Robin EY08D, EY08BN Service Manual

ROBIN

AMERICA, INC.

ROBIN

TO

WISCONSIN

ROBIN

ENGINE

MODEL

CROSS REFERENCE

LIST

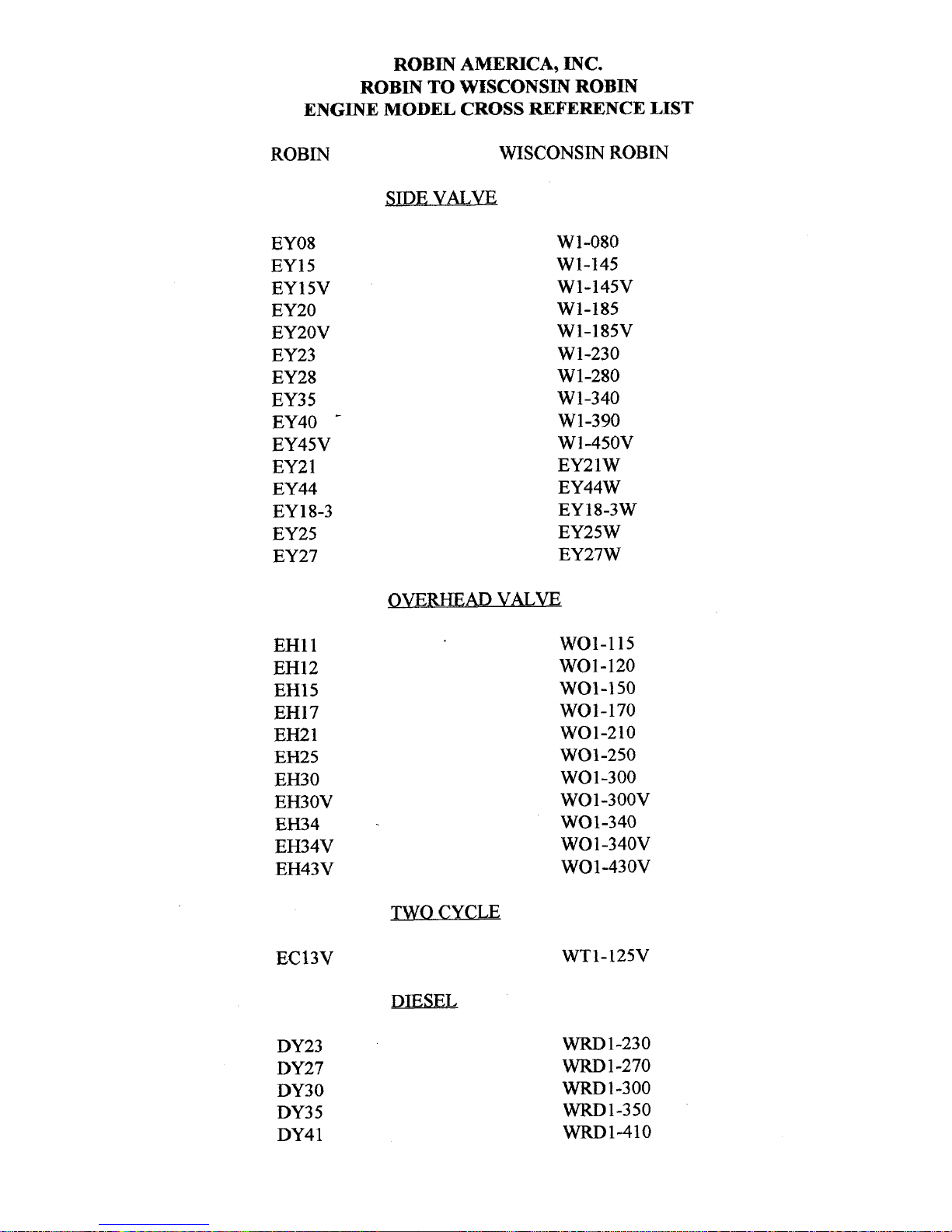

ROBIN

EY08

EY15

EY 15V

EY20

EY2OV

EY23

EY28

EY3

5

EY40

-

EY45V

EY2

1

EY44

EY 18-3

EY25

EY27

EH11

EH12

EH15

EH17

EH21

EH25

EH30

EH30V

EH34

EH34V

EH43V

EC13V

DY23

DY27

DY30

DY3

5

DY4 1

WISCONSIN

ROBIN

SIDE

VALVE

W

1-080

W1-145

W1-145V

W1-185

W1-185V

W1-230

W 1-280

W

1-340

W 1-390

Wl-45OV

EY21W

EY44W

EY18-3W

EY25W

EY27W

OVERHEAD

VALVE

WO1-115

wo1-120

WO1-150

WO1-170

wo1-210

WOl-250

WO 1-300

WO1-300V

WO1-340

WO

1

-340V

WO 1-43 OV

TWO CYCLE

WT1-125V

DIESEL

WRD

1-230

WRD

1-270

-1-300

WRD1-350

WRD1-410

0

0

0

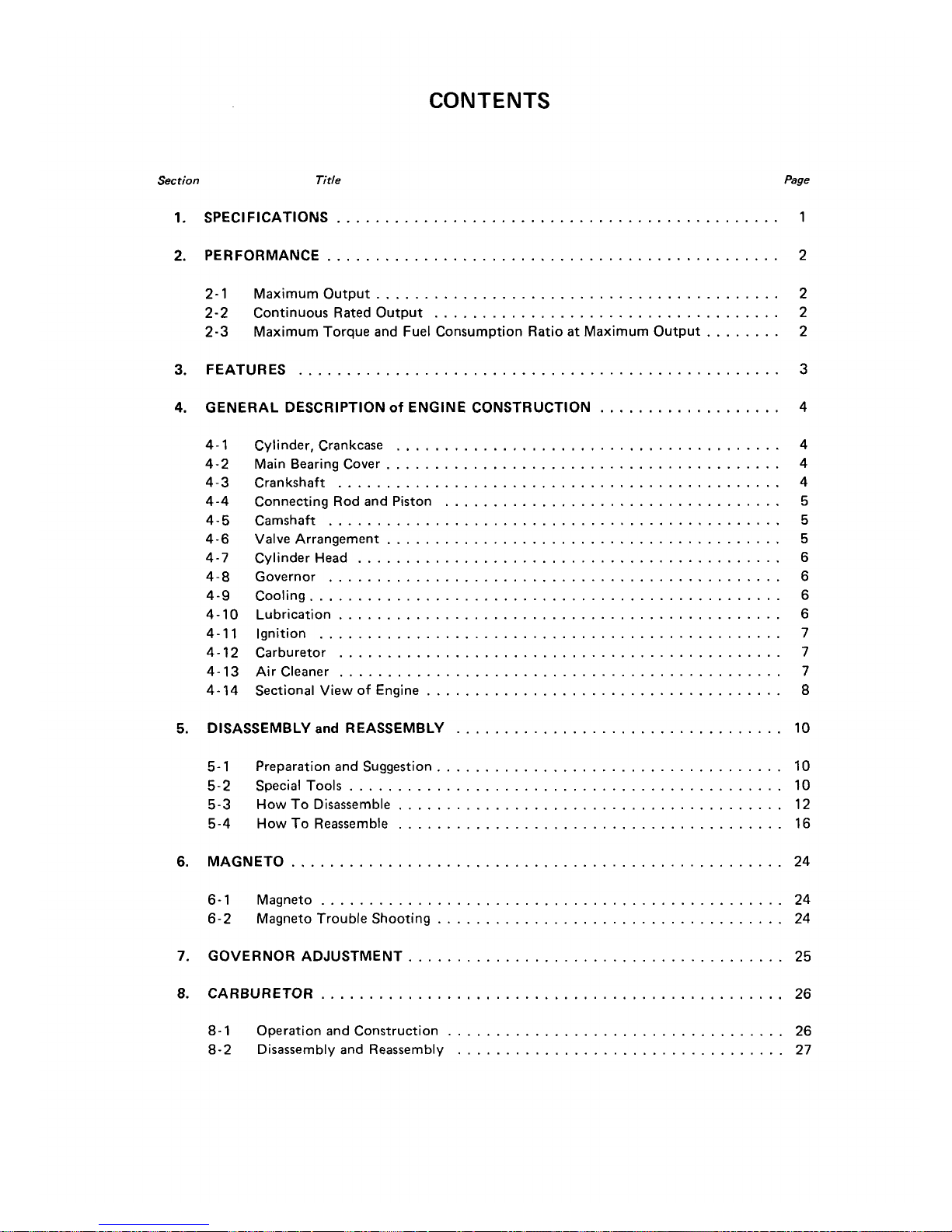

CONTENTS

Section

Title

Page

1

.

SPECIFICATIONS

..............................................

1

2

.

PERFORMANCE

...............................................

2

2-1

Maximum Output

..........................................

2

2-2

Continuous Rated Output

....................................

2

2-3

Maximum Torque and Fuel Consumption Ratio

at

Maximum Output

........

2

3

.

FEATURES

..................................................

3

4

.

GENERAL DESCRIPTION

of

ENGINE CONSTRUCTION

...................

