Page 1

®

• Blixer

• Blixer

• Blixer

• Blixer

23

®

30

®

45

®

60

P.O. Box 16625, Jackson, MS 39236-6625

280 South Perkins St., Ridgeland, MS 39157

e-mail: robocoup@misnet.com - website: www.robotcoupeusa.com - Phone : 1-800-824-1646

Page 2

SUMMARY

ENGLISH

WARRANTY

IMPORTANT WARNING

INTRODUCING THE NEW

®

EMULSIFIER-MIXER Blixer

• Blixer

SWITCHING ON THE MACHINE

• Advice on electrical connections

• Control panel

• Safety indicator lights

ASSEMBLY

WIPER ASSEMBLY

HELPFUL TIPS

• Emptying the bowl

®

30 • Blixer®45 • Blixer®60

23

EXAMPLES OF USE

CLEANING

MAINTENANCE

• Blades

• Shaft seals

• Replacement of motor shaft seal

• Bowl seal

• Dismantling the blade assembly

• Lid seal

TECHNICAL SPECIFICATIONS

• Bowl capacities

• Weight

• Dimensions

• Installation

• Noise level

• Electrical data

• Blade assembly

MAXIMUM PROCESSING CAPACITIES

ASSEMBLING AND USE OF THE BLADE ASSEMBLY

• Assembling the 2-blade assembly

SAFETY

TECHNICAL DATA

• Before Starting

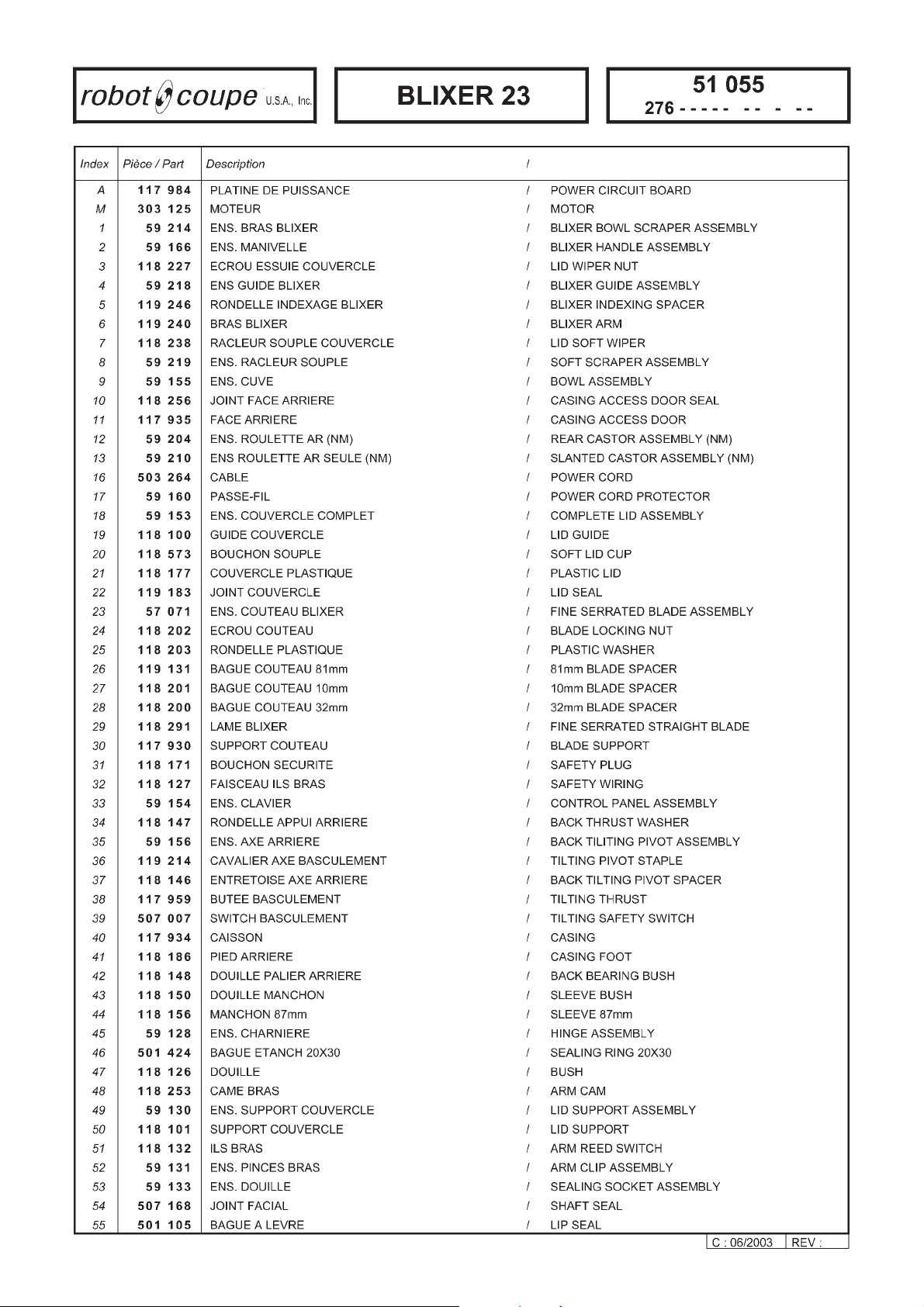

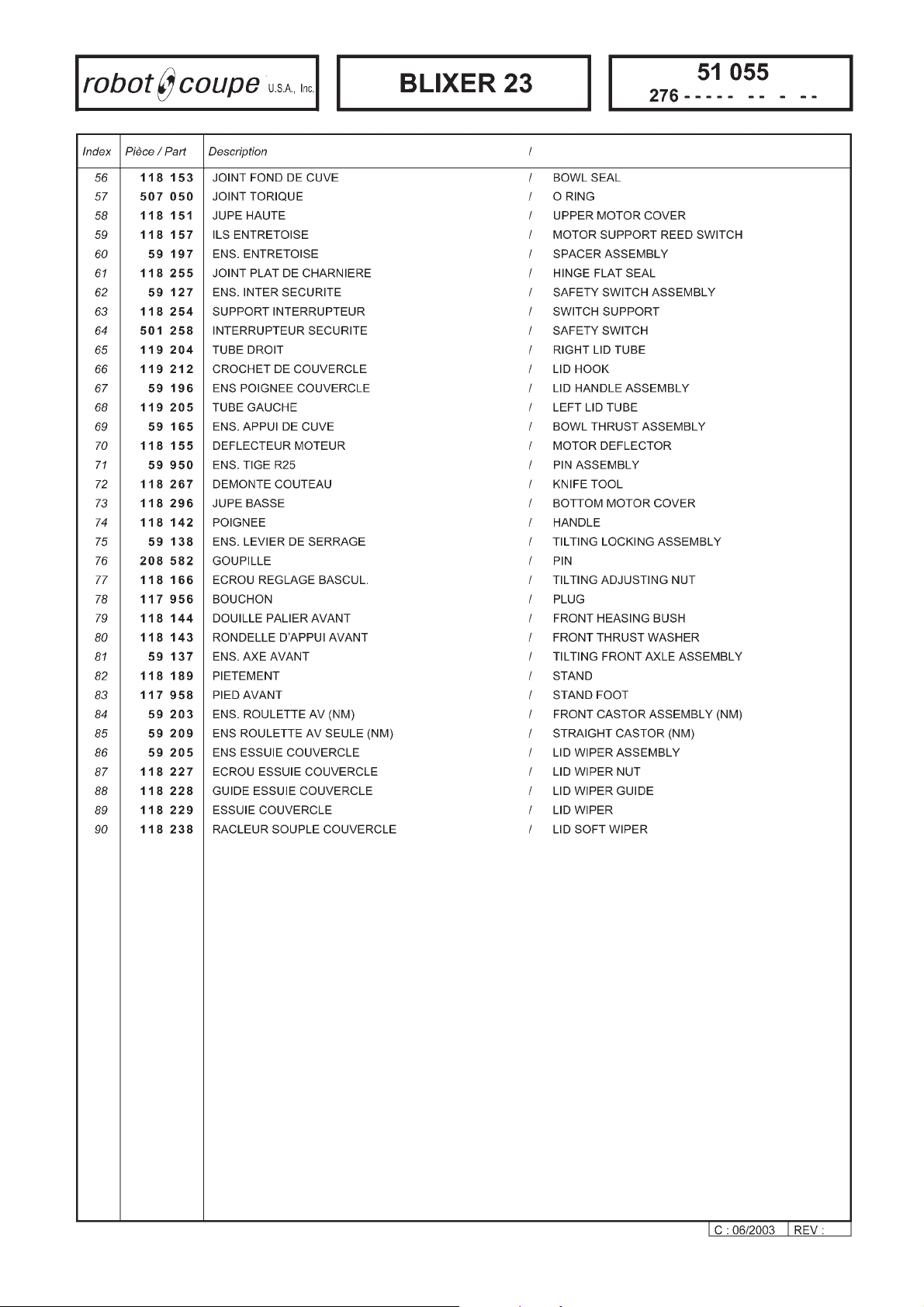

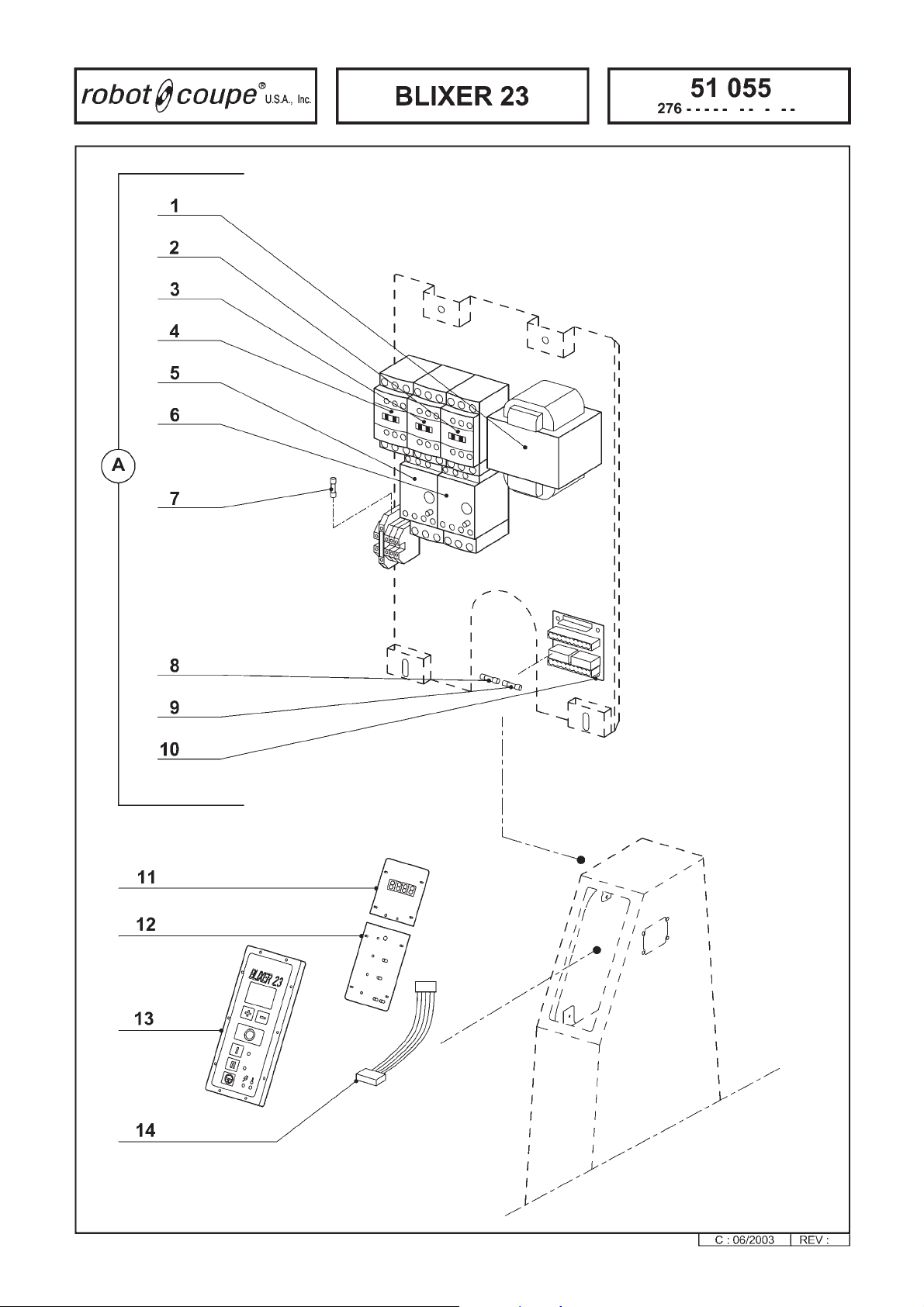

• Exploded views

• Electrical and wiring diagrams

3

Page 3

ROBOT COUPE U.S.A., INC. LIMITED WARRANTY

280 South Perkins St., Ridgeland, MS 39157

e-mail: robocoup@misnet.com - website: www.robotcoupeusa.com - Phone : 1-800-824-1646

YOUR NEW ROBOT COUPE

PRODUCT IS WARRANTED TO THE

ORIGINAL PURCHASER FOR A

PERIOD OF ONE YEAR FROM THE

DATE OF PURCHASE.

This LIMITED WARRANTY is against

defects in the material and/or

workmanship, and includes labor for

replacement of defective parts,

provided repairs are performed by

an authorized service agency (see

attached list).

The Customer must inform the

Service Agency of the possibility of

warranty coverage and provide a

copy of the dated sales or delivery

receipt BEFORE WARRANTY REPAIRS

ARE BEGUN.

Replacement parts and accessories

are warranted for ninety (90) days

from the date of purchase when

purchased separately and will be

verified by dated sales receipt OR

packing slip which lists that item.

All parts or accessories replaced

under warranty must be returned to

the Service Agency.

THE FOLLOWING ARE NOT COVERED BY THE ROBOT COUPE U.S.A.

INC LIMITED WARRANTY:

Damage caused by abuse, misuse, drop-

1 -

ping, or other similar damage caused by

or resulting from failure to follow assembly, operating, cleaning, user maintenance or storage

instructions.

2 - Labor to sharpen and/or replacements for

blades that have become blunt, chipped or worn

after a normal or excessive period of use.

3 - Materials or labor to replace or repair scrat-

ched, stained, chipped, pitted, dented or discolored surfaces, blades, knives, attachments or

accessories.

4 - Any alteration, addition, or repair that has

not been carried out by the company or an

approved service agency.

5 - Transportation of the appliance to or from

an approved service agency.

6 - Labor charges to install or test new

attachments or accessories (i.e., bowls, plates,

blades, attachments), which have been replaced

for any reason.

7 - The cost of changing direction-of-rotation of

three-phase electric motors (Installer is

responsible).

8 - SHIPPING DAMAGES. Visible and/or

hidden damage is the responsibility of the freight

carrier. The consignee must inform the carrier

