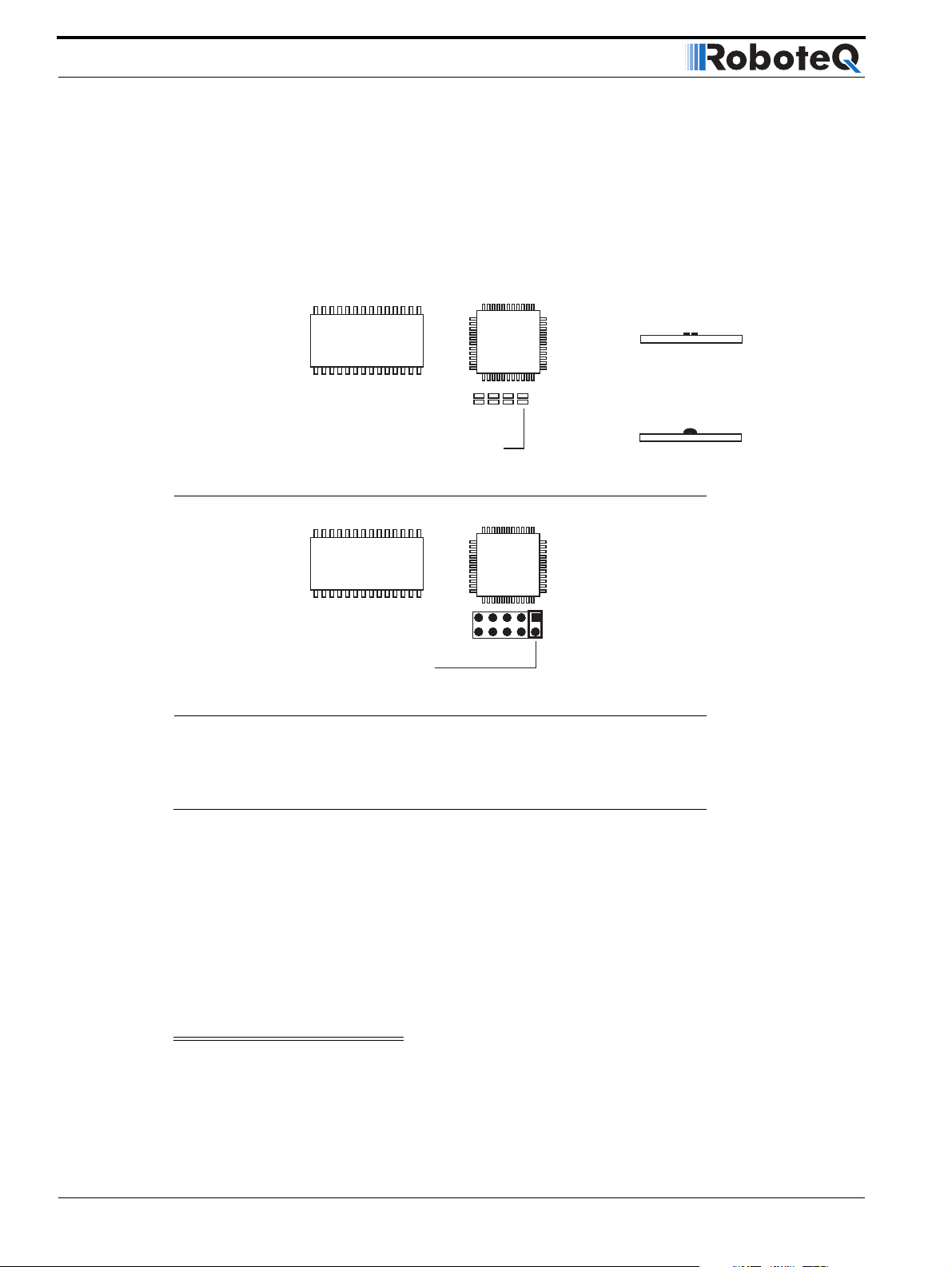

Converting the AX2550 to Single Channel

The AX2550 can be easily modified into a Single Channel version by placing a jumper on

the PCB. This step must be undertook only if you have the proper tooling and technical

skills.

• Disconnect the controller from power

• Open the controller’s case by removing the front bracket and sliding the cover off

• Depending on the board’s revision, place a drop of solder on the PCB jumper pad

shown in Figure 13 or insert a jumper as shown in Figure 14.

• Place the cover and bracket back

M1-

M1+

VCon

Controller

GND

GND

GND

M2-

M2+

Pwr Ctrl

12V to 40V

GND

VMot

Before paralleling the outputs,

• Place the load on channel 1 and verify that it is activated by commands on channel

1.

AX2550 Motor Controller User’s Manual 35

Page 36

Connecting Power and Motors to the Controller

• Then place the load on channel 2 and verify that is also activated by commands on

channel 1.

• Commands on channel 2 should have no effects on either output.

It will be safe to wire in parallel the controller’s outputs only after you have verified that

both outputs react identically to channel 1 commands.

MCU

Single Channel

FIGURE 13. Solder Jumper setting for Single Channel Operation

Jumper "open"

Xilinx

Place solder ball to close

jumper and enable single

channel mode

MCU

Jumper In for

Single Channel

FIGURE 14. Jumper setting for Single Channel Operation - RevB Hardware

Xilinx

Power Fuses

For low Amperage applications (below 30A per motor), it is recommended that a fuse be

inserted in series with the main battery circuit as shown in the Figure 10 on page 32.

The fuse will be shared by the two output stages and therefore must be placed before the

Y connection to the two power wires. Fuse rating should be the sum of the expected current on both channels. Note that automotive fuses are generally slow will be of limited

effectiveness in protecting the controller and may be omitted in high current application.

The fuse will mostly protect the wiring and battery against after the controller has failed.

Important Warning

Fuses are typically slow to blow and will thus allow temporary excess current to flow

through them for a time (the higher the excess current, the faster the fuse will blow).

This characteristic is desirable in most cases, as it will allow motors to draw surges

36 AX2550 Motor Controller User’s Manual Version 1.9b. June 1, 2007

Page 37

during acceleration and braking. However, it also means that the fuse may not be

able to protect the controller.

Wire Length Limits

The AX2550 regulates the output power by switching the power to the motors On and Off

at high frequencies. At such frequencies, the wires’ inductance produces undesirable

effects such as parasitic RF emissions, ringing and overvoltage peaks. The controller has

built-in capacitors and voltage limiters that will reduce these effects. However, should the

wire inductance be increased, for example by extending the wire length, these effects will

be amplified beyond the controller’s capability to correct them. This is particularly the case

for the main battery power wires (thick red and black cables).

Important Warning

Avoid extending the black and red Motor Power wires beyond their original length,

as the added inductance may cause damage to the controller when operating at high

currents. Try extending the motor wires instead since the added inductance is less

harmful on this side of the controller.

Wire Length Limits

If the controller must be located at a longer distance, the effects of the wire inductance

may be reduced by using one or more of the following techniques:

• Twisting the power and ground wires over the full length of the wires

• Use the vehicle’s metallic chassis for ground and run the positive wire along the sur-

face

• Add a capacitor (5,000uF or higher) near the controller

Electrical Noise Reduction Techniques

As discussed in the above section, the AX2550 uses fast switching technology to control

the amount of power applied to the motors. While the controller incorporates several circuits to keep electrical noise to a minimum, additional techniques can be used to keep the

noise low when installing the AX2550 in an application. Below is a list of techniques you

can try to keep noise emission low:

• Keep wires as short as possible

• Loop wires through ferrite cores

• Add snubber R/C circuit at motor terminals

• Keep controller, wires and battery enclosed in metallic body

Power Regeneration Considerations

When a motor is spinning faster than it would normally at the applied voltage, such as

when moving downhill or decelerating, the motor acts like a generator. In such cases, the

current will flow in the opposite direction, back to the power source.

AX2550 Motor Controller User’s Manual 37

Page 38

Connecting Power and Motors to the Controller

It is therefore essential that the AX2550 be connected to rechargeable batteries. If a power

supply is used instead, the current will attempt to flow back in the power supply during

regeneration, potentially damaging it and/or the controller.

