Page 1

Instructions Manual

Manuel d’Instructions

Bedienungsanleitung

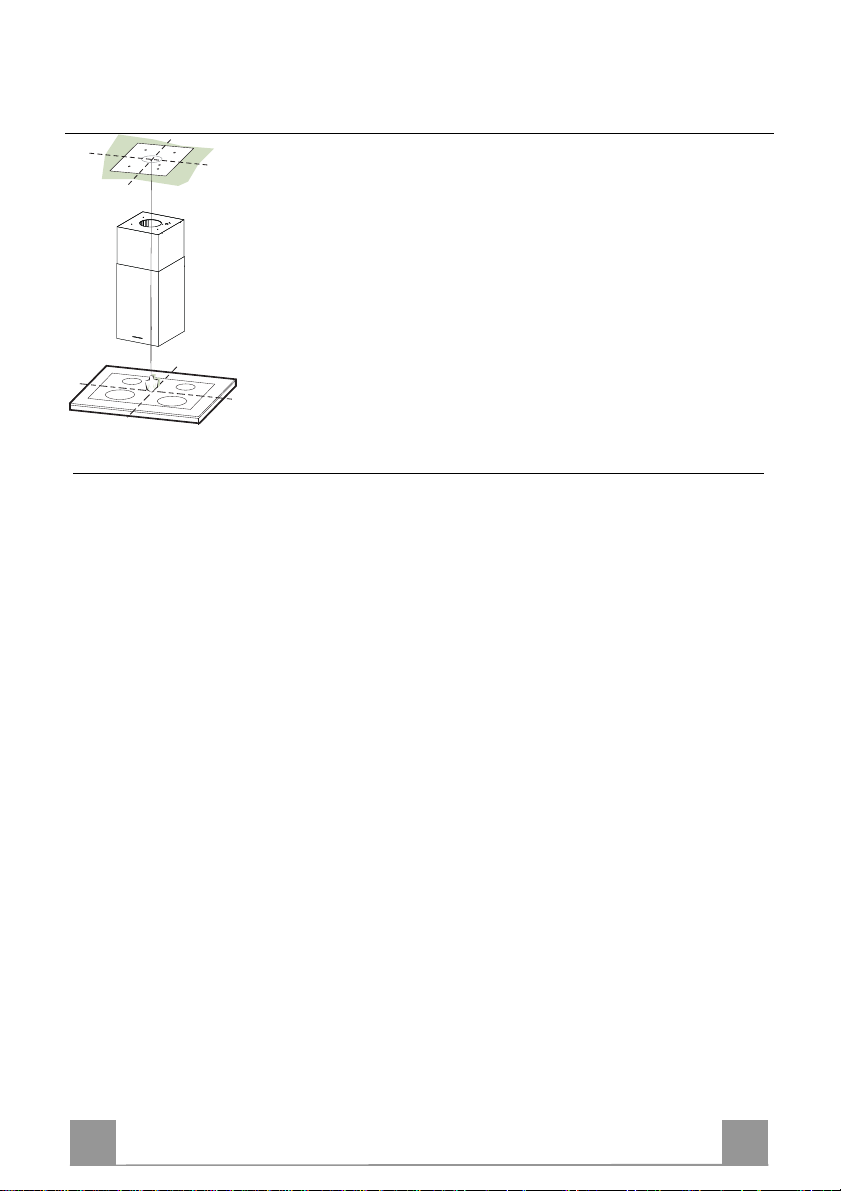

Cubix Centrale 600

Libretto di Istruzioni

Page 2

EN

Instructions Manual

INDEX

RECOMMENDATIONS AND SUGGESTIONS....................................................................................................................17

CHARACTERISTICS............................................................................................................................................................18

INSTALLATION ....................................................................................................................................................................20

USE.......................................................................................................................................................................................24

MAINTENANCE....................................................................................................................................................................25

3

3

Page 3

FR

Manuel d’Instructions

SOMMAIRE

CONSEILS ET SUGGESTIONS ..........................................................................................................................................28

CARACTERISTIQUES.........................................................................................................................................................29

INSTALLATION ....................................................................................................................................................................31

UTILISATION........................................................................................................................................................................35

ENTRETIEN..........................................................................................................................................................................36

4

4

Page 4

EN 117

650 mm min.

