Robostar Co., Ltd

Robostar Robot Controller Manual

www.robostar.co.kr

√

RRoobboossttaarr RRoobboot

t

N11 SSeerriieess

N

Deevviiccee

D

Option Module

- DeviceNet

Oppttiioonn

O

Neett

N

www.robostar.co.kr

Robostar Co., Ltd

Robostar Robot Controller Manual

√

RROOBBOOSSTTAARR RROOBBOOT

T

N11 SSeerriieess

N

Deevviiccee

D

Option Module

- DeviceNet

Oppttiioonn

O

Neett

N

Copyright ⓒ ROBOSTAR Co., Ltd 2012

The copyright of this user manual is owned by Robostar Co., Ltd. No part of this manual may be

used in any form or by any means without Robostar Co., Ltd. Specifications are subject to change

without prior notice.

Product Warranty

Address and Contact Details for Robostar Co., Ltd

Head Office and Factory

700, Suin-ro, Sangnok-gu,

Ansan-City, Gyeonggi-do, Republic of

South Korea (426-220)

2

nd

Factory

108, Saneop-ro, Gwonseon-gu,

Suwon-City, Gyeonggi-do, Republic of

South Korea (441-813)

Service Inquiry and Product Inquiry

- Sales Inquiry

TEL. 031-400-3600

FAX. 031-419-4249

- Customer Inquiry

TEL. 1588-4428

www.robostar.co.kr

Regarding Product Warranty

Robostar products are manufactured under strict quality control and all Robostar products

are covered under one year warranty from the date of manufacture. We offer free services

during this warranty period only for mechanical breakdowns caused by faults by Robostar or

breakdowns which arise from problem in design and manufacturing faults during normal use.

No free service is provided to the following occasions.

(1) After the warranty period expires

(2) Mechanical troubles caused by inappropriate repairs, alteration, movement and other negligent

handling directed by your company or a third party.

(3) Mechanical troubles caused by use of other products than the ones assigned by our company,

such as components and grease

(4) Mechanical troubles caused by fires, disasters, earthquakes, storm and flooding and other natural

disasters

(5) Malfunction due to use in environment beyond our product specifications, such as in excretions

and flooding

(6) Malfunction due to normal wear of consumable parts

(7) Malfunction due to lack of carrying out maintenance work checklist as listed in User Manual and

Handling Manual

(8) Damage not included in robot repair costs

i Robostar Co., Ltd

Composition of User Manual

CCoommppoossiittiioonn ooff UUsseerr MMaannuuaall

The User Manual of this product is composed of the following. If this is the first time to use

this product, fully understand each and every detail in the manual before use.

DeviceNet

Explains how to connect a connector to N1 series using DeviceNet communication modules as

well as how to use it.

ii Robostar Co., Ltd

Table of Content

Table of Contents

CHAPTER 1. OVERVIEW ....................................................................................................................................... 1-1

1.1 WHAT IS A DEVICENET OPTION BOARD? .......................................................................................................... 1-1

1.2 SYSTEM CONFIGURATION ................................................................................................................................. 1-1

CHAPTER 2. FUNCTION ........................................................................................................................................ 2-1

2.1 SPECIFICATIONS OF DEVICENET OPTION BOARD .............................................................................................. 2-1

2.2 CHARACTERISTICS AND FUNCTIONS OF DEVICENET ......................................................................................... 2-1

CHAPTER 3. SPECIFICATIONS ............................................................................................................................ 3-1

3.1 DEVICENET SPECIFICATIONS ............................................................................................................................ 3-1

3.2 STATUS DISPLAY LED ...................................................................................................................................... 3-2

3.3 STATION NUMBER SETTING .............................................................................................................................. 3-3

3.4 DISPLAY OF COMMUNICATION POWER AND COMMUNICATION LINE ................................................................. 3-3

3.5 I/O SIZE SETTING ............................................................................................................................................ 3-5

3.6 CABLE SPEC ..................................................................................................................................................... 3-6

3.7 HOW TO INSTALL HARDWARE ........................................................................................................................... 3-1

CHAPTER 4. INSTALLATION AND OPERATION SETTING ........................................................................... 4-1

4.1 HOW TO CONNECT DEVICENET FIELD NETWORK CABLE ................................................................................. 4-1

4.2 CONTROLLER SETTING ..................................................................................................................................... 4-2

4.2.1 FIELD BUS(DeviceNet) Setting............................................................................................................... 4-2

4.2.2 USER I/O Setting ..................................................................................................................................... 4-4

4.3 PLC DATA TRANSFER SPEED ................................................................ ................................ ............................ 4-5

CHAPTER 5. EXAMPLES OF DEVICENET SETTING ...................................................................................... 5-1

5.1 EXAMPLES OF AB PLC RSNETWORK SETTING ................................................................................................ 5-1

CHAPTER 6. MEMORY MAPPING ....................................................................................................................... 6-1

6.1 N1 CONTROLLER DATA MAPPING ..................................................................................................................... 6-1

6.1.1 N1 Series System Input #1 ........................................................................................................................ 6-2

6.1.2 N1 Series System Input #2 & FIELDBUS INPUT#1 ................................................................................ 6-3

6.1.3 N1 Series FIELDBUS INPUT #2 ............................................................................................................. 6-3

6.1.4 N1 Series System Output #1 ..................................................................................................................... 6-3

6.1.5 N1 Series FIELDBUS Output #2 ............................................................................................................. 6-4

6.2 PRECAUTIONS FOR USE IN N1 SERIES SYSTEM MODE ...................................................................................... 6-4

iii Robostar Co., Ltd

Table of Content

6.3 N1 SERIES FIELDBUS(CC_LINK) TIMING DIAGRAM ........................................................................................ 6-5

6.3.1 Operation in AUTO RUN MODE ............................................................................................................ 6-5

6.3.2 JOB Program Change during JOB Operation ......................................................................................... 6-7

6.3.3 JOB Program Change after Completing JOB Program .......................................................................... 6-9

6.3.4 JOB Program START after Disabling Alarm ......................................................................................... 6-11

6.3.5 JOB Program Restart after Disabling Alarm ......................................................................................... 6-13

6.3.6 SERVO OFF ........................................................................................................................................... 6-15

6.3.7 Rebooting ............................................................................................................................................... 6-17

6.3.8 MODE(AUTO, STEP, JOG) Change ..................................................................................................... 6-19

6.3.9 STEP MODE .......................................................................................................................................... 6-21

6.3.10 Operation in JOG MODE ...................................................................................................................... 6-23

6.3.11 Forward Operation in JOG MODE ....................................................................................................... 6-25

6.3.12 Read RPM, TRQ..................................................................................................................................... 6-27

6.3.13 Read Current Position ........................................................................................................................... 6-28

6.3.14 Read GLOBAL Point .............................................................................................................................. 6-29

6.3.15 Write GLOBAL Point ............................................................................................................................. 6-31

6.3.16 Read GLOBAL Integer ........................................................................................................................... 6-33

6.3.17 Write GLOBAL Integer .......................................................................................................................... 6-34

6.3.18 Read GLOBAL Float .............................................................................................................................. 6-35

6.3.19 Write GLOBAL Float ............................................................................................................................. 6-36

iv Robostar Co., Ltd

Overview

Chapter 1. Overview

1.1 What is a DeviceNet Option Board?

A DeviceNet Option Board is a board in charge of DeviceNet field network system communication

of Robostar N1 controller. N1 controller allows the use of a DeviceNet Option Board to enable

communicating with systems such as PC or PLC using DeviceNet protocols. DeviceNet, one of

fieldbus communication methods getting the most spotlight over recent years, is considered the

most successful technology among a variety of fieldbuses due to its short system response time

and high reliability through the use of CAN (Controller Area Network) protocols.

1.2 System Configuration

The upper network can be interfaced with a DeviceNet master station such as PC or PLC, while a

master station utilizes DeviceNet field network to communicate with sub-slave stations.

Fig. 1.1 DeviceNet System Configuration

1-1 Robostar Co., Ltd

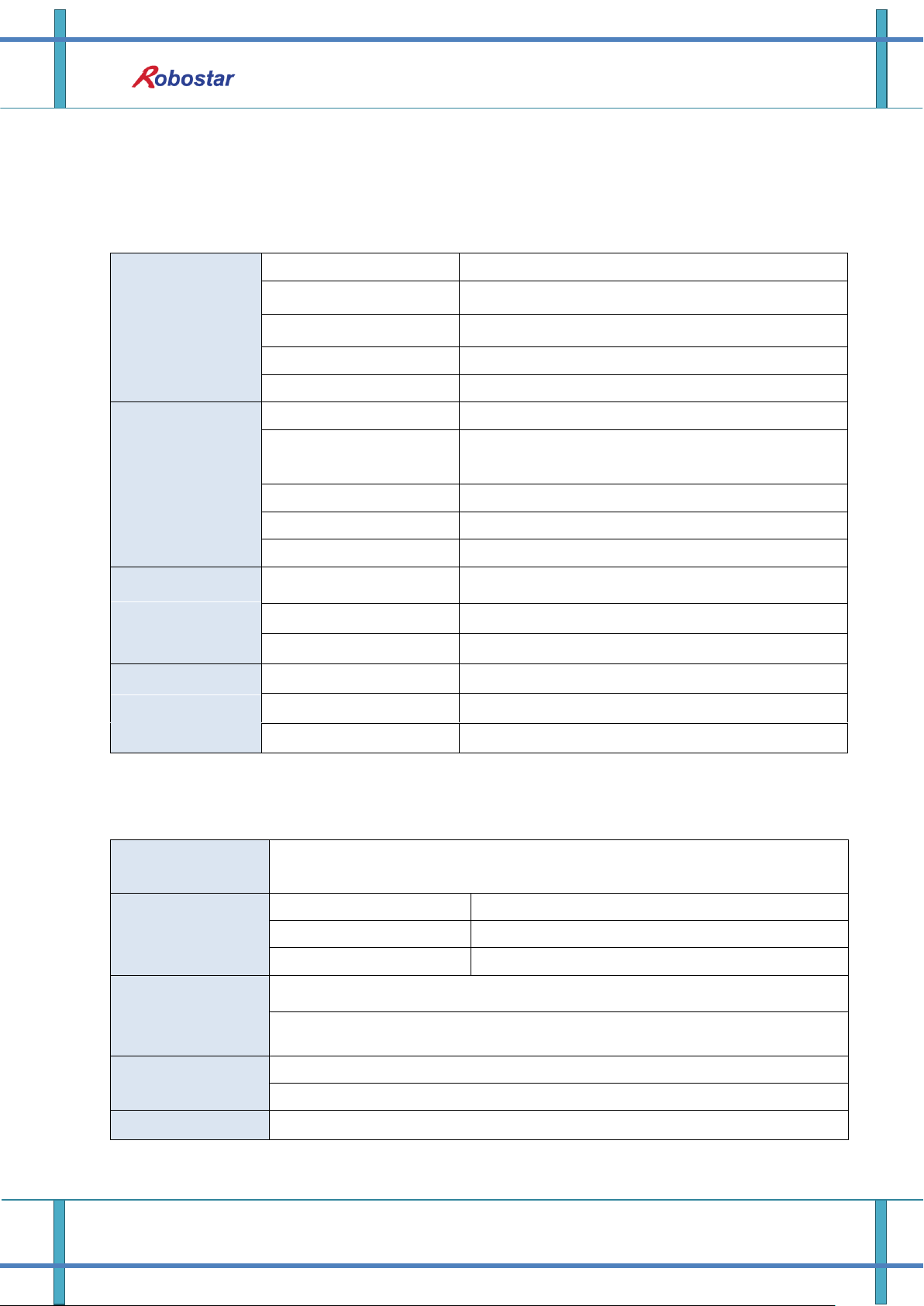

DeviceNet

connections

Connector

Pluggable connector(5.08mm, 5-pin)

Data Transfer Method

CAN(Controller Area Network)

Transfer Cable

DeviceNet dedicated cable (4-wire shield cable)

Withstand Voltage

500VDC

Terminating Resistance

120 Ohm

Communications

Communication Protocol

ODVA 2.0

Communication Speed

125/250/500Kbaud (Set automatically depending on

master)

Product Code

0x10/0x11

Product Type

0(Generic)

Vendor ID

1055

Electrical

Communication Power

11~25V DC

Communication Current

Below 30mA

Control Power

5V DC(Provided from Robostar controller)

Environment

Operating Temperature

0 ~ 40℃

Storage Temperature

-15 ~ 60℃

Operating Humidity

20~80% PH

Max Number of

Stations to use

64 stations (0-63)

Communication

Distance per

Speed

125Kbps

500m

250Kbps

250m

500Kbps

100m

Data

Transmit/Receive

Methods

Explicit Message(Parameter input/output data)

Polled I/O Message(Real-time input/output data)

Transmit/Receive

Length

Explicit Message: Flexible depending on parameter length

Polled I/O Message: Max 32Byte(Default:8Byte)

Device Type

Group2 Only Server(Predefined Master/Slave Connection Set)

Chapter 2. Function

2.1 Specifications of DeviceNet Option Board

Function

2.2 Characteristics and Functions of DeviceNet

2-1 Robostar Co., Ltd

Specifications

Signal

Connector

Description

V- 1 Communication Power, Ground(0V)

CAN_L

2

Communication Signal, Low

Drain

3

Shield

CAN_H

4

Communication Signal , High

V+ 5 Communication Power , +24V DC

① ② ③ ④ ⑤

Program Change

NS_R

NS_G

MS_G

MS_R

Station 1x

Rotary Switch

Station 10x

Rotary Switch

I/O Size

V+

CANH

Drain

CANL

V-

DeviceNet

Communication

Chapter 3. Specifications

3.1 DeviceNet Specifications

DeviceNet Option Board is connected to the external fieldbus through a 5-pin connector and

connected to Robostar N1 controller through a built-in Dual_Port memory. DeviceNet Option Board

consists of DeviceNet 5-pin connector, module status display LED, network status display LED, prefix

setup switch, I/O SIZE setup switch, and RS-232 connector(DB9).

Fig. 3.1 DeviceNet Board Block-diagram

Table 3.1 DeviceNet Connector Setting

3-1 Robostar Co., Ltd

Specifications

LED Status

Description

NS_R(Red)

NS_G(Green)

Off Off

DeviceNet Option Board not On-line.

-.Board not connected to master yet.

-. Power to Module status display not provided with LED OFF.

Off

On

Board is On-line, connecting normally to master.

Off

Blinking

Board is On-line by passing check for a duplicate node but not in

communication with master.

Blinking

Off

I/O Connection(Poll I/O) in Time-Out.

On

Off

Board unable to connect to network. (ID duplicated or Bus-Off)

LED Status

Description

MS_R(Red)

MS_G(Green)

Off

Off

Power not provided.

Off

On

Board under normal operation.

Off

Blinking

Board is on Stand-by or a certain error occurred in the course of

initializing network parameters.

Blinking

Off

Error generated on Board which is likely to go back to normal.

On

Off

Error generated on Board which is unable to go back to normal.

