Page 1

SERVICE

MANUAL

Models

EY15-3, EY20-3

ENGINES

PUB-ES1609

Rev. 12/01

Page 2

940 Lively Blvd. • Wood Dale, IL 60191 • Phone: 630-350-8200 • Fax: 630-350-8212

e-mail: sales@robinamerica.com • www.robinamerica.com

© Copyright 2001 Robin America, Inc.

Page 3

CONTENTS

Section Title Page

1. SPECIFICATIONS....................................................................................................... 1

2. PERFORMANCE ........................................................................................................2

2-1 MAXIMUM OUTPUT........................................................................................................ 2

2-2 CONTINUOUS RATED OUTPUT .................................................................................... 2

2-3 MAXIMUM TORQUE ....................................................................................................... 2

2-4 PERFORMANCE CURVES ............................................................................................. 3

3. FEATURES (compared with former models)........................................................... 5

4. GENERAL DESCRIPTION OF ENGINE COMPONENTS .......................................... 6

4-1 CYLINDER AND CRANKCASE....................................................................................... 6

4-2 MAIN BEARING COVER ................................................................................................. 6

4-3 CRANKSHAFT.................................................................................................................6

4-4 CONNECTING ROD AND PISTON ................................................................................. 7

4-5 CAMSHAFT ..................................................................................................................... 7

4-6 VALVE ARRANGEMENT ................................................................................................. 7

4-7 CYLINDER HEAD............................................................................................................ 8

4-8 GOVERNOR SYSTEM .................................................................................................... 8

4-9 COOLING SYSTEM......................................................................................................... 8

4-10 LUBRICATION SYSTEM ............................................................................................... 8

4-11 IGNITION SYSTEM........................................................................................................ 9

4-12 CARBURETOR.............................................................................................................. 9

4-13 AIR CLEANER ...............................................................................................................9

4-14 SECTIONAL VIEW OF ENGINE.................................................................................. 10

5. DISASSEMBLY AND REASSEMBLY ....................................................................... 12

5-1 PREPARATIONS AND SUGGESTIONS........................................................................ 12

5-2 SPECIAL TOOLS ........................................................................................................... 12

5-3 DISASSEMBLY PROCEDURES.................................................................................... 13

5-4 REASSEMBLY PROCEDURES..................................................................................... 20

5-5 BREAK-IN OPERATION OF REASSEMBLED ENGINE ............................................... 27

6. GOVERNER ADJUSTMENT.....................................................................................28

7. CARBURETOR ......................................................................................................... 30

7-1 OPERATION AND CONSTRUCTION............................................................................ 30

7-2 DISASSEMBLY AND REASSEMBLY ............................................................................ 31

8. MAGNETO ................................................................................................................ 33

8-1 FEATURES .................................................................................................................... 33

8-2 BASIC PRINCIPLE OF U.T.C.I. ..................................................................................... 33

8-3 MAGNETO TROUBLESHOOTING................................................................................ 34

Page 4

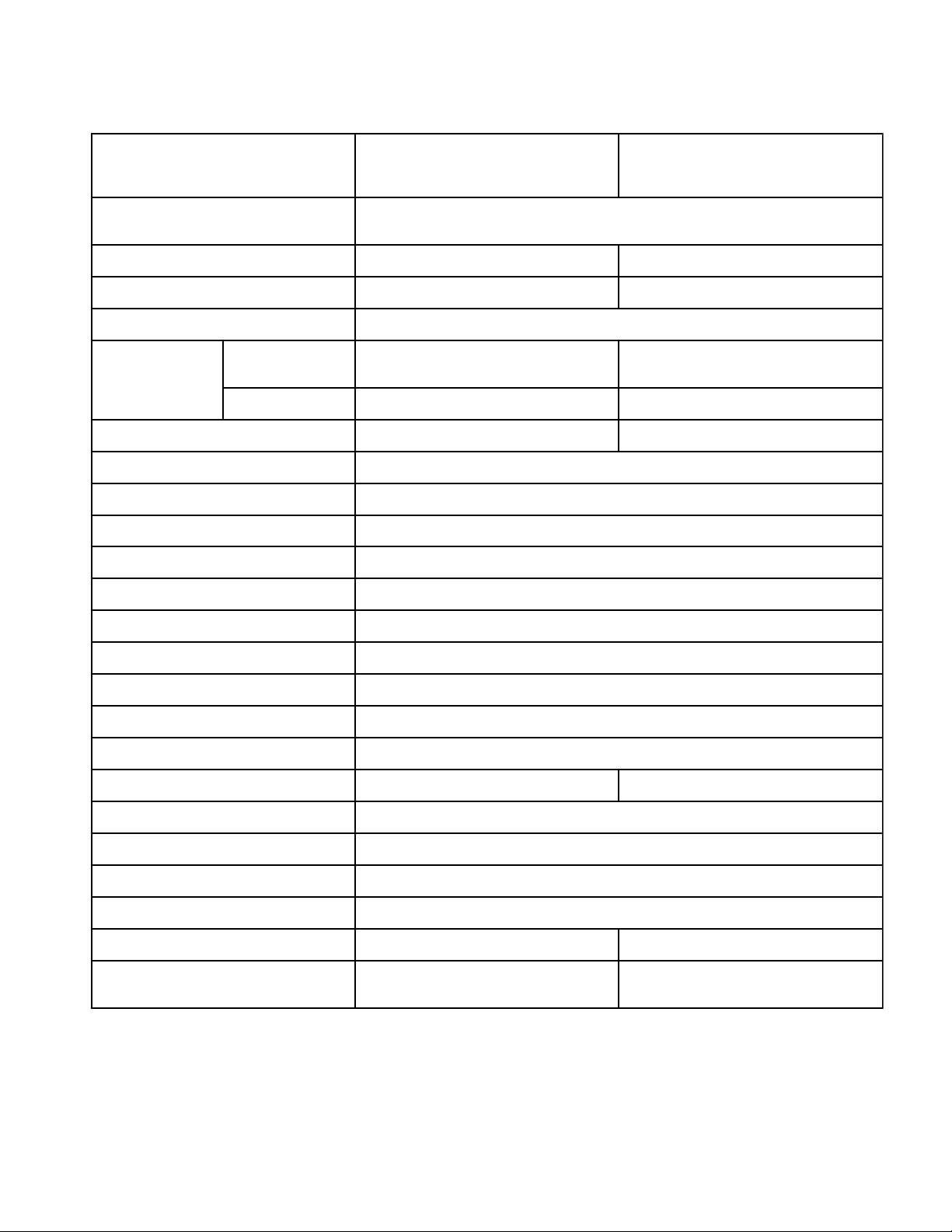

1. SPECIFICATIONS

LEDOMD3-51YED3-02YE

epyT

ekortSxeroB).ni18.1x84.2(mm64x36).ni50.2x46.2(mm25x76

tnemecalpsiDnotsiPmc341

3

oitaRnoisserpmoC 3.6

suounitnoC

tuptuO

.xaM.m.p.r0004/)PH5.3(Wk6.2.m.p.r0004/)PH0.5(Wk7.3

euqroT.xaM

N7.6 ・ fgk86.0(m ・ .m.p.r0082/)mN3.9 ・ fgk59.0(m ・ .m.p.r0082/)m

noitatoRfonoitceriD edistfahs.O.T.PmorfdeweivsaesiwkcolcretnuoC

metsysgnilooC gnilooCriAdecroF

tnemegnarrAevlaV evlaVediS

noitacirbuL epyThsalpS

tnacirbuL rehgihroESssalC;03-W01ro03#,02#EASliOelibomotuA

tnacirbuLfoyticapaC ).lag.S.U651.0(sretil6.0

roterubraC epyTtaolF,tfarDlatnoziroH

).ni.uc37.8(mc381

.m.p.r0003/)PH2.2(Wk6.1

.m.p.r0063/)PH7.2(Wk0.2

,rednilyC-elgniS,elcyC-4,delooC-riA

enignEenilosaG,evlaVediS

3

).ni.uc71.11(

.m.p.r0003/)PH0.3(Wk2.2

.m.p.r0063/)PH5.3(Wk6.2

leuF enilosaGdedaelnUelibomotuA

oitaRnoitpmusnoCleuFWk/g083

metsySdeeFleuF epyTytivarG

yticapaCknaTleuF).lag.S.U47.0(sretil8.2).lag.S.U00.1(sretil8.3

metsySnoitingI )etatSdiloS(otengaMleehwylF

gulPkrapS SH6BKGN

metsySgnitratS retratSlioceR

metsySronrevoG epyTthgiewylFlagufirtneC

thgieWyrD).bl1.92(gk2.31).bl1.33(gk0.51

)HxWxL(snoisnemiD

Specifications are subject to change without notice.

・ PH/g082(h ・ tuptuOdetaRsuounitnoCta)h

mm863xmm403xmm492

mm293xmm813xmm303

).ni94.41x.ni79.11x.ni75.11(

).ni34.51x.ni25.21x.ni39.11(

- 1 -

Page 5

2. PERFORMANCE

2-1 MAXIMUM OUTPUT

The maximum output is the output of an engine with its throttle valve fully opened and considering that all

the moving parts are properly broken in .

A new engine may not produce full maximum output while its moving parts are still not broken-in.

NOTE :

Power curves shown in the following charts are made in conformity with SAE internal combustion engine

standard test code J1349.

2-2 CONTINUOUS RATED OUTPUT

The continuous rated output is the output of an engine at optimum governed speed which is most favorable from the view point of engine's life and fuel consumption.

When the engine is installed on a certain equipment, it is recommended that the continuous output

required from the equipment should be kept below this continuous rated output.

2-3 MAXIMUM TORQUE

The maximum torque is the torque at the output shaft when the engine is producing maximum output at

a specified r.p.m..

- 2 -

Page 6

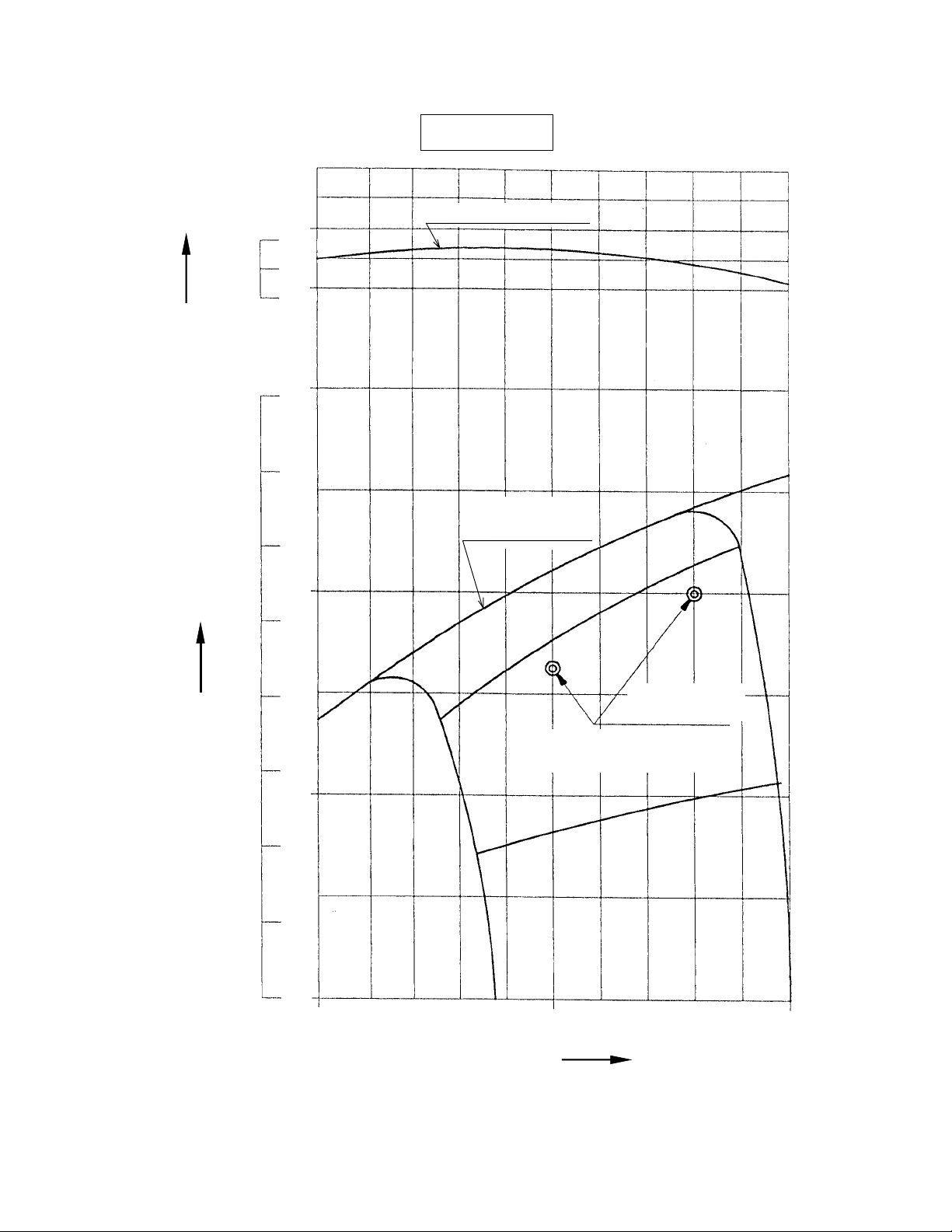

2-4 PERFORMANCE CURVES

(kgf.m) N.m

7

0.7

EY15-3D

MAXIMUM TORQUE

TORQUE

OUTPUT

0.6

(HP) kW

4

3

2

6

3

MAXIMUM

HORSEPOWER

2

CONTINUOUS

RATED HP

1

1

00

2 0 0 0

RECOMMENDED

HORSEPOWER RANGE

3 0 0 0

REVOLUTION

- 3 -

4 0 0 0

r.p.m.