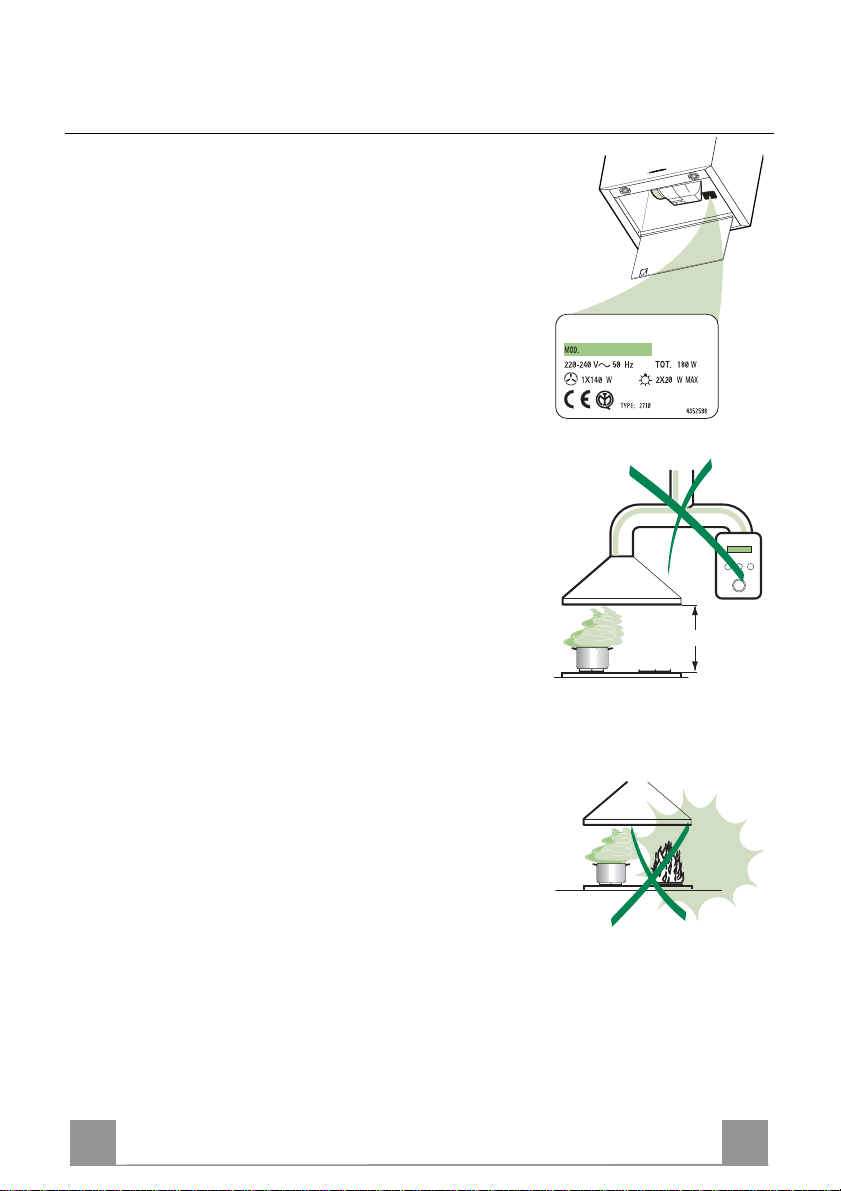

RECOMMENDATIONS AND SUGGESTIONS

INSTALLATION

• The manufacture r will not be held liable for any damages resulting

from incorrect or improper installation.

• The minimum safety distance between the cooker top and the extrac tor hood is 650 mm.

• Check that the mains voltage corresponds to that indicated on the

rating plate fixed to the inside of the hood.

• For Class I applianc es, c heck t hat th e domes tic po wer suppl y gua rantees adequate earthing.

Connect the extractor to the ex haust flue through a pi pe of minimum

diameter 120 mm. The route of the flue must be as short as possible.

• Do not connect the extractor hood to exhaust ducts carryi ng combustion fumes (boilers, fireplaces, etc.).

• If the extractor is used in conjuncti on with non-electrical appliances

(e.g. gas burning appliances), a suffici ent degree of aeration must be

guaranteed in the room in order to prevent the backflow of exhaust

gas. The kitchen must have an opening communicating directl y with

the open air in order to guarantee the entry of clean air.

USE

• The extractor hood has been designe d ex cl usi vely for domesti c us e to

eliminate kitchen smells.

• Neve r use the hood for pu rposes other than fo r which it has ben designed.

• Never leave high naked flames under the hood when it is in operation.

• Adjus t the flame intensity to direct it onto the bottom of the pan only,

making sure that it does not engulf the sides.

• Deep fat fryers must be continuously monitored during use: overheated oil can burst into flames.

• The hood should not be used by chil dren or persons not inst ructed in

its correct use.

MAINTENANCE

• Switch off or unplug the appliance from the mains supply before carrying out any maintenance work.

• Clean and/or replace the Filters after the specified time period.

• Clean the hood using a damp cloth and a neutral liquid detergent.

