RoboLabs ROBOJETFLOSS ACB-09-120, ROBOJETFLOSS PRO ACB-09-120-PRO, ROBOJETFLOSS RENT ACB-09-120-R Operation Manual

COTTON CANDY MACHINE ACB-09-120 rev 11-May-18

OPERATION MANUAL

COTTON CANDY MACHINES

ROBOJETFLOSS (ACB-09-120)

ROBOJETFLOSS PRO (ACB-09-120-PRO)

ROBOJETFLOSS RENT (ACB-09-120-R)

2018

2

COTTON CANDY MACHINE ACB-09-120 rev 11-May-18

SAFETY REQUIREMENTS

Read the ENTIRE MANUAL before operating.

Only allow TRAINED PERSONNEL to operate the Robo JetFloss.

1. DO NOT TURN ON until transport fastening nuts are fully RAISED.

2. DO NOT OVERFILL spinning head with flossugar.

3. WEAR eye protection during operation.

4. DO NOT TOUCH head while it is still rotating.

5. Spinning head remains HOT after use - DO NOT TOUCH until cool.

6. Avoid OVERHEATING, motor should rest 15 min. per hour of operation.

7. Do not MODIFY the design of the machine.

8. UNPLUG the power cord before cleaning or servicing.

In accordance to EN 60335-1:2012 standard the machine can be used by

children aged 8 years and above and persons with reduced physical,

sensory or mental capabilities or lack of experience and knowledge if they

have been given supervision or instruction concerning use of the appliance

in a safe way and understand the hazards involved. Children shall not play

with the appliance. Cleaning and user maintenance shall not be made by

children without supervision.

3

COTTON CANDY MACHINE ACB-09-120 rev 11-May-18

1. OVERVIEW AND OPERATION

1.1. DESIGNATION

ACB-09-120 is intended to produce cotton candy using sugar with or

without flossine. Due to the patented design, the equipment allows

operation under high ambient temperature and relative humidity. Candy

floss leaves the machine vertically, producing servings up to 6 feet in

diameter. With practice, you can move up to 16 feet away from the

machine and continue to make candy as the stream will follow you in a

continuous trail!

1.2. TECHNICAL SPECIFICATIONS

MODEL ROBOJETFLOSS

ACB-09-120

ROBOJETFLOSS PRO

ACB-09-120-PRO

ROBOJETFLOSS RENT

ACB-09-120-R

Productivity up to 11 lbs/hr up to 11 lbs/hr up to 11 lbs/hr

‘Cold start’ time 60 sec 20 sec 60 sec

Spinning rate 3300 rpm 3300 rpm 3300 rpm

Rated current, not more 16 A 16 A 12 A

Rated voltage 120V/60Hz 120V/60Hz 120V/60Hz

Dimensions (machine only) 15x16x15 in 15x16x15 in 15x16x15 in

Dimensions (pan included) 26x26x19 in 26x26x19 in 26x26x19 in

Weight, not more 33 lbs 33 lbs 33 lbs

The RoboJetFloss will produce results at ambient temperatures up to

104°F (41°C) with relative humidity no greater than 50%. As relative

humidity increases the maximum operating temperature decreases. For

example, with a RH of 90% the maximum recommended temperature

decreases to 68°F.

As temperature and humidity increase above these ranges, cotton candy

can still be produced, but it will be very dense and heavy. Most importantly,

being a sugar product, it may begin to melt shortly after being production.

Altitude above sea level should not exceed 3280 ft.

Ingress protection rating IP20 (IEC 60529).

4

COTTON CANDY MACHINE ACB-09-120 rev 11-May-18

1.3. DELIVERY SET

Delivery set of ACB-09-120 includes the following:

Cotton candy machine 1 pc

Plastic/aluminum floss pan

1

1 pc

‘No-Snow’ tool 1 pc

Silicone sealing collar 1 pc

Silicone adjustment ring 2 pcs

Power supply cord 1 pc

Operation manual 1 copy

THE FLOSS PAN IS AN INTEGRAL PART OF THE MACHINE AND MUST

BE INSTALLED FOR SAFE OPERATION!

Plastic/aluminum floss pan dimensions are 27” x 27” x 10” with net weight

of 3.3 and 4.4 lbs respectively.

1.4. MACHINE DESIGN AND OPERATION PRINCIPLE

The RoboJetFloss includes the following main components: Housing (1);

Chassis (2) with electric motor and Spinning Head (3). The spinning head

and electric motor are mounted on the chassis, which itself is connected to

the housing by four spring-mounted supports. These spring supports

dampen vibrations and allow the motor to self-balance during operation.

