Roberts 10-60 Owner's Manual

WARNING Read and understand

all instructions. Failure to follow all

instructions listed below may result

in serious bodily injury.

SAVE THESE INSTRUCTIONS

FOR FUTURE REFERENCE.

AVERTISSEMENT Lire et comprendre

toutes les directives. Le non-respect

des directives décrites ci-dessous

peut causer des blessures graves.

VEUILLEZ CONSERVER CES DIRECTIVES

POUR RÉFÉRENCE ULTÉRIEURE.

ADVERTENCIA Lea y comprenda

todas

las instrucciones. Si no se cumplen todas

las instrucciones enumeradas a continuación

se puede producir lesiones físicas graves.

CONSERVE ESTAS INSTRUCCIONES PARA

CONSULTARLAS EN EL FUTURO

9" Flooring Cutter

OWNER’S MANUAL

Cisaille pour revêtement

de sol de 220mm

MANUEL D’UTILISATION

Cortador para pisos de 220mm

MANUAL DE OPERACIÓN

10-60

1. READ AND UNDERSTAND THIS INSTRUCTION MANUAL BEFORE

OPERATING THE 9" FLOORING CUTTER.

2. If you are not thoroughly familiar with the operation of the 9" Flooring

Cutter, obtain advice from a qualified instructor or call 866-435-8665

3. Stay alert. Do not operate while under the influence of drugs, alcohol, or

medication.

4. Always wear safety approved eye protection with side shields (ANSI Z87.1)

5. Keep wo

rk area and free of debris.

6. Keep children and unauthorized persons away from the 9" Flooring Cutter

and work area.

7. Make sure tool is secure. Operate only on a firm substrate or solid stand.

8. Use the right tool. Do not force the 9" Flooring Cutter or use it for a job for

which it was not designed; use only on approved materials.

9. Keep blade sharp. A dull blade will not perform properly.

10. Always ke

ep hands away from blade while operating or carrying.

11. Do not alter or misuse this tool. The 9" Flooring Cutter is precision built;

modifications not specified in this manual may result in a dangerous

condition.

12. Maintain the 9" Flooring Cutter with care. Keep blade sharp and clean.

Follow instructions for lubricating and changing accessories.

13. Use only recommended accessories. The use of improper

accessories may

cause hazards or injury.

14. Never leave the 9" Flooring Cutter unattended. Secure the handle with the

lock chain when not in use.

15. Warning: The dust generated by cutting certain wood, wood fiber and / or

PVC products can be harmful to your health.

SAFETY RULES FOR THE 9" FLOORING CUTTER

WARNING: FAILURE TO FOLLOW THESE RULES MAY RESULT IN SERIOUS

INJURY! USING THIS MACHINE WITH RESPECT AND CAUTION WILL

CONSIDERABLY LESSEN THE POSSIBILITY OF PERSONAL INJURY.