and consignor immediately, or upon discovery in

the case of hidden defects.

KEEP ALL ORIGINAL CONTAINERS AND PACKING MATERIALS FOR CARRIER INSPECTION.

Neither ROBOT COUPE U.S.A., INC. nor its

affiliated companies or any of its distributors,

directors, agents, employees, or insurers will be

liable for indirect damage, losses, or expenses

linked to the appliance or the inability to use it.

The ROBOT COUPE U.S.A., INC. warranty

is given expressly and in lieu of all other

warranties, expressed or implied, for merchantability and for fitness toward a particular

purpose and constitutes the only warranty

made by ROBOT COUPE U.S.A., INC..

4

Page 4

WARNING

IMPORTANT WARNING

KEEP THESE INSTRUCTIONS

IN A SAFE PLACE

WARNING: In order to limit accidents such as electric shocks, personal injury or fire, and in order to limit material damage due to

misuse of the appliance, please read these instructions carefully and follow them strictly. Reading the operating instructions will

help you get to know your appliance and enable you to use the equipment correctly. The operation manual should be kept within

easy access to all users for reference and should be read completely by all first time users of the machine.

ENGLISH

UNPACKING

• Carefully remove the equipment from the packaging

and take out all the boxes or packets containing

attachments or specific items.

• WARNING-some of the parts are very sharp e. g.

blades … etc.

INSTALLATION

• Install your machine on a stable solid base.

CONNECTION

• Always check that your power supply corresponds

to that indicated on the serial number plate and that

it is properly sized.

HANDLING

• Always wear cut-resistant gloves when handling

the cutting blades.

ASSEMBLY PROCEDURES

• Follow the various assembly procedures carefully

(see page 7) and make sure that all the attachments

are correctly positioned.

USE

• Do not open the bowl lid until the blades have

come to a complete stop.

• Never tamper with or defeat the purpose of the

locking and safety systems.

• Never put a hand or nonfood object into the

bowl.

• Do not overload the machine.

• The blades are sharp. Wear cut-resistant gloves

when handling the blades.

CLEANING

• Always unplug your appliance before cleaning.

• Always clean the appliance and attachments at

the end of each use.

• For parts made of aluminum alloys, use cleaning

detergents suitable for aluminum. Presently, there

are no aluminum alloys on the surface of the

machine.

• Do not spray or pressure-wash the machine.

• For plastic parts, do not use detergents that are

too alkaline (i.e., containing too much caustic soda

or ammonia…).

MAINTENANCE

• Always unplug the appliance before servicing.

• Check the seals regularly and ensure that the

safety devices are in good working order.

• It is particularly important to maintain and check

the attachments since certain products contain cor-

rosive agents e.g. citric acid.

• NOTICE

power cord or plug has been damaged. If the

machine fails to operate as described in this

manual, or if the machine malfunctions in any way,

remove the machine from use and have it serviced.

Additionally, discard all food processed at the time

of the malfunction.

•Contact your local ROBOT-COUPE Authorized

Service Agency if something appears to be wrong.

