Page 1

cr'''l'

!-

d6a

Er

l-

r+l

€

=+

L

Vi'

5

o\

{

tno

d6

o.)

sd

|Jl\

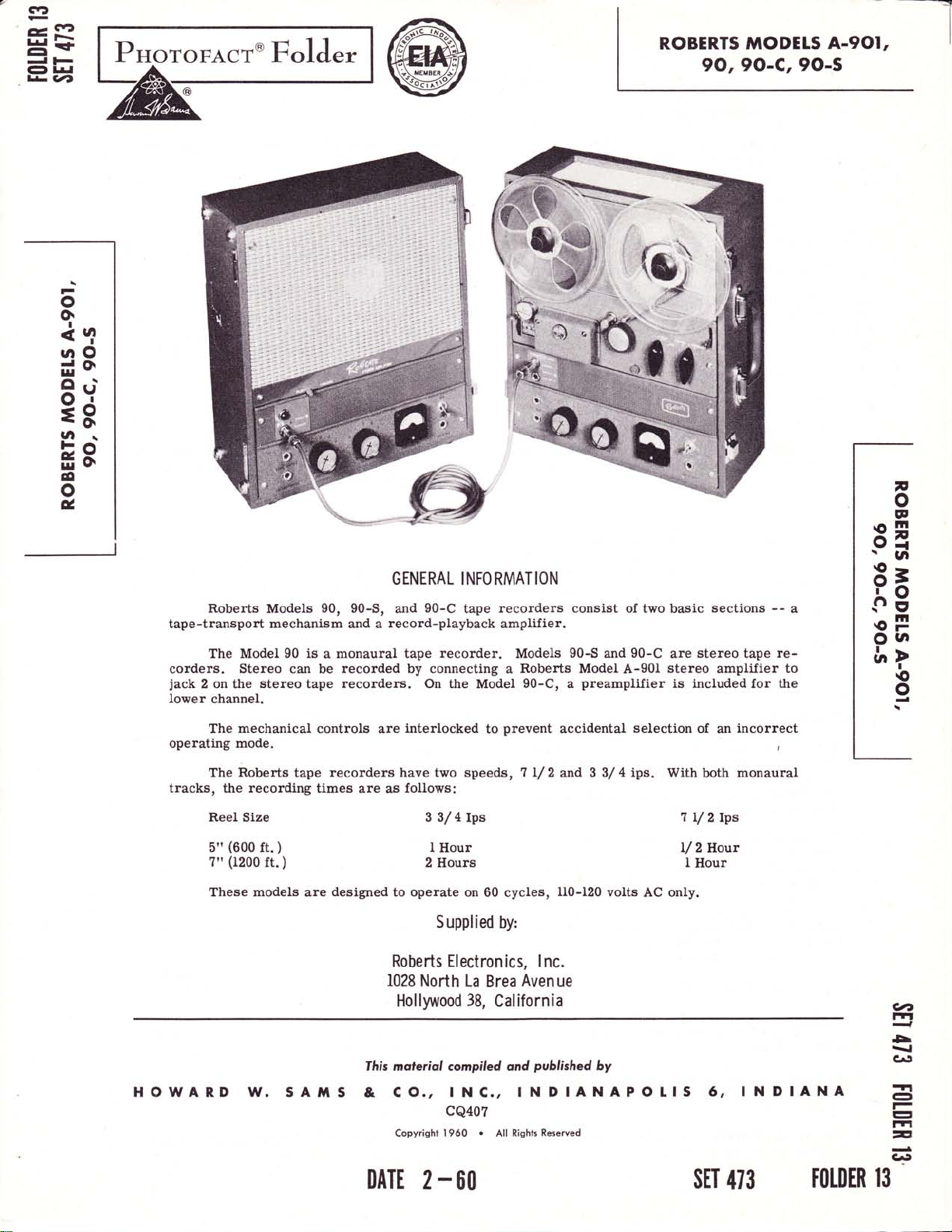

PnoroFAcr' FolJ"t

.i,

ROBERTS MODELS

gO-C,9O-S

9q^,

A.9OI.

I

Eg

o

o

d,

Roberts

tape-transport

The Model

corders.

jack

on

2

lower

channel.

The mechanical controls

operating mode.

The

tracks,

Reel Size

5"

?"

These models

Models

mechanism

Stereo

stereo tape recorders. On the

the

Roberts

recording

the

(600

ft.

ft.

)

)

(1200

90,

90 is

a

can be

recorders have

tape

times are

are

h&gn+**::.1*Y.";ffi--ffi

GENERAL INFO RMAT

90-S,

and a

monaural tape

recorded

designed

90-C

and

record-playback

by

interlocked

are

follows:

as

3

2 Hours

operate

to

ION

recorders consist of two

tape

amplifier.

recorder.

connecting a Roberts Model

two speeds,

Model

prevent

to

Models

7

90-C,

L/

2 and

90-S

and

preamplifier

a

accidental

3 3/

3/4Ips

I

Hour

on 60

cycles,

lI0-120

volts

90-C

A-901

selection

4

ips.

AC

sections

basic

stereo tape re-

are

stereo

amplifier to

is included

of an

With

both

7 L/

2l:ps

L/ 2

Hour

I Hour

only.

--

the

for

incorrect

r

monaural

n

o

E

tE

\la

a

iE

oF

ola

&'P

I

9

HOWARD \f.

SAtnS

Supplied

Roberts Electronics, lnc.

1028 North

Hollywood

This msterial compiled and

CO.,

&

Copyright

DATE

lNC., INDIANAPOtIS

cQ40?

1960

2

-

La

38,

$O

by:

Brea

California

.

All Rights

Avenue

pvblished

Reserved

by

6, INDIANA

sET

473

F0[0ER

13

c-2

Frl

-f

5

L.I

C.5

r-r

e

F

E

Frl

-

d

c+

Page 2

l.

2.

Remove

Remove

storage

lid

from

camying

microphone

compartment

and

on left

case.

AC

supply

side

P

REPAR ING

cord from

of

canying

FO

R O

PERAT

3.

case.

Make

tion-

ION

certain

all

controls

are in

the

Stop

posi-

0n-0ff

When it

the

90-C,

pushed

the

position,

Off

Vol

volume

counterclockwise

cord

Tone

it

response;

will

Play-Record

Switch

On the

is

amplifier

it

is

to

the

amplifier

power

position

ume

Turning

in

playback.

or

This

clockwise

control

turning

attenuate

This is

Model

in

the

and tape deck.

3-position

a

AII On

and tape

turns

this

either

from

tie response.

and

a 3-position

g0,

t}is

position,

On

switch.

position,

deck.

is

applied

the

to the

power

control

record

decreases

firnctions

position

it

counterclockwise

Record

or

inplayback

5 will

Lock

control:

is

a 2-position

power

On the Models

power

When it

off to

clockwise

When

tape

the

is

is

is in

deck

entire

increases

playback.

the

volume

only.

increase

from

Stop,

FUNCTIONS

switch.

turned

the switch

turned

the

g0-S

Amp

on to

on to

only.

unit.

Turning

in

either re-

Turning

the

treble

position

play,

and

Off

The

the

and

OF

CONTROLS

Record.

position

Lock

the

is

it

b

NOTE:

Wind-Rewind

ttte

NOTE: This

Pause

from

engaged.

stops.

NOTE:

Turning

places

and turning

same

time,

This

Rewind

bef ore

Turning

position;

Wind

Record

before the

When this

the drive

This

This

this

the

unit in

the control

places

control

control.

ttte

Wind

-Rewind c ontrol

this

controlto

to

the right,

control

control.

play-Record

lever

capstan,

permits

control

is

control

the

clockwise

ptay.

Depressing

to the Record position

unit

in

Record.

is interlocked

It must

is

It

is

not

be in

the

left

in

interlocked

must

be

control

raised,

and the

spot

pressure

take-up

editing

on the

the Rewind position.

in

Model

from

the Stop

the Record

with

the Wind-

the

can

places

with

the Stop position

can

and momentary

Stop

be op e

tlreunit

the

be

is

reel

g0.

position

rated.

play-

operated.

removed

is dis_

at

in

Threading

l.

Place

(6?),

protrusions

on

the

2.

Unwind

reel.

the

faces

3. Insertthe

inthe

end

secure

To

Make

I. P-lug

place

Line

2. Depress

turn

sition.

3.

Adjust

reading

the

Tape

a full reel

making

take-up

slots

tape

spindle (2?),

engage

about

Hold

a

slot,

the rear

freeendof

hub

of the

place,

in

t}te

tape

a

Monaural

a microphone

signal

a

jack.

