Page 1

USER’S GUIDE

RoboBuilder Co., Ltd.

Innovative DIY Robot kit with Motion File Shared on the Internet

Age 14 and up

Page 2

Page 3

4

Safety Instructions

Be cautious when assembling and using ROBOBUILDER kit for safety reasons.

This is especially important as ROBOBUILDER is a DIY assembly kit which users will

frequently build and disassemble, some of these components cause harm to the user.

The user should assume all responsibility for any accident caused by their careless

handling of the product. Attention must be paid to the following safety instructions.

Please read through this user’s guide and make sure you fully understand all the

instructions before assembling and operating this product.

Handling Electric Power

·Do not use any damaged power cord, plug, or loose outlet.

It may cause an electric shock or fire.

·Make sure that the power plug is inserted firmly into the outlet so that the power cord

can’t get loose. A loose connection may cause a fire.

·Do not forcibly bend or pull the power cord or place it under a heavy object.

It may cause an electric shock or fire.

·Do not handle the power cord with wet hands. It may cause an electric shock.

·Do not connect multiple electric devices to one outlet.

It may cause an abnormal heat or fire.

If this instruction is not properly followed, a serious injury, harm, or death may occur

to the user

If this instruction is not properly followed, an injury to user or physical damage may

arise.

Caution

·This product is not waterproof. Never operate the product in a wet place.

·Do not keep or operate the product in direct sunlight.

Caution

Warning

Warning

Page 4

5

Safety Instructions

·Do not assemble the product when you are tired or in a bad physical condition,

particularly whilst intoxicated.

·Do not place your face too close to the robot.

·Do not use dangerous tools such as a knife or a drill but only recommended tool.

·Keep the remote control that contains batteries away from children’s reach.

Should your child swallow a battery, consult with a doctor immediately.

·Do not keep or operate the robot in a place of high temperature or humidity.

·Keep small parts such as bolts, nuts, and joints away from children’s reach.

Should your child swallow any product part, consult with a doctor immediately.

Handling RoboBuilder Kit

·This product is available only for users aged 14 and up.

·Use the product only in an indoor environment.

·Do not arbitrarily disassemble, repair, and modify the product parts.

·Do not connect or disconnect cables while the robot product is in operation.

It may cause a damage or failure to the product.

·Make sure that only designated devices be connected to connectors or connection

ports of the product. It may cause a damage or failure to the product.

·When cleaning the product, do not use water or solvent such as benzene, and

alcohol but use a soft and dry cloth only. It may cause a failure to the product.

·Keep the robot or parts away from children’s reach.

·Do not leave the product with power on.

Battery damage may cause a product failure.

·Accumulated gear backlash may cause abnormal robot actions if the product is

operated for a long time or executes repeatedly excessive motions, which can

transmit mechanical overload stress to wCK actuator modules.

·Do not give excessive force while a torque is applied to the wCK actuators of the

robot. A gear damage may cause a product failure.

·In some cases wCK actuator module can vibrate a little under operation.

This is not a product failure but a phenomenon that is caused by improper

settings of gains and torque values of the wCK modules. When you set proper

values for them, this phenomenon disappears.

·When wCK actuator modules get twisted by running wrong motions while

programming, turn the power off quickly to prevent excessive torque from being

transmitted to the robot.

·If your finger is caught between actuator modules, turn the power off quickly and

remove force applied to robot to prevent any physical injury.

·Do not operate and let the robot touch any human life or animal.

It may cause injury to the life or product failure.

Caution

Warning

Page 5

Safety Instructions 4

Chapter 1.

Introduction to RoboBuilder 7

Product Features 8

Robot File Sharing on Internet 9

KIT Part List 10

Standard Robot Platforms 11

HUNO 11

DINO 12

DOGY 13

Play Guide 14

KIT Models 14

Chapter 2.

Assembling RoboBuilder 15

Before Assembly 16

Transformation of RoboBuilder 20

HUNO 22

Upgrade HUNO 36

DINO 38

DOGY 52

Chapter 3.

Operating RoboBuilder 65

Installing the Software 66

Software Components 68

MotionBuilder 68

RBC Upgrade Tool 70

Connecting RoboBuilder with PC 71

Checking PC serial port 71

Checking Robot Platform 72

Operating Control Box 73

Using Remote Control 74

Programming 75

Creating New Robot File 76

Modifying Robot File. 81

Quick & Easy Motion-Teaching

Programming Method 84

Modifying Downloaded Robot File 86

Transferring Robot File to Control Box 88

Playing with Robot 90

Recharging Battery 91

Replacing Battery 92

Setting Home Posture 93

Using the Package Tray 93

Adjusting Home Posture Manually 97

Manipulating Home Posture File 100

Upgrading Firmware 101

Chapter 4.

Troubleshooting 103

Table of Contents

Page 6

RoboBuilder is a DIY robot with multiple axes and

multiple functions, which is built by joining various

parts such as wCK robotic module, controller, joints,

and other body parts.

Users can build three standard robot platforms (HUNO,

DINO, and DOGY) for which building instructions are

provided with the kit. Various other robots of user’s

own design can also be easily created.

The robot can easily perform complex motions by

running robot files that are programmed by user or

from robot files that can be downloaded from the Internet.

Chapter 1.

Introduction to RoboBuilder

Page 7

8

Product Features

Short Building Time

Approximately 1 hour building is required to create a robot that is ready to run with

advanced functions and 16 degrees of freedom.

Robot File Sharing

The robot files that define a robot’s motions and actions can be shared over Internet.

(Realized for the first time in the world through precise motion control technology)

Quick & Simple Joint Assembly

Various types of joints enable the user to quickly build new articulated robotic creatures.

Precise Motion Control

Smooth and Natural motions realized through precise motion control both in wheel

mode (360˚) and position control mode(0 to 332˚).

Distributed Controls

Quick and Easy troubleshooting and upgrading are ensured as the main

control(control box) and remote control(wCK joint actuators)are separated.

Built-in Connector

You can easily connect signal line and power line by using two built-in connectors

installed on the wCK module.

Attractive Design

RoboBuilder has an attractive design with curved body lines.

The user can customize their unique robots with various optional accessories.

Creative Robot Building

You can make any desired robot with your own ideas and designs as well as three

standard robot platforms.

Page 8

9

Chapter 1. Introduction to RoboBuilder

Robot File Sharing on Internet

RoboBuilder has adopted the technology of sharing robot files on internet for the first time in the

world. A robot file uploaded on internet by a user can be downloaded and run by another user.

This new technology enables multiple robots with the same hardware structure to share motions

through the Internet.

To upload and download robot files, access the RoboBuilder homepage

(http://www.RoboBuilder.net) and go to COMMUNITY page.

ㆍ Motion files created by a user with MotionBuilder can be shared online as well as offline. However, any motion

files that are modified after being downloaded must but uploaded back to the RoboBuilder homepage if the user

wishes to share these with other users.

ㆍ All downloaded motion files from the homepage may not work perfectly when executed in a different user’s robot.

ㆍ In order to modify downloaded motion files, the user should first add the file to a project in MotionBuilder.

Page 9

10

KIT Part List

The Parts included in a RoboBuilder kit are as follows:

wCK module ×16

Body Frame ×1 Chest Cover ×1 Foot Part ×2

Hand Part ×2

Head Part ×1

(Sensor Module)

wCK module Cable ×20

J2

×8

J1

×2

J3

×3

Control Box ×1

Leg Cover ×2

B5 ×12 B16 ×24B12 ×17

B8 ×15

Nut ×84

B40 ×66

Shoe Plate ×2

Power Supply ×1

PC Cable ×1

Remote Controller ×1

J6

×7

J5

×1

J7

×3

J9

×1

J8

×1

J11

×5

J12

×2

J4

×3

J10

×3

B6 ×9

Software CD ×1 User’s guide ×1

User’s guide

B Gold ×10

※The parts within this product are subject to change without notice, this may occur

if the design of the product changes or is improved.

Page 10

11

Chapter 1. Introduction to RoboBuilder

Standard Robot Platforms

The specifications of three standard robot platforms(HUNO, DINO, and DOGY) are as follows:

HUNO

170

105

105 170

285

Item Specifications

Size (mm)

Approx. 285 (H) x 170 (W) x 105 (D)

Weight (kg)

1.25

Degree of freedom

16

Power

Battery: 8.4V Ni-MH

Power adapter: 12V

Controller

Atmega 128

External case

Engineering plastic

Battery operating time

Approx. 10 - 30 minutes

Introduction

HUNO is a humanoid walking robot designed to resemble a human being. This robot is one of

the best robots that can be built with RoboBuilder kit. A simple remote control can be used to

initiate basic motions such as walking, running, kicking, and a hand stand. The user can also

enjoy more complex motions such as dancing, performing Taekwon-do, responding to sounds,

and detecting objects by programming new robot files.

Page 11

12

DINO

180

170

180

285

170

Item Specifications

Size (mm)

Approx. 285 (H) x 170 (W) x 180 (D)

Weight (kg)

1.25

Degree of freedom

16

Power

Battery: 8.4V Ni-MH

Power adapter: 12V

Controller

Atmega 128

External case

Engineering plastic

Battery operating time

Approx. 10 - 30 minutes

Introduction

DINO is a three-legged robot designed to resemble a dinosaur This robot can perform

fun motions using its tail. It can move faster than the HUNO and can use it’s tail to demonstrate various motions. The user can enjoy entertaining motions such as dancing,

tail show, tail attacks, responding to sounds, and detecting objects by programming

new robot files.

