Page 1

Page 2

ROBIN

AMERICA, INC.

ROBIN

TO

WISCONSIN

ROBIN

ENGINE

MODEL

CROSS REFERENCE

LIST

ROBIN

EY08

EY15

EY 15V

EY20

EY2OV

EY23

EY28

EY3

5

EY40

-

EY45V

EY2

1

EY44

EY 18-3

EY25

EY27

EH11

EH12

EH15

EH17

EH21

EH25

EH30

EH30V

EH34

EH34V

EH43V

EC13V

DY23

DY27

DY30

DY3

5

DY4 1

WISCONSIN

ROBIN

SIDE

VALVE

W

1-080

W1-145

W1-145V

W1-185

W1-185V

W1-230

W 1-280

W

1-340

W 1-390

Wl-45OV

EY21W

EY44W

EY18-3W

EY25W

EY27W

OVERHEAD

VALVE

WO1-115

wo1-120

WO1-150

WO1-170

wo1-210

WOl-250

WO 1-300

WO1-300V

WO1-340

WO

1

-340V

WO 1-43 OV

TWO CYCLE

WT1-125V

DIESEL

WRD

1-230

WRD

1-270

-1-300

WRD1-350

WRD1-410

0

0

0

Page 3

CONTENTS

Section

Title

Page

1

.

SPECIFICATIONS

..............................................

1

2

.

PERFORMANCE

...............................................

2

2-1

Maximum Output

..........................................

2

2-2

Continuous Rated Output

....................................

2

2-3

Maximum Torque and Fuel Consumption Ratio

at

Maximum Output

........

2

3

.

FEATURES

..................................................

3

4

.

GENERAL DESCRIPTION

of

ENGINE CONSTRUCTION

...................

4

4-1

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-9

4-10

4-1 1

4-12

4-13

4-14

Cylinder. Crankcase

........................................

4

Main Bearing Cover

.........................................

4

Crankshaft

..............................................

4

Connecting Rod and Piston

...................................

5

Camshaft

...............................................

5

Valve Arrangement

.........................................

5

Cylinder Head

............................................

6

Governor

...............................................

6

Cooling

.................................................

6

Lubrication

..............................................

6

Ignition

................................................

7

Carburetor

..............................................

7

Air Cleaner

..............................................

7

Sectional View

of

Engine

.....................................

8

5

.

DISASSEMBLY

and

REASSEMBLY

..................................

10

5-

1

Preparation and Suggestion

....................................

10

5-2

Special Tools

.............................................

10

5-3

How

To

Disassemble

........................................

12

5-4

How

To

Reassemble

........................................

16

6

.

MAGNETO

...................................................

24

6-1

Magneto

................................................

24

6-2

Magneto Trouble Shooting

....................................

24

7

.

GOVERNOR ADJUSTMENT

.......................................

25

8

.

CARBURETOR

................................................

26

8-1

Operation and Construction

...................................

26

8-2 Disassembly and Reassembly

..................................

27

Page 4

Section

Title

Page

9

.

BREAK-IN OPERATION

Of

REASSEMBLED ENGINE

.....................

28

10

.

ROBIN SOLID STATE IGNITION ENGINE (U.T.C.I.)

.....................

29

10-1

Features

................................................

29

10-2

Basic Principle of U.T.C.

I

.....................................

29

I1

.

ROBIN OIL SENSOR SYSTEM (FLOAT

SYSTEM)

.......................

30

11-1

Features

................................................

30

11

-2

Basic Principle

............................................

30

11

-3

Checking Procedures

........................................

32

11

-4

Precautions

..............................................

33

11-5

Wiring

.................................................

33

12

.

TROUBLE SHOOTING

...........................................

34

12-

1

Starting Difficulties

.........................................

34

12-2

Engine Misfires

............................................

35

12-4

Engine Overheat

...........................................

35

12-3

Enginestops

.............................................

35

12-5 Engine Knocks

............................................

36

12-6

Engine Backfires through Carburetor

.............................

36

13

.

INSTALLATION

...............................................

37

13-1

Installing

................................................

37

13-2

Ventilation

..............................................

37

13-3

Exhaust Gas Discharge

.......................................

37

13-4

Power Transmission to Driven Machines

...........................

37

13-5

Wiring

.................................................

38

14

.

CHECKS

and

CORRECTIONS

......................................

39

15

.

TABLE

of

CORRECTION STANDARDS

...............................

40

16

.

MAINTENANCE

and

STORING

.....................................

45

16-1

Daily Checks and Maintenance

.................................

45

16-2

Every

20

Hours Checks and Maintenance

..........................

45

16-3

Every

50

Hours

(IO

days)

Checks and Maintenance

....................

45

16-4

Every

100

.

200

Hours (Monthly) Checks and Maintenance

..............

45

16-5

Every

500

.

600

Hours (Semiannual) Checks and Maintenance

............

46

16-6

Every

1000

Hours (Yearly) Checks and Maintenance

...................

46

16-7

Preparation for Long Abeyance

.................................

46

Page 5

1.

SPEC1

FICATIOMS

Model

EY08BN EY08D

Air-Cooled, 4-Cycle, Vertical, Single Cylinder Gasoline Engine

Bore x Stroke (in)

77.6 cc (4.74 cu. in) Piston Displacement (cu. in)

51

mm

'x

38

mm

(2.01"

x

1.50")

Compression Ratio

6.5

Continuous Rated Output (HP/rpm)

1.0/3000

1.4/3600

1

.O?

1 500

1.4/1800

Max. Output (HP/rpm)

0.72/1600 0.36/3200

Max. Torque (kg-m/rpm)

2.0/2

1

00

2.0/4200

Direction of Rotation

1

Counterclockwise Facing to P.T.O. Shaft

Clockwise Facing to P.T.O. Shaft

Cooling System

I

Forced Air Cooling

~

Lubrication

Splashing Type

Lubricant

Automobile Oil Class

SC

~~

Carburetor

Horizontal Draft, Float Type

~~

Fuel

320

at

continuous rated output operation Fuel Consumption Ratio (gr/Hp-h)

Non-leaded Automobile Gasoline

Fuel Feed

I

Gravity Type

Fuel

Tank

Capacity

I

Approx.

1.5

liter (0.40

U.S.

gal.)

Reduction Ratio

I

-

1

/2

Speed Governor

8.5 kg (18.7 Ibs.)

8 kg (17.6 Ibs.)

Dry Weight (Ibs.)

Recoil Starter

Starting System

-

Lighting Capacity (V-W)

NGK-BM4A (S.T.D.)

Spark Plug

Flywheel Magneto Type (Solid

State

Ignition) Ignition System

Centrifugal Flyweight Type

Length (in)

326

mm

(12.83")

Height

(in)

264

mm

(10.39")

Width (in)

Dimensions

252 mrn (9.92")

-1

-

Page 6

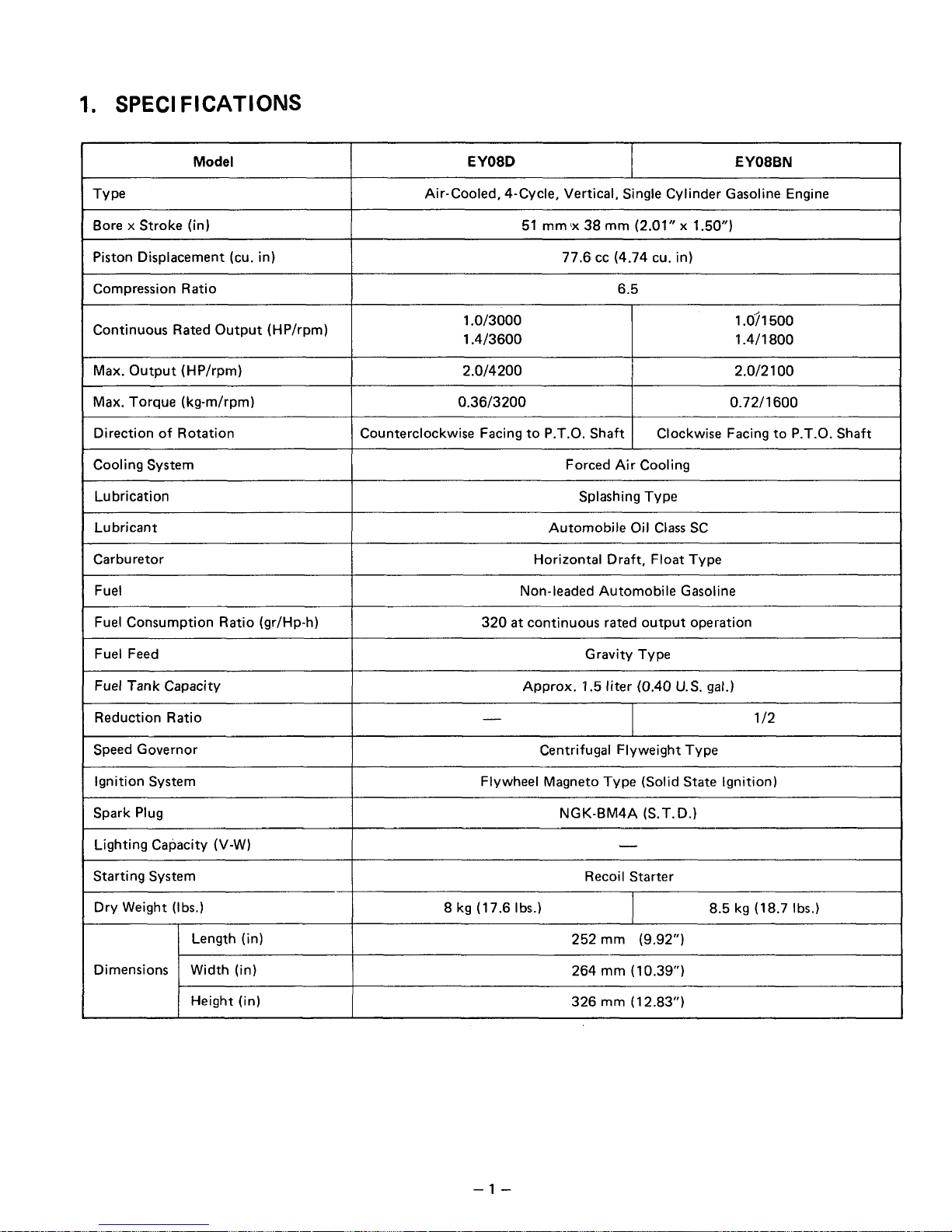

2.

PERFORMANCE

2-1

MAXIMUM OUTPUT

The maximum output of an engine

is

such standard power as developed by the engine, after its initial break-in

period with all the moving parts properly worn in, when operating with a fully open throttle valve, Therefore,

a new engine may not develop the maximum output in the beginning because the moving parts are not in a

properly worn-in condition.

2-2

CONTINUOUS RATED OUTPUT

The continuous rated output of an engine

is

such power as developed

by

that engine when running continuously at an optimum speed, and most favorable from the viewpoint of engine life and fuel consumption ratio,

with the governor in operation. It is suggested, therefore, that when designing a driving system

for

any mech-

anism, with this engine

as

prime mover, the continuous power requirement

of

that mechanism be kept below

the continuous rated output specified.

2-3

MAXIMUM TORQUE

and

FUEL CONSUMPTION

RATIO

at

MAXIMUM OUTPUT

These mean the maximum torque of the output shaft and fuel consumption ratio at the maxiumum output

of

an

engine.

HP

L

W

0

a

3’

L

0

I

PERFORMANCE

CURVE

MODEL

EY08D

( )

for

BN

type

0.45

0.40

0.35

0.30

2.5

2.0

1.5

1

.o

0.5

2000

3000

4000

(1

000)

(1

500)

(2000)

Revolution

-

r.p.m.

