Robot Coupe C 80, C 120, C 200, C 200 V.V. User Manual

C80•C120•C200 • C 200 V.V.

Robot-Coupe SNC - 12 avenue du Maréchal Leclerc – BP 134 – 71305 Montceau-les-Mines Cedex - France

Robot-Coupe

SNC:

- EN 12100 -1 & 2 - 2004: Safety of machinery – General

principles for design,

- EN 60204-1 -2006: Safety of machinery – Electrical

equipment of machines,

- EN 12852: Food Processors and Blenders,

- EN 1678-1998: Vegetable Cutting Machines,

- EN 454: Blender-Mixers,

- EN 12853: Hand-held Blenders and Whisks (stick

blenders),

- EN 14655: Bread Slicers,

- EN 13208: Vegetable Preparation Machines,

- EN 13621: Salad Spinners,

- EN 60529-2000: Degrees of protection,

- IP 55 for the electrical controls,

- IP 34 for the machines.

Declares that the machines identified by their type above,

comply with:

• The essential requirements of the following European

directives and with the corresponding national

regulations:

- Directive «Machinery» 2006/42/EC,

- Directive «Low voltage» 2006/95/EC,

- Directive «Electromagnetic compatibility»

2004/108/EC,

- Regulation (EC) n°1935/2004 «Materials and articles

intended to come into contact with food»,

- Regulation (EU) n°10/2011 «Plastic materials and

articles intended to come into contact with food»,

- Directive «Reduction of Hazardous Substances (RoHS)

2002/95/EC,

- Directive «WEEE» 2002/96/EC,

• The requirements of the European harmonized standards

and with the standards specifying the hygiene and

safety requirements:

DECLARATION OF CONFORMITY

Signed in Montceau en Bourgogne on 19 February 2013

Alain NODET

Industrial Director

15

Eng

SUMMARY

WARRANTY

IMPORTANT WARNING

INTRODUCTION TO YOUR NEW

AUTOMATIC SIEVE MACHINE

C 80 • C 120 • C 200 • C 200 V.V.

SWITCHING ON THE MACHINE

• Advice on electrical connections

• Control panel

OPERATING PROCEDURE

RECOMMENDATIONS FOR USE

USES AND EXAMPLES

OPTIONS

CLEANING

MAINTENANCE

• Paddles

• Motor seal

TECHNICAL SPECIFICATIONS

• Weight

• Dimensions

• Working height

• Noise level

• Electrical data

SAFETY

STANDARDS

RECIPES

TECHNICAL DATA

• Exploded views

• Electrical and wiring diagrams

16

ROBOT-COUPE S.N.C., LIMITED WARRANTY

Your new ROBOT-COUPE product is warranted to the original buyer for a period of

one year from the date of sale if you

bought it from ROBOT-COUPE

S.N.C.

If you bought your ROBOT-COUPE product

from a distributor your product is covered

by your distributor’s warranty (Please check

with your distributor terms and conditions

of the warranty).

ROBOT-COUPE

S.N.C., Limited warranty is

against defects in material and/or workmanship.

The ROBOT-COUPE S.N.C . warranty is

given expressly and in lieu of all other

warranties, expressed or implied, for merchantability and for fitness toward a particular purpose and constitutes the only

warranty made by ROBOT-COUPE

S.N.C.,

France.

THE FOLLOWING ARE NOT COVERED

UNDER ROBOT-COUPE

S.N.C

. WAR-

RANTY:

1 - Damage caused by abuse, misuse, drop-

ping, or other similar damage caused by or as

result of failure to follow assembly, operating,

cleaning, user maintenance or storage instructions.

2 - Labour to sharpen and/ or parts to replace

knife assemblies or blades which have become

dull, chipped or worn due to normal use or

abuse.

3 - Material or labour to renew or repair scrat-

ched, stained, chipped, pitted, dented or discoloured surfaces, blades, knives, attachments or

accessories.

4 - Alteration, addition or repair that have not

been carried out by the company or an authorised service agency.

5 - Transportation to or from an authorised ser-

vice agency for repairs of any machine.

6 - Labour charges to install or test attachments

or accessories (i.e., bowls, plates, blades, attachments) which are replaced for any reason.

