Page 1

-Rain G

Mot~ti’ RG

RGX240,

issu E

EMU - GS0068

q

Page 2

CONTENTS

1. SPECIFICATIONS ..........................................

2. PERFORMANCE ...........................................

2-1 Model RGX180 ......................................

2-2 Model RGX240 ......................................

2-3 Model RGX240D .....................................

2-4 DC OUTPUT (RGX240, RGX240D) ........................

3. FEATURES ..............................................

4. GENERAL DESCRIPTION of GENERATOR ........................

4- 1 External View of Generator ..............................

4-2 RGX180 Panel .......................................

4-3 RGX240 Panel .......................................

4-4 RGX240D Panel. .....................................

5. CONSTRUCTION and FUNCTION ...............................

5- 1 Construction ........................................

5-2 Functions ..........................................

5-3 Description of Generator Operation .........................

5-4 Change of Engine Parts .................................

6. SAFETY PRECAUTIONS .....................................

7. RANGE of APPLICATIONS. ...................................

8. MEASURING PROCEDURE ...................................

9. CHECKING FUNCTIONAL MEMBERS. ...........................

9- 1 Stator Assembly ......................................

9- 2 Rotor Assembly ......................................

9- 3 Brushes. ...........................................

9-4 AVR (Automatic Voltage Regulator) ........................

9- 5 Fuse Holder and Circuit Breaker ...........................

9-6 Receptacle and AC Plug .................................

9- 7 Voltmeters and Pilot Lamp ...............................

9-8 Diode Stack Assembly ..................................

9-9 Primary Exciting Circuit ................................

10. DISASSEMBLY and REASSEMBLY ..............................

10- 1 Preparations and Suggestions .............................

10- 2 How to Disassemble ...................................

10- 3 How to Reassemble ....................................

10-4 Control Box Check, Disassembly, and Reassembly

...............

11. TROUBLE-SHOOTING .......................................

12.OPTIONS.. ..............................................

12-1 Caster .............................................

13. CIRCUIT DIAGRAM

........................................

Page

1

2

2

3

4

5

6

8

8

9

10

11

12

12

13

19

22

26

27

30

34

34

35

36

36

38

39

39

39

40

41

41

41

47

55

56

60

60

61

Page 3

r----r

,

I

I

I -I

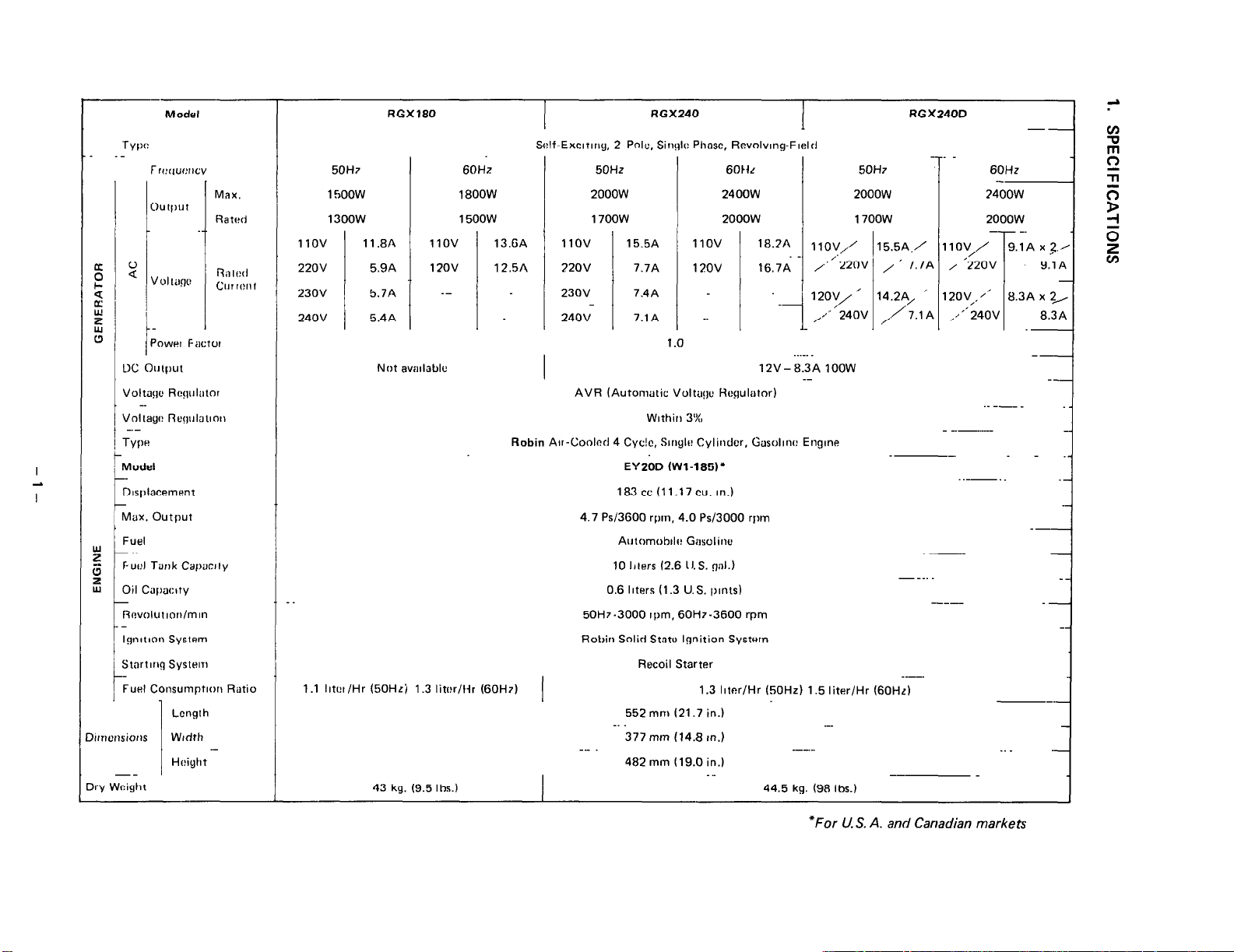

RGX180

RGXZ40

I

RGX240D

I -

Self-Excltlry, 2 Pole, Single Phosc, Revolving-Fwlrl

6OHi!

50H7

15oow

13oow

1lOV 11.8A

22ov

5.9A

50Hz

2ooow

1700w

1lOV

15.5A

?2OV 7.7A

230V 7.4A

24OV 7.lA

24OOW

2ooow

11OV ( 18.21-1

50H7

Max. Output

Fuel

F WI Tank Caf,ac~ ly

Oil Capacity

Rt?vnltl I lonlmln

Ignltlon SVSIWTl

Stwtlrlg SystRlrl

Fuel Consumption Ratio

1

Length

hrrrcnsiorts

Width

.-

Height

-_

)ry Weight

23OV

b.7A

24OV 5.4A

18OOW

1500w

1lOV

13&A

12ov

12.5A

.-

12ov

16.7A

_-

.

2ooow

1 1 0 y/

15.5A.i

/

/’ 22OV

* , 7.7A

12OV/ ’ 14.2$, *’

/“24OV ,,./ 7.1 A

1 .o

I

.._.

Not avir~lablu 12V-8.3A IOOW

_-

AVR (Automatic Voltagv Hcgulijtor)

WIthin 3%

_.

Robin Atr-Cooled 4 Cyc!c, S~rtgltr Cylinder, Gasol~rw Engine

EYZOD (Wl-186)’

183cc~11.17cu.1n.)

4.7 Ps/3600 rpm, 4.0 Ps/3000 rpm

Automohllt! Gwolinc

10 lrters 12.6 LJ.S. gal.)

0.6 Ilters (1.3 U.S. plntsl

50H7.3000 rpm, 60H7-3600 rpm

Hohin Solid State Ignition System

Recoil Starter

_.--.

1 .l Iltcl /Hr (5OHrj 1.3 litc!r/Hr (60H7)

1.3 IItw/Hr (5OH.z) 1.5 liter/Hr (60H~)

--.

552 mm (21.7 in.)

_.

.__

377 mm 114.8 wt.)

_._ .--...

. .

482 mm (19.0 in.)

.

--

43 kg. (9.5 Ihs.1

I

44.5 kg. (98 Ihs.)

*For U. S. A. and Canadian markets

Page 4

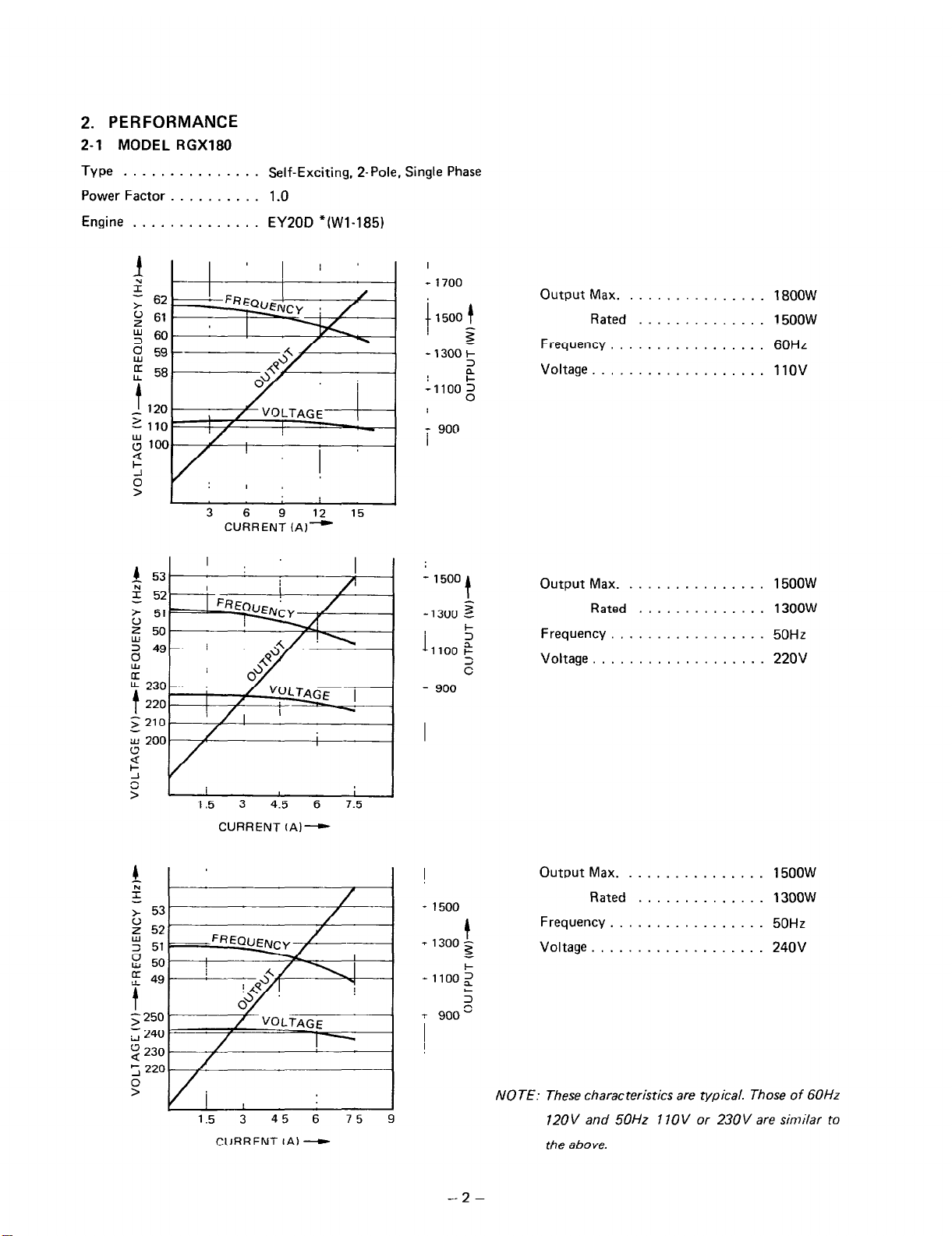

2. PERFORMANCE

2-1 MODEL RGX180

Type . _ . . . . . . . . . .

Power Factor . . . . . . . .

Engine . . . . . . . . . . .

. .

Self-Exciting. 2-Pole. Single Phase

. .

1.0

. .

EY20D “(Wl-185)

t 62

z” 61

“3 60

f 59

,” 58

1

’ 120

LO

I I

1

3 6

9

1;

15

CURRENT (Al-

l

53

I

I

1.5 3 4.5 6 7.5

CURRENT IA)-

1.5 3 45 6 75 9

CURRENT IA) -

I

- 1700

t 1

1500

5

-13005

E

-1100 2

r 900

I

- 1500

t

z

-1300 -

i f

1100 k

2

C

- 900

!

- 1500

t

- 1300 s

c

- 1100 2

3

T 900 c

1

Output Max.

...............

18OOW

Rated

..............

15OOW

Frequency. ................ 60Hz

Voltage.

..................

11OV

Output Max. ............... 15OOW

Rated .............. 13OOW

Frequency ................. 50Hz

Voltage. .................. 220V

Output Max. ............... 15OOW

Rated .............. 13OOW

Frequency. ................

50Hz

Voltage. .................. 240V

NOTE: These characteristics are typical. Those of 6OH.z

120V and 5OHz 71OV or 230V are similar to

the above.

-2-

Page 5

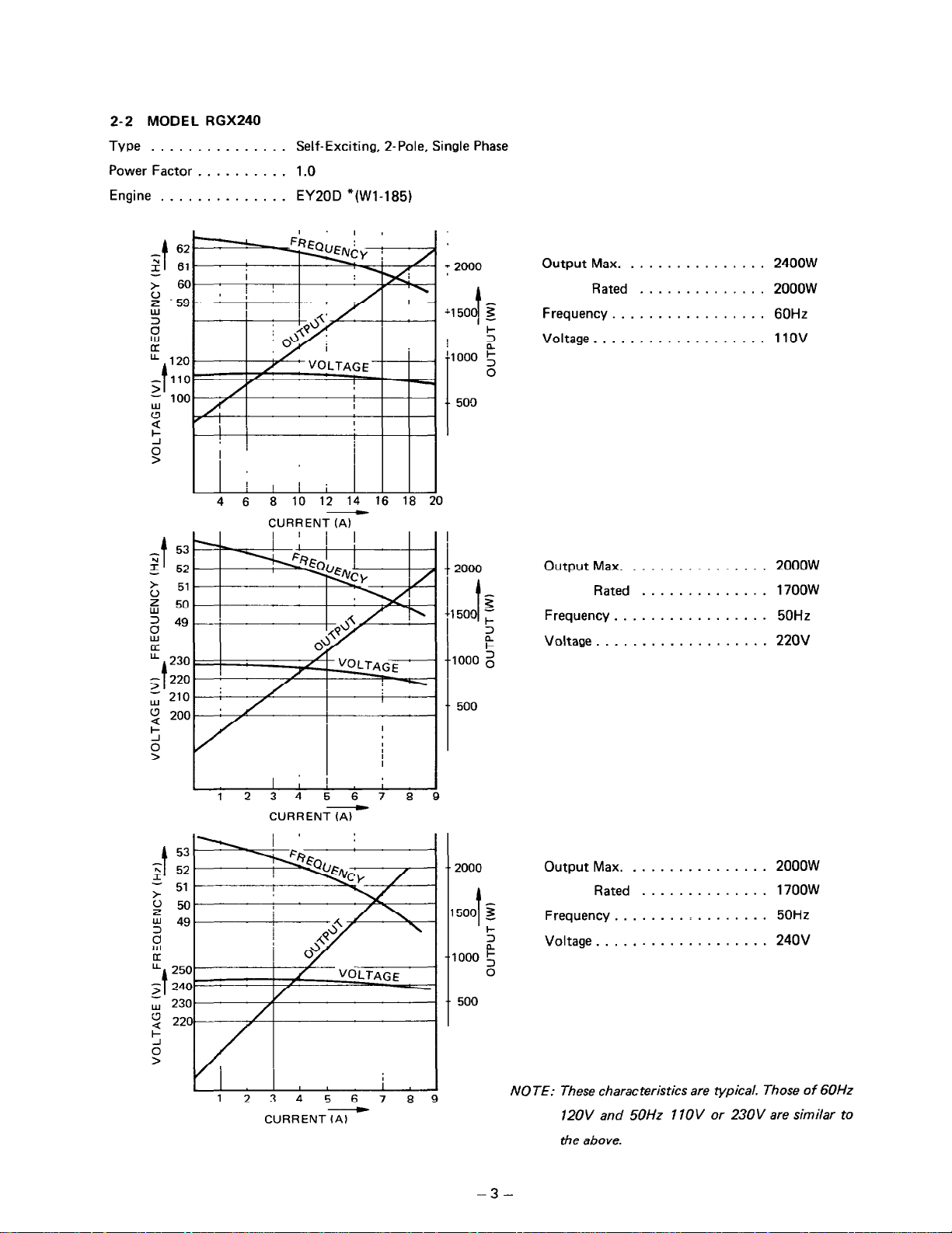

2-2 MODEL RGX240

Type

...............