1

ACB-09-120-R machine delivery set includes aluminum pan

5

COTTON CANDY MACHINE ACB-09-120 rev 11-May-18

The front panel has the following controls: Switch (11) turns on the electric

motor which rotates the spinning head; Switch (12) turns on the heating

element; Adjustment Knob (13) regulates power to the heating element and

thus controls its temperature; Voltmeter (14) indicates actual voltage

supplied to the heating element.

The ‘PRO’ version includes a ‘Quick Start’ button (15) which temporarily

sends maximum power to the heating element, even when the electric

motor is not running.

See the figure above for ACB-09-120 front panel. Appearance may vary

depending on your specific model.

7

COTTON CANDY MACHINE ACB-09-120 rev 11-May-18

2. INTENDED USE

2.1. PROTECTORS AND LOCKUPS

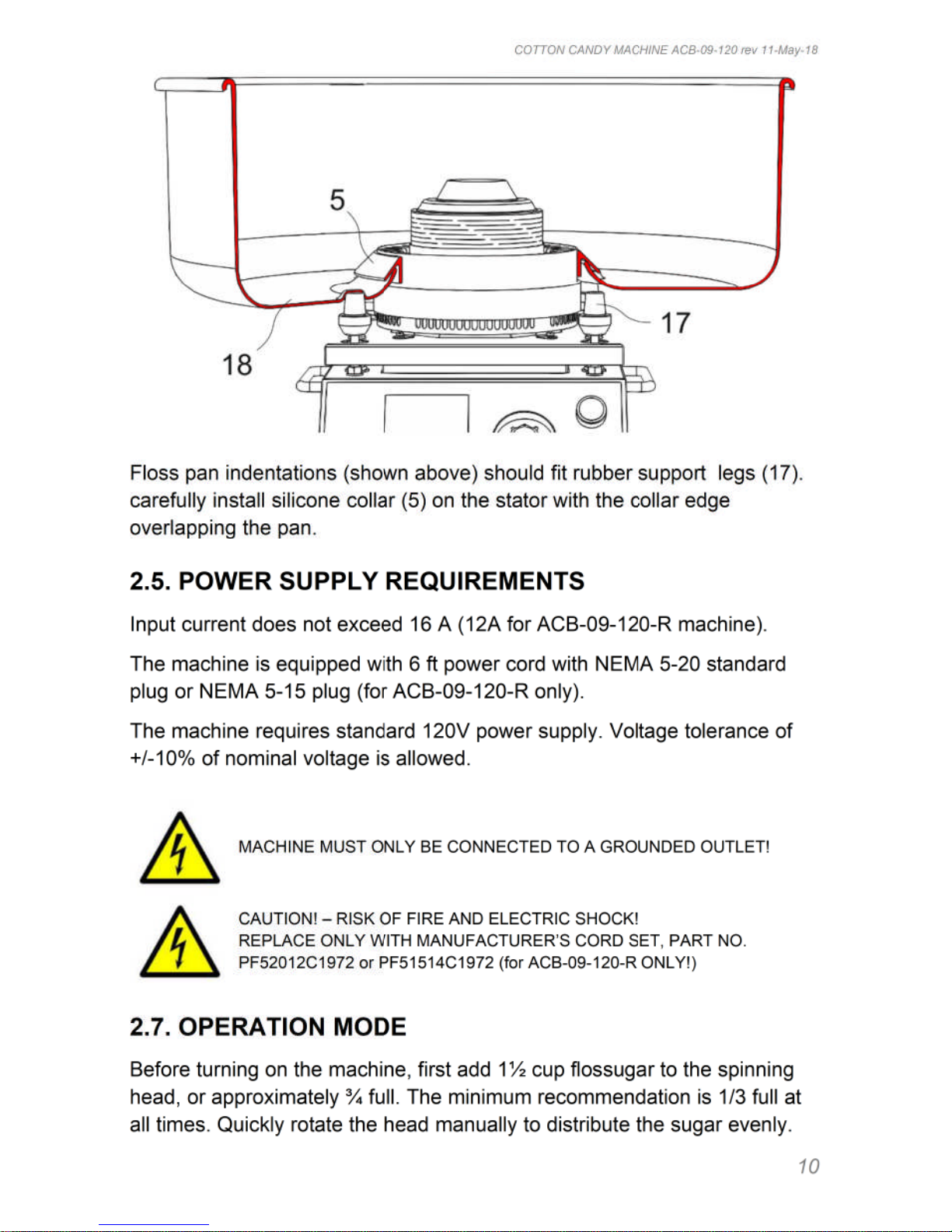

Four nuts secure the spring-loaded chassis during transportation to prevent

damage to the motor. They are located on the threaded support studs at

each corner of the deck.