Input

the

the

Play-Record

the

Volume

on

the

of

certain

on the

14

section

making

turn

from

Record

tape

the reel

pan.

protrusions

the

inches

of

of

sure

the recorder.

thetape

take-up reel.

the reel

to

the reel.

Recording

into

some

Lock

control

control

VU meter

OPERAT

on

feed reel

slots

place

again

of tape

tape

taut

the

engage

an

empty reel

making

on thJpan.

from

and insert

dull-coated

intooneofthe

While

two

the

Microphone

other

holding

orthree

sburce

and simultaneously

to

ttre Record

until

is

-b.

the

ING

spindle

the

certain

the supply

into

side

slots

the

times

to

jack,

or

into

t}re

po_

average

INSTRUCTIONS

CAUTION:

impedance

recording.

a

To

Make a

l.

Connect

Channel-2

Model

2.

Move

AII On.

to

On.

3.

Turn

reads

4.

PIug

jacks,

t}te Line

5. Depress

turn

port

6.

PlacethePlay-Record

in Record.

?.

On Model

preamplifier,

Do

not

connect

load

to

the

Stereo

the

microphones

the

head

4-901

the

On-Off

Move

Volume

-5.

orplace

Input

Recording

interconnecting

jack

amplifier.

switch

the

On-Off

control

signals

jacks.

the Record

the Record-play

to Record.

90-C,

turn

on

bottom

speaker

a

Output

to the

stereo

on

the

switchon

until

into

the Microphone

from

another

Lock

and simultaneously

control

switchon

the

on the

switch

of the

or

while

cable

channel

tape

other low-

making

from

recorder

jack

theamplifier

the

VU

meter

sourceinto

tape

trans_

A-g0Iamplifier

on

the

built_in

case,

to Out.

the

inthe

to

Input

Page

2

Page 3

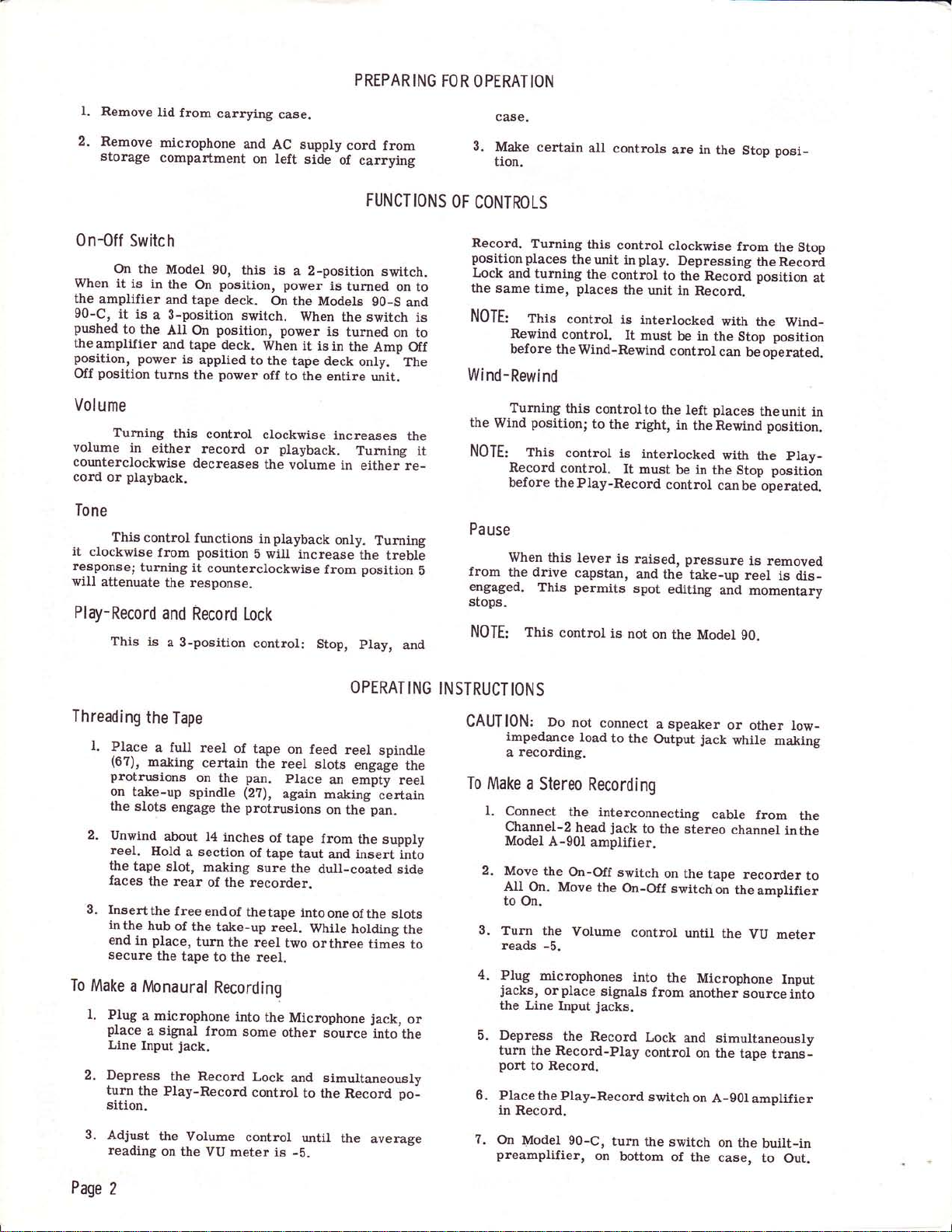

FIG.

I

TOP

VIEW OF MECHANISM

WITH

ESCUTCHEON

REMOVED.

tT

'ta

F

o

E

It/lonaural

1. Thread

2.

Turn

to

3. Turn

4.

Adjustthe

ing leveI.

l.

Thread

Turn

2.

the

3.

Connect

Channel-2

jack

4.

Make

amplifier

5.

Turn

port

Playback

Stereo

6. Adjust

and amplifier to

Speed

Change

To change

Playback

the

the

warm up.

the

Play-Record

the tape

the

tape

A-90I amplifier switch

on

the amplifier.

certain

the Play-Record

to Play.

theVolume

(see

tape

unit

on

volume

recorder

interconnecting

the

jack

is in

the tape from 7

"Threading

and allow a few seconds for

andtone

(see

"Threading

the

of

tape

the Play-Record

Play.

controls onthe

a

balanced output.

control

controlon

to Play.

to thedesired

switch

to

to

In.

cable from

recorderto

2 to 3 3/

V

the Tape").

listen-

the Tape").

Alt On. Turn

the

Stereo

the

switch

the tapetrans-

tape

on the

recorder

4

ips, re-

move the

When

bushing

it

lndex Counter

Index

be noted

reference.

External Speaker

Output

when

Erasing

top of the head

tothe half-track

same

Iowersthe

the unit is

automatically

made.

cording

Play-Record

To Use

thumbscrew

the

bushing

post.

After

Counter

at the beginning

An

external

jack.

using

an

Tape

To

erase

time,

erase

in

To

on

the

l. Turn

the

and bushing from

is

not

being used, store

is

atape

The internal

erase

it,

Second

threaded

to

"000".

external

one track

clockwise.

position.

turn

headto

the Record position,

positioned

turn

control

Play-Record

The index

of each

speaker

may

speakerwill

speaker.

of a tape,

This raises

the

the

To erase

knob

the full-track position.

before

tape

without

the

volume

to Record.

(ltylonaurall

Track

the capstan.

it

on

onthe recorder,

numbers

selection,

plugged

be

be

turn the knob

the

both tracks

set the

can

for future

into

fusconnected

erase head

counterclockwise.

the

erase

a new

putting

to minimum

control

to Stop.

head

recording

new

a

and

the

then

the

on

at the

This

When

re-

the

is

is

€F

our

ti'

F

"n

O

I

n

u)

7

€

8g

Page

3

Page 4

I

I

2.

3.

To

Remove

it

on the

Place

spindle.

Remove

I.

Remove

in

each

reel

the

left

the empty reel

Tape

the two screws

pan),

containing

(supply)

Transport

the

reel

spindle.

on the right

Mechanisn

in

the

spindle

tape,

(take-up)

from

place

and

reel

Case

pans (one

D

ISASSEMBLY

4.

3.

4.

Thread

described

as

cording.