Power Factor ..........

Engine ..............

Self-Exciting, 2-Pole, Single Phase

1.0

EY20D “(Wl-185)

I

4 6 ;I 10 12 14

16 18 20

-

CURRENT (A)

2

t

53

52

5 51

E 50

’

EI

49

u

u

- t

230

3

220

PJ 210

2 200

123456789

CURRENT7

250

/ VC%TAGE

240-

230

220

‘23456789

CURRENT(A)

- 2000

Output Max. . . . . . . . . . . . . . . . 2400W

Iit

Rated . . . . . . . . . . . . . . 2000W

‘150 ( 3

Frequency. . . . . . . . . . . . . . . . . 60Hz

I

2

Voltage . . . . . . . . . . . . . . . . . . . 11 OV

‘1000

I

k

:

500

I

c

2000

Output Max. . . . . . . . . . . . . . . . 2000W

Rated ..............

17OOW

Frequency.

................

50Hz

Voltage. ..................

220V

I

500

.. 2000

Output Max. ...............

2000W

f

Rated ..............

17OOW

-1 500 z

Frequency .................

50Hz

c

I

-3

Voltage . . . . . . . . . . . . . . . . . . .

1000

b

2

t

500

240V

NOTE: These characteristics are typical. Those of 6OHz

12OV and 5OHz 1 IOV or 230V are similar to

the above.

-3-

Page 6

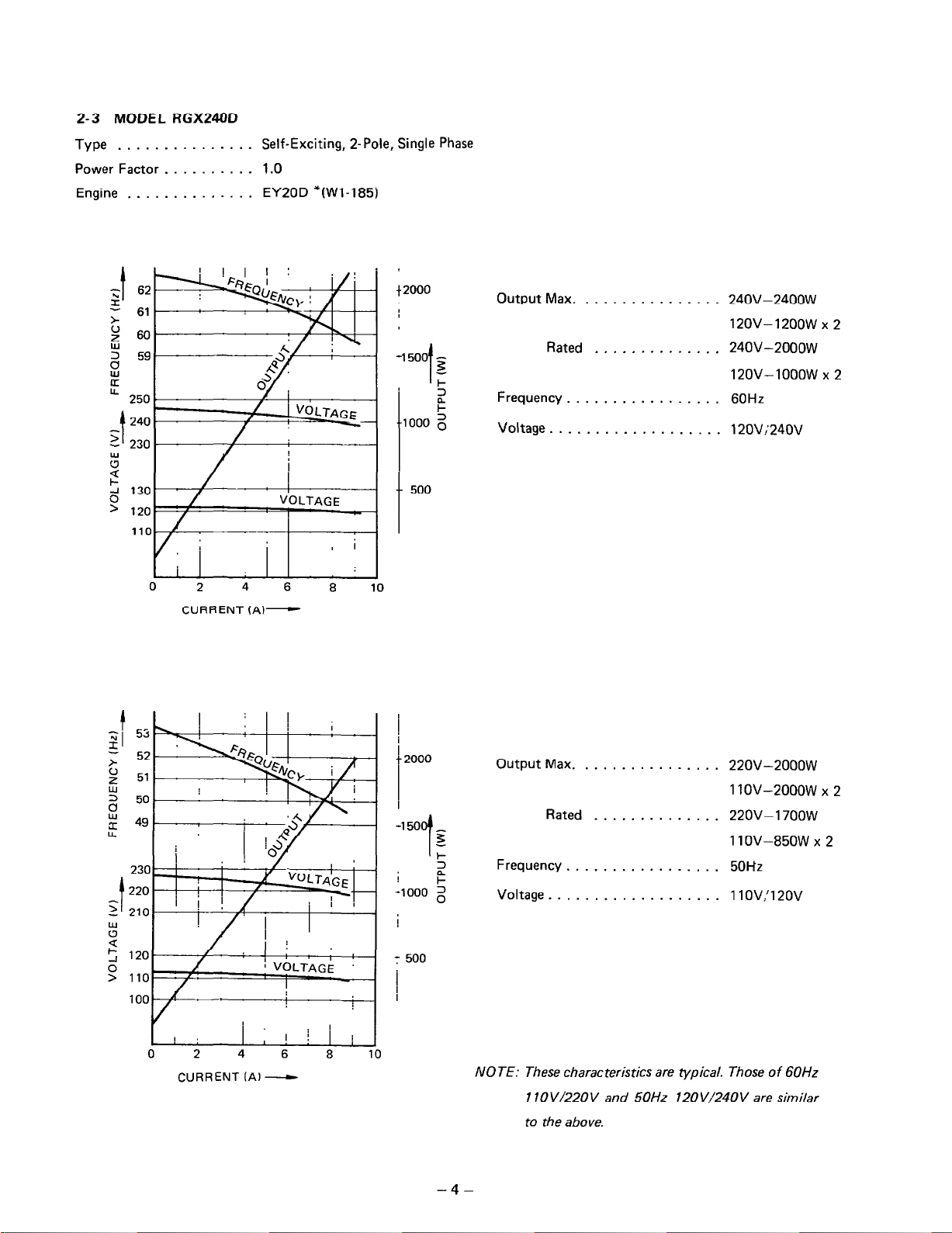

2-3 MODEL RGX240D

Type ...............

Self-Exciting, 2-Pole, Single Phase

Power Factor ..........

1 .O

Engine ..............

EY20D ‘(Wl-185)

61

60

59

250

240

230

I i I

1

0 2

4 6 8 10

CURRENT (A)-

0 2 4

6 8 10

CURRENT (Al

-

1500 -

, I

3

5

b

.-1000

2

t

500

Output Max. . . .

Rated . .

. ~ . . . . . .

Frequency. . . . .

Voltage . . . . . . .

........

........

. .

24OV-2400W

12ov- 1200w x 2

, .

24OV-2000W

12ov- 1 ooow x 2

. . 60Hz

. .

12OV;24OV

Output Max. . . . . . . . . . . . . . . . 22OV-2000W

11ov-2oooW x 2

Rated _ . . . . . . . . . . . . . 22OV-1700W

11 OV-850W x 2

Frequency . . . . . . . . . . . . . . . . . 50Hz

Voltage . . . . . . . . . . . . . . . . . llOV:ll2OV

NOTE: These characteristics are typical. Those of 6OHz

1 lOV/22OV and 5OHz 120!/1/24OV are similar

to the above.

-4-

Page 7

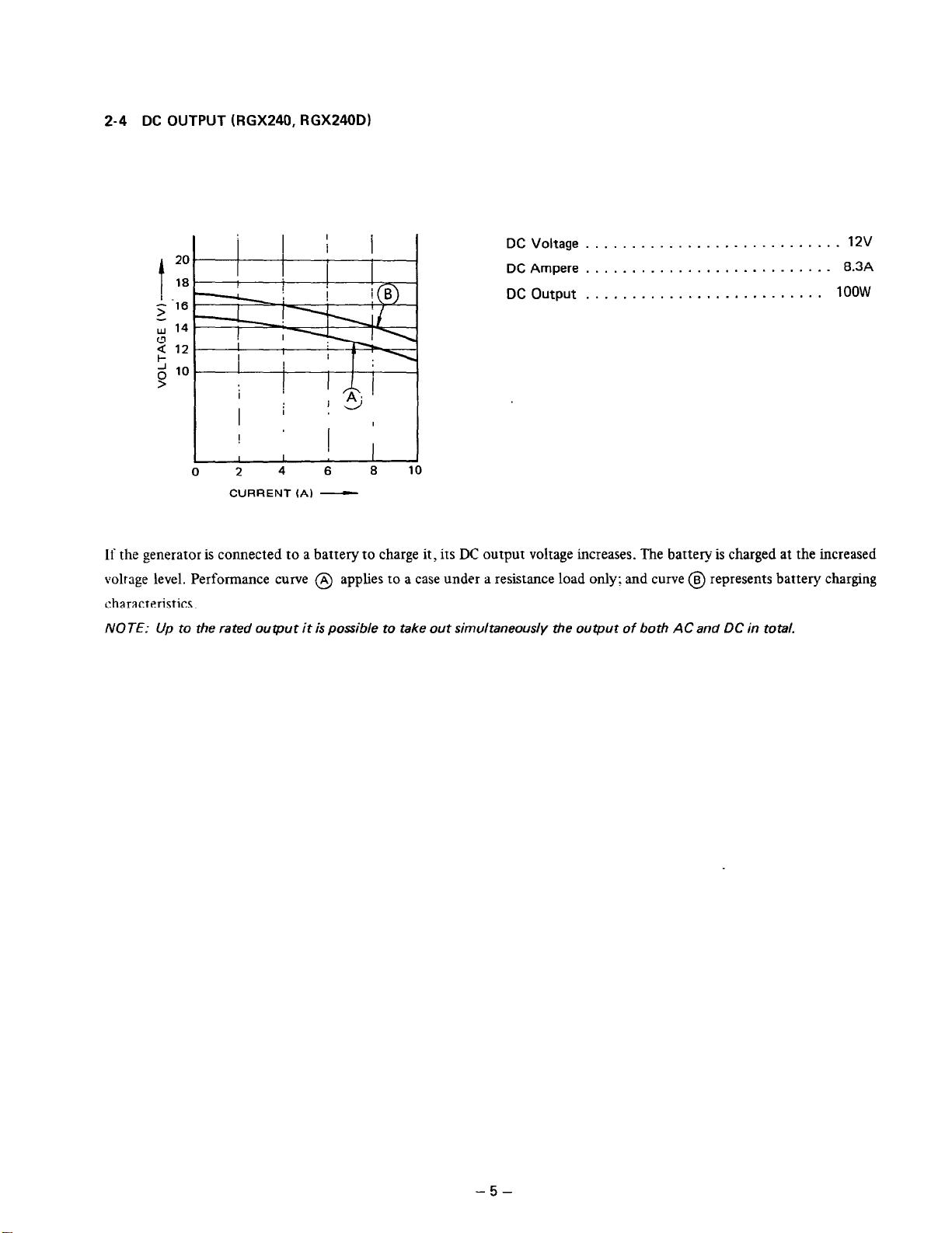

2-4 DC OUTPUT (RGX240, RGX24OD)

DC Voltage

............................ 12V

DC Ampere

........................... 8.3A

DC Output

..........................

1OOW

CURRENT (A) -

If the generator is connected to a battery to charge it, its DC output voltage increases. The battery is charged at the increased

voltage level. Performance curve @ applies to a case under a resistance load only; and curve @ represents battery charging

characteristics.

NOTE: Up to the rated output it is possible to take out simultaneously the output of both AC and DC in total.

-5-

Page 8

3. FEATURES

1. Lightweight, Compact

The Robin engine and revolving field generator designs provide added output poxer per weight and economical operation.

7. Centralized Control

The witches. meters. and receptacles

are

located together on a large-sized control box. and all operating controls are

located on top of the engine for eas)- generator operation.

3. Large IO-Liter Gas Tank

*IO-liter (2.6 LT.S. gal.) fuel tank is provided for nine hours of operation for Model RGSl8O and eight hours ior 1lodel

RGX240 (at the 5OHz rated output power,).

*The tank has a

fuel

gauge which shows the remaining amount of fuel m the tank.

4. Solid State Ignition System

*Unlike the breaker point svstem. the solid state rgnition s>-stem has no contact points so that maintenance

dur

to

point wear is unnecessary- and constant output power can be maintained ior long periods.

*Increased spark eners makes starting cask-.

5.

Extra-Quiet Operation

*X11 models are equipped with a large-sized. low-noise muifler.

*All models have a cl-clone type air cleaner of a low-noise, dustproof type.

6. Small Voltage Fluctuations by XVR (Automatic Voltage Regulator)

The automatic voltage regulator wtomatisally adjusts

th2

exciting current to hold voltage regulation down to

less

than 35. This helps prolong product life without dama-@ng the electric devices.

7.

DC Output for Battery Charging (RGX240. RGX240D)

The generaror can generate a DC output ( 13.. lOO\V) whtle generating an XC output so that batteries <an be charged

during XC operation. In this case, make sure that the total XC and DC output does not exceed the rated output.

8. Dual Voltages are Available on RGX240D.

* -4 du-al voltage type lvhich supplies AC voltage is available.

9. Output Voltage Waveform Close to Sine Wave

The output voltage a-aveform is close to a sine wave and is free of surges so that the load w-ill not be damaged

10. Resistant to Inductive Load

Exiting poner is obtained tram the sub coil which is wound apart irom the main

coil. This means less output roltage

fluctuations against load variation. and thus a stead!- level ofpawer. This feature is efiective partrcularly for induction

motors. for example. kvhich are subject to sharp current variation.

11. 1005 Copper Windings

The windings are made onI>- of copper having lon internal resistance. This feature also helps improve generator effimien+ and prolong generator

lif2.

-6-

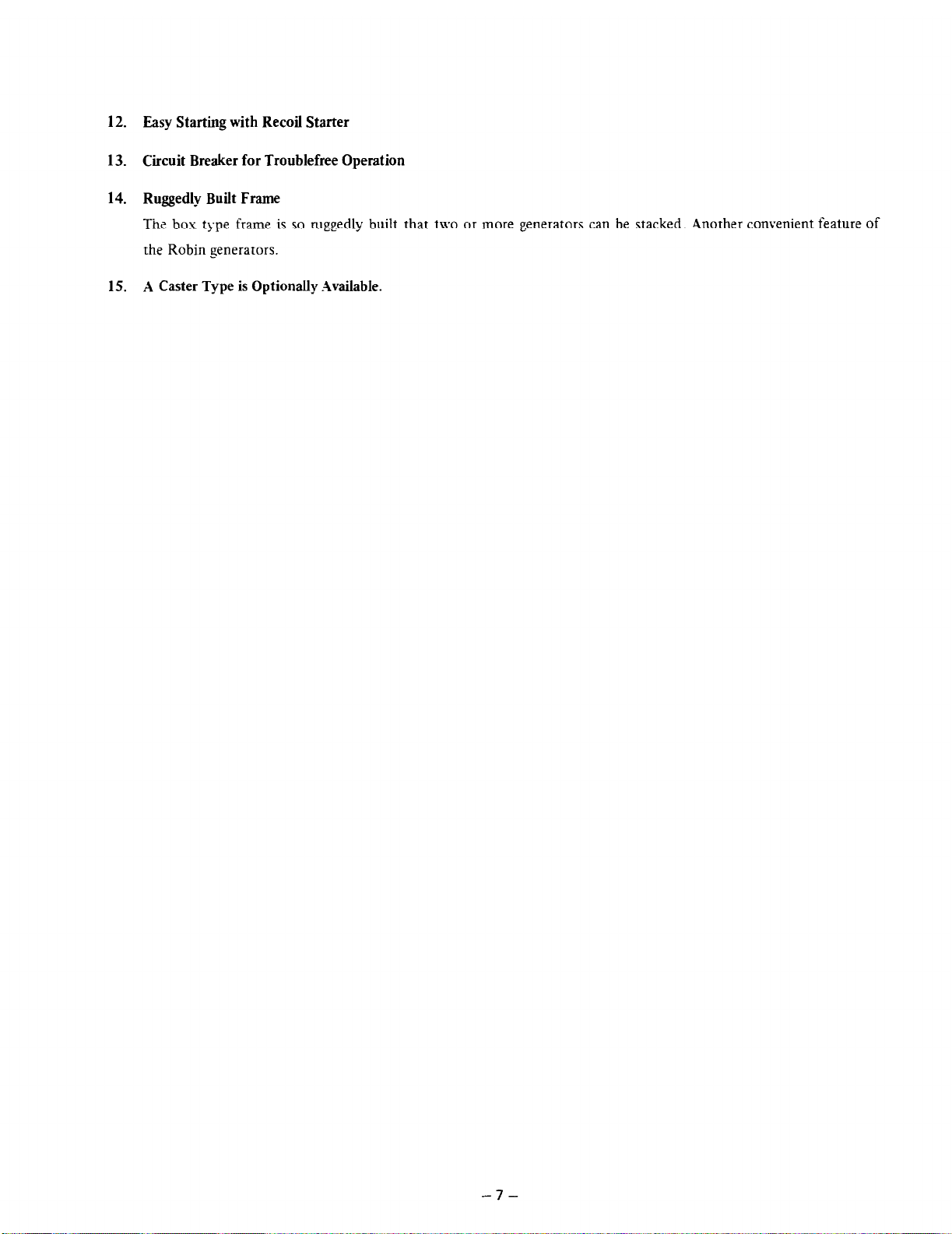

Page 9

12. Easy Starting with Recoil Starter

13. Circuit Breaker for Troublefree Operation

14. Ruggedly Built Frame

The box type frame is so ruggedly built that two or more generators can be stacked. Another convenient feature of

the Robin generators.

