KTS1625

Digital Multifunction Tester

Users Manual

KTS1625

Digital Multifunction Tester

Users Manual

September 2011, Rev.1

©2011 Amprobe Test Tools.

All rights reserved. Printed in China

English

Limited Warranty and Limitation of Liability

Your Amprobe product will be free from defects in material and workmanship for 1 year from

the date of purchase, unless local laws require otherwise. This warranty does not cover fuses,

disposable batteries or damage from accident, neglect, misuse, alteration, contamination, or

abnormal conditions of operation or handling. Resellers are not authorized to extend any other

warranty on Amprobe’s behalf. To obtain service during the warranty period, return the product

with proof of purchase to an authorized Amprobe Test Tools Service Center or to an Amprobe

dealer or distributor. See Repair Section for details. THIS WARRANTY IS YOUR ONLY REMEDY.

ALL OTHER WARRANTIES - WHETHER EXPRESS, IMPLIED OR STAUTORY - INCLUDING IMPLIED

WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE OR MERCHANTABILITY, ARE HEREBY

DISCLAIMED. MANUFACTURER SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL

OR CONSEQUENTIAL DAMAGES OR LOSSES, ARISING FROM ANY CAUSE OR THEORY. Since

some states or countries do not allow the exclusion or limitation of an implied warranty or of

incidental or consequential damages, this limitation of liability may not apply to you.

Repair

All test tools returned for warranty or non-warranty repair or for calibration should be

accompanied by the following: your name, company’s name, address, telephone number, and

proof of purchase. Additionally, please include a brief description of the problem or the service

requested and include the test leads with the meter. Non-warranty repair or replacement charges

should be remitted in the form of a check, a money order, credit card with expiration date, or a

purchase order made payable to Amprobe® Test Tools.

PFC PSC

KTS1625 Digital Multifunction Tester

1

2

3

6 7 5

LCD Display

1

Function Buttons (F1, F2, F3, F4)

2

F1: Display Backlight

Continuity Buzzer

0° or 180° phase selection for RCD test

L - N or L - PE loop test

F2: Lock Test

RCD 30s count-down test

Sine wave selection for RCD test

Half-wave selection for RCD test

F3: Test Lead resistance zero

Test data recall for RCD Auto Test

F4: I

n selection for RCD Test

4

Test Button

3

Rotary Switch

4

COM / N Terminal(Black)

5

L / V / Ω Terminal(Red)

6

PE terminal(Green)

7

PFC PSC

Screen Display

1 2 3 4 5 6 7 8 9

16 20

17

18

19

L – N or L – PE Loop Test

1

Presence of Hazardous

2

Voltages

Continuity Buzzer

3

Over-temperature! Allow

4

the Tester to cool down

Sine wave signal (AC Current)

5

Half-wave Signal

6

30s Count-down Test

7

Test Lock for Continuous

8

Measurement

Test Data Recall For RCD

9

Auto Test

Test Lead Resistance Zero

10

RCD Test at X1/2, X1, X5

11

RCD Auto Test

12

10

Fault Voltage Between N and

13

PE Conductor Exceeds 50V

RCD Ramp Test

14

Low Battery Indicator

15

Noise Between N and PE Conductor

16

RCD Test Phase Selection 0° / 180°

17

Over-temperature! Allow the

18

Tester to cool down

Wiring correction Check for Loop

19

and RCD Test

Prospective Earth Fault Current

20

Prospective Short-Circuit Current

21

DC Voltage

22

AC Voltage

23

12 13 14 15

23 22

21

KTS1625 Digital Multifunction Tester

CONTENTS

SYMBOL .................................................................................................................2

SAFETY INFORMATION .........................................................................................2

UNPACKING AND INSPECTION .............................................................................3

FEATURES ...............................................................................................................4

MAKING MEASUREMENT .....................................................................................5

Rotary Switch Positions ....................................................................................5

Function Buttons ..............................................................................................6

Measuring AC Voltage .....................................................................................8

Measuring Insulation Resistance .....................................................................9

Measuring Continuity ......................................................................................11

Measuring Loop Impedance ............................................................................14

Measuring RCD Tripping Time .........................................................................17

Using Test Probe with Remote Test Button ....................................................23

SPECIFICATION ......................................................................................................24

MAINTENANCE ......................................................................................................28

BATTERY AND FUSE REPLACEMENT .....................................................................28

1

SYMBOLS

SAFETY INFORMATION

The Meter complies with:

