Page 1

Mini MP 160 V.V.

Mini MP 190 V.V.

Mini MP 240 V.V.

Mini MP 190 Combi

Mini MP 240 Combi

Page 2

We reserve the right to alter at any time without notice the technical specifications of this appliance.

None of the information contained in this document is of a contractual nature. Modifications may be made at any time.

© All rights reserved for all countries by: ROBOT-COUPE s.n.c.

OPERATING INSTRUCTIONS

1

Page 3

SUMMARY

WARRANTY

IMPORTANT WARNING

YOU HAVE JUST PURCHASED

A MINI POWER MIXER

SWITCHING ON THE APPLIANCE

• Advice on electrical connections

OPERATING THE APPLIANCE

• Starting and stopping the power mixer

• Variable-speed operation

WORKING POSITION

ASSEMBLING / DISMANTLING

USES & EXAMPLES

HYGIENE

CLEANING

• Motor unit

• Foot and bell

• Blade and emulsifying disc

• Whisk

MAINTENANCE

• Blade

• Whisk

• Foot seal

TECHNICAL SPECIFICATIONS

• Weight

• Dimensions

• Working height

• Noise level

• Electrical data

SAFETY

PROBLEMS

STANDARDS

TECHNICAL DATA

• Exploded views

• Electrical and wiring diagrams

(Page 13)

3

Page 4

ROBOT-COUPE S.N.C., LIMITED WARRANTY

Your new ROBOT-COUPE appliance

is warranted to the original buyer

for a period of one year from the

date of sale if you bought it from

ROBOT-COUPE

S.N.C.

If you bought your ROBOT-COUPE

product from a distributor your

product is covered by your distributor’s warranty (Please check

with your distributor terms and

conditions of the warranty).

The ROBOT-COUPE S.N.C. limited

warranty is against defects in

material and/or workmanship.

THE FOLLOWING ARE NOT

COVERED BY THE ROBOT-COUPE

S.N.C

. WARRANTY:

1-Damage caused by abuse, misuse,

dropping, or other similar damage caused by

or resulting from failure to follow assembly,

operating, cleaning, user maintenance or

storage instructions.

2-Labour to sharpen and/ or replacements for

blades which have become blunt, chipped or

worn after a normal or excessive period of use.

3-Materials or labour to replace or repair

scratched, stained, chipped, pitted, dented or

discoloured surfaces, blades, knives, attachments

or accessories.

4-Any alteration, addition or repair that has

not been carried out by the company or an

approved ser vice agency.

5-Transportation of the appliance to or from

an approved service agency.

6-Labour charges to install or test new attach-

ments or accessories (i.e., bowls, discs, blades,

attachments) which have been arbitrarity replaced.

7-The cost of changing direction-of-rotation of

electric motors (Installer is responsible).

8-SHIPPING DAMAGES. Visible and latent

defects are the responsibility of the freight

carrier. The consignee must inform the carrier

and consignor immediately, or upon discovery in

the case of latent defects.

KEEP ALL ORIGINAL CONTAINERS AND

PACKING MATERIALS FOR CARRIER INSPECTION.

Neither ROBOT-COUPE

companies or any of its distributors, directors,

agents, employees, or insurers will be liable for

indirect damage, losses, or expenses linked to

the appliance or the inability to use it.

S.N.C. nor its affiliated

The ROBOT-COUPE S.N.C. warranty

is given expressly and in lieu of all

other warranties, expressed or

implied, for merchantability and

for fitness toward a particular purpose and constitutes the only warranty made by ROBOT-COUPE

S.N.C. France.

4

Page 5

WARNING

IMPORTANT WARNING

KEEP THESE INSTRUCTIONS IN A SAFE PLACE

WARNING : In order to limit accidents such as electric shocks or personal injury, and in order to limit material damage due to misuse

of the appliance, please read these instructions carefully and follow them strictly. Reading the operating instructions will help you get to

know your appliance and enable you to use the equipment correctly. Please read these instructions in their entirety and make sure that

anyone else who may use the appliance also reads them beforehand.

UNPACKING

• WARNING - some of the tools are very sharp e.g.

blades, etc..

INSTALLATION

• We recommend that you install your appliance on

its wall frame.

CONNECTION

• Always check that your mains supply corresponds

to that indicated on the identification plate on the

motor unit and that it can withstand the amperage.

• Never plug your appliance into the mains supply

before placing it inside the preparation bowl.