15. A Caster Type is Optionally Available.

-7-

Page 10

SPEED CONTROL LEVEH

CONTI301. BOX

\

CHOKE KNOB

STOP BUTTON

/

i

I

I

GENEHATOR

FlJEl S~~-~AINEH

AlI{ CLEANLIt

MUFFLEt

FUEL GAUGE imd TANK CAP

FUEL TANK

I

SPARK PLUG

1

,

OIL GAUGE

, , .I,’

/ \

HUBBEH MOUNT I-iECOlL STARTEt7 tiANDLE

/

FlJEI COCK

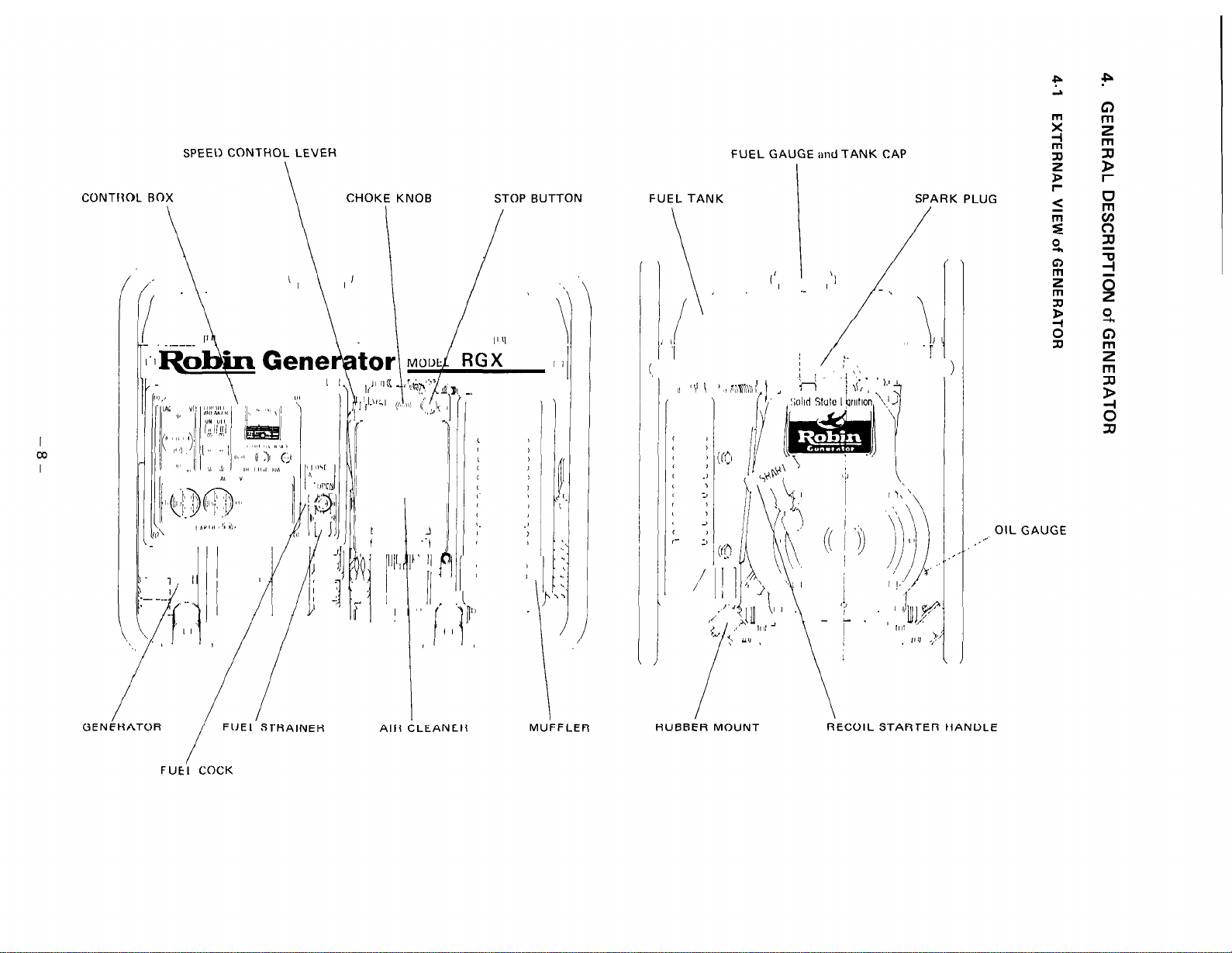

Page 11

4-2 RGX180 PANEL 4-2-l 1 lOV, 120V

CIRCUIT BREAKER

AC RECEPTACLE 1

I

‘dc vi

i “.

! ‘k.. I

/../- NEON LAMP

/

FUEL COCK

EARTH (GROUNDI TERMIN/AL

FiJEL STRAINER

4-2-2 220V. 23OV, 240V

CIRCUIT BREAKER

\

AC RECEPTACLE 1

EARTH fGROIJNDl TERMINAL

FUEL STRAINER

/ NEON LAMP

/

FUEL COCK

_- 9 -

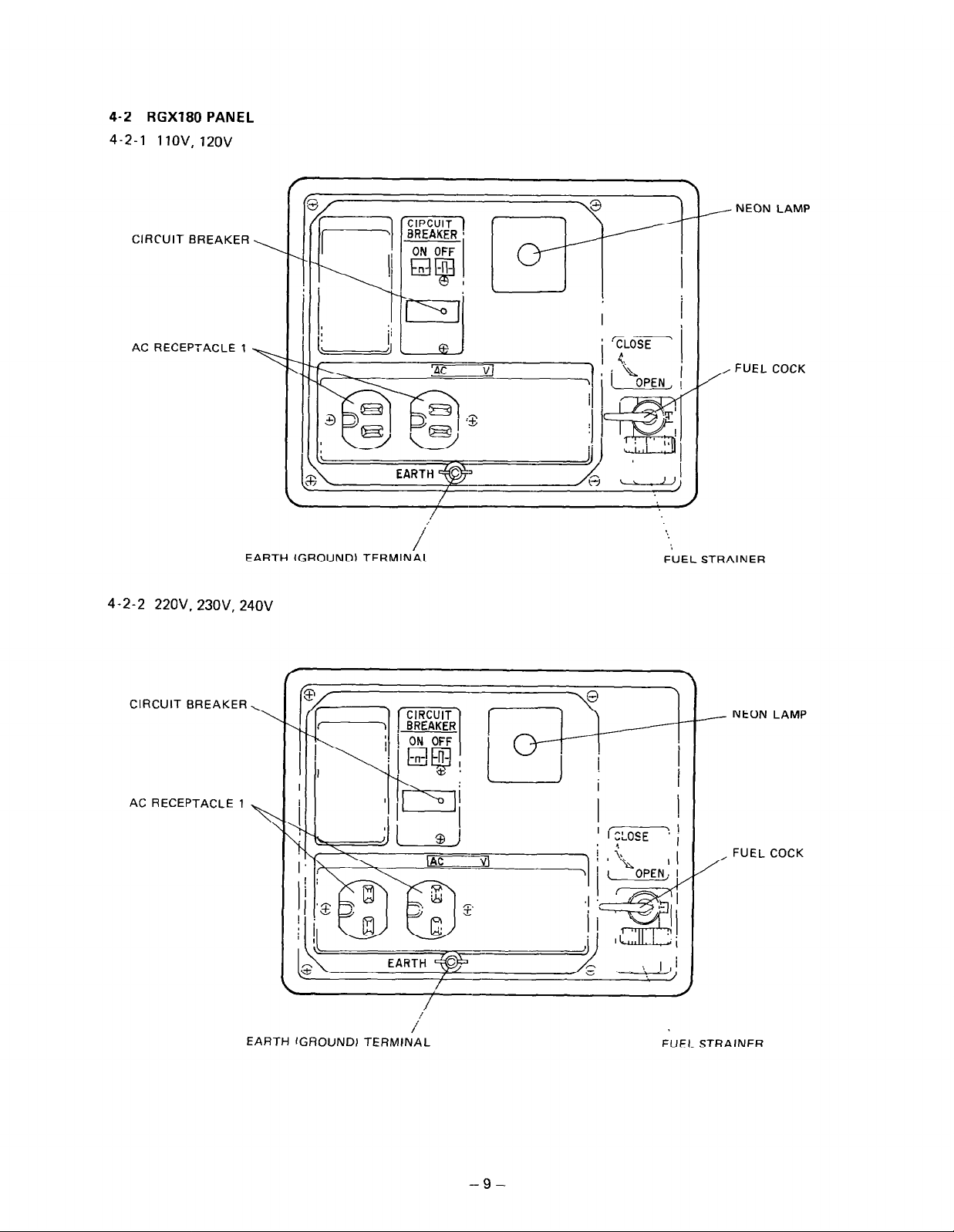

Page 12

4-3 RGX240 PANEL

4-3-l 1 lOV, 120v

CIRCUIT BREAKER ,,

AC RECEPTACLE 1 -

.LOPEN, 1

, VOLTMETER

, DC FUSE 10A

DC OUTPUT

- TERMINAL

FUEL COCK

i

;/

/

/’

;

EARTH !GROUNDI TERMINAL

FUEL STRAINER

4-3-2 22OV. 23OV, 240V

CIRCUIT BREAKER

AC RECEPTACLE 1 \

/

,,‘.

,’

, VOLTMETER

/ DC FUSE 10A

- DC OUTPUT

TERMINAL

, FUEL COCK

EARTH (GROUND1 TERMINA;

FUEL STRAINER

-10-

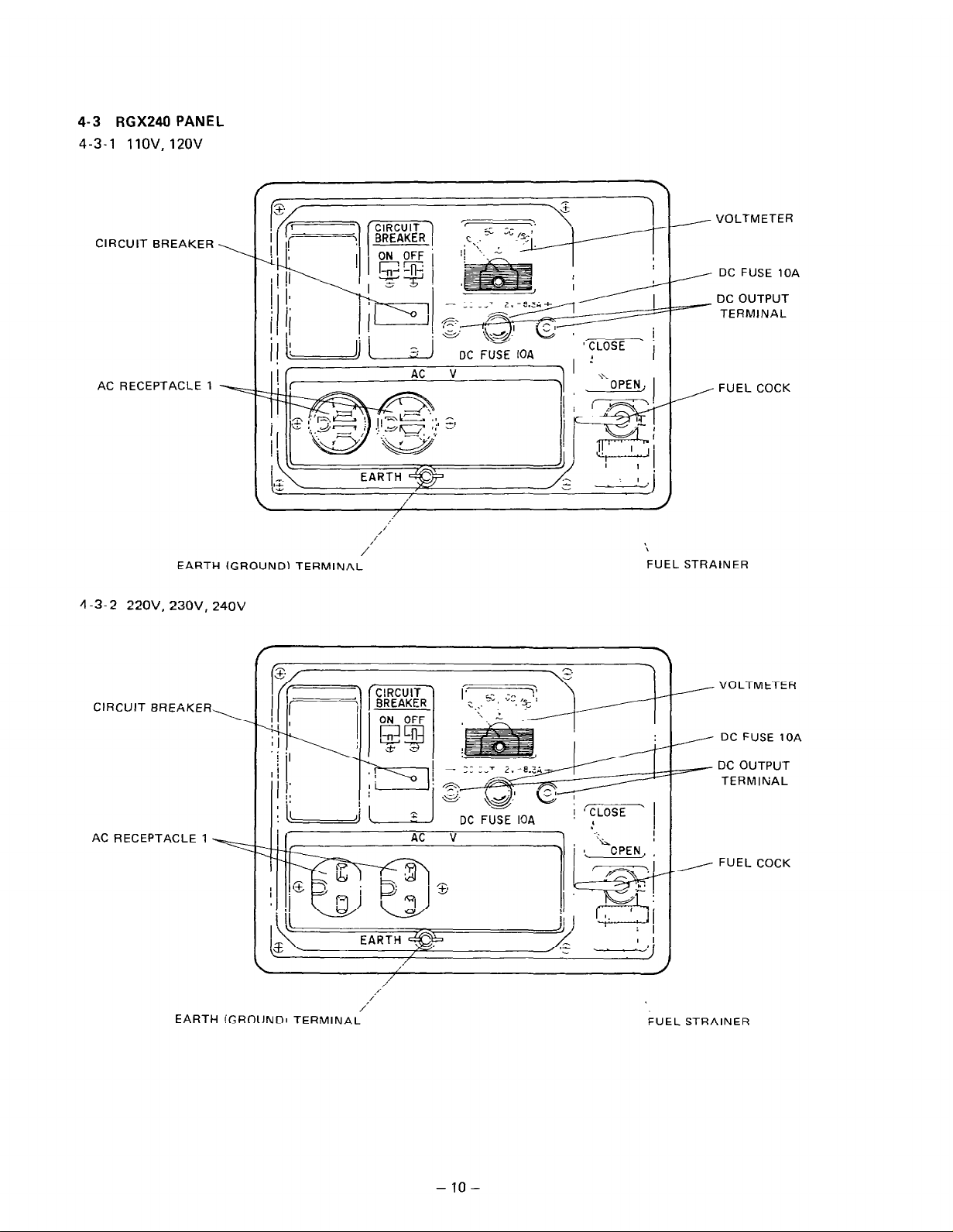

Page 13

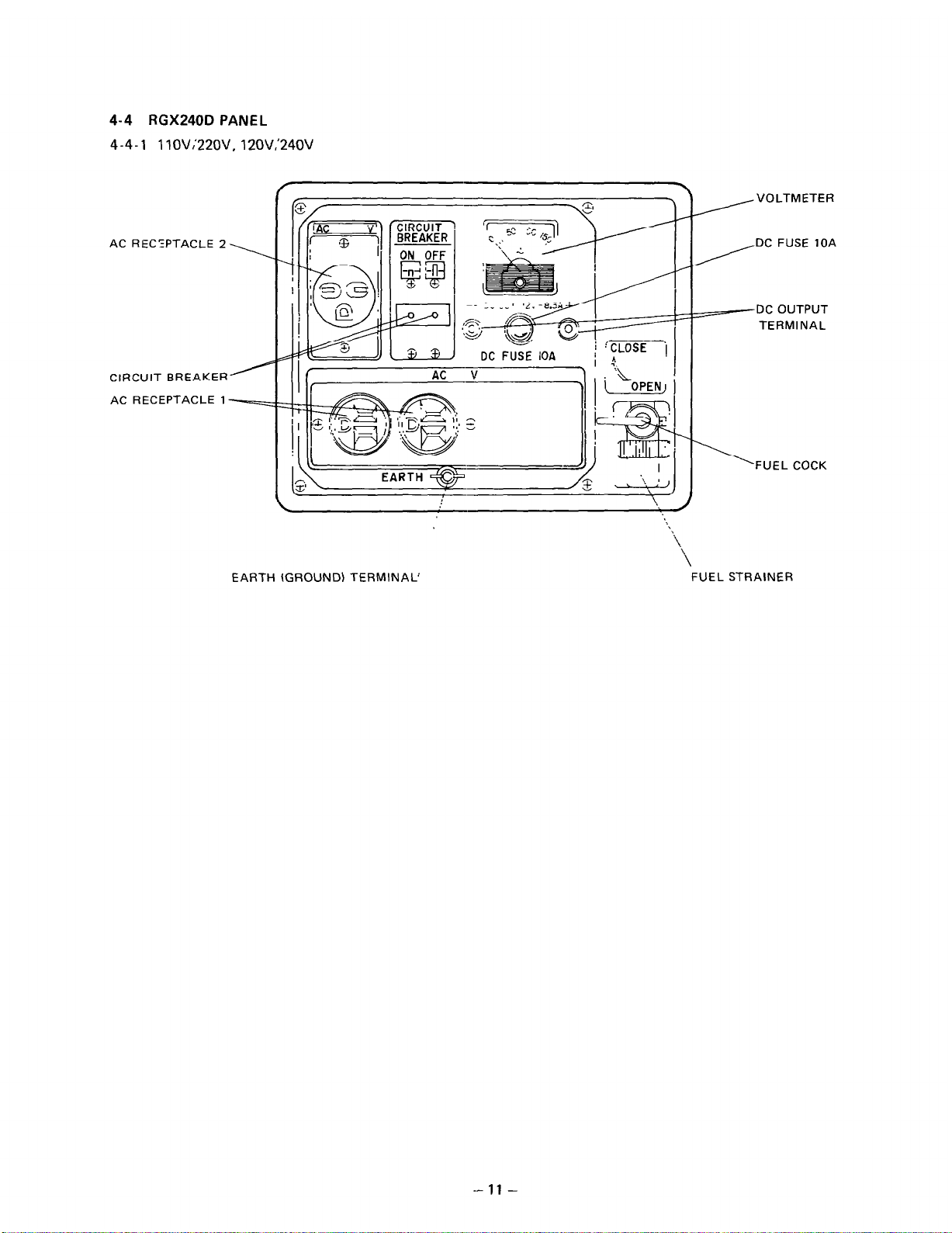

4-4 RGX240D PANEL

4-4-l llOV,‘22OV, 12OV,‘24OV

AC REC’IPTACLE 2

CIRCUIT BREAKER/

AC RECEPTACLE l-

-!

