Page 1

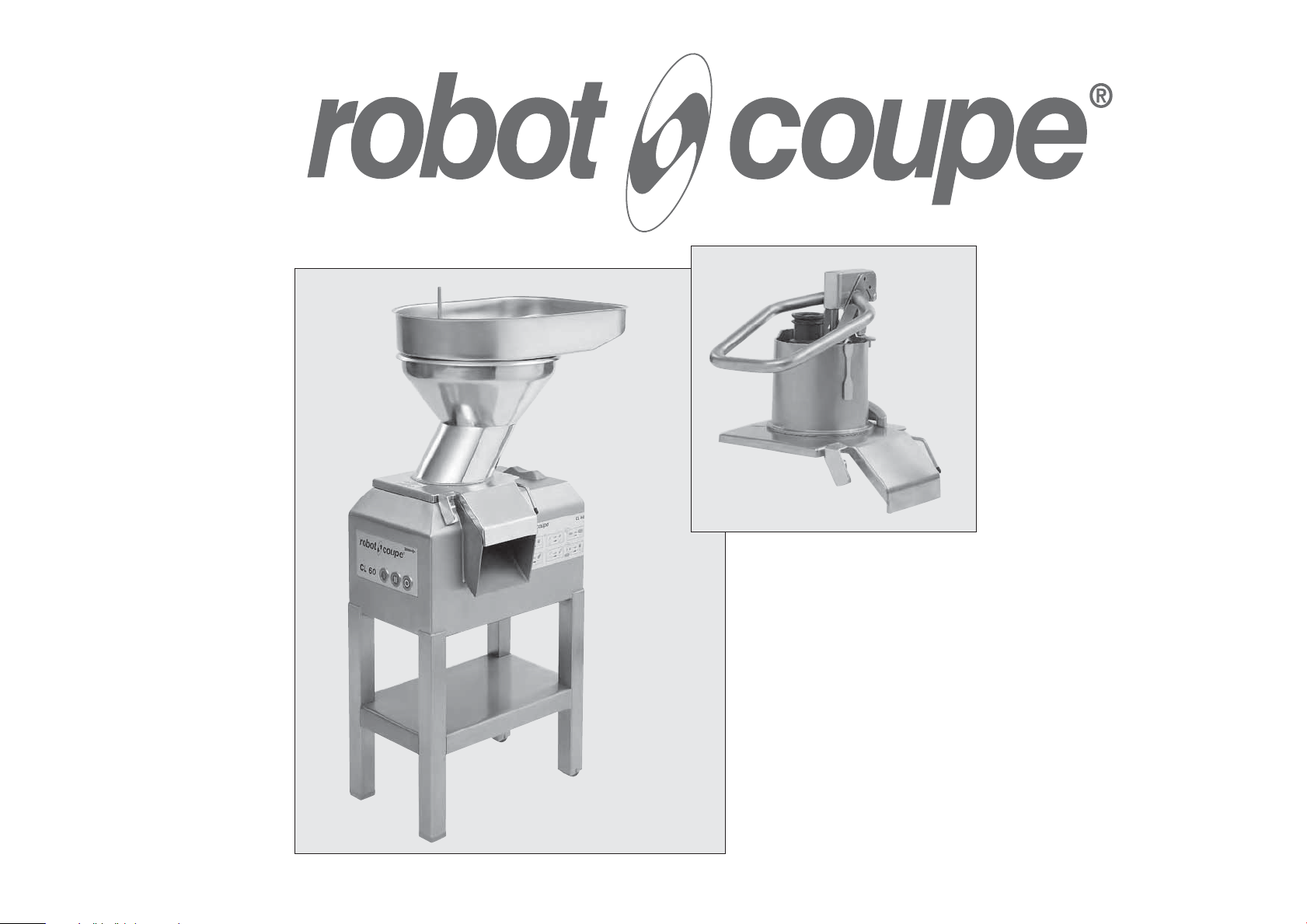

• CL 60 E

• CL 60 E V.V.

Page 2

DECLARATION OF CONFORMITY

Robot-Coupe

SNC:

Declares that the machines identified by their type above,

comply with:

• The essential requirements of the following European

directives and with the corresponding national

regulations:

- Directive «Machinery» 2006/42/EC,

- Directive «Low voltage» 2006/95/EC,

- Directive «Electromagnetic compatibility»

2004/108/EC,

- Regulation (EC) n°1935/2004 «Materials and articles

intended to come into contact with food»,

- Regulation (EU) n°10/2011 «Plastic materials and

articles intended to come into contact with food»,

- Directive «Reduction of Hazardous Substances (RoHS)

2002/95/EC,

- Directive «WEEE» 2002/96/EC,

• The requirements of the European harmonized standards

and with the standards specifying the hygiene and

safety requirements:

- EN 12100 -1 & 2 - 2004: Safety of machinery – General

principles for design,

- EN 60204-1 -2006: Safety of machinery – Electrical

equipment of machines,

- EN 12852: Food Processors and Blenders,

- EN 1678-1998: Vegetable Cutting Machines,

- EN 454: Blender-Mixers,

- EN 12853: Hand-held Blenders and Whisks (stick

blenders),

- EN 14655: Bread Slicers,

- EN 13208: Vegetable Preparation Machines,

- EN 13621: Salad Spinners,

- EN 60529-2000: Degrees of protection,

- IP 55 for the electrical controls,

- IP 34 for the machines.

