Robot Coupe CL 60 Installation Manual

CL 60

Series ”D”

P.O. Box 16625, Jackson, MS 39236-6625

280 South Perkins St., Ridgeland, MS 39157

e-mail: robocoup@misnet.com - website: www.robotcoupeusa.com

Phone : 1-800-824-1646

WARNING: In order to limit accidents such as electric shocks, personal injury or fire, and in order to limit material damage due to

misuse of the appliance, please read these instructions carefully and follow them strictly. Reading the operating instructions will

help you get to know your appliance and enable you to use the equipment correctly. The operation manual should be kept within

easy access to all users for reference and should be read completely by all first time users of the machine.

IMPORTANT WARNING

UNPACKING

• Carefully remove the equipment from the packaging and take out all the boxes or packets containing

attachments or specific items.

•WARNING-some of the parts are very sharp e. g.

blade, plates … etc.

INSTALLATION

•We recommend that you install your machine on a

stable solid base at a comfortable working height.

CONNECTION

•Always check that your power supply corresponds

to that indicated on the serial number plate and that

it is properly sized.

NOTICE

: DRIVE SHAFT ROTATION

• Three phase motors may rotate

either direction.

• The required motor rotation is counterclockwise.

• Changing the motor rotation requires a qualified

electrician.

• See note on end of power cord.

HANDLING

•Always wear cut-resistant gloves when handling

the cutting plates.

ASSEMBLY PROCEDURES

•Follow the various assembly procedures carefully

(see page 7) and make sure that all the attachments

are correctly positioned.

USE

•Do not open the feed head until the motor has

come to a complete stop.

•Never tamper with or defeat the purpose of the

locking and safety systems.

•Never put a hand or nonfood object in the entry or

exit chutes.

•Do not overload the machine.

• Do not leave the machine running unattended.

CLEANING

•Always unplug your appliance before cleaning.

•Always clean the appliance and attachments at the

end of each use.

•Never place the motor unit in water.

•For parts made of aluminum alloys, use cleaning

detergents suitable for aluminum.

•For plastic parts, do not use detergents that are too

alkaline (i.e., containing too much caustic soda or

ammonia…).

• Robot-Coupe can in no way be held responsible

for the user’s failure to follow the basic rules of cleaning and maintenance.

MAINTENANCE

•Always unplug the appliance before servicing.

•Check the seals regularly and ensure that the safety devices are in good working order.

•It is particularly important to maintain and check

the attachments since certain products contain

corrosive agents e.g. citric acid.

•NOTICE

: Never operate the appliance if the

power cord or plug has been damaged. If the

machine fails to operate as described in this

manual, or if the machine malfunctions in any way,

remove the machine from use and have it serviced.

Additionally, discard all food processed at the time

of the malfunction.

• Contact your local Authorized Service Agency if

something appears to be wrong.

KEEP THESE INSTRUCTIONS

IN A SAFE PLACE

W ARNING

1

ENGLISH

FRANÇAIS

OPERATING INSTRUCTIONS

MANUAL DE INSTRUCCIÓN

NOTICE D’INSTRUCTIONS

We reserve the right to alter at any time without notice the technical specifications of this appliance.

© All rights reserved for all countries by : ROBOT-COUPE

S.N.C

.

Nos reservamos el derecho de modificar en todo momento y sin previo aviso las características técnicas de este aparato.

© Todos los derechos para cada pais reservados por: ROBOT-COUPE S.N.C.

Nous nous réservons le droit de modifier à tout moment et sans préavis les caractéristiques techniques de cet appareil.

© Tous droits réservés pour tous pays par : ROBOT-COUPE S.N.C.

ESPAÑOL

SUMMARY

WARRANTY

IMPORTANT WARNING

INTRODUCTION TO YOUR

NEW VEGETABLE PREPARATION

MACHINE CL 60 Series “D”

SWITCHING ON THE MACHINE

• Advice on electrical connections

• Control panel

FUNCTIONS OF HEADS

AND THEIR TOOLS

• Bulk feed head

• Whole head feed “Pusher” assembly

• Tube feed heads

ASSEMBLY

• Bulk feed head

• Whole head “Pusher” feed head

• Tube feed heads

USES AND CHOICE OF PLATES

CLEANING

MAINTENANCE

• Blades and grids

• Motor seal

SAFETY

TECHNICAL DATA

(Page 27)

• Exploded views

• Electrical and wiring diagrams

3

ENGLISH

4

ROBOT-COUPE U.S.A., INC. LIMITED WARRANTY

YOUR NEW ROBOT-COUPE PRODUCT IS

WARRANTED TO THE ORIGINAL PURCHASER

FOR A PERIOD OF ONE YEAR FROM THE

DATE OF PURCHASE.