-1-

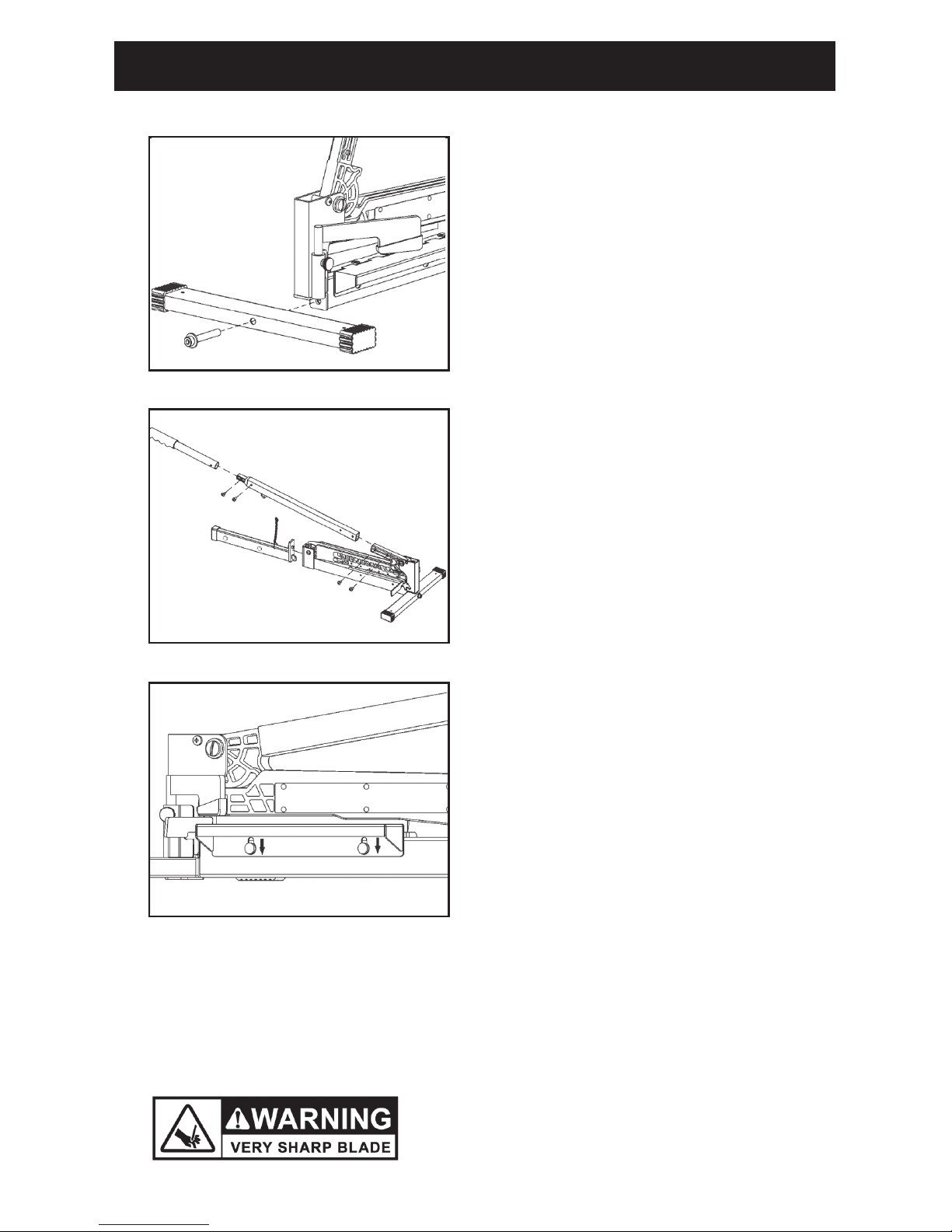

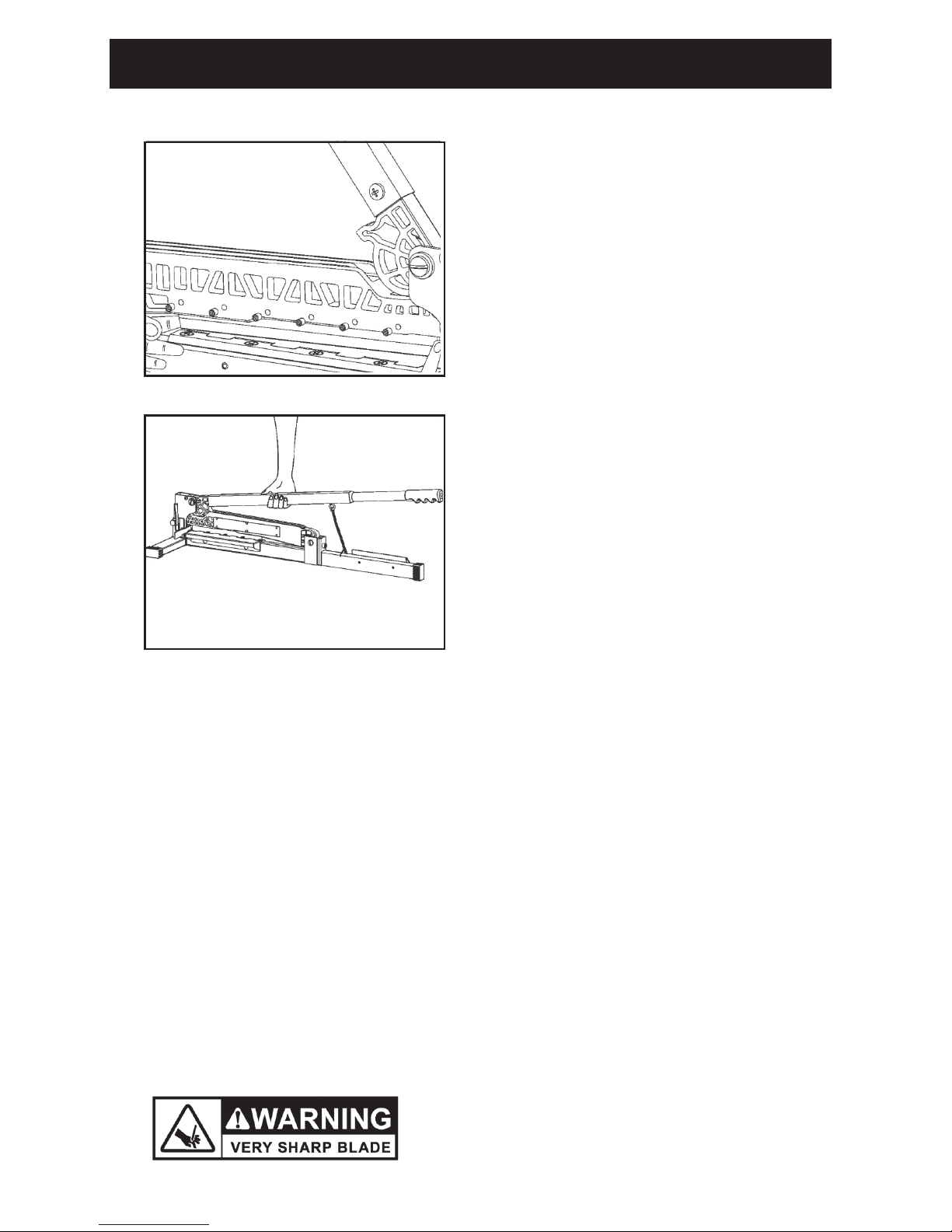

SET UP

1. Installation of the Cutter

Install the cross bar to the cutter

base with provided bolt as

shown.

Warning: Do not put your fingers

against the sharp edge of the

blade at any time.

2. Installation of the Cutter

Insert the handle to the base and

install the rear base to the front

base with provided screws as

shown.

Warning: Do not put your fingers

against the sharp edge of the

blade at any time.

3. Working Table

Install the working table as

shown.

Warning: Do not put your fingers

against the sharp edge of the

blade at any time.