: Never operate the appliance if the

5

Page 5

INTRODUCING THE NEW

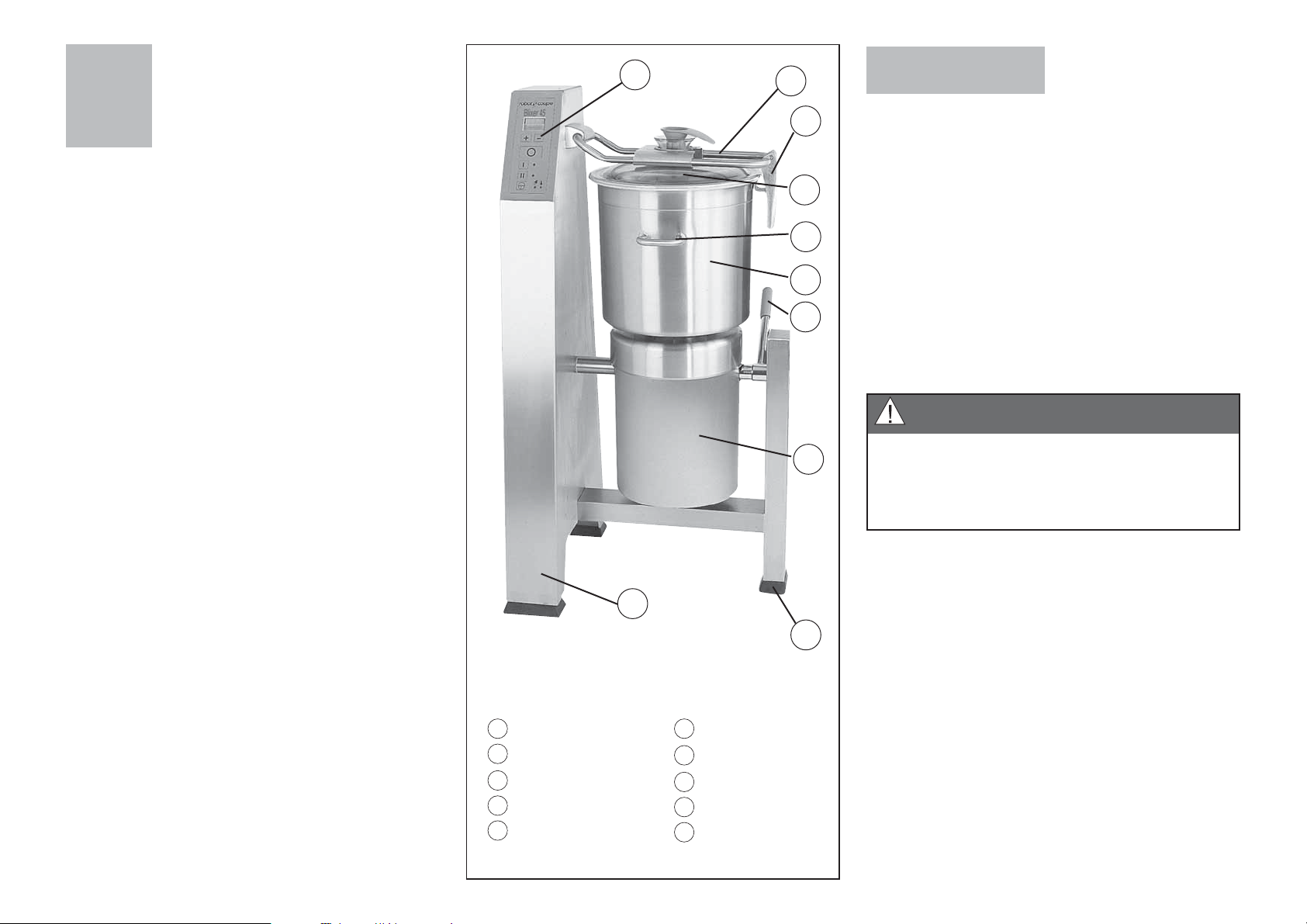

5

6

EMULSIFIER-MIXER

Blixer

Blixer

®

23 • Blixer®30

®

45 • Blixer®60

SWITCHING ON

1

4

THE MACHINE

3

• ADVICE ON ELECTRICAL CONNECTIONS

ROBOT-COUPE has developed a new concept in

®

food processing equipment: the Blixer

.

The Blixer®combines the features of two well-known

appliances: the cutter and the blender-mixer.

®

The Blixer

is perfectly geared to professional needs.

It can perform any number of tasks which you will

soon discover as you use it.

®

The Blixer

will make it easy to prepare mixed liquid

or semi-liquid, raw or cooked meals.

®

The Blixer

runs at two speeds: 1.800 and 3.600 rpm.

Thanks to your appliance's simple design, all components requiring frequent handling for maintenance or cleaning can be fitted and removed with the

greatest of ease.

For optimum convenience, this manual describes the

various assembly operations on a step-by-step basis.

It places special emphasis on explaining the various

actions that cause the motor to stop, as the

appliance is equipped with safety devices which

prevent access to the blade assembly until it has

come to a complete standstill.

10

2

The wiring must be installed by a qualified

electrician.

Before plugging your appliance in, check that your

power supply voltage is the same as that indicated

6

on the rating plate.

If your appliance is not connected to the mains via

7

a plug and socket, it must be connected to an electrical disconnect switch that can be padlocked.

RISK OF ELECTROCUTION

8

9

• The machine must be grounded electrically.

• The appliance is only insulated from the

mains supply when it is unplugged.

With the blade removed and the bowl empty, turn

on the machine. The shaft should rotate in a counterclockwise direction.

CHANGING MOTOR ROTATION REQUIRES A

QUALIFIED ELECTRICIAN

This manual contains important information

designed to help you get the most out of your

vertical cutter-mixer.

We therefore recommend that you read the

manual carefully before using your appliance.

We have also included examples of a few processing

tasks to help you get the feel of your new appliance

and appreciate the full range of its many useful

features.

6

1

Control panel

2

Transparent lid

3

Locking catch

4

Lid support arm

5

Handle

Bowl

7

Tilting lever

8

Motor unit

9

Wheels

10

Stainless-steel frame

Appliances are designed to operate on a

208-240 Volt, 60 Hz,

3 Phase power supply.

Page 6

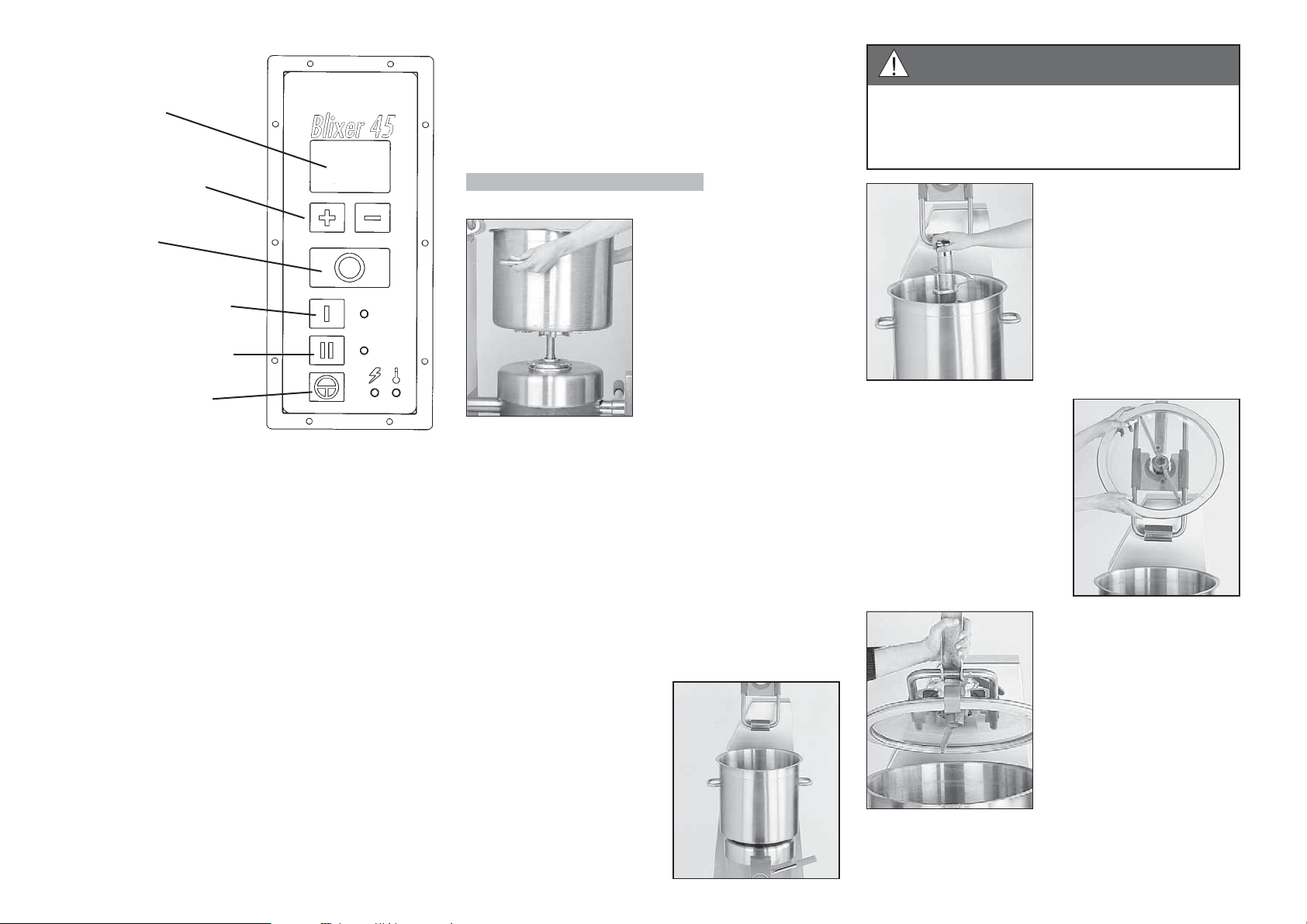

• CONTROL PANEL

Timer display

screen

Buttons for setting

timer

“Off” button

“On” button

Low speed (1.800 rpm)

“On” button

High speed (3.600 rpm)

Pulse control button

Low speed (1.800 rpm)

• SAFETY INDICATOR LIGHTS

For models Blixer® 23 • 30 • 45 • 60 :

• The orange light comes on when the appliance is

plugged in. If none of the lights come on, this either

means that the appliance is not plugged in properly or that one of the safety devices is not activated.

• 2 green lights indicate that the appliance is ready

for use (see starting procedure on page 6).