Rubber legs and a spring suspension supports the chassis in order to

minimize vibration and allow the spinning floss head to balance itself at

high speed.

The stator prevents operators and objects from coming into contact with the

rapidly rotating impeller.

There is a 16A circuit breaker provided for short circuit protection.

2.2. PREMISES REQUIREMENTS

The equipment may be operated in temperatures ranging from +41° F to

+104° F with relative humidity not exceeding 50% at 104° F.

2.3. RAW MATERIAL REQUIREMENTS

Use only 100% pure sugar (beet or cane) with flossine or ready to use

flossugar. Do not use sugars with starch, dextrose or similar additives as

they can result in poor quality floss and/or clog the heater coil assembly.

2.4. GETTING STARTED

Unpack machine and save packaging for future shipping.

Put the machine on a stable table or cart.

Before attaching power cord, fully raise all four transportation fastening

nuts (16) until they reach the rubber floss pan supports.

8

COTTON CANDY MACHINE ACB-09-120 rev 11-May-18

‘Cold start’ Procedure

When the Robo JetFloss has been off for more than 15 minutes, it will take

at least 60 seconds before the heating coil has warmed enough for the

production of cotton candy to begin. If the machine has only been off for a

brief time, such as to add more flossugar, this time will be reduced

substantially.

Users of the ‘Pro’ version can press and hold the ‘Quick start’ button (15)

for 10 - 15 seconds. This will send full power to the heating element and

can be done whether the main power switch is on or not. This will

substantially reduce the time required to begin candy production.

Owners of the standard version can achieve a similar result by manually

adjusting the voltage regulator. After switching on both the motor (11) and

heating element (12), an experienced operator can adjust the voltage

regulator to the maximum (13). But, again for only 10 – 15 seconds, and

then decreasing the voltage back to the recommended operating range

between 70-80 V and proceeding as normal from there.

However, in neither case above should maximum voltage be applied for

more than 10 -15 seconds as you risk overheating the element and burning

12

COTTON CANDY MACHINE ACB-09-120 rev 11-May-18

the flossugar. Doing so could result in overheating the flossugar and the

the cotton candy would then be produced in a narrow rope that is difficult to

capture. In an extreme scenario, the floss would be burnt and ejected as

irregular flakes and sugar dust that would create a mess covering

everything nearby in the immediate area.

