Page 1

Page 2

CONTENTS

Section

Tifle

Page

1

.

SPECIFICATIONS

.......................................................................................................

1

2

.

PERFORMANCE

........................................................................................................

2

2-1

MAXIMUM OUTPUT

.........................................................................................................

2

2-2

MAXIMUM TORQUE

........................................................................................................

2

2-3

PERFORMANCE CURVES

..............................................................................................

3

3

.

FEATURES

..................................................................................................................

5

4

.

GENERAL DESCRIPTION

OF

ENGINE COMPONENTS

..........................................

6

4-1

CYLINDER AND CRANKCASE

........................................................................................

6

4-2

MAIN

BEARING

COVER

..................................................................................................

6

4-3

CRANKSHAFT

..................................................................................................................

6

4-4

CONNECTING

ROD

AND PISTON

..................................................................................

7

4-5

PISTON RINGS

................................................................................................................

7

4-6

CAMSHAFT

......................................................................................................................

7

4-7

CYLINDER HEAD

.............................................................................................................

8

4-8

VALVE ARRANGEMENT

..................................................................................................

8

4-9

GOVERNOR SYSTEM

.....................................................................................................

8

4-1 0 COOLING SYSTEM

........................................................................................................

9

4-11

LUBRICATION SYSTEM

.................................................................................................

9

4-12

IGNITION SYSTEM

........................................................................................................

9

4-1

3 CHARGING SYSTEM

.....................................................................................................

9

4-14

CARBUREJOR

.............................................................................................................

10

4-1 5 AIR CLEANER

..

..........................!.................................................................................

10

4-1 6 FUEL PUMP

..................................................................................................................

10

4-17

SECTIONAL

VIEW

OF

ENGINE

....................................................................................

11

5

.

DISASSEMBLY

AND

REASSEMBLY

.......................................................................

13

5-1

PREPARATIONS AND SUGGESTIONS

.........................................................................

13

5-2

SPECIAL

TOOLS

............................................................................................................

13

5-3 DISASSEMBLY PROCEDURES

.....................................................................................

14

5-4 REASSEMBLY PROCEDURES

.............

........................................................................

27

5-5

BREAK-IN OPERATION

.................................................................................................

43

6

.

MAGNETO

................................................................................................................

44

6-1

OPERATION

AND

FUNCTION

.......................................................................................

44

7

.

LUBRICATION

SYSTEM

..........................................................................................

46

7-1

OPERATION AND FUNCTION

.......................................................................................

46

Page 3

Section

8

.

CARBURETOR

8-1

OPERATION AND FUNCTION

8-2

COMPORNENT PARTS

9

.

ELECTRIC STARTER

9-1

OPERATION

9-2

COMPORNENT PARTS

Title

........................................................................................................

.......................................................................................

.................................................................................................

..............................................................................................

AND

FUNCTION

.................................................................................................

.......................................................................................

Page

47

47

49

50

50

51

10 . TROUBLESHOOTING

10-1

.

NO

ENGINE OPERATION

10-2 . STARTING DIFFICULTIES

10-3

.

INSUFFICIENT OUTPUT

10-4

.

OVERHEAT

10-5

.

ROUGH IDLING

10-6

.

HIGH ENGINE OIL CONSUMPTION

10-7

.

HIGH FUEL CONSUMPTION

10-8

.

DETONATION

10-9

.

ENGINE MISFIRE

11

.

INSTALLATION

11-1

INSTALLING

11 -2

VENTlLATlON

11

-3

EXHAUST GAS DISCHARGE

11-4

POWER

12

.

SERVICE

12-1

CLEARANCE DATA AND LIMITS

12-2

TORQUE SPECIFICATIONS

12-3

OIL GRADE CHART

..................................................................................................................

...........................................................................................................

..............................................................................................................

........................................................................................................

......................................................................................................

..................................................................................................................

...............................................................................................................

TRANSMISSION TO DRIVEN MACHINES

DATA

...................................................................................................... 59

...........................................................................................

...........................................................................................

.........................................................................................

.............................................................................................

...........................................................................

......................................................................................

......................................................................................

....................................................

.................................................................................

........................................................................................

.....................................................................................................

52

52

53

54

54

55

55

56

56

57

58

58

58

58

58

59

65

66

A

13

.

MAINTENANCE AND STORAGE

13-1 DAILY MAINTENANCE

13-2 PERIODIC MAINTENANCE SCHEDULE

13-3

ENGINE STORAGE

.................................................................................................

......................................................................................................

..........................................................................

.....................................................................

67

67

67

69

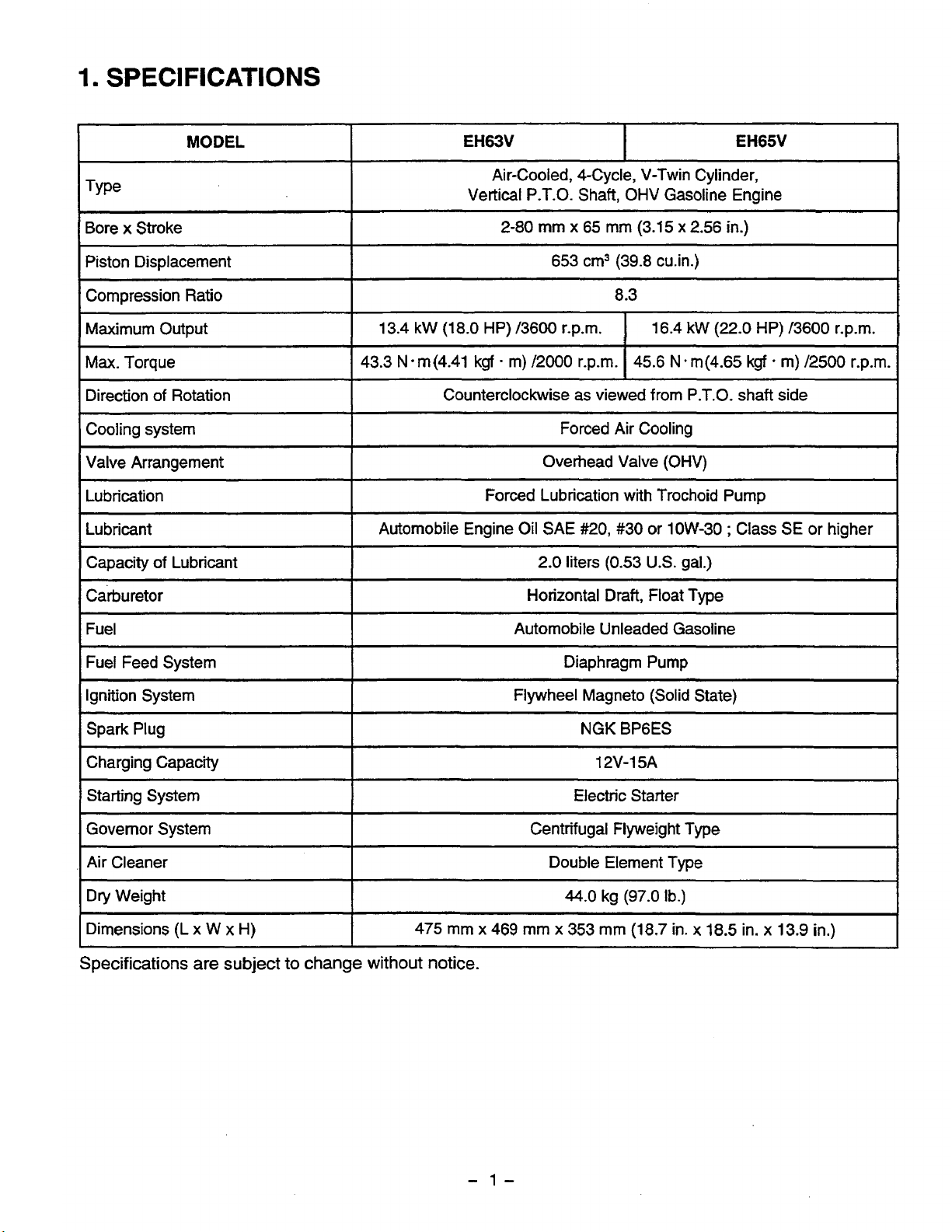

Page 4

1

SPECIFICATIONS

MODEL

Type

Bore

x

Stroke

Piston Displacement

Compression Ratio

Maximum Output

Max.

Torque

Direction of Rotation

Cooling system

Valve Arrangement

Lubrication

Lubricant

Capacity of Lubricant

Caburetor

Fuel

Fuel Feed System

Ignition System

Spark Plug

Charging Capacrty

Starting System

Governor System

Air Cleaner

Dry

Weight

Dimensions (L

x

W

x

H)

-

EH63V

Vertical P.T.O. Shaft, OHV Gasoline Engine

Air-Cooled, 4-Cycle, V-Twin Cylinder,

EH65V

2-80 mm x 65

mm (3.15 x 2.56 in.)

653 cm3

(39.8

cu.in.)

Overhead Valve

(OHV)

Forced Air Cooling

Counterclockwise

as

viewed from P.T.O. shaft side

45.6 N.rn(4.65 kgf m)

/2500

r.p.m.

43.3 N.rn(4.41 kgf

-

m)

/2000

r.p.m.

16.4

kW

(22.0

HP) /3600 r.p.m. 13.4

kW

(18.0 HP) /3600 r.p.m.

8.3

Forced Lubrication

with

Trochoid Pump

Automobile Engine Oil

SAE

#20,

#30 or 1OW-30

;

Class

SE or higher

2.0

liters (0.53

U.S.

gal.)

Horizontal Draft, Float

Type

Automobile Unleaded Gasoline

Diaphragm Pump

Flywheel Magneto (Solid State)

NGK

BP6ES

12V-15A

Electric Starter

Centrifugal Flyweight Type

Double Element Type

44.0

kg

(97.0

Ib.)

475 mm x 469 mm x 353 mm

(18.7

in.

x

18.5

in.

x

13.9 in.)

Specifications

are

subject

to

change

without notice.

-

1-

Page 5

2.

PERFORMANCE

2-1

MAXIMUM OUTPUT

The maximum output is the output

all the moving parts are properly broken in after the initial break-in period.

A

new engine may not produce full maximum output while its moving parts are still

NOTE

Power curves shown in the following charts are made in conformity with

standard test code

2-2

The maximum torque

certain revolution.

:

J1349

MAXIMUM TORQUE

is

the torque at the output shaft when the engine is producing maximum output at

of

a

.n engine with its throttle valve fully open

SAE

led under the c mdition that

not

broken-in.

internal combustion engine

-

2-

Page 6

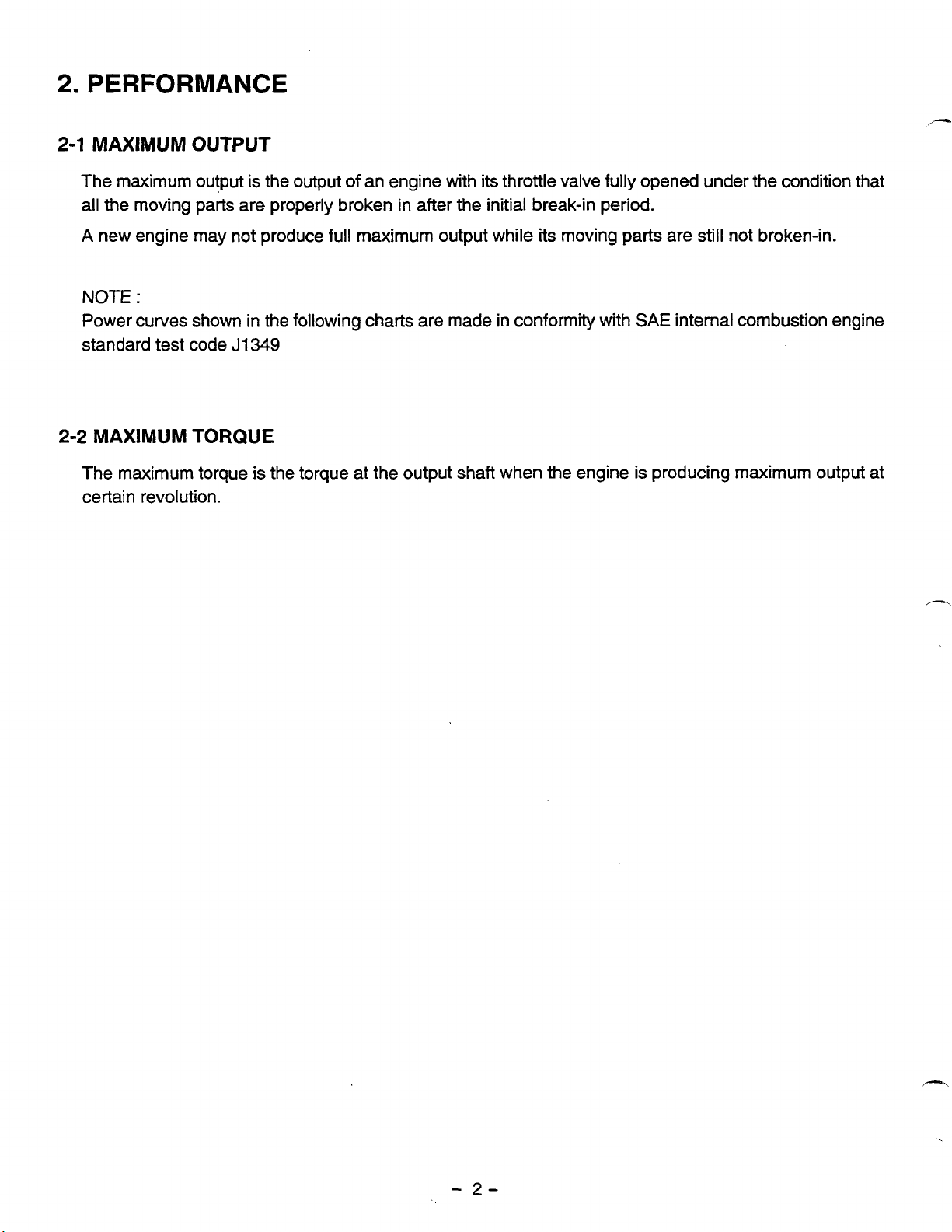

2-3

PERFORMANCE CURVES

EH63V

15

(20.1

1

t

10

(1

3.4)

5

(6.7)

MAXIMUM TORQUE

.I

I

MAXIMUM

HORSEPOWER

-

I

t

I

N-m

(kgf-m)

45

(4.59)

t

35

(3.57)