Lift

the

reassemble,

To

dure.

the

tape,

under

"

amplifier

proceed

and

"To

from

reverse

with

Make

the case.

the

foregoing

the recording

a Monaural

proce-

Re-

2. Remove

and

3. Remove

cutcheon

side.

4.

Remove

Remove

5.

knobs.

Remove

6.

't

Remove

-

port

8.

Unplug

speaker,

case.

9. To

To Remove

2.

reassemble,

dure.

l.

Remove

and escutcheon

Unplug

the two screws

remove

to

the dressplate.

screw

one

the

and

pressure

the

the

Play-Record

the escutcheon.

four

the

the

case.

all connections

lift

and

Amplifier

the four screws

all connecting

on the right

7

V2-tps

screws

the

reverse

from

to the

plugs.

holding

t}le dress

side

bushlng

roller.

and Wind-Rewind

holding

to the

tape transport

Case

case.

the tape trans-

tape transport

the foregoing

holding

the

of

from

from

amplilier

plate,

the

es-

left

the

and

the

proce-

To Renove

l. Remove

case,

2. Unplug

Lift

3.

4.

To

dure.

To Remove

l. Remove

to the

Remove

2.

cover

Disconnect

3.

4. Feed

compartment.

5. Lift

To reassemble,

6.

cure.

Prean:p

fron

the

two screws

aII connecting plugs.

preamp

the

reassemble,

Model A-901

the

case.

the

on,

theAC

ttre amplifier

from

reverse

four

screws

four screws

the speaker.

cord

throughthe

from

reverse

Case

on A4odel

from

the case.

the

Anplifier

holding

the

the foregoing

the

foregoing

fron,

holding

hole

case.

90-C

bottom of the

proce-

Case

the

amplifier

the speaker

inthe storage

proce-

Record-Playback

Alignment

l.

2.

3,

4.

5. Insert

6.

Page

Tape

Thread

Connect a

phono

jack.

Turn

Remove

remove

the tape

plug,

the Tone control

thetwoscrews

the head

a

head

shield, into

Play

back thetape

Lubricate

4

screwdriver,

the following

Alignment

Head

(see

0.5-volt

insert

and

cover.

the

"Threading

voltmeter

AC

the

to

fromthehead

through

alignment

at full

parts

With

the Tape").

plug

into

maximum.

the hole in

screrr.

volume,

every

Standard

to a standard

the Output

cover, and

rotate

and

three months

ADJUSTMENTS

Record-Playback

Music

1.

2. PLay

loosen

few degrees

BR ICAT

in

Brake

ION

heavy

the

the

LU

alignment

10,000-cycle

ing.

Tape

Thread

and adjust

mum

When

the tape

back

clarity

Shoes

brake

the mounting

until

service,

screw

the

the

in

either

givesthe

note

Head Alignment

(see

"Threading

tape

at a normal

head

alignment

of high-pitched

(34)

shoes

screws

a new

every

and

braking

six

months

direction

highest

With

instruments.

(80)

and

rotate

surface

in

meter read-

Con

the

Tape").

listening

screw

become

the shoes

is

moderate

until

mercial

level,

for

maxi-

worn,

exposed.

the

a

ser-

Page 5

ffi

''--ii,':.',

tl.:::

:!F.-l

ffii:-;i''-',,.,.1r,

':#;*'

.

.

:.

rrlr'

:.-

-

*"

'-L

&

_.rN,

tvr

..:::

+ff*.

.f

'{t

t,

vice,

or once

l. Feed

drops

2. Rewind

bearing, with two drops

each

3.

Apply

Most defects,

be traced

stan,

and

residue,

year

a

and take-up

light

of

idler

bearing.

liberal

a

todirty

pinch

wheel

which is

in light

machine

bearing

other

surfaces.

worn off the tape

reel

amount of

than wear

The

(4)

may

service,

spindle

oil on

and

of

recording

accumulate

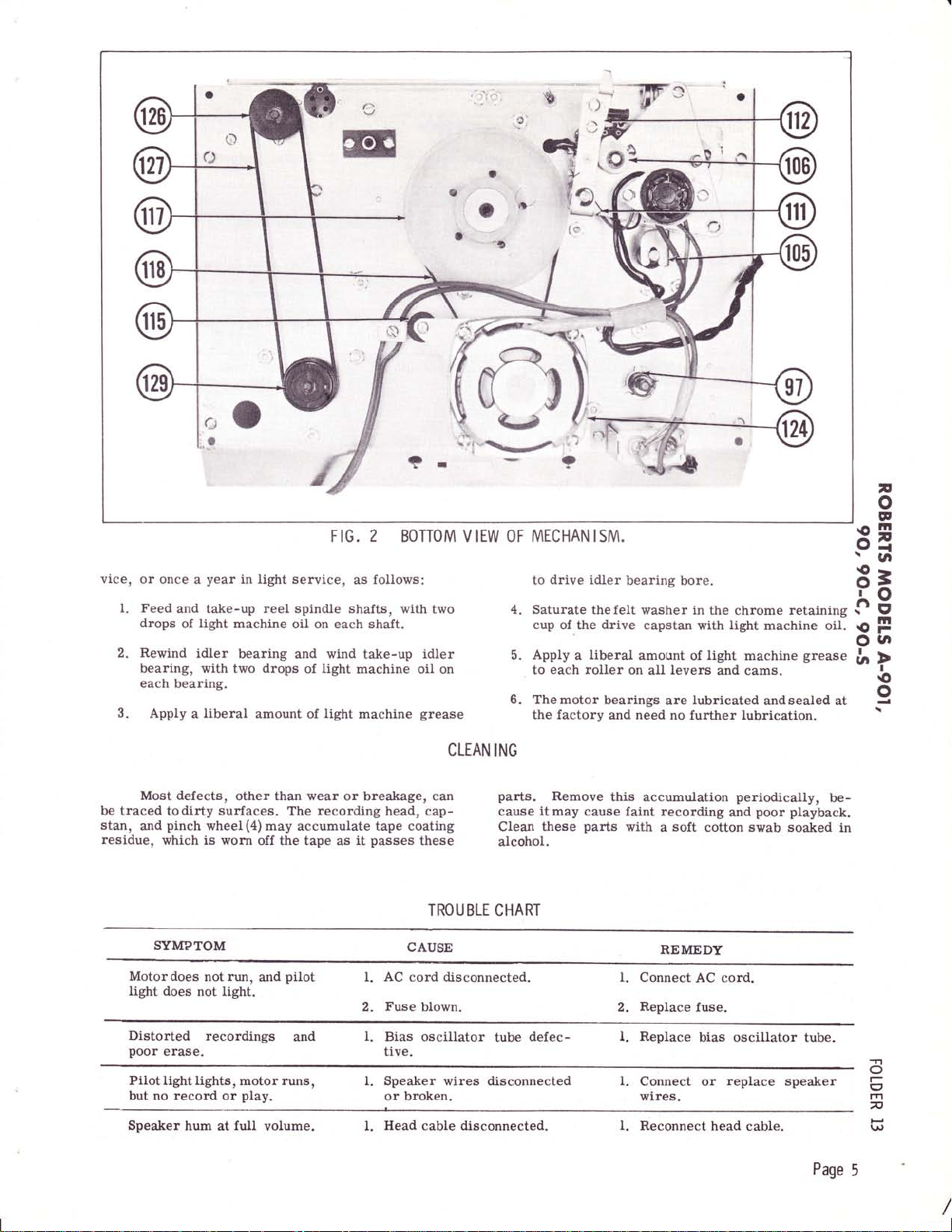

F IG.

as

shafts, with

each shaft.

wind

take-up

Iight

machine

light

machine

or

breakage,

it

as

ffiffi

,fr#

o$

€ilr

2

BOTTOM V IEW OF

follows:

two

idler

oil on

grease

CLEAN

can

cap-

head,

coating

tape

passes

these

'$

&#

MECHAN I

drive idler

to

Saturate

4.

cup

of.the

Apply

5.

to each roller

Themotor

6.

the factory

ING

parts.

cause

Clean these

alcohol.

Remove

it

may

SM.

bearing bore.

thefelt

liberal

a

washer in

drive

capstan with

amount

on

bearings

and need

of

levers

all

lubricated

are

no further lubrication.

this accumulation

cause faint recording

parts

with

a

soft

the chrome retaining

light

machine oil.

light

machine

and cams.

grease

andsealed

periodically,

poor playback.

and

cotton swab

soaked in

at

be-

F

o

tp

tT

\la

is

€F

ola

p

tit

€

9

SYMPTOM

Motordoes

light does

Distorted

poor

Pilot light lights,

no

but

Speaker

erase.

record

hum

notrun,

not light.

recordings

or

at

pilot

and

motor runs,

play.

fuII

volume.

and

TROUBLE CHART

CAUSE

AC

cord disconnected.

l.