Page 12

13

Chapter 1. Introduction to RoboBuilder

DOGY

215

170

260

215 170

Item Specifications

Size (mm)

Approx. 260 (H) x 170 (W) x 215 (D)

Weight (kg)

0.9

Degree of freedom

16

Power

Battery: 8.4V Ni-MH

Power adapter: 12V

Controller

Atmega 128

External case

Engineering plastic

Battery operating time

Approx. 10 - 30 minutes

Introduction

DOGY is a four-legged walking robot designed to resemble a dog. This robot can move

the fastest amongst the three standard robots. The user can enjoy entertaining motions

such as push-ups, handstands, standing on two legs, rolling, etc. The user can also

program motions so that the robot responds to sounds and object detection.

Page 13

14

Play Guide

KIT Models

Below are the RoboBuilder kit models available for order :

Model

wCK Module

Color

Sound

Recognition

Speaker

Degree of

Freedom

Actuator

Torque

Distance

Sensor

LED on

Actuator

CREATOR

5710K

Black Y

N

16

8kg·cm-12 EA

11kg·cm-4 EA

N N

CREATOR

5720T-S02

Transparent Y Y 16

8kg·cm-12 EA

11kg·cm-4 EA

Y Y

EXPERT

5730K

Black Y Y

Y N

Page 14

This Chapter provides the user with the required

procedures and skills needed to assemble the

three different standard robot platforms(HUNO,

DINO, and DOGY).

The user can apply the same information andknowledge to create their own robots using thesame parts included in the package.

Chapter 2.

Assembling RoboBuilder

Page 15

16

[HUNO Basic Posture]

[DINO Basic Posture] [DOGY Basic Posture]

Before assembly

The user should carefully read and familiarize themselves with the instructions before

starting assembly.

A beginner should first watch the video version of building instructions, this can be found in CD or

at RoboBuilder’s homepage(www.RoboBuilder.net). The user is responsible for any damage to the

robot and its components that are the result of the user not following the instructions, any such damage will not be repaired as a warranty claim.

A user who is not able to assemble a robot for themself can contact local distributor or agent who

can provide a robot-building service(this will incur an additional cost as set by the local distributor

or agent).

The Basic Postures of the three standard robot platforms are as shown in below pictures. If a robot

doesn’t show the exact Basic Posture when you push the red button(

) on the remote controller,

the robot doesn’t move properly or the red Error lamp is turned on, then the robot may not be built

correctly or may have another problem.

In this case, please refer to Chapter 4 [Troubleshooting] to solve the problem. Always make sure that

you start the robot from the correct Basic Posture. Trying to play the robot continuously with the Error

lamp on may cause a serious product failure or damage.

(When Error lamp is turned on, the robot doesn’t take any command signals from the remote control

for 30 seconds, which is designed to protect possible damage to product.)

Page 16

17

Chapter 2. Assembling RoboBuilder

In the process of building a robot the user may encounter a situation where the rotating axis of a

wCK module is stiff and won’t move smoothly. This is not a product fault but a situation caused

by the tight arrangement of the internal gears. Tight gear arrangement is designed for precise

motion control. In this case, please refer to troubleshooting material available on the product CD

and information from our homepage to help fix the problem.

1 hour of assembly time is the average time that is required for a user who has average building

skill to build one of the three standard robot platforms. Thus the building time may vary depending

on the level of the user and work environment.

Be careful not have a nut or a bolt slip inside the control box or wCK module, this may cause a

product fault or a failure.

Page 17

18

Adjusting the rotating axis of wCK module

When assembling wCK modules, there are cases where it is required to adjust the rotating axis

of the wCK module. In this case, rotate the axis using the joint part as shown in figure below:

Putting wCK module and joint together

When putting a wCK module and a joint together, be careful to set the direction of the rotating axis

of the wCK module as shown in below:

Wrong assembly (X) Correct assembly (O)

Recommended tool

EDISON EDM 100 [precision screwdriver (+ type)]

Blade thickness 3mm, Blade length 100mm

Page 18

19

Chapter 2. Assembling RoboBuilder

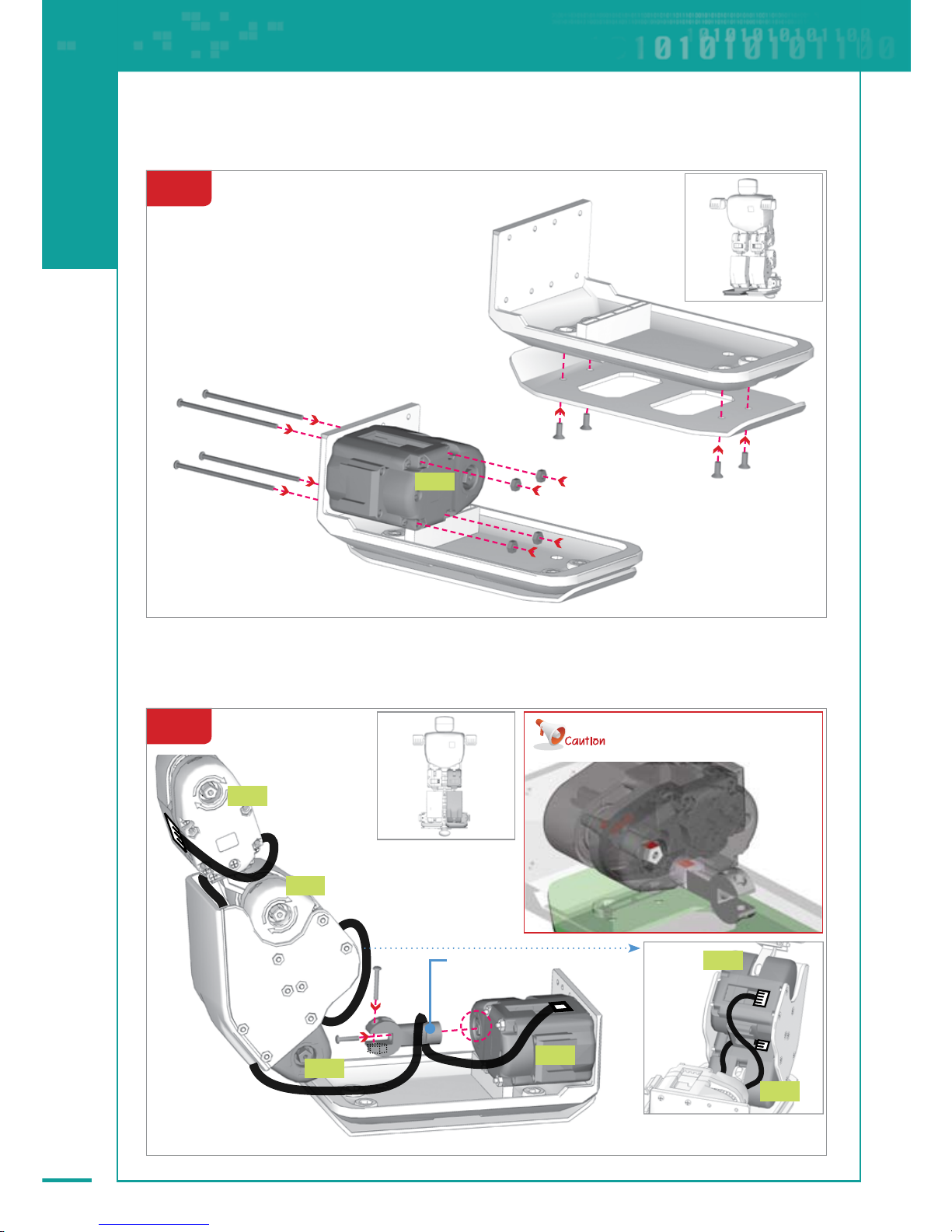

How to read the building instructions

Each step of the building instructions contains the assembly sequence, parts to be used,

cautions, etc. The following is an example STEP from the building instructions.

1) Prepare the parts required for the corresponding assembly step.

(Body Frame, wCK ID 10, J2, B8, B40, Nut)

2) Connect both cables to wCK(ID10) first before attaching it to body frame.

3) Attach ID 10 to the body frame using B40(4 EA) and nuts(4 EA). (①②③④)

4) Attach J2(ⓐ) to wCK(ID 10) using B8(1 EA). Follow caution to correctly set the axis angle. (⑤)

5) Arrange cables as shown in the picture.

Caution area requires special attention

When putting some wCK modules and joints together, adjusting

the alignment angle is important.

In this case, adjust the axis angle of the wCK module correctly

by following the illustration shown in the CAUTION picture.

A red highlight is added to help highlight this.

If not assembled as shown in the picture, it may cause

abnormal operation or a failure.

The angle adjustment is

critically important.

① displays the STEP number.

② displays the position of assembly.

(Left or right from the robot’s view point)

③ displays the information on bolts and joints required

for the step.(B40: 40mm Bolt, J2: Joint 2)

④ displays the ID number of the wCK module.

⑤ displays the caution area in which user should pay

more attention.

⑥ The joint part information.

⑦ displays the position of the inserted nut.

⑧ displays the assembly sequence.

⑨ illustrate the caution area (⑤)to help clear understanding.

STEP 01

Left

Connect both wCK cables first

before attaching it to body frame.

ⓐ

①

②

③

④

The adjustment of

connecting angle is

critically important.

ID 10

①②③④ : B40, ⑤ : B8

ⓐ : J2

ID 10

⑤

①

②

③

④

⑤

⑥

⑦

⑧

⑨

Page 19

20

Transformation of RoboBuilder

DOGY

The RoboBuilder kit has been designed for users to easily transform a robot to another standard

platform robot. For example, by reassembling some parts of a HUNO the user can transform it into

a DOGY in approximately 30 minutes. When the robot transformed from the HUNO to DOGY, the

PF LED on the control box must be set to change the platform type - then the DOGY is ready for

action and can be controlled by the remote control. The sound generated by the

robot is automatically changed for the various standard platforms.

Page 20

21

Chapter 2. Assembling RoboBuilder

HUNO

DINO

Page 21

22

HUNO

HUNO’s name comes from Humanoid as it resembles the appearence of a human

being. The assembly of HUNO consists of total 20 steps. The required parts for each

step and the related assembly instructions are provided here.