-2-

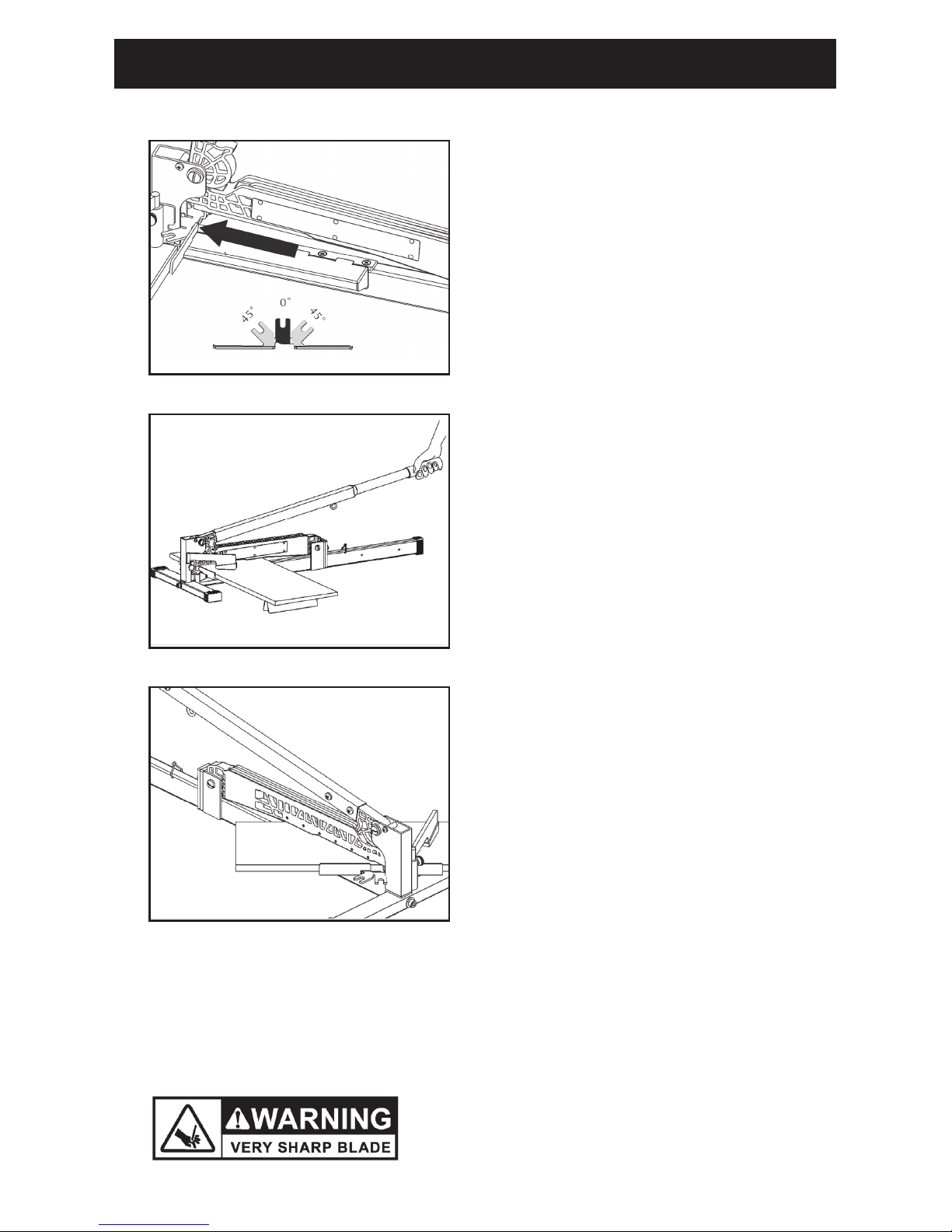

CUTTING

Cutting Preparation

Place the angle attachment into the

cutter head and push it as much as

you can to the bottom. Change the

cutting angle from 90° to 45° as

needed.

Warning: Do not put your fingers

against the sharp edge of the

blade at any time.

Straight Cut (90° angle)

Insert material between the cutting

blade and the base as shown and

hold the material with the flooring

holding bar , then push handle down

to complete a cut.

Warning: Maintain control of the

handle. Do not allow handle to

slam back after making a cut.

Angle Cut (45° angle)

Install the 0-45° Attachment as

shown. Position the cutting angle to

the 45° angle.

Warning: Maintain control of the

handle. Do not allow handle to

slam back after making a cut.

-3-

-4-

MAINTENANCE

Changing the Blade

Use Roberts #10-460 9" Replacement

Blade. Use the provided Allen

wrench to remove the five screws,

then hold the blade at each end and

carefully move the blade out of

blade holder.

Note: The flat side of the blade

should face the table.

Warning: Do not put your fingers

against the sharp edge of the

blade at any time.

Carry

Hook the chain to the ring on the

handle and carry the cutter as

shown.