4

4-1

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-9

4-10

4-1 1

4-12

4-13

4-14

Cylinder. Crankcase

........................................

4

Main Bearing Cover

.........................................

4

Crankshaft

..............................................

4

Connecting Rod and Piston

...................................

5

Camshaft

...............................................

5

Valve Arrangement

.........................................

5

Cylinder Head

............................................

6

Governor

...............................................

6

Cooling

.................................................

6

Lubrication

..............................................

6

Ignition

................................................

7

Carburetor

..............................................

7

Air Cleaner

..............................................

7

Sectional View

of

Engine

.....................................

8

5

.

DISASSEMBLY

and

REASSEMBLY

..................................

10

5-

1

Preparation and Suggestion

....................................

10

5-2

Special Tools

.............................................

10

5-3

How

To

Disassemble

........................................

12

5-4

How

To

Reassemble

........................................

16

6

.

MAGNETO

...................................................

24

6-1

Magneto

................................................

24

6-2

Magneto Trouble Shooting

....................................

24

7

.

GOVERNOR ADJUSTMENT

.......................................

25

8

.

CARBURETOR

................................................

26

8-1

Operation and Construction

...................................

26

8-2 Disassembly and Reassembly

..................................

27

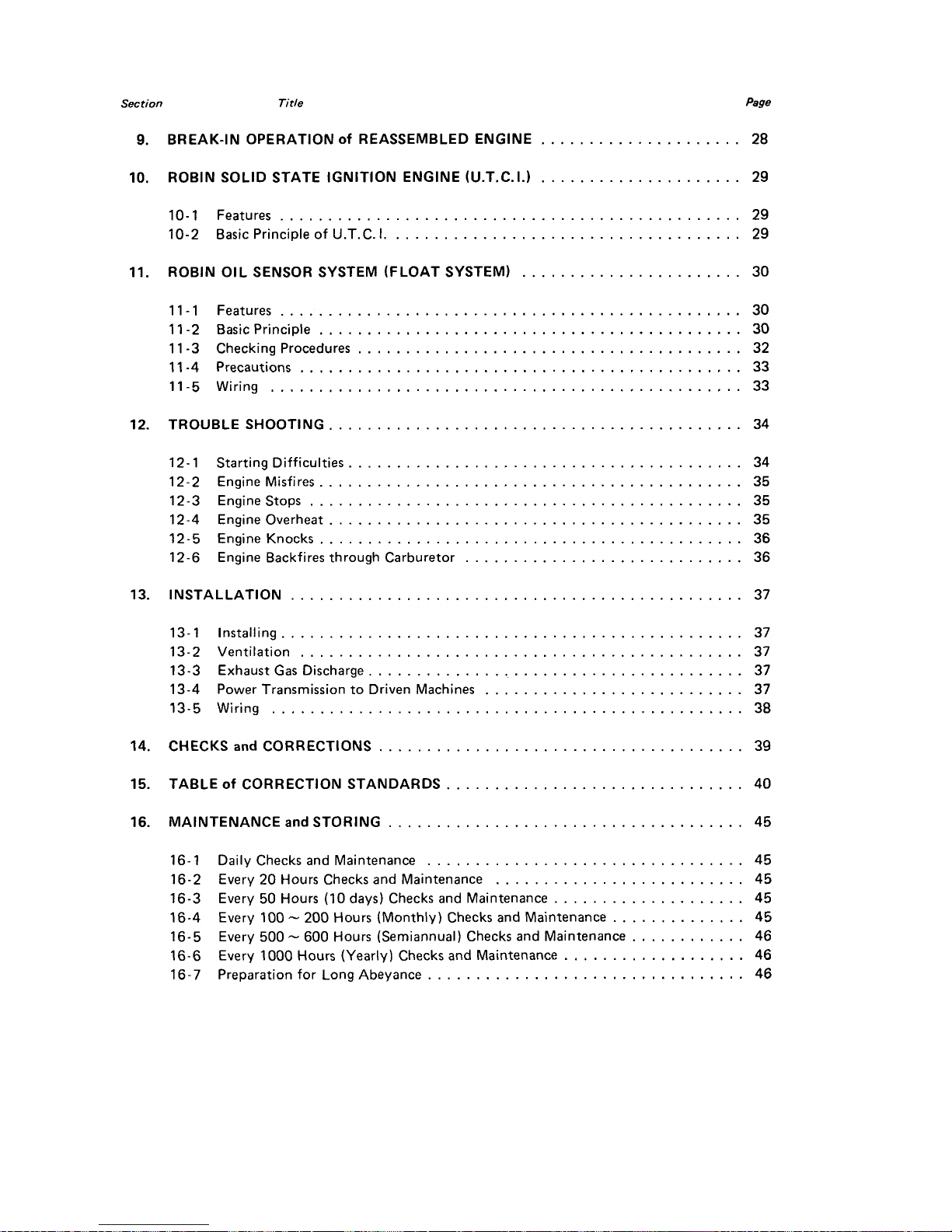

Section

Title

Page

9

.

BREAK-IN OPERATION

Of

REASSEMBLED ENGINE

.....................

28

10

.

ROBIN SOLID STATE IGNITION ENGINE (U.T.C.I.)

.....................

29

10-1

Features

................................................

29

10-2

Basic Principle of U.T.C.

I

.....................................

29

I1

.

ROBIN OIL SENSOR SYSTEM (FLOAT

SYSTEM)

.......................

30

11-1

Features

................................................

30

11

-2

Basic Principle

............................................

30

11

-3

Checking Procedures

........................................

32

11

-4

Precautions

..............................................

33

11-5

Wiring

.................................................

33

12

.

TROUBLE SHOOTING

...........................................

34

12-

1

Starting Difficulties

.........................................

34

12-2

Engine Misfires

............................................

35

12-4

Engine Overheat

...........................................

35

12-3

Enginestops

.............................................

35

12-5 Engine Knocks

............................................

36

12-6

Engine Backfires through Carburetor

.............................

36

13

.

INSTALLATION

...............................................

37

13-1

Installing

................................................

37

13-2

Ventilation

..............................................

37

13-3

Exhaust Gas Discharge

.......................................

37

13-4

Power Transmission to Driven Machines

...........................

37

13-5

Wiring

.................................................

38

14

.

CHECKS

and

CORRECTIONS

......................................

39

15

.

TABLE

of

CORRECTION STANDARDS

...............................

40

16

.

MAINTENANCE

and

STORING

.....................................

45

16-1

Daily Checks and Maintenance

.................................

45

16-2

Every

20

Hours Checks and Maintenance

..........................

45

16-3

Every

50

Hours

(IO

days)

Checks and Maintenance

....................

45

16-4

Every

100

.

200

Hours (Monthly) Checks and Maintenance

..............

45

16-5

Every

500

.

600

Hours (Semiannual) Checks and Maintenance

............

46

16-6

Every

1000

Hours (Yearly) Checks and Maintenance

...................

46

16-7

Preparation for Long Abeyance

.................................