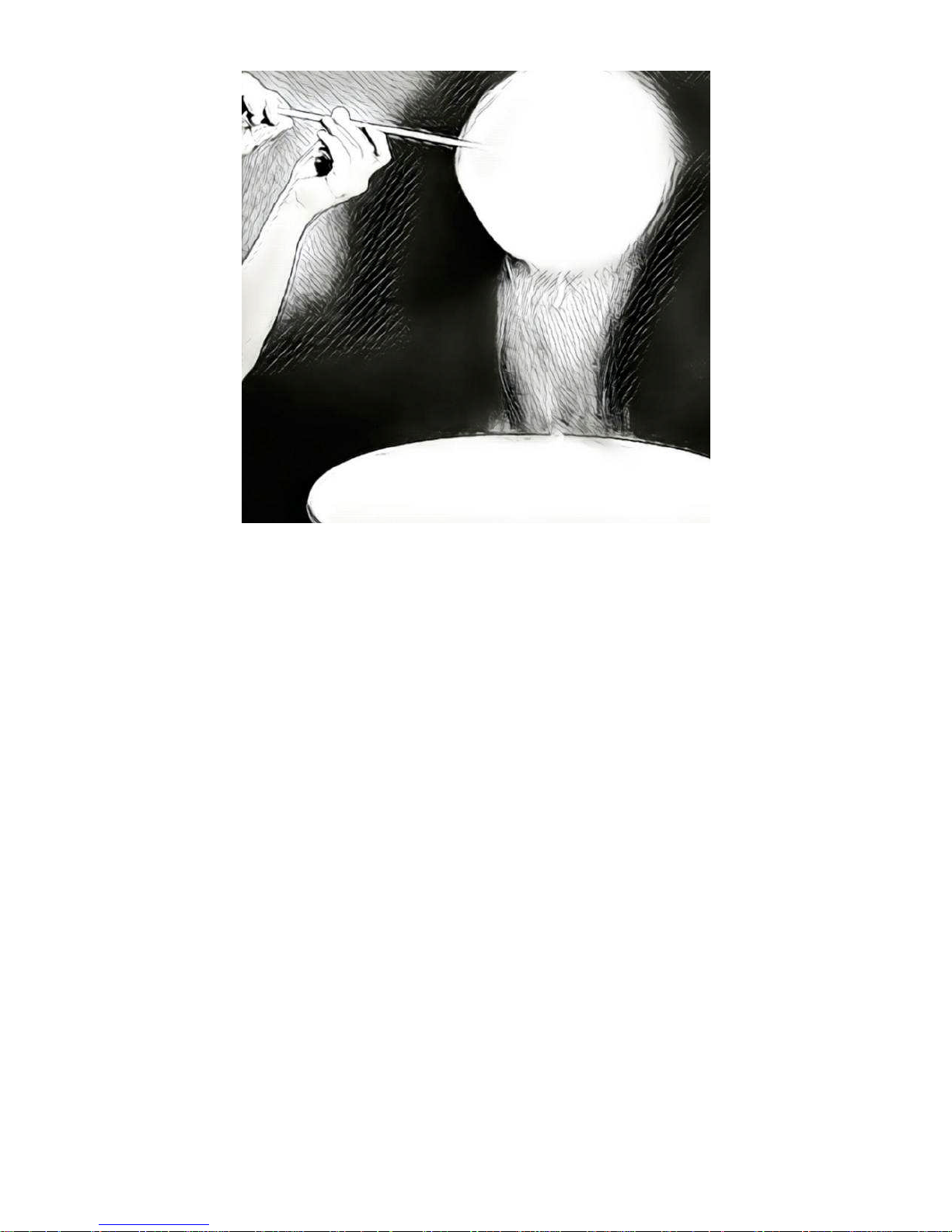

The figure below shows an example of mildly overheated heating element.

Notice the cotton candy is rising more like a ‘rope’ than a wide “sleeve.”

Keep in mind that once the heating element and sidewall have reached

such a high temperature, reducing the voltage will not immediately produce

the desired effect. Due to thermal lag, any changes in voltage will only

slowly take effect over the next 15 to 30 seconds (or longer, depending on

ambient temperatures) so it is very important to avoid overheating the

element in the first place.

‘No-Snow’ Tool

In the production of cotton candy, “snow” includes flakes, flecks, small

filaments and sugar dust that are all too small to be collected in the normal

winding process of producing a cotton candy serving.

There are four situations when “snow” will be emitted from the spinning

head:

13

COTTON CANDY MACHINE ACB-09-120 rev 11-May-18

1. At the very beginning of operation.

2. During the end of production.

3. When there there is not enough flossugar remaining.

4. If the coil and sidewall are overheated.

In both the beginning and ending of operation, snow is produced as the

heating element crosses the temperature threshold at which it can evenly

and uniformly melt the flossugar in the bowl into quality cotton candy floss.

The same is true when there is not enough flossugar left in the head

because the remaining sugar will not be evenly distributed and that will

cause some of the material to overheat. Keeping the floss head at least 1/3

full at all times will prevent this from occurring.

Finally, if the coil and sidewall become extremely overheated then brunt

sugar flecks and dust will be produced instead. Paying attention to Voltage

regulation and not excessively preheating the coil during cold startup will

ensure this does not happen.

Regardless of the cause, you can prevent the distribution of snow (which

can create a mess) by placing the ‘No-Snow’ tool (26) over the spinning

head, where it will capture the snow as it is ejected.

However, you should not leave the ‘No-Snow’ tool in place for long periods

of time as it will eventually become filled with floss and this will then collect

on the spinning head itself.

To help prevent this, the inside of the “No Snow” tool should be wiped off in

between each use to prevent accumulation of spent flossugar.