Regeneration can also cause potential problems if the battery is disconnected while the

motors are still spinning. In such a case, and depending on the command level applied at

that time, the regenerated current will attempt to flow back to the battery. Since none is

present, the voltage will rise to potentially unsafe levels. The AX2550 includes an overvoltage protection circuit to prevent damage to the output transistors (see “Overvoltage Protection” on page 38). However, if there is a possiblity that the motor could be made to spin

and generate a voltage higher than 40V, a path to the battery must be provided, even after

a fuse is blown. This can be accomplished by inserting a diode across the fuse as shown

in Figure 10 on page 32.

Please download the Application Note “Understanding Regeneration” from the

www.roboteq.com for an in-depth discussion of this complex but important topic.

Important Warning

Use the AX2550 only with a rechargeable battery as supply to the Motor Power wires

(thick black and red wires). If a transformer or power supply is used, damage to the

controller and/or power supply may occur during regeneration. See “Using the Controller with a Power Supply” on page 39 for details.

Important Warning

Avoid switching Off or cutting open the main power cables (thick black and red

wires) while the motors are spinning. Damage to the controller may occur.

Overvoltage Protection

The AX2550 includes a battery voltage monitoring circuit that will cause the output transistors to be turned Off if the main battery voltage applied on the thick red and black wires

rises above 43V.

This protection is designed to prevent the voltage created by the motors during regeneration to be “amplified” to unsafe levels by the switching circuit.

The controller will resume normal operation when the measured voltage drops below 43V.

Undervoltage Protection

In order to ensure that the power MOSFET transistors are switched properly, the AX2550

monitors the internal 12V power supply that is used by the MOSFET drivers. If the internal

voltage drops below 10V, the controller’s output stage is turned Off. The rest of the control-

ler’s electronics, including the microcomputer, will remain operational as long as the internal voltage is above 8V.

The internal voltage will be the output of the DC/DC converter which will be a solid 12V as

long as either of the main battery or backup voltage is higher than 12.5V. If the main and

38 AX2550 Motor Controller User’s Manual Version 1.9b. June 1, 2007

Page 39

Using the Controller with a Power Supply

backup voltage drop below 12.V, the DC/DC converter’s output will be approximately 0.5V

lower than the highest input.

Using the Controller with a Power Supply

Using a transformer or a switching power supply is possible but requires special care, as

the current will want to flow back from the motors to the power supply during regeneration. As discussed in “Power Regeneration Considerations” on page 37, if the supply is not

able to absorb and dissipate regenerated current, the voltage will increase until the overvoltage protection circuit cuts off the motors. While this process should not be harmful to

the controller, it may be to the power supply, unless one or more of the protective steps

below is taken:

• Use a power supply that will not suffer damage in case a voltage is applied at its

output that is higher than the transformer’s own output voltage. This information is

seldom published in commercial power supplies, so it is not always possible to

obtain positive reassurance that the supply will survive such a condition.

• Avoid deceleration that is quicker than the natural deceleration due to the friction in

the motor assembly (motor, gears, load). Any deceleration that would be quicker

than natural friction means that braking energy will need to be taken out of the system, causing a reverse current flow and voltage rise. See “Programmable Acceleration” on page 47.

• Place a battery in parallel with the power supply output. This will provide a reservoir

into which regeneration current can flow. It will also be very helpful for delivering

high current surges during motor acceleration, making it possible to use a lower

current power supply. Batteries mounted in this way should be connected for the

first time only while fully charged and should not be allowed to discharge. The

power supply will be required to output unsafe amounts of current if connected

directly to a discharged battery. Consider using a decoupling diode on the power

supply’s output to prevent battery or regeneration current to flow back into the

power supply.

• Place a resistive load in parallel with the power supply, with a circuit to enable that

load during regeneration. This solution is more complex but will provide a safe path

for the braking energy into a load designed to dissipate it. To prevent current from

flowing from the power supply into the load during normal operation, an active

switch would enable the load when the voltage rises above the nominal output of

the power supply.

AX2550 Motor Controller User’s Manual 39

Page 40

Connecting Power and Motors to the Controller

40 AX2550 Motor Controller User’s Manual Version 1.9b. June 1, 2007

Page 41

Basic Operation

SECTION 5 General

Operation

This section discusses the controller’s normal operation in all its supported operating

modes.

Basic Operation

The AX2550’s operation can be summarized as follows:

• Receive commands from a radio receiver, joystick or a microcomputer

• Activate the motors according to the received command

• Perform continuous check of fault conditions and adjust actions accordingly

Multiple options are available for each of the above listed functions which can be combined

to produce practically any desired mobile robot configuration.

Input Command Modes

The controller will accept commands from one of the following sources

• R/C radio

• Serial data (RS232)

• Analog signal (0 to 5V)

A detailed discussion on each of these modes and the available commands is provided in

the following dedicated chapters: “R/C Operation” on page 109, “Serial (RS-232) Controls

and Operation” on page 131, and “Analog Control and Operation” on page 123.

The controller’s factory default mode is R/C radio. The mode can be changed using any of

the methods described in “Programming using built-in Switches and Display” on page 171

and “Loading, Changing Controller Parameters” on page 181.

AX2550 Motor Controller User’s Manual 41

Page 42

General Operation

Selecting the Motor Control Modes

For each motor, the AX2550 supports multiple motion control modes. The controller’s fac-

tory default mode is Open Loop Speed control for each motor. The mode can be changed

using any of the methods described in “Programming using built-in Switches and Display”

on page 171 and “Loading, Changing Controller Parameters” on page 181.

Open Loop, Separate Speed Control

In this mode, the controller delivers an amount of power proportional to the command

information. The actual motor speed is not measured. Therefore the motors will slow

down if there is a change in load as when encountering an obstacle and change in slope.

This mode is adequate for most applications where the operator maintains a visual contact

with the robot.