• The red light is a motor temperature indicator.

When it comes on, it means that the motor has

reached a temperature of 120° C and may shortly

stop to avoid overheating. This allows you to stop

your processing task and avoid possible motor

damage. It is best to wait until the red light has gone

out before resuming your task.

• In case of motor thermal overload, the red and

orange lights will stay on until the motor has cooled

down. The machine will not start while the orange

light is on.

• In case of overload trip, the motor stops and only

the orange light is on. After the automatic resetting

of the overload device, the orange light turns off,

both green lights switch on and the machine can be

restarted.

ASSEMBLY

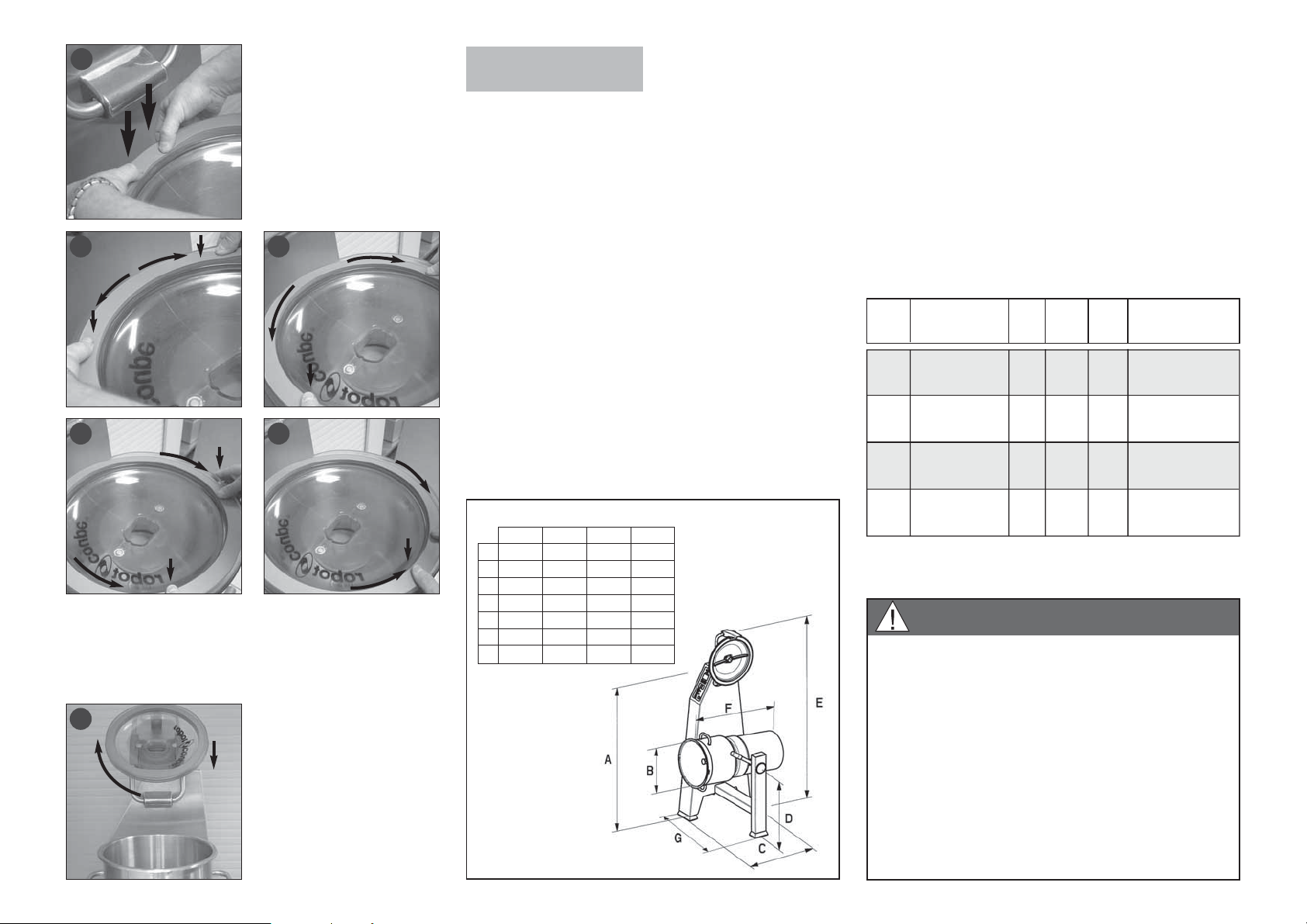

1) Notice the lip on the

bowl. On one side, directly

over one of the handles,

the lip extends straight out

rather than being curled.

This feature is for pouring

and should be to your left

as you place the bowl onto

the machine.

Facing the tilting lever end of the machine, lower the

bowl over the motor shaft until it rests on the top surface of the motor unit. Turn the bowl handles in a

clockwise direction about 45° as shown until you feel

it drop down a bit. Once you feel the bowl bottomout, turn it back in a counterclockwise direction until it

comes to a complete stop and feels tight and stable.

When viewed from the tilting lever end, the handles

should be directly to your left and right. The bottom

of the bowl should be parallel with the top surface of

the motor unit.

2) Before you continue,

make sure the bowl is in

the upright position. Check

the locking lever. It should

be rotated to the right (as

you are facing the locking

lever end of the machine)

and pressed down, locking the bowl in the

upright position.

DANGER : RISK OF INJURY

The blades are extremely sharp.

For this reason, always make sure you have

removed the blade assembly before doing any job

inside the bowl, such as cleaning or emptying.

ENGLISH

3) Place the blade assembly

on the motor shaft.

Then lower it to the bottom

of the bowl by rotating it.

Always check that the

blade assembly is correctly

positioned at the bottom

of the bowl before placing

the ingredients you wish to

process in the bowl.

4) Position the lid in the

space provided in the lid

support arm, then rotate it

90° to lock it into position.

5) To close the lid, fit the

locking catch over the

edge of the bowl and push

the handle down. The

appliance is now ready for

use. The green lights

should be on.

If the safety indicator lights do not become green,

check all the assembly procedures according to

page 41.