HANDLING

• Always take care when handling the blades, as

they are extremely sharp.

ASSEMBLY PROCEDURES

• Follow the various assembly procedures carefully

(see page 7) and make sure that all the attachments

are correctly positioned.

USE

• Never try to override the safety systems

• Never insert an object into the preparation.

• Never switch the appliance on unless it has been

placed in the preparation bowl.

• Before dismantling the foot, bell or whisk always

check that the power mixer is unplugged.

• We recommend that you tilt the appliance at

a slight angle to prevent the bell from touching the

bottom of the container.

WARNIN G

Procedure to follow if the stick blender is accidentally

immersed during use.

1) Do not touch either the power mixer, the bowl or the

work surface.

2) Unplug the mixer’s power cord from the wall socket.

3) Remove the power mixer from the preparation.

4) Tilt the power mixer to drain off as much liquid as

possible.

5) Do not switch the power mixer back on, as there is

still a risk of electrocution.

6) Send the power mixer to a Robot-Coupe approved

after-sales service to have the electrical components

cleaned and dried.

CLEANING

• As a precaution, always unplug your appliance

before cleaning it.

• Always clean the appliance and its attachments at

the end of each cycle.

• Never immerse the motor unit in water.

• For parts made from aluminum, use cleaning

fluids intended for aluminum.

• For plastic parts , do not use detergents that are

too alkaline (e.g., containing too much caustic soda

or ammonia).

• Robot-Coupe can in no way be held responsible for

the user’s failure to follow the basic rules of cleaning

and hygiene.

MAINTENANCE

• Before opening the motor housing, it is absolutely

vital to unplug the appliance.

• Check the seals and washers regularly and ensure

that the safety devices are in good working order.

• It is particularly important to maintain and check

the attachments since certain ingredients contain

corrosive agents, e.g. citric acid.

• Never operate the appliance if the power cord

or plug has been damaged or if the appliance fails

to work properly or has been damaged in any way.

• Do not hesitate to contact your local Maintenance

Service if something appears to be wrong.

5

Page 6

YOU HAVE JUST PURCHASED

A MINI POWER MIXER

The new Mini MP 160 V.V., Mini MP 190 V.V., Mini

MP 240 V.V., Mini MP 190 Combi and Mini MP 240

Combi models are the latest additions to Robot-

Coupe’s range of power mixer. They have been specially designed for processing smaller quantities.

They are fitted with a foot, blades and an emulsifying disc which can be entirely dismantled, and

their tubes measure 160, 190 and 240 mm long

respectively.

Models

Min i M P 1 60 V.V.

Min i M P 1 90 V.V.

Min i M P 2 40 V.V.

Mini MP 190 Combi

Mini MP 240 Combi

These power mixer are tools which are totally adapted

to the needs of professionals. They will enable you to

make soups, vegetables purées and cereal preparations without any effort.

The whisk function is ideal for making pancake batter,

mayonnaise, beaten egg whites, chocolate mousse,

butter sauces, whipped cream or smooth fromage

frais.

The whisk is composed with a metallic gear box

even more resistant when processing pan cakes or

mashed potatoes.

The variable-speed function will enable you to

adjust the speed to suit each preparation and to start

the processing at a lower speed in order to reduce

splashing.

Speed

variation

•

•

•

•

•

6

Mixer

attachment

160 mm

190 mm

240 mm

190 mm 185 mm

240 mm 185 mm

Whisk

attachment

Each power mixer is supplied with a wall support

for easy storage.

The simple design of these appliances allows the

assembly and dismantling of the moving parts in no

time at all, to ease maintenance and cleaning.

These instructions contain important information that

will enable you to extract the greatest return on your

investment.

We therefore strongly advise you to read these

instructions carefully before using the appliance.

SWITCHING ON

THE APPLIANCE

• ADVICE ON ELECTRICAL CONNECTIONS

This class II appliance (double insulation) requires a

single-phase alternating current but does not need

an earthed socket. The universal-type motor is fitted

with an interference suppressor.

The power supply must be protected by a

differential circuit breaker and a 10 A fuse.

Check that you have a standard 10/16 A

single-phase socket.

Make sure that the voltage of your power supply

matches that shown on the identification plate of

your appliance.

Robot-Coupe supplies these models with different

types of motors:

230 V / 50 Hz for power supplies of:

220 V to 240 V.

120 V / 60 Hz

220 V / 60 Hz

The power mixer is supplied with a single-phase

plug connected to a power cord.

