Page 1

6

Generator

Model

16072, LG102,lG152, LGZOl,LG301

LG2OlD,

LG301D

LGK102, LGK152

Page 2

CONTENTS

Section

Title

Page

1 . SPECIFICATIONS

..........................................

1

2

.

PERFORMANCE

............................................

3

2-1 AC Output

.........................................

3

2-2 DCOutput

.........................................

10

3

.

FEATURES

..............................................

11

4 . GENERAL DESCRIPTION

of

GENERATOR

........................

12

4-1 External View

of

Generator [MODEL LG0721

.................

12

4-2 External View

of

Generator [MODEL LG1021

.................

13

4-3 External View

of

Generator [MODELS LG152 & LG2011

..........

14

4-4 External View

of

Generator [MODELS LGK102 & LGK1521

........

15

4-5 External View

of

Generator [MODEL LG3011

.................

16

4-6 External View

of

Generator Panel

..........................

17

5

.

CONSTRUCTION

and

FUNCTIONS

..............................

18

5-1 Construction

........................................

18

5-2 Functions

..........................................

19

5-3 Description

of

Generator Operation

.........................

24

6

.

SAFETY PRECAUTIONS

.....................................

25

7

.

APPLICABLE RANGESof GENERATOR

..........................

26

8.-

MEASURING PROCEDURE

...................................

29

8- 1 Meters

.............................................

29

8-2 AC Output Measuring

..................................

31

8-3 DC Output Measuring

..................................

31

8-4 Insulation Resistance Measuring

...........................

31

9

.

CHECKING FUNCTIONAL MEMBERS

............................

33

9-1 Stator Assembly

......................................

33

9-2 Rotor Assembly

.......................................

33

9-3 Brushes

.............................................

34

9-4 AVR (Automatic Voltage Regulator)

........................

34

9-5 Fuse Holder and No-Fuse Breaker

..........................

36

9-6 Receptacle and AC Plug

.................................

37

9-7 Voltmeters

.........................................

37

9-8 Diode Stack Assembly

..................................

37

9-9 Primary Exciting Circuit

................................

38

10

.

DISASSEMBLY

and

REASSEMBLY

..............................

39

10-1 Preparations and Suggestions

..............................

39

10-2 How to Disassemble

...................................

39

10-3 How to Reassemble

....................................

45

10-4 Control Box Disassembly and Reassembly

......................

51

11 . TROUBLE.SHO0TlNG

.......................................

52

12

.

CIRCUIT DIAGRAMS

.......................................

56

Page 3

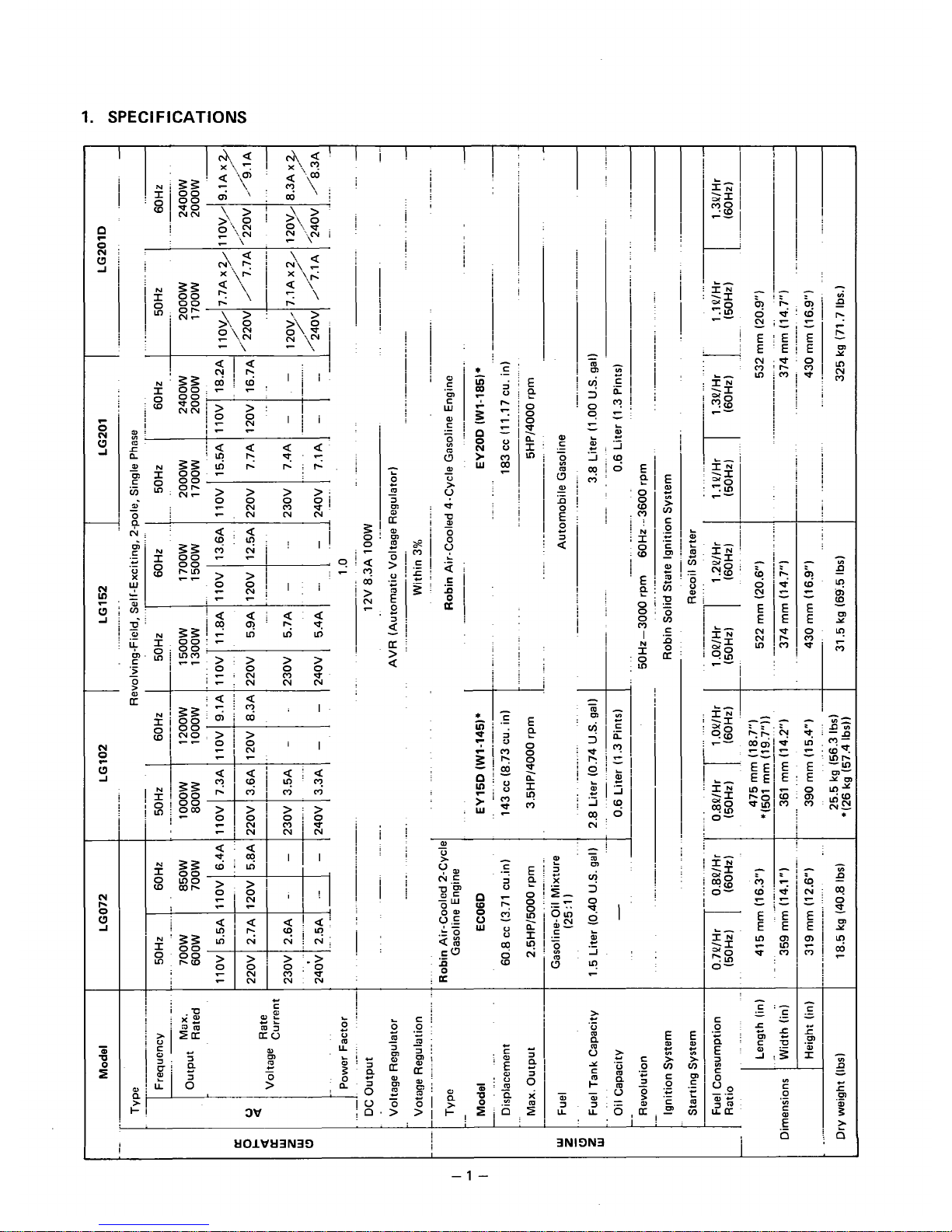

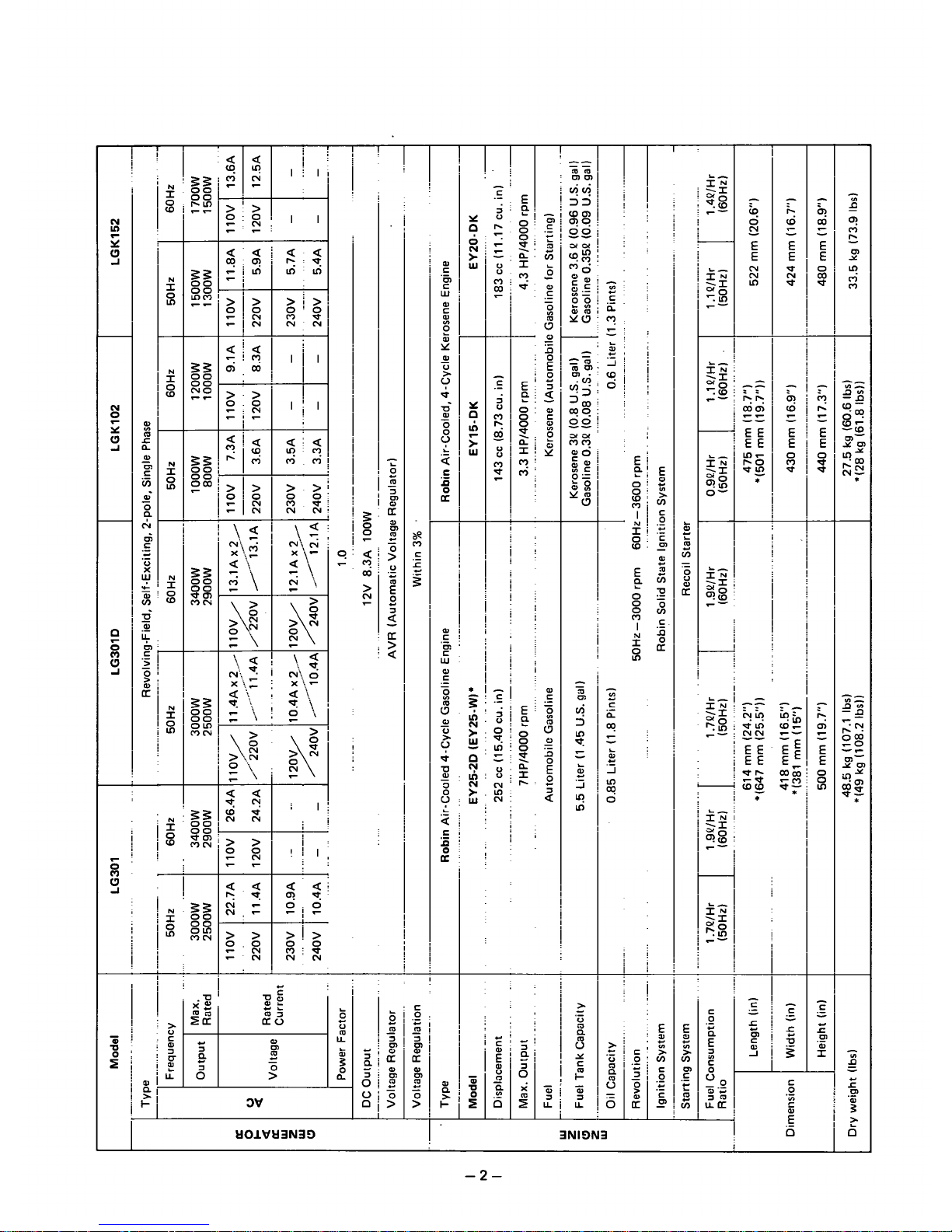

1.

SPECIFICATIONS

T

N

I

0

m

E

P

f

0

0

0

n

I

m

N

I

P

P

-

0

V

-

.-

-

'a

p

9

'I

f

a, a

a

-m

mm

"

a-

Y

:-

I

i

I

-

LT

>

a

I

t

i

I

!

!

1

I

i

I

-

9

0

W

-

E

E

0

0

0

P

n

I

m

m

.

I

i

!

i

!

!

..

.:

I

c

.-

>

3N19N3

t101Vt13N30

I

-1

-

Page 4

-

;9

0

N

-

E

E

N

N

m

-

N

I

54

-

N

I

W

0

-

N

I

5:

-

N

0

I

W

aa

'I.0

rnm

>i>

a00

NN

L

I

9

r

..

.I

!.

..

i:

I.

..

I

i

t

L

L

.-

ai

:i

I

!I

I,

..

..

c

>>

zz

"

T

!

i

>!>

00

mi*

NN

3NION3

I

-2-

Page 5

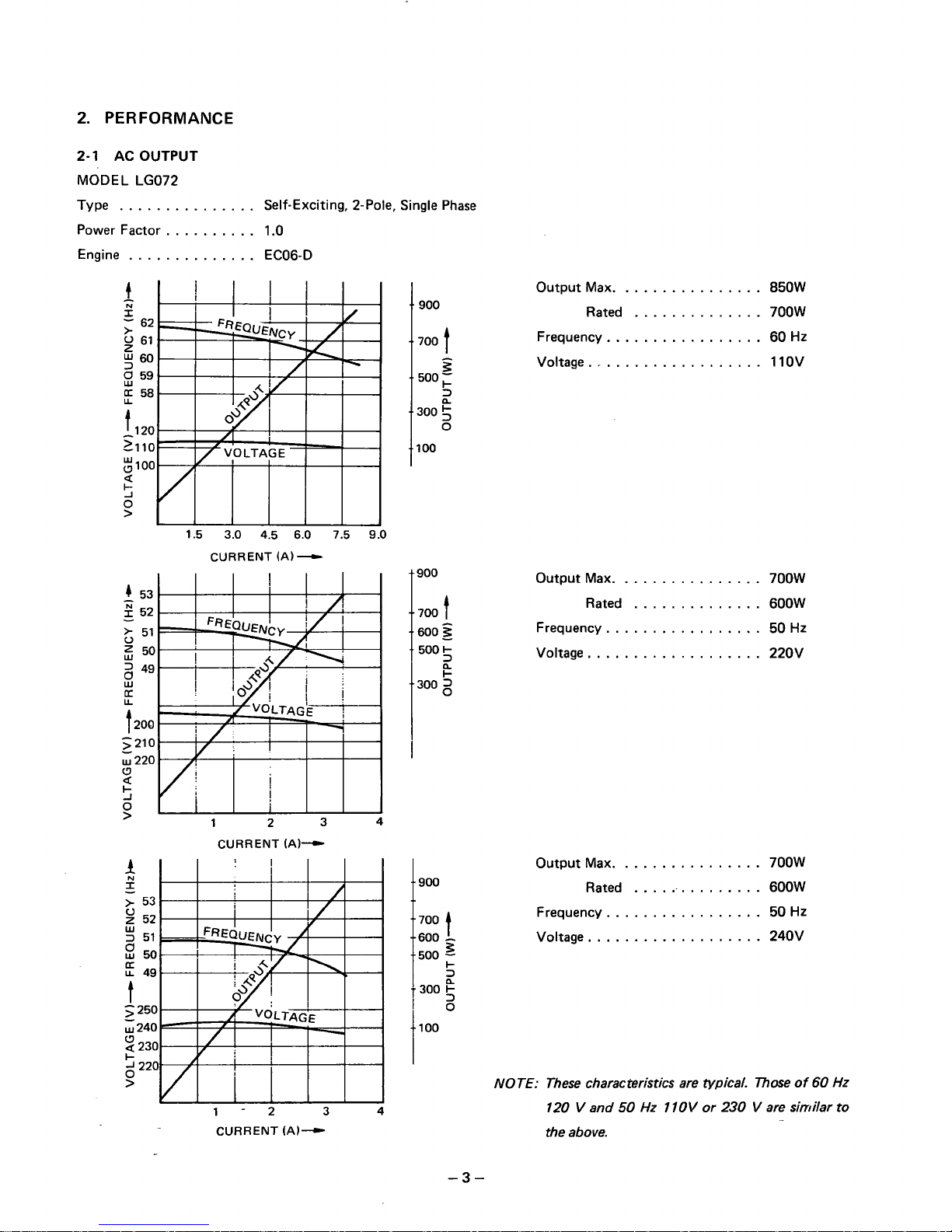

2.