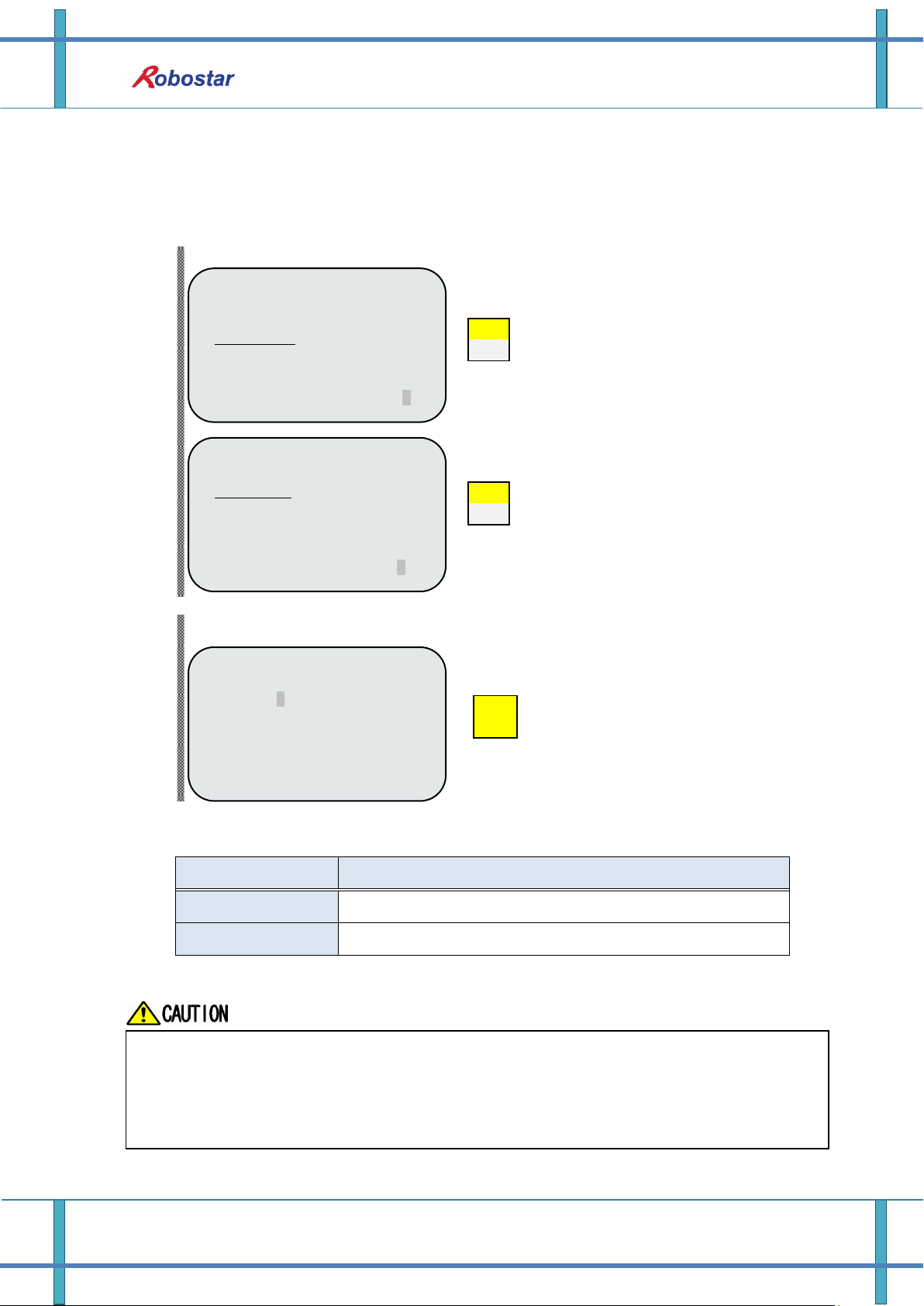

3.2 Status Display LED

DeviceNet Option Board has two LEDs – a module status display LED(MS_R, MS_G) indicating the

Board status and a network status display LED(NS_R, NS_G) indicating the communication status.

Table 3.2 Network Status Display LED

Table 3.3 Module Status Display LED

LED Check

When DeviceNet Option Board is powered, LED check is done with the following procedure.

1. Turn all LEDs Off

2. Turn all Green LEDs On(25ms)

3. Turn all Red LEDs On(25ms)

4. Turn all LEDs Off

5. Under normal operation

3-2 Robostar Co., Ltd

Specifications

Communication Power

Connect to Terminal 1 (-V, Black) and 5 (+V, Red).

Communication Line

Connect to Terminal 2(CANL, Blue) and 4 (CANH, White).

3.3 Station Number Setting

Use the Station 10x Rotary Switch and Station 1x Rotary Switch in Fig. 3.1 ② and change into

Station Number set in Master to have communication with DeviceNet Master. Rotary Switch makes

use of a decimal number so you can set a tenth place with 10x Rotary Switch and the first place with

1x Rotary Switch.

Fig. 3.2 Examples of Station Number Setting

Station Number setting can be done from Station 0 to 64, where the remote device station where

DeviceNet Option Board belongs is capable of setting from Station 1 to 64. Fig. 3.2 shows an

example set by 17 stations. When resetting a prefix, be sure to change the power from OFF->On.

3.4 Display of Communication Power and Communication Line

Fig. 3.3 Connector Pin Layout

3-3 Robostar Co., Ltd

Specifications

Measured Value

Measures

Below 50 Ω

Possible error is on the board connected. Remove error by checking the

terminating resistance.

50 – 70 Ω

Under normal condition

70 – 125 Ω

Either CANH or CANL disconnected, or the terminating resistance is installed

only at one end.

Over 125 Ω

The terminating resistance is not installed, or CANH or CANL disconnected.

Terminating resistance (120 Ω) should be installed in termination of communication.

V-

CAN

L

SLD

V+

CAN

H

Upon completion of wiring, check that the wiring has been properly conducted by measuring the

resistance value on both ends (CANH, CANL) of the communication line.

Fig. 3.4 Resistance Measurement

See Table 3.4 for reference for details about the resistance values measured.

Table 3.4 Resistance Measurement for Presence of Connection Error

Terminating resistance (120Ω, ±1%) is connected between Connector CANL(2PIN) and CANH(4PIN).

For how to connect, refer to “Fig. 3.5 How to Connect Terminating Resistance”.

Fig. 3.5 How to Connect Terminating Resistance (120Ω)

3-4 Robostar Co., Ltd

Specifications

Input/Output Data Size Setting Value

Value

IN Data Size

OUT Data Size

0

48 Kbyte

48 Kbyte

1

46 Kbyte

40 Kbyte

2

8 Kbyte

8 Kbyte

Values other

than the above

values

Error

3.5 I/O SIZE Setting

This product allows an easy I/O SIZE setting with a choice of switches. I/O SIZE can change

depending on the location of Switch 3. If Switch3 is positioned in 0, I/O SIZE is 48X48 SIZE and if 1,

I/O SIZE is 46X40 for use.

Fig. 3.6 Example of Data Size Setting Table 3.5 Input/Output Size Setting Value

3-5 Robostar Co., Ltd

3.6 Cable Spec

Specifications

Fig. 3.7 Thick Cable

Fig. 3.8 Thin Cable

- When using 24 Volts DC on a thick cable or flat cable, the maximum for use is 8A but

NEC Class 2 requirements permit only 4A. (Applies only to North America)

- A maximum of 3A is possible when using 24 Volts DC on a thin cable.

3-6 Robostar Co., Ltd

Installation and Operation Setting

For FieldBus network cable, use a certified DeviceNet cable.

When using a non-dedicated cable, it may lead to malfunction due to noise.

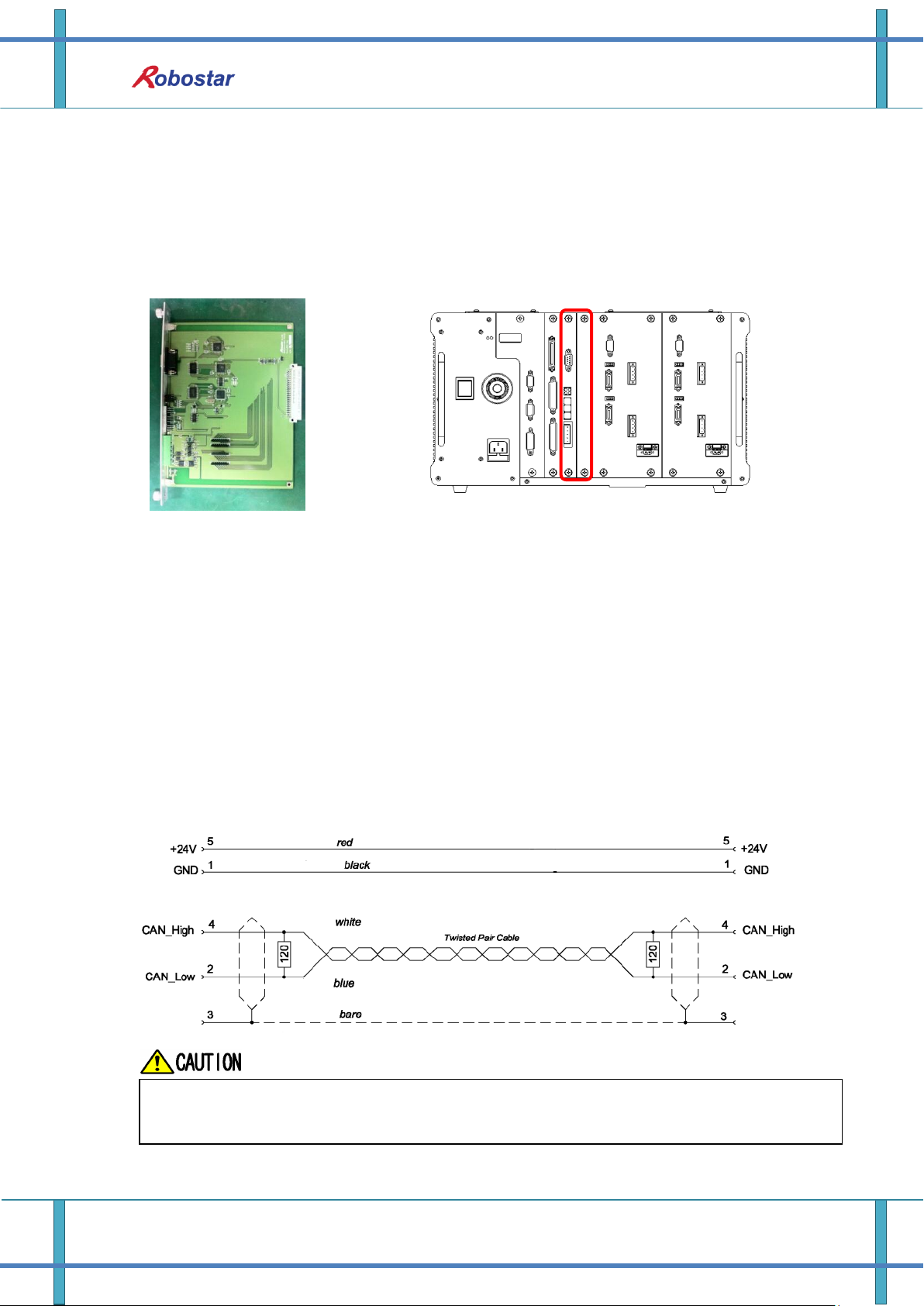

3.7 How to Install Hardware

Take the following procedure to be able to use DeviceNet Option Board of N1 series controller.

1) Turn power OFF.

2) Attach DeviceNet Option Board to PCI slot on N1 Controller.

Fig. 4.1 How to Install Option Board

3) Turn power back ON.

Chapter 4. Installation and Operation Setting

4.1 How to Connect DeviceNet Field Network Cable

A STL(Z) 950 5-pin OPEN Connector is used for how to connect between Cable and Connector

DeviceNet Option Card, therefore a screw driver is used to fix 4 wires on DeviceNet field network ---

V+(Red), CANH(White), CANL(Blue), V-(Black). Basically use a certified DeviceNet cable. For wiring

between cable and Connector, refer to “Fig. 4.2”, “Fig. 3.3”.

Fig. 4.2 How to Connect Network Cable

4-1 Robostar Co., Ltd

Installation and Operation Setting

4

L

F3

1

Q

<MAIN MENU>

1. JOB 2. RUN

3. HOST 4. PARA

5. ORIGIN 6. I/O

7. SYSTEM 8. GPNT

9. INT/FLT A. ALARM

SELECT #

<PARAMETER>

NO TYPE

*CH1 XYZW

CH2 XY_TEST

SEL INFO PUB EXIT

<PUBLIC PARAMETER>

1: HW CONF 2: PALLET

3: PLC 4: ETC

group #

Open initial MAIN screen

Select 4: PARA

Select 1:HW CONF

Open PUBLIC PARAMETER group screen

Press F3 button to move to PUB

4.2 Controller Setting

To use DeviceNet from N1 Controller, the following Software setup is required.

4.2.1 FIELD BUS(DeviceNet) Setting

1. Setting Procedure

Step1. Move to PUBLIC Parameter screen

4-2 Robostar Co., Ltd

2

R

ESC

ENTER

1

Q

2

R

4

L

<HW CONF - COM>

COMMUNICATION SET

1: RS232C

2: FIELD BUS

3: LINE SEPARATOR

group #

Select 2: FIELD BUS

Select 2:COMM

<PUBLIC-HW CONF(0)>

1: TMR 2: COMM

3: I/O 4: D-MAN

5: SVON 6: A I/O

item #

<COM-FDBUS >

1: CARD

2: USER I/O

3: PROFIBUS ENDIAN

4: MAP EXTENTION

Input: ■

Select 1: CARD

<FDBUS-CARD>

OPT COM CARD

1: NONE 2: CC-LINK

3: PROFIBUS 4: D-NET

Updata OK?(ENT/ESC) ■

Press ESC and then ENTER to save

<FDBUS-CARD>

OPT COM CARD

1: NONE 2: CC-LINK

3: PROFIBUS 4: D-NET

Selected : CC-LINK■

Select 2: D-NET

When there is no DeviceNet B/D, a message “Not Card!” comes up at bottom of

T/P screen and fails to be saved.

Step2. Move to FIELD BUS screen

Installation and Operation Setting

Step3. OPTION CARD setup screen

4-3 Robostar Co., Ltd

2

R

ENTER

2

R

Item

Description

SYS USER I/O

Input/output using USER I/O of N1 System IO B/D

FIELDBUS USER I/O

Input/output using USER I/O in Field Bus card

<COM-FDBUS>

1: CARD

2: USER I./O

3: PROFIBUS ENDIAN

4: MAP EXTENTION

input #

Select 2: USER I/O

<FDBUS-USER I/O>

USER IN/OUT SEL

USER IO : SYS U I/O

Select SYS U I/O” or “FIELD U I/O

<HW CONF - COM>

COMMUNICATION SET

1: RS232C

2: FIELD BUS

3: LINE SEPARATOR

group #

Open COMM screen

Select 2: FIELD BUS

Data(USER I/O area) input/output are restricted due to communications in setting SYS

USER I/O.

When setting FIELDBUS USER I/O, Data(User I/O) input/output via I/O Board are restricted.

For further details about User I/O, refer to “Handling Manual 3.3.6”.

4.2.2 USER I/O Setting

1. Setting Procedure

Step1. Move to USER I/O screen

Installation and Operation Setting

Step2. USER I/O setup screen

When using a Field Bus card, a method of using USER I/O is set.

4-4 Robostar Co., Ltd

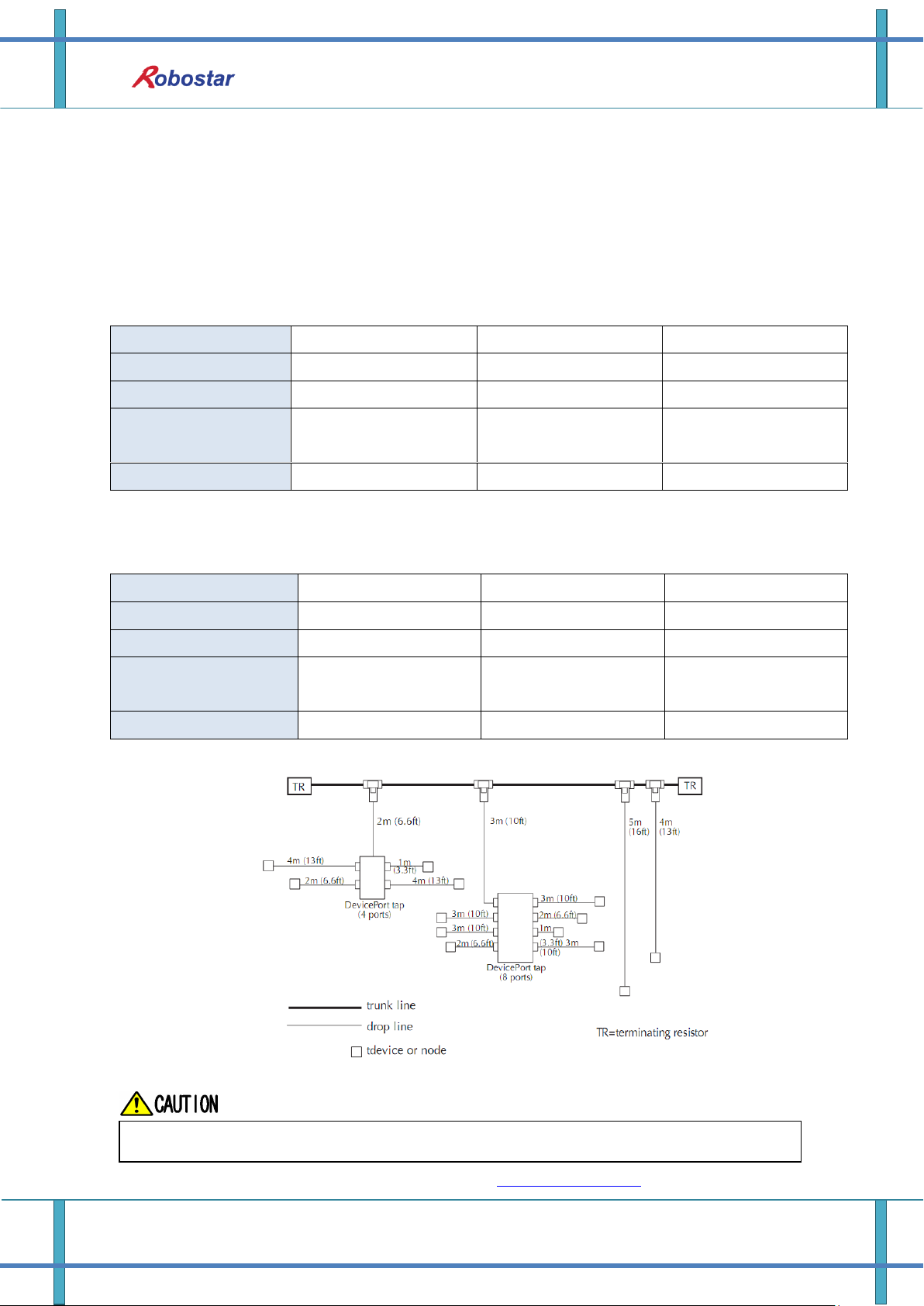

Installation and Operation Setting

Transfer Rate

125 Kbps

250 Kbps

500 Kbps

Transfer Distance

500m

250m

100m

Longest Drop Length

6m

6m

6m

Cumulative Drop

Length

153m

77m

38m

Number of Nodes

64

64

64

Transfer Rate

125 Kbps

250 Kbps

500 Kbps

Transfer Distance

100m

100m

100m

Longest Drop Length

6m

6m

6m

Cumulative Drop

Length

153m

77m

38m

Number of Nodes

64

64

64

DeviceNet communication speed can be set on a PLC.