7

Page 7

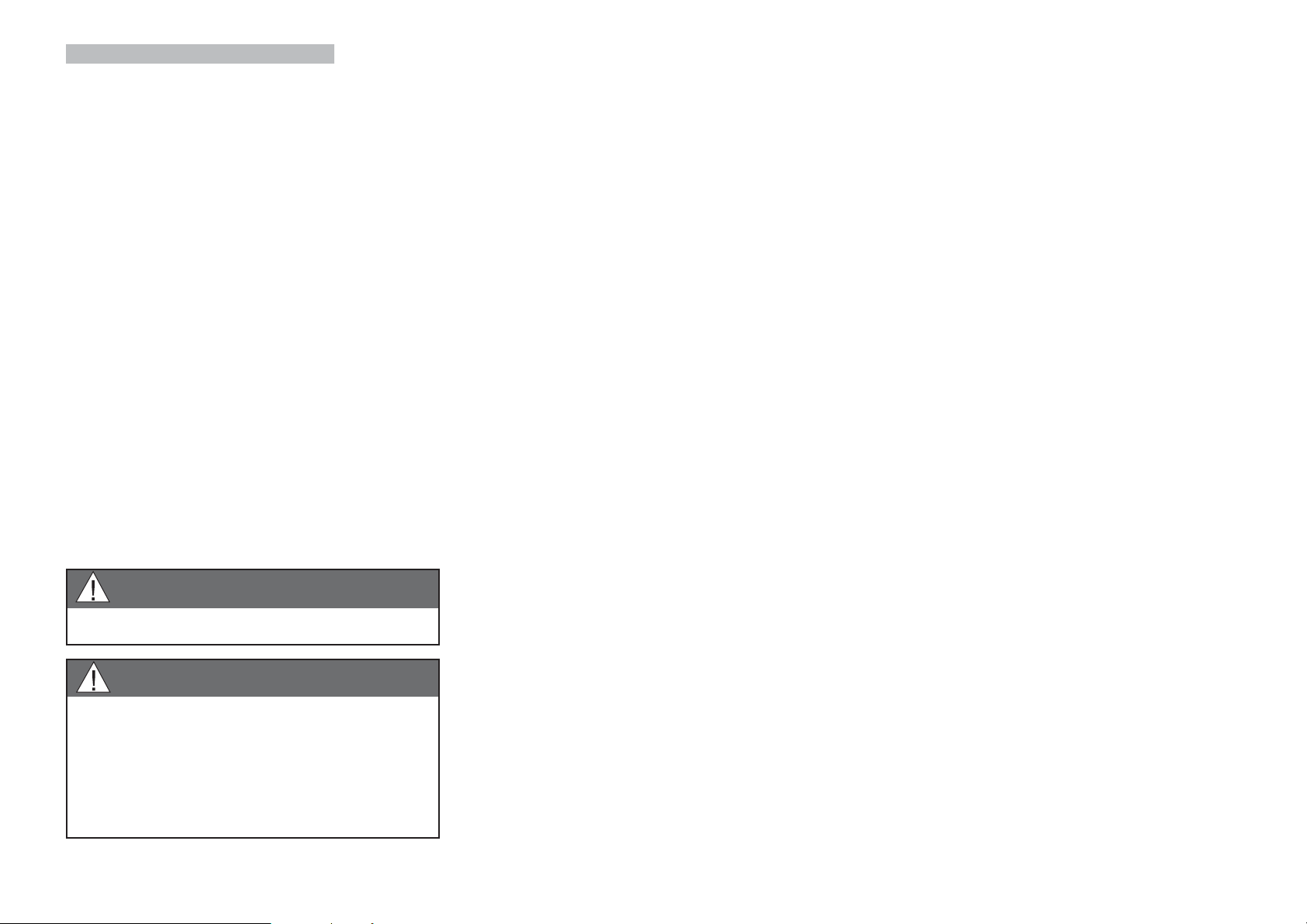

Maximum

processing

capacities

Liquids at

low speed

Blixer

®

23 30 45 60

9 9 13 13

to to to to

34 Lbs 44 Lbs 66 Lbs 100 Lbs

16 21 31 42

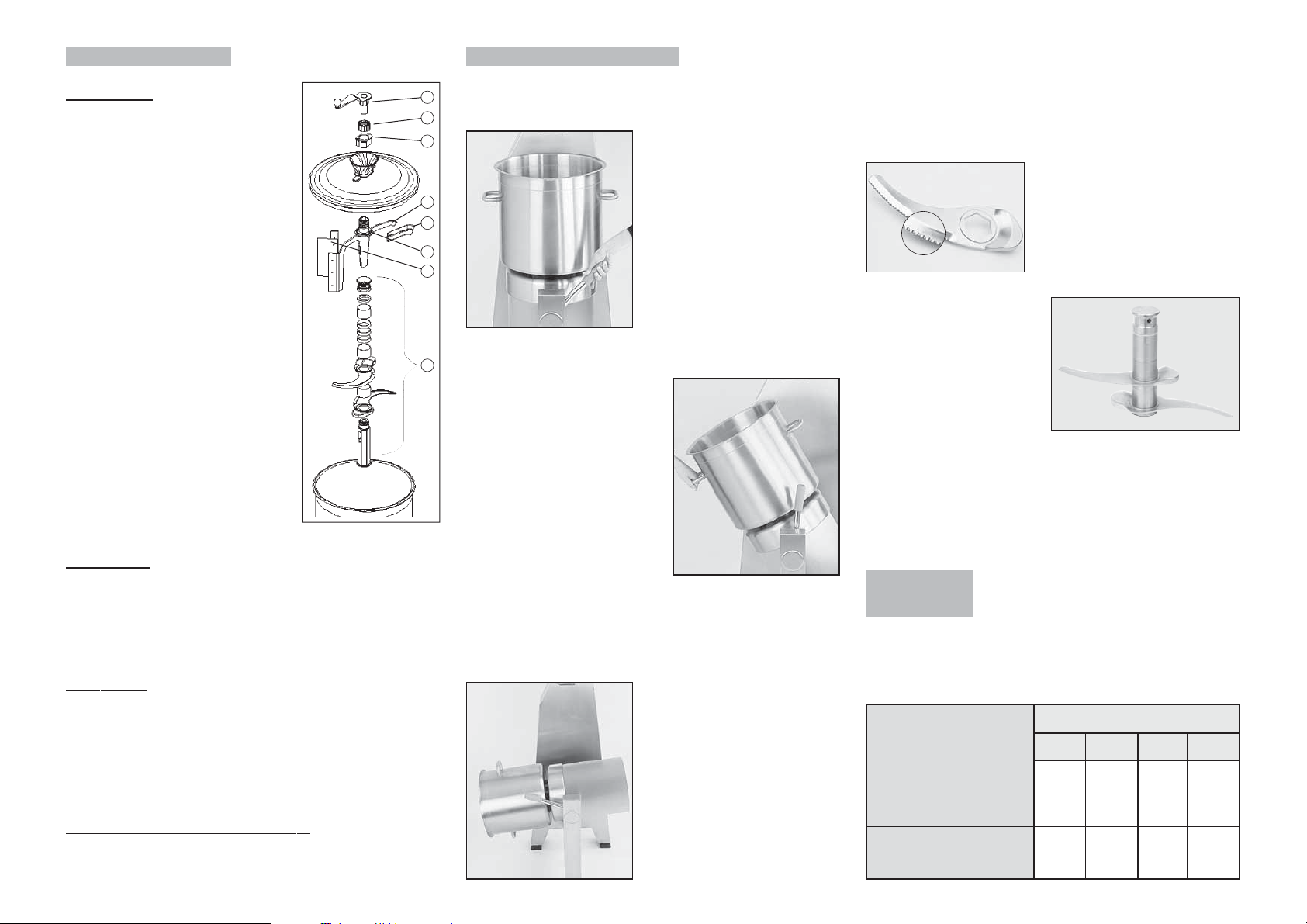

WIPER ASSEMBLY

Assembly :

• Remove the lid from the

machine and place it on a

table or level surface.

• Place the guild 3 (with the

flared end up) into the cone

shaped opening and push

down firmly with both

thumbs, until the bottom is

level with the underside of

the lid.

• Put the lid back on the

machine, and ,with the lid

open, insert 4 through the

underside of the lid.

• Screw the nut number 2

onto number 4 as tight as

possible.

• Assemble the handle number

1 into the nut number 2 to

turn the wiper assembly.

Aftercare :

• The lid scraper 5, the ring 6 and the flexible wiper

7 must be regularly inspected to ensure that they

are still working properly. If these parts become

worn, they should be replaced.

Warning !

The arm should only be operated in a clockwise

direction. The arm will only rotate

1

/

2

turn in the

counterclockwise direction

NEVER FORCE THE ARM IN THE COUNTERCLOCK-

WISE DIRECTION.

Leave the handle 1 in the ar

m while using the

appliance in order keep the nut from working

loose.

7

1

2

3

4

5

6

8

HELPFUL TIPS

• EMPTYING THE BOWL

1) Open the lid by freeing

the locking handle. Release

the tilting lever by raising it.

2) Depending on the product, it may be possible to

remove the blade assembly before tilting the bowl.

If it is not practical to

remove it, hold the blade

assembly down with one

hand while tilting the bowl

with the other.

CAUTION: It is advisable to wear cut-resistant gloves when handling the blades.

• BLADE ASSEMBLIES

In order to minimize vibration and to ensure optimum cutting quality, Robot Coupe has developed a

new patented blade design.

Fine serrated edge for all

blending tasks and smooth

or fine-textured preparations.

The standard blixer

blade assembly.

To obtain the best results, it is important to get the

spacing between the blades right and to take into

account the maximum processing capacities (see

table).

MAXIMUM PROCESSING

CAPACITIES

The maximum processing capacities are given in

the table below.

8

3) With a receptacle in

place, tilt and empty the

bowl.

Page 8

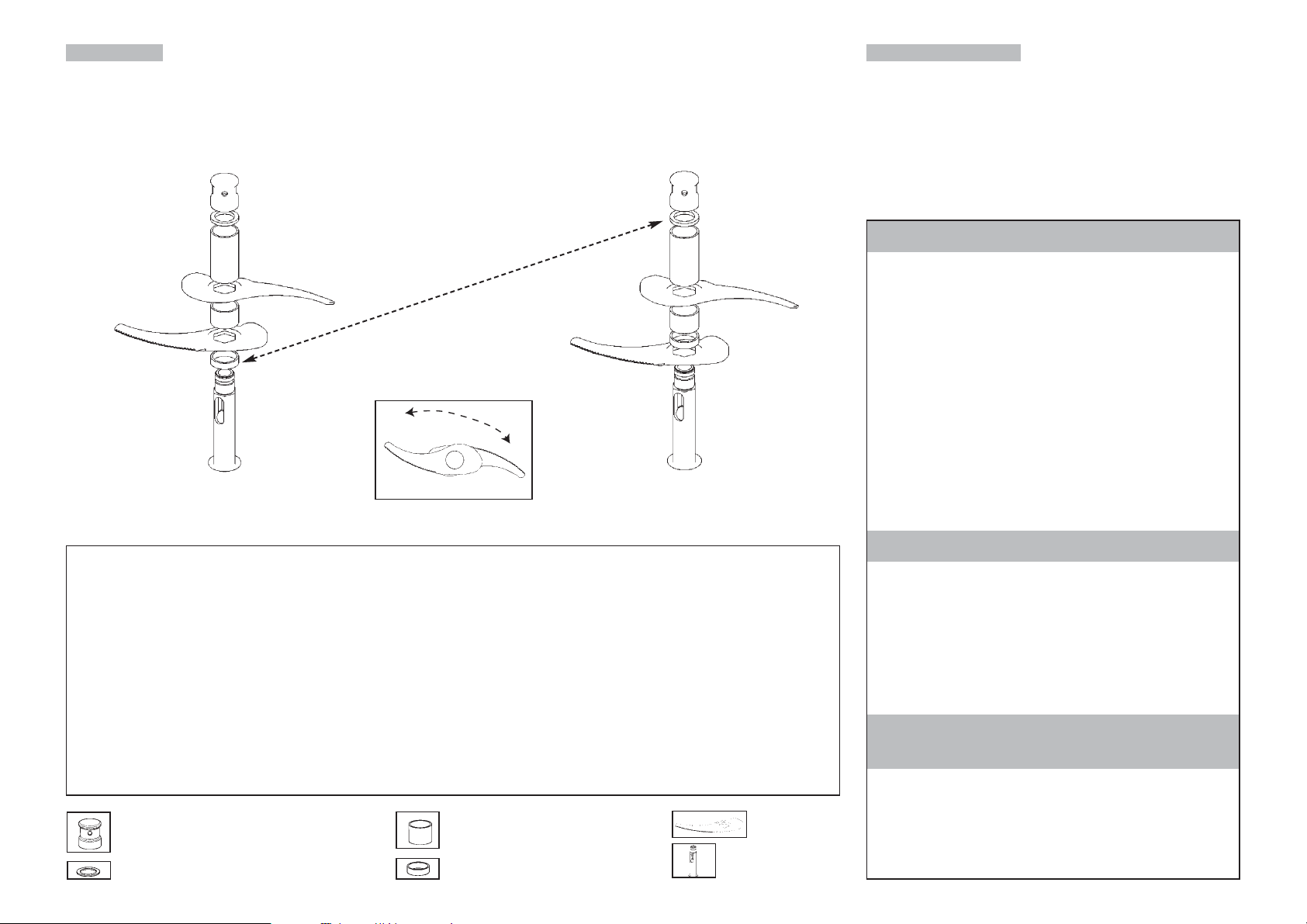

ASSEMBLING AND USE OF THE BLADE ASSEMBLY

Locking nut

Wide spacer

Blade

Locking spacer

Narrow spacer

Blade shaft

POSITION 1: With spacer between lower blade and blade shaft.