7 - Charges to change Direction-Of-Rotation of

three-Phase electric motors (Installer is responsible).

8 - SHIPPING DAMAGES. Visible and hidden

damages are the responsability of the freight carrier. The consignee must inform the carrier and

consignor immediately, or upon discovery in case

of hidden shipping damages.

KEEP ALL ORIGINAL CONTAINERS AND PACKING MATERIALS FOR CARRIER INSPECTION.

ROBOT-COUPE

S.N.C., its affiliated companies or

any of its distributors, officers, directors, agents,

employees, or insurers will not be liable for consequential or other damages, losses, or expenses in

connection with or by reason of or the inability to

use the machine for any purpose.

17

WARNING: In order to limit accidents such as electric shocks, personal injury or fire, and in order to limit material damage due to

misuse of the appliance, please read these instructions carefully and follow them strictly. Reading the operating instructions will

help you get to know your appliance and enable you to use the equipment correctly. Please read these instructions in their entirely

and make sure that anyone else who may use the mixer also reads them beforehand.

IMPORTANT WARNING

UNPACKING

• Carefully remove the equipment from the packaging

and take out all the boxes or packets containing

attachments or specific items.

• WARNING - some of the tools are very sharp

e.g. blade, discs... etc.

INSTALLATION

• We recommend you install your machine on a

perfectly stable solid base.

CONNECTION

• Always check that your mains supply corresponds

to that indicated on the rating plate on the motor

unit and that it can take the amperage.

• The machine must be earthed.

• With the three-phased version, always check that

the blade rotates in an anti-clockwise direction.

HANDLING

• Always take care when handling the blades or

discs - they are very sharp.

USE

• Never try to override the locking and safety

systems.

• Never introduce any object into the container

where the food is being processed.

• Never push the ingredients down with your hand.

• Do not overload the appliance.

• Never switch the appliance on while it is empty.

CLEANING

• As a precaution, always unplung your appliance

before cleaning it.

• Always clean the appliance and its attachments at

the end of each cycle.

• Never place the motor unit in water.

• For parts made of aluminum alloys, use cleaning

fluids suitable for aluminum.

• For plastic parts , do not use detergents that are too

alkaline (i.e., containing too much caustic soda or

ammonia...)

• Robot-Coupe can in no way be held responsible

for the user’s failure to follow the basic rules of cleaning and hygiene.

MAINTENANCE

• Before opening the motor housing, it is absolutely

vital unplung the appliance.

• Check the seals and washers regularly and

ensure that the safety devices are in good working

order.

• It is particularly important to maintain and check

the attachments since certain ingredients contain

corrosive agents e.g. citric acid.

• Never operate the appliance if the power cord

or plug has been damaged in any way or if

the appliance fails to work properly or has been

damaged in any way.

• Do not hesitate to contact your local Maintenance

Department if something appears to be wrong.

W A R N I N G

Eng

KEEP THESE INSTRUCTIONS

IN A SAFE PLACE

18

INTRODUCTION TO YOUR

NEW AUTOMATIC SIEVE

MACHINE C 80 • C 120

• C 200 • C 200 V.V.

The automatic sieve is perfectly geared to professional

needs. It can perform any number of tasks, which

you will gradually discover as you use it.

When it comes to straining soups, bisques or

sauces, extracting fruit pulps or separating fibres

from vegetables, the automatic sieves make light

work of these tasks.

Its numerous functions will open the door to a whole

new culinary world.

Thanks to its simple design, all components requiring

frequent handling for maintenance or cleaning can

be fitted and removed in a trice.

To make things easier for you, this manual gives a

breakdown of all the various fitting operations. We

place special emphasis on those actions which

cause the machine to stop. The automatic sieve is

fitted with numerous safety devices which prevent

access to the food during processing.

This manual contains important information designed

to help the user get the most out of the automatic sieve

machine.

We therefore recommend that you read it carefully

before using your machine.

We have also included a few examples to help you

get the feel of your new machine and appreciate its

numerous advantages.

