Page 1

LE GENERATOR

210~

Page 2

Section

CONTENTS

Page

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

SPECIFICATIONS

..........................................................................

1

PERFORMANCE CURVES

...............................................................

2

2-1

AC Output

..............................................................................

2

2-2 DC Output ..............................................................................

3

FEATURES ..................................................................................

4

GENERAL DESCRIPTION OF THE GENERATOR

..................................

5

4-1

External View of Generator

...........................................................

5

4-2 Location of Serial Number and Specification Number ...............................

6

CONSTRUCTlON AND FUNCTION

.....................................................

7

5-1 Construction

...........................................................................

7

5-2 Function ................................................................................

7

5-3 Description of Generator Operation

................................................ 10

SAFETY PRECAUTIONS

................................................................

12

RANGE OF APPLICATIONS

............................................................

13

MEASURING PROCEDURES

.......................................................... 17

8-1 Measuring Instruments

...............................................................

17

8-2 AC Output Measuring

................................................................

20

8-3 DC Output Measuring

...............................................................

20

8-4 Measuring Insulation resistance

.....................................................

21

CHECKING FUNCTIONAL MEMBERS

...............................................

23

9-1

Control panel..

........................................................................

23

9-2 Stator ..................................................................................

24

9-3 Rotor ..................................................................................

25

9-4 Condenser

............................................................................

26

9-5 Diode Rectifier

........................................................................

26

DISASSEMBLY AND ASSEMBLY

....................................................

2 7

10-1

Preparation and Precautions

........................................................

27

10-2 Disassembly Procedures

.............................................................

28

10-3 Assembly procedures

................................................................

38

TROUBLE SHOOTING

..................................................................

44

11-1 No AC Output. .......................................................................

44

11-2

AC voltage is too high or too low

...................................................

46

WIRING DIAGRAM

......................................................................

47

Page 3

RG-32

S E R \/I C E

NEWS

September-1995

Rk Generators

@ FUJI HEAVY INDUSTRIES LTD.

INDUSTRIAL PRODUCTS DIV.

I

MODEL

I

SUBJECT

I

R1210

Oil Sensor change

This Service News is to inform of the change of the oil sensor and wiring equipped with

the ROBIN engine EY 15 for R1210 generator set.

1. Purpose

To improve the performance of the oil sensor.

2. Main points of the modification

1) The oil level sensing mechanism of the oil sensor is changed from piezo-resonator

type to potentiometer type.

2) The electric wiring and clamp are also changed.

3. Change of part number -

For the detail, refer to the attached figures.

New Parts set

NO. Part Name

Part number

1. Oil sensor CP.6

KS3-11015-01

+?k

2.

Wire 7 CP.

227-73 107-O 1 1

3. Clamp

056-60002-50

1

Current parts set

NO.

Part name

Parl number

Q’tv

4.

Oil level sensor CP.

227-76035-01

1

5.

Wire 22 CP.

214-73122-01

1

6.

Clamp CP.

206-75501-01

1

Interchangeability

It is interchangeable only when the all parts are replaced as a set; that is to say,

the current parts set (item NO.4 to 6) can be replaced with new parts set (item NO. 1

to 3).

However, there is no interchangeability for the individual part.

4. Execution

This oil sensor change is adopted to the new ROBIN generator set to be produced in

and after September 1995.

-1-

Page 4

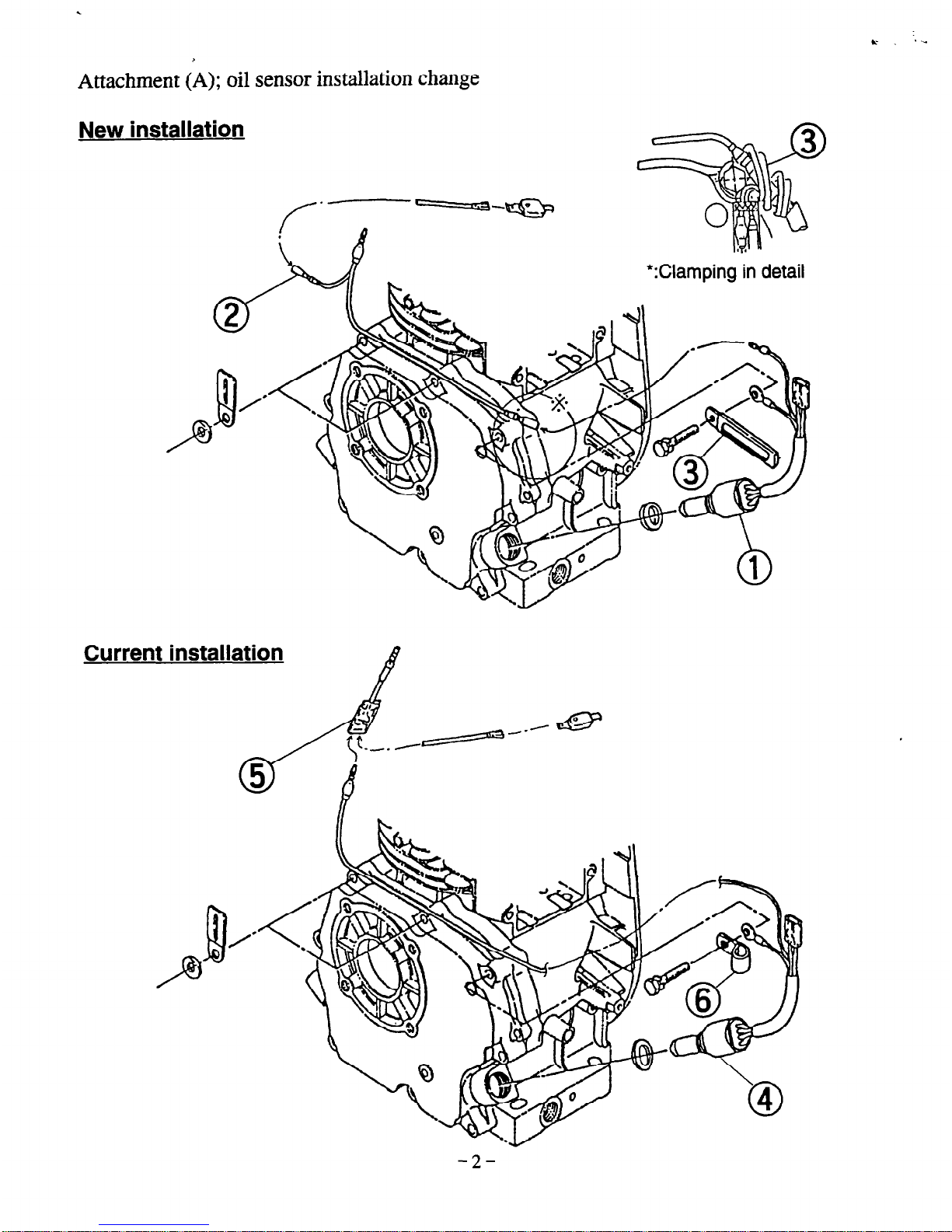

Attachment (A); oil sensor installation change

New installation

*:Clamping in detail

Current installation

Page 5

Attachment (B)