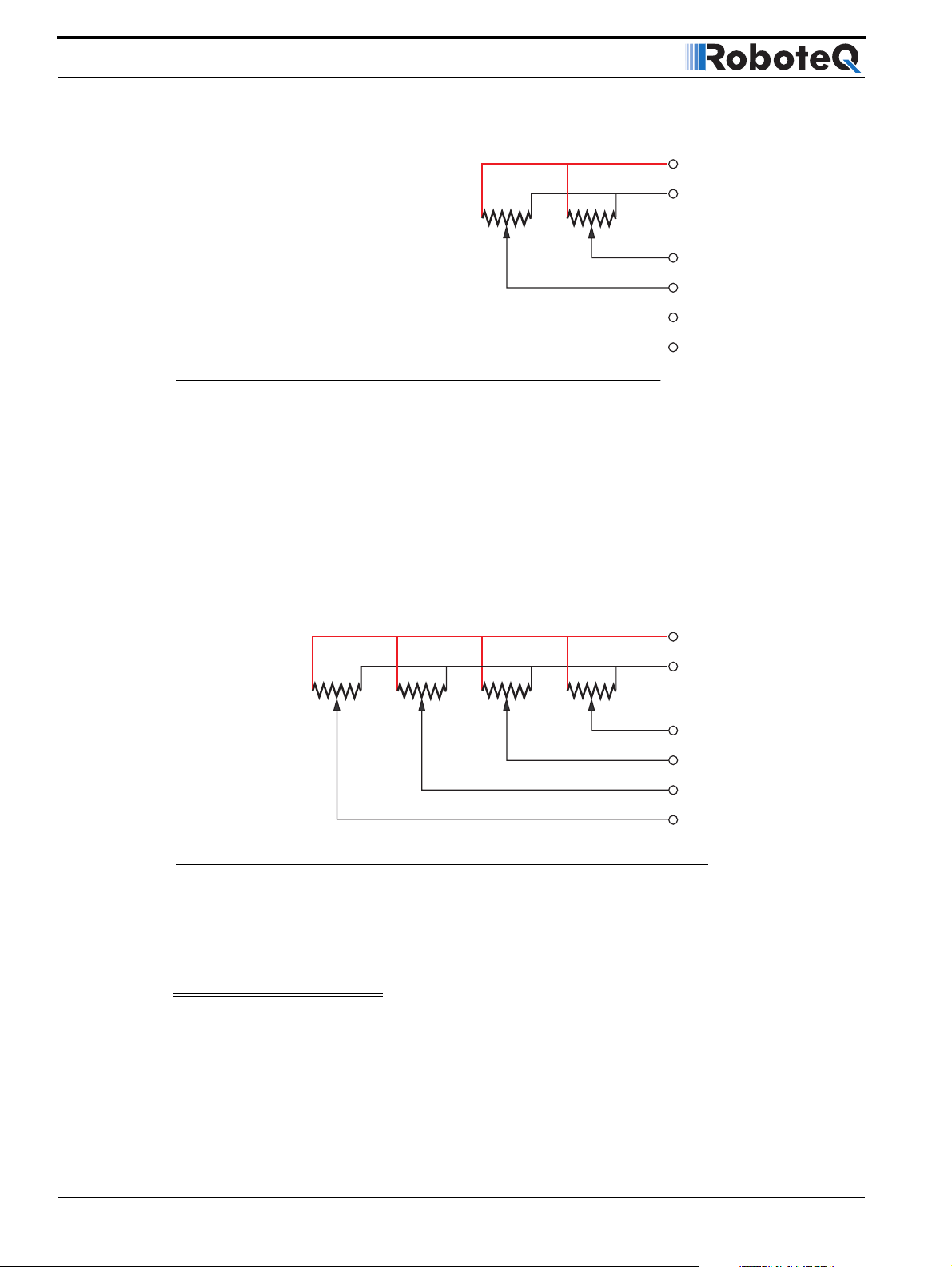

In the separate speed control mode, channel 1 commands affect only motor 1, while channel 2 commands affect only motor 2. This is illustrated in Figure 15 below.

Controller

FIGURE 15. Examples of effect of commands to motors in separate mode

Open Loop, Mixed Speed Control

This mode has the same open loop characteristics as the previously described mode. However, the two commands are now mixed to create tank-like steering when one motor is

used on each side of the robot: Channel 1 is used for moving the robot in the forward or

reverse direction. Channel 2 is used for steering and will change the balance of power on

each side to cause the robot to turn.

Figure 16 below illustrates how the mixed mode works.

42 AX2550 Motor Controller User’s Manual Version 1.9b. June 1, 2007

Page 43

Selecting the Motor Control Modes

Controller

FIGURE 16. Effect of commands to motors examples in

mixed mode

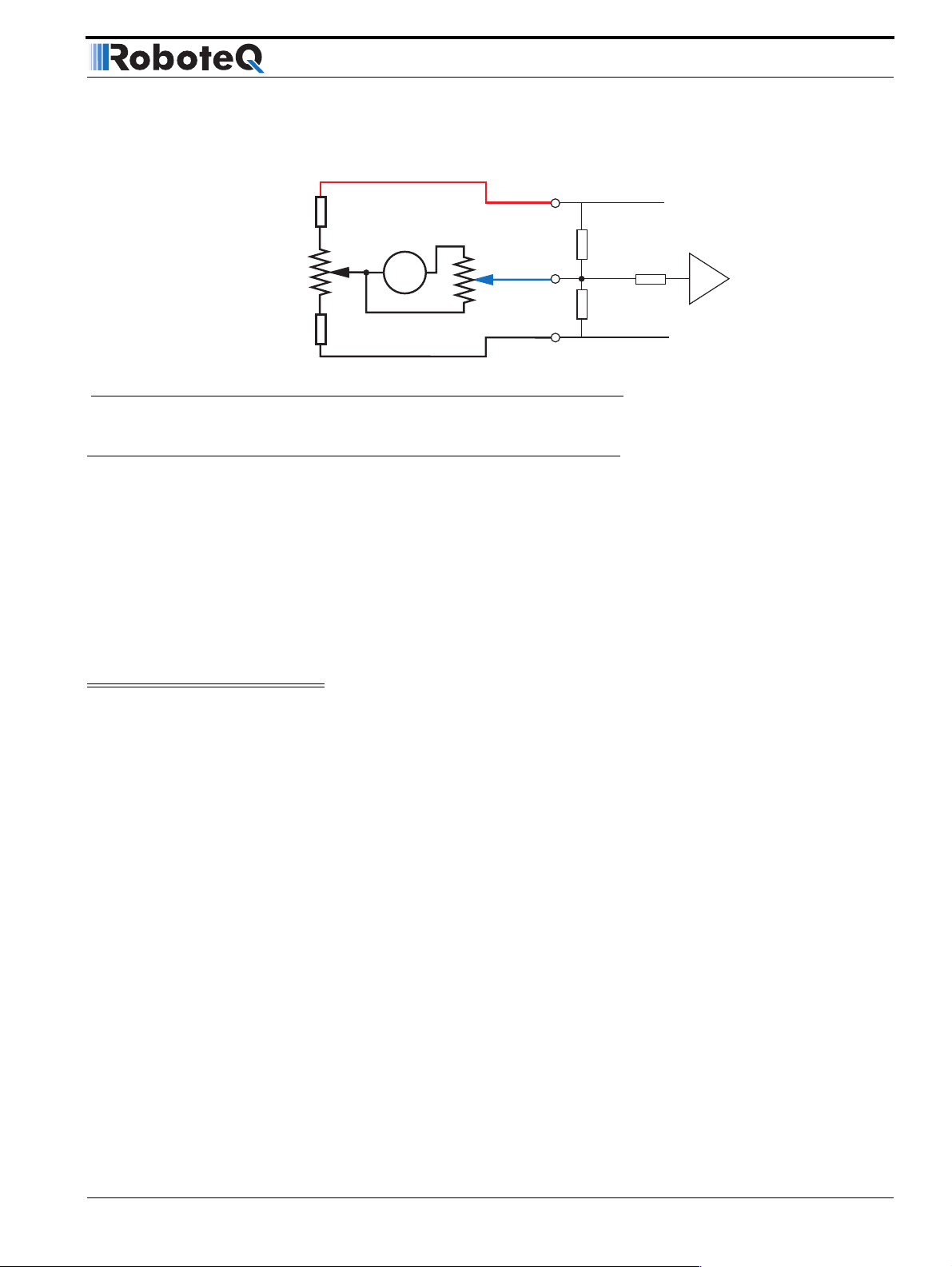

Closed Loop Speed Control

In this mode, illustrated in Figure 18, an analog tachometer or an optical encoder (AX2850

only) is used to measure the actual motor speed. If the speed changes because of changes

in load, the controller automatically compensates the power output. This mode is preferred

in precision motor control and autonomous robotic applications. Details on how to wire the

tachometer can be found in “Connecting Tachometer to Analog Inputs” on page 64.

Closed Loop Speed control operation is described in “Closed Loop Speed Mode” on

page 97.