Page 5

EN 118

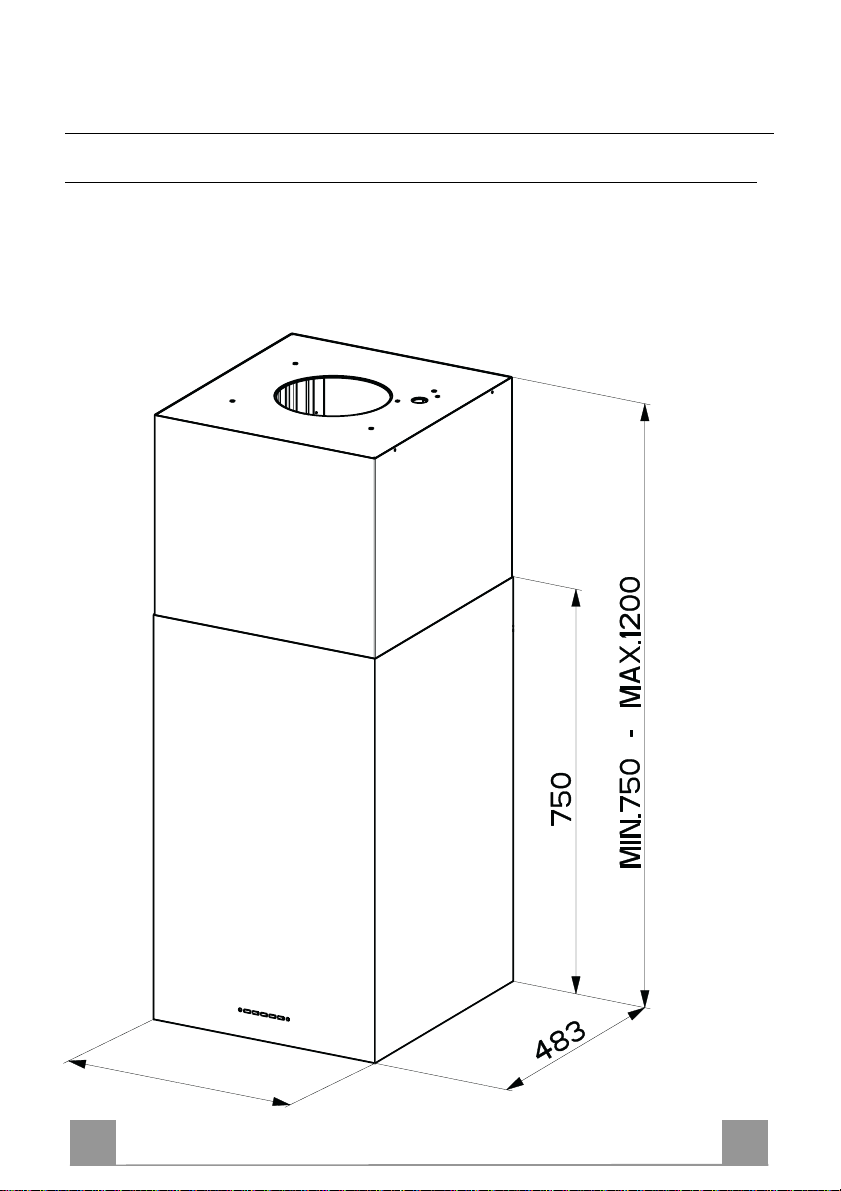

CHARACTERISTICS

Dimensions

448-598

Page 6

EN 119

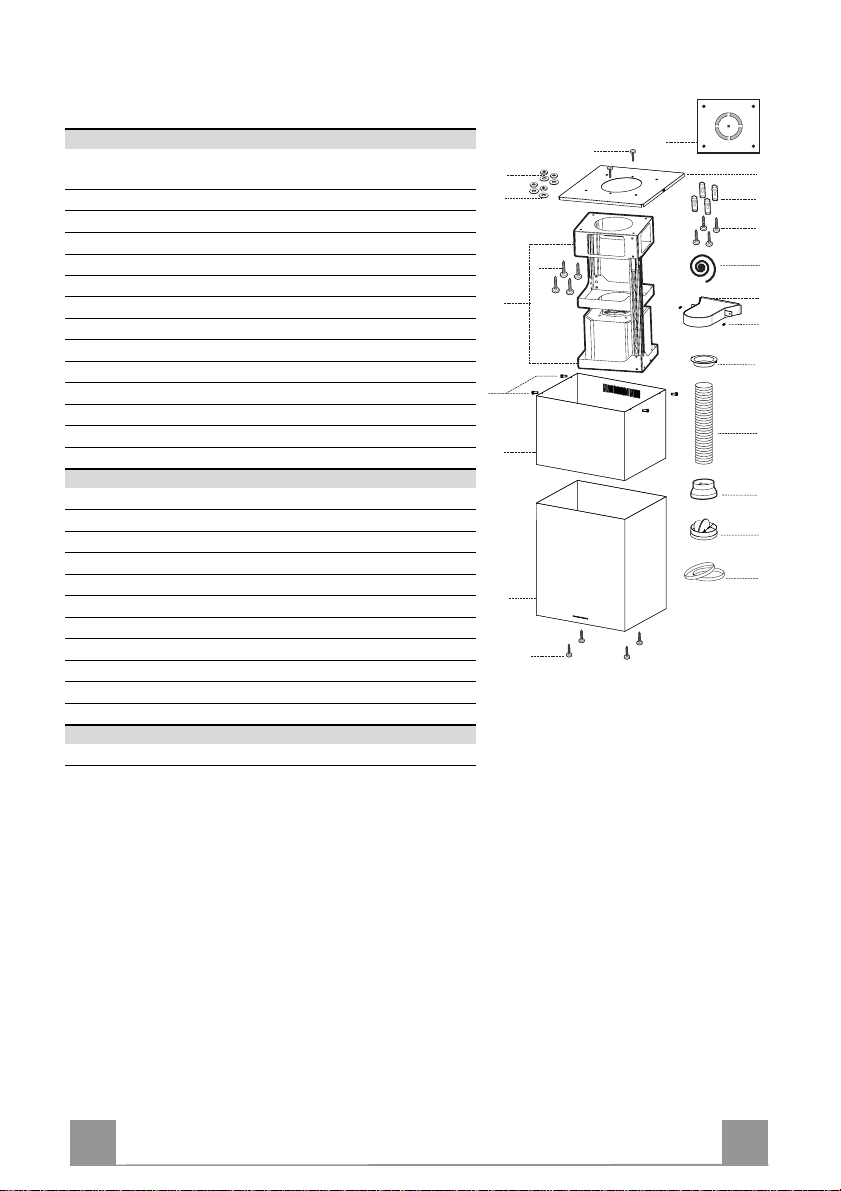

Components

Ref. Q.ty Product Components

1 1 Hood Body, complete with: Controls, Light, Blower,

Filters

2 1 Upper Chimney

7.1 1 Telescopic f rame complete with extrac tor, consisting of:

7.1a 1 Upper frame

7.1b 1 Lower frame

9 1 Reducer Flange ø 150-120 mm

10 1 Damper

13 1 Gasket

14 1 Hood Body Air Outlet Extension Piece

15 1 Air Outlet Conn ection

25 2 Pipe clamps

26 1 Fixing Part of the upper Chimney

29 1 Air outlet connection tube

Ref. Q.ty Installation Components

11 4 Wall Plugs ø 10

12c 4 Screws 2,9 x 9, 5

12f 4 Screws M6 x 15

12g 4 Screws M6 x 80

12h 4 Screws 5,2 x 70

12w 2 Screws M3 x 8

21 1 Drilling template

22 4 6.4 mm int. dia washers

23 4 M6 nuts

24 2 Fixing knobs for the air outlet connection piece

Q.ty Documentation

1 Instruction Manual

12w

23

22

7.1a

12g

7.1

7.1b

12c

2

1

12f

21

26

11

12h

13

15

24

14

29

9

10

25

Page 7

EN 220

INSTALLATION

Drilling the Ceiling/shelf and fixing the frame

DRILLING THE CEILING/SHELF

• Use a plumb line to mark the centre of the hob on the ceiling/support shelf.

• Place the drilling template 21 provided on the ceiling/support shelf, making sure that the

template is in the correct position by lining up the axes of the template with those of the hob.

• Mark the centres of the holes in the template.

• Drill the holes at the points marked:

• For concrete ceilings, drill for plugs appropriate to the screw size.

• For hollow brick ceilings with wall thickness of 20 mm: drill ø 10 mm(immediately insert

the Dowels 11 supplied).

• For wooden beam ceilings, drill according to the wood screws used.

• For wooden shelf, drill ø 7 mm.

• For the power supply cable feed, drill ø 10 mm.

• For the air outlet (Ducted Versio n), drill according to t he diameter of the external air exhaust duct connection.

• Insert two screws of the following type, crossing them and leaving 4-5 mm from the ceiling:

• For concrete ceilings, use the appropriate plugs for the screw size (not provided).

• for Cavity ceiling with inner space, with wall thickness of approx. 20 mm, Screws 12h,

supplied.

• For wooden beam ceilings, use 4 wood screws (not provided).

• For wooden shelf, use 4 screws 12g with washers 22 and nuts 23, provided.