This LIMITED WARRANTY is against defects in

the material and/or workmanship, and

includes labor for replacement of defective

parts, provided repairs are performed by an

authorized service agency (see attached list).

The CUSTOMER must inform the Service

Agency of the possibility of warranty coverage and provide a copy of the dated sales or

delivery receipt BEFORE WARRANTY REPAIRS

ARE BEGUN. Replacement parts and accessories are warranted for ninety (90) days

from the date of purchase when purchased

separately and will be verified by dated sales

receipt OR packing slip which lists that item.

All parts or accessories replaced under warranty must be returned to the Service Agency.

THIS WARRANTY IS GIVEN EXPRESSLY AND

IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, FOR MERCHANTABILITY AND FOR FITNESS TOWARD A PARTICULAR PURPOSE AND CONSTITUTES THE

ONLY WARRANTY MADE BY ROBOTCOUPE, U.S.A., Inc.

THE FOLLOWING ARE “NOT” COVERED UNDER WARRANTY:

1 - Damage caused by abuse, misuse, drop-

ping, or other similar incidental damage caused

by or as a result of failure to follow assembly,

operating, cleaning, user maintenance, or storage instructions.

2 - Labor to sharpen and/or parts to replace

knife assemblies or blades which have become

dull, chipped, or worn due to normal use.

3 - Material or labor to renew or repair

scratched, stained, chipped, dented or discolored

surfaces, blades, knives, attachments, or accessories.

4 - Transportation charges to or from an autho-

rized service agency for repairs of a machine

designated as "CARRY IN SERVICE" (table top

models).

5 - Labor charges to install or test attachments

or accessories (i.e., bowls, cutting plates, blades,

attachments) which are replaced for any reason.

6 - Charges to change Direction-of-Rotation

of Three Phase electric motors (INSTALLER IS

RESPONSIBLE).

7 - SHIPPING DAMAGE IS NOT COVERED BY

WARRANTY. Visible and hidden damages

are the responsibility of the freight carrier. The

consignee must file a damage claim promptly

against the carrier, or upon discovery in the case

of hidden damage.

KEEP ALL ORIGINAL CONTAINERS AND PACKING MATERIALS FOR CARRIER INSPECTION.

Robot-Coupe U.S.A., Inc., or any of their affiliates,

distributors, officers, directors, agents, employees,

or insurers will not be obligated for consequential

or other damages, losses, or expenses in connection with or by reason of the use of or inability to

use the machine for any purpose.

5

ENGLISH

WARNING: In order to limit accidents such as electric shocks, personal injury or fire, and in order to limit material damage due to

misuse of the appliance, please read these instructions carefully and follow them strictly. Reading the operating instructions will

help you get to know your appliance and enable you to use the equipment correctly. The operation manual should be kept within

easy access to all users for reference and should be read completely by all first time users of the machine.

IMPORTANT WARNING

UNPACKING

• Carefully remove the equipment from the packaging and take out all the boxes or packets containing

attachments or specific items.

•WARNING-some of the parts are very sharp e. g.

blade, plates … etc.

INSTALLATION

•We recommend that you install your machine on a

stable solid base at a comfortable working height.

CONNECTION

•Always check that your power supply corresponds

to that indicated on the serial number plate and that

it is properly sized.

NOTICE

: DRIVE SHAFT ROTATION

• Three phase motors may rotate

either direction.

• The required motor rotation is counterclockwise.

• Changing the motor rotation requires a qualified

electrician.

• See note on end of power cord.

HANDLING

•Always wear cut-resistant gloves when handling

the cutting plates.

ASSEMBLY PROCEDURES

•Follow the various assembly procedures carefully

(see page 7) and make sure that all the attachments

are correctly positioned.

USE

•Do not open the feed head until the motor has

come to a complete stop.

•Never tamper with or defeat the purpose of the

locking and safety systems.

•Never put a hand or nonfood object in the entry or

exit chutes.

•Do not overload the machine.

• Do not leave the machine running unattended.

CLEANING

•Always unplug your appliance before cleaning.

•Always clean the appliance and attachments at the

end of each use.

•Never place the motor unit in water.

•For parts made of aluminum alloys, use cleaning

detergents suitable for aluminum.

•For plastic parts, do not use detergents that are too

alkaline (i.e., containing too much caustic soda or

ammonia…).

• Robot-Coupe can in no way be held responsible

for the user’s failure to follow the basic rules of cleaning and maintenance.

MAINTENANCE

•Always unplug the appliance before servicing.

•Check the seals regularly and ensure that the safety devices are in good working order.