PERFORMANCE

2-1

AC

OUTPUT

MODEL LG072

Type

...............

Self-Exciting, 2-Pole, Single Phase

Power Factor

..........

1.0

Engine

..............

ECOG-D

I

1

N

I

-

62

>

y

61

$60

8

59

58

I

t

1

20

21

10

"

100

a

5

W

0

>

Output Max.

...............

850W

Rated

..............

700W

Frequency.

................

60

HZ

Voltage

.............

....

110v

t

loo

1.5 3.0 4.5 6.0 7.5

9.0

CURRENT

(A)

-

900

Output Max.

...............

700W

-

4

53

..............

-

?

52

t700,

Rated

600W

&

51

600

Frequency.

50

Hz

5

50 500

+

Voltage.

..................

220V

=

49

................

I

2

8

+

U

300

2

LL

1200

-

-

>

210

W

220

0

a

I

5

0

>

1

2 3 4

CURRENT

(A)-

f

Output Max.

...............

700W

2

Rated

...............

600W

1

..

900

I-

u

49

L

-500

-

8

50

Frequency. 50

Hz

-700

1

2

52

>

53

T

300

2

250

0

~240

IlOO

I-

................

W

2

51

"600

-

Voltage.

..................

240V

CT

t

2

-

230

$220

>

NOTE:

These characteristics are typical.

Those

of

60

Hz

1-2 3 4

120

V

and

50

Hz

1

1OV

or

230

V

are similar to

CURRENT

(A)-

the above.

-3-

Page 6

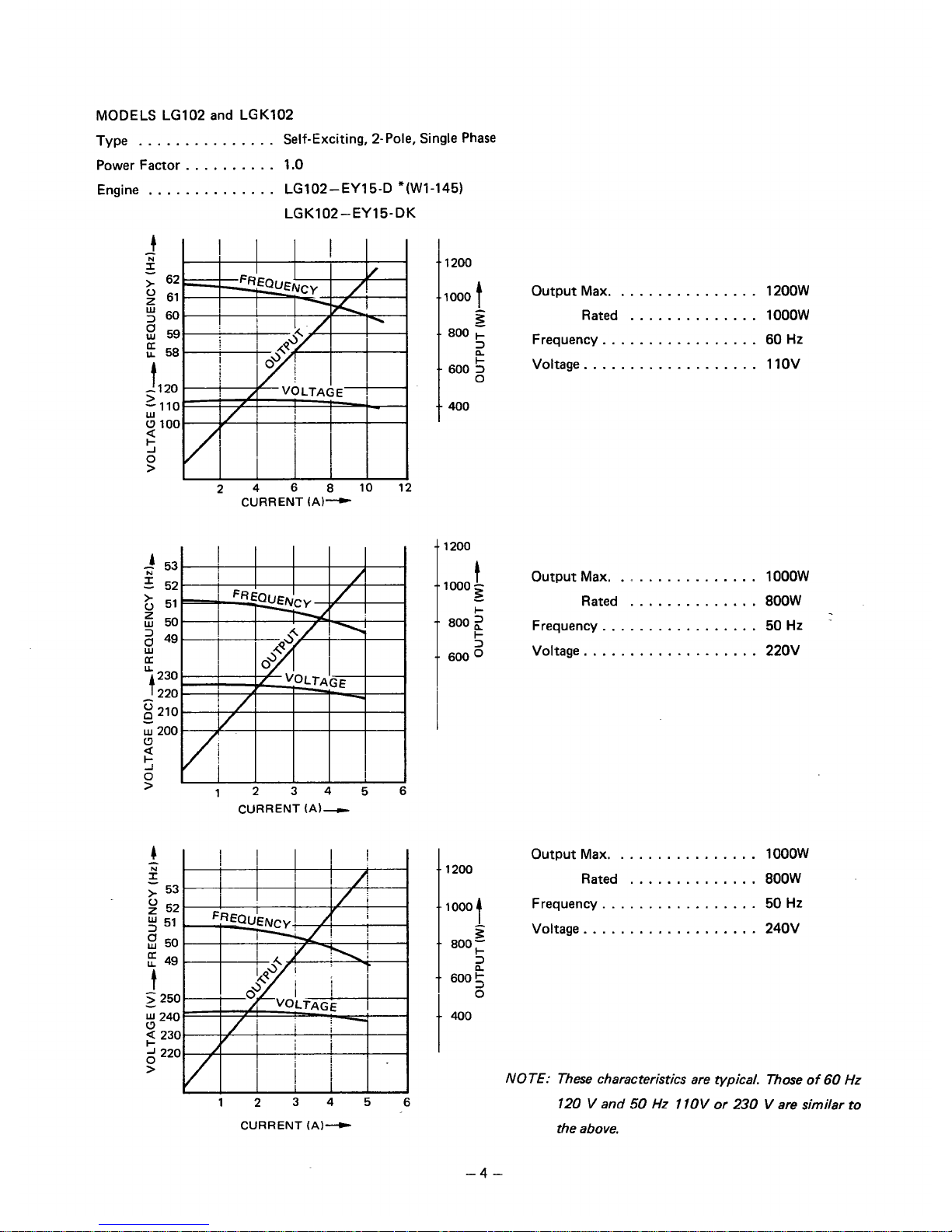

MODELS LG102 and LGK102

Type

...............

Self-Exciting, 2-Pole, Single Phase

Power Factor

..........

1.0

Engine

..............

LG102-EY15-D "(Wl-145)

LGK102-EY15-DK

CURRENT

(A)-

CURRENT

(A)-

123456

CURRENT

(A)-

I

-.

1200

-1000

3

..

800

f

.-

600

3

0

--

400

-.

1200

t

.-

1000

-

+

I-

.-

600

o

3

--

aoo

2

i

I

I

..

1200

..

1000

1

3

..

aoo;

2

t

-.

600

5

Output Max.

...............

12OOW

Rated

..............

1

OOOW

Frequency.

................

60

HZ

Voltage.

..................

110V

Output Max.

...............

1OOOW

Rated

..............

800W

Frequency.

................

50

Hz

Voltage.

..................

220V

Output Max.

...............

1OOOW

Rated

..............

800W

Frequency.

................

50

HZ

Voltage.

..................

240V

NOTE: These characteristics are typical. Those of

60

Hz

120

V

and

50

Hz

1

1OV

or

230

V

are similar to

the above.

-4

-

Page 7

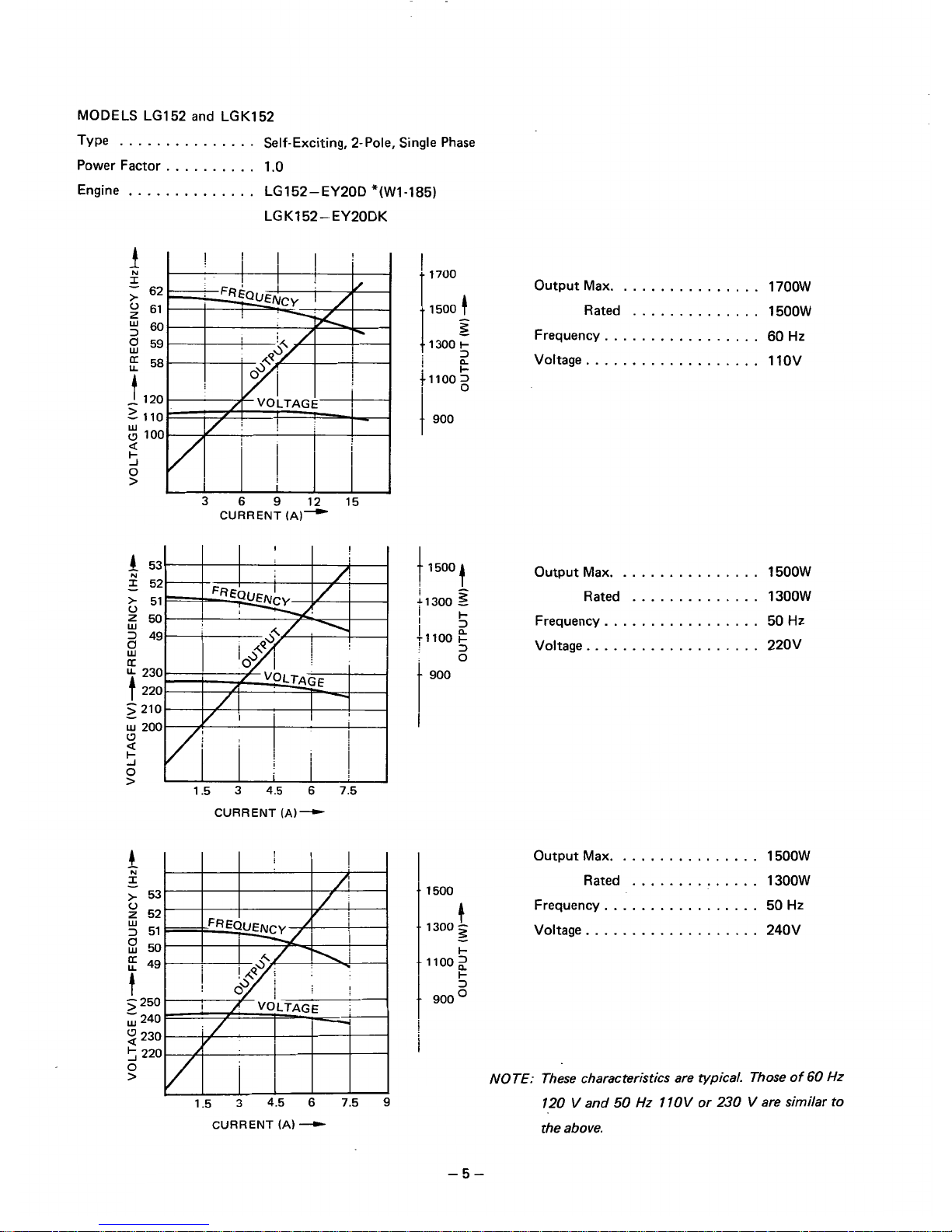

MODELS LG152 and LGK152

Type

...............

Self-Exciting, 2-Pole, Single Phase

Power Factor

..........

1

.O

Engine

. .

I

t

0

W

z

3

-

El

U

[r

t

I

>

0

W

-

a

5

0

>

4

N

-

I

>

0

z

3

W

t

............

LG152-EY20D "(Wl-185)

LGK152--EY20DK

CURRENT

(A)-

CURRENT

(A)--)

1.5 3 4.5

6

7.5

9

CURRENT

(A)

"-c

'

1700

I

1500

I

-

3

1300

I-

I-

2

ill00

I

900

1

1500

1

41300

2

I

I

I

II-

3

tlloo

E

t

0

3

1

.. 1 500

4

..

1300

2

I-

I-

-

--

1100

2

t

900:

i

i

Output Max.

...............

1700W

Rated

..............

1500W

Frequency.

................

60

Hz

Vcltage

...................

1 1OV

Output Max.

...............

1500W

Rated

..............

1300W

Frequency.

................

50

Hz

Voltage.

..................

220V

Output Max.

...............

1500W

Rated

..............

1300W

Frequency.

................

50 Hz

Voltage.

..................

240V

NOTE: These characteristics are typical. Those

of

60

Hz

120

V

and

50

Hz

1

IOV

or

230

V

are similar

to

the above.

-5-

Page 8

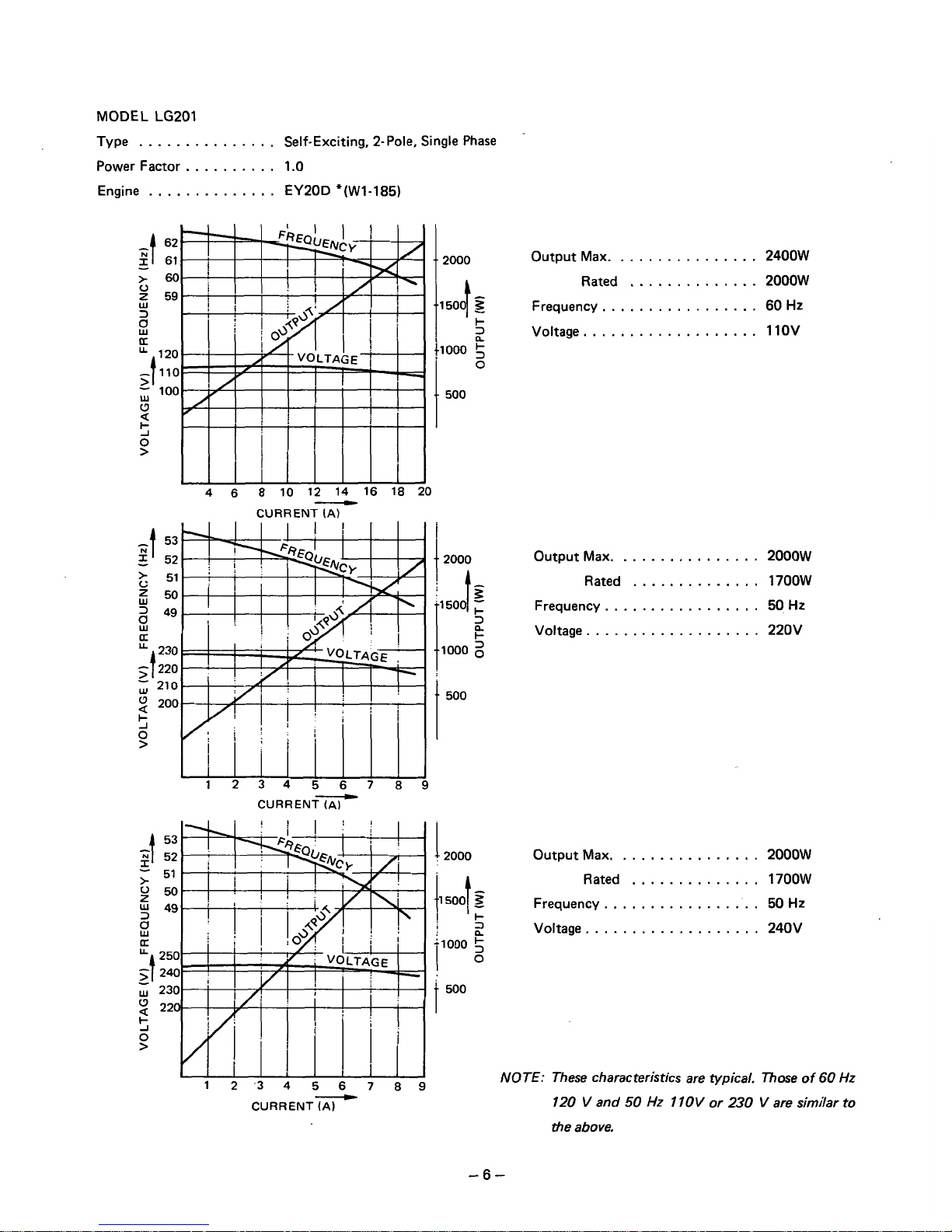

MODEL

LG201

Type

...............