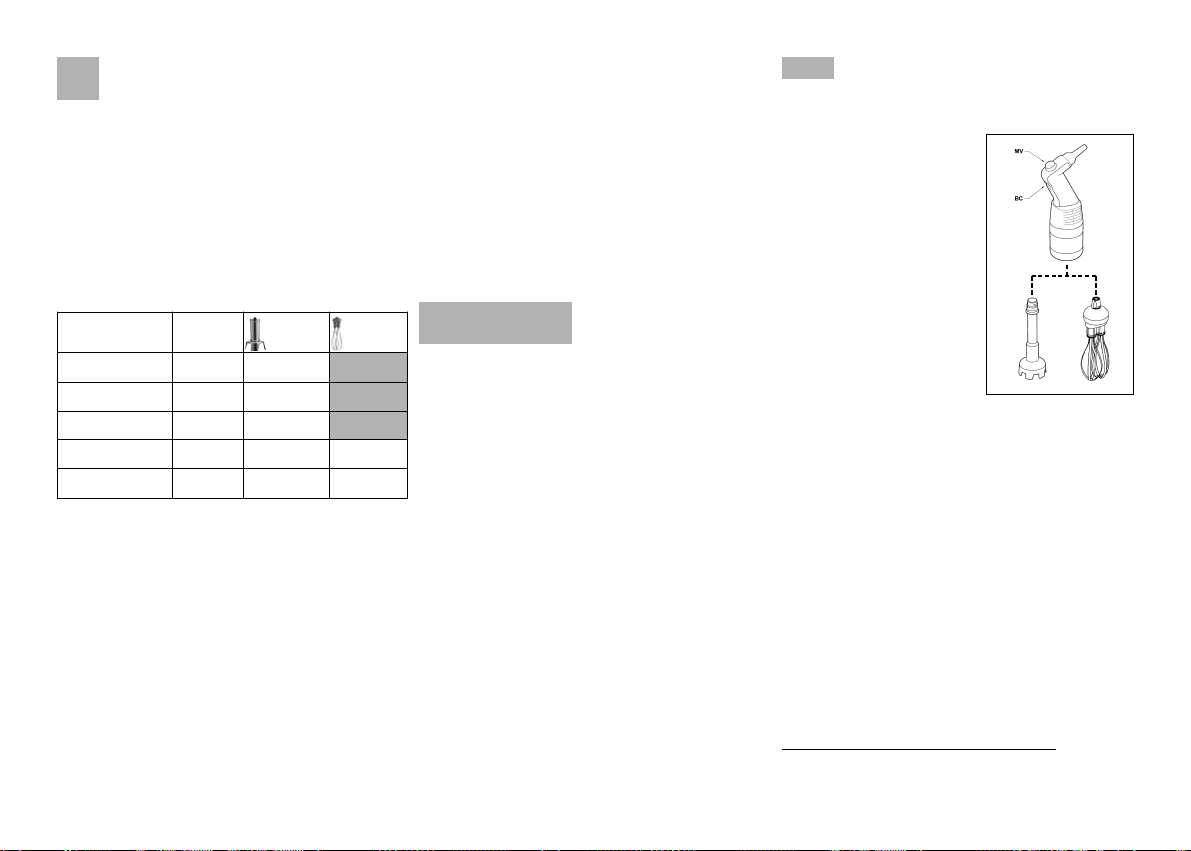

OPERATING THE APPLIANCE

• STARTING AND STOPPING

1. Plug your appliance into

the mains, making sure you

do not press the button

(BC).

2. Insert the foot into the

preparation.

3. Press the control button

(BC), and the power mixer

will start up.

4. To stop the power mixer,

release the control button

(BC).

• VARIABLE-SPEED OPERATION

Follow steps 1 to 4 above, then:

5. Change the speed of the motor by turning the

variable speed button (MV) towards the maximum

or minimum as required.

Whisk function (Mini MP 190 Combi, Mini MP 240

Combi): speed between 350 and 1 560 rpm.

For making mashed potatoes, you need to process at

low speed for a good quality result.

Mixer function (Mini MP 160 V.V., Mini MP 190 V.V.,

Mini MP 240 V.V., Mini MP 190 Combi, Mini MP

240 Combi): speed between 2 000 and 12 500 rpm.

It is advisable to start at a low speed when using the

whisk.