4.3 PLC Data Transfer Speed

When transmitting data from PLC, a maximum of 10ms delay time may occur. As the Controller

takes20ms for data scanning time, an accurate operation may not be guaranteed if a data value is

changed for less than 20ms.

Thick Trunk

Thin Trunk

Fig. 4.3 Example of Drop Line

For other details about DeviceNet, refer to ODVA (WWW.ODVA.OR.KR).

4-5 Robostar Co., Ltd

Examples of DeviceNet Setting

Chapter 5. Examples of DeviceNet Setting

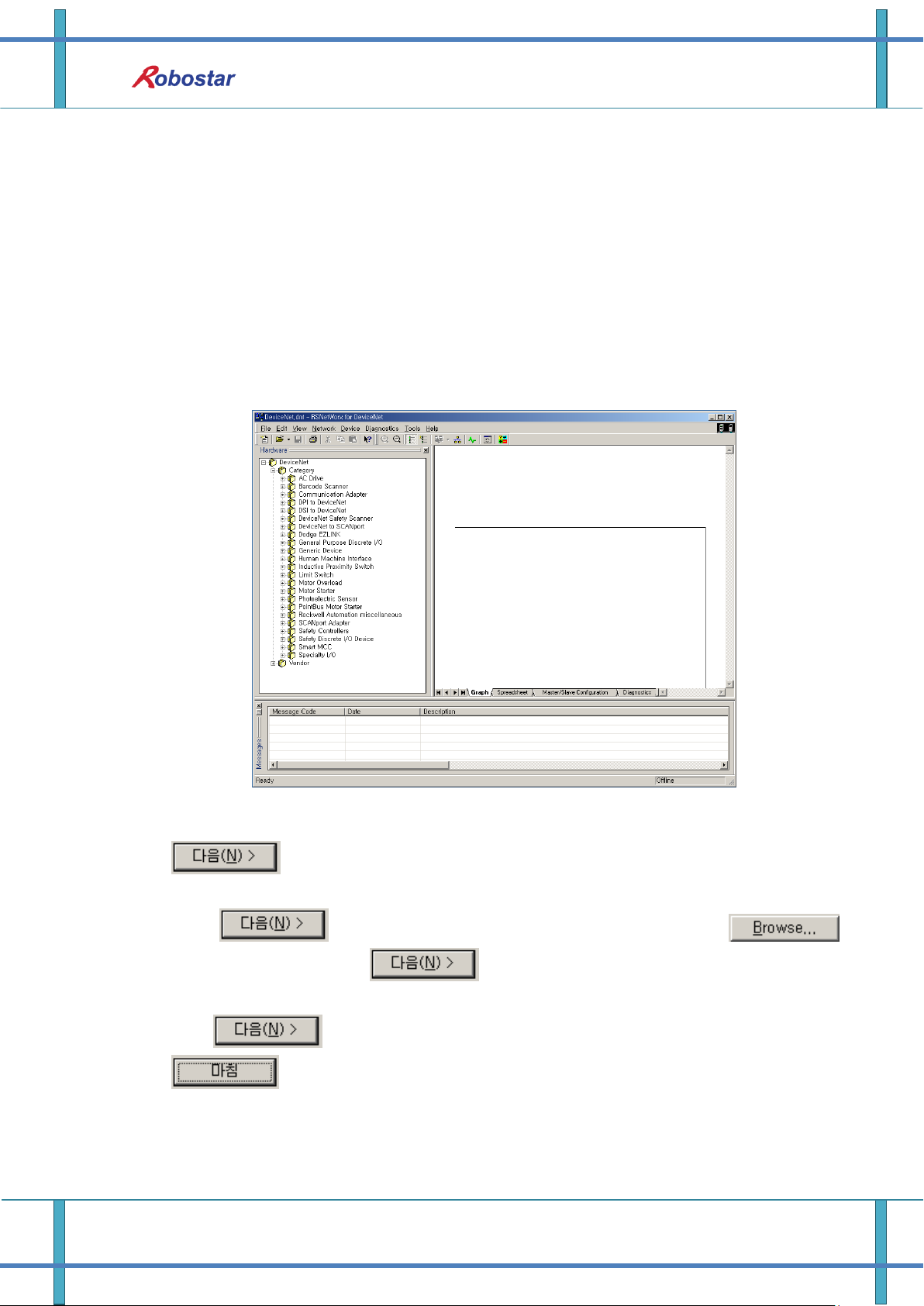

5.1 Examples of AB PLC RSNetwork Setting

How to set DeviceNet stated in this Manual made use of PLC model 1756 Compactlogix made by AB

as a PLC, and used RSLinx, RSNetworx and RSLogix 5000 made by AB as software.

1) Set the N1 node address.

2) Confirm the connection to DeviceNet network before running RsNetworx. With RsNetwor

running, a screen opens up as shown below.

[Fig. 5.1 RSNetwork In-progress Screen]

3) Click Tools -> EDS Wizard on the menu, the EDS Wizard screen comes up. Then, click

icon at the screen. When the Option screen comes up, a Register an EDS File

is checked as default.

4) Click once again, a Registration screen comes up. Click the

icon, find N1.EDS and click , then the EDS File Installation Test Results window

appears.

5) Click three times in a row when no error is found in this window, click

lastly, then the EDS file Install is complete. Once the EDS file has been

normally installed, you can check a directory Robostar has been created at lower end of the

Vendor directory at the Hardware window on the left in Fig. 5.2, with N1 generated in its sub

directory.

5-1 Robostar Co., Ltd

Examples of DeviceNet Setting

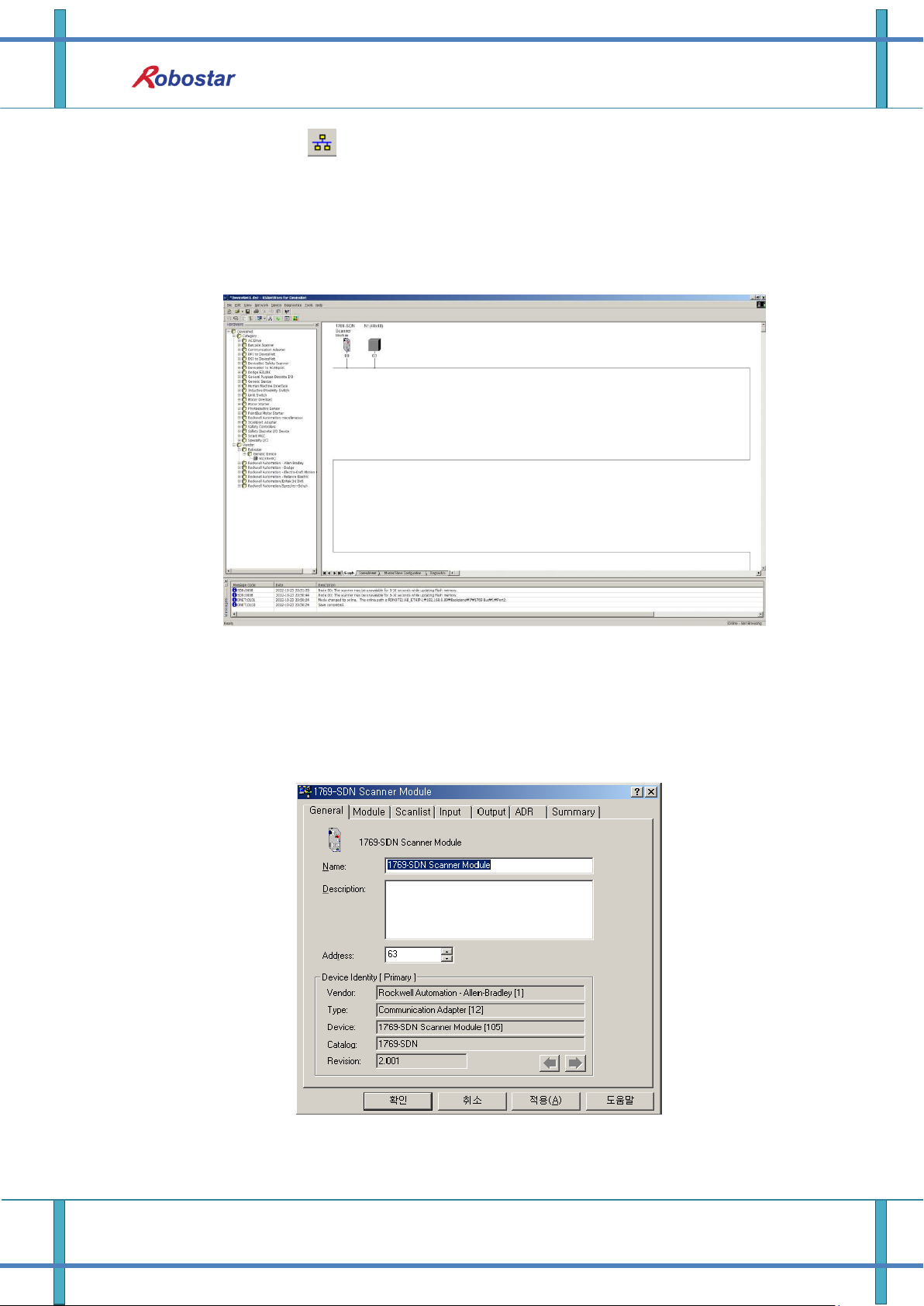

6) In Fig. 5.2, click (Online) icon and a window comes up. Click Check button and

RsNetworx automatically begins to scan Network to find out DeviceNet modules, and a

window showing the results of the scanning, as shown below, according to NODE numbers

set to N1. (The set value for SW3 in Fig. 5.2 is 0(48x48). The node values of the two examples

are set to 3.)

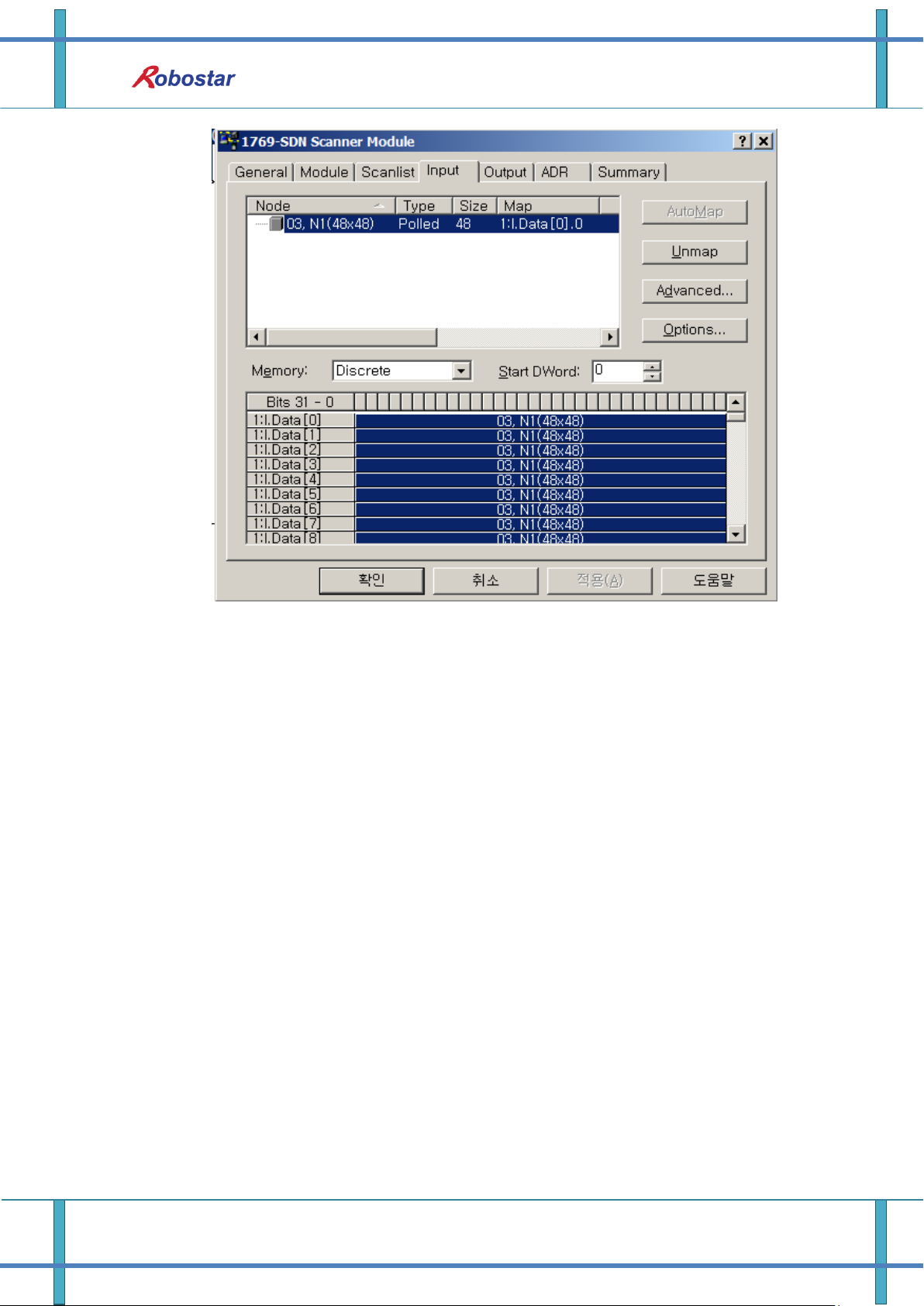

[Fig. 5.2 Screen I/O Allocation 48x48 after Auto Scan]

7) Double-click the 1796-SDN Scanner module and the Fig. 5.4 screen comes up. Click the

Module tab and select CompactLogix used as the example when asked to pick a 1769-SDN

Platform.