,

CIRCUIT

r-

BREAKER

I ON OFF

DC

FUSE iOA

EARTH IGROUND) TERMINAL’

VOLTMETER

DC FUSE 10A

-DC OUTPUT

TERMINAL

FUEL COCK

\

FUEL STRAINER

-11-

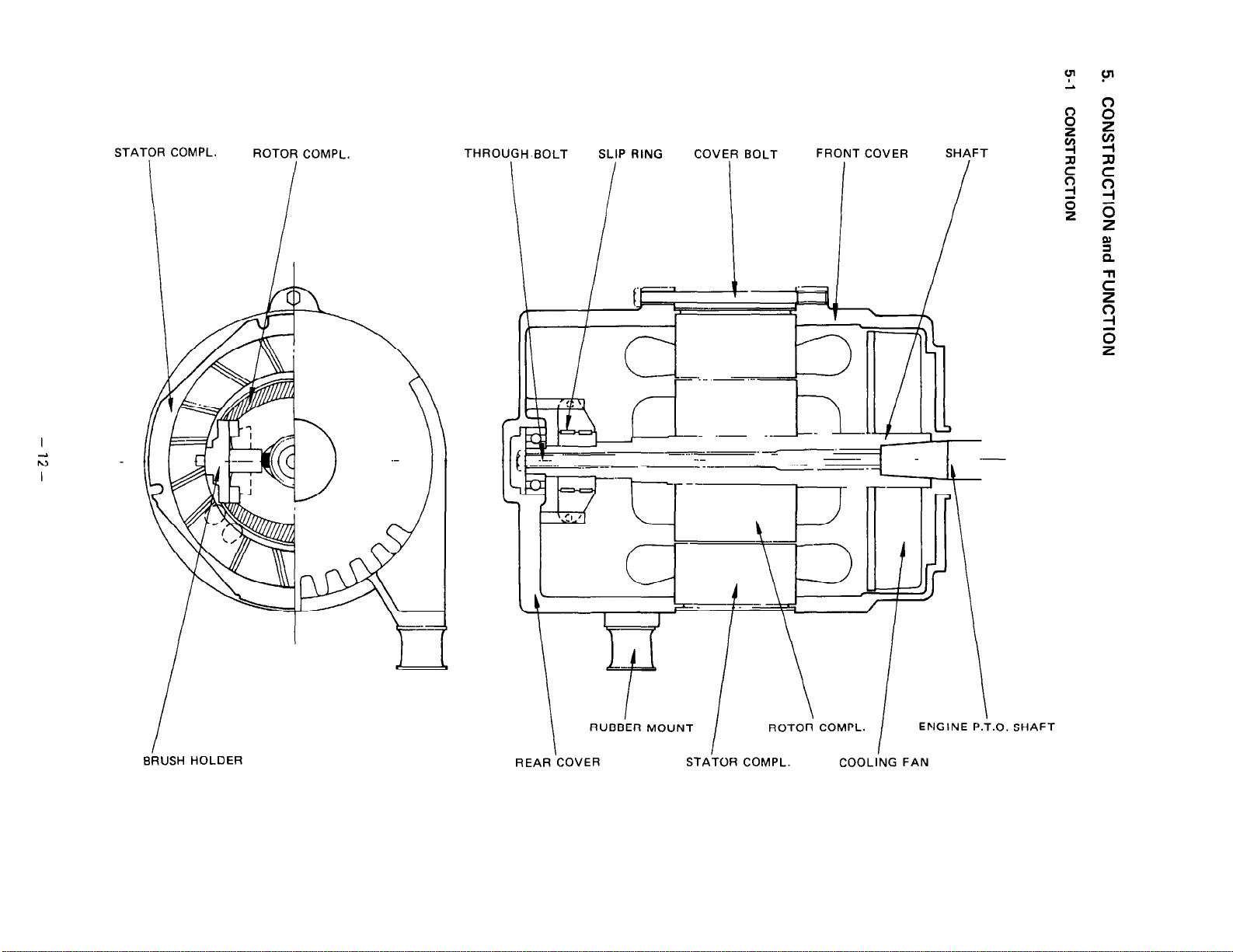

Page 14

STATOR COMPL.

ROTOR COMPL.

I

;s

I

BRUSH HOLDER

THROUGH.BOLT

SLIP RING COVER BOLT

FRONT COVER

SHAFT

-_ .- __

.--

RUBB’ER MOUNT RDTOd COMPL.

ENGINE P.i.0.

SHAFT

REAR COVER

STATOR COMPL.

COOLING FAN

Page 15

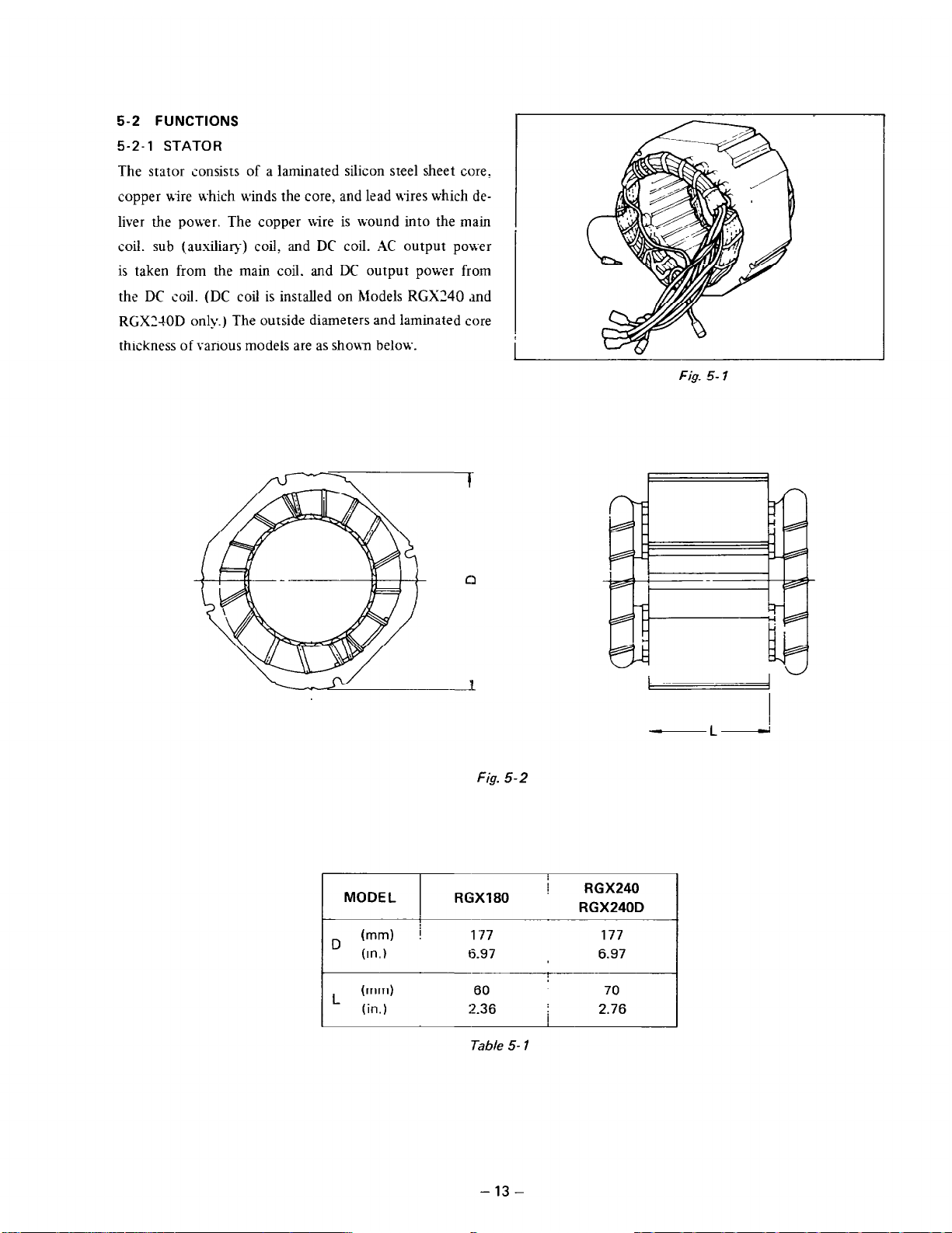

5-2 FUNCTIONS 5-2-l STATOR

The stator consists of a laminated silicon steel sheet core,

copper wire which winds the core, and lead wires which de-

liver the power. The copper wire is wound into the main

coil. sub (.ausiliary) coil, and DC coil. XC output power

is taken from the main coil. and DC output power from

the DC coil. (DC coil is installed on Models RGX240 .md

RGXIOD only.) The outside diameters and laminated core

thickness of various models are as show below.

Fig. 5 I

Fig. 5-2

MODEL

RGXISO

RGX240

RGX240D

I

60

70

2.36

2.76

I

Table 5 1

- 13 -

Page 16

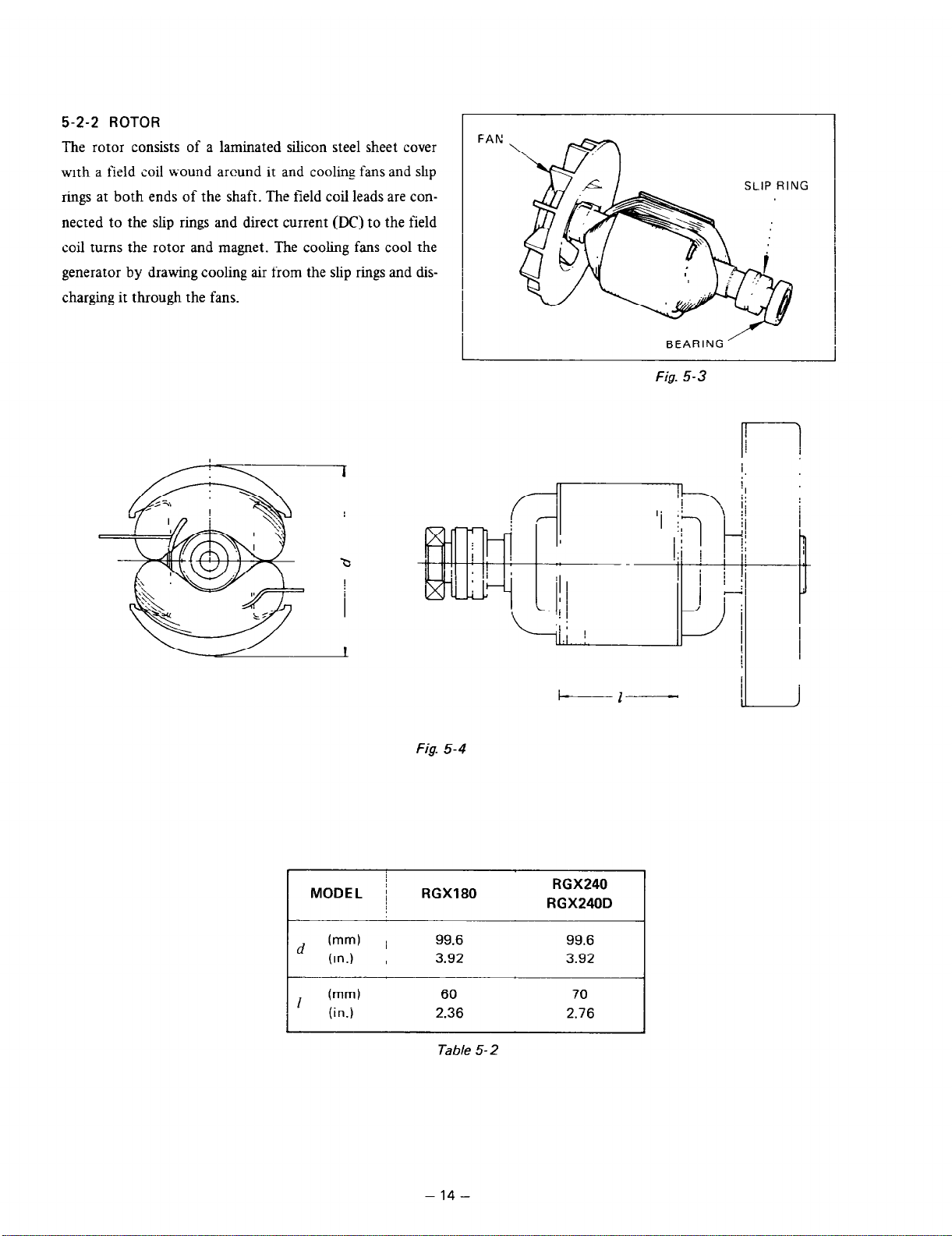

5-2-2 ROTOR

The rotor consists of a laminated silicon steel sheet cover

with a iield coil wound arcund it and cooling fans and slip

rings at both ends of the shaft. The field coil leads are connected to the slip rings and direct current (DC) to the field

coil turns the rotor and magnet. The cooling fans cool the

generator by drawing cooling air from the slip rings and dis-

charging it through the fans.

FAN

SLIP RING

BEARING ’

Fig. 5-3

I’

c----l----

II-

Fig. 5-4

MODEL / RGX180

RGX240

RGX240D

d

(mm) i 99.6 99.6

(In.) , 3.92 3.92

I (mm)

60 70

(in.i

2.36 2.76

Table 5- 2

-14-

Page 17

An exciting current is supplied from the AVR to the rotor.

The brushes are made of carbon, and the brush-holders of

plastic. It is necessary to keep the contact pressure between

the brushes and slip rings within specitic limits. Thus. care

must be taken about brush length.

(See 9-3 BRUSHES.)

Fig. 5-5

5-2-3 BRUSHES

5-2-4 AVR (AUTOMATIC VOLTAGE REGULATOR)

The automatic voltage regulator employs an electronic cir-

cuit to automatically regulate voltage.