•It is particularly important to maintain and check

the attachments since certain products contain

corrosive agents e.g. citric acid.

•NOTICE

: Never operate the appliance if the

power cord or plug has been damaged. If the

machine fails to operate as described in this

manual, or if the machine malfunctions in any way,

remove the machine from use and have it serviced.

Additionally, discard all food processed at the time

of the malfunction.

• Contact your local Authorized Service Agency if

something appears to be wrong.

KEEP THESE INSTRUCTIONS

IN A SAFE PLACE

W ARNING

6

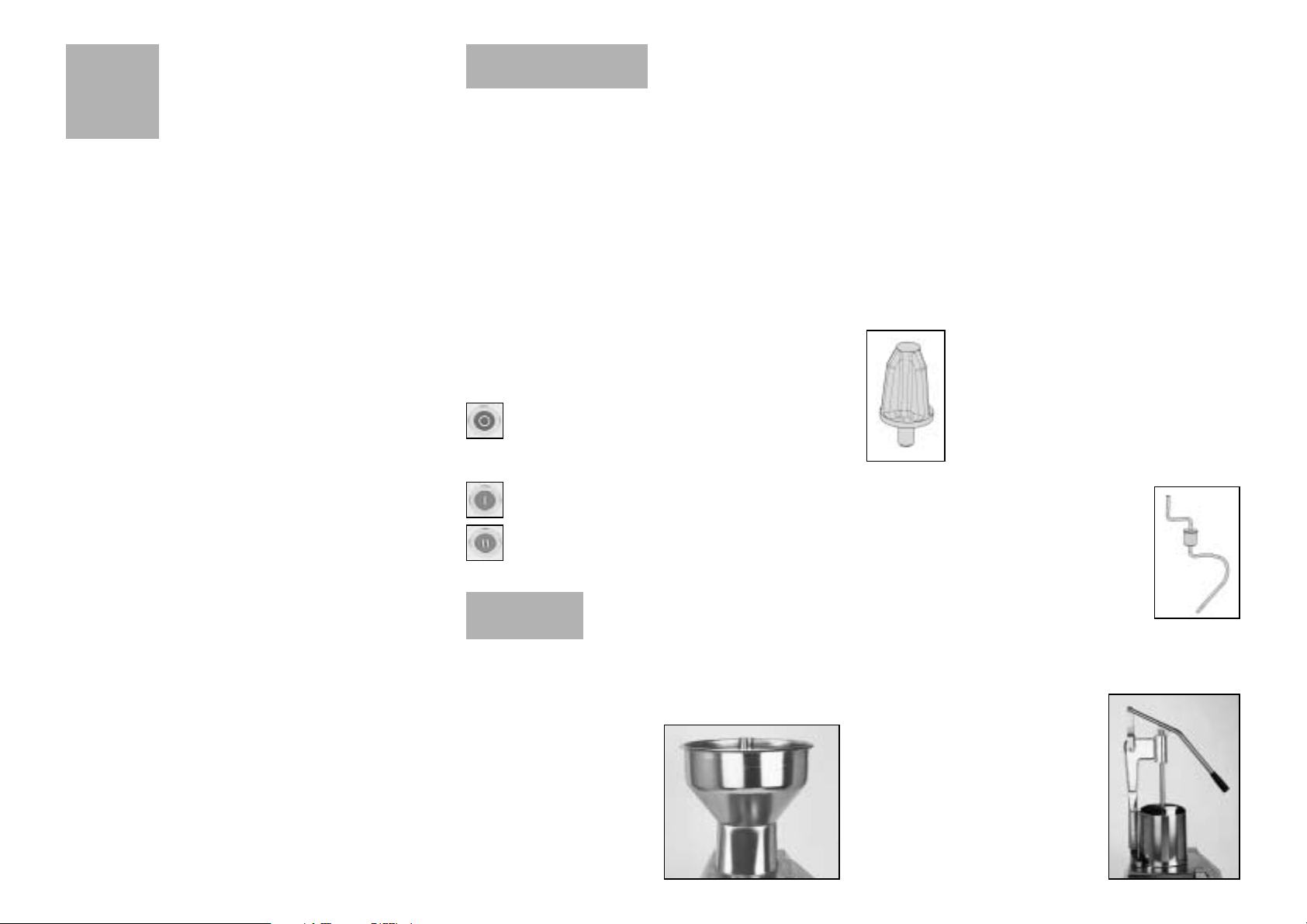

INTRODUCTION TO

YOUR NEW VEGETABLE

PREPARATION MACHINE

CL 60 Series ”D”

The CL 60 is a versatile machine designed to

meet your professional needs. It can perform any

number of tasks, which you will gradually discover

as you use it.