2000

2400

2800

3200

3600

SPEED

-

r.p.m

-

3-

Page 7

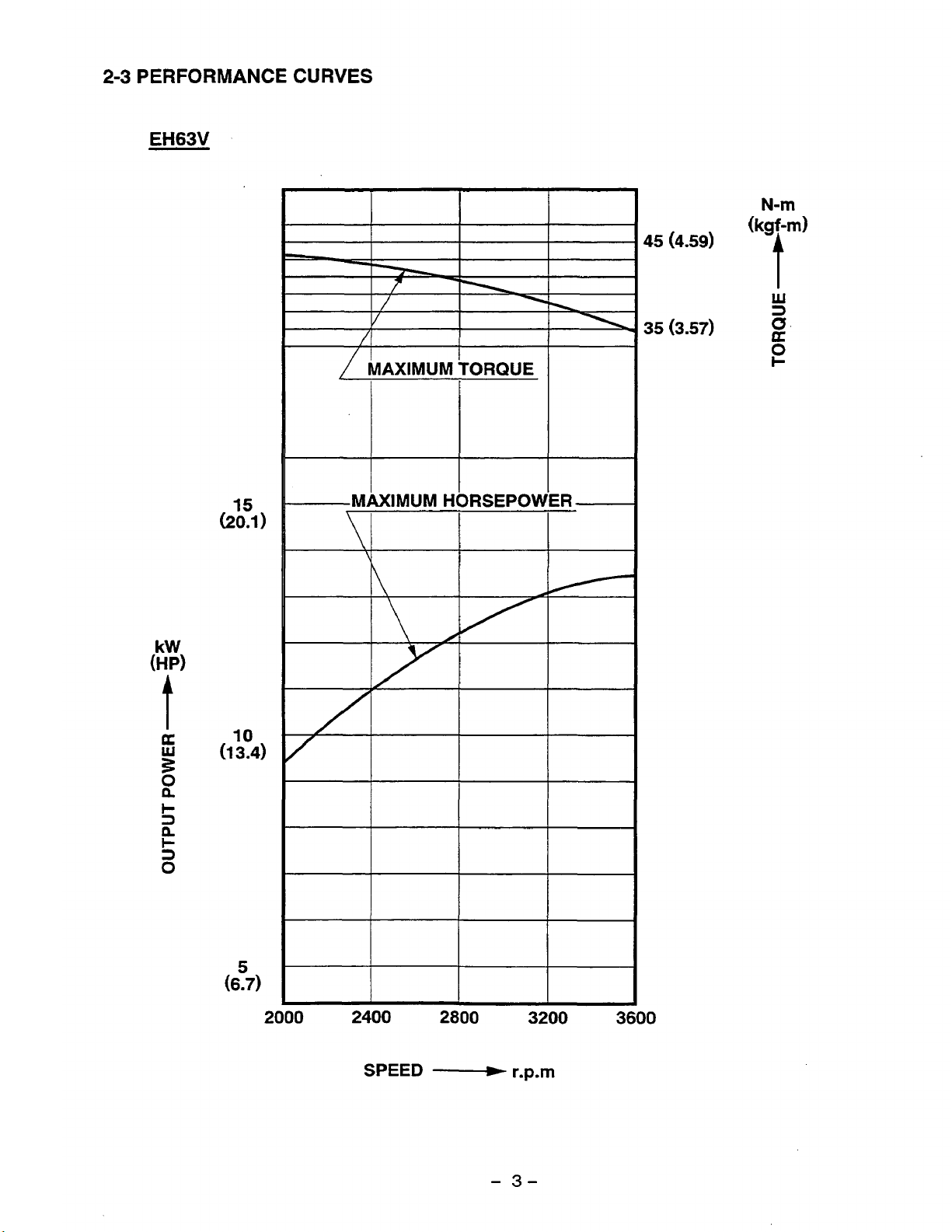

EH65V

X

/1

/MAXIMUM

TORQUE

35

(3.57)

N-m

W

3

0

K

0

F

15

(20.1

10

(1

3.4)

MAXIMUM

\I

HORSEPOWER

I

I

I

I

/"

5

(6.7)

2000

2400

SPEED

2800 3200

-

-

r.p.m

4-

3600

Page 8

3.

FEATURES

The overhead valve arrangement is adopted for ensuring high power, low fuel consumption and low oil

consumption.

The adoption of twin-cylinder in the angle

of

90

degree

(V

arrangement) and crankcase in one piece,

plastic blower housing etc. offers a compactness and light weight, making the arrangements for installing

the engine much easier for various powered equipments.

The forged steel crankshaft and high loading direct supporting aluminum bearing offer high durability,

and full pressure lubrication system with trochoid type oil pump and large capacity air cleaner with dual

elements enhance the reliability.

The effective combustion chamber shape and the precisely tuned intake and exhaust valve system

enhance the low exhaust emission and ensure the engine characteristics

of

high torque at low speed.

The carburetor with fuel cut valve,

12V-15A

alternator and pulse

type

fuel pump are employed as stan-

dard features

so

that the engine can be utilized for many usage.

-

5-

Page 9

4.

GENERAL DESCRIPTION

OF

ENGINE

COMPONENTS

/"

ROBIN

gine. The twin-cylinder is located in the angle

in

4-1

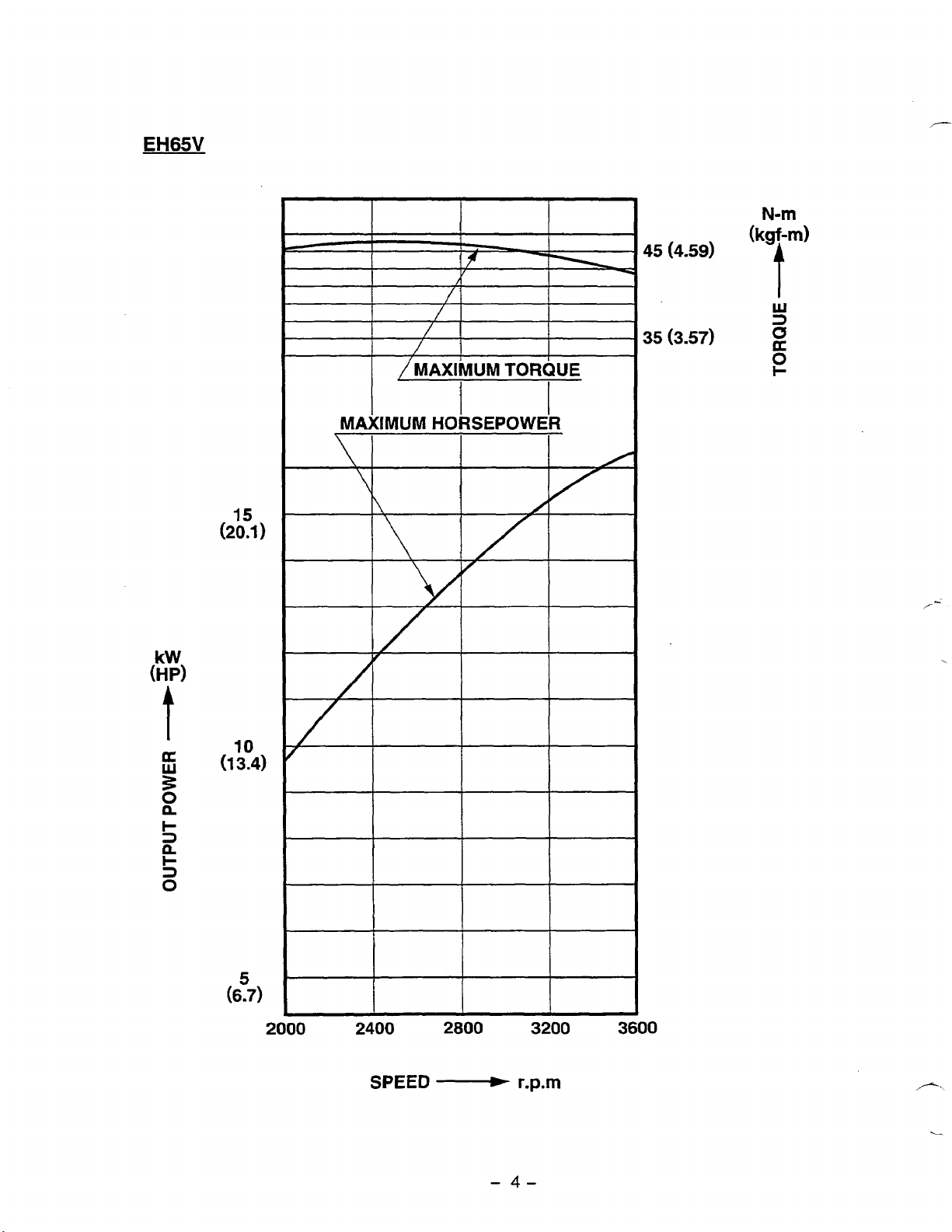

CYLINDER

The twin-cylinder and crankcase is single piece

aluminum die-casting.

The cylinder liner, made

molded into the aluminum casting.

The crankcase has a mounting surface on the out-

put shaft side, where the main bearing cover is

attached.

4-2

MAIN

EH63V/

LH

side as viewed from flywheel (cooling fan) side.

BEARING

65V

AND

series engine is air-cooled, 4-stroke, twin-cylinder,

CRANKCASE

of

special cast iron,

COVER

of

90 degree;

is

#I

cylinder is in the

OHV

arrangement gasoline en-

RH

side and

Fig.

4-1

#2

cylinder

The main bearing cover is an aluminum die-casting, which

the crankcase.

It

is

easy to inspect inside

moving the main bearing cover.

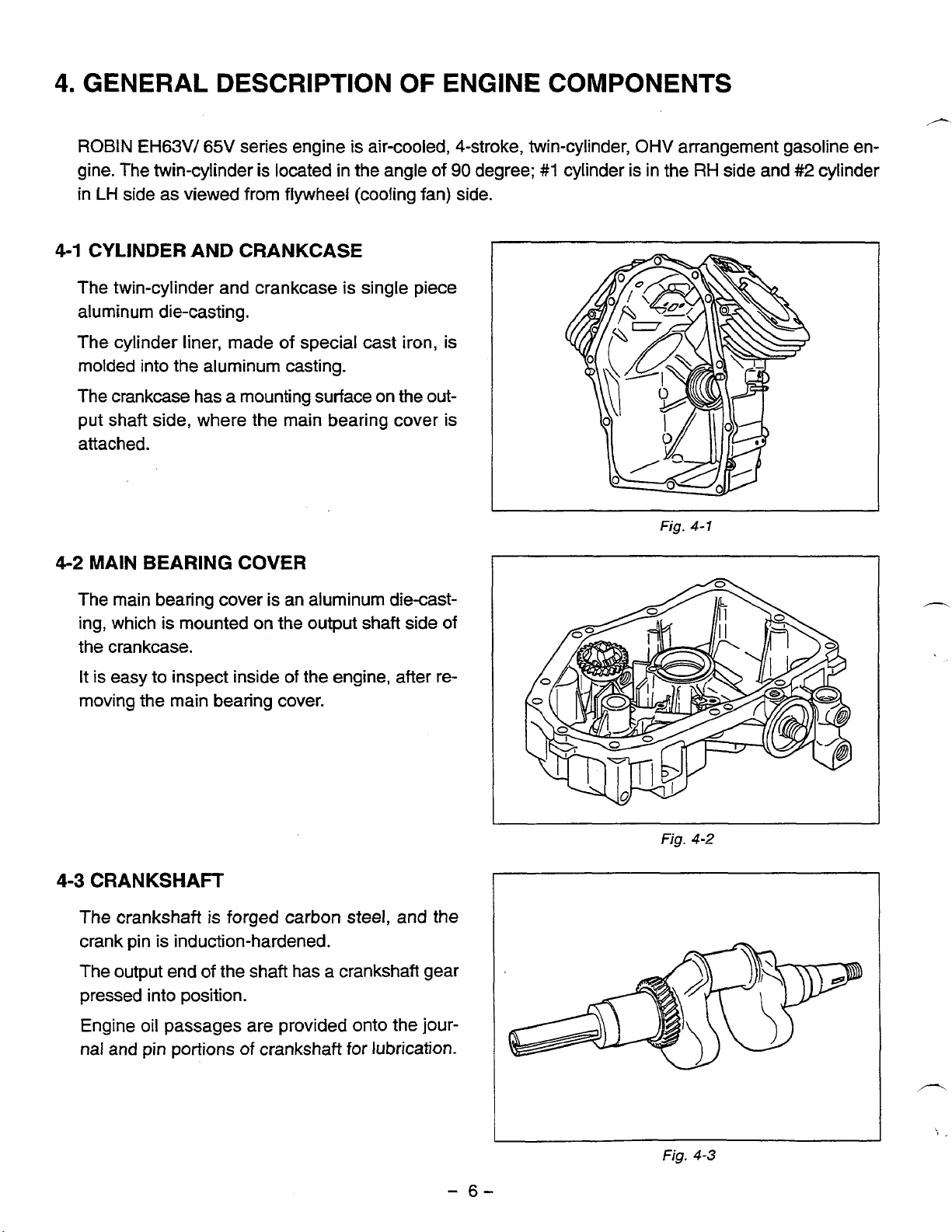

4-3

CRANKSHAR

The crankshaft is

crank pin is induction-hardened.

The output end of the shaft has a crankshaft gear

pressed into position.

Engine oil passages are provided onto the jour-

nal and pin

is

mounted on the output shaft side

of

the engine, after re-

forged

portions

carbon

of

crankshaft

steel, and the

for

lubrication.

of

Fig.

4-2

-

6-

I

Fig.

4-3

Page 10

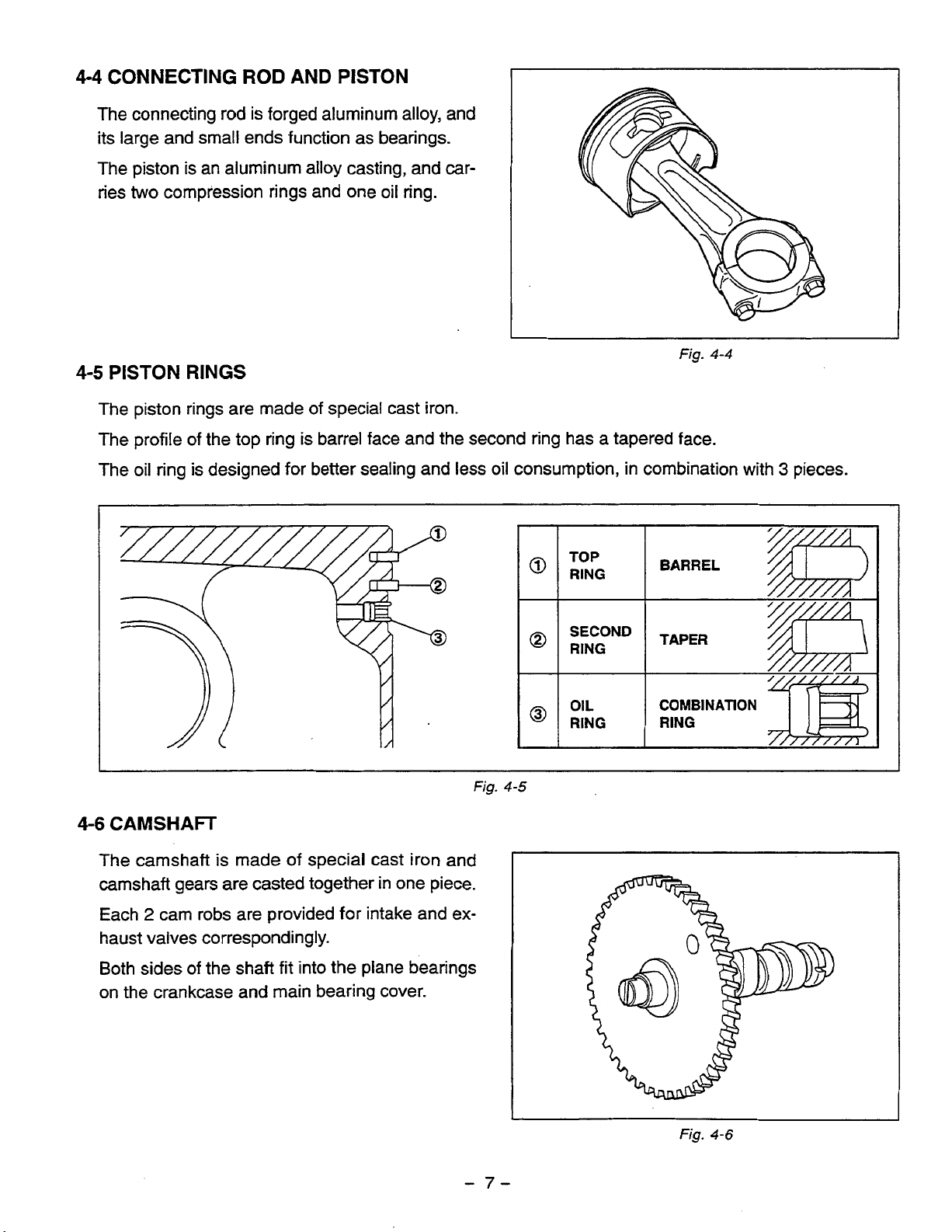

4-4

CONNECTING

ROD

AND PISTON

The connecting rod is forged aluminum alloy, and

its large and small ends function as bearings.

The piston is an aluminum alloy casting, and car-

ries

two

compression rings and one oil ring.

Fig.