EN 61010-1 3nd Edition, Category III 300 Volts, Pollution degree 2,

IP40 as per EN 60529

EN 61010-2-030

EN 61010-2-31 for test leads

EMC EN 61326-1

EN 61557-1/-2/-3/-4/-6/10

Measurement Category III (CAT III) is for measurements performed in the

building installation. Examples are measurements on distribution boards,

circuit- breakers, wiring, including cables, bus-bars, junction boxes, switches,

socket-outlets in the fixed installation, and equipment for industrial use

and some other equipment, for example, stationary motors with permanent

connection to the fixed installation.

Caution ! Risk of electric shock.

Caution! Refer to the explanation in this Manual

The equipment is protected by double insulation or

reinforced insulation

Do not use in distribution systems with voltages higher

than 440V

Earth (Ground)

Battery

Complies with European Directives

Do not dispose of this product as unsorted municipal waste.

Contact a qualified recycler.

2

CENELEC Directives

The instruments conform to CENELEC Low-voltage directive 2006/95/EC and

Electromagnetic compatibility directive 2004/108/EC

Warning: Read Before Using

• To avoid possible electrical shock or personal injury, follow these

instructions and use the Meter only as specied in this manual.

• Do not use the Tester or test leads if they appear damaged, or if the

Meter is not operating properly. If in doubt, have the Tester serviced.

• Always use the proper function and range for measurements.

• Before rotating the function range selection switch, disconnect test

probe from circuit under test.

• Verify the Tester’s operation by measuring on a known voltage source.

• Do not apply more than the rated voltage, as marked on the Tester,

between the test probe or between any test probe and earth ground.

• Use the Tester with caution for voltages above 30 Vac rms, 42 Vac peak,

or 60 Vdc. These voltages pose electrical shock hazards.

• Disconnect circuit power and discharge all high-voltage capacitors before

testing insulation resistance and continuity.

• Do not use the Tester around explosive gas or vapor.

• When using the test leads, keep your ngers behind the nger guards.

• Remove test leads from the Tester and turn off the Tester before opening

the Tester case or battery door.

• Do not use in distribution systems with voltages higher than 440V AC or

DC.

• Follow the operating manual at all times when using the Tester and have

the operating manual in an easily accessible place.

• Incorrect operation will cause incident and damage to the Tester.

• Before and after testing, conrm that no hazardous voltage at the

terminals presents.

3

UNPACKING AND INSPECTION

Your shipping carton should include:

1 KTS1625 Digital Multifunction Tester

1 3-Wire Mains Test Cord Set

1 Test Lead set (Red, Black, Green)

1 Test Probe set (Red, Black, Green)

1 Alligator clip set (Red, Black, Green)

1 Red Test probe with Remote Test Button

8 1.5V alkaline AA battery

1 Users manual

1 Strap

1 Carrying case

If any of the items are damaged or missing, return the complete package to

the place of purchase for an exchange.

FEATURES

Safety and performance are two most critical requirements for every electrical

system. The quality of insulation, properly working grounding system and

active protection are “must have” to assure safety of the people, electrical

systems and buildings against electrocution, fire, and other equipment

damage. They are critical to prevent loss of productivity due to power

interruption.

Robin-Amprobe KTS1625 is a multifunction installation tester measuring

various parameters of the electrical system to provide complete safety

analysis. It features loop impedance measurements as well as measurement of

continuity and insulation resistance of motors, transformers or wires, testing of

RCD systems, measuring voltage and frequency.

• Insulation Resistance Functions:

- Tests insulation of wires, cables, transformers and electrical motors

- Selectable test voltages 250V, 500V and 1000V

- Test button lock for dielectric absorption ration test

- Automatic discharge of test object after completion of measurement

4

• Continuity Functions:

- Earth continuity @ 200mA

• Line / Loop Impedance Functions:

- Prospective Fault Current

- Prospective Short-Circuit current

• RCD Functions:

- Phase switch selection 0° and 180° for positive and negative semi-cycle testing

- RAMP Slope measurement

- 30 Seconds Countdown Measurement

- RCD Half-Wave test

- Auto RCD test

• Designed to allow testing to BS7671 IEE 17th Edition regulations

• Voltage and Frequency Measurements

• Instant correct wiring status check

• Dual measurement result display

• Large, backlit display

• Low Battery Indication

• Safety CAT III 300V

MAKING MEASUREMENT

1. Use the proper function and range for measurements.

2. To avoid possible electrical shock, personal injury or damages to the

Tester, disconnect circuit power and discharge all high-voltage capacitors

before testing insulation resistance and continuity.