(0.9)

kg-rn

-2-

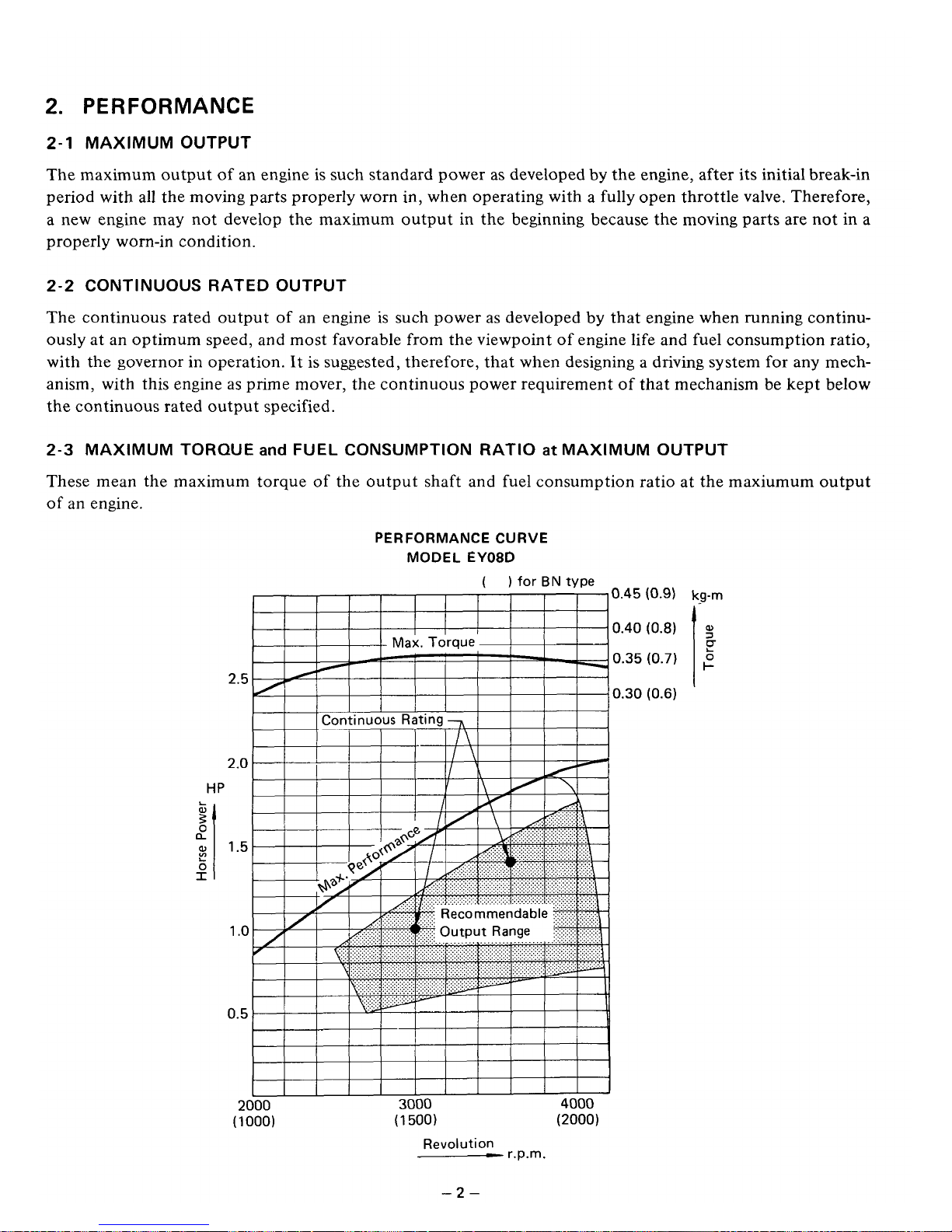

Page 7

3.

FEATURES

1.

Compact, lightweight, durable, powerful 4cycle air cooled engine embodying ingenious design techniques

and skilful workmanship.

2.

Simple construction, smart appearance, maximum easiness

of

start owing to automatic decompression

device

3.

Pointless Solid State ignition system is newldy adopted for preventing poor igniting.

4.

Reliable prime mover for varietyof purposes with smooth speed controlrby a governor under varying load

conditions.

5.

Economical because fuel consumption is very low

-3-

Page 8

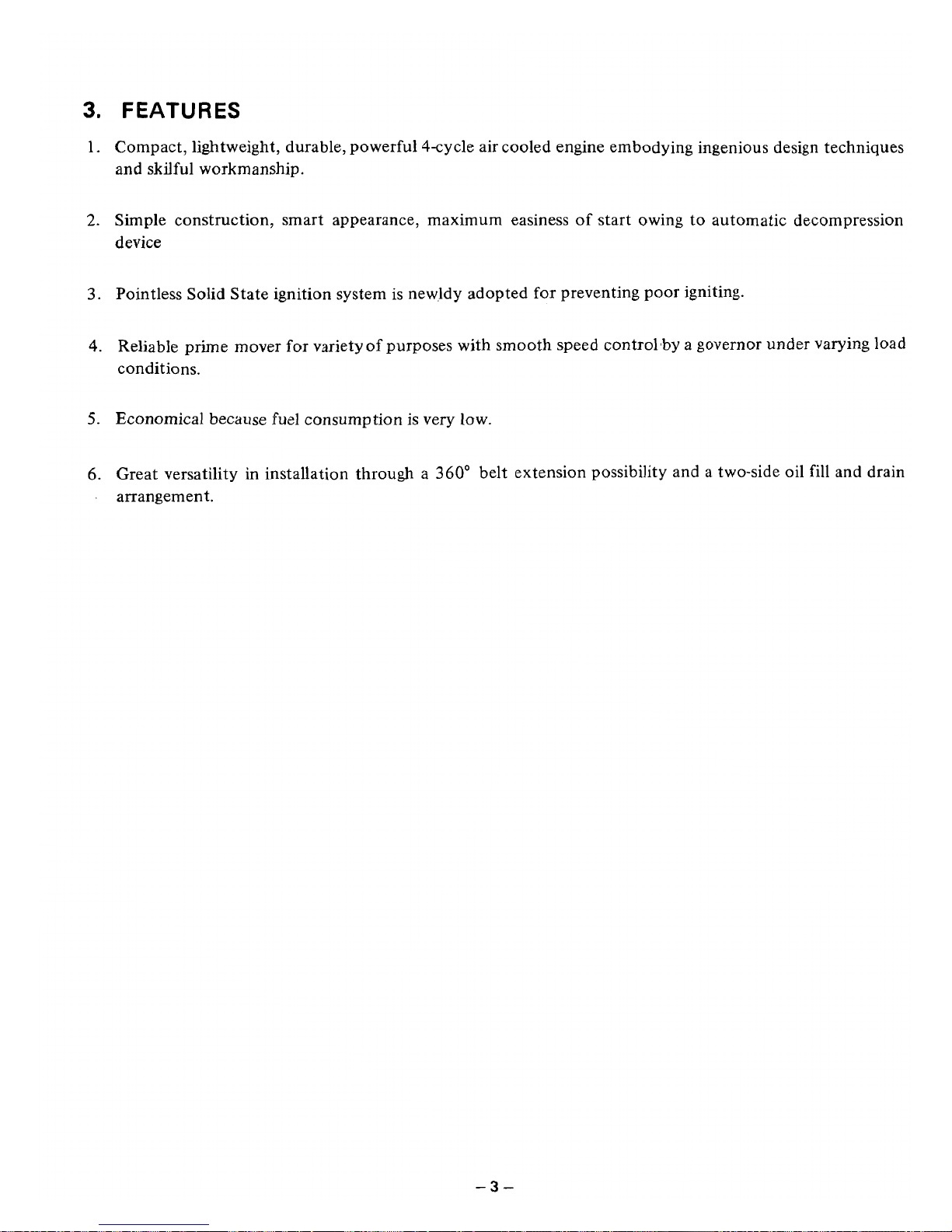

4.

GENERAL DESCRIPTION

of

ENGINE CONSTRUCTION

4-1

CYLINDER, CRANKCASE

The cylinder and crankcase are single piece aluminum die casting. The cylinder liner, made of special

cast iron, is built into the alminum casting. The

in-

take and exhaust ports are located on one side

of

the cylinder, and are also inserted into the casting.

The crankcase is separable on the output shaft side,

where the main bearing cover

is

attached to it.

(See Fig.

1

.)

Fig.

1

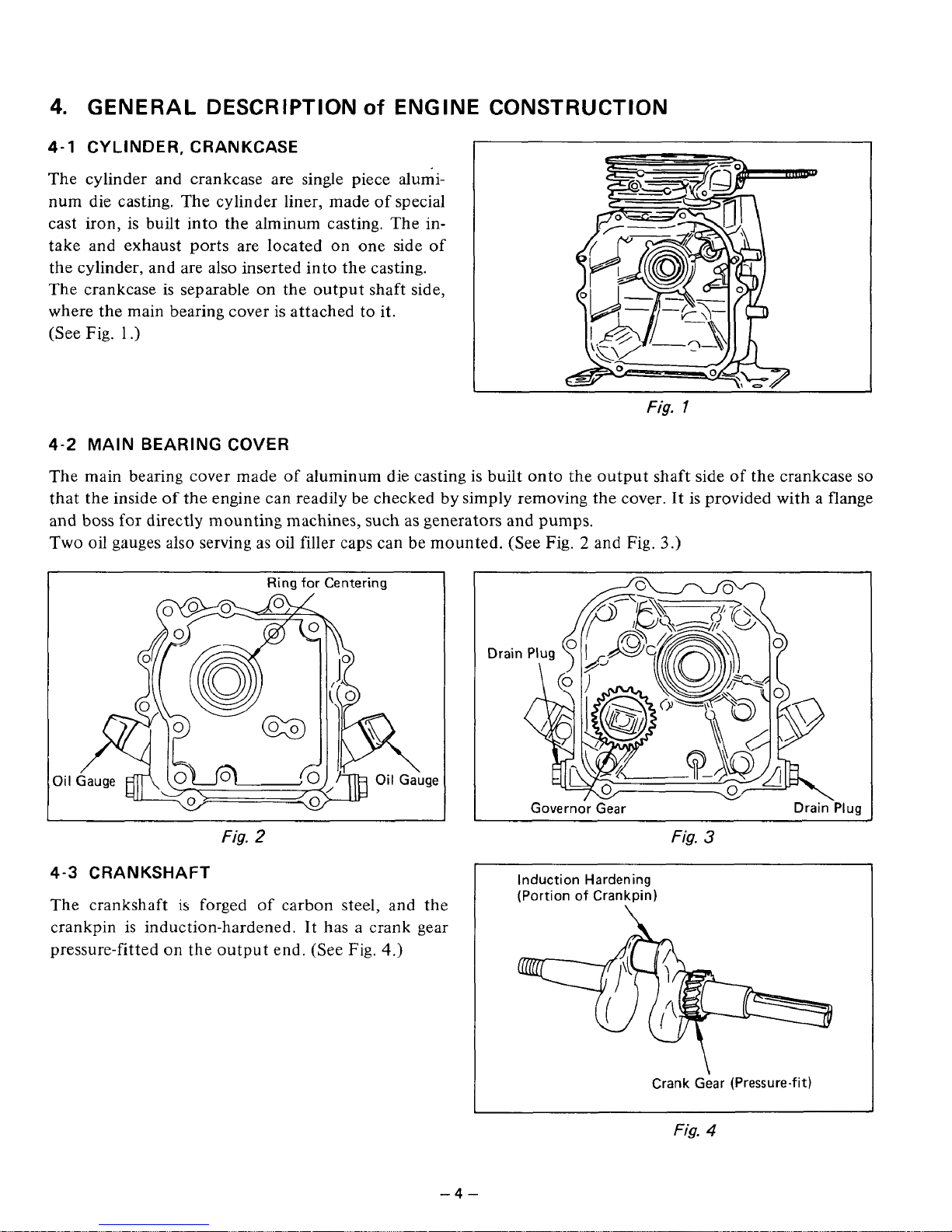

4-2

MAIN

BEARING

COVER

The main bearing cover made

of

aluminum die casting is built onto the output shaft side

of

the crankcase

so

that the inside of the engine can readily be checked by simply removing the cover. It is provided with a flange

and boss for directly mounting machines,

such

as

generators and pumps.

Two oil gauges also serving

as

oil filler caps can be mounted. (See

Fig.

2

and

Fig.

3.)

Oi

I

Ring

for Centering

!ID

Oil

Gauge

Fig.

2

4-3

CRANKSHAFT

The crankshaft is forged of carbon steel, and the

crankpin

is

induction-hardened. It has a crank gear

pressure-fitted on the output end. (See

Fig.

4.)

Fig.

3

~~

Induction Hardening

(Portion of Crankpin)

\

Crank Gear (Pressure-fit)

Fig.