With the self-regulating speed system

have selected a speed, it will remain constant, even

if the consistency of your mixture changes.

, once you

Page 7

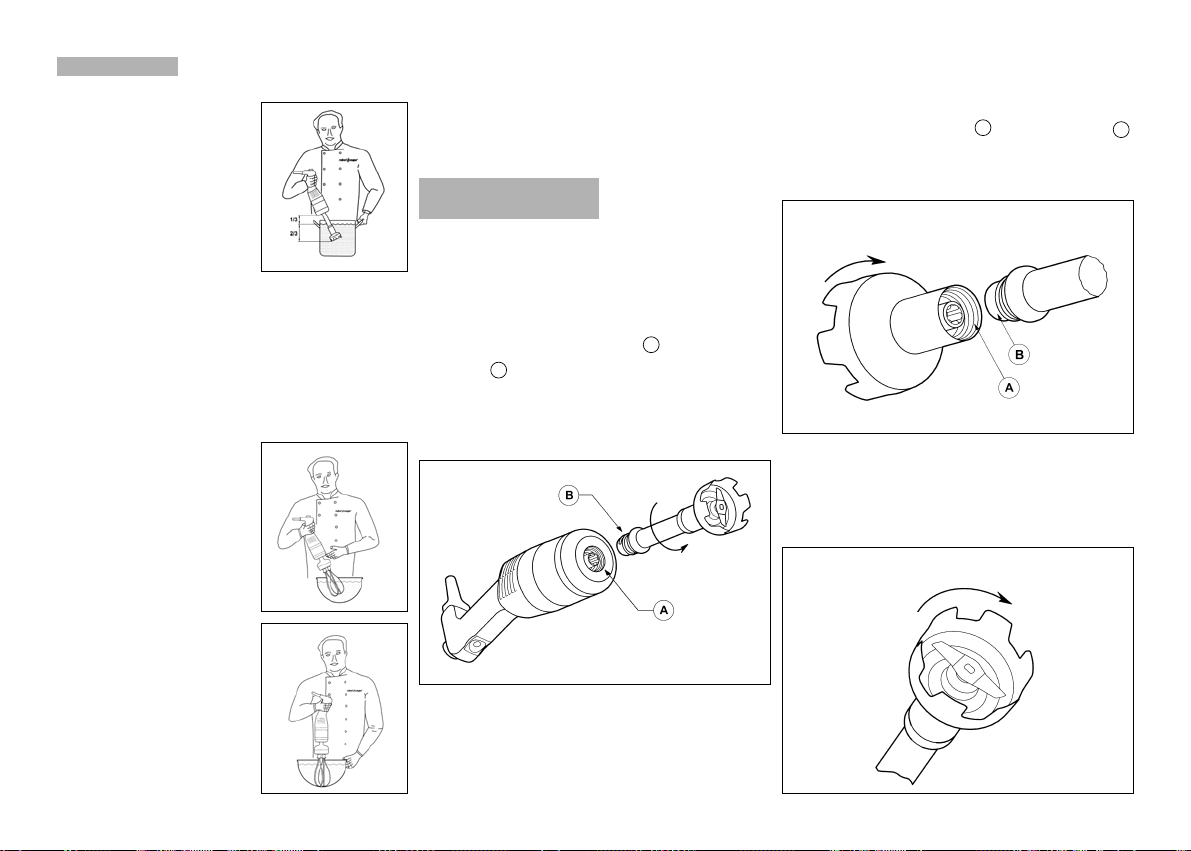

WORKING POSITION

For a more ergonomic

approach, we recommend

that you hold the handle of

the appliance in one hand

and the container in the other .

It is a good idea to lean forward slightly, making sure

that the bell does not touch

the bottom of the container.

Always make sure that the bell is sufficiently immersed

to avoid splashing and that the air vents of the motor

unit does not come into contact with any liquid.

For optimum efficiency, two thirds of the foot should

be immersed in the preparation.

• WHISK FUNCTION

You can also hold the

appliance by the handle

with one hand, leaving the

other hand free to hold the

bowl, if necessary.

touching the sides of the bowl. For maximum

efficiency, at least one-fifth of the whisk length should

be immersed. We also strongly advise you to start

the processing at a low speed.

ASSEMBLING/

DISMANTLING

• BLADE FUNCTION

Attaching the tube to the motor unit.

- Check that the appliance is not plugged in.

- Insert the threaded section right into the

housing of the motor unit.