46

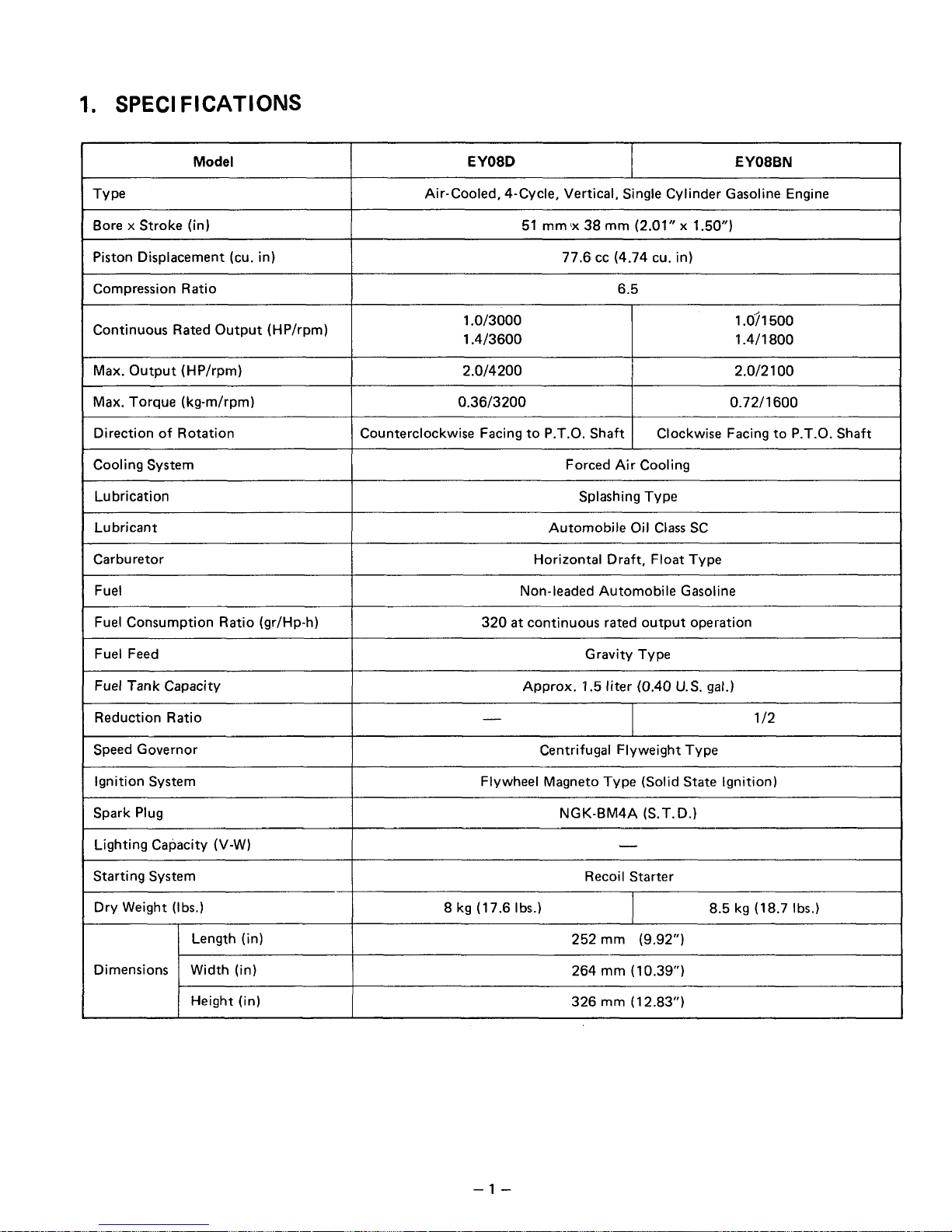

1.

SPEC1

FICATIOMS

Model

EY08BN EY08D

Air-Cooled, 4-Cycle, Vertical, Single Cylinder Gasoline Engine

Bore x Stroke (in)

77.6 cc (4.74 cu. in) Piston Displacement (cu. in)

51

mm

'x

38

mm

(2.01"

x

1.50")

Compression Ratio

6.5

Continuous Rated Output (HP/rpm)

1.0/3000

1.4/3600

1

.O?

1 500

1.4/1800

Max. Output (HP/rpm)

0.72/1600 0.36/3200

Max. Torque (kg-m/rpm)

2.0/2

1

00

2.0/4200

Direction of Rotation

1

Counterclockwise Facing to P.T.O. Shaft

Clockwise Facing to P.T.O. Shaft

Cooling System

I

Forced Air Cooling

~

Lubrication

Splashing Type

Lubricant

Automobile Oil Class

SC

~~

Carburetor

Horizontal Draft, Float Type

~~

Fuel

320

at

continuous rated output operation Fuel Consumption Ratio (gr/Hp-h)

Non-leaded Automobile Gasoline

Fuel Feed

I

Gravity Type

Fuel

Tank

Capacity

I

Approx.

1.5

liter (0.40

U.S.

gal.)

Reduction Ratio

I

-

1

/2

Speed Governor

8.5 kg (18.7 Ibs.)

8 kg (17.6 Ibs.)

Dry Weight (Ibs.)

Recoil Starter

Starting System

-

Lighting Capacity (V-W)

NGK-BM4A (S.T.D.)

Spark Plug

Flywheel Magneto Type (Solid

State

Ignition) Ignition System

Centrifugal Flyweight Type

Length (in)

326

mm

(12.83")

Height

(in)

264

mm

(10.39")

Width (in)

Dimensions

252 mrn (9.92")

-1

-

2.

PERFORMANCE

2-1

MAXIMUM OUTPUT

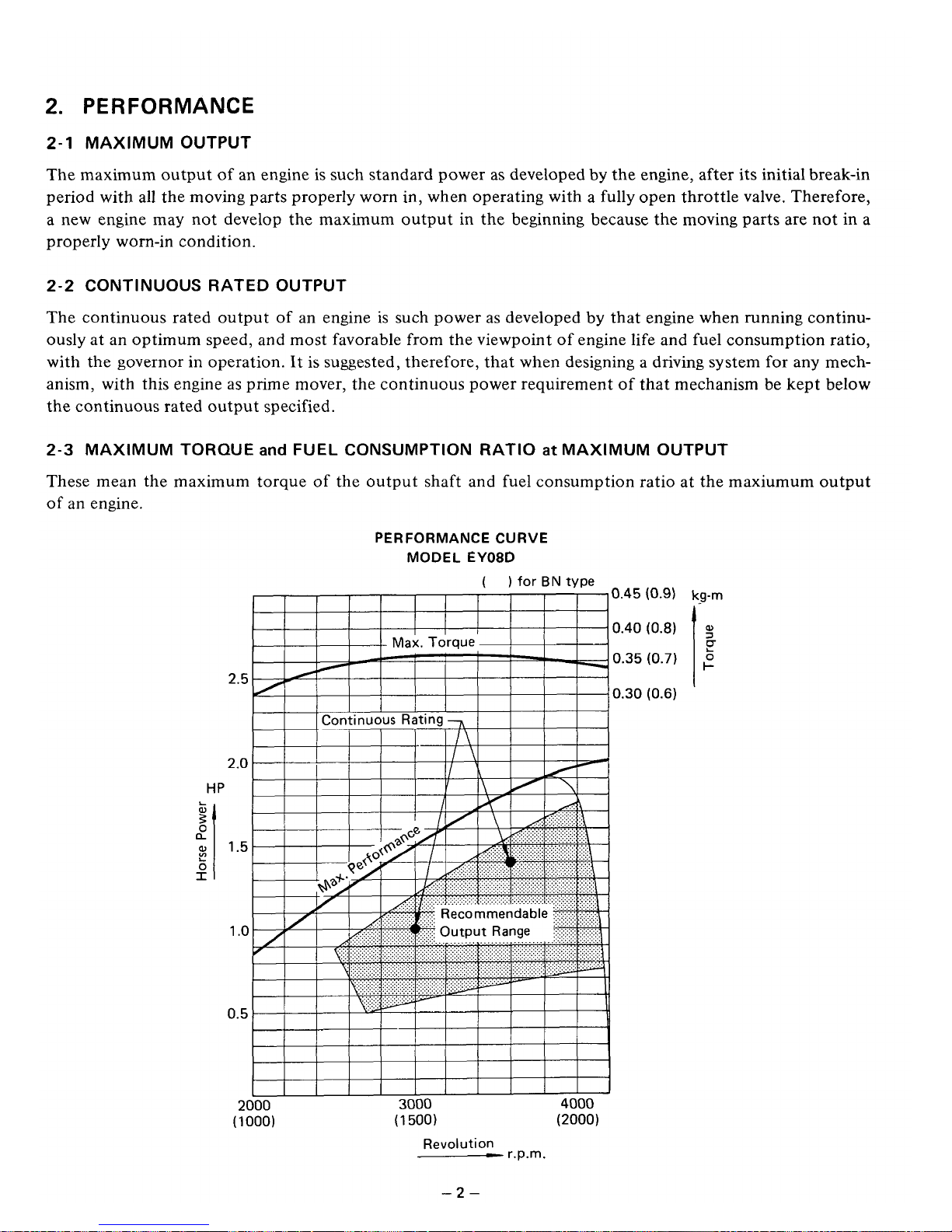

The maximum output of an engine

is

such standard power as developed by the engine, after its initial break-in

period with all the moving parts properly worn in, when operating with a fully open throttle valve, Therefore,

a new engine may not develop the maximum output in the beginning because the moving parts are not in a

properly worn-in condition.

2-2

CONTINUOUS RATED OUTPUT

The continuous rated output of an engine

is

such power as developed

by

that engine when running continuously at an optimum speed, and most favorable from the viewpoint of engine life and fuel consumption ratio,

with the governor in operation. It is suggested, therefore, that when designing a driving system

for

any mech-

anism, with this engine

as

prime mover, the continuous power requirement

of

that mechanism be kept below

the continuous rated output specified.

2-3

MAXIMUM TORQUE

and

FUEL CONSUMPTION

RATIO

at

MAXIMUM OUTPUT

These mean the maximum torque of the output shaft and fuel consumption ratio at the maxiumum output

of

an

engine.

HP

L

W

0

a

3’

L

0

I

PERFORMANCE

CURVE

MODEL

EY08D

( )

for

BN

type

0.45

0.40

0.35

0.30

2.5

2.0

1.5

1

.o

0.5

2000

3000

4000

(1

000)

(1

500)

(2000)

Revolution

-

r.p.m.

(0.9)

kg-rn

-2-

3.

FEATURES

1.

Compact, lightweight, durable, powerful 4cycle air cooled engine embodying ingenious design techniques

and skilful workmanship.

2.

Simple construction, smart appearance, maximum easiness

of

start owing to automatic decompression

device

3.

Pointless Solid State ignition system is newldy adopted for preventing poor igniting.

4.

Reliable prime mover for varietyof purposes with smooth speed controlrby a governor under varying load

conditions.

5.

Economical because fuel consumption is very low

-3-

4.