Fuse

2.

I.

t.

I.

blown.

Bias oscillator

tive.

Speaker wires disconnected

broken.

or

Head

cable disconnected.

tube

defec-

REMEDY

Connect

I.

t

Replace

l. Replace

l.

Connect or

wires.

t.

Reconnect

AC cord.

fuse.

bias oscillator

replace

head cable.

tube.

speaker

Page

O

cf

n

t^)

5

I

/

Page 6

TROU BLE CHART

(CON'T"

)

SYMPTOM

Motorruns.

no record

speaker

;

does

No record

slight

with volume

Noisy

pilotlightlights, I. Defective

or

hum, and VU meter 2.

not read

on

or

speaker hum

control.

playbackor poorhigh-

frequency response.

Wow or flutter

speed.

lnsufficientdrive

3

3/4-ips

Tape

wind or

speeds. wheel

spills

when

rewind

CAUSE

Replace

Replace

playback,

no

Defective

rectifier tube. I.

output

tube. 2.

record.

playfack,

but

l. Preamplifier

tube defective.

I. Replace

variable

I. Heads misaligned.

Heads magnetized. 2.

2,

at? L/2-ips 1. Speed change

ping

on shaft.

at?

L/

2-or

I. Defective

main drive

(3i).

Oil on

2.

3.

Main

capstan.

drive

belt

bushing

([8)

slip- l. Tighten screw

idler

defec-

I.

See

Dernagnetize heads.

l. Replace

wheel

See

2.

Replace

3.

tive.

Drive

4.

going

rom I. Reel diameters

f

stop. diameter.

to

motor(I24)or starting

capacitor

defective. starting

unequal.

4. Replace drive

Tape

l.

REMEDY

rectifier

output tribe.

tube.

preamplifier

Alignment.

"Head

(120).

main

(3I).

"Cleaning.

main drive

drive idler

"

beft

motor

capacitor.

reels mustbave the same

tube.

"

(IlB).

(I24)

or

lndex

function.

Ref

.

No-

I

2

3

4

5

6

7

I

9

l0

n

t2

l3

t4

l5

r6

l?

t8

l9

20

20A

2T

Counter

Part

No.

90-50-43

90-50-r5

90-50-47

90-50-64

90-52-27

90-50-16

90-38

90-50-22

90-50-r?

90-50-30

90-50-89

90-50-79

90-50-81

90-50-80

90-52-23

90-52-r2

90-50-94

90-50-32

2. Brake

worn or out of adjustment.

does

not

Description

Reel Table

Reel

Table

Pinch Wheel Screw

Pinch

Wheel-Models

Pinch Wheel-Model

Transport

Deck Panel

Record-Play

Set Screw

Wind-Rewind

Transport Deck Panel,

Controls

Take-up

Spring Post Brackel

Bracket

Wind-Take-up

Models

90

&

Bracket

Retaining Ring

Take-up Brake

Take-up Brake Spring

Take*up Brake Bar

Pause Lever-Model 90-C

Pause-

Lever Load

90-c

Wind-Rewind Operating

Set Screw

Steel Ball.

I.

Screw(2)

(2)

Knob

Knob

Slide

90-S

Link Lever

Counter belt

broken.

MECHANICAL PARTS LIST

90 & 90-S

90-C

Bar

Lever

Spring-Model

Head

Spring-

Cam

shoes

&

(34)

(I27)

Ref.

No.

22

23

24

25

26

27

28

29

30

3t

32

33

34

35

36

3?

38

39

40

(80)

and

worn or

Part

No.

90-50-86

90-50-90

90-50-?8

90-50-8?

90-50-25

90-50-24

90-50-36

90-50-?2

90-50-92

90-50-82

90

-50-7?

90-50-5r

90-50-39

90-50-91

90-52-43

90-50-93

Replace

2.

(3a)

l. Replace

oradjust

(80).

and

counter belt

brake

Description

Rewind-Take-up

Control

Roller

Take-up Brake Link Spring

Main-Brake Pivot

Wind-Take-up

Lever-Models

Deck

Baseplate

Take-up

Splined Roller

Retaining

Washer

Spindle

Ring

Main-Drive

Drive

Idler Load Spring

Wind-Take-up

Bar

Control Pivot

90 & 90-S

(State

Idler Wheel

ldler

Lever

Brake Shoe, Small

Main-Drive

Screw

Spindle Mounting Plate

Roller

Drive

Models 90

Drive

Idler Pivot

Securing Screw

Idler Pivot

&

Idler

Lever-

90-S

Pivot Lever-

Model 90-C

Roller

Plav-Record Operating

shoes

(127).

Pivot

Lever

Model)

Pivot Bar

Lever

Cam

Page

6

Page 7

-1

4l

42

43

44

irs

46

47

4B

49

50

5I

52

53

54

60

6l

62

63

64

65

66

6?

6?A

6B

69

?0

?i

72

?3

74

?5

?6

17

?8

?9

80

8i

82

B3

84.

85

86

90-52-21

90-52-08

90-51-??

90-5r-06

90-50-5?

90

-52-04

90

-52-0?

90-52-26

90

-52-tI

90-50-48

90-5r-96

90-5r-?3

90-51-18

90-50-55

90-31

90-5r-64

90-51-?2

90

-5I-95

90-52-05

90-52-13

90-52-r0

90-50-44

90-50-45

90-50-63

90-52-46

90-50-02

90-52-06

90-52-42

90-50-36

90

-50-39

90-50-65

90-50-?7

90-50-?5

90-50-76

90-50-0?

90-50-39

90-50-33

MECHAN ICAL

Shorting Switch

Ch. 2

Rewind Activating

Record Lock Button

Record

Record Lock Screw

Lockwasher

Lock

Lever

Spring

Insulator

Insulator

Rewind Idler Wheel

Rewind Positioning

Tape-Drive Idler

Rewind Intermediary-Idler

Spring

Head Cover Screw

Head

Cover-Model

Head Cover-Model

Head Cover-Model

Head Screw

Michigan

Mag. Head Ass'y.,

Stereo-Model

Head Ass'y.

Head

Multierase

Model

Retaining

Washer

Rewind Intermediary-Idler

Model 90-C

Ass'

90-C

,

y.,

Head

Ring

Intermediary-Idler

Screw

Lever

Load Spring

90-C

90-S

90

90-S

Monaural-Model

Stereo-Model

Ass'y.

,Stereo-

Spring

Intermediary-Idler Spring

6?

Ass'y.

90 & 90-S

Screw

(State

Ass'y.

Plate

Spring

thru

Lever

Rewind-Idler Release

Tape

-Guide

Tape-Guide Top Plate

Tape-Guide !trasher

Tape-Guide BaII Bearing

Feed-Reel Spindle Ass'y.

90-C

Feed-Reel Spindle

Rewind-Models

Rubber

Model 90-C

Conical

Washer

Retaining Ring

Splined

Washer

Spindle

Spindle Mounting Plate

Take-up Spindle Spring

Washer

Retaining Ring

Brake-Shoe

Brake

Feed-Reel

Brake-Shoe

Feed-Reel

Index-Counter

Spindle Mounting

BalI-Bearing

Includes

Items

Rewind Drive Ring-

Spindle Spring

Roller

Housing

Mounting Screw

Shoe, Large

Brake Bar

Nut

Brake-Spring

Control Ass'y. Bracket

Load

90-S

Whee

Lever

Lever

Screw

-Model

72

Belt

Size)

PARTS

90

Ref

No.

8?

88

89

90

91

92

93

94

95

96

9?

98

99

r00

I0l

r02

I03

r04

r05

r06

IO?

r08

109

ll0

lu

ll2

u3

II4

u5

lr6

li?

ll8

rr9

120

r2l

122

i23

t24

125

r26

r27

12B

129

130

(CON'T.

LIST

Part

.

No, Description

)

Wind-Rewind Detent

Fiber Washer

Cam

90-50-98

90-50-09

Load Spring

Idler-Lift Operating Cam

Set Screw

Wind-Rewind Control

Bottom Plate-Control

Bracket

Lockwasher

90-50-66

90-50-38

Screw

Take-Up Spindle

Retaining Cup

Flat

90-50-53

90-50-9?