Page 7

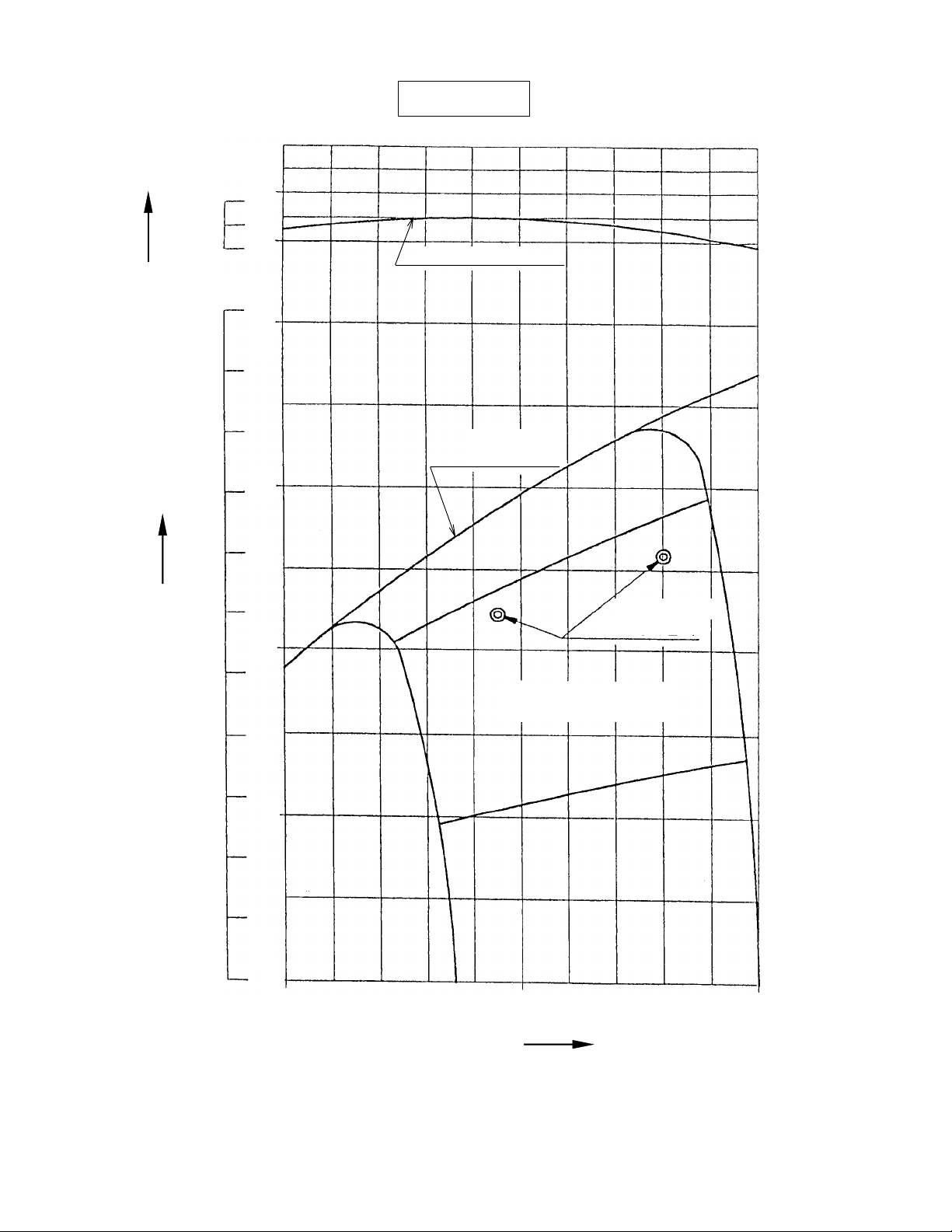

(kgf.m) N.m

EY20-3D

1.0

TORQUE

0.9

OUTPUT

10

9

(HP) kW

4

5

3

4

3

3

2

MAXIMUM TORQUE

MAXIMUM

HORSEPOWER

CONTINUOUS

RATED HP

2

1

0

1

0

2 0 0 0

RECOMMENDED

HORSEPOWER RANGE

3 0 0 0

REVOLUTION

4 0 0 0

r.p.m.

- 4 -

Page 8

3. FEATURES (compared with former model)

1. Re-designed outlook

Thinner recoil starter, newly designed air cleaner and muffler are adopted.

Also, innovate the image that express the reliability of Robin engine more by adopting new labels

and new color.

2. Shorter length increased mount-ability

Thinner recoil starter realized shorter length than former model. It eases to mount the engines to

many applications.

3. Development of dust proof air cleaner

Newly developed dual element air cleaner, which has bigger dust holding capacity, realized higher

reliability in dusty condition than former model.

4. Deep consideration on human and environment

New muffler realized quieter operation. Also, the engine meets with EPA Phase 1 exhaust emission

regulation, European emission gas regulations starting from 2002, and Japanese voluntary reguations

start from 2003, with dual element or cyclone type air cleaner.

5. Unchanged durability

Durability is the same as that of former model. Robin keeps producing reliable and dependable engine.

6. Parts interchangeability

Almost of all spare parts are interchangeable between new and former models. The air cleaner and

carburetor should be exchanged at the same time.

- 5 -

Page 9

4. GENERAL DESCRIPTION OF ENGINE COMPONENTS

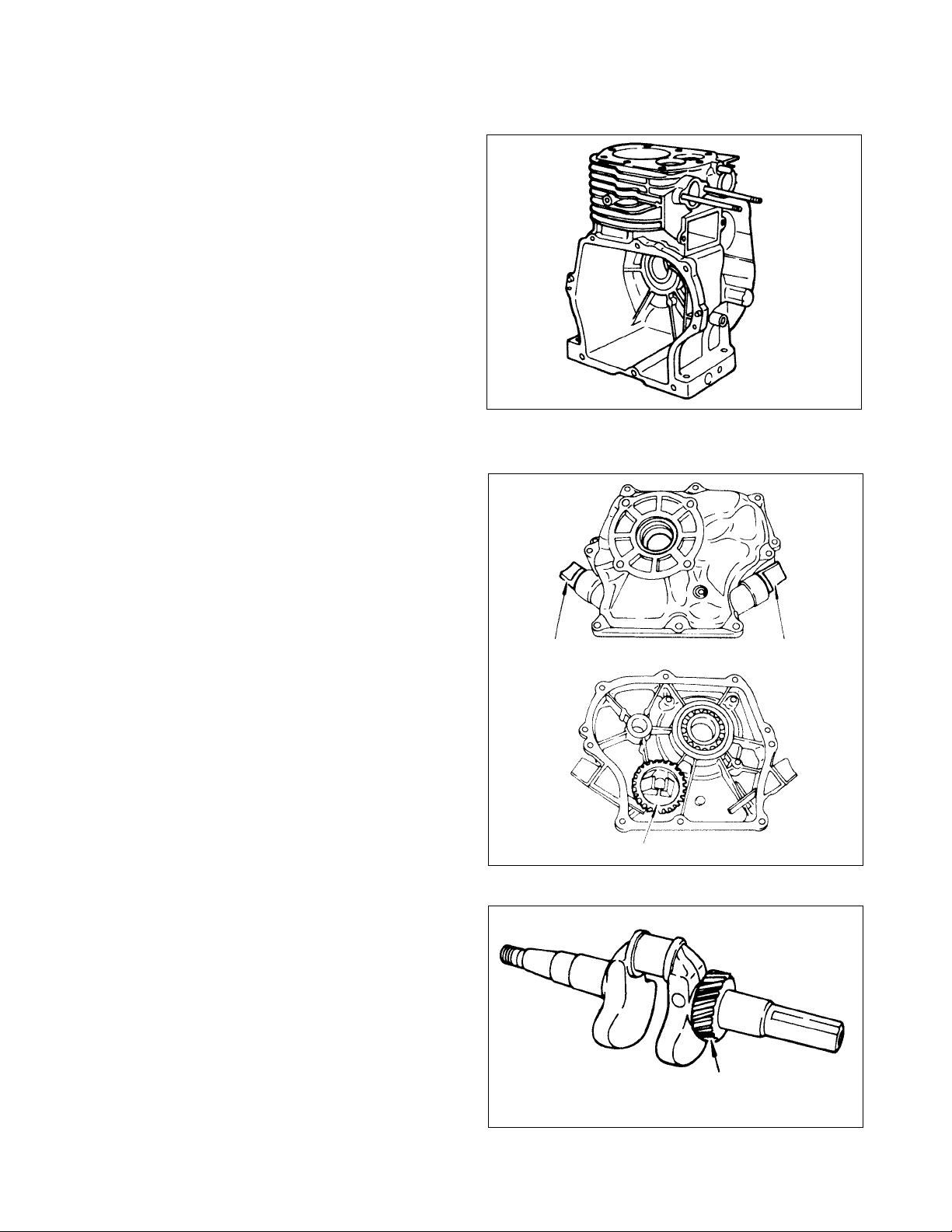

4-1 CYLINDER AND CRANKCASE

The cylinder and crankcase are single piece aluminum die-casting.

The cylinder liner, made of special cast iron, is

molded into the aluminum casting.

The intake and exhaust ports are located on one

side of the cylinder, and are also inserted into the

casting.

The crankcase has a mounting surface on the output shaft side, where the main bearing cover is

attached.

4-2 MAIN BEARING COVER

The main bearing cover is an aluminum die-casting, which is mounted on the output shaft side of

the crankcase.

Fig. 4-1

Remove the main bearing cover to inspect inside

of the engine.

Pilots and bosses are machined on the cover for

direct mounting of the engine onto such machines

as generators and pumps.

Oil gauges (fillers) are on both sides of the cover

for easy maintenance.

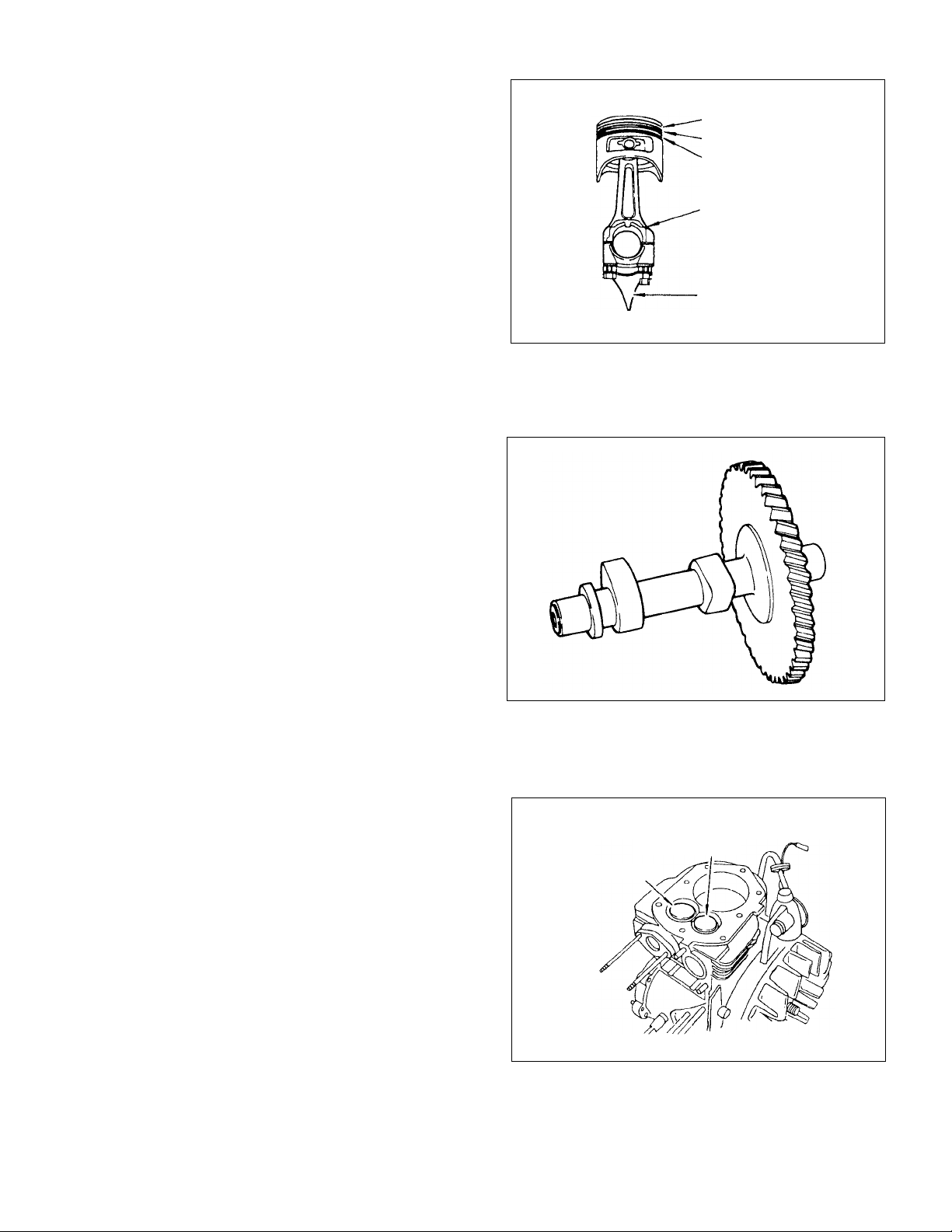

4-3 CRANKSHAFT

The crankshaft is forged carbon steel, and the

crank pin is induction-hardened.

The output end of the shaft has a crankshaft gear

that is pressed into position.

Oil Gauge Oil Gauge

Governor Gear

Fig. 4-2

- 6 -

Crank Gear

Fig. 4-3

Page 10

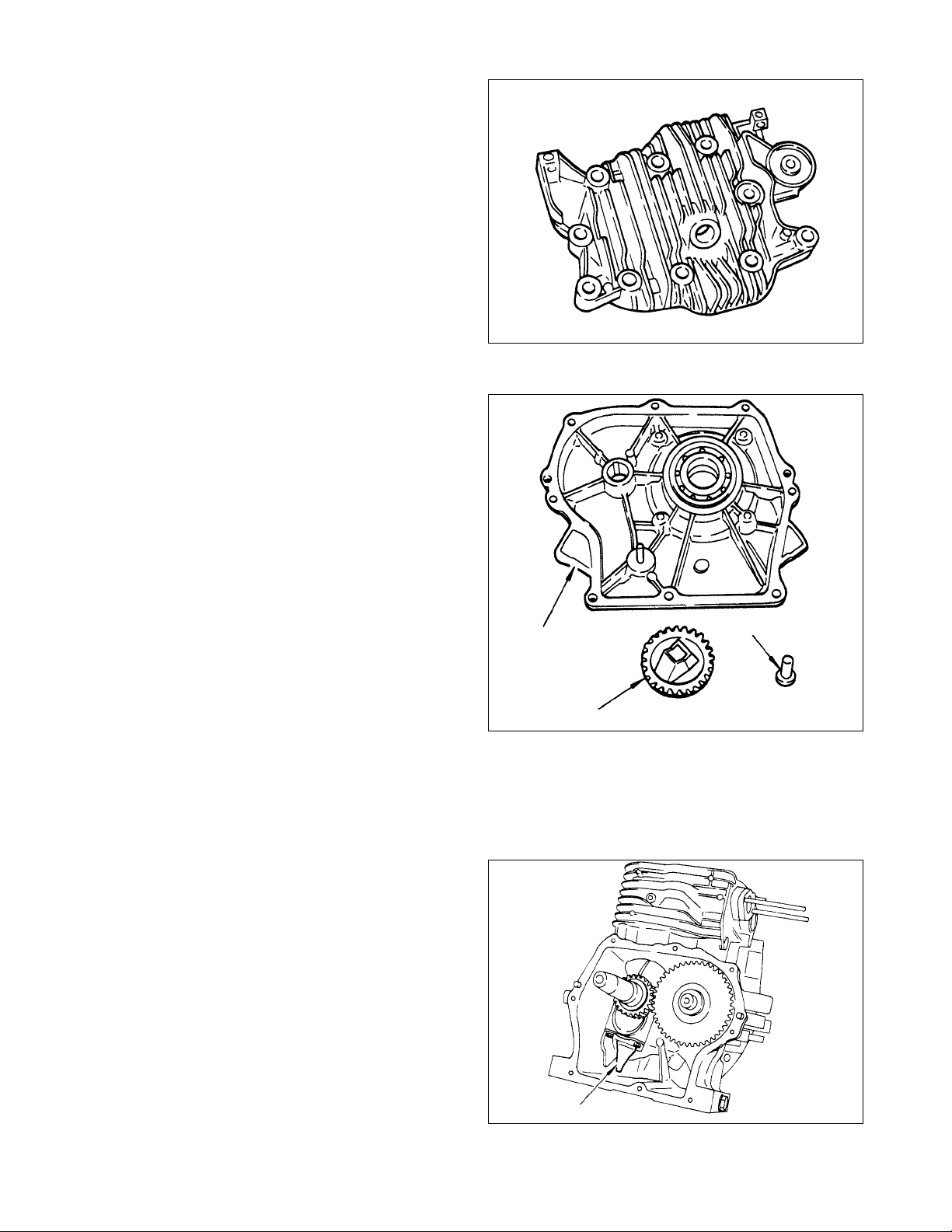

4-4 CONNECTING ROD AND PISTON

The connecting rod is forged of aluminum alloy,

and its large and small ends fanction as bearings.

The large end has a built-in oil scraper for splashing the lubricating oil.

The piston is an aluminum alloy casting, and carries two compression rings and one oil ring.

4-5 CAMSHAFT

The camshaft is made of special cast iron, and

camshaft and gear are cast together in one piece.