3. Connecting test leads:

• Connect PE test lead (green) to the circuit before connecting the live leads;

• After measurement, remove live leads before removing PE test lead

from the circuit

5

Rotary Switch Positions

Switch Position Measurement Function

Volts AC Voltage / Frequency measurement.

250V Insulation Resistance at DC 250V.

Insulation

Continuity Ω Continuity measurement.

Loop

RCD

500V Insulation Resistance at DC 500V.

1000V Insulation Resistance at DC 1000V.

NO TRIP L – PE(PSC) or L – N(PFC) Loop impedance NO TRIP mode

Hi

L – PE Loop Impedance and Prospective Short-Circuit

PSC

Current

Auto Automatic tripping test for unknown RCD.

X ½ Non-Tripping RCD test.

X 1 Tripping RCD test.

X 5 Fast tripping RCD test.

Ramp Test, 50%~110% Default nominal residual

currents (I

Ramp

Increasing by 10%, total 7 steps of residual current.

n).

Function Buttons

TEST Button

Press TEST button to begin selected measurement function on the rotary switch.

F1 Button

Press > 2 sec to turn the display backlight on or off.

Insulation resistance < 2MΩ buzzer will sound. Continuity

test < 20Ω buzzer will sound.

RCD test phase selection (0 or 180 degrees).

L-N/L-PE

Loop Impedance (L-PE) or Line Impedance (L-N)

measurement for NO TRIP mode.

6

F2 Button

“Test Lock” for continuous measurement. Press F2 to enable

Test Lock mode (

press TEST button for continuous measurement. Under Test

Lock mode, TEST button will hold for Dielectric Absorption

Ratio Test (DAR) purpose. DAR value can be calculated by

Riso(1min)/Riso(30s).

To exit Test Lock mode, press F2 or turn rotary switch to

another function position.

Selective mode. A 30 second time delay.

AC current to test type AC (standard AC RCD).

Half-wave current to test type A (pulse-DC sensitive RCD).

Press F2 to select the RCD test-current waveform:

F3 Button

ZERO

RCL

Delayed response to test S-type AC (time delayed AC RCD)

Half-wave current to test type A (pulse-DC sensitive RCD)

Delayed response to S-type A

(time delayed pulse-DC sensitive RCD)

AC current to test type AC (standard AC RCD)

Test Lead / Probe Zeroing. Press F3 to zero the test lead / probe.

Can subtract up to 10Ω of lead resistance. Buzzer audio

warning sound for lead resistance >10 Ω.

Error message and buzzer audio sound for resistance >10 Ω.

Data recall for RCD Auto test. Press F3 to scroll the test results.

symbol is shown on the screen) and

F4 Button

Press F4 to select I

n (RCD current rating 10, 30, 100, 300, or 500 mA).

7

Error message display

PFC

1. Over-temperature: wait while the temperature cools down for next measurement

2. Fault Voltage: Check voltage between N and PE conductor.

Measuring AC Voltage

• To avoid personal injury or damage to the tester, do not apply voltage

higher than 440V.

• Connecting test leads:

- Connect COM test lead (black) to the circuit before connecting the live leads;

- After measurement, remove live leads before removing COM test lead

from the circuit

To measure voltage and frequency:

1. Turn the rotary switch to Volts position.

2. Use red and black (V – COM) terminals for this test. You can use test

leads or 3-wire mains test cord when measuring AC voltage.

The primary display shows the Voltage.

The secondary (smaller digits on the right side) display shows the Frequency.