90-50-96

905r-03

Retaining

Idler

Switch

Screw

Hex Nut

Idler Lifting

Amplifier Switch- Bar

Cam

Set Sr:rew

FIat

Cotter Pin

90-5r-32

90

-5I-38

90-50-99

Amplifier-Switch

Amplifier

Load Spring

Amplifier-Switch

Lever

Fiber

Retaining Ring

90-51-?5

90-51-?6

90-50-95

90

-52

-53

90-51-04

90-52-03

90-50-34

90-50-46

Rubber Motor Mount

Motor

Flywheel and Capstah-Models

90

Flywheel and Capstan-Model

Main

Main Drive

Motor-Mount

Speed-Change Bushing

screw-Models 90

90-52-42

Speed-Change Bushing

screw-Model 90-C

90-50-21

90-52-44

Speed-Change Bushing-Models

90

Speed-Change Bushing-Model

90-c

90-51-94

Upper Knurled Bushing-Models

90-S

Motor Mounting Screw

*

90-50-14

90

-50-6?

90-50-68*

90-50-69

Drive Motor

Set Screw

Counter

Counter Beit

Set Screw

Spindle

Cotter

*

l4l0-54

Shaft

Ass'y.

Spring

Washer

Ring

Lifting-Levet

Shaft

Load Spring

Lever

Control

$'asher

Bar Screw

-Switch

Washer

Grounding

90-S

and

Drivd

90-S

and

90-C

and

Pulley

Index-Counter

Slide-Bar

Operating-

Spring

Belt-Models

Belt-Model

Plate

Bracket

90-S

&

*

90

90-C

ThumbThumb-

Pulley

Pin

Counter ReIt Welsco Prrt

Bar

90-C

&

90-l

I,l

s

o

I

o

h

€

o

F

o

tp

m

v

-{

(t

3

t

o

I

m

F

ta

I

I

I

o

Page

o

(t

n

lJJ

7

Page 8

I

gg

++

lgfll

iH._l

ig-t

ll

tl

rl

it_ )

I

I

I

I

I

F]

i6-+@

i6i ai rh

tr?,t

i

Page

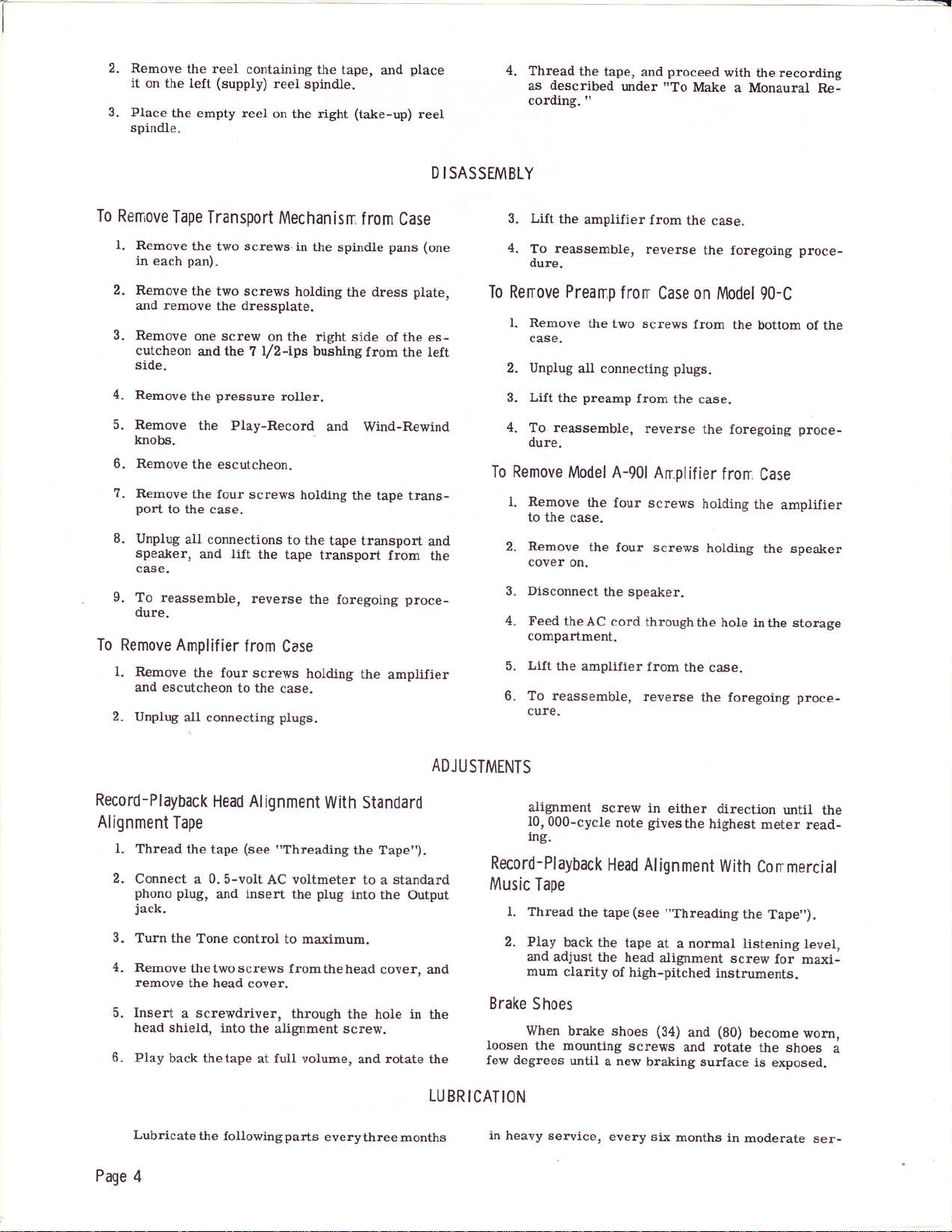

A PHOTOFACT

EXPLODED V IEW OF

3A

F IG.

8

@Howard

"EXPLODED" VIE!|T

W, Samr &

Co.,

lne. 1960

PARTS

ABOVE

BASEPLATE.

Page 9

IE

\Ul

8g

€F

out

t"P

€

9

7

o

E

IG. 38

F

PHOTOFACT

@Howard

EXPLODED

W.

Samr &

"EXPLODED"

Co.,lnc. 1960

V

IEW OF

VIE\T

PARTS

BELOW

BASEPLATE.

Page

-n

C)

1-

TJ

rrr

n

H

\^)

9

Page 10

6AR5

6AQ5

6X4

6AU6

ffiffiii:i#i;lirigfiffi

6AU6

9O-C

AMP.

CHASSIS

TOP

VIEW.

Page

l0

9O.C

AMP.

CHASS

IS

BOTTOM

V

IEW.

Page 11

6AR5

6BQ5

i'iiii:

;

ii::,lj:;::i:,

ffi

A-9OT AMP.

;ii-*-tiir:::::iil.#tii:ii::iiill;li:#iiiiiiiffiiiill

".'-N*L.+,.....,..,;;;+;;;

r1iftx

6X4

:;i;iiii:;;f

li;::liil:"'::::: :::1: ::. r:r

i,..',;,iti:/',,i,.,,.,:,,,,iii,,/.:iit,,,!i;:

*-.4

CHASSIS

: :;

i i iii;;;;;:::;:ia:

, &:'' ti

TOP VIEW.

6AU6

ilii:

j;::

trr

ll::

6AU6

Til

{.""

7

o

E

ltt

€

n

o

-l

UI

€

3

o

I

o

rl

I

ilt

F

UI

CHASS

IS

BOTTOM V

IEW.

.TI

o

t-

E7

n

ld

u)

s

o

d

t

Page

ll

Page 12

PAGE

T2

CJ

()

=

U

(9

IJ

z

z

o

-

4

5

t-

vt

tlt

o

c)

a

(J

lrlJIrlJd.

F

I

z.

o

t4l

-

F

e.

a

J

a/,

a

=

la

I

J

ra

F

4

4

F

I

EI

J

EI

j

C"F

z

l-

Ee

r{i6@roo9=I

fr&&E&E&frH

o

d

o

tr

7

9:SRFgRFR

!d

slMM14=.VUB

gooo><ooo

-'E

vtg

d!c

o=

l-

!!8

l/l glll

c,

q.

--

P

!t

o

6

-

,n

lu

4

{

u

d

Ei

P:59r99RF

frtrxec4frefre

o

z

ts

e

fiiHEHHBsH

!