4

-4-

Page 9

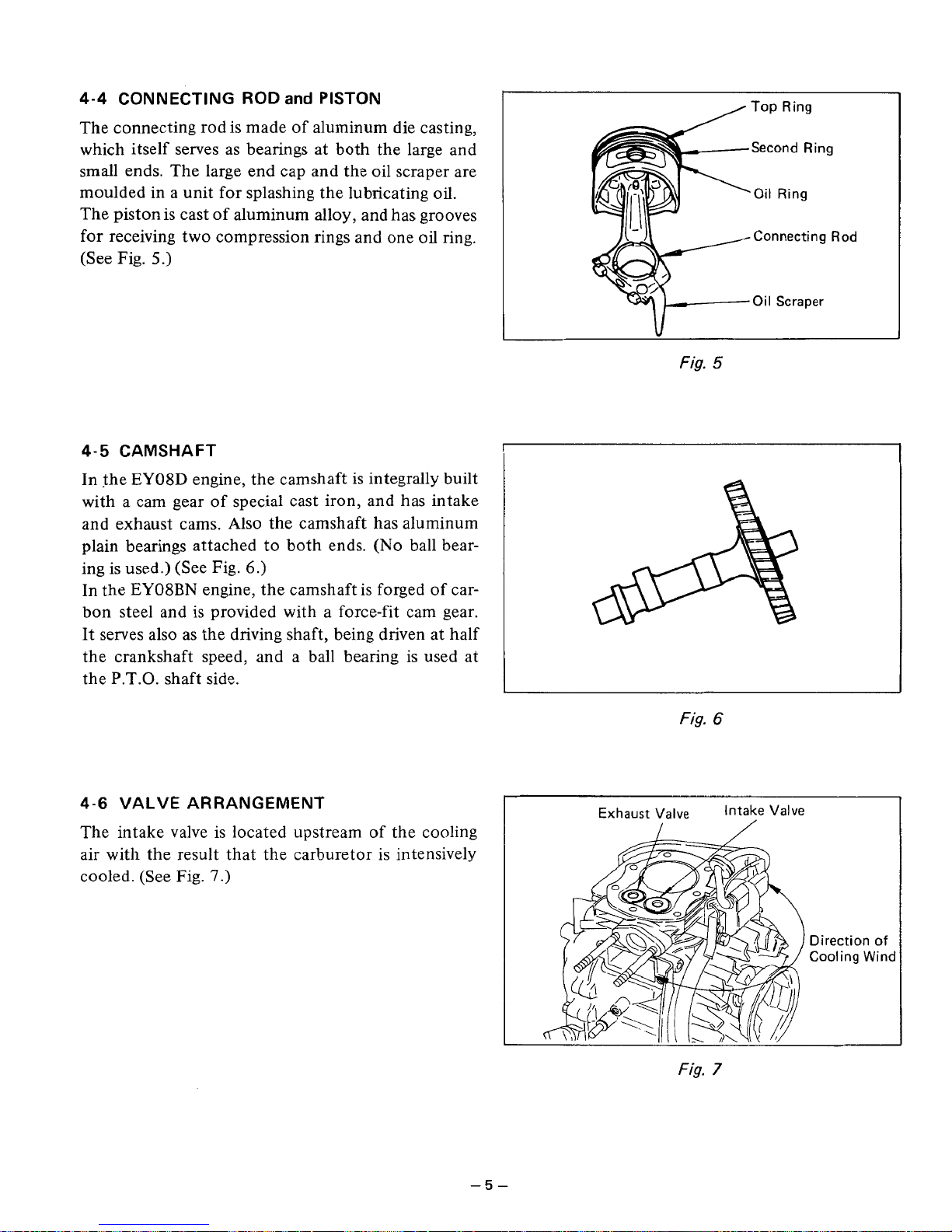

The connecting rod is made of aluminum die casting,

which itself serves as bearings at both the large and

small ends. The large end cap and the oil scraper are

moulded in a unit for splashing the lubricating oil.

The piston is cast

of

aluminum alloy, and has grooves

for receiving two compression rings and one

oil

ring.

(See Fig.

5.)

4-4

CONNECTING ROD

and

PISTON

4-5 CAMSHAFT

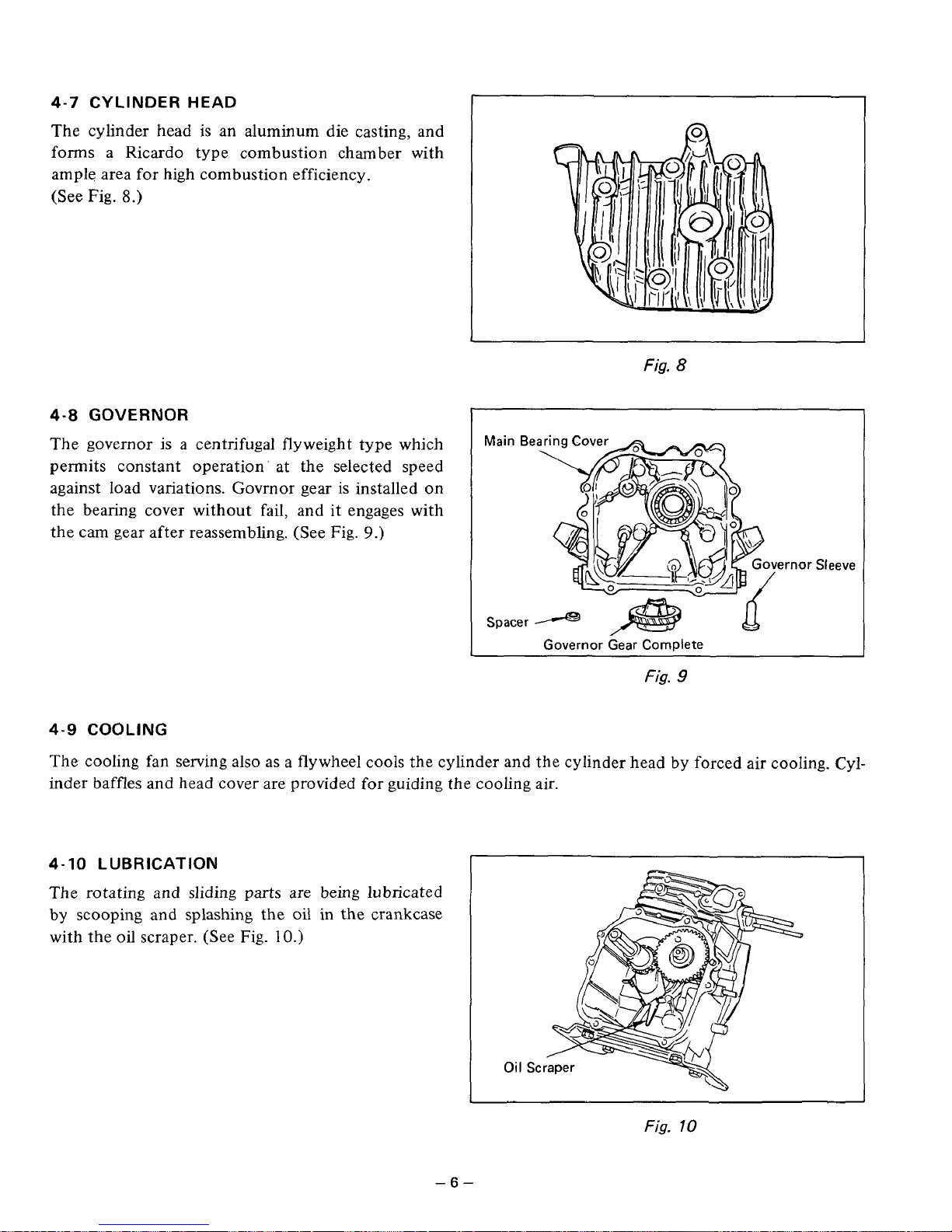

In the EY08D engine, the camshaft is integrally built

with a cam gear of special cast iron, and has intake

and exhaust cams. Also the camshaft has aluminum

plain bearings attached to both ends.

(No

ball bear-

ing is used.) (See Fig.

6.)

In the EY08BN engine, the camshaft is forged of carbon steel and is provided with a force-fit cam gear.

It serves also

as

the driving shaft, being driven at half

the crankshaft speed, and a ball bearing is used at

the P.T.O. shaft side.

4-6

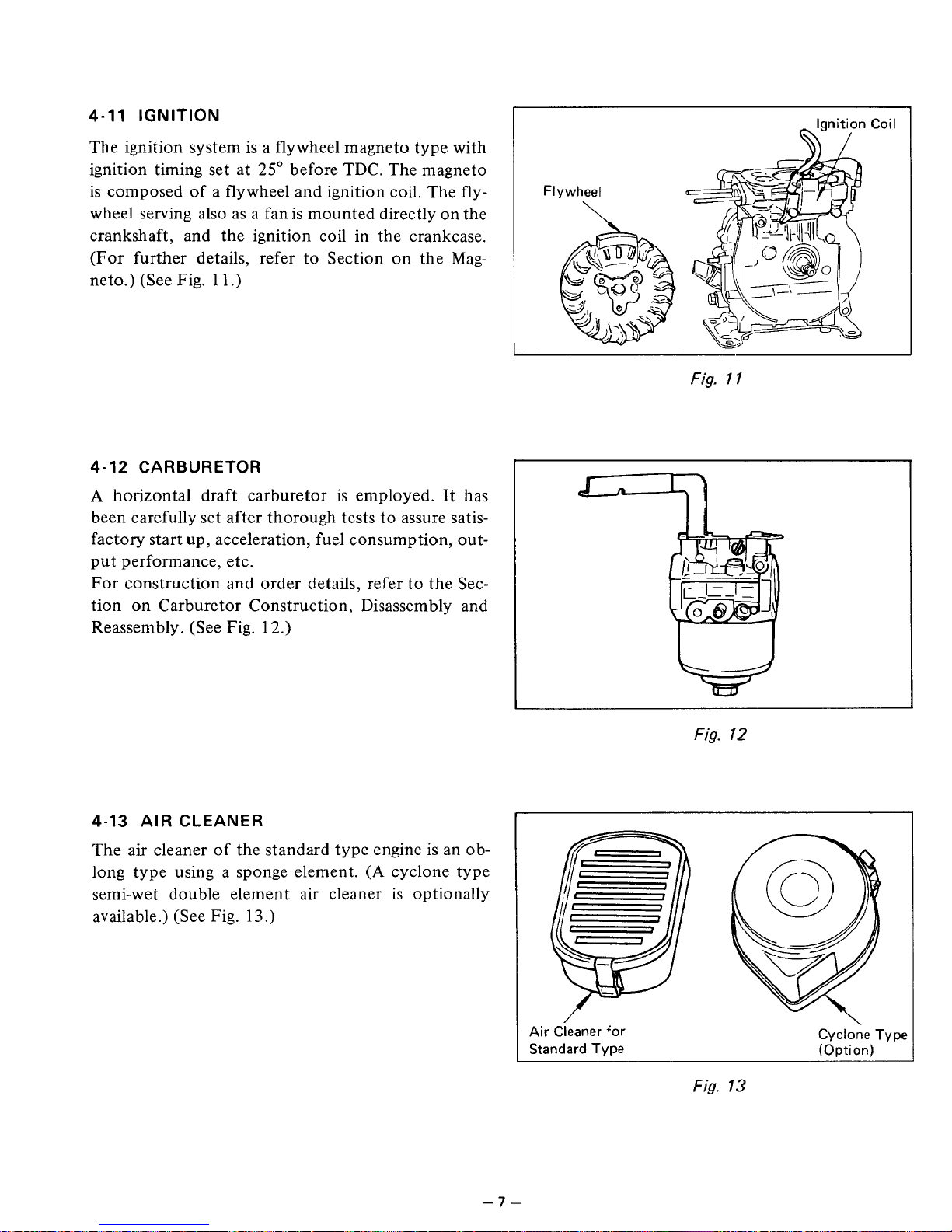

VALVE ARRANGEMENT

The intake valve is located upstream

of

the cooling

air with the result that the carburetor is intensively

cooled. (See Fig.

7.)

Top

Ring

Second Ring

Oil

Ring

Connecting

Rod

Oil

Scraper

\I

L

Fig.

5

:

Fig.

6

Direction

of

Cooling

Wind

Fig.

7

-5-

Page 10

4-7

CYLINDER HEAD

The cylinder head

is

an aluminum die casting, and

forms a Ricardo type combustion chamber with

ample area for high combustion efficiency.

(See

Fig.

8.)

4-8

GOVERNOR

The governor is a centrifugal flyweight type which

permits constant operation- at the selected speed

against load variations. Govrnor gear is installed on

the bearing cover without fail, and

it

engages with

the cam gear after reassembling. (See Fig.

9.)

I

Fig.

8

Main

Be

!mor

Sleeve

Spacer

Q

-

Governor Gear Complete

Fig.

9

4-9

COOLING

The cooling fan serving also as a flywheel cools the cylinder and the cylinder head by forced air cooling. Cylinder baffles

and

head cover are provided for guiding the cooling air.

4-10

LUBRICATION

The rotating and

sliding

parts are being lubricated

by scooping

and

splashing the

oil

in the crankcase

with the

oil

scraper. (See Fig.

10.)

Fig.