8

v

V

COM

F1 b u tt on

Figure 1: Measuring AC voltage by test leads

9

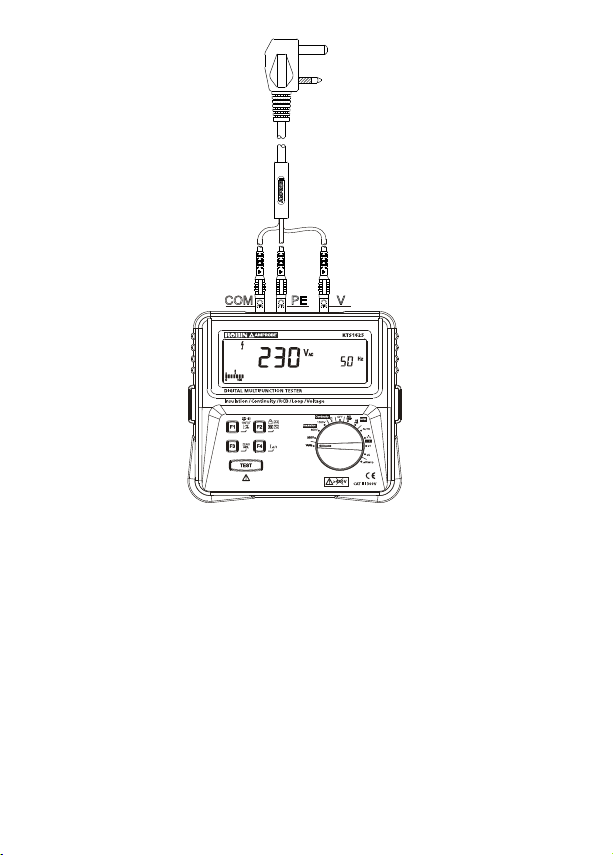

COM PE

V

Figure 2: Measuring AC voltage by 3-wire mains test cord

Measuring Insulation Resistance

• Make sure disconnecting circuit power and de-energize the circuit before test.

• When measuring insulation resistance, make sure test leads are separated

and are not twisted together.

• Do not short circuit two test leads when output DC voltage presents at

the output terminals.

• Do not measure insulation resistance at live high voltage circuit.

• Do not carry out measurement when the battery compartment is open or

accessible.

10

• When the measurement is completed, do not touch the circuit as the

circuit may store energy, which may cause electric shock. Allow time for

circuit to discharge

• Warning buzzer will sound when the Tester detects a voltage >30Vac or

dc. Display shows symbol and the detected voltage.

Figure 3: Tester detects a voltage >30Vac

Figure 4: Tester detects a voltage >30Vdc

To measure voltage and frequency:

1. Turn the rotary switch to Insulation position (250V, 500V, or 1000V).

2. Use the red and black (L – N) terminals for this test with test leads.

3. Press F1 to activate

4. Press F2 to activate Test Lock mode for continuous measurement.

Note: Testing is inhibited if voltage is detected in the circuit under

measurement.

5. Press TEST button to begin measurement.

The primary display shows the insulation resistance.

The secondary (smaller digits on the right side) display shows the actual

test voltage.

, buzzer will sound when resistance < 2MΩ.

11

LN

R

F 1 F 2

Figure 5: Measuring insulation resistance

Measuring Continuity

• Disconnect circuit power and de-energize the circuit before test.

• Do not measure continuity at live high voltage circuit.

• Do not carry out measurement when the battery compartment is open

or accessible.

• Warning buzzer will sound when the Tester detects a voltage >30Vac or

dc. Display shows

symbol and the detected voltage.

12

Figure 6: Tester detects a voltage >30Vac

Figure 7: Tester detects a voltage >30Vdc

To measure continuity:

1. Turn the rotary switch to Continuity position.

2. Use the red and black (Ω – COM) terminals for this test with test leads.

3. Before making a continuity measurement, use ZERO function to zero

the test leads.

Test lead resistance zeroing:

Step 1: Connect test leads to Ω and COM terminals and short-circuit the

test leads/probes.

Step 2: Press and hold F3 (ZERO) button. The measured resistance of

the test leads is shown on the primary display until a beep is heard and

the ZERO annunciator appears. When Display shows 0.00Ω, test lead

resistance zero is complete.

The tester measures test leads / probe resistance, stores the reading in

memory, and subtracts it from readings. The resistance value of test leads

/ probe is saved even when the Tester is switched off. When the next time

you switch on the Tester, you do not need to repeat test lead / probe

zeroing step every time you use the Tester. When using a different set of

test leads / probes, zeroing has to be repeated.

Note: The ZERO function can subtract up to 10Ω of lead resistance.

Warning buzzer audio sound for lead resistance >10 Ω.

13

4. Press TEST button

COM

R

F1 F 2 F3

ZERO

The primary display shows the continuity resistance.