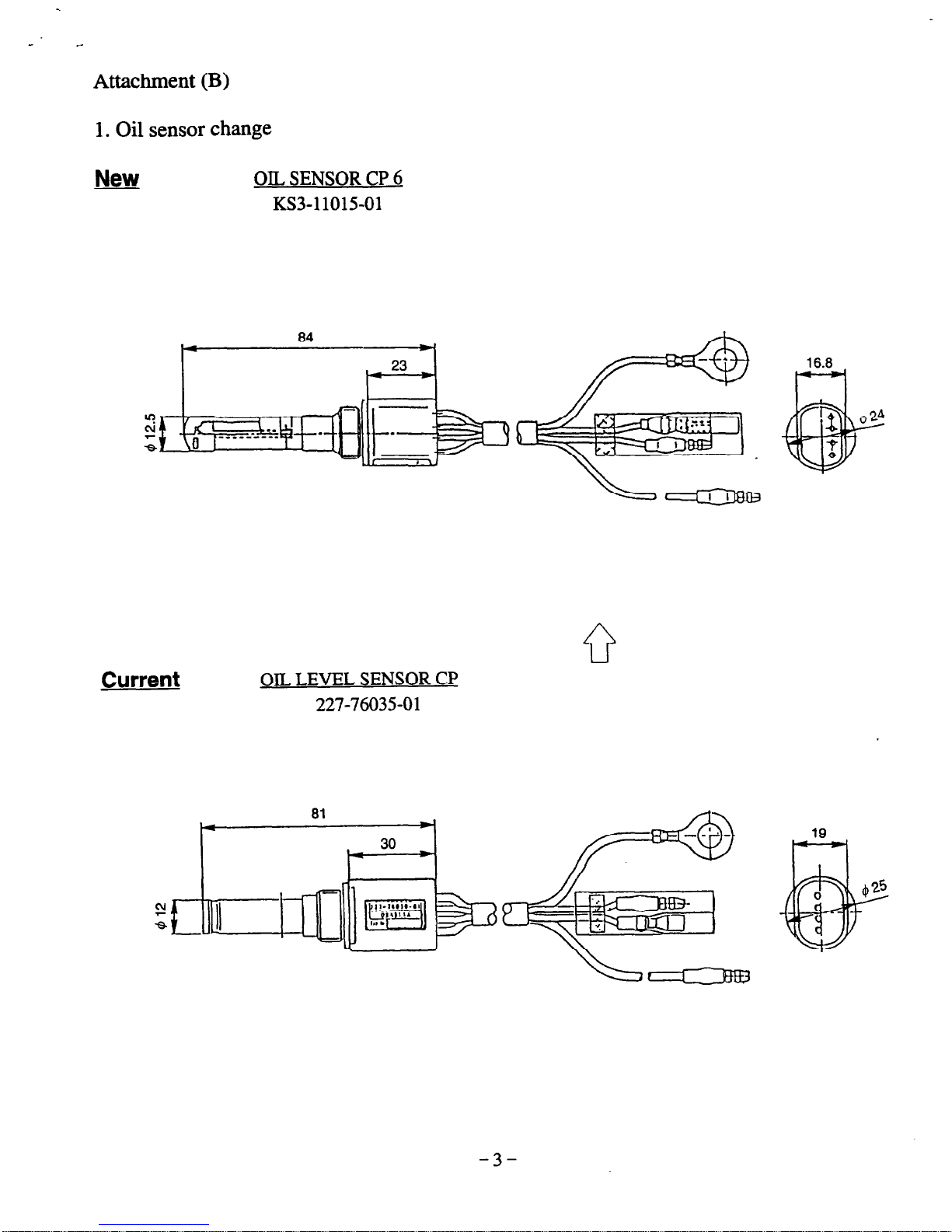

1. Oil sensor change

New

OIL SENSOR CP 6

KS3-11015-01

Current

OIL LEVEL SENSOR CP

227-76035-01

-3-

Page 6

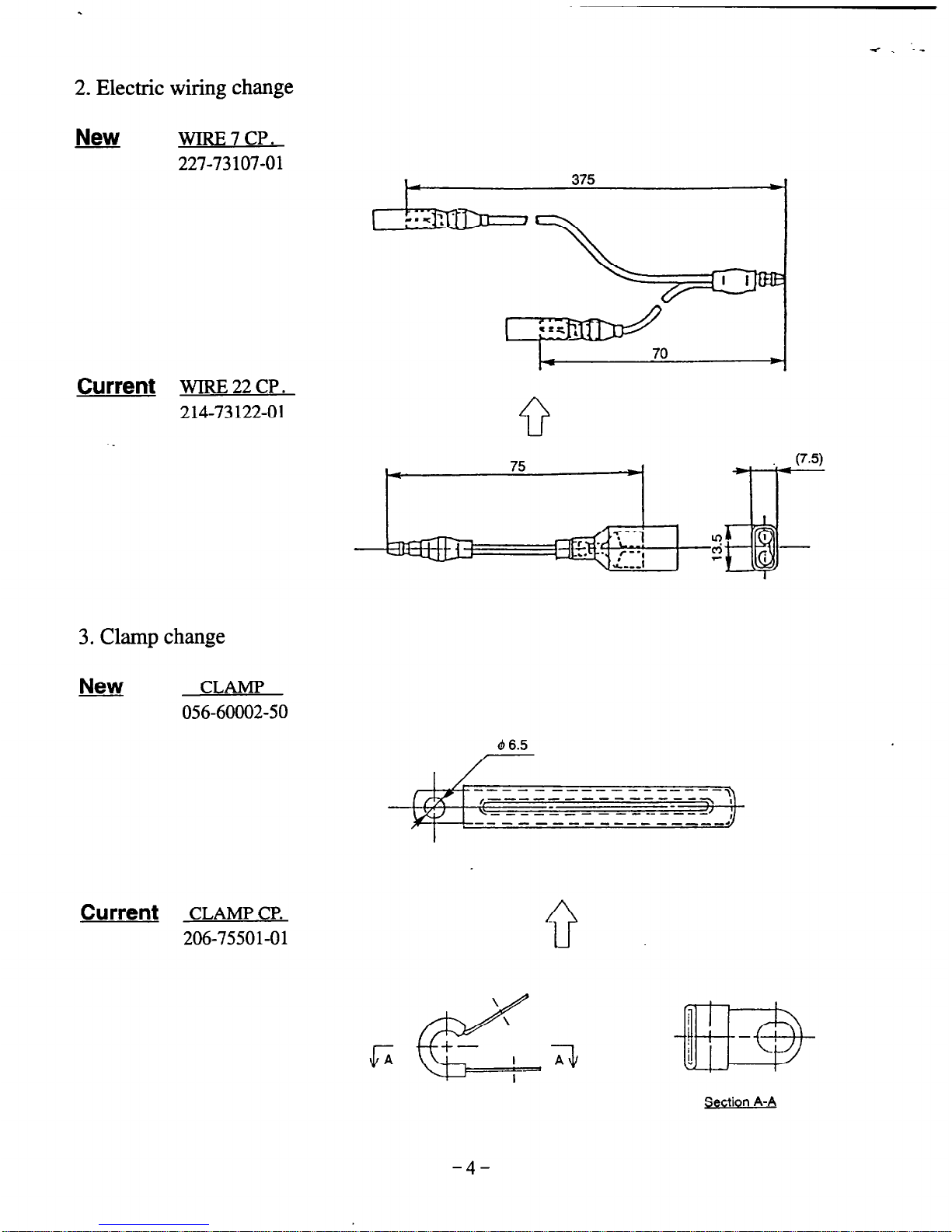

2. Electric wiring change

New

wIRE7CP.

227-73107-01

Current wm

22 cP .

214-73122-01

3. Clamp change

New

CLAMP

056-60002-50

d 6.5

Current

CLAMP CP.

206-75501-01

3 I

\

\

J--

IA

c

+-

I

-3

A

I

Section A-A

-4-

Page 7

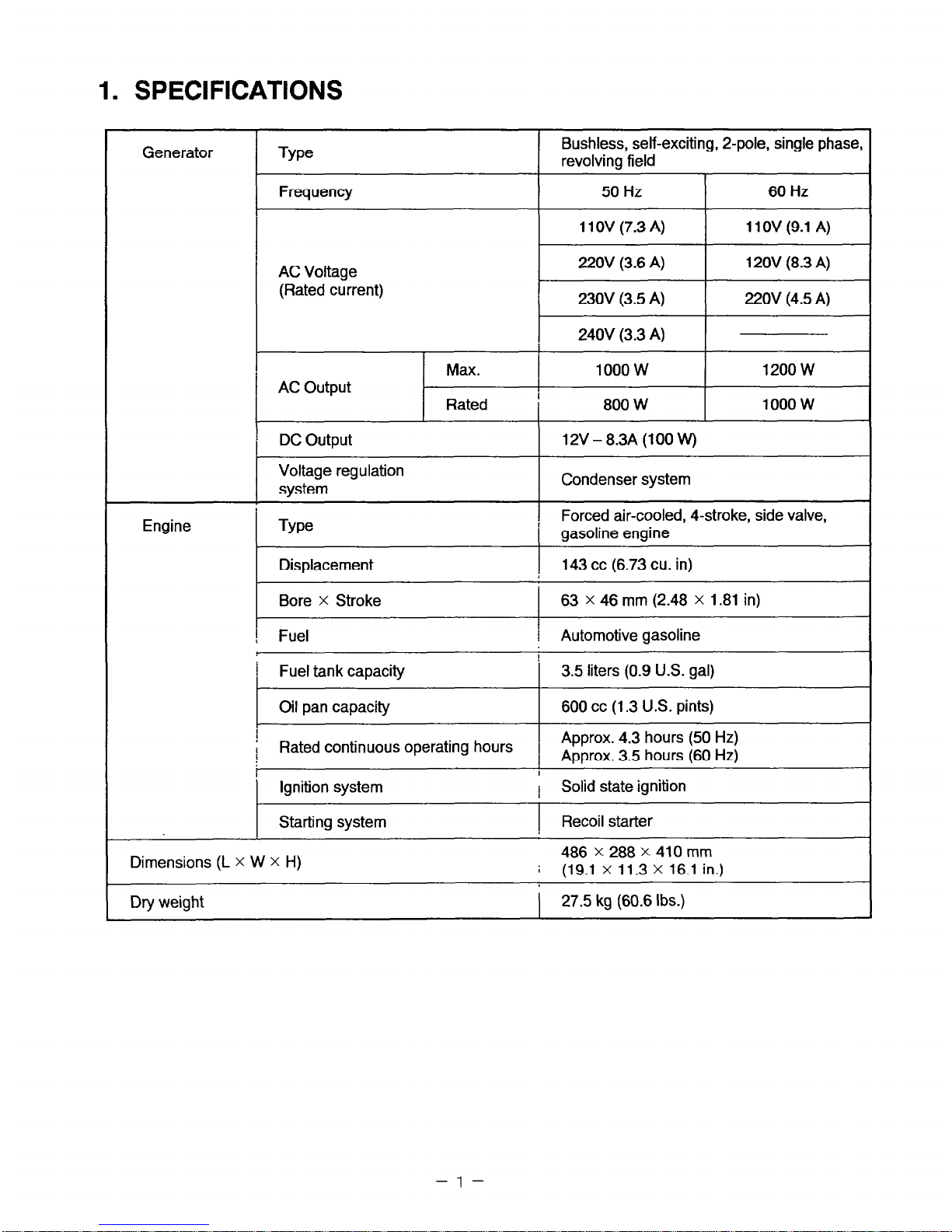

1. SPECIFICATIONS

Generator

Type

Frequency

AC Voltage

(Rated current)

Bushless, self-exciting, 2-pole, single phase,

revolving field

50 Hz

60 Hz

11 OV (7.3 A)

11OV (9.1 A)

220V (3.6 A)

12OV (8.3 A)

230V (3.5 A) 220V (4.5 A)

240V (3.3 A)

Engine

/ AC Output

Max. 1000 w

1200 w

Rated :

800 W

1000 w

/ DC Output

12V-8.3A(lOOW)

Voltage regulation

system

Condenser system

Type

Forced air-cooled, 4-stroke, side valve,

’ gasoline engine

Displacement

, 143 cc (6.73 cu. in)

Bore x Stroke

63 x 46 mm (2.48 x 1.81 in)

I Fuel

I Automotive gasoline

! Fuel tank capacity

3.5 liters (0.9 U.S. gal)

Oil pan capacity

600 cc (1.3 U.S. pints)

Rated continuous operating hours

Dimensions (L X W X H)

Dry weight

486 x 288 x 410 mm

; (19.1 x 11.3 X 16.1 in.)

27.5 kg (60.6 Ibs.)

-5-

Page 8

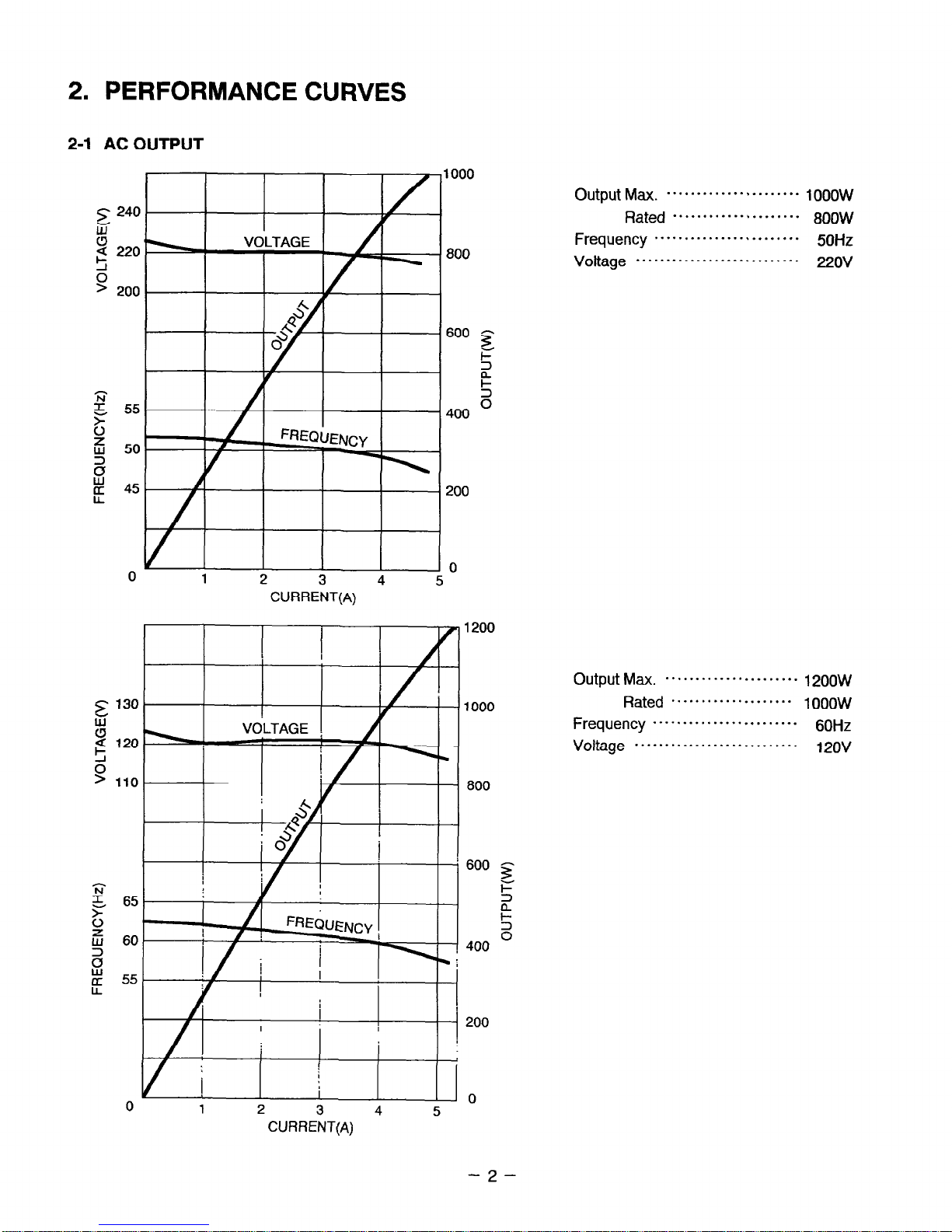

2.

2-1

PERFORMANCE CURVES

AC OUTPUT

>^ 240

E

9 5 220

800

9 200

600 $

F

i?

2 A 55

5 400

0 5

6 50

3

s

E 45 200

1, I t I I

5

0 0 1

2 3 4 5

CURRENT(A)

oI;i

1

2

3

4

5

600 =g

i=

z

s

400

200

0

Output Max.

...................... 1 (-J)()w

Rated ..................... 8OOW

Frequency ........................ 50Hz

Voltage

...........................

220v

Output Max.

......................

12o()w

Rated

....................

,oooW

Frequency

........................

60~~

Voltage

...........................