Signed in Montceau en Bourgogne on 19 February 2013

Alain NODET

Industrial Director

Robot-Coupe SNC - 12 avenue du Maréchal Leclerc – BP 134 – 71305 Montceau-les-Mines Cedex - France

Page 3

SUMMARY

WARRANTY

IMPORTANT WARNING

INTRODUCTION TO YOUR NEW

VEGETABLE PREPARATION MACHINE

CL 60 E • CL 60 E V.V.

SWITCHING ON THE MACHINE

• Advice on electrical connections

• Control panel

FUNCTIONS OF HOPPERS

AND THEIR TOOLS

• Pusher feed-head

• Hole feed head

• Automatic feed head

INSTALLING THE DISCS AND TOOLS

CLEANING

MAINTENANCE

• Motor seal

• Blades and plates

• Grating discs

TECHNICAL SPECIFICATIONS

• Weight

• Dimensions

• Working height

• Noise level

• Electrical data

SAFETY

INSTALLING THE HOPPERS

• Pusher feed-head

• Hole feed head

• Automatic feed head

CHANGING THE DISCS

CHOOSING THE RIGHT DISC

VARIABLE SPEED CL 60 V.V.

STANDARDS

TECHNICAL DATA

• Exploded views

• Electrical and wiring diagrams

17

Page 4

ROBOT-COUPE S.N.C., LIMITED WARRANTY

Your new ROBOT-COUPE appliance is

warranted to the original buyer for a

period of one year from the date of sale

if you bought it from ROBOT-COUPE

If you bought your ROBOT-COUPE product

from a distributor your product is covered

by your distributor’s warranty (Please check

with your distributor terms and conditions

of the warranty).

The ROBOT-COUPE

is against defects in material and/or workmanship.

S.N.C. limited warranty

S.N.C.

THE FOLLOWING ARE NOT

COVERED BY THE ROBOT-COUPE

S.N.C. WARRANTY:

1 -

dropping, or other similar damage caused

by or resulting from failure to follow assembly,

operating, cleaning, user maintenance or storage

instructions.

Damage caused by abuse, misuse,

2 - Labour to sharpen and/ or replacements

for blades which have become blunt, chipped or

worn after a normal or excessive period of use.

3 - Materials or labour to replace or repair

scratch ed, stained, chipped, pitted, dented or

discoloured surfaces, blades, knives, attachments

or accessories.

4 - Any alteration, addition or repair that has not

been carried out by the company or an approved

service agency.

5 - Transportation of the appliance to or from an

approved service agency.

6 - Labour charges to install or test new

attachments or accessories (i.e., bowls, discs,

blades, attachments) which have been arbitrarity

replaced.

7 - The cost of changing direction-of-rotation

of three-phase electric motors (installer is

responsible).

8 - SHIPPING DAMAGES. Visible and latent

defects are the responsibility of the freight carrier.

The consignee must inform the carrier and

consignor immediately, or upon discovery in the

case of latent defects.

KEEP ALL ORIGINAL CONTAINERS AND

PACKING MATERIALS FOR CARRIER

INSPECTION.

Neither ROBOT-COUPE

companies or any of its distributors, directors,

agents, employees, or insurers will be liable for

indirect damage, losses, or expenses linked to the

appliance or the inability to use it.

The ROBOT-COUPE S.N.C. warranty is given

expressly and in lieu of all other warranties, expressed or implied, for merchantability and for fitness toward a particular

purpose and constitutes the only warranty

S.N.C. nor its affiliated

18

made by ROBOT-COUPE

S.N.C. France.

Page 5

ATTENTION

CONSERVER CES INSTRUCTIONS

IMPORTANT WARNING

WARNING: In order to limit accidents such as electric shocks or personal injury or fire, and in order to limit material damage

due to misuse of the appliance, please read these instructions carefully and follow them strictly. Reading the operating instructions

will help you get to know your appliance and enable you to use the equipment correctly. Please read these instructions in their

entirety and make sure that anyone else who may use the appliance also reads them beforehand.

UNPACKING

• Carefully remove the equipment from the packaging and take out all the boxes or packets containing

attachments or specific items.

• WARNING - some of the tools are very sharp e.g.

blades, discs, etc..

INSTALLATION

• We recommend you install your machine on a

perfectly stable solid base.

CONNECTION

• Always check that your mains supply corresponds

to that indicated on the identification plate on the

motor unit and that it can withstand the amperage.

• The machine must be earthed.

• With the three-phase version, always check that

the blade rotates in an anti-clockwise direction.

HANDLING

• Always take care when handling the blades or

discs, as they are extremely sharp.

USE

• Never try to override the locking and safety systems.

• Never insert an object into the container where the

food is being processed.

• Never push the ingredients down with your hand.

• Do not overload the appliance.

• Never switch the appliance on when it is empty.

CLEANING

• As a precaution, always unplug your appliance

before cleaning it.

• Always clean the appliance and its attachments at

the end of each cycle.

• Never immerse the motor base in water.

• For parts made from aluminum, use cleaning fluids

intended for aluminum.

• For plastic parts , do not use detergents that are

too alkaline (i.e. containing too much caustic soda

or ammonia).