FITTING: • Fit the blades and spacers so that they are the right distance apart, according to the:

- type

- weight and

- volume of the foodstuffs to be processed.

POSITION 2: No spacer between lower blade and blade shaft.

• For fine chopping and emulsions.

DISMANTLING : • Unscrew the locking nut

• Remove the spacers.

EXAMPLES OF USE

The Blixer®will enable you to perform all your

cutting tasks in minimum time. We recommend

therefore, that you keep a close eye on the mixture

in order to obtain the desired results.

HOSPITAL USES:

SPOON FEEDING

• Minced foods: meat, fish

etc

. • Vegetable purees

• Mousses: vegetables, fish

etc

. • Compotes of stewed fruit

SEMI-LIQUID FEEDING

This simply entails diluting spoon-feeding preparations:

• Minced meat + gravy • Puree + liquid (broth, milk.

etc

.)

• Soups / creamed soups • Fruit compotes + syrup or water

LIQUID FEEDING (for use via tubes)

• Soups and any preparations that can be liquidized.

DELICATESSEN USES:

• Butter mixtures: snail butter, salmon butter, anchovie butter…

• Sauces: green sauce, mayonnaise, remoulade, ailloli, emulsi-

fied sauces with tomatoes, cream, parsley…

• Vegetable mousses.

• Grinding: lobster, scampi, seashells...

PHARMACEUTICAL AND CHEMICAL

LABORATORY USES:

• Grinding: herbs, seeds, powders, tablets....

• Mixing: homogeneization of creams, ointments, mixed compo-

nents, varied ingredients...

• ASSEMBLING THE 2-BLADE ASSEMBLY:

blade assembly (top view)

Position 1

Correct positioning of

180°

Position 2

ENGLISH

9

Page 9

CLEANING

WARNING

UNPLUG THE APPLIANCE BEFORE CLEANING.

WEAR CUT-RESISTANT GLOVES WHEN HANDLING THE BLADE ASSEMBLY.

All parts that come into contact with food are easy

to remove and clean. Failure to keep the machine

clean can result in tainted food, high repair costs,

and shortened machine life. Follow the cleaning

instructions detailed below, or clean according to

local Health Department Regulations.

Pre-rinse the attachments before washing to remove

any bulk food on the parts. A stiff bristle brush or

power sprayer faucet attachment is effective in

knocking the food out of the crevices of the attachments

as a pre-rinse procedure. Follow the instructions

below for individual parts.

CLEANING THE BLADE ASSEMBLY

For the purpose of sanitation, the blades must be

disassembled (see the maintenance section for

instructions) and cleaned at the end of each prep

session or three times a day. The blade assembly

should be completely disassembled before washing.

The blade assembly can be washed in a dish

machine or three-tank system pot sink. The washer

should have an industry-standard wash, rinse, and

sanitization cycle. Allow the parts to air-dry after

sanitizing. Apply a little food-grade oil or grease to

the threads on the top locking nut before reassembly.

CLEANING THE BOWL

Wash the bowl in a dish machine or three-tank

system pot sink. The washer should have an industrystandard wash, rinse, and sanitization cycle. Allow

the bowl to air-dry after sanitizing and before

reassembly.

10

CLEANING THE LID

Wash the lid by hand in a three-tank system pot sink.

The high temperatures of dish machines can shorten

the life of plastics. Wash the lid with a detergent

suitable for cleaning plastic parts. Allow the lid to

air-dry after sanitizing and before reassembly.

CLEANING THE EXTERIOR FRAME AND HOUSING

Always unplug the machine before cleaning. Do not

pressure-wash the machine. Use a cloth dampened

with a soapy-water solution to wipe down the exterior.

CLEANING THE SEALS

The seals under the bowl protect the motor and

seal the bottom of the bowl. Clean the seals with a

soapy-water solution. If necessary, use a small

brush to help loosen food particles. After cleaning,

lubricate the seals with a food-grade grease or oil.

IMPORTANT

Like the bowl and lid, the blade assembly

should also be removed for cleaning after use.

Always dry all the metal parts carefully, especially the blades, to avoid oxidization.

When you are not using your appliance, keep the

lid open and do not leave the bowl in the locked

position (this will prevent the seals from becoming

worn).

IMPORTANT

Check that your detergent is suitable for cleaning the plastic parts.

Certain washing agents are too alkaline (e.g.

high levels of caustic soda or ammonia) and

totally incompatible with certain types of

plastic, causing them to deteriorate rapidly.

MAINTENANCE

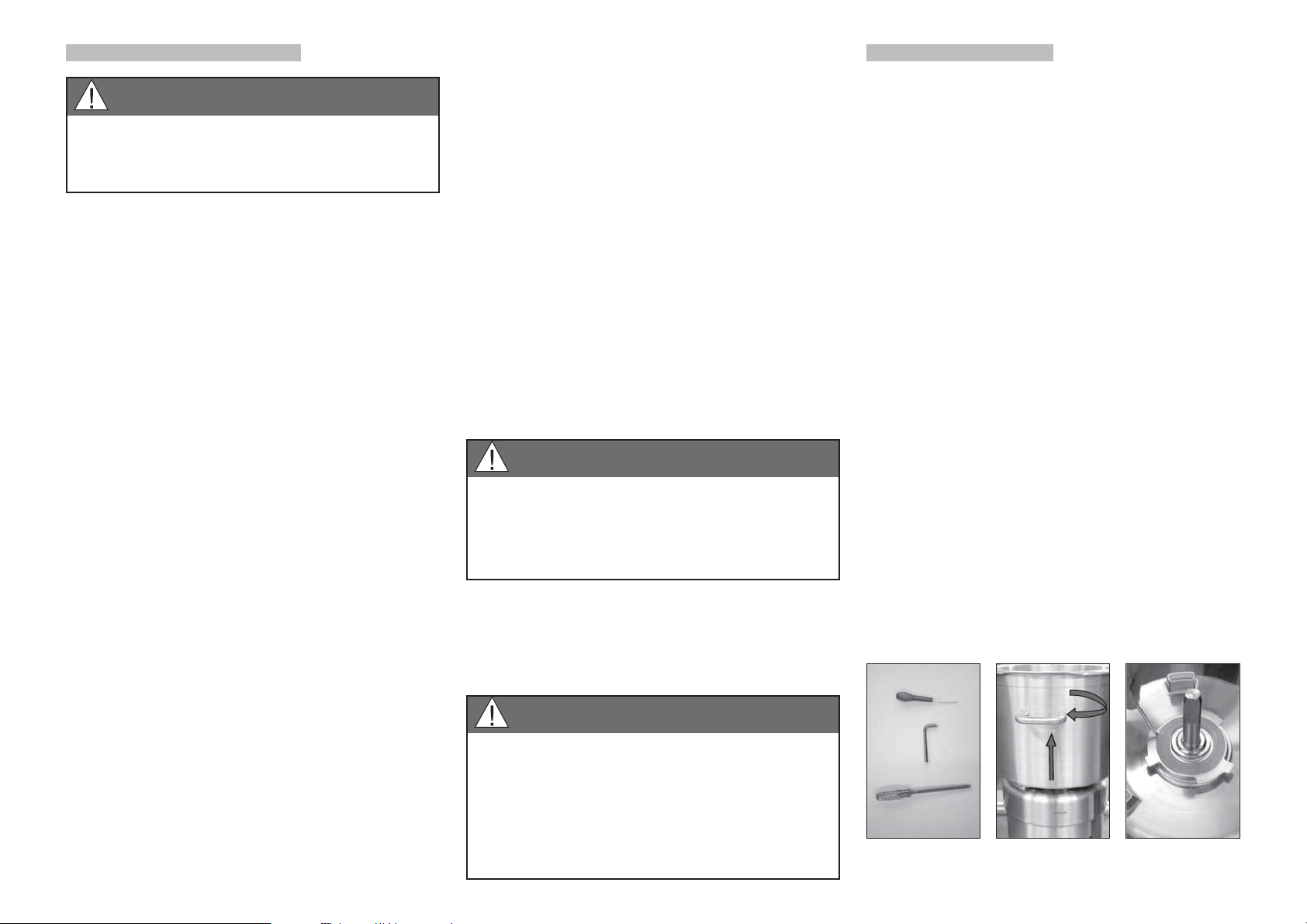

• BLADES

Wear cut-resistant gloves when handling the blade

assembly.

The blades do not need to be razor sharp to

provide a quality cut. However, they will need

sharpening from time to time. Use the honing stone

shipped with the machine, or have the blades

sharpened professionally if you prefer. If they

become too worn to sharpen, replacement blades

are available.