14

COTTON CANDY MACHINE ACB-09-120 rev 11-May-18

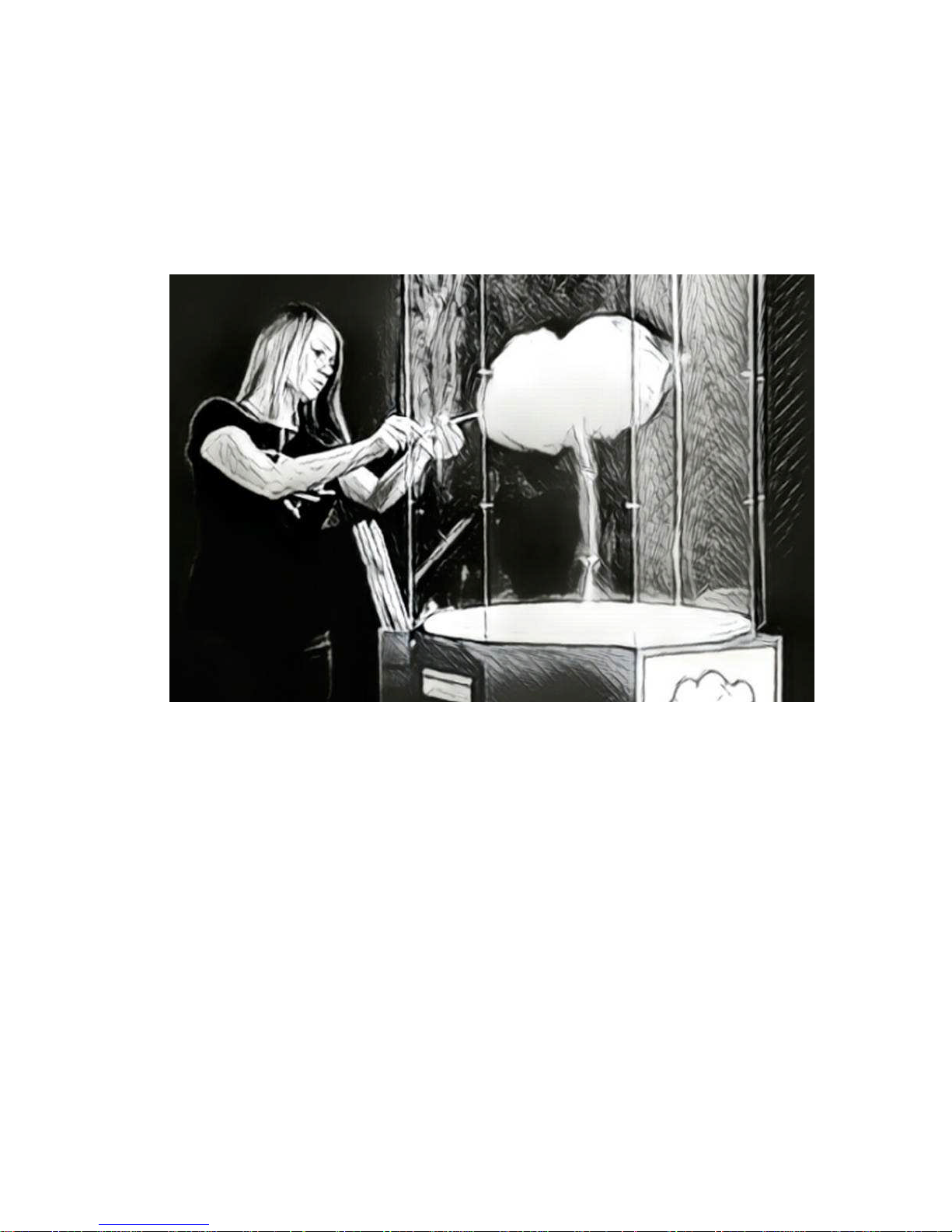

stick, you will find that you can modify the shape of the snake.

Once you have the hang of it, you will be able to step away from the

machine, as far as 10' to 15' (depending on conditions) and the snake will

follow you if you continue the proper winding rate.

You can find more information at www.flyingcottoncandy.com

Shutting Down

When shutting down for periods of less than 24 hours, you may leave any

remaining flossugar in the spinning head.

Turn off power to the heating element switch (12) and capture the

remaining cotton candy as the head cools down. When the coil cools to the

point that “snow” is produced, then cover the head with the “No Snow” tool

and allow the head spin for 5-7 minutes to fully cool down before turning off

the main power switch (11).

Once cool to the touch, wipe out the inside of the “No Snow” tool, and put it

back over the spinning head for protection. You can also cover this with a

paper or plastic bag to protect the flossugar from dust, debris and insects.

The machine and Floss Pan should be wiped down with a damn cloth to

remove excess flossugar as needed.

17

COTTON CANDY MACHINE ACB-09-120 rev 11-May-18

If you are shutting down for longer than one day, then you should perform a

complete cleaning of the spinning head as described in the Technical

Maintenance section below.

Do not leave unused flossugar in the spinning head for more than a day or

two as it can harden/caramelize and effect the balance of the head during

future sessions, which could ultimately result in failure of the machine.

During transportation always secure the chassis using the transportation

lock-down nuts. This will prevent possible damage of the machine and

prolong the lifetime.

18

COTTON CANDY MACHINE ACB-09-120 rev 11-May-18

3. TECHNICAL MAINTENANCE

3.1. GENERAL INSTRUCTIONS

ATTENTION! THISPART OF OPERATION MANUAL IS INTENDEDONLY FOR

TRAINEDPERSONNEL EXPERIENCED WITHELECTRICALEQUIPMENT.

The purpose of technical maintenance is extend the working life of the

machine while fulfilling all safety requirements.