Self-Exciting, 2-Pole, Single Phase

Power Factor

..........

1.0

Engine

..............

EY20D "(Wl-185)

Output Max.

...............

2400W

Rated

..............

2000W

Frequency

.................

60

Hz

Voltage.

..................

110V

i

4

2000

i

500

CURRENT

(AI

-

I

2000

11

!

504

!-

2

;loo0

5

Io

I

12-34 56 7 89

-

CURRENT

(A)

Output Max.

...............

2000W

Rated

..............

1700W

Frequency

.................

50

HZ

Voltage.

..................

220V

Output Max.

...............

2000W

Rated

..............

1700W

Frequency

.................

50

Hz

Voltage.

..................

240V

I

500

NOTE:

These characteristics are typical. Those

of

60

Hz

120

V

and

50

Hz

1

IOV

or

230

V

are similar to

ihe above.

-6-

Page 9

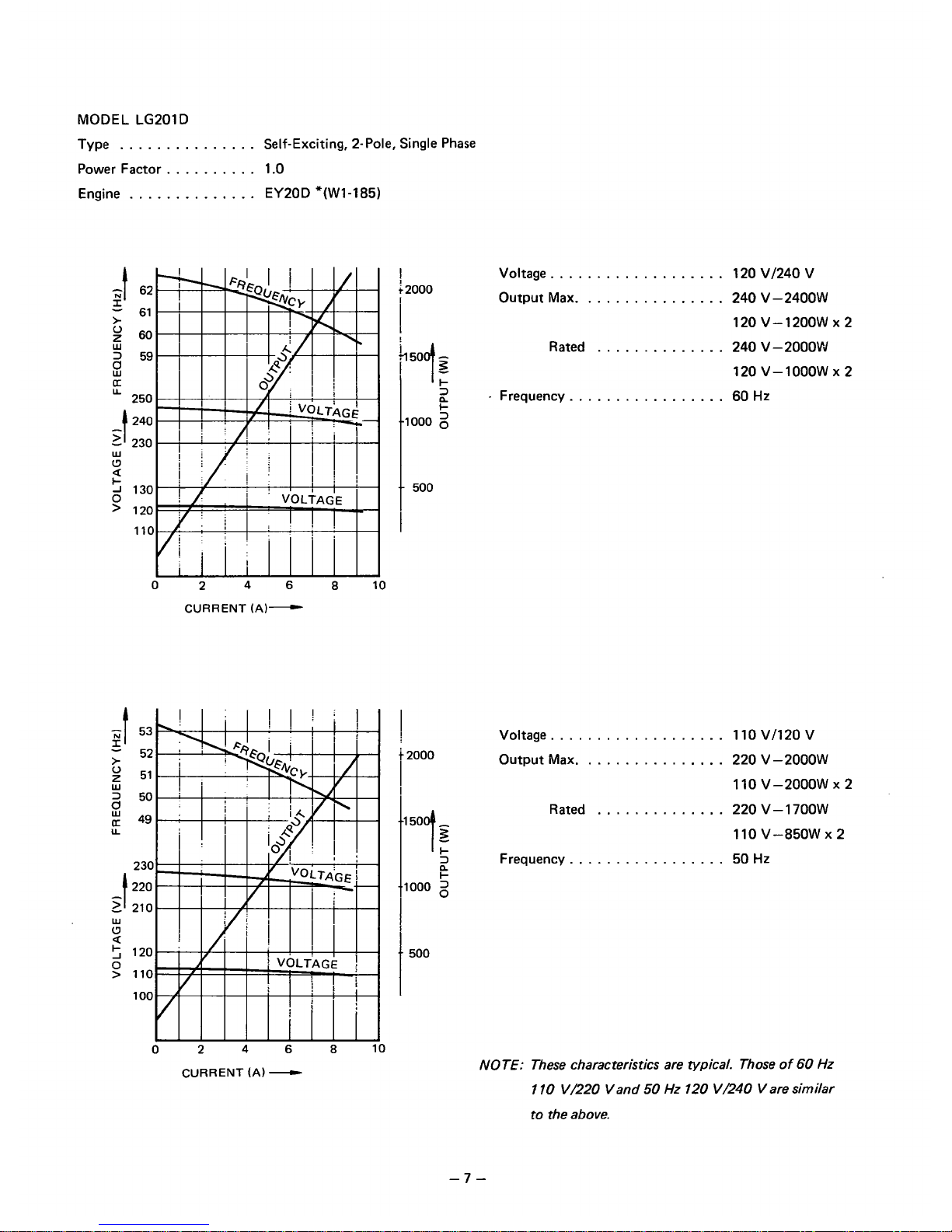

MODEL LG201D

Type

...............

Self-Exciting, 2-Pole, Single Phase

Power Factor

..........

1.0

Engine

..............

EY20D "(Wl-185)

U

-t

-

>

Lu

CJ

+

J

0

>

a

0

2

46

8

10

CURRENT

(A)-

I

j2000

I

z

"000

2

I-

.-

500

I

Voltage

...................

120 VI240 V

Output Max.

...............

240 V-24OOW

120 v-12oow x 2

Rated

..............

240 V-2OOOW

120 v-1ooow x 2

.

Frequency.

................

60

Hz

n

U

-

>

t

UI

0

a

5

0

>

CURRENT

(A)

-

Voltage

...................

1

10 VI1 20 V

Output Max.

...............

220 V-2OOOW

110

v-2ooow x 2

Rated

..............

220 V-17OOW

110 V-850W

X

2

Frequency

.................

50

Hz

NOTE: These characteristics are typical. Those of

60

Hz

110

V/220 Vand

50

Hz

120

V/240

V are similar

to the above.

-7-

Page 10

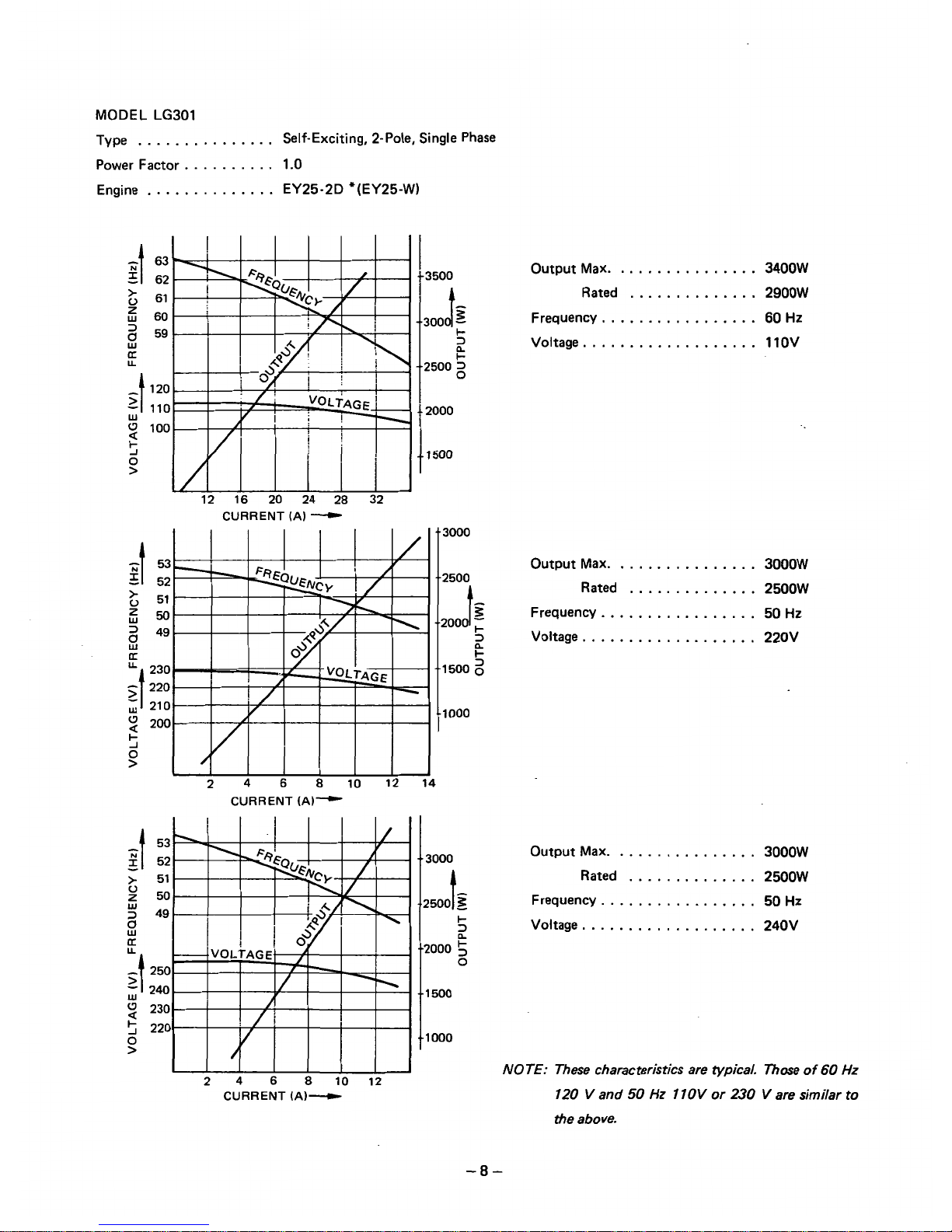

MODEL LG301

Type

...............

Self-Exciting, 2-Pole, Single Phase

Power Factor

..........

1.0

Engine

..............

EY25-2D *(EY25-W)

I

>

0

z

3

W

s

U

U

-

-t

>

W

U

a

5

0

>

I

f

3500

-1300C/z

I-

5

-2500

2

4

2000

2

4

6

8

10 12'

CURRENT

(A)-

14

Output Max.

...............

3400W

Rated

..............

2900W

Frequency

.................

60

Hz

Voltage

...................

1

1OV

CURRENT

(A)

"--c

3000

Output Max.

...............

3000W

2500

A

~~ ~

Rated

..............

2500W

-

................

200,I~

Frequency.

50

Hz

Voltage. 220V

..................

z

1500

2

1000

CURRENT

(A)---

Output Max.

...............

3000W

Rated

..............

2500W

Frequency.

................

50 Hz

Voltage.

..................

240V

..

3000

-2500

t

3

I-

2

"000

5

0

..

1

500

"000

NOTE: These characteristics are typical. Those

of

60

Hz

120

V

and

50

Hz

110V

or

230

V

are similar

to

the above.

-8-

Page 11

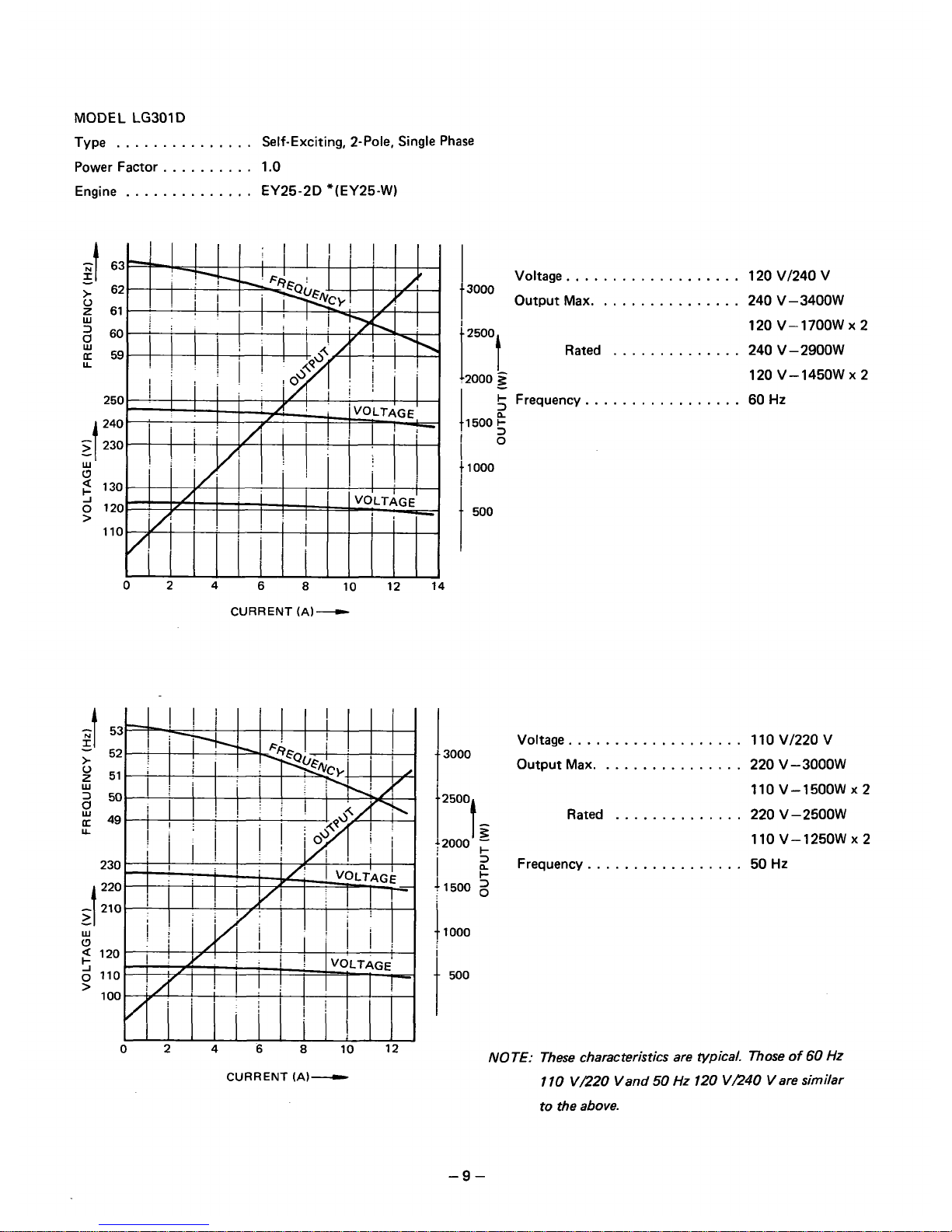

MODEL

LG301

D

Type

...............