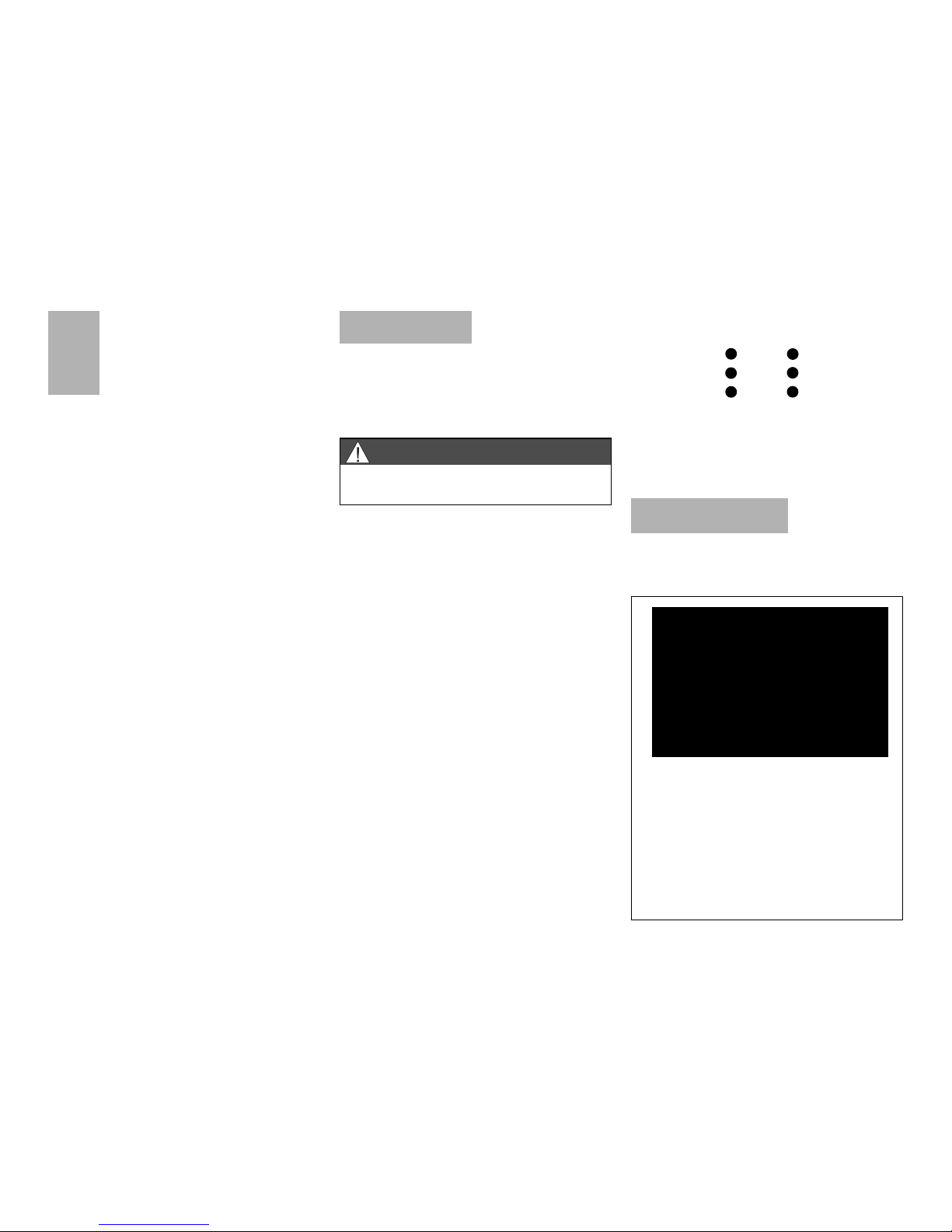

SWITCHING ON

THE MACHINE

• ADVICE ON ELECTRICAL CONNECTIONS

Before plugging in, check that your power supply

corresponds to that indicated on the machine’s

identification plate.

GREEN/YELLOW is the earth,

DO NOT DISCONNECT

Swap either: the and the

the and the

the and the

• CONTROL PANEL

Red switch = Stop switch.

Green switch = “On” switch.

OPERATING

PROCEDURE

Whatever the model used, the operating procedure

remains the same.

313

2

2

1

C80 or C120 single phase

The machine comes with a single-phase plug

connected to a power cord.