GENERAL DESCRIPTION

of

ENGINE CONSTRUCTION

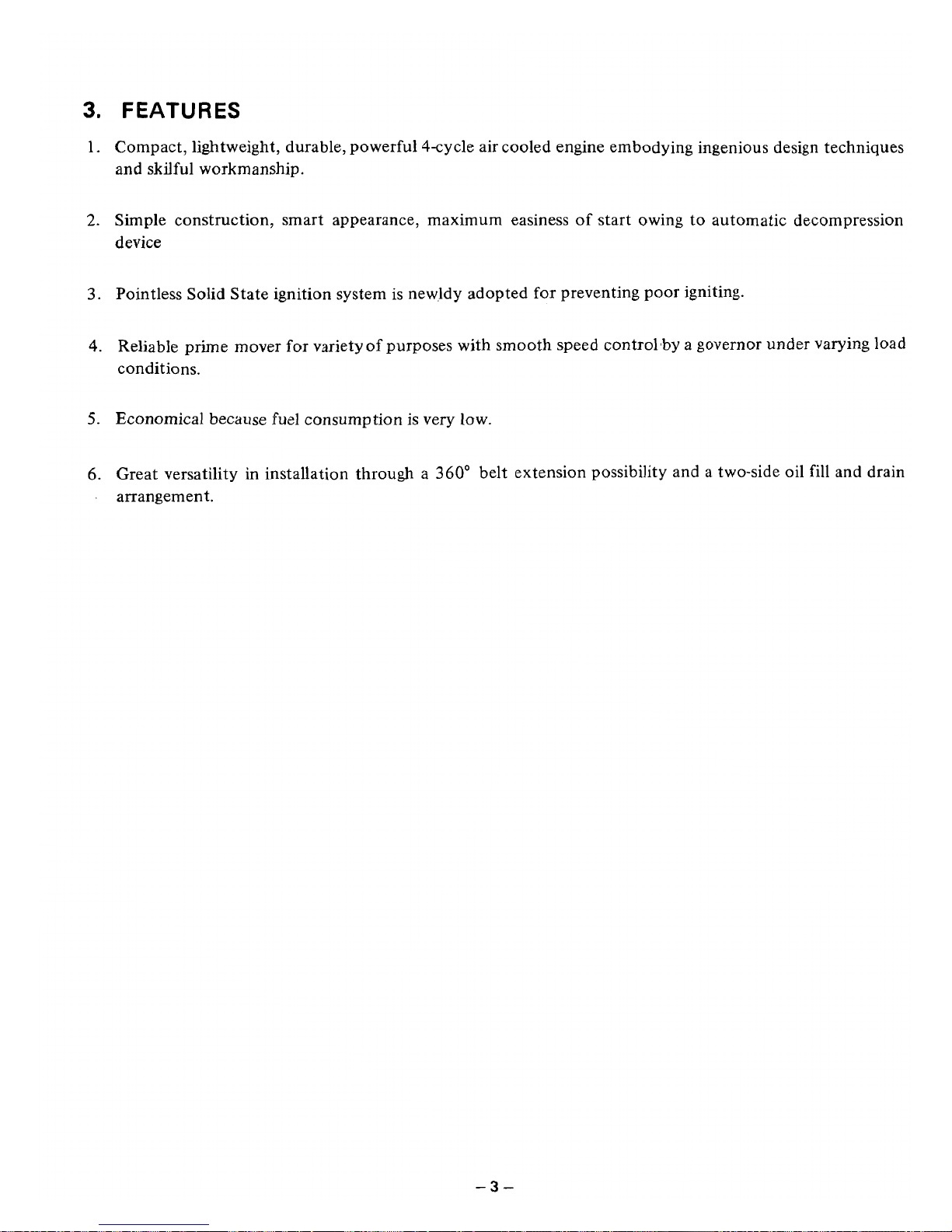

4-1

CYLINDER, CRANKCASE

The cylinder and crankcase are single piece aluminum die casting. The cylinder liner, made of special

cast iron, is built into the alminum casting. The

in-

take and exhaust ports are located on one side

of

the cylinder, and are also inserted into the casting.

The crankcase is separable on the output shaft side,

where the main bearing cover

is

attached to it.

(See Fig.

1

.)

Fig.

1

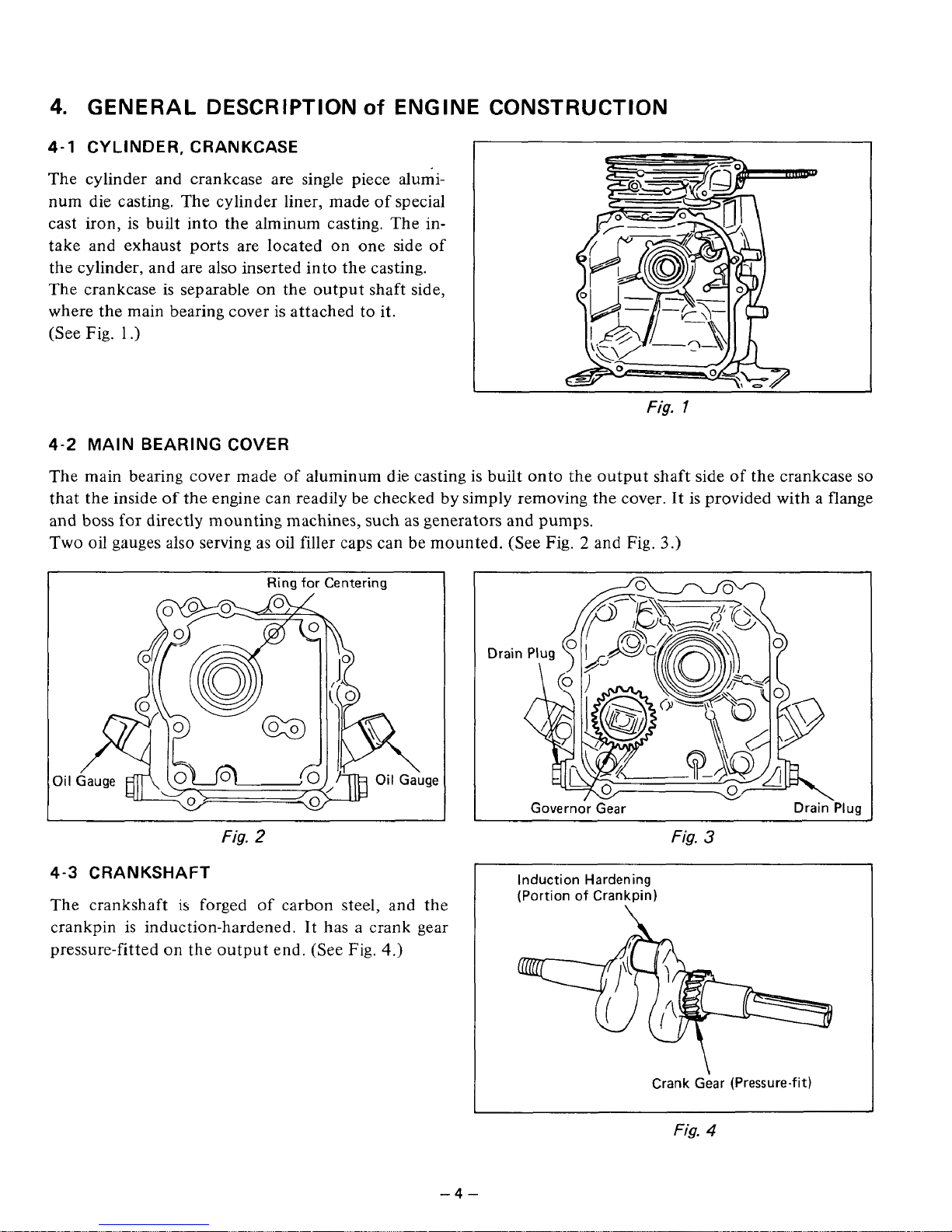

4-2

MAIN

BEARING

COVER

The main bearing cover made

of

aluminum die casting is built onto the output shaft side

of

the crankcase

so

that the inside of the engine can readily be checked by simply removing the cover. It is provided with a flange

and boss for directly mounting machines,

such

as

generators and pumps.

Two oil gauges also serving

as

oil filler caps can be mounted. (See

Fig.

2

and

Fig.

3.)

Oi

I

Ring

for Centering

!ID

Oil

Gauge

Fig.

2

4-3

CRANKSHAFT

The crankshaft is forged of carbon steel, and the

crankpin

is

induction-hardened. It has a crank gear

pressure-fitted on the output end. (See

Fig.

4.)

Fig.

3

~~

Induction Hardening

(Portion of Crankpin)

\

Crank Gear (Pressure-fit)

Fig.