Page 8

EN 221

quired, then

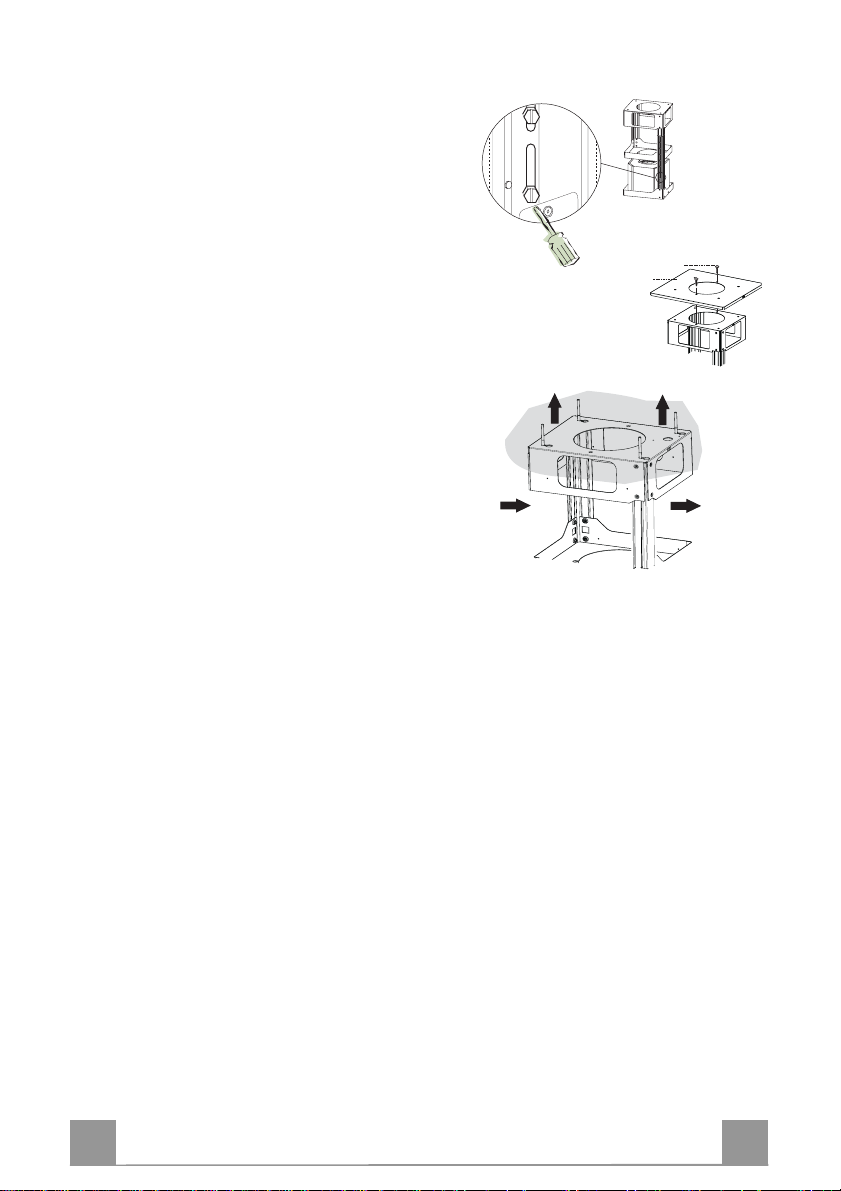

FIXING THE FRAME

If you wish to adjust the height of the frame, pro ceed

as follows:

• Unfasten the eight metric screws joining the two columns, located at the sides of the frame.

• Adjust the frame to the height re

replace all the screws removed as above.

• Fix the Fixing Part of the Upper Chimney 26 to th e

hanging kit using the 2 screws 12w (M3 x 8).

• Lift up the frame, fit the frame slots onto the screws

up to the slot end positions.

• Tighten the two screws and fasten the other two

screws provided; before locking the screws com-

pletely, it is possible to adjust the frame by turning it,

making sure that the screws do not come out of their

housing in the adjustment slot.

• It is no w possible to place and tighten the 4 safety

screws, Proceed as follows:

• drill the ceiling with a 10 mm ø bit taking as refer-

ence the holes of the side parts of the upper

chimney fixing part.

• insert the 4 dowels (provided).

• insert the washers (provided) to the screws and

tighten the screws

• The Frame must be securely fastened so as to support

both the weight of the Hood and the stress caused by

occasional axial pressure against the fitted Appliance. After fixing, make sure that the base is stable

even when the Frame is subjected to lateral stress.

• If the Ceiling is no t strong enough in the area where

the hood is to be fixed, the Installer must strengthen

the area using suitable plates and counterplates anchored to resistant structures.

12w

26

1

2

1

2

Page 9

EN 222

Connections

DUCTED VERSION AIR EXHAUST SYSTEM

When installing the ducted version, connect th e hood to

the chimney using either a flexible or rigid pipe ø 150

or 120mm, the choice of which is left to the installer.

To install a ø 150

• To install the dumper 10

• Fix the pipe in position using sufficient pipe clamps

(not supplied).

To install a ø 120

• To install a ø 120 mm air exhaust connection, insert

the reducer flange 9 on the dumper 10.

• Fix the pipe in position using sufficient pipe clamps

(not supplied).

• Remove an y activated charcoal filters.

ø 150

25

10

ø 120

25

9

10

RECIRCULATION VERSION AIR OUTLET

• Insert the reducer flange 9 on the air outlet of the extractor.

• Attach the adhesive Novastik gasket 13 to the air outlet connection 15 and fix this to the upper frame using the 2 knobs 24.

• Fix th e ai r outlet connection extensio n piece 14 to the

air outlet connection 15.

• Pl ace the air outlet connectio n tube 29 between the

two air outlets.

24

15

15

14

15

14

29

9

Page 10

EN 223

12c

12f

Flue assembly - Mounting the hood body

• Place the upper chimney section and fix the upper part to the

the Fixing Part of the Upper Chimney using the 4 screws 12c

(2,9 x 9,5) provided.

Recirculation version

• It is necessary to make sure that t he air ou tlet conn ection 15 is

placed correctly so that the ai r outlet grid in it corresponds to

that of the chimney.

• If the grids of the two parts are not corresponding to each

other, it will be necessary to remove the chimney and to adjust

the position of the air outlet connection 15, and at last to assembly the parts again by following the earlier indications.

Before fixing the hood body to the frame:

• Open the suction panel by turning the specific knob.

• Disconnect the panel from the hood canopy by sliding the fixing pin lever.

• Remove the grease filters from the hood body.

• Remove an y activated charcoal filters.

• From below, use the 4 screws 12f (M6 x 10) provided to fix the

hood body to the frame.

ELECTRICAL CONNECTION

• Connect the Hood to the mains power supply, inserting a twopole cut-out switch with contact aperture of at least 3 mm

along the line.

• Pull the Comfort Panel to open it, ensure that the supply cable

connector is properly insert ed into the Suction device socket

• Join the connectors.

• Install the odour filter and the charcoal filter in case the hood is

to be used in recycling version.