The C80/C120 comes with different types of

motors:

230 V / 50 Hz

115 V / 60 Hz

C120 or C 200 three phase

The C120/C200 come with different types of

motors:

230 x 400 V switchable / 50 Hz

220 V / 60 Hz

If you have a 4-pin plug:

1) Connect the green and yellow earth wire to the

earth pin.

2) Connect the three other wires to the remaining

pins.

If you have more than 4 pins in the plug, please note

the ROBOT-COUPE does not require a neutral wire.

Switch on the empty machine, making sure

that the paddle is rotating properly in an

anti-clockwise direction by looking through the

hopper.

On the motor unit, a red arrow marks the paddles

rotating direction. If the paddles turn in a clockwise

direction, swap over two wires.

TRAY

Continious feeding of washed

products, no need tostone or peel.

PERFORATED BASKET

Products fall inside the basket

wherethey arer sieved.

PADDLES

Paddles assembly rotating at

1500 rpm to extract maximum

pulp and juice.

END PRODUCT EJECTION

CHUTE

From this chute is collected the

readyto use pulp, bitter free asno

pips,stone or bones… have been

ground.

WASTE EJECTION CHUTE

I. E. skins, pips, stones, tails,

bones,shells, fibres…

STAR KNOB

used to lock the paddles.

W A R N I N G

This appliance must be plugged into an

earthed socket (risk of electrocution).

19

These indications are given for your guidance and

may vary according to the quality and the consistency

of the product. The C 80 can be run for 20 minutes

non-stop. The C 200 is designed for intensive use and

for applications in the food industry.

OPTIONS

Each of our models is supplied with a standard

1 mm sieve. Two other sieves are available on

option for specific uses. These are a 0.5 mm sieve

for very fine sieving (sauces, etc.) and a 3 mm

sieve for fruit with stones.

CLEANING

RECOMMENDATIONS

FOR USE

• Before each use, check that the star knob used to

lock the paddles is correctly tightened.

• It is advisable to start up the appliance and place

a receptacle under the discharge ports before putting in the food to be processed.

• When using for the first time, you are advised to

run the appliance after pouring in hot water with, if

you wish, two peeled lemons chopped into pieces.

Your appliance will then be ready to use.

• Pour the food products into the hopper and push

them steadily towards the feed chute. For certain

foods, if you think there is still enough juice, pulp or

stock left in the waste, you should feed it through a

second time to obtain an optimum yield.

• Do not feed food into the machine too quickly.

• Only use well ripened fruit. In the case of “hard”

fruit, such as Granny Smith apples, it must first be

processed in a cutter.

• Never feed in excessively large pieces as they

may cause the appliance to vibrate and, even,

block the scrapers and this could damage the

motor.

USES AND EXAMPLES

Oranges, lemons, melons and pineapples must be

peeled and cut into pieces before being fed into the

machine.

Apricots, plums, redcurrants and blackcurrants must

be heated to burst them before they are put into the

centrifuge.

Strawberries, raspberries, mulberries and grapes

must be perfectly ripe.

Stalks, skin, peel, pips and stones are ejected

without being crushed so that the juice is not bitter.

When making apple compote, cook the apples

whole (with peel and pips). They must be well

cooked before they are put through the sieve.

When preparing vegetable mousses or purées, it is

recommended to cook the vegetables well before

feeding them through the sieve.

For fish soups, you are advised to grind the shellfish

with a cutter first.