Both sides of the shaft fit into the plain bearings

on the crankcase and main bearing cover.

Top Ring

Second Ring

Oil Ring

Connecting Rod

Oil Scraper

Fig. 4-4

4-6 VALVE ARRANGEMENT

The exhaust valve is located upstream of the cooling air with the result that the exhaust valve is

intensively cooled for improved engine durability .

Fig. 4-5

Exhaust Valve

Intake Valve

Fig. 4-6

- 7 -

Page 11

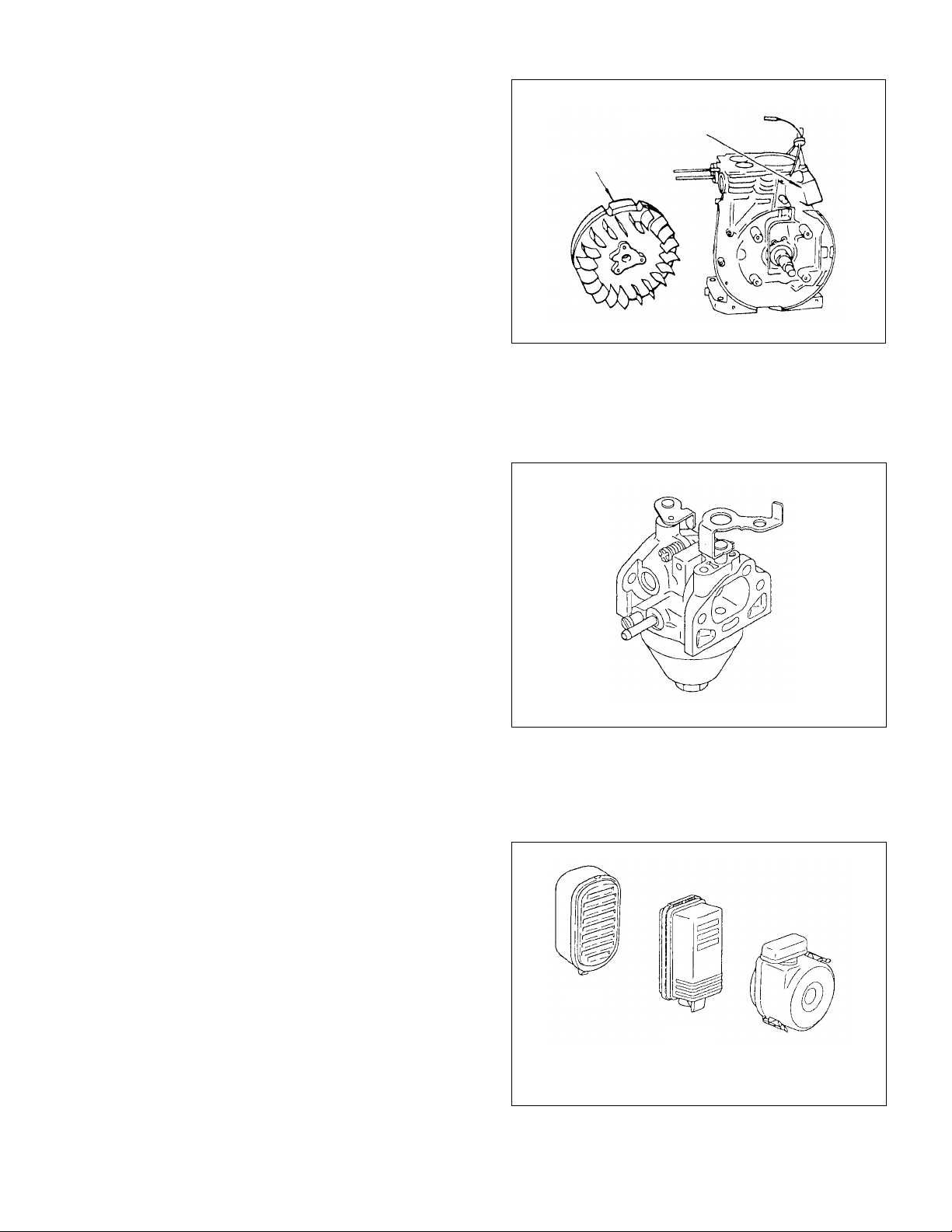

4-7 CYLINDER HEAD

The cylinder head is an aluminum die-casting, and

forms a Ricardo type combustion chamber with

squish area for high combustion efficiency. The

spark plug is tilted for easy mounting of the fuel

tank.

4-8 GOVERNOR SYSTEM

The governor is a centrifugal flyweight type which

ensures constant operation at the selected speed

during load variations.

The governor gear with governor weights is installed on the main bearing cover.

Fig. 4-7

Main Bearing Cover

Governor Gear Complete

Fig. 4-8

Governor Sleeve

4-9 COOLING SYSTEM

The large fins on the flywheel provide sufficient cooling air capacity for the cylinder and cylinder head.

The cylinder baffle and head cover are provided for guiding the cooling air.

4-10 LUBRICATION SYSTEM

All the rotating and sliding parts are splash- lubricated by the oil scraper on the connecting rod.

- 8 -

Oil Scraper

Fig. 4-9

Page 12

4-11 IGNITION SYSTEM

The ignition system is a transistor controlled magneto system which consists of a flywheel and an

ignition coil with a built-in transistor mounted on

the crankcase.

4-12 CARBURETOR

The engine is equipped with a horizontal draft carburetor that has a float controlled fuel system and

a fixed main jet.

The carburetors are calibrated carefully for sure

starting, good acceleration, less fuel consumption

and sufficient output.

Ignition Coil

Flywheel

Fig. 4-10

For details, refer to page 30, section “7 CARBURETOR”.

4-13 AIR CLEANER

The air cleaner of the standard engine is an oblong type using an urethane foam(semi-wet).

As optional parts,dual-element type and cyclone

chimney type are available.

STD type

Fig. 4-11

Dual-element type

(Option)

Cyclone chimney type

(Option)

- 9 -

Fig. 4-12

Page 13

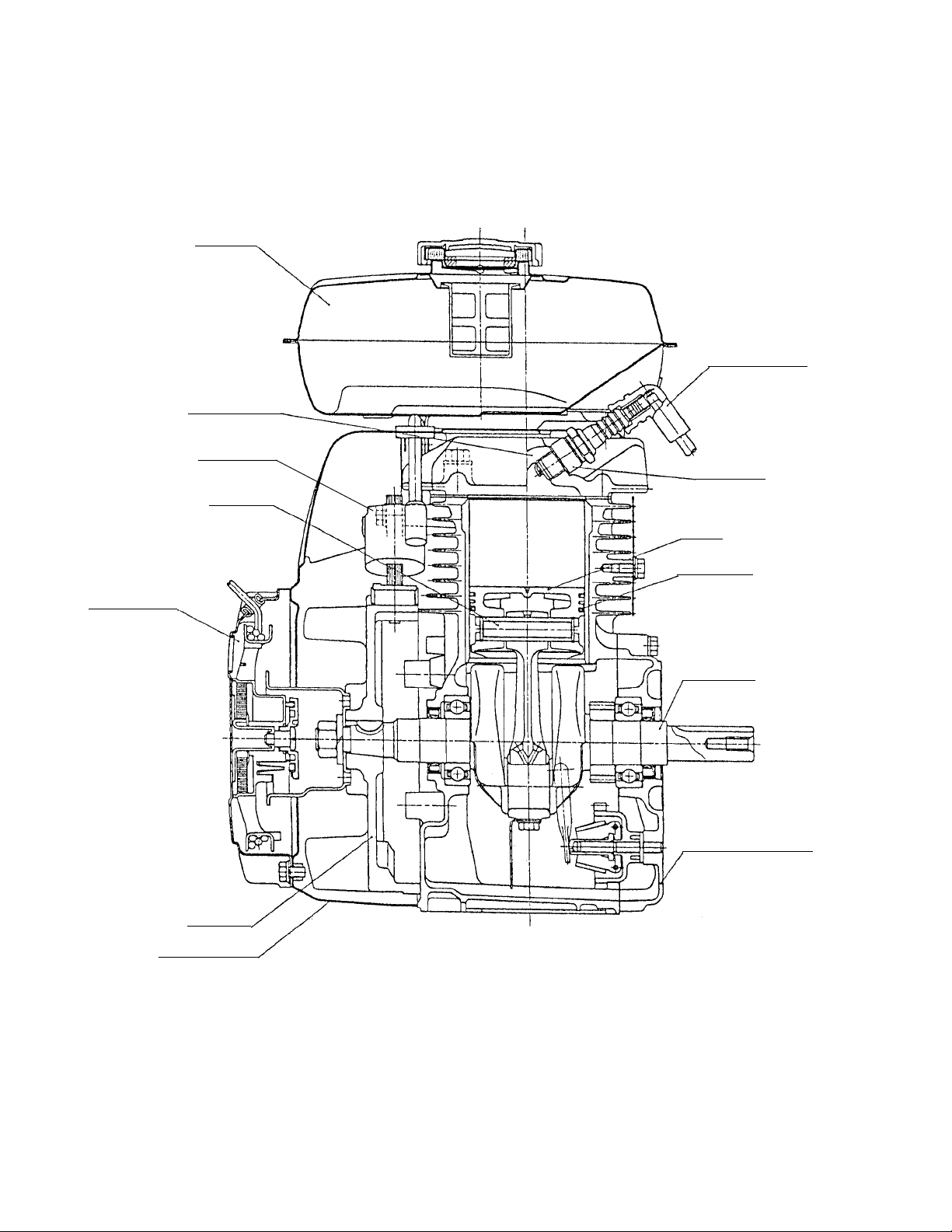

4-14 SECTIONAL VIEW OF ENGINE

Fuel Tank

Cylinder Head

Ignition Coil

Piston Pin

Spark Plug Cap

Spark Plug

Piston

Recoil Starter

Blower Housing

Piston Ring

Crankshaft

Main Bearing Cover

Flywheel

Fig. 4-13

-

10

-

Page 14

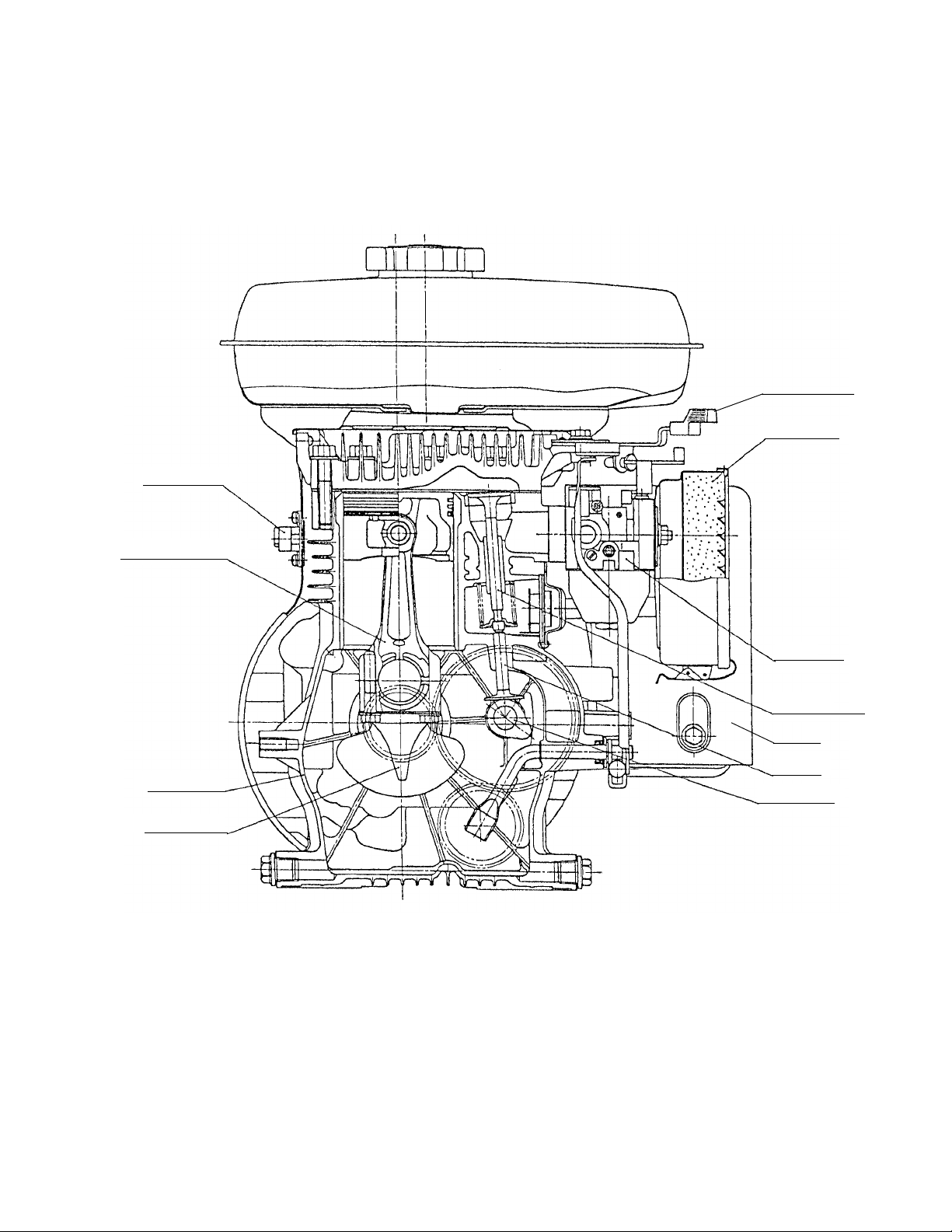

Stop Switch

Connecting Rod

Crankcase

Speed

Control Lever

Air Cleaner

Carburetor

Intake and

Exhaust Valve

Muffler

Tappet

Camshaft

Oil Scraper

Fig. 4-14

-

11

-

Page 15

5. DISASSEMBLY AND REASSEMBLY

5-1 PREPARATIONS AND SUGGESTIONS

1) When disassembling the engine, memorize the locations of individual parts so that they can be

reassembled correctly. If you are uncertain of identifying some parts, it is suggested that tags be

attached to them.

2) Have boxes ready to keep disassembled parts by group.

3) To prevent losing and misplacing, temporarily assemble each group of disassembled parts.

4) Carefully handle disassembled parts, and clean them with washing oil if necessary.

5) Use the correct tools in the correct way.