10

-6-

Page 11

4-11

IGNITION

The ignition system

is

a flywheel magneto type with

ignition timing set at

25"

before TDC. The magneto

is composed

of

a

flywheel and ignition coil. The fly-

wheel serving also as a fan is mounted directly on the

crankshaft, and the ignition coil in the crankcase.

(For further details, refer to Section

on

the Mag-

neto.) (See

Fig.

1 1

.)

4-12 CARBURETOR

A

horizontal draft carburetor is employed. It has

been carefully set after thorough tests to assure satisfactory start up, acceleration, fuel consumption, output performance, etc.

For construction and order details, refer to the Section on Carburetor Construction, Disassembly and

Reassembly. (See Fig. 12.)

4-13 AIR CLEANER

The air cleaner

of

the standard

ty

:ngine

is

an

0

b-

long type using a sponge element.

(A

cyclone type

semi-wet double element air cleaner is optionally

available.) (See

Fig.

13.)

I

Ignition Coil

Fig.

1

1

Fig.

12

Air Cieaner for

Standard Type

Cyclone Type

(Option)

Fig.

13

-7-

Page 12

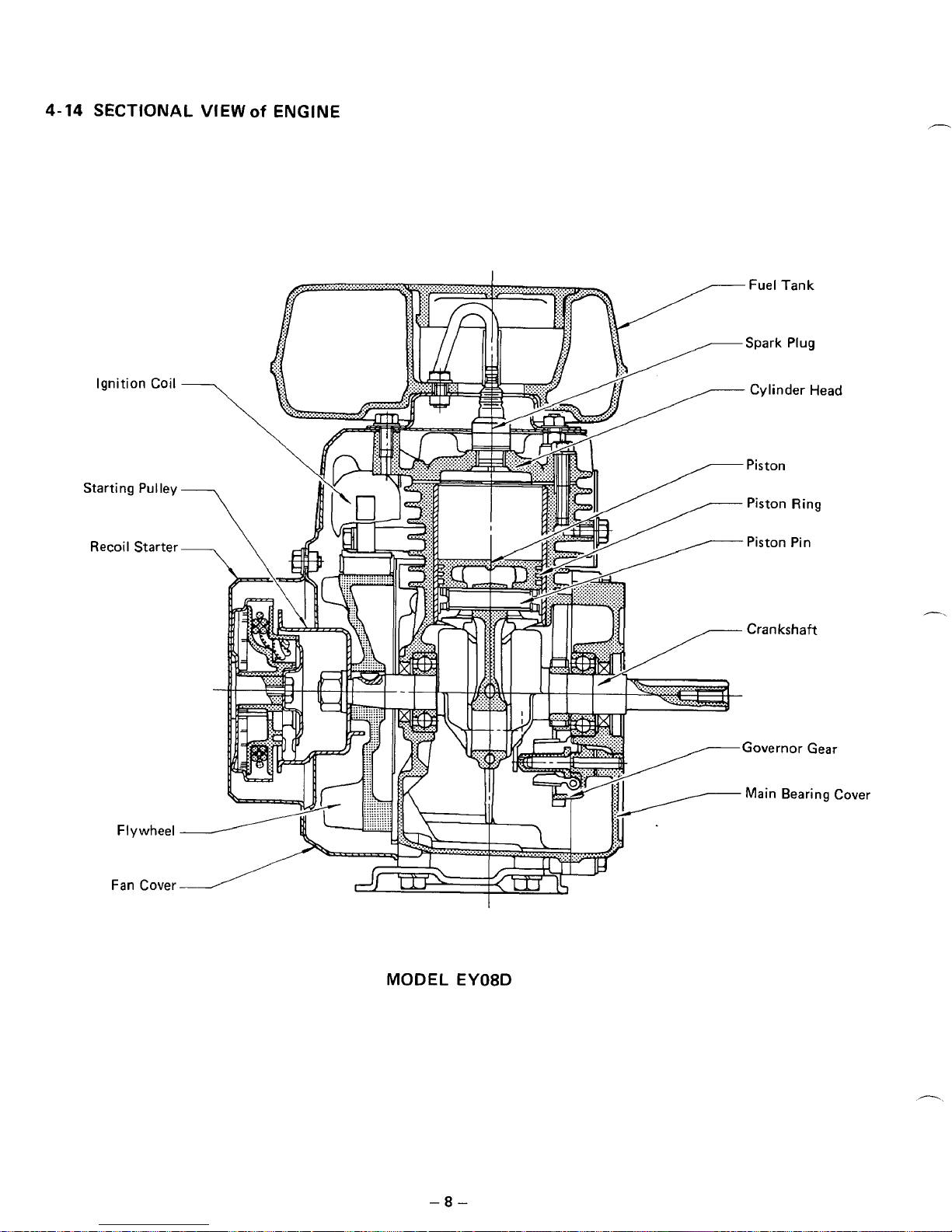

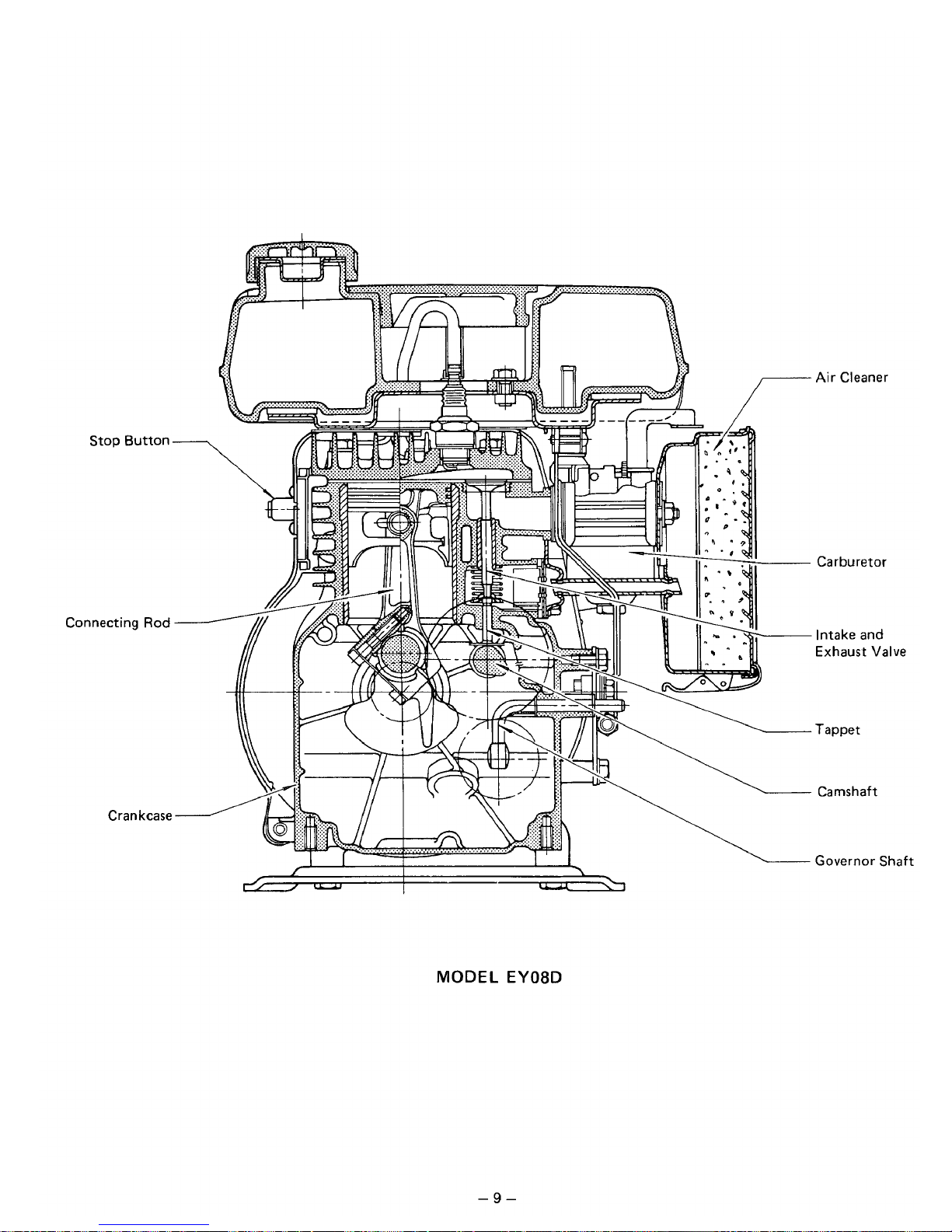

4-14

SECTIONAL

VIEW

of

ENGINE

MODEL

-8-

EY08D

Page 13

Stop Button

Connecting

Rod

Crankcase

MODEL

EY08D

Air

Cleaner

Carburetor

Intake and

Exhaust Valve

Tappet

Camshaft

Governor

Shaft

-9-

Page 14

5.

DISASSEMBLY

and

REASSEMBLY

5-1

PREPARATIONS

and

SUGGESTIONS

1)

When disassembling the engine, remember well the locations of individual parts

so

that they can be reas-

sembed correctly.

If

you are uncertain

of

identifying some parts, it

is

suggested that tags be attached

to

them.

2)

Have boxes ready

to

keep disassembed parts by group.

3)

To

prevent missing and misplacing, temporarily assemble each group of disassembed parts.

4)

Carefully handle disassembed parts, and clean them with washing oil.

5)

Use the correct tools

in

the correct way.

5-2

SPECIAL

TOOLS

For

your reference, the following shows special tools of Robin Engine for Disassembly, Measuring and Inspec-

tion Instruments.

Part

No.

2099500407

2309500107

2079500307

2309500207

2059500107

Tool

Flywheel Puller

(with

bolt)

Valve Spring

Retainer

Valve Guide

Puller

Use

For pulling

off

Flywheel

For mounting and

dismounting Valve

Spring Retainer

and Retainer

Lock

For pulling off

Valve guide

Applicalbe

Model

EY08

EY10, 13, 14

EY

15,18,

20

EY23, 25, 27,

EY33

EY35,40,44

EC05.07, 10

EC17,25.37

EY08

EY10,13, 14

EY 15, 18,20

EY23

EY25.27, 33

EY35,40,44

EY08

EY10

EY13,

14

Shape

-10-

Page 15

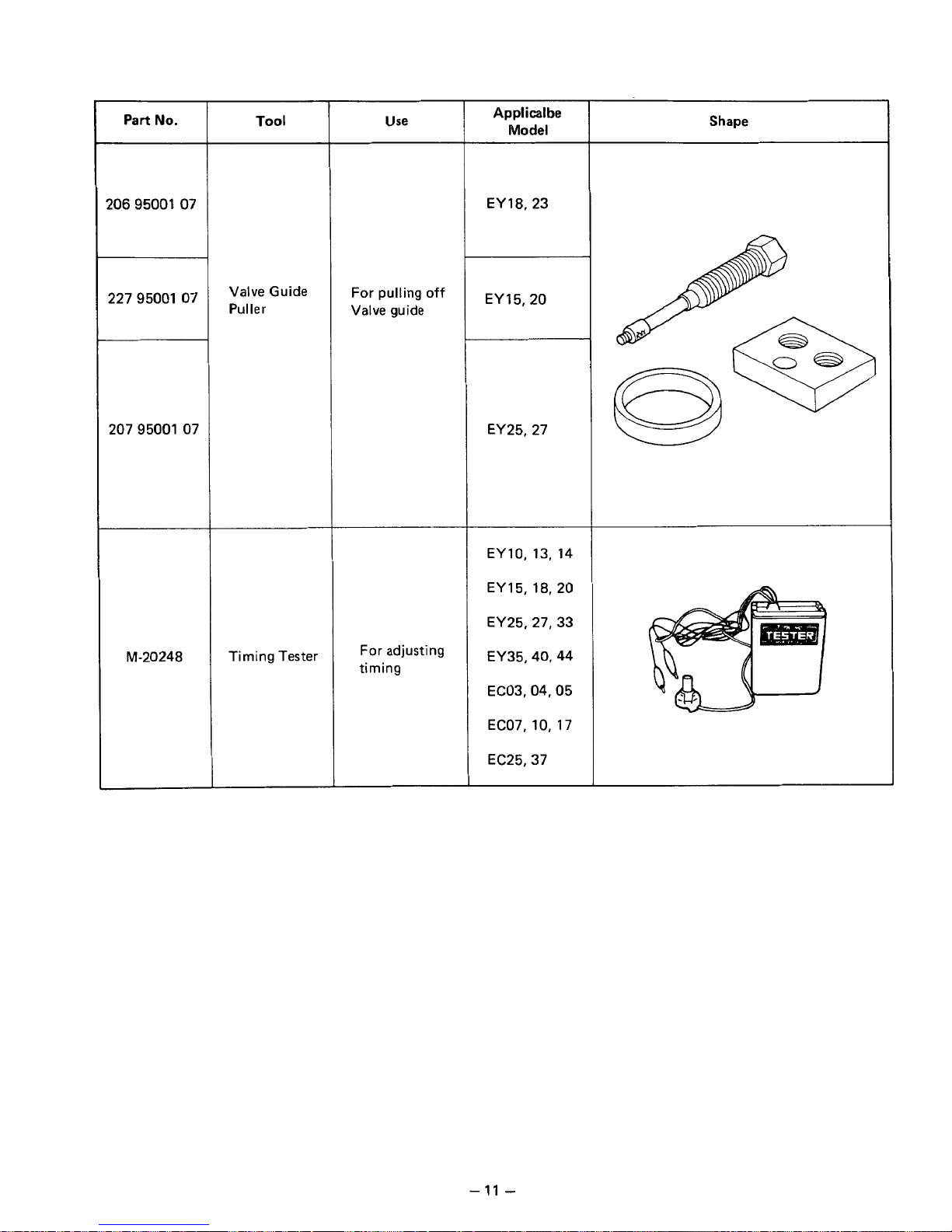

Part

No.