4-4

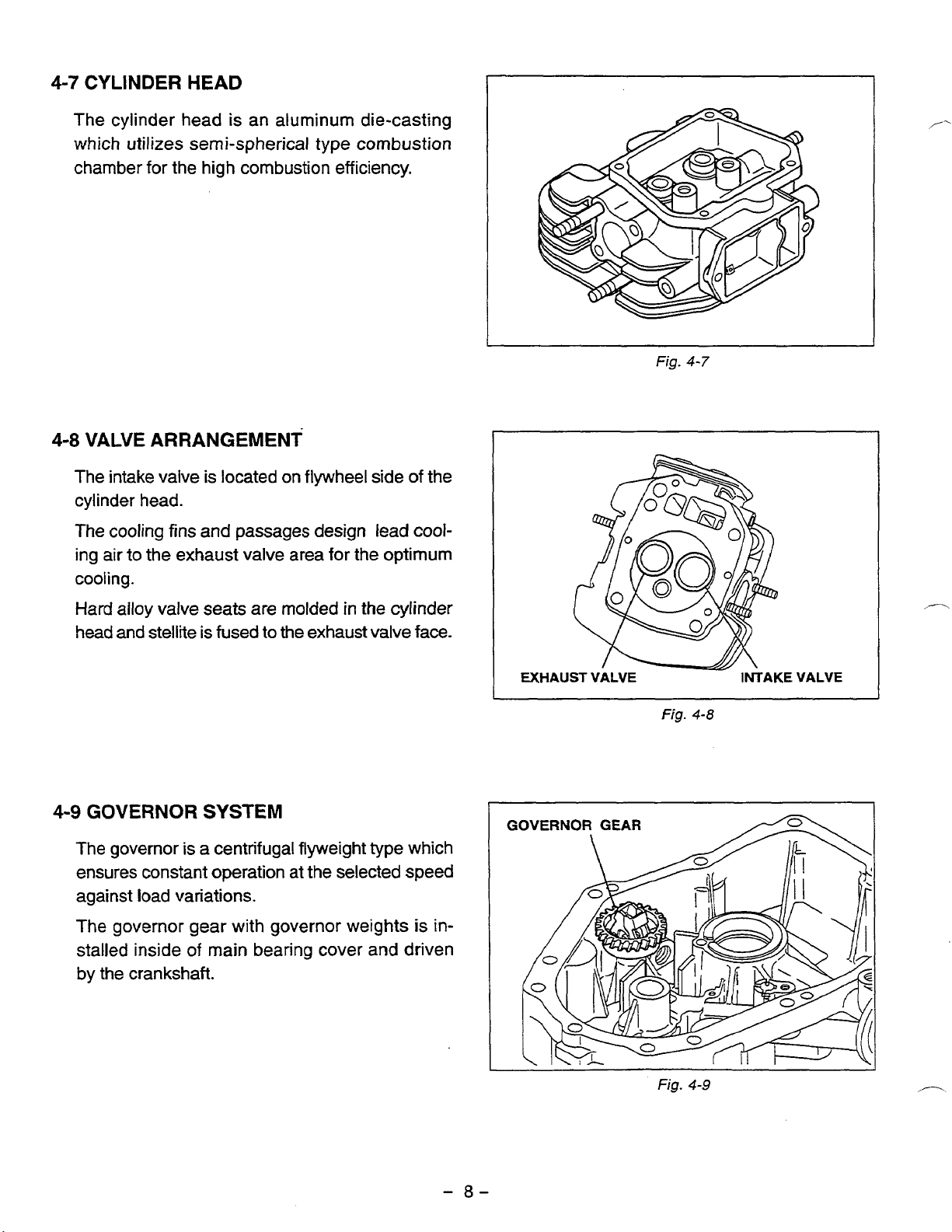

4-5

PISTON

RINGS

The piston rings are made of special cast iron.

The profile of the top ring is barrel face and the second ring has a tapered face.

The oil ring is designed for better sealing and less oil consumption, in combination with

3

pieces.

TOP

@

RING

BARREL

@

TAPER

RING

@

RING

RING

OIL

COMBINATION

Fig.

4-5

4-6

CAMSHAFT

The camshaft is made of special cast iron and

camshaft

gears are casted together in one piece.

Each

2

cam robs are provided for intake and ex-

haust valves correspondingly.

Both sides of the shaft

fit

into the plane bearings

on the crankcase and main bearing cover.

Fig.

4-6

-

7-

Page 11

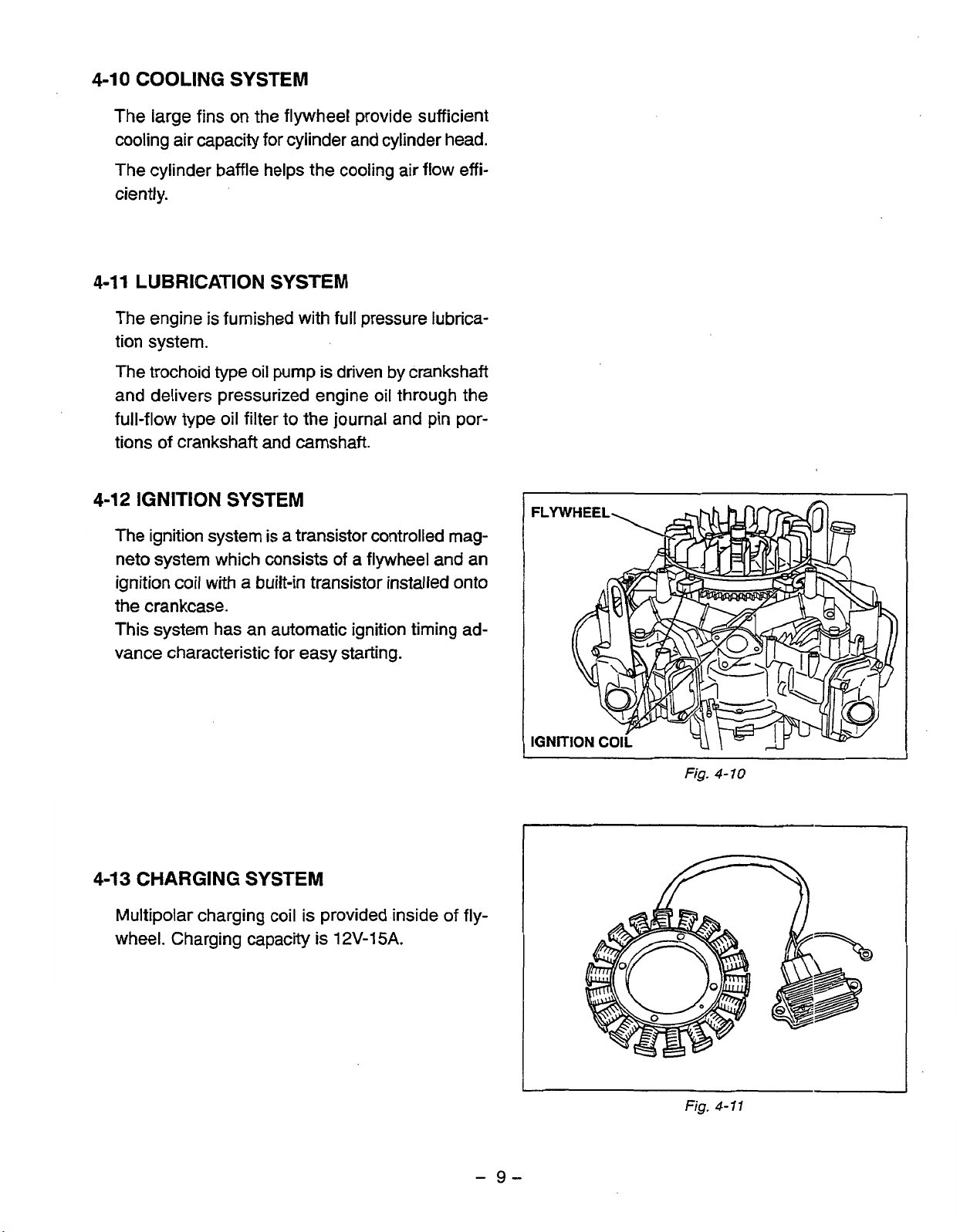

4-7

CYLINDER

HEAD

The cylinder head

is

an aluminum die-casting

which utilizes semi-spherical type combustion

chamber

4-8

VALVE ARRANGEMENT

The intake valve is located on flywheel side

for

the high combustion efficiency.

of

cylinder head.

The cooling fins and passages design

lead

cooling air to the exhaust valve area for the optimum

cooling.

Hard

alloy

valve

seats

head and stellite is fused

are molded in the cylinder

to

the

exhaust valve face.

the

Fig.

f'

4-7

,A

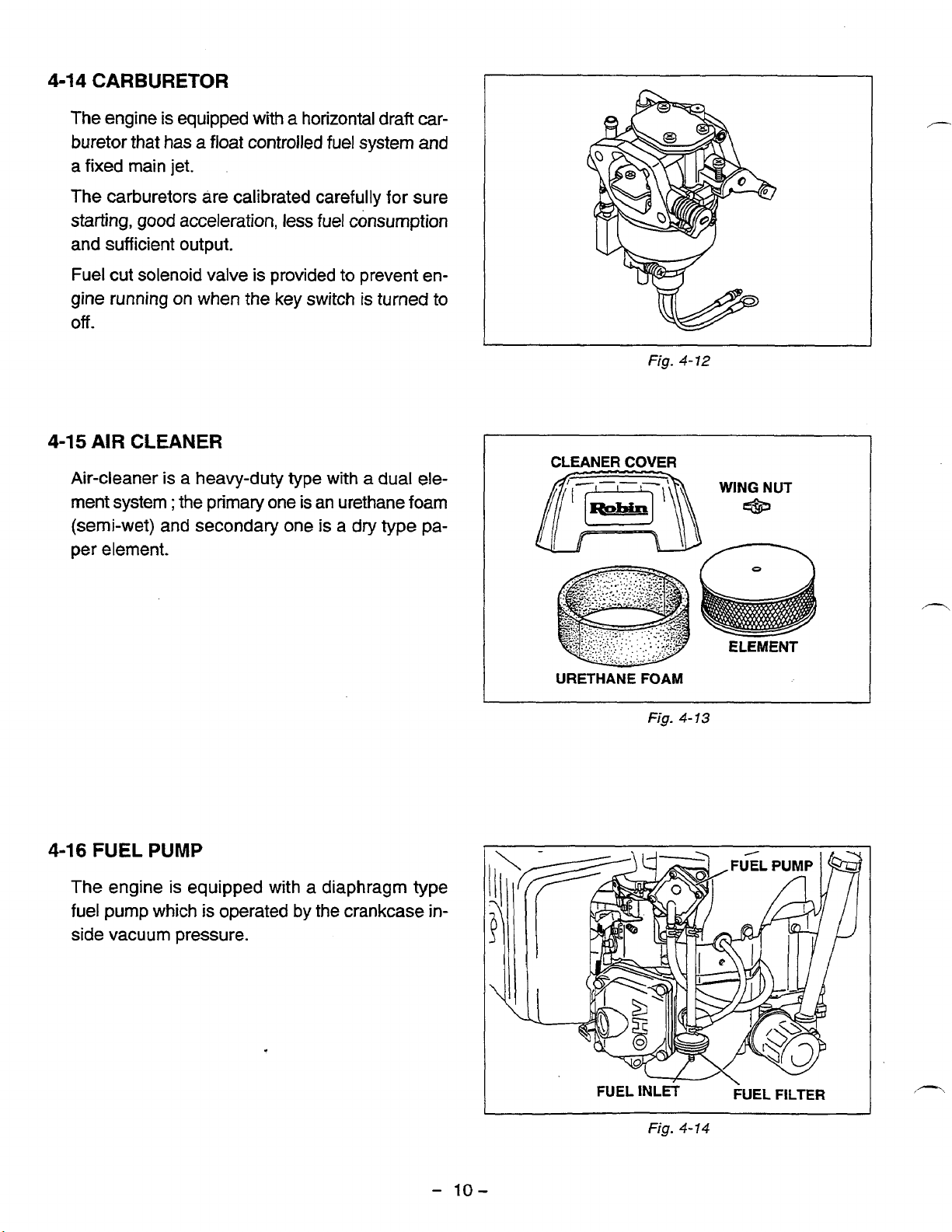

4-9

GOVERNOR

The

governor is a centrifugal flyweight type which

SYSTEM

ensures constant operation at the selected speed

against load variations.

The

governor gear with governor weights is

stalled inside

by

the crankshaft.

of

main bearing cover and driven

in-

EXHAUST

VALVE

Fig.

Fig.

4-8

4-9

INTAKE

VALVE

-

8-

Page 12

4-10

COOLING

SYSTEM

The large fins

on

the flywheel provide sufficient

cooling air capacity for cylinder and cylinder head.

The cylinder baffle helps the cooling air flow effi-

ciently.

4-11

LUBRICATION

SYSTEM

The engine is furnished with full pressure lubrication system.

The trochoid type oil pump is driven by crankshaft

and delivers pressurized engine oil through the

full-flow type oil filter to the journal and pin portions

of

crankshaft and camshaft.

4-1 2 IGNITION SYSTEM

The ignition system

is

a transistor controlled mag-

neto system which consists of

a

flywheel and

an

ignition coil with a built-in transistor installed onto

the crankcase.

This system

has

an automatic ignition timing ad-

vance characteristic for easy starting.

1

Fig.

4-10

4-13 CHARGING SYSTEM

Multipolar charging coil is provided inside of flywheel. Charging capactty

is

12V-15A.

Fig.

4-71

-

9-

Page 13

4-14

CARBURETOR

The engine is equipped with a horizontal draft

buretor that

a fixed main jet.

The

carburetors are calibrated carefully for sure

starting, good acceleration,

and sufficient output.

Fuel

cut solenoid valve is provided

gine running on

Off

-

4-15

AIR

Air-cleaner is a heavy-duty

ment system

(semi-wet) and secondary one

per element.

has

a

float

when

CLEANER

;

the primary one is an urethane foam

controlled

the

key switch is turned to

fuel

system and

less

fuel consumption

to

prevent en-

type

with a dual ele-

is

a

dry

type

car-

pa-

CLEANER

COVER

WING NUT

4-16

FUEL

The engine is equipped with a diaphragm type

fuel pump which is operated

side vacuum pressure.

PUMP

by

the crankcase

in-

URETHANE

FUEL

FOAM

Fig.

4-13

INLET

Fig.