12ov

CURRENT(A)

-2-

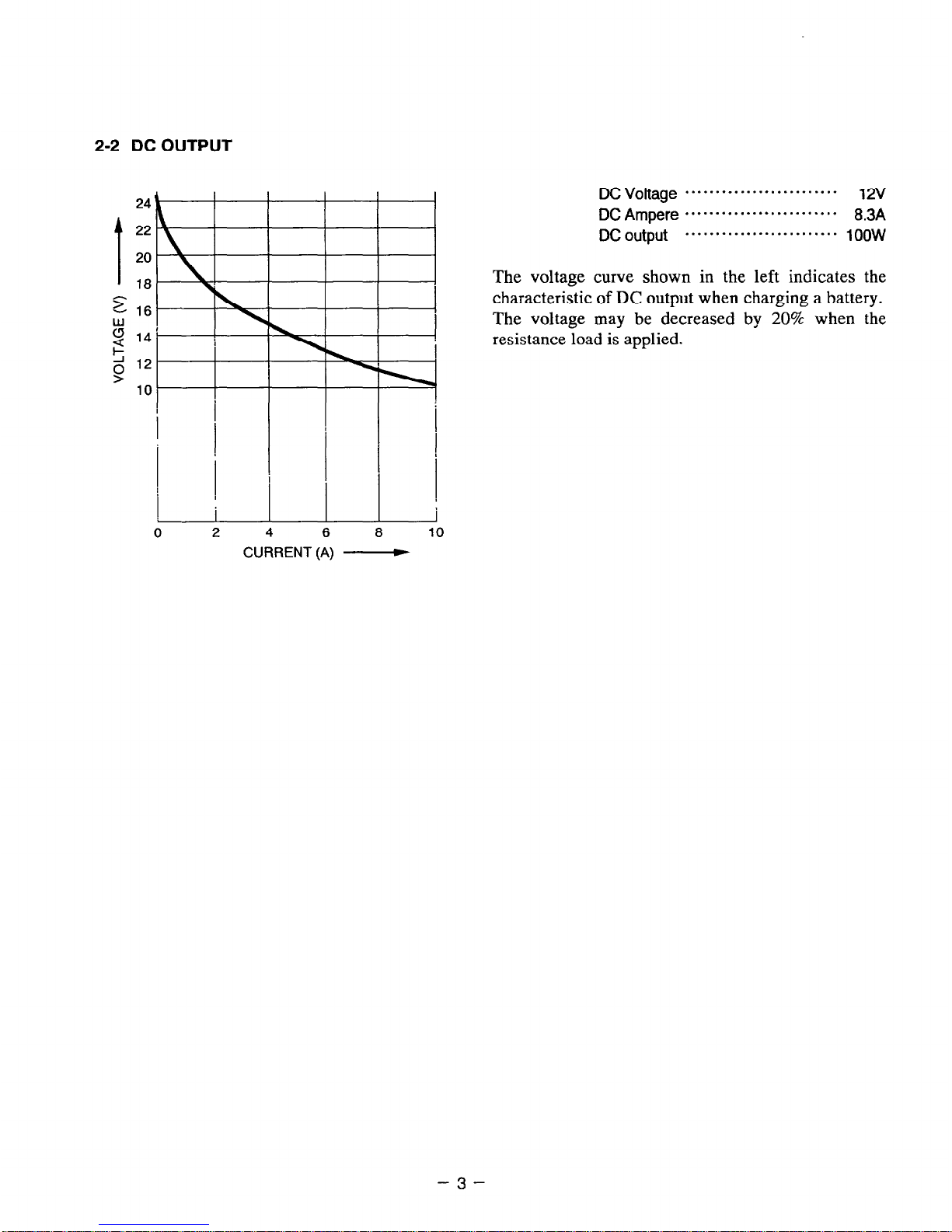

Page 9

DC OUTPUT

m voltage

.........................

,2v

DC Ampere

......................... 8.3A

DC output

.........................

,()ow

The voltage curve shown in the left indicates the

characteristic of DC output when charging a battery.

The voltage may be decreased by 20% when the

resistance load is applied.

I

0 2

4 6

8 10

CURRENT (A)

-

-3-

Page 10

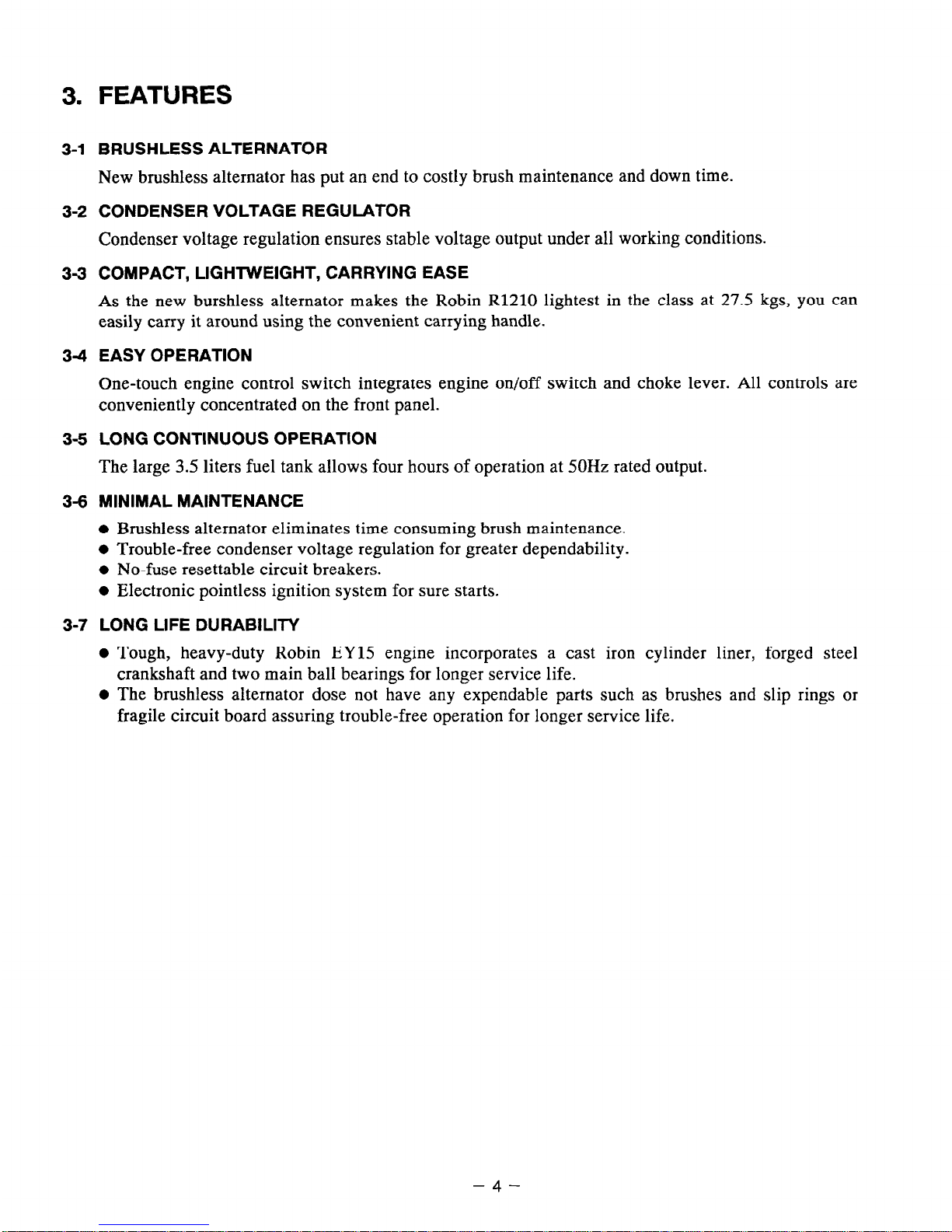

3. FEATURES

3-l BRUSHLESS ALTERNATOR

New brushless alternator has put an end to costly brush maintenance and down time.

3-2 CONDENSER VOLTAGE REGULATOR

Condenser voltage regulation ensures stable voltage output under all working conditions.

3-3 COMPACT, LIGHTWEIGHT, CARRYING EASE

As the new burshless alternator makes the Robin R1210 lightest in the class at 27.5 kgs, you can

easily carry it around using the convenient carrying handle.

34 EASY OPERATION

One-touch engine control switch integrates engine on/off switch and choke lever. All controls are

conveniently concentrated on the front panel.

3-5 LONG CONTINUOUS OPERATION

The large 3.5 liters fuel tank allows four hours of operation at 50Hz rated output.

3-5 MINIMAL MAINTENANCE

l

Brushless alternator eliminates time consuming brush maintenance.

l

Trouble-free condenser voltage regulation for greater dependability.

l

No-fuse resettable circuit breakers.

0 Electronic pointless ignition system for sure starts.

3-7 LONG LIFE DURABILITY

l

Tough, heavy-duty Robin EY15 engine incorporates a cast iron cylinder liner, forged steel

crankshaft and two main ball bearings for longer service life.

0 The brushless alternator dose not have any expendable parts such as brushes and slip rings or

fragile circuit board assuring trouble-free operation for longer service life.

-4-

Page 11

4. GENERAL DESCRIPTION OF THE GENERATOR

4-1 EXTERNAL VIEW of GENERATOR

DC Circuit Breaker

Engine Control Switch

(CHOKE-RUN-STOP)

AC Receptacle

Ground Terminal

Air Cleaner Cover

Spark Plug

Cover

Fuel

Tank

/

Drain Plug

\-

Oil Filler Cap

-5-

Carrying Handle

- Fuel Tank Cap

Page 12

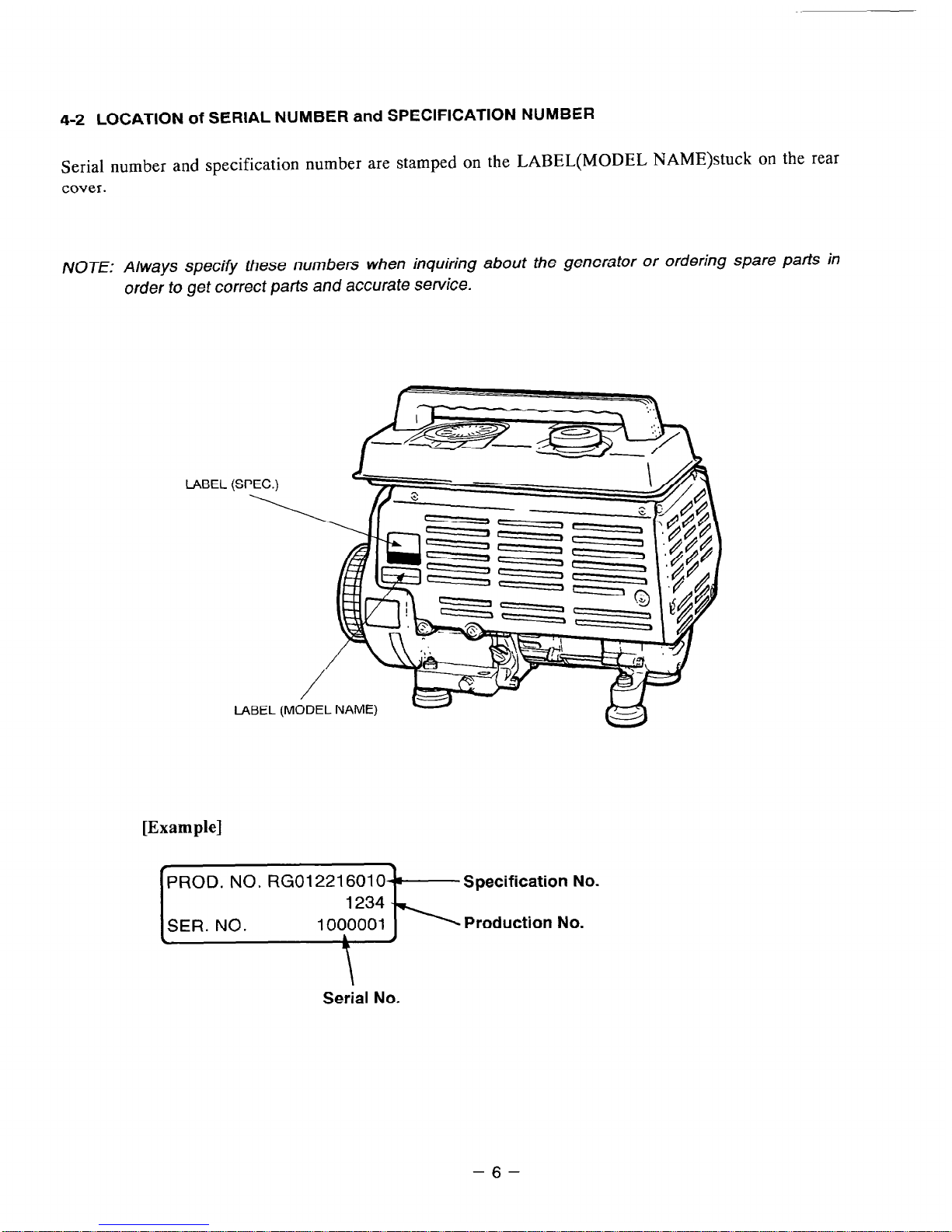

4-2 LOCATION of SERIAL NUMBER and SPECIFICATION NUMBER

Serial number and specification number are stamped on the LABEL(MODEL NAME)stuck on the rear

cover.