6

6

o

e

I

.n

Y

U

d

=;

=

'=

dt

6

o

6

qt

{

.t)

Y

4

u

4

o

z

F

I

Ei

c{!@{ror.)F€oo

6{NdNNNNNO

Hg€HHH€HE

AE&frtrHtr.tr.fr

I,la

tE'

o:

I

F

4

I

4

(,

|n

lr|

o

EE

d,E

a<o

f;-e

t-z

A

U

oooo6@b

NNN6INNNO66I

o croooo(J()c)

Itr^-tr.o.oFoo

N

@*

.Qss

-po

9

E*

()()()ooooooo()o()()()(J()()()()()

HQir:iieEQe*SE€SEeeee

Od N €s b@Foo

a n n

d

-

-;

; N NNN

O

-Na

ail

N6t6t6t

@@FOOO

N

N

o

Ei

tr.frfr

E

t,U

6z

H<

8vB

ooo

6@O

iNm

5E

E4E

klqS

tr H€

F

o

oooo

6@Oc)@@@@Cr<

e@ooNNNooE

ooF

NXo

j5i

H

-

c!

R*

!eto

tscr

=€

rE

a,

o

z

d

ba

6

TBBBBT

$s$$$!{

TR

a

{r$ $

BB

tFEReR

666

I Bs

ER

@

${

ER

@

g

+

z

o

F

FP

tt,

F

F

=

frl

t*

fid

R

6

o oooooooo

o

tttttttrt

llrltlttt

3=rr:rBs

66io@b66=

ooor60000

drN'^

*93 [F

?t E

tr90

,9'

4

p3

FIF

i:i

66@

ooo

ooo

ttt

F. c;

RZ

aaio

'=X

=

ul

Ps

em9

a

Eie

.ij

.E

.5

;b

>.E

4

.@v-6

v

llt

4

t?

<A

T

H

eeHHfiee

PHHEEPE

E*

ia

;8

kn

gH go

i:

c.!.s

J

gta

qe

E

-

.n

9l

q<

<A

CH$*$*gEEEFEACFEgFFEF

I

-lc

&aE

gar

6

o

E OOOnntqQ

'iry-2

(

@ RRR

; nn*nnus

6i

14trFqflnfitr

666

,aE I

-EF

of

s *

iJ.: o

os-E

A. o d=-

h

6

*

| \-e

M 1e d

c3=

R

.g

!

ud

{r

<1

EL

22

x-

9i

f?++?HsH$F3f;

TEEESEHETEHH

z

U

{

qIJLqe

=F

o ootstsF.ooc)

II @ONNN@OF

F{

[rFFFT{trtit{

*

@ c n

6t

E

E. PiE

e

YE=

ruto

-lJ

e

(et

j'ci

6

H

H HH$g

I

4

I

F

J

o

F

(J

tlt

J

HHNt

HFR E

ef;+++

Eg88E 8

z

o

(J

I

iz

qd

otr

lt

da

6

<2.

gzF

<c;

cr6

@N

I

HE$

E

gH

+

l'I

J

o

u,

F

6d

U;{

u)LOped

F

<d

tF

Od o

+jtr

:o

Er!

EH

ae6

H

ts

oz

le XXX

:<

6@666000

NN6I

+

i h

o

ir

6@G

E

FoF

5 N

ao*

tn

ts

E

Fi t<t{HHtrE{F

AAAAAAA

? c

E 5

d

gE

a! 0.

=z

{p

de

A NNNNNS6

r

*o.

-lO

+e

.:E

b'g

Es

z

{

(,

g

J

E

u

igi

47

ri

z-

qF

EA

EstiiiiHHrrns:snt=:ni

9_r _r _r .r

*eeHq$eggeqs

I I

cro

I

I

Oo6

ggHsgeege

iijij'aT6-f

'Eo

oz

=5

UO

h

o

HC;

oz

JE

A<

6L

Oc;

6 oo

=

-i

OONNN@6

ooF@@

I I I I I

qo

I I

8!

O.

vi

FoF

o,

ui

=!

66@@nC)O

L

o

€@@@@de

oooooooo

@(0Ndd@@N

FF{F{F{F{t{F{O

I I I I t I t=

o

F

o;o

oz

>;

c:

sEEEEEEssEEsssEsgEEgE

el+d6==o

tn

o

z

r

F

.o

i

s

at

bD

-

c

t

5,-d

0a

uta

*!

EH

g**ggatH$;aE

S=---R-

*a*EE

tin5

g$

o

rh

u

F

o

z

z

F

3

J

ts

at,

z

.r : e

>FE

ool

.i'()

E.tr

.d

Egg

9-q

c)

k

d

E

6t

i:

J

frz

N

,1

E:

F

ie

N

F{

6i

A

a

it

iNO$

>>>E

=

=6

c

@

n

)a

uE

o

>o

do

d

oo6

IJ

tn

c

aa(az

B F },9

d-j

U

il

e::

o

s

>.:

6qc

o

e

AA

Lt

U

z

@

I

ts

**+k

ooo

p9

o

a

z

tn

J

o

L)

ginf

o

U

o

U'

u

u

c

o

N

2e=

)ug

F

gf

3i

trl F

(Dq

6

o

o

o

I@I

L,): C

UE

<e(

Fd-

;d

o

*

F

o

z

F

U

U

@.

,d@

bB

€^

6(q

u

UGF

o

u

I

>o

>d

l<{

a6

LjZ

tr.

fat

od

tr

az

€

6I6Ie

o

U

c

=

t

r0

6

I

p3

o

o

I

vt

z

c,

t-

TE

;<

iL

o.

ltr

N

F

o

.A

JLq

t

Ri

Eo-

3e

frl

F

6

6

@

o

I

g

H=

la6

oooo

6060

o-lo-1

o@o6

tlt!

tz

60

60

u

RT

o

e,

t!

oo

U

e

()<

d

c,

lltFJ

t!

E<

I4

h;

f'lF

N

Ntd

I

o

@

t

c,

o

LL

r/t

z

a:

lrj

&'

[r]

F

6I6

r

=

o

U

{

r

lrJ

(J

c,

L

I

z

J

Ofia

d

a.i

OF

o

N

o

J

EBe

€p

E<

-d

llt

c,

U

c

u

.=L

d

o

ut

o.

(

FoF

6X.

2i

{-

c

o

€

N

z

lr,l

.{*

B#3

YOd

g

OzOF!d

:iY

E

d

o

LO

os

s

ufu

z

4e

p

v

z

rHr

ABO

uJ

oO

D

(J

oO

OF

I

t!

l!

c,

I

.9F

if

I

4

c'

:)

Ez

o

@

&,

ll|

o

=t

b9

CL

OL

a

ut

Y

o

.=-

<d

OF

ai

F6F

tt)

4

o

@

r

o

N

I

e

ut

=

o

o-

I

d

,=-

OF

A

o

o

,;<

LO8zCL

O'e

q

Foo

o

I

o

o

o

o

t{

E

4

o

d

9

o

c;

{i

Er

=t

-7

c

o

ee

E

OF

o

44

-z

E

OF

G

o

F

D

4Ff

pE

tc

F

Ee

o.

o<

N

F

o

a

o

z

q)

t

oco

o

tsr

d

d

o

,;<

F

o4

6<

d&

q

6

4d

-z

E

OF

d

d

LOO7CF

Oq

For

a

LOo7trts

'oZ

OL

td

L

o

6

@

a

N

I

tn

A

F

k

cd

x

9<

N

q<

z

o

a/,

q

F

C;

-oF

o

@

()

o

EF

o

Ld

o

o

I

aZ

E.

oo

o

4

o

o

X

I

pZ

o

c,

oo

4

C;

o

z

tn

u

F

6

o

F

I

3t

6

u

ts

o

c$c

*$n

8r;

-9t

Fr oF

cl

.or

I

Page 13

01

<O

s1E

kla=t

Fl Lio

ll|

III

-l

l-

<

E

cnt

o

f

l-

(J

e.

o

lrl

J

u

JEl!

z.

Lr,l

ct

!E

:TE

o. !+

F

t

I

tn

ll|

o

l4l

+

F

d.

(,

a

z.

.J,

a

A

J

F

e,

z.

|n

la

I

J

F

z

A

frc

@

,l

|n

EI

a

u

tt)

)

o

r0

n

@

.d

tr,

4

-

F

r

4

o

ln

z

trl

J

6

I

!a ciE7EIF

x<

E

6

€

6to

6

I

o<

d

t-

=

t!