Self-Exciting, 2-Pole. Single Phase

Power Factor

..........

1.0

Engine

..............

EY25-2D "(EY25-W)

02

4

6

8

10

12

14

CURRENT

(A)

-

CURRENT

(A)-

...................

t

3000

Voltage

Output Max. 240 V-34OOW

...............

120 VI240 V

..............

120 V-17OOW

Rated 240 V-29OOW

120 V-145OW

+

Frequency.

................

60

Hz

1500

1

1000

I

t

500

x2

x2

...................

t

3000

t2000

;

110 V-125OW X 2

i+

...............

Voltage 1 10 VI220 V

Output Max. 220 V-3OOOW

110 V-15OOW

X

2

..............

t2500t

z

Rated 220 V-25OOW

................

2

Frequency. 50

Hz

11500

2

11000

t

500

MOTE: These characteristics are typical. Those

of

60

HZ

1

10

VE20 Vand

50

Hz

120

VR40 V are similar

to the above.

-9-

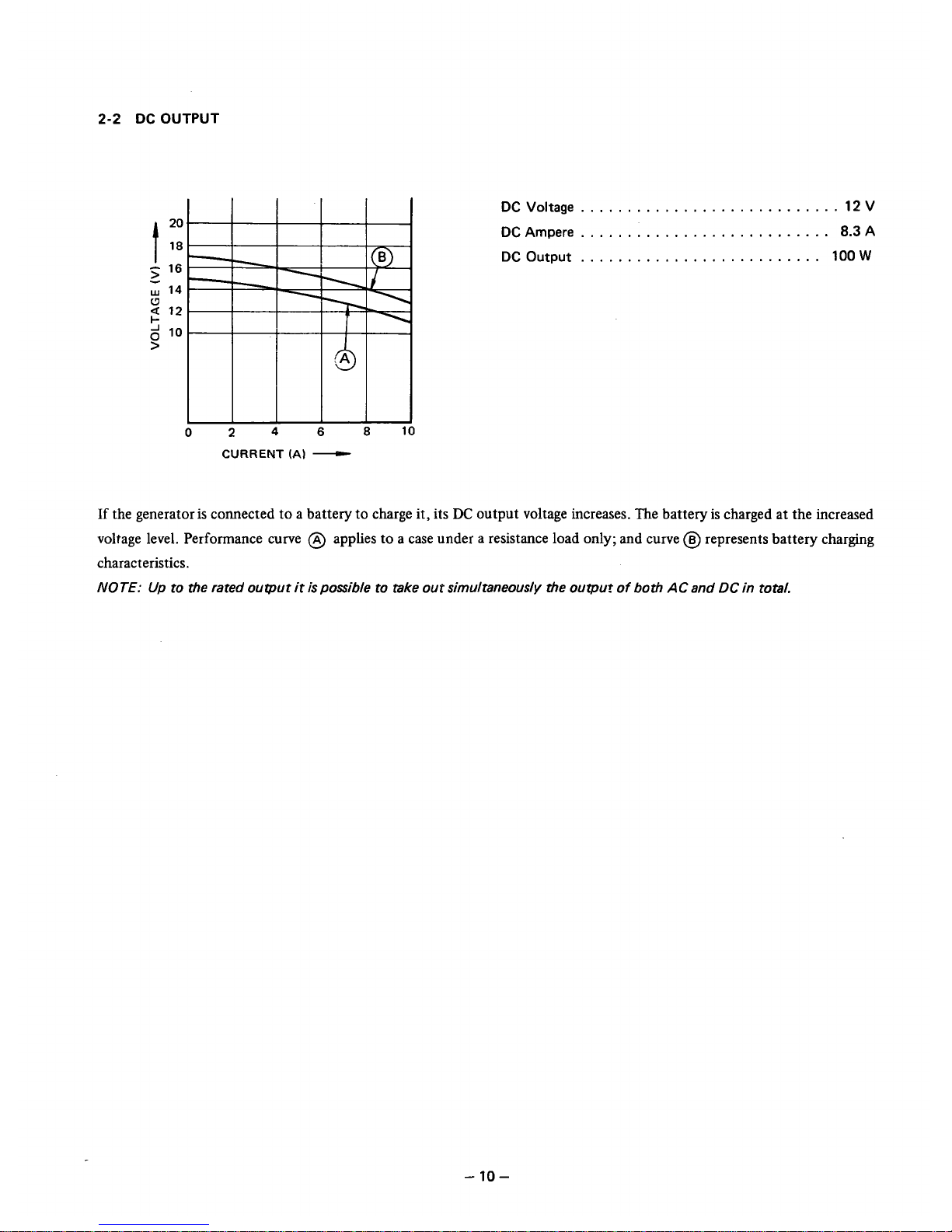

Page 12

2-2

DC

OUTPUT

DC

Voltage

............................

12

V

DC

Ampere

...........................

8.3

A

DC

Output

..........................

100

W

024

6

8

10

CURRENT

(Al

-

If

the generator is connected

to

a battery

to

charge it, its

DC

output voltage increases. The battery is charged at the increased

voltage level. Performance curve @ applies

to

a

case under a resistance load

only;

and curve

(iJ

represents battery charging

characteristics.

NOTE:

Up

to the rated ouqout

it

is

possible to take out simultaneously the

output

of

both

AC

and

DC

in total.

-

10-

Page 13

3.

FEATURES

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

Portable, Light in Weight, Compact, and Easy to Carry

*The LC102 and LC152 employ lightweight, compact, powerful EY15D and EY2OD engines.

*All

models employ a lightweight, high-efficiency, revolving field type generator.

Solid State Ignition System

*Compared to the contact point type. this system has no contact points to wear out or replace. Therefore, mainte-

nance is reduced and constant output power can be maintained for a longer period of time.

*Easy to start with increased starting spark energy.

Extra Quiet Operation

*All

models are equipped with a large capacity, low-noise muffler.

*.a

models are equipped with a cyclone type air cleaner which reduces noise and is excellent in keeping dust out.

Effective Voltage Regulation with AVR (Automatic Voltage Regulator)

*The built-in AVR automatically regulates the exciting current to keep voltage regulation at less than

3%,

thereby pro-

tecting the load (an electrical product) and prolonging its product life.

DC Output for Battery Charging

*A DC output of 12 V 100

W

is simultaneously available with an AC output. Therefore, the generator can charge a

battery from its DC output terminal while also supplying an AC output. The combined AC and

DC

outputs must be

kept undr the rated level.

Dual Voltages Are Available

on

LC201 D and LG301 D

*A dual voltage type which supplies two AC voltages is available in the 2 kW and

3

kU' classes.

Output Voltage Waveform Close to Sine Wave

*Output voltage waveforms are close to a sine wave without a surge

so

that the load electrical product will not be dam-

aged.

Resistant to Induced Load

*Excited power is obtained from the sub coil that is wound separately from the main coil, output voltage fluctuations

are

small

as compared with load current fluctuations and constant power can be obtained. This means greater resist-

ance to loads which are subject to sharp current fluctuations-and easier starting of an induction motor.

100%

Copper Windings

*The use of pure copper which has low internal resistance for windings assures

high

efficiency and long generator life.

Easy Starting with a Recoil Starter

Trouble-Free with a

Fuse

or

No-Fuse Breaker

LGK Type Operating on Kerosene

*Automatic fuel changing system uses gasoline to start the generator and automatically changes it to kerosene in nor-

mal operation.

-

11

-

Page 14

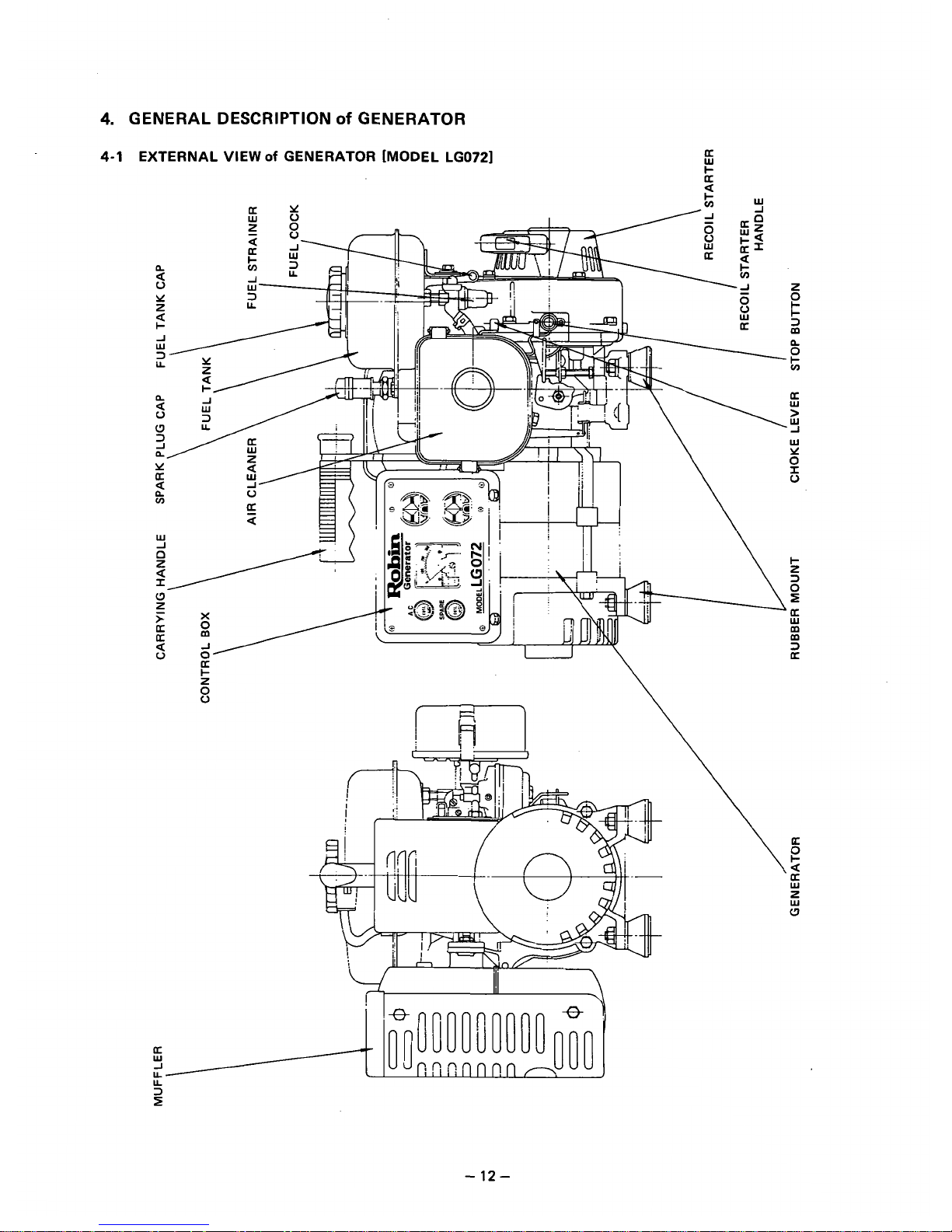

4.