2069500107

2279500107

207 95001 07

“20248

Tool

Valve Guide

Puller

Timing Tester

Use

For pulling

off

Valve guide

For

adjusting

timing

Applicalbe

Model

EY18.23

EY 15,ZO

EY25, 27

EY10,

13,

14

EY 15, 18,20

EY25,27,33

EY35,40,44

EC03,04,05

EC07,10,

17

EC25,37

Shape

-

11

-

Page 16

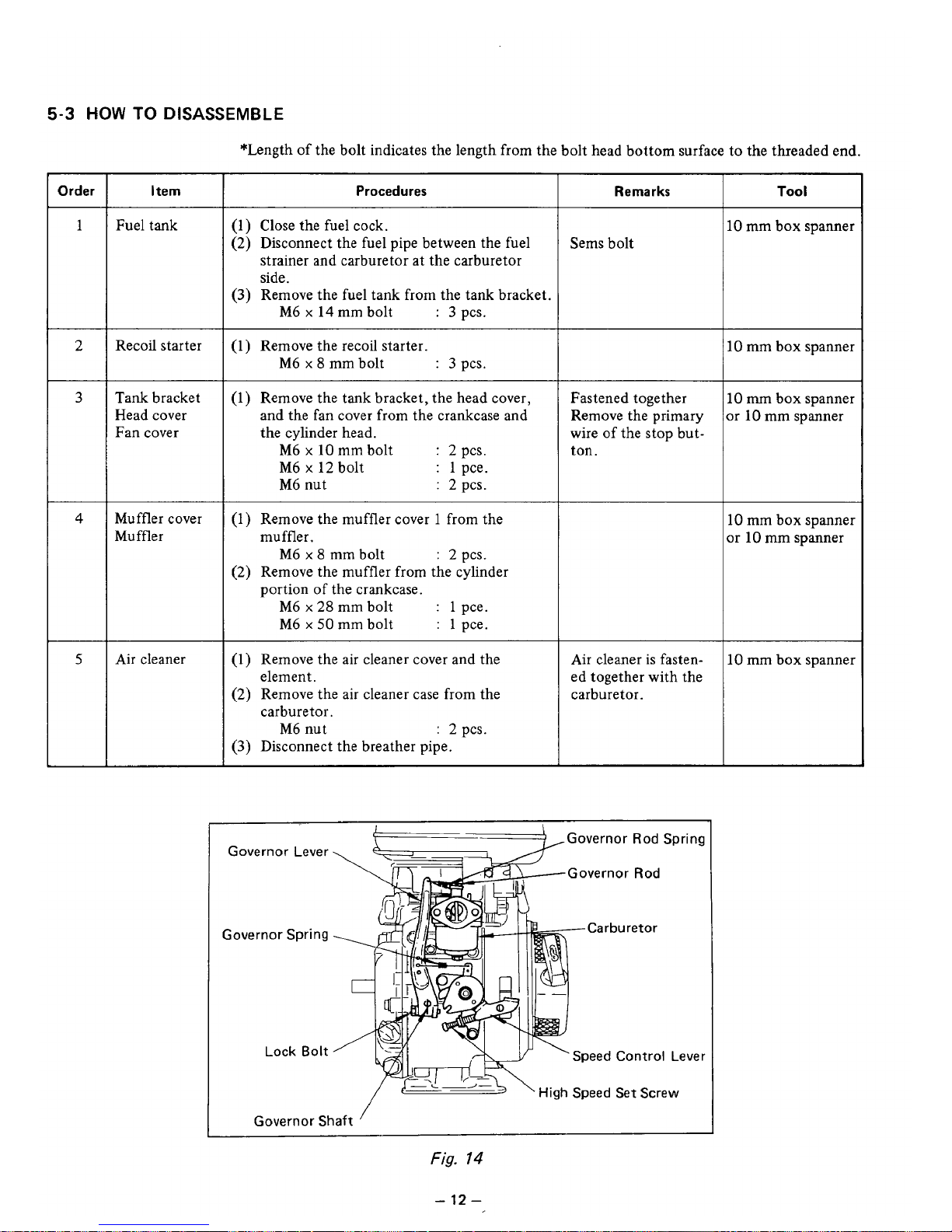

5-3

HOW

TO

DISASSEMBLE

*Length of the bolt indicates the length from the bolt head bottom surface to the threaded end.

Order

5

I

tern

Fuel tank

Recoil starter

Tank bracket

Head cover

Fan cover

Muffler cover

Muffler

Air cleaner

Procedures

(1)

Close the fuel cock.

(2)

Disconnect the fuel pipe between the fuel

strainer and carburetor at the carburetor

side.

(3) Remove the fuel tank from the tank bracket.

M6

x

14

mm bolt

:

3

pcs.

(1)

Remove the recoil starter.

M6

x

8

mm bolt

:

3

pcs.

(1)

Remove the

tank

bracket, the head cover,

and the fan cover from the crankcase and

the cylinder head.

M6

x

10

rnm

bolt

:

2

pcs.

M6

x

12

bolt

:

1

pce.

M6 nut

:

2

pcs.

(1)

Remove the muffler cover 1 from the

muffler.

M6

x

8

mm bolt

:

2

pcs.

(2)

Remove the muffler from the cylinder

portion

of

the crankcase.

M6

x

28

mrn bolt

:

1

pce.

M6

x

50 mm bolt

:

1

pce.

(1)

Remove the air cleaner cover and the

(2)

Remove the

air

cleaner case from the

element.

carburetor.

M6 nut

:

2

pcs.

(3) Disconnect the breather pipe.

Remarks

Sems bolt

Fastened together

Remove the primary

wire of the stop button.

Air cleaner is fastened together with the

carburetor.

Governor Lever

Governor Spring

Lock

Bolt

{--)

,Governor Rod Spring

Governor

Rod

Lever

L

'

High

Speed Set

Screw

Governor

Shaft

Fig.

14

Tool

10

mm box spanner

IO

mm box spanner

10

m

box spanner

Ir

10

mm spanner

10

mm box spanner

x

10

mm

spanner

10

mm box spanner

-

12

-

Page 17

Order

Itern Procedures

I

Remarks

I

Too

I

6

Governor lever

and the relative

parts

Carburetor

Starting pulley

Flywheel

(1)

Remove the governor Iever from the gover-

M6

x

25 mm bolt

:

1

pce.

nor shaft.

(2) Remove the governor rod and rod spring

(3) Remove the carburetor from the

from the carburetor.

cylinder portion

of

the crankcase.

Just loosen the bolt,

unnecessary to take

out the bolt.

10

mm box spanner

or

10

mm spanner

(1) Remove the starting pulley from the

fly-

Be

careful not to

wheel.

damage the blades

of

M12 nut

:

1

pce.

the flywheel with

a

Fit a box

or

socket wrench over the fly-

wheel nut, and strike it hard with a ham-

driver and a like.

wise with a hammer.

mer to remove the nut and spring washer.

Strlke counterclock(See Fig.

15)

17

mm box spanner

or

socket wrench

(1)

Remove the flywheel from the crankshaft.

Fit the flywheel

puller as shown

in

Fig.

16,

turn the

center bolt clockwise and pull out

the flywheel.

Fig.

15

Fig.

16

Order

I

tern

Procedures

~ ~~~~~~~~~~~ ~ ~~

9

(1)

Remove the plug terminal from the spark

Ignition coil

plug and remove the ignition coil from the

crankcase.

M6

x

25

mm

bolt

:

2

pcs.

10

(1)

Remove the spark plug from the cylinder

Spark plug

he ad

Remarks

Sems bolt

7

10

mm

box

spanner

I

19 mm box spanner

-

13

-

Page 18

Order

I

Item

11 Cylinder head

I

l2

I

Intake and

exhaust valve

13

I

Main bearing

cover

Procedures

(1)

Remove the

M6

bolts and remove the cylin-

M6

x

32

mm bolt

:

5

pcs.

M6

x

40

mm bolt

:

2

pcs.

(2)

Remove the cylinder head gasket from the

der head from the crankcase

crankcase.

(1)

Remove the inner and outer tappet covers

M6

x

12

mm bolt

:

2

pcs.

from the crankcase.

(2)

Pull out the intake and exhaust valve.

(3)

Remove the valve spring and the valve

spring retainer.

(1) From the crankcase remove the bolt fasten-

M6

x

25

mm bolt

:

6 pcs.

(2)

Remove the cover, lightly tapping the cover

ing the main bearing cover.

evenly with a plastic hammer.

\

(-)

Driver

\

Fig.

17

Remarks

M6

x

40

mm bolt

is

special bolt.

Put the notch on the

outer circumference

of the spring retainer

on this side.

Hook the medium

size

(-)

driver at the

dent (lower side)

of

the spring retainer

and pull out the

valves, while pulling

the spring retainer

toward you.

(See Fig.

17.)

Sems bolt

Be careful not to

damage the oil seal.

(See Fig.

18.)

Tool

10

mm

box

spanner

The front is this

sidf

(-)

driver

10 mm

box

spanner

Main/Bearing Cover

I

Plastic Hammer

Fig.

18

-

14

-

Page 19

Procedures

I

Remarks

I

Too

I

(1)

Remove the camshaft from the crankcase. To prevent the tap-

pets from falling or

damaging, place the

crankcase

on

the

side. (See Fig.

19

.)