Completed HUNO

Page 22

23

Chapter 2. Assembling RoboBuilder

HUNO Part List

wCK module ×16

Body Frame ×1

Chest Cover ×1

Foot Part ×2

Hand Part ×2

Head Part ×1

(Sensor Module)

wCK module Cable ×16

J4

×2

J2

×6

J6

×4

Control Box ×1

Shoe Plate ×2 Leg Cover ×2

B5 ×8 B16 ×16B12 ×10B8 ×9Nut ×56 B40 ×40

※The components within this product are subject to change without notice, this may occur if the design of the

product changes or is improved.

B Gold ×3

H

U

N

O

B6 ×7

Page 23

24

Assembly Sequence

STEP 01, 02, 03, 04

01

STEP 05, 06

02

STEP 07, 08

03

STEP 09, 10

04

STEP 11, 12

05

STEP 13

06

All building instructions for HUNO are exactly the same as the ones for DINO except for the arms

and the tail.

STEP 14

07

STEP 15, 16

08

Page 24

25

Chapter 2. Assembling RoboBuilder

ID MAP

Front View Rear View

The ID map of the wCK robot modules for HUNO are as follows:

11 14

1512

1310

06

01

0500

07

02

0803

0904

14

15

11

12

13 10

06

01

05 00

07

02

08 03

09 04

STEP 17

09

STEP 18, 19, 20

10

H

U

N

O

Page 25

26

STEP 01

Right

Connect both wCK cables first

before attaching it to body frame.

ⓐ

⑤

①

②

③

④

STEP 02

ID 13

Left

Connect both wCK cables first

before attaching it to body frame.

ⓐ

①

②

③

④

ID 10

①②③④ : B40, ⑤ : B8

ⓐ : J2

①②③④ : B40, ⑤ : B8

ⓐ : J2

ID 10

ID 13

⑤

The adjustment of the

connecting angle is critically

important.

The adjustment of the

connecting angle is critically

important.

8mm Bolt

40mm Bolt

Joint 2

Page 26

27

Chapter 2. Assembling RoboBuilder

①

②

③

④

STEP 03

Right

STEP 04

⑤

①

②

③

④

Left

The adjustment of the

connecting angle is

critically important.

ID 00

ⓐ

The adjustment of the

connecting angle is

critically important.

ID 05

ⓐ

①②③④ : B40, ⑤ : B8

ⓐ : J2

Connect both wCK cables first

before attaching it to body

frame.

①②③④ : B40, ⑤ : B8

ⓐ : J2

Connect both wCK cables first

before attaching it to body

frame.

ID 00

ID 05

⑤

H

U

N

O

Page 27

28

①

②

⑦

ID 14

ID 15

STEP 05

STEP 06

①

②

ID 11

ID 12

ⓐ

⑦

⑤

⑥

③

④

ID 12

ⓑ

Left

①②③④⑤⑥ : B16, ⑦ : B12

ⓐ : J6, ⓑ : J4

Right

①②③④⑤⑥ : B16, ⑦ : B12

ⓐ : J6, ⓑ : J4

③

④

⑦

⑤

⑥

ID 15

ⓐ

ⓑ

ⓐ

⑦

ⓐ

Page 28

29

Chapter 2. Assembling RoboBuilder

ID 06

ID 07

ID 08

STEP 07

ID 01

ID 02

ID 03

Connect wCK cables as

above before attaching leg

cover.

Left

Connect wCK cables as

above before attaching

leg cover.

Right

STEP 08

②

①

⑪

①② : B16, ③④⑤⑥⑦⑧⑨⑩ : B40, ⑪ : B12

ⓐ : J6

①② : B16, ③④⑤⑥⑦⑧⑨⑩ : B40, ⑪ : B12

ⓐ : J6

ⓐ

ID 02

ID 03

ID 07

ID 08

⑩

⑨

⑧

⑦

⑥

⑤

④

③

⑪

②

①

⑩

⑨

⑧

⑦

⑥

⑤

④

③

※The pentagon-shaped rotation axes of

wCK ID01,02,03 should all face to same

direction(outwards)

※The pentagon-shaped rotation axes of

wCK ID06,07,08 should all face to same

direction(outwards)

ⓐ

H

U

N

O

Page 29

30

STEP 09

Left

STEP 10

①②③④ : B5, ⑤⑥⑦⑧ : B40

ID 04

⑧

⑦

⑥

⑤

④

③

②

①

R i g h t

①②③④ : B5, ⑤⑥⑦⑧ : B40

ID 09

⑧

⑦

⑥

⑤

④

③

②

①

※ Make sure that the front side of the

shoe plate has a narrower width of

its folded surface than rear side.

※ Make sure that the front

side of the shoe plate has

a narrower width of its

folded surface than rear

side.

Page 30

31

Chapter 2. Assembling RoboBuilder

STEP 11

Right

STEP 12

Left

The adjustment of the connecting

angle is critically important.

The adjustment of the connecting

angle is critically important.

① : B8, ② : B12

ⓐ : J2

① : B8, ② : B12

ⓐ : J2

ID 03

ⓐ

ID 04

②

ⓐ

②

ⓐ

ID 09

ID 08

①

①

ID 01

ID 02

ID 06

ID 07

ID 02

ID 03

ID 07

ID 08

H

U

N

O

Page 31

32

STEP 13

STEP 14

Left, Right

②

①

①② : B12

①②③④ : B6

②

①

④

③

ID 13

ID 10

ID 13

ID 10

ID 14

ID 06

ID 01

ID 06

ID 01

ID 00

ID 05

ID 15

ID 06

ID 01

ID 05

ID 00

ID 05

ID 00

ID 13

ID 10

Page 32

33

Chapter 2. Assembling RoboBuilder

STEP 15

Right

STEP 16

Left

① : B12

① : B12

①

①

ID 13

ID 10

ID 06

ID 11

ID 10

ID 11

ID 10

ID 11

ID 13

ID 10

ID 14

ID 13

ID 14

ID 14

ID 13

ID 01

H

U

N

O

Page 33

34

STEP 17

①

STEP 18

②

①②③ : B6

Left Arm

Right Arm

Head

Left Arm

Right Leg

Left Leg

③

ID 11

ID 14

ID 12

ID 11

Left Leg

Right

Leg

Right Arm

Head

Page 34

35

Chapter 2. Assembling RoboBuilder

Right Arm

Head

Left Arm

Right Leg

Left Leg

ID 11 ID 14

ID 12 ID 15

STEP 19

With the control box half slid

down, insert the cables from

both legs to the connectors on

the control box before the control box is fully pushed down

and secured. All cables, other

than the sensor cable from the

head, can be plugged into any

of the connectors.

STEP 20

①: Power ON

②: Check PF1

Blue LED

③: Check the basic

posture (

)

※ If battery is not sufficiently charged, connect

the power adapter to run the robot.

H

U

N

O

Page 35

36

Upgrade HUNO

Upgraded HUNO is a modified platform of HUNO enhanced by adding two more degrees of

freedom(2 more wCK module). With its waist twisting freely, the various motions that can be

programmed are much more natural and human like.

Page 36

37

Chapter 2. Assembling RoboBuilder

H

U

N

O

Page 37

38

DINO

DINO’s name comes from the Dinosaur as it resembles a dinosaur with a tail. The assembly of DINO consists of 20 steps. The required parts for each step and the related

assembly instructions are provided here.

Completed DINO

Page 38

39

Chapter 2. Assembling RoboBuilder

DINO Part List

J7

×2

J2

×5

J3

×2

J4

×2

J11

×1

J6

×4

wCK module ×16

Body Frame ×1

Chest Cover ×1

Foot Part ×2

Hand Part ×2

Head Part ×1

(Sensor Module)

wCK module Cable ×16

Control Box ×1

Shoe Plate ×2 Leg Cover ×2

※The components within the product are subject to change without notice, this may occur if the design of the

product changes or is improved.

B Gold ×3

B5 ×8 B16 ×16B12 ×11B8 ×9Nut ×56 B40 ×44

D

I

N

O

B6 ×7

Page 39

40

Assembly sequence

STEP 01, 02, 03, 04

01

STEP 05

02

STEP 06, 07, 08, 09,

10, 11

03

STEP 15

07

STEP 16

08

STEP 12

04

STEP 13

05

STEP 14

06

All building instructions for DINO are exactly the same as the ones for HUNO except for the arms and the tail.