• Install the grease filter again, and successively the suction

panel.

Page 11

EN 224

has been triggered, and the filters need to be washed.

replaced; the metal grease filters must also be washed.

USE

Control Panel

The hood can be switched on pushing directly onto the requested speed without firstly having

to select 0/1 button.

KEY LED FUNCTIONS

L 0/1 Light Turns lighting on and off.

T1 0/1 Motor on First speed.

When pressed for about 2 seconds the motor is switched off.

Flashing 24h Changeover

This is enabled by pressing and holding the button for

T2 Speed on Second speed.

Flashing Delay (30')

Press the button for approximately 2" to enable auto-

T3 Speed on Third speed.

T4 Speed Fixed Max. speed

Flashing Intensive speed.

Suitable for the strongest cooking vapours and odours.

S1 Led Fixed Indicates that the Metal grease filters saturation alarm

approximately 5". It allows a suction level of 100 m3/h

with a noise level of just 28dB(A). Can be enabled at

any speed, even with the hood turned off. To disable,

press and hold the button f or appr ox ima t e ly 5" .

matic shutdown with a 30' delay. Suitable to complete

elimination of any residual smells. Can be enabled at

any speed and is disabled by pressing the button

briefly.

The function becomes active when the button is pushed

for about 2 seconds. After 10 minutes of functioning it

turns off automatically. This function can be interrupted by means of pressing any of the buttons.

The alarm is triggered after 100 working hours. (Reset;

check the Maintena nce-paragraph)

Flashing indicates that the activated charcoal odour filter satura-

tion alarm has been triggered, and the filter has to be

The activated charcoal odour filter is triggered after

200 working hours. (Activation and Reset; check the

Maintenance-paragraph)

Page 12

EN 225

MAINTENANCE

REMOTE CONTROL (OPTIONAL)

The appliance can be controlled using a remote control powered

by a 1.5 V carbon-zinc alkaline batteries of the standard LR03AAA type.

• Do not pl ace the remote control near to heat sources.

• Used batteries must be disposed of in the proper manner.

Cleaning the Comfort Panels

• Pull the Comfort Panel to open it.

• Disconnect the panel from the hood canopy by sliding the fixing pin lever.

• The comfort panel must never be washed in a dishwasher.

• Clean the outside using a damp cloth and neutral liquid detergent.

• Clean the inside as well using a damp cloth and neutral detergent; do not use wet cloths or sponges, or jets of water; do not

use abrasive substances.

• When the above operation has been completed, hook the panel

back to the hood canopy and close it by turning the knob in the

opposite direction.

Page 13

EN 226

Grease filters

CLEANING METAL SELF- SUPPORTING GREASE FIL-

TERS

Alarm signal reset

• Switch off the lights and extractor motor.

• P r ess button T3 for at least 3 seconds, until the leds

start to flash.

Cleaning the filters

• The filters are washable and must be cleaned when

the LED S1 lights up or at least every 2 months of

operation, or more frequently for particularly heavy

usage.

• Re move the filters one at a time by pushing them towards the back of the group and pulling down at the

same t ime.

• Wash the filters, taking care not to bend them. Allow

them to dry before refitting.

• When refitting the filters, make sure that the handle

is visible on the outside.

Page 14

EN 227

Activated charcoal filter (Recirculation version)

• The filter is not washable and cannot be regenerated. It must be replaced when led S1

flashes or at least every 4 months. The alarm signal will only light up when the extractor

motor is switched on.

Alarm signal activation

• In Recirculation version Hoods, the Filter saturation alarm can be enabled on installation or

at a later date. Turn the Lights and the suction Motor off.

• Disconnect the Hood using the Main switch or the double-pole switch on the mains power

supply.

• Restore the connection by pressing and holding T1.

• Release the button. All five LEDs are turned on

• Within 3 seconds press T1 until LEDs T1 and T4 flash in confirmation:

LED flashes twice - Activated charcoal filter saturation alarm ENABLED

LED flashes once - Activated charcoal filter saturation alarm DISABLED

REPLACING THE ACTIVATED CHARCOAL FILTE R

Alarm signal reset

• Switch off the lights and extractor motor.

• Press button T3 for at least 3 seconds, until the leds start to

flash.

Replacing the Filter

• Pull the Comfort Panel to open it.

• Remove the metal grease filters

• Remove the saturated activated carbon filter by releasing the

fixing hooks

• Fit the new filter by hooking it into its seating

• Replace the metal grease filters.

Lighting

LIGHT REPLACEMENT

20 W halogen light.

• Remove the 2 screws fixing the Lighting support, and pull it

out of from the Hood.

• Extract the lamp from the Support.

• Replace with another of the same type, making sure that the

two pins are properly inserted in the lamp holder socket holes.

• Rep lace the Support, fixing it in place with the two screws removed as above.

Page 15

FR 228

INSTALLATION

650 mm min.

CONSEILS ET SUGGESTIONS

• Le fabricant d écline toute responsabilité en cas de dommage dû à

une installation non correcte ou non conforme aux règles de l’art.

• La di stance minimale de sécurité entre le plan de cuisson et l a hotte

doit être de 650 mm au moins.

• Vérifier que la tensi on du sec teu r c or respond à l a val eur qui fi gu re s ur

la plaquette apposée à l’intérieur de la hotte.

• Pour les Appareils appartenant à la Ière Classe, veiller à ce que la

mise à la terre de l’installation électrique domestique ait été effectuée

conformément aux normes en vigueur.

• Connecter la hotte à la sortie d’air aspiré à l’aide d’une tuyauterie

d’un diamètre égal ou supérieur à 120 mm. Le parcours de la

tuyauterie doit être le plus court possible.

• Eviter de connecter la hotte à des conduites d’évacuation de fumées

issues d’une combustion tel que (Chaudière, cheminée, etc…).

• Si vous utilisez des appareils qui ne fonctionnent pas à l’électricité

dans la pièce ou est installée la hotte (par exemple: des appareils

fonctionnant au gaz), vous devez prévoir une aération suffisante du

milieu. Si la cuisine en est dépou rvue, pratiquez une ouverture qui

communique avec l’extérieur pour garantir l’infiltration de l’air pur.

UTILISATION

• La hotte a é té conçue exclusivement pour l’usage domestique, dans

le but d’éliminer les odeurs de la cuisine.

• Ne jamais utiliser abusivement la hotte.