The CL 60 Series “D” is built from stainless steel

(100% stainless steel motor base and automatic feed

head). It has been designed to operate at two speeds,

425 and 850 rpm, giving the user more control over

the speed and quality of the operation.

It can be fitted with any one of 4 different feed heads,

in order to increase the machine’s output, make the

user’s job easier and offer the most appropriate tool

for each type of preparation. The heads are designed

to be tilted in line with the motor base, in order to

reduce space and facilitate use.

The CL 60 is supplied with a wide range of plates

and grids to satisfy even the most demanding chefs

when it comes to processing fruit and vegetables, as

they can be used for slicing, julienne, grating,

shredding, dicing, pulping, ripple-cutting and French

fry.

Its numerous functions will open the door to a whole

new culinary world.

Thanks to its simple design, all components requiring

frequent handling for maintenance or cleaning can

be easily assembled and disassembled.

These instructions contain important information

designed to help the user get the most out of the CL 60

vegetable preparation machine.

All users should read the manual before operating

the machine. We have also included a few examples

of use to help you get the feel of your new machine

and appreciate its many advantages.

This

head

is not suitable for specific jobs such as :

- slicing long vegetables (which should be done

using the specially-designed tube feed heads),

- the preparation of bulky foodstuffs too big to be fed

into this head (the whole head “Pusher” feed head

has been designed to cope with these).

All types of cutting can be performed using this

head. However, when dicing vegetables, it is advisable to use the tube feed heads or pusher feed head

in order to avoid mis-cuts. A feed tray designed to

facilitate continuous input can be fitted to this head.

A rubber agitator is supplied and must

be used with the bulk feed attachment.

The agitator helps to guide the

vegetables into the cutting blade.

The crank is used to free large

vegetables which may become

jammed.

• WHOLE HEAD FEED “PUSHER” ASSEMBLY

The pusher feed assembly has

been specifically designed for

processing bulky vegetables

such as cabbage, celery,

lettuce, etc.. It features an

integrated tube for processing

long and fragile vegetables.

SWITCHING ON

THE MACHINE

• ADVICE ON ELECTRICAL CONNECTIONS

Before plugging in your appliance, check that your

power supply corresponds to that indicated on the

machine’s serial number plate.

Three phase motors may rotate either direction. The

required motor rotation is counterclockwise.

Changing the motor rotation required a qualified

electrician.

A red arrow on the lid marks the blade rotation

direction.

• CONTROL PANEL

”OFF” button

2 green buttons :

“LOW” button for the low speed (425 rpm)

“HIGH” button for the high speed (850 rpm)

FUNCTIONS OF HEADS

AND THEIR TOOLS

• BULK FEED HEAD

This head is designed for

certain tasks involving

large quantities and is

suitable for grated carrot

and sliced potato, for

example.