Warning: Do not put your fingers

against the sharp edge of the

blade at any time.

-5-

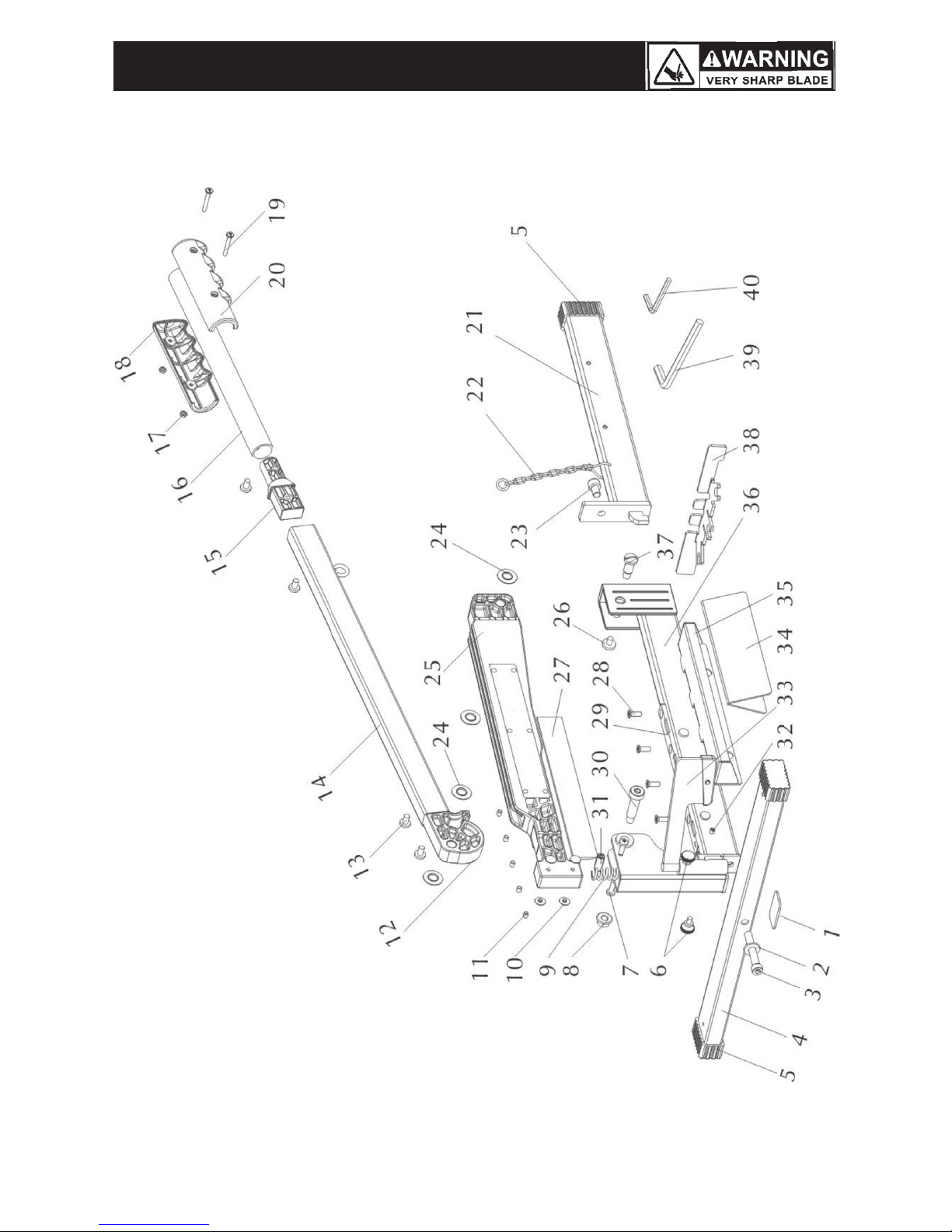

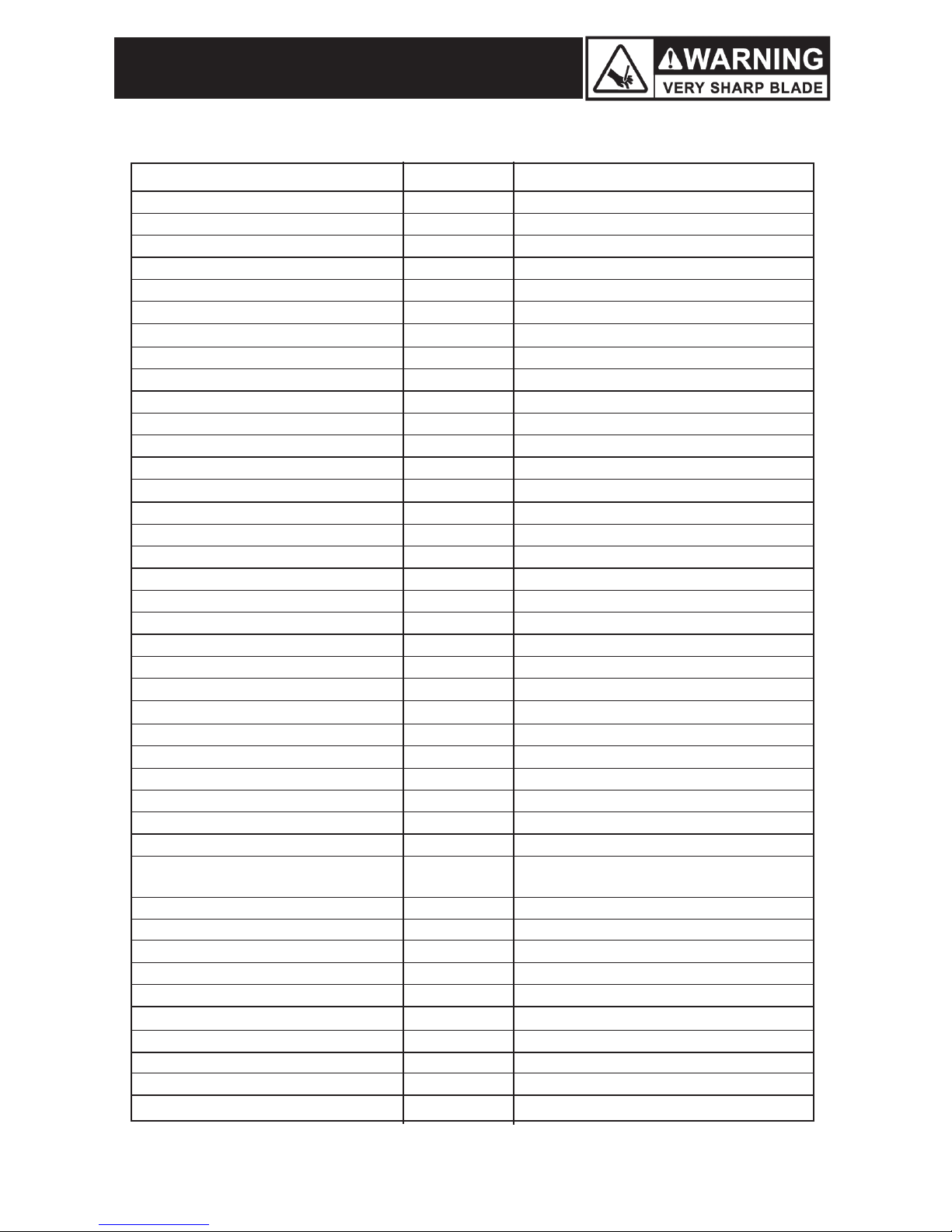

PART LIST

-6-

1 Rubber Pad 1 21 Rear Base 1

2 Plain Washer Φ8 1 22 Chain 1

3 Hex Head Screw M8 × 52 1 23 Hex Head Screw M8 × 12 1

4 Cross Bar 1 24 Nylon Washer-2 2

5 End Cap 3 25 Blade Holder 1

6 Knurled Screw M5 2 26 Customized Screw M6 1

7 Cross Head Screw M5 × 10 2 27 Blade 1

8 Nylon Lock Nut M8 1 28 Cross Head Screw M5 × 10 5

9 Spring 1 29 Nylon Bar 1

10 Nylon Washer-1 4 30 Customized Screw M10 1

11 Hex Head Screw M5 × 10 5 31 Round Tube Stopper 1

12 Eccentric Handle 1 32 Hex Head Screw M5 × 6 1

13 Cross Head Screw M6 × 10 4 33 Flooring Holding Bar 1

14 Square Tube Handle 1 34 Supporting Stand 1

15 Handle Connector 1 35 Working Table 1

16 Round Handle 1 36 Cutter Base 1