GENERAL DESCRIPTION

of

GENERATOR

4-1

EXTERNAL VIEW

Of

GENERATOR [MODEL LGO721

f

-

12-

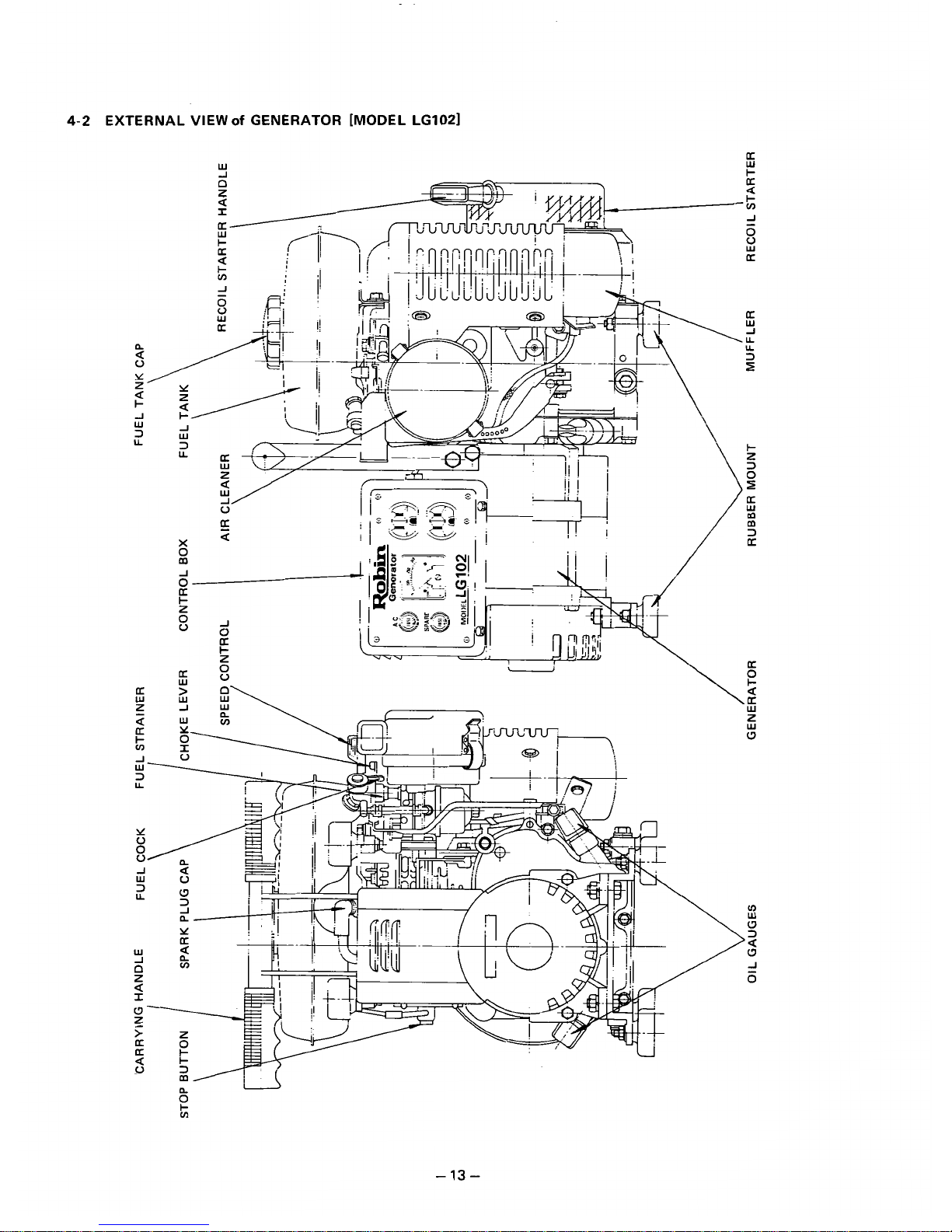

Page 15

4-2

EXTERNAL VIEW

of

GENERATOR [MODEL LG1021

W

U

UI

-

13-

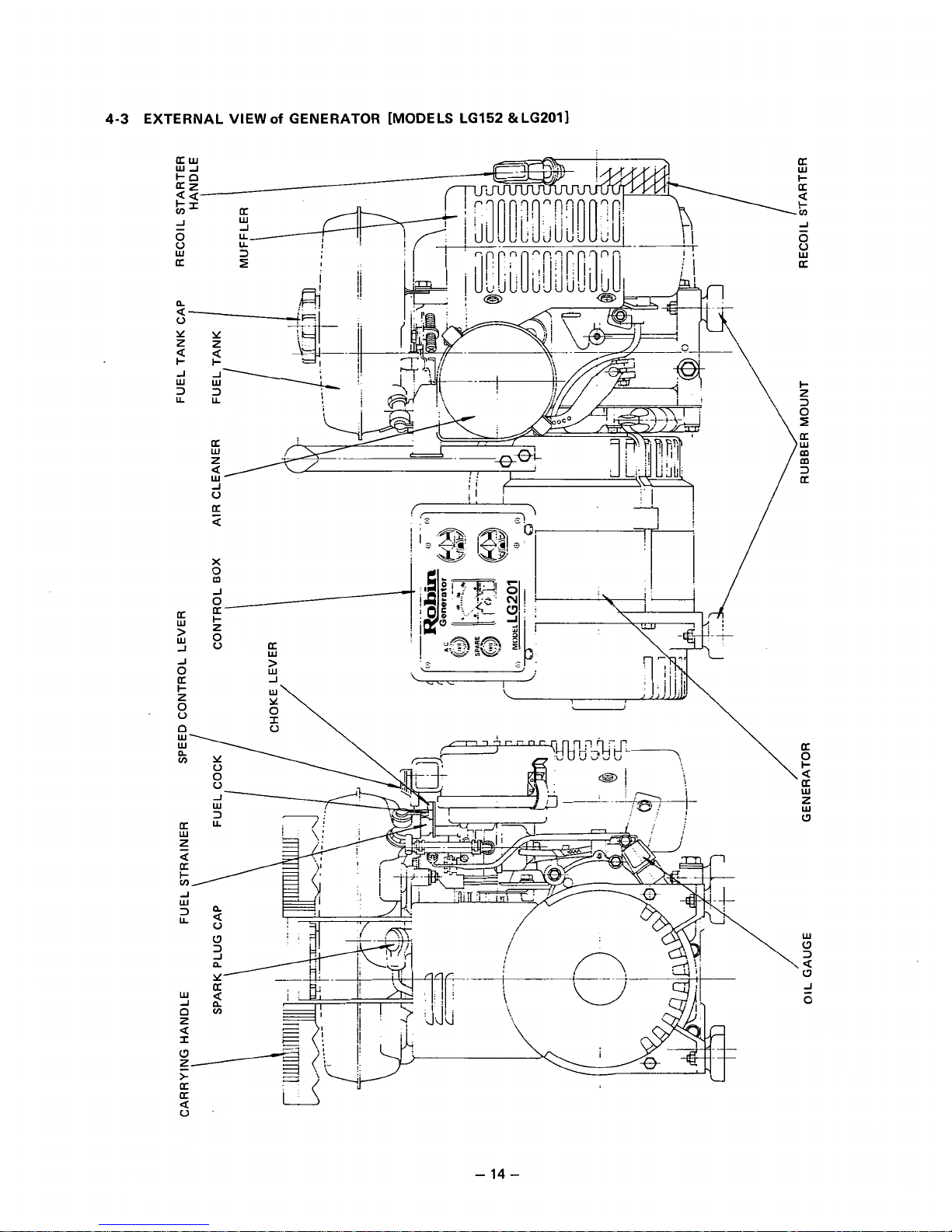

Page 16

4-3

EXTERNAL VIEW

of

GENERATOR [MODELS LG152 aLG2011

-

14-

Page 17

4-4

EXTERNAL VlEWof GENERATOR [MODEL LGKlO2

&

LGK1521

-

15-

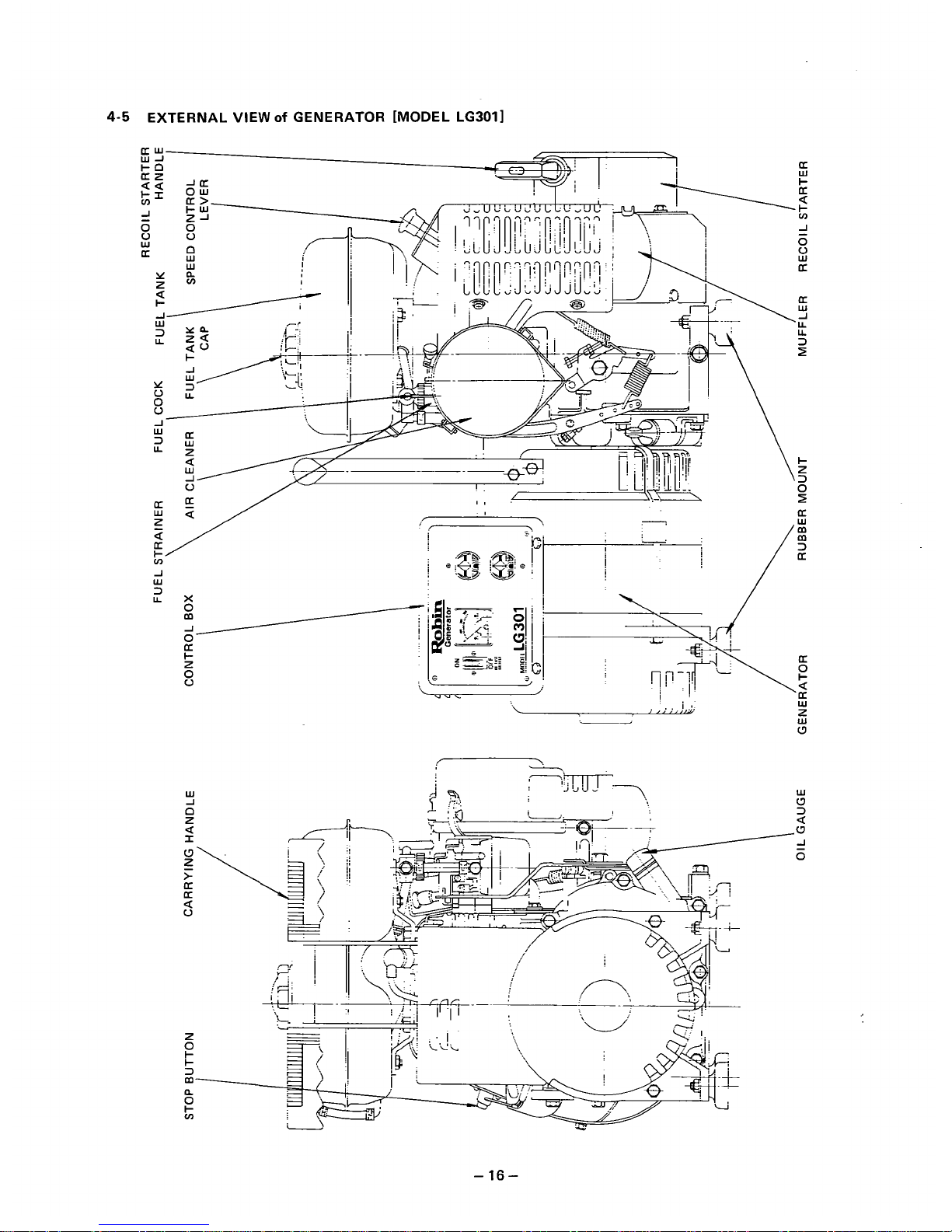

Page 18

4-5

EXTERNAL VIEW

of

GENERATOR [MODEL LG301I

-

16

-

Page 19

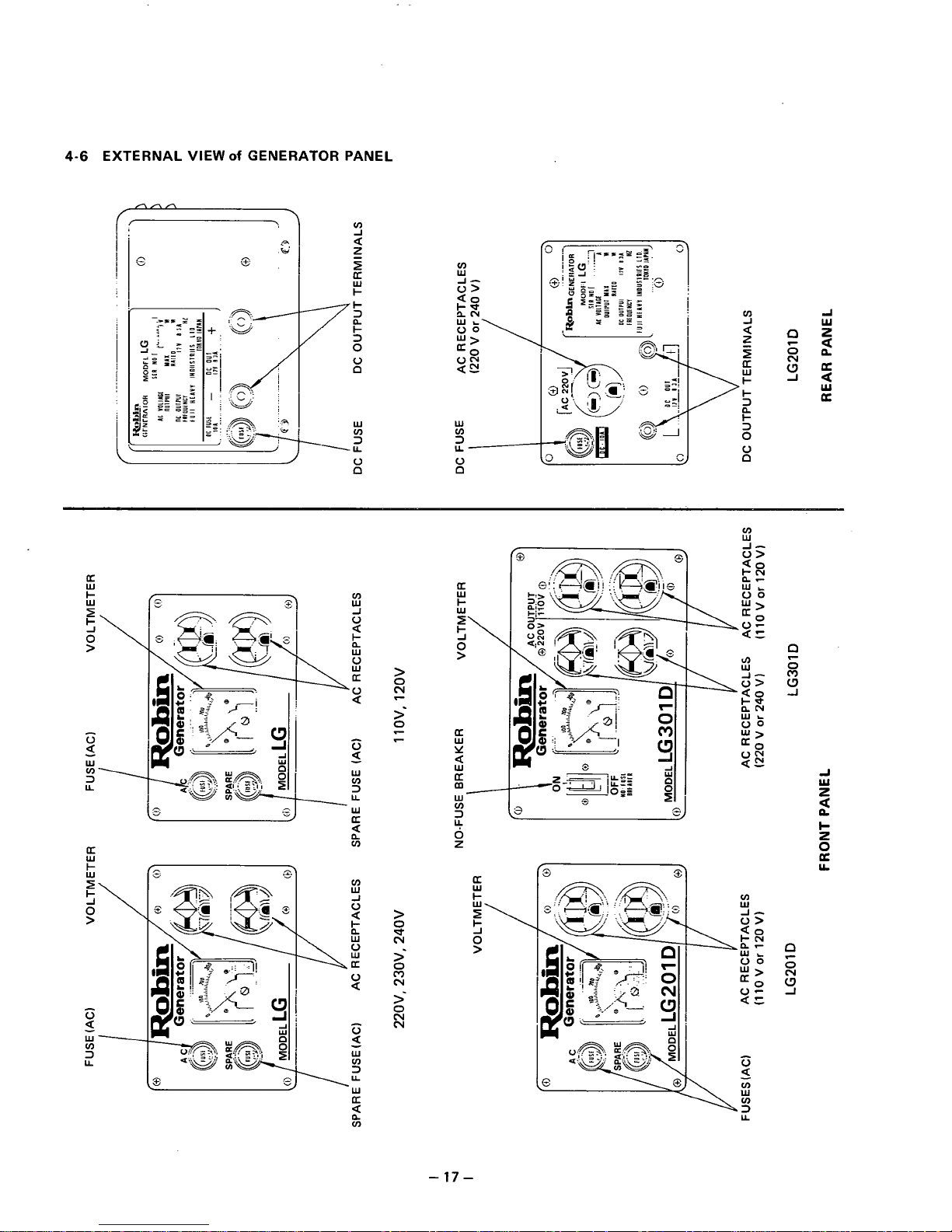

4-6

EXTERNAL

VIEW

Of

GENERATOR PANEL

75

0

W

v)

"3

.U

V

a

W

v)

,>"-

V

0

v)

c3

0

N

c

I?

n

v)

U

W

I-

W

I

0

>

-

,J

- -

v)

W

J

V

5

a

t

W

W

V

U

V

a

V

a

-

W

v)

3

U

V

a

-

W

v)

3

U

W

>

0

N

c

>-

z

-

0

>

N

d

2

2

l7

N

N

N

v)

W

U

2

v)

-17-

Page 20

5.

CONSTRUCTION and FUNCTIONS

5-1

CONSTRUCTION

-

18-

Page 21

5-2

FUNCTIONS

5-2-1

STATOR

The stator consists of a laminated silicon steel sheet core,

copper wire which winds the core. and lead wires w-hich deliver the power. The copper wire is wound into the main coil.

sub (auxiliary) coil, and

DC

coil.

AC

output power is taken

from the main coil, and

DC

output power from the

DC

coil.

The outside diameters and laminated core thicknesses

of

various models are as shown below.

Fig.

5-

1

Fig.

5-2

LG102 LG152

1

LG201 I LG301

LG072

1

LGKlO2

1

LGK152 I LG2OlD I LG301 D

D

(mm)

5.47

I

5.47

1

6.97 6.97 6.97

(inch)

139 139

'

177

1

177

i

177

2.76 3.94 2.17

i

2.76 2.36

(inch)

70

:

100

55 70 60

(mm)

1

L

Table

5-

1

-

19

-

Page 22

5-2-2

ROTOR

The rotor consists of a laminated silicon steel sheet cover

with a field coil wound arount it and cooling fans and slip

rings at both ends of the shaft. The field coil leads are connected to the slip rings and direct current

(DC)

to the field

-

coil turns the rotor and magnet. The cooling fans cool the

generator by drawing cooling air from the slip rings 2nd dis-

charging it

through

the fans.

BEARING

~ ~

Fig.

5-3

Fig.