15

Tappet

~~~ ~~~~ ~~~ ~~

I

(1) Remove the tappets from the crankcase.

Before removing put

a mark of intake or

exhaust

on

each

tappet.

Order

16

17

18

I

tern

Connecting rod

and piston

Piston and

piston pin

Crankshaft

Camshaft

Procedures

(1)

Scrape off carbon and other foreign deposits

from the upper parts of the cylinder and

piston, and then straighten out the bent

tabs of the lock washers

on

the connect-

ing rod, and remove two pieces of the bolt.

(2)

Remove the lock washer and the connecting

rod cap from the crankshaft.

(3)

Turn the crankshaft until the piston is raised

up to the hghest position, push the connecting rod

up,

and

remove the piston out of the

top

of

the cylinder.

(1) Remove the two clips, pull out the piston

pin, and take the piston off from the small

end of the connecting rod.

(2)

Spread the open ends of the piston rings

and remove them from the piston.

(1)

Remove the woodruff key (for the magneto).

(2)

Lightly hammer the magneto end of the

crankshaft, and pull it out of the crankcase.

-

15

-

Remarks

I

Tool

8

mm

box

spanner

or

8

mm spanner

Pay attention to the

direction

of

the con-

necting rod cap.

Be careful

not

to

damage the inside of

the small end of the

connecting rod.

Be careful not to

break the rings by

spreading too much.

Be careful not to

damage the oil seal.

Page 20

5-4

HOW

TO

REASSEMBLE

.Precaution in reassembling

Every and each part should be cleaned thoroughly. Especially, pay utmost care and attention to the cleanliness of the piston, cylinder, crankshaft, connecting rod and bearings.

Scrape completely off carbons from the cylinder head and the upper part of the piston; especially the

carbon adhered in the groove of the piston ring should be carefully and completely taken out.

Carefully check the lip portion of every

oil

seal. If faulty one is found, replace it without any hesitation.

Apply enough oil

to

the lip portion of the oil seal when reassembling.

Replace all the gaskets with new ones.

Replace the key, pin, bolt, nuts, etc. with new one, if necessary.

Whenever tightening torque

is

specified, conform to the specified figures.

Apply oil to the revolutionary parts and friction surfaces, when reassembling.

Check and adjust the clearances of various portions and then reassemble.

When some main portions are assembled in the course of reassembling, turn

or

move the gadgets by hand

and pay attention to the frictional noise and resistance.

*Sequence and precautions in reassembling

5-4-1 GOVERNOR

SHAFT

1)

Insert the governor shaft into the crankcase.

2)

Place the clips

on

the governor shaft.

5-4-2 CRANKSHAFT

1) Inser the crankshaft into the crankcase as shown

.

Note: Be careful not to damage

the

oil

seal

lip.

in Fig.

20.

2)

Put woodruff key (for magneto) in place.

Shaft

Fig.

20

-16-

Page 21

3)

Dimensions

of

Crankshaft

Pin

D

(Crankshaft Pin Dia.)

20

dia.

-0.037

-

0.050

W

(Crankshaft Pin Width)

PISTON TO CYLINDER AT PISTON SKIRT

THRUST FACE

I

PISTON RING

GAP

tx"--+

TOP, SECOND

0.008L

-

0.047L

0.2

L - 0.4L

0.05L

-

0.25L (Cutter Ring)

PISTON RING CLEARANCE

IN

GROOVES

i

TOP RING

SECOND RING

OIL RING

CONNECTING ROD TO CRANK PIN

DIA

0.09OL -0.135L

0.060L

-

0.105L

0.01OL

-

0.065L (Cutter

Ring)

0.037L - 0.063L

0.1

L - 0.7L

CONNECTING ROD TO PISTON PIN

PISTON PIN TO PISTON

0.010L

-

0.029L

0.009T

-

0.01OL

L:

LOOSE

Fig.

21

-

17-

T:

TIGHT

Page 22

5-4-3

PISTON and

PISTON

RING

1) If

no

ring expander is available, install the rings by placing the open ring ends over

the

first land of the

piston and spreading the rings only far enough to slip them over the correct ring grooves.

Note:

Pay

attention not to break the rings by twisting. Install the oil ring first followed by the second

ring and then top ring. Meantime, the surfaces of the second ring and the top ring with carved

carved marks are to be faced up.

Note: When replacing the piston rings with new ones, install the rings

for

replacement

as

shown in Fig.

22.

n

I

@

STD

I

Replacement Parts

I

Top Ring Taper

I

I

Taper

Second Ring

Taper

Undercut

Ql

Oil

Ring

Cutter Ring

Assembly type

a

Fig.

22

2)

Reassemble the piston and the connecting rod by

means of the piston pin.

Note: Apply enough oil to the

small

top end of

the connecting rod.

Be sure to place the clips on both ends of

the piston pin.

3)

When installing the connecting rod into place,

hold piston rings with the ring guide

as

shown in

Fig.

24

(if

no ring guide

is

available, keep pressing the piston rings with finger tips and gently

strike the top

of

the piston with a wooden piece

or the like

to

push

it

in), and check that the sym-

bol

@

or mark

MA

on the connecting rod

is

i

the direction

of

the flywheel magneto.

Note: Apply enough oil

to

the piston rings, con-

necting rod plain bearings and cylinder

wall before reassembling.

Note: The open ends of the piston rings must be

90"

apart from one another on the piston

periphery.

Note: The clearance between the piston and cyl-

inder must be measured

at

the piston skirt

thrust surface.

Fig.

23

Crank Case

(Magneto Side)

Fig,

24

-

18

-

Page 23

5-4-4

CONNECTING

ROD

1)

Turn the crankshaft to the bottom dead center,

lightly hammer the piston head until the connecting rod contacts the crankpin, and assemble.

2)

When reassembling the connecting

rod

cap, set it

so

that the

oil

scraper

is

in the right.bottom.

(See Fig.

25.)

Note: Use new lock washers, and bend the tabs

Note: After reassembly, confirm that the

con-

Note: Connecting rod cap tightening torque:

Note:

For

the piston,

piston

ring

and-

rod

clear-

securely,

necting rod moves lightly.

60

-

80

kg-cm

ance,

see

Fig.

2

1.

5-4-5

TAPPET and CAMSHAFT

Insert the tappets back into their holes first, and

then mount the camshaft.

Note: Align the timing mark at the root

of

a

tooth

of

the cam gear with the one

on

the crank

gear.

If

the valve timing

is

wrong, the engine

cannot operate properly

or

at

all.

(See Fig.

26.

)

Note:

If

the intake tappet and exhaust tappet were

assembled contrarily each other, the tappet

clearance cannot

be

kept correctly.

Fig.

25

Fig.

26

-

19

-

Page 24

5-4-6

Install the main bearing cover

Note:

Note: When installing main bearing cover, apply oil

Note: In the

MAIN BEARING COVER

to

the.crankcase.

As

the'governor gear

bearing cover side, install the main bearing

cover while checking that

teeth

of

the cam gear. (See Fig. 27.) Meantime,

if

the oil seal need be replaced, pressure-fit a

new oil seal before installing the main bearing

cover.

to the bearing and oil seal

guide over the crankshaft

tect the oil seal lip from damage. Then place

the main bearing cover

Check the crankshaft

0 - 0.2

justing shim. (See Fig. 28,)

the cam shaft with the adjust shim

from

mm; and if not, adjust

BN

type, adjust the side clearance of

0

to

0.2

mm.

is

mounted on the main

it

meshes with the

lip.

Fit the oil seal

or

camshaft to

on.

if

its

side clearance

it

with the ad-

so

that

pro-

it

is

is

-1

Pay attention to the engagement of

the governor ear and cam gear.

It

Fig.

27

Note: Main bearing cover tightening torque:

80

-

100

kg-cm

29

Note: Fig.

the crankshaft side clearance between the

machined face

collar.

chined face of the crankcase, adjust the clearance

account. (See Fig.

shows one of the methods measuring

of

the crankcase and adjusting

As

a paper packing

by

taking this thickness of0.22

29.)

is

used

on

the ma-

mm

into

1

(*-*

Fig.

28

Dial Indicator

Ground Surface

(The surface

to be put together with the surface of the main bearing cover.)

Fig.

29

of

of

the crankcase

is

-

20

-

Page 25

5

-4-7

INTAKE

and

EXHAUST

VALVES

Remove carbon and gum deposite

from

the valves, valve seats, intake and exhaust

ports

and valve guides,

Note:

If

the valve face

is

dinted

or

warped, replace the valves with new ones.

Note:

If

there

is

an excessive clearance between the valve guide and valve stem, replace the valve guide with a

spare.

For

replacing,

pull

out the valve guide, using the valve guide pulling base and

bolts

as shown

in

Fig.

30,

and pressure-fit a new valve guide into place.

Valve

Face

%

Spring Retainer

Fig.

30

VALVE

and

VALVE

GUIDE

CLEARANCE

I

A-VALVE FACE ANGLE

I

4

5"

I

I

B-

SEAT

ANGLE

I

45"

I

C-GUIDE INSIDE DIA.

5.5

dia.

+0.018

0

I

MAXIMUM ALLOWABLE

0.056L

-

0.092

L

EXHAUST

CLEARANCE BETWEEN C and

D

0.020L

-

0.050L

INTAKE

L:

LOOSE

Fig.

31

-

27

-

Page 26

5-4-8

TAPPET ADJUSTMENT

Lower the tappet all the way down, push the valve, and insert a thickness gauge between the valve and tap-

Fig.

pet stem to measure the clearance. (See

Note: The correct tappet clearance for both intake and exhaust valves

when the engine

is

cold.

32.)

is

0.1

mm

k0.02

mm as measured

-

Note:

Fig.

If

the clearance

On the contrary,

I

Thickness Gauge

32

is

smaller than specified, slightly grind the top of the valve stem, and measure

if

the clearance

is

too large, replace the valve with new one, and polish

Valve

Valve Spring

Valve Spring Retainer

fig.

33

it

its

again.

contact

surface with a compound to obtain a good fit. Then adjust the clearance.

Note: After the tappet clearance adjustment, install the valve springs and the valve spring retainers, and turn

the crankshaft, and measure the tappet clearance once again if

it

is

correct.

n

Note: INSTAL

Place the notch

the retainer toward this side and insert the retainer, like pushing in, using a special tool.

a driver

5-4-9

CYLINDER HEAD

LA

TION of SPRING RETAINERS

on

the outer circumference of

is

used, insertion may be easier.

Front

should

be

this

side.

lf

\-I

Driver

‘\

Fig.

34

Valve

Spl

l

Retainer

kg

Remove carbon from the cylinder head, particularly its combustion chamber, and make clean the cooling

Also

fins.

check the head for distortion.

Note: Replace the cylinder head gasket with a new one.

Note: Cylinder head tightening torque:

90

-

110

kg-cm

/”-.

-

22

-

Page 27

5-4-10 SPARK PLUG

Tightening torque of the spark plug: 230

-

250

kg-cm.

Note:

If

the spark plug

is

new, tighten the spark plug at

120

-

150

kg-cm torque.

5-4- 11 IGNITION COIL, FLYWHEEL and STARTER PULLEY

1)

Temporarily fasten the ignition coil to the crankcase, and install the flywheel to the crankshaft. Starting

pulley is fastened together with the flywheel.

Note: Before installing, wipe out oil from the crankshaft and the tapered portion

of

the flywheel.

Note: Before installing the starting pulley, check

if

the woodruff key

is

correctly inserted.

Note: Flywheel tightening torque:

450 - 500

kg-cm.

2) After measuring the air gap between the ignition

coil and flywheel, retighten the ignition coil.

(See Fig.

35.)

Air gap:

0.3

-

0.5

mm

I

Fig.

35

5

-4- 12 CARBURETOR

To the cylinder portion of the crankcase install in the order of the gasket, insulator, gasket and carburetor,

and then mount the air cleaner case and fasten with two pieces

of

M6 nut.

5

-4-

13

GOVERNOR LEVER

When reassemblying, refer to the

7.

GOVERNOR

ADJUSTMENT.

5-4-14 MUFFLER and MUFFLER COVER

Install the muffler cover

2

to the muffler and fasten the muffler

to

the crankcase and then install the muf-

fler cover 1.

Note: Muffler tightening torque:

100

-

720

kg-cm

Note: Clamp the muffler and tighten the bolts after the engine has been fully cooled.

5-4-15

HEAD COVER, FUEL TANK, FUEL TANK BRACKET and FAN COVER

Install in the order

of

the head cover, fan cover, fuel tank bracket and fuel tank.

Note: Install the grommet of the ignition coil to the head cover before installing the fan cover.

5-4- 16 RECOIL STARTER

With 3 pieces of M6

x

8

mm

bolt fasten the recoild starter.

Note:

It

is

feared that the bolt longer than 8 mm may damage

the

blade.

-

23

-

Page 28

6.

MAGNETO

6-1

MAGNETO

/-

The spark for ignition is furnished by the magneto assembly. The magneto consists

of

the flywheel and the

ignition coil of which flywheel is mounted on crankshaft and ignition coil is mounted in crankcase directly.

6-2

MAGNETO TROUBLE SHOOTING

When the engine does not start or starts with difficulty, or when its operation is unstable, the following tests

in

will clarify if they are caused by a defect

1)

Check ignition cable for possible corrosion, broken, worm insulator or lose connection.

2)

Check the sparking as described later in this section.

3)

If no spark takes place, replace ignition coil.

*SPARK

TESTING

the magneto.

Remove the spark plug from the cylinder head and place it on the cylinder head, with the ignition cable

connected to it.

Crank the engine several times

the spark

is

strong, the ignition system can be eliminated as the source

by

recoil starter and observe the spark

in

the spark gap

of

trouble. (Remove the primary

of

spark plug.

If