Page 40

41

Chapter 2. Assembling RoboBuilder

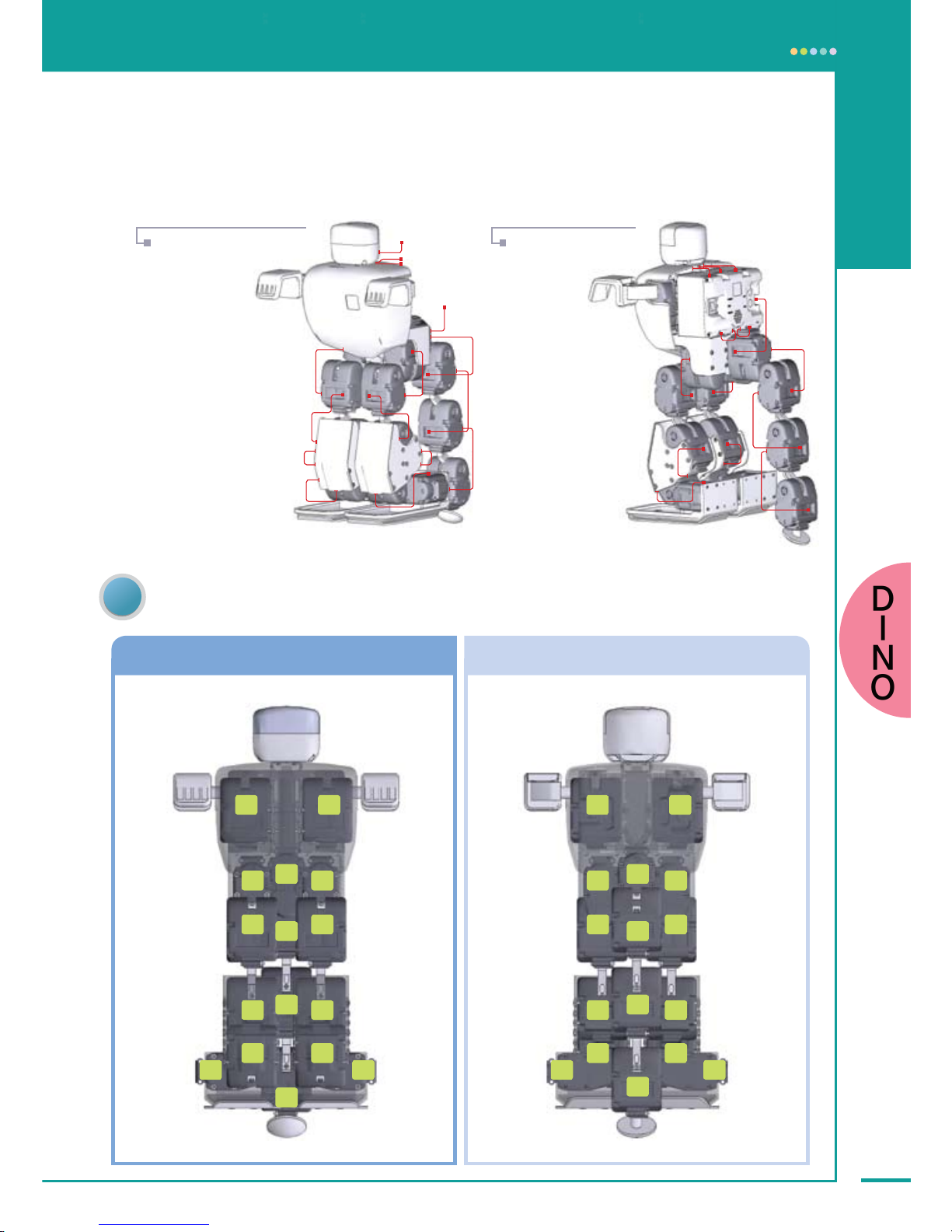

ID MAP

STEP 17

09

STEP 18, 19, 20

10

Front View Rear View

The ID map of the wCK robot modules for DINO are as follows:

13

11

12

14

15

09 04

06

05

07

08

10

01

00

02

03

10

11

12

14

15

04 09

01

00

02

03

13

06

05

07

08

D

I

N

O

Page 41

42

STEP 01

Right

Connect one wCK cable first as above

before attaching it to body frame.

ⓐ

①

②

③

④

STEP 02

ID 13

Left

Connect one wCK cable first as above

before attaching it to body frame.

ⓐ

①

②

③

④

ID 10

①②③④ : B40, ⑤ : B8

ⓐ : J3

①②③④ : B40, ⑤ : B8

ⓐ : J3

ID 10

ID 13

⑤

⑤

The adjustment of the

connecting angle is critically

important.

8mm Bolt

40mm Bolt

Joint 3

The adjustment of the

connecting angle is critically

important.

Page 42

43

Chapter 2. Assembling RoboBuilder

①

②

③

④

STEP 03

Right

STEP 04

①

②

③

④

Left

ID 00

ⓐ

ID 05

ⓐ

①②③④ : B40, ⑤ : B8

ⓐ : J2

Connect both wCK cables first

before attaching it to body

frame.

①②③④ : B40, ⑤ : B8

ⓐ : J2

Connect both wCK cables first

before attaching it to body

frame.

ID 00

ID 05

⑤

⑤

ID 10

ID 13

ID 13

ID 10

The adjustment of the

connecting angle is

critically important.

D

I

N

O

The adjustment of the

connecting angle is

critically important.

Page 43

44

STEP 06

ID 01

ID 02

ID 03

Connect wCK cables as above

before attaching leg cover.

Left

⑪

①② : B16, ③④⑤⑥⑦⑧⑨⑩ : B40, ⑪ : B12

ⓐ : J6

ⓐ

ID 02

ID 03

STEP 05

Left

①② : B16

ⓐ : J7, ⓑ : J4

①

②

ⓐ

ⓑ

③

Right

①② : B16

ⓐ : J7, ⓑ : J4

①

②

ⓐ

ⓑ

③

②

①

⑩

⑨

⑧

⑦

⑥

⑤

④

③

※The pentagon-shaped rotation axes of

wCK ID01,02,03 should all face to same

direction(outwards)

Page 44

45

Chapter 2. Assembling RoboBuilder

ID 06

ID 07

ID 08

Connect wCK cables as

above before attaching leg

cover.

Right

STEP 07

②

①

①② : B16, ③④⑤⑥⑦⑧⑨⑩ : B40, ⑪ : B12

ⓐ : J6

ID 07

ID 08

⑩

⑨

⑧

⑦

⑥

⑤

④

③

ⓐ

⑪

STEP 08

Left

①②③④ : B5, ⑤⑥⑦⑧ : B40

ID 04

⑧

⑦

⑥

⑤

④

③

②

①

※ The pentagon-shaped rotation axes

of wCK ID06,07,08 should all face to

same direction(outwards)

※ Make sure that the front

side of the shoe plate has a

narrower width of its folded

surface than rear side.

D

I

N

O

Page 45

46

STEP 10

Left

① : B8, ② : B12

ⓐ : J2

ID 03

ⓐ

ID 04

②

ⓐ

①

ID 01

ID 02

ID 02

ID 03

STEP 09

Right

①②③④ : B5, ⑤⑥⑦⑧ : B40

ID 09

⑧

⑦

⑥

⑤

④

③

②

①

The adjustment of the connecting

angle is critically important.

※ Make sure that the front side of the shoe

plate has a narrower width of its folded

surface than rear side.

Page 46

47

Chapter 2. Assembling RoboBuilder

Right

STEP 11

① : B8, ② : B12

ⓐ : J2

②

ⓐ

ID 09

ID 08

①

ID 06

ID 07

ID 07

ID 08

STEP 12

① : B8, ②⑤⑧ : B12, ③④⑥⑦⑨⑩ : B16

ⓐ : J2, ⓑⓒ : J6, ⓓ : J11

②

③

④

⑤

ID 12

ID 11

ID 14

ⓑ

⑥

⑦

⑧

⑨

⑩

ID 14

ID 15

ⓑ

ⓓ

①

ⓐ

The adjustment of the connecting

angle is critically important.

ⓒ

D

I

N

O

Page 47

48

STEP 14

Left, Right

②

①

①② : B12

ID 06

ID 01

ID 06

ID 01

ID 00

ID 05

ID 06

ID 01

ID 05

ID 00

ID 05

ID 00

ID 13

ID 10

STEP 13

①②③④ : B6

②

①

④

③

ID 13

ID 10

ID 13

ID 10

Page 48

49

Chapter 2. Assembling RoboBuilder

STEP 15

ID 13

ID 10

STEP 16

①

③

②

①②③ : B6

Right Front Leg

Head

Left Front Leg

Left

Rear Leg

Right

Rear Leg

D

I

N

O

Page 49

50

STEP 18

STEP 17

①

③

④

②

①②③④ : B40

ID 01

ID 06

ID 11

ID 12

ID 02

ID 07

Page 50

51

Chapter 2. Assembling RoboBuilder

STEP 19

Head

Left Front Leg

Left Rear Leg

Left

Rear Leg

Right

Rear Leg

Tail

With the control box half slid

down, insert the cables from

both legs to the connectors on

the control box before the control box is fully pushed down

and secured. All cables, other

than the sensor cable from the

head, can be plugged into any

of the connectors.

STEP 20

①: Power ON

②: Check PF1

Pink LED

※ If battery is not sufficiently charged connect

the power adapter to run the robot.

③: Check the basic

posture (

)

D

I

N

O

Page 51

52

DOGY

DOGY’s appearance resembles that of a dog.

The assembly of DOGY consists of 18 steps. The required parts for each step and

the related assembly instructions are provided here.

Completed DOGY

Page 52

53

Chapter 2. Assembling RoboBuilder

DOGY Part List

J10

×1

J2

×4

B6 ×2

B16 ×18B12 ×11B8 ×9Nut ×32 B40 ×16

J11

×4

J6

×5

Body Frame ×1

wCK module ×16

Control Box ×1

wCK module Cable ×16

Sensor Module ×1

J12

×2

※The components within the product are subject to change without notice, this may occur if the design of the

product changes or is improved.

B Gold ×5

D

O

G

Y

Page 53

54

Assembly Sequence

STEP 01, 02, 03, 04

01

STEP 05, 06

02

STEP 07

03

STEP 08

04

STEP 09, 10

05

STEP 11, 12

06

STEP 13

07

STEP 14

08

Page 54

55

Chapter 2. Assembling RoboBuilder

ID MAP

STEP 15

09

STEP 16, 17, 18

10

Bottom View Back View

The ID map of the wCK robot modules for DOGY are as follows:

14

15

09

06

11

12

04

01

07

08

02

03

13

05

10

00

13

11

12

14

15

0904

06

05

07

08

10

01

00

02

03

D

O

G

Y

Page 55

56

STEP 01

Right

The adjustment of the

connecting angle is

critically important.

STEP 02

Left

ⓐ

①

②

③

The adjustment of

the connecting angle is

critically important.

ID 05

①②③ : B40, ④ : B8

ⓐ : J2

①②③ : B40, ④ : B8

ⓐ : J2

①

②

③

④

④

ⓐ

ID 00

Connect both wCK cables first

before attaching it to body frame.