4

-4-

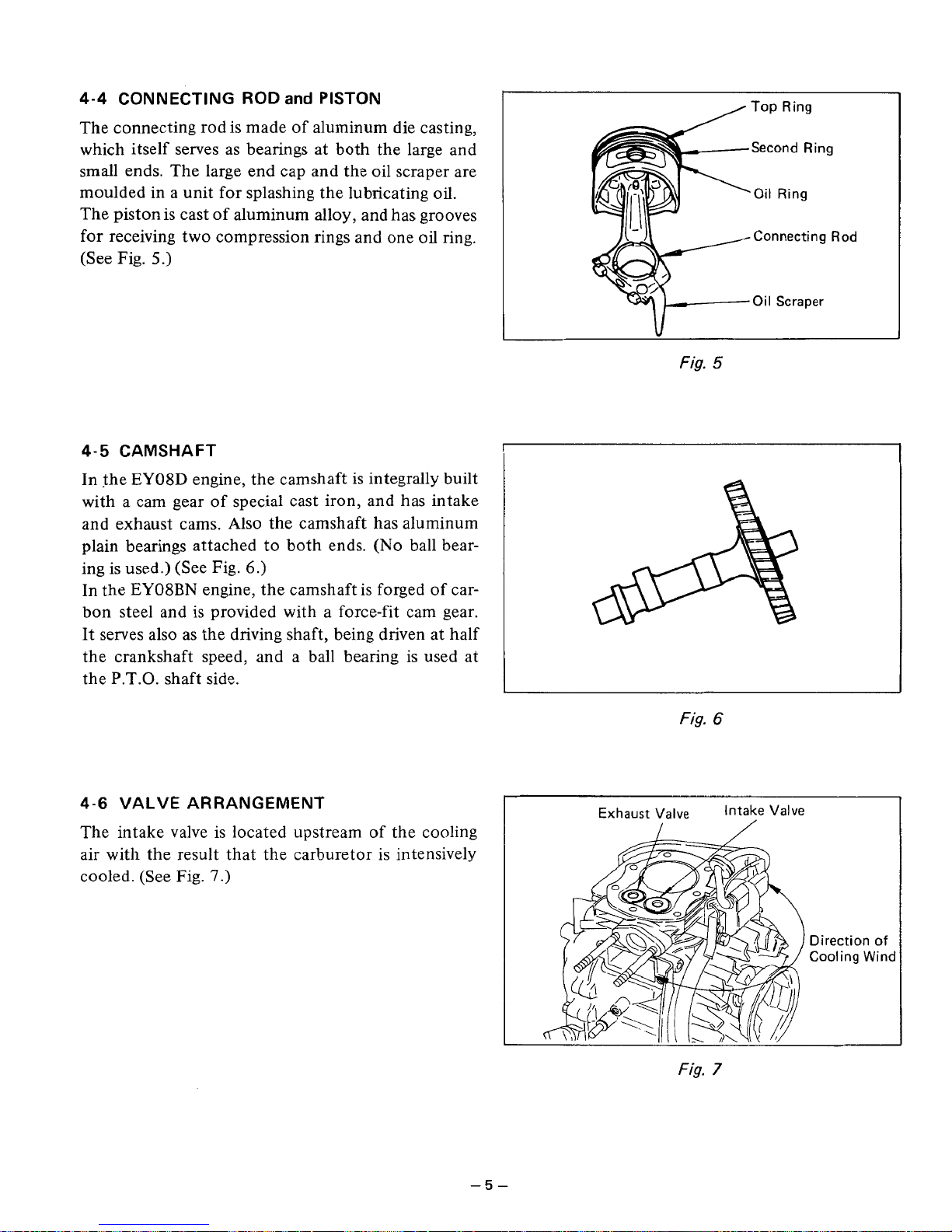

The connecting rod is made of aluminum die casting,

which itself serves as bearings at both the large and

small ends. The large end cap and the oil scraper are

moulded in a unit for splashing the lubricating oil.

The piston is cast

of

aluminum alloy, and has grooves

for receiving two compression rings and one

oil

ring.

(See Fig.

5.)

4-4

CONNECTING ROD

and

PISTON

4-5 CAMSHAFT

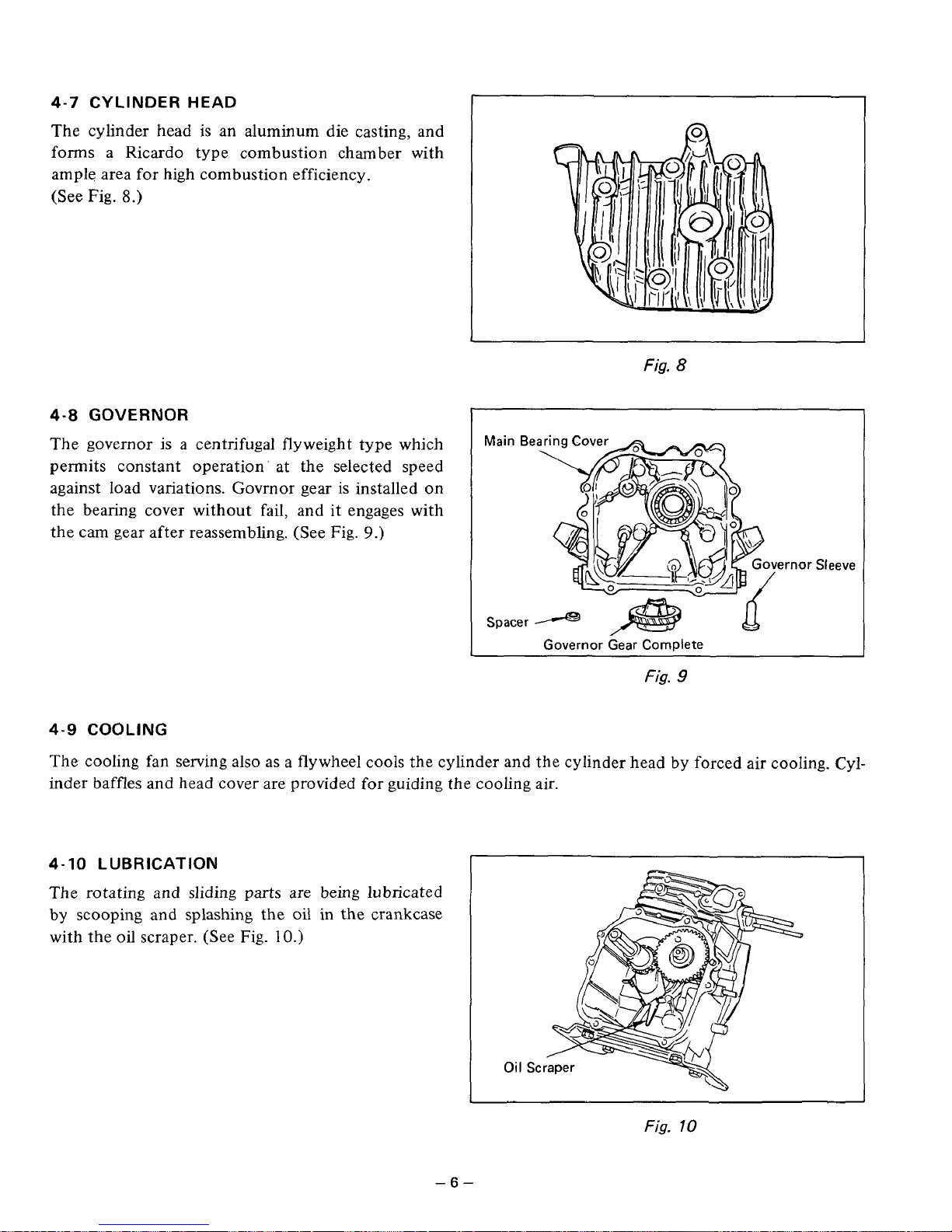

In the EY08D engine, the camshaft is integrally built

with a cam gear of special cast iron, and has intake

and exhaust cams. Also the camshaft has aluminum

plain bearings attached to both ends.

(No

ball bear-

ing is used.) (See Fig.

6.)

In the EY08BN engine, the camshaft is forged of carbon steel and is provided with a force-fit cam gear.

It serves also

as

the driving shaft, being driven at half

the crankshaft speed, and a ball bearing is used at

the P.T.O. shaft side.