L

Fig. 5-6

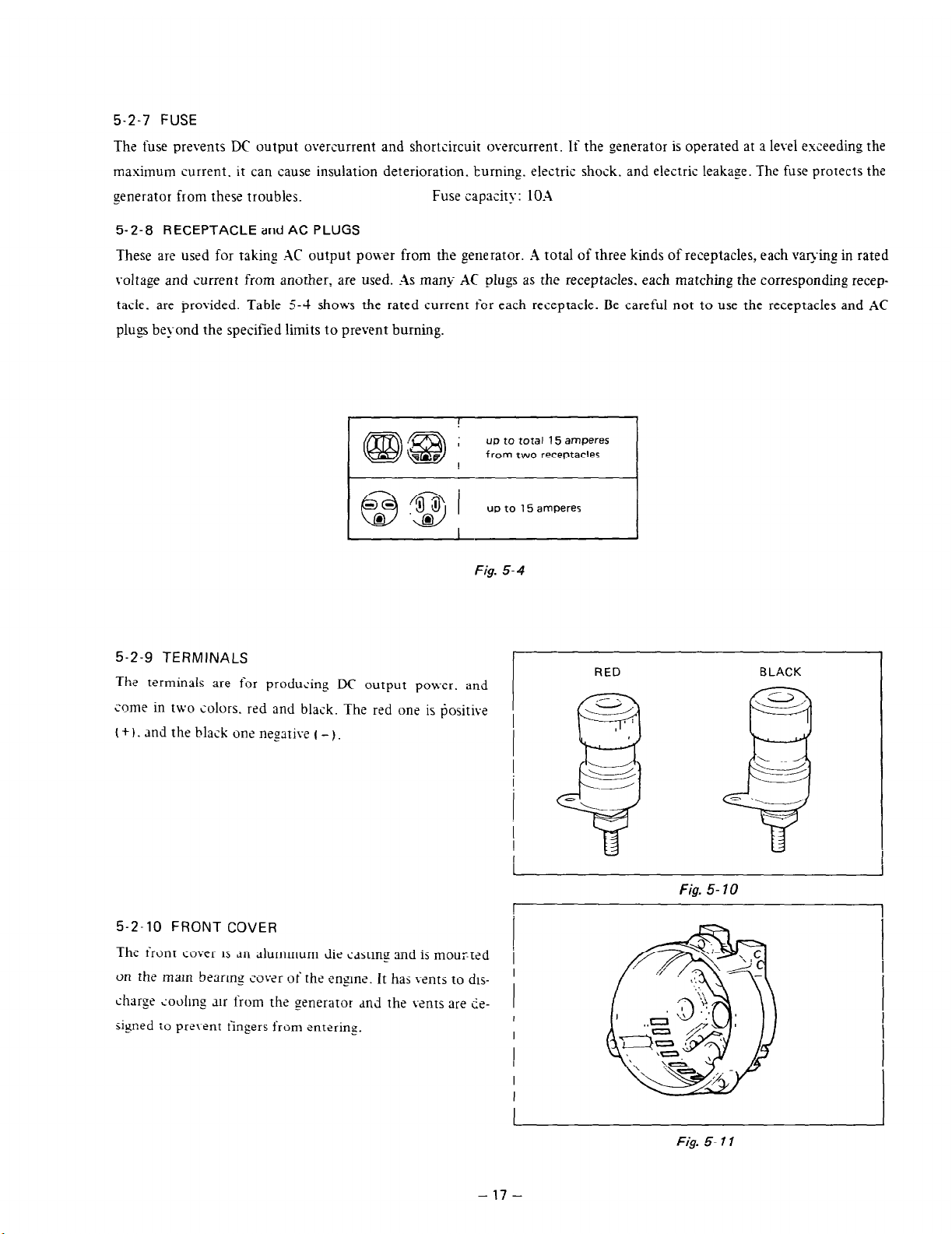

5-2-5 VOLTMETER and PILOT LAMP

Models RGX340 and RGX21OD hav-e a voltmeter that

__

comes in t\vo t>-pes: 15OV maximum tppe and 3OOV maxi-

mum type. The tl-pe of voltmeter indicates generator output voltages. The generators with a generated voltage of

11OV or 13OV and dual voltage type use the 15OV msimum

’

t!-pe voltmeter: and those of 22OV. 23OV and 24OV specifi-

~-::,i;--

cations use the 3OOV maximum type voltmeter.

1

300V MAX.

15OV MAX.

Model RGXISO employs a pilot lamp. The lamp hghts

:

i22OV. 23OV. 24OV)

(llOV, 12OV)

when a voltage is generated. The pilot lamp also comes in

Fig. 5-7 (1)

two types: 12% t>-pe and 3OV type. These t>-pes are

selected to suit generator output voltage.

1

J

Fig. 5- 7 (11)

- 15-

Page 18

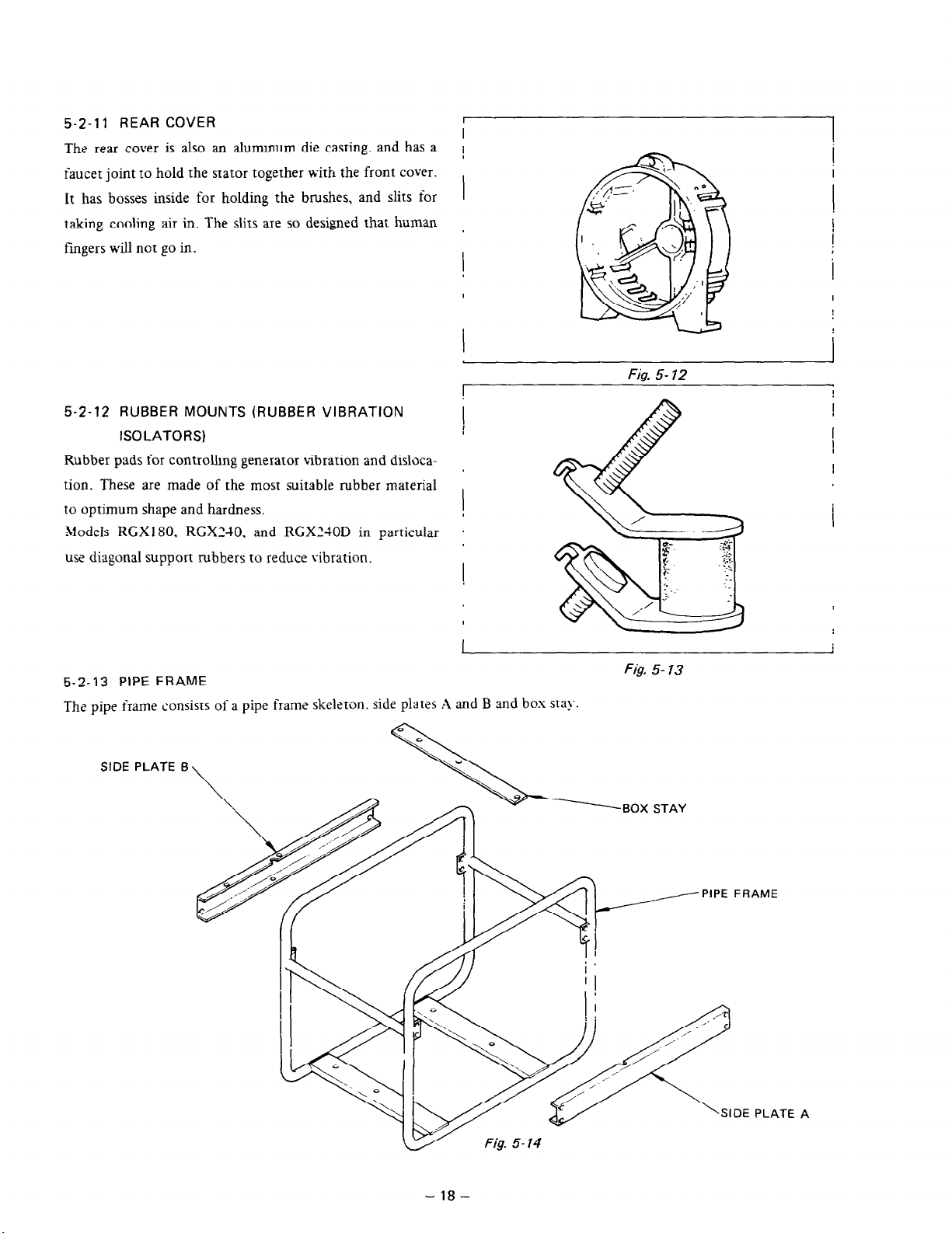

5-2-6 CIRCUIT BREAKERS

Models RGX180 and RGX240 have a pushbutton circuit

breaker and Model RGX240D two pushbutton circuit 1

breakers. Nomrallp, the pushbutton circuit breaker is closed

with the button pushed into the panel to keep the circuit :

live. If an overcurrent runs. the button comes out to break

the circuit. The circuit can be closed again by simply pushing the button in. The circuit breaker is a thermo-sensitive i

type so. if the temperature inside the circuit breaker is still

high immediately after the circuit has opened, the button

may not be able to be pushed in to the ON position. or ma>-

1

come back out again at once. In that case, wait a while until

the inside temperature falls. and then push the button in.

Fig. 5-8

Circuit breaker capacities are as follows:

1

Model Specification

Circuit Breaker ’ Quantity

Capacity per Unit

RGX180 11ov.

120v

15A ’

1

RGX180 ,

22OV, 23OV. 240V 8A

1

I

RGX240 1 lOV, 120v

20A

1

RGX240 220V. 230V. 240V

10A

1

RGX240D 11 Ol22OV. 12Ol24OV

10A

2

Table 5-3

- 16 -

Page 19

5-2-7 FUSE

The fuse prevents DC output overcurrent and short<ircuir overcurrent. Ii the generator is operated at a level exceeding the

maximum current. it can cause insulation deterioration. ‘curninp. electric shock. and electric leakage. The fuse protects the

generator from these troubles. Fuse capxiry: 10.1

5-2-8 RECEPTACLE and AC PLUGS

These are

used

for raking XC output power from the generator. A total of rhree kinds of receptacles, each var)-ing in rated

voltage and current from another, are used. As man; XC plugs as the receptacles. each matching the corresponding recep-

tacle. are provided. Table 5-4 shows the rated current for each receptacle. Be careful not to use the receptacles and XC

plugs beyond the specified limits to prevent burning.

Fig. 5-4

5-2-9 TERMINALS

The terminals are for producing DC output power. and

come in two colors. red and black. The red one is $ositive

I + 1. and the black one negative I - )

5-2-10 FRONT COVER

Ths front cover 1s dn alummum die CastmE and is mow-ted

on the mam besrmg cover

ai

the ensns. It has \~ents to dlscharge ;oolmg dir from the generator anil the vents are Lesigned to pwent fingers from entering.

I

RED BLACK

1

Fig. 5- 10

1

I

I

Fig. 5- I 1

- 17 -

Page 20

5-2-11 REAR COVER

The rear cover is also an alumrnum die casting. and has a

faucet joint to hold the stator together w-ith the front cover.

It has bosses inside for holding the brushes, and slits for

taking cooling air in. The slits are so designed that htrman

fmgers will not go in.

5-2-12 RUBBER MOUNTS (RUBBER VIBRATION

ISOLATORS)

Rubber pads for controlling generator vibration and dislocation. These are made of the most suitable rubber material

to optimum shape and hardness.

Models RGX180. RGX240. and RGXI4OD in particular

use diagonal support rubbers to reduce vibration.

5-2-13 PIPE FRAME

Fig. 5- 12

I

1

I

Fig. 5- 73

The

pipe frame consists of a pipe frame skeleton. side plates X and B and box stak-.

SIDE PLATE B

Page 21

5-3 DESCRIPTION of GENERATOR OPERATION

5-3-l REVOLVING ARMATURE TYPE and REVOLVING FIELD TYPE

1

AC VOLTMETER

CONTROL BOX

\

I

NO-FUSE BREAKER ‘....

NEON LAMP

\ \

/

SOCKET PLUG

FRONT COVER

YOKE

; ENGINE FLANGE

I

.<‘G ---+---

POLE ASSY

-FIELD COIL

SHAFT

/ J!-kFT&f~- ,

‘zzz,

I I

/

’ 1 i

;)’

t’ ENGlNiE P.T.C

ARMATURE ASSY

FIELD COIL ’

ASSY ;

SHAFT

/

RUBBER VIBRATION ISOLATOR

COOLING FAN

Fig. 5- 15

ROTOR COMPL. ~

\

SLIP RING

:

COVER BOLT

,, FRONT COVER

ii

I I

1.

BRUSH HOLDER

n

/

COOLING FAN

/’

/

ROTO; COMPL.

REAR COVER /

RUBBER b&NT

STA’TOR COMPL

ENGINE P.T.6.

SHAFT

Fig. 5- 16

- 19-

Page 22

The RG Series 1s the revolving armature type. and the RGX Series is the revolving field tk-pe. The differences between these

types and then features are described below. The constructron of the revolving armature t>-pe is shoxn in Fig. 5 -15. and that

of the revolvmg field type in Fig. 5 -16.

The basic operating principle of the generator is this. As a conductor moves in a magnetic flus (between poles S and S of a

magnet). a voltage is generated in the conductor and can be taken out as electric power. Generally. an electromagnet is used

for generators. The ele.ztromagnet consists of poles and field coils wound around them, and the poles become magnets as a

direct current runs through the field coils. The revolvtig armature type has static poles and a revolving armature which consists ot‘ a conductor for taking electric power out. The revolution of the armature generates a voltage.

It was earlier explained that a conductor moves in a magnetic flux. Actually, howev-er. a relative speed between the two is

sufficient for generating a voltage. That is. a voltage can also be generated bl- rotating the magnet while keeping the conductor still.

The revolving field type falls in the latter categor!-: The pole serving as an electromagnet rotates. and armature ivhich consists

of

a conductor remains still.

The features of the revolving field type are as follows:

a)

b)

Cl

Only two slip rings

AS generator applications diversified! it became necessary for generators to meet increasingly varied conditions involving XC output. DC output, dual voltage, three-phase, and usefulness with induction motors. Accordingly. AC windings.

DC windings. auxiliary windings, etc. became necessary for generators. Because the revolving armature type takes elecrric power from the revolving part. it requrres as many slip rings as the number of winding output termmals. and this

increases the generator dimensions. The revolving field type is small in size because it requires only two slip rings <or

feeding a current to operate the electromagnet.

Easy maintenance

As man)- brushes as the number of slip rings are necessary. The revolving field type is easier to maintain than the revolving armature type because it has fewer slip rings and brushes than the latter.

Lightweight

The revolving armature type is heavT because it requires yokes to fix the poles and serve as tlus passage. The revolving

field type is light in %-eight because the stator and rotor can be made by laminating steel sheets of the same material.

- 20 -

Page 23

5-3-2 PRIMARY EXCITING ACTION

The RGX Series employs an exciting coil in the engine magneto for raising the primary voltage. This action is explained. The RG Series generates a voltag2 when the generator IS

started again because of the residual magnetism remaintng

FC

in the yokes and poles. If a generator of this type is disas-

r-----1

sembled and stored for a long period of time. the residual

I

I

magnetism. may dissipate so that the generator may not

generate a voltage when it is restarted. The RGX Series

rc& ; 1 $EC;

has an exciting coil for primary exciting action to eliminate

I

I

L-----J

such a phenomenon.

The primary exciting action of the new type is explained

below.

ENGINE MAGNETO

Fig. 5- 17(A)

When the generator is started. th2 permanent magnet on the

2ngine rotates to generat a voltage in th2 ssciting coil. This

voltage is regulated by a diode in the .AVR to f22d a current

to the generator field coil (FC). (See Fig. 5-l

7(A).)

The rotor is turnsd into an electromagnet by that sun-ent

and rotates so that voltages are generated in ths stator coils

(main coil, sub coil: and DC coil). The voltage generated in

the sub coils is operated by th2 .AVR to f22d a current to in-

crease the field co11 current (See Fig. 5-17(B).) As a result.

the rotor magnetism increases. This operation is repeated to

generate the rated voltage at 50~~ or 6OHz in the main coil

and

DC

coil.

5-3-3 VOLTAGE REGULATING MECHANISM

Connect a load to the AC output terminal and increase cur-

rent. Output voltage varies as shown in Fig. 5-17(C) depend-

ing on whether an automatic voltage regulator is

used

or

not. The operation of the AVR is explained below.