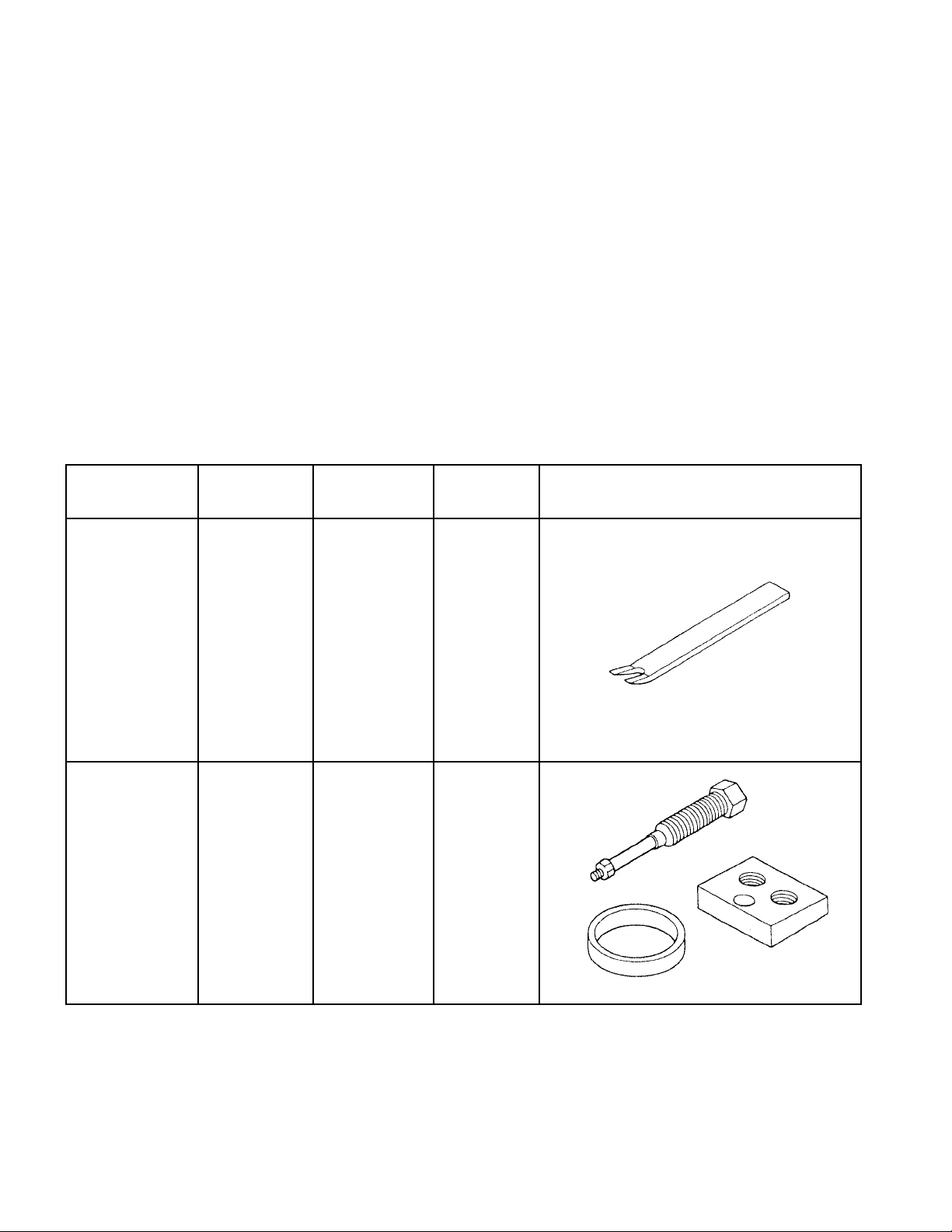

5-2 SPECIAL TOOLS

.oNtraPlooTesU

70-30059-722

70-10059-722

gnirpSevlaV

reniateR

ediuGevlaV

relluP

evlaVediuG

elbacilppA

ledoM

gnitnuomroF

gnirpSevlaV

dnareniateR

kcoLreniateR

ffognilluproF

82YE

41,31,01YE

02,81,51YE

72,52,32YE

02,51YE

epahS

1-5.giF

2-5.giF

-

12

-

Page 16

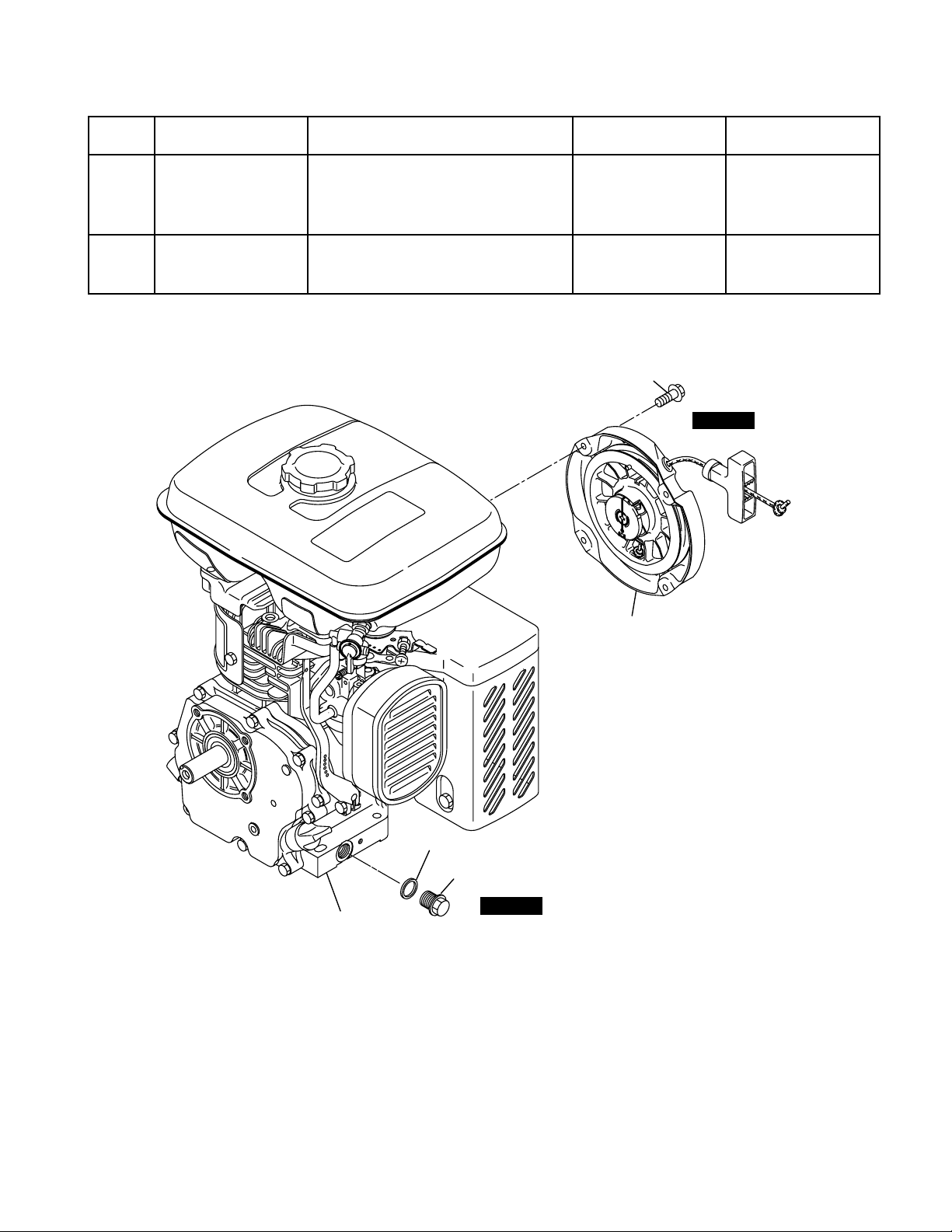

5-3 DISASSEMBLY PROCEDURES

petSevomerotstraPserudecorPskrameRlooT

gulPniarD)1(.lioenigneniarD

1

fosedishtobnosgulpniarD

ottonluferaceB

.teksagehtesol

rennapsxoBmm41

tloB21x41M.esacknarceht

2

.scp4:tlobegnalF8x6M

M6 x 8 Flange bolt : 4 pcs.

STEP 2

retratSlioceR)1(.retratsliocerevomeR

rennapsxoBmm01

STEP 2

Crankcase

Recoil Starter

Gasket

Drain Plug

STEP 1

Fig. 5-3

-

13

-

Page 17

petSevomerotstraPserudecorPskrameRlooT

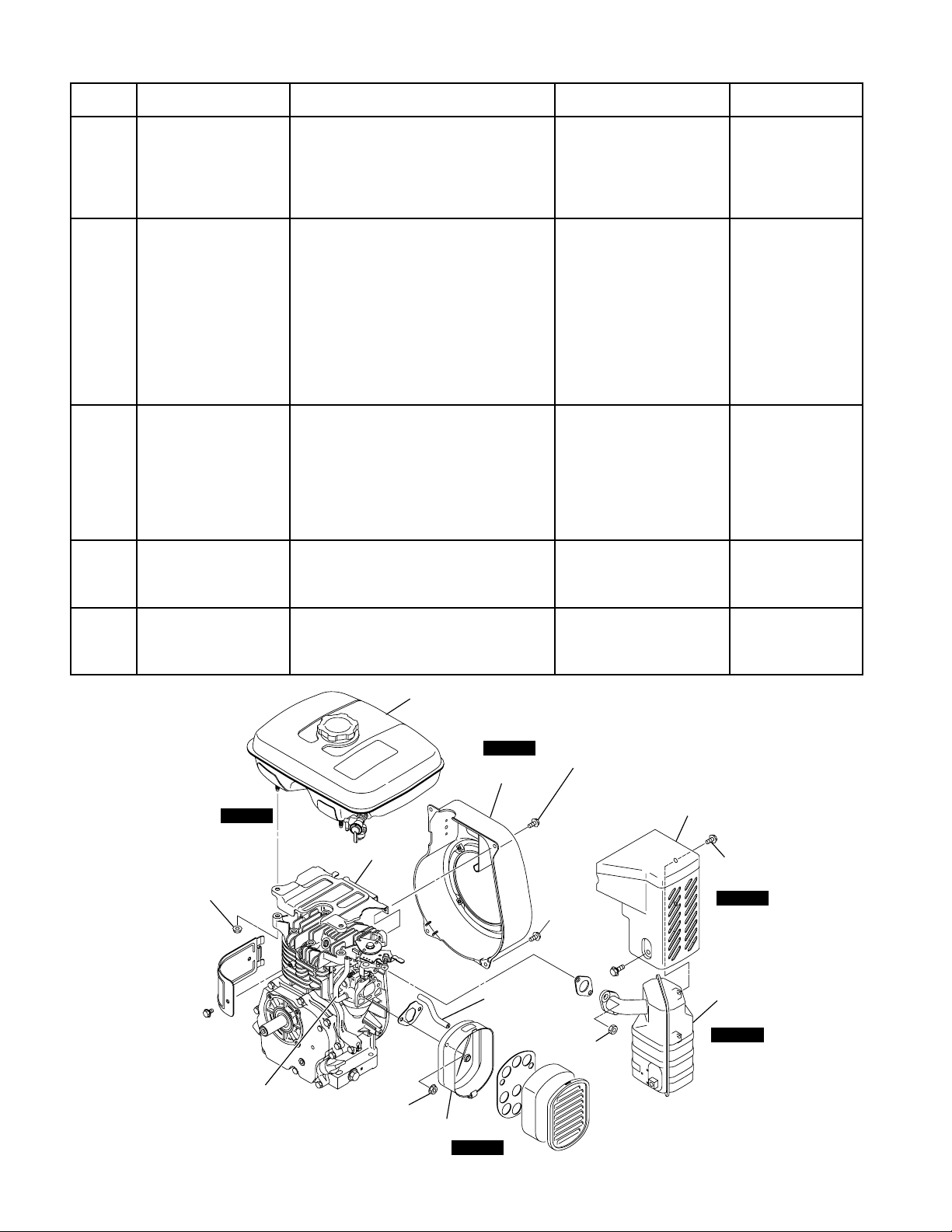

gnisuoHrewolB)1(gnisuohrewolbehtevomeR

ehtdnaesacknarcehtmorf

3

.daehrednilyc

signisuohrewolB

rehtegotdenetsaf

.knatleufehthtiw

rennapsxoBmm01

.scp2:tlobegnalF21x6M

.scp2:tlobegnalF41x6M

dnaknaTleuF

revoCdaeH

)1(

)2(

.kcocleufehtesolC

epipleufehttcennocsiD

rennapsxoBmm01

rennapSmm01ro

reniartsleufehtneewteb

leufehtmorfroterubracdna

4

)3(

.reniarts

morfknatleufehtevomeR

.daehrednilyceht

.scp2:tuN6M

)4(

revocdaehehtevomeR

.daehrednilycehtmorf

renaelCriA)1(

)2(

5

renaelcriaehtevomeR

.tnemelednarevoc

renaelcriaehtevomeR

siesacrenaelcriA

rehtegotdenetsaf

.roterubracehthtiw

.roterubracehtmorfesac

rennapsxoBmm01

.scp2:tuN6M

)3(

rehtaerbehttcennocsiD

.epip

revoCrelffuM)1(revocrelffumehtevomeR

6

.relffumehtmorf

rennapsxoBmm01

.scp3:tlobegnalF8x6M

relffuM)1(morfrelffumehtevomeR

7

ehtfonoitroprednilyceht

rennapSmm21

.scp2:tuN8M.esacknarc

Fuel T ank

STEP 4

M6 Nut : 2 pcs.

Head Cover

STEP 3

Blower Housing

Breather

Pipe

M6 x 14 Flange bolt : 2 pcs.

Muffler Cover

M6 x 12

Flange bolt

: 2 pcs.

M8 Nut :

2 pcs.

M6 x 8

Flange bolt : 3 pcs.

STEP 6

Muffler

STEP 7

Fig. 5-4

Fuel Pipe

M6 Nut : 2 pcs.

Air Cleaner

-

STEP 5

14

-

Page 18

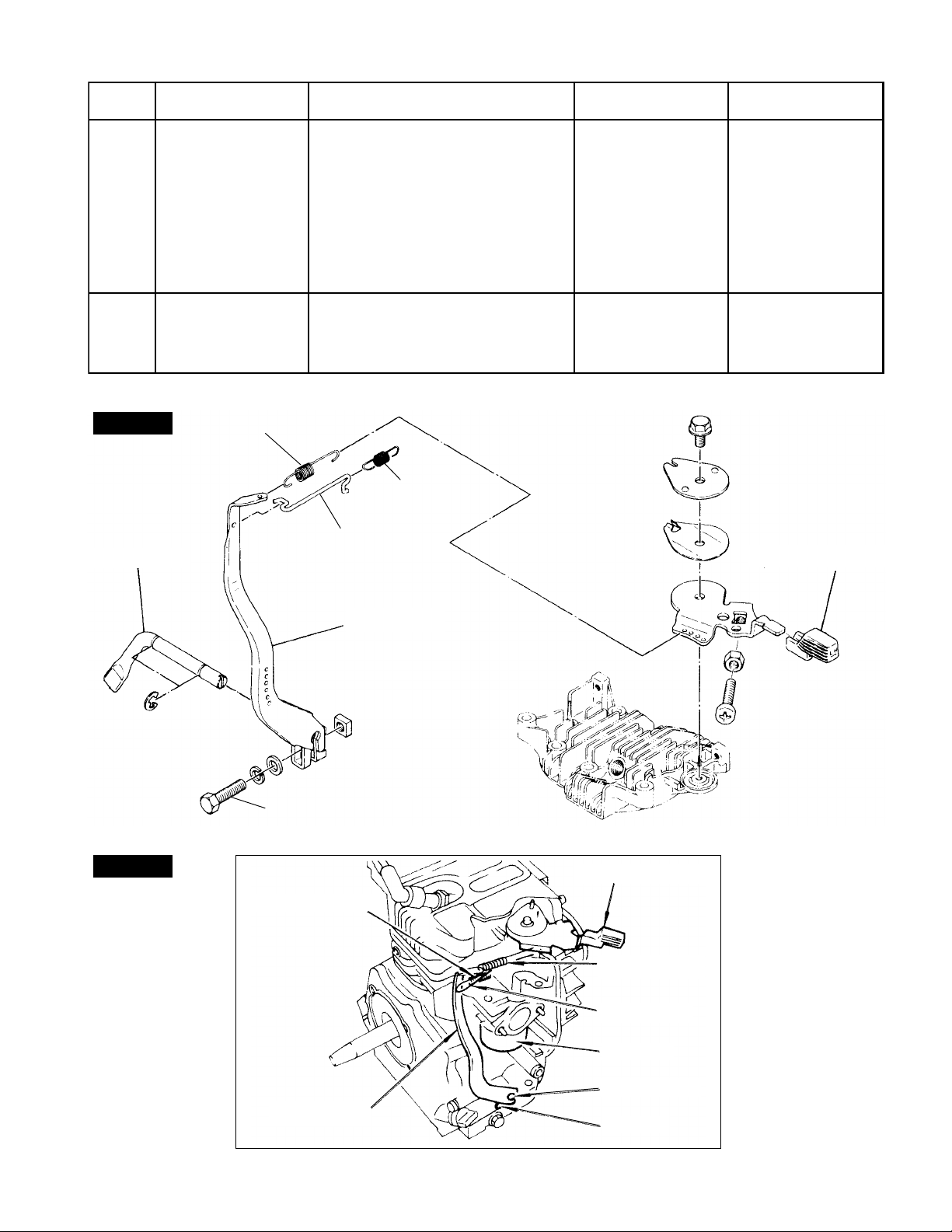

petSevomerotstraPserudecorPskrameRlooT

8

9

STEP 8

Governor Shaft

strap

roterubraC)1(morfroterubracehtevomeR

Governor Spring

reveLronrevoG

evitalerehtdna

Governor Rod

)1(

evomerdnatlobehtnesooL

ehtmorfrevelronrevogeht

.tfahsronrevog

.cp1:tloB52x6M

)2(

dorronrevogehtevomeR

.tlob

ehtnesooltsuJ

yrassecennu,tlob

ehttuoekatot

rennapsxoBmm01

rennapSmm01ro

ehtmorfgnirpsdordna

.roterubrac

ehtfonoitroprednilyceht

.esacknarc

Rod Spring

Speed Control Lever

STEP 9

Governor Lever

Fig. 5-5

M6 x 25 Bolt : 1 pc.