• Robot-Coupe can in no way be held responsible for

the user’s failure to follow the basic rules of cleaning

and hygiene.

MAINTENANCE

• Before opening the motor housing, it is absolutely

vital to unplug the appliance.

• Check the seals and washers regularly and ensure

that the safety devices are in good working order.

• It is particularly important to maintain and check

the attachments since certain ingredients contain cor-

rosive agents, e.g. citric acid.

• Never operate the appliance if the power cord

or plug has been damaged or if the appliance fails

to work properly or has been damaged in any way.

• Do not hesitate to contact your local Maintenance

Service if something appears to be wrong.

19

Page 6

INTRODUCTION TO

YOUR NEW VEGETABLE

PREPARATION MACHINE

CL 60 E • CL 60 E V.V.

The CL 60 is perfectly geared to professional needs.

It can perform any number of tasks, which you will

gradually discover as you use it.

The CL 60 “E” version is built from stainless steel

(100% stainless steel motor base and automatic

feed head). It has been designed to operate at two

speeds, 375 and 750 rpm, in order to ally accuracy

of cut with rapidity.

It can be fitted with any one of 4 different feed heads,

in order to increase the machine’s output, make the

user’s job easier and offer the most appropriate tool

for each type of preparation. The heads are designed

to be tilted in line with the motor base, in order to

reduce space and facilitate use.

The CL 60 is supplied with a wide range of discs

and grids to satisfy even the most demanding chefs

when it comes to processing fruit and vegetables, as

they can be used for slicing, ribbon cutting, grating,

shredding, dicing,chipping and ripple-cutting.

Its numerous functions will open the door to a whole

new culinary world.

Thanks to its simple design, all components requiring

frequent handling for maintenance or cleaning can

be fitted and removed in a trice.

To make things easier for you, this manual supplies a

breakdown of all the various fitting operations.

These instructions contain important information

designed to help the user get the most out of the CL60

vegetable preparation machine.

We therefore recommend that you read them

carefully before using your machine.

20

We have also included a few examples of use to help

you get the feel of your new machine and appreciate

its many advantages.

SWITCHING ON

THE MACHINE

• ADVICE ON ELECTRICAL CONNECTIONS

Before plugging in your appliance, check that your

power supply corres ponds to that indicated on the

machine’s identi fication plate.

WARNING

THIS APPLIANCE MUST BE PLUGGED INTO AN EARTHED

SOCKET (RISK OF ELECTROCUTION).

CL 60 Three-phase

ROBOT-COUPE CL 60 models are fitted with various

types of motors : 230 / 400 V switchable / 50 Hz / 3

400 V / 50 Hz / 3

220 V / 60 Hz / 3

380 V / 60 Hz / 3

The machine is supplied with a cable to which you

simply attach the appropriate electrical plug for your

system. The cable has four wires, one earth wire,

plus three phase wires.

If you have a 4-pin plug :

1) Connect the green and yellow earth wire to the

earth pin.

2) Connect the three other wires to the remaining

pins.

If you have more than 4 pins in the plug please note

the ROBOT-COUPE does not require a neutral wire.

Switch on the empty machine, making sure that

the blade is rotating properly in an anti-clockwise

direction.

On the motor unit, a red arrow marks the blade

rotation direction. If the blade turns in a clockwise

direction, swap over two wires :

Since GREEN/YELLOW is the earth,

DO NOT DISCONNECT.

Swap either : the

the

the

CL 60 V.V. Single phase (variable speed)

This model is fitted with a 180-260V/50-60 Hz

three-phase motor.

However, the machine has a single-phased power

supply, which a frequency regular converts into

three-phase.

The machine is supplied with a power cord to which

you simply attach the appropriate electrical plug for

your system. The cable has 3 wires: one earth wire,

plus a phase conductor and a neutral wire.

The machine must be fitted with a 20-amp plug.

and the

and the

and the

• CONTROL PANEL

”Off” button

2 green button :

“On” button for the first speed (375 rpm)

“On” button for the second speed (750 rpm)

CL 60 V.V.:

Speed Variation from

100 to 1000 rpm.