The secondary (smaller digits on the right side) display shows the actual

output DC voltage.

When

symbol on screen, buzzer threshold ≤ 20Ω

Figure 8: Measuring continuity

14

Measuring Loop Impedance

• The Tester is designed for measurement on single phase system only – AC

230V, 50Hz (operating voltage range: AC 230V +10%/-15%, 50Hz).

• Make sure the wiring is correct and the ground wire is reliably connected

earth. The tester displays symbols of “L-PE”, “L-N” and “N-PE” to indicate

the correct wiring connections. Blinking of symbols “L-PE” or “L-N” or

“N-PE” indicates incorrect wiring.

• Make sure the grounding of the socket-outlet is connected to Earth. The

symbol of “L-PE” and “N-PE” on the display means grounding wire is not

connected to earth or not well-connected to earth.

• When measuring the loop impedance/prospective short-circuit current,

make sure line and neutral wires are connected correctly. Pay attention to

the wiring symbols on display.

• Use Volts function to check the circuit voltage before the measurement.

• “HOT” symbol on screen indicates over-temperature. Allow time for the

Tester to cool down for next measurements.

Connecting to the circuit

Correct wiring: “L-PE” and“L-N” symbols are displayed – proceed to test

Incorrect wiring: when wiring symbols are blinking on display – STOP!

Check the wiring connections.

• “L-PE” and “L-N” symbols blinking indicate missing L wiring connection

or incorrect wiring of line conductor

• “L-PE” and “N-PE” symbols blinking indicate missing PE wiring

connection or incorrect wiring of PE conductor

• “L-N” and “N-PE” symbols blinking indicate missing N wiring connection

or incorrect wiring of N conductor

15

N LPE

PFC

F

(NO TRIP only)

(NO TRIP only)

1 button

Figure 9: Measuring Loop by 3-wire mains test cord

16

PE

NEUTRAL

EARTH

PHASE

PFC

N L

Figure 10: Measuring Loop by test leads

Loop Impedance (Line to Protective Earth L-PE)

To measure L-PE loop impedance:

1. Turn the rotary switch to Hi PSC position.

2. Use the red, green and black (L – PE – N) terminals for this test. You can

use test leads or mains test cord when measuring loop impedance.

Check the signs of wiring connection before proceeding test.

3. Press TEST button

The primary display shows the L-PE loop impedance.

The secondary (smaller digits on the right side) display shows PEFC.

17

Measuring loop impedance NO TRIP mode:

To prevent tripping RCDs in the circuit:

• Use the NO TRIP function for loop measurements.

• An RCD with a nominal fault current of 15mA or above will trip.

To measure L-PE loop impedance NO TRIP mode:

1. Turn the rotary switch to NO TRIP position. L-PE symbol on the screen

(upper-left corner) indicates L-PE loop impedance.

2. Use the red, green and black (L – PE – N) terminals for this test. You can

use test leads or mains test cord when measuring loop impedance.

Check the signs of wiring connection before proceeding test.

3. Press TEST button

The primary display shows the L-PE loop impedance.

The secondary (smaller digits on the right side) display shows PFC.

To measure L-N loop impedance NO TRIP mode:

1. Turn the rotary switch to NO TRIP position.

2. Press F1 button to select L-N loop impedance measurement. L-N symbol

displays on the screen (upper-left corner).

3. Use the red, green and black (L – PE – N) terminals for this test. You can

use test leads or mains test cord when measuring loop impedance.

Check the signs of wiring connection before proceeding test.

4. Press TEST button

The primary display shows the L-N loop impedance.

The secondary (smaller digits on the right side) display shows PSC.

Measuring RCD Tripping Time

• The Tester is designed for measurement on single phase system only – AC

230V, 50Hz (operating voltage range: AC 230V +10%/-15%, 50Hz).

• Any test and measurement procedures in circuits equipped with residual current

devices should only be performed after having consulted the operator terminals

(data processing systems, material processing, motors, etc.).

• Equipment, which is connected downstream of a residual current

protective device (RCD) may cause a considerable extension of the

operating time. Examples of such equipment might be connected

capacitors or running motors.

• The protective earth must be free of external voltage for the RCD test.

However if an extraneous voltage is present (>50V fault voltage), the

18

Tester indicates >50V Uf having been generated by the measurement.