• Ne pas lai sser les flammes libres à forte intensité quand la hotte es t

en service.

• Toujours régler les flammes de manière à éviter toute sortie latérale

de ces dernières par rapport au fond des marmites.

• Contrôler les friteuses lors de l’utilisation car l’huile surchauffée

pourrait s’enflammer.

• La hotte ne doit pas être utilisée par des enfants ou des per sonnes ne

pouvant pas assurer une utilisation correcte.

ENTRETIEN

• Avant de procéder à toute opération d’entretien, retirer la hotte en

retirant la fiche ou en actionnant l’interrupteur général.

• Effectuer un entretien scrupuleux et en temps dû des Filtres, à la

cadence conseillée.

• Pour le nettoyage des surfaces de la hotte, il suffit d’utiliser un

chiffon humide et détersif liquide neutre.

Page 16

FR 229

CARACTERISTIQUES

Encombrement

448-598

Page 17

FR 330

Composants

Réf. Q.té Composants de Produit

1 1 Corps Hotte équipé de: Comandes, Lumière, Filtres

2 1 Cheminée Supérieure

7.1 1 Treillis télescopique avec Aspirateur, formé par:

7.1a 1 Treillis supérieur

7.1b 1 Treillis inférieur

9 1 Flasque de Réduction ø 150-120 mm

10 1 Buse avec clapet

13 1 Joint

14 1 Rallonge Sortie Air Corps Hotte

15 1 Raccord Sortie Air

25 2 Colliers de serrage serre-tube

26 1 Fixation de la Cheminée Supérieur

29 1 Tuyau Raccord Sortie de l’Air

Réf. Q.té Composants pour l’installation

11 4 Chevilles ø 10

12c 4 Vis 2,9 x 9,5

12f 4 Vis M6 x 15

12g 4 Vis M6 x 80

12h 4 Vis 5,2 x 70

12w 2 Vis M3 x 8

21 1 Gabarit de perç age

22 4 Rondelles øi 6,4

23 4 Écrous M6

24 2 Pommeaux de fixation Raccor d Sortie de l’ Air

Q.té Documentation

1 Manuel d’instructions

12w

23

22

7.1a

12g

7.1

7.1b

12c

2

1

12f

21

26

11

12h

13

15

24

14

29

9

10

25

Page 18

FR 331

INSTALLATION

Perçage Plafond/Étagère et Fixation Treillis

PERÇAGE PLAFOND/ETAGERE

• À l’aide d’un Fil à plomb, reporter sur le Plafond/Étagère de support le centre du Plan de

Cuisson.

• Poser contre le Plafond/Étagère le Gabarit de Perçage 21 fourni avec l’appareil, en faisant

coïncider son centre avec le centre projeté et en alignant les ax es du Gabarit avec les axes du

Plan de Cuisson.

• Marquer les centres des Trous du Gabarit.

• Percer les t r ous qui ont été marqués:

• Plafond en Béton massif: en fonction des Goujons pour Béton utilisés.

• Plafond en Briques avec cha mbre à air, avec épaisseu r résistant e de 20 mm: ø 10 mm (in-

sérer immédiatement les Chevilles 11 fournies avec l’appareil).

• Plafond en Poutrage en Bois: en fonction des Vis à Bois utilisées.

• Étagère en Bo is: ø 7 mm.

• Passage du Câble électrique d’Alimentation: ø 10 mm.

• Sortie Air (Version Aspirante): en fonction du diamètre de la connexion avec les Tuyaux

d’Évacuation Externe.

• Visser deux vis en les croisant et en laissant 4-5 mm. de distance par rapport au plafond:

• pour le Béton massif, des Goujons pour Béton, non fournis avec l’appareil.

• pour Briques percées, ayant u ne épaisseur résistante de 20 mm. en viron, utiliser les Vis

12h, fournies avec l'appareil.

• pour le Poutrage en bois, 4 Vis à bois, non fournies avec l’appareil.

• pour l’Ét agère en Bois, 4 Vis 12g avec Rondelles 22 et Écrous 23, fournis avec l’appareil.

Page 19

FR 332

FIXATION DU TREILLIS

Si l’on souhaite régler la hauteur du treillis, effectuer

les opérations suivantes:

• Dévisser les huit vis métriques q ui unissent les deux

co-lonnes, qui se trouvent sur les côtés du treillis.

• Régler la hauteur souhaitée du treillis et revisser les

vis qui ont été précédemmen t retirées.

• Fixer la Fixation de la Cheminée Supérieure 26 au

trellis à l’aide des 2 Vis 12w (M3 x 8).

• Soulever le treillis, encastrer les oeillets sur les vis et

faire coulisser jusqu’à la butée;

• Serrer les deux vis et visser les deux autres vis four nies avec l’appareil; avant de serrer défini-tivement

les vis, il est possible d’effectuer des réglages en

tournant le treillis, en veillant à ce que les vis ne sortent pas du logement de l’oeillet de réglage.

• Maintenant il est possible de visser les 4 vis de sécurité; pour effectuer cette opération, suivre les instructions suivantes :

• percer le plafond,avec une mèche de ø 10, en uti-

lisant les trous qui se trouvent sur les côtés u dispositif de fixation de la cheminée supérieure.

• Insérer les 4 chevilles fournies avec l’appareil.

• Insérer les Rondelles fournies avec l’appareil dans

les vis, puis serrer.

• La fixation du Treillis doit être effectuée de façon

sûre, en fonction du poids de la Hotte et des contraintes provoquées par des poussées latérales occasionnelles de l’Appareil monté. Après avoir effectué la

fixation, vérifier que la base soit stable, même si le

Treillis est soumis à des contraintes de flexion.

• Dans toutes les éventualités selon lesquelles le Plafond ne serait pas suffisamment robuste en correspondance du point de suspension, l’Installateur devra

se charger de le rendre plus solide avec des plaques

et contre-plaques approp riées, ancrées aux parties résistantes, du point de vue structu rel.

12w

26

1

2

1

2

Page 20

FR 333

Branchements

SORTIE AIR VERSION ASPIRANTE

En cas d’installation en version aspirante, brancher la

hotte à la tuyauterie de sortie via un tube ri-gide ou

flexible de ø 150 ou 120 mm, au choix de l’installateur.

branchement avec un tube de ø150

• Insérer la buse avec clapet 10.

• Fixer le tube par des colliers appropriés. Le matériau

nécessaire n’est pas fourni.

branchement avec un tube de ø120

• Insérer le flasque de réduction 9 sur la buse avec clapet 10.