Speed Control Lever

Rod Spring

Governor Spring

Governor Rod

Carburetor

Governor Lever

Governor Shaft

Bolt

-

15

-

Fig. 5-6

Page 19

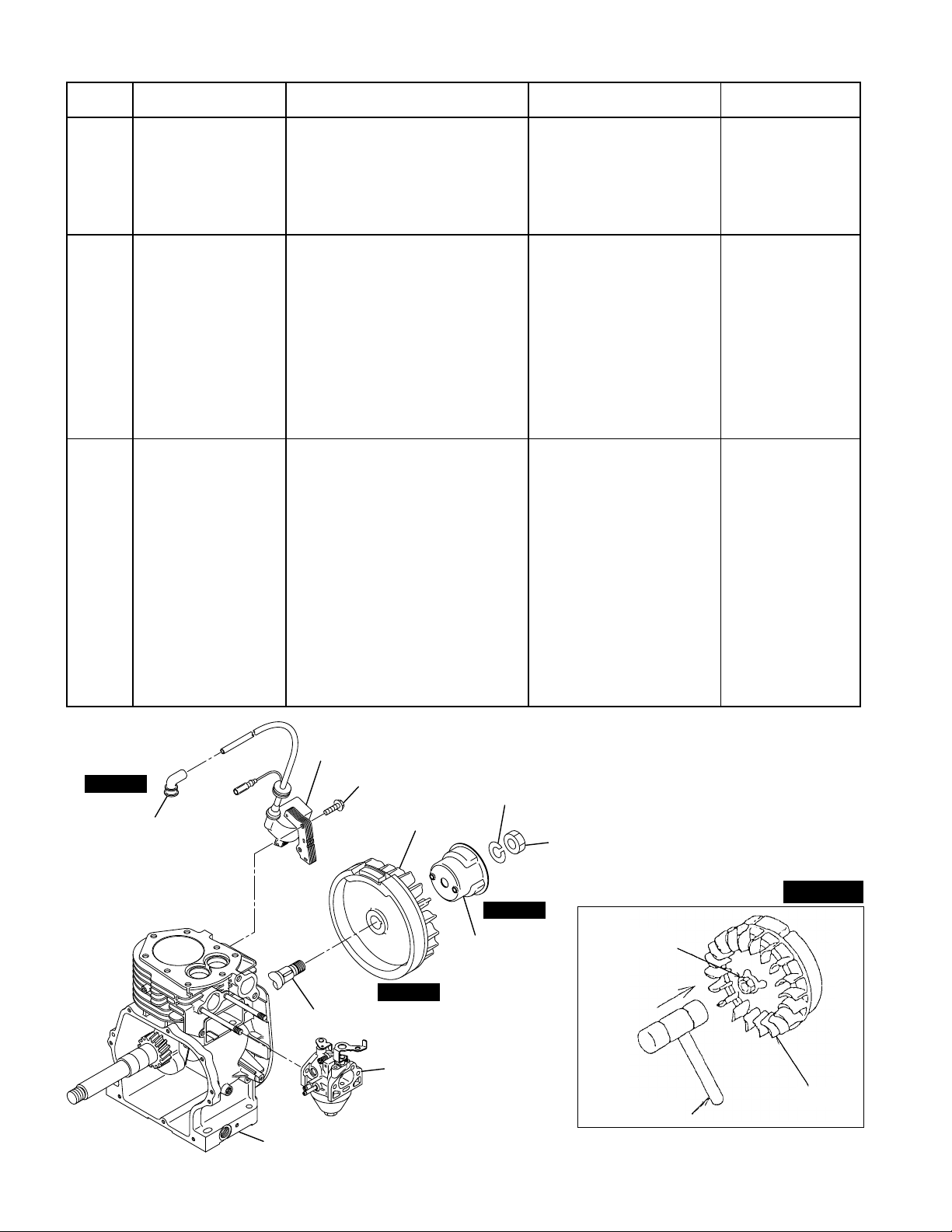

petSevomerotstraPserudecorPskrameRlooT

lioCnoitingI)1(gulpkrapsehtevomeR

tlobsmeS

rennapsxoBmm01

,gulpkrapsehtmorfpac

01

noitingiehtevomerdna

.esacknarcehtmorflioc

.scp2:tloB52x6M

yelluPgnitratS)1(gnitratsehtevomeR

.leehwylfehtmorfyellup

.cp1:tuN41M

tekcosroxobatiF

11

leehwylfehtrevohcnerw

drahtiekirtsdna,tun

ottonluferaceB

fosedalbehtegamad

ahtiwleehwylfeht

ekirtS.ekiladnarevird

htiwesiwkcolcretnuoc

.remmaha

rennapsxoBmm91

hcnerwtekcoSro

otremmahahtiw

)mm41(tunehtevomer

.rehsawgnirpsdna

leehwylF)1(

)1(

ehtelbmessayllaropmeT

ehtottungnixif

litnudaerhttfahsknarc

)2(

.ecafdneeht

)2(

21

ahtiwtungnixifehtpaT

otremmahcitsalP

.leehwylfehtevomer

.remmah

yltceridpattonoD

.remmahleetsahtiw

ottonluferaceB

daerhtehtegamad

gnisunehwnoitrop

.remmahleetsa

tungnixifehtpaT

gnitresniretfa

rabmunimula

gnixifehtneewteb

leetsadnatun

STEP 10

Spark Plug Cap

Ignition Coil

Crankshaft

Crankcase

M6 x 25 Bolt : 2 pcs.

Flywheel

STEP 12

Carburator

Fig. 5-7

-

Spring Washer

STEP 11

Starting Pulley

16

-

M14 Nut : 1 pc.

STEP 12

Fixing Nut

Flywheel

Hammer

Fig. 5-8

Page 20

petSevomerotstraPserudecorPskrameRlooT

gulPkrapS)1(gulpkrapsehtevomeR

31

daeHrednilyC)1(

.daehrednilycehtmorf

dnatlobmm8ehtevomeR

rennapsxoBmm12

rennapsxoBmm21

daehrednilycehtevomer

41

)2(

.esacknarcehtmorf

.scp8:tloB04x8M

daehrednilycehtevomeR

.esacknarcehtmorfteksag

dnaekatnI

evlaVtsuahxE

51

)1(

revocteppatehtevomeR

morfetalprehtaerbehtdna

.esacknarceht

.scp2:tloB21x6M

)2(

dnaekatniehttuolluP

.edis

.evlavtsuahxe

)3(

gnirpsevlavehtevomeR

.reniaterevlavehtdna

.uoy

gniraeBniaM

revoC

)1(

fotlobgnixifehtevomeR

morfrevocgniraebniameht

ehtnohctonehttuP

foecnerefmucricretuo

sihtnoreniatergnirpseht

)-(ezismuidemehtkooH

rewol(tnedehttarevird

gnirpsehtfo)edis

ehttuollupdnareniater

ehtgnillupelihw,sevlav

drawotreniatergnirps

.edis

revirD)-(

rennapsxoBmm01

sihtsitnorfehT

rennapsxoBmm01

.esacknarceht

61

)2(

.scp8:tloB03x6M

ylthgil,revocehtevomeR

ylneverevocehtgnippat

ottonluferaceB

.laeslioehtegamad

.remmahcitsalpahtiw

M8 x 40 Bolt : 8 pcs.

STEP 13

Spark Plug

Main Bearing Cover

STEP 16

Oil Gauge

M6 x 30 Bolt : 8 pcs.

STEP 14

Crankcase

Fig. 5-9

Cylinder Head

Intake & Exhaust Valve

STEP 15

Breather Plate

Tappet Cover

Drain Plug

M6 x 12 Bolt : 2 pcs.

-

17

-

Page 21

Push the Valve

(-) Driver

Plastic Hammer

Fig. 5-10 Fig. 5-11

Polyvinyl tape

Main Bearing Cover

petSevomerotstraPserudecorPskrameRlooT

71

81

Intake Valve

tfahsmaC)1(morftfahsmacehtevomeR

teppaT)1(morfsteppatehtevomeR

Exhaust Valve

Valve Spring

Spring Retainer

Tappet

STEP 18

steppatehttneverpoT

.esacknarceht

,gnigamadrognillafmorf

ehtotesacknarcehttup

.nwodedisleehwylf

atup,gnivomererofeB

.esacknarceht

tsuahxeroekatnifokram

.teppathcaeno

Camshaft

Governor Gear

Fig. 5-12

STEP 17

Camshaft

Tappet

Fig. 5-13

-

18

-

Page 22

petSevomerotstraPserudecorPskrameRlooT

doRgnitcennoC

notsiPdna

)1(

rehtodnanobracffoeparcS

reppuehtmorfstisopedngierof

,notsipdnarednilycehtfostrap

mm01

rorennapsxoB

rennapSmm01

foseceipowtevomernehtdna

.tlobdorgnitcennoc

)2(

91

dnareparcslioehtevomeR

ehtmorfpacdorgnitcennoc

.tfahsknarc

)3(

ehtlitnutfahsknarcehtnruT

daedpototsemocnotsip

gnitcennoctuohsupdna,retnec

ehtmorfylbmessanotsipdnador

.rednilycfopot

gniRdnanotsiP)1(

ehttuollup,spilcowtehtevomeR

ffonotsipehtekatdna,nipnotsip

ehtfodnellamsehtmorf

02

)2(

.dorgnitcennoc

ehtfosdnenepoehtdaerpS

mehtevomerdnasgnirnotsip

.notsipehtmorf

ottonluferaceB

ybsgnirehtkaerb

ootgnidaerps

.hcum

tfahsknarC)1(

ehtrof(yekffurdoowehtevomeR

.)otengam

12

)2(

fodneleehwylfehtnoylthgilpaT

.laes

ottonluferaceB

lioehtegamad

otremmahtfosahtiwtfahsknarc

.esacknarcmorftievomer

Clip

Piston Pin

Woodruff Key

STEP 20

STEP 19

Piston Ring

Piston

Connecting Rod

STEP 21

Crankshaft

Fig. 5-14

Oil scraper

Connecting Rod Bolt : 2 pcs.

-

19

-

Page 23

5-4 REASSEMBLY PROCEDURES

● PRECAUTIONS FOR REASSEMBLY

1) Clean parts thoroughly before reassembly.

Pay most attention to cleanliness of piston, cylinder, crankshaft, connecting rod and bearings.

2) Scrape off all carbon deposits from cylinder head, piston top and piston ring grooves.

3) Check lip of oil seals. Replace oil seal if the lip is damaged. Apply oil to the lip before reassembly .

4) If the gasket is stuck on the mount ing surface, remove it carefully by ta king care not to damage the

surface.

5) Replace all the gaskets with new ones.

6) Replace keys, pins, bolts, nuts, etc., if necessary.

7) Torque bolts and nuts to specification refer to the "TORQUE SPECIFICATIONS" (See page 56).

8) Apply oil to rotating and sliding portions.

9) Check and adjust clearances and end plays where specified in this manual.

10) When the main parts are assembled, check the movement and sound by rotating it manually .

5-4-1 CRANKSHAFT

(1) Insert crankshaft in ball bearing of crankcase

wrapping the key-way with polyvinyl tape to

avoid damage to oil seal.

(2) Install woodruff key for flywheel on crankshaft.

5-4-2 PISTON AND PISTON RINGS

1) If no ring expander is available, install the ring

by placing the open end over the first land of

the piston, and spreading the ring only far

enough to slip it over the correct ring groove.

NOTE : Pay attention not to break the rings by

twisting. Install the oil ring first followed by the

second ring and then top ring. The surfaces of

the second ring and the top ring with marks are

to be faced up.

Crankshaft

Polyvinyl tape

Fig. 5-15

Open End of

Piston Ring

Fig. 5-17

-

20

-

Page 24

3-51YE3-02YE

gniRpoT

lerraB

ecaF

repaT

dna

gniRdnoceStuCrednUrepaT

gniRliO

gniRrettuC

rednapxElioChtiw

Table. 1

2) Reassemble the piston and connecting rod with the piston pin.

NOTE :Apply enough oil to the small end of the connecting rod. Be sure to place the clips on both

sides of the piston pin.

3) When installing the connecting rod assembly

into the cylinder, hold piston rings with the ring

guide as shown in Fig.5-18 (if no ring guide is

available, keep pressing the piston rings with

Connecting Rod

Piston Ring Guide

Mark

finger tips and gently strike the top of the piston with a plastic hummer or the like to push it

in), and check that the symbol or mark MAG

on the connecting rod is to face the flywheel

magneto side.

Crankcase

(Magneto Side)

levebrennl

NOTE : Apply enough oil to the piston rings,

connecting rod plain bearings and cylinder bore

Fig. 5-18

before assembly.

NOTE : The open ends of the piston rings must be 90°apart from each other before assembly.

5-4-3 CONNECTING ROD

1) Turn the crankshaft to the bottom dead center, lightly tap the piston head until the large end of connecting rod contacts the crankpin.

2) When reassembling the connecting rod cap,

match the alignment projection mark on the rod.

3) Oil scraper is to be set on the magneto side.

NOTE : After reassembly, confirm that the con-

necting rod moves lightly.

NOTE : Connecting rod cap tightening torque :

EY15-3 EY20-3

9-11.5N.m 17-22N.m

(90-115kg.cm) (170-200kg.cm)

(6.5-8.3ft.lb) (12.3-14.5ft.lb)

Alignment Mark

Fig. 5-19

Oil Scraper

-

21

-

Page 25

5-4-4 TAPPET AND CAMSHAFT

Insert the tappets into the crankcase holes first,

and then mount the camshaft.

NOTE : Align the timing mark on the root of the

cam gear with the one on the crank gear. If the

valve timing is wrong, the engine cannot operate

properly or at all.

NOTE : If the intake tappet and exhaust tappet

were assembled opposite each other, the tappet

clearance cannot be kept correctly.

Timing Mark

Timing Mark

5-4-5 MAIN BEARING COVER

Fig. 5-20

Install the main bearing cover to the crankcase.

NOTE: As the governor gear is mounted on the main bearing cover side, install the main bearing cover

with checking that the governor gear meshes with the cam gear. (See Fig.5-21&22.) If the oil seal needs

to be replaced, press-fit a new oil seal before installing the main bearing cover.

Pay attention to the engagement of

the governor gear and cam gear

Governor Gear

Fig. 5-21

Fig. 5-22

NOTE: When installing the main bearing cover,

apply oil to the bearing and oil seal lip. Wrap the

keyway of crankshaft with polyvinyl tape to avoid

damage to the oil seal lip. Then place the main

bearing cover on.