ID 05

ID 00

Connect both wCK cables first

before attaching it to body frame.

8mm Bolt

40mm Bolt

Joint 2

Page 56

57

Chapter 2. Assembling RoboBuilder

STEP 03

Right

STEP 04

Left

①②③ : B40, ④ : B8

ⓐ : J2

①②③ : B40, ④ : B8

ⓐ : J2

The adjustment of

the connecting angle is

critically important.

①

②

③

④

ⓐ

ID 05

ID 13

ID 00

①

ⓐ

ID 00

ID 10

ID 05

④

③

②

Connect both wCK cables first

before attaching it to body frame.

ID 13

ID 10

Connect both wCK cables first

before attaching it to body frame.

D

O

G

Y

The adjustment of

the connecting angle is

critically important.

Page 57

58

Right

STEP 05

①②③④ : B16, ⑤ : B12

ⓐ : J6, ⓑ : J11

Left

①②③④ : B16, ⑤ : B12

ⓐ : J6, ⓑ : J11

Left

STEP 06

①②③④ : B16, ⑤ : B12

ⓐ : J6, ⓑ : J11

Right

①②③④ : B16, ⑤ : B12

ⓐ : J6, ⓑ : J11

①

②

③

④

⑤

①

②

③

④

⑤

①

②

③

④

⑤

ID 06

ID 09

①

②

③

④

⑤

ⓑ

ID 01

ID 04

ID 14

ID 15

ID 11

ID 12

ⓐ

ⓑ

ⓐ

ⓐ

ⓑ

ⓐ

ⓑ

Page 58

59

Chapter 2. Assembling RoboBuilder

STEP 07

STEP 08

②④ : B12

ⓐ : J10

①② : B16, ③ : B12, ④ : B Gold

ⓐ : J6, ⓑ : J12

②

③

④

①

The adjustment of the connecting

angle is critically important.

ⓐ

ID 03

ID 02

For easy assembly, insert two nuts into

the nut holes of J10 using a screwdriver.

And then fasten the bolt with the nuts held with your finger.

①

②

③

④

ID 08

ID 07

ⓐ

ⓑ

D

O

G

Y

The adjustment of the connecting angle is critically

important.

Page 59

60

Left

STEP 09

Right

STEP 10

① : B12

① : B12

①

①

The adjustment of the connecting angle is critically important.

ID 05

ID 06

ID 00

ID 01

The adjustment of the connecting angle is critically important.

Page 60

61

Chapter 2. Assembling RoboBuilder

STEP 11

STEP 12

Right

① : B12

Left

① : B12

①

①

ID 13

ID 14

ID 10

ID 11

ID 15

ID 12

The adjustment of the connecting angle is critically important.

The adjustment of the connecting

angle is critically important.

D

O

G

Y

Page 61

62

①

②

ID 10

ID 07

ID 13

STEP 13

STEP 14

The adjustment of the connecting angle is critically important.

With the control box half slid down, insert the

cables from both legs to the connectors on

the control box before the control box fully

pushed down and secured.

①

②

③

①② : B6

ID 06

ID 09

ID 05

ID 04

ID 14

ID 12

ID 11

ID 15

ID 13

Right Front Leg

Left Front Leg

Page 62

63

Chapter 2. Assembling RoboBuilder

STEP 15

①②③④ : B40

STEP 16

①②③④ : B Gold

The adjustment of the connecting angle is critically important.

①

②

③

④

①

②

③

④

⑤

ID 03

ID 02

ID 03

ID 02

Head

Right Front Leg

Left Front Foot

D

O

G

Y

After the head part is fixed

to the body frame, release

the control box half way to

insert the wCK cable from

wCK module ID02 into the

connector on the control

box.

Page 63

64

STEP 17

Sensor

Head

Left Front Leg

Right Front Leg

Tail

Right Rear Leg

Left Rear Leg

All cables, other than the sensor

cable from the head, can be

plugged into any of the connectors

STEP 18

③: Check the basic posture ( )

①: Power ON

②: Check PF1

Red LED

※ If battery is not sufficiently charged connect the

power adapter to run the robot.

Page 64

This chapter explains how to install the

software, connect RoboBuilder with your

PC, create and modify motion program

files, and operate the fully assembled

RoboBuilder.

Chapter 3.

Operating RoboBuilder

Page 65

66

Installing the Software

Before programming and operating your assembled robot you will need to install the software from

the installation CD provided with product package. Insert the CD into CD-ROM and run Setup.exe.

02 Click [Install] to start the program installation.

01 Click [Next] when Installation Wizard window pops up.

Page 66

67

Chapter 3. Operating RoboBuilder

04 The shortcut icons of the software programs are registered on Desktop and Start Menu.

03 When the Installation Wizard Complete window appears, click [Finish] to end the

installation procedure.

[Desktop]

[Start]

Page 67

68

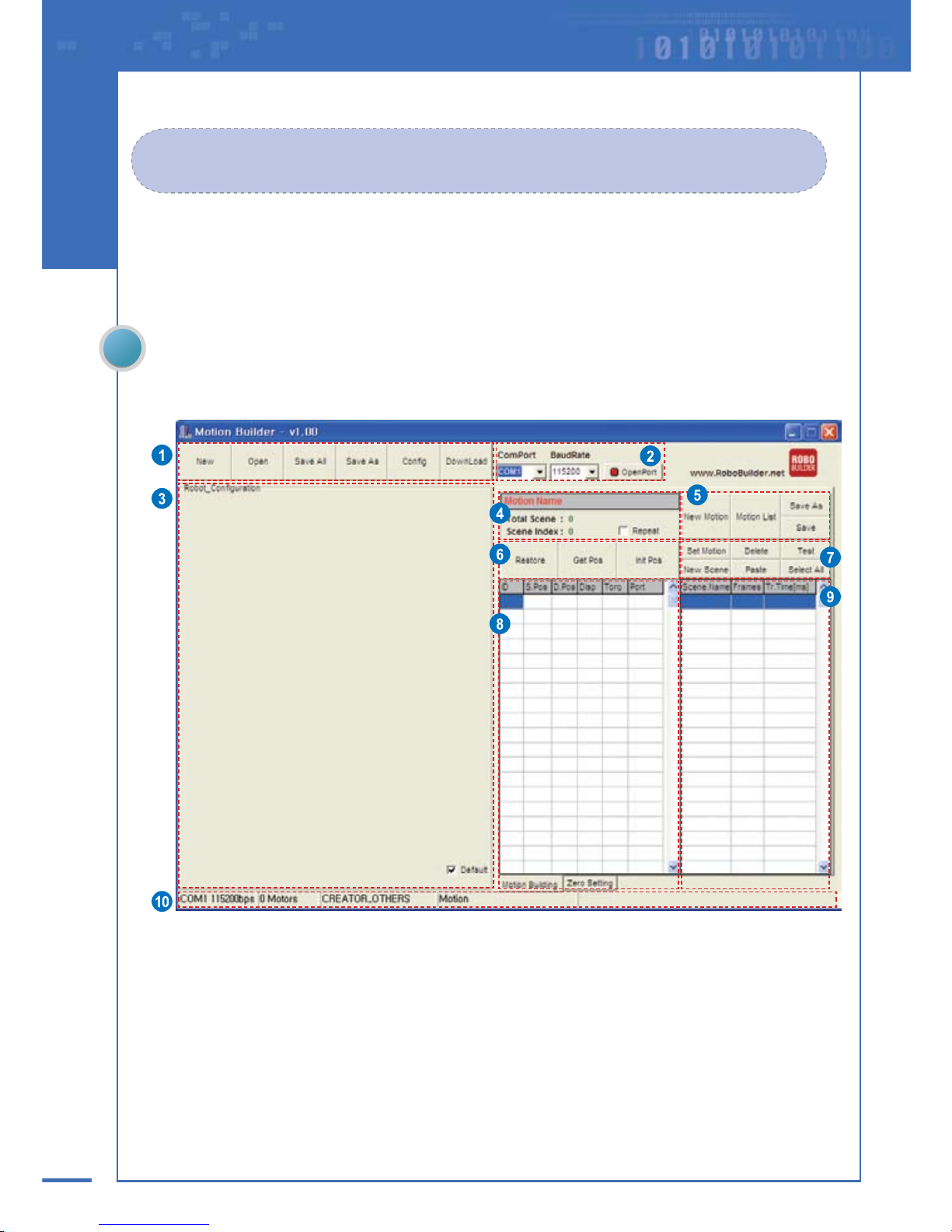

Software Components

The RoboBuilder software consists of MotionBuilder and the RBC Upgrade tool. MotionBuilder is used

to create and modify robot files, transfer robot files to RoboBuilder, and adjust the home posture.

RBC Upgrade tool is used to upgrade the firmware of the main control board inside the control box.

MotionBuilder

The MotionBuilder screen layout is as below.

Page 68

69

Chapter 3. Operating RoboBuilder

No. Area Name Functions & Descriptions

①

Menu Bar

ㆍ New: creates a new project by defining project name, file path, robot type etc.

ㆍOpen: opens an existing project file. (*.prj)

ㆍSave All: stores the running project file and all data related to the project.

ㆍSave As: saves the running project file as a different name.

ㆍConfig: configures and sets the wCK module.

ㆍDownload: transfers robot files to control box.

②

PC Port

connection

ㆍComPort: sets the port on PC to connect RoboBuilder with.

ㆍBaudRate: sets the data communication speed. (default: 115,200kbps)

ㆍOpenPort: opens the set PC port to connect RoboBuilder with.

③

Robot

Configuration

ㆍ This area illustrates the mechanical construction of the wCK modules. Using the jog

dial pad, you can control the movement of each wCK module.

* If the [Default] button is not checked, you can freely relocate the jog dial pads of the wCK mod-

ules by dragging them with your mouse(right-click).

When [Default] is selected, they return to their original default position.