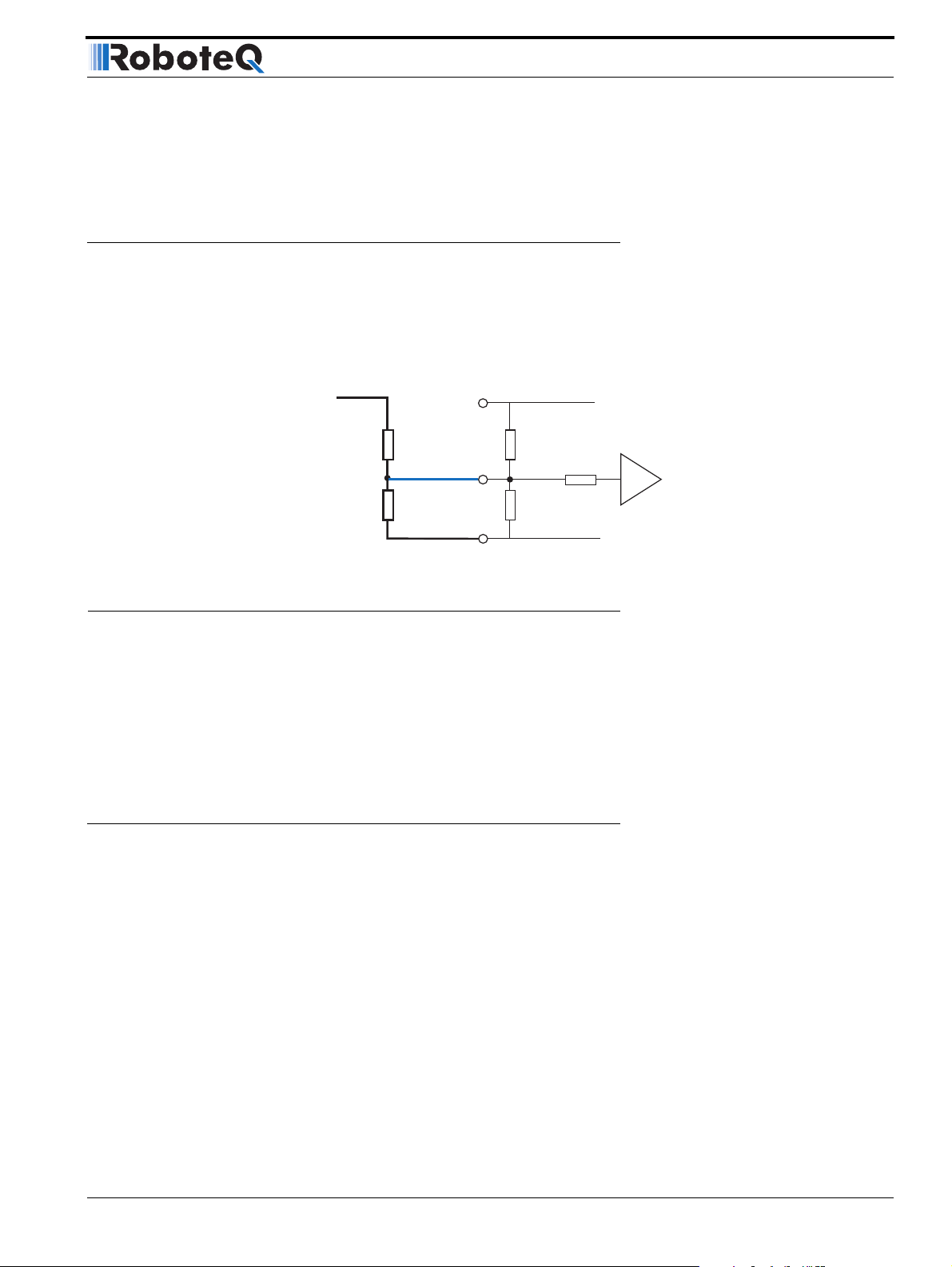

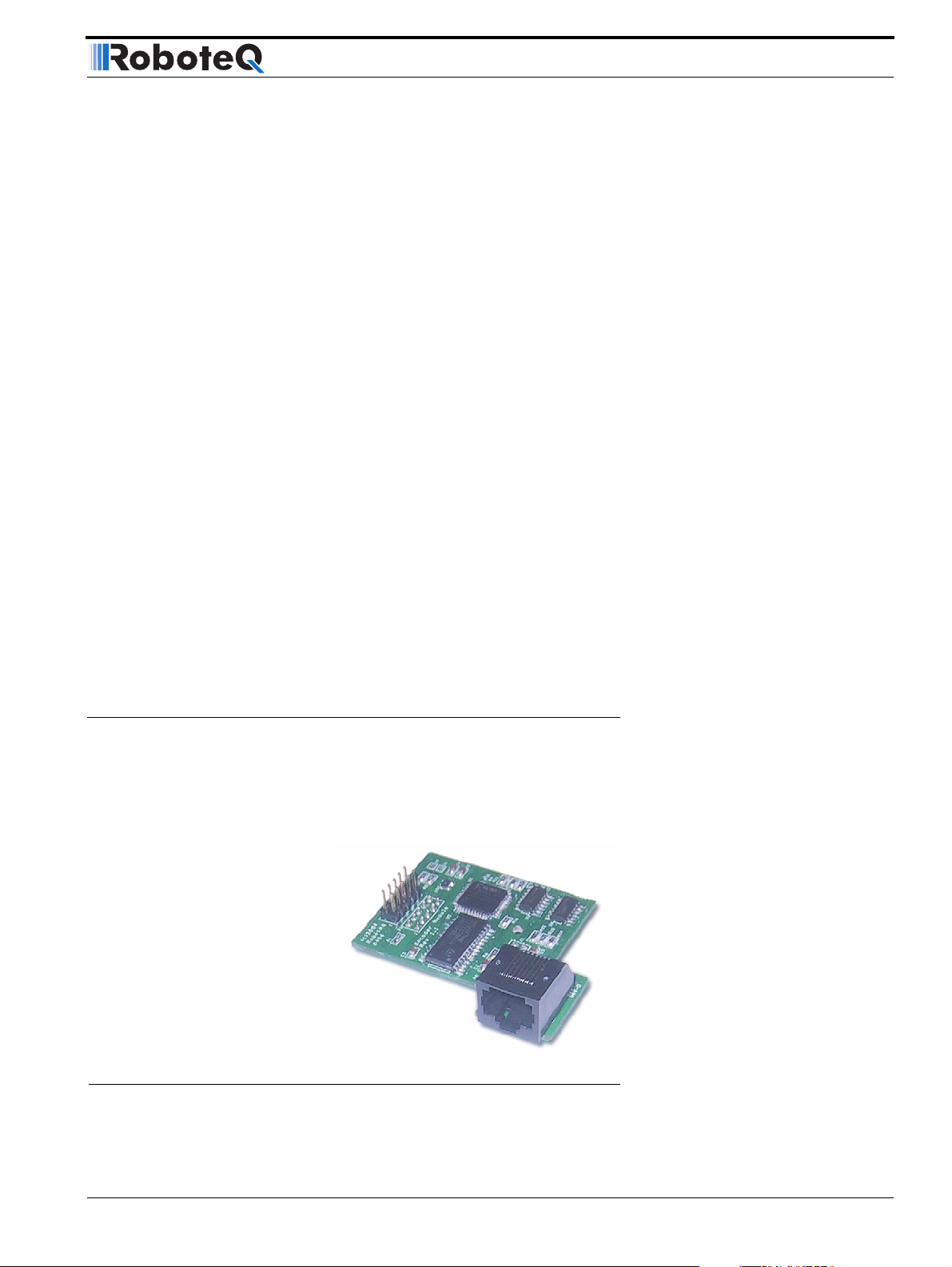

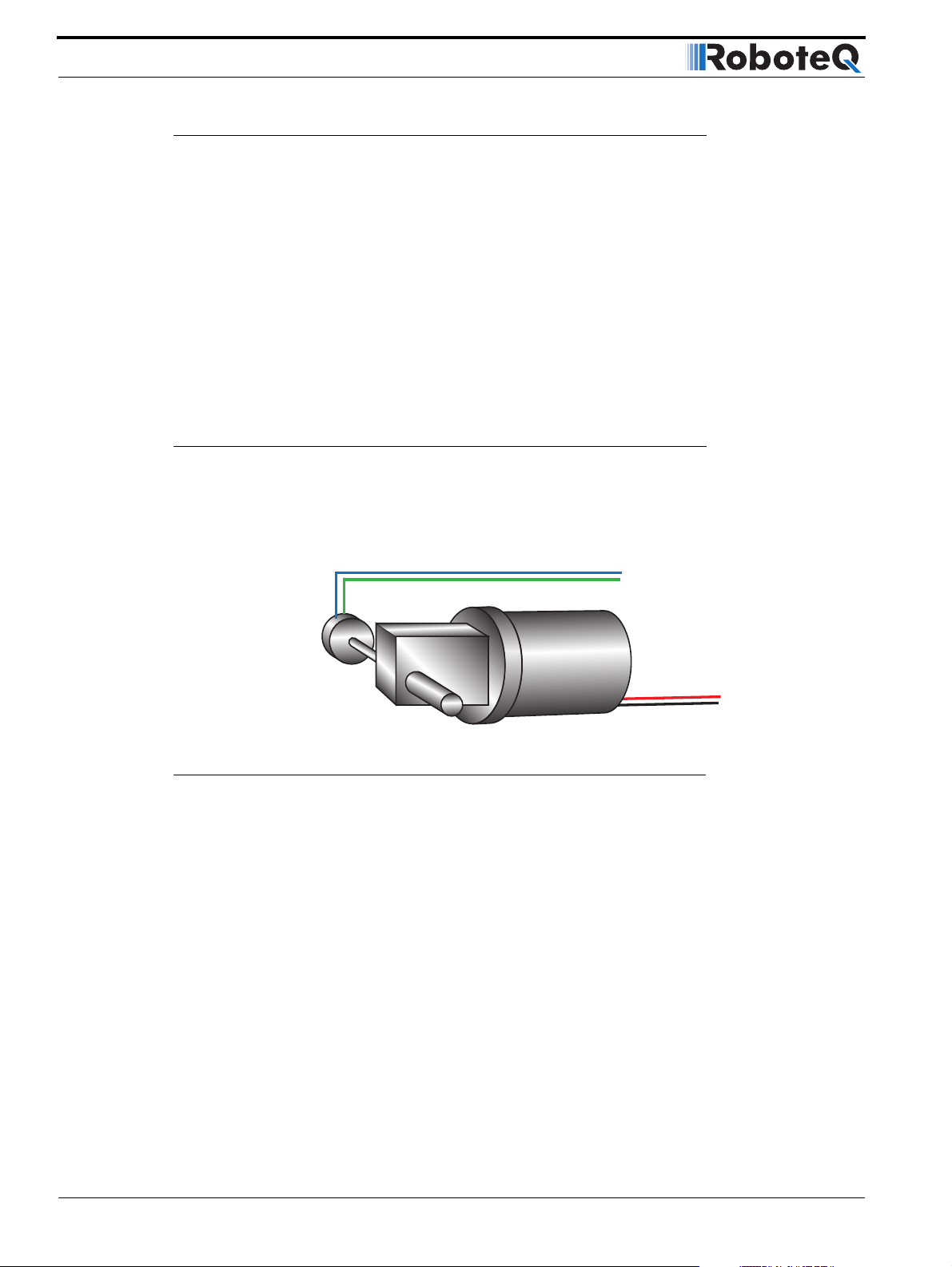

FIGURE 17. Motor with tachometer or Encoder for Closed Loop Speed operation

Close Loop Position Control

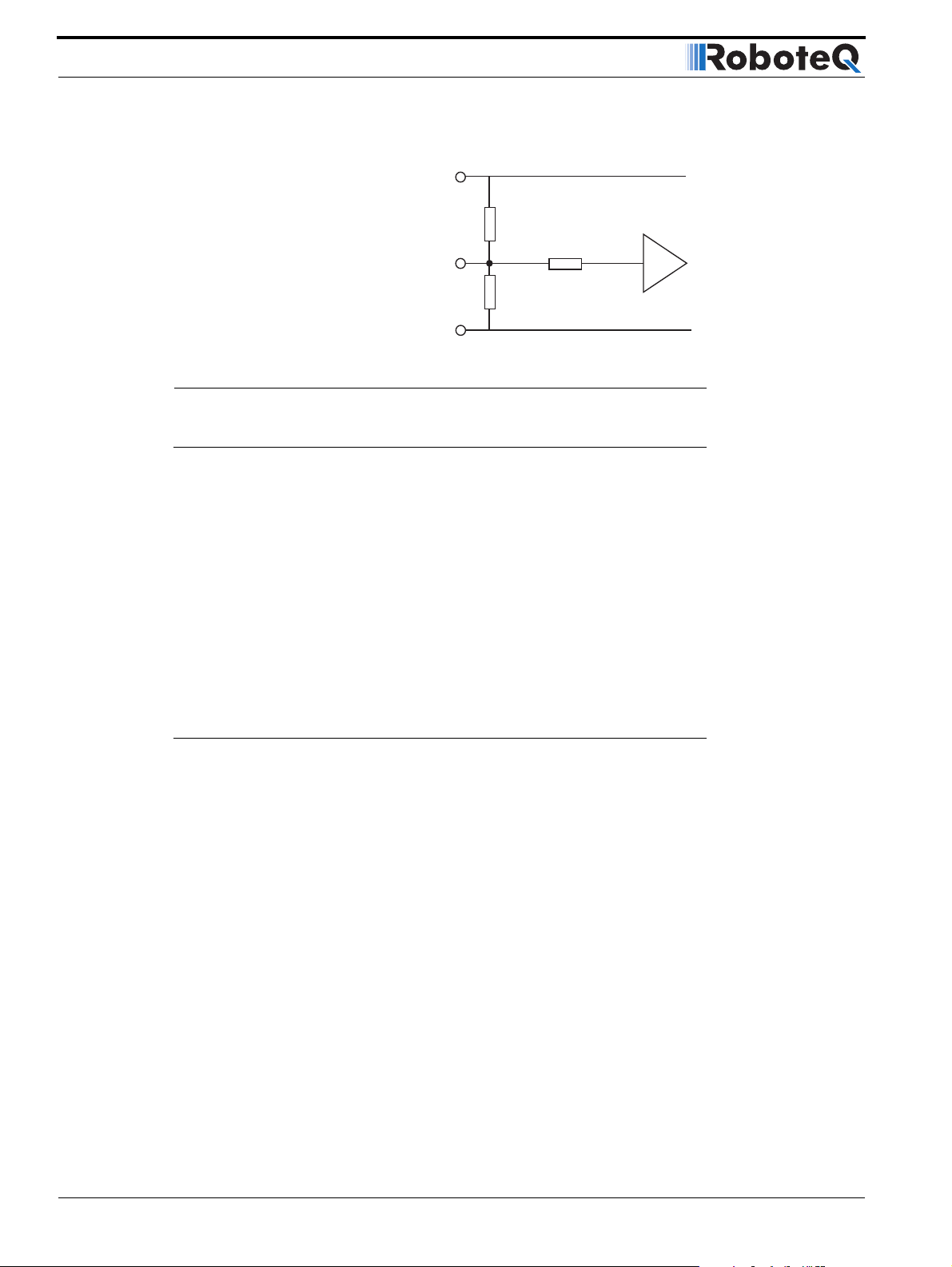

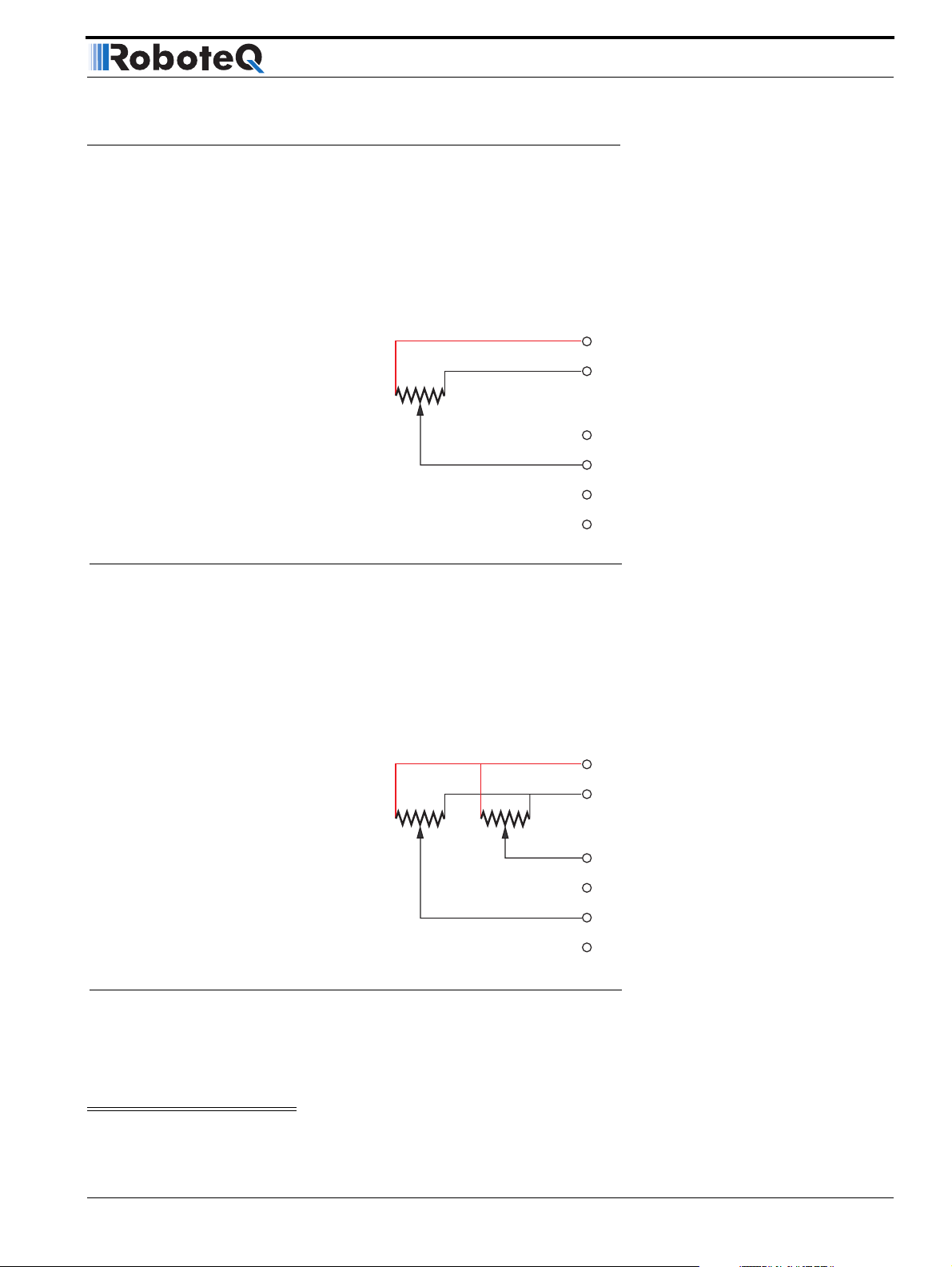

In this mode, illustrated in Figure 18, the axle of a geared down motor is coupled to a

potentiometer that is used to compare the angular position of the axle versus a desired

position. This AX2550 feature makes it possible to build ultra-high torque “jumbo servos”

that can be used to drive steering columns, robotic arms, life-size models and other heavy

loads. Details on how to wire the position sensing potentiometers and operating in this

mode can be found in “Closed Loop Position Mode” on page 85.

AX2550 Motor Controller User’s Manual 43

Page 44

General Operation

Position Sensor

Gear box

FIGURE 18. Motor with potentiometer assembly for Position operation

User Selected Current Limit Settings

The AX2550 has current sensors at each of its two output stages. Every 16 ms, this current is measured and a correction to the output power level is applied if higher than the

user preset value.

Position Feedback

The current limit may be set using the controller’s switches or the supplied PC utility. Using

the switches, 7 limits may be selected as shown in the table below.

TABLE 4. Current limit settings using the switches