5-4

i

LG102 I LG152

LG2OlD

.

LG301D

i

LGKlO2 ' LGK152

LG201

I

MODEL

I

LG072

LG301

I

I

,

(mm) I 55 70

I

60 70

100

(inch)

2.17 2.76

I

2.36

I

2.76

I

3.94

I

Table

5-

2

-

20

-

Page 23

5-2-3 BRUSHES

~~ ~ ~ ~ ~ ~

~.

An

exciting current is supplied from the

AVR

to

the rotor.

The brushes are made

of

carbon and the brush-holders of

'

plastic. It is necessary to keep the contact pressure between

the brushes and slip rings within specific limits. Therefore,

care must be taken about brush length. (See

9-3

BRUSHES.)

5-2-4 AVR (AUTOMATIC VOLTAGE REGULATOR)

The automatic voltage regulator employs an electronic cir-

cuit to automatically reglate voltage.

Fig.

5-6

5-2-5 VOLTMETER

The voltmeter comes in two types, a

150

V

maximum type

and a

300 V maximum type. The voltmeter indicates generator output voltages. The generators with a generated voltage -of 110

V

or 120 V use the 150 V maximum type volt-

meter; and those

6f

220

V,

230

V,

and

240

V

specifications

and dual voltage type generators use the

300

V

maximum

type voltmeter.

300

V

MAX.

150

V

MAX.

(220

V.

230

V.

240

V)

I110

v,

120

V)

-

~

-

.~~

Fig.

5-7

-

21

-

Page 24

These prevent output over current and short circuit over cur-

rent. If a generator is operated at more than the maximum

current, the temperature inside the generator rises

so

that

the insulations are adversely affected, possibly causing electric shock or current leakage. The fuse and no-fuse breaker

prevent the insulations from deteriorating and protect the

generator.

CAUTION:

Use

fuses

of

the

correct capacity.

FUSE

5-2-7 RECEPTACLE and AC PLUGS

These are used for taking

AC

output power from the gener-

I

~~ ~ ~

RECEPTACLES

ator. Each generator has two receptacles (three or four receptacles for the dual voltage type). The 125

V

maximum

(1

10

V,

120

V)

type and 250 V maximum

(200

V,

230

V,

240

V)

type differ from each other in the shape of the indi-

vidual output terminals.

"

L;

AC PLUG

The

AC

plugs

also

differ in shape between the 125 V maxi-

mum type

and

250 V maximum type. The same number of

(220

v,

230

v,

240

VI

(110

v,

120

V)

AC

plugs as that of receptacles are provided.

250

V

MAX

125

V

MAX

..

~.

~

~-

~.

Fig.

5-9

5-2-8 TERMINALS

The terminals are for producing

DC

output power and

come in two colors, red and black. The red one is positive

(+)!

and the black one negative

(-).

RED

-

22

-

Page 25

5-2-9

FRONT

COVER

The front cover is an aluminum die casting and is mounted

on the main bearing cover

of

the engine. It has vents to discharge cooling air from the generator and the vents are designed to prevent fingers from entering.

5-2-10 REAR COVER

The rear cover is also an aluminum die casting

and

has

a

It

has bosses inside for holding the brushes and vents for

taking cooling air in. The vents are designed to prevent

fingers from entering.

5-2-11 RUBBER MOUNTS (RUBBER VIBRATION

I

SO

LATO

RS)

Specially designed rubber pads for controlling generator

vi-

bration and dislocation. These are made of superior quality

rubber material for optimum shape and hardness.

5-2-12 CARRYING HANDLE

The

LC072

has a single-hand carrying handle and the other

models have two-hand carrying handles. The handles differ

in height from one model to another and feature a rubber

grip(s) for easy holding.

~~201

D,

3oi

D

LG072.102

Fig.

5-

1

I

LG K152

LGKl02'

.

~ ~~ ~

.~

~"

~

..~

"

-23-

Page 26

5-3

DESCRIPTION

Of

GENERATOR OPERATION

5-3-1 PRIMARY EXCITING ACTION

One of the differences between the old type and the new

-

type is that the new type has an exciting coil

(EC)

while

the old type does not.

The old type used a rotor of carbon steel sheets that started

the primary exciting action of the generator with its residual

r-----l

I

I

magnetism.

This

type loses its residual magnetism if the gen-

1'

I

erator is disassembled and stored and may fail to generate

I

electric power when it is started after storage. The new type

FC

I

/

I

p

,

I

EC

I

I

\

I

I

is equipped with an exciting coil on the engine magnet for

primary exciting action to eliminate such an occurance.

The primary exciting action of the new type is explained

below.

When the generator is started, the permanent magnet on the

engine rotates to generate voltage in the exciting coil.

This

voltage is regulated by a diode in the

AVR

to feed current

into the generator field coil

(FC).

(See Fig.

5-15.)

The rotor turns an electromagnet with that current and

rotates

so

that voltage is generated in the stator coils (main

coil, sub coil, and

DC

coil). The voltage generated in the sub

coil is regulated by the

AVR

to feed current in order to in-

crease the field and current. (See Fig.

5-16.)

As

a result,

the rotor magnetism increases.

Ths

operation is repeated to

generate the rated voltage at

50

Hz

or

60

Hz

in the main

coil and

DC

coil.

5-3-2 VOLTAGE REGULATING MECHANISM

Connect a load to the

AC

output terminal and increase cur-

rent. Output voltage will vary as shown in Fig.

5-17

depending on whether an automatic voltage regulator is used or not.

When

AC

output is drawn, the engine becomes loaded and

its rpm falls.

Also,

the

AC

voltage falls due to the voltage

drop caused by the internal resistances of the coil. The

AVR

caused by the internal resistances of the coils. The

AVR

detects this voltage drop and its built-in

SCR

automatically

increases the current that

floCs

to the field coil.

As

a result,

the rotor magnetism increases, the voltage decrease caused

by the load current

is

raised, and the output voltage

is

kept

constant. If the

AC

output is reduced, the

SCR

operates in

the opposite way to similarly keep the output voltage constant.

I I

ENGINE MAGNETO

!"-"-J

Fig.

5-

15

MC

i

Fig.

5-

16

WITH 'AVR

-A

Fig.

5-

17

-

24

-

Page 27

6.

1.

2.

3.

4.

5.

6.

SAFETY PRECAUTIONS

Use

extreme caution near gasoline. A constant danger of explosion

or

fire exists.

Do not fill the fuel tank with gasoline while the engine is running. Do not smoke or use open flame nea the fuel tank.

Be careful not to spill fuel when refueling. If spilt, wipe it and let dry before starting the engine.

Do

not place inflammable materials near the generator.

Be careful not

to

ptt gasoline, matches, gunpowder,

oil

cloth, straw, trash and any other inflammables near the genera-

tor.

Do

not operate the generator in a room, cave

or

tunnel. Always operate in a well-ventilated area.

Otherwise the engine may become overheated and also, the poisonous carbon monoxide contained in the exhaust gases

will endanger human lives. Keep the generator at least

1

m

(4

feet) away from structures or facilities during use.

Operate the generator

on

a level surface.

If the generator is tilted or moved duricg use, there is a danger of fuel spillage and a chance that the generator may tip

over.

Do

not

operate with wet hands

or

in the rain.

Severe electric shock may occur.

If

the generator is moistened by rain or snow: wipe it and fully dry it before starting.

Don't pour water over the generator directly or wash it with water.

If the generator is wet with water, the insulations will be adversely affected and may cause current leakage and electric

shock.

Do

not connect the generator to the commercia! power lines.

This

may cause a short-circuit or destroy the generator. Use a transfer switch for connecting with indoor wiring.

NOTE: The parts numbers of the transfer switches and of the plastic box

to

store them are as shown in Table

6-

1.

Part

No.

!

Part

Name

Q'ty Current

365 45604

08

.

TRANSFER SWITCH

i11

15A

367 45605

08

1

TRANSFER SWITCH

i1

30A 367 43008

08

PLASTIC

BOX

i1

30

A

Table

6-

1

7.

Use fuses of the correct capacity.

If the generator rpm is increased exorbitantly in the overload condition by using a fuse in excess of the rated capacity,

the generator could be burnt and the

AVR

be damaged.

CAUSTION: if the fuse is burnt out or the circuit breaker tripped off as a result of using an electrical appliance, the

cause can be an overload or a short-circuit. In such a case, stop operation immediately and carefully check the e!ectrical

appliance and AC plugs for faulty wiring.

-

25

-

Page 28

7.

RANGE

of

APPLICATIONS

Generally. the rated power of an electrical appliance often refers

to

the amount of work that can be done by it. The electric

power required for operating an electrical appliance is

not

necessarily equal

to

the amount of work that can be done by

it.

Electrical products generally have a label showing their rated voltage, frequency, and power consumption (input power). The

power consumption of an electrical products is the power necessary for using it. When using

a

generator for operating an

electrical product, however, the power fxtor and starting current must

also

be taken into consideration.

Determine the required capacity of your generator from the power required for operating electrical products that are classified as follows:

1.

2.

3.

4.

Incandescent lamps, hot plates, etc. with a power factor of

1

.O

Total power consumption must be equal to or less than the rated output

of

the generator.

Example:

A

generator with a rated output power of

1000

W

can light ten

100

W

lamps.

Fluorescent lamps, mercury lamps, etc. with

a

smaller power factor

Select a generator with a rated output equivalent to

1.2

to 2 times the power consumption of the load.

Example:

A

generator with a capacity

of

100

W

to 160 W is necessary for lighting a

80

W

fluorescent lamp. A generator

with a rated output of

1000

W

can

light

6

to 10

40

W

fluorescent lamps.

NOTE: Wattage of the fluorescent lamp generally does not indicate the power consumption but indicates the ouwut of

the lamp. Therefore, if the fluorescent lamp has

no

special indication as to the power consumption or input power,

efficiency should be taken.into accounts as explained

in

Item

5

on

the followingpage.

Electric

tools,

etc. that are driven

by

a motor

Power

1

.Z

to 3 times the power consumption of a motor-driven tool is required for starting

so

select a generator with a

maximum output

1.3

to

3

times the power consumption

of

the load.

Example:

A

300

W

motor-driven drill requires a generator with a maximum output of

400

to

900

W

or more.

Water pumps, compressors, etc. that are driven

by

a

motor which

is

loaded at starting

3

to 5 times the power consumption of the load is necessary for starting

so

select a generator with a maximum output

3

to

5

times its power consumption.

Example:

A

water pump with a power consumption

of

400

W

requires a generator with a maximum output

of

1200

to

2000 W or more.

NOTE

7:

Motor-driven products mentioned in

Items

3

and 4 required the aforementioned generator capacities

only

when starting their motors. Once their motors are started, the products consume only about

1.2

to 2 times their rated

power consumption

SO

that the excess po wer generated by the generator can be used for other electrical appliances.

NOTE

2:

Motor- driven products mentioned in Items 3 and 4 vary in their required motor starting power depending

on

the

kind

of motor and start-up load. If it

is

difficult to determine the optimum generator capacity, select a generator

with a larger capacity.

-

26

-

Page 29

5.

Appliances without any indication as to power consumption

Some appliances have no indication as to power consumption; but instead the work load (output) is indicated. In such a

case, power consumption is to be worked out according to the numerical formula mentioned below.

(Output of electrical appliance)

(Efficiency)

=

(Power consumption)

Efficiencies of some electrical appliances are

as

follows:

Single-phase motor

..........

0.6

Three-phase motor

..........

0.65

-

0.9

Fluorescent lamp

0.7

-

0.8

-

0'75

3

The smaller the capacity, the worse the efficiency,

and vice versa.

...........

Example

1:

A

40 W fluorescent lamp means that its luminous output is

40

W.

Its efficiency is

0.7

and accordingly,

power consumption will be

40

+

0.7 = 57

W.

As

explained in Item

2,

multiply this power consumption

value

of

57

W

by 1.2 - 2 and

YOU

will get the figure of the necessary capacity of a generator. In other

words, a generator with a rated output of 1000

W

capacity can light

9

-

14 40 W fluorescent lamps.

Example

2:

Generally speaking, a

400

W

motor means that its work load is 400

W.

Efficiency

of

this motor is

0.7

and

power consumption will be 400

+

0.7

=

570

W.

When this motor is used for a motor-driven tool, th2 capa-

city of the generator should be multipled by 1.2 to

3

and

570

W

as explained in the Item

3.

Model

Frequency

hot plate, etc.

Incandescent lamp,

Fluorescent lamp,

mercury lamp, etc.

Motor-driven tool,

general-purpose

motor. etc.

Water pump,

compressor, etc.

LG072

LG102

I

LGK102

I

LGK152

,

LG301D*

I

LG301DC

LG 152

I

LG201 LG301

I

50HZ

60HZ

2500W j 2900W

2000W

600W

1

700W 1 8OOW j lOOOW , 1300W ! 1500W 1700W

60Hz

50Hz

60Hz

50HZ

I

60Hz I 50Hz I 60Hz I 50Hz

about

I

about

about

.

about

about about

1

about

about

I

about

1

about

350W

I

400W I 450W

,

60OW

I

850W

1

1 OOOW , 1 lOOW

1

1300W

I

1650W 19OOW

I

about i about I about i about about about about about I about I about

350W

;

400W I 500W I 600W I 750W I 850W

;

looow

;

1200w

I

1500 I 1700W

about

'

about

i

about

about.

about about

'

about about

1

about

about

150W

I

18OW I 230W I 250W I 350W

I

400

,

500W I 600W : 750W I 850W

*The load that ca be connected to one 11011

20

V

receptacle

of

the dual voltage type

is

up to only

one half

of

the atove wattages.

Table

7-

1

-

27

-

Page 30

NOTE: Wiring between generator and electrical appliances

1.

Allowable current of cableUse a cable with a allowable current that

is

higher than the rated input current of the load (electrical appliance). If the

input current is higher than the allowable current of the cable used, the cable will become excessively heated and de

teriorate the insdation, possibly buring

it

out. Table

7-2

shows cables and their allowable currents for your reference.

2.

Cable length

If a long cable is used, a voltage drop occurs due to the increased resistance in the conductors

so

that the input voltage

to the load (electrical product) decreases. As a result, the load can be damaged, table

7-2

shows voltage drops per

100

meters of cable.

Current Amp.