NOTE: Always specify these numbers when inquiring about the generator or ordering spare parts in

order to get correct parts and accurate service.

LABEL

(SPEC.)

[Example]

LABEL

/

/

(MODEL

r

PROD. NO. RGOl2216010-*

Specification No.

1234 -

SER. NO.

1000001 1

Production No.

L

L

4

Serial No.

-6-

Page 13

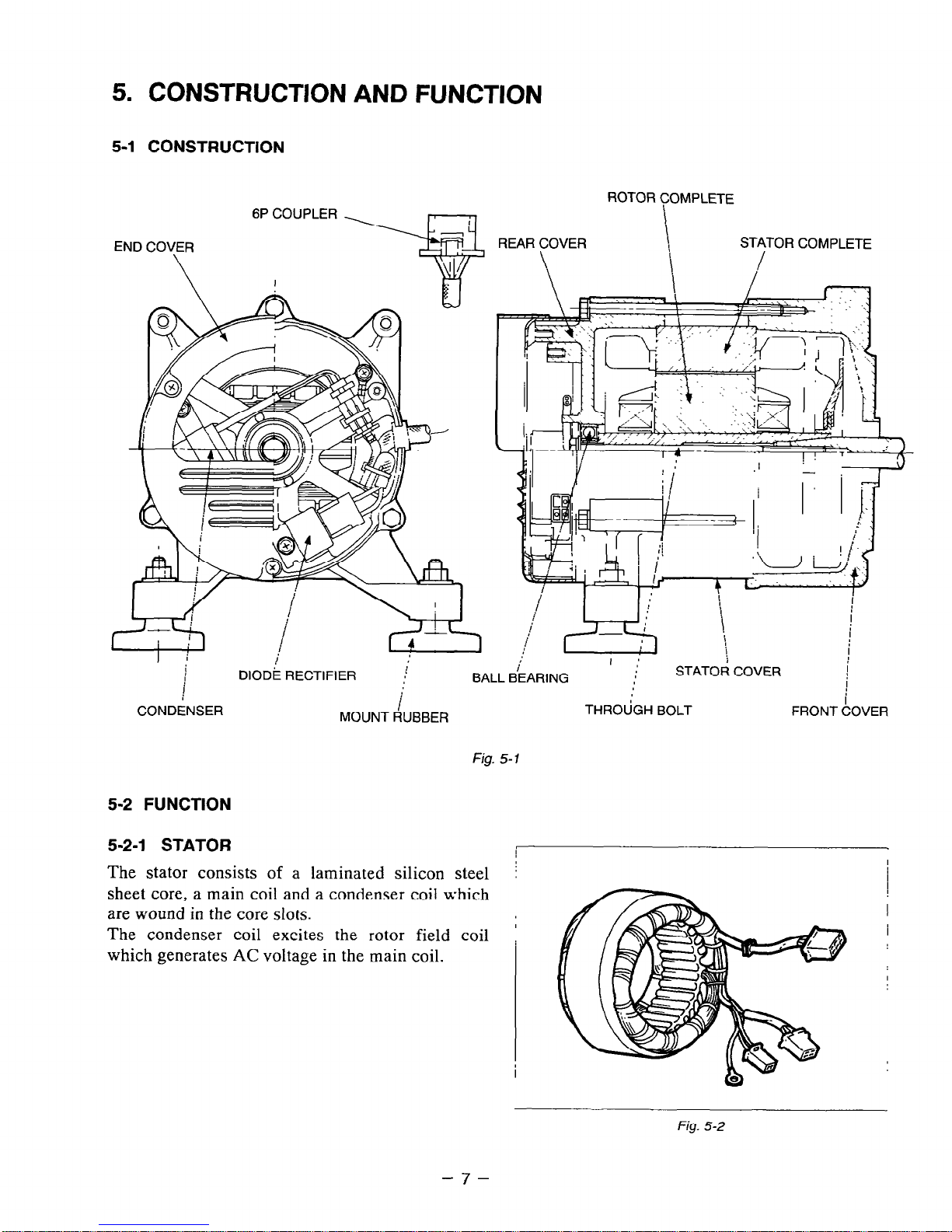

5. CONSTRUCTION AND FUNCTION

5-1 CONSTRUCTION

ROTOR COMPLETE

END COVER

\

tip Co”PLER y- REAR YOVER

\ STATOR COMPLETE

,

,

BALL BLARING

’ ,

i

DlODi RECTIFIER :

STATOR COVER

I

;

I

CONDiNSER

MOUNT

&BBER

THROtiGH BOLT

FRONT ~&OVER

Fig. 5-7

5-2 FUNCTION

5-2-i STATOR

The stator consists of a laminated silicon steel

sheet core, a main coil and a condenser coil which

are wound in the core slots.

The condenser coil excites the rotor field coil

which generates AC voltage in the main coil.

I

I

I

I

I

Fig. 5-2

-7-

Page 14

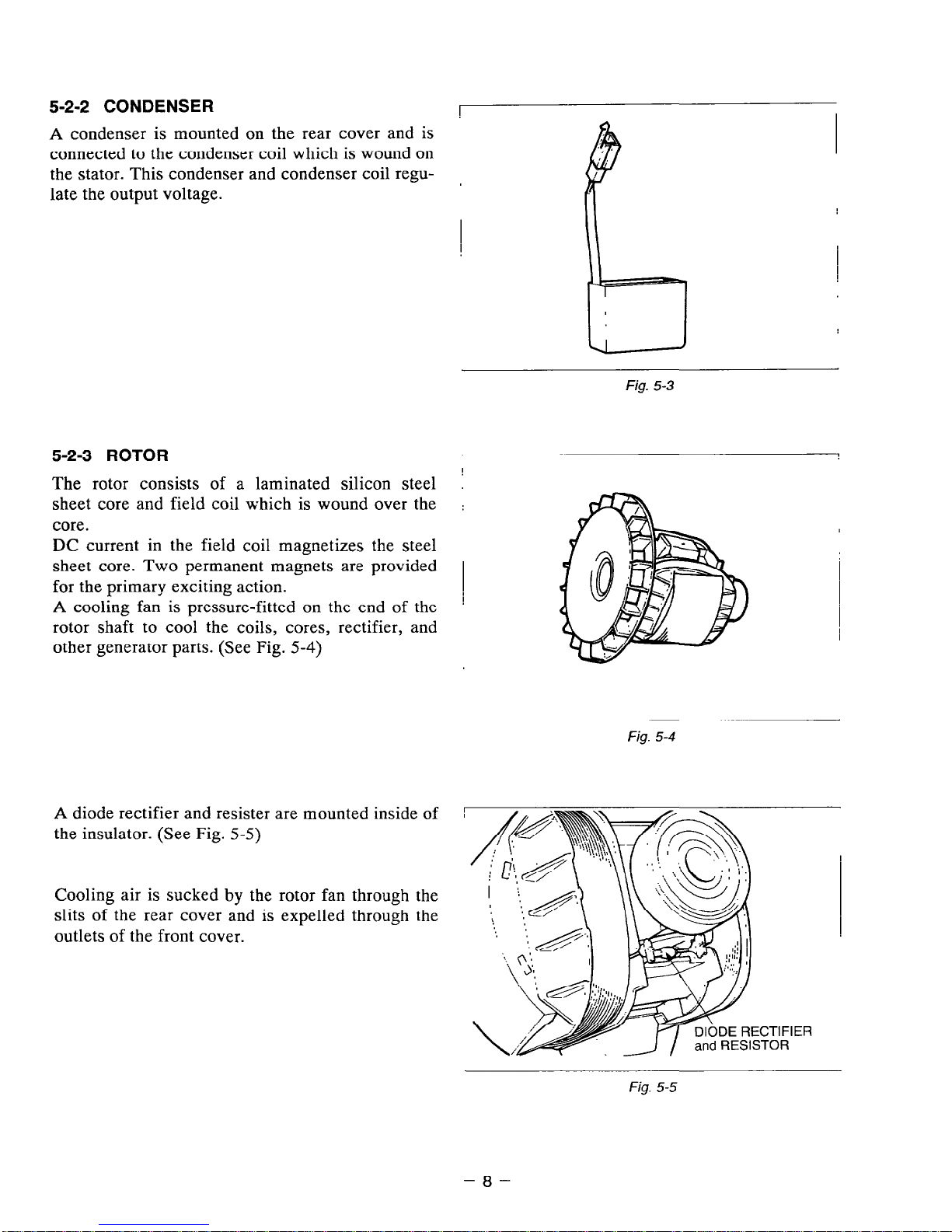

5-2-2 CONDENSER

A

condenser is mounted on the rear cover and is

connected to the condenser coil which is wound on

the stator. This condenser and condenser coil regulate the output voltage.

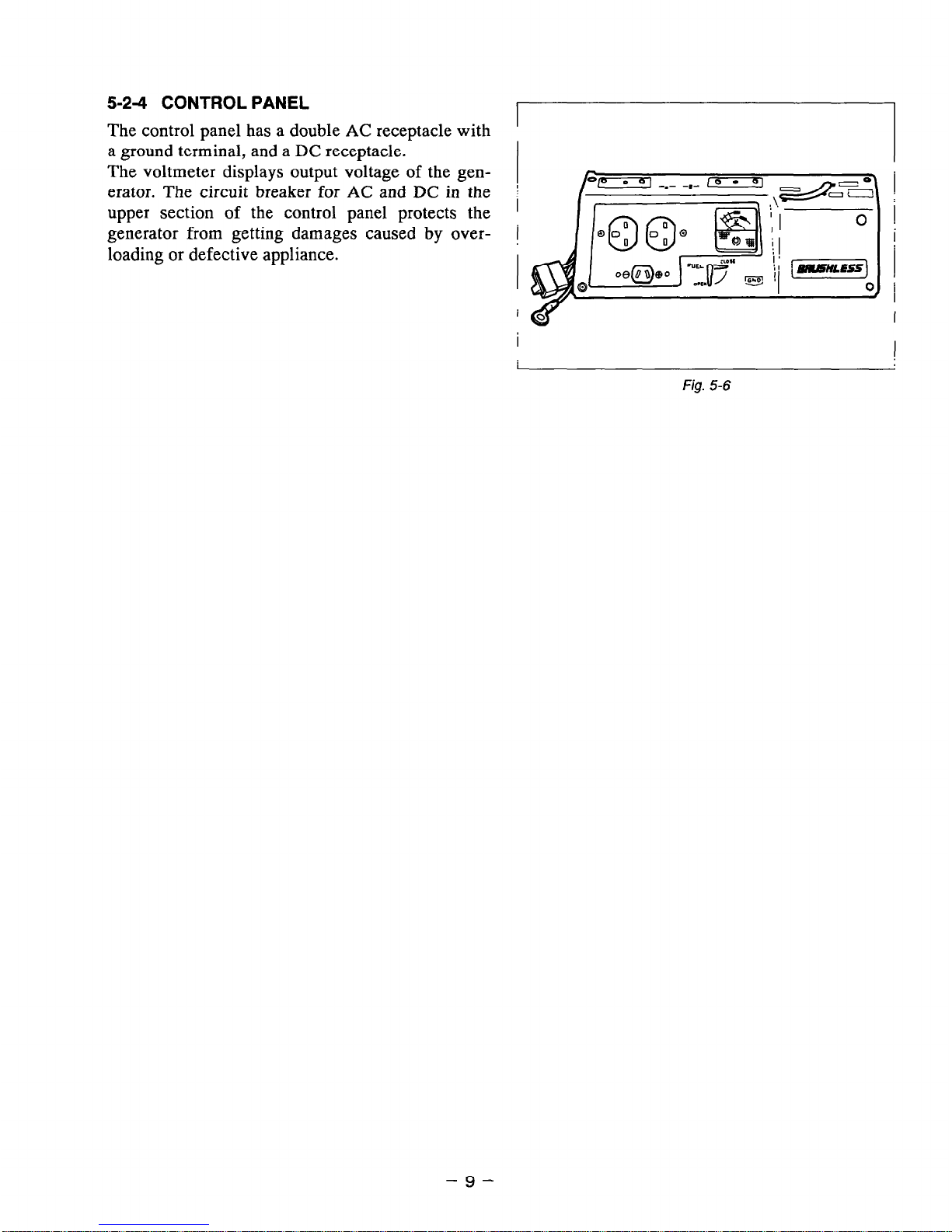

5-2-3 ROTOR

The rotor consists of a laminated silicon steel

sheet core and field coil which is wound over the

core.