[Fig. 5.4 Scanner Setup Screen]

5-2 Robostar Co., Ltd

Examples of DeviceNet Setting

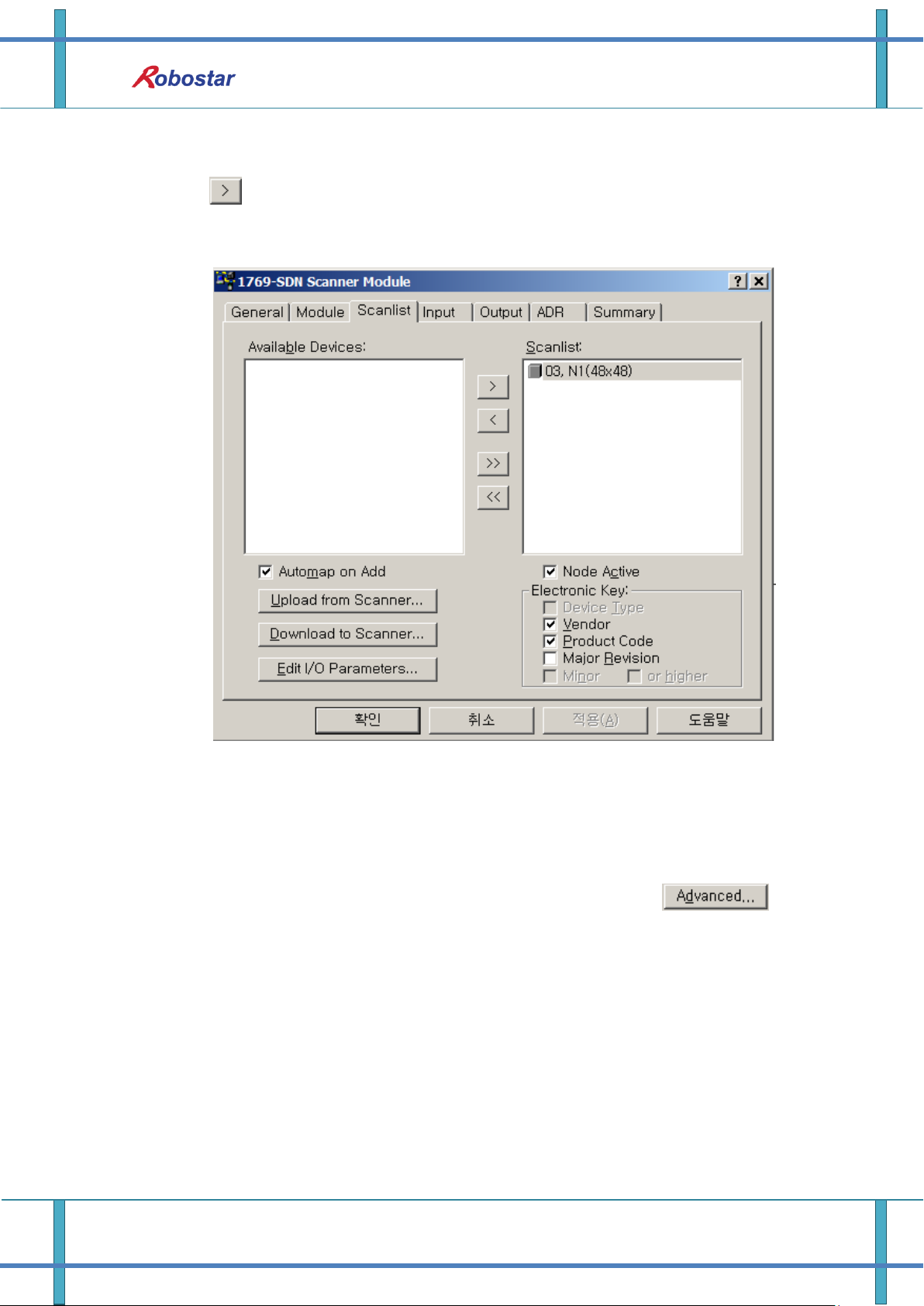

8) Click the Scanlist tab and the Fig. 5.5 screen pops up. Select the N1 in Available Devices and

click , and N1 moves to Scanlist. Click the Download to Scanner on the bottom left and

N1 is registered in the 1769-SDN Scanlist.

[Fig. 5.5 Scanlist Setup Screen]

9) Click the Input tab and you can check the tag numbers in which Input data of N1 is

allocated as shown below. Click the Output tab and you can check the allocated tag numbers

as done in Input data. To modify the tag number manually, click the icon.

5-3 Robostar Co., Ltd

Examples of DeviceNet Setting

[Fig. 5.6 Screen for setting Input data area]

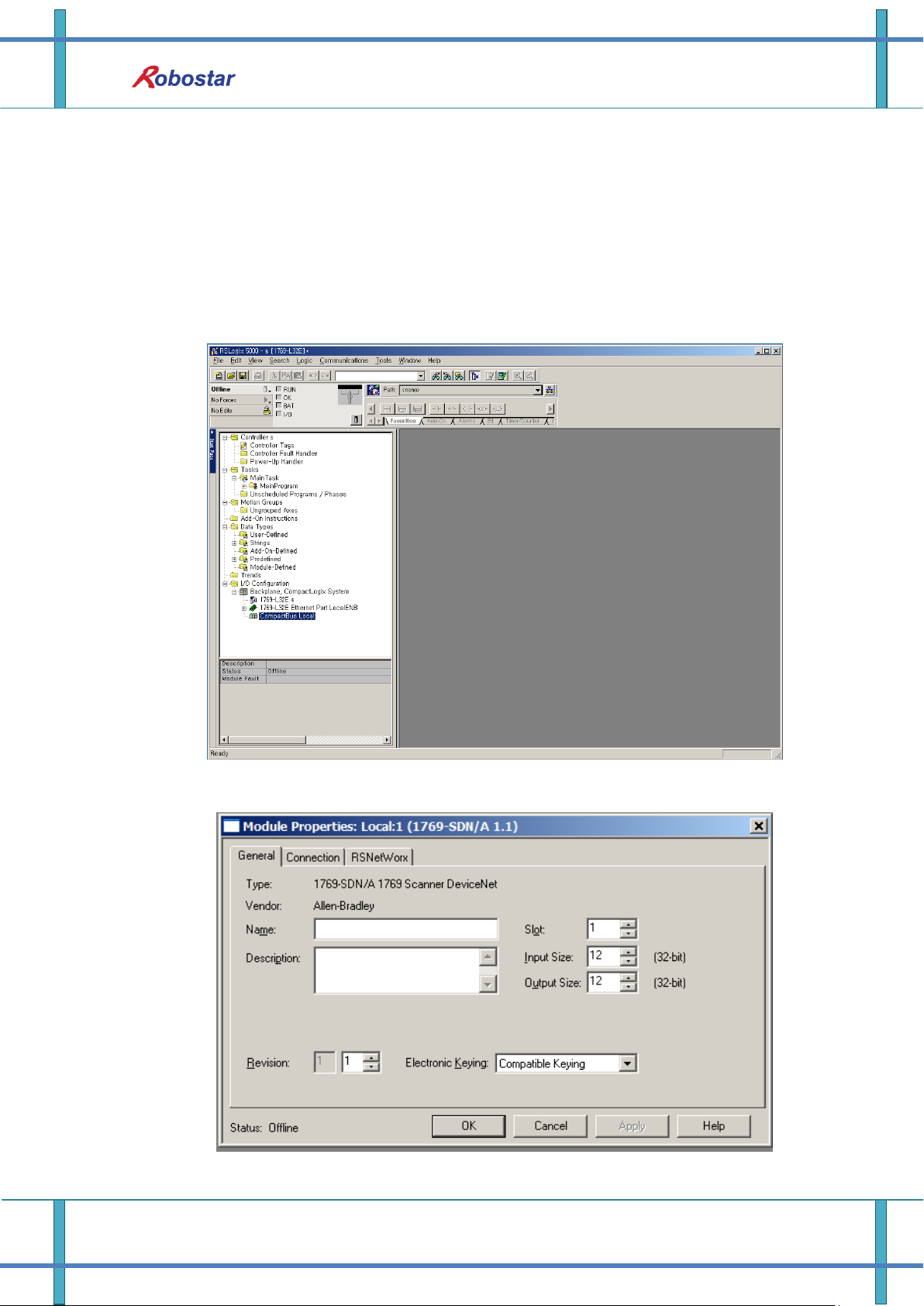

10) Run Rslogix 5000, select File -> New to create a new project. Once a new project has been

created, a screen comes up as shown in Fig. 5.7, in which when you right-mouse click a New

module from CompactBus Local on the bottom left of the screen, a Select module window

comes up. Click the Communications tab and 1769-SDN Scanner pops up. When clicking and

selecting it, you can see 1769-SDN has been created below CompactBus Local tab and Fig.

5.8 screen comes up.

5-4 Robostar Co., Ltd

Examples of DeviceNet Setting

11) In Fig. 5.8, write a name for module management in the ‘name’ section, putting in the I/O

size to use in Devicenet Network when asked about Input size and Output size. In the

example program, Input size is set to 12(46byte) and Output size to 10(40byte) as one N1

module is connected. For reference purpose, Input size and Output size should be set

identically to I/O size set to Scanlist in RSNetworx. Click the Confirm button and RSNetworx

tab to configure the path of the RSNetworx file set and saved in Ch.5 “6)”.

Fig. 5.7 In-progress RsLogix 5000 Screen

Fig. 5.8 1769-SDN Setup Screen

5-5 Robostar Co., Ltd

Examples of DeviceNet Setting

12) Click the Controller Tags on top left in Fig. 5.7 and a screen in Fig. 5-9 comes up, enabling

you to check that the I/O tag values set in Fig. 5.6 found matching and were displayed on

the screen accordingly.

Fig. 5.9 DeviceNet I/O tag screen

13) In the OMROM PLC, I/O data is connected for a real-time exchange upon registering

DeviceNet modules on the Scanlist using Configuration tool. But, the AB PLC allows you to

exchange I/O data only by enabling CommandRegister.Run bit in Fig. 5.10 though registered

on Scanlist.

Fig. 5.10 I/O Run Program

5-6 Robostar Co., Ltd

Controller Data Mapping

DeviceNet Data

Description

DeviceNet Data

Description

INPUT0

System Input #1

OUTPUT0

System Output #1

INPUT1

User Input

OUTPUT1

User Output

INPUT2

Option Input 0

OUTPUT2

Option Output 0

INPUT3

System Input #2

OUTPUT3

Error Code Read

INPUT3

FieldBus Input #1

INPUT4

Option Input 1

OUTPUT4

Option Output 1

INPUT5

Option Input 2

OUTPUT5

Option Output 2

INPUT6

Option Input 3

OUTPUT6

Option Output 3

INPUT7

FieldBus Input #2

OUTPUT7

FieldBus Output #2

INPUT8

1-axis Position Value Input

OUTPUT8

Current 1-axis Position Value Output

INPUT9

OUTPUT9

INPUT10

2-axis Position Value Input

OUTPUT10

Current 2-axis Position Value Output

INPUT11

OUTPUT11

INPUT12

3-axis Position Value Input

OUTPUT12

Current 3-axis Position Value Output

INPUT13

OUTPUT13

INPUT14

4-axis Position Value Input

OUTPUT14

Current 4-axis Position Value Output

INPUT15

OUTPUT15

INPUT16

Global Integer Input

OUTPUT16

Global Integer Output

INPUT17

Global Integer Index

OUTPUT17

Global Float Output

INPUT18

JOG VEL Rate Input

OUTPUT18

INPUT19

Global Point Index

OUTPUT19

Info Data 1 Output

INPUT20

Pull Up Value Input

OUTPUT20

Info Data 2 Output

INPUT21

Global Float Input

OUTPUT21

Info Data 3 Output

INPUT22

OUTPUT22

Info Data 4 Output

INPUT23

Global Float Index

OUTPUT23

Program Num Output

Chapter 6. Memory Mapping

6.1 N1 Controller Data Mapping

Memory Mapping

Note) When using Option I/O, change Parameter I/0 EXT B/D value to 2. (Operation Manual”

1.3.1.3 Extension I/O Board Setting”.)

Note) JOG Velocity Rate Input of RWw10 applies when in JOG Mode, with a setting range from

1 to 100%. The value set is converted by percent per axis based on the Jv values of JOINT

6-1 Robostar Co., Ltd

Memory Mapping

System Input #1

0

CH SEL

8

MODE 1 / AXIS 1

1

PROG 0

9

MODE SEL

2

PROG 1

A

JOG VEL

3

PROG 2

B

VEL+ / MOV+

4

PROG 3

C

VEL- / MOV-

5

PROG 4

D

REBOOT

6

PROG SEL

E

ORG #1

7

MODE 0 / AXIS 0

F

START #1

For description of functions of each Bit, refer to Operation Manual “3.3.4 System

Input/Output Functions”.

MOTION parameters.

6.1.1 N1 Series System Input #1

N1 series has System Bits commonly used between Robot Channel 1 and 2, and these bits operate

differently between channels depending on CH_SEL Bit setting. If CH_SEL Bit set value is Low, it

corresponds to Robot Channel 1, High to Robot Channel 2.

Commonly-used bits are PROG_0 ~ PROG_4, PROG_SEL, MODE0/AXIS0, MODE1/AXIS1, MODE SEL,

JOG VEL, VEL+/MOV+, VEL-/MOV- . Check the CH SEL Bit set value when using the commonly-used

bits. When the CH SEL Bit set value is not correct, an unwanted robot channel may operation. The

FieldBus timing diagram marked in this Manual is examples for Channel 1, and for handling and

operating Channel 2 change CH_SEL Bit set value in Channel 1 timing diagram to High. Reading and

writing Global Integer and Global Float Data CH_SEL Bit can be used regardless of setting.

6-2 Robostar Co., Ltd

Memory Mapping

System Input #2

FieldBus Input #1

0

STOP #1

8

DATA TYPE: XY Coordinates

1

Reserved

9

DATA TYPE: Angle Coordinates

2

SERVO ON #1

A

Data Type: Pulse (Read Only)

3

ORG #2

B

Mode Select (/Current OR GPNT)

4

START #2

C

Write Enable Flag(Position,GINT)

5

STOP #2

D

READ Enable Flag(Position, GINT)

6

Reserved

E

Reserved

7

SERVO ON #2

F

Reserved

FieldBus Input #2

0

JOG A(X)+

8

AUTO RUN MODE

1

JOG A(X)-

9

STEP RUN MODE

2

JOG B(Y)+

A

JOG MODE

3

JOG B(Y)-

B

JOG Forward SEL

4

JOG Z+

C

Reserved

5

JOG Z-

D

Reserved

6

JOG W+

E

Info Data Mode SEL #0

7

JOG W-

F

Info Data Mode SEL #1

System Output #1

0

CH SEL

8

ORG OK #2

1

ALL ALARM

9

RUNNING #2

2

READY #1

A

INPOS/INRNG #2

3

ORG OK #1

B

SERVO ON #2

4

RUNNING #1

C

Reserved

5

INPOS/INRNG #1

D

Reserved

6

SERVO ON #1

E

Reserved

7

READY #2

F

Reserved

6.1.2 N1 Series System Input #2 & FIELDBUS INPUT#1

6.1.3 N1 Series FIELDBUS INPUT #2

6.1.4 N1 Series System Output #1

6-3 Robostar Co., Ltd

FieldBus Output #2

0

Write Complete Flag

8

Auto Run Mode DIS

1

Read Complete Flag

9

Step Run Mode DIS

2

Reserved

A

JOG Mode DIS

3

Forward Moving State DIS

B

Reserved

4

Reserved

C

TRQ Info Data Mode

5

Brake State DIS

D

RPM Info Data Mode

6

Reserved

E

Reserved

7

Reserved

F

Reserved

Times displayed in Field Bus timing diagram are as follow.

T1: 20ms, T2: 30ms, T3: 40ms.

The pulse width entered when applying Field Bus should be kept over a minimum of 20ms.

The time interval between signals entered when applying Field Bus should be over at least

20ms.

6.1.5 N1 Series FIELDBUS Output #2

6.2 Precautions for Use in N1 Series System Mode

Memory Mapping

1. < Precaution for Use in Auto Mode >

① As GINT, GFLOAT and GPNT commonly use Read / Write Enable Flag, the index

values of unused variables are allocated at a time when no change is desired.

② Of Data types, XYZW and ABZW are only Coordinate Write functions available for

use.

③ PROGRAM NUM output generates only the PROGRAM NUM entered in SYSTEM

MODE.

④ VEL output is capable of generating robot’s moving speed in JOG MODE and AUTO

MODE.

2. < Precautions for use in JOG Mode >

① JOG_VEL input is available for use only in JOG MODE and when the value is 0 it runs

at 1% speed.

② VEL output is capable of generating robot’s moving speed in JOG MODE and AUTO

MODE.

③ Pulse inputs should be made to enter AUTO RUN MODE, STEP RUN MODE and JOG

MODE in Field Bus Input #2. (When each mode is set to High, the selected bit on

Jog axis in FieldBus Input #2 is operated under abnormal conditions.)