The following schedule3is recommended:

PROCEDURE PERIOD

Cleaning machine and pan surfaces removing

sugar and cotton candy

Once a day

Sidewall and heater cleaning Twice a month

Brush unit maintenance Every 6 months

3.2. SAFETY MEASURES

DO NOT CLEAN THE SPINNING HEAD OR COMPONENTS WITH SHARP

OR METAL PARTS. HOT WATER, A SPONGE OR SOFT BRISTLE BRUSH

IS ALL THAT IS REQUIRED OR PERMITTED!

DISCONNECT THE POWERSUPPLY BEFORECLEANINGORPERFORMING

TECHNICALMAINTENANCE!

3

Technical maintenance may be required sooner if individual parts become fouled prior to

scheduled service.

19

COTTON CANDY MACHINE ACB-09-120 rev 11-May-18

handle in order to loosen the parts.

The sidewall is made of high-grade stainless steel. Nevertheless, the part

might be damaged by excessive tightening the screws, by throwing, or by

heavy impact.

4. Remove central wing nut (21), steel washer (20), plastic holding washer

(19). Then, using a 7mm nut driver or wrench, remove the nuts that are

securing the wire ends to the terminal posts. Remove the nuts, lock

washers, terminal ends and washers and you can then lift off the sidewall

with heating element (9) as one unit.

5. Wash the sidewall and heating element with very hot water in order to

melt the flossugar. When the bulk of the flossugar is removed, carefully

separate the heater coil from the sidewall to clean the areas where they

contact one another.

DO NOTIMMERSE HEATINGELEMENT TERMINAL LEADS IN WATERAS

THIS MAY CAUSE FAILURE!

6. The sidewall and heating element must be dry before reinstalling.

ABRASIVE OR MECHANICALCLEANINGOFHEATING ELEMENTAND

SIDEWALL IS PROHIBITED!

Re-assembly of the spinning head is done in the reverse order. Once

completed, turn on the motor and power to the heating coil for

approximately 30 seconds in order to spin off any remaining moisture.