4-14

FUEL

FILTER

-

10-

Page 14

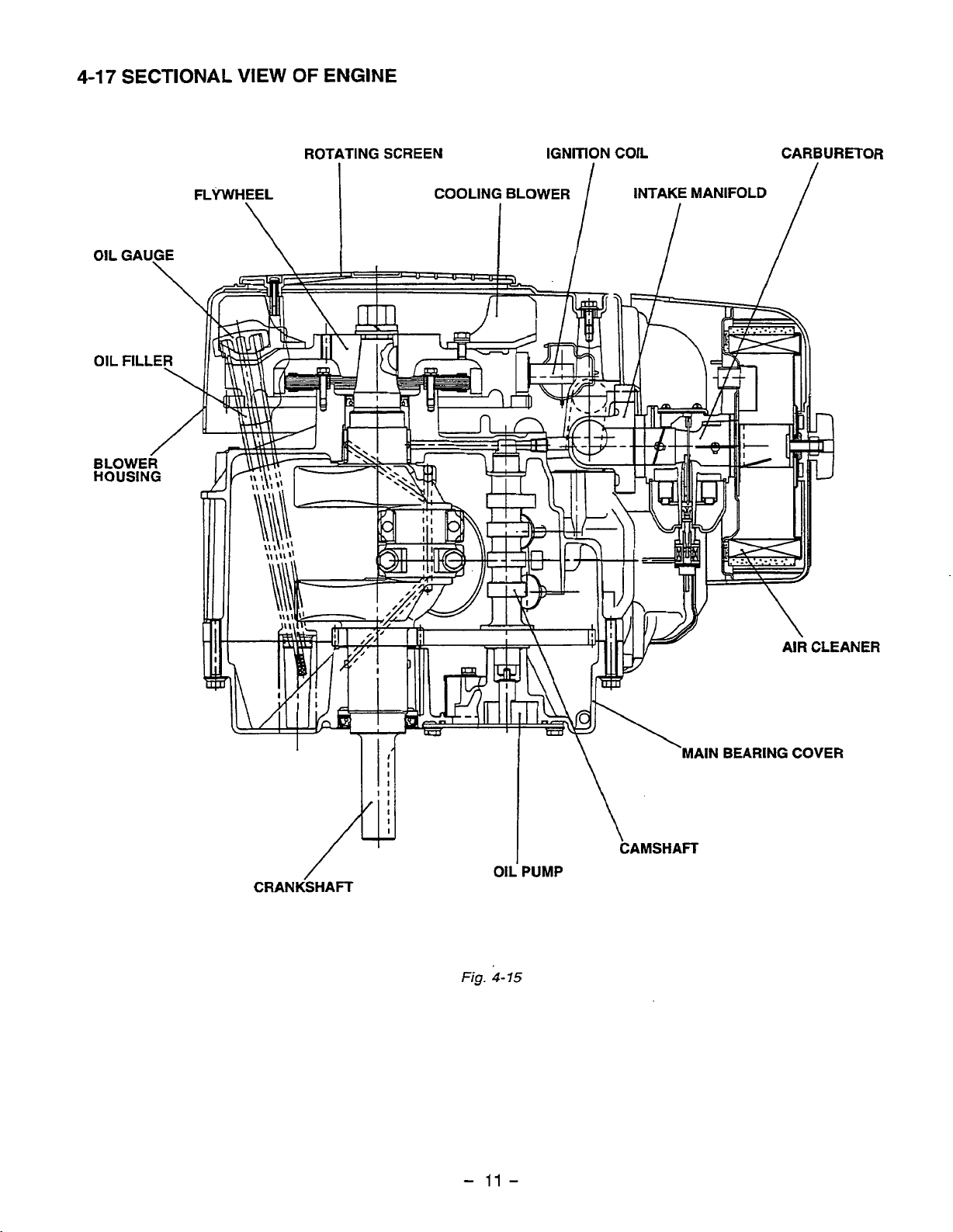

4-17

SECTIONAL

VIEW

OF

ENGINE

/

oti

PUMP

CRANKSHAFT

Fig.

4-15

\

CAMSHAFT

-

11

-

Page 15

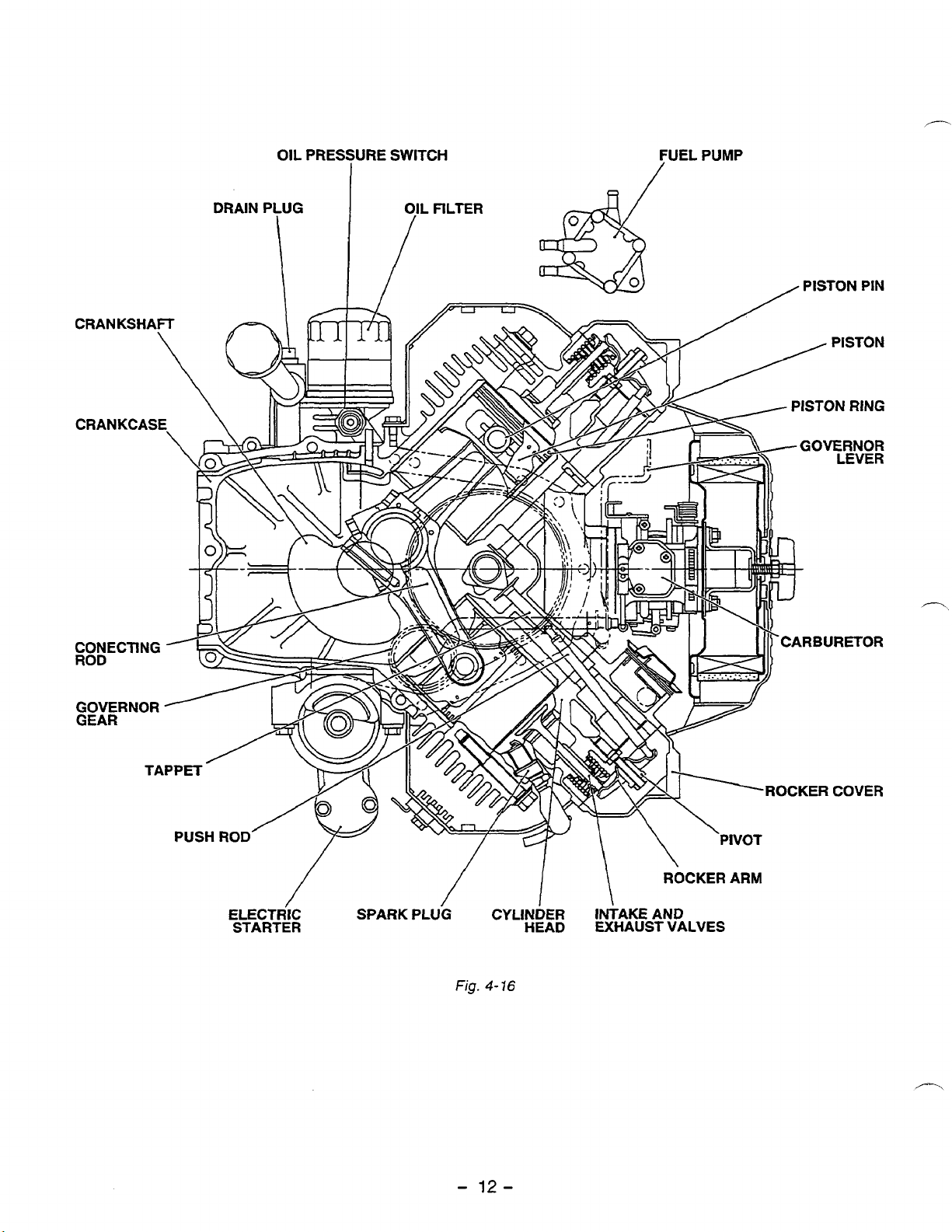

CRANKSHAFT

OIL

PRESSURE

SWITCH

FUEL PUMP

PISTON

CARBURETOR

ROCKER COVER

RING

ELECTRIC

STARTER HEAD EXHAUST VALVES

SPARK

PLUG

Fig.

-

12

CYLINDER

4-16

-

INTAKE

AND

Page 16

5.

DISASSEMBLY AND REASSEMBLY

5-1

PREPARATIONS

AND

SUGGESTIONS

When disassembling the engine, memorize the locations of individual parts

so

that they can be reas-

sembled correctly.

If

you

are uncertain

of

identifying some parts, it

is

suggested that tags be attached to

them.

Have boxes ready to keep disassembled parts

by

group.

To

prevent losing and misplacing, temporarily assemble each group

of

disassembled parts.

Carefully handle disassembled parts, and clean them with washing

oil

if necessary.

Use the correct

tools

in the correct way.

5-2

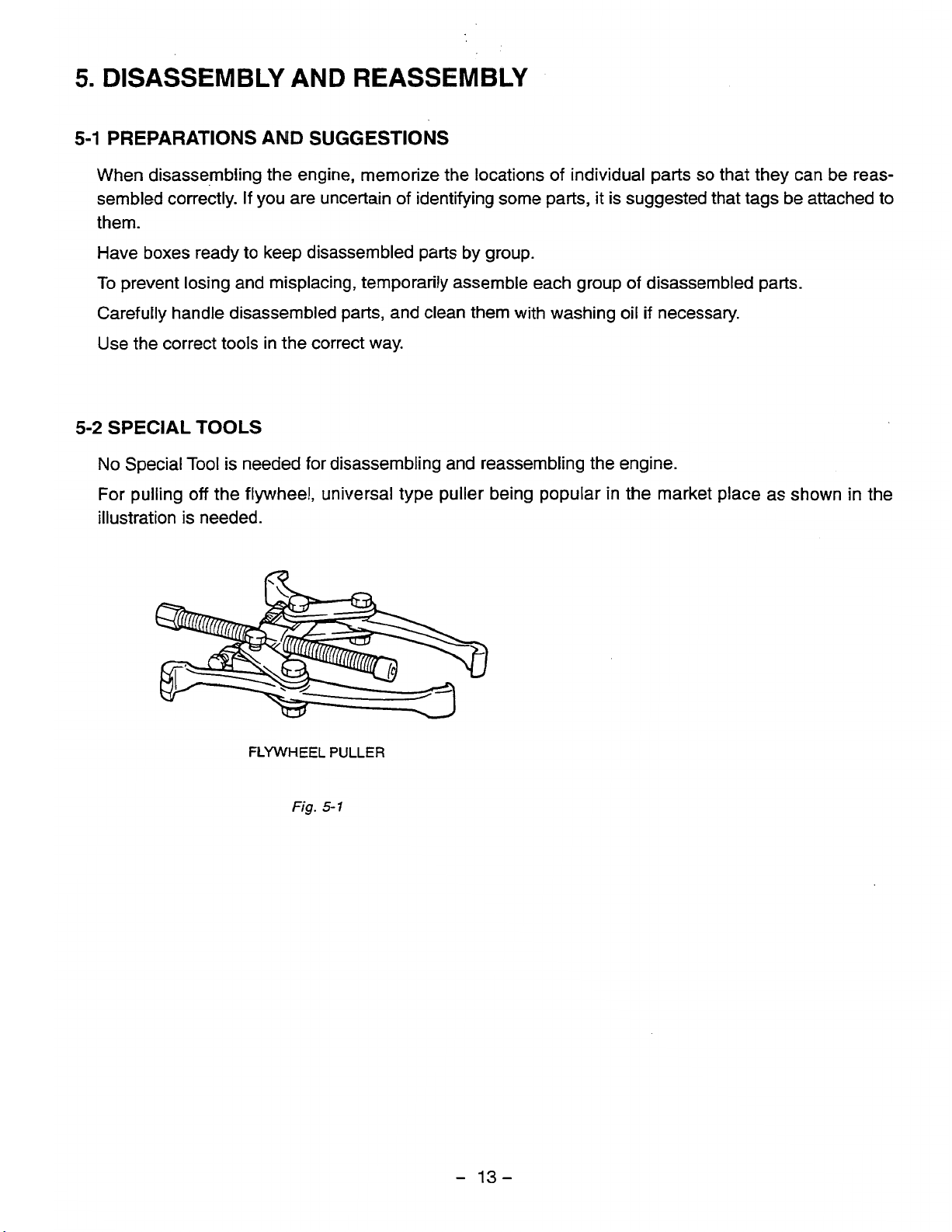

SPECIAL

TOOLS

No

Special

Tool

is needed for disassembling and reassembling the engine.

For pulling

off

the flywheel, universal type puller being popular in the market place as shown in the

illustration is needed.

FLYWHEEL PULLER

Fig.

5-1

-

13-

Page 17

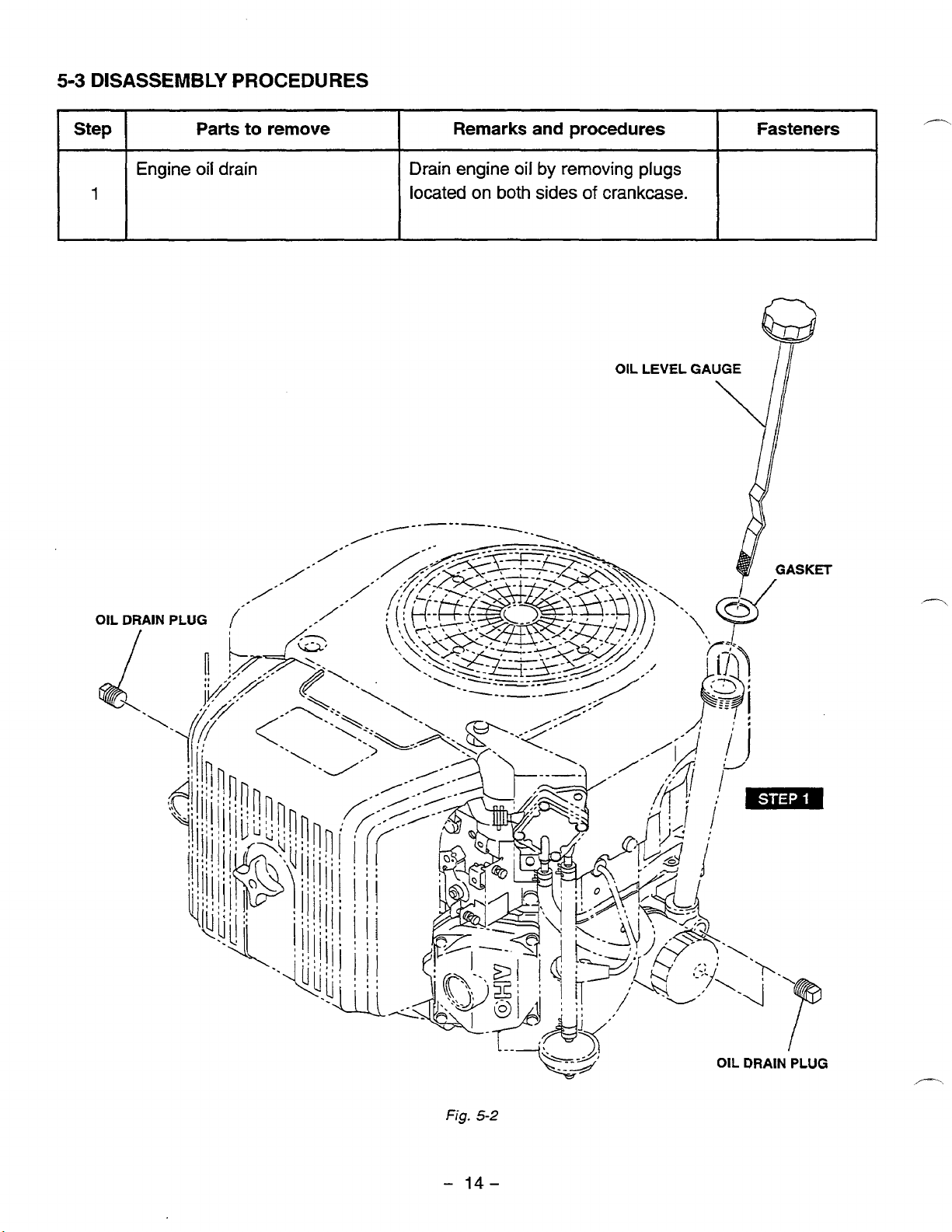

5-3

DISASSEMBLY PROCEDURES

to

Step

Parts

remove

Remarks and procedures

Fasteners

w

,"-.

1

OIL

Engine

DRAIN

oil

drain

Drain

engine

located

on

oil

both

by

removing

sides

plugs

of

crankcase.

Fig.