• SHAFT SEALS

The watertighness is achieved by a sealing socket

that holds two shaft seals, a stainless steel deflector

with integrated V-ring (upperside) and an O-ring

(lowerside).

To ensure that the motor remains totally watertight,

it is advisable to check the seals for wear once a

month, and replace them if necessary.

When the seals are worn, liquid may first run into

the bearings, then reach the motor. If this happens,

the seals, the bearings and even the motor may

have to be replaced.

The seals are easy to replace without having to

remove the motor, so you are strongly advised to

keep an eye on their state of wear.

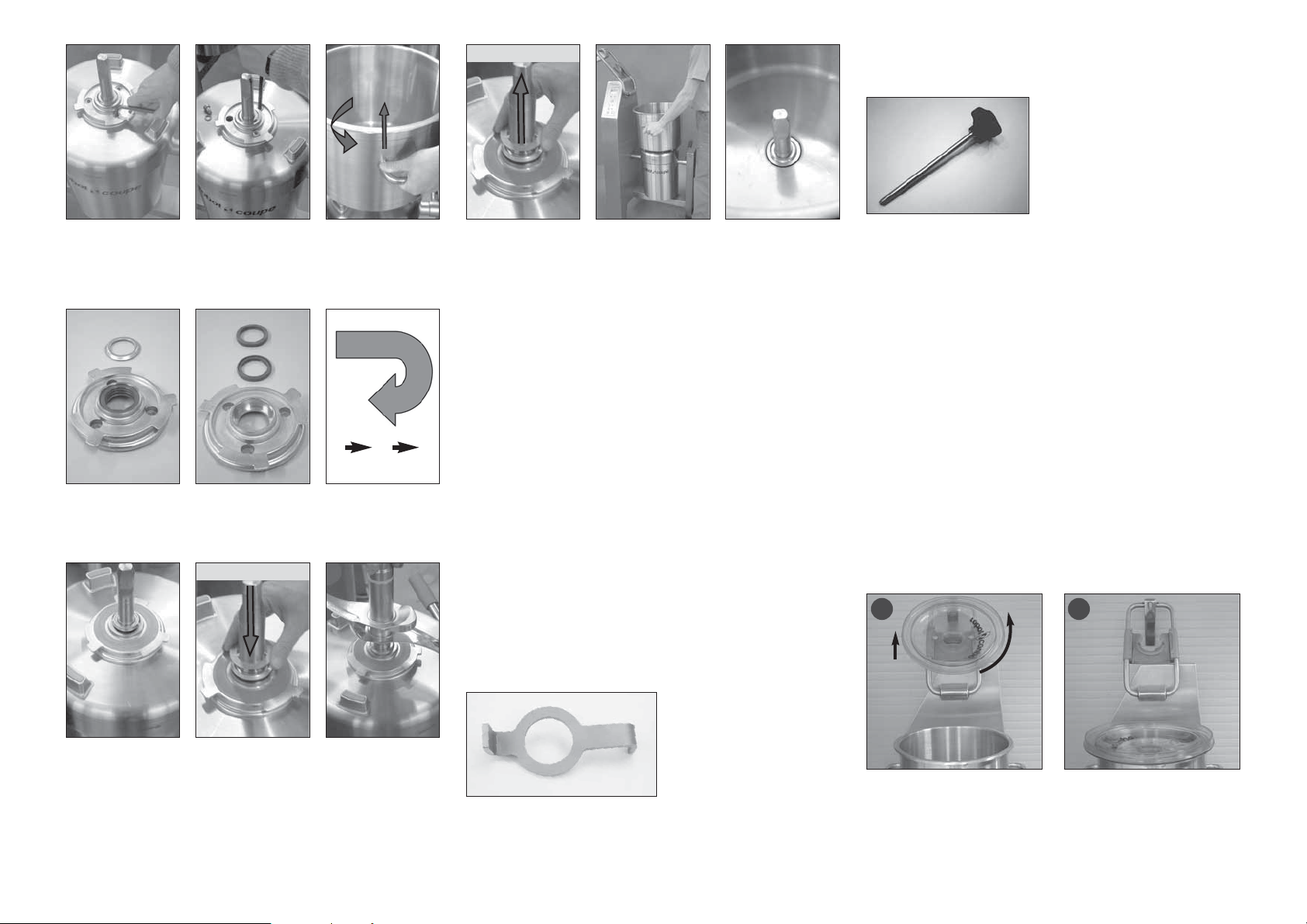

• REPLACEMENT OF MOTOR SHAFT SEAL

2

1) Tools needed 2) Remove the

bowl

3) Remove the

bowl seal

Page 10

Blixer®45 / 60

b

a

:

- Place the blade stop on the motor shaft.

- Put the blade assembly back in position.

1

2

- Loosen the top locking

nut with the provided

tool, turning it counterclockwise.

ENGLISH

- Dismantle the blade

assembly by hand.

4) Unscrew the

3 bolts

7) Socket and

top seal are free

5) Remove bolts

and washers

8) Replace shaft

seals

Blixer®45 / 60

6) Put the bowl

back on and

pull up

5 4 3

9) 5 to 3 in

reverse order

13) Remove

1 mm thick

washer

14) Attach the

bowl with the

pouring lip on the

15) It’s done !

left hand side.

• BOWL SEAL

The bowl seal, located between the bowl and the

bushing, ensures that the bowl remains watertight.

This sealing part must be regulary lubricated with

food-grade oil and be changed. Check it monthly for

signs of wear, as the watertightness of the bowl

depends on it.

In order to make it easier for you to clean your

appliance, the bowl sealing assembly is located on

the underside of the bowl.

As a result, a small area here may fill up with

foodstuff, though it will empty itself when the bowl is

released.

• DISMANTLING THE BLADE ASSEMBLY

WEAR CUT-RESISTANT GLOVES WHEN HANDLING

THE BLADES

- To reassemble the blades, follow these instructions

in the reverse order. Also, refer to the illustrations

on page 9.

- Make sure you tighten the top locking nut

firmly so that the blade assembly will not come

apart.

• LID SEAL

The lid is designed to be completely watertight

within the limits set out on page 9 (see examples

of use). In order to ensure that it remains that way,

you may have to change the seal occasionally,

depending on how regularly you use your machine.

If you do not use your machine regularly, we

recommend that you leave the lid open when it is

not in use.

SEAL REPLACEMENT

1

1

/

4

2

10) Replace

shaft top seal,

place it on shaft

chamfer

11) Place 1 mm

thick washer

12) Push down

blade assy, stop

when hits motor

shaft

- For the purpose of

sanitation, the blades

should be disassembled

Blade stop

and cleaned following

each meals prepara-

tion, or at least three times a day.

- Remove the blade assembly.

- Remove the bowl.

1-With the lid in the open position, turn it 1/4in either

direction. Then, lift the lid up and out of the slot in the

holding bracket.

2- Put the lid upside down on top of the bowl.

11

Page 11

3

8

b

a

a

a

a

b

:

1

/

4

a

b

a

b

b

a

a

b

a

b

b

• INSTALLATION

We recommend that you install your vertical

cutter-mixer on a flat, stable surface.

• NOISE LEVEL

The equivalent continuous sound pressure level when

running these appliances empty is less than 70

dB (A).

• ELECTRICAL DATA

Three-phase machine.

*

NOTE

Model

Motor

Blixer

®

Minimum branch *

circuit protection

required (A)

Rated

current

(Amp)

Rated

power

(watts)

Speed

(rpm)

TECHNICAL

SPECIFICATIONS

In order to obtain good results when mincing meat,

grinding and kneading, do not fill the bowl over half

full.

• BOWL CAPACITIES

Blixer®23: 24 quarts

Blixer

®

30: 31 quarts

Blixer

®

45: 47 quarts

Blixer

®

60: 63 quarts

• WEIGHT (lbs)

Net weight Gross weight

Blixer

®

23 / Blixer®30 : 223 289

Blixer

®

45 : 305 364

Blixer

®

60 : 331 390

• DIMENSIONS (in inches)

23

30

45

60

208-240 V/60Hz/3ph

1800 3700 16,0

3600 4500 18,2

30

208-240 V/60Hz/3ph

1800 4400 18,6

3600 5400 23,1

40

208-240 V/60Hz/3ph

1800 7000 27,0

3600 10000 35,0

60

208-240 V/60Hz/3ph

1800 8400 32,5

3600 12000 45,0

60

* Recommendation only, local electrical codes must be followed if

applicable.

When the appliance is switched on, the current is

several times greater than the rated current.

“The starting current of appliances must be taken into

account when determining the conductor gauge and

choosing the overcurrent protective devices to prevent

excessive voltage drops during the starting phase

and unexpected protective device tripping.”

A protective device dedicated to AC induction

motor must be used. See recommended size in the

table above. In every case, you must comply with

the legislation currently in force.

Blixer

®

23 30 45 60

49

1

/449 1/455 1/455 1/

4

12 3/414 1/415 3/417 3/

4

23 3/423 3/423 3/423 3/

4

23 1/423 1/425 1/425 1/

4

64 64 71 71 3/

4

31 1/431 1/234 1/434 1/

4

27 3/428 1/230 32

A

B

C

D

E

F

G

3 - Install the seal with the

seam (where the two ends

are joined) on the hinged

side of the lid. The inner

portion of the seal is grooved to fit the corresponding

raised rim on the lid.

4 5

6 7

4 to 7 - Begin installing the seal on the hinged side of

the lid, pressing down on the inner portion of the seal

and working your way along each side, until the seal is

completely installed.

8 - Put the lid back in the

bracket, and give it a

1

/

4

turn.

12

Page 12

SAFETY

These appliances are fitted with four interlocking

devices.