When an AC output is taken, the engine is loaded and its

rpm falls. Also the AC voltage falls due to the voltage arop

caused

by the internal resistance of the coils.

The

XVR

detects this voltage drop and its built-in SCR automatically

increases the current flows to the field coil. As a result, the

rotor magnetism increases. th2 voltag2 lowered b>- th2 .oad

current is raised. and the output voltage is kept constant. If

the AC output is reduced. the SCR operates in the opposite

way to similarly keep the output voltags constant.

MC

4

E

FC

3

AVR

SC

Fig. 5- 17(B)

WITHOUT AVR

RATED VOLTAGE

VilTH AVR

-A

Fig. 5- 17(C)

-21-

Page 24

5-3-4 DUAL VOLTAGE TYPE (RGX240D)

The dual voltage t)-pe can generate two Foltages from a single generator. It comes in two varieties: 12OV~‘11OV and

1 lOV!ZOV. The circuit is shown in Fig. 5-l 8.

Each of MC1 and MC2 generates an AC 12OV (or 1lOV)

with

the

same phase, which is one half the rated output

voltage. This model has two receptacles to output one half

of the rated voltage from each of the receptacles (112OV or

1 lOV,.

MC1 and MC2 are connected in series to each other so that

the rated voltage (21OV or 21OVj can be obtained from the

receptacles. (See Fig. 5 - 19 .)

I

Fig. 5- 78

240 (22O)V

Fig. 5- 19

5-4 CHANGE of ENGINE PARTS

For details of the engine. please refer to the EYZO service manual. The RGS Series ?mplgs engine parts specia! to the

RGX to suit the modified engine. The engine parts can be classified b>- ignition system.

control system. fuel system. and

cooling system. The engine parts fur each of these systems are explained belox.

5-4-l IGNITION SYSTEM

RGX Series employs a solid state ignition system (T.I.C.). Please rcfcr to the section on Robin Solid State Ignition Engine in

the EYl5. EYlO Service Manual.

All models use a primary exciting coil of especial performance and lead length.

NOTE: Be careful not to use an excitingcoil of different performance because itcan damage the automatic voltage regulator.

- 22 -

Page 25

5-4-2 CONTROL SYSTEM

The control parts are certainly located to permit centralized

control at the top of the engine. The parts added or changed

are as shown in Fig. 5 -20.

NUT

SPRIVG

WASHER

\

\

PANEL CP. 2

/

CONTROL

ROD

WIRE 1 CP.

WIRE 2 CP.

STOP

KNOB

NUT

BUTTON

e BRACKETCP.2

GOVERNOR

LEVER

SPEED CONTROL

CONTROL SPRING

SCREW

Fig. 5-20

-23-

Page 26

5-4-3 FUEL SYSTEM

The large-sized IO-liter fuel tank is mounted in the frame.

The

fuel piping was changed as a result as shown in Fig. 5-Z 1.

FUEL

GAUGE

TANK

HOSE

CLAMP

/--A

.g

^ &

fo

CARBURETOR

HOSE CLAMP

BANJO

FUEL STRAINER

Fig. 5-21

5-4-4 COOLING SYSTEM

-4 baffle is provided to prevent engine cooling air from raising the temperature of otherparrs. X large siz2d rubber pip2

shown in Fig. 5 -21 prevents vapor lock even at high ambienr trmperature (up to about 13°C).

The air guide discharges the engine cooling air in the back of

the generator. A cylinder baffle with an opening is used to

improv2 air flow.

AIR GUIDE

CYLINDER BAFFLE

- 24 -

Fig. 5-22

Page 27

5-4-5 CARBURETOR

The carburetor has an air vent and a rubber pipe to ensire stabilized performance at high temperature.

RU3BER PIPE (to be connected to AIR VENT) [085 10408 501

/

HOSE CLAMP 1056 10800 101

CARBURETOR ASSEMBLY [227

62320 101

Fig. 5-23

5-4-6 OTHERS

The air cleaner and muffler were modified in shape, but are installed in the same way as before. The air cleaner element is

the same as the one used in the cyclone type.

AIR CLEANER

MUFFLER COVER

Fig. 5-24

- 25 -

Page 28

6. SAFETY PRECAUTIONS

1. Use extreme caution near gasoline. A constant danger of explosion or fire exists.

Do not fill the fuel tank with gasolin u-hi12 the engin is runmng. Do not smoke or use open tlame near the fuzl tank.

Be

car2ful not to spill fuel when refuueling. Ii spilt. wipe it and let dry before starting the engine.

2. Do not place inflammable materials near the generator.

Be careful not to put gasoline. matches. c

wnpowd2r. oil cloth. straw. trash or an>- other inflammables near th2 gsnera-

tor.

3. Do not operate the generator in a room. cave or tunnel. Always operate in a well-ventilated area.

Otherwiss the engme may become overheated and also, the poisonous carbon monoxide contained m th2 exhaust gases

will endanger human lives. Keep the generator at least 1 m (4 fset) away from structums or facilities during

use.

4. Operate the generator on a level surface.

If the generator is tilted or movzd during use. there is a dangsr of fuel spillage and a chance that the gensrator ma>- tip

over.

5.

Do not operate with wet hands or in the rain.

Severe electric shock may occur. If th2 generator is moistened by rain or snow. wipe it and fully drk- it before starting.

Don’t pout Lvater over the generator directly- or wash it tvith water

If the generator is wet with Lvater. th2 insulations will be adverssly affected and may cause current leakage and electric

shock.

6. Do not connect the generator to commercial pow-er lines.

This may cause a short-circuit or destroy the generator. Use a transf2r switch for connzcting with indoor lviring.

NOTE: The parrs numbers of the transfer switches and of the plastic box to store them are as shown in Table 6- 1.

Part No.

Part Name

’ O’ty

; Phase Allowable Current

I_

( 365 45604 08 Transfer Switch 1

1 15A

3674560508 Transfer

Switch 1 1

30A

3404560608 Transfer

Switch 1 1

60A

340 45608 08 1 Transfer Switch

1 3

15A

3484560908

;

Transfer Switch

1 3

30A

3674300808 : Plastic Box

1 1.3

30A

3484300908

/ Plastic Box

1

1

60A

Table 6- 1

7. Use fuses of the correct capacity.

If th2 generator rpm is increased exorbitantly in the overload condition by using a

fus2

in excess of th2 rated capaiitl-.

th2 gwerator could

be

burnt and the XYR 02 damaged.

CAUTION: If the fuse is burned out or the circuit breaker tripped off when using an electrical appliance, the cause may

8.

be an overload or a short-circuit. in such a case, stop operation immediately and carefully check the electrical appliance

and AC plugs for faulty wiring.

stopping

In stopping the gensrator. turn the speed control lever to the low position to slow it down to idling speed. and th2n stop

it. If the generator is stopped suddenly from high speed. the sngiw may backfire.

- 26 -

Page 29

7. RANGE of APPLICATIONS

Generally. the rat2d power of an electrical apphan<e oiten refers to the amount oi work that can be don2 b?- it. The electric

power required t?r operating an electrical apphance is not necessarily

equal

to the amount of work that can be done bk- it.

Eiectri4 produ~rs generally ha\2 a lsb2L showing their ra

ted voltage. irrequeniy. and polver consumption (input power!. The

polv2r consumption of an 2lectrical product is the power newssark

for using it. Nhen using a generator for operating an

ele;tri<al product. hwe\er. the po\ver factor and starting current must also be taken into consideration.

Determine th2 requir2d capacity of your g2nerator frown the

power

requirsd ior operaring electrical products that are classi-

lied as iollows:

incandescent lamps. hot plates. etc. with a power factor of 1 .O

Total power consumption must be squal to or less than the rated output af the gen2rator.

Example: .A gsnerator with a rated output power ci TOOOK can l@t ten TOON’ lamps,

Fluorescent lamps. mercury lamps. etc. with a smaller power factor

S212~r a generator v-ith a rated output equivalent to 1.2 to 2 times the poser consumption of the load.

Example: ..I generator with a capacity oi 1OOK to 16OK is necessary for lighting a 8OW fluorescent lamp. A generator

Lvith a rated output of lOOOK can light six to ten 4OF fluorescent lamps.

NOTE: Wattage of the fluorescent lamp generally does not indicate the power consumption but indicates the output of

the lamp. Therefore, if the fluorescent lamp has no special indication as to the power consumption or input power,

efficiency should be taken into account as explained in

Item

5 on the following page,

Electric tools. etc. that are driven by a motor

Po\ver 1 .Z to 3 times the poRer consumption of a motor-driven tool is requrmd ior starting so select a generator with a

maGrnum output 1 .J to 3 times the power consumption of the load.

Example: .L\ 3OO\V motor-driven drill requires a g2wrator Lvith a maximum output of-IO0 to 9OOK or more.

Hater pumps. compressors. etc. that are driven by a motor w-hich is loaded at starting

3 to 5 tmr2s the power consumption of the load is nxessark- f‘or starting so select a generator with a ma.ximum output

3 to 5 tun2s its po\ver consumption.

Esample: X watsr pump \r-ith a po\ver consumption of 1OO\V requires a generator rvith a maximum output of 1’700 to

TOOOW or more.

NOTE 1: Motor-driven products mentioned in

Items

3 and 1 require the aforementioned generator capacities only

when startmg their motors. Once their motors are started, rhe products consume only about 1.2 to 2 times their rated

power consumption so that the excess power generated by the generator can be used for other electrical appliances.

NOTE 2: MO tar- driven products mentioned in Items 3 and 4 vary in their required ma tor starting power depending on

the kind of motor and start-up load. If it is difficult to determine the optimum generator capacity, select a generator

with a larger capacity.

- 27 -

Page 30

5.

Lhppliances without any indication as to power consumption

Some appliances have no indication as to power consumption: but instead the work load (outpurj is indicated. In such a

case. power consumption is to be worked out according to the numerical formula indicated below.

(Output of slectrical appliance)

(Efficiency,l

= (Power consumption)

Efficiencies of some electrical appliances are as follows:

Single-phase motor _ . . _ . . 0.6 - 0.75 -

- The smaller the capacity. the wors2 the efficiency.

Three-phase motor . _ . . _ . . . . . 0.65 - 0.9 ~

and dce versa.

Fluorescent lamp . . . . . . . _ . . 0.7 - 0.8

Example 1: X 4ON fluorescsnt lamp means that its luminous output is 4OK. Its efficiency is 0.7 and accordin&. pow-

er consumption will be 40 - 0.7 = 5XV. As explained in Item 2.

multiply this pow2r consumption value

of 57lV b>- 1.’ - 2

and you will get th2 figure of necessar>- capacity of a generator. In other Lvords. a gen-

erator with a rated output of lOOON- capacity- can li@t nine to fourteen 4017 tluorescent lamps.

Example 2: GeneraIl!- speakin,.

0 a -lOON- motor means that its work load is -lOON-. Efficiency oi this motor is 0.7 and

power consumption Lvill be 100 +- 0.7 = 57OK. W12n this motor 1s us2d ior a motor-driven tool. the capacity of the generator should be multipled b>- 1 .Z to 3 and

5701V as explained in Item 3. Moreover. when

this motor is used for the submerged pump or air compr2sser. it requir2s 3

- 5

times

as powveriul a genera-

tor as in Item 4.

I

Model

I

RGX180

I

RGX240

RGX240D

Frequency

Incandescent lamp,

hot plate, etc.

50Hz ’

60Hz

50Hz ! 60Hz

1300w

15oow

i 1700~ 1 2000~

Fluorescent lamp,

about

about

about about

mercury lamp, etc.

j 850W

1ooow 11oow

13oow

Motor-driven tool,

general-purpose

motor, etc.

about ’

about

750w

850W

about

1 ooow

about

12oow

Water pump,

compressor

I

about

about ’

about about

350w

4oow

5oow ’ 600W

Table 7- 1

- 28 -

Page 31

NOTE: Wiring between generator and electrical appliances

1. Allowable current of cable

Use a cable with a allowable current that is higher than the rated input current of the load (electrical appliance). If the

input current is higher than the allowable current of the cable used, the cable will become excessively heated and deteriorate the insulation, possibly burning it out.

Table 7-2 shows cables and their allowable currents for yourreference.

2. Cable length

If a long cable is used, a voltage drop occurs due to the increased resistance in the conductors so that the input voltage

to the load (electrical produc t) decreases. As a result, the load can be damaged. Table 7-2 shows voltage drops per

100

meters of cable.

Nominal cross

Allowable ; No. of

section current

Resistance ’ Current Amp.

t

I I

I

’ Ci,lOOm 1A I 3A 1 5A I 8A , 10A

I

mm:

A

No.imm

12A ; 15A j

r .75

7 I

30;0.18 2.477 , 2.5V 1 8V 12.5V 1 - 1 - - , -

!

I

’

1 25 12 50i0.18

. 1 .486 1.5v 5v 7.5v I 12v :5V

, 18V -

’

2.0 17 37/0.26

0.952 1v

,

3V 5V 8V a 1ov

12v 15V !

,

-

3.5 1 23 45:0.32

0.517 I I - 1 .5v 2.5V14V 5V

,

6.5V 7.5v

r-5.5 ~~~ ‘~

I

35 70i0.32

’ 0.332 - 1v ! 2v 2.5V 3.5v

4v 5v

Table 7-2

Voltage decrease indicates as V = & x R x I x %

R means resistance (LL’lOOm) on the above table

I means electric currznt through the Loire (.-A).

i-means the length of the wire (.rnj.

The length of the wire indicates round length. it means twice the length from generator to electrical tools.

-29 -

Page 32

8. MEASURING PROCEDURE r

8-1 METERS

8-l-l VOLTMETERS

XC and DC vo!tmeters are necessary. The approximate XC

voltage ranges of the voltmetsrs to be used for various types

of g2nerators are as follows:

I

I

0 to 150\-:

Type with an output voltage of I 10 or 13OV

,

q

.n

I

--?

0 to 3OOV: Tl-pe with an output voltage of X0. 230. or

:

w‘

3)

.d

‘4OV.

FOR AC

FOR DC

0 to ISOV. il to 3OOV:

Dual \-oltage r>-pe

I

Ths DC x:oltmeter range is approsimately from 0 to 30V.

Fig. 8- 1

8-l -2 AMMETERS

AC and DC ammetsrs are necessan-. Xn AC ammeter lvith a

range that can be changed according to ths current rating of

a given generator is most desirable. (About 10-a. 20.4.

100 A)

The DC ammeter range is approximately from 0 to 15.4.

I

FOR AC

FOR DC

1

Fig. 8-2

8-1-3 FREQUENCY METER

!

Frequency range: About 45 to 65Hz

NOTE: Be careful of the frequent y meter’s input voltage

range.

I

I

Fig. 8-3

- 30 -

Page 33

8-l-4 TESTER

Used for measuring resistance, etc.

8-l-5 MEGGER TESTER

Used for measurmg generator insulation resistance. Select

one lvith testing voltage range of SOOk-.

Fig. 8-4

Fig. 8-5

8-l -6 TACHOMETER

There are various types of tachometers. such as contactless i

CONTACTLESS TYPE

i

type. contact

:ype.

and strobe type. The contact type can ’

be used only when the generator and engine have been disassembled. The contactless t>-pc is recommended.

I

I

CONTACT TYPE

I

STROBE TYPE

Fig. 8-6

-31-

Page 34

8-2 AC OUTPUT MEASURING

;a LOA;

TOACd/LE+@ $))

Use a circuit like the one shown in Fig. 8-7 for measuring XC output. A hot plate or lamp Lvith a power factor of 1 .O ma>-

be used as a load. Adjust the load and rpm. and check that the voltage range 1s as

specified in Table 5-1 at the rated amperage

and rated rpm

I

Rated voltage

1lOV

120v

220v 230V ’

240V

I

Voltage range

108 - 115V

118 - 125V 218 - 225V

228 - 235V

238 - 245V

I

Table 8- 1

8-3 DC OUTPUT MEASURING

Fig. 8-8

Switch the powr on. Khen 1.45R resistance is attached as a load.

check that the voltage is within the 13 to 1 IL7 range.

NOTE:

If a battery is connected as the load, the output voltage increases by about 7 TO ZV, possibly causing battery over-

charge. Control battery liquid level during charging to prevent overcharging.