-

5-2

14-

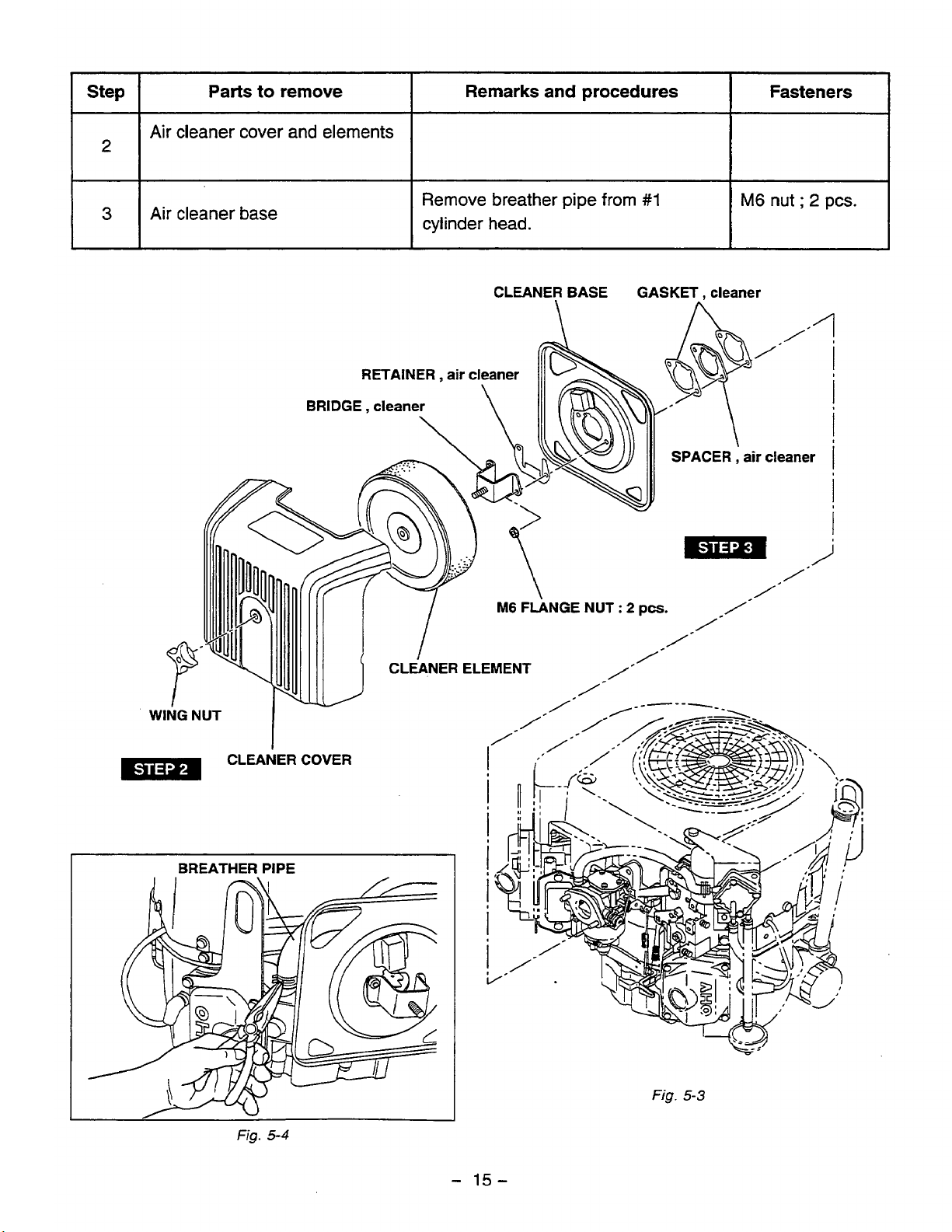

Page 18

Step

Fasteners

Remarks and procedures

Parts

to

remove

2

Air

cleaner cover and elements

Remove breather

pipe

from

#1

M6

nut

;

2

pcs.

cylinder head.

3

Air

cleaner base

CLEANER

COVER

BREATHER

PIPE

Fig.

5-4

CLEANER BASE

GASKET,

cleaner

/-

/””“

”_

Fig.

5-3

15

-

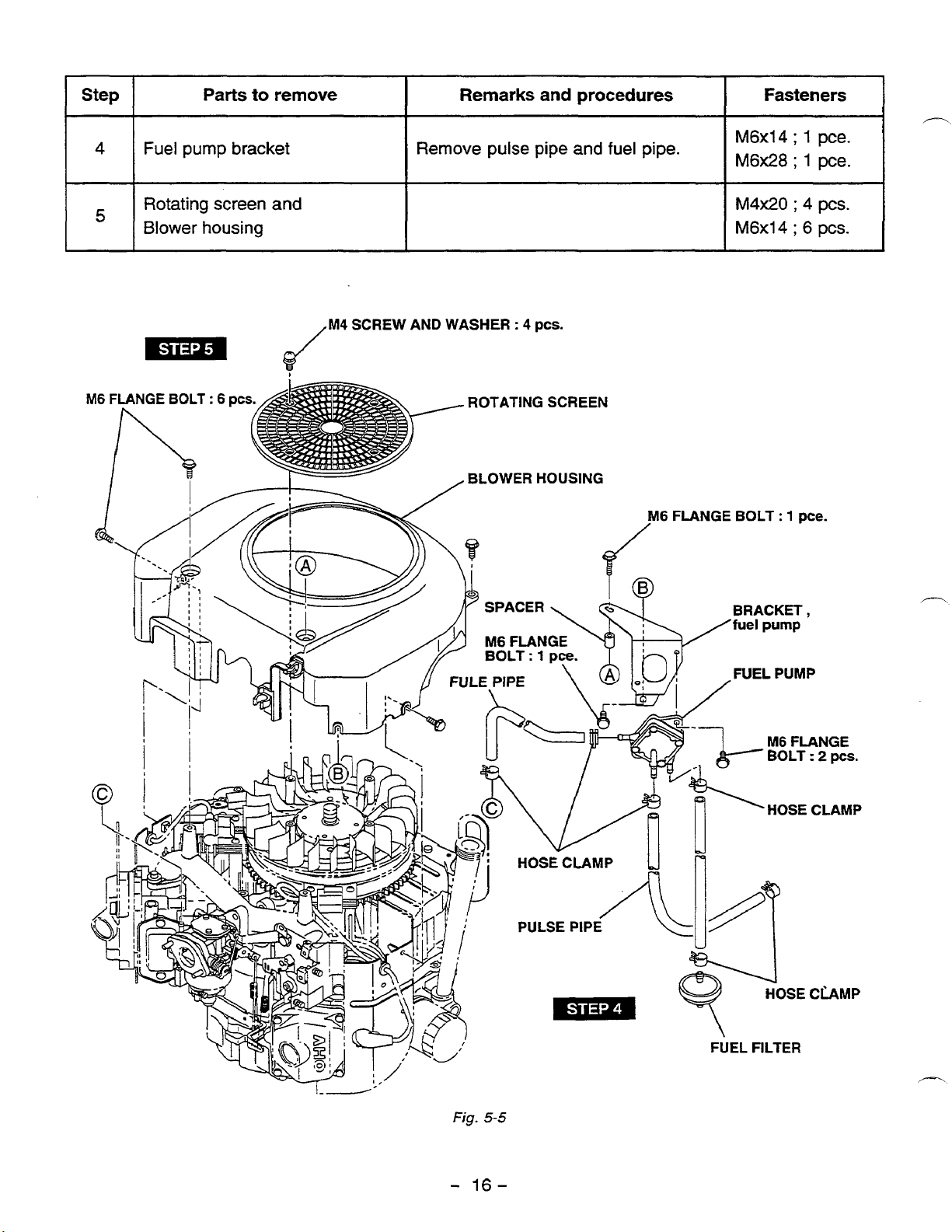

Page 19

I

1 4 I

I

I

Fuel pump bracket

Parts

to remove

I

I

I

Remove

I

Remarks

pulse

and

pipe

procedures

and

fuel pipe.

I

I

I

M6x14

M6x28

Fasteners

;

1

pce.

;

1

pce.

1

1

I

/1

5

Rotating screen and

Blower housing

-/

M4

SCREW

AND

WASHER

M4x20

M6x14

:

4

pcs.

;

4 pcs.

;

6

pcs.

PULSE

I”’

Fig.

5-5

-

16-

PIPE

4

RT

U

FUEL

I

FILTER

Page 20

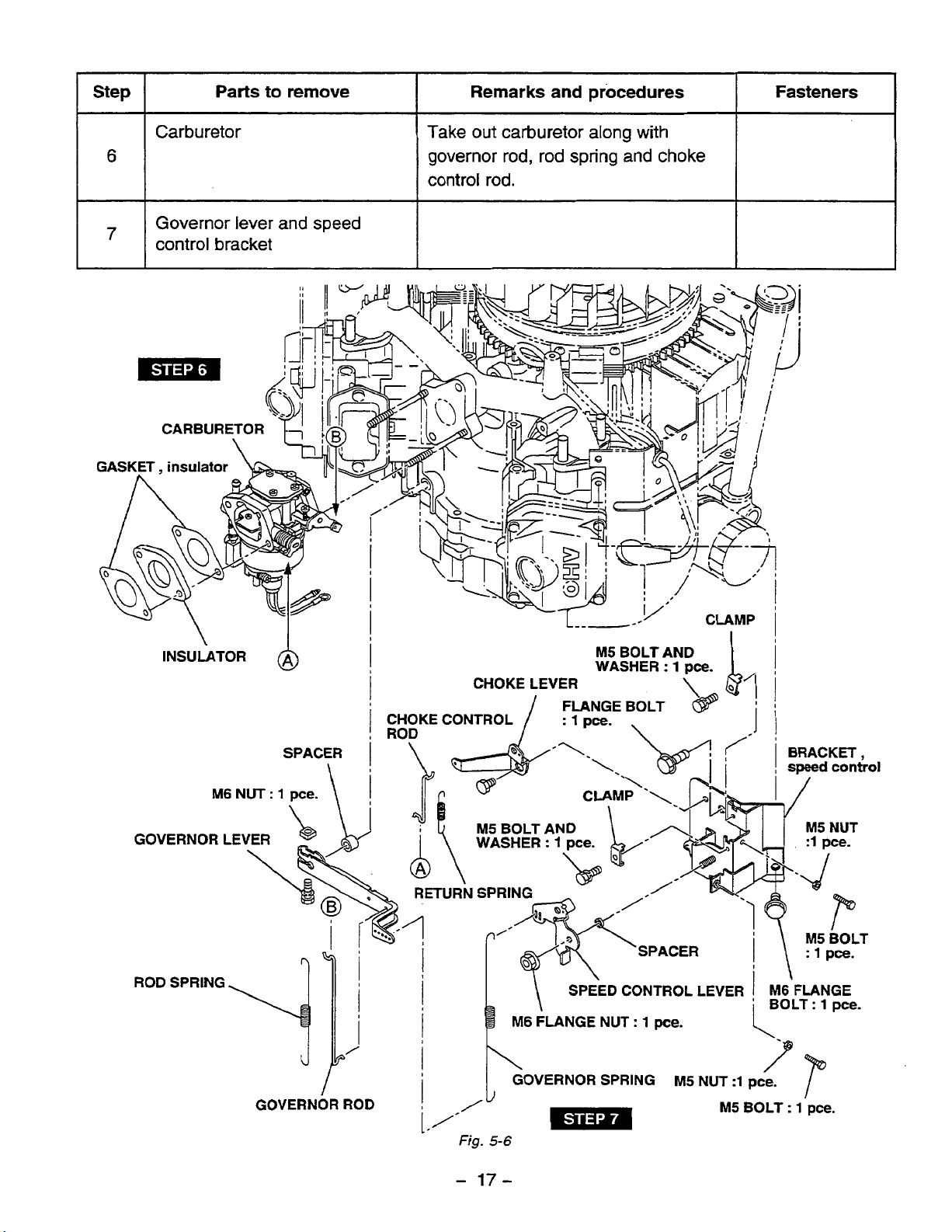

Step

Fasteners

Remarks

and

procedures

Parts

to

remove

Carburetor

governor rod, rod spring and

choke

6

Take

out

carburetor along

with

control

rod.

Governor lever and speed

control bracket

INSULATOR

@

SPACER

M6

NUT

:

1

pce.

\

GOVERNOR

M5 BOLT AND

WASHER

:

1

pce.

CHOKE LEVER

\

FLANGE BOLT

CHOKE

CONTROL

:

1

pce.

!

ROD

LE

M5 BOLT AND

WASHER

:

1

pce.

RETURN SPRlN

I

ROD SPRING

/

I

I

L.

\

SPEED CONTROL LEVER

M6

FLANGE NUT : 1

pce.

i

3

BRACKET,

speed

control

/

M5 NUT

:1

pce.

-.J

'P

\

M5B0LT

1

:

1

pce.

M6 FLANGE

BOLT

:

1

pce.

'.

7%

I

.

GOVERNOR SPRING

M5

NUT

:1

pce.

/

GOVERNOR

ROD

M5 BOLT

:

1

pce.

I

-

17-

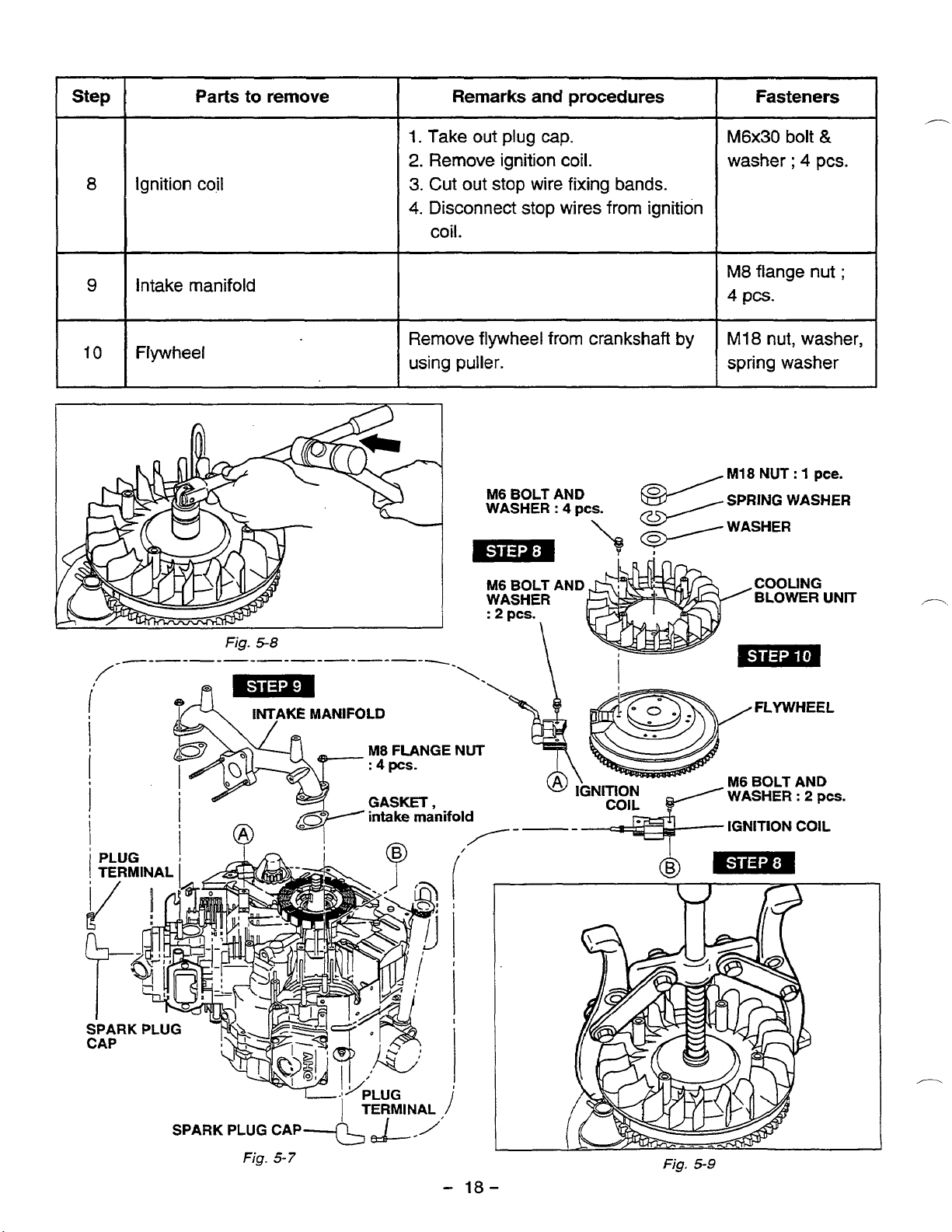

Page 21

Step

8

9

10

1

Ignition cojl

I

Intake manifold

Parts

I

Flywheel

to

remove

I

I

Remarks

1.

Take out plug

2.

Remove ignition coil.

3.

Cut out stop

4.

Disconnect

coil.

Remove flywheel from crankshaft

using

puller.

and

wire

stop

M6

BOLT

WASHER

procedures

cap.

fixing bands.

wires

from ignition

AND

:

4

pcs.

by

I

Fasteners

M6x30

washer

M8

flange nut

I

4pcs.

I

MI

8

spring

SPRING

bolt

&

;

4

pcs.

;

nut, washer,

washer

WASHER

I

/?

Fig-

58

M6

BOLT

AND

BLOWER UNIT

M6

BOLT AND

WASHER

IGNITION COIL

:

2

pcs.

.-

SPARK PLUG

Fig.