6-4 Robostar Co., Ltd

PLC(PC)

-> N1 Series

N1 Series

-> PLC(PC)

Brake State DIS

H

L

PROG: 2

PROGRAM NUM

RUNNING #1

HLH

L

READY #1

AUTO RUN MODE

DIS

ORG OK #1

HLHLH

L

L

SERVO ON #1

H

L

ORG #1

H

L

PROG SEL

H

CH SEL

H

L

AUTO RUN MODE

H

L

START #1

L

PROG 0:4

H

H

PROG: 2

CH DIS

H

L

L

T1

T3

Memory Mapping

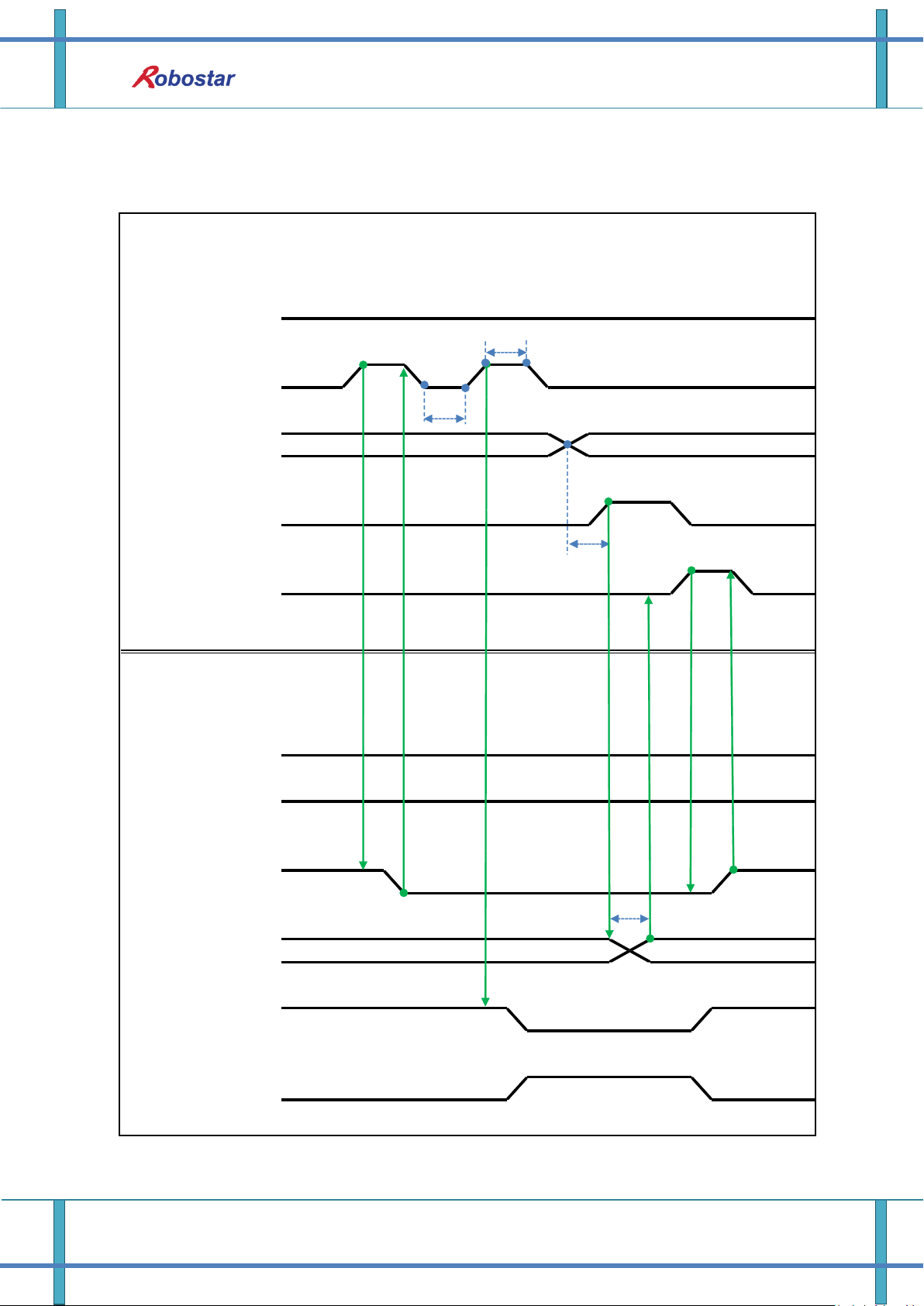

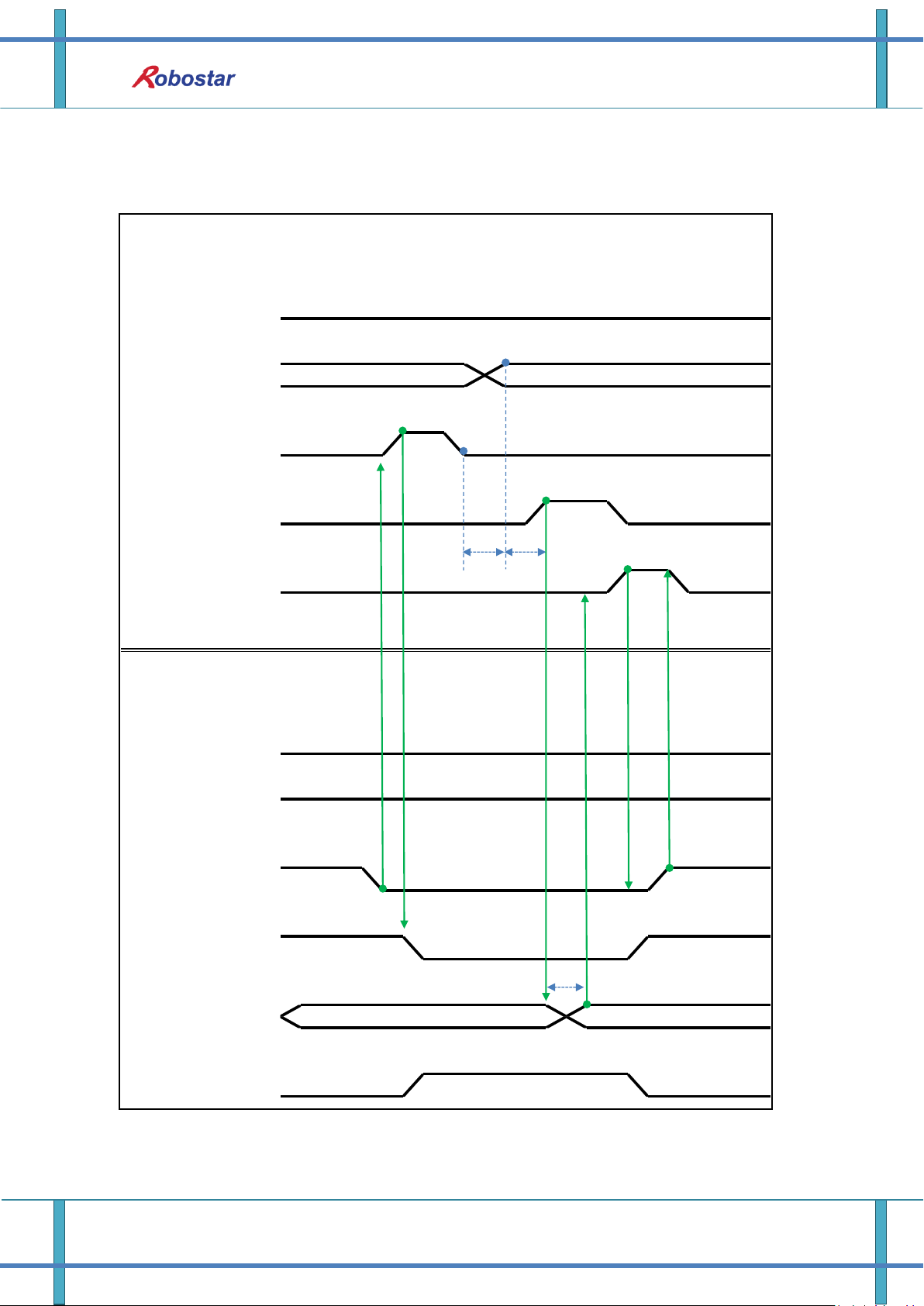

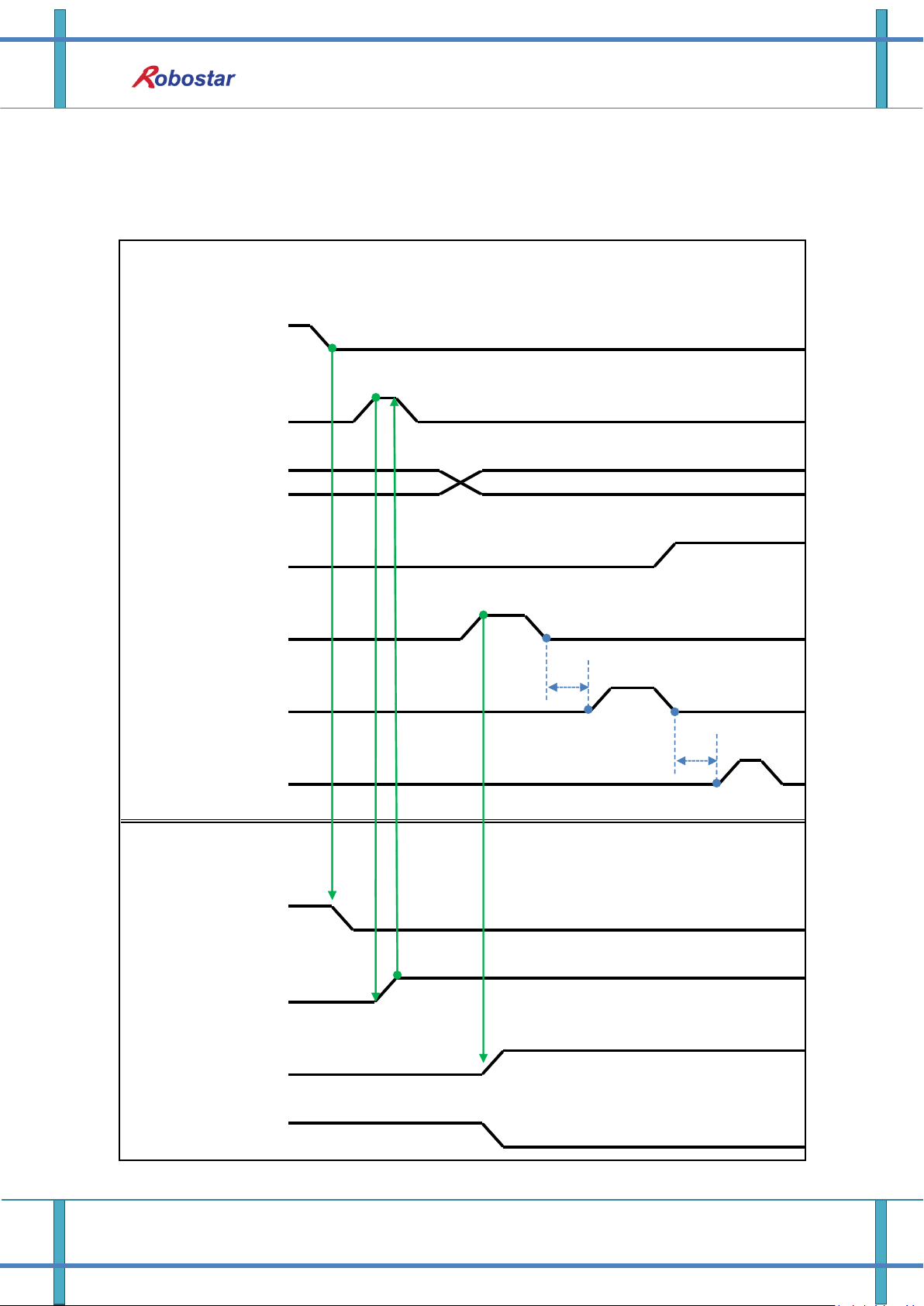

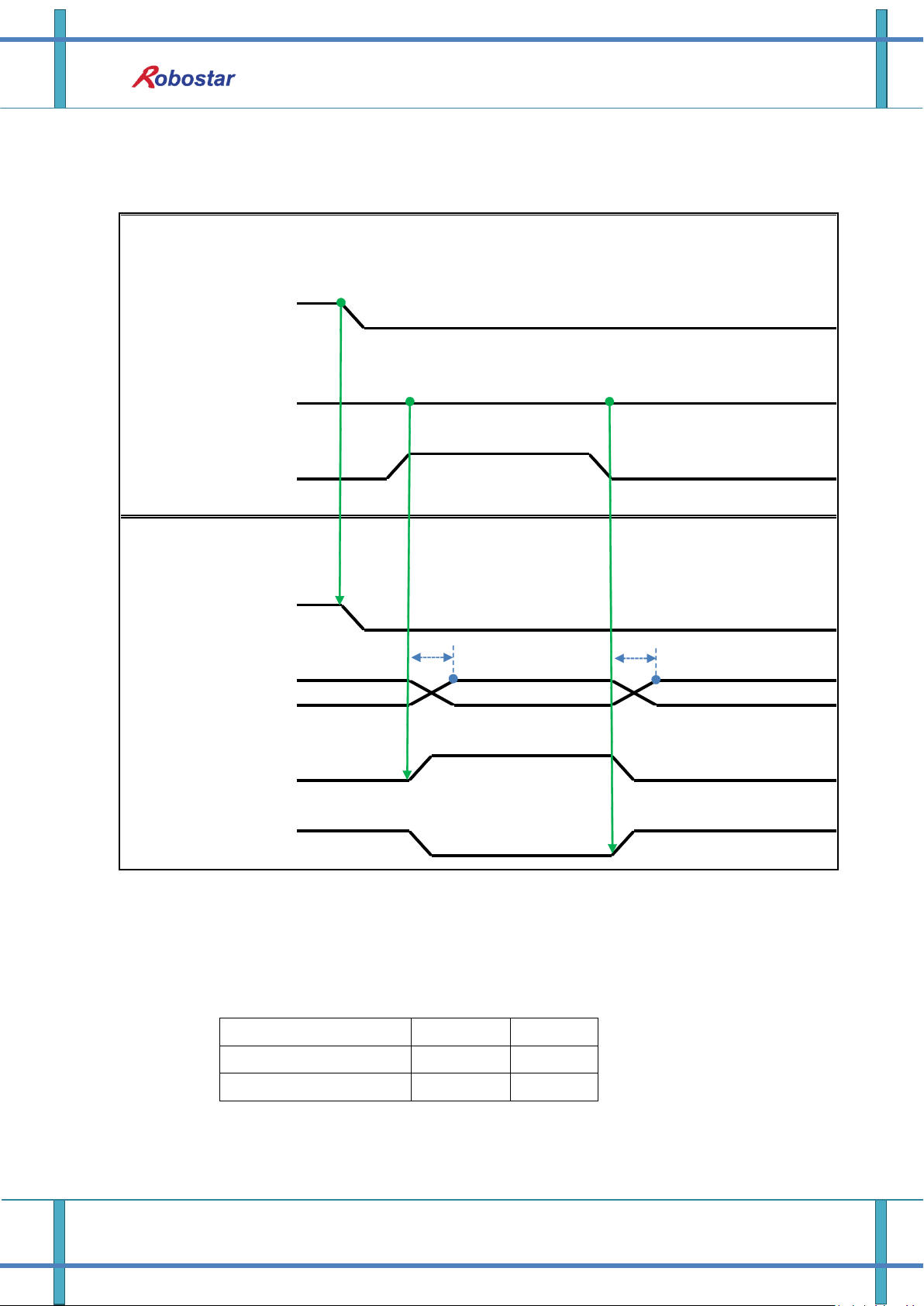

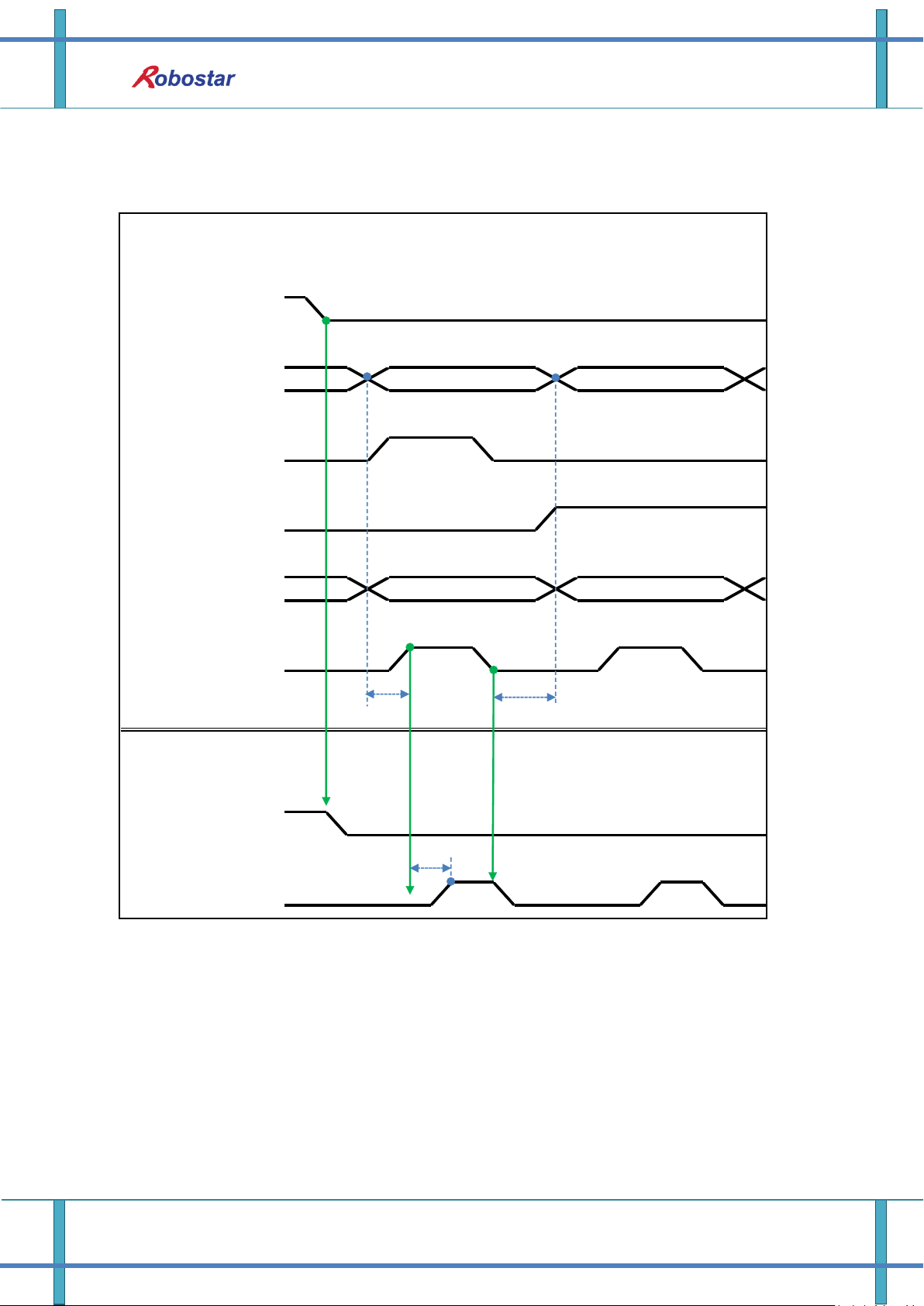

6.3 N1 Series FieldBus(CC_Link) Timing Diagram

.