DC current in the field coil magnetizes the steel

sheet core. Two permanent magnets are provided

for the primary exciting action.

A cooling fan is pressure-fitted on the end of the

rotor shaft to cool the coils, cores, rectifier, and

other generator parts. (See Fig. 5-4)

A diode rectifier and resister are mounted inside of

the insulator. (See Fig. 5-5)

Cooling air is sucked by the rotor fan through the

slits of the rear cover and is expelled through the

outlets of the front cover.

I

Fig. 5-3

Fig. 5-4

DE RECTIFIER

Fig. 5-5

-8-

Page 15

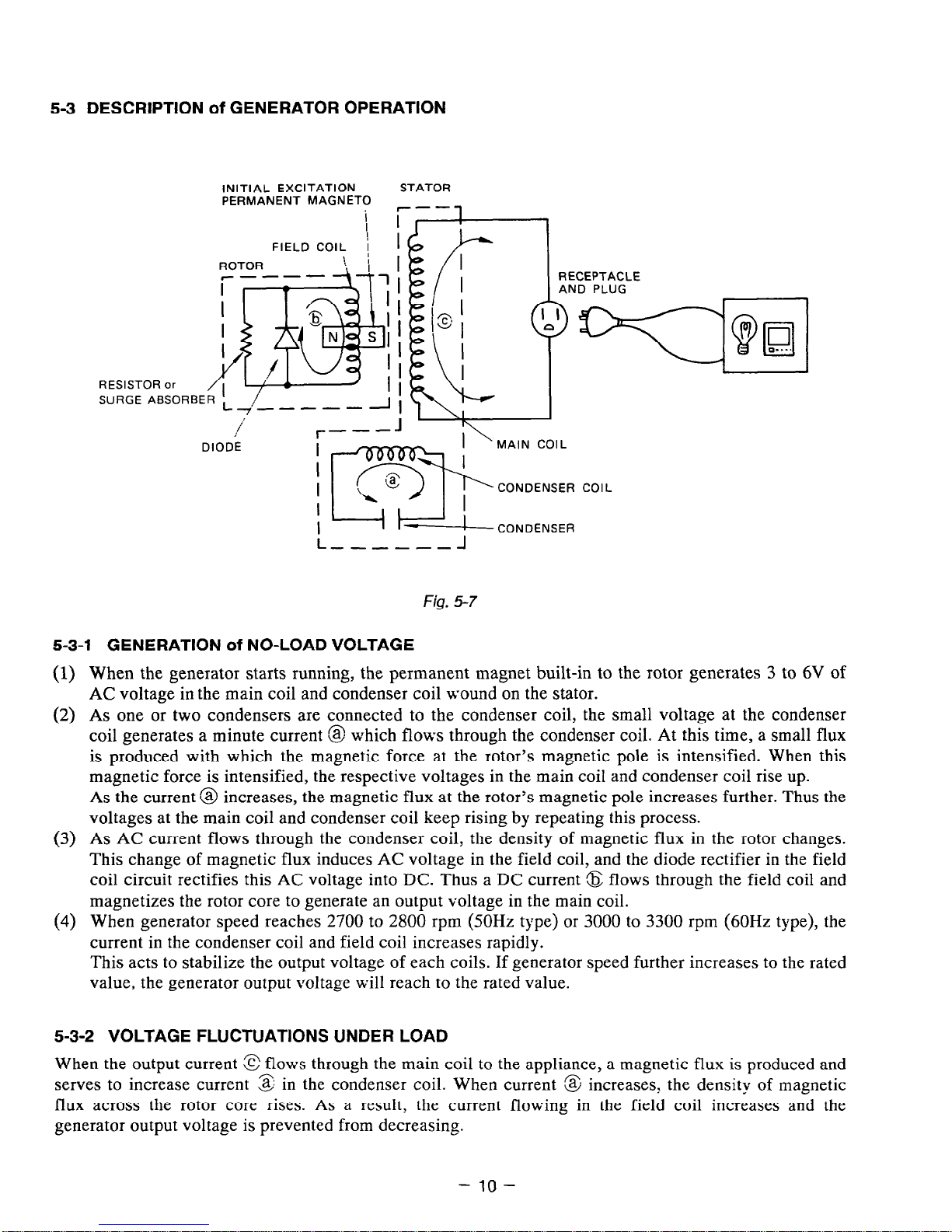

5-2-4 CONTROL PANEL

The control panel has a double AC receptacle with

a ground terminal, and a DC receptacle.

The voltmeter displays output voltage of the generator. The circuit breaker for AC and DC in the

upper section of the control panel protects the

generator from getting damages caused by overloading or defective appliance.

I

Fig. 5-6

-9-

Page 16

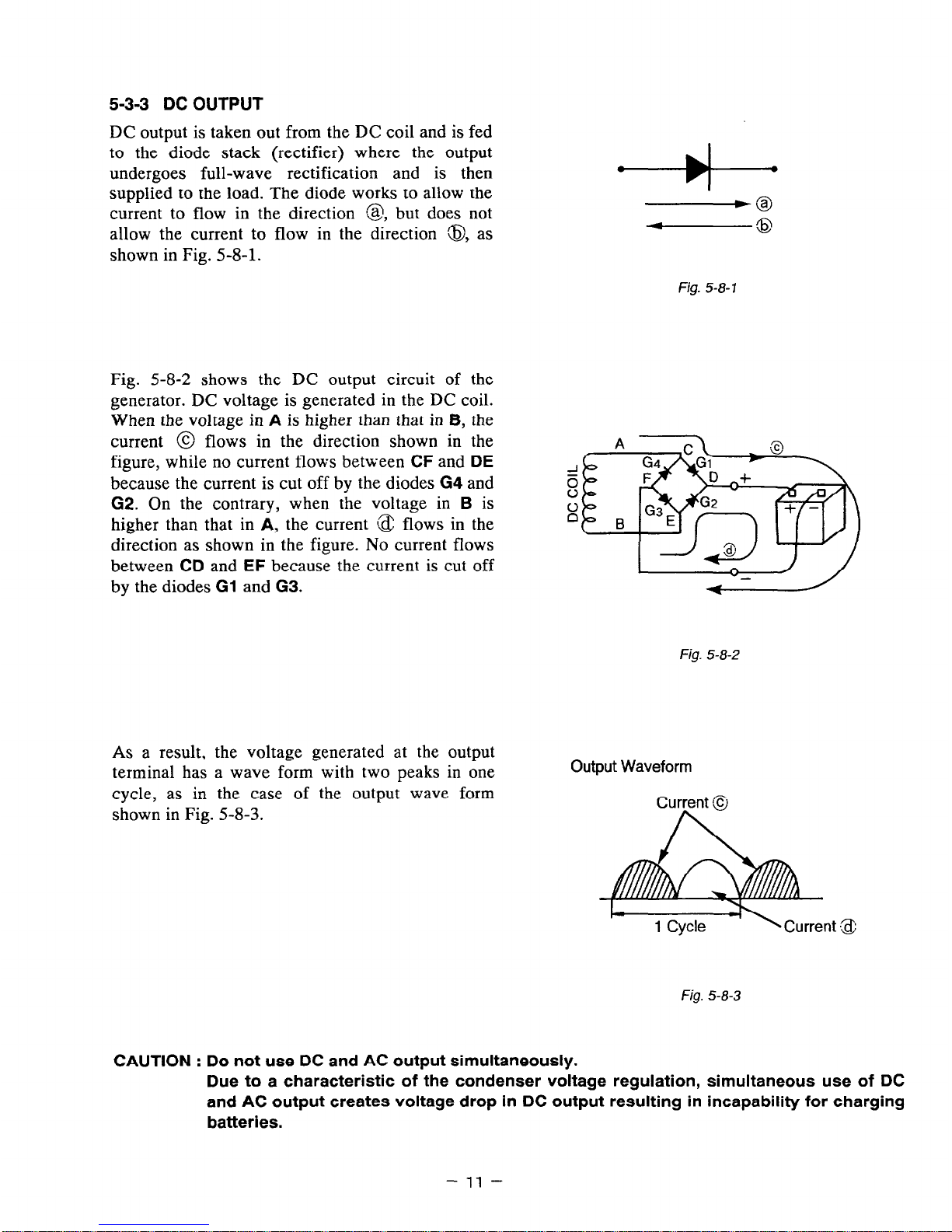

5-3 DESCRIPTION of GENERATOR OPERATION

INITIAL EXCITATION INITIAL EXCITATION

STATOR STATOR

PERMANENT MAGNETO PERMANENT MAGNETO

FIELD COIL

ROTOR ROTOR

7 ----_---It

RESISTOR or RESISTOR or

/

---

r-

DIODE DIODE

MAIN COIL

CONDENSER COIL

Fig. 5-7

5-3-l GENERATION of NO-LOAD VOLTAGE

(1) When the generator starts running, the permanent magnet built-in to the rotor generates 3 to 6V of

AC voltage in the main coil and condenser coil wound on the stator.

(2) As one or two condensers are connected to the condenser coil, the small voltage at the condenser

coil generates a minute current @ which flows through the condenser coil. At this time, a small flux

is produced with which the magnetic force at the rotor’s magnetic pole is intensified. When this

magnetic force is intensified, the respective voltages in the main coil and condenser coil rise up.

As the current @ increases, the magnetic flux at the rotor’s magnetic pole increases further. Thus the

voltages at the main coil and condenser coil keep rising by repeating this process.

(3) As AC current flows through the condenser coil, the density of magnetic flux in the rotor changes.

This change of magnetic flux induces AC voltage in the field coil, and the diode rectifier in the field

coil circuit rectifies this AC voltage into DC. Thus a DC current %$ flows through the field coil and

magnetizes the rotor core to generate an output voltage in the main coil.

(4) When generator speed reaches 2700 to 2800 rpm (50Hz type) or 3000 to 3300 rpm (60Hz type), the

current in the condenser coil and field coil increases rapidly.

This acts to stabilize the output voltage of each coils. If generator speed further increases to the rated

value, the generator output voltage will reach to the rated value.

5-3-2 VOLTAGE FLUCTUATIONS UNDER LOAD

When the output current g flows through the main coil to the appliance, a magnetic flus is produced and

serves to increase current 3 in the condenser coil. When current @ increases, the density of magnetic

flux across the rotor core rises. As a result, the current flowing in the field coil increases and the

generator output voltage is prevented from decreasing.