④

Motion File

Information

ㆍMotion Name: displays the name of the motion file running.

ㆍTotal Scene:

displays the total number of scenes that constitutes the motion file running.

ㆍScene Index: displays the number of the selected scene in the running motion file.

ㆍRepeat: is used to repeat and test the selected one or more scenes.

⑤

Motion File

Management

ㆍNew Motion: creates a new motion file.

ㆍMotion List: add, open, modify, or remove motion files.

ㆍSave As: saves the running motion file as a different name.

ㆍSave: saves the running motion file.

⑥

Position Control

ㆍRestore: sets all modules’ displacement angles of the selected scene to “0”.

ㆍGet Pos: captures the desired posture of a robot after adjusting the posture manually

with user’s hands. Captured posture is saved as in a scene.

ㆍInit Pos: sets the initial torque and angle of the selected wCK module.

⑦

Scene

Management

ㆍSet Motion: sets the name and saved path of the motion file, configures PID gains of

wCK modules.

ㆍDelete: deletes the selected scene.

ㆍTest: run the selected scene.(multiple scene selection available)

ㆍNew Scene: adds a new scene.

ㆍPaste: pastes the copied scene in the selected position.

ㆍSelect All: selects all scenes in a motion file.

⑧

wCK module

Control Detail

ㆍID: displays the ID number of the wCK module.

ㆍS.Pos: stands for Start Position and it displays the start position of the wCK module in

unit of control angle.

ㆍD.Pos: stands for Destination Position and it displays the destination position of the

wCK module in unit of control angle.

ㆍDisp: stands for Displacement and it displays the control angle difference between

S.Pos and D.Pos.

ㆍTorq: It displays the speed of the wCK module.(0: Very fast, -4: Very slow)

ㆍPort: displays the status of the LED installed on the I/O port of the wCK module.

⑨

Scene Editing

ㆍScene Name: displays the scene name.

ㆍFrames: displays the number of frames, into which a scene is divided.

ㆍTr.Time[ms]:

displays the transition time that is used for operating the corresponding scene.

⑩

Task Info

ㆍ displays the task related information such as the PC port connected, communication

speed, number of wCK modules connected, robot type, etc.

Page 69

70

RBC Upgrade Tool

The screen layout of the RBC Upgrade Tool is as below.

No. Area Name Descriptions

①

Connection It selects the port connected between PC and RoboBuilder and the transfer speed

②

File Selection

It selects the firmware file to upgrade.

Click [Click here and Push Button] for upgrade.

(Press the Reset button that is located between PF1 and PF2 LEDs on the control box)

③

Upgrade It displays the upgrade status of the status display line.

④

Exit It ends the firmware upgrade program.

Page 70

71

Chapter 3. Operating RoboBuilder

Connecting RoboBuilder with PC

RoboBuilder robot connects to a PC via an RS232 serial cable. First check the PC’s com port

number assignment and connect the RS232 cable to the RoboBuilder.

The appropriate platform type(HUNO, DINO, DOGY) should be set on the control box (use PF1 or

PF2 button) as instructed on page 72.

Checking PC serial Port

01 Right-click [My Computer] icon on Desktop

and select the [property(R)] button.

Check the com port number assigned to the port into which the RS232 communication cable will be

plugged.

02 Select the [Hardware] tab in the

[System Registration Information] window

and click [Device Manager].

03 Select [Port] in the [Device Manager]

window and check the serial port number

assigned from PC.(COM1, COM2, etc.)

When the PC has no serial port, separately

purchase and use a USB to Serial converter

to connect RoboBuilder with PC.(refrain from

using a converter of poor quality)

Connecting the Serial Cable

After checking the port assigned from PC, plug the

RS232 cable that is provided in the product package

to connect the RoboBuilder and PC.

Page 71

72

Setting Robot Platform

Appropriate platform type(HUNO, DINO, DOGY) should be set on the control box before connecting

RoboBuilder with a PC. For example, it your robot is a HUNO but control box is set as DOGY platform,

the robot won’t operate properly. Robobuilder will think the robot is in the form of the configured

platform. Below is how to set and check the correct robot platform type on control box.

In case your robot is a non-standard platform(other than HUNO, DINO, and DOGY), press PF2 button

for 3 seconds until PF2 LED turns on orange.

HUNO - PF1 turns on blue LED

DINO - PF1 turns on pink LED

DOGY - PF1 turns on red LED

Press PF1 button

for 3 seconds

Press PF1 button

for 3 seconds

Press PF1 button

for 3 seconds

Non-standard platform - PF2 turns on orange LED

Page 72

73

Chapter 3. Operating RoboBuilder

Operating Control Box

By manipulating the control box, you can turn on the robot, select the platform type as well as

change to different modes such as PC control mode, battery recharge mode, firmware upgrade mode.

Function Manipulation Descriptions

Power ON Turn on the power switch.

It performs self-test(LEDs sequentially turns on and

off) and set as the most recently used platform.

ㆍHUNO: PF1 LED turns blue

ㆍDINO: PF1 LED turns pink

ㆍDOGY: PF1 LED turns red

ㆍNon-standard mode: PF2 LED turns orange

Power OFF Turn off the power switch. All LEDs turned off.

Power Status LED display

Different Power LED indicates different status of

battery charge level.

ㆍPOWER LED Green: Battery charge is sufficient

ㆍPOWER LED Red: Battery charge insufficient

ㆍPOWER LED Red turns on and off:

Immediate charge required

ㆍPOWER LED Green turns on and off:

In Charging mode

Home Posture

Turn on the power with PF1 button pressed

and release the button after 2 seconds.

Robot slowly takes the home posture.

(Only applicable for HUNO)

PC Control

Mode

Turn on the power with PF2 button pressed

and release the button after 2 seconds.

The control box is changed to PC control mode.

ㆍPF1 LED: Blue LED turns off

ㆍPF2 LED: Orange LED turns off

Platform

Setting

Press PF1 or PF2 button for 3 seconds.

Each time PF1 button pressed for 3 seconds, the

platform is changed in sequence

(HUNO ⇒ DINO ⇒ DOGY)

ㆍHUNO: PF1 LED turns blue

ㆍDINO: PF1 LED turns pink

ㆍDOGY: PF1 LED turns red

* When PF2 button is pressed for 3 seconds, it is changed

to non-standard platform. (Orange LED turns on)

Remote

Controller

Registration

Turn on the power switch with both PF1 and

PF2 buttons pressed and release the buttons

after 2 seconds. When the blue Run LED

blinks, use remote control and press the red

button (

) in the middle towards robot.

Press the red button(

) of the remote control

within 10 seconds for successful registration.

If registration is successfully completed, all LEDs of

control box blink together three times and the robot

turns into standby mode.

* When firmware of control box is upgraded, user should

register the remote controller again.

Power Switch

PF1 Button

(Standard platform)

PF2 Button

(Non-standard platform)

Reset Button

Page 73

74

Using Remote Control

The best way to use the remote control is to have remote controller point to the top of robot’s head.

Because the IR sensor unit is installed inside the top cover of head.

Whenever a robot is turned on, press red button in the middle to have your robot take basic posture

before playing with other buttons. Otherwise the buttons won’t work properly.

(This is a setting to prevent users from being injured by robot’s unexpected sudden action)

Button Motion Button Motion

Perform motion number 1

Perform motion number 11

Perform motion number 2

Perform motion number 12

Perform motion number 3

Perform motion number 13

Perform motion number 4

Perform motion number 14

Perform motion number 5

Perform motion number 15

Perform motion number 6

Perform motion number 16

Perform motion number 7

Perform motion number 17

Perform motion number 8

Perform motion number 18

Perform motion number 9

Perform motion number 19

Perform motion number 10

Perform motion number 20

ㆍ Do not use the remote control under a strong fluorescent lamp light. The IR sensor unit inside the top cover of head

may be affected by the fluorescent light.

ㆍ Maximum 5 remote controls can be registered to one control box, which means 5 different users can control a robot

together. If a user registers a 6th remote control, the 1st remote control information is deleted, so the control box only

remembers the most recently registered 5 remote controls.

Stand Up A

Stand Up B

Move Forward

Left Turn

Right Rurn

Side Step to the left

Side Step to the right

Arm Attack to the left

Arm Attack to the right

Move Backward

Basic Posture.

Buttons for downloaded

motions

Buttons for Basic Motions

Buttons for User

Defined Motions

(press a numeric button with

button pressed)

Page 74

75

Chapter 3. Operating RoboBuilder

Programming

Before starting programming, turn on your PC, run the MotionBuilder program, and then connect

RoboBuilder with your PC through the PC cable. Set RoboBuilder to “PC Control Mode” before it

is connected with PC. If you are planning on programming for long time connect the

power adapter too.

A motion file is what defines the RoboBuilder’s movements(file extension is .rbm).

If RoboBuilder can display a motion, then this motion file is played in the control box. A project file

includes more than one motion file and is used to manage multiple motion files efficiently. A motion file

consists of more than one scene.

ㆍProject file: It consists of multiple motion files that are created or edited by a user.

ㆍMotion file: It consists of multiple scenes and executes a complete motion.

ㆍScene: It is a smaller motion unit that constitutes a complete motion file, which contains the information such as

frames, Tr. Time, movement of wCK modules, LED lighting, etc.

ㆍFrame: It is a smaller motion unit that constitutes a scene.

The greater the number of frames, the smoother the robot’s motion will tend to be.

Page 75

76

Creating New Robot File(example, HUNO)

02 Select [New] on the menu bar. In the [New Project] window, assign project name, select the

location to save the project file, and robot platform type. Then click [OK].

03 new project for HUNO is created and HUNO image shows up and the basic information of the

wCK modules appear on the [Robot Configuration] area.

01 Set ComPort and BaudRate, and click OpenPort( ). If the connection between PC and

RoboBuilder is normal, the button changed to ClosePort(

).