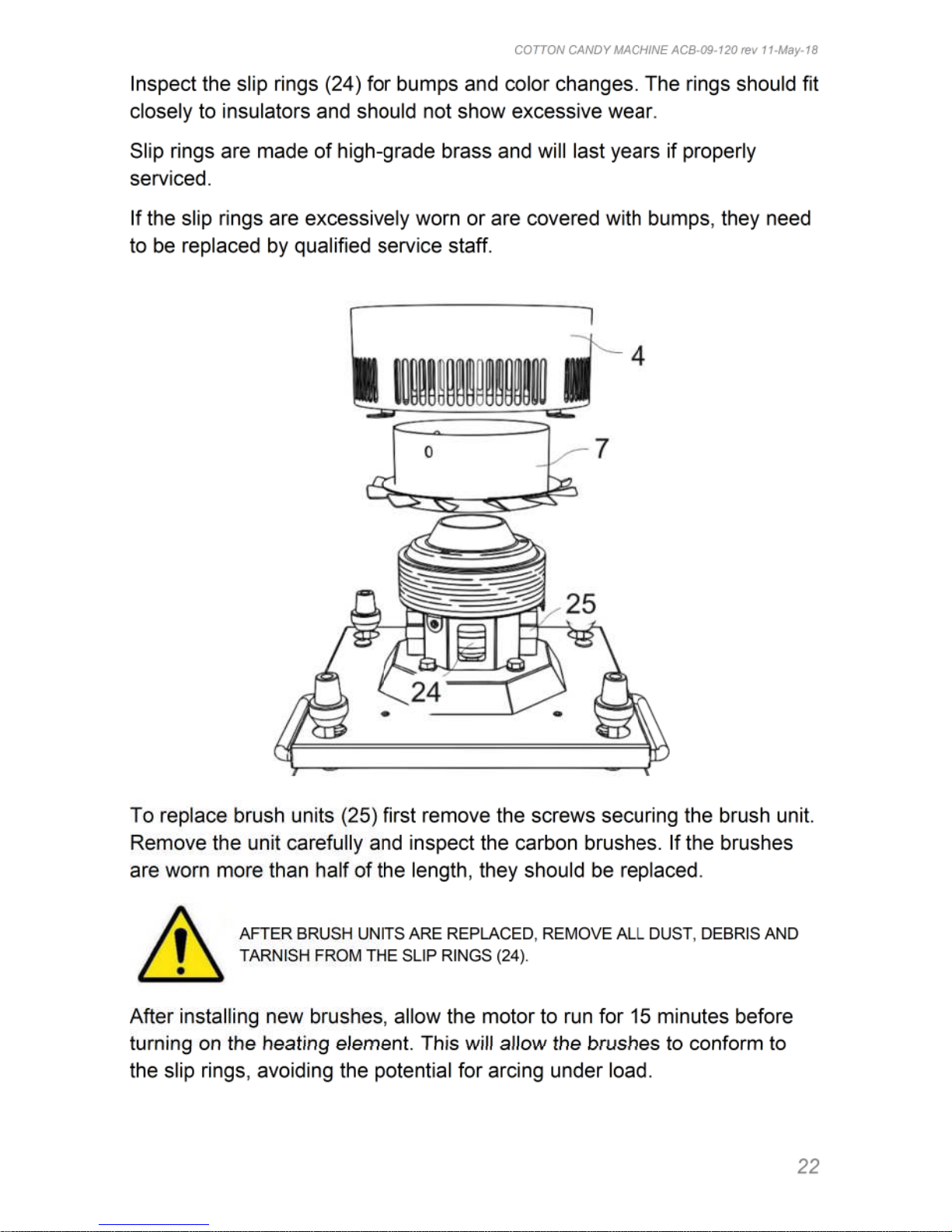

Brush unit maintenance

As with most electrical motors, the Robo JetFloss utilizes brushes and slip

rings which are subject to wear and require inspection, maintenance and

eventual replacement.

To inspect and maintenance the brush unit it is necessary to take off the

stator (4) by removing the four fastening screws. Next remove the impeller

(7) by removing three fastening screws.

21

COTTON CANDY MACHINE ACB-09-120 rev 11-May-18

3.4. STORAGE

If the unit is not used for a prolonged period of time, then the routine

maintenance must be performed before it is placed back into service.

23

COTTON CANDY MACHINE ACB-09-120 rev 11-May-18

3.5. TROUBLESHOOTING

DISCONNECT THE POWER SUPPLY BEFORE

DIAGNOSTICS AND REPAIR. EMI FILTER MUST BE

DISCHARGED BY CLOSING ALL THE PINS IN THE PLUG!