8-4 MEASURING INSULATION RESISTANCE

Connect a meger tester to one of the two receptacle output

terminals and the ground terminal. then measure rhe insulation rssistanx. An insulation resistance of 1 megohms or

more is nxmal. (The original insulation resistance at the

time oishlpment from tht factor! is 10 megohms or more.)

Ji it is I?ss than 1 mqohm. disassembl? the generatnr and

measure the insulation resistance of the statOr. rotor and

cant;01 bc!x indi\!dual!~-.

I

I

I

1

. .

Fig. 8-9

-32-

Page 35

l

STATOR

Measure the insulation resistance between the red or white

coupler from the stator and the core.

Fig. 8- 10

. ROTOR

1

Measure the insulation resistance between the core and

one of the slip rings of the rotor.

. CONTROL BOX

Measure the msulation between the live parts and the

casing or grounded part. Close the no-fuse breaker inst.

then measure it.

An>- part ivhich has an msulation resistance of less thar. 1

megohm has a faults insulation. ivhich can cause elcxtric

shock or

leakag2.

Replace such parts.

Fig. 8- 11

I

t

I

I

I

Fig. 8- 12

-33 -

Page 36

9. CHECKING FUNCTIONAL MEMBERS

9-l STATOR ASSEMBLY

9-l-l MEASURING WINDING RESISTANCE

Check the resistances of the leads from the stator Lvith a

tester (See Fig. o - 1.)

Check

all the

leads \\hich are shown b>-

typ2

m the tables

belc?w- An> !ead which IS mxtive is fault)-.

NOTE: Testers are not so accurate that some margin of error need not be taken into account when reading the tester

against the values shown in the tables.

It is measured bv wheatstone bridge in regularly. In this

time, please care enough not to exist the con tact resistance.

l

RGxl80

l

50Hz 22OV. 23OV. 240V

1

.50Hz 11OV

ai

.60Hz 11ov. 120v

ai

+RGX240, RGX240D

.50Hz 22OV. 23OV. 240V

‘11

.50Hz 11OV

@j

.60Hz 11ov. 120v

STATOR ASSY

I

I

Wire color

BLUE

BLUE 0.3 II

Fig. 9- 1

- 34 -

Page 37

l

50Hz 11

OVi22OV.

12OVf24OV

I

Wire color

RED , BLACK

I

WHITE ’

1.15Q

I “,“:y - $1

1.15x? !

l

60Hz

1 lou;22ou. 12oui24ou

9-l-2 MEASURING INSULATION RESISTANCE

Refer to

8-4 MEASURING INSULATION RESISTANCE.

9-2 ROTOR ASSEMBLY

ROTOR

9-2-l WI-NDING RESISTANCE MEASURING

Check the resistance between the two slip rings with a test-

er. (See Fig. 9-2.)

The resistance is normal if it is an>vhere from 6 ohms to

13 ohms.

TESTER

Fig. 9-2

9-2-2 MEASURING INSULATION RESISTANCE

Refer to

8-4 MEASURING INSULATION RESISTANCE.

9-2-3 CLEANING SLIP RINGS

The slip ring surfaces must be uniformly bright. Slip :-ings

showing black spots. excessive wear, or uneven wear must

be repaired. A stained slip ring lowers generator effi;rency

and output voltage. Polish the slip rings with fine sandpaper

while turning the rotor until rough spots disappear. Care

should be taken not to touch the rotor ~011s with the sandpaper. (See Fig. 9 -3 .)

ROTOR

f=-%

SLIP RING

-\

. . . .

\

Fig. 9-3

-35-

Page 38

9-3 BRUSHES

The brushes must be smooth where they contact the slip

rings. If not. polish the brushes smooth with sandpaper. X

brush that is not smooth produces arcs between the brush

and slip ring leading to possible damage. Usable brush lengths

are from 5mm to ljmm as shown in Fig. 9-3. .a brush

shorter than 5mm must be replaced because decreased contact pressure between the brush and slip ring lowers generator efficiency and output voltage.

15mm

- 5mm

Fig. 9-4

9-4 AUR (AUTOMATIC VOLTAGE REGULATOR)

AVR trouble may be identified -by simply looking at the AVR, or by checking the inter-lead resistance with a tester. or actually mounting it in the generator and operating it.

9-4-l AUR TROUBLE IDENTIFICATION by APPEARANCE

If an AVR electronic part is burnt dark. or the surface epoxy resin melted, it often indicates .r\VR trouble.

9-4-2 IDENTIFYING AUR TROUBLE by CHECKING

INTER-LEAD RESISTANCE

Check the inter-lead resistance of the AVR with a tester.

(See Fig. 9 -5 .)

If the tester readings vary greatly from the

values specified in the Table 9-I. rhe AVR is faulty.

NOTE: Take tester inaccuracy in to account in reading the tester.

TESTER

Fig. 9-5

- 36 -

Page 39

MODEL RGX305, RGX305D

I

I

Tester polarity i

Yellow 1 Red

Green 1 Brown

-I

I

I

I

Yellow j

One wire: OR 1

700K - 1 MZ

72K - 120KSl

65K - 10KC

Another: 00

7

One wire: 0.0,

400K - 500KG ’ 72K - 120KR

! 6%

- lOK,o,

i Another: m

Red

-

I

-

250K-300KR ’ 00

, 400K - 500KQ

1

-

-

I 130K - 140Kn

00

220K - 250KR

*Upper rows are for the 220, 230, 240U specifications; lower rows for the 110, 120U specifications

and the dual voltage type.

Table 9- I

White

Green

-

250K-300KC! ’ -

-

I

m

; 45K- 50KR

-

130K - 140KC!

-

c.2

45K - 50K!C?

-

600K-1MR - 70K-llOK,c ’ - 7K - 9.5KR

-

SOOK - 500KS ! 70K - 1lOKQ

-

6.5K - 8.5KS1

Brown

-

400K - 50OKr1 40K-46KQ 1 =

I -

I

-

1 250K - 300K-r; 40K - 46K,o,

00

-

I

9-4-3 IDENTIFYING AUR TROUBLE by MOUNTING AVR in THE GENERATOR and OPERATING AUR

SCR or transistor damage cannot be detected by simply looking at the AVR or checking the lead resistances. Check it by

mounting the suspectedly faulty AVR in a normal generator, or mount a normal AVR in a generator which fails to generate

voltage.

- 37 -

Page 40

9-5 FUSE HOLDER and CIRCUIT BREAKER 9-5-l CIRCUIT BREAKER

Push the power switch on and check continuity. If current

flows, it is normal.

Devices such as that shown in Fig. 92 are necessary for

checking the circuit breaker if it properly operates. The

rated current is shown on the side of the circuit breaker.

Adjust the load switch until the ammeter reads about twice

the rated current marked on the circuit breaker. The circuit

breaker is normal if it turns off an)-where between 0.5 and

30 seconds.

Fig. 9-6

Commercial power supply

a large-capacity generator

or

--

AMMETER

Fig. 9-7

9-5-2 FUSE HOLDER

FUSE HOLDER

Check that a fuse is in the fuse holder and check its continuity with a tester. (-See Fig. 9-g.) If it carries current. it is

normal.

If there is no current, take the fuse out and check it for

continuity. If the fuse carries current. the fuse holder is

faulty. If the fuse carries no current, replace it with a fuse

of the correct capacity, and check the fuse holder again for

continuity.

Fuse capacity 1s 10.4.

Fig. 9-8

-38-

Page 41

9-6 RECEPTACLE and AC PLUG

Check the current-carrying parts of the receptacles and AC plugs and their leads and plastic parts for burns.

9-7 VOLTMETERS and PILOT LAMP

Apply AC voltage to a terminal and check if the voltmeter

AC

reads normal or pilot lamp lightens.

VOLTMETER

9-8 DIODE STACK ASSEMBLY

--

I-

Fig. 9- 70

Fig. 9-9

Fig. 9- 7 1

The internal circuitry of the diode stack assembly is as

shown in Fig. 9 -10. Check inter-terminal continuity with a

tester as shown in Fig. 9 - 11 to see that the results are as

shown in Table 9 - 2.

TERMINAL’

CURRENT : TERMINAL

1-j

NOTE:

+

A --+--- 6 Current flows from A (+-I to B (-1.

C e D Current does not flow from C (+I to D l-1.

- Check both terminals.

Table 9- 2

- 39 -

Page 42

9-9 PRIMARY EXCITING CIRCUIT

As described

m 5-3 DESCRIPTION of GENERATOR OP-

ERATION.

the primary exiting coil is in the magneto

mounted on the engine. and the AVR has a circuit for it.

9-9-l EXCITING COIL

The normal inter-terminal reststance of the exciting coil is

about 10 to 30 ohms. Its voltage at the rated rpm is about

AC 10 to 3OV. Check the resistance and voltage with a test-

er to see if they meet these requirements.

9-9-2 OTHERS

30 output voltage from the genzrator.

Fig. 9- 72

If the trouble cannot be dztected by Step 9-9- 1 above.

shsck the primary exciting circuit as follows:

.I\. Disconnect the control box and opersts thr gsnerator at the rated rpm. Dixonn2:t th2 tRo k-2liow Lv-ires from th2 exit-

ing cot] to the XVR. and momentarily- ;onntlc‘t th2 positive i-i.1 an3 negatiw t -1 Isads of a 13’ batter>- m their ~1x2. Ii

no output voltag2 is generated. reconnect th2 battzr>- Gads th2 oth2r a-a!.

Ii output l-oitage 1s gen2rated. th2 232iting

2oi! IS def22tive.

R. If no output voltage is generated by the test conducted as described in Step A.. operate the generator at the rated rpm and

momentarily connect a 1ZV battzrk- to th2 brush2s. Th2 green I2ad is posrtil2 (+.I and th2 black or brown lead n2gatne

(--I (Se2 Fig. 9-13.). If output I-oltag:. is gsnerated. the p:imdr~- exiting

ci:.xlt I~I th2 XL-R 1s def2ctive. R2nlac2 the

AVR

Fig. 9- 73

-40-

Page 43

10. DISASSEMBLY and REASSEMBLY

10-I PREPARATIONS and SUGGESTIONS

1) When disassembling the engine ~ remember the locaticns of individual parts well so that they can be reassembed correctly.

Ii

you are uncertain of identify-ing some parts, it is suggested that tags be attached to them.

2) Have boxes ready to keep disassembled parts in groups.

3 !

To

prevent losing or misplacin,.

o temporarily assemble 2ach group of disassembled parts.

4) L’se the correct tools in the correct way.

IO-2 HOW TO DISASSEMBLE

-

Order ’

I

I

Item

I

Procedure

Remarks

Tool

-

1 1 FuelTank f 1) R2mov2 the front pan21. (See Fig. 10-l.) I

1 (+:I screwdriver

I

40 screw 4 PCS.

-

,

( Zi Discharge th2 fuel. Absolutzly no smokmg.

I

Closz thr fu21 stramrr. rrmol-2 the cap.

place some v2sssI for gasoline undsr the

, Cse a

vsssel

large enough

to recsivs the rrmaining

1

I

stranxr. and oprn the strainer to dis-

gasoline.

I

charge ths fuel. I

See

Fig. 1 O- 2 )

-.

I

I

( 3 r Dissonxct ths

iusl

pipe. Appl> a drop of oil to

’ ( -I screwdriver

ioosen th2 hose clamp on top of the

th2 nut on top of the

I

strainsr. and disconnect the

he1

pip2

, strainer to smooth re-

that connects the fuel tank to the

fuel

moral.

!

strainer. I S22 Fig. 1 O-3.!

!

t 4) Remove the fu21 tank bolts.

tS22

Fig. 10-4.1

6Q bolt -t pss.

I

13mm spanner or

’ box spanner

( 51 Remove the tit21 tank.

I

Be careful not to lose th2 ,

rubbrr washers located

I

-

, betwren th2

fuel

tank

mountmg side plates.

Fig. 10- 1

Fig. 10-2

-41-

Page 44

Fig. 1 O-3

Fig. 1 O-4

I

1

1

Order ’

Item [

Procedure

!

Remarks

Tool

I

2 / Control Box

( 1 I Remove the grommet from the rear of

1

the control box.

I

I

1 (2) Pull out the conmxtor from the control

box. and take it ofi.

I

PUSH

The <onncxtor and

PULL - - PULL

coupler are so designed

I

Fig. 10-5 (I)

YS to lock. so push and

;

pul! out as shown in

(3) Remove the coupler that is connected to

Fig. 10-s.

the rear of the control box.

I

!

I 4 I Remove the fuel strainer.

l4mm spannrr

Remove the nut on top of the fuel

strainer locatctd beside The control

I

box. ~See Fig. 10-6 I

( 5) Remove ths control box bolts and ths

control bos.

Be car&l not to lose Th? 10mm spanner

spacer betwvzen the con-

]

or box spanner

Rrmo\~-s the bolts from the frame and

box sta! (Se Fig. lo-- )

6~ bolt 4 2s

trol box and frame.

-42-

Page 45

Fig. 10-6

Fig. 10-7

I

-

Order

Item 1 Procedure Remarks

Tool

-’

a Frame

I. 1) Remove ths box sTa)-.

I

1Omm spannsr

6~ bolt 3 PCS.

. 2 pcs.

- -

( 2, Remove ths side platss. front and rear.

I

I See Fig. 10-8.~

1 Black spscial bolts are

used.

/ 1Omm spanner

or box spann2r

60 bolt -I pi..

L

! ! 3) Rzmovs th2 g2nsrator mounting nuts. 13mm spannsr

Remove the nuts that fast22 ths sngine

and rubber mount and the nuts that

fastsn the gsnsrator and rgjber mount.

8g nut . 3 pcs.

_--.

[

I 4) Remove the g2nsrator.

B2 car2ful about the

Lift th2 generator with a r.hain block.

generator balance.

and rsmox-2 ths framr. <SC-S Fig. 10-9.)

I

-

I 5) Rrmov2 thr rubb2r mount.

13mm spanner

Turn the frame on its side. and rzmow ! or box spannrr

the nuT3 that fasten the rubber mounts

to the bottom of the frame

8Q nut . 4

pzs.

-

Fig. IO-8

Fig. 10-9

-- 43 -

Page 46

1 Order 1

item 1

Procedure

Remarks , Tool

4

Brush holder

( 1) Remove the brush cover.

!

Remove the brush cover in the back of

the rear cover.

40 screw . 2 pcs.

I (2) Remove the brush holders.

(See Fig. 10-10.)

Disconnect the terminals wired to the

brushes before removing the brush

holders.

56 screw 2 pcs.

I

1 ( + j screwdriver

1 Be

sure to remove the

brush holders first be- !

cause if the rear cover 1s

removed from the generator without removing

the brush holders. the

I brushes will break.

5

Rear cover i 1) Loosen the cover bolts and remove

them

4~ bolt. 3 pcs.

1 Omm spanner or

!

I

box spanner

(2) Remove the stator cover.

i. -) screwdriver

Turn up the stator cover edge and

I

remove the stator cover.

I

,

’ t.31 Remove the rear cover.

(See Fig. 10-l 1.)

Lightly tap the rear cover with a

plastic hammer. and remove it.

The type that uses a con-

nectar does not permit

complete separation of

the stator and rear cover

because the connector

i cannot be pulled out of

the rear cover or grommet. In this case. simply ,

remove the rear cover

!

’ from the bearing.

Fig. lo- 70

Fig. 10-71

- 44 -

Page 47

-

Order 1

Item Procedure

I

Remarks

Tool

-.

6 Stator i 1) Remove the stator.

, Sever hammer the wind- Plastic hammer or

Puil out the stator from the front cover

ings and leads.

(.-j screwdriver

by lightly tapping the outside of the

Be careful not to peel

core with a plastic hammer. (See Fig. lo- ’ stator steel sheets.

the

11.) If the stator does not come out.

I

insert a screwdrive betaeen the front

cover and stator. and twist it.

I

-

,

I 2) Separate the stator and rear- co\-er.

It is not necessary to

Separate the connector ar d wire.

separate the stator and

Push the terminal locks in the con-

rear corer except when re-

nector with a pin havmg a needle-like

placing the stator. rear

sharp point. and remove the terminals.

cover. or diode stack.

i

(See Fig. lo- 13.)