Setting Continuous High Amps

030A

145A

260A

375A

490A

5 - default 105A

6120A

Using the PC utility is it possible to set the limit with a 1A granularity from 15A to 120A

During normal operation, current limiting is further enhanced by the techniques described

in the following sections.

Temperature-Based Current Limitation

The AX2550 features active current limitation that uses a combination of a user defined

preset value (discussed above) which in turn may be reduced automatically based on measured operating temperature. This capability ensures that the controller will be able to work

safely with practically all motor types and will adjust itself automatically for the various load

conditions.

44 AX2550 Motor Controller User’s Manual Version 1.9b. June 1, 2007

Page 45

Battery Current vs. Motor Current

When the measured temperature reaches 80oC, the controller’s maximum current limit

begins to drop to reach 0A at 100oC. Above 100oC, the controller’s power stage turns itself

off completely.

TABLE 5. Effect of Case temperature on Max Amps Limit

Temperature Max Amps

Below 80 oC 120A

80 oC 120A

85 oC 80A

90 oC 40A

95 oC 20A

100 oC 0

Above 100 oC Both Power Stages OFF

The numbers in the table are the max Amps allowed by the controller at a given temperature point. If the Amps limit is manually set to a lower value, then the controller will limit

the current to the lowest of the manual and temperature-adjusted max values.