The measurement interruption caused by excess of Uf is only generated

by the actual voltage present between the neutral conductor (N) and the

protective earth (E).

• Time-delayed residual current devices trip at nominal residual current

within 130…500ms, for double nominal fault current within 60…200ms.

• Such RCDs are implemented as main residual current protection devices

(please refer to IEC 61008-1) and are marked with the symbol “ S ”.

• At a measuring circuit without probe, available voltages between PE and

earth can influence the measurement.

• Before using the N-conductor as probe check that all neutral points have

low ohm resistance to the main neutral line. A available voltage of the N

conductor to the earth can influence the measurement.

• The measuring function uses the N-conductor as a probe. Check rst

the connection between the neutral point of the distribution system

and earth before the test is started. A possible voltage between the

N-conductor and earth may influence the measurements.

• Leakage currents in current circuits following the RC circuit breaker may

have an influence on the test as well as a voltage between protective

conductor or neutral conductor and ground.

• Attached loads or operating supplies which contains capacitors or

circulating machines can elongate the trip time.

• Measurements may be inuenced by potential elds of other grounding

systems.

• Measurements must be carried out in compliance with the respectively

valid standards and regulations.

• Make sure the wiring is correct and the ground wire is reliably connected

earth. The tester displays symbols of “L-PE”, “L-N” and “N-PE” to indicate

the correct wiring connections. Blinking of symbols “L-PE” or “L-N” or

“N-PE” indicates incorrect wiring.

Connecting to the circuit

Correct wiring: “L-PE” and“L-N” symbols are displayed – proceed to test

Incorrect wiring: when wiring symbols are blinking on display – STOP!

Check the wiring connections.

• “L-PE” and “L-N” symbols blinking indicate missing L wiring connection

or incorrect wiring of line conductor

• “L-PE” and “N-PE” symbols blinking indicate missing PE wiring

PE

F1 button F2 button F4 button

10mA

30mA

100mA

300mA

500mA

10mA

30mA

100mA

300mA

N L

connection or incorrect wiring of PE conductor

• “L-N” and “N-PE” symbols blinking indicate missing N wiring connection

or incorrect wiring of N conductor

Figure 11: Measuring RCD trip time by 3-wire mains test cord

20

PE

NEUTRAL

EARTH

PHASE

N L

Figure 12: Measuring RCD trip time by test leads

To perform Auto RCD test:

1. Turn the rotary switch to AUTO position.

2. Use the red, green and black (L – PE – N) terminals for this test. You can

use test leads or mains test cord when measuring loop impedance.

Check the signs of wiring connection before proceeding test.

3. Press F4 button to select tripping current

10mA, 30mA, 100mA

10mA, 30mA

21

4. Press F2 to select waveform or selective mode (a 30 second time delay)

5. Press TEST button

Auto RCD test automatically performs a sequence of 6 RCD trip time tests

with a single press on TEST button.

Auto RCD test sequence:

½I

n / 0°→ ½I n / 180°→ I n / 0°→ I n / 180°→ 5I n / 0°→ 5 n / 180°

Each time the RCD trips, re-set RCD to continue unfinished the test

sequence until the whole sequence is completed.

When AUTO test is completed, “RCL” symbol is displayed on screen.

Press F3 to display the measurement results. The measurement result is

displayed in the order of the test sequence. Press F3 again to show the

next measurement result.

To measure RCD tripping time (X1/2, X1, X5):

1. Turn the rotary switch to the desired test current multiplier

(X1/2, X1 or X5) position.

Normally X1 is used for this test.

X1/2 for non-tripping test. RCD shall not open.

X1 for tripping test. RCD shall open.

X51 for fast tripping test. RCD shall open.

2. Use the red, green and black (L – PE – N) terminals for this test.

You can use test leads or mains test cord when measuring loop

impedance. Check the signs of wiring connection before proceeding test.

3. Press F4 button to select tripping current

Delayed response to test S-type AC

(time delayed AC RCD)

Half-wave current to test type A

(pulse-DC sensitive RCD)

Delayed response to S-type A

(time delayed pulse-DC sensitive RCD)

AC current to test type AC

(standard AC RCD)

22

X1/2, X1

10mA, 30mA, 100mA, 300mA, 500mA

10mA, 30mA, 100mA, 300mA

X5

10mA, 30mA, 100mA

10mA, 30mA

4. Press F1 button to select test current phase 0° or 180°.

5. Press F2 button to select waveform or selective mode

6. Press TEST button

The primary display shows the L-PE loop impedance.