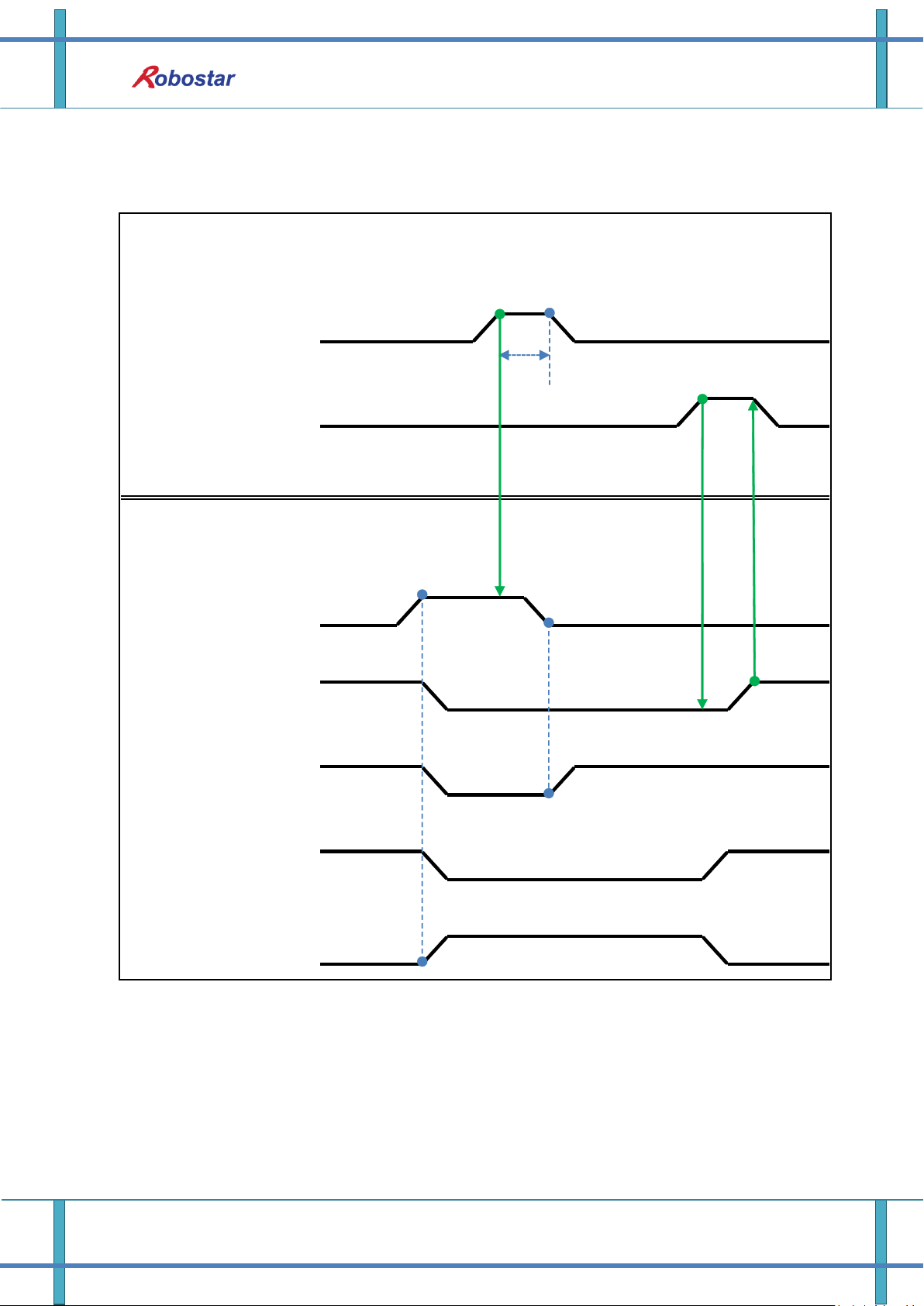

6.3.1 Operation in AUTO RUN MODE

6-5 Robostar Co., Ltd

Memory Mapping

Check AUTO SERVO ON for setting in Parameter of N1 Series. (Refer to Operation

Manual “1.3.1.5 Auto Servo On”.)

When Auto Servo ON is not set, output SERVO ON #1 Bit as High prior to

sending out START #1 Signal.

When in Auto Servo ON

When not in Auto Servo ON

Description :

Set CH SEL Bit. (Low: Channel 1, High: Channel 2)

Enter AUTO RUN MODE Bit into pulse format. (High status should be kept over 20ms.)

When ORG OK#1 Signal is Low in N1 Series, set ORG #1 Bit to High.

When ORG OK #1 is changed to High, combine PROG 0~4 Bits to set the desired JOB

Program num. (PROG0 Bit is the lowest (LSB) Bit and PROG4 Bit is the highest (MSB) Bit.)

With completion of setting JOB Program num, set PROG SEL Bit to High.

Check PROGRAM NUM sent from N1 Controller and set START #1 Bit to High.

Description :

Set CH SEL Bit. (Low: Channel 1, High: Channel 2)

Set AUTO RUN MODE Bit into pulse format. (High status should be kept over 20ms.)

When ORG OK#1 Signal is not set to High in N1 Series, set ORG #1 Bit to High.

When ORG OK #1 is changed to High, combine PROG 0~4 Bits to set the desired JOB

Program num. (PROG0 Bit is the lowest (LSB) Bit and PROG4 Bit is the highest (MSB) Bit.)

With completion of setting JOB Program num, set PROG SEL Bit to High.

Enter SERVO ON#1 Bit in Pulse format. Check SERVO ON#1 of System Output #1 in N1

Series to see if SERVO is ON. (High status should be kept over 20ms.)

Check PROGRAM NUM sent from N1 Controller and set START #1 Bit to High.

6-6 Robostar Co., Ltd

PLC(PC)

-> N1 Series

N1 Series

-> PLC(PC)

Brake State DIS

H

L

CH SEL

H

L

CH DIS

H

PROG: 2

PROGRAM NUM

SERVO ON #1

H

LHL

H

STOP #1

PROG 0:4

PROG SEL

START #1

ORG #1

RUNNING#1

LHLHLHL

LHL

PROG:3

H

L

PROG:3

PROG: 2

T3

T1

T1

Note 1

Note 2

Note 3

T1

Memory Mapping

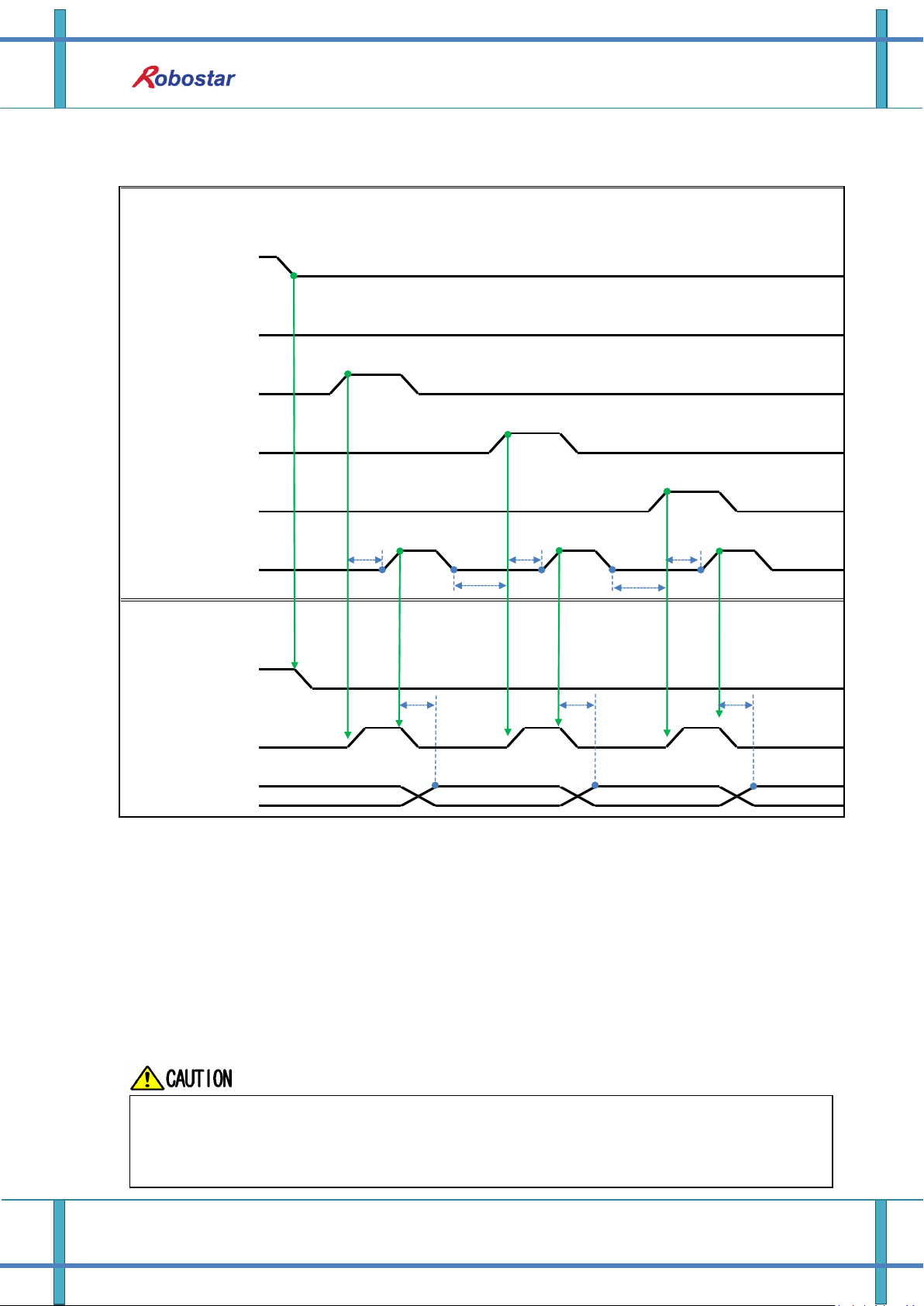

6.3.2 JOB Program Change during JOB Operation

6-7 Robostar Co., Ltd

Memory Mapping

Changing JOB Program can only be made with Servo OFF. Prior to changing JOB

Program, check the Servo OFF status.

When in Auto Servo ON

When not in Auto Servo ON

Description :

Enter STOP #1 Signal into pulse. (High status should be kept over 20ms.)

Combine PROG 0~4 Bits to enter the desired JOB Program num. (PROG0 Bit is the lowest

(LSB) Bit and PROG4 Bit is the highest (MSB) Bit.)

With completion of setting JOB Program num, set PROG SEL Bit to High.

Check PROGRAM NUM sent from N1 Controller and set START #1 to High.

Note 1) Signal for stopping JOB Program from operating while running JOB Program.

Note 2) Signal for changing SERVO OFF status and initializing JOB Program.

Note 3) Robot Moving speed may lead to a difference in time taken for change to Low.

(Maximum delay time lasts as At time as set in Joint/Linear Motion Parameter.)

Description :

Enter STOP #1 Signal into pulse. (High status should be kept over 20ms.)

Instead of entering the 2

nd

STOP #1 Signal, enter SERVO ON #1 Signal in Pulse. (High status

should be kept over 20ms.)

Combine PROG 0~4 Bits to enter the desired JOB Program num. (PROG0 Bit is the lowest

(LSB) Bit and PROG4 Bit is the highest (MSB) Bit.)

With completion of setting JOB Program num, set PROG SEL Bit to High.

Check PROGRAM NUM sent from N1 Controller and enter SERVO ON #1 Signal in Pulse.

(High status should be kept over 20ms.)

Set START #1 to High.

6-8 Robostar Co., Ltd

PLC(PC)

-> N1 Series

N1 Series

-> PLC(PC)

LHLHL

Brake State DIS

HLHLH

PROG:3

PROG: 2

PROG:3

PROG: 2

PROG 0:4

PROG SEL

START #1

ORG #1

RUNNING#1

PROGRAM NUM

H

L

CH SEL

H

L

CH DIS

H

L

STOP#1

H

H

L

L

SERVO ON#1

H

L

T1

T3

Note 1

T1

Memory Mapping

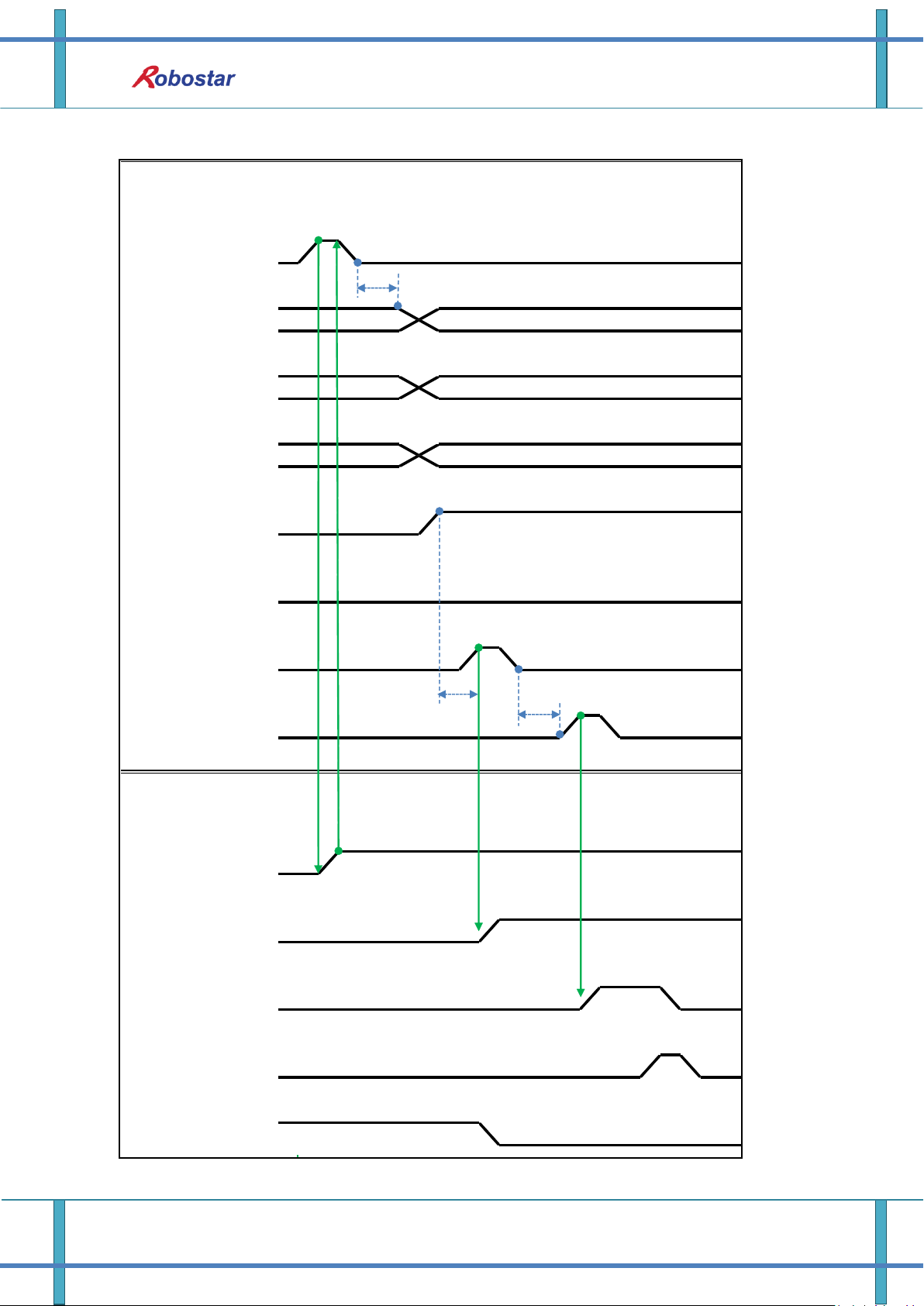

6.3.3 JOB Program Change after Completing JOB Program

6-9 Robostar Co., Ltd

Memory Mapping

When in Auto Servo ON

When not in Auto Servo ON

Description :

Check if RUNNING#1 Bit is Low.