Do not be surprised because the robot

can move suddenly at this moment.

Page 76

77

Chapter 3. Operating RoboBuilder

04 Select [New Motion] to add a new motion file into the project. Select the motion file name

and save path etc, and click [OK]

06 The new scene is now registered and the total scene is changed to “1.”

05 Register the first scene in the created motion file. Set the name of the scene, the number of

frames, and Tr.Time, and click [OK].

Tr.Time/Frame = 20~50 recommended,

Do not set this value less than 20.

Page 77

78

No. Name Description

①

ID It displays the ID number of the wCK module.

②

S.Pos It displays the start position of the wCK module as in control angle.

③

D.Pos It displays the destination position of the wCK module as in control angle.

④

Disp It displays the displacement between D.Pos and S.Pos as in control angle.

⑤

To rq It displays the motion speed of the wCK module.

⑥

Port

It displays the LED status of the wCK module.

(only available for transparent wCK module)

⑦

Scene.Name It displays the name of the scene.

⑧

Frames It displays the number of frames.

⑨

Tr.Time[ms] It displays the transition time of the corresponding scene. (Unit: ms)

The control angle 1 means the physical angle 1.05° (degree).

07 When you press [Test] button, the robot moves to the destination position of the selected scene

and the [Test] button get changed to [Return] button. In this state, set the posture of the robot

by adjusting the angles of wCK modules. You can drag the red point in the jog buttons for wCK

modules on the [Robot Configuration] area.

When you adjust the angle by using the red point on the wCK module jog button, slowly rotate the red

point because a sudden movement of robot may cause the robot to fall or an injury to user.

The angle setting is available within the

range of the minimum and maximum

value stored in the [Config] menu.

Page 78

79

Chapter 3. Operating RoboBuilder

08 When the desired posture with required destination positions are set, click [Return].

The changed settings are saved in the scene and the [Return] button is changed back to [Test].

If a scene is clicked, the robot moves to start position of the corresponding scene.

If you click on a scene click [Test], the robot shows the motion saved in the scene by moving to the destination

position. More than one scene can be selected and tested by dragging multiple scenes. If the [Repeat] check box

is selected in the Motion File Information area, the robot repeatedly performs the selected scenes.

For more precise control of the wCK module angle when setting the destination

position, the user can follow the three different methods instructed below:

1. Adjusting by changing D.Pos value

① Select the scene to change and click [Test].

② When the button is changed to [Return],

double-click the D.Pos value of the wCK module to change.

③ Type in the numeric D.Pos value and press ENTER.

④ Click [Return] to save the changed value.

2. Adjusting by changing Disp value

① Select the scene to change and click [Test].

② When the button is changed to [Return],

double-click the Disp value of the wCK module to change.

③ Type in the numeric Disp value and press ENTER.

④ Click [Return] to save the changed value.

3. Teaching Method(Posture Capture using [Get Pos] button)

Refer to P84 for details about Motion-Teaching method

① Select the scene to change and click [Test].

② When the button is changed to [Return], click [Get Pos].

③ Select the wCK modules to adjust and click [Close].

④ Now the selected wCK modules are in Teaching Mode so manually

adjust posture of the robot using hands.

⑤ Click [Capture].

⑥ Click [Return] to save the changed settings.

Page 79

80

10 Select added scene, click [Test] (it is changed to [Return] button), and adjust the posture for the

destination position.

11 When programming is completed, click [Save All] to save the project and motion file information.

09 Click [New Scene] to add another scene. Give the new scene a name, the required number

of frames, and the Tr.time. Then click [OK]. A new scene is added.

Repeat the process of adding scenes as shown above until you finish a complete motion file.

Page 80

81

Chapter 3. Operating RoboBuilder

Modifying Robot File(example, HUNO)

To modify an existing motion file, follow the instructions below:

01 Set ComPort and BaudRate, and click OpenPort( ). If the connection between PC and

RoboBuilder is normal, the button changed to ClosePort(

).

02 Select [Open] on the menu bar. Select the desired project in the [Open Project] window and

click [Open]. (e.g. HunoBasic.prj)

03 The settings of the wCK modules appear in the [Robot Configuration] window. At the same time,

the first motion file that is saved in the project opens.

In case of HunoBasic.prj, the

HunoBasic_PunchLeft motion opens.

In order to modify a motion file that

you downloaded from Internet, add the

motion file to a desired project first.

Page 81

82

04 Open [Motion List] menu. Choose a motion file to modify and click [Open to Edit].

The selected file opens.

05 When the scene to modify is selected, the robot moves to the start position of the corresponding

scene and the wCK module angle appears in the [Robot Configuration] window. Detailed control

information is shown on the [wCK Module Control Detail] area in the middle of the screen.

06 When the selected scene is double-clicked, the detail information of the scene will appear

in a pop-up window. Change the scene name, number of frames, and Tr.Time if needed.

Page 82

83

Chapter 3. Operating RoboBuilder

07 To change a scene, select the scene and click [Test]. The robot moves to destination position and

stops. Use the jog buttons of wCK modules in the [Robot Configuration] area to adjust the angles

of required wCK modules. When the angle adjustment is completed, click [Return] to save the

change.

08 When the required scene modification is completed, click [Save All] to save the project

and motion file.

For more precise control of the wCK module angle when setting destination

position, user can follow the three different methods instructed below:

1. Adjusting by changing D.Pos value

① Select the scene to change and click [Test].

② When the button is changed to [Return], double-click the D.Pos value

of the wCK module to change.

③ Type in the numeric D.Pos value and press ENTER.

④ Click [Return] to save the changed value.

2. Adjusting by changing Disp value

① Select the scene to change and click [Test].

② When the button is changed to [Return], double-click the Disp value

of the wCK module to change.

③ Type in the numeric Disp value and press ENTER.

④ Click [Return] to save the changed value.

3. Teaching Method(Posture Capture using [Get Pos] button)

① Select the scene to change and click [Test].

② When the button is changed to [Return], click [Get Pos].

③ Select the wCK modules to adjust and click [Close].

④ Now the selected wCK modules are in Teaching Mode so manually

adjust posture of the robot using hands.

⑤ Click [Capture].

⑥ Click [Return] to save the changed settings.

Refer to P84 for details about Motion-Teaching method

Page 83

84

Quick & Easy Motion-Teaching Programming Method

What is the Motion-Teaching Programming Method?

The motion-Teaching Programming Method is a quick & easy way of creating robot’s motions.

When editing a scene, click the [Get Pos] button in the middle of screen and use your hands to

adjust the angles of desired wCK modules freely.

The captured posture is saved as the destination position of the selected scene.

The destination position is automatically saved as the start position of the next scene.

01 Select a scene to edit and click [Test].

Robot moves to destination position of the scene and the [Test] button is changed to [Return].

02 Click [Get Pos] in the middle of screen.

A wCK module selection window appears and the button is changed to [Capture].

You can either add a new scene or select an existing scene.

Page 84

85

Chapter 3. Operating RoboBuilder

06 Click [Return] to save the change and close.

07 If the adjusted posture is not perfect, repeat the step 01 to 06.

03 Check the desired IDs of wCK modules to be adjusted and click [Close].

If you touch and handle the wCK modules with your hands, you can feel the selected modules

are now free of Torque and freely movable.

Now the selected wCK modules are in “Teaching Mode”. The unselected wCK modules are powered with torque

and difficult to rotate, which is set to help the robot stand still.

05 When finished with manual posture adjusting, click [Capture] to load in the change.

The [Capture] button returns to [Get Pos] buttion.

04 Use your hands to freely adjust the desired posture of the robot.

Be careful not to forcefully rotate the unselected wCK modules.

Page 85

86

Modifying Downloaded Robot File

The following section explains how to modify robot files that a user has downloaded from the Internet.

01 Set ComPort and BaudRate, and click OpenPort( ). If the connection between PC and

RoboBuilder is normal, the button changed to ClosePort(

).

02 Select [Open] on the menu bar. Select the desired project in the [Open Project] window and

click [Open]. (e.g. HunoBasic.prj)

Page 86

87

Chapter 3. Operating RoboBuilder

03 Choose [Motion List] menu and click [Add to Project] to select the file that you downloaded

from Internet and saved in your hard disk.

Click [Open to Edit] button to open the motion file.

04 Follow the steps of 05~08 of [Modifying Existing Robot File] section in page 82~83.

Page 87

88

Transferring Robot File to Control Box

You should first transfer and save robot files to control box before playing the robot using remote

control. Any robot file that you created with Motion Builder or downloaded from the Internet can be

used. The file transfer is done as per the instructions below.

01 Set ComPort and BaudRate, and click OpenPort( ). If the connection between PC and

RoboBuilder is normal, the button changed to ClosePort(

).

02 Click [Download] on the menu bar.

Select the robot file to transfer to control box, and click [Open].