The machine can be started only if the following

conditions are achieved:

- The bowl is locked in the right angular position,

- The bowl and the motor are in vertical position,

- The lid is locked on its support in the correct

angular position,

- The lid is closed on the bowl.

Caution: Allow product circulation to stop before

opening the lid.

These models are also fitted with a thermal protection

system (with automatic reset) which stops the motor

if it is overloaded. A red warning light signals that

the machine is becoming too hot and is about to

stop.

If this happens, wait until the appliance has cooled

down before switching it back on (the orange light

will switch off and the green lights will switch on

again).

ENGLISH

WARNING

The blades are extremely sharp. Handle with care.

REMEMBER

Never try to override the locking and safety

systems.

Never insert a nonfood object into the container

where the food is being processed.

Never push the ingredients down with your hand.

Do not overload the appliance.

13

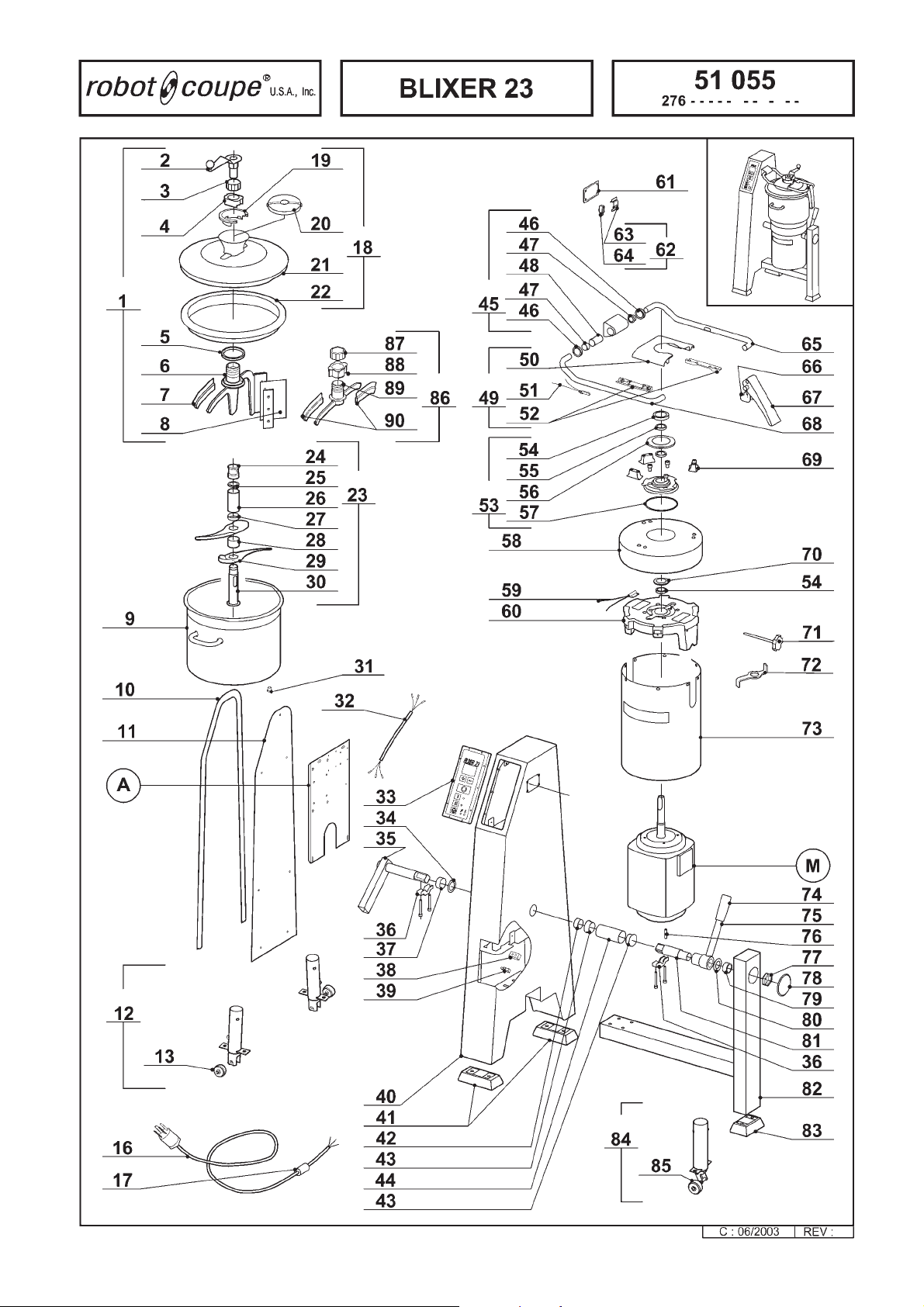

Page 13

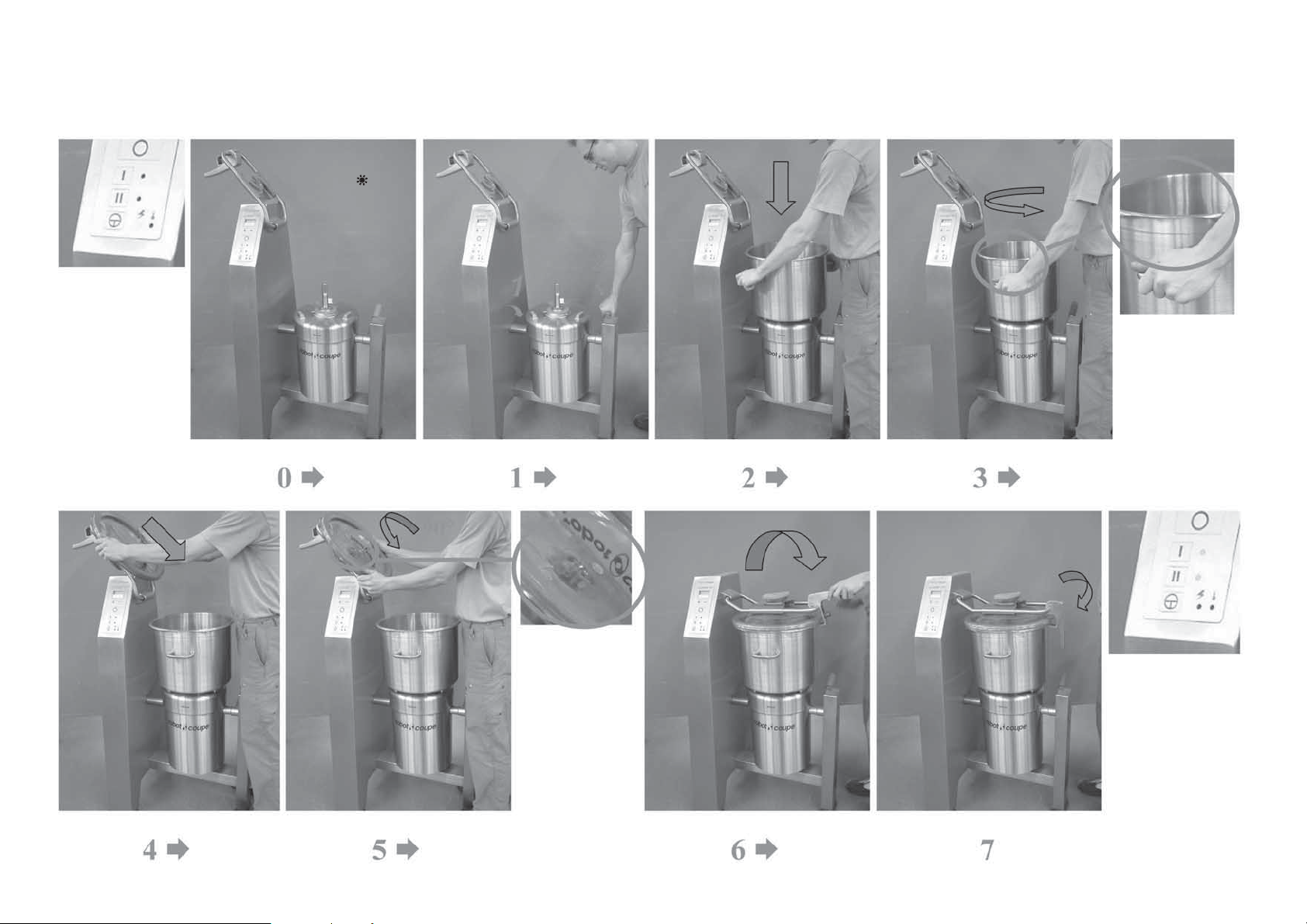

BEFORE STARTING • ANTES DE PONER EN MARCHA • AVANT DE DÉMARRER

41

Page 14

42

Page 15

43

Page 16

4546474849

Page 17

Page 18

Page 19

Page 20

Page 21

5152535455

Page 22

Page 23

Page 24

Page 25

Page 26

5758596061

Page 27

Page 28

Page 29

Page 30

Page 31

6364656667

Page 32

Page 33

Page 34

Page 35

Page 36

6970717273

Page 37

Page 38

Page 39

Page 40

Page 41

7576777879

Page 42

Page 43

Page 44

Page 45

Page 46

8182838485

Page 47

Page 48

Page 49

Page 50

Page 51

8788899091

Page 52

Page 53

Page 54

Page 55

Page 56

P.O. Box 16625, Jackson, MS 39236-6625

280 South Perkins St., Ridgeland, MS 39157

e-mail: robocoup@misnet.com

website: www.robotcoupeusa.com

Phone : 1-800-824-1646

Réf. : 450 161

Loading...

Loading...