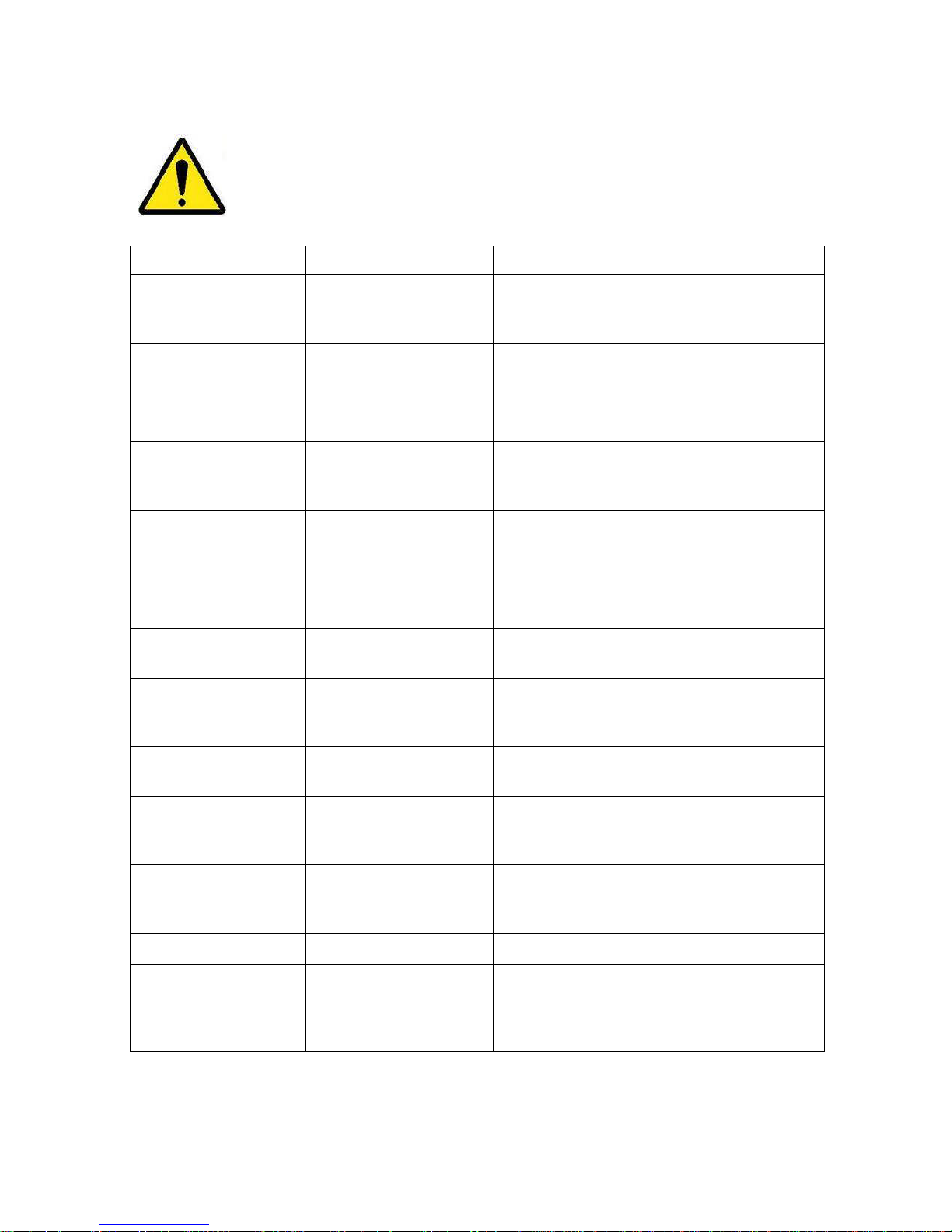

FAILURE POSSIBLE CAUSE REMEDY

Machine doesn’t turn

on when power switch

is activated.

No power at the wall

socket.

Use a tester to check the voltage on all

phases. Provide power in the wall socket.

Power supply cord is

damaged.

Use a tester to check the cord for

breakage, replace defective cord.

Blown fuse Use a tester to check the fuse, replace if

necessary.

Motor is spinning, but

the machine doesn’t

produce cotton candy.

Power regulator is out

of order.

If voltmeter pointer doesn’t move upon

adjustment knob action, then replace the

power regulator.

The heating element is

out of order.

Use a tester to check the heating element,

replace if necessary.

Brush unit damage. Check the brush unit. Brushes must fit

closely to the slip rings, without sparking.

Replace the brush unit if necessary.

Low productivity. Caramel sticking on the

sidewall.

Clean the sidewall and heating element in

accordance with instructions.

Low voltage from the

outlet.

Check the voltage from the outlet or

extension cord. Low voltage is a frequent

cause of low productivity.

Smoke from the

spinning head.

Sidewall overheating. Reduce the voltage on the heating element

with adjustment knob.

Power regulator is out

of order.

If the pointer of voltmeter doesn’t move

during adjusting, replace the power

regulator.

Significant vibration of

the machine.

Spinning head

imbalance.

Fill in the head at least ¾ full with flossugar

and rotate the head manually to spread

sugar evenly.

Check the head for foreign objects.

Check the head for caramel stuck on the

heating element. Clean the sidewall and

heating element in accordance with

instructions.

24

COTTON CANDY MACHINE ACB-09-120 rev 11-May-18

4. TRANSPORTATION AND STORAGE

The equipment may be transported by any kind of covered vehicle, in

accordance with local regulations.

Ambient temperature during the transportation and storage must be

between -13° F and +131° F.

5. TEST CERTIFICATE

ACB-09-120 machine has met mandatory requirements of the state

standards, actual technical documentation, and approved for use.

TEST CERTIFICATE

ACB-09-120

Product Name

_____________

Serial No.

The equipment is made with accordance to mandatory requirements of the state standards, actual

technical documentation, and approved for use.

QC Engineer

STAMP HERE

_________________

Signature

_________________

DD.MM.YYYY

_________________

Full Name

25

COTTON CANDY MACHINE ACB-09-120 rev 11-May-18

6. WARRANTY OBLIGATIONS

The manufacturer guarantees trouble-free operation of the equipment

during 12 months from the date of receiving the equipment by dealer (in

accordance with transport documentation); or, in case of purchase directly

through Business Russia LLC, from the purchase date, given that terms of

using, transportation and storage are met.

The warranty repair is performed upon presentation of this manual and

filled warranty card with the seller’s seal and the date of sale.

Technical specifications of the equipment can be changed by manufacturer

at any time due to improvements and/or other reasons. Technical

specifications stated in this document are intended to act as a reference

point, which is necessary to evaluate suitability of the equipment for the

customer’s needs, and are not the subject of warranty policy.

The information stated in this document has been thoroughly checked and

considered as accurate one; nevertheless, the manufacturer is not

responsible for any typographical errors or misprints.

Due to constant improvement of the equipment, technical

specifications are subject to change without prior notice!

7. MANUFACTURER DETAILS

NPO Tvertorgmash LLC

11 Industrial Street, Tver, 170000 Russia

Technical support is available:

Email: support@robolabs.pro

Phone: +7 495 956 4000

26

Loading...

Loading...