4-6

VALVE ARRANGEMENT

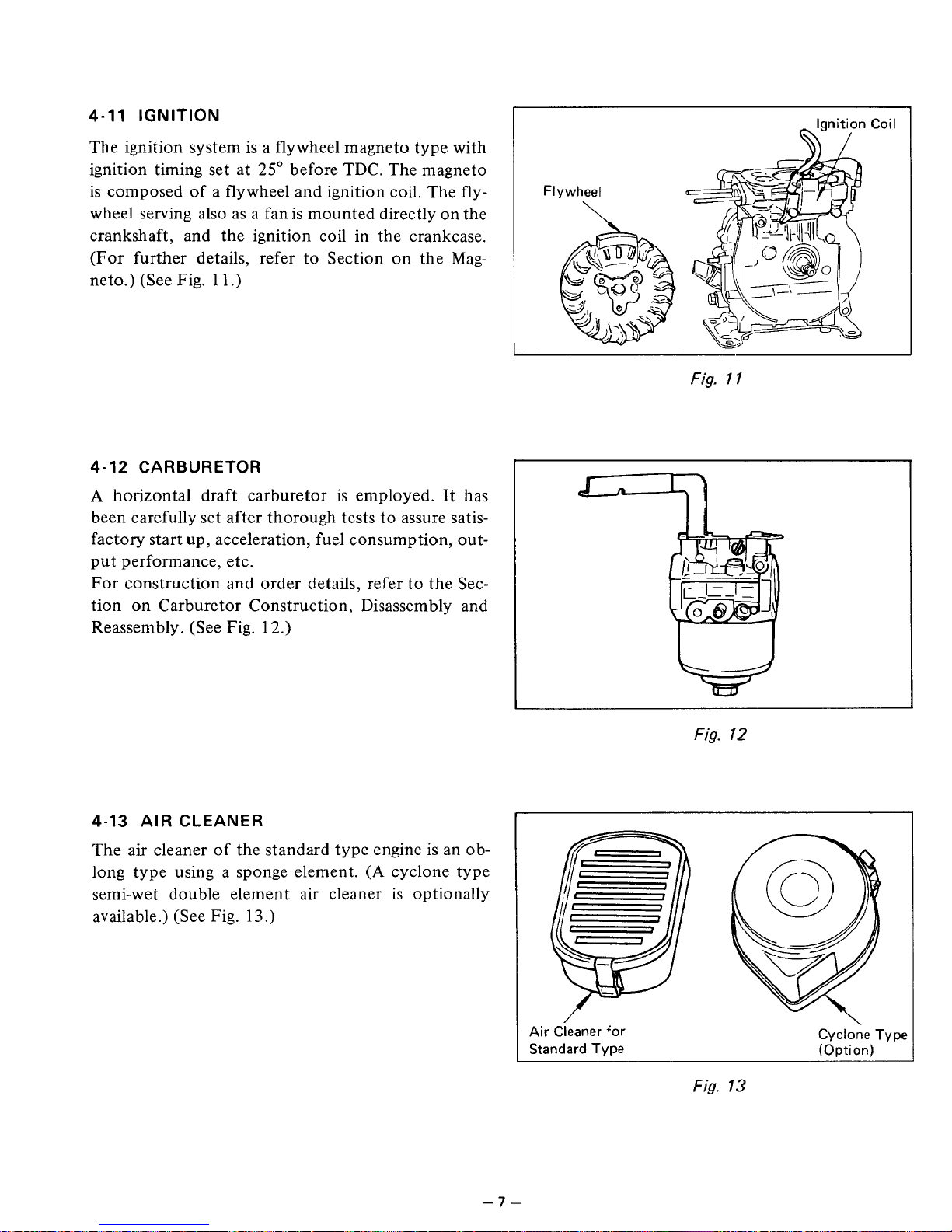

The intake valve is located upstream

of

the cooling

air with the result that the carburetor is intensively

cooled. (See Fig.

7.)

Top

Ring

Second Ring

Oil

Ring

Connecting

Rod

Oil

Scraper

\I

L

Fig.

5

:

Fig.

6

Direction

of

Cooling

Wind

Fig.

7

-5-

4-7

CYLINDER HEAD

The cylinder head

is

an aluminum die casting, and

forms a Ricardo type combustion chamber with

ample area for high combustion efficiency.

(See

Fig.

8.)

4-8

GOVERNOR

The governor is a centrifugal flyweight type which

permits constant operation- at the selected speed

against load variations. Govrnor gear is installed on

the bearing cover without fail, and

it

engages with

the cam gear after reassembling. (See Fig.

9.)

I

Fig.

8

Main

Be

!mor

Sleeve

Spacer

Q

-

Governor Gear Complete

Fig.

9

4-9

COOLING

The cooling fan serving also as a flywheel cools the cylinder and the cylinder head by forced air cooling. Cylinder baffles

and

head cover are provided for guiding the cooling air.

4-10

LUBRICATION

The rotating and

sliding

parts are being lubricated

by scooping

and

splashing the

oil

in the crankcase

with the

oil

scraper. (See Fig.

10.)

Fig.

10

-6-

4-11

IGNITION

The ignition system

is

a flywheel magneto type with

ignition timing set at

25"

before TDC. The magneto

is composed

of

a

flywheel and ignition coil. The fly-

wheel serving also as a fan is mounted directly on the

crankshaft, and the ignition coil in the crankcase.

(For further details, refer to Section

on

the Mag-

neto.) (See

Fig.

1 1

.)

4-12 CARBURETOR

A

horizontal draft carburetor is employed. It has

been carefully set after thorough tests to assure satisfactory start up, acceleration, fuel consumption, output performance, etc.

For construction and order details, refer to the Section on Carburetor Construction, Disassembly and

Reassembly. (See Fig. 12.)

4-13 AIR CLEANER

The air cleaner

of

the standard

ty

:ngine

is

an

0

b-

long type using a sponge element.

(A

cyclone type

semi-wet double element air cleaner is optionally

available.) (See

Fig.

13.)

I

Ignition Coil

Fig.

1

1

Fig.

12

Air Cieaner for

Standard Type

Cyclone Type

(Option)

Fig.