Page 7

FUNCTIONS OF HOPPERS

AND THEIR TOOLS

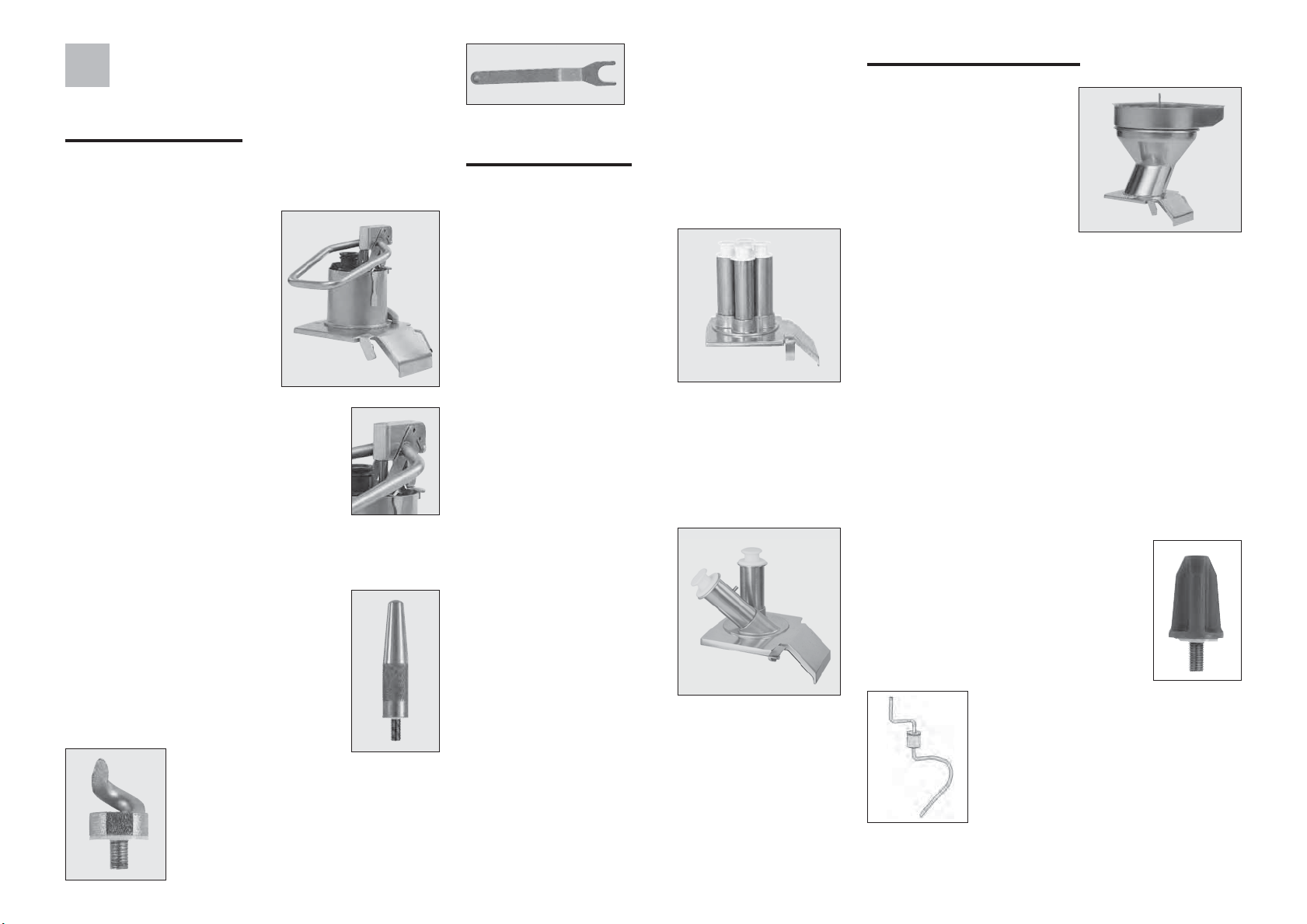

• PUSHER FEED-HEAD

This hopper allows you to prepare all types of

vegetables:

- the large feed hopper is

used to prepare bulky

vegetables such as

cabbage, celery, lettuce,

etc.,

- the tube is used to prepare

long or fragile fruit or

vegetables.

The lever-fitted feed tube can be

adjusted to 3 positions depending on

the height of the operator. To change

the position, loosen the attachment

and adjust to the desired position.

Two types of tool are designed for the lever-type

hopper:

1) The loading cone, which guides

the vegetables (except for cabbage)

towards the blades. This tool must be

screwed firmly onto the motor shaft.

2) The hollowing cutter used only to

prepare cabbage.

A special tool for unlocking

the cabbage corer.

• HOLE FEED HEADS

4 TUBES FEED-HEAD

This feed-head is equipped

with 4 straight holes: 2

straight tubes of 50 mm

diameter and 2 straight

tubes of 70 mm diameter.

This hopper is designed

for the preparation of long

vegetables like carrots, cucumbers,leeks, etc., or

of fragile fruit and vegetables such as tomatoes,

bananas, etc.

STRAIGHT AND SLOPING TUBE HOPPER

This hopper consists of

two straight tubes with

a diameter of 75 mm

diameter, a 50 mm insert

and 2 pushers of 50 mm

and 70 mm. The insert

allows you to modify the

diameter of the tubes.

This hopper performs the same functions as the

one described above with its straight tube. But it is

different in that it is equipped with a sloping tube

especially designed for slanted cutting.

No special tool is required to attach these hoppers

onto the disc.

• AUTOMATIC FEED-HEAD

This hopper is intended for

continuous cutting tasks.

It is ideal for slicing

delicate vegetables such as

mushrooms and tomatoes,

grating carrots, slicing

potatoes and cutting french

fries, to mention but a few

of its uses.

This hopper is not suitable for certain specific tasks,

such as :

- slicing long vegetables (use the hole feed-heads).

- preparing bulky vegetables which are too big to

be fed into this hopper (use the pusher feed-head).

Make sure that the agitator is in place, in order to

avoid blockages and variations in cutting quality.

It is vital that this tool be fitted each time the

automatic hopper is used.

Two types of tool are designed for the lever-type

hopper:

1) The agitator, which guides the

vegetables (except for cabbage)

towards the blades.

2) Introducing the vegetables too

quickly can result in a logjam. If this

occurs, clear the blockage using the

crank supplied for that purpose (all

other means are strictly prohibited).

The crank serves to clear the machine if it becomes

clogged up with bulky vegetables.