- 10-

Page 17

5-3-3 DC OUTPUT

DC output is taken out from the DC coil and is fed

to the diode stack (rectifier) where the output

undergoes full-wave rectification and is then

supplied to the load. The diode works to allow the

current to flow in the direction 83, but does not

allow the current to flow in the direction 8, as

shown in Fig. 5-8-l.

Fig. 5-8-7

Fig. 5-8-2 shows the DC output circuit of the

generator. DC voltage is generated in the DC coil.

When the voltage in A is higher than that in 6, the

current @ flows in the direction shown in the

A

figure, while no current flows between CF and

DE

because the current is cut off by the diodes G4 and

G2. On the contrary, when the voltage in B is

higher than that in

A,

the current (2 flows in the

x

B

direction as shown in the figure. No current flows

between

CD

and

EF

because the current is cut off

by the diodes

Gl

and G3.

Fig. 5-8-2

As a result, the voltage generated at the output

terminal has a wave form with two peaks in one

cycle, as in the case of the output wave form

shown in Fig. 5-B-3.

Output Waveform

Fig. 5-8-3

CAUTION : Do not use DC and AC output simultaneously.

Due to a characteristic of the condenser voltage regulation, simultaneous use of DC

and AC output creates voltage drop in DC output resulting in incapability for charging

batteries.

- 11 -

Page 18

6. SAFETY PRECAUTIONS

1.

2.

3.

4.

5.

6.

7.

Use extreme caution near fuel. A constant danger of explosion or fire

exists.

Do not fill the fuel tank while the engine is running. Do not smoke or use open flame near the fuel

tank. Be careful not to spill fuel when refueling. If spilt, wipe it and let dry before starting the engine.

Do not place inflammable materials near the generator.

Be careful not to put fuel, matches, gunpowder, oily cloth, straw, and any other inflammables near the

generator.

Do not operate the generator in a room,cave or tunnel. Always operate in a well-ventilated area.

Otherwise the engine may overheat and also, the poisonous carbon monoxide contained in the exhaust

gases will endanger human lives. Keep the generator at least 1 m (4 feet) away from structures or

facilities during use.

Operate the generator on a level surface.

If the generator is tilted or moved during use, there is a danger of fuel spillage and a chance that the

generator may tip over.

Do not operate with wet hands or in the rain.

Severe electric shock may occur. If the generator is wet by rain or snow, wipe it and thoroughly dry it

before starting.

Don’t pour water over the generator directly nor wash it with water.

If the generator is wet with water, the insulations will be adversely affected and may cause current

leakage and electric shock.

Do not connect the generator to the commercial power lines.

This may cause a short-circuit or damage to the generator.

Never connect the generator to the existing house wiring. If connected, the generator

will

burn out

when the commercial power source is recovered.

Don’t operate the generator with its cover removed.

The operator may be injured or suffer electric shock.

CAUTION; If the circuit breaker tripped off as a result of using an electrical appliance, the cause

can be an overload or a short-circuit.

In such a case, stop operation immediately and carefully check the electrical

appliance and plugs for faulty wiring.

- 12 -

Page 19

7.

RANGE OF APPLICATIONS

Generally, the power rating of an electrical appliance indicates the amount of work that can be done by it.

The electric power required for operating an electrical appliance is not always equal to the output wattage

of the appliance. The electrical appliances generally have a label showing their rated voltage, frequency,

and power consumption (input wattage). The power consumption of an electrical appliance is the power

necessary for using it. When using a generator for operating an electrical appliance,the power factor and

starting wattage must be taken into consideration.

In order to determine the right size generator, it is necessary to add the total wattage of all appliances to

be connected to the unit.

Refer to the followings to calculate the power consumption of each appliance or equipment by its type.

(1) Incandescent lamp, heater, etc. with a power factor of 1.0

Total power consumption must be equal to or less than the rated output of the generator.

Example:

A rated 1OOOW generator can turn ten 1OOW incandescent lamps on.

(2) Fluorescent lamps,mercury lamps, etc. with a smaller power factor

Select a generator with a rated output equivalent to 1.2 to 2 times of the power consumption of the

load.

Example:

A 400W mercury lamp requires 600W to 700W power source to be turned on.

A rated 1OOOW generator can power one 400W mercury lamp.

NOTE I: If a power factor correction capacitor is not applied

to

the mercury lamp or fluorescent

/amp, the more power shaN be required to drive those lamps.

A rated 1 OOOW generator may unable to drive a 400W mercury lamp without power

factor correction capacitors.

NOTE 2: Nominal wattage of the fluorescent lamp generally indicates the output wattage of the

lamp.

Therefore, if the fluorescent lamp has no special indication as to the power consumption,

efficiency should be taken into account as explained in item (5) on the following page.

(3) Motor driven tools and light electrical appliances

Generally the starting wattage of motor driven tools and light electrical appliances are 1.2 to 3 times

lager than their running wattage.

Example:

A rated 250W electric drill requires a 400W generator to start it.

(4) Initially loaded motor driven appliances such as water pumps,compressors,etc.

These appliances require large starting wattage which is 3 to 5 times of running wattage.

Example:

A rated 9OOW compressor requires a 4500W generator to drive it.

NOTE 7: Motor-driven appliances require the aforementioned generator output only at the starting.

Once their motors are started. the appliances consume about 7.2 to 2 times their rated

power consumption so that the excess power generated by the generator can be used

for other electrical appliances.

NOTE 2: Motor-driven appliances mentioned in items (3) and (4) vary in their required motor

starting power depending on the kind of motor and start-up load. If it is difficult

to

determine the optimum generator capacity,

select

a generator with a larger capacity.

- 13-

Page 20

(5) Appliances without any indication as to power consumption

Some appliances have no indication as to power consumption; but instead the work load (output) is

indicated. In such a case, power consumption is to be worked out according to the numerical formula

mentioned below.

(Output of electrical appliance) = (Power consumption)

(Efficiency)

Efficiencies of some electrical appliances are as follows:

Single-phase motor - a * . . e . - * . * * . . * . - 0.6 - 0.75

The smaller the motor, the

Three-phase motor * * a . - . * * * - * . . * * * 0.65 - 0.9

It-

lower the efficiency.

Fluorescent lamp - * * . * * . * * * . * * . . - . * * 0.7 - 0.8

Example

1: A 40W fluorescent lamp means that its luminous output is 40W. Its efficiency is 0.7 and

accordingly, power consumption will be 40 + 0.7= 57W. As explained in

item(2),

multiply

this power consumption value of 57W by 1.2

- 2 and you will get the figure of the necessary

capacity of a generator. In other words, a generator with a rated output of 1OOOWcapacity

can light nine to fourteen 40W fluorescent lamps.

Example 2:

Generally speaking, a 400W motor means that its work load is 400W. Efficiency of this

motor is 0.7 and power consumption will be 400 + 0.7= 57OW. When this motor is used for

a motor-driven tool, the capacity of the generator should be multiplied by 1.2 to 3 and 570W

as explained in the

item(3).

Electrical appliance

Applicable limit

50Hz 60Hz

lncandesent lamp, heater, etc.

Fluorescent lamp, mercury lamp, etc.

approx.800W

I

approx.1 OOOW

approx. SOW

I

approx. 650W

Motor-driven tool, general-purpose motor, etc.

Water pump, compressor, etc.

approx. 500W

approx. 250W ’

approx. 600W

approx. 300W

Table 7-1

NOTES: Wiring between generator and electrical appliances

1.

Allowable current of cab/e

2.

Use a cable with an allowable current that is larger than the rated input current of the load

(electrical appliance). If the input current is larger than the allowable current of the cable used, the

cable will become excessively heated and deteriorate the insulation, possibly burning it out.

Table 7-2 shows cables and their allowable currents for your reference.

Cable length

If a long cab/e is used, a voltage drop occurs due to the increased resistance in the conductors

decreasing the input voltage to the load (electrical appliance). As a result, the load can be

damaged.

Table 7-2 shows voltage drops per 100 meters of cab/e.

- 14-

Page 21

’ Nominal cross

sectlon

/ Redstance I

Current Amp.

Table 7-2

Voltage drop indicates as V =

&XRxIxt?

R

means

resistance ( 9 /lOO m) on the above table.

I means electric current through the wire (A).

Q

means the length of the wire

(m).

The length of wire indicates round length, it means twice the length from generator to electrical tools.

7-1 DC OUTPUT

NOTE : Do not use DC and AC output simultaneously.

Due to a characteristic of the condenser voltage regulation, simultaneous use of DC and AC

output creates voltage drop in DC output resulting in incapability for charging batteries.

When the generator is employed to charge batteries, attentions should be paid to the specific gravity of

electrolyte in the battery.

7-2-l SPECIFIC GRAVITY OF BATTERY ELECTROLYTE

The specific gravity of electrolyte varies by temperature

; so it must be converted to the one at 20°C.

s20 = St + 0.0007 (t-20)

where

S20 : The specific gravity at 20°C

St

: Measured value

t : Temperature at the time of measurement (Electrolyte)

- 15 -

Page 22

7-2-2 SPECIFIC GRAVITY OF BATTERY ELECTROLYTE AND CHARGING CONDITION

Speclflc gravity (20%) Charging condintion

1,260 100

1,240 87

1,220 75

1,200 62

1,180 50

1,160 37

1,140 25

Remarks

Charging is not necessary.

Charging is necessary.

Immediate Charging is necessary.

Table 7-3

7-2-3 BAlTERY CAPACITY

The battery capacity is expressed in the unit of AH (ampere-hour). One AH stands for the capacity

capable of one ampere current for one hour.

-16-

Page 23

8. MEASURING PROCEDURES

8-1 MEASURING INSTRUMENTS

8-l -1 “Dr. ROBIN” GENERATOR TESTER

The “Dr. Robin”generator tester is exclusively

designed for fast, easy diagnosis and repair of

Robin generators.

The “Dr. Robin” has the following features:

(1) Functions of voltmeter, frequency meter,

megger tester, capacitance meter and circuit

tester are combined in one unit.

(2) Fast and easy readout by digital indicator.

(3) Built-in automatic battery checker indicates

the time to change batteries.

(4) Tester and accessories are installed in a

handy, sturdy case for easy carrying.

Fig.

8-1

l

SPECIFICATIONS

Model

Part Number

Voltage

i!l

2 : Frequency

P Resistance

‘C

2

9

Condenser Capacity

2

Insulation Resistance

Circuit Protector

Power Source

Accessories

Dimensions (L X W X H)

Weight

Dr. Robin

388-47565-08

0-500V AC

25-70Hz

0.1-l ,999 0

lo-100 ,YF

3MQ

Fuse

2 x 6F44P (006P) Dry Cell Battery

Test leads with needle probes . . . 1 set

Test leads with jack plugs . . . . . . 1 set

285 mmx200 mmxll0 mm

1.6kg

Table 8-l

The “Dr. Robin”generator tester can be ordered from Robin generator distributors by the following part

number.

Dr. Robin Part Number : 388-47565-08

If you do not have a “Dr. Robin’generator tester,use the instruments described in the following section

for checking generator parts.

-

17-

Page 24

8-l-2 INSTRUMENTS

I

(1) VOLTMETER

AC voltmeter is necessary. The approximate

AC voltage ranges of the voltmeters to be

i

used for various types of generators are as

follows:

0 to 150V: Type with an output voltage of

’

110 or 12OV

0 to 300V: Type with an output voltage of

220,230 or 240V

0 to 15OV, 0 to 330V: Dual voltage type

For AC

Fig. 8-2

(2) AMMETERS

AC ammeter is necessary. An AC ammeter

with a range that can be changed according to

the current rating of a given generator is most

desirable. (About lOA, 20A, 1OOA)

For AC

-

1

Fig. 8-3

(3) FREQUENCY METER

Frequency range : About 45 to 65Hz

NOTE: Be careful of the frequency meter’s

input voltage range.

Fig. 8-4

- 18-

Page 25

(4) CIRCUIT TESTER

I

(5)

This circuit tester is used for measuring re-

!

sistance, etc.