13

-7-

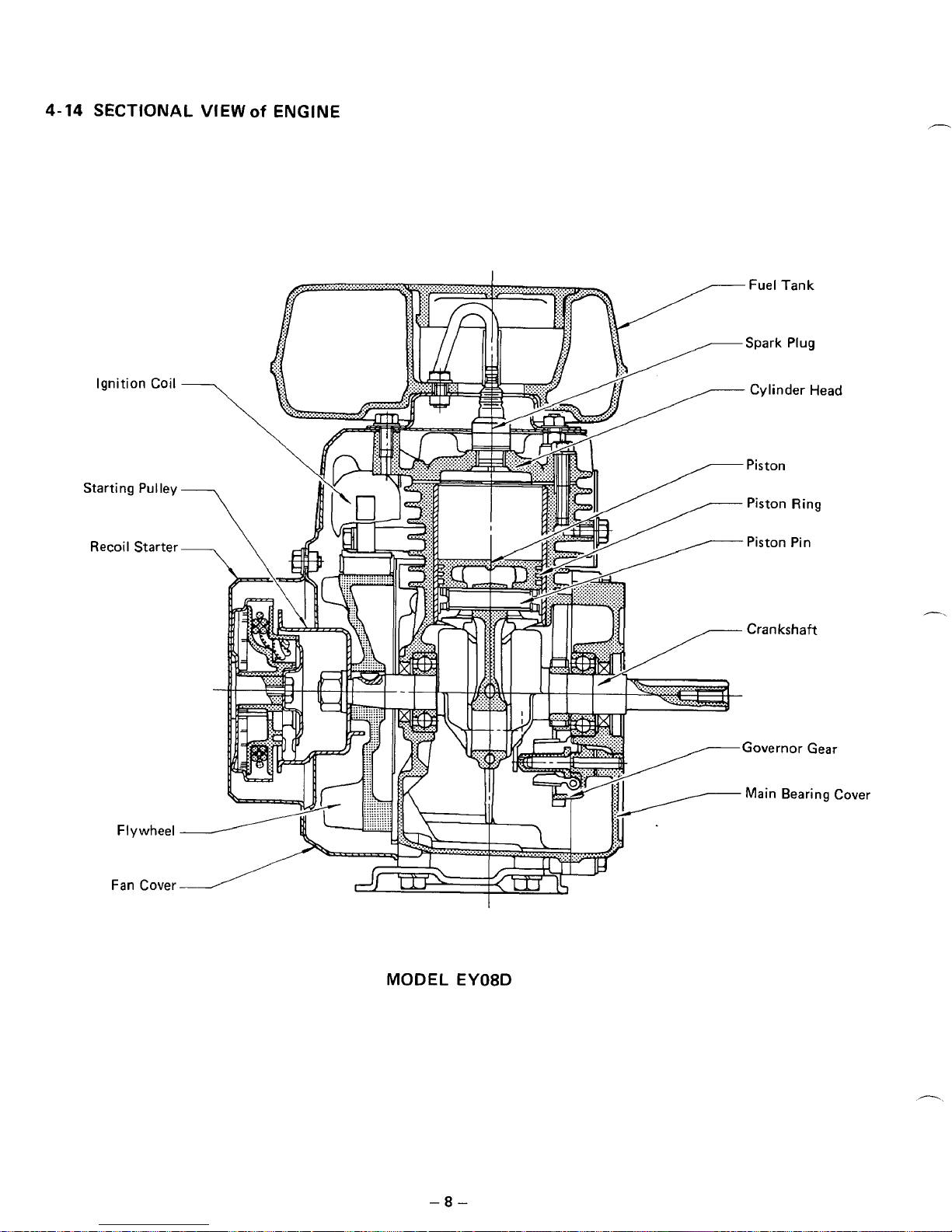

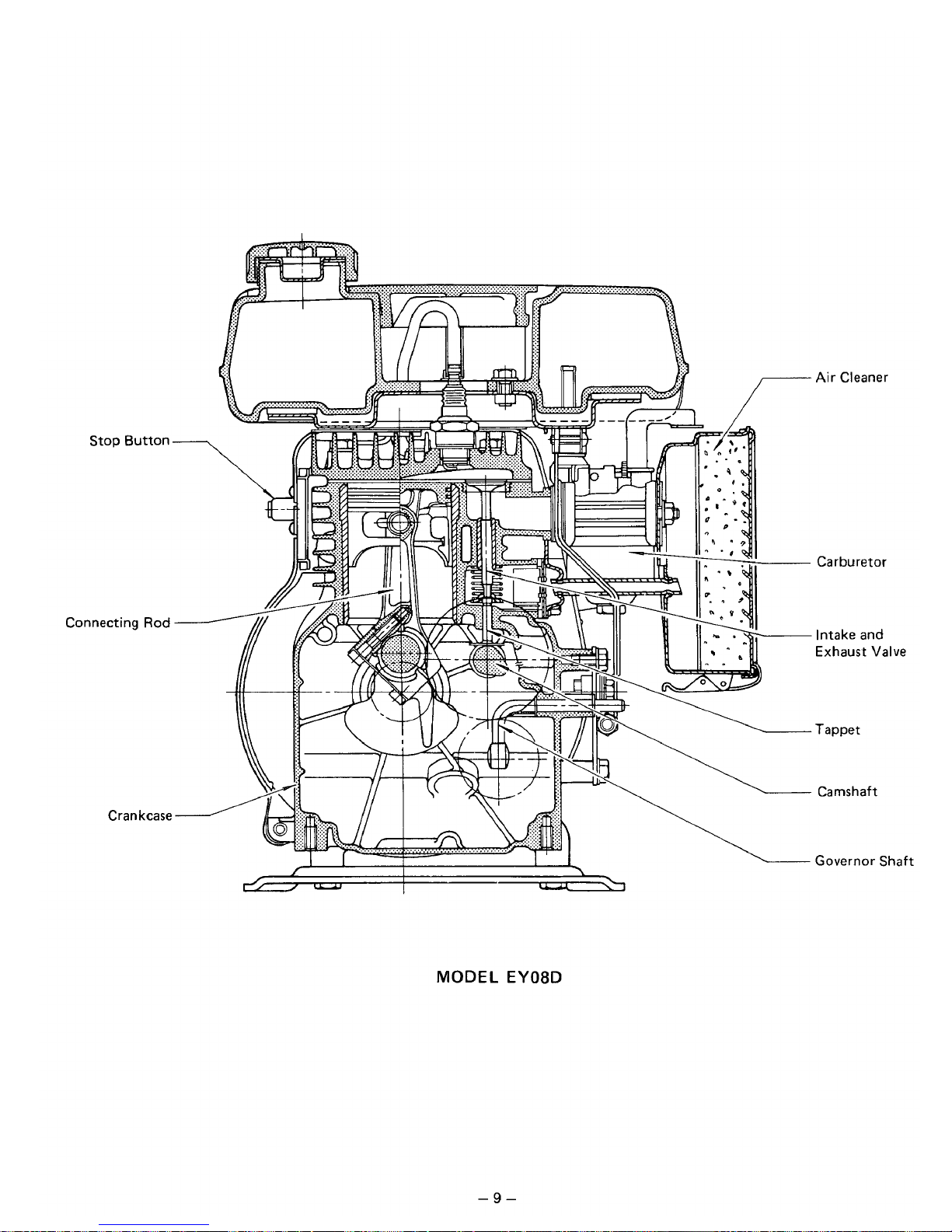

4-14

SECTIONAL

VIEW

of

ENGINE

MODEL

-8-

EY08D

Stop Button

Connecting

Rod

Crankcase

MODEL

EY08D

Air

Cleaner

Carburetor

Intake and

Exhaust Valve

Tappet

Camshaft

Governor

Shaft

-9-

5.

DISASSEMBLY

and

REASSEMBLY

5-1

PREPARATIONS

and

SUGGESTIONS

1)

When disassembling the engine, remember well the locations of individual parts

so

that they can be reas-

sembed correctly.

If

you are uncertain

of

identifying some parts, it

is

suggested that tags be attached

to

them.

2)

Have boxes ready

to

keep disassembed parts by group.

3)

To

prevent missing and misplacing, temporarily assemble each group of disassembed parts.

4)

Carefully handle disassembed parts, and clean them with washing oil.

5)

Use the correct tools

in

the correct way.

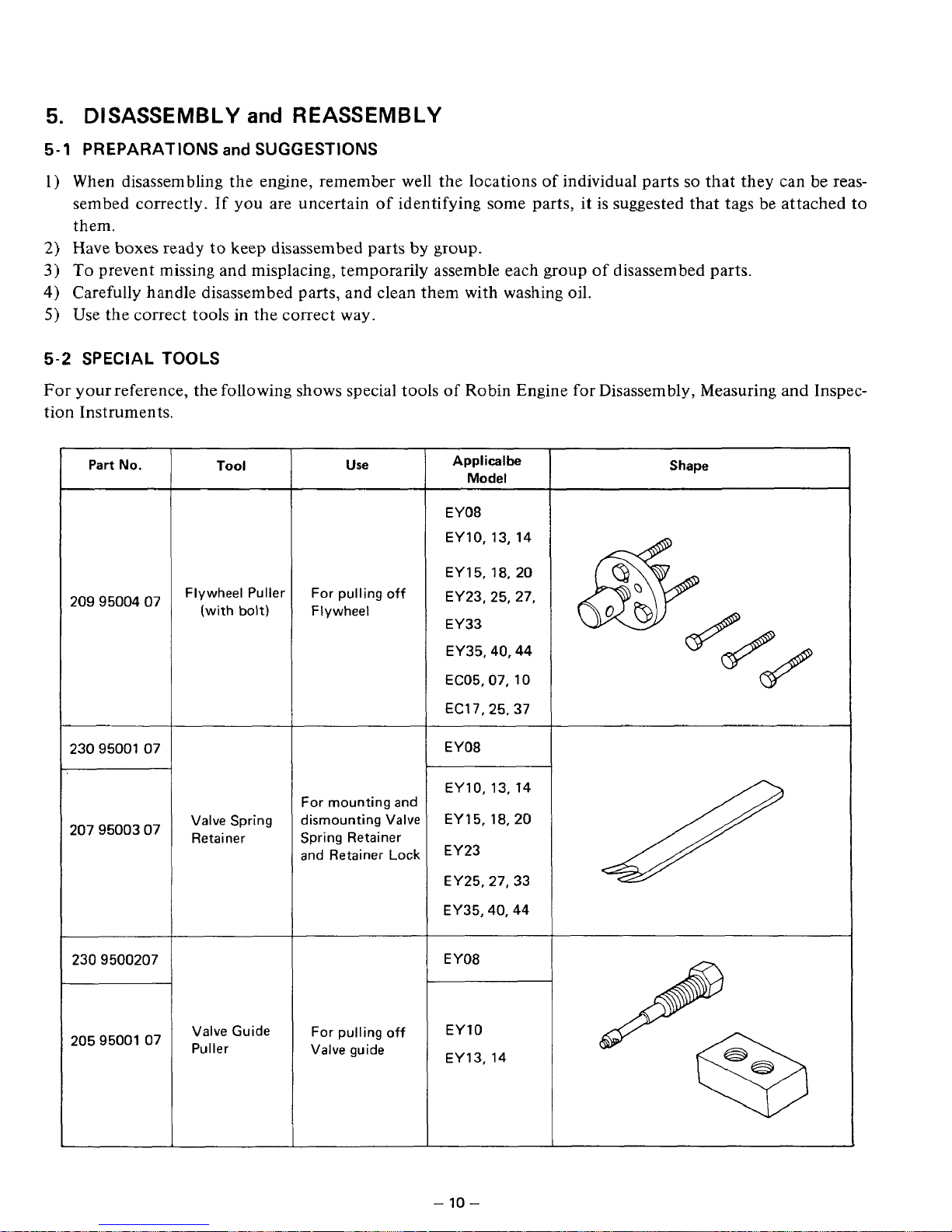

5-2

SPECIAL

TOOLS

For

your reference, the following shows special tools of Robin Engine for Disassembly, Measuring and Inspec-

tion Instruments.

Part

No.