21

Page 8

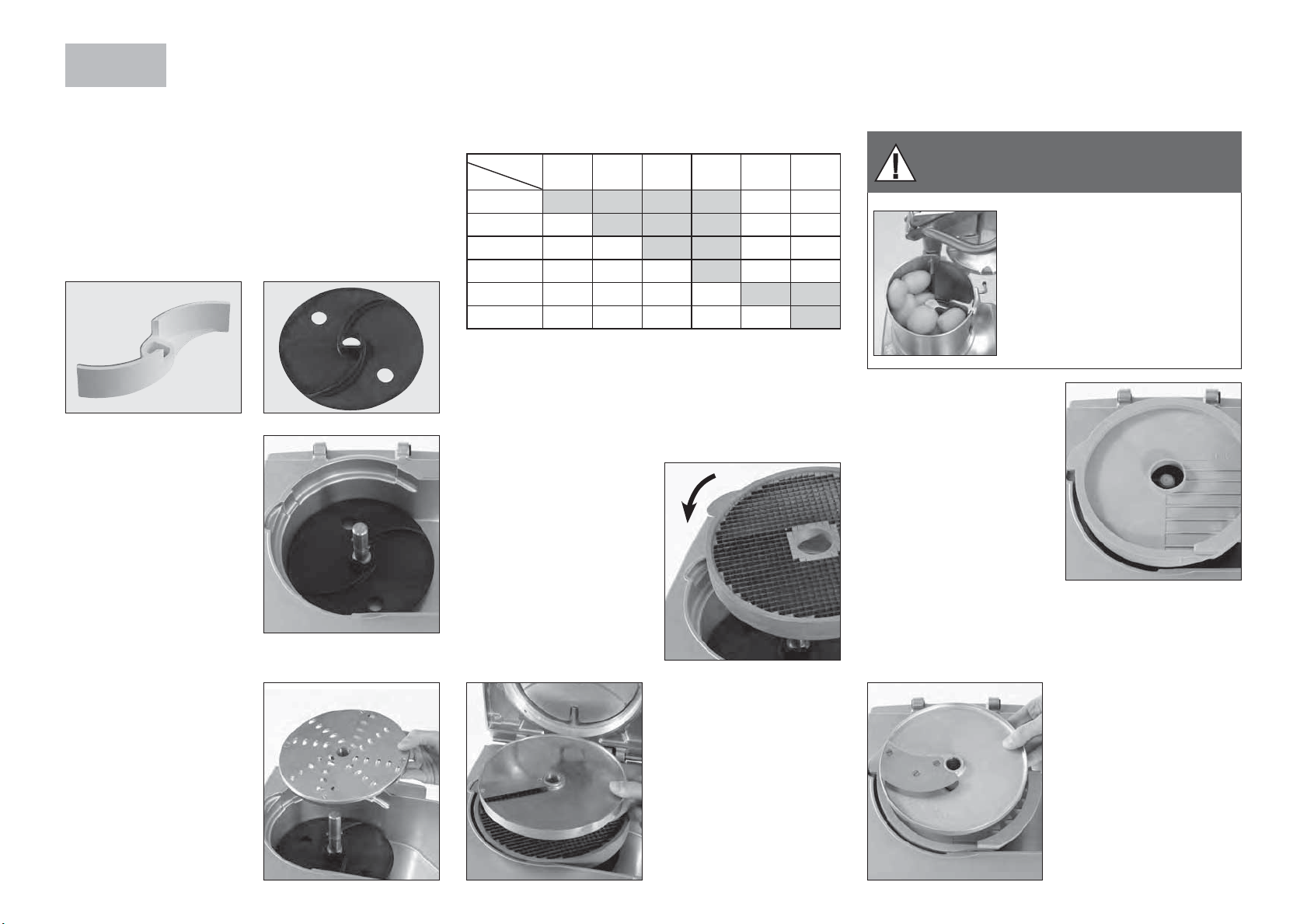

INSTALLING THE DISCS

AND TOOLS

Two ejection tools:

The CL 60 is supplied with two ejection tools. The

white ejector has been specially designed to cope

with cabbage. For all other vegetables, use the black

plastic ejector disc.

With the motor unit

facing you, slot the black

or white ejection tool

onto the motor shaft and

check that it is properly

positioned at the bottom

of the bowl.

Position your chosen disc:

b) You have chosen a dicing unit:

i.e. a grid and a special slicing disc for diced

vegetables.

Slicing discs and dicing grids can be mounted in the

following combinations:

Dicing grid

Slicer

5 mm

8 mm

10 mm

14 mm

20 mm

25 mm

You will find all the combinations marked • on our

machines and accessories price list.

The dimensions of the dicing grid should always be

equal to or greater than those of the slicing disc.

Place the dicing grid in

the bowl of the vegetable

processor.

Make sure that the spur on

the grid is fully engaged

in the locking slot of the

motor unit.

5x5 mm8x8 mm10x10 mm14x14 mm20x20 mm25x25

mm

• •••••

• • ••••

••• • ••

•••• ••

••••• •

••••••

c) If you want to use the French fries potatoes

cutting equipment:

This equipment comprises a French fries grid and a

special French fries slicing disc.

WARNING

PUSHER FEED HEAD

To get the very best results

when cutting french fries,

remember to insert the removable

divider in the hopper and

load the potatoes into the lefthand compartment (see photo

opposite).