Check that the crankshaft side clearance is 0〜

0.2mm; and if not, adjust it with the adjusting

shims.

Main Bearing Cover Tightening torque

8-10N・m

(80-100kg・cm)

(5.8-7.2ft・lb)

-

22

Adjusting Shim

Main Bearing Cover

Polyvinyl tape

Packing

Fig. 5-23

-

Page 26

NOTE: Fig 5-24 shows one of the methods measuring the crankshaft side clearance between the

machined face of the crankcase and shims. As a

paper packing is used on the machined face of

the crankcase, adjust the clearance by taking this

thickness of 0.22mm into account.

Dial Indicator

Ground Surface of Crankcase

5-4-6 INTAKE AND EXHAUST VALVES

Fig. 5-24

Remove carbon and gum deposite from the valves, valve seats, intake and exhaust ports and valve

guides.

NOTE: If the valve face is dinted or warped, replace the valve with new one.

NOTE: If there is an excessive clearance between the valve guide and valve stem, replace the valve

guide with a spare. For replacing, pull out the valve guide, using the valve guide puller as shown in Fig.

5-26, and press fit a new valve guide into place.

Valve Guide Puller

Valve Guide Puller

Crankcase

Valve Guide

Fig. 5-25

Fig. 5-27

Valve Guide

Fig. 5-26

ELGNAECAFEVLAV-A °54

ELGNATAES-B °54

.AIDEDISNIEDIUG-C

EKATNI

.AIDEDISTUOMETSEVLAV-D

TSUAHXE

ELBAWOLLAMUMIXAM

DdnaCNEEWTEBECNARAELC

ELGNATLITMETSEVLAV-E"35°3

EKATNIL260.0~L520.0

TSUAHXEL001.0~L650.0

Table. 2

-

23

-

Nut

3-02YE3-51YE

220.0+.aid5.6

0

520.0-.aid5.6

040.0-

650.0-.aid5.6

870.0-

L : LOOSE

Page 27

5-4-7 TAPEET ADJUSTMENT

Lower the tappet all the way down, push the valve, and insert a thickness gauge between the valve and

tappet stem to measure the clearance. (See Fig.5-28.)

NOTE: The correct tappet clearance for both intake and exhaust valves is 0.1mm ±0.02mm when the

engine is cold.

Valve Spring

Thickness Gauge

(0.1mm ±0.02)

Valve

Tappet

Fig. 5-28 Fig. 5-29

Intake, Exhaust Valve

Spring Retainer

NOTE: If the clearance is smaller than specified, slightly grind the top of the valve stem, and measure it

again. On the contrary if the clearance is too large, replace the valve with new one, and polish its contact

surface with a compound to obtain a good fit. Then adjust the clearance.

NOTE: After the tappet clearance adjustment, install the valve springs and spring retainers, and turn the

crankshaft, and measure the tappet clearance once again if it is correct.

NOTE: INSTALLATION of SPRING RETAINERS

Place the notch on the outer circumference of the spring retainer toward this side and insert the retainer,

like pushing in, using a special tool. (Valve Spring Retainer)

(-) Driver

Front should be this side

Valve Spring Retainer

Fig. 5-30

Fig. 5-31

-

24

-

Page 28

k

5-4-8 CYLINDER HEAD

Remove carbon from the cylinder head, particularly its combustion chamber, and clean the cooling fins.

Also check the head surface for flatness.

If the gasket is stuck on the upper surface of crankcase and on the cylinder head, separate it carefully by

taking care not to damage the mating surface.

NOTE: Replace the cylinder head gasket with a new one.

NOTE: DISTINGTION between the GASKET of EY 15-3 and EY20-3

The pitch of the mounting holes and the outer circumference dimensions of the gasket for EY15-3 and

EY20-3 are same. However, the inner dimensions are different each other.

Furthermore, the marking is provided at the position shown below for identification.

15

EY15-3

"15" mark "20" mar

Fig. 5-32

With 8 pieces of 8mm bolt fasten the cylinder head.

Cylinder Head Tightening torque

22-26N・m

(220-260kg・cm)

(15.9-18.8ft・lb)

NOTE: DISCRIMINATION of CYLINDER HEAD

As stated above, the pitch of the holes of cylinder

head is common to both EY15-3 and EY20-3. For

enabling to discriminate the cylinder head of EY153 from that of EY20-3, an embossed mark 15 is

given to the EY15-3 cylinder head, while no embossed mark is given to the EY20-3 cylinder head.

NOTE: Embossed mark for

EY15-3 Kerosene engine is 15-K, and

EY20-3 Kerosene engine is 20-K.

20

EY20-3

Embossed mark

Fig. 5-33

5-4-9 SPARK PLUG

Install spark plug to cylinder head.

Spark plug : NGK B6HS or BR6HS

NEW SPARK PLUG RETAIGHTENING

12-15N・m 23-27N・m

(120-150kg・cm) (230-270kg・cm)

(8.7-10.8ft・lb) (16.6-19.5ft・lb)

-

25

-

Page 29

5-4-10 IGNITION COIL, FLYWHEEL AND STARTER PLLEY

Fit the flywheel on to the crankshaft.

Also, fasten the starter pulley together with the flywheel.

NOTE: Before installing, wipe out oil from the crankshaft and the tapered portion of the flywheel.

Flywheel Tightening torque

60-65N・m

(600-650kg・cm)

(43.4-47.0ft・lb)

Ignition Coil

Fasten the ignition coil to the crankcase temporarily and adjust air gap between the ignition coil and the flywheel, then fasten the ignition coil tightly.

Air gap: 0.3 ~ 0.5mm

Thickness Gauge

5-4-11 CARBURETOR

Fig. 5-34

To the cylinder portion of the crankcase, install the gasket, insulator, gasket and carburetor in order , and

then mount the air cleaner case and fasten them with two pieces of 6mm nut.

(0.5mm)

5-4-12 GOVERNOR LEVER

When reassembling, refer to the 6. GOVERNOR ADJUSTMENT.

5-4-13 MUFFLER AND MUFFLER COVER

If the muffler gasket is stuck to the crankcase and to the muffler flange surface, remove it carefully by

taking care not to damage the surfaces.

Be sure to replace the muffler gasket with a new gasket.

Install the muffler to the cylinder with 2 pieces of stainless steel nuts, then mount the muffler cover.

5-4-14 HEAD COVER, FUEL TANK AND BLOWER HOUSING

Install the head cover, fuel tank and blower housing in order.

NOTE: If these parts are installed in the order of the head cover, blower housing and fuel tank, removal

of the blower housing would be impossible.

5-4-15 RECOIL STARTER

Fasten the recoil starter with 4 pieces of M6 x 8 mm bolt.

NOTE: It is feared that the bolt longer than 8mm may damage the blades.

Install the plastic recoil for the pump specification of model EY15-3 with 4 pieces of

M6 x 12 mm bolt.

-

26

-

Page 30

5-5 BRAKE-IN OPERATION OF REASSEMBLED ENGINE

An overhauled engine must be operated at low speed to break-in the parts. A thorough break-in is indispensable particularly when the cylinder, piston, piston rings or valves are replaced with new ones.

The recommended break-in schedule is shown below.

petSdaoLdeepSenignEemiT

1petS daoLoNmpr005,2.nim01

2petS daoLoNmpr000,3.nim01

3petS daoLoNmpr006,3.nim01

3-51YE)PH53.1(Wk0.1

4petS

mpr006,3.nim03

3-02YE)PH57.1(Wk3.1

3-51YE)PH7.2(Wk0.2

5petS

mpr006,3.nim06

3-02YE)PH5.3(Wk6.2

Table. 3

-

27

-

Page 31

6. GOVERNER ADJUSTMENT

Models EY15-3 and EY20-3 employ a centrifugal flyweight type governor. The governor is mounted on

the governor gear and the throttle valve of the carburetor is automatically regulated by a lever which is

connected to the governor in order to maintain constant engine speed against load variations.

The adjustment procedure of the governor is as follows (See Figs. 6-1 and 6-2.):

1) Connect the carburetor throttle lever to the

governor lever with the governor rod and rod

spring, and mount the governor lever onto the

governor shaft.

2) Install the speed control lever to the cylinder

head.

3) Connect the governor lever to the speed control lever with the governor spring.

Speed Control Lever

Long Hook

High Speed

Rod Spring

Governor Lever

Speed Control

Lever

Governor

Spring

Governor

Rod

Carburetor

Governor

Shaft

Bolt

Fig. 6-1

Governor Spring

Governor Lever

Fig. 6-3

*The hole where the governor spring is to be

hooked :

For EY15-3 the governor spring is to be hooked

to the hole 1, while it is to be hooked to the hole 2

for EY20-3.

4) Turn the speed control lever towards high

speed, and confirm that the carburetor throttle

valve is fully opened.

-

5) Insert a (

) screwdriver in the groove of the

governor shaft, turn it clockwise fully until the

governor shaft no longer moves, and then lock

the governor lever to the governor shaft with

the governor lever tightening bolt.

(See Fig.6-4)

Low Speed Stopper

(Carburetor)

Governor Lever

High Speed Stopper

(Speed Control Lever)

Fig. 6-2

Fig. 6-4

-

28

-

Page 32

*Dimensions of the governor spring for the engine to be connected to the generator:

The dimensions of the governor spring to be used are different each other according to the Hz.

The governor spring for the standard engine is same as that for the engine to be connected to the 60Hz

generator.

Discrimination according to the dimensions:

EY15-3/60Hz (Standard)

(a) 10 mm

(Longer Hook Side)

EY20-3/60Hz (Standard)

(a) 10 mm

(Longer Hook Side)

Fig. 6-5

EY15-3/50Hz

(A) 15 mm

(Longer Hook Side)

EY20-3/50Hz

(A) 15 mm

(Longer Hook Side)

*For EY15-3 and EY20-3, the governor spring longer in the length of (A) is for 50 Hz.

*Both ends of the spring for EY15-3 are bended to the same direction, while both ends of the spring for

EY20-3 are bended to contrary directions.

-

29

-

Page 33

7. CARBURETOR

7-1 OPERATION AND CONSTRUCTION (See Fig.7-1)

7-1-1 FLOAT SYSTEM

The float chamber is located just below the carburetor body, and the float (F) and the float valve (F.V)

maintain a constant fuel level during engine operation.

The fuel flows from the fuel tank into the float chamber through the float valve. When the fuel rises to a

specific level, the float (F) rises; and when its buoyancy and fuel pressure are balanced, the float valve

(F.V) close to shut off the fuel, thereby keeping the fuel at the reference level.

Slow Port

(S.P)

Idle Port

(I.P)

Slow Jet

(S.J)

Slow Air Bleed

(S.A.B)

Main Nozzle

(M.N)

Main Air Bleed

(M.A.B)

Choke

(C)

Throttle Valve

(T.H.V)

燃料Fuel

Float Valve

(F.V)

Main Jet

(M.J)

Fig. 7-1

-

30

Float

(F)

-

Page 34

7-1-2 SLOW SYSTEM

The pilot system feeds the fuel to the engine during idling and low-speed operation.

The fuel is fed through the main jet (M.J) to the slow jet (S.J), where it is metered, and mixed with the air

metered by the slow air bleed (S.A.B).

The fuel-air mixture is fed to the engine through the idle port (I.P) and slow port(S.P).

During engine idling, the fuel is mainly fed from the idle port (I.P).

7-1-3 MAIN SYSTEM

The main system feeds the fuel to the engine during medium and high-speed operation.

The fuel is metered by the main jet (M.J) and fed to the main nozzle (M.N). The air metered by the main

air bleed (M.A.B) is mixed with the fuel through the bleed holes in the main nozzle (M.N), and the mixture

is atomized out of the main bore. It is mixed again with the air taken through the air cleaner into an

optimum fuel-air mixture, which is supplied to the engine.

7-1-4 CHOKE

The choke (C) is used for easy start in the cold season. When the recoil starter is pulled with a closed

choke (C), the negative pressure applied to the main nozzle increases and draws much fuel accordingly;

thus easily start up the engine.

7-2 DISASSEMBLY AND REASSEMBLY (See Fig.7-2)

Apart from mechanical failures, most of carburetor troubles are caused by an incorrect mixing ratio,

which may arise mainly due to a clogged up air or fuel passage in jets, or fuel level variations. In order to

assure proper flow of air and fuel, the carburetor must be kept clean at all times. The carburetor disassembly and reassembly procedures are as follows.

-8

-22

-11

-32

-4

-3

-61

-15

-14

-18

-19

7-2-1 THROTTLE SYSTEM

(1) Remove the Philips screw (-2) and throttle

valve (-1), and pull out the throttle shaft (-1 1).

When reassemble the throttle valve, apply a

screw-lock agent to philips screw and tighten

it with a tightening torque of 0.39~1.47 N・m

(4~15 kg・cm) (0.3~1.1ft・lb).

(2) The spring (-41) can be taken out by removing

the throttle stop screw (-40).

*Exercise care not to damage throttle valve edge.

7-2-2 CHOKE SYSTEM

-40

-2

-1

-41

-5

(1) Remove the clip (-4) and choke valve (-3), and

pull out the choke shaft (-8).

(2) When mounting the choke valve, mark sure

that the cutout of the choke valve locates on

the right side when viewed from the outside.

-

31

-16

-17

-12

Fig. 7-2

-

Page 35

7-2-3 SLOW SYSTEM

(1) Remove the slow jet (-5), using correct tool to avoid damage to it.

(2) When fitting the slow jet, screw it in fully and turn it back, accurately by the rotation specified in the

table of correction standards.

7-2-4 MAIN SYSTEM

(1) Remove the bolt (-12) and take out float chamber body (-16).

(2) Remove the main jet (-22) from the body.

(3) Fasten the main jet securely to the body . Otherwise, the fuel may become too rich and cause engine

malfunction.

Main jet Tightening torque

0.98-2.94N・m

(10-30kg・cm)

(0.7-2.1ft・lb)

(4)

Bolt(-12) Tightening torque

7.85-11.77N・m

(80-120kg・cm)

(5.8-8.7ft・lb)

7-2-5 FLOAT SYSTEM

(1) Pull out the float pin (-15) and remove the float (-19) and float valve (-14).

CAUTION :

When cleaning the jets, use neither a drill nor a wire (because of possible damage of the

orifice which will adversely affect fuel flow). Be sure to use compressed air to blow them

clean.

NOTE ; Check that the gasket (float chamber) is correctly fitted before mounting the float chamber body.

-

32

-

Page 36

8. MAGNETO

8-1 FEATURES

Ignition system of the model EY15-3 and EY20-3 is a maintenance-free electronic pointless magneto

system.

The electronic circuit is based on the cut off of the electric current by power transistor, and employs

U.T.C.I. (Universal Transistor Control Ignition) circuit which always controls the ignition voltage to maximum.

Thanks to the U.T.C.I., the ignition performance is always stable against environmental changes such as

temperature, etc..

8-2 BASIC PRINCIPLE OF U.T.C.I.

ROBIN electronic ignition system consists of the

ignition coil with built-in U.T.C.I. circuit and the flywheel magnet.

(1) When the flywheel rotates and the magnet

passes the ignition coil, magnetic flux changes

to induce voltage across the primary ignition

coil.

Resultant electric current in the primary coil

is switched by power transistor in the circuit.

(2) When the flywheel rotates further to the igni-

tion timing, ignition timing detection circuit is

activated to turn on the thyristor which cut off

the current to the power transistor suddenly.

The U.T.C.I. controls to cut off the current induced in the primary always at around the

maximum level.

(3) Sudden cut off of primary current induces a

high voltage across the secondary coil to

spark the spark plug.