7

ENGLISH

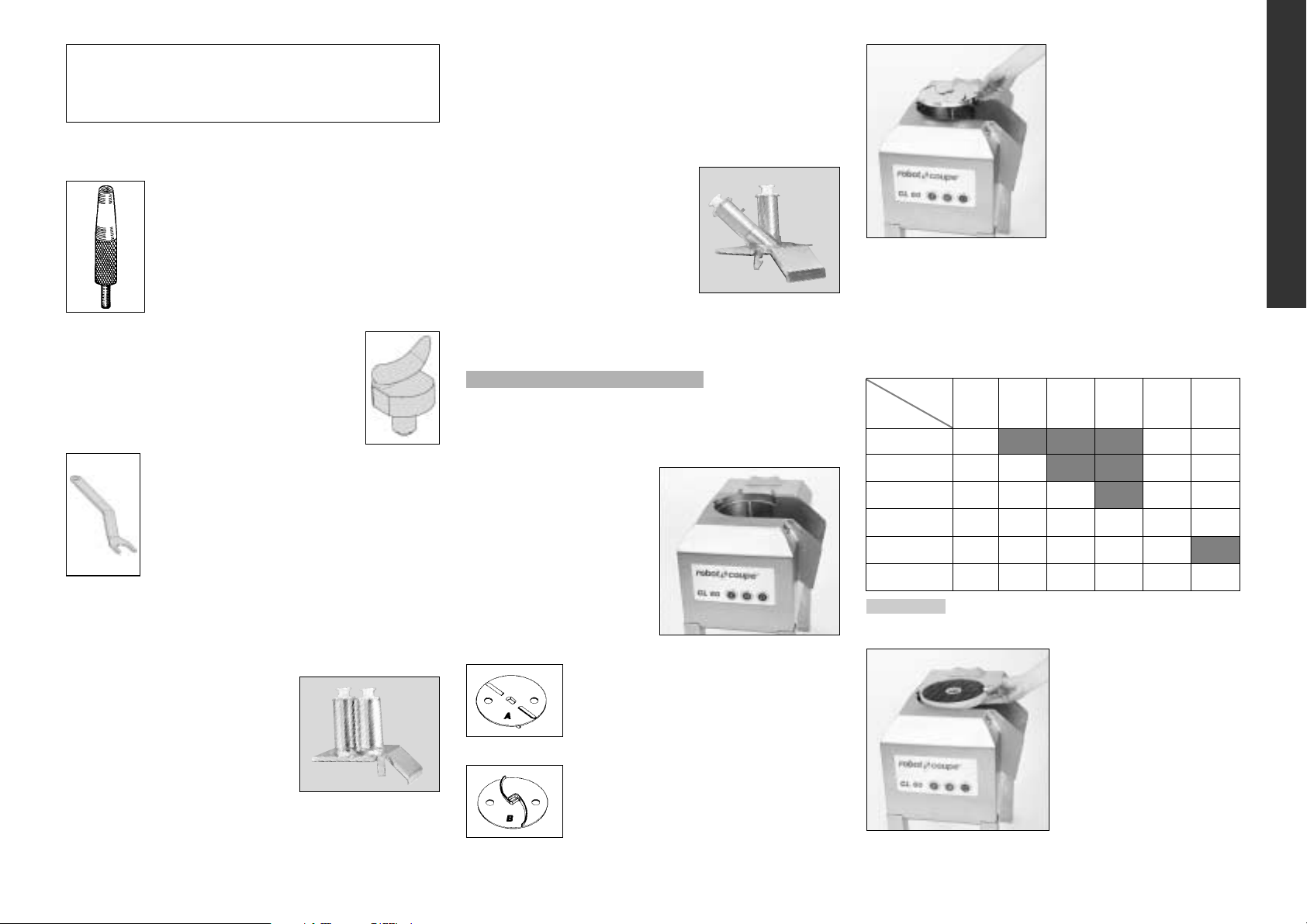

Two types of tools have been designed for the pusherfeed head:

1) The long locking nut which holds the

plate for processing all vegetables

except for cabbage.

2) The hollowing nut, which is used

solely to prepare cabbage. Thanks to

this tool, you can slice or grate a whole

cabbage without first having to chop

it up.

A special tool has also been designed

to remove this hollowing nut.

• TUBE FEED HEADS

STRAIGHT TUBE FEED HEAD

This head consists of two

straight tubes with a diameter

of 3 inches, a 2 inches insert

and two pushers. The insert

allows you to modify the

diameter of the tubes.

This head is designed for the preparation of long

vegetables such as carrots, cucumbers, leeks, etc., or

fragile fruit and vegetables such as tomatoes and

bananas.

The tubes can also be used as cutting guides for

special preparations requiring high cutting precision

and a limited number of mis-cuts.

ANGLE FEED HEAD

This head performs the same

functions as the one described

above for the straight tubes.

However it is different in that it

is equipped with a biais cut

tube especially designed for

slanted cutting.

No special tool is required to attach the disc.