Position the French fries

grid in the vegetable

preparation bowl.

Check that it is correctly

positioned with the French

fries plate positioned at

the outlet.

No tools (loading cone or cabbage corer) are

required when using the divider.

a) If you have opted

for a slicing, grating or

julienne disc:

Position the disc on the

motor shaft. To ensure that

it is correctly positioned,

turn it in a clockwise

direction.

22

Next, fit the corresponding

slicing disc (straightedged blade) and rotate

in a clockwise direction to

ensure that it is correctly

positioned.

Next fit the appropriate

slicing disc and rotate in

a clockwise direction to

check that it i correctly

positioned.

Page 9

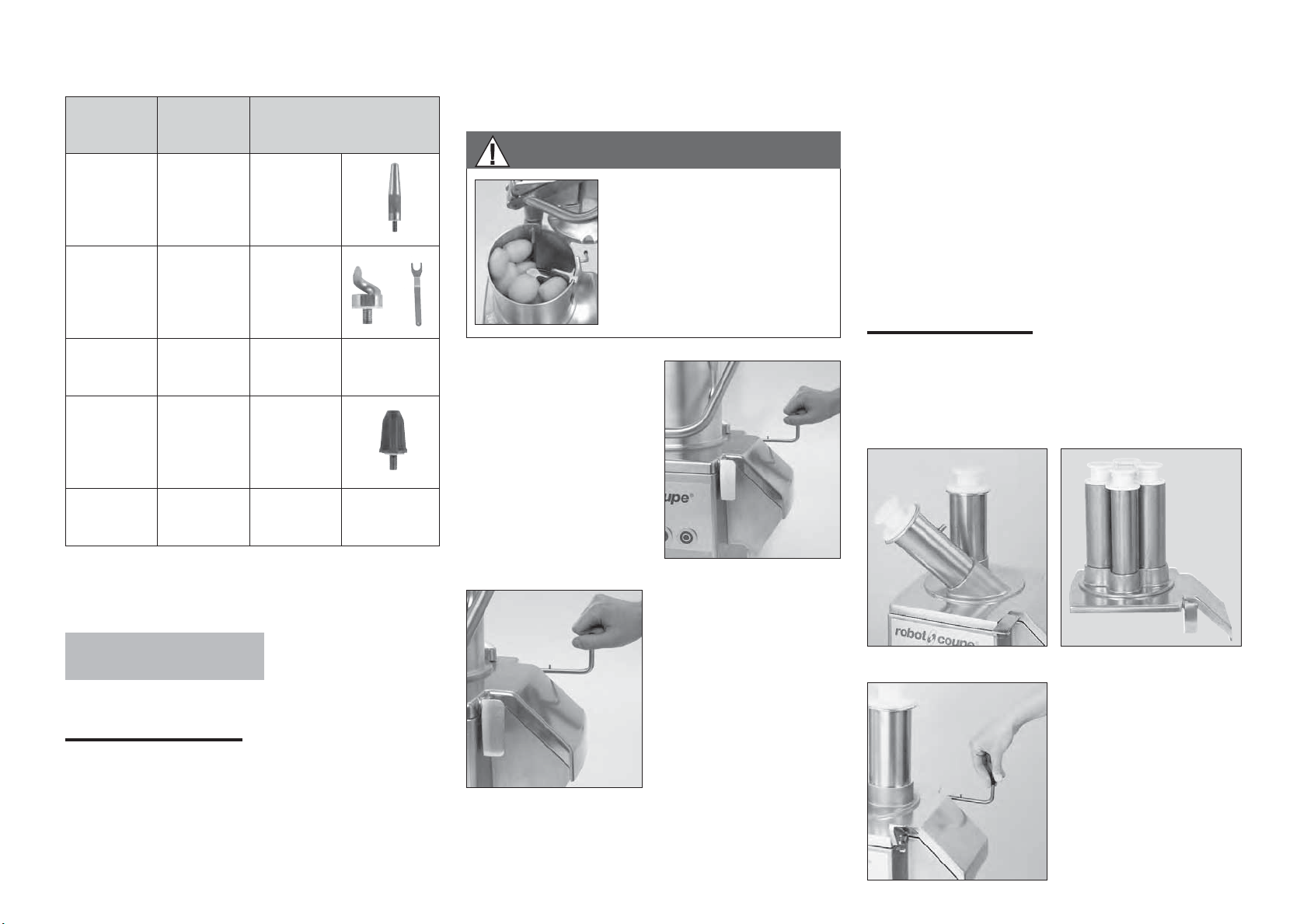

The choice of disc-fixing tool will vary according

to the hopper and the type of vegetable:

Always press the vegetables down with a pusher

toimprove cutting efficiency.

- Press the pusher down to guide the food through

the machine. The exact amount of pressure

Hopper Vegetable Tool

Pusher

Pusher Cabbage

Pusher French fries

Automatic All Agitator

4-hole All No tool

All types except

for cabbage and

french fries

Loading cone

Cabbage corer

+ key

Removable

partition

+

HOW TO USE THE CYLINDRICAL HOPPER

WARNING

To get the very best results

when cutting french fries,

remember to insert the

removable divider in the

hopper and load the potatoes

into the left-hand compartment

(see photo opposite).

Position the veg prep

hopper on the motor unit.