0.75

~

7 3010.1

a

2.477

i

2.5~

I

av

I

12.5~

U

-

1av

12v 15v

1.25 12 5010.1a

1

1.486 i 1.5~ ' 5v . 7.5~

n

-

-

-

I

-

%

e

2

.o

i

17

:

3710.26

I

0.952

IV

3v 1 5v

2

15v 12v

av

'

IOV

3.5

'

7.5V

~

6.5V

5V

0.51

7

-

1

1.5V I 2.5V ! 4V 4510.32

23

5.5

5V

4V

3.5V

2.5V 2V

1V

-

0.332

7010.32

35

Table

7-2

-

28

-

Page 31

8-1

METERS

8-1

-1

VOLTMETERS

AC and

DC

voltmeters are necessary. The approximate

AC

voltage ranges of the voltmeters to be used for various types

of generators are as follows:

0

to 150

V:

Type with an output voltage of

110

or 120

V

0

to 300

V:

Type with an output voltage of 220, 230, or

240

V

0

to

150

V,

0

to

300

V:

Dual voltage type

The DC voltmeter range

is

approximately from

0

to

200

V.

Fig.

8-

1

FOR

AC

FOR

DC

~~

.

~~

..

8-1

-2

AMMETERS

""

.

AC and DC ammeters are necessary.

An

AC ammeter with a

'

range that cap be changed according

to

the current rating of

a given generator is most desirable. (About

10

A, 20 A,

100

A)

The DC ammeter range

is

approximately from 0 to

15

A.

:

FOR

AC

FOR

DC

"~

"

~.

~

~.~

.

~~

~..~~

-~

~ ~ ~ ~

."

."

Fig.

8-2

8-1-3 FREQUENCY

METER

.

.

~.

~

~

.~~

Frequency range: About 45 to

65

Hz

NOTE:

Be careful of the frequency meter's input voltage

range.

~~

~~.

-~

~

~

"

~~~~~~

Fig.

8-3

~ ~~ . ~~

-

29

-

Page 32

8-1

-4

TESTER

Used for measuring resistance, etc.

8-1-5 MEGGER TESTER

Used for measuring generator insulation. Select one with a

:

voltage capacity of

500

V.

8-1

-6

TACHOMETER

..

~

~

.

~ ~ ~

"

-~

"

"

~~

.

-%

;.

There are various types of tachometers, such as contact-less

-

type: contactftype, and strobe type. The contact type can

j

C_@JTA~TLE~$

TYPE

be used only when the generator and engine have been disassembled. The contact-less type

is

recommended.

Q

=.

3.

-

-

\

C0NTisC.T

TYPE

\

STRO-BE-

IYP-E

-~

~

.~

~~

-

-

~~

.~

~

"

..

.~

-~

-~

~

-

-

Fig.

8-6

-30

-

Page 33

8-2

AC OUTPUT MEASURING

TO

A

Fig.

8-

7

;e a circuit like the one shown in Fig.

8-7

for measuring

AC

output. A hot plate or lamp with a power factc

)r

of

1

.O

may

be used as a load. Adjust the load and rpm, and check that the voltage range is as specified in Table

8-1

at the rated amperage

and rated rpm.

Ratedvoltage

I

11OV

1

12OV

1

22OV 230V

238-245V

Voltagerange

'

108-115V j 118-125V I 218-225V 1 228-235V

I

240

V

I

8-3

DC OUTPUT MEASURING

Table

8-

1

00

SWITCH

@

DC

TERMINAL

Fig.

8-8

Switch the power on: adjust the load to

8.3

A

at the rated rpm, and check that the voltage is within the range of

13

to

11

V.

NOTE: If

a battery

is

connected as the load, the ouwut voltage increases by about 1 to

2

V,

possibly causing battery over-

charge. Control battery liquid level during charging to prevent overcharging.

8-4

MEASURING INSULATION RESISTANCE

Connect a megger tester to one of the two receptacle output

terminals and the ground terminal, then measure the insulation resistance.

(Ifyourgenerator is the no-fise breaker type,

close the no-fuse breakerand measure it. If yourgenerator

is

the dual voltage type, any voltage receptacle may be used.)

An

insulation resistance of 1 megohms or more is normal.

(The original insulation resistance at the time of shipment

from the factory is

10

megohms or more.) If it is less than

1

megohm, disassemble the generator and measure the

insulation resistance of tne stator, rotor and control box

individually.

Fig.

8-9

-

31

-

Page 34

STATOR

Measure the insulation resistance between the red or white

coupler from the stator and the core.

0

ROTOR

Measure the insulation resistance between the core and

one of the slip rings

of

the rotor.

*CONTROL

BOX

.

.

~-

~~~~~..

~ ~ ~~ ~ ~

~.

.

~ ~ ~

Measure the insulation between the live parts and the

:

casing or grounded part.

i~-

=

~=

=

.~

_~~c

"

.g

.~

~~

Any

part which has an insulation resistance of less than

1

megohm has a faulty insolation, which can cause electric

shock or leakage. Replace such parts.

Fig.

8-

12

-32

-

Page 35

9.

CHECKING FUNCTIONAL MEMBERS

STATOR ASS'Y

9-1 STATOR ASSEMBLY

9-1-1

MEASURING WINDING RESISTANCE

Check the resistances of the leads from the stator with a

tester. (See Fig.

9

-

1

.)

Check all the leads mrhich are shown by type in the tables

below.

Any

lead which is inactive is faulty.

NOTE: Testers are not

so

accurate that some margin

of

er-

ror must be taken into account when reading the tester

against the values shown in the Tables

9-

I,

9-2,

and 9-3.

I

WHITE

I

0.7

-

6.5!2

I

0.1

-

0.9R ! 2.5

-

5.0R

I

Table

9-

1

LG152, LG201, LG301, LGK152

WHITE

0.2 - 3.1R

I

1.5 - 4.lQ

BLUE-BLUE

0.1

-0.5R

Table

9-2

Fig.

9-

1

LG201

D,

LG301

D

Wire

cotor

'

RED

BLACK

1

GREEN

I

WHITE

I

0.4 - 1.3R

0.4

-

1.3s1 ; 1.7 - 3.6R

A

BLUE-BLUE

0.1

-

0.5R

Table

9-3

9-1

-2

MEASURING INSULATION RESISTANCE

ROTOR

Refer to

8-4

MEASURING INSULATION RESISTANCE.

9-2 ROTOR ASSEMBLY

9-2-1

WINDING RESISTANCE MEASURING

SLIP

RING

Check the resistance between the two

slip

rings with a test-

er. (See

Fig.

9-2.)

The resistance is normal if it is anywhere from

6

ohms

to

13

ohms.

TESTER

Fig.

9-2

-33-

Page 36

9-2-2

MEASURING INSULATION RESISTANCE

Refer to

8-4 MEASURING INSULATION RESISTANCE.

9-2-3

CLEANING SLIP RINGS

The slip ring surfaces must be uniformly bright. Slip rings

showing black spots, excessive wear, or uneven wear must

be repaired.

A

stained slip ring lowers generator efficiency

and output voltage. Polish the slip rings with fine sandpaper

while turning the rotor until rough spots disappear. Care

should be taken not to touch the rotor coils with the sandpaper. (See Fig.

9

-3

.)

9-3 BRUSHES

The brushes must be smooth where they contact the slip

rings.

If

not, polish smooth the brushes with sandpaper.

A

brush that is not smooth produces arcs between the brush

and slip ring leading to possibie damage. Usable brush lengths

are from

5

mm to

15

mm as shown in Fig.

9-4.

A

brush

shorter than

5

mm must be replaced because decreased contact pressure between the brush and slip ring lowers generator efficiency and output voltage.

Fig.

9-3

f

i15mm-5mm

15m.m-5m

Fig.

9-4

9-4 AVR (AUTOMATIC VOLTAGE REGULATOR)

AVR

trouble may be identified.by simply koking at the

AVR,

or by checking the inter-lead resistance with a tester, or actu-

ally mounting it in the generator and operating it.

9-4-1

AVR TROUBLE IDENTIFICATION

by

APPEARANCE

If

an

AVR

electronic part is burnt dark,

or

the surface epoxy resin melted, it often indicates indicates

AVR

trouble.

9-4-2

IDENTIFYING AVR TROUBLE

bf

CHECKING

INTER-LEAD RESISTANCE

Check the inter-lead resistance

of

the

AVR

with a tester.

(See Fig.

9-5.)

If the tester readings vary greatly from the

values specified in the tables below, the

AVR

is faulty.

NOTE:

Take tester inaccuracy into account in reading the tester.

TESTER

Fig.

9-5

-34-

Page 37

MODEL LG072, LG102, LGKlO2

I

!

I

Tester polarity

Yellow Red White

j

Green Brown

I

1.

i

I

i

I

m

'

600K

1MR

75K - 120KR

1

One

wire:

OR

!

m

1

400K - 500KQ I 75K - 120KS1

I

i

One wire:

09

1

7K- 10KQ

~

!

Another:

m

:

7K - 1OKR

Yellow

I

Red

I-

I

i

250K - 300KR

m

1

400K - 500KR

I

-

I-I-

120K - 130Kfl

1

m

i

200K - 220KR

I

~

i

250K - 300KR

i

-

-

m

White

j

45K - 50Ka

-

:

120K- 300KR

1

-

m

'

45K -5OKR

i

~~~ ~~~ ~

-

~~~ ~

j

500K- 1MR

j

75K- 11OKR

I

i

-----

"

~~

Green

-

j

7K-9KS1

-

-

t

200K - 250KR I 40K - 46Ka

I

m

I

-

400K - 500KR ' 75K - 11OKR

'

-

'

7K-9KR

-

Black

400K

-

500KQ 40K

-

46KR

m

-

*Upper rows are for the 220, 230, 240 V specifications; lower rows for the 110, 120 V specifications.

Table

9-4

MODEL LG152, LG201, LG301, LGK152, LGZOID, LG301D

Tester polarity

!

I

1

Yetlow

j

Red White

:

Green

i

Brown

1

!

i

I

Im

i

700K- 1MR

~

72K - 120KQ

Another:

One wire:

OS2

i

6.5K - 10KQ

Yellow

t

I

m

400K - 500KR 72K - 120KR

Another:

oo

I

I

!

:

250K - 300KR

Red

m

I

400K - 500Kn

._

-

130K - 140KR

m

220K - 250KQ

White

I

-

i

130K - 140KR

I

-

m

i

45K - 50KSL

600K

-

1MS2

i

70K - 110KQ

i

400K - 500Kn - 70K - 11OKR

I

i

-

-

7K - 9.5KR

I

6.5K - 8.5KQ

Green

-

-

I

400K - 500KR , 40K -46KR

1

200K - 300Kfi i 40K - 46Kn

j

m

I

-

-

m

!

Black

-

-

*Upper rows are for the 220, 230, 240 V specifications; lower rows for the 110, 120 V specifications

and the dual voltage

type.

Table

9-

5

9-4-3 IDENTIFYING AVR TROUBLE

by

MOUNTING AVR in THE GENERATOR and OPERATING AVR

SCR

or transistor damage cannot be detected

by

simply

looking at

the

AVR

or checking

the

lead

resistances.

Check

it

by

mounting

the

suspectedly faulty

AVR

in

a

normal generator, or mount a normal

AVR

in

a

generator which

fails

to generate

voltage.

-

35

-

Page 38

9-5

FUSE HOLDER

and

NO-FUSE HOLDER

9-5-1 FUSE HOLDER

Check that a fuse is

in

the fuse holder and check its conti-

nuity with a tester. (See Fig.

9-6.)

If it carries current, it is

normal.

FUSE

HOLDER

If there is no current, take the fuse out and check it for

continuity. If the fuse carries current, the fuse holder is

faulty. If the fuse carries no current, replace it with a fuse

of the correct capacity, and check the fuse holder again for

continuity.

Fuse capacities are shown

in

the table below.

Fig.

9-6

TESTER

50Hz

60Hz

110V

I

220V

I

230V

I

240V 11ov

I

120v

DC

I

I

I

I

6A

I

3A

I

3A 7A

6A

I

3A

LG072

I

10A

1

10A

4A 4A 10A

8A

~

4A

LG 102

.

LG152

15A 6A

I

6A

.

6A 15A

I

15A

i

LG201

20A

15A 8A

1

8A 8A

;

20A

Table

9 - 6

50Hz

1201240V

!

1 1 Ol220V

1

1 Ol220V

60Hz

1201240V

DC

LG2Ol-D 10A

8Ax2

:

10Ax 2 10Ax 2

8Ax2

"LG301, LG301 D

employ

a

no-fuse breaker.

Table

9-

7

9-5-2 NO-FUSE BREAKER

Only the

LC301

and

LG301D

have a no-fuse breaker.

Push the power switch off and check continuity. If no current flows, it is normal. Then push the power switch on and

check continuity again. If current flows, it is normal.

If the breaker is a two-pole type, the two pairs of terminals

must carry current.

Fig.

9-7

-36-

Page 39

9-6

RECEPTACLE

and

AC PLUG

Check the current-carrying parts

of

the receptacles and AC plugs and their leads and plastic parts

for

bums.

9-7

VOLTMETERS

Apply AC voltage to a terminal and check if the voltmeter

reads normal.

9-8

DIODE STACK ASSEMBLY

"

Fig.

9-9

The internal circuitry of the diode stack assembly is as

shown

in

Fig.

9-9.

Check inter-terminal continuity with a

tester as shown in Fig.

9-10

to see that the results are as

shown in Table

9

-8.

VOLTMETER

Fig.

9-8

/_1

-I

+I

--"--I

Fig.

9-

10

NOTE:

A

$

B

Current flows from

A

(+)

to

B

6).

C

++"

D

Current does not flow

from

C

(+I

to

D

(-1.

-

Check both terminals.

Table

9-8

-37

-

Page 40

9-9

PRIMARY EXCITING CIRCUIT

As described in

5-3

DESCRIPTION

of

GENERATOR OP-

ERATION,

the primary exciting coil is in the magneto

mounted on the engine, and the AVR has a circuit for it.

9-9-1

EXCITING COIL

The normal inter-terminal resistance of the exciting coil is

about

10

to

30

ohms.

Its voltage at the rated rpm is about

AC

10

to

30

V.

Check the resistance and voltage with a test-

er to see if they meet these requirements.

9-9-2

OTHERS

No

output voltage from the generator.

Fig.