CAP-

5-7

gd-1'

-

18-

Fig.

5-9

Page 22

I

I

I

I

Step

Fasteners

Remarks and procedures

Parts

to

remove

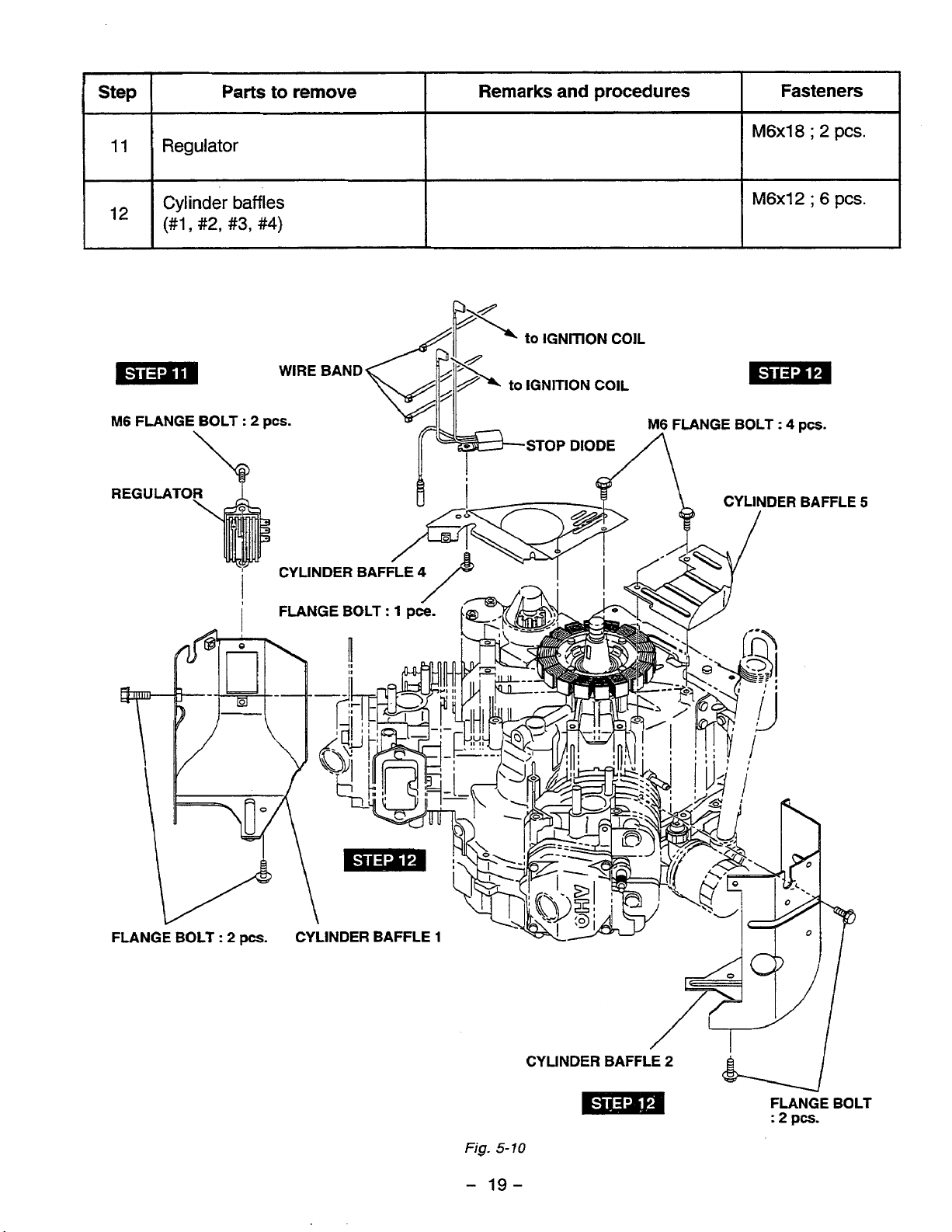

M6x18 ; 2

pcs.

11

Regulator

Cylinder

baffles

(#1,

#2,

#3,

#4)

M6x12

; 6 pcs.

to

IGNITION

COIL

to

IGNITION COIL

-

FLANGE BOLT

:

4

pcs.

CYLINDER BAFFLE

5

FLANGE

BOLT

:

2

pcs.

CYLINDER BAFFLE

1

Fig-

5-10

-

19-

Page 23

Step

Parts

to

remove

Remarks and

procedures

Fasteners

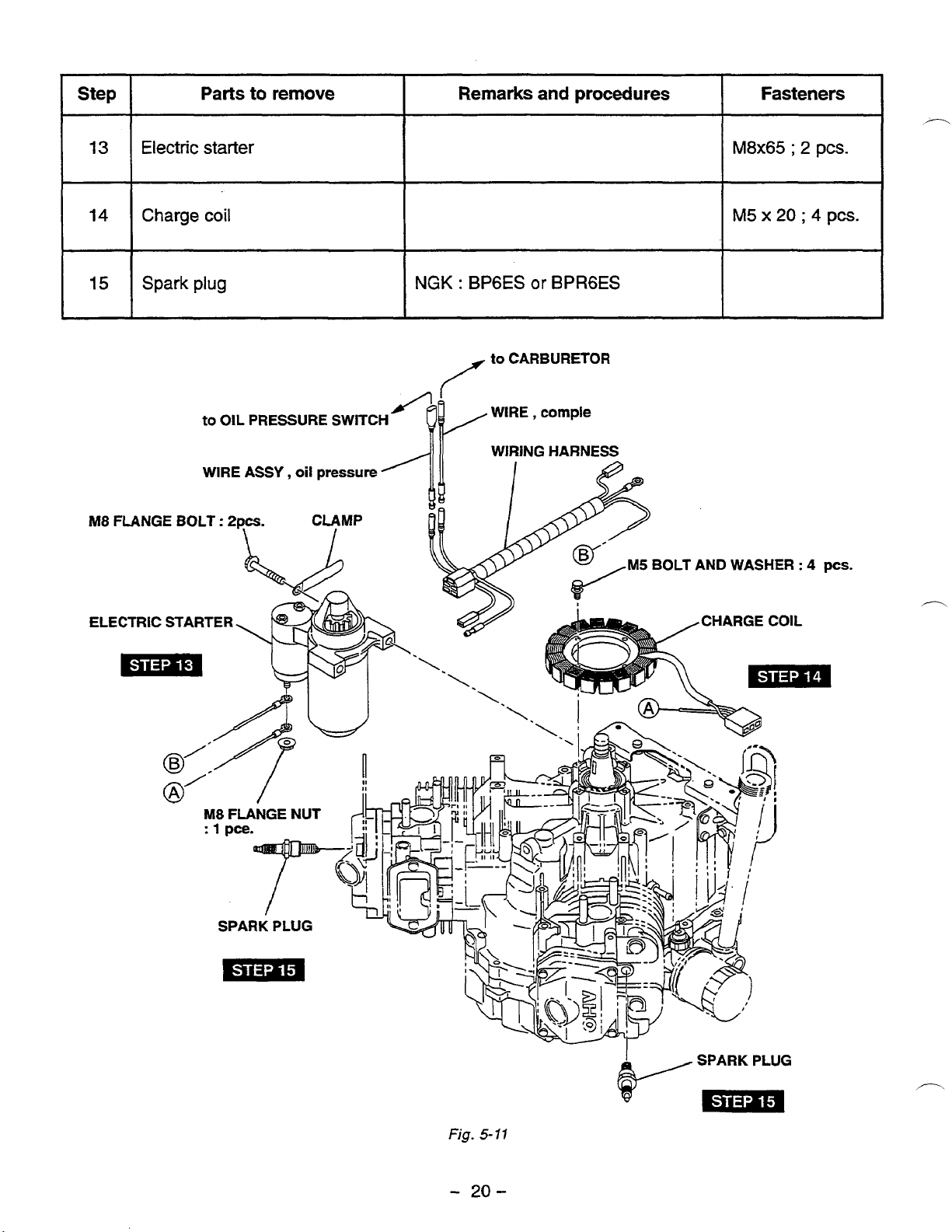

13

14

15

Electric

Charge

Spark

starter

coil

plug

NGK

:

BPGES

or

BPRGES

M8x65

M5x20;4pcs.

;

2

pcs.

Fig.

-

5-

1

I

20-

I

SPARK

PLUG

Page 24

Parts to remove

I

Remarks and procedures

I

Fasteners

16

Rocker cover

M6x12

;

4

pcs.

17

Cylinder head, Push rod,

Rocker arm and

oil

filler

Temporally

fit

the flywheel, when

MlOx65

;

8

pcs.

removing rocker arm,

turn

and adjust

flywheel

at

TDC with the marking

"T

faced

to

"1

I'

or

"2"

on

each cylinder

head.

PIVOT BOLT pivot

:

2 pcs.

M6

NUT

:

2

pcs.

GUIDE PLATE

SUPPORT, blower housing

DOWEL PIN

:

2

pcs.

I

\

M6

FLANGE

BOLT

:

2

pcs.

I

'I

I

"A

-!

LIFTING EYE

1

M10

FLANGE

I

\

BOLT:4pcs.

,

M10

FL

BOLT

:

"

"

LIFTING EYE

2

M6 FLANGE

ROCKER GASKET

COVER rocker cover cvlinder head

1

DOWEL PIN

:

2

pcs.

GASKET,

cylinder

head 2

GUIDE PLATE

------

CYLINDER HEAD

2

M10 FLANGE BOLT

:

4

pcs.

PUSH ROD

BOLT, pivot

:

2

pcs. GASKET, rocker cover

ROCKER

ARM

ROCKERCOVER

PIVOT

-8

-

-

M6 NUT-@

-

@

b"M10

FLANGE BOLT

:

4

pcs.

:

2 pcs.

Fig.

5-

12

-

21

-

Page 25

Step

18

Intake

&

Breather

Breather

Parts

to

exhaust

cover

plate

remove

valves

Remarks

and

procedures

Fasteners

/?

EXHAUST

VALVE

Fig.

-

5-13

22-

Page 26

Parts

to

remove

I

Remarks and procedures

I

Fasteners

I

Main bearing cover

*Oil pump

'Oil filter

*Oil pressure switch

*Oil

relief

spring

&

ball

Take

out

key

from

PTO

shaft.

edge.

not

to

damage

oil

seal

by key groove

M8x75

; 3 pcs.

Wrap

PTO

shaft

with polyvinyl tape

M8x44 ; 7

pcs.

Fig.

5-

16

GOVERNOR

GEAR

SHAFT

M8

FLANGE

MAIN

BEARING

SHAFT,

oil

pump

OUTER

ROTOR

OIL

PUMP

COVER

fig.

5-75

-

23-

Page 27

Step

20

Parts

Camshaft and tappet

to remove

Fig.

5-

18

Remarks

Mate the

crankshaft gear and

and then take

markings

and

out

camshaft.

procedures

both

on

camshaft

Fasteners

r?

gear

h.

i

\

'.

9

-

Fig.

5-1

7

p""""'

TAPPET

-

24-

Page 28

Step

21

22

~~ ~

Parts

to

remove

Piston and Connecting rod

'Piston pin clips

'Piston pin

'Piston rings

Crankshaft

CUP

-

\

PISTON

PIN CONNECTING

Ill

v

-cup

PISTON

RING

~

~ ~~

Remarks and procedures

Fasteners

1.

Remove connecting rod bolts.

2.

Take

out connecting rod cap.

M8

;

4

pcs.

3.

Push the connecting rod upwards

and take out along with piston.

Put the marking

of

original position

onto each piston, ring, clip, piston

pin, connecting

rod

and cap for

reassembly.

1.

Remove key from crankshaft.

2.

Remove crankshaft tapping at the

flywheel end

using

plastic hammer.

L

CONNECTING

-

CLIP

WOODRUFF

KEY

Im

CRANKSHAFT

-

\

SPACER

(Select

1

piece only)

Fig.

5-19

Fig.

5-20

-

25-

Page 29

Step

23

Parts

Crankcase

*Governor lever

*Leaf

valve

to

remove

shaft

Remarks

and

procedures

CRANKCASE

Fasteners

LEAF

VALVE

RETAINER

M4

SCREW

AND

WASHER : 2

PLATE

pcs

I

/-

"

SNAP PIN

7

GOVERNOR

SHAFT

/

LEVER

Fig.

-

5-21

26-

Page 30

5-4

REASSEMBLY

PROCEDURES

5-4-1

PRECAUTIONS

FOR

REASSEMBLY

1)

Clean parts thoroughly before reassembly.

Pay

most attention

to

cleanliness

of

piston, cylinder, crankshaft, connecting rod and bearings.

2)

Scrape

off

all carbon deposits from cylinder head, piston top and piston ring grooves.

3)

Check lip

of

oil seals. Replace oil seal

if

the lip is damaged. Apply oil to the lip before reassembly.

4)

Replace all the gaskets with new ones.

5)

Replace keys, pins, bolts, nuts, etc., if necessary.

6)

Torque

bolts

and

nuts

to

specification referring

to

the

"TORQUE

SPECIFICATIONS".

7)

Apply oil to rotating and sliding portions.

8)

Check and adjust clearances and end plays where specified in this manual.

5-4-2

Pre-assembly

A.

CRANKCASE

(1)

Fit governor lever

shaft

with snap pin.

(2)

Attach

leaf

valve to crankcase.

SNAP

M4

SCREW

AND

WASHER

:

2

pcs

I

RETAINER

PLATE

LEAF VALVE

PIN

GOVERNOR LEVER

SHAFT

.CRANKCASE

Fig.

5-22

-

27-

Page 31

B.

CYLINDER

NOTE

Clean valves and wash cylinder head thoroughly.

Remove carbon and gum deposits from the valves, seats, ports and guides.

;

HEAD.

VALVES

and

ROCKER

ARM

~

Inspect valves, valve

*

Replace valves that are badly burned, pitted or warped.

Valve

(Refer to

If exceeds, draw valve guides

After replacing valves and guides, lap valves in place until a uniform ring shows around

the face of the valve.

(1)

Attach

(2)

Apply oil

Place

SPRING

guides

SERVICE

oil

seal

to

valve

cylinder

RETAINER

should

both onto

spring

head on flat table

\

seats

be

DATA for clearance specifications.

and varve guides.

replaced when valve

out

and press new guides in.

intake

and valve stem.

d,

and

exhaust valve

and

install valve

SPRING

RETAINER

COLLET-VALVE

VALVESPRING

stem

guide.

spring,

cIearance

exceeds

)

valve and spring retainer.

specifications.

COLLET-VALVE

VALVE

SPRING

fig.

5-24

EXHAUST

SEAL-INTAKE

VALVE

VALVE

(BLACK)

Fig.

523

-

28-

Page 32

C.

PISTON

and CONNECTING

ROD

(1)

Install

oil

ring first, then second ring and top

ring.

Spread ring only far enough

to

slip over piston and

into correct groove.

Use

care not

to

distort ring.

NOTE

;

*

Install second ring with punched mark beside the gap face upward.

*

Top

ring can be fit either way.

*

As

for oil ring, rails should be placed

on

and below

the

expander.

(2)

Apply

enough oil

to

small

end

of

connecting rod and piston pin, and fix connecting rod to piston with

piston pin.

(3)

Use clips on the

both

side

of

the piston pin to secure piston pin in position.

TOP

RING

BARREL

TAPER

@

RING

@

RING

RING

OIL

COMBINATION

Fig.

5-25

-

29-

Page 33

D.

Main bearina cover and aovemor aear

(1)

Insert washer into governor gear shaft.

(2)

Insert governor gear along with sleeve into governor gear shaft.

(3)

Insert ball and spring into the

oil

relief valve

hole

and tighten bolt

by

the

specified torque.

Tightening Torque

(4)

Tighten oil drain plugs on both side

OIL DRAIN PLUG

RETAINER PLATE

:

6.9 - 8.8

GOVERNOR

SLEEVE

GOVERNOR

GEAR

WASHER

N

-

m

(70

-

90

of

main bearing cover.

7

kg

acm,

5.1

-

6.5

ft

q-.OIL

-

Ib.)