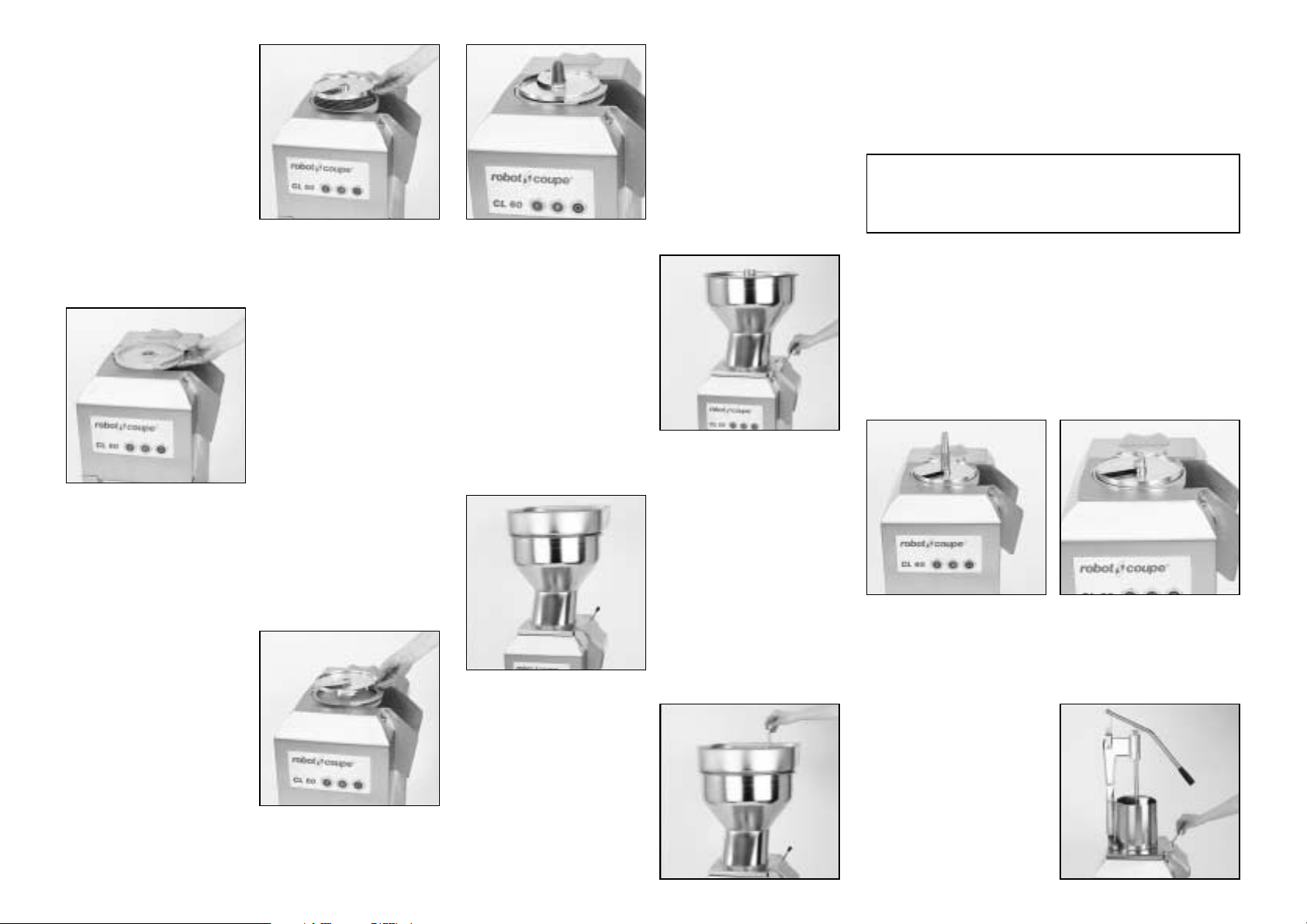

ASSEMBLY

• BULK FEED HEAD

1) With the motor base

unit facing you, place the

discharge plate on the

motor shaft.

SIDE A facing upwards (ejection

rib downwards) for fragile vegetables

or citrus fruit (e.g. as tomatoes or

mushrooms).

SIDE B facing upwards (ejection rib

upwards) for all other types of fruit or

vegetables.

2) Position the plate or attachment you require :

a) If you have opted for

a slicing, grating or

julienne plate :

Position the plate on the

motor shaft.

Rotate the plate until it

drops into place onto the

motor shaft pin. The slot

in the center stem of the

plate should be resting on the motor shaft pin.

b) If you have chosen a dicing combination :

i.e. a grid and a special slicing plate.

Slicing plates and dicing grids can be mounted in

the following combinations :

5x5 8x8 10x10 14x14 20x20 25x25

5 mm 28110

8 mm 28111

10 mm 28112

14 mm 28113

20 mm 28114

25 mm 28115

The shaded areas indicate combinations

that can be used.

dicing

grid

Plate

Fit the dicing grid over

the motor shaft. As

shown in the picture, the

grid rests on a ledge in

the motor base.

This ledge must be clean

and free of product in

order for the machine to

operate correctly. Make

sure the plastic tab on the outer rim of the grid is fully

seated in the corresponding slot in the motor unit.

mm mm mm mm mm mm

IMPORTANT : This feed head cannot be used for

making french fries and can therefore not be

fitted with the corresponding attachments.

8

• WHOLE HEAD “PUSHER” FEED HEAD

To assemble the discharge plate, slicing, grating

or julienne disc or dicing equipment, follow the

procedure for the automatic head in steps 1) and 2).

3) Then, screw the long locking nut or hollowing

nut onto the motor shaft according to the type of

vegetable being processed.

It should be remembered that the long locking nut

is suitable for all types of vegetables except for

cabbage, for which the hollowing nut has been

designed.

4) Position the pusher feed head on the motor base.

The fastening hook should now be facing you, on

your right.

Slide the hinge pin into

the holes provided at the

back of the motor base.

Then, lock the head onto

the motor base with the

fastening hook.