wire from the connector.)

is

If the spark

The

correct electrode gap

weak or there

is

no spark at all, repeat the checks.

is

0.6

-

0.7

mm. (Refer to section

“14.

CHECKS and CORRECTIONS.”)

Flywheel

Fig.

I

36

/“

-

24

-

Page 29

7.

GOVERNOR

ADJUSTMENT

Model

EY08

emploies a centrifugal flyweight type governor. The governor is mounted on the govenor gear

nor in order

to

maintain constant engine speed against load variations.

The adjustment procedure

of

the governor is as follows (See Figs.

37 - 39.):

1)

Connect the carburetor throttle lever

to

the governor lever with the governor rod and the rod spring and

2)

Install the speed control lever

to

the crankcase.

3)

Connect the governor lever

to

the control lever with the governor spring.

and the throttle valve

of

the carburetor

is

automatically regulated by a lever which is connected to the gover-

mount the governor lever onto the governor shaft.

Governor Lever

Governor

Rod

Governor

Spring

Governor

Shaft

Fig.

37

4)

Turn the control lever towards high speed, and

confirm that the carburetor throttle valve is fully

opened. Control lever can stay wherever it is

required.

*Position

to

hang the

governor

spring

The standard position

is

2-A.

But, in case of a

50Hz

generator, the governor should be hung at

3-B .

5)

With a screwdriver in the groove

of

the governor

shaft, turn it “clockwise” fully until the governor shaft no longer moves, and then look the

governor lever to the governor shaft with the

governor lever tightening bolt. (See Fig.

39.)

An example

of

the governor spring being hooked.

Fig.

38

Governor Lever

Fig.

39

-

25

-

Page 30

8.

CARBURETOR

/-

8-1

OPERATION

and

CONSTRUCTION

(See

Fig.

40.)

8-

1

-

1

FLOAT

SYSTEM

The float chamber

is

located just below the carburetor body and, with a float and a needle valve, maintains

a constant fuel level during engine operation.

The fuel flows from the fuel tank into the float chamber through the needle valve. When the fuel rises to a

specific level, the float rises; and when

its

buoyancy and fuel pressure are balanced, the needle valve close

to

the shut off the fuel, thereby keeping the fuel at the reference level.

Pilot Jet, ,,"--Pilot Air Jet

r

Pilot

Jet

Main Air Jet

/-

Needle Valve

Float

-

fig.

40

-

26

-

Page 31

8-1

-2

PILOT

SYSTEM

The pilot system feeds the fuel to the engine during idling and low-speed operation.

The fuel

is

fed through the main jet

to

the pilot jet, where it is metered, and mixed with the air metered by

the pilot air jet.

The fuel-air mixture is fed .to the engine through the pilot outlet and the by-pass.

During engine idling, the fuel is mainly fed from the pilot outlet.

8-

1-3

MAIN SYSTEM

The main system feeds the fuel to the engine during medium- and high-speed operation.

The fuel is metered by the main jet and fed to the main nozzle. The air metered by the main air jet is mixed

with the fuel through the bleed holes in the main nozzle, and the mixture is atomized out

of

the main bore.

It is mixed again with the air taken through the air cleaner into an optimum fuel-air mixture, which is

supplied

to

the engine.

8-

1

-4

CHOKE

The choke is used for easy start in the cold season. When the recoil starter

is

pulled with a closed choke, the

negative pressure applied

to

the main nozzle increases and draws much fuel accordingly; thus easily start up

the engine.

8-2 DISASSEMBLY

and

REASSEMBLY

Apart from mechanical failures, most of carburetor troubles are caused by an incorrect mixing ratio, which

may arise mainly due to a clogged up air or fuel passage in jets, or fuel level variations. In order to assure

proper flow

of

air and fuel, the carburetor must be kept clean at all times. The carburetor disassembly and

reassembly procedures are as follows: (See Fig.

41

.)

18

8-2-

1

THROTTLE

SYSTEM

1)

Remove the Philips screw (1

8)

and throttle valve

2)

The spirng

(21)

can be taken out by removing

*Exercise care not to damage throttle valve ends.

(19), and pull out the throttle shaft

(20).

the throttle stop screw (22).

8-2-2

CHOKE

SYSTEM

1)

Remove the Philips screw

(14)

and

choke valve

(1

S),

and pull out the choke shaft

(1

6).

2)

When reassembling the choke shaft, make sure

that the cutout in the choke valve faces the main

air jet.

8-2-3

PILOT

SYSTEM

Remove the pilot jet (23) using correct tool to

avoid damage to it.

Reassembly

Tighten the pilot jet securely. Otherwise, the fuel

may leak, causing engine malfunction.

17

7

12

A

Fig.

4

1

-

27

-

Page 32

8-2-4

MAIN

SYSTEM

1) Remove the bolt (12) and take out float chamber body

(10).

2)

Remove the main jet (1

3)

from the body

(6).

3)

Reassembly

a) Fasten the main jet securely to the body. Otherwise the fuel may become too rich and cause engine

b) The bolt tightening torque

is

70

kg-cm.

malfunction.

8-2-5

FLOAT

SYSTEM

Pull out the float pin

(9)

and remove the

float

(8)

and needle valve

(1

7).

If

the

needle valve need be re-

placed, replace it with rubber needle.

Caution: When cleaning the jets, use neither a drill nor a wire (because of possible damage of the orifice

which will adversely affect fuel flow). Be sure to use compressed air

to

blow them clean.

When removing the needle valve and floats, gently tap the reverse side using the rod more slender than

the float pin and remove because the float pin is calked to the carburetor body.

BREAK-IN OPERATION

of

REASSEMBLED ENGINE

An overhauled engine must be operated at low speed break-in the parts. A thorough break-in is indispensable

particularly when the cylinder, piston, piston rings or

valves

are replaced with new ones.

The recommended break-in schedule

is

shown below.

/-

I

LOAD

SPEED

(Crankshafr

Rev.)

TIME

I

2,500

rpm

10

minutes

NO

LOAD

3,000

rpm

10

minutes

NO

LOAD

30

minutes

3,600

rpm

0.7

PS

10

minutes

3,600

rpm

1.4

PS

60

minutes

3,600

rpm

-

28

-

Page 33

10.

ROBIN

SOLID

STATE IGNITION ENGINE'

(U.T.C.I.)

10-1

FEATURES

EY08 emploies a pointless ignition system, called Solid State Ignition, which is the circuit breaker type ignition device, utilizing the power transistor as an element for controling electric current.

This

ignition system is

called U.T.C.I. (Universal Type Transistor Controlled Ignition), and it is based on an external coil system

in which an ignition coil is installed outside the flywheel and the unit is mounted on an

iron

core of the coil.

Being different from the breaker point type ignition system, this brand-new system is completely free from

such troubles as starting-up failure owing to dirty, burnt or oxidized point surface, lowering

of

ignition effi-

ciency being caused by moisture, rough surface to breaker point and incorrect timing resultant from worn

mechanical parts.

10-2

BASIC PRINCIPLE

OF

U.T.C.!.

(See

Fig.

42.)

Electricity is generated

in

the primary ignition coil by rotation of the flywheel, and the current a flows,

by which the condenser is charged.

When the flywheel goes round further, direction

of

the current changes, and the current b flows, causing

the current

c

and the current d flow to the power transistor and the transistor for signals for each. The

condenser8is charged by the current

d

contrarily to the case

1).

When the flywheel goes round further more, the current generated in the primary coil gets to its peak,

and then begins decreasing.

Then, voltage between

C

(Collector) and E (Emitter) of the transistor for signals becomes zero, and the

transistor is turned

OFF,

while the current

d

changes to the current

e

and goes into the gate of the

thyrister

(SCR),

thus turning the

SCR

ON.

When the SCR is switched

ON

and the current

b

flows into the

SCR

(Current

f),

the current c flowing

the power transistor is interrupted abraptly, generating high voltage by the current change in the secondary coil, thus giving sparks to the spark plug.

ignition

Coil

Fig.

42

-

29

-

Page 34

1.1.

ROBIN

OIL

SENSOR

SYSTEM

(FLOAT

SYSTEM)

/-

In the

EYOS,

an oil sensor is available as a maker option.

11 - 1

FEATURES

1) The engine oil sensor detects the quantity of engine oil and automatically stops the engine, if

it

falls

below the specified level, to prevent the engine from burning due to oil maintenance failure

or

for other

reasons.

If the

oil

shortage warning lamp is connected to the connecting terminal for it. the warning lamp is lit

when the engine stops.

2)

If the engine oilis short when the engine is started, the engine can not be started, even

if

the recoil starter

is pulled. If the warning lamp is connected, the lamp is lit to indicate oil shortage.

3)

As

the power generated by the igniter

is

used, any special power supply unit is not necessary.

4)

On-tatch stop is possible also by using the stop button, which is generally incorporated in the unit, based

on a push button system. (Self-maintaining and automatic restoration circuits are incorporated in the

unit.)

5)

This system features the malfunction preventing structure depending on outer magnetic field.

11

-2

BASIC

PRINCIPLE

This oil sensor system consists of a flywheeI magneto, an igniter, an oil level controller, and an oil level

sensor.

As

shown in Fig.

43,

when the oil level is above the specified one, the lead switch contact

is

OFF,

and the

engine can run normally (sensor OFF condition). If the oil becomes short and position

of

the float in the

/"

sensor case goes down to the specified level shown in Fig.

44,

the lead switch contact

is

turned

ON

by the

magnetic field of the permanent magnet incorporated in the float (sensor

ON

condition).

When the oil level sensor is turned

ON,

the current

il

generated by the counter-electromotive voltage

VI

in

the primary ignition coil flows from the primary wire of the igniter via the delaying circuit of the oil level

controller, both

of

which are shown in the block diagram. When the current

iI

generated by the counter

electromotive voltage

VI

goes

up

to a certain level, the current

il

is loaded to the SCR gate from the delay-

ing circuit via the self-maintaining circuit if

V,

is loaded.

Then, the SCR is turned

ON,

thus starting operation of the warning lamp driving circuit, lgighting the warn-

ing lamp to indicate the oil shortage condition, and completely short-circuiting the regular electromotive

voltage

V,

in the primary coil

of

the igniter

for

the igniter not to generate sparks.

This

condition is con-

tinued until the engine is stopped

by

the self-maintaining circuit.

In normal stopping operation

of

the engine, the current

i,

generated by the regular electromotive voltage

V,

in the primary coil

of

the igniter is loaded, via the stop switch, to the self-maintaining circuit of the oil

level controller.

This

current is loaded to the

SCR

gate via the self maintaining curcuit, and the

SCR

is turned

ON.

When the SCR is turned

ON,

the driving circuit of the warning lamp starts operating, thus lighting the

warning lamp, and completely short-circuiting the regular electromotive voltage

V,

in the primary coil of the

igniter for the igniter not to generate sparks.

This condition is continued until the engine is stopped by the self-maintaining circuit.

In restarting, the engine stopping operation

is

cancelled by automatically restoring mechanism, and the en-

gine can be started normally.

-

30

-

Page 35

Permanent Magnet

,,

[Fd Switch

Oil

Scraper

Shield

Case

7

Oil

Level)

.ankcase

,!-

Tightening Torque:

80

-

90kg-cm

Sensor

OFF

(Running

Mode)

Fig.

43

Sensor

ON

(Stop)

Fig.

44

Fig.

45

-31

-

Page 36

11-3

CHECKING

PROCEDURE

/-

When the engine can not be started, supply oil up to the maximum oil level, and pull the recoil keeping the

engine in the horizontal position. Engine

oil

is

supplied up till the maximum level; but it doesn't start yet,

please check the engine

in

the following manner.

1)

Oil Level Sensor Checking (See

Fig.

46.)

Disconnect the sensor from the controller, and check with a tester continuity between the sensor lead

wire (yellow) and the grounding wire of the engine.

When there is

no

continuity under the condition that the oil has been supplied up to the specified level

(about

280

cc), the oil level sensor is normal.

If

there

is

continuity, replace it with a new one.

When there is continuity under the condition that the

oil

level is below the specified one

(200

cc), the

sensor

is

normal. If not, replace the sensor with a new one.

Fig.

46

2)

Oil Level Controller Checking (See Fig.

47)

Disconnect the sensor from the controller (don't

disconnect the stop button

from

the controller),

and start operation of the stop switch after setting rpm

of

the engine at more than 1,200 rpm.

(Don't continue depressing it, and restore

it

to

the normal position soon.)

Warning lamp is lit in a few seconds and the

engine is stopped, the controller is normal. If