9-

10

If the trouble cannot be detected by Step

9-9-

1

above, check the primary exciting circuit as follows:

A. Disconnect the control box and operate the generator at the rated rpm. Disconnect the two yellow wires from the excit-

ing coil to the AVR, and momentarily connect the positive

(+)

and negative

(-)

leads of a battery

in

their place. If no

output voltage is generated, reconnect the battery leads the other way.

If

output voltage is generated, the exciting coil is

defective.

B.

If no output voltage is generated by the test conducted as desribed in Step A., operate the generator at the rated rpm

and momentarily connect a battery to the brushes. The green lead is positive

(+)

and the black or brown lead negative

(-)

(See Fig.

9-1

1.).

If output voltage

is

generated, the primary exciting circuit in the AVR is defective. Replace the

AVR.

Fig.

9-

11

-38-

Page 41

10.

DISASSEMBLY

and

REASSEMBLY

10-1

PREPARATIONS and SUGGESTIONS

1)

When disassembling the engine, carefully remember the locations of individual parts

so

that they can be reassembled cor-

rectly. If you are uncertain

of

identifying some parts, it is suggested that tags be attached to them.

2)

Have boxes ready

to

keep the disassembled parts separated by group.

3)

To

prevent loss or misplacement, temporarily assemble each group of disassembled parts.

4)

Use the correct tools in the correct way.

10-2

HOW

TO

DISASSEMBLE

Order

Remarks

I

Tool

Procedures Item

1

Remove cord bushing

by

j

(3)

Disengage lead connector which con-

i

ently for correct reassem-

I

connector which connects generator to

i

(2)

Move control box, and disengage lead

1

Leads are colored differ-

or

(+)

screwdriver

:

generator. (See Fig.

10-

1.)

8

mm box wrench

Control box

,

(1) Remove bolts fastening control box to

:

i

So

bolt.

.

.4

pcs

,

control box.

bly.

nects AVR in control box

to

engine,

remove cord bushing from control box,

pulling

it

hard.

and

pull

out leads. (See Fig.

10-2.)

Note: The disassembly and reassembly of the internal parts

of

the control

box

are mentioned in

10-4.

Fig.

10-

1

Fig.

10-2

-39-

Page 42

Order

I

~~

Procedures

I

Remarks

Tool

1

*LG072, LG102: LGK102:

Remove brushholder in the upper part

of

rear cover

by

taking off screws.

(See Fig.

10-3.)

49

screw

. . .

2

pcs.

*LG152, LG201, LGZOlD, LG301,

LG301D, LGK152:

Brushholder is located inside brush cover

which

is

at the side

of

rear cover.

Remove brushholder. (See Fig.

10-4.)

Brush cover:

40

screw

.

. . 2

pcs.

Brushholder:

60

screw.

. .

2

pcs.

If

rear cover is removed

I

(+)

screwdriver

from generator without

!

brushholder, brush will

break

so

be sure

to

re-

move brushholder.

(+)

screwdriver

Fig.

10-3

Fig.

10-4

I

Order

Remarks

I

Tool

Item

I

Procedures

i

!

I

I

3

!

Rear cover I (1 j Loosen and remove cover bolts.

I

10

mm

box

wrench

I

*

LG072, LG 102, LGK 101,

*LGlS2, LG201, LG?OlD, LG301,

I

I

50

bolt.

.

.

3

pcs.

i

I

!

i

LG301D, LGK152

1

i

!

69

bolt.

.

.

3

pcs.

i

(2)

Remove rear cover by uniformly

and

I

lightly tapping it

with

a plastic hammer.

I

I

(3)

Pull

out leads from hole in rear cover.

I

I

!

(See

Fig.

10-5.)

i

I

-40

-

Page 43

Order

1

Item

Procedures Remarks

Tool

I

I

-

i

I

!

4

1

Stator

i

(1) Remove stator cover.

(2) Remove stator from front cover.

If it is difficult to remove, lightly

i

strike outside of core with plastic

hammer. (See Fig. 10-6.)

,

Never strike coil leads.

!

I

Fig.

10-5

Fig.

10-6

Order

I

Item

I

I

Procedures Remarks

I

Tool

5

Rotor

I

(1) Remove through bolt.

I

Insert box wrench or socket wrench.

1

1

strike it hard counterclockwise

w

hammer

to

loosen through bolt.

I

(See Fig. 10-7.)

*

LG072

6Q bolt.

.

.

1

PC.

I

*LG102: 152, 201, ZOlD: LGKl

I

LGKl52

i

89

bolt.

. .

1

PC.

*LG301, 301D

I

lOQ

bolt.. . 1

PC.

‘ith

I

I

02,

I

(2)

Remoye rotor. Lightly tap rotor core

I

with plastic hammer and remove rotor

i

from engine taper shaft. If it is difficult

to remove, tap at a different angle.

!

I

(See Fig. 10-8.)

I

Be careful not to let

1

screwdriver be caught

j

by rotor fan.

10 mm box wrench

or socket wrench

i

13 mm box wrench

or socket wrench

17 mm box wrench

or socker wrench

Sever strike slip rings and

1

winding.

-

41

-

Page 44

Fig.

10-

7

Fig.

10-8

NOTE:

It

is rather difficult

to

pull

out the rotor from the models LG301, LG301D and the models LG

152,

LG201, LG201D,

LG301, and LG301

D

for

U.S.A.

and Canadian markets.

1.

Therefore, prepare the tool in the dimensions of the following for pulling out the rotor.

L,

U

Ti

k

L

FF

,

c4

MODEL

Pitch

D

C

B

A

1

L

LG301

LG301

D

For

U.S.A.

and .Canadian markets

250 mm 1.5 mm 20 mm 12 mm

33 mm 910 mm

I

g8

mm

I

LG152 0.79"

Q0.31"

I

00.24"

7.2"

!

1.3"

0.39"

1

0.06"

LG201

LG201 D

7.7"

I

1.3" ! 90.31'' 1 90.24"

0.79

0.39"

0.06

LG301

LG301D

I

I

I

8.6"

90.24'' 0.79" 0.39"

i

0.06"

1.2" ' 90.31"

i

I

Table

10-

1

-42

-

Page 45

Parts numbers of the rotor puller are as follows:

I

Part

NO.

Part

Name

;

Generator Model

I

367 54333 08

I

SHAFT LG301, LG301

D

367 54334 08 BOLT LG301, LG301

D

U.S.A. and Canadian markets

I

365 54335 08

I

SHAFT

I

LG152

I

I

366 54337 08

j

SHAFT I LG201, LG201

D

I

I

367 54339 08

I

SHAFT

LG301, LG301

D

I

3655433608 BOLT LG152, LG201, LG201D, LG301, LG301

D

Table

10-2

2.

Remove a throughbolt and insert the shaft of rotor puller into the hole for throughbolt and push

it

up

till

the shaft

reaches the screw hole of the

P.

T.

0.

shaft on the side of engine.

3.

As

hown in Fig.

10-9,

screw up the rotor puller shaft and remove the rotor.

~

Fig.

10-9

-

-43

-

Page 46

*

LG072:

*Others:

89

bolt

.

. .

4

pcs.

!

(The

LG102, LG301, LG301D

for

:

j

I

U.S.A.

and Canada have a spacer be-

tween main bearing and front cover,

so

longer bolts are used. Remove

spacer, too.)

(2)

Remove handle and front cover.

!

*LG072:

*Others:

69

bolt

. . . 2

pcs.

Tool

Order

I

Item

I

Procedures Remarks

I

6

j

Front cover

(1)

Remove bolts which fasten engine main

;

!

bearing cover and front cover together.

j

;

10

mm box wrench

13

mm box wrench

10

mm box wrench

I

I

I

!

86

bolt.

. .

3

pcs.

i

13

mm box wrench

I

-

44

-

Page 47

10-3

HOW

TO

REASSEMBLE

10-3-1

FRONT

COVER

1)

Reassemble the handle and front cover.

*LG072:

69

x

15

mm bolt

.

.

.2

pcs.

*Others:

8Q

x

18 mm bolt

.

.

.3

pcs.

2)

Install the front cover

on

the engine main bearing cover,

engaging the faucet joint and making sure that the han-

dle is up.

*LG072:

60

x

18

mm bolt

.

.

.4 pcs.

Tightening torque

48

to

60

kg-cm

*Others:

89

x

18

mm bolt

.

.

.4 pcs.

Tightening torque

120

to 140 kg-cm

..

~.~

~ ~

"~

.

.

NOTE: The front covers may appear the same, but differ in

bolt pitch depending on the type of engine.

NOTE: The LG102, LG301, and LG301D for

U.S.A.

and Canada have a spacer between the main bearing cover

and frontcover. (See Fig. 10- 1

1.)

Thus, the bolts are 45mm

long for LG

102

and

25

mrn long for L G301, L G301 D and

are tightened together with the spacer.

~~.

.

FOR

LG301, LG301

D

FOR

LG102

Fig. 10- 1

1

10-3-2

ROTOR

-.

~.?

..

.

1) Wipe the engine output shaft taper and rotor female

taper to remove oil and dirt, using a cloth.

2)

Install the rotor, and tighten the through bolt. (See Fig.

10-12.)

NOTE: The outside diameter and laminated thickness of

the rotor are shown in Item

2.

Rotar,

5-2

FUNCTIONS.

NOTE: Theshape of the through bolts is shown on page 44.

NOTE: The mark

refers to the models for

U.S.A.

and

Canada.

Fig.

10-

12

-45

-

Page 48

3

c

I

A

r

i

i

I-'

MODEL

LG072

20mm

6mm

;

170mm

I

S

~

*5/16

LGK102 '7.09''

I

*0.98"

LG 102

1

8mm

172mm

1

20mm

LG152 8mm

i

222 mm

j

25 mm

LGK152

1

"5/16"

!

"7.09"

I

"0.98"

LG201

i

8 mrn 1 230 mm i 25

mm

LG201

D i *5/16" "7.48" "0.98"

LG301

"8.66" "0.98"

*5/16"

LG301

D

240mm 25mm 10mm

!

The mark " refers to the models for U.S.A.

and Canada.

10-3-3

STATOR

Table

10-2

I.

LG072, LG102, LGK102

1)

Place the stator

in

the stator cover.

2)

Align

it with the

front

cover faucet joint and install the stator. (See

Fig.

10-14.)

NOTE: Make sure that the arc of the stator matches the faucet joint. (See Fig.

10- 13.)

The leads

must

be

up

so

they can

be taken out from the top.

FRONT

COV

ATOR

COVER

Fig.

IO-

13

NOTE: The outside diameter and laminated thickness

ER

,

of

&e

si

Fig.

70-

14

'ator are shown in Item

(1)

STATOR,

5-2

FUNCTIONS.

-46

-

Page 49

II.

LG152, LGK152, LG201, LG201D, LG301, LG301D

Install only the stator, making sure that it matches the faucet joint of the front cover.

NOTE: Install the stator cover after mounting the rear cover. The leads must be up

so

they can be taken out from the top.

Connection to the brushes should be made at the rear brush mounting position.

10-3-4 REAR COVER

1)

Install the diode stack in the rear cover. (See Fig.

10-

15.)

39

x

12

mm screw

.

.

.

1

PC.

NOTE: Solder an assembly of leads, of the colors that

meet the specifications of the circuit diagram, and a

connector, to the diode stack.

DIODE

I

Fig.

10-

15

The diode has markings

of

input

(-),

positive

(+)

and negative

(-1,

in

this part.

LG072, LG102, LGK102:

(-)

is yellow and white;

(+)

blue; and

(-1

brown.

LG152, LG201, LG201

D,

LG301, LG301

D,

LGK152:

Two

(-)

leads are blue;

(+)

orange; and

(-1

brown.

Pass all the leads that come out of the hole in the top

of the rear cover, from the stator and the diode.

NOTE:

LG152, LGK152, LG201, LG201D, LG301,

LG301

D

must have a grommet

(365

57501

08)

in-

serted into

this

hole.

Install the rear cover to match the

rotor

bearing. Light-

ly and uniformly tap the rear cover around its circum-

ference with a plastic hammer. (See Fig.

10-16.)

NOTE: Be careful not to let the leads be caught between the stator and rear cover.

-

47

-

Page 50

4)

Tighten the cover bolt.

NOTE: The bolt cannot be tightened unless the front cover andrearcover are positioned correctly.

The shape of the cover bolt is shown below.

Table

10-3

1

MODEL

d

1

S

I

LG072

90

rnrn

15 mm

3.54 0.54

90

mm

15 mm

LG152. LGK152

1

E.:;

3.54

0.54

I

LG201, LG2OlD

i

:.:;

I

loo

3.94

mrn i l5

0.54

rnrn

I

I

LG301, LG301

D

I

E,:;

1

30

mm

I

l5

mm

5.1 2"

I

0.54

I

5)

LG152, LGK152, LG201, LG201D, LG301, LG301D has a stator cover which must be installed. Place it between

the stator and cover bolt, and fold the edge around it to fasten it.

10-3-5

BRUSH

HOLDER

1) Install the brush holder in the rear cover.

Pass the mounting screws through the brush holders, and tighten the screw while pressing to the slip ring perpendicular

to

it. (See Figs. 10-17 and 10-18.)

*LG072, LG102, LGKl02:

4$

x

20

mm screw

. . .

2

pcs.

*LG152, LG201, LG201D, LG301, LG301D, LGKl52:

50

x

18 mm screw

. . .

2 pcs.

NOTE: If the brush holder

is

mounted obliquely to the slip ring, the brush holder may break when the screws are tightened or when the engine started.

After mounting the brush holder, measure the resistance between the brush terminals with a tester if

it

is anywhere

from

6

ohms to

13

ohms

Fig:

10-

17

Fig.

10-

18

-48

-

Page 51

NOTE: Remember that the brush holder

comes

in two kinds

as

shown below.

LG072, LG102

LG K102

LG152, LG2C1, LG2OlD

LG301, LG301D, LGK152

Fig.

10-

19

NOTE:

LG072,

LG702,

LGK102:

The green lead

(+)

must be on the stator side.

BLACK WIRE

(-1

7

,-GREEN WIRE

(+I

BRUSHHOLD

ENGINE P.T.O.

FRONT COVER

COOLING FAN

REAR

COVER

1

\

STATOR COIL STATOR COMPL.

RUBBER

I

MOUNT

SHAFT

Fig.

10-20

-49

-

Page 52

THE FOLLOWING APPLY

TO

THE LG152, LG201, LG201D. LG301, LG3OlD

and

LGK152

ONLY.

2)

Attach the connector

to