IL

c,

t!

I

.!F

=f

LO

o-

E

rd

OF

llt

oq

o

E

()

e,

F

o

F

2e

b9

CL

Oq

I

EI

lz

=.

<e

4

d

ee

a-

-z

E

OF

A

o

z

o

V'

r

F

o

{:

u

>2.

d

U

.:J

o(3006@6

N616INNNN@

Jtr*-rt

o oooooo

o o()()()(Jo

6@F

,o

o

A

o

fit

F??ii:?3E??3R=?

oN*

OOOdNO$n@F€OOiN

O @

()()()c)()cro()o(,oL)oLlc)

ir

r{.

{r

it

$ $

S8- oPB

tt \i$

qi

@ 6 6

*

60

dN

oe

E!HRFEF

eir6@Fo6

ooa@oo@

4

-E

nl

nz

g<

E!

oo

e

tr

pvvvEu

frz

fifi

Ei

trtr.04tr.&frfr

PAGE

o

F

oooo o@6o|ol6@@O

s@oodNNo

F<

tr

d

z

F

e

oooooo

oooooct

:f

\t{ rtr

s!

!r

.{.

oo e

oo

tr ttr

:tl

o

t

r1)

k

o

c

o

tr

=

z

o

p

o

N

I

@

@ @@@

d

v,FF

Pf

o

o, oooogro

oooooo

ae

s

ER

BESBR

d

c

EA

u

e

tslp

qld

R SPfsrK

ttttltl

ltttttl

dJritt6 666@@@

E oo

-g

tr EC

ou

nt

l{F

oo

Y

e

:

fr2.

=

c

o

N

bo

'Ug

u

o

39

o@ttn@lloo

al,

g_d

E >.:

9-u

E

FO

,i

Tg

!a

e

g

v,

+

ulJtlt

E HHHBHfi

oE

go

J

o

4

t-

(J

5e

8T

<A;

3

n

I

cqo!qpqtra

eeHHHc

R

D (f=3

g

gI.E

Xc

--o

tr.l

c}a

e:

.:

E

E

-

x-

9i

9r

q<

<A

R^*

OOOTiOOo:oOOo:O

o

ezzzzzzaQzzae e2

sfiF333$gg$$g$sn

l r r r r

--3

I

o6l

5-3^

t

ooc)

o

|

o

I

U

=e

z<

qd

otr

tt

dG

o

<z

dF

<C;

o@

@N

4--

ag

o

o

3

t!

fri

:t :n

frfrfrfr8frfr

{. <. ir $

G

-

e

FH$gHEH

OdNO$6@

o

z

F

(J

I

F

€EE

86t

njt42

ic, c

o

ooo

o

NdEETE{.

g

OONNNO

trtr€aqG

B

@@@

NNN

*,4,4

d

I

4,

i5

9 XXX

:

t] 00NNNO

o

F.

@@6660

()oFrF{F.c)

htiFt{liF{

o

ts

4

(

Et

6tNd

@66

-

€ .s'E

.S l/ta O

!

s

s <;.9

E <.E:

A

FE?

uto

E-<

9! t

{c

<-

Er

ud

T*++++FEHfH3f;

HEEEEETHESTHP

q

B

vt

J

o

c,

F

z

bf

F

<d

u)1Oped

saE

4

o=

F

tll ulll

vtE

-c,

,/i

{

4

o

U

bo

a E= b

C

A-(J

\JC

E,

u

A

J

u

e

!Er

J'a;

i4)

HganegagessHHan

vr4

=5

uci

d7

lF

'=

(D

€,

o

,n

v

4

ttt

=z

r*

{p

ed

P

'i

A NNNNNS

E

F{

TTTTTS

eo66a

AAAAAA

tststsFiF.F{

I

.o

ci

*q

,,ioE gIJ

8!

og

L9

F

o

z

u{u

o,Uiz'

*E

ila

qr

E

i A n a o a a

a${r$!.{$--@$---@

tiaf;

a a a a A. o6!6! o o.

i

iEan I

-l,t

a o,.1

eEHn

c!

6! c!

-1,.t

a

a

t-e

oz.

pqt.E

Ei

ra@OiN

<.$+G6C

frfrx&x&

oci

t6r oo

Fl

F HF{FrFtrtr

ltttttt

@66@60

@

o

o

(,

O.

ci

oz

i!

N

gEEEEEEgBEEgBgE

!'l > > > > > >

r

r r r t I

z

@

!X oooood

Y @@NNN@

@@666J

5

.{

i

bo

c

IE

!{

T,)A

EI

E

ofl=66==-

$:n{${$$N,AOqNSF@

**t*

oL

Hd

JE

A<

o4

E*ai

Nx

r'l ei

E

N=---K

> E

I

E

r

sssE

NNN

r'r r'r H

>

I

z

z

o

z

F

J

J

ts

at,

N

z=

oA

>F.

qii

d

HE- E NE

==o@h@

oo

z

F

E-a

ON

4a

h9

c)

=

U

e

o

frt

to

o

u

F

Fl

fe

o

F{

!

o

t

u:

o.

frc

Fi

{

fri

A

a

ah

o

q

E*

.))

v

&

Ltu-e=

d-j

li;

uE

=6

.d@

d

o

o

6

6

€

N

o

o

aaa

o

N

6

r$

F

e

6.

36

>a

F

>l

u

u

z

o

uL=

U

6

r

o

@

I

UGF

oJu

N

q

U

z

Fd4

EEt

F E.g

U

z

y3

u

rug

(JE

<e(

Fd-

Uf,C

39

c

tr

t1

>s

ts

ooo

u-

gf

aa;

trj

f{F

g)e

N

N

@

o

o

I

I

z

e,

F

Pf

Fe

trl F

g:l

d

r

6

o

o

I@I

=

c,olr

vl

z

c,

F

jp

Ef

?t

L

F

c)

$

N

a

z

q

=

U

U

J

4

u

d

!4 ci

Ez

GIF

p3

o

@

FIo

o

L

J

IrI

v

d-

Fld

rad

t4 Z

o€o

:IT

@66

ooo

ttl

=

o

F

otr

-oE

'E<

:c4

o

@

a

o

N

llr

u,

o

tt,

=

II

=ts

E<

TC

oo

Lz

o

s

e,

tlt

g

=

u

U

J

c

u

u

<e

<<

N

I

@

IL

J

z

.=L

&e

OF

A

o

p

o

o

v

lll

o-

tn

F

6

6*.

2i

{*

L

@

o

N

vtulvt

3

o

z

trl

3

z

ox

_r5

Eo

-ed

-a

$f,

c9

.l

o

z

4

-

oO

f

OF

I

.=-

o

o

OF

o

I

,;<

a

r

.=-

d

o

oir

t

E

4e

E

OF

c

o

q

o

o

c,

Iti

,;<

n7

-z

E

OF

4

F

f

-d

gz

F

ooo

k

o

o

o

G

d

F

:)

o-

TE

!G

F

ad

IL

6<

F

o

{i

N

a

o

F

z

o

>l

qt

s

o

<d

c.

d

N

C)

I

=

A

c,

=3

OF

c.

9

o

FoF

-z

E

r

o

o

@

&,

ut

@

IA

./l

6

q

o

(D

GA

KF

U|l<{

og

-,la

a

E

lr

(A

ts1

8.

o

>r

l-

6<

I

de

U

o

*d

3F

9<

LO

o7

oi

{r

N

F

6

I

o

F

TF

+d

LO

oz

CF

-Le

OL

c

@

@

a

I

v,

oo

o

Ed

9<

'aZ

o

N

o

o

t

a

FX6

d

-aZ

c.

oo

o

4

d

T

o

X

'oZ

o

c,

o

.t)

o

z

U

F

o

FI@

I

2e=

0

a

d

F

o

o

€o

ri<

:.6

EIF

RI

EL

6

6I6Io

o

U

=

@I@

13

\ti

.tg

i">

o(a

9F

€-

o)

-

I

tt

E'

9

I

I

o

F

trt

tT

o

E

v

Page 14

Page

14

I tz

l-rl r*r

lzlA

lzl =l<l o-

tEt

CL

g

=

J

=3

r-r

*e

\C,

@:

@:

@:

=

o-

F=O

Y

o

A

@

@

'2,

cLo

z<.

lrl

t-

-e.

ci

lrJ

si

;

F

o-il

cv{

zz

-2,

tri c)

Z.e

z<'+9cr!!

rI

e.

=

-l

CL

!L

=

3=

Jz.