2099500407

2309500107

2079500307

2309500207

2059500107

Tool

Flywheel Puller

(with

bolt)

Valve Spring

Retainer

Valve Guide

Puller

Use

For pulling

off

Flywheel

For mounting and

dismounting Valve

Spring Retainer

and Retainer

Lock

For pulling off

Valve guide

Applicalbe

Model

EY08

EY10, 13, 14

EY

15,18,

20

EY23, 25, 27,

EY33

EY35,40,44

EC05.07, 10

EC17,25.37

EY08

EY10,13, 14

EY 15, 18,20

EY23

EY25.27, 33

EY35,40,44

EY08

EY10

EY13,

14

Shape

-10-

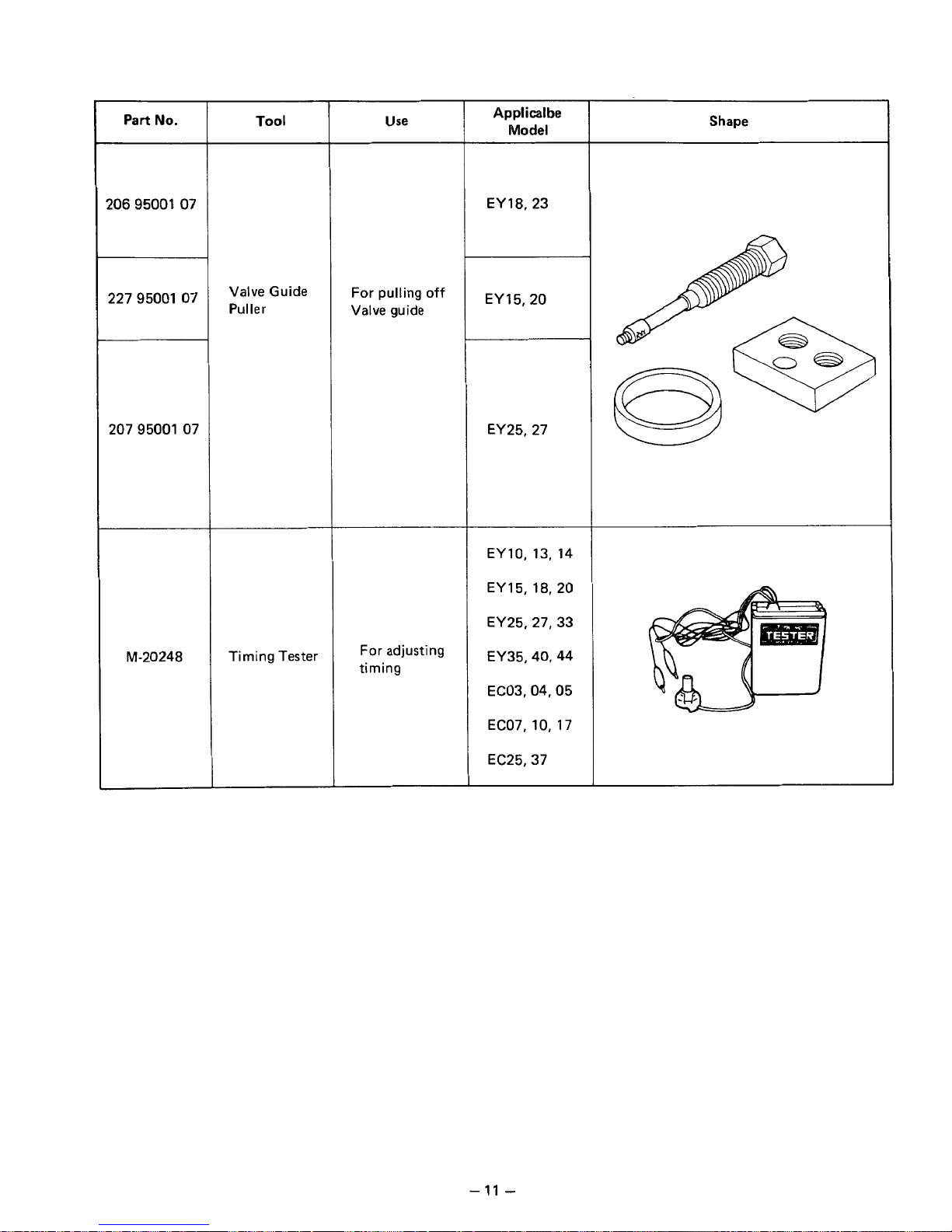

Part

No.

2069500107

2279500107

207 95001 07

“20248

Tool

Valve Guide

Puller

Timing Tester

Use

For pulling

off

Valve guide

For

adjusting

timing

Applicalbe

Model

EY18.23

EY 15,ZO

EY25, 27

EY10,

13,

14

EY 15, 18,20

EY25,27,33

EY35,40,44

EC03,04,05

EC07,10,

17

EC25,37

Shape

-

11

-

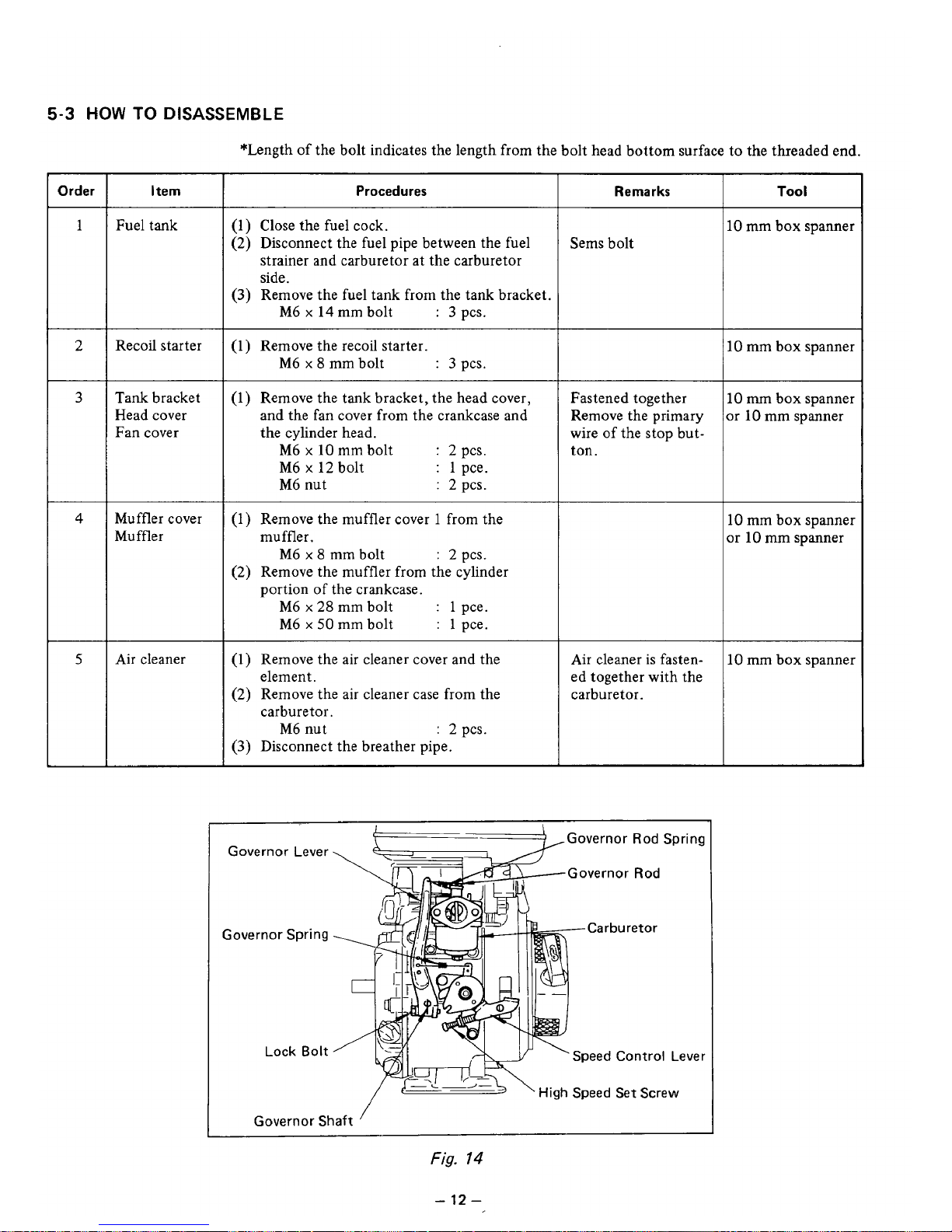

5-3

HOW

TO

DISASSEMBLE

*Length of the bolt indicates the length from the bolt head bottom surface to the threaded end.

Order

5

I

tern

Fuel tank

Recoil starter

Tank bracket

Head cover

Fan cover

Muffler cover

Muffler

Air cleaner

Procedures

(1)

Close the fuel cock.

(2)

Disconnect the fuel pipe between the fuel

strainer and carburetor at the carburetor

side.

(3) Remove the fuel tank from the tank bracket.

M6

x

14

mm bolt

:

3

pcs.

(1)

Remove the recoil starter.

M6

x

8

mm bolt

:

3

pcs.

(1)

Remove the

tank

bracket, the head cover,

and the fan cover from the crankcase and

the cylinder head.

M6

x

10

rnm

bolt

:

2

pcs.

M6

x

12

bolt

:

1

pce.

M6 nut

:

2

pcs.

(1)

Remove the muffler cover 1 from the

muffler.

M6

x

8

mm bolt

:

2

pcs.

(2)

Remove the muffler from the cylinder

portion

of

the crankcase.

M6

x

28

mrn bolt

:

1

pce.

M6

x

50 mm bolt

:

1

pce.

(1)

Remove the air cleaner cover and the

(2)

Remove the

air

cleaner case from the

element.

carburetor.

M6 nut

:

2

pcs.

(3) Disconnect the breather pipe.

Remarks

Sems bolt

Fastened together

Remove the primary

wire of the stop button.

Air cleaner is fastened together with the

carburetor.

Governor Lever

Governor Spring

Lock

Bolt

{--)

,Governor Rod Spring

Governor

Rod

Lever

L

'

High

Speed Set

Screw

Governor

Shaft

Fig.

14

Tool

10

mm box spanner

IO

mm box spanner

10

m

box spanner

Ir

10

mm spanner

10

mm box spanner

x

10

mm

spanner

10

mm box spanner

-

12

-

Loading...

Loading...