This capability ensures that the controller will be able to work safely with practically all

motor types and will adjust itself automatically for the various load and environmental conditions. The time it takes for the heat sink’s temperature to rise depends on the current

output, ambient temperature, and available air flow (natural or forced).

Note that the measured temperature is measured on the heat sink near the Power Transistors and will rise and fall faster than the outside surface.

Battery Current vs. Motor Current

The controller measures and limits the current that flows from the battery. Current that

flows through the motor is typically higher. This counter-intuitive phenomenon is due to the

“flyback” current in the motor’s inductance. In some cases, the motor current can be

extremely high, causing heat and potentially damage while battery current appears low or

reasonable.

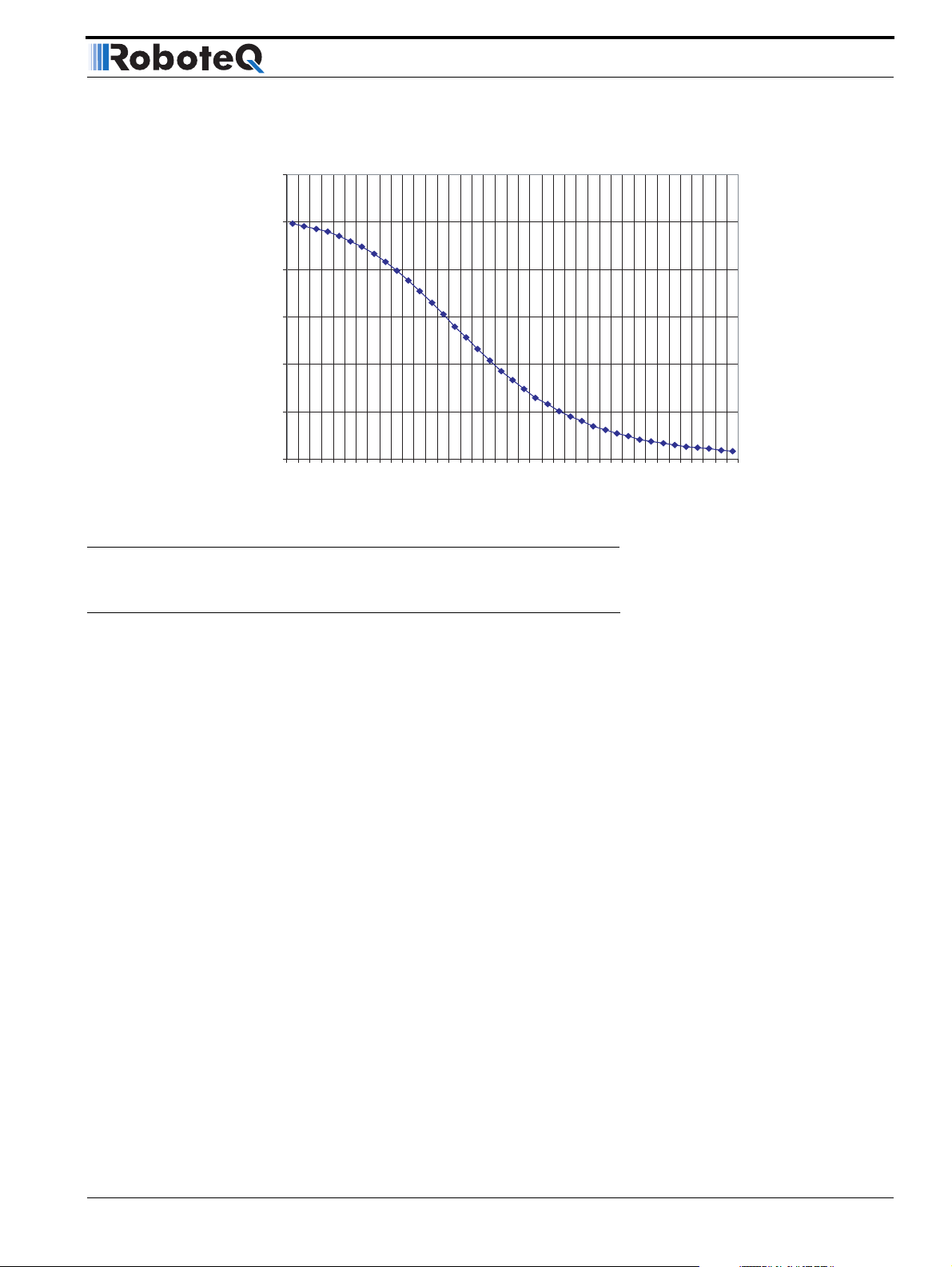

The motor’s power is controlled by varying the On/Off duty cycle of the battery voltage

16,000 times per second to the motor from 0% (motor off) to 100 (motor on). Because of

the flyback effect, during the Off time current continues to flow at nearly the same peak and not the average - level as during the On time. At low PWM ratios, the peak current and therefore motor current - can be very high as shown in Figure 20, “Instant and average

current waveforms,” on page 46.