Page 88

89

Chapter 3. Operating RoboBuilder

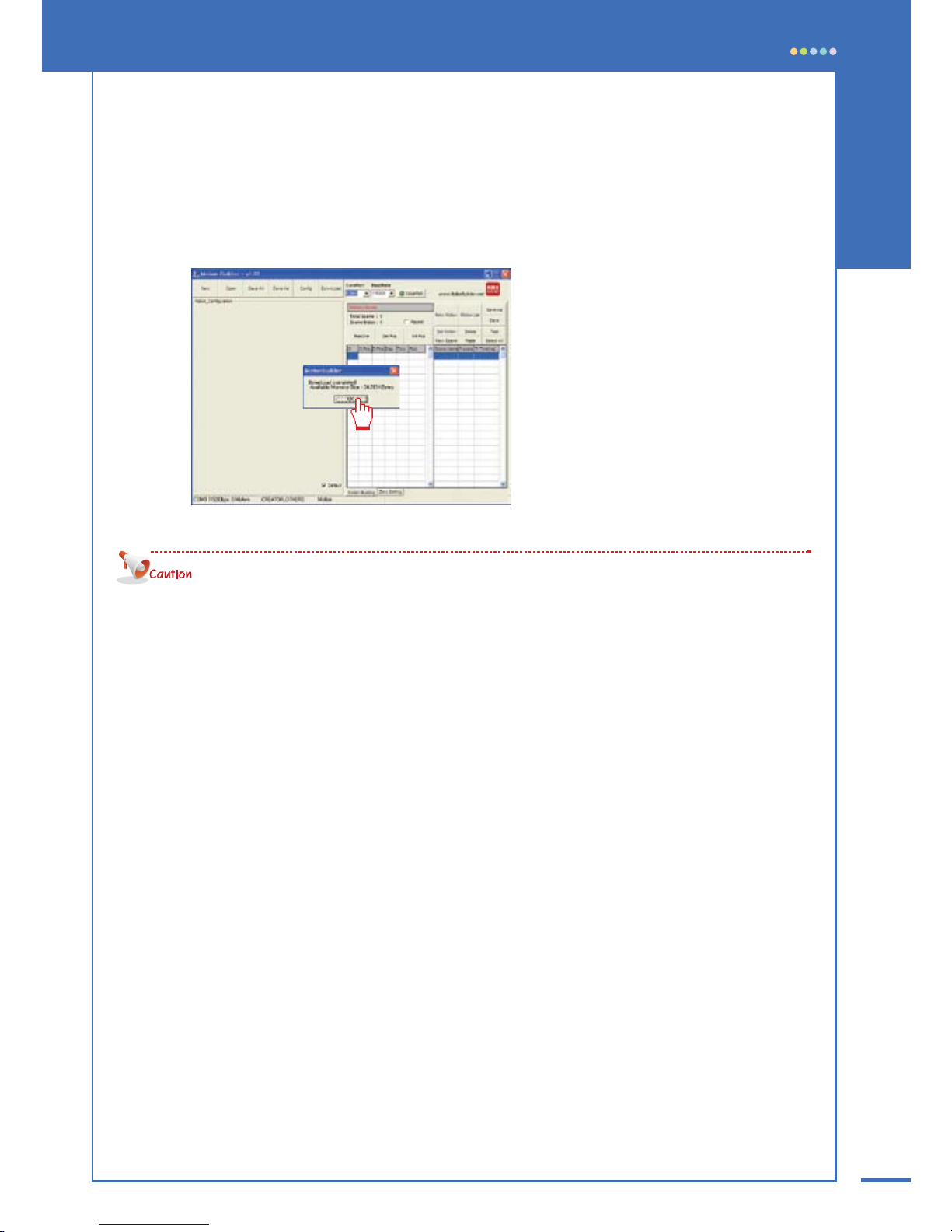

03 The selected [motion file] is transferred to control box. When download completed, success

message appears. Click [OK] to finish.

Repeat step 02 and step 03 until you transfer all required files.

· Once file transfer starts, all robot files already existing in control box are deleted and new files saved from

the beginning. So the first file transferred is assigned to button 1 of remote control, the second file transferred is

assigned to button 2, and the third file to buttion 3 and so on. So you have to plan and decide which robot

file to be assigned to which button of remote control before you actually start the file transfer.

· If the size of a certain robot file is too large, the control box may not be able to save up to 20 files.

· The motion performed with MotionBuilder can be a little bit different from the motion actually performed with

the transferred motion file.

Page 89

90

Playing with Robot

When building and programming are completed, you can play the RoboBuilder and have it play

the motions saved in control box by using remote control.

01 Turn on the control box and press the basic posture button ( ) on the remote control.

(Unless the basic posture button is pressed, other buttons do not work.)

02 According to platform type, the Robot takes its basic posture.

03 Perform motions by pressing the basic motion buttons or user defined motion buttons on

the remote control.

04 RoboBuilder performs best when the robot is located on a flat, horizontal, and hard floor.

A robot may lose balance, fall down, or show an awkward movement on a floor which is

uneven, or made from rough material such as carpet, rug etc.

05 The basic motions of the standard platform robots(HUNO,DINO,DOGY) are available and

playable immediately after building is completed. Use the buttons for basic motions.

For more information on the remote control, refer to the “Using Remote Control” section on page 74.

Page 90

91

Chapter 3. Operating RoboBuilder

Recharging Battery

To charge the battery enclosed in the control box, connect the adapter to the control box as shown

in below picture and turn on the power to prepare for charging.

The battery charging takes one and a half hour and automatically stops when finished.

Press the

button and button

on the remote control at the same time.

When charging begins, the green LED starts blinking.

Blinking stops when charging finished.

· If you choose to press PF1 and PF2 buttons on the control box, make sure the two buttons are pressed

simultaneously. Otherwise robot may execute another function.

·When shipped from the factory the battery pack are not charged.

So please use power adapter to operate the robot the first time.

·The enclosed power supply is used not only for recharging the battery but also for supplying direct power to the robot.

So it can be used as an alternative to the battery and be used to operate the robot continuously

(This function is not supported when recharging battery).

How to Start Battery Charging

Press the PF1 button and PF2

button at the same time for more

than 3 seconds.

Or

· If battery is fully charged, the robot can operate continuously approximately for 10 minutes to 30 minutes.

The operation time varies depending on the characteristics of a robot file, i.e. the types of motions performed.

·If you leave the controller on for long time with power on, it may cause a failure or a damage to battery.

·When you recharge the battery more than twice consecutively, it may cause a failure or a damage to

the battery.

Page 91

92

Replacing Battery

The battery replacement procedure is as follows:

01 Remove the four bolts from the cover of control box.

02 Replace the batteries after disconnecting the connector.(Battery Type: 8.4V Ni-MH)

03 Close the cover of the control box and screw in the four bolts.

Page 92

93

Chapter 3. Operating RoboBuilder

Setting Home Posture

In case of HUNO, if RoboBuilder’s motion is unstable or abnormal, you can choose to adjust the

Home Posture. For example, if robot’s movement is different from what it is supposed to be and it

doesn’t move as the way the robot file defines, you can correct the problem by adjusting the Home

Posture. The Home Posture adjustment is done as follows:

Using the Package Tray

You can adjust the home posture by using the plastic tray provided with the product package.

01 Prepare fully assembled HUNO and tray.

02 Run MotionBuilder software and connect RoboBuilder with PC using PC cable.

Set Com port and BaudRate and click OpenPort(

). If the connection between PC

and RoboBuilder is normal, the button will change to ClosePort(

).

When the connection is ready, select the [ZERO Setting] tab.

RS232 Cable

Page 93

94

04 Click [Open] on the menu bar to open a HUNO project. Any HUNO project will work.

05 Click [ZeroCaptureReady] and use hands to make sure that HUNO is correctly inserted into

the tray. The front HUNO should be tightly touching the hollow surface of tray.

03 Lay down HUNO into the tray as shown in the picture.

Turn on the control box as in PC Control Mode.

Page 94

95

Chapter 3. Operating RoboBuilder

Make sure that HUNO is laid down tightly into the tray by pressing some points of robot’s back side.

Follow the sequence as shown below.

① Press position 1( ) vertically together by using thumbs and index fingers of two hands.

② Use one hand to vertically press position 4(

) and use the other hand to press position 2( ).

③ Press position 3( ) vertically with two hands.

④ Repeat step② to press position 4( ) and position 2( ) together.

Correct Home Posture can be secured only when the front of the robot is tightly attached to the hollow surface

of tray.

06 If robot is laid correctly, click [ZeroCapture]. The current posture is copied in as one of the

five sampling postures and pop-up windows appears saying “4 times left”. Click [OK].

Page 95

96

07 Pull out HUNO from tray and release wCK modules.

Follow step 05 and 06 to complete the required 5 of posture captures.

When the adjustment is completed, a pop-up window appears saying “Complete!”. Click [OK].

08 Click [Save Zero & Set to RBC] to save the home posture and apply it to control box.

click [OK].

09 Remove HUNO from the tray and click [ZeroPose] to check if new home posture is correctly

configured or not.

Page 96

97

Chapter 3. Operating RoboBuilder

Adjusting Home Posture Manually

Without using the tray, you can also adjust robot’s home posture manually.

01 Run MotionBuilder software and connect RoboBuilder with PC using PC cable.

Set Com port and BaudRate and click OpenPort(

). If the connection between PC

and RoboBuilder is normal, the button will change to ClosePort(

).

When connection is ready, select the [ZERO Setting] tab.

02 Click [Open] on the menu bar to open a HUNO project. Any HUNO project will work.

RS232 Cable

Page 97

98

03 When you click [ZeroControlReady], the screen is changed to a mode where you can manually

adjust the home posture.

04 Adjust the home posture by using the jog buttons of wCK modules in the

[Robot Configuration] area.

Page 98

99

Chapter 3. Operating RoboBuilder

05 When adjustment is completed, click [StopZeroControl].

06 Click [Save Zero & Set to RBC] to save the home posture and apply it to control box.

Page 99

100

Manipulating Home Posture File

This button fetches the zero point file saved in control box.

This button applies the changed

home posture values to control box.

This button makes the robot take the

corresponding home posture.

This button saves a copy the home

posture file as a different name.

This button loads up any home posture

file separately saved elsewhere.

Page 100

101

Chapter 3. Operating RoboBuilder

Upgrading Firmware

The procedure to upgrade control box with up-to-date firmware is as follows.

01 Run “RBC Upgrade Tool” software and turn on the control box.

02 Connect control box with PC using RS-232 cable. Set Com Port and Baud Rate.

03 Select the firmware file to use for upgrade by clicking the folder icon.

click [Open] when firmware hex file is selected.

04 Click [Click here and Push Button] to enter “upgrade ready state”.

Loading...

Loading...