B

- Turn the tube in the direction of the arrow (see

figure) until it is locked into place moderately

tightly.

A

Attaching the bell to the tube

- Check that the machine is not plugged in.

- Insert the threaded section into the housing

A

of the bell. Turn the bell in the direction of the arrow

(see drawing) until it starts to tighten.

TURN TO ATTACH BELL

Mini MP 190 V.V.

Mini MP 190 Combi

Mini MP 240 V.V.

Mini MP 240 Combi

Removing the bell from the foot

- Check that the machine is not plugged in.

- Turn the bell in the direction of the arrow (see

drawing) to detach it from the tube.

TURN TO REMOVE BELL

B

While you process the preparation, we recommend

that you move the whisks

around in the bowl, in order

to ensure that the mixture is

completely homogeneous.

We strongly advise you to

keep the whisks from

Mini MP 160 V.V.

Mini MP 190 V.V.

Mini MP 240 V.V.

Removing the tube from the motor unit

- Check that the appliance is unplugged.

- Turn the tube in the opposite direction to when you

assembled it until it is completely unscrewed.

Mini MP 190 V.V.

Mini MP 190 Combi

Mini MP 240 V.V.

Mini MP 240 Combi

7

Page 8

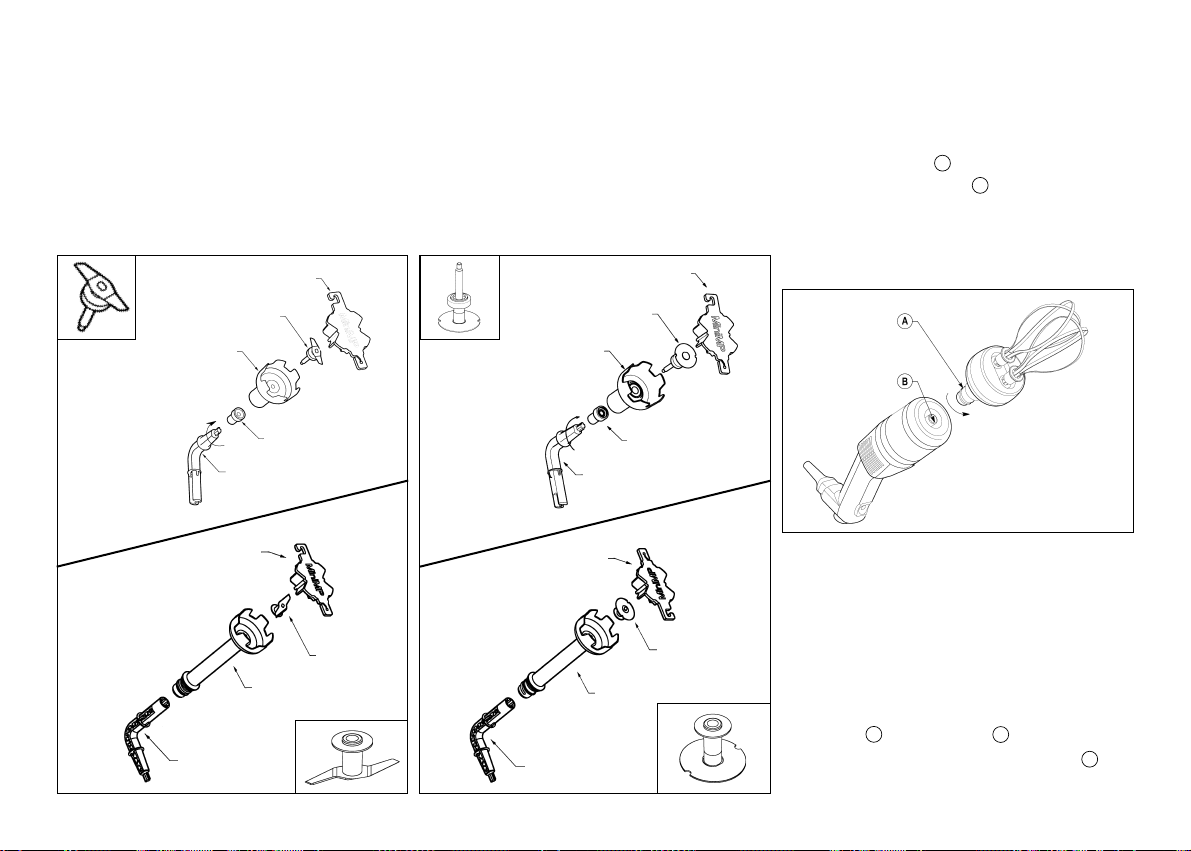

Removing the blade

- To remove the blade safely, hold them with the tool

provided or an oven glove or a thick cloth.