Then, fit the corresponding slicing plate onto the

motor shaft. Rotate the

plate until the slot in the

blade hub drops onto the

pin in the motor shaft.

Continue to rotate the

blade a full 360 degrees

to make sure the plate

doesn’t scrub against the plastic grid. If rubbing

occurs, do not proceed. Call your authorized service agency.

c) If you want to use

the French fry cutting

equipment : a grid and

a special slicing plate.

Position the French fry

grid over the motor shaft.

As shown in the picture,

the grid rests on a ledge

in the motor base. This

ledge must be clean and free of product in order for

the machine to operate correctly. Make sure the

plastic tab on the outer rim of the grid is fully

seated in the corresponding slot in the motor unit.

The cutting blades on the grid should be facing the

exit chute.

Next fit the appropriate

slicing plate onto the

motor shaft. Rotate the

plate until the slot in the

blade hub drops onto the

pin in the motor shaft.

Continue to rotate the

blade a full 360 degrees

to make sure the plate

doesn’t scrub against the plastic grid. If rubbing

occurs, do not proceed. Call your authorized

service agency.

3) Screw the rubber agitator onto the motor

shaft.

4) Position the bulk feed

head on the motor base.

The fastening hook

should now be facing

you, on your right.

5) Slide the hinge pin

into the spaces provided

at the back of the motor

base. Then, lock the lid

onto the motor base with

the fastening hook.

6) If you have a feed

tray, position it on the

top of the bulk feed

head.

7) Insert the crank into

the central hub of the

head. Turn it until the

part is inside the hub.

IMPORTANT : This feed head cannot be used for

making french fries and can therefore not be

fitted with the corresponding attachments.

9

ENGLISH

• TUBE FEED HEADS

1) and 2) Follow the procedure for the bulk feed

head.

3) Position one or the

other of the tube feed

heads on the motor

base, with the fastening

hook facing you, on your

right.

4) Slide the hinge pin into

the holes provided at the

back of the motor base.

The fastening hook should

now be facing you on

your right.

CHANGING THE PLATES :

The machine should be switched off (by pressing the

red button) before you start to change the disc.

1) With the motor base facing you, use your right

hand to release the aluminum fastening hook

used to lock the head onto the motor base.

2) a) For the bulk feed head :

Tilt the head.

b) For the pusher-feed head :

Lift the lever and turn it to the left so that the head

can be tilted. Unscrew the long locking nut or

hollowing nut. For the hollowing nut, use the

wrench provided for that purpose.

c) For the tube feed heads :

First remove the inserts and pushers, then raise

the head and tilt it backwards.

3) Lift out the plate holding it by its edges.

For dicing equipment, we recommend you lift out

the grid and disc assembly at the same time.

Next, remove the discharge plate using the two

holes.

If the plate is stuck, turn it slightly in a counterclockwise direction.

4) When fitting the dicing equipment, we recommend

that you clean the inside of the bowl thoroughly

with a damp cloth or sponge, especially the part

onto which the grid is to be fitted.

Always use a clean grid.

5) Then fit the discharge plate, slicing, grating or

julienne disc or dicing equipment as described in

steps 1) and 2) in the previous section, according

to your choice of head.

6) The machine can now be switched on again.

USES AND

CHOICE OF PLATES

A complete range of plates is available allowing for

a wide range of cuts. Fruits and vegetables may be

sliced, wave sliced, grated, and shredded. Julienne

cuts, dices, and fries can also be achieved.

W ARNING

The blades on the cutting plates and grids are

sharp. Always wear cut-resistant gloves and

use caution when handling the cutting plates.

SLICING PLATES

C444SA-1/32 carrot / cabbage / cucumber / onion / potato / leek

C445SA-5/64 - C446SA-1/8 lemon / carrot / mushroom / cabbage / potato /

cucumber / onion / leek / bell pepper

C477SA-5/32 - C437SA-3/16 beets / carrot / mushroom / cucumber / bell pepper/

radish / lettuce / potato / leek / tomato

C436SA-5/16 - C435SA-3/8 potato / carrot / rhubarb / okra / bell peppers

C434SA-9/16 potato / carrot / spinach / pineapple

RIPPLE CUT SLICING PLATES

C445W-5/64 potato / carrot / radishes / cucumbers

C446W-1/8 potato / carrot / kiwi / cucumbers

C464W-3/16 potato / carrot / radishes / oranges / peppers

GRATING PLATES

C494GPA-1/32 cheese / graham crackers / chocolate / almond powder

C451GPA-5/64 carrot / cheese / romano / chocolate / almond powder

C450GPA-1/8 carrot / potatoes / coconut / nut meats / chocolate

C453GPA-3/16 cabbage / cheese / eggs / mozzarella / nut meats

C475GPA-5/32 chocolate / coconut / potatoes / nut meats

C478GPA-9/32 cabbage / cheese / eggs / carrots

C433GPA-3/8 cabbage / onions / provolone / chocolate / radish

C452GPA powder hard cheese / almond powder / graham / crackers

C495GPA-1/32 pulping / ginger root / white radish / lotus root / burdock

JULIENNE PLATES

C460JA-5/64x5/64 carrot / potato / zucchini / beets

C483JA-5/64x5/32 carrot / potato / beets / cabbage / zucchini

C484JA-5/64x1/4 carrot / potato / cucumbers / radishes

C486JA-5/64x5/64 zucchini / potatoes / carrots / radishes

C462JA-5/32x5/32 eggplant / potato / tomatoes / zucchini / carrots

C438JA-1/4x1/4 eggplant / potato / carrots

C466JA-5/16x5/16 potatoes / carrots / onions / eggplant

DICING COMBINATIONS

28110-3/16x3/16 carrot / cucumber / potatoes / carrot / zucchini

28111-5/16x5/16 potato / carrot / celery / beets

28112-3/8x3/8 potato / carrot / celery / apples

28113-9/16x9/16 potato / carrot / peaches / apples / pineapple

28114-3/4x3/4 potato / cantaloupe / pineapple / melon

28115-1”x1” potato / turnip / apple (fruit) / melon / watermelon

10

CLEANING

After removing the hinge pin and releasing the

fastening hook, remove the head and, take out the

plate, holding it by its edges, and if necessary, remove

the grid and its support followed by the discharge

plate.

Now clean all the parts.

The continuous feed head, discharge plates, and

cutting plates can be cleaned in a dishwasher.

However, we suggest that you use a mild (noncorrosive) detergent designed for “soft metals” such as

aluminum. Dishwashers are best avoided in order to

prevent the aluminum from becoming tarnished. We

recommend that you clean the attachments by hand

using a “soft metal safe” detergent. Clean the

attachments in a 3-pot sink system or according to

local health department regulations.

Never immerse the motor base in water. Clean it

with a damp (not dripping) cloth or sponge.

2) The CL 60 is fitted with a thermal safety device

which automatically stops the motor if the machine is

overloaded.

If this happens, allow the machine to cool completely

before restarting. If the machine has become jammed

press the off button and UNPLUG the machine

from the wall outlet. Remove the feed head and

Clear the jam (wear cut-resistant gloves). And restart by first pressing the reset button located on the

bottom of the motor base, then closing the

head/attachment and pressing the on button.

MAINTENANCE

• BLADES AND GRIDS

The blades on the slicing discs, the combs on the

julienne discs and the graters are all wearing parts,

which have to be changed every so often to maintain

constant high quality cutting.

• MOTOR SEAL

The seals around the motor shaft should be lubricated regularly using a food-safe lubricant.

In order to keep the motor completely watertight, it is

advisable to check these seals regularly for wear and

tear and replace if necessary.

The seals can be easily replaced without having to

remove the motor, so we strongly advise you to ensure

that they are in good running order.

SAFETY

1) The CL 60 is equipped with a safety system that

turns the machine off when the pusher (on the pusher

feed head) is turned out away from the opening. The

machine will start again, once the pusher is swung

back into place over the feed opening.

W ARNING

IMPORTANT

W ARNING

FRENCH FRY COMBINATIONS

(

Bulk feed head

and Tube feed heads)

28134-5/16x5/16 potato / carrots / onions / eggplant

28135-3/8x3/8 potato / zucchini / yellow squash / sweet potatoes

W ARNING

French fries can be made using a special attachment,

available in two dimensions 8 x 8 mm and 10 x

10 mm.

IMPORTANT : The French fry cutting equipment

can only be used with the bulk feed head or tube

feed heads.

The discs are extremely sharp. Handle with care.

Do not open the feed head / attachment until

the motor has come to a complete stop.

Never tamper with the locking or safety

systems or defeat their purpose.

Never place anything other than food

products into the entry port.

Never put anything into the exit port.

Always use the food pushers to force the food

through the entry ports.

Do not overload the machine or apply excess

pressure with the food pushers.

ALWAYS UNPLUG YOUR MACHINE BEFORE

CLEANING (RISK OF ELECTRIC SHOCK).

Check that your detergent is suitable for

cleaning plastic parts. Some cleaning agents

are too alkaline (e.g. high levels of caustic

soda or ammonia) and totally incompatible

with certain types of plastic, causing them to

deteriorate rapidly.

Loading...

Loading...