• Fixer le tube par des colliers appropriés. Le matériau

nécessaire n’est pas fourni.

• Retirer les éventuels filtres anti-odeur au charbon

actif.

ø 150

25

10

ø 120

25

9

10

SORTIE AIR VERSION FILTRANTE

• Insérer la Flasque de raccord 9 sur la sortie de

l’Aspirateur.

• Fixer la Garniture Adhésive Novastik 13 sur le Raccord Sortie de l’Air 15 et fixer celle-ci au treillis supérieur, au moyen des 2 Pommeaux 24.

• Fixer la Flasque de Raccord Sortie de l’Air 14 au

Raccord Sortie de l’Air 15.

• Connecter les deux sorties au Tuyau Raccord Sortie

de l’Air 29.

24

15

15

14

15

14

29

9

Page 21

FR 334

12c

12f

Montage de la Cheminée et Fixation du Corps de la

Hotte

• Placer la Cheminée sup érieure et fixer celle-ci à la partie supérieure de la fixation du conduit Supérieure à l’aide de 2 Vis 12c

(2,9 x 9,5) fournies avec l’appareil.

Version Filtrante

• S’assurer que le Raccord Sortie de l’Air 15 se trouve en

correspondance de la Grille de la Cheminée.

• Si tel n’est pas le cas, retirer la cheminée et ajuster la position

du Raccord Sortie de l’Air 15; ensuite, remonter les pièces

comme décrit précédemment.

Avant de fixer le Corps de la Hotte au Treillis:

• Ouvrir le panneau aspirant, en tournant le bouton spécialement

prévu.

• Décrocher le panneau du corps de la hotte, en faisant coulisser le

levier du goujon de fixation spécialement prév u.

• Retirer les Filtres anti-graisse du Corps de la Hotte .

• Retirer les éventuels Filtres Anti-odeur a u

• Ensuite, fixer par le bas, au moyen de 4 Vis 12f fournies avec

l’appareil, le Corps de la Hotte au Treillis prévu.

BRANCHEMENT ÉLECTRIQUE

• Brancher la Hotte au Réseau d’Alimentation, en interposant un

Interrupteur bipolaire avec ouverture des contacts de 3 mm. au

moins.

• Ouvrir le Comfort Panel, en tirant ce dernier s’assurer que le

connecteur du Câble d’alimentation soit inséré correctement

dans la prise de l’Aspirateur.

• Effectuer les connexions des connecteurs.

• Pour la Version Filtrante, monter le Filtre Anti-odeur aux

Charbons actifs.

• Remonter les filtres Anti-graisse puis, par la suite, le panneau

aspirant.

Page 22

FR 335

UTILISATION

Tableau des commandes

Il est possible d’allumer la hotte directement à la vitesse demandée en pressant la touche sans devoir

d’abord utiliser la touche 0/1

TOUCHE LED FUNCTIONS

L 0/1 écl airage Allume et éteint l'éclairage.

T1 0/1 Moteur Allumé Première vitesse.

Cette touche permet d’éteindre la hotte en y pressant pour

Clignotement Changement 24h

On l'active en appuyant sur la touche pendant 5" environ.

T2 Vitesse Allumé Deuxième vitesse.

Clignotement Delay (30')

En appuyant pendant 2" environ sur la touche, on active

T3 Vitesse Allumé Troisième vitesse.

T4 Vitesse Fixe Vitesse maximum.

Clignotement Vitesse turbo.

S1 Led Fixe Signale la satu ration des filtres m étalli ques et la nécessi té

Clignotement Signale, lorsqu' il est activé, la saturation des filtres

.

environ 2 secondes .

Cette fonction permet d'obtenir une aspiration de 100

m3/h. avec un bruit de 28dB(A) uniquement. Son activation est possible depuis n'importe quelle vitesse, même

quand la hotte est éteinte. Pour désactiver cette fonction,

il faut appuyer sur la touche pendant 5" environ.

l'extinction automatique retardée de 30'. Cette fonction est

idéale pour compléter l'élimination des odeurs résiduelles.

Il est possible de l'activer depuis n'importe quelle vitesse;

on la désactive en appuyant brièvement sur la touche.

Cette vitesse est conseillée pour de grandes émissions de

vapeurs de cuisson. Elle peut être insérée en pressant pour

2 secondes envi ron la touch e. Elle s ’ é tei nt en au t omati qu e

après 10 minutes de fonctionnement. On peut l’éteindre

manuellement en pressant n’importe quelle touche.

de les laver. L'alarme se met en marche après 100 heures

de fonctionnement effectif de la hotte. (Reset. Voir para-

graphe Entreti en)

à charbon et la nécessité de les remplacer et d e laver les filtres métalliques. L'alarme saturation des

filtres à charbon se déclenche après 200 heures de

fonctionnement effectif de la hotte. (Mise en activi-

té et Reset. Voir paragraphe Entretien)

Page 23

FR 336

ENTRETIEN

TELECOMMANDE (FOURNIE SUR DEMANDE)

Il est possible de commander cet appareil au moyen d’une télécommande, alimentée avec des piles alcalines zinc-charbon 1,5 V

du type standard LR03-AAA.

• Ne pas ranger la télécommande à proximité de sources de chaleur.

• Ne pas jeter les piles; il faut les déposer dans les récipients de

récolte spécialement prévus à cet effet.

Nettoyage des Confort Panel

• Ouvrir le Confort Panel, en tirant ce dernier.

• Décrocher le panneau du corps de la hotte, en faisant coulisser

le levier du goujon de fixation spécialement prévu.

• En aucun cas, le confort panel ne doit être lavé au lavevaisselle.

• Le nettoyer à l’extérieur à l’aide d’un chiffon humide et d’un

détergent liquide neutre.

• Le nettoyer également à l’intérieur, en utilisant un chiffon humide et un détergent neutre; ne pas utiliser des chiffons ou des

éponges mouillées, ni des jets d’eau; ne pas utiliser des substances abrasives.

• Lorsque l‘opération est ach evée, accrocher à nouveau le panneau sur le corps de la hotte, puis le refermer, en tournant le

bouton dans le sens inverse par rapport à l’ouverture.

Page 24

FR 337

Filtres anti-graisse

NETTOYAGE FILTRES ANTI-GRAISSE METALLIQUES

AUTOPORTEURS

Remise à l’état initial du signal d’alarme

• Éteindre les Lumières et le Moteur d’aspiration.