- Using the removal tool, unscrew the drive

coupling.

- As soon as the drive coupling has been unscrewed,

the blade can be removed for cleaning.

B

LADE LOCKING

B

LADES WITH WATERTIGHT SEALS

B

ELL

REMOVAL

DIRECTION

D

RIVE COUPLING

B

LADE LOCKING

BLADE REMOVAL

BLADE REMOVAL

BLADE

FOOT

Mini MP 160 V.V.

Mini MP 190 V.V.

Mini MP 190 Combi

Mini MP 240 V.V.

Mini MP 240 Combi

8

Installing the emulsifying disc

- In order to install it safely, introduce the disc into

the bell, then hold it in place using the locking

tool.

- Next, turn the drive coupling with this tool until it

starts to tighten.

Removing the emulsifying disc

- The disc can be removed in exactly the same way

as the blades.

B

LADE LOCKING

S

OLID EMULSIFYING DISC

B

ELL

REMOVAL

DIRECTION

D

RIVE COUPLING

B

LADE LOCKING

BLADE REMOVAL

BLADE REMOVAL

FOOT

EMULSIFYING DISC

Mini MP 160 V.V.

Mini MP 190 V.V.

Mini MP 190 Combi

Mini MP 240 V.V.

Mini MP 240 Combi

• WHISK FUNCTION

(Mini MP 190 Combi and Mini MP 240 Combi)

Attaching the gear box to the motor unit.

- Check that the machine is not plugged in.

- Align the flat side of the conical part of the

gear box with the catch on the inside of the

aluminium casing.

- Turn the gear box in the direction of the arrow

(see figure) until it is locked into place moderately

tightly.

Removing the casing

- Check that the machine is not plugged in.

- Turn the gear box in the opposite direction to that

used when attaching it.

Fitting the whisks into the gear box

- Grasp the holder in one hand.

- With the other hand, take the first whisk and insert

the shaft into the bore of the gear box

A

drive shaft. Make sure the drive lugs are

properly aligned with the notches.

A

B

B

D

Page 9

- As you push the whisk into the gear box drive

C

shaft , rotate it slightly in order to slot the drive

lugs into the notches of the drive shaft ,

thereby locking the whisk into place inside the

shaft.

- To check that the whisk is properly fixed inside the

C

shaft , gently tug the metal wires.

- Repeat this procedure with the second whisk. If

you cannot push it in properly, remove it, rotate it

90° and start again.

Removing the whisks from the gear box

Pull the ejector in

direction to the arrow,

gripping the ejector

in one hand and the

B

holder in the other.

E

A

The foot, the blades, Emulsifying disc and the

whisks can be entirely dismantled, (Robot-

Coupe’s exclusive patented system), thereby

C

ensuring easy cleaning, perfect hygiene and

simple maintenance.

USES & EXAMPLES

The mixer function carries out all types of mixing in

small quantities in a minimum of time, and we thus

recommend you to supervise carefully all food

preparations in order to obtain the best results.

CATERING AND RESTAURANT WORK

• Soups, creamed soups

• Vegetable purees : carrots, spinach, celery,

turnips, French beans, potatoes etc.

• Mousses : vegetable, fish

• Fruit compotes

• Sauces : green, rouille, remoulade, cream

emulsions, tomato or parsley

• Bisques : langoustines and shellfish

• Pancake batter

• Chocolate mousse, butter cream, Whipped cream

• Cheese soufflé

HYGIENE

The equipment must be clean at all stages of

production.

It is vital to clean the power mixer thoroughly

between each job using a detergent or disinfectant.

• N.B. NEVER USE PURE BLEACH

- Dilute the detergent/disinfectant following the

manufacturer’s instructions on the label.

- Scrub well if necessary.

- Leave the disinfectant/detergent to take effect if

necessary.

- Rinse thoroughly.

- Dry properly using a clean cloth.

CLEANING

WARNING

As a precaution, always unplug your appliance

before cleaning it (risk of electrocution).

After using the power mixer in a hot preparation,

cool the bottom of the foot in cold water before dismantling the bell from the foot.

After completion of preparation, clean immediately

to prevent food from sticking to surfaces.