Spark Plug

Secondary Coil

Spark Plug

Flywheel

Primary Coil

Stop Switch

Fig. 8-1

BLACK

Ignition Coil

Oil Sensor

Fig. 8-2

Ignition timing

detection circuit

Thyristor

Power transistor

Stop Switch

-

33

-

Page 37

8-3 MAGNETO TROUBLESHOOTING

When the engine does not start or starts with difficulty, or when its operation is unstable, the following

checks will clarify if they are caused by a defect of the magneto.

(1) Check ignition cable for possible damage, worn insulator or loose connection.

(2) Check the spark.

1) Remove the spark plug from the cylinder head and connect the spark plug to the plug cap, then

ground it to the cylinder head or the like (The correct gap of electrodes is 0.6 ~ 0.7mm).

2) Pull the recoil starter to rotate the flywheel to check the spark of the spark plug and spark intensity

(disconnect primary wiring at the connector before the test).

3) If no spark is found between the plug electrodes, remove both the plug and the plug cap and place

the tip of ignition (high voltage) cable a few mm away from the cylinder head to check the spark

from the cable tip when the recoil starter is pulled.

-

34

-

Page 38

9. OIL LEVEL SENSOR (OPTION)

9-1 FUNCTION

When the oil level sensor detects the insufficient level of engine oil, it halts engine for warning and

protection of engine.

9-2 PRINCIPLE

(1) Though it is very little, engine oil has electrical conductivity, while air is completely nonconductive.

Utilizing this difference, presence of oil is identified by the current between electrodes of the sensor .

(2) On the basis of this principle the sensing elements are merely fixed electrodes without mobile part,

hence, it is possible to conduct reliable measurement without influence of vibration. And it is also

shockresistant and free of deterioration.

Outer electrode

Inner electrode

Conduction

-

Fig. 9-1

35

-

In case of no oil

Page 39

10. RECOIL STARTER

10-1 RECOIL STARTER (STEEL)

Tools to be prepared: Driver, Pinchers (Pliers) and Protective Glasses

WARNING

Before starting the disassembly, make sure to wear the protective glasses.

10-1-1 DISASSEMBLY STEPS

(1) Relieve the spring power

-1: Hold the starter knob and extract the starter

rope.

-2: Extract the rope fully and hold the rope so

that the knot of the rope in the reel makes

a straight line with the rope guide.

-3: Hold the reel with the thumbs of both hands

firmly so that the rope will not be wound

back. (Fig.10-1)

-4: Pull out the knot of the rope out of the reel,

and unfasten the knot and pull it out toward

the starter knob. (2 people required)

-5: By controlling the reel with the thumbs of

both hands, unwind the reel gently until the

rotation of the reel stops.

WARNING

The spring power is at its maximum when the

rope is fully extracted. Do not put off your hand

nor loosen the pressure of your finger suddenly.

(2) Remove the component parts (Fig.10-2)

-1: Loosen the set-screw.

-2: Remove the set-screw, the latchet guide,

the friction spring and the latchet.

Fig. 10-1

Set Screw

Ratchet

Guide

Friction

Spring

Ratchet

Reel

(3) Remove the reel (Fig.10-2)

-1: Hold the reel lightly so that it will not float.

Move the reel clockwise and counter-clockwise about a quarter circle for several times

until it moves smoothly.

Starter

case

Fig. 10-2

-

36

-

Page 40

-2: Hold up the reel gradually and slowly and

remove it from the case.

-3: If the spring in the reel likes to jump out,

redo the steps of (3)-1 and (3)-2 again.

WARNING

Do not drop nor shake the reel. Put it on a level table because the spring is set in the

disassembled reel.

Disassembly is completed.

WARNING

Before starting the assembly, make sure to wear the protective glasses.

10-1-2 ASSEMBL Y STEPS

(1) Setting the reel into the case.

-1: Apply grease to the case. (Fig.10-3)

-2: Adjust the position of the inner end of the

spring, which is set in the reel. (Fig.10-3)

Grease

-3: Hold the reel so that the hook and the inner

end of the spring are hooked together.

Set the reel gently from the above into the

case.

-4: Move the reel slightly counter-clockwise and

make sure the spring is hooked.

(2) Assemble the component parts.

-1: Set the latchet into the reel. (Fig.10-4)

Hook

The end of the spring touches

the rib of the bearing.

Fig. 10-3

Set the latchet to the close-position

Fig. 10-4

-

37

-

Page 41

-2: Holding the latchet position, mount the

latchet-guide sub-assembly. (Fig.10-5)

Set screw

(3) Tightening the set-screw.

-1: Push the latchet-guide lightly by hand so

that the latchet guide won’t move and

tighten the set-screw.

(4) Storing the spring-power.

-1: Hold the case tightly and wind up the reel

counter-clockwise 6 times by both hands.

-2: Hold the reel at the position where the rope

hole of the reel and the rope guide make a

straight line. (Fig.10-6)

WARNING

The spring power is at its maximum when the

reel is being wound. Do not put off your hand

nor loosen the pressure of your finger unintentionally.

(5) Setting the rope. (2 people required)

Ratchet guide

Friction Spring

LATCHET GUIDE SUB-ASSEMBLY

Fig. 10-5

About 200mm from the reel

-1: Pass the rope end through the rope guide

and the rope hole of the reel and pull the

end about 20cm out of the reel. (Fig.10-6)

-2: Fasten the rope end. (Fig.10-7)

-3: Put the rope end into the reel, whereby

make sure that the rope end will not float.

(Fig.10-8)

-4: Hold the rope firmly with the hand at the

position about 50 cm from the rope guide

and keep the rope slightly pull so that the

rope will not be wound in.

-5: Release the hand of the reel gently and wind

the rope slowly by the winding power of the

spring until the knob reaches the rope

guide.

Assembly is completed.

Fig. 10-6

About 20mm

Fig. 10-7

*The disassembly and the reassembly have been

completed, however carry out the following to

check if the necessary components have surely

been assembled.

-

38

Fig. 10-8

-

Page 42

10-1-3 CHECK AFTER REASSEMBLY

(1) Pull the starter knob a few times to check if :

A. The starter knob is too heavy to pull, check that each part has been assembled as specified.

B. The ratchet does not function, check if parts such as friction spring have been missing.

(2) Pull the starter knob and pull out the rope fully to see if:

A. If the starter rope remains in the groove of the reel, immoderate strain is imposed to the spiral

spring. Pull out the rope by approx. 30 cm, and pull it out toward inner side of the recoil starter with

holding the reel firmly with your thumb.

Then rewind the reel 1 to 2 turns while applying a brake with your thumb.

B. The return power of the rope is weak or the starter knob droops on the way, apply grease or mobile

oil to the rotating and the frictional parts.

If the problem is not solved, wind the reel 1 to 2 turns. (In this case, check that the spring is not over-

stressed.)

C. The spring comes off with a sound and the starter rope cannot be wound in the reel, reassemble

the starter from the beginning.

10-1-4 OTHER GUIDES

(1) When the spring jumps out of the reel:

With a thin wire, make a ring whose diameter

is smaller than spring housing.

Hook the outer end of the spring to the ring

and re-wind the spring into the wire ring as

shown in Fig. 10-9, then put it into the spring

housing of the reel.

Remove the ring slowly while holding down

the spring with fingers so as not to come out

of place.

The ring can easily be removed by prying it

with the tip of a screwdriver.

If the wire ring is not available, re-wind the

spring directly into the housing.

(2) Lubricate the rotating and frictional parts with

grease (If possible, heat-resistant type is preferable) or mobile oil when the starter is disassembled or prior to long term storage.

Wire ring

Spring

Fig. 10-9

-

39

-

Page 43

10-2 RECOIL STARTER (SYNTHETIC RESINS)

Tools to be prepared: Driver, Pinchers (Pliers) and Protective Glasses

WARNING

Before starting the disassembly, make sure to wear the protective glasses.

10-2-1 DISASSEMBLY STEPS

(1) Relieve the spring power

-1: Hold the starter knob and extract the starter

rope.

-2: Extract the rope fully and hold the rope so

that the knot of the rope in the reel makes

a straight line with the rope guide.

-3: Hold the reel with the thumbs of both hands

firmly so that the rope will not be wound

back. (Fig.10-10)

-4: Pull out the knot of the rope out of the reel,

and unfasten the knot and pull it out toward

the starter knob. (2 people required)

-5: By controlling the reel with the thumbs of

both hands, unwind the reel gently until the

rotation of the reel stops.

WARNING

The spring power is at its maximum when the

rope is fully extracted. Do not put off your hand

nor loosen the pressure of your finger suddenly.

(2) Remove the component parts (Fig.10-11)

-1: Fix the case and loosen the set-screw.

-2: Remove the set-screw, the friction plate, the

friction spring and the latchet in the order

from the above.

(3) Remove the reel. (Fig.10-11)

-1: Hold the reel lightly so that it will not float.

Move the reel clockwise and counter-clockwise about a quarter circle for several times

until it moves smoothly.

Fig. 10-10

Fig. 10-11

-

40

-

Page 44

-2: Hold up the real gradually and slowly, and remove it from the case.

-3: If the spiral spring in the reel likes to jump out of the reel, stop the procedure and push the

reel against the case to redo the step of section (3)-1 and (3)-2.

WARNING

Since the spiral spring is set in the reel, do not drop or shake it. Put it on a flat place.

Disassembly is completed.

WARNING

Before starting the assembly, make sure to wear the protective glasses.

10-2-2 ASSEMBL Y STEPS

(1) Setting the reel into the case.

-1: Peep at the boss of reel to check the inner

end of the spring.

-2: Hook the inner end of spring to the hook of

case and put the reel into the case.

(Fig.10-12)

(2) Assemble the component parts.

-1: Put the ratchet in the reel so that the receiving area of the reel is within the area

illustrated in Fig.10-13.

-2: Assemble the friction spring to the shaft in

the case.

-3: Insert the legs of friction plate (2 places) in

ratchet holes. (Fig.10-14)

(3) Tighten the center screw. (2 people required

for this step.)

-1: Adjust the tip of center shaft to the hole of

friction plate and compress the friction

spring by pushing the friction plate with your

fingers.

-2: Tighten the center screw counterclockwise

(as it is reverse screw).

WARNING

Wear work gloves during operation to avoid a

possible injury by a sharp edge of the friction

plate.

Hook of Case

Ratchet

Claw

Receiving

area of

the Reel

Leg of

Friction plate

Inner end

of spring

Boss of real

Fig. 10-12

Within this area

Fig. 10-13

Ratchet hole

Fig. 10-14

-

41

-

Page 45

(4) Wind the spiral spring.

-1: Hold the case tightly and rotate the reel

counterclockwise until it stops. (It stops

when it is wound approx. 6 turns.)

-2: Turn back the reel slowly by approx. 3/4

turns and hold the reel at the position where

the rope hole of the reel and the rope guide

of the case are aligned.

WARNING

The spring power is at its maximum when the

reel is being wound. Do not put off your hand

nor loosen the pressure of your finger unintentionally.

(5) Setting the rope. (2 people required)

-1: Pass the rope end through the rope guide

to the rope hole on the reel and make a

knot as shown in Fig.10-15.

ABOUT

20 mm

-2: Put the rope-end-knot in the reel paying

attention that it will not touch the case.

(Fig.10-16)

-3: Hold the rope firmly with the hand at the

position about 50cm from the rope guide

and keep the rope slightly pull so that the

rope will not be wound in.

-4: Release the hand of the reel gently and wind

the rope slowly by the winding power of the

spring until the knob reaches the rope

guide.

Assembly is completed.

*The disassembly and the reassembly have been

completed, however carry out the following to

check if the necessary components have surely

been assembled.

Fig. 10-15

Rope-end

Fig. 10-16

-

42

-

Page 46

10-2-3 CHECK AFTER REASSEMBLY

(1) Pull the starter knob a few times to check if :

A. The starter knob is too heavy to pull, check that each part has been assembled as specified.

B. The ratchet does not function, check if parts such as friction spring have been missing.

(2) Pull the starter knob and pull out the rope fully to see if:

A. If the starter rope remains in the groove of the reel, immoderate strain is imposed to the spiral

spring. Pull out the rope by approx. 30 cm, and pull it out toward inner side of the recoil starter with

holding the reel firmly with your thumb.

Then rewind the reel 1 to 2 turns while applying a brake with your thumb.

B. The return power of the rope is weak or the starter knob droops on the way, apply grease or mobile

oil to the rotating and the frictional parts.

If the problem is not solved, wind the reel 1 to 2 turns. (In this case, check that the spring is not over-

stressed.)

C. The spring comes off with a sound and the starter rope cannot be wound in the reel, reassemble

the starter from the beginning.

10-2-4 OTHER GUIDES

(1) When the spring jumps out of the reel:

With a thin wire, make a ring whose diameter

is smaller than spring housing.

Hook the outer end of the spring to the ring

and re-wind the spring into the wire ring as

shown in Fig. 10-17, then put it into the spring

housing of the reel.

Remove the ring slowly while holding down

the spring with fingers so as not to come out

of place.

The ring can easily be removed by prying it

with the tip of a screwdriver.

If the wire ring is not available, re-wind the

spring directly into the housing.

(2) Lubricate the rotating and frictional parts with

grease (If possible, heat-resistant type is preferable) or mobile oil when the starter is disassembled or prior to long term storage.

Wire ring

Spring

Fig. 10-17

-

43

-

Page 47

11. INSTALLATION

Engine life, ease of maintenance and inspection, frequency of checks and repairs, and operating cost

are all depend on the way in which the engine is installed. Review the following instructions carefully for

installing the engine.

11-1 INSTALLING

When mounting the engine, carefully examine its position, the method of connecting it to a machine, the

foundation, and the method of supporting the engine.

When determining its mounting position, in particular, make sure that gasoline and oil can easily be

supplied and checked, the spark plug can easily be checked, the air cleaner can easily be serviced, and

that the oil can easily be discharged.

11-2 VENTILATION

Fresh air is necessary for cooling the engine and burning the fuel.

In the case the engine is operated under a hood or in a small room, temperature rise in the engine room

can cause vapor lock, oil deterioration, increased oil consumption, loss of power, piston seizure, shorter

engine life, etc., making it impossible to operate the engine properly . It is necessary, therefore, to provide

a duct or baffle to guide cooling air to the engine to prevent recirculation of he hot air used for engine

cooling, and temperature rise of the machine. Keep the engine room temperature below 50°C even in the

hottest period of the year.

11-3 EXHAUST GAS DISCHARGE

Exhaust gas is noxious. When operating the engine indoors, be sure to discharge the exhaust gas

outdoors. If a long exhaust pipe is used in such a case, the internal resistance increases causing loss of

engine power. Thus pipe inside diameter must be increased in proportion to exhaust pipe length.

Exhaust pipe : Less than 3 m long, pipe inside diameter 30 mm,

Less than 5 m long, pipe inside diameter 33 mm.

NOTE:Fit safety covers to the exhaust pipe and to the muffler.

11-4 FUEL SYSTEM

If the fuel tank removed from the engine, set the height of the bottom of fuel tank and the fuel joint of

carburetor to a level between 5 cm and 50 cm.Pay attention that the too low level of fuel tank allows fuel

not to be supplied and the too high may cause the carburetor overflow.

When piping, in addition, pay attention to the pipe for its heat transfer thickness, bend and leaking

in joints to prevent air-lock and vapour-lock.And length of the pipe should be as short as possible.

-

44

-

Page 48

11-5 POWER TRANSMISSION TO DRIVEN MACHINES

11-5-1 BELT DRIVE

Take the following notes into consideration.

* V-belts are preferable to flat belts.

* The driving shaft of the engine must be parallel to the driven shaft of the machine.

* The driving pulley of the engine must be in line with the driven pulley of the machine.

* Install the engine pulley as close to the engine as possible.