• Appuyer sur la touche T1 pendant 3 secondes au

moins, jusqu’au clignotement de confirmation des

dels.

Nettoyage Filtres

• Ils peuvent être lavés au lave-vaisselle et nécessit ent

d’être nettoyés lorsque la Led S1 s'allume ou, au

moins, environ tous les 2 mois d’emploi ou plus fréquemment en cas d’emploi particulièrement intense.

• Retirer les filtres l’un aprés l’autre, en les poussant

vers la partie arrière du groupe et en ti rant simultanément vers le bas.

• Laver les filtres en évitant de les plier et les laisser

sécher avant de les remonter.

• Remonter les filtres en veillant à ce que la poignée

reste vers la partie visible externe.

Page 25

FR 338

Filtre anti-odeur (Version filtrante)

• Il n’est pas lavable ni régénérab le, il faut le remplacer lo rsque la del S1 clignote ou tous les

4 mois au moins. La signalisation d’Alarme a lieu uniquement lorsque le Moteur

d’aspiration est actionné.

Activation du signal d’alarme

• Pour les Hottes dans la Version Filtrante, la signalisation d'Alarme de saturation Filtres doit être

activée au moment de l'installation ou par la suite. Éteindre l'Éclairage et le Moteur d'aspiration.

• Déconnec ter la Hotte en act ionnant l' Interru pteur bi polair e interpos é sur l' alimentat ion du Résea u

ou en intervenant sur l'Interrupteur général.

• Rétablir la connexion, en maintenant appuyée la touche T1.

• Relâcher la touche, les cinq dels sont allumées en position fixe.

• Dans un délai de 3 s econdes, appuyer sur la Touche T1 jusqu'au clignotement de confi rmation des

Dels T1 et T4:

2 cl ignotements Del - Alarme de saturation Filtre anti-odeur au Charbon acti f ACTIVÉE.

1 clignotement De l - Alarme de satu ration Filtre an ti-odeur au Charbon actif DÉSACTIVÉE .

REMPLACEMENT FILTRE AU CHARBON ACTIF

Remise à l’état initial du signal d’alarme

• Éteindre les Lumières et le Moteur d’aspiration.

• Appuyer sur la touche T3 pendant 3 secondes au moins, jus-

qu’au clignotement de confirmation des dels.

Remplacement Filtre

• Ouvrir le Comfort Panel, en tirant ce dernier.

• Retirer les filtres anti-graisse métalliques.

• Retirer le filtre anti-odeur au charbon actif colmaté, en agissant

sur les crochets prévus à cet effet.

• Monter le nouveau filtre anti-odeur au charbon actif.

• Remonter le filtres anti-graisse métalliques.

Eclairage

REMPLACEMENT LAMPES

Lampe halogène de 20 W.

• Retirer les 2 Vis qui fixent le Support éclairage et ôter ce d ernier de la Hotte.

• Extraire la Lampe du Support.

• Re mplacer par un e nouvelle lampe possédant les mêmes caractéristiques, en veillant à ce que les deux fiches soient correctement insérées dans le logement de la Douille.

• Remonter le Support en le fixant à l’aide des deux Vis précédemment retirées.

Page 26

Dir. 89/336/CEE

73/23/CEE

93/68/CEE

Il simbolo sul prod otto o s ulla c onfez i one i ndic a c he il pr odott o no n deve es s ere c onsi der ato c om e un nor mal e ri fiuto d omes ti co,

ma deve essere port at o nel punt o di r acc olta appr opr iat o per il ric icl aggio di ap par ecchi atur e el ettr ich e ed el ettr oni ch e. Prov v ede nd o a

smaltire ques to pr od otto i n m odo a ppr opr iat o, s i contr ib uisc e a ev it are pote nzi ali c ons egu enz e ne gati ve per l’ ambi en te e p er l a salute,

che potrebber o d er i v are da uno smaltimento ina de guato del prodotto. Per i nf or m az i o ni pi ù dettagliate sul rici c l aggi o di questo prodotto,

contattare l’ufficio comunale, il servizio locale di smaltime nto rifiuti o il negozio in cui è sta to acquistato il prodotto.

The symbol on th e product or on its packaging i ndi c a tes that this product may not be tr e ated as household waste. Ins t ead it shall

be handed over to the appl icable col lection p oint for t he recycli ng of electr ical and el ectronic equipment . By ensurin g this product is

disposed of correctly, you will help prevent potential negative consequences for the environment and human health, which could otherwise be caused by inap propr iat e wast e ha ndl ing of this pro duc t. For mor e det ail ed inf ormati o n about recy cli ng of this pro duc t, ple ase

contact your local city office, your household waste disposal service or the shop where you purchased the product.

Le symbole s ur l e produi t ou so n em ball age i ndi que q ue c e pro dui t ne pe ut êtr e tr aité com m e déc het m éna ger. Il doi t plut ôt êtr e

remis au point de ramassage concerné, se chargeant du recyclage du matériel électrique et électronique. En vous assurant que ce

produit est éli miné cor rectem ent, v ous fav orise z la prév entio n des cons équ ences né gativ es po ur l’env ironnem ent et l a sant é humaine

qui, sinon, serai e nt le résultat d’un traiteme nt inapproprié des déchets de ce produit. Pour obteni r pl us de dé tai ls sur le recyclage de ce

produit, veuillez prendre contact avec le bureau municipal de votre région, votre service d’élimination des déchets ménagers ou le

magasin où vous av ez acheté le produit.

Das Symbol auf dem Pro dukt o der s einer V erpack ung wei st dar auf hin, dass di eses P roduk t nic ht als norm aler H aushal tsa bfall

zu behandeln is t, so nder n an ei nem Sam mel pu nkt f ür das Rec ycl ing v on elek tri sc hen und elek tr onisc he n G eräte n abg egeb en w er den

muss. Durch Ihren Beitrag zum korr ek te n Entsorgen dieses Prod uk ts s chützen Sie die Umwelt und die Gesundheit Ihrer M i tm enschen.

Umwelt und Ges undheit werden durc h falsches Entsorge n gefährdet. Weitere Informationen über das Recycling dieses Pr odukts

erhalten Sie von Ihrem Rathaus, Ihrer Müllabfuhr oder dem Geschäft, in dem Sie das Produkt gekauft haben.

436002659_ver1

Loading...

Loading...