• MOTOR UNIT

Never put the motor unit and its handle in water,

clean them with a damp cloth or a sponge.

• FOOT AND BELL

It is possible to proceed in two ways:

• Simple cleaning procedure

- Place the foot and bell into a suitable container

with water and switch on for a few seconds to

clean the bell and the foot.

- After unplugging the appliance - essential -, making

sure that no water finds its way into the foot.

9

Page 10

- Detach the bell from the foot to avoid a build-up

of condensation (Mini MP 190 V.V., Mini MP

240 V.V., Mini MP 190 Combi and Mini MP

240 Combi).

• Complete cleaning procedure

- Unplug the power mixer.

- Rinse the bell under the tap.

- Remove the bell from the foot, then remove the

blades. Be careful to avoid damaging the surface

of the blade shaft and the watertight seals. Do not

use too strong a detergent when cleaning the

parts.

- Ensure that all the different parts are thoroughly

dried before reassembly.

• BLADE AND EMULSIFYING DISC

In order to clean the appliance thoroughly, the

blades and the disc must be removed from the bell

beforehand.

After they have been cleaned, make sure you

always dry the disc or blades properly to avoid

oxidation.

• WHISK

The whisks can be cleaned either by hand or in a

dishwasher.

Never immerse the gear box in water.

Never put in the dishwasher the gear box.

Clean it with a slightly damp cloth or sponge.

10

IMPORTANT

Check that your detergent is suitable for

cleaning plastic parts. Some washing agents are

too alkaline (e.g. high levels of caustic soda or

ammonia) and totally incompatible with certain

types of plastic, causing them to deteriorate

rapidly.

MAINTENANCE

• BLADE

The performance of the cut essentially depends on

the state of your blades and their wear. The blades

are subject to wear and as such need to be replaced

from time to time to ensure the consistent quality of

the end product.

You are also advised to change, at the same time,

the washer and the watertight seals.

• WHISK

The success of your preparation will depend

essentially on the state of the metal wires and their

amount of wear and tear. They should therefore be

replaced from time to time in order to ensure

optimum quality of the finished product.

• FOOT SEAL

In order to maintain a per fect watertight seal

between the foot and the bell it is necessary to

check the wear of the seal regularly and replace it if

necessary.

WARNING

Fromtimetotime,check:

- The state of the button’s watertight membrane.

Even the tiniest cracks will allow liquid to seep in.

- The state of the blender housing. This, should not

show any signs of cracking or any abnormal

openings which could allow access to the live

components.

TECHNICAL

SPECIFICATIONS

• WEIGHT AND DIMENSIONS (in mm)

Page 11

Models

Mini MP

160 V. V.

Mini MP

190 V. V.

Mini MP

240 V. V.

Mini MP

190 Combi

Mini MP

240 Combi

Dimensions (mm) Weight (Kg)

A B C D E F

78 430 65 160 1,41 1,94

78 470 65 190 1,44 1,97

78 520 65 240 1,47 2,00

78 470 65 190 255 100 1,95 2,68

78 520 65 240 255 100 1,98 2,70

Net Gross

• WORKING HEIGHT

We recommend that you ensure that the container is

placed on a stable and solid work surface.

• NOISE LEVEL

The equivalent continuous sound level when the foot

is not immersed in anything is less than 70 dB (A).

• ELECTRICAL DATA

Single-phase machine Mini MP 160 V.V.

Motor

Mixer Speed Power Intensity

(rpm) (watts) (Amp.)

230 V/50 Hz 2000 to 12500 220 1.1

120 V/60 Hz 2000 to 12500 215 1.9

220 V/60 Hz 2000 to 12500 200 1

Single-phase machine Mini MP 190 V.V.

Motor

Mixer Speed Power Intensity

(rpm) (watts) (Amp.)

230 V/50 Hz 2000 to 12500 250 1.3

120 V/60 Hz 2000 to 12500 245 2.4

220 V/60 Hz 2000 to 12500 230 1.2

Single-phase machine Mini MP 240 V.V.

Motor

Mixer Speed Power Intensity

(rpm) (watts) (Amp.)

230 V/50 Hz 2000 to 12500 270 1.5

120 V/60 Hz 2000 to 12500 265 2.6

220 V/60 Hz 2000 to 12500 250 1.4

Single-phase machine Mini MP 190 Combi

Motor

230 V/50 Hz

120 V/60 Hz

220 V/60 Hz

Mixer Speed Whisk Speed Power Intensity

(rpm) (rpm) (watts) (Amp.)