Enter STOP #1 Signal into pulse. (High status should be kept over 20ms.)

Combine PROG 0~4 Bits to enter the desired JOB Program num. (PROG0 Bit is the lowest

(LSB) Bit and PROG4 Bit is the highest (MSB) Bit.)

With completion of setting JOB Program num, set PROG SEL Bit to High.

Check PROGRAM NUM sent from N1 Controller and set START #1 to High.

Note 1) When JOB ends in JOB Program by EOP, RUNNING#1 Bit is changed into Low.

Description :

Instead of STOP #1 Signal, enter SERVO ON#1 Signal into pulse. (High status should be kept

over 20ms.)

Combine PROG 0~4 Bits to enter the desired JOB Program num. (PROG0 Bit is the lowest

(LSB) Bit and PROG4 Bit is the highest (MSB) Bit.)

With completion of setting JOB Program num, set PROG SEL Bit to High.

Check PROGRAM NUM sent from N1 Controller and enter SERVO ON #1 Signal into pulse.

(High status should be kept over 20ms.)

Set START #1 to High.

6-10 Robostar Co., Ltd

Memory Mapping

PLC(PC)

-> N1 Series

N1 Series

-> PLC(PC)

HLH

LHLHLHLHL

SERVO ON #1

STOP #1

START

ALL ALARM

RUNNING#1

READY #1

L

Brake State DIS

H

T1

Note 1

Note 2

T1

6.3.4 JOB Program START after Disabling Alarm

6-11 Robostar Co., Ltd

When in Auto Servo ON

When not in Auto Servo ON

Description :

Enter STOP #1 Signal into pulse twice. (High status should be kept over 20ms.)

Set START #1 to High.

Note 1) Signal for disabling an alarm.

Note 2) Set JOB Program STEP Line for the first time.

Description :

Enter STOP #1 Signal into pulse twice. (High status should be kept over 20ms.)

Set START #1 to High.

Memory Mapping

6-12 Robostar Co., Ltd

Memory Mapping

PLC(PC)

-> N1 Series

N1 Series

-> PLC(PC)

L

Brake State DIS

H

SERVO ON #1

STOP #1

START

ALL ALARM

RUNNING#1

READY #1

HLHLHLHLH

LHL

T1

6.3.5 JOB Program Restart after Disabling Alarm

6-13 Robostar Co., Ltd

When in Auto Servo ON

When not in Auto Servo ON

Description :

Enter STOP #1 Signal into pulse. (High status should be kept over 20ms.)

Set START #1 to High.

Description :

Enter STOP #1 Signal into pulse. (High status should be kept over 20ms.)

Enter SERVO ON #1 Signal into pulse. (High status should be kept over 20ms.)

After checking SERVO ON, set START #1 to High.

Memory Mapping

6-14 Robostar Co., Ltd

Memory Mapping

PLC(PC)

-> N1 Series

N1 Series

-> PLC(PC)

STOP #1

SERVO ON #1

HHH

L

L

L

Brake State DIS

HLH

READY #1

RUNNING#1

L

Note 1

Note 2

T1

T1

6.3.6 SERVO OFF

6-15 Robostar Co., Ltd

When not in Auto Servo ON, Servo OFF does not apply though the 2

nd

STOP #1

Signal is sent out.

To keep Servo OFF, send SERVO ON #1 Signal via Pulse.

When in Auto Servo ON

When not in Auto Servo ON

Description :

Enter STOP #1 Signal into pulse. (High status should be kept over 20ms.)

Note 1) Signal for stopping JOB Program from operating.

Note 2) Signal for turning SERVO OFF.

Description :

Enter STOP #1 Signal into pulse. (High status should be kept over 20ms.)

Instead of the 2

nd

STOP #1 Signal \, enter SERVO ON #1 Signal into pulse.

(High status should be kept over 20ms.)

Memory Mapping

6-16 Robostar Co., Ltd

PLC(PC)

-> N1 Series

N1 Series

-> PLC(PC)

HLHLHLHLHLHLHLHLH

L

REBOOT

PROG 0:4

PROG SEL

START #1

RUNNING#1

PROG: 3

PROG:3

READY #1

ALL ALARM

PROGRAM NUM

PROG:3

PROG: 3

SERVO ON #1

T1

R

E

B

O

O

T

I

N

G

more than 100ms

Note 1

T3

Memory Mapping

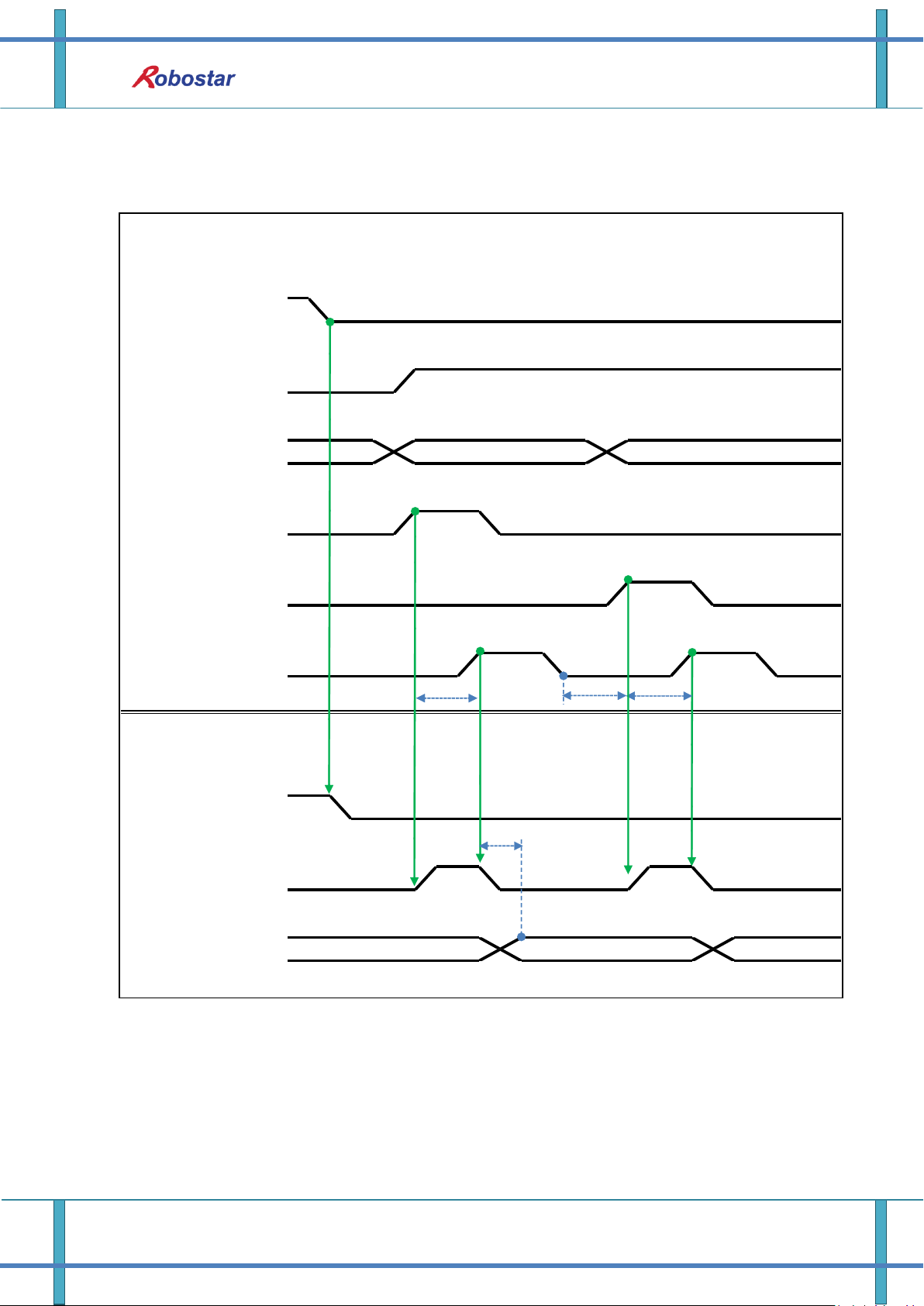

6.3.7 Rebooting

Description :

Set REBOOT Bit to High. Rebooting becomes available only when High status is kept over

100ms. When kept below 100ms, Rebooting may not be performed.

When Rebooting is complete yet alarm conditions are not disabled, ALARM Bit maintains

High status. In this case, disable all alarm conditions and retry Rebooting.

6-17 Robostar Co., Ltd

Memory Mapping

Note 1) When Rebooting, Signals may malfunction so use caution.

A timing diagram upon completion of Rebooting is identical to “6.3.2 AUTO RUN.

When Rebooting is complete, READY #1 Signal turns into High, when JOB Program num is

set.

Check PROGRAM NUM sent from N1 Controller and set START #1 Bit to High.

6-18 Robostar Co., Ltd

PLC(PC)

-> N1 Series

N1 Series

-> PLC(PC)

L

HHHLH

L

JOG MODE DIS

CH SEL

STEP RUN MODE DIS

AUTO RUN MODE

DIS

H

LHL

L

CH SEL

JOG MODE

STEP RUN MODE

AUTO RUN MODE

HLH

L

Memory Mapping

6.3.8 MODE(AUTO, STEP, JOG) Change

6-19 Robostar Co., Ltd

Description :

MODE can be converted only with SERVO OFF.

Check CH SEL Bit before changing MODE.

When CH SEL Bit is wrongly set, another Channel MODE changes.

Use CH SEL Bit to select the desired Channel. (Low: Channel 1, High: Channel 2)

Select the desired operation MODE(AUTO RUN, STEP RUN, JOG).

Enter MODE Signal in Pulse format when High status should be kept over 20ms.

Memory Mapping

6-20 Robostar Co., Ltd

Memory Mapping

PLC(PC)

-> N1 Series

N1 Series

-> PLC(PC)

VEL-/MOV-

H

L

READY #1

H

SERVO ON#1

H

L

CH DIS

H

PROG 0~4

H

L

L

CH SEL

H

L

RUNNING

STEP MODE

PROG 0~4

PROG_SEL

START

VEL+/MOV+

STEP MODE DIS

HLHLHLHLHLHLH

L

PROG 0:4

L

PROG 0:4

T1

T1

T1

Running ROBOT

T1

T3

T1

Note 1

Note 2

Note 3

Note 4

Note 5

Note 6

When in Auto Servo ON

6.3.9 STEP MODE

Description:

Enter STEP MODE Bit in System Input #2 into pulse. (High status should be kept over 20ms.)

Once STEP MODE has been set, STEP MODE DIS is set to High.

Combine PROG 0~4 Bits to set the desired JOB Program num. (PROG0 Bit is the lowest (LSB)

Bit and PROG4 Bit is the highest (MSB) Bit.)

Once JOB Program num setting is complete, set PROG SEL Bit to High.

Check PROGRAM NUM sent from N1 Controller.

Use START Bit in System Input #1 to run JOB.

Use VEL+/ VEL- Bit in System Input #1 to select the desired JOB step.

Select the desired STEP to operate, enter START#1 Bit into pulse.

6-21 Robostar Co., Ltd

Memory Mapping

When not in Auto Servo ON

Use START Bit and run it with one STEP increase at a time.

To view the only desired motion, use VEL+/VEL- Bit, set to the desired motion STEP Line, use

START #1 Bit for operation.

Note 1) Means JOB Program START. (Currently Step Line: 1)

Note 2) Add +1 to JOB program Step. (Currently Step Line: 2)

Note 3) Run the current Step Line. Add +1 to Step. (Step Line: 3)

Note 4) Subtract -1 from the current Step. (Step Line: 2)

Note 5) Subtract -1 from the current Step. (Step Line: 1)

Note 6) Run the current Step Line. Add +1 to Step. (Step Line: 2)

Description :

Enter STEP MODE Bit in System Input #2 into pulse. (High status should be kept over 20ms.)

Once STEP MODE has been set, STEP MODE DIS is changed to High.

Combine PROG 0~4 Bits to set the desired JOB Program num. (PROG0 Bit is the lowest

(LSB) Bit and PROG4 Bit is the highest (MSB) Bit.)

Once JOB Program num is complete, change PROG SEL Bit to High.

Check PROGRAM NUM sent from N1 Controller.

Enter SERVO ON#1 Bit into pulse. Check SERVO ON#1 in System output # on N1 Series to

see if it is in SERVO ON.

Use START Bit in System Input #1 to operate JOB.

Use VEL+/ VEL- Bit in System Input #1 to select the desired JOB step.

Select the desired STEP to operate and enter START#1 Bit into Pulse.

Use START Bit and run it with one STEP increase at a time.

6-22 Robostar Co., Ltd

PLC(PC)

-> N1 Series

N1 Series

-> PLC(PC)

SERVO ON #1

H

L

L

CH SEL

H

L

H

HLH

L

H

JOG VEL : 10

JOG VEL : 20

HLHLH

L

JOG MODE

JOG VEL

JOG A(X) +

JOG Z +

SERVO ON #1

CH DIS

H

Brake State_DIS

L

JOG MODE DIS

JOG VEL RATE

LHL

T1

T1

Memory Mapping

6.3.10 Operation in JOG MODE

6-23 Robostar Co., Ltd

Memory Mapping

When Velocity Rate Input is 0, operation is performed at 1% speed.

In JOG MODE SET BIT, enter PULSE.

When operating JOG, Auto Servo ON does not apply regardless of setting Auto

Servo ON.

When operating JOG, be sure to send out SERVO ON #1 Signal to turn into Servo

ON.

When not selecting a coordinate, it operates by Angle coordinate.

Description:

Enter JOG MODE Bit in FIELDBUS INPUT #2 into Pulse.

Once JOG MODE has been set, JOG MODE DIS is set to High.

Use JOG MODE DIS for details about the currently selected MODE, maintaining its state until

AUTO MODE or STEP MODE is selected.

Set the moving speed during JOG operation, with an input range of 0 to 100%.

Setting is done selectively among JOG X(A)+ ~ JOG W- in FIELDBUS INPUT #2.

When setting JOG VEL Bit to Low, operation is performed at speed of the set value for

JOG VEL RATE.