17 Thin Nut M4 2 37 Customized Solenoid M6 1

18 Right ABS Handle 1 38 Angle Attachment 1

19 Cross Head Screw M4 × 31 2 39 Allen Wrench M8 1

20 Left ABS Handle 1 40 Allen Wrench M5 1

PART LIST

Parts Q’ty Parts Q’ty

-7-

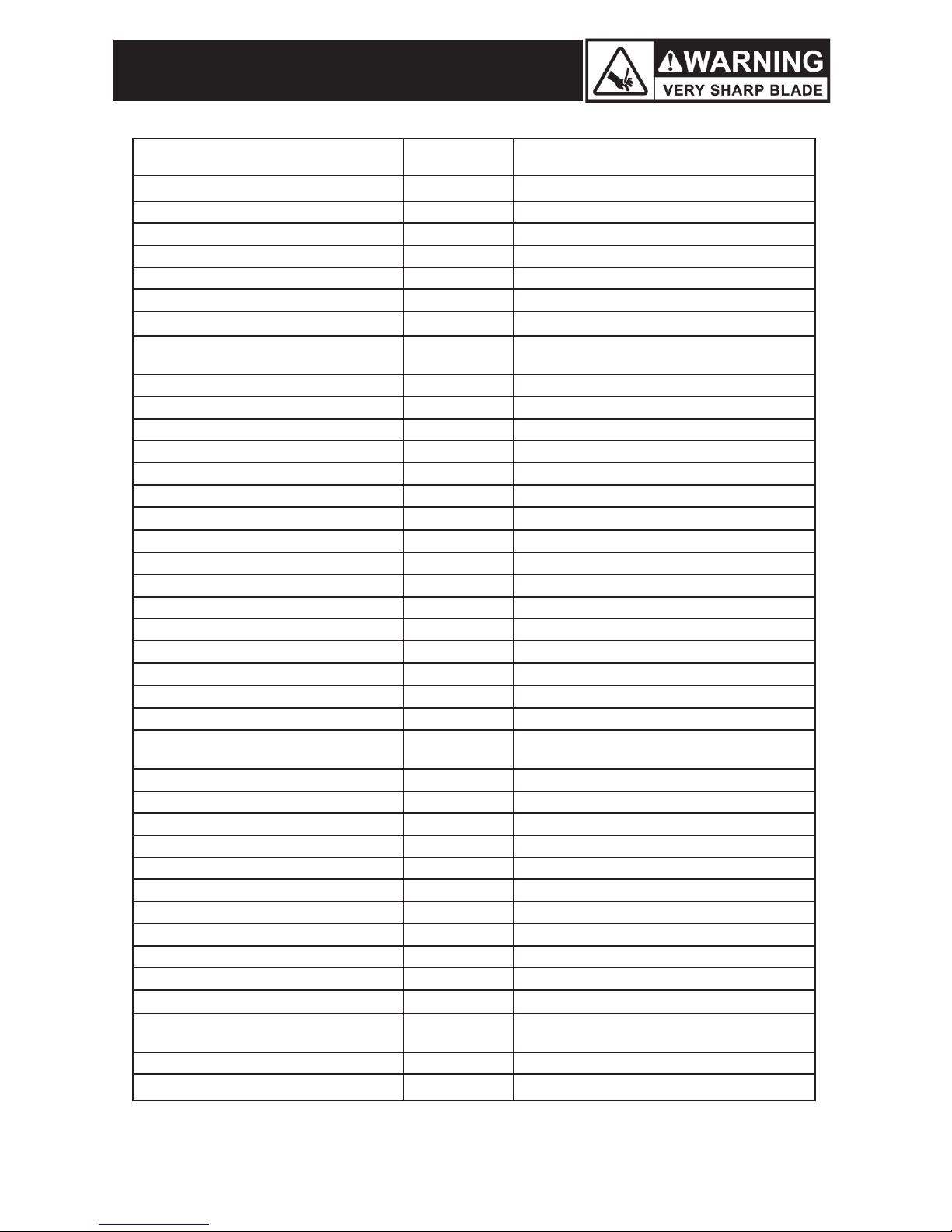

ROBERTS 10-60

CUTTING CAPACITY CHART

Eastern White Pine 380

Basswood 410

White Pine 420

Hemlock 500

Chestnut 540

Larch 590

Douglas Fir 660

Southern Yellow Pine

690

(Loblolly and Shortleaf)

Shedua 710

Sycamore 770

Parana 780

Lacewood / Leopardwood 840

Southern Yellow Pine (Longleaf) 870

Cedar 900

Paper Birch 910

Boire 940

Black Cherry / Imbuia 950

Sakura 995

Teak 1000

Black Walnut 1010

Boreal 1023

Makore 1100

Brazilian Eucalyptus / Rose Gum 1125

Cocobolo 1136

Carbonized Bamboo

1180

(r

epresents one species)

Heart Pine 1225

Movingui 1230