2000 to 12500 350 to 1560

2000 to 12500 350 to 1560

2000 to 12500 350 to 1560

250 1.3

245 2.4

230 1.2

Single-phase machine Mini MP 240 Combi

Motor

230 V/50 Hz

120 V/60 Hz

220 V/60 Hz

Mixer Speed Whisk Speed Power Intensity

(rpm) (rpm) (watts) (Amp.)

2000 to 12500 350 to 1560

2000 to 12500 350 to 1560

2000 to 12500 350 to 1560

270 1.5

265 2.6

250 1.4

SAFETY

WARNIN G

The blades are extremely sharp.

Handlewithcare.

ROBOT-COUPE power mixers are equipped with a

safety system comprising of a :

- safety control button,

- safeties on motor: thermal and overload protection.

• Safety control button

This safety mechanism prevents any unintentional

starting of the power mixer. In fact, it is necessary to

press down two buttons to start the power mixer.

In order to start the machine, read the paragraph

entitled OPERATING THE APPLIANCE (page 6).

• Thermal and overload protection

If there is an obstruction in the container (a spoon

or utensil) or the machine is exposed to over

use/overload, the thermal safety mechanism

automatically stop the motor. In this case, wait for

the power mixer to cool down completely before

restarting, see paragraph entitled OPERATING THE

APPLIANCE (page 6).

REMEMBER

Never tr y to override the locking and safety

mechanisms.

Never insert an object into the preparation.

Never switch the appliance on unless it has been

placed in the preparation bowl.

Before dismantling the foot or bell, always check

that the power mixer is unplugged.

We recommend that you tilt the power mixer at

a slight angle to prevent the bell from

touching the bottom of the container.

11

Page 12

PROBLEMS

STANDARDS

At first, try to identify precisely what has caused the

power mixer to stop.

• If it is due to a powercut if the appliance has

been unplugged.

- Release the control button (BC).

- Check the power supply.

- Restart the power mixer following the paragraph

entitled OPERATING THE APPLIANCE (page 6).

• If you cannot locate the cause of the problem

- Release the control button (BC).

- Unplug the power mixer.

- Check :

- the plug,

- that the blades are free to rotate in the bell,

- the state of the power cord,

- that the drive shaft is free to rotate. To do this,

remove the bell and test the rotation of the end of

the drive shaft manually.

If a malfunction occurs which is not on our list of

possible faults, consult your retailer or return the

appliance to the after-sales service.

MACHINES IN COMPLIANCE WITH:

• The following European directives and related

national legislation:

- Modified "machinery" directive 98/37/EEC,

2006/42/EEC,

- "Low voltage" directive 73/23/EEC,

2006/95/EEC,

- "EMC" directive 89/336/EEC, 2004/108/EEC,

- "Materials and parts in food contact" directive

89/109/EEC,

- Commission Directive 2002/72/EC of 6 August

2002 relating to plastic materials and articles

intended to come into contact with foodstuffs.

• The following European harmonized standards

and standards setting out health and safety rules:

- We certify that the Mini MP comply with

the essential requirements of the standard

EN 292 - 1 and 2: machine safety - general design

principles,

- EN 60204 -1 (2006).

- For hand-held blenders and whisk : EN 12853.

(Procedure to follow if the stick blender is

accidentally immersed during use).

12

Page 13

TECHNICAL DATA

13

Page 14

141516171819202122

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

23

Page 24

25

Page 25

FABRIQUÉ EN FRANCE PAR ROBOT-COUPE S.N.C.

Administration Commerciale France

& Service Après-Vente

Tél.:0385695000-Fax:0385695007

12, avenue du Maréchal Leclerc - BP 134

71305 Montceau-en-Bourgogne Cedex

email : france@robot-coupe.fr

Agence de Service Après-Vente

pour la Région Parisienne

Tél. : 01 43 98 88 15 - Fax : 01 43 74 36 26

48, rue des Vignerons

BP 157

94305 Vincennes Cedex - France

Export Department

Tel.:+33143988833-Fax:+33143743626

48, rue des Vignerons - BP 157

94305 Vincennes Cedex - France

http://www.robot-coupe.com - email : international@robot-coupe.com

Réf. : 410 294 - 09/2008 - Nouveaux Mini MP - Anglais

Loading...

Loading...