The relation between Battery Current and Motor current is given in the formula below:

Motor Current = Battery Current / PWM ratio

Example: If the controller reports 10A of battery current while at 10% PWM, the current in

the motor is 10 / 0.1 = 100A.

AX2550 Motor Controller User’s Manual 45

Page 46

General Operation

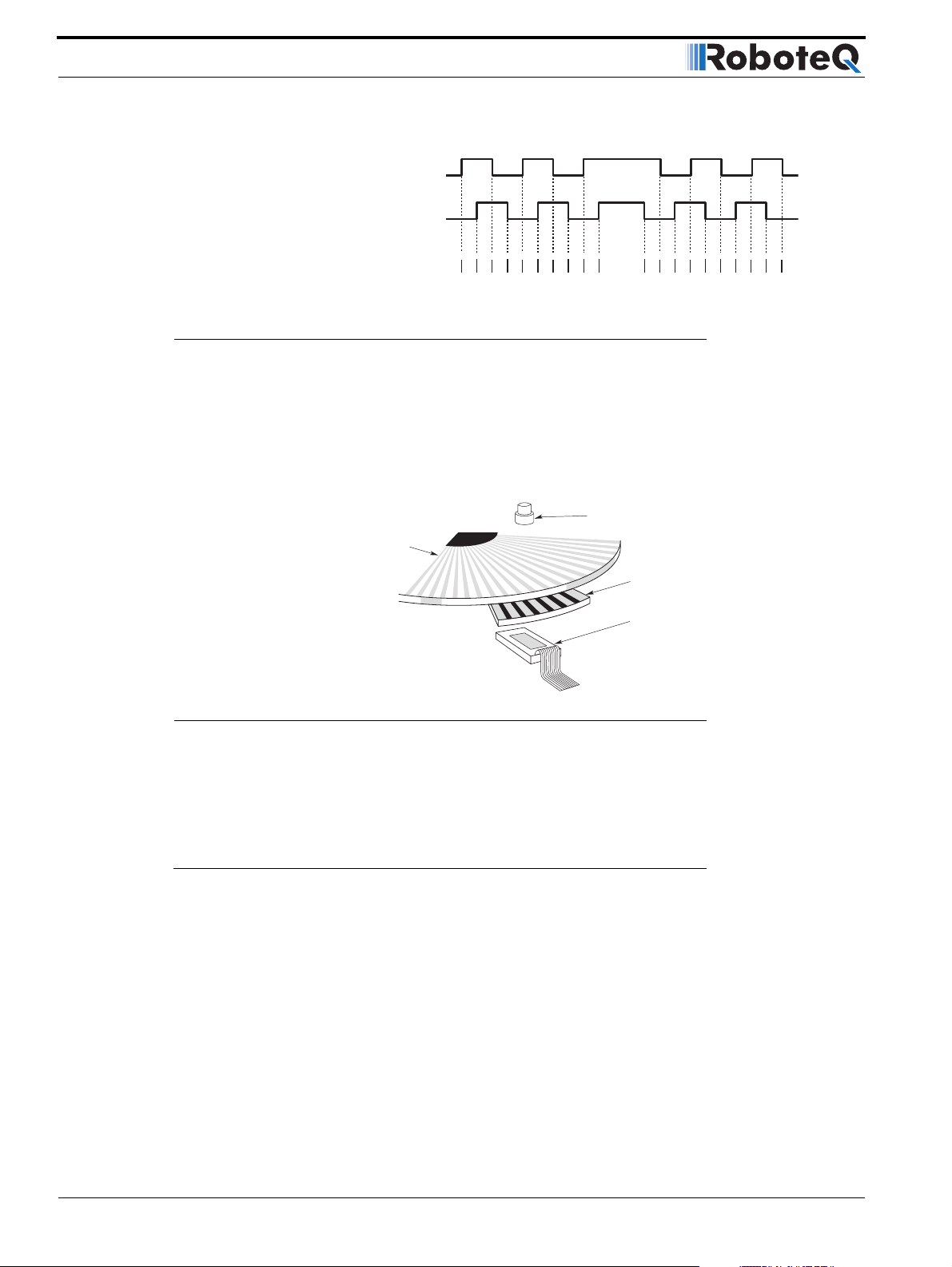

FIGURE 19. Current flow during operation

Vbat

On

Motor

Off

On

FIGURE 20. Instant and average current waveforms

The relation between Battery Current and Motor current is given in the formula below:

Motor Current = Battery Current / PWM Ratio

Example: If the controller reports 10A of battery current while at 10% PWM, the current in

the motor is 10 / 0.1 = 100A.

Important Warning

Do not connect a motor that is rated at a higher current than the controller. While

the battery current will never exceed the preset Amps limit, that limit may be

reached at a PWM cycle lower than 100% resulting in a higher and potentially unsafe

level through the motor and the controller.

Off

I mot

Avg

I bat

Avg

Regeneration Current Limiting

The AX2550’s current sensor is capable of measuring current in the reverse flow (regeneration). Using this capability, the controller will automatically relax the braking effect of the

power output stage to keep the regeneration current within safe values. Because of the

controller’s high current handling capabilities, this protection mechanism activates only

when abrupt deceleration are applied to high-inertia, ultra-low impedance motors.

46 AX2550 Motor Controller User’s Manual Version 1.9b. June 1, 2007

Page 47

Programmable Acceleration

Programmable Acceleration

When changing speed command, the AX2550 will go from the present speed to the

desired one at a user selectable acceleration. This feature is necessary in order to minimize

the surge current and mechanical stress during abrupt speed changes.

This parameter can be changed by using the controller’s front switches or using serial com-

mands. When configuring the controller using the switches (see “Configuring the Controller using the Switches” on page 171), acceleration can be one of 6 available preset values,

from very soft(0) to very quick (6). The AX2550’s factory default value is medium soft (2).

When using the serial port, acceleration can be one of 24 possible values, selectable using

the Roborun utility or entering directly a value in the MCU’s configuration EEPROM.

Table 6 shows the corresponding acceleration for all Switch and RS232 settings.

Numerically speaking, each acceleration value corresponds to a fixed percentage speed

increment, applied every 16 milliseconds. The value for each setting is shown in the table

below.