* If possible, span the belt horizontally.

* Disengage the load when starting the engine.

If no clutch is used, use a belt tension pulley or the like.

11-5-2 FLEXIBLE COUPLING

When using a flexible coupling, runout and misalignment between the driven shaft and engine shaft must

be minimized. Runout and misalignment tolerance are specified by the coupling manufacturer.

12. CHECKS AND CORRECTIONS

After disassembling and cleaning the engine, check and repair, if necessary, according to the correction

table. The correction table applies whenever the engines are repaired. It is important for the servicemen

to be familiar with the contents of this table. Correct maintenance is recommended by observing the

correction standards specified.

The meanings of the terms used in the correction table are as follows:

1) Correction

Repair, adjustment or replacement of any engine parts.

2) Correction Limit

The limit on wear, damage or functional deterioration of engine parts beyond which normal engine

performance cannot be expected without repairing such parts.

3) Use Limit

The limit beyond which parts can no longer be used in respect of performance or strength.

4) Standard Dimensions

The design dimensions of new parts minus tolerance.

5) Correction Tolerance

Tolerance on the dimensions of engine parts refinished or adjusted.

-

45

-

Page 49

13.TROUBLESHOOTING

13-1 STARTING DIFFICULTIES

If a sign of malfunction is found on the engine it is necessary to find out the cause immediately and take

proper measures to prevent it from spreading.

The section can not cover all the cause and measures to be taken for the faults but covers them only for

possible faults.

Generally speaking, one cause of trouble can overlaps with the other, so you are requested to take

complete measures by exerting experience and judgment accumulated so far.

nonemonehPsesuacelbissoPydemeR

gulpkrapS)1

paggulpkrapsreporpmI*

noitalusnioN*

1

metsysnoitingI

noitcnuflam

stisopednobraC*

liocnoitingI)2

ytiunitnocsidronoitalusnioN*

edocnoitingifoytiunitnocsidronoitcennocrooP*

tsujdA

ecalpeR

naelC

ecalpeR

ecalperroriapeR

leehwylfdnaliocnoitingineewtebpagriareporpmItsujdA

knatleufnileufoN)1llifeR

dehcniprodeggolcesohleuF)2ecalperronaelC

2

3

metsysleuF

noitcnuflam

roterubraC)5

wolfrevO*

erocenignE

stnenopmoc

noitcnuflam

eruziesevlaV)4riapeR

senilleufotnigniximriA)3

noitartlifniretawroenilosagreporpmI)4ecalpeR

degamadrodeggolC*

evlavelttorhtfonoitareporeporpmI*

stlobdaehrednilycfogninethgittneiciffusnI)1 nethgiterdnakcehC

rednilycro/dnagnirnotsip,notsipforaeW)2ecalperroriapeR

taesdnaevlavfotcatnocreporpmI)3riapeR

ecnaraelcevlavreporpmI)5tsujdA

egakaelteksagdlofinamekatnI)6

egakaelteksagroterubraC)7

noitrop

tsujdA

tsujdadnakcehC

teksagecalperro

teksagecalper

gnitcennoctsujdadnakcehC

naelcdnaylbmessasiD

stlobdlofinamekatninethgiteR

rostlobroterubracnethgiteR

gulpkrapsfogninethgittneiciffusnI)8nethgiteR

-

46

-

Page 50

13-2. INSUFFICIENT OUTPUT

nonemonehPsesuacelbissoPydemeR

woL

1

noisserpmoc

gulpkrapsnesooL)1 teksagecalperronethgiteR

egakaelteksagdaehrednilyC)2 teksagecalperronethgiteR

raewroeruzies)s(gnirnotsiP)3ecalpeR

raewrednilycronotsiP)4 ecalperroriapeR

tcatnoctaesdnaevlavtcerrocnI)5 ecalperroriapeR

eruziesmetsevlaV)6 ecalperroriapeR

ecnaraelcevlavreporpmI)7tsujdA

ytluafgulpkrapS)1ecalpeR

2

3

4

emulov

metsysnoitingI

noitcnuflam

metsysleuF

noitcnuflam

riaekatniwoL

13-3. OVERHEAT

nonemonehPsesuacelbissoPydemeR

ytluafliocnoitingI)2ecalpeR

leehwylfdnaliocnoitingineewtebpagriareporpmI)3tsujdA

noitazitengamedotengaM)4ecalpeR

deggolcroterubraC)1 naelcdnaylbmessasiD

deggolcesohleufroreniartsleuF)2 ecalperronaelC

senilleufotnigniximriA)3

noitartlifniretawroenilosagreporpmI)4ecalpeR

deggolcrenaelcriA)1 ecalperronaelC

ytluafevlavelttorhT)2 ecalperroriapeR

gnitcennoctsujdadnakcehC

noitrop

)1noitropelffabrednilycrotelnitadetcurtsbowolfriagnilooCnaelC

lioenignereporpmI)2ecalpeR

gnitaehrevO

daol-revO)5 daoldetarotegnahC

erutximleuf/rianaeL)3 roterubractsujdadnakcehC

metsystsuahxefoerusserpkcabevissecxE)4 ecalperronaelc,kcehC

-

47

-

Page 51

13-4. ROUGH IDLING

nonemonehPsesuacelbissoPydemeR

1roterubraC

deepsgnildiwoL)1tsujdA

deggolcegassapmetsyswolsroterubraC)2 naelcdnakcehC

2metsysekatnI)1metsysekatniriafonoitropgnitcennocmorfgniximriA

3daehrednilyC)yb-wolb(ytluafteksagdaehrednilyC)1ecalpeR

ecnaraelcevlavreporpmI)1tsujdA

4metsysevlaV

5metsysnoitingIkrapsnoitingikaeW)1

taesevlavmorfegakaeL)2 tcatnoctaesevlavtsujdA

ediugdnametsevlavneewtebecnaraelcevissecxE)3ecalpeR

13-5. HIGH ENGINE OIL CONSUMPTION

nonemonehPsesuacelbissoPydemeR

gulpniardnesooL)1nethgiT

degamadteksaggulpniarD)2ecalpeR

ecalperronethgit,kcehC

teksag

krapsecalperdnakcehC

gulp

1egakaelliO

2noitulidliO

stlobrevocgniraebniamnesooL)3nethgiT

degamadteksagrevocgniraebniaM)4ecalpeR

degamadlaesliotfahsknarC)5ecalpeR

ytluafgnirlionotsiP)1ecalpeR

tcatnocrooproraew,eruziessgnirnotsiP)2ecalpeR

rednilycdnanotsipforaewevissecxE)3ecalpeR

metsevlavforaewevissecxE)4ecalpeR

levelliohgiH)5levelliotsujdA

ytluafrehtaerB)6 ecalperroriapeR

-

48

-

Page 52

13-6. HIGH FUEL CONSUMPTION

nonemonehPsesuacelbissoPydemeR

deggolcrenaclcriA)1 ecalperrpnaerC

1metsysleuF

2

erocenignE

stnenopmoc

13-7. DETONATION

nonemonehPsesuacelbissoPydemeR

1

2

metsysnoitingI

noitcnuflam

metsysleuF

noitcnuflam

)2rebmahctaolfnilevelleufhgihro/dnaytluafevlaveldeeNecalperrotsujdA

.yllufnepotonseodevlavkcohC)3 ecalperroriapeR

noisserpmocwoL)1 riaperrokcehC

gniloocrevO)2

sgniriwmetsysnoitingifonoitcennocrooP)1 ylreporptcennocdnakcehC

gulpkrapsdegamadroreporpmI)2 ecalperronaelC

erutximleuf/riahcirronaeL)1 ecalperrotsujda,naelC

degamadroterubraC)2 naelcdnaylbmessasiD

degamadrodeggolcsenilleuF)3 ecalperronaelC

daoltsujdadnakcehC

deepsenignero/dna

3daehrednilyC

4metsysevlaV

)4metsysekatniriafonoitropgnitcennocmorfgniximriA

ecalperroylreporptcennoC

teksag

rebmahcnoitsubmocnitisopednobraC)1naelC

)yb-wolb(ytluafteksagdaehrednilyC)2ecalpeR

ecnaraelcevlavreporpmI)1tsujdA

noitaroiretedtaehevlaV)2ecalpeR

noitaroiretedgnirpsevlaV)3ecalpeR

gnimitevlavreporpmI)4tsujdA

-

49

-

Page 53

14. SERVICE DATA

“STD” in the following table is the parts dimension from the brand new engine or the spare parts.

Whereas, “Limit” shows the maximum allowance for the parts to be used on the engine.

If the measurement exceeds beyond the “Limit”, the part needs to be replaced and/or repaired.

14-1 CLEARANCE DATA AND LIMITS

METI

DAEHREDNILYC

ssentalF*

htdiwtcatnoctaesevlaV*

Unit : mm (in.)

3-02YE,3-51YE

DTStimiL

NAHTSSEL

1.0

)400.0(

.XE.NI

5.1-2.1

)1950.0-2740.0(

51.0

)600.0(

5.2

)890.0(

.aidedisniediugevlaV*

225.6-005.6

)8652.0-9552.0(

56.6

)8162.0(

-

50

-

Page 54

Unit : mm (in.)

3-51YE3-02YE

METI

DTStimiLDTStimiL

REDNILYC

.aidedisnI*

DTS

ts1

gnirober

ts2

gnirober

910.36-0.36

)1184.2-3084.2(

962.36-052.36

)9094.2-2094.2(

915.36-005.36

)7005.2-3084.2(

derobereboT

ehtnehw

ecnereffid

.xamneewteb

.nimdna

retemaidfo

1.0otdehcaer

.)400.0(

ottiD

--------------------

910.76-000.76

)5836.2-8736.2(

962.76-052.76

)4846.2-6746.2(

915.76-005.76

)2856.2-5756.2(

derobereboT

ehtnehw

ecnereffid

.xamneewteb

.nimdna

retemaidfo

1.0otdehcaer

.)400.0(

ottiD

--------------------

.gniroberretfassenidnuoR*

NAHTSSEL

10.0

)400.0(

--------------------

NAHTSSEL

10.0

)400.0(

--------------------

.gniroberretfayticirdnilyC*

NAHTSSEL

510.0

)6000.0(

--------------------

NAHTSSEL

510.0

)6000.0(

--------------------

NOTSIP

tsurhtnitrikstA(ezisnotsiP*

)noitcerid

DTS

s/ots1

s/odn2

89.26-69.26

)5974.2-7874.2(

32.36-12.36

)4984.2-6884.2(

84.36-64.36

)2994.2-4894.2(

88.26

)6574.2(

31.36

)4584.2(

83.36

)3594.2(

89.66-69.66

)0736.2-2636.2(

32.76-12.76

)9646.2-1646.2(

84.76-64.76

)7656.2-9556.2(

88.66

)1336.2(

31.76

)9246.2(

83.76

)8256.2(

-

51

-

Page 55

Unit : mm (in.)

3-51YE3-02YE

METI

DTStimiLDTStimiL

NOTSIP

ecnaraelcedisevoorggniR*

poT

dn2

gnirliO

531.0-90.0

)3500.0-5300.0(

501.0-60.0

)1400.0-4200.0(

560.0-010.0

)6200.0-4000.0(

51.0

)9500.0(

51.0

)9500.0(

51.0

)9500.0(

590.0-50.0

)7300.0-0200.0(

550.0-10.0

)2200.0-4000.0(

560.0-010.0

)6200.0-4000.0(

51.0

)9500.0(

51.0

)9500.0(

51.0

)9500.0(

elohnipnotsiP*

200.41-199.31

)3155.0-8055.0(

530.41

)6255.0(

200.41-199.31

)3155.0-8055.0(

530.41

)6255.0(

.aidedistuonipnotsiP*

000.41-299.31

)2155.0-9055.0(

069.31

)6945.0(

000.41-299.31

)2155.0-9055.0(

069.31

)6945.0(

dnanotsipneewtebecnaraelC*

trikstarednilyc

.aera

950.0-020.0

)3200.0-8000.0(

52.0

)010.0(

950.0-020.0

)3200.0-8000.0(

52.0

)010.0(

pagdnegnirnotsiP*

poT

dn2

gnirliO

4.0-2.0

)610.0-300.0(

3.0-1.0

)210.0-400.0(

5.1

)1950.0(

5.1

)1950.0(

52.0-5.0

)010.0-200.0(

52.0-5.0

)010.0-200.0(

5.1

)1950.0(

5.1

)1950.0(

-

52

-

Page 56

Unit : mm (in.)

3-51YE3-02YE

METI

DTStimiLDTStimiL

DORGNITCENNOC

.aidedisnidneegraL*

310.42-000.42

)4549.0-9449.0(

dneegraldorneewtebecnaraelC*

nipknarcdna.aidedisni

1.42

)8849.0(

310.62-000.62

)1420.1-6320.1(

1.62

)6720.1(

360.0-730.0

)5200.0-5100.0(

2.0

)800.0(

360.0-730.0

)5200.0-5100.0(

2.0

)800.0(

.aidedisnidnellamS*

120.41-010.41

)0255.0-6155.0(

80.41

)3455.0(

120.41-010.41

)0255.0-6155.0(

80.41

)3455.0(

llamsneewtebecnaraelC*

nipnotsipdna.aidedisnidne

920.0-010.0

)1100.0-4000.0(

21.0

)7400.0(

920.0-010.0

)1100.0-4000.0(

21.0

)7400.0(

ecnaraelcedisdneegraL*

3.0-1.0

)930.0-400.0(

0.1

)040.0(

3.0-1.0

)930.0-400.0(

0.1

)040.0(

TFAHSKNARC

.aidedistuonipknarC*

369.32-059.32

)4349.0-9249.0(

5.32

)2529.0(

369.52-059.52

)2220.1-7120.1(

5.52

)400.1(

.aidlanruoJ*

D1 D2

2D,1D

799.42-889.42

)1489.0-8389.0(

-

53

-

2D,1D

59.42

)3289.0(

2D,1D

799.42-889.42

)1489.0-8389.0(

2D,1D

59.42

)3289.0(

Page 57

Unit : mm (in)

3-51YE3-02YE

METI

DTStimiLDTStimiL

TFAHSMAC

).XEdna.NI(thgiehmaC*

50.52-58.42

)689.0-879.0(

7.42

)279.0(

9.82-7.82

)831.1-031.1(

55.82

)421.1(

.aidedistuolanruoJ*

epyt"D"

D

1

D

1

D

2

D

2

489.41-379.41

)9985.0-5985.0(

489.41-379.41

)9985.0-5985.0(

59.41

)6885.0(

59.41

)6885.0(

489.41-379.41

)9985.0-5985.0(

489.41-379.41

)9985.0-5985.0(

59.41

)6885.0(

59.41

)6885.0(

EVLAV

.aidedistuometsevlaV*

.NI

.XE

574.6-064.6

)9452.0-3452.0(

444.6-224.6

)7352.0-8252.0(

53.6

)0052.0(

53.6

)0052.0(

574.6-064.6

)9452.0-3452.0(

444.6-224.6

)7352.0-8252.0(

53.6

)0052.0(

53.6

)0052.0(

metsevlavneewtebecnaraelC*

evlavdna.aid

.ediug

.NI

.XE

260.0-520.0

)4200.0-0100.0(

001.0-650.0

)9300.0-2200.0(

3.0

)210.0(

3.0

)210.0(

260.0-520.0

)4200.0-0100.0(

001.0-650.0

)9300.0-2200.0(

3.0

)210.0(

3.0

)210.0(

ecnaraelcevlaV*

woleb

50.0

.XE/.NI

)dloc(

-

54

21.0-80.0

)7400.0-1300.0(

-

)200.0(

evoba

52.0

)010.0(

21.0-80.0

)7400.0-1300.0(

woleb

50.0

)200.0(

evoba

52.0

)010.0(