The locking handle should

be facing you, on the

right.

required will depend on the nature of the cut,

bearing in mind that too much force reduces

cutting quality without increasing throughput.

- Cut cabbages in half and remove the core before

processing, in order to avoid unnecessary strain

and ensure an end-product of a higher quality.

- Lift the pusher and allow access to the feed tube.

• HOLE FEED HEADS

Position the 4-hole hopper, or the straight and

inclined hole hopper, on the motor unit. The locking

handle should now be facing you, on the right.

Screw the tool (unless you are using the removable

partition) firmly onto the motor shaft.

INSTALLING

THE HOPPERS

• PUSHER FEED-HEAD

USING THE FEED TUBE

Fill the feeder right up to the top with vegetables.

Apply a downwards pressure on the pusher and

maintain it until all the vegetables have been

processed.

Slide the hinge pin into

the slots provided at the

back of the motor base.

Next, lock the lid onto

the motor unit using the

locking handle.

- Fill the feeder right up to the top with vegetables.

- Lower the pusher so that it is flush with the top of

the feed opening.

Slip the hinge pin into

the locations provided at

the back of the motor

base. The locking handle

should now be facing

you, on the right.

23

Page 10

• AUTOMATIC FEED-HEAD

Proceed as specified for the pusher-feed

et

head.

Screw the agitator

onto the motor shaft.

Screw the agitator onto

the motor shaft.

Insert the crank into

the central hub of the

head. Turn it until the

part is inside the hub.

Free the disc by lifting it by its edges.

For dicing equipment, you are advised to pull out

the grid and disc assembly together. Then remove

the discharge disc using the two holes.

If the disc is stuck, turn it slightly in the anticlockwise

direction.

Slide the hinge pin

into the slots provided

at the back of the motor

base.

Then, lock the lid onto

the motor base using the

fastening hook.

24

Position the automatic

hopper on the motor

base. The fastening hook

is now facing you on

your right.

CHANGING

THE DISCS

The machine should be switched off (by pressing the

red push-button) before starting to change the disc.

With the motor unit facing you, use your right

hand to release the aluminium fastening hook

used to lock the hopper onto the motor base.

a) Feed opening fitted with a lever:

Lift the pusher and release the bowl by tilting

it to the left so that the hopper can be tittled

backwards. Then inscrew the loading cone or

the hollowing cutter. For the hollowing cutter,

use the dismantling tool provided for that

purpose.

b) With hole feed-head:

First remove the inserts and the pushers and

then lift the fastening hood in order to tilt the

hopper backwards to release the bowl.

c) Automatic feeder:

Lift the fastening hook in order to tilb the

hopper backwards to release the bowl.

When fitting dicing equipment, it is advisable to

clean the inside of the bowl thoroughly with a

damp cloth or sponge, especially the part onto

which the grid is to be fitted.

We recommend that your remove the grid and disc

together. To make the job easier, turn the ejector

disc.

Always use a properly cleaned grid. Never process

soft foodstuffs after hard ones without properly

cleaning the grid beforehand.

Use our D-Clean Kit (ref. 39881) to clean your 5x5,

8x8 and 10x10 dicing grids quickly and easily.

Then fit the discharge disc, the slicing, grating

or julienne disc, or the dicing equipment as

described in steps 1) and 2) in the previous

section on the relevant hopper.

Close the hid using the fastening hook.

Page 11

CHOOSING

THE RIGHT DISC

SLICERS

S 0,6

amands

S 0,8

cabbage

S 1 carrot /

S 2 / S 3

S 4 / S 6 courgette / beetroot / carrot /mushroom / cucumber /

S 8 / S 10

S 1 4

RIPPLE CUT SUCER

R 2

R 3

R 5

GRATER

G 1,5

G 2

G 3

G 5

JULIENNE

J 1x8

J 2x2

J 2,5x2,5

J 2x4

J 2x6

J 2x10

J 4x4

J 6x6

J 8x8

cabbage / cucumber / onion / potato / leek

lemon / carrot / mushroom / cabbage / potato / cucumber /

courgette / onion / leek / bell pepper

bell pepper /radish / lettuce / potato / leek / tomato

courgette / potato / courgette / carrot

potato / courgette / carrot

beetroot / potato / carrot / courgette

beetroot / potato / carrot / courgette

beetroot / potato / carrot / courgette

celeriac / cheese

carrot / celeriac / cheese

carrot

cabbage / cheese

carrot / celeriac / potato / courgette

carrot / celeriac / potato

carrot

carrot / beetroot / courgette / potato

carrot / beetroot / courgette / potato

carrot / beetroot / courgette / potato / celeriac

egglant / beetroot / courgette / potato

egglant / beetroot / celeriac / courgette / potato

céleriac / patato

G 7

G 9

Parmesan/chocolate

Radish

cabbage / cheese

cabbage / cheese

DICE

D 5x5

D 8x8

D 10x10

D 14x14

D 20x20

D 25x25

D 50X75

carrot /courgette / cucumber / celeriac

potato / carrot / courgette / beetroot

potato / carrot / courgette / beetroot /turnip / onion /

apple (fruit)

potato / carrot / courgette / turnip / celeriac

potato / carrot / courgette / pineapple / turnip

potato / courgette / turnip / apple (fruit) / melon /

watermelon

salad

FRENCH FRIES

F 8x8

F 10x10

F 10x16

potato

potato

potato

CLEANING

WARNING

As a precaution, always unplug your appliance

before cleaning it (risk of electrocution).