!

I

!

I

Fig. lo-13

-

.Fig, lo- 72

-45-

Page 48

Order /

item

Procedure

Remarks Tool

!

- Rotor ( 11 Pull out the through-bolt. Fit a box

If an air spanner is at-ail-

Hammer

spanner or socket wrench orer the

head of the through-bolt. strike it

hard <ounterclockwse with a hammer to loosen. and remove the

through-bolt. ISee Fig. 10-1-l.)

100 bo:t . . 1 pze.

able, use it for easy- re-

Box spanner. or

moval.

socket wrench

I4m.m

I

I.2) Remove the rotor.

1 Sever strike the slip rings

Strike the rotor by the core with a plas-

! or windings.

tic hammer. and remob-e the rotor from

I

the engine taper shaft. If the roror does

not come out. change its angle and

I

strike it again. (See Fig. lo- 15.1

1

Fig. lo-14

Fig. lo- 75

I

Order

Item

Procedure

Remarks

Tool

-8 t Front cover

i 1 I Remove the front colder.

13mm bo.x spanner

Remove the bolts that fasten the en-

gine’s main bearing cover to the front

cover.

80 bolt 3 pis.

- 46 -

Page 49

10-3 HOW TO REASSEMBLE

10-3-l FRONT COVER

Attach the front cover to the engine main bearing cover.

Match the faucet joint. and tighten the bolts.

89

x 18mm bolt . .1 PCS.

80 spring washer . 4 pcs.

Tightening torque 130 to 110 kg-m

NOTE: Make sure that the slits for cooling air are down.

10-3-Z ROTOR

1) Clean the tapered part of the engine output shaft and

the female tapered part of the rotor shaft of oil and

other forergn matter with waste cloth.

21 Install the rotor and tighten the through-bolt. (.See

Ftg. 10-17.)

Tighten the through-bolt by strikmg a box spanner

or socket wrench hard clockwise.

NOTE: The outside diameter and lamination thickness of the rotor is shown in 5-2-2 ROTOR under

Paragraph

5-2 FUNCTIONS.

NOTE: The through-bolt is shaped as shown below.

Fig. 70-16

n

Fig. lo-17

I

Model d I ! 5

: 8mm

’ 222 mm

25 mm

RGX180

i 5..16 In.

’ 8.74 in.

/

0.98 in.

-

’

RGX240 8 mm

230 mm

25 mm

RGX240D I

5.‘16 in.

( 9.06 in.

0.98 In.

Table lo- 1

-47 -

Page 50

10-3-3 STATOR

Install the stator to tit the faucet joint of the front cwer.

If it does not fit properly. lightl>- strike the stator cnre \vltil a plasti,

_ hammer as shown in Fig. 1 O-19.

NOTE: Never strike the winding.

NOTE: Make sure that the wires to the control box areup and that the wires to the brushes are to the back. (See Fig. 70-78.)

y., ta COYTROL BOX

STATOR

:cj BRUiti liOL%R

VER

I

STACY [

WIRES)1

I

Fig. IO-18

10-3-4 REAR COVER

1) Install the diode stackin the rearcover.(See Fig. 10-20)

39 x 12 mm screw. . . 1 pc.

NOTE: Solder an assembly of leads, of the colors that

meet the specifications of the circuit diagram, and a

connector, to the diode stack.

DIODE

I

Fig. lo-19

Fig. IO-20

L The diode has markings of input ( -J, positive (-) and negative (-j, on this side.

Two (5) leads are blue; (+ J orange; and (-j brown.

Fig. 70-21

3) Pass the wires Lvhich connect to the control b~,x from

the stator through the hole in the top of the rear co~r.

-

48 -

Page 51

3)

3)

Tighten the cover bolt.

NOTE: The bolt cannot be tightened unless the front cover and rear cover are positioned correctly.

The shape of the cover bolt is shown below.

Install the rear cover to fit the rotor bearing.

Lightly strike the circumference of the rear cover

evenly with a plastic hammer. (See Fig. lo- 22.)

NOTE: Be careful not to pinch the wires between

the stator and rear cover.

Fig. lo-22

r=

I

,

Model

d

1 1 s

I

RGX180 i

6mm j

90mm ’ 15mm

0.24in. 1 3.54 in.

0.54 in.

RGX240

6.3 mm

100 mm 15mm

RGX240D

0.24 in.

3.94 in. 0.54 in.

Table 10-2

Install the stator cover.

Fit the stator cover between the stator and cover bolts

until it covers all the cover bolts. and fold back -:he

edge.

Pass the wires out of the top of rear cover through the

grommet. and fit the grommet into the hole in the rear

cover. (See Fig. 10-X .i Then. reverse the bushing for

mountmg the control box and place it on the grommet.

The bushing has a larger diameter than the grommet.

Fig. lo-23

- 49 -

Page 52

7j Insert the wires into the connectors.

The connrctor positions and wtr2 colors are shown in Table 10-J.

NOTES: Terminals 3 through ‘z; and cj,

@are for 2mm’ wire, terminals ‘5,s. for 1.25 mm’ wire, and .z~ through

c$ij for 0.75 mm’ wire.

Fig. lo-24

n

I

I

3

::z / 12; ’ .zj !

RGX180 - -

-

WHITE RED i BROWN GREEN WHITE

RED

I

RGX240 1 - -

I

I

i WHITE

RED

ORANGE

WHITE

RED BROWN GREEN - -

I

1

RGX240D -

BLACK

WHITE RED

WHITE RED

BROWN GREEN 1

I

I

Table 70-3

10-3-5 BRUSH hOLDER

:.

I

I.

II

1) Install the brtish holders in the rear cover.

.I

II

,

Pass the mounting screws through ths brush holders,

,I I

., c

,I ’

I

push the brush holders SO that the brushes w-111 be prr-

/

I

‘1 I

I

pendicular to.

the

slip rings. and tighten

ths

screws.

j

I

I

-

(Se2 Fig. lo-~5.j

I

-Qslgmmscrew...?pcs.

50 washzr . 2 PCS.

5~ spring washer 2 pcs.

Fig. lo-25

Fig. lo-26

- 50 -

Page 53

2 I Attach the connector to the brush holder. Connect the green lead to the stator side and the brown lead to the bearing

side.

Ficr. 7 O-27

3) Install the brush cover.

49 x 10 mm screw . . 3 pcs.

10-3-6 FRAME

1 I The frame has holes for the rubber mount locks. Hold

the rubber mounts so their locks are in line with the

ho!es. and tighten the nuts on the bottom of the frame.

(See Fig. 10-28.)

8~ nut . .4 pcs.

8Q

spring washer -! pcs.

GREEN WIRE

FRAME UPPER

Fig. 10-28

NOTE: The rubber mounts are so selected as to assure optimum vibration depending on model and frequency. Be sure

to use the rgbber mounts of the correct parts number. Rubber mounts may appear the same in shape but differ

in hardness. Especially, models RGX780, RGX240. and RGX240D use diagonal support rubber mounts.

-51 -

Page 54

2> Install the generator in the frame.

Lift the generator with a chain b!ock. install it in the

Dame. and tighten the nuts. (See Fig. 10-29.)

8Qnuts. . _ . . . . . . . .4pcs.

SQ washers . . . . . . . .-I pcs.

8~

spring washers . . . .-I PCS.

Fig. lo-29

3) Attach the side plates to the frame.

&fount the side plate that reads “Robin Generator Model” to the front, and the blank side plate to the rear.

NOTE: Use the black bolts for tightening them.

50 x 13 mm bolts . . .8 PCS.

4) Attach thcr box stay to the side plates.

6ox 15mmbolts . . . .Ipcs.

60 washer . . _ .Z PCS.

6o spring washer . _ . .2 PCS.

6onut . . . . . . . . .2 pcs.

10

11

-3-7 CONTROL BOX

Fasten the control box to the frame and box stay.

NOTE: Spacers must be placed between the frame and

controi box. (See Fig. 10-30.)

68 x 15 mm bolts . .3 pcs.

6~

washer . . . . .4 pcs.

6~ spring washer . . . 4 pcs.

Attach the control box to the frame in sub-assembling

the control box.

Refer to Paragraph 10-4 for sub-assembling the control

box.

I

I

-’

Fig. IO-30

2) NYre the primary exciting crrcuit.

Connect the two yellow wires of the automatic voltage regulator in the control box to the exciting coil

wires

of

the en-tie, and clamp them to the control

box with cord bushings. t&e Fig. 10-3 1:)

INSERT

Fig. lo-31

- 52 -

Page 55

3) Connect the connectors to the control box. And push

the connectors into the control box.

4j

Install the bushing on the control box.

NOTE: No clearance is allowed between the grommet

and bushing. (See Fig. 10-32.)

I-

‘1 -

Fig. lo-32

10-3-8 FUEL TANK

1) Connect the rubber pipe to the engine carburetor and fasten it with the hose clamp. Attach the banjo to the opposite

end of the rubber pipe. tighten it with the hose clam?. and fasten the pipe to the fuel strainer with the banjo bolt.

3 I Attach the strainer bracket to the control box.

lox 10mmbolts . . . . .2pcs.

4~ spring washer . . _ . .2 pss.

3) Fasten the strainer to the strainer bracket with the joint nuts.

4) Mount the fuel tank on the side plates with rubber washers between the t\vo.

6d x 20 mm bolts _ . . _ .4 PCS.

69 washers . . . . . . . .4 PCS.

60 spring washers . _ . 1 PCS.

NOTE: For easy tank assembly, glue the rubber washers around the holes in the side plates.

5) Connect the rubber pipe

First. fit the hose clamps on the rubber pipe. connect the strainer and fuel tank. then fasten the rubber pipe wth the

hose clamps.

NOTE: Apply a drop of oil to the rubber pipe so that it may easily be connected to the strainer and the fuel tank.

- 53 -

Page 56

FUEL TANK

FUEL GAUGE

RUBBER PIPE

4 ’

- HOSE CLAMP

I i

STRAINER BRACKET

FUEL STRAINER

BANJO BOLT

/

BANJO BOLT

RUBBER PIPE

HOSE CLAMP

Fig. lo-33

- 54 -

Page 57

10-4 CONTROL BOX CHECK, DISASSEMBLY, and REASSEMBLY

10-4-l CHECK

Check the wiring bp removing the control box from

the

frame and taking the panel B (rear panel) off,

10-4-2 DISASSEMBLY

1) Remove the control box panel B (.rear panel) and the

front panel from the control box. (See Fig. 10-34.)

2) Remove the connectors from the control box, and

the wires from the connectors.

NOTE: Push the terminal locks in the connectors

with a long, pointed pin to unlock the terminals, and

remove them. (See Fig. 10-35.)

3) Remove the automatic voltage regulator.

4) *After disconnecting the wire from each part, remove

the parts.

NOTE:

The DC fuse and the full power switch have

their wires soldered to them. Unsolder their wires

first, and then remove them.

10-4-3 REASSEMBLY

Keverse the disassembly procedure.

NOTE: The wires are colored for identification of capacity

and gauge. Be sure to use the same wires when disconnected.

Fig. lo-34

PUSH

9

PUSH

C

--I

Fig. lo-35

NOTE: Terminals 3 through ,$land j-j;. g are for2mm’

wire, terminals

i

m? are for 1.25 mm’, and terminals

L'd

z

through @ are for 0.75 mm’.

Fig. lo-36

I

MODEL

:@ ,T,

d

RGXl80

- -

-:- -

BROWN

GREEN WHITE

RED RED WHITE

I

i

BROWN

RGX240

WHITE 1

ORANGE

WHITE

RED - - BROWN

’ GREEN WHITE RED - I -

I

-

BROWN

RGX240D ORANGE WHITE

RED - BLACK BROWN

GREEN 8 WHITE

RED - -

WHITE

I

I

Table 10-4

- 55 -

Page 58

11. TROUBLE-SHOOTING

When rhe generator is in trouble. carefully check the trouble and remed)- IL

(11

(

Voltmeter does not work or pilot lamp does not light.

I

(Cause)

(Remedy)

1

I

1

Voltmeter or pilot

lamp is defective

0 Replace.

Wrong wiring or some

leads unconnected

l

Wire correctly.

y Primary

Exciting coil

defective

l

Replace exciting coll.

7 OK

>

Resistance outsrde

range of 5 --7.5R

I

qy-Eq

(Check winding resistance.)

I

Field coil shorr

range of 5 -7.5-Q

(See the description of winding

resistance in 9-l .I

Main coil broken

.

Replace stator.

Sub coil broken

l

Replace stator.

resistance in 9-l .I

AVR broken

.

Replace AVR.

l

Clean, replace.

0 Check, replace.

l

Replace.

l

Replace AVR.

- 56 -

Page 59

(Cause)

(Remedy)

&+x+

See (1) Voltmeter does not work.

Fuse burnt out

OK

Wrong wiring

Characteristics faulty

Diode broken

DC coil broken

Rpm unadjusted

OK

f

Check AVR

AVR broken

. Check for cause and replace.

. Wire correctly.

l

Replace.

. Replace stator.

l

Replace ctator.

0 Adjust.

0 Wire correctly.

c Replace.

- 57 -

Page 60

(4) (

Voltage too low

J

Uhusel

I

If AC voltage is less than 1OV. voltmeter needle should not deflect.

Rpm unadjusted

I

OK

Wiring checked?

1

loose wire joints

1

Wrong wiring

;OK

i

than 4f2

Field coil shorted

I

OK

OK

Brush defective

*- ----+

Main co11 shorted

. Replace stator.

!OK

AVR broken

.

(Remedy)

Adjust.

Wire correctly.

Adjust.

Replace rotor.

Clean, replace.

Check, replace.

l

Replace stator.

Replace.

- 58 -

Page 61

/

’ Off-load voltage is normal, but load cannot be

(Cause)

jOK

IOK

AC plug crecked

for shortcl-cult!

AC plug shorted

1

I

L

‘IsI Loadshorted 1

I L__1

Resistance infinite

I

Load defective !

l

1

(Remedy)

Adjust

Change load.

Correct.

Check and correct load.

Correct.

Charge FUo-Fuse breaker.

Check and correct load.

l

Replace.

Check. Correct. Repiace.

Clean. Replace.

Check. Replace.

-

: Net cnecked properly. Or, opera-

,-A

:

;lon returns to norm21 byhen AVR

rm

l

Replace.

is replaced with anorhe: one.

I

EngIn? output power

Ins4ft,cienr

I----

See Englne Trouble-shoo:lng

--

59 -

Page 62

12. OPTIONS

12-l CASTER

1)

The caster base IS fitted with rubber casters 5Omm in diameter and the caster base 1s bolted to rhe frame.

2)

The frame has threaded holes for mounting the caster bases.

BOLT6ox15... 16 pa.

:

,;’

/’

BOLT6~~15...16pcs.

WASHER 60.. .16 pa.

NUT 60. 16 PCS.

- 60 -

Page 63

13. CIRCUIT DIAGRAM

MODEL RGX240

GENERATOR

CONTFOL BOX

ENGINE

---

---

r

r

/

i

7

II

1 i

It

I

1

c

/

I

(

’ II

.

7

MG

-1

EC! SB

I d

-CB-

I i

I II

L

UHANti

(RED

WHITE

I--

1 I

DC OUT

O-T

YELLOW

I

I

I

-

YELLOW

I

I

I

l-r

jj-

II

]j

I ---- 1

E

II

MODEL RGX240D

GENERATOR

CONTROL BOX

ENGINE

I

I

I I !

CB

DC OUT

-...-.

: lT.I.C.1

----Gil-

0

i

i,T YELLOW -T j 1

I

----I -

BLUE

-21

YELLOW

! i

I

---I __ -~--

e

---

i I

I--

__-

-61 -

Page 64

MODEL RGXIBO

GENERATOR

CONTROL BOX

ENGINE

--

. SYMBOLS

Symbols

I ~~

Name of Parts

MC :

AC Winding

I

SC

1 Auxiliary Winding

r

Symbols Name of Parts

I

RW :

Receptacle (11 OV or 12OV)

I

I

RECl j Receptacle (220V or 24OV)

I

I

DC 1

DC Winding

I

I T 1 Terminal

FC ! Field Winding

I

B !

Brush

CB

Circuit Breaker

SP :

Spark Plug

I