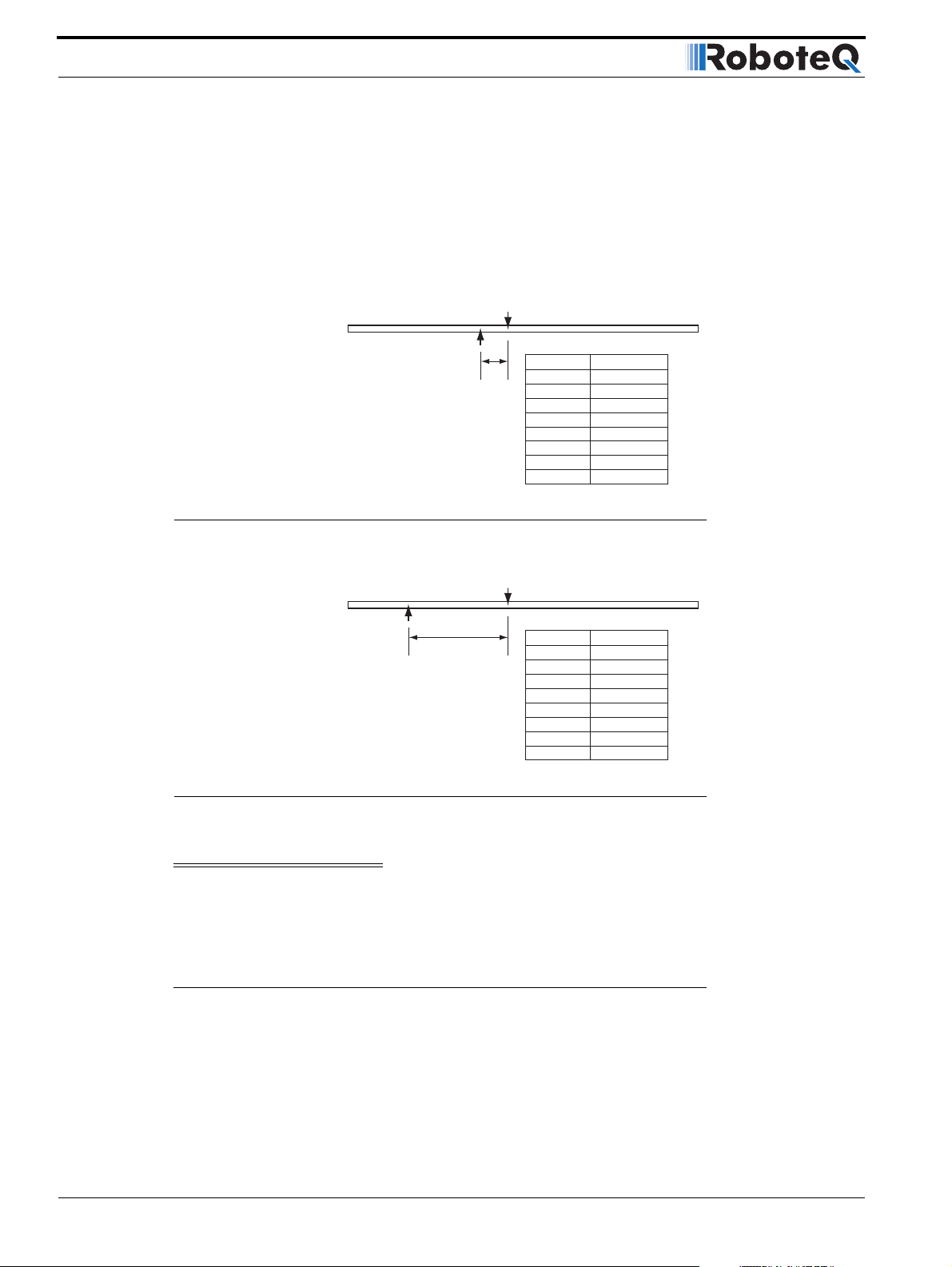

TABLE 6. Acceleration setting table

Acceleration

Setting Using

RS232

30 Hex 0.78% 2.05 seconds

20 Hex 1.56% 1.02 seconds

10 Hex 2.34% 0.68 second

00 Hex 0 3.13% 0.51 second

31 Hex 3.91% 0.41 second

21 Hex 4.69% 0.34 second

11 Hex 5.47% 0.29 second

01 Hex 1 6.25% 0.26 second

32 Hex - 7.03% 0.23 second

22 Hex - 7.81% 0.20 second

12 Hex - 8.59% 0.19 second

02 Hex 2 (default) 9.38% 0.17 second

33 Hex - 10.16% 0.16 second

23 Hex - 10.94% 0.15 second

13 Hex - 11.72% 0.14 second

03 Hex 3 12.50% 0.128 second

34 Hex - 13.28% 0.120 second

24 Hex - 14.06% 0.113 second

14 Hex - 14.84% 0.107 second

04 Hex 4 15.63% 0.102 second

35 Hex - 16.41% 0.097 second

25 Hex - 17.19% 0.093 second

Acceleration

Setting Using

Switches

%Acceleration per

16ms

Time from 0 to

max speed

AX2550 Motor Controller User’s Manual 47

Page 48

General Operation

TABLE 6. Acceleration setting table

Acceleration

Setting Using

RS232

15 Hex - 17.97% 0.089 second

05 Hex 5 18.75% 0.085 second

When configuring the acceleration parameter using the Roborun utility, four additional

acceleration steps can be selected between the six ones selectable using the switch,

extending the slowest acceleration to 2.04 seconds from 0 to max speed. See “Power Settings” on page 182 for details on how to configure this parameter using Roborun.

Acceleration

Setting Using

Switches

%Acceleration per

16ms

Time from 0 to

max speed

Important Warning

Depending on the load’s weight and inertia, a quick acceleration can cause consider-

able current surges from the batteries into the motor. A quick deceleration will cause

an equally large, or possibly larger, regeneration current surge. Always experiment

with the lowest acceleration value first and settle for the slowest acceptable value.

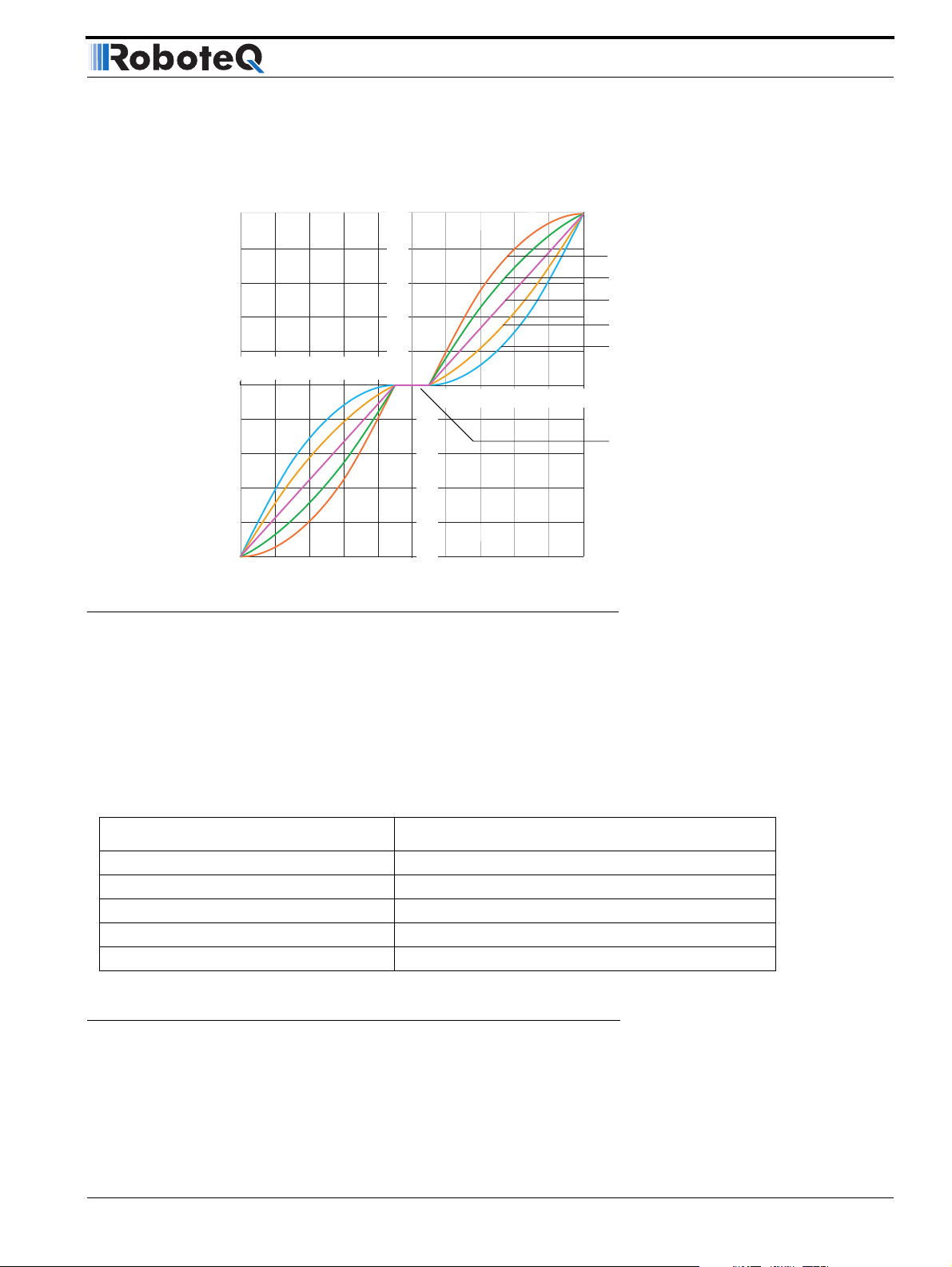

Command Control Curves

The AX2550 can also be set to translate the joystick or RS232 motor commands so that the

motors respond differently whether or not the joystick is near the center or near the

extremes.

The controller can be configured to use one of 5 different curves independently set for

each chan nel.

The factory default curve is a “linear” straight line, meaning that after the joystick has

moved passed the deadband point, the motor’s speed will change proportionally to the joystick position.