PUMP FILTER

OIL

PRESSURE

MAIN BEARING

5-4-3

Reassembly

1)

CRANKSHAFT

(1)

Install crankshaft

key-way with polyvinyl tape to avoid

to

oil

seal.

Note:

Apply

crankcase. For easy installation, put

crankcase

(2)

Install woodruff key for flywheel on crankshaft.

enough oil to bearing

on

on

box

crankcase wrapping the

damage

portion

or

wood

blocks.

of

Fig.

-

5-26

30-

Fig.

-

5-27

Page 34

2)

PISTON

and CONNECTING

ROD

(1)

Install piston and connecting rod assembly into

cylinder by using a piston ring compressor to

hold piston rings.

Note:

The

"1

'I

mark

of

the

connecting

rod

for

#I

cylinder and

"2"

mark for

#2

cylin-

der

should

be

faced to the main bear-

ing cover side when assembled.

Apply

enough

oil

to piston rings,

con-

necting rod bearings (large end) and

cylinder bore before

assembly.

the illustration.

*

Set

gaps of piston rings

as

shown

in

:2)

Temporary

fit flywheel and

turn

crankshaft

to

BTDC

(bottom dead center). Lightly tap the

top

of

piston until large end

of

the rod meet

the pin portion

of

crankshaft.

(3)

Set connecting rod cap to connecting rod with

the alignment marks mated and the clinching

portion clinched. Tighten

bolts

by the speci-

fied torque.

Tightening Torque : 22.1 - 27.0

N-m

(225

-

275

kg-cm)

(1

6.3

-

19.9

ft-lb.)

(4)

Check for free movement

of

piston and con-

necting rod

by

turning crankshaft

slowly.

3)

TAPPFT

and

CAMSHAFT

(1)

Apply oil to tappets and install in their original

position. Push in fully to avoid damage during

camshaft installation.

(2)

Lubricate

bearing surfaces

of

camshaft. Install

camshaft into the crankcase with the timing

mark on both crankshaft gear and camshaft

alined.

CAUTION

:

Incorrect

alinement

will cause malfunc-

tion

of

the

engine.

PISTON RING COMPRESSOR

\A

CONNECTING ROD

Fig.

5-28

ALIGNMENT MARKS

n

Fig.

5-29

TIMING

MARK

CRANKSHAFT

GEAR

\

//

CAMSHAFTGEAR

Fig.

5-30

-

31

-

Page 35

4)

Adjust crankshaft

(1)

Adjust end play

The proper spacer may be determined following manner.

i

)

Measure

ii)

Measure

the

the

end

to

depth

height

play

the specified values using the proper spacer.

"A"

(From the mating

"B"

(From

the mating

surface

surface

to the

to the crank

boss.)

gear.)

-

-

-

-

-

(B=

0

-

0)

(A+0.36)-B=

(SIDE

(A+O.O14)-B= SIDE CLEARANCE (in.)

(SIDE

Following are available spacer shims.

CLEARANCE)-0.2

CLEARANCE)-0.008 in.= THICKNESS

SPACER

I

SIDE

SHIMS

CLEARANCE (mrn)

mm

=THICKNESS

T=

0.6

mm

T=

0.8

mm

T=

1.0

mm

Table.

5-1

MAIN

(0.024

(0.031

(0.039

OF

CRANKSHAFT

OF

CRANKSHAR SHIM (in.)

in.)

in.)

in.)

SHIM

(rnm)

READING

@

SPACER

Fig.

5-31

3

with

gasket

tightened)

CRANKCASE

-

32-

Fig.

I

5-32

Page 36

5)

MAIN

BEARING

COVER

(1)

Put a oil

seal

guide onto

PTO

shaft portion to avoid damaging the main bearing cover oil seal.

(2)

Place gasket onto the mating surface of crankcase.

(3)

Lubricate oil seal lip potion and bearing surfaces, and install main bearing cover.

Tighten

bolts

evenly to the specified torque.

I

Tightening Torque

:

d

6.7 - 18.6

N-m

(170

-

190

kg-cm,

12.3

-

13.7

ft-lb.)

1

NOTE

;

Before installing main bearing cover, be sure to check the installation

of

governor lever

shaft,

oil relief valve and oil pump filter

in

position.

Tap cover with

a

soft

hammer until tacthing the crankcase mating surface, engaging

with governor gear and camshaft gear properly.

Rotate crankshaft

slowly

to check for smooth operation and side clearance.

6)

OIL

PUMP

and

COVER

(1)

Apply oil to inner and outer rotors

of

oil pump and attach them in position.

(2)

Set

O-ring in position.

(3)

Install oil pump cover.

FLANGE

BOLT

:

4

pcs.

/

OIL

PUMP

COVER

INNER

ROTOR

Fig.

5-33

-

33-

Page 37

7)

CYLINDER

HEAD

n

NOTE

Be sure

(1)

Place new head gasket onto crankcase.

(2)

Install

8)

ROCKER

(I)

Insert push rods into crankcase.

tip

(2)

Apply oil to rocker

cylinder head using pivot and nut.

1

st

9.8

(100

(7.2

in the

;

to

check dowel

#I

and

step

N

.rn

kg

mcrn)

ft

-

Ib.)

ARMS

hollow

pin,

and replace

#2

cylinder heads. Tighten bolts evenly in three steps

Tightening torque

2

nd

step

19.6

N

-rn

(200

kg

-

crn)

(1

4.5

ft

Ib.)

AND

PUSH

of tappet top.

arms

RODS

and assemble

Put

push rod

I

(340-420

(24.6-30.4

them

with

new one

Final

Step

33.3-41.2

kg

to

N

ft

m

'crn)

.

Ib.)

if

damaged.

by

the specified torque.

A

GUIDE

ROCKER

M6

:

PLATE

ARM

NUT

2

pcs.

bzzs

@ @

Ezm

-

34-

Fig-

5-34

Page 38

9)

VALVE CLEARANCE ADJUSTMENT

NOTE

:

Temporally fit the flywheel in position for easy operation.

(1)

Rotate crankshaft clockwise to the TDC (top dead center) of compression stroke by matching the

(2)

Loosen the nut on rocker

am

and turn the pivot to adjust the clearance between rocker arm and valve

mark

"T"

of flywheel with the mark

"1"

of

#1

cylinder head.

stem end,

and

then tighten the nut by the specified torque.

Valve Clearance

:

0.085 - 0.115

mm

(Cold condition)

(0.0033

-

0.0045

in.)

Tightening Torque

:

7.8

-

9.8

N-rn

(80 - 100

kg-cm)

(5.8 - 7.2

ft-lb.)

ICKNT GAUG;

(3)

Adjust valve clearance of

#2

cylinder side in

the same manner.

(4)

Rotate crankshaft several times and be sure

to

check valve clearance again. Adjust valve

clearance

if

necessary.

Fig.

5-35

'

FLYWHEEL

Fig.

5-36

-

35-

Page 39

10)

ROCKER COVER

Install rocker cover with new gasket.

lightening Torque

11)

BREATHER

Attach breather plate (breather

cover to crankcase

Put breather plate

valve opens outside.

Note:

Never tighten the

fied torque,

cut.

Replace gaskets

they

are

torn

:

PIPE

using

in

or

gasket

or

damaged.

6.9

-

8.8

(70

-

90

kg

(5.1

-

6.5

and

COVER

valve)

proper gaskets.

such position as its reed

(30

-

50

bolts

over

is

damaged and

with

N

-

m

-

cm)

ft

.

Ib.)

and breather

kg

-

cm)

the

speci-

new ones

if

GASKET

,

breather plate

&I

GASKET,

breather piate

BREATHERCOVER

Fig.

5-37

/

M6FLANGE

BOLT : 2

pcs.

12)

SPARK

Install spark

Spark

Newplug-11.8-14.7N-m(120-150kg-cm,8.7-10.8ft~Ib.)

Current plug

PLUG

plug

to

plug : NGK

-

22.5 - 26.5

each

-

BPGES

cylinder head.

or

BPRGES

Tightening

N

-

m

(230 - 270

Torque

:

kg cm,

16.6 - 19.5

ft

-

Ib.)

-

36-

Page 40

13)

CHARGE

COIL

Install charge

coil

with the wiring located at

5-

o’clock

position.

lightening

Torque

:

1.5 - 3.4

N

-

m

(15

-

35

kg

-

cm)

(1.1

-

2.5

ft . Ib.)

14)

ELECTRIC

STARTER

Install electric

starter.

Tightening

Torque

:

16.7 - 18.6

N

*

m

(170

-

190

kg

-

cm)

(1 2.3 - 13.7

ft

-

Ib.)

CHARGE CPlL

ELECTRIC

STARTER

M8

FLANGE

BOLT : 2

pcs.

Fig.

5-38

-

37-

Page 41

15)

OIL FILLER and SUPPORT (BLOWER HOUSING)

Install

16)

Attach cylinder baffle

17)

Attach regulator

oil

filler and

CYLINDER BAFFLE

REGULATOR

support

to

cylinder

(blower housing)

#I,

#2,

#3

baffle.

and

#4.

M6

FLANGE

BOLT

A

:

4

pcs.

77

CYLINDER

BAFFLE

5

Fig.

5-39

-

38-

M6

FLANGE

BOLT : 2

pcs.

Page 42

18)

FLYWHEEL

(1)

Wipe

off

oil

and grease thoroughly from

tapered

portion

of crankshaft and flywheel

center hole.

(2)

Install flywheel to crankshaft and tighten

flywheel nut

with

spring washer and washer.

Tightening

Torque

:

83.3

-

93.1

N - m

(850 - 950

kg

-

cm)

(61.5

-

68.7

ft

*

Ib.)

19)

INTAKE MANIFOLD

Set gasket (special paper) onto

both

#I

and

#2

cylinder head and install intake manifold.

Tightening

Torque

:

16.7 - 18.6

N

*

m

(1

70

-

I90

kg

-

cm)

(1

2.3 - 13.7

ft

.

Ib.)

20)

IGNITION

COIL

Temporally fit ignition coil

to

crankcase.

Adjust air

gap

between ignition coil

and

flywheel

using a thickness gauge and tighten bolts.

Ignition

coil

air

gap

:

0.3

-

0.5

mm

(0.012

-

0.020

in.)

Torque

:

6.9 - 8.8

N

-

m

~ ~~~ ~~~~ ~ ~~~ ~ ~~

(70

-

90

kg

-

cm)

(5.1 - 6.5

ft

.

Ib.)

Connect wiring from stop diode

to

the primary

terminal

of

ignition

coil.

21)

CARBURETOR

Set gasket onto intake manifold and install

carbu-

retor.

IGNITION

COIL

THICKNESS

GAUGE

1

I

fig.

5-40

Tightening

Torque

:

6.9

-

8.8

N

m

(70

-

90

kg

-

cm)

(5.1

-

6.5

ft

'

Ib.)

-

39-

Page 43

22)

GOVERNOR LEVER

Attach governor rod and

rod

spring between governor lever and carburetor throttle lever, and insert the

governor lever to governor shaft. Tighten locking bolt temporarily.

23)

SPEED CONTROL

LEVER

and

CHOKE

LEVER

Attach governor spring between governor lever and speed control lever as

Attach chock control

rod

between carburetor chock lever and chock control lever.

shown

in

the illustration.

,-.

Fig.

5-41

ROD

SPRING

GOVERNOR

i

I

ROD

I

CHOKE

M6

FLANGE

NUT

:

I

~G~~ERNOR

/

SPRING

Fig-

5-42

M5

1

pce.

BOLT

CONTROL

LEVER

AND

M5

NUT

'.

:1

M5

BOLT : 1

M6

BOLT

pee.

FLANGE

:

1

pce.

pce.

-

40-

Page 44

24)

ADJUST

GOVERNOR

SYSTEM

(1)

Turn the speed control lever

all

the way to-

ward the high speed position and fix

it

by tight-

ening nut.

(2)

Check that governor lever

is

pulled by gover-

nor spring and carburetor throttle valve

is

fully

open.

(3)

Turn governor shaft counterclockwise all the

way and tighten lock bolt to secure the lever

on the shaft.

(4)

Loosen the nut

to

allow

the

speed control le-

ver to move freely.

I

U

Fig.

5-43

25)

BLOWER

HOUSING

Attach

blower

housing

to

crankcase.

26)

FUEL

PUMP

Install fuel pump onto

#2

cylinder baffle. Connect

fuel

pipe

between carburetor and fuel pump.

FUEL

INLET

NEL

FILTER

27)

AIR

CLEANER

(1)

Connect breather pipe to air cleaner base.

(2)

Fit air cleaner base onto carburetor.

(3)

Connect breather pipe to

#1

cylinder head.

(4)

Set air cleaner element along with urethane

foam onto base.

(5)

Install air cleaner cover with knob.

Fig.

5-44

I

AIR

CLEANER

BASE

/

BRIDGE,

cleaner

Fig.

5-45

-

41

-

Page 45

28)

OIL

PRESSURE

Install oil pressure switch onto main bearing cover.

SWITCH

Tightening

Apply oil to O-ring and install oil filter by tighten-

ing about

cover

surface.

lightening

Torque

314

turns after attaching main bearing

Torque

:

5.9

-

9.8

(60

-'IO0

(4.3 - 7.2

:

About

(About

(About

N

kg

ft

12.3

125

9.0

-

m

*

ft

-

cm)

Ib.)

N

-

kg

-

m

*

cm)

Ib.)

Fig.

5-46

A

30)

FUEL

Connect fuel pipe between fuel pump and crank-

case

31)

FINAL CHECK

Be sure to check loosen bolts and nuts, and also

electric wiring connections.

PUMP

nipple.

PLUSE

PIPE

-

42-

0

RING

@

Fig.

5-47

Page 46

32)

ENGINE

OIL

Refill engine

oil

and start the engine. Engine

oil will be lubricated oil passages and

oil

filter.

Check the engine

oil

level and refill again to

the upper level

of

oil level gauge.

Note:

*

Total engine

oil

capacity

is

about

2.0

L.

*

Use

"SE" (API

classification)

or

higher

grade

engine

oil.

OIL

LEVEL

GAUGE

OIL

FILLER

LEVEL

Fig.

5-48

5-5

BREAK-IN

OPERATION

*

An

engine that has been completely overhauled by being fitted with a new piston, rings, valves and

connecting rod should be thoroughly RUN-IN before being put back into service.

Good

bearing sur-

faces and running clearances between the various

parts

can only be established

by

operating the

engine under reduced speed and loads for a short period

of

time.

I

Load

I

I

I

EH63V

I

EH65V

I

Time

I

Engine

Speed

I

Step

1

Step

2

10

min.

2,500

rpm

No

Load

10

min.

3,600

rpm

No

Load

Step

3

10

min.

3,000

rprn

No

Load

Step

4

Step

5

5.4

kW

(1

7

HP)

(1

4.5

HP)

12.7

kW

10.8

kW

(8.5

HP)

(7.3

HP)

6.3

kW

3,600

rprn

30

min.

3,600

rpm

30

min.

I

I

I

1

I

Table.

5-2

While the engine is being tested, check for oil

leaks.

*

Make final carburetor adjustment and regulate the engine operating speed.

-

43-

Page 47

6.

MAGNETO

6-1

OPERATION

AND

FUNCTION

The ignition system is a pointless flywheel magneto with automatic advancing characteristic.

Being different from the breaker point type ignition system, this system is completely free from such

troubles as starting-up failure due to dirty, burnt or corroded point surface.

The

electronic automatic advancing ensures extremely easy

starts

and stable high performance at oper-

ating speed by advancing the ignition timing to the most suitable point.

Ignition

liming

Control

Circuit

Automatic

Advancing

Control

Circuit

*

BASIC

(1)

THEORY

Revolution

current

current

I1

L

fig.

6-1

(a)

(B.T.D.c.)

26.5O

ELECTRONIC ADVANCING

MAGNETO

SYSTEM

FLYWHEEL

t

500

of

the flywheel generates electricity on the primary side of the ignition coil, and the base

flows to the power transistor. Current

I1

turns the power transistor

flows.

1000

ENGINE

REVOLUTION

Fig.

6-1

(b)

2000

3000

"ON"

and the electric

(r.p.rn.)