<a

==

2,t

irl

=

ol

-

R

*!frr''l

\-LI

@EH

o

@

r'\

sE

,rit

\z

Cz.

rol

)El

^nr\.4

F

z.

H=

J6

@

o

\o

s{

-

@

c]

1r

E*e

ET\

@

g

m

o

(\r

(\I

=f

q

c

o

o

(J

z.

r

-t

z

c\t

lrl

o-

=

o

F

F

--->

\rr': f

+3II

g

lH

l:l

l=l

--v-Yi.-E

FgbE*; EE

8?,He.5E E=

s sE

c\r

(Yt

d i'Er

=r

rt\

\o

e

L/6)

l!

oFo

I

o-

E

E

E;19g:^**-

i6

=

Efig

p

o;.!s^

Elg

E Fs.:

X..'=

=

2>

r-E

at,oFI

<,;

(r

E:

b

EEE

(€

3=

>

E

6-

E,E

5

F

@

E E

:

E€;giEE

P=E

AE:;

5'a;r

F

t

EEE

E'6

F

H,a

g

d

og

Fri

F

o.q

<c

zu

06

-\%

o--P

/-)

7

-t

=

.f

Eo

(J>-L)<c:(-,

o > o=

E

=egEe

=

o);

zB

(9

O.

r-

c

l/l

-=

cga.:3

lrlJ.(t

o

J

lrl

Hg

A;z'

=

E

o

gxE

(gc.o

e,E

Y

F

F

Esr<i

h2qn,(D

i=Er): fi

b

e@

--{f-

€/

/5\

o

Y

R

o

GI

F

=

o

E

E

S^

-(9

t!

6

O

;€

\o

\o

\o

\.>

Ee

r\

?,<

o

co

t

=f

x

jF==

-

ct&

\o

\o)\o

tf\

r.r\

<

t-ri trJ

r.()

LccF

rn

o

rn

o

rn

'C\l

SJ

EFnn

-^iEcu

42-?4

5EF=

<=o-

E2E=

|J.t=e;

-t

o

o

Y.

o

o

c

o

o

\z

o

o

z

=;=)

s=-E=

2;=4

9-U

p9<

a

ur

z<,=

.tl

a.r,

CE

E

IJJ

st2

Lrl

<,

c!

.E

o-

11

q

r\

c

\zoo

rn

4C

zo

o

oo

o

co

()

3z=

=-:--

z??=

=E---?

-lrto

3d=

ctEz

=Ez

^E>

o<o

<./,6l!,

c)zF

E

cf\

o-

o

o

L^

o

H

C>

rn

c

o

o

f'\

c

c

o

6

c

o

oo

c

c

FE=

;FO

c:(J-

l4l

-r

fEH

l+J

E.

s

=8

3u, A

o

z.

L

o

(t'\

{-

o

o

H

rn

sl

iJ\

{-

()

z.

..4

<t1

zz

6

(9te=:1=Lrt

h6-

^'S-

ozffi

@

tll

(9

v

rt\

Y,

rn

c

o

c

=-

-o

o=

=6?

!z

idOO

ct

Y3e3

cD

u-

rr-r

@

!a\

o

€

o

€

lJ\

{-

(J

z

o

C\l

o

H

(\l

c

=+

; O

z

18e

\Z

Y,

c

?.= 6

z>o

aLz

5

z.

(\t

z

e-

2r

ii

c

ooo

ooo

o

<t

\6

c)

EE

2io- h

6

Rp

rB

:a

@

1J

I

.tt

o

\o

6t

?

(J

&

o

trl

O.

o

ta./l

J

o

lrl(JE

+!J

I

t-

Oz.l-rl

(/)

lrJ

<J

c/)

c/)

U)

-J-

F5

@"

@

i(

-f

_E

FOA

O\

crr

(^o

ii:

@

^O)

=3o

F+r

lrJ

Oo.

5

=

o

F

f,

o\

c

c)

z.

z.

c)

(>orn

+

c

C-)&.c)

lrl:rF

j

J

@

+ut

ro

o

C\l

E

E

F"l

lrl

(f

ct)

L,!l

=

=

5

o-

=

o-

o

vtoEoc)IJE

I

@

a

o

(

E

T

o

;

F

=

C)

c,

O

o

p

I

u

Er

J

ur

Ll

F

o

I

Page 15

Page 16

g

la

ra

I

+

I

4

=

I

llr

4,

4

o

lrl

4

EI

F

ln

la

z

o

I

F

4

-

d

g

ra

EI

a

o

Zo

<i

_E

bv

Ul

rJ

-o

l/1

F

d

o

v

(,

IIl

o

ru

o

F

t\

o

N

an

u

F

o

z

4

o

-z

E

OF

d4

c

o

aL

=.

<d

4

d

OL

{ir

d

Lo

a+

'; iv

if

!o

vt

At

rn

e

Fr

E

OF

Ld

o<

a.

ko

uz

H-

EK

o<

Gr

u

tn

l

rlt

ttt

:)

4

IL

N

@

I

o

6

I

o

o

o

C)

,&

o

t

tr

E

t

o

.]

q

o

J

r

o

o

!

o

ttZ

rn

e:

u

tJ,

N

f

C)

L

(5

o

v,

g

ts

o

z

fi2

g3

E;

u

z

F

e

c

is

A6

6E

.9>

to

Jio

zk o

a@

^.9

O(,lo={P.odf;

g

SE€S

?>E:fi

EBAEE

E*flET

i-: o o d

> >

a>.?

6

N{.@tll

? l.??'r

ii-iiOd

@om@@@o

ttttttt

oooo(foo

oooo)ooo

@oo

ooe

d<<< o

.d--- c

,9HXH e

*ooo

oE!dE4 s 5'

Hppp#3b

fi555f;8E

ooo

tr frtr

6r d@

EE

EE

e

u

o

u.

tno

L

$!E

tr<

=a

ge

FIF

p3

fre

o

J

o

@

o

6

I

o

3t

o

6

:)

N

q

ra

o

f

Hx

L

trl

o<

z

o

J

N

J

d

u

T

trt

o

o

J

L/

o

o

I

g,

o

-

6

U

Y

at)

@

f,

l

L

o

o

o

z

F

sF

e

u

4

o

F

s

o

F

o

F

z

u

u

=

U

I

c

r

.;i

f/n

d,2

f:

Ft

Irtg

I

6i

_<x

l.',

odf

.rrJ

i!

72

=o

o.=

<t

(Je

.E

o

(J

06

z

o

I

F

I

4

&

-.l-o

U

rh

q

o

vt-

o

06

o

tr)

z

c

F

E

o

d

!

o

c

o

3

=

4

=

z

PAGE

h

o

o

Fl

o

o*

>.:

:

tsdE

9€E

H b{

=od

o o3

>trF

+"1

€o

-1

606

ttt

ooo

@oo

.o !.o

ooo

cdEt

Mld14

N

T7

Page 17

Page

18

sz

ii(

='A

lr

-t

al

o

o

o

oo

==e!;*;

4

6r

IJ.

h

";.

E

6

-E

=i./r

2==Hs=E

=<=EhdH

=

l^t

? 6

=

J

lrJ

F

d

T- tii

-o-

q,

*s

+3

H<

a-€

!:

E

o.od,

uz.o

I

o-

z.

F

=

CL

F

=

z.

o

c)

u

o

F

tll

ZY

oFd

C.)

2<

adl

6€

cta\?t

-\2t

t,^.o

-;g

'o

E

.(5

5

=

-

ET

e,

a

d.

o

g

=

;*x

F

Htu

Ee

OE

iFt

ao

z,=.

oo

a+J t+I

5t

Hlx

-

\C'

>N

<l-

rjll

?=?

E*l

H3"

c)6 |

IL

Eg

=

l4J Lr,

:3

a

cl

N

=,

E

C\t

6

o-

J

e,

g

!!

=

z

4

A=

ct) ctt

U'

q)

6

=

o-

F

o

l-

(J

=

T

tttu

oH o

5o

=o

z. <.

o

(.,

e,

=

o

vt

t4l

Io

o

=

o

ttt

l4l

c,

u

o

(J

e,

=

ttt

trl

a-

I

(r

.6

c

o

o

EI

c,

o

I'l

F

=

o

lr|

o

o\

-l

:l

F

lr,

x

tt

o9

Fdi

F

fr.;

zB

<l

o-

e.E

2;

Fa

(/t!oFT

>v

<,;

lo

oFo

Loading...

Loading...