MEGGER TESTER

Used for measuring generator insulation

sistance.

Select one with testing voltage range

5oov.

(6) TACHOMETER

Use the contact-less type tachometer.

re-

of

Fig. 8-5

I

1

Fig, 8-6

Fig. 8-7

- 19 -

Page 26

8-2 AC OUTPUT MEASURING

To

AC

Fig. 8-8

Measurement is executed with the circuit as shown in Fig. 8-8. An electric heater or an incandescent

lamp with a power factor of 1.0 is suitable as a load for the generator. When the AC output measured at

the rated load and rated speed is confirmed to be within the voltage range specified in the table below,

the AC output is normal.

Rated voltage 1lOV

120v ! 220v

240V

Voltage range 1

107-119v

i

117-130V ( 215-236V 235-260V

Table 8-2

8-3 DC OUTPUT MEASURING

4

To AC Receptacle

1

Load

Fig. 8-9

Measurement of DC output is executed with the swirch turned OK while the current is regulated at 8.3A

by adjusting the load to the generator. If the voltage is within the range from 1OV to 14V, the voltage

output is normal.

Note : If a battery is connected as a load to the generator, the DC output voltage will increase by

approximately I to 2V. Therefore, carefully observe the electrolyte level and do not overcharge

the battery.

- 20 -

Page 27

84 MEASURING INSULATION RESISTANCE

Use a “Dr. Robin”generator tester in megger tester

;

mode or use a megger tester to check the insulation resistance. Connect a megger tester to one

of receptacle output terminals and the ground terminal, then measure the insulation resistance. An

insulation resistance of 1 megohm or more is

normal. (The original insulation resistance at the

time of shipment from the factory is 10 megohm

or more.)

If it is less than 1 megohm, disassemble the I

generator and measure the insulation resistance of

the stator, rotor and control panel individually.

Fig. 8-10

l

STATOR

(1) Measure the insulation resistance between

BROWN lead and the core.

(2) Measure the insulation resistance between

YELLOW lead and the core.

(3) Measure the insulation resistance between

BLACK lead and the core.

l

ROTOR

Measure the insulation across one of the soldered

terminals of the rotor and the core.

Fig. 8-i 1

Fig. 8-12

- 21 -

Page 28

l

CONTROL PANEL

Measure the insulation resistances between the

live parts and the grounded parts.

Fig. 8-13

Any part where the insulation resistance is less than 1MQ has faulty insulation, and may cause electric

leakage and electric shock.

Replace the faulty part-

- 22 -

Page 29

9. CHECKING FUNCTIONAL MEMBERS

9-l CONTROL PANEL

9-1-1 AC RECEPTACLES

Using a “Dr. Robin”or a circuit tester, check continuity between the two terminals at the rear of the AC

receptacles while the receptacle is mounted on the control panel. When continuity is found between the

output terminals of the receptacle with a wire connected across these terminals, the AC receptacle is

normal. When the wire is removed and no continuity is found between these terminals, the receptacles

are also normal.

WIRE

Fig. 9- 1A

9-l-2 DC RECEPTACLE

Check continuity between the DC terminals at the

rear of the receptacle using a circuit tester, under

the condition that the receptacle is mounted on the

control panel.

When continuity between the DC terminals of the

receptacle is confirmed with a wire connected

across the terminals, and is not confirmed if the

wire is removed, the DC receptacle is normal.

Fig. 9-16

Fig. 9-2

9-l-3 CIRCUIT BREAKER

Check continuity between the two terminals at the

rear side of the circuit breaker using a circuit tester

while it is mounted on the control panel.

If continuity is confirmed when the breaker is ON,

and no continuity is confirmed when the breaker is

OFF, the circuit breaker is normal.

Fig. 9-3

- 23 -

Page 30

9-l-4 VOLTMETER

Check the voltmeter if it operates correctly by

applying specified voltage. Voltmeters cannot be

checked with a circuit tester because its internal

resistance is too large.

9-2 STATOR

Disengage connectors on the wires from stator and

check the resistance between wires with a “Dr.

Robin” or a circuit tester referring to the following

table.

Voltmeter

Fig. 9-4

COUPLER

- k

Fig. 9-5

(Rx1 Q +10”/,)

Hz

Specification

Voltage

1 AC Winding DC Winding Condenser Winging

i

I Brown /White

Yellow / Red

Black / Black

11ov

I 1.7 0

0.84 0

220v

50

# 6.3 Q

4.9

0

220V O/DE spec.)

i 7.3 0 1.0 0

240V

8.1 Q 0.84 Q

11ov

1.0 0

!

12ov

1.3 0

60

0.56 0 4.2

220v

Q

4.0 Q

I

,

I

240V

5.0 n

Table 9- 1

NOTE: If the circuit tester is not sufficiently accuratejt may not show the values given and may give

erroneous readings.

Erroneous reading will also occur when there is a wide variation of resistance among coil

windings or when measurement is performed at ambient temperatures different from 2O”C(68”F).

- 24 -

Page 31

9-3 ROTOR

1) Using the “Dr. Robin”or a circuit tester, measure the resistance of the field coil.

(See Fig. 9-6.)

(RxlQ+lo%)

I

Resistance

I

I

8.5 Q

I

NOTE 7: Because a diode is soldered to the coil

ends at the terminals, resistance may

;

be measured on/y when tester probes i

touch the terminals in one combination

of polarity. Therefore, if no resistance

i

reading appears,

try checking in re-

verse polarity.

NOTE 2: If the circuit tester is not sufficiently

accurate, it may not show the values

given

and may give erroneous

readings.

Erroneous reading will also occur when

there is a wide variation of resistance

among coil windings or when measurement is performed at ambient tempera tures different from 20°C(68”F).

Fig. 9-6

2) Measure the resistance of the resister.

I

Normal resistance

I

3) Measure the resistance of the diode.

CATHODE MARK

POLARITY OF

CIRCUIT TESTER

I

[Continuity exists]

I

[“Ql

Fig. 9-7

- 25 -

Page 32

9-4 CONDENSER

H Use a “Dr. Robin” in capacitance meter mode to check the capacity of condensers. (See Fig. 9-8.)

NOTE: Be sure to discharge condensers by

shorting condenser leads each other be-

fore checking their capacitance,or the

accurate reading cannot be obtained.

L

Fig. 9-8

n

If such an instrument is unavailable, the condenser can be checked by replacing with a new one.

If the generator performs good with new condenser,

the cause of trouble is defect in original

condenser.

9-5 DIODE RECTIFIER

Green

Red

Green

Red

Green Green

Fig. 9-9

DIODE RECTIFIER

CIRCUIT TESTE

Fig. 9-10

The internal circuit of the diode rectifier is as shown in Fig. 9-9.

Check continuity between each terminal using a circuit tester as shown in Fig. 9-10.

- 26 -

Page 33

w Checking table for analogue circuit tester.

Apply black 0 needle of the circuit tester

Analogue circuit tester

Green Green

Red

Apply red @ needle

of the circuit tester

Green

Green

Red

No continuity

Table 9-2- 1

n

Checking table for digital circuit tester.

Apply red @needle of the circuit tester

Digital circuit tester

Green

Green Red

Green

Apply black @ needle

of the circuit tester

Green

Red

NOTE I:

Because of the difference of measuring method between the analogue circuit tester and the

digital circuit tester, polarity of tester needles should be reversed.

NOTE 2:

“Continuity” means forward direction characteristics of the diode, and different from short

circuit condition (in which a pointer of the tester goes out of its normal scale), shows

resistance to some extent. When result of the checking indicates failure even in one

section,replace with a new one.

NOTE 3:

“Simpson” brand analogue testers have the characteristic as same as the digital circuit tester.

Table 9-2-2

10.

DISASSEMBLY AND ASSEMBLY

1 O-l PREPARATION and PRECAUTIONS

1) Be sure to memorize the locarion of individual parts when disassembling the generator so that the

generator can be reassembled correctly. Tag the disassembled part with the necessary information to

facilitate easier and smoother reassembling.

2) For more convenience, divide the parts into several groups and store them in boxes.

3) To prevent bolts and nuts from being misplaced or installed incorrectly, place them temporarily back

at their original position.

4) Handle disassembled parts with care; clean them before reassembly using a neutral cleaning fluid.

5) Use all disassembly, assembly tools properly, and use the proper tool for each specific job.

- 27 -

Page 34

10-2 DISASSEMBLY PROCEDURES

tep Part to remove

Description

Remarks

Tool

1.

Side cover

(1) Remove the side cover by unscre\xing

(+) Plus screw

four M5 X 8 screws. (See Fig. 10-l.)

driver

2.

Rear cover (1) Remove the rear cover by unscrewing

(+) Plus driver

three M5 X 8 screws and two M8 X 10 ’

screws. (See Fig. 10-2.)

-

3. Control panel

Fig. lo-2

(1) Pull the knob off the control lever and

remove the control panel by unscrewing

four M.5 X 8 screws. (See Fig. 10-3.)

. . _,,,

Fig. IO-3

(+) Plus driver

- 28 -

Page 35

step

4.

I

t

I

‘art to remove 1

Description

I

Remarks

I

Tool

Couplers

and plugs

(Disconnection)

(1) Disengage the couplers of stator wires

from the wires of control panel.

6P couplers (Yellow, Red, Green:

Yellow, Brown, White)

(See Fig. 10-4.)

(2) Disengage the connector of grounding

wire.

Pin terminal (GreenA’ellow)

(See Fig. 10-T)

Pull the couplers while

pushing the locking

hook.

Fig. 10-4

Fig. 10-5

Press the hook of the coupler and

’

pull out to disconnect.

CONTROL PANEL SIDE

STATOR SIDE

I

Fig. IO-6

I

- 29 -

Page 36

Step Part to remove

Descrlptlon

Remarks

Tool

5.

Front cover

(1) Remove the element cover by

(-) Driver

unscrew.-ing M6 X 12 scre\v.

(See Fig. 10-7.)

(2) Remove the front cover by unscrewing

three $15 X 8 screws. (See Fig. 10-S.)

(+) Driver

6. Fuel pipe

and plug

(Disconnection)

Fig. 10-7

Fig. 10-8

(1) Discharge fuel from the tank.

Use utmost care about

1. Shut the fuel striner.

2. Remove the strainer cup.

I fire hazard.

3. Put a vessel to receive fuel under the i Wipe off spilt fuel

strainer and open the fuel cock to

throughly.

discharge fuel. (See Fig. 10-9.)

4. Attach the strainer cup to the strainer

body

(2) Disconnect fuel hose from the strainer.

Loosen the hose clamp on top of the

strainer and pull out the fuel hose from

the strainer. (See Fig. 10-10.)

Do not lose the filler

screen.

/ Pliers

Fig. 10-9

Fig. lo-10

- 30 -

Page 37

! I

‘art to remove

Descrlptlon

I

Remarks

Tool

I

Step

7.

Fuel tank

handle

(1) Remove the handle cover by unscrewing

the

hvo I43 X

10 screws.

The fuel tank can be

removed without

disassembling the

handle.

(+) Driver

(2) Pull off the breather pipe.

(3) Remove the handle body by taking off

the

hv0

M8 nuts.

Handle cover

\

13mm box wrench

Breather pipe

A Handle

M3x IO Screw (2 PCS.)

Full tank

M8xNut (2 pm.)

Fig. 10-11

- 31 -

Page 38

I Step I Part to remove

8. Fuel tank

Remarks Descrlptlon

(1) Remove the two M6X 12 flange bolts

from the blower housing.

(See Fig.

10-12.)

(2) Remove the fuel tank by taking off the

hv0

M8 nuts from the bottom of the

tank. (See Fig. 10-13.)

I ’

I I

Tool

1Omm box wrench

13mm box wrench

Bracket

(Cover)

End cover

Fig. 10-72

Fig. 70-13

(1) Remove the bracket cover from the

generator by loosening the two M8 X 30

bolts. (See Fig. 10-14.)

(1) Remove the end cover from the

generator by unscrewing the three %I

X

8 screws. (See Fig. 10-14.)