The secondary (smaller digits on the right side) display shows PFC.

To perform RAMP test:

1. Turn the rotary switch to RAMP position.

2. Use the red, green and black (L – PE – N) terminals for this test. You can

use test leads or mains test cord when measuring loop impedance.

Check the signs of wiring connection before proceeding test.

3. Press F4 button to select tripping current

4. Press F2 to select waveform or selective mode

5. Press TEST button

Delayed response to test S-type AC

(time delayed AC RCD)

Half-wave current to test type A

(pulse-DC sensitive RCD)

Delayed response to S-type A

(time delayed pulse-DC sensitive RCD)

AC current to test type AC

(standard AC RCD)

23

Using Test Probe with Remote Test Button

R

N L

CAT IV 600V

CATI II10 00V

10A

TEST Button

This test probe with remote test button allows users to perform

measurement by pressing TEST button on the probe when both hands are

holding test probes during measurement.

Below measurements can be made by using the test probe with remote test button:

• Continuity

• Insulation resistance

WARNING

Follow the instructions in “Measuring Insulation Resistance” section and

“Measuring Continuity” section before marking measurements.

Figure 13: Testing with test probe with remote test button

24

SPECIFICATION

Ambient temperature: 23°C ±5°C (73.4°F ±9°F); Relative temperature: ≤75%

Accuracy: ±(% of reading + LSD)

Display: maximum reading is 9999.

Over-range indication: maximum reading

Operating Condition: 0°C to +40°C, <85% Relative Humidity

Storage Condition: -20°C to +60°C, <90% Relative Humidity

Dimension (L x W x D): 189 × 167 × 85mm (7.43 x 6.65 x 3.35in)

Weight: approx. 1.3 kg (2.87 lb) with batteries installed

Low Battery warning indication: “

Power Supply: Alkaline Battery 1.5V (AA Battery or equivalent) × 8pcs

The number of possible tests with a fresh set of batteries is >1000.

Fault Voltage detection: 50Vrms.

”

AC Voltage Measurement

Range Resolution Accuracy Overload Protection

0 – 400V 1V

±(5% Rdg +2 LSD)

@ 45 – 65Hz

440Vrms

Insulation Resistance Measurement

DC Test

Voltage

250V

1000V ≥1mA@ 1MΩ

Resolution Test Current Accuracy

≥1mA@ 0.25MΩ

1V

0 to +10%500V ≥1mA@ 0.5MΩ

Measuring Range

(auto ranging)

0.00MΩ – 9.99MΩ 0.01MΩ

100MΩ – 1999MΩ 1MΩ

Note: Buzzer threshold: 2MΩ

Live circuit detection: >30Vac or dc

Resolution Accuracy

25

± (5% Rdg + 5 LSD)10.0MΩ – 99.9MΩ 0.1MΩ

Continuity Measurement

Range

(Auto ranging)

1.99Ω 0.01Ω >4Vdc

199Ω 1Ω >4Vdc

Note: Measuring current (short-circuited) ≥ 200mA

Nominal open-circuit output voltage: 5Vdc

Buzzer threshold: 20Ω

Live circuit detection: >30Vac or dc

Test probe zeroing: can subtract up to 10Ω of lead resistance.

Range Test Voltage Accuracy

± (2% Rdg +5 LSD)19.9Ω 0.1Ω >4Vdc

Loop Impedance Measurement

Operating Rated Voltage: 195 – 253Vac, 45 – 65Hz

Range Resolution Accuracy

Line Impedance

(L-N)

@25A

Loop Impedance

(L-PE)

@25A

Loop impedance

without tripping

@15mA

Prospective Short

Circuit Current

@25 A

Prospective Earth

Fault Current

@25 A

0.01Ω - 1.99Ω

2.0Ω - 19.9Ω

20Ω - 2000Ω

0.01Ω - 1.99Ω

2.0Ω - 19.9Ω

20Ω - 2000Ω

1.00Ω - 1.99Ω

2.0Ω - 19.9Ω

20Ω - 2000Ω

0.00A~1.99A

2.0A~19.9A

20A~199A

200A~1.99kA

2.0kA~26kA

0.00A~1.99A

2.0A~19.9A

20A~199A

200A~1.99kA

2.0kA~26kA

± (5% Rdg +5 LSD)