the

oil

warning lamp is not lit and the engine is

stopped, replace the warning lamp with a new

one.

If

the engine does not stop in a few seconds

(about 2 seconds), inner section of the controller

is defected,

so

replace it with a new one.

Controller

Stop

Switch

111

Fig.

47

-32

-

Page 37

11

-4

PRECAUTIONS

1) The oil level sensor used in this controlling system has a float which can automatically detect the oil level

according to the

oil

level change. However, if degraded oil, oil of improper grade, or oil with viscocity

which is not appropriate for the periopheral temperature should be used, sometimes the float does not

operate normally and fails in detecting the oil level.

2)

Don’t drop the

oil

level sensor and the oil level controller, nor add any physical impact to them. Don’t

pull the wire.

3)

In removing the oil level sensor from or mounting

it

to the crankcase, be careful not to damage the

O-ring. Don’t disassemble the

oil

level sensor removed.

In cleaning the

oil

level sensor, use the engine oil.

If

cleaned with gasoline or kerosene, the O-ring may

swell.

4)

Mount the oil level sensor under the condition that the crankcase has been fully cooled. Use a 21mm

spanner for tightening the bolts. Tightening torque:

80

-

90

kg-cm. (If a box spanner is used, the wire

may be damaged.) Wire connection should be done

as

shown in the wiring diagram. Be careful in tighten-

ing or wiring not to give damages to the wire.

5)

If

the warning lamp is broken soon, it suggest the possibility

of

the warning lamp’s capacity shortage.

Standard

Lamp

:

6V

-

0.6W

Light emitting diode:

30

mA

(ID)

11-5

WIRING

Igniter

Green

r

E

Oil

Level

m

3

Controller

a

.-

m

-

1

4”

I

+-

.-

mZETm

m

-

-

m

-

-

-

-

-

-

0

Oil

Level Sensor

Oil

Level

Flywheel

I

1

Yellow

I

Oil

Shortage Warning Lamp

\

Connecting Terminal

#e‘1ow

Crankcase

Oil

Shortage

Warning Lamp

-

-

(Crankcase)

Fig.

48

-33

-

Page 38

12.

TROUBLE

SHOOTING

The following three conditions must be satisfied for satisfactory engine start.

1.

The cylinder filled with a proper fuel-air mixture.

2. An appropriate compression in the cylinder.

3.

Good sparks at the correct time to ignite the mixture.

The engine cannot be started unless these three conditions are met. There are also other factors which make

engine start difficult, e. g., a heavy load on the engine when it is about to start at low speed, and a high back

pressure due

to

a long exhaust pipe, just to say a few.

The most common causes

of

engine troubles are given below:

12-1

STARTING

DIFFICULTIES

12-

1

-

1

FUEL

SYSTEM

1)

No

gasoline in the fuel tank; or the fuel cock is closed.

2)

The carburetor is not choked enough, particularly when the engine is cold.

3)

Water, dust or gum

in

the gasoline block flow

of

the fuel to the carburetor.

4)

Inferior grade gasoline or poor quality gasoline is not gasfied enough to produce the correct fuel-air

5)

The carburetor needle valve is held open by dirt or gum.

This

trouble can be detected as the fuel

flows

out of the carburetor when the engine is idling. (Overflow)

This trouble may be remedied, depending on cases, by lightly tapping the float chamber with the grip

of

a screwdriver

of

the like.

r

6)

If the carburetor overflows, excessive fuel runs into the cylinder when starting the engine, making the

fuel-air mixture too rich to burn. If this happens, remove the spark plug, and pull the recoil starter a few

turns in order to let the rich fuel-air mixture out of the spark plug hole into the atmosphere. Keep the

carburetor choke open during this operation.

Dry

the spark plug well, screw it into place, and

try

to start

again.

mixture.

12-

1

-

2

COMPRESSION

SYSTEM

If starting difficulties and

loss

of

power are not due

to

the fuel system or ignition system, the following must

be checked for possible lack of compression.

1)

Engine inside is completely dried up because of a long period of non-operation.

2)

Loose

or

broken spark plug.

This

causes a hissing noise made

by

mixture gas running out

of

cylinder in

3)

Damaged head gasket or loose cylinder head. A similar hissing noise

is

produced during compression

4)

In correct Tappet Clearance

If the correct compression is not obtained even after remedying the above, disassemble the engine and

check further as follows:

a)

Valve stuck open due to carbon or gum

on

the valve stem.

b) If the piston rings are stuck

on

the piston, remove the piston and connecting rod from the engine,

compression stroke during cranking.

stroke.

and clean, remedy or replace the parts.

-

34

-

Page 39

12-

1

-

3

ELECTRICAL SYSTEM

Check the following for lack of sparks.

1) Leads of the ignition coil or spark plug disconnected.

2)

Ignition coil damaged and shorted.

3)

Spark plug cable wet or soaked with oil.

4)

Spark plug dirty or wet.

5)

Spark plug electrode gap incorrect.

6)

Spark plug electrodes in contact with each other.

7)

Incorrect spark timing.

(Is

the flywheel set in the correct position by the key?)

12-2

ENGINE MISFIRES

1)

Incorrect spark plug electrode gap. Adjust it to anywhere between

0.6

and

0.7

mm.

2)

Ignition cable worn and leaking.

3)

Sparks weak.

4)

Ignition wire connections loose.

5)

Water in gasoline.

6)

Insufficient compression.

12-3

ENGINE

STOPS

1)

Fuel tank empty. Water, dirt, gum, etc. in gasoline.

2)

Vapor lock,

i.

e., gasoline evaporating in the fuel lines due to overheat around the engine.

3)

Vapor lock in the fuel lines or carburetor due

to

the use of too volatile winter gas in the hot season.

4)

Air vent hole in the fuel tank cap plugged.

5)

Bearing parts seized due to lack of oil.

6)

Magneto

or

ignition coil faulty.

12-4

ENGINE OVERHEAT

1)

Crankcase oil level low. Add

oil

immediately.

2)

Spark timing incorrect.

3)

Low grade gasoline

is

used, or engine is overloaded.

4)

Cooling air circulation restricted.

5)

Cooling air party misdirected causes

loss

of cooling efficiency.

6)

Cylinder head cooling fins clogged up with dirt.

7)

Engine operated in an ecnlosed space without fresh supply

of

cooling air.

8)

Exhaust gas discharge restricted, or carbon deposits in the combustion chamber.

9)

Engine running on low-octane gasoline detonates due to heavy load

at

low speed.

-

35

-

Page 40

12-5

ENGINE KNOCKS

/-

1)

Low-quality gasoline.

2)

Engine operating under heavy load at low speed.

3)

Carbon or lead deposits in the cylinder head.

4)

Spark timing incorrect.

5)

Loose

connecting rod bearing due

to

wear.

6)

Loose

piston

pin

due

to wear.

7)

Causes

of

engine overheat.

12-6

ENGINE BACKFIRES through CARBURETOR

1)

Water or dirt

in

gasoline, or low-grade gasoline.

2)

Intake valve stuck.

3)

Valves overheated, or red-hot carbon particles in the combustion chamber.

4)

Engine cold.

Page 41

13.

INSTALLATfON

Engine life, ease

of

maintenance and inspection, frequency of checks and repairs, and operating cost all de-

pend on the way

in

which the engine is installed. Carefully observe the following instructions for installing

the engine.

13-1 INSTALLING

When mounting the engine, carefully examine its position, the method of connecting it to a load (machine),

the foundation, and the mehtod of supporting the engine.

When determining its mounting position, in particular, make sure that gasoline and oil can easily be supplied

and checked, the spark plug can easily be checked, the air cleaner can easily be serviced, and that the oil can

easily be discharges.

13-2 VENT1 LATION

Fresh air

is

necessary for cooling the engine and burning the fuel.

In case where the engine is operated under a hood or in a small room, temperature rise in the engine room

can cause vapor lock, oil deterioration, increased oil consumption, loss of power, piston seizure, shorter

engine life, etc., making it impossible to operate the engine properly. It is necessary, therefore, to provide

a

duct or baffle to guide cooling air to the engine to prevent recirculation of he hot air used for engine cooling,

and temperature rise of the load (machine).

Take steps as necessary

to

keep the engine room temperature below

50°C

even in the hottest period of the

year.

13-3 EXHAUST GAS DISCHARGE

Exhaust gas in noxious. When operating the engine indoors, be sure to discharge the exhaust gas outdoors. If

a

long exhaust pipe

is

used in such a case, the internal resistance increases causing loss

of

engine power. Thus

pipe inside diameter must increase in proportion to exhaust pipe length.

Exhaust pipe: Less than

3

m long, pipe inside diameter

25

mm,

Less

than 5 m long, pipe inside diameter

30

mm.

13-4 POWER TRANSMISSION

to

DRIVEN

MACHINES

13-4- 1 BELT

DRIVE

Take the following notes into consideration.

*

V-belts are preferable to flat belts.

*

The driving shaft of the engine must be parallel to the driven shaft

of

the load.

*

The driving pulley of the engine must be in line with the driven pulley

of

the load.

*

Install the engine pulley

as

close to the engine as possible.

*

If possible, span the belt horizontally.

*

Disengage the load when starting the engine.

If

no clutch is used, use a belt tension pulley or thelike.

13-4-2

FLEXIBLE COUPLING

When using a flexible coupling, runout and misalignment between the driven shaft and engine shaft must be

minimized. Runout and misalignment tolerance are specified by the coupling manufacturer.

-37

-

Page 42

13-5

WIRING

Wire

as

shown

in

the

wiring

diagram

below.

u.

T.

c.

I.

Ignition

Coil

cn

3

-

n

5

m

P

UJ

Fig-

49

/"

-

38

-

Page 43

14.

CHECKS

and

CORRECTIONS

After disassembling and cleaning the engine, check and repair, if necessary, according

to

the correction table.

familier with the contents of this table. Correct maintenance is recommended by observing the correction

standards specified.

The meanings

of

the terms used in the correction table are as follows:

The correction table apolies whenever the engines are repaired. It is important for the servicemen to be

Correction

Repair, adjustment or replacement

of

any engine parts.

Correction Limit

The

limit

on wear, damage or functional deterioration of engine parts beyond which normal engine performance cannot be expected without repairing such parts.

Use Limit

The limit beyond which parts can no longer be used in respect of performance or strength.

Standard Dimensions

The design dimensions

of

new parts minum tolerance.

Correction Tolerance

Tolerance on the dimensions of engine parts refinished or adjusted.

-

39

-

Page 44

Page 45

USE

LIMIT

REMARKS

TOOL

CORRECTION

METHOD

ITEM

1

STANDARD

SIZE

CORRECTION

-IMIT

TOLERANCE

0

-0.008

+0.013

0

0.037-0.063

+0.021

+0.010

0.010-0.029

0.1

-

0.7

0.05

2

0.1

-0.037

-0.050

Less

than

0.005

Less

than

0.005

Less than

0.008

-

0.003

-

0.01

2

io.1

-0.01

3

-0.028

-0.003--0.012

-0.01

3--0.028

Micrometer

Replace

-

0.04

-

0.04

+0.1

Piston pin O.D.

11 dia.

Replace

+0.1

Large end

I.D.

20

dia.

Cylinder

Micro-

meter

gauge.

Cylinder

gauge

Clearance between

rod large end

I.D.

and crankpin

0.2

Replace

0.2

+0.08

+0.08

Replace

Small end

I.D.

11 dia.

0.1

2

Cylinder

gauge,

meter

Micro-

Clearance between

small

end

I.D.

and

pinston

pin

Large end side

clearance

Parallelism between

large end and

small end bores

Replace

0.1

2

Re-machine

or

Replace

1

.o

0.1

k0.15

1

.o

0.1

Test bar

and Dial

gauge

Re-machine

or Replace

Distance between

large

end

and

small end bores

66

Re-machine

or

Replace

Micro.

meter

-0.1

5

-0.1

5

Crankpin O.D.

20

dia.

Micrometer

Crankpin

0.

D.

roundness

Micro-

meter

Crankpin O.D.

cylindricity

Dial

gauge

Crankpin

O.D.

parallelism

for D

Micrometer

Replace

Drive

S.

20

dia.

Mag.

S.

17

dia.

Crankshaft

-

0.05

-0.05

journal O.D.

Drive

S.

Mag.

S

17 dia.

for

BN

Micrometer

Micro-

meter

Cam

lobe

height

I

18.4

-0.25

-0.25

Replace

Drive

S.

Mag.

S.

dia,

Journal O.D.

for

D

Replace

-0.05

-0.05

for

BN

I

Mag.

S.

10

dia.

-41

-

Page 46

1

1

ITEM

STANDARD

CORRECTION

USE

SIZE

TOLERANCE

I

LIMIT LlMlT

REMARKS

lzl

5.5

dia.

1-1

-0.1

5

-0.020-

-0.032

Valve stem

O.D.

Exhaust

-0.056

-

-0.092

:

Clearance between

stem and guide

+

Intake

0.020

-

0.050

Exhaust

0.056

-

0.092

0.3

0.3

At

middle

below

1

Tappet clearance

0.1

0

+0.02

above When cold

0.25

Clearance between

groove and retainer

0.1

-

0.3

1

0.5

0.5

I

Stem end length

'

Intake

Exhaust

3.5

-1

.o

-1.0

~

Total length

20.8

I

+0.06 - 0

1

-0.5

1

-0.5

Clearance between

stem and guide

Spark plug

NGK

BM4A

Spark gap

Spark timing

25"

before

T.D.C.

TOOL

I

CORRECTlOh

METHOD

Vernier

calipers

Replace

Square Replace

Micrometer

Replace

Cylinder

Replace

gauge

Feeler

gauge

Replace

Vernier

calipers

Replace

Vernier

calipers Replace