Fig. lo-14

13mm box wrench

(+) Driver

- 32 -

Page 39

Step

11.

Dart to remove

Rear bracket

Description

(1) Loosen and take out the three M6

bracket bolts. (See Fig. 10-15.)

(2) Remove condenser from rear bracket.

(3) Remove the connector of the diode

rectifier and then remove the earth cable

terminal from the rear bracket.

(See Fig. 10-16.)

Remarks

Tool

1Omm box wrench

Box spanner

Box spanner ant

screw driver (+)

Bracket bolt (3 PCS.)

Fig. IO-15

(4) Remove the rear bracket, tapping it

evenly with a plastic mallet.

(See Fig. 10-U.)

(5) Remove mount rubbers from rear cover.

(See Fig. 10-18.)

Fig. 70-16

Plastic mallet

Wrench

mallet

Fig. IO-17

Fig. 10-18

- 33 -

Page 40

Step Part to remove

Descrlptlon

Remarks

Tool

12. Stator

(1) Remove the stator cover.

(See Fig. 10-19.)

(2) Pull off the stator from the front cover

tapping the core with a plastic mallet.

(See Fig. 10-20.)

Never tap on the

winding and the lead.

Plastic mallet

Fig. 10-79

Fig. IO-20

Fig. 70-22

Page 41

Step

13.

I

i

‘art to remove

Rotor

!

t-

t

i

Fig. 10-23

(2) Put the engine on the working table

recoil slarter side down.

(3) Use a bolt and oil as a rool for pulling

out rotor in the follo\ving procedures :

1. Pour engine oil into the center hole of

rotor shaft.

I

Fill with oil to the shaft end.

(See Fig. 10-24.)

2. Prepare a

bolt

with the following

thread size : M8 X P 1.25

3. Apply a few turns of seal tape around

the tip of the bolt.

(See Fig. 10-25.)

!

Descrlptlon Remarks

(1) Take off the through bolt.

Apply a box wrench on the head of

through bolt. Hit the wrench handle with

a hammer counter-clockwise to loosen.

I

Tool

Box wrench

Plastic hammer

Fig. 70-24

Fig. 1 O-25

-

35

-

Page 42

Step

13.

tart to remove

Rotor

Front bracket

-I-

Description

4. Screw the bolt into the thread of the

rotor shaft.

5. Torque the bolt using a socket wrench

until the rotor comes off loose.

* The hydraulic pressure inside the rotor

shaft takes apart the rotor from the

engine shaft.

(4) Wipe off oil throughly from rotor shaft

and engine PTO shaft.

Remarks

Fig. 10-26

(1) Remove the front bracket. which is

mounted on the main bearing cover of

the engine, by taking out four M8 X 18

bolts. (See Fig. 10-27.)

Socket wrench

! 13 mmbox spanner

Fig. 10-27

- 36 -

Page 43

itep

15.

‘art to remove

Mount

rubbers

Description

(1) Remove mount bracket from engine.

Remove mount rubbers from mount

bracket.

Remarks

8

@I Nut : 3pcs. or Zpcs.

Mount bracket

Mount rubber

\

Fig. 10-28

Tool

12 mm wrench

- 37 -

Page 44

10-3 ASSEMBLY PROCEDURES

10-3-l FRONT BRACKET

Install the front bracket on the main bearing cover

of the engine, engaging the faucet joint.

(See Fig. 10-29.)

M8 X 20mm bolt and washer ass’y .*-*.... 4pcs.

10-3-2 ROTOR

Fig. 70-29

1) Wipe off oil from the tapered portion of engine shaft and matching tapered hole of rotor shaft.

(See Figs. lo-30 and 10-31.)

Fig. lo-30

Fig. 10-31

2) Install rotor on the engine shaft and tighten the

I

through-bolt.

Apply a wrench on the head of through bolt

i

and hit wrench handle clockwise with a ham-

;

mer to tighten. (See Fig. 10-32.)

If an impact wrench is available, use it.

I

I

I

Fig. 10-32

- 38 -

Page 45

10-3-3 STATOR

(1) Holding the rear bracket and stator, fit them

to the front bracket. Match the mounting hole

of the rear bracket and that of the rotor bear-

ing, and softly strike the outside periphery of

the rear bracket with a plastic hammer. (See

Fig. 10-33.)

(2) Attach the stator cover around the stator.

Fig. lo-33

(3)

(4)

Tighten the three M6 bolts to fix the rear bracket to the front bracket .

TIGHTENING TORQUE

(Rear bracket)

55 -

75 kg-cm

535 -

735

N *cm

4.0 -

5.4

ft l Ibs.

Put the grommet in the groove of the rear bracket and secure the wire.

Note : Fix the wire from the stator and diode stack with the clamp at the bottom of the groove.

10-3-4 CONDENSER

Put condenser to rear cover.

5 o X 10

mm

tapping screw ...*..*-....*.- 2 PCS.

Condenser S

Fig. 1 O-34

- 39 -

Page 46

10-3-S END COVER

Set the end cover on the rear bracket with three

M4 X 8 screws.

10-3-6 BRACKET (COVER)

Mount the bracket (cover) on the rear bracket and

secure them with M8 X 30 bolts.

1 AlIz-

End cover a

\ i!

I

lCd/

Fig. 10-35

10-3-7 FUEL TANK AND FUEL PIPE (CONNECTION)

(1) Connect the rubber pipe to the engine carburetor and fasten it with a hose clamp, Attach the banjo to

the opposite end of the rubber pipe, tighten it with a hose clamp, and fasten the pipe to the fuel

strainer with the banjo bolt.

Note : Mount the fuel strainer with the banjo outlet upward.

(2) Fasten the strainer to the front bracket with the joint nuts.

(3) Secure the mounting tab on the bottom of the fuel tank and the blower housing with M6 X 12 bolts.

Insert the attaching bolts on the other end of tank into the mount bracket hole and secure it with two

M8 nuts.

(4) Connect the rubber pipe

First, fit the hose clamp on the rubber pipe, connect the strainer and fuel tank, then fasten the rubber

pipe with the hose clamps.

Note : Apply a drop of oil to the rubber pipe so that it may easi/y be connected to the strainer and the

fuel tank.

10-3-8 FUEL TANK HANDLE

(1) Match the handle hole with the bolt on the top of the fuel tank and secure it with M8 nuts.

(2) Completely insert the breather pipe over the bolt.

Note : There is a hole at the center of the breather pipe for air bleeding. Set the breather pipe so that the

hole is directed upward.

(3) Fix both ends of the handle cover with M3 X 10 screws.

- 40 -

Page 47

nanale cover

M3X 10 Screw (2pc.s.)

to Carburetor

f

M8 Nut (2Gcs.) ;

fy/-

Fuel tank cap

\Ai

Fuel filter

M8 Nut

(2 PCS.)

Rubber hose,

-

k

Hose clamp

Fuel strainer

Cup

Rubder hose

Fig. lo-36

10-3-9 FRONT COVER AND ELEMENT COVER

(1)

Secure the front cover, on which fuel strainer have been mounted, with three M5 X 8 screws.

(See Fig. 10-37.)

(2)

Secure the element cover with M6 X 12 screws. (See Fig. 10-38.)

Fig. lo-37

- 41 -

Fig. lo-38

Page 48

10-3-10 CONNECTION OF WIRES

(1) Connect the wires drawn out from the stator to the wires from the control box. (See Fig. 10-39.)

(2) Press the couplers until the locking hook engages securely.

(3) Connect the grounding wire. (See Fig. 10-40.)

Fig. lo-39

Fig. 1 O-40

WIRE CONNECTIONS BETWEEN CONTROL PANEL AND STATOR]

6P coupler

Wire color : Yellow, Red, Green/Yellow, Brown, White

Green/Yell

Brown

Yellow

Red

White

CONTROL PANEL SIDE

STATOR SIDE

0 Earth (Ground) wire : Pin terminal Wire color Green/Yellow

10-3-11 CONTROL PANEL

(1) Put the control panel over the control lever

and secure it with four M5 screws.

(2) Attach the knob to the control lever.

Note :After the couplers and connectors have

been connected and secured

to

the control

panel, secure the wires with a wire band to

the control panel.

Fig. IO-41

- 42 -

Page 49

10-3-12 REAR COVER

r

I

I

Secure the reaT cover with three M5X8 screws and !

two M8 X 10 screws.

I

--

Fig. lo-42

10-3-13 SIDE COVER

I

r’

II

L-----r :.

I

Secure the side cover with four M5X 8 screws.

I

Fig. IO-43

- 43 -

Page 50

11. TROUBLESHOOTING

II-I NO AC OUTPUT

II-I -1 CHECKING STATOR

n

Remove control panel and disconnect cou-

plers on wiring.

n

Measure the resistance between terminals on

stator leads.

Refer to Table 9-l on page 24 for normal

resistance.

IRemedy

If stator is defective, replace with new one.

I

I

I

Fig. 17-1

11-I-2 CHECKING CONDENSER

n

If an instrument (Q.C.-meter or C-meter) for measuring capacity of condenser is available, check the

capacity of condenser.

n

NORMAL CAPACITY OF CONDENSER

n

If you do not have such an instrument, you can check condenser by replacing with new one and test

running.

If the generator perform normally with new condenser, the cause of trouble is defect in original

condenser.

1 l-l-3 CHECKING ROTOR

n

Remove rear

cover

and stator.

I

I

I

DIODE RECTIFIER

and RESISTOR !

Fig. 7 l-2

- 44 -

Page 51

n

Measure the resistance of field coil with a

circuit tester. (See Fig. 11-3.)

n

NORMAL RESISTANCE

(RXlQ+-10%)

RESISTANCE

8.5 R

IRemedy

H If the resistance is not normal, replace rotor

with new one.

I

Fig. 1 l-3

H Unsolder and take out the diodes and the resistors.

w Measure the resistance of 2 pieces of diode.

CATHODE MARK

P0LARll-Y OF

CIRCUIT TESTER

[Continuity exists]

n

Measure the resistance of each resistor.

NORMAL RESISTANCE

n

Check the magnetic force of magnets molded in the rotor.

[Remedy1

1. If the magnetic force is weak, replace the rotor with a new one.

2. If the diode or the resistor is faulty, replace them with new one. When all these parts are good,

assemble them and then solder.

- 45 -

Page 52

(Reassembling]

1. Place the resistors at the bottom.

2. On the resistors put the diodes, taking care of

its polarity.

3. Solder them to the terminal.

*Resistor has no polarity.

(CROSS SECTION)

RlklSTOR (1 pee.)

SOLDERING

Fig. II-4

11-2 AC VOLTAGE IS TOO HIGH OR TOO LOW

11-2-1 CHECKING ENGINE rpm .

If the engine rpm is too high or too low, adjust it to the rated rpm .

mow to adjust engine rpm .]

n

Loosen the nut on the adjusting screw.

n

Turn the adjusting screw clockwise to decrease engine speed or counter-clockwise to

increase engine speed.

Normal engine speed at no load is :

3150 - 3200 rpm for 50 Hz type

3750 - 3800 rpm for 60 Hz type

1 l-2-2 CHECKING STATOR

Check stator referring to Step 11-1-1.

1 l-2-3 CHECKING CONDENSER

Check condenser referring to Step 11-1-2.

11-2-4 CHECKING ROTOR

Check rotor referring to Step 11-1-3.

Fig. 1 l-5

- 46 -

Page 53

FIELD COIL

MAIN COIL

AC CIRCUIT BREAKER

AC RECEPTACLE

RESISTOR

\

SPARK PLUG

I

DIODE, 1

$‘J+=-

whltn

I

/

I

, -

t

/

/

V

- IGNITION

I

COIL

I

I

-‘MAGNETO

DC COIL

CONDENSER

COIL 1

/

I

I

2P COUPLER

i

DIODE STACK ASSY

I

(RECTIFIRE)

DC RECEPTACLE GROUND TERMINAL

\

CONDENSER

DC dlRCUlT BREAKER STOP SWITCH

Page 54

Page 55

a

FUJI

HEAVY INDUSTRIES LTD.

Loading...

Loading...