6-24 Robostar Co., Ltd

PLC(PC)

-> N1 Series

N1 Series

-> PLC(PC)

JOG VEL RATE

GPNT INDEX

PULLUP VALUE

H

H

L

LLLHL

H

HLH

HLHLH

JOG MODE

Angle 좌표

H

L

JOG MODE DIS

H

L

L

Velocity Rate Input

GPNT Index

PULL UP VALUE

XY 좌표

H

L

SERVO ON#1

L

H

JOG FWD

SERVO ON #1

FORWARD STATE DIS

INPOS/INRNG #1

Brake state DIS

T1

T1

T1

Memory Mapping

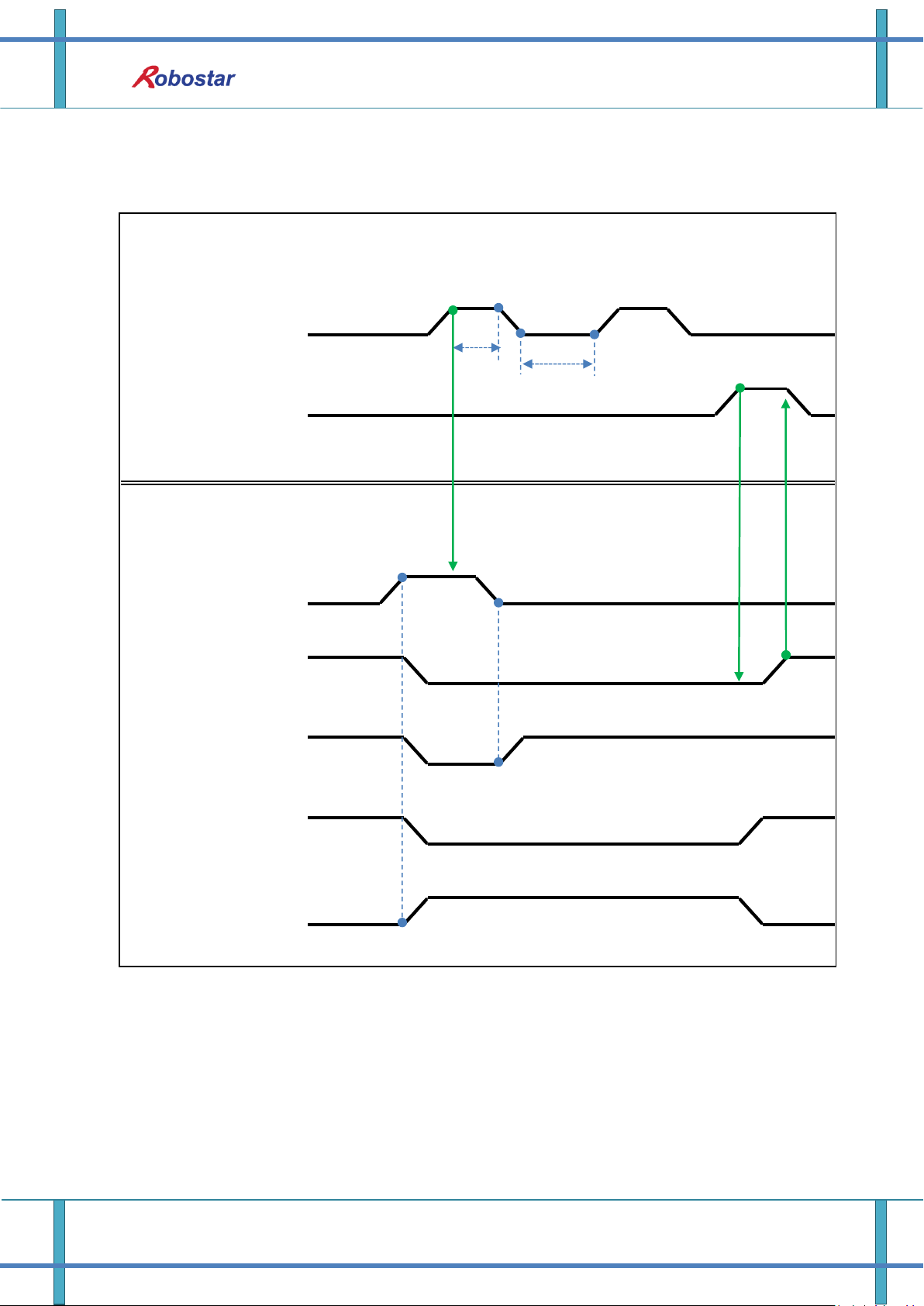

6.3.11 Forward Operation in JOG MODE

6-25 Robostar Co., Ltd

Memory Mapping

When Velocity Rate Input is 0, operation is performed at 1% speed.

In JOG MODE SET BIT, enter PULSE.

When operating JOG, Auto Servo ON does not apply regardless of setting Auto Servo

ON.

When operating JOG, be sure to send out SERVO ON #1 Signal to turn into Servo ON.

When selecting Angle coordinate from Scara Robot Type, JMOV operates and when

selecting XY coordinates operation is performed by LMOV.

Description:

Use JOG MODE DIS state Bit for details about the currently selected MODE, maintaining its

state until selecting AUTO MODE or STEP MODE.

Set the speed to apply when performing JOG FWD operation, with input range of 0 to 100%

and initial value of 1%)

Set the GP Point Index to move.

Set the PULL UP value to apply during FWD operation.

Enter JOG FWD Bit in FIELDBUS INPUT #2 into Pulse.

When running Forward operation, Forward State DIS bit is set to High and turns into Low

with completion of operation.

6-26 Robostar Co., Ltd

Memory Mapping

PLC(PC)

-> N1 Series

N1 Series

-> PLC(PC)

TRQ

RPM

TRQ

HLH

H

LLLHLHL

L

H

TRQ Info Data Mode

H

CH DIS

Info Data Mode SEL

#0

Info Data Mode SEL

#1

CH DIS

Info Data 1:4

RPM Info Data Mode

T3

T3

TRQ

RPM

Info Data Mode SEL #0

LOW

LOW

Info Data Mode SEL #1

LOW

HIGH

6.3.12 Read RPM, TRQ

Description:

Sends out TRQ or RPM value according to Info Data Mode 0:1 setting.

Information about current output values can be confirmed via TRQ Info Data Mode Bit and

RPM Info Data Mode Bit.

6-27 Robostar Co., Ltd

Memory Mapping

PLC(PC)

-> N1 Series

N1 Series

-> PLC(PC)

L

CH DIS

HLH

H

Read Ready &

Complete Flag

Position Value :

Read Enable Flag

LHL

Mode :

/Current , GPNT

Data Type :

XY

Data Type :

Angle

Data Type :

Pulse

H

L

LHLHL

H

CH SEL

H

L

CURRENT POSITION(XY Data)

CURRENT POSITION(Angle Data)

(Pulse Data)

CURRENT POSITION

T1T3T2

T1

T1

T2

T3

T3

If Data Type is not changed to Low in Read Enable Flag High, Read Ready & Complete

Flag instantly turns back into High.

The minimum standby time is required in Current Position Read following change to

Data Type.

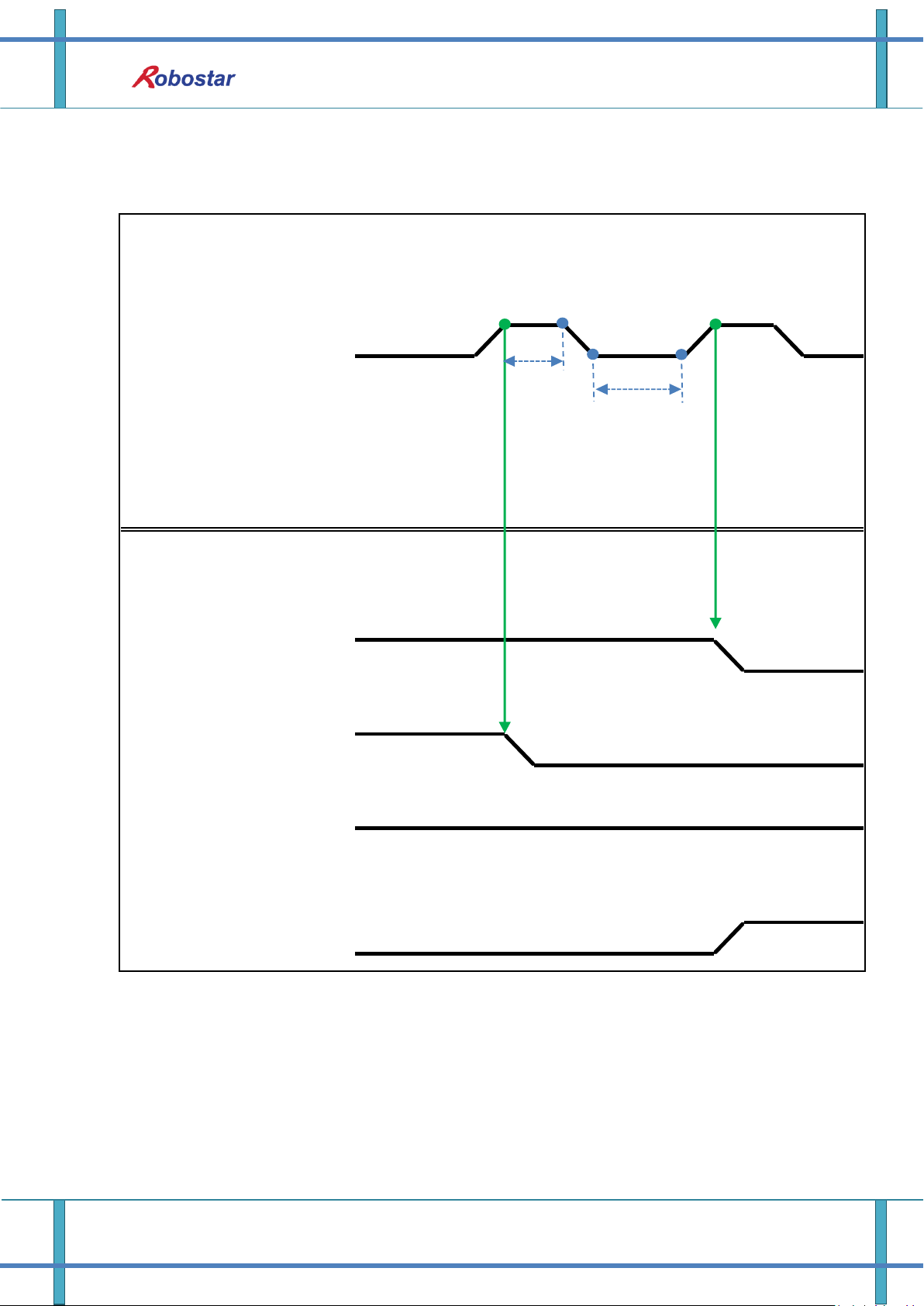

6.3.13 Read Current Position

Description:

Sets CH SEL Bit. (Low: Channel 1, High: Channel 2)

Set Data Type(XYZW, ABZW) for reading the Current Position.

To read the current position, set Mode Select bit to Low. (Low: Reads robot’s current

coordinate, High: Reads Global Point)

Enable determining if readable using Read Ready & Complete Flag Bit in System OUT2.

Use Read Enable Flag to be able to read the current position value.

The minimum standby time (T2:30ms) is needed when reading the current position in

accordance with change to Data Type.

6-28 Robostar Co., Ltd

Memory Mapping

PLC(PC)

-> N1 Series

N1 Series

-> PLC(PC)

H

CH DIS

H

Data Type :

XY

H

L

GPNT Index

GPNT Index

Data Type :

Angle

L

Read Enable Flag

H

L

Read Ready &

Complete Flag

Position Value :

CH SEL

H

L

GPNT Index

H

L

Mode :

/Current , GPNT

H

L

LHL

GLOBAL POINT

(Angle Data)

H

L

GLOBAL POINT(XY Data)

T1

T3

T2

T1

6.3.14 Read GLOBAL Point

6-29 Robostar Co., Ltd

Memory Mapping

If Data Type is not changed to Low in Read Enable Flag Signal High, Read Ready

& Complete Flag instantly turns back into High.

The minimum standby time is required in continual Global Point Read.

Description :

Set CH SEL Bit. (Low: Channel 1, High: Channel 2)

Set Mode Select bit to High. (Low: (Low: Reads robot’s current coordinate, High: Reads

Global Point)

Set GPNT Index.

After delaying as much time as T1(20ms), set Read Enable Flag Bit to High, when Read

Ready&Complete Flag state should be High.

Depending on a Data Type choice, the values saved in Global Point can be read by XY

coordinate value or Angle value.

When Read Enable Flag Bit in Field Bus Input #1 is set to High, GLOBAL Point of N1 Series is

set.

When Global Point Read occurs continually, a delay time of T2(30ms) is needed.

6-30 Robostar Co., Ltd

Memory Mapping

PLC(PC)

-> N1 Series

N1 Series

-> PLC(PC)

Position Value(Angle Date)

Position Value(XY Data)

Write Enable Flag

H

L

Position Value :

H

L

GPNT Index

Data Type :

XY

H

L

GPNT Index

H

L

GPNT Index

Write Complete Flag

H

L

CH DIS

H

L

CH SEL

H

L

Data Type :

Angle

H

L

T1

T3

T2

6.3.15 Write GLOBAL Point

6-31 Robostar Co., Ltd

Memory Mapping

Data Type is available only in XY coordinates and Angle coordinate.

GINT, GFLOAT and GPOINT commonly use Read Enable Flag so the Index value of

an unused variable is allocated at a time when no change is desired.

The minimum standby time is required in continual GPOINT Write.

Description:

Set CH SEL Bit. (Low: Channel 1, High: Channel 2)

Set Global Point Index and Data Type(XYZW, ABZW).

Set the position data of each axis to save.

With completion of setting GPNT Index and Data Type, set Write Enable Flag Bit in Field Bus

Input #1 to High.

When the saving process is complete in N1 Series, Write Complete Flag is changed into High.

When Write Enable Flag Bit is set to Low, Write Complete Flag is also changed to Low.

When saving the continual Global Point, a delay time of T2(30ms) is needed.

6-32 Robostar Co., Ltd

Memory Mapping

PLC(PC)

-> N1 Series

N1 Series

-> PLC(PC)

GINT Index 입력

Read Enable Flag

GINT Value 출력

H

Integer Index

L

L

H

Integer Value

L

Integer Index

H

Integer Value

T1

T3T2T1

GLOBAL Integer, GLOBAL Float, and GLOBAL Point commonly use Read Enable

Flag so caution should be taken in setting the Index value of an unused variable

at a time when no change is desired.

6.3.16 Read GLOBAL Integer

Description :

Set the Index of a Global Integer to read.

After setting the Index, set Read Enable Flag Bit in Field bus Input#1 to High.

Check the Global Integer value sent from N1 Series.

When continually reading Global Integer value, as much delay time as T2(30ms) is needed.

6-33 Robostar Co., Ltd

Memory Mapping

PLC(PC)

-> N1 Series

N1 Series

-> PLC(PC)

GINT Index 입력

HLHLH

L

GINT Value 입력

Write Enable Flag

Write Complete Flag

H

L

Integer Index

Integer Index

Integer Value

Integer Value

T1

T3

T2

GLOBAL Integer, GLOBAL Float, GLOBAL Point commonly use Read Enable Flag so

caution should be taken in setting the Index value of an unused variable at a time

when no change is desired.

6.3.17 Write GLOBAL Integer

Description :

Set the values of Global Integer Index and Global Integer to write.

Set Write Enable Flag to High.

When the saving process is completed in N1 Series, Write complete Flag changes from Low

to High.

When setting Write Enable Flag to Low, Write Complete Flag Bit is changed to Low.

In case of saving Global Integer values continually, a delay time of T2(30ms) is required.

6-34 Robostar Co., Ltd

Memory Mapping

PLC(PC)

-> N1 Series

N1 Series

-> PLC(PC)

GFloat Index 입력

H

Float Index

Float Index

L

Read Enable Flag

Folat Value

L

L

GFOT Value 출력

H

Folat Value

H

T1

T2

T3

T1

GLOBAL Integer, GLOBAL Float, GLOBAL Point commonly use Read Enable Flag so

caution should be taken in setting the Index value of an unused variable at a time

when no change is desired.

6.3.18 Read GLOBAL Float

Description:

Set the Index of Global Float to read.

After setting Index, set Read Enable Flag Bit in Field bus Input#1 to High.

Check the Global Float value sent from N1 Series.

When continually reading Global Integer values, as much delay time as T2(30ms) is needed.

6-35 Robostar Co., Ltd

Memory Mapping

PLC(PC)

-> N1 Series

N1 Series

-> PLC(PC)

GFloat Index 입력

H

Float Index

Float Index

L

GFloat Value 입력

H

Float Value

Float Value

L

Write Enable Flag

H

L

Write Complete Flag

H

L

T1

T3

T2

GLOBAL Integer, GLOBAL Float, GLOBAL Point commonly use Write Enable Flag so

caution should be taken in setting the Index value of an unused variable at a time

when no change is desired.

6.3.19 Write GLOBAL Float

Description :

Set the values of Global Float Index and Global Float to write.

Set Write Enable Flag to High.

When the saving process is complete in N1 Series, Write complete Flag changes from Low to

High.

When setting Write Enable Flag to Low, Write Complete Flag Bit changes into Low.

In case of saving Global Integer values continually, a delay time of T2(30ms) is required.

6-36 Robostar Co., Ltd

Rev.

Date of

Revision

Content

Modifier

S/W

Version

V.1

2012.10.30

First Edition Print

N1 ROBOT CONTROLLER

CONTROLLER MANUAL

FIRST EDITION OCTOBER 2012

ROBOSTAR CO, LTD

ROBOT R&D CENTER

Robostar Co., Ltd

Loading...

Loading...