± (5% Rdg +5 LSD)

± (5% Rdg +12 LSD + Noise

Margin (1.00 - 1.99Ω)

PSC accuracy derived from

measured loop impedance

specification and measured

voltage specification

PFC accuracy derived from

measured loop impedance

specification and measured

voltage specification

26

RCD Measurement

Operating Rated Voltage: 195 – 253Vac, 45 – 65Hz

Function

RCD

AUTO

test

RCD

RAMP

test

X1/2

RCD Test Current Selection

10mA 30mA 100mA 300mA 500mA

√ √ √

√ √

√ √ √ √ √

√ √ √ √ √

√ √ √ √ √

√ √ √ √ √

Accuracy

0% to +10% at

X1 and X5

-10% to 0% @

1/2X

50%~110%

Default nominal

residual currents

(I n). Increasing

by 10%, total 7

steps of residual

current.

-10% to 0%

X1

√ √ √ √ √ 1)

√ √ √ √ √ 1)

√ √ √

X5

√ √ √

Note: 1) Selective mode only.

Function RCD type *

Tripping Time

Measurement Range

X1/2 G 2000ms

X1/2 S 2000ms

X1 G 300ms

X1 S 500ms

X5 G 40ms

X5 S 40ms

0% to +10%

0% to +10%

Accuracy

± (2% Rdg +2 LSD)

27

Note: *G – General, no delay

*S – Time delay

EN 61557 Measurement Range

Function Display Range

Volts

EN 61557-1

Insulation

EN 61557-2

Loop

EN 61557-3

Continuity

EN 61557-4

T, I

EN 61557-6

100Vac – 400Vac,

0.05MΩ - 1000MΩ

0.01Ω - 2000Ω

0.00Ω - 199Ω

T 0ms – 2000ms

N

I

N

/ 100mA / 300mA /

45Hz – 65Hz

Hi Current

NO TRIP

1Ω - 2000Ω

10mA / 30mA

500mA

EN 61557

Measurement Range

Operating Error

10Vac – 400Vac,

45Hz – 65Hz

±(5% + 2 LSD)

0.25MΩ - 1000MΩ

±(5% + 5 LSD)

0.5Ω - 2000Ω

±(5% + 5 LSD)

1Ω - 2000Ω

±(5% + 12 LSD)

0.2Ω - 199Ω

±(2% + 5 LSD)

20ms – 2000ms

±(2% + 2 LSD)

10mA / 30mA /

100mA / 300mA /

500mA

±(10% + 2 LSD)

Nominal Values

U

= 230Vac

N

f = 50Hz

U

= 250/ 500/

N

1000Vdc

I

= 1.0mA

N

U

=230Vac

N

f = 50Hz

Ik=26kA

Uo = 5Vdc (typical)

I

≥ 200mA

N

T = 10 / 30 / 100

/ 300 / 500mA

IN = 10 / 30 / 100

/ 300 / 500mA

28

MAINTENANCE AND REPAIR

If the Tester fails to operate, check battery, test leads, etc., and replace as

necessary.

Double check the followings:

1. Check the battery. Replace the battery immediately when the symbol

” appears on the display.

“

2. Review the operating instructions for possible mistakes in operating

procedure.

Except for the replacement of the battery, repair of the Tester should be

performed only by an Authorized Service Center or by other qualified

instrument service personnel.

The front panel and case can be cleaned with a mild solution of detergent and

water.

Apply sparingly with a soft cloth and allow to dry completely before using. Do

not use aromatic hydrocarbons, Gasoline or chlorinated solvents for cleaning.

BATTERY AND FUSE REPLACEMENT

WARNING

To avoid shock, injury, or damage to the Tester, disconnect test leads/test

cord before opening case.

Replacing BATTERY follow below steps:

1. Disconnect the test lead probe from measuring circuit.

2. Turn the rotary switch to OFF position.

3. Remove the screws from the battery cover and open the battery cover

4. Remove the batteries and replace with 8 x 1.5V Alkaline Batteries (AA or

equivalent). Pay attention to the polarity signs.

5. Put the battery cover back and re-fasten the screw.

29

Battery:1.5V Alkaline Batteries (AA or equivalent).

30

31

• Catalog

• Application notes

• Product specifications

• User manuals

Loading...

Loading...