-

44-

Page 48

(2)

At lower engine revolution, when the flywheel reached the ignition point the low speed ignition timing

control circuit operates to run the base current

13

to turn the signal transistor

A

"ON"

allowing the

current

I1

to

bypass

as current

14.

At this moment the power transistor

turns

"OFF"

and the current h is abruptly shut resulting in the high

voltage generated in the secondary coil which produces

sparks

at the

spark

plug.

(3)

At higher engine revolution, the advancing control circuit operates at the ignition timing to

run

the

base current

IS

to turn the signal transistor

B

"ON"

allowing the current

11

to bypass as current

16.

At this moment the power transistor turns

"OFF"

and

the current

L

is

abruptly shut resulting

.in

the high

voltage generated in the secondary

coil

which produces sparks at the spark plug.

The operating timing

of

the advancing control circuit advances in accordance with the increase

of

'

engine speed resulting

in

the advancing

of

ignition timing.

*

WIRING

DIAGRAM

Connect

key

switch, magnetic switch and battery with wirings

of

proper gauge

as

shown

by

the dotted

lines

in

the wiring diagram.

Fig.

6-2

-

45-

Page 49

7.

LUBRICATION

7-1

OPERATION

Full

lubrication system is adopted, in combination with torchoid oil pump and cartridge type oil filter.

*

The trochoid type oil pump

pin portions of crankshaft, camshaft etc.

AND

SYSTEM

FUNCTION

is

driven

by

camshaft, and delivers pressurized engine oil to the journal and

*The engine oil in the oil pan is fed through the oil pump filter into oil pump and

is adjusted by the relief valve after discharging from oil pump. Through the cartridge type oil filter, the

engine oil

camshaft. The splashed engine

*

The by-pass valve is incorporated into the cartridge type

clogged, the engine

is

provided onto the rotating portions

oil

is provided to the cylinder, piston, cylinder head valve system.

oil

is fed through the by-pass valve into the crankcase oil passage.

such

as journal and pin portion of crankshaft and

oil

filter. In case that the oil filter element is

the

engine oil pressure

ESSURE

SWITCH

c

OIL

PUMP

L

PUMP

fig.

-

46-

7-1

ELlEF

FILTER

VALVE

OIL FILTER

Page 50

8.

CARBURETOR

8-1

OPERATION

AND

FUNCTION

w

I1

1

cum

U

Fig.

8-1

-

47-

Page 51

8-1

-1

FLOAT SYSTEM

a

The float system is consists of

operation.

The fuel flows from the fuel tank into the float chamber through float valve.

to

When the fuel rises

balanced, the float valve closes to shut

a specific level, the float rises, and when its buoyancy and fuel pressure are

float and a float valve, and maintains a constant fuel level during engine

off

the fuel, thereby keeping the fuel at the predetermined level.

~

8-1-2

The pilot system feeds the fuel to the engine during idling and low-speed operation.

The fuel is fed through the main jet to the pilot

the pilot air jet.

The fuel-air mixture is fed into the combusion chamber through the idle

At idling speed, the fuel is mainly fed from the idle port.

8-1-3

The main system feeds the fuel

The fuel is metered by the main jet and fed to the main nozzle. The air metered by the main air jet is

to the combusion chamber.

8-1

The choke

When the starter

PILOT

MAIN

mixed

mixed again with the air taken through the air cleaner into an optimum fuel-air mixture, which

nozzle increases and draws much fuel accordingly; thus easily start up the engine.

with

-4

CHOKE

SYSTEM

jet,

where it is metered, and mixed with the air metered by

port

and the

SYSTEM

to

the engine at medium-and high-speed operation.

the fuel through the emulsion hole, and the mixture is atomized out of the main bore.

is

used for easy start when engine is cold.

is

operated with a choke valve fully closed, the negative pressure applied to the main

slow

port.

is

supplied

It

is

8-1-5

ACCELERATOR-PUMP SYSTEM

When the throttle is opened rapidly for acceleration, air flow and manifold vacuum change almost instan-

taneously. Because fuel is heavy and lags behind air flow, a momentary leaness results. The accelera-

tor-pump suplies extra fuel for smooth operation during this condition.

At constant load condition, a vacuum passage in the carburetor applies manifold vacuum to the pump

diaphragm and the pump diaphragm is held to pull position.

When the throttle is opened rapidly for acceleration, the manifold vacuum is droped, the pump dia-

phragm moves by the diaphragm spring, the fuel in the pump chamber push out by the pump diaphragm

and the fuel gush out from the accelerator-pump nozzle.

8-1

-6

FUEL

Fuel cut valve, operated with starter key switch,

ing engine running on and after burning.

When the key switch is

When the key switch is

spring

CUT

VALVE

on,

the valve is activated and the plunger is pulled in to open the main jet.

off,

the power source to the valve is

and stop the fuel flow of main jet.

is

equipped with main system of carburetor for prevent-

off.

The plunger is pushed out by the retum

-

48-

,-

Page 52

8-2

COMPORNENT PARTS

1.

Carburetor

Ass’y

2.

Slow

jet

Ass’y

3.

Main

nozzle

4.

Float

5.

Float valve

6.

Float pin

7.

Float chamber gasket

8.

Float chamber compl.

9.

Passage cover gasket

10.

Passage cover

11.

Screw

12.

Throttle shaft

Ass’y

13.

Choke shaft

Ass’y

14.

Choke lever

Ass’y

15.

16.

17.

18.

19.

20.

21.

22.

23.

24

25

26

27

28

Q.

8-2

Choke arm return spring

29.

Round machine screw

Choke lever ring

30.

Solenoid valve

Ass’y

Choke

collar

31.

Vaccum hose

Throttle valve

32.

Fuel

hose

Screw,

valve

set

33.

Nylon

band

Choke valve

34.

Jet

Needle

compl.

35.

Float chamber

Ass’y

Expansion

plug

36.

Cover

compl.

Air filter

37.

Spring

Filter, choke

shaft

38.

Diaphragm

Ass’y

Main jet

39.

Screw

Gasket

40.

Choke

valve

Slow

air bleed jet

41.

C-ring

Spring, throttle adjust screw

-

49-

Page 53

9.

ELECTRIC STARTER

I

NOTE;

For Electric starter operation, electric wiring

key

switch

and

battery as shown in the diagram.

should

Oil

Warning

(Option

be

connected

Lamp

Parts)

r----T

among

"""""

"""""

etectric starter,

t;\

"""

If,

I

"-0

,I

I,,,

I,,,

I,,,

~IIOI

I,,,,

c

fig.

9-1

OPERATION AND

9-1

When key switch

coil is excited. The plunger

FUNCTION

is

turned

ON,

lower electric current

is

pulled and higher current

(M

When electric starter is operated, pinion gear is pushed out by

with ring gear and flywheel and crankshaft are rotated.

M

+

"""""""

I

I

SI

1

I

I

I

I

I

I

STARTING MOTOR

I

I""""""""""""""I

ELECTRIC STARTER

Fig-

9-2

-+)

(S

i

12V-30AH

"""_""

flows

through coil

-

)

flows through electric starter.

the

shift lever.

KEY

4

SWKCH

of

magnetic switch and

The

pinion gear

BATTERY

is

engaged

1

the

-

50-

Page 54

9-2

COMPORNENT PARTS

1.

Starting motor

Ass’y

2.

Armature

Ass’y

3.

Thrust

washer

kit

4.

Pinion stopper set

5.

Yoke

Ass’y

6.

Rear cover

Ass’y

7.

Starter metal

8.

Brush holder

Ass’y

9.

Brush

(-)

10.

Brush

set

11.

Brush spring

12.

Pinion

Ass’y

1

3.

Gear

case

Ass’y

14.

Starter metal

Fig.

9-3

15.

Gear

case

metal

cover

16.

Dust

cover

kit

17.

Shift lever

kit

18.

Magnetic

switch

Ass’y

19.

Through

bolt

20.

Bolt

21.

M

terminal cover

-

51

-

Page 55

IO.

TROUBLESHOOTING

The following three conditions must be fulfilled for satisfactory engine start.

(1)

The cylinder filled with a proper fuel-air mixture.

(2)

Good compression in the cylinder.

(3)

Good

The engine cannot

spark, properly timed, to ignite the mixture.

be

started unless these three conditions

are

met.

There are

is about to start at low speed, and

The most common

10-1

NO

Phenomenon

I

I

I

1.

Electric starter

does not

operate.

I

I

I

I

I

I

also

other factors which make engine start difficult,

ENGINE

I

I

I

I

I

I

I

I

causes

of

OPERATION

1)

Poor connection

2)

Wiring discontinuity between key switch and starter

motor

3)

Wiring discontinuity between battery and starter

motor

4)

Improper battery

battery

5)

Poor

connection

6)

Starter magnetic switch faulty

7)

Starter motor faulty

8)

Crankshaft seizure

9)

Seizure between piston

e.g.,

a

high back pressure due to a

engine troubles are given below:

Possible

of

key switch wiring

(low

of

battery terminal

causes

capacity) or discharged

and

cylinder

a

heavy load

long

exhaust pipe.

Check, repair or replace

Replace

I

Replace

I

Charge

Check, clean or replace

Check, clean, repair

1

Repair or replace

I

Check, repair or replace

I

Check, repair or replace

on

or

replace battery

the engine when it

Remedy

or

replace

I

I

I

I

I

1

I

I

I

Electric starter

operates, but

engine does

not start.

2)

Poor

connection or discontinuty of ignition system

wirings

3)

Electric starter faulty

-

52-

Check,

Repair or replace

repair

or

rep,ace

Page 56

10-2

STARTING

DIFFICULTIES

Phenomenon

1.

Low

engine

speed at

starting

2.

Ignition

system

malfunction

3.

Fuel system

malfunction

4.

Engine core

components

malfunction

Possible

causes

Remedy

1)

Battery discharged

Clean or repair

3)

Poor connection between battery and ground

Clean or repair

2)

Poor connection between battery and starter motor

Charge battery

4)

Electric starter faulty

I

Repair or repiace

5)

Improper engine oil

Replace

with

recommended

engine oil

-

Spark plug

*

Improper spark plug gap

Replace

No

insulation

Adjust gap

0.7

mm

to

0.8

mm

Carbon deposits

Ignition

coil

No

insulation or discontinuity

Poor connection or discontinuity of ignition code

Improper air gap between ignition coil and flywheel

1)

No

fuel in fuel tank

2)

Fuel pump clogged

3)

Fuel hose clogged or pinched

4)

Air

mixing into fuel lines

Clean

Replace

Repair or replace

Adjust

Refill

Clean

Clean or replace

Check and adjust connecting

portion

5)

Improper gasoline or water infiltration

Replace

6)

Carburetor

*

Overflow

Adjust

*

Clogged or damaged

Check and adjust

*

Improper operation of throttle valve

Disassembly and clean

7)

Poor connection

of

fuel cut valve wiring

Check and repair

1)

Insufficient tightening of cylinder head bolts

Check and retighten

2)

Wear

of

piston, piston ring and/or cylinder

Repair or replace

3)

Improper contact of valve and seat

Repair

4)

Valve seizure

Repair

5)

Improper valve clearance

Adjust

6)

Intake manifold gasket leakage

Retighten intake manifold bolts

or

replace gasket

7)

Carburetor gasket leakage

Retighten carburetor bolts or

replace gasket

8)

Insufficient tightening of spark plug

Retighten

-

53-

Page 57

10-3.

INSUFFICIENT

OUTPUT

2.

Ignition

system

malfunction

Possible

1

)

Loosen spark plug

2)

Cylinder head gasket leakage

3)

Piston ring(s) seizure or wear

4)

Piston or cylinder wear

5)

Incorrect valve and seat contact

6)

Valve stem seizure

7)

Improper valve clearance

1)

Spark plug faulty

2)

Ignition

3)

Improper air gap between ignition coil and flywheel

4)

Magneto demagnetization

1)

Carburetor clogged

coii faulty

causes

Remedy

Retighten or replace gasket

Retighten

Replace

Repair

Repair or replace

Repair or replace

Adjust

Replace

Replace

Adjust

Replace

Disassembly and clean

or

replace gasket

or

replace

3.

Fuel system

malfunction

I

4.

Low

intake

air volume

10-4.

I

I

OVERHEAT

Phenomenon

Overheating

2)

Improper fuel pump operation

3)

Fuel strainer or fuel hose clogged

~~~~ ~~~ ~~ ~~

4)

Air mixing into fuel lines

5)

Improper gasoline

1)

Air cleaner clogged

2)

Throttle valve faulty

I

1)

Cooling air

portion

2)

Improper engine oil

3)

Lean aidfuel mixture

flow

or

water infiltration

Possible

obstructed at inlet or cylinder baffle

causes

Disassembly and clean

Clean or replace

Check and adjust connecting

portion

Replace

Clean or replace

Repair

I

I

or

replace

Remedy

Clean

I

Replace

Check and adjust carburetor

I

4)

Excessive back pressure of exhaust system

5)

Over-load

-

54-

Check, clean or replace

Change

to

rated load

Page 58

10-5.

ROUGH

IDLING

Possible

causes

I

Remedy

~

I

I

I

I

1)

Low

idling speed

I

Adjust

I

I

2)

Carburetor slow system passage clogged

I

Check and clean

2.

Intake

svstem svstem

1)

Air mixing from connecting portion

of

air intake

Check

,

tighten or replace gasket

3.

Cylinder

I

head

I

1)

Cylinder head gasket faulty (blow-by)

I

Replace

1)

Improper valve clearance

Adjust valve seat contact

2)

Leakage from valve seat

4.

Valve system

Adjust

3)

Excessive clearance between valve stem and guide

Replace

1

1)

Weak ignition spark

system

1

Check and replace spark plug

10-6.

HtGH

ENGINE

OIL

CONSUMPTION

Phenomenon

I

Possible

causes

I

Remedy

I

1.

Oil leakage

2.

Oil dilution

I

1)

Loosen drain plug

I

Tighten

I

I

2)

Drain plug gasket damaged

I

Replace

I

3)

Incorrect oil filter frtting

Tighten

4)

Loosen

main

bearing cover bolts

Repair

Repair

or

replace

6)

Breather faulty

Adjust oil level

5)

High

oil

level

Replace

4)

Excessive wear

of

valve stem

Replace

3)

Excessive wear

of

piston and cylinder

Replace

2)

Piston

rings

seizure, wear

or

poor

contact

Replace

1)

Piston oil ring faulty

Replace

6)

Crankshaft oil seal damaged

Replace

5)

Main bearing cover gasket damaged

-

55-

Page 59

10-7.

HIGH

Phenomenon

1.

Fuel system

2.

Engine core

FUEL

I

I

CONSUMPTION

Possible

~

1)

Over-size main jet

2)

Needle valve faulty and/or high fuel level in float

chamber

3)

Chock

1)

Low

valve does not open fully. Repair or replace

compression Check or repair

causes

~

Remedy

I

Replace

Adjust or replace

I

Check and adjust load and/or

engine speed

10-8.

I

DETONATION

Phenomenon

1.

Ignition

system

malfunction

2.

Fuel system

malfunction

3.

Cylinder

head

4.

Valve system

Possible

1)

Poor connection

2)

Improper or damaged spark plug

1)

Lean or rich aidfuel mixture

2)

Carburetor damaged

3)

Fuel lines clogged or damaged

4)

Air mixing from connecting portion of air intake

system

1)

Catbon deposit

2)

Cylinder head gasket faulty (blow-by)

1)

Improper valve clearance

2)

Valve heat deterioration

3)

Valve spring deterioration

of

ignition system wirings

in

combustion chamber

causes

Remedy

Check and connect properly

Clean or replace

Clean, adjust or replace

Disassembly and clean

Clean or replace

Connect properly

gasket

Remove and clean

Replace

Adjust

Replace

Replace

or

replace

4)

Improper valve timing

-

Adjust

56-

Page 60

10-9.

ENGINE

MISFIRE

Phenomenon

Remedy

Possible causes

1)

lmprpper spark plug gap or damaged electrode

2)

ignition coil faulty

Clean, adjust

or

replace

Replace

3)

Damaged ignition system wirings

Replace

1.