Yellow Birch 1260

Carribean Heart Pine 1280

Red Oak (Northern) 1290

American Beech 1300

Ash (White) 1320

Ribbon Gum 1349

Tasmanian Oak 1350

White Oak 1360

Australian Cypress 1375

Natural Bamboo

1380

(represents one species)

Coffee Bean 1390

Hard Maple / Sugar Maple 1450

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

No

No

No

No

No

No

No

Limit on Engineered Wood Flooring

Janka Rate

WOOD FLOORING

-8-

ROBERTS 10-60

CUTTING CAPACITY CHART

Sweet Birch

Curupixa

Sapele / Sapelli

Kambala

Peroba

True Pine / Timborana

Zebrawood

Tualang

Wenge / Red Pine

Highland Beech

Locust

Kempas

Merbau

Blackwood

African Padauk

Rosewood

Bangkirai

Afzelia / Doussie

Hickory / Pecan / Satinwood

Goncalo Alves / Tigerwood

Purpleheart

Jarrah

Amendoim

Merbau

Tallowwood

Cameron

Bubinga

Sydney Blue Gum

Karri

Brushbox

Pradoo

Santos Mahogany /

Bocote / Cabreuv

a

Mesquite

Brazilian Cherry / Jatoba

Spotted Gum

Red Mahogany / Turpentine

Bloodwood

Angelim Pedra

Brazilian Redwood / Paraju

Ebony

Cumaru / Brazilian Teak

Ipe / Brazilian Walnut / Lapacho

1470

1490

1510

1540

1557

1570

1575

1624

1630

1686

1700

1710

1712

1720

1725

1780

1798

1810

1820

1850

1860

1910

1912

1925

1933

1940

1980

2023

2030

2135

2170

2200

2345

2350

2473

2697

2900

3040

3190

3220

3540

3684

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

N

o

No

No

No

No

No

No

No

No

No

No

No

No

No

No

Limit on Engineered Wood Flooring

Janka Rate

WOOD FLOORING

Strictly follow this Cutting Capacity Chart. Any attemptto cut flooring harder

than what is listed may causepersonal injury as well as damage to the product.

Loading...

Loading...