After removing the head of the vegetable

preparation machine, take off the disc, followed by

the grid and discharge plate where necessary.

Dishwashers are best avoided in order to prevent

the aluminium from becoming tarnished. Instead we

recommend that you clean the machine by hand using

washing-up liquid.

If you do put your machine in a dishwasher, we suggest that you use a detergent designed specially for

alu minium.

Never immerse the motor base in water. Clean it

with a damp cloth or sponge.

IMPORTANT

Check that your detergent is suitable for

cleaning plastic parts. Some washing agents are too

alkaline (e.g. high levels of caustic soda or

ammonia) and totally incompatible with certain types

of plastic, causing them to deteriorate rapidly.

MAINTENANCE

• MOTOR SEAL

The motor seal on the shaft should be lubricated

regularly using a food safe lubricant.

In order to keep the motor completely watertight, it is

advisable to check the motor seal regularly for wear

and tear and replace if necessary.

The motor seal can be easily replaced without

having to remove the motor, so we strongly advise

you to ensure that is in good condition.

• BLADES AND PLATES

The blades on all our discs are wearing parts

that need to be replaced from time to time, in

order to maintain consistently high cutting

quality.

• GRATING DISCS

Grating discs deteriorate over time. We recommend

you replace them from time to time, in order to

maintain consistently high cutting quality

25

Page 12

TECHNICAL

• WORKING HEIGHT

SAFETY

SPECIFICATIONS

• WEIGHT

Net Gross

Motor base

Automatic feed-head

Pusher feed-head

Hole feed-heads

Trolley 8 kg 10 kg

Disc

0,5 kg 0,6 kg

• DIMENSIONS (in mm)

43 kg 57 kg

13 kg 16 kg

7 kg 12 kg

8 kg 11 kg

We advise you to place your CL 60 on a stable

surface. There is no recommended working height

as this is a floor-standing model.

• NOISE LEVEL

The equivalent continuous sound level when the CL 60

is operating on no-load is less than 70 dB (A).

• ELECTRICAL DATA

CL 60 V.V. single-phase supply

Motor

230 V/50-60 Hz 100 to 1000 5,8

CL 60 three-phase

Motor

230/400 V/50 Hz

switchable

400 V/50 Hz

220 V/60 Hz

Speed

(rpm)

Speed

(rpm)

375

750

375 2,7

750 3,4

450 4,7

900 6,5

Intensity

(amp.)

Intensity

(amp.)

230 V=4,5

400 V=2,6

230 V=4,1

400 V=2,3

WARNING

THE DISCS ARE EXTREMELY SHARP.

HANDLE WITH CARE.

The CL 60 is fitted with magnetic safety system

which stops the motor as soon as the large hopper

or lid is opened, thus preventing any access to the

cutting tool while it is in motion.

As soon as the lid opens, the motor stops.

To restart your machine, simply relock the lid and

press the green switch.

When using the hopper equipped with a lever, the

motor is stopped as soon as the lever is removed

from the bowl. To start the machine again, you

should simply position the lever at the aligned with

the base of the bowl.

These models are fitted with a thermal safety device

which automatically stops the motor if the machine

is left on for too long or is overloaded.

26

450 2,5

380 V/60 Hz

900 3,5

- Power shown on data plate.

The hinge pin must be fitted in its position at the back

of the motor unit before the machine is switched on.

Page 13

REMINDER

STANDARDS

Never try to override the locking and safety

systems.

Never insert an object into the container

where the food is being processed.

Never push the ingredients down with your

hand.

Do not overload the appliance.

Never switch the appliance on when it is

empty.

CL 60 V.V.

VARIABLE SPEED

• CHARACTERISTICS

The CL 60 V.V. variable speed model allows for

an even greater quality of cut thanks to a range of

speeds going from 100 to 1000 rpm.

Consult the declaration of compliance on page 2.

This speed variation allows you to adapt the speed

according to the type of cut and texture of the fruit or

vegetable being processed. This guarantees optimum

accuracy and quality of cut.

The standard CL 60 V.V. variable speed model is

fitted with a stainless steel automatic feed head. It

can be equipped as an option with a pusher feed

head and a hole feed head.

27

Page 14

174

Page 15

175

Page 16

177

Page 17

178

Page 18

179

Page 19

181

Page 20

182

Page 21

183

Page 22

185

Page 23

186

Page 24

187

Page 25

188

Page 26

189

Page 27

Head Office, French,

Export and Marketing Department:

48, rue des Vignerons

94305 Vincennes Cedex- France

Tel.: 01 43 98 88 15 - Fax: 01 43 74 36 26

Email: international@robot-coupe.com

Robot Coupe Australia Pty Ltd:

Unit 3/43 Herbert St

Artarmon NSW 2064 Australia

T (02) 9478 0300

F (02) 9460 7972

Email: orders@robotcoupe.com.au

Robot-Coupe U.K. LTD:

Fleming Way, Isleworth,

Middlesex TW7 6EU

Tel.: 020 8232 1800

Fax: 020 8568 4966

Email: sales@robotcoupe.co.uk

www.robot-coupe.com

Réf. : 404 13 - 1/2013

Loading...

Loading...