Eng

W A R N I N G

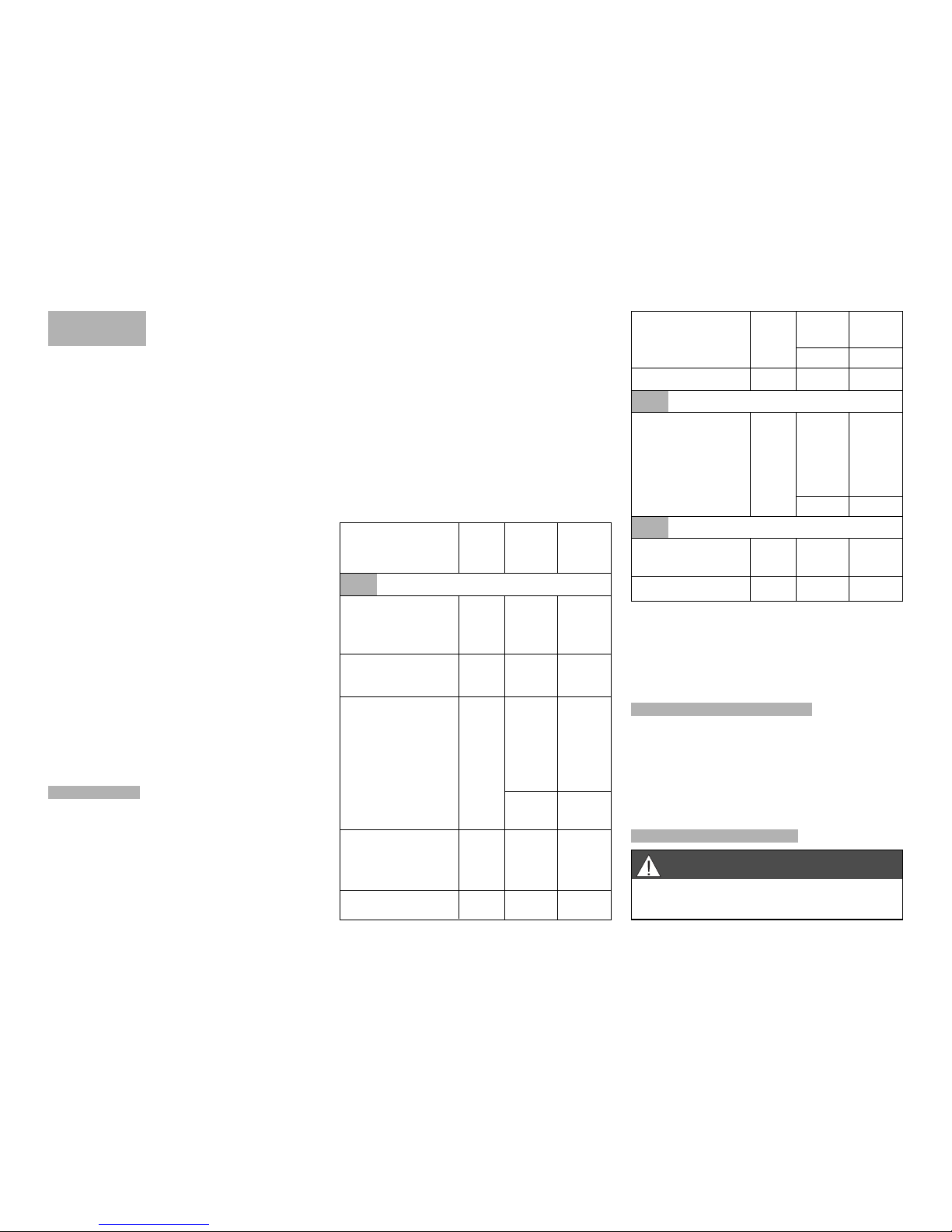

Juice

Hourly Hourly

USES

Output

Output Output

C80 C120/C200

FRUIT JUICE AND PULP

Strawberries 90%

Raspberries 90%

60 kg/h 150 kg/h

Blackberries 90%

Red currants 75%

40 kg/h 100 kg/h

Black currants 75%

Bilberries 90%

Tomatoes 90%

Mirabelle plums - withstones 80% 60kg/h 150kg/h

Cherries - with stones 80%

Plums - with stones 80 %

Peaches - with stones 80 %

40 kg/h 100 kg/h

Apricots - with stones 80%

Melon 90%

Lemons 80% 40kg/h 100kg/h

Oranges 80%

Grapes 80% 40kg/h 100kg/h

Apples (Granny Smith) 85%

40 kg/h 100 kg/h

Coconut 85%

Pineapple 90% 60kg/h 150kg/h

Apple puree 90% 40kg/h 100kg/h

VEGETABLE MOUSSE/PUREE

Asparagus 80%

Carrots 90%

Celery 90% 40kg/h 100 kg/h

Cucumbers 95%

Leeks 80%

Sweet peppers 95% 60 kg/h 150 kg/h

SOUPS

Fish 75%

Shellfish 90%

60 l/h

150l/h ormore

Sauces 60 l/h

150l/h ormore

As a precaution, always unplug your appliance

before cleaning it